Pin shaping apparatus for integrated circuit and pin shaping method

A technology of integrated circuits and equipment, applied in the field of devices for correcting the pins of integrated circuits with poor pins, can solve the problems of high manufacturing/acquisition costs, complex structures, etc. The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

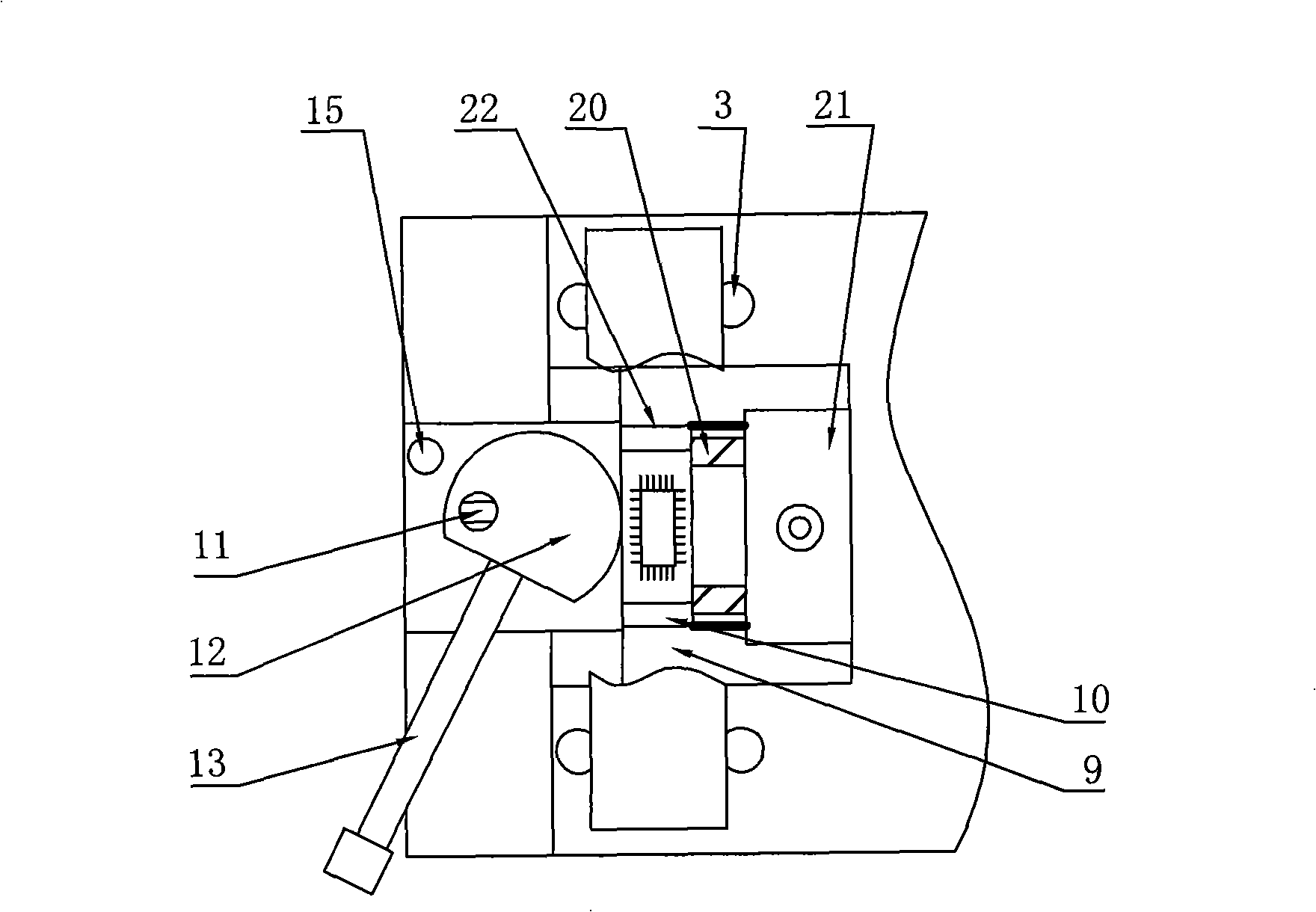

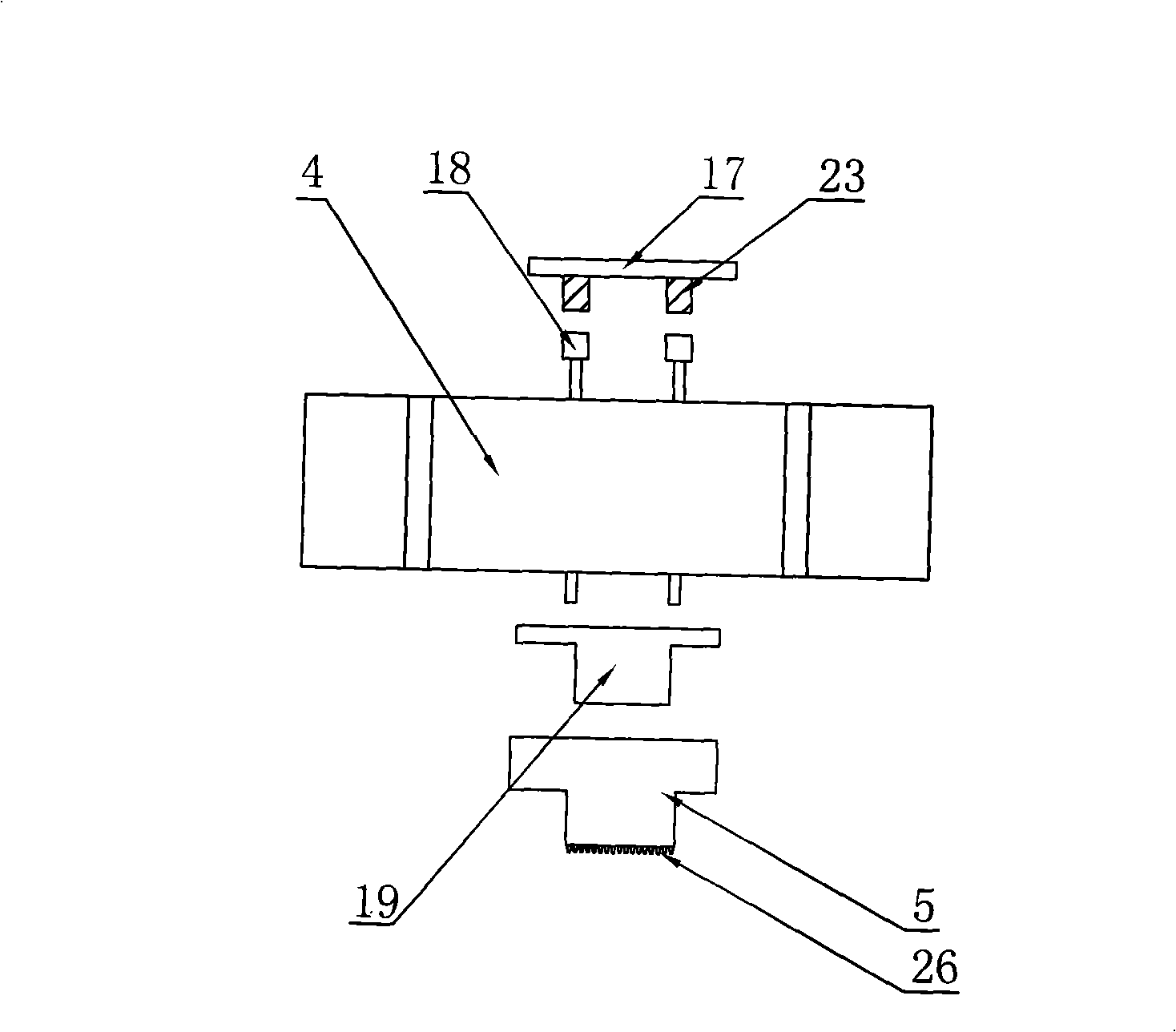

[0030] figure 1 Among them, a base 1 is included, and a gantry 2 is arranged on the base; a guide post 3 and an upper module block 4, 5 that can move longitudinally along the guide post are set on the base below the gantry; The first eccentric wheel assembly 6, 7, 8 that can drive the upper module block to move longitudinally is set on the frame; the second eccentric wheel assembly 11, 12, 13 that can drive the lower module to move laterally is set on the base under the portal frame .

[0031] Wherein, a first return spring 16 is arranged on the guide post between the base and the upper module block.

[0032] The first eccentric wheel assembly includes a first fixed shaft 6 arranged on the portal frame, a first eccentric wheel 7 located on the first fixed shaft, and a first operating handle 8 arranged on the side of the eccentric wheel; The second eccentric wheel as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com