Patents

Literature

34results about How to "Compatible with practical engineering applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calibration and estimation method for state of charge (SOC) of lithium battery based on charge mode

InactiveCN105093127AHigh precisionCompatible with practical engineering applicationsElectrical testingTerminal voltageEstimation methods

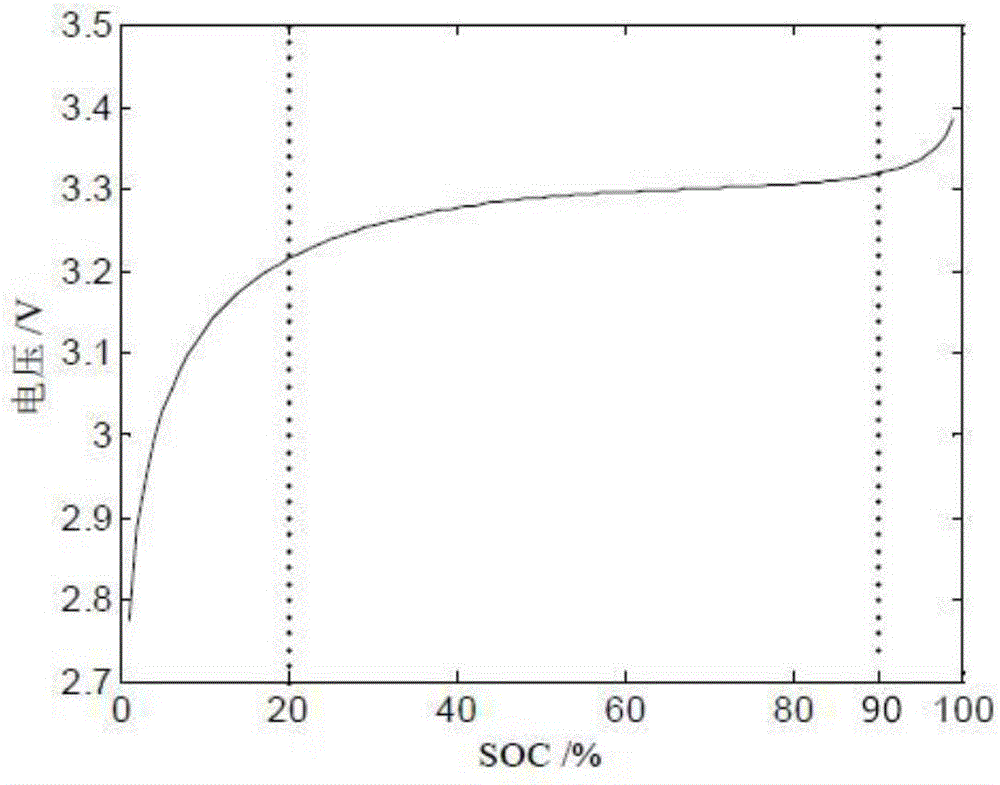

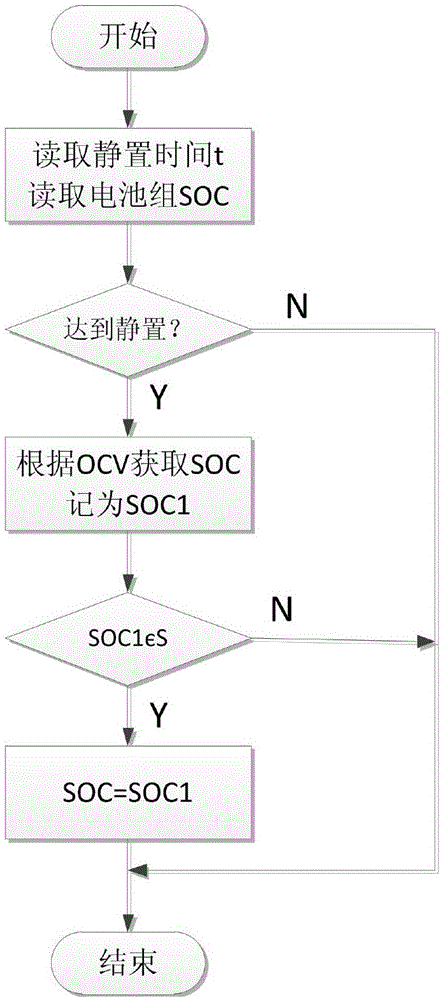

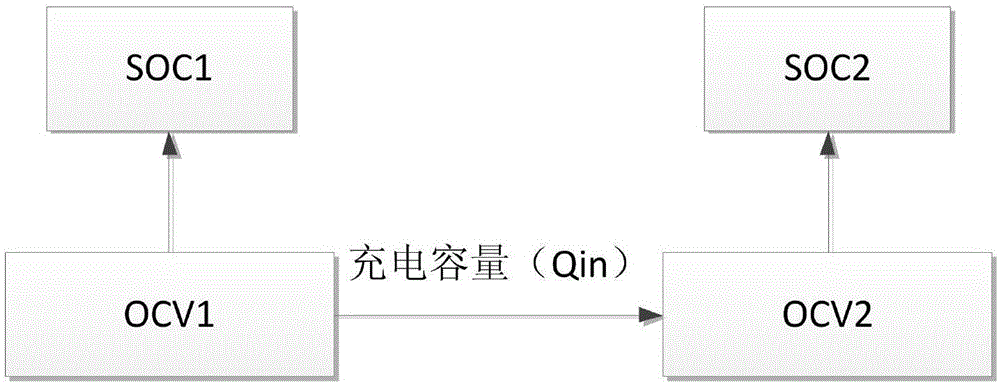

The invention relates to a calibration and estimation method for a state of charge (SOC) of a lithium battery based on a charge mode. An error source of an Ampere-hour integral method is analyzed, an SOC initial value is calibrated by using an open-circuit voltage (OCV) of the lithium battery in a static state, the total capacity is calibrated by using the SOC values estimated through the OCV in the static state before and after charging, a mapping relationship between terminal voltages and the SOC values is established, and high-precision estimation of the SOC value of the lithium battery system within a discharge cycle is realized by using battery characteristics of different charge phases of constant current and constant voltage.

Owner:HEFEI SIWILL INTELLIGENT

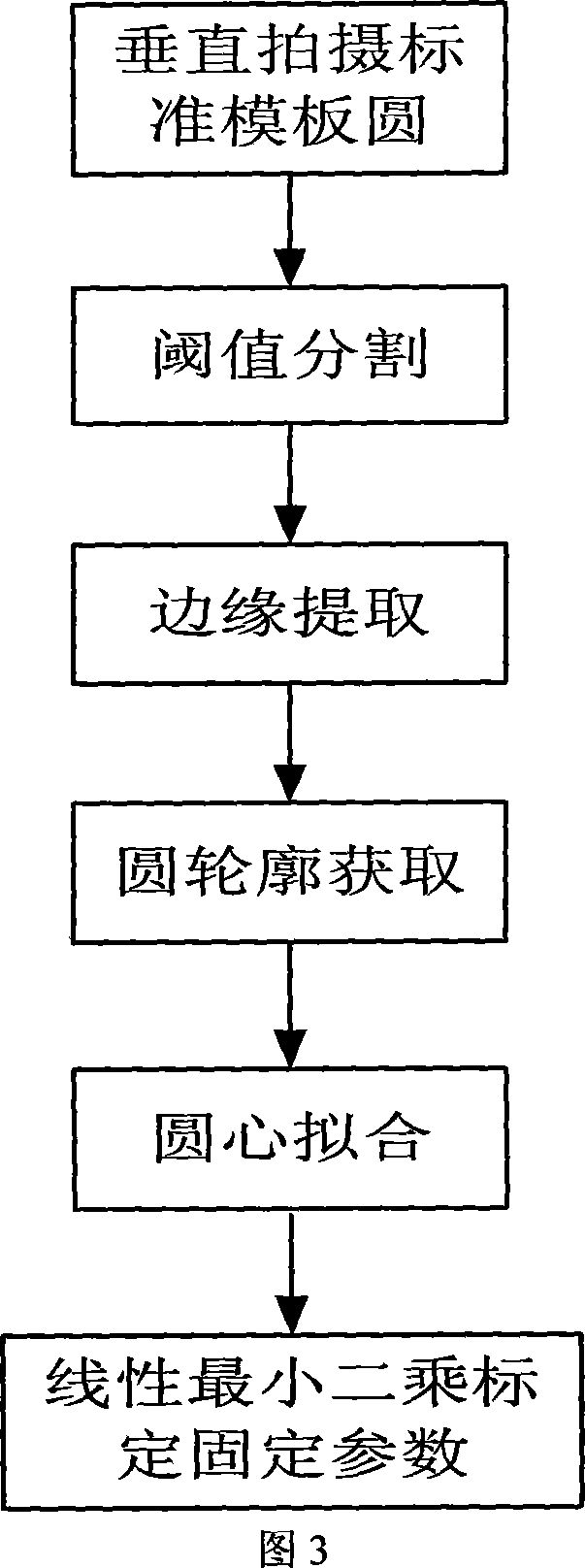

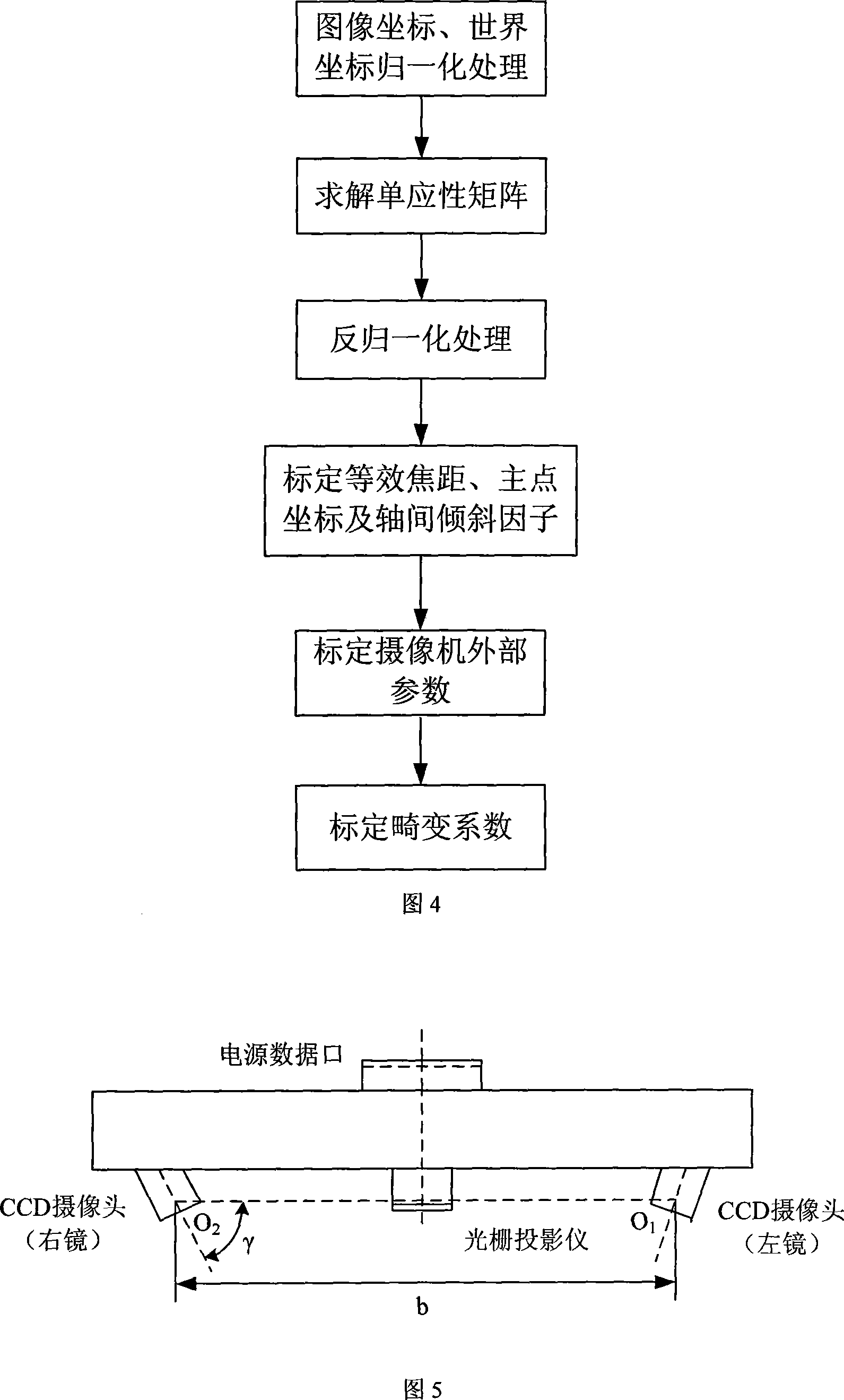

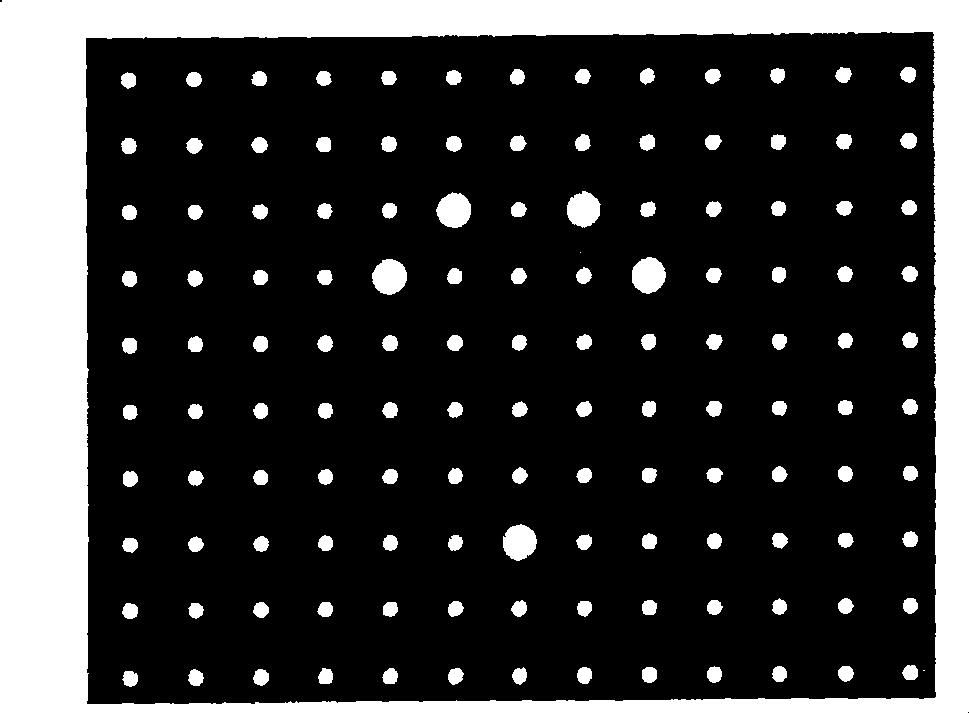

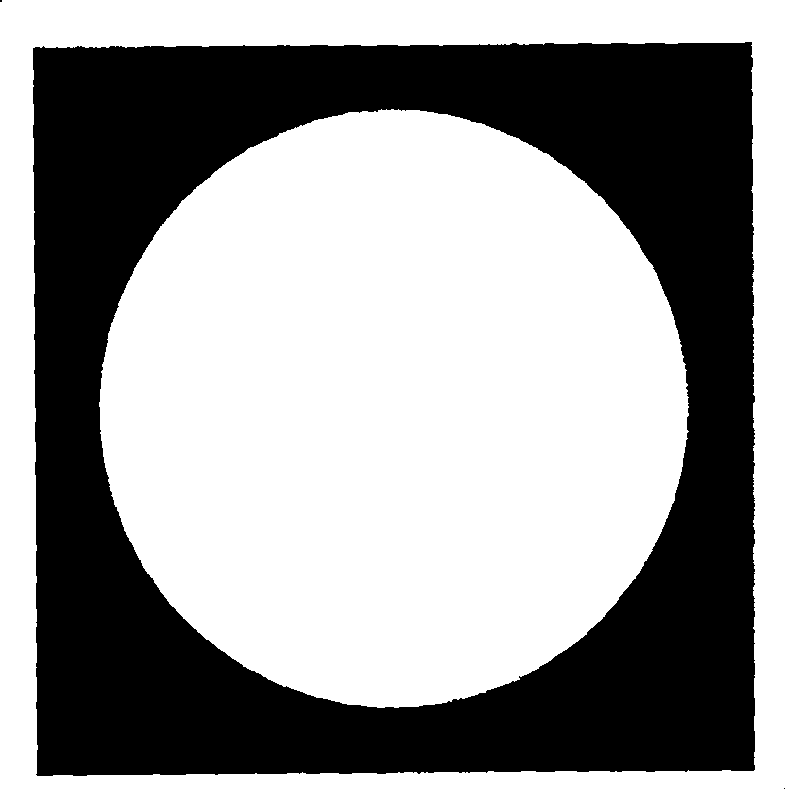

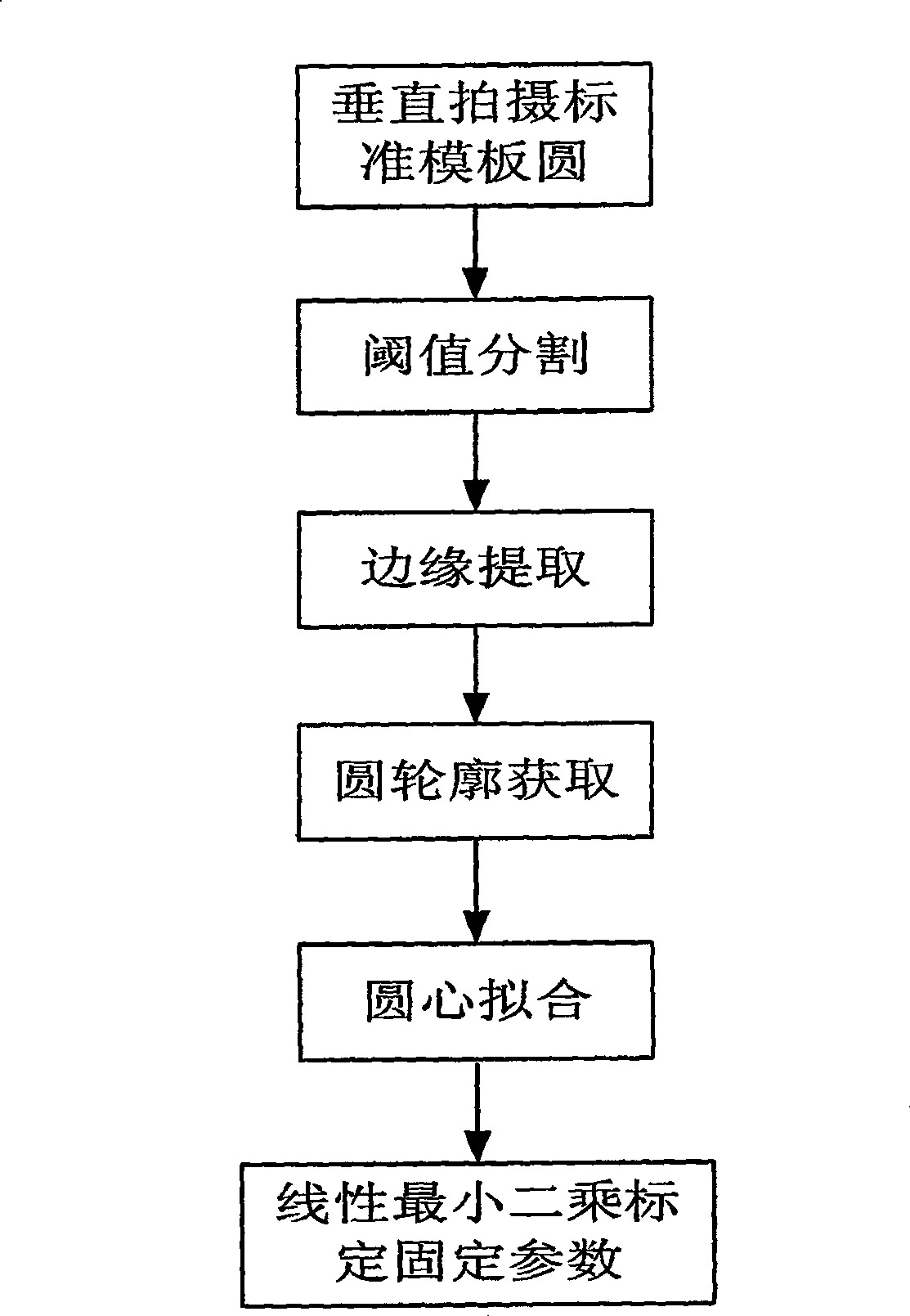

Calibrating method based on fixed parameters and variable parameters for three-dimensional scanning system

InactiveCN101025824ACompatible with practical engineering applicationsCalibration Distortion CoefficientImage analysisImaging processingModel parameters

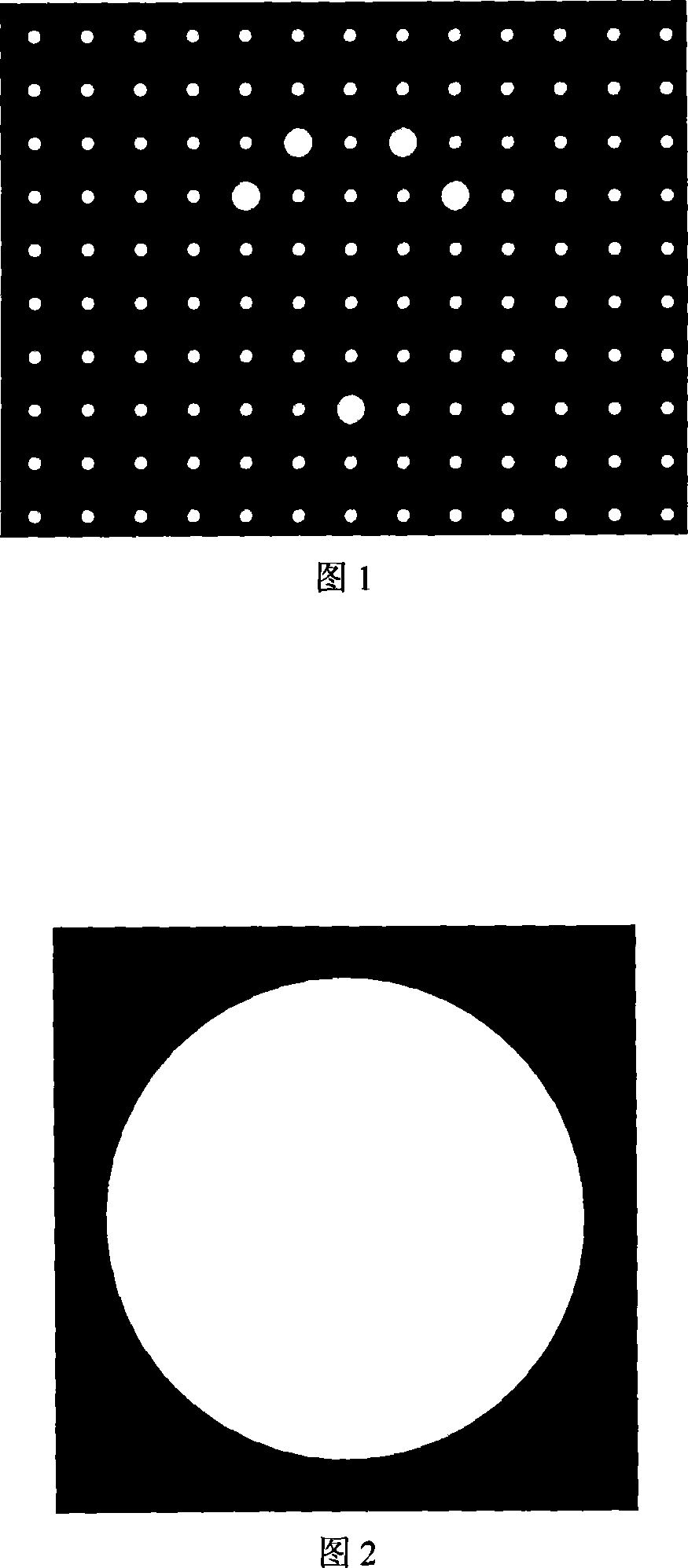

A calibration method based on fixed and variable parameters in three-dimensional scanning system relates to the camera model parameter calibration in the visual system including the following steps: (1) fixed parameters calibration is primarily to acquire coordinates of sampling points on circular contour and heart in image coordinates through image processing techniques, and then use n sampling points to get aspect ratio through least squares method, (2) after obtaining the fixed parameters, it uses the image coordinates of image midpoint and the corresponding space coordinates of world midpoint to demarcate the initial value of variable parameters for the camera, including the equivalent focal length, main point coordinates, axis tilt factor, distortion factor and external parameters, (3) after demarcation, it takes fixed parameters as a constraint for nonlinear optimization objective function to establish a binding target function and get the optimal solution of variable parameters through the nonlinear optimization method.

Owner:南通鑫唐纺织印染有限公司 +1

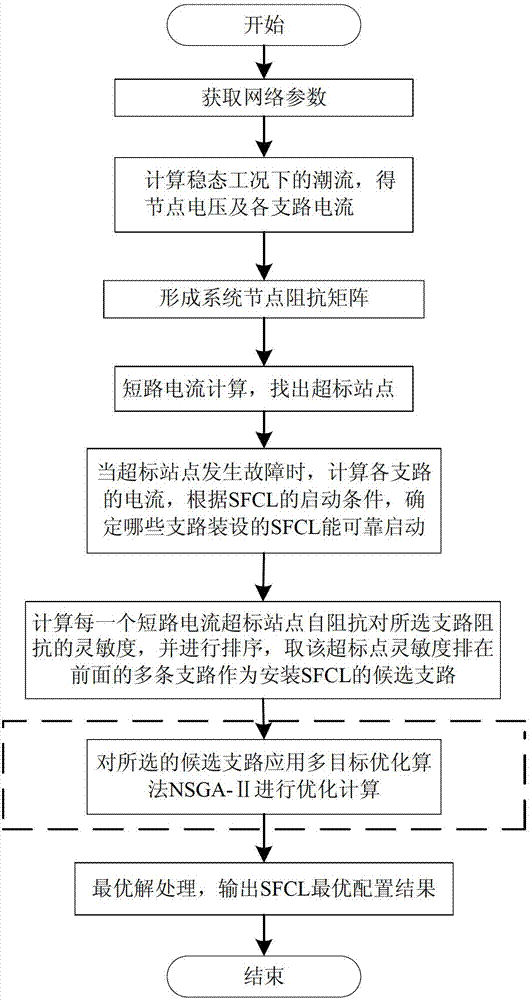

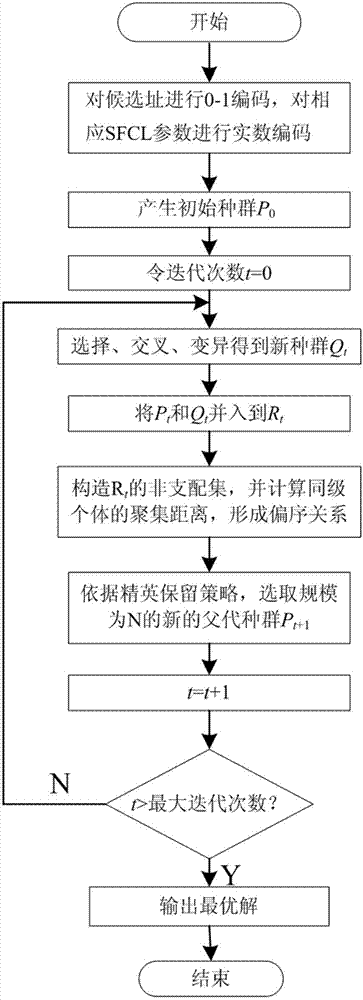

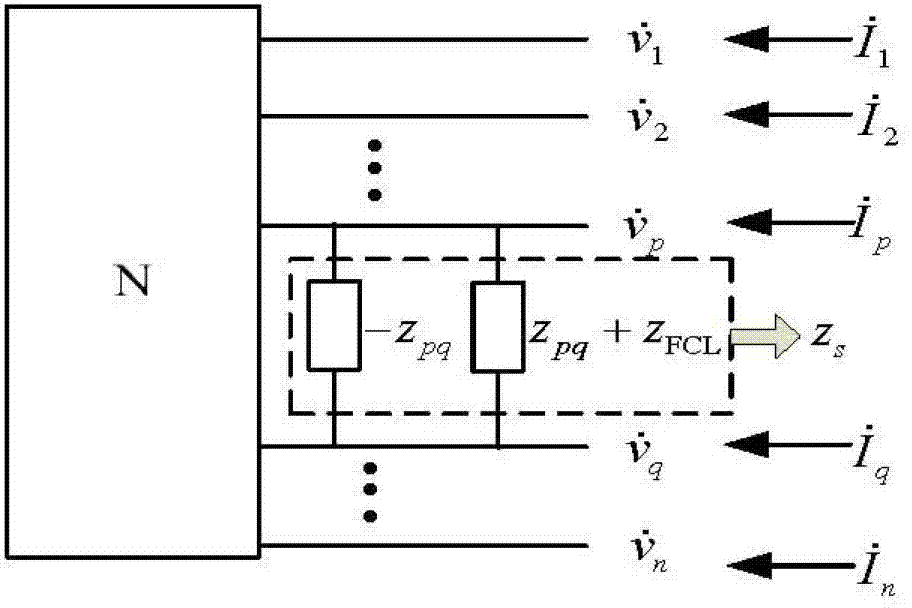

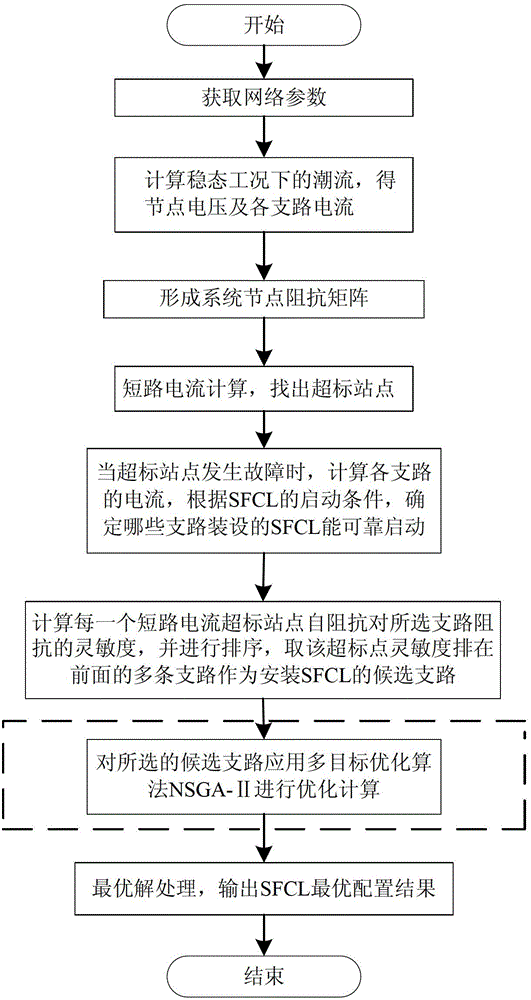

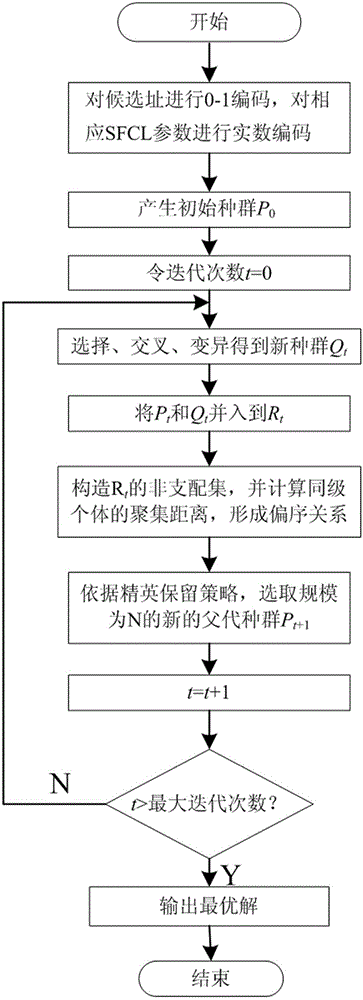

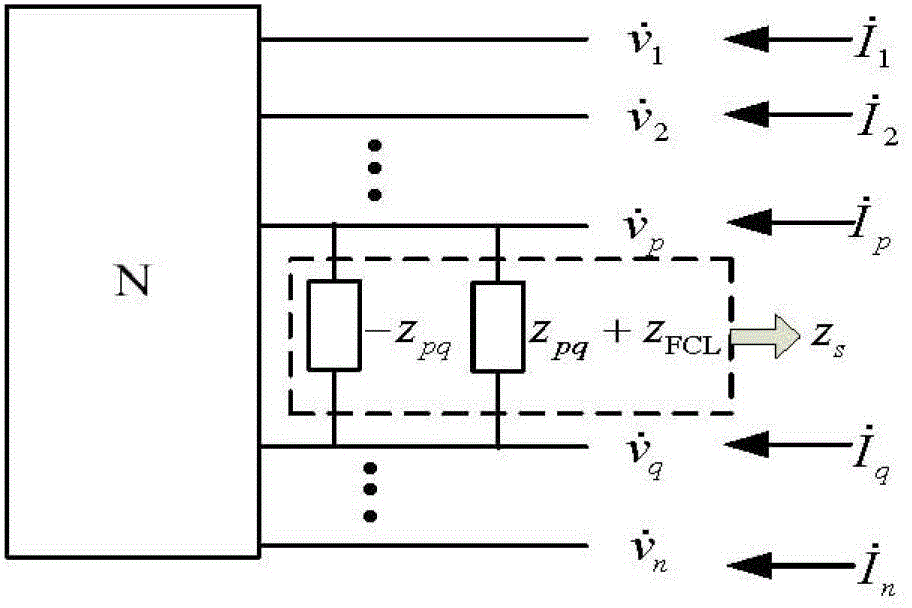

Method of optimal configuration of superconducting fault current limiter based on sensitivity technology

InactiveCN102738780AReliable startPractical applicationEmergency protective arrangements for limiting excess voltage/currentSuperconductor elements usageMulti objective optimization algorithmDecision maker

The invention discloses a method of optimal configuration of a plurality of superconducting fault current limiter based on a sensitivity technology, which comprises the steps of: calculating the three-phase short-circuit current of all nodes in a whole system, and finding b nodes with the short-circuit current exceeding the standard value; determining braches for installation and reliable startup of the SFCLs (superconducting fault current limiter) according to startup conditions of the SFCLs; calculating the sensitivity of self-impedance of each station with the short-circuit current exceeding the standard value, sequencing the stations in a sensitivity descending order, and taking the top a branches as candidate braches for installation of the SFCLs; and taking c candidate braches as optimal branches for a multi-objective optimization algorithm NSGA-II (non-dominated sorting genetic algorithm-II) in next step, determining a scheme with the optimal installation positions of the SFCLs, the number of SFCLs to be installed and the impedance, thereby realizing global optimum configuration. By adopting the method, the search space to be understood is reduced greatly, the speed of calculation is increased, and optimization results are more suitable for actual applications. Meanwhile, the problem of weight selection resulting from conversion of multi-objective optimization to single-objective optimization can be avoided, and a decision-maker can make final decisions according to actual engineering needs.

Owner:HOHAI UNIV

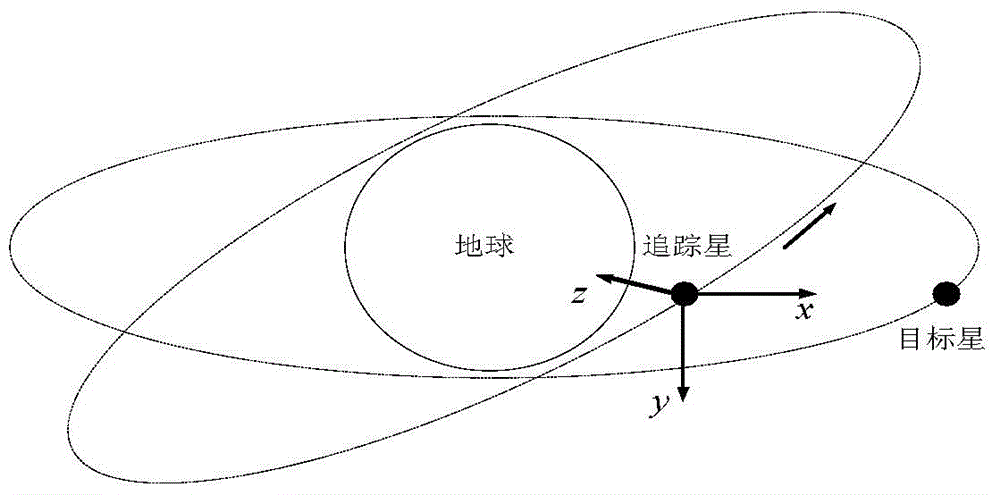

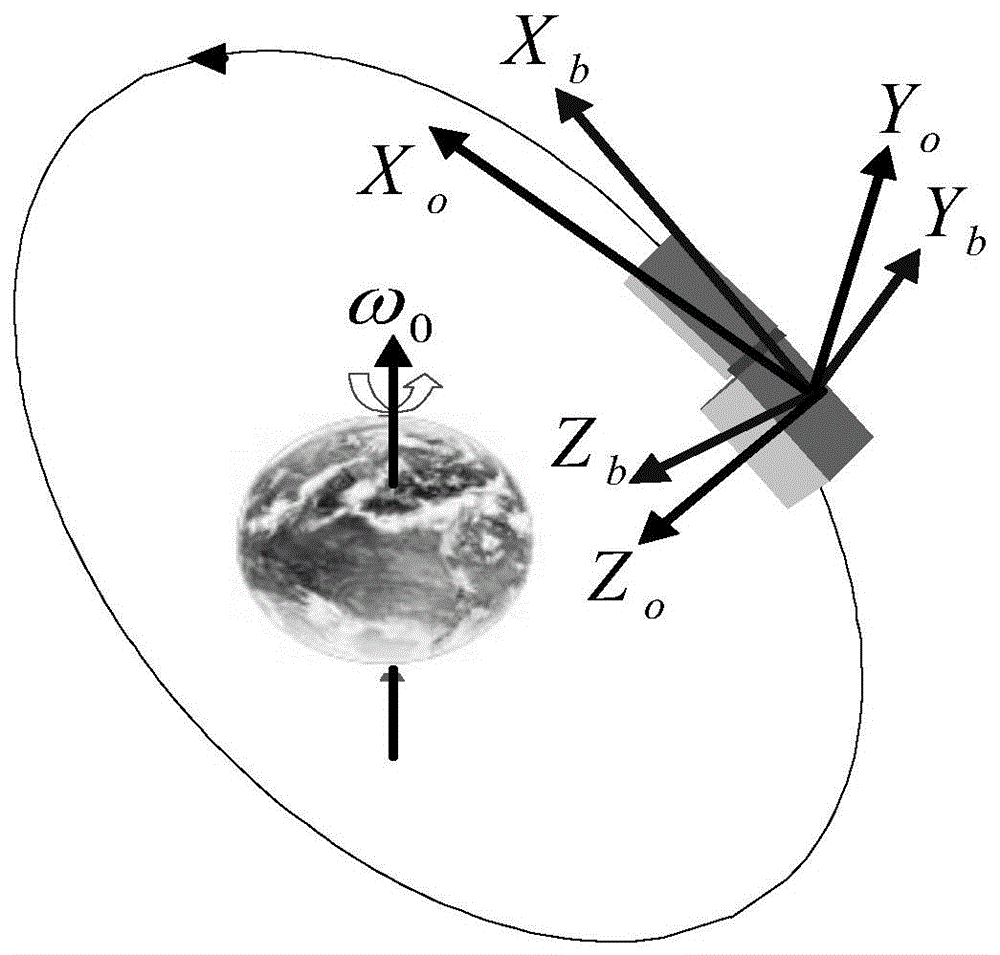

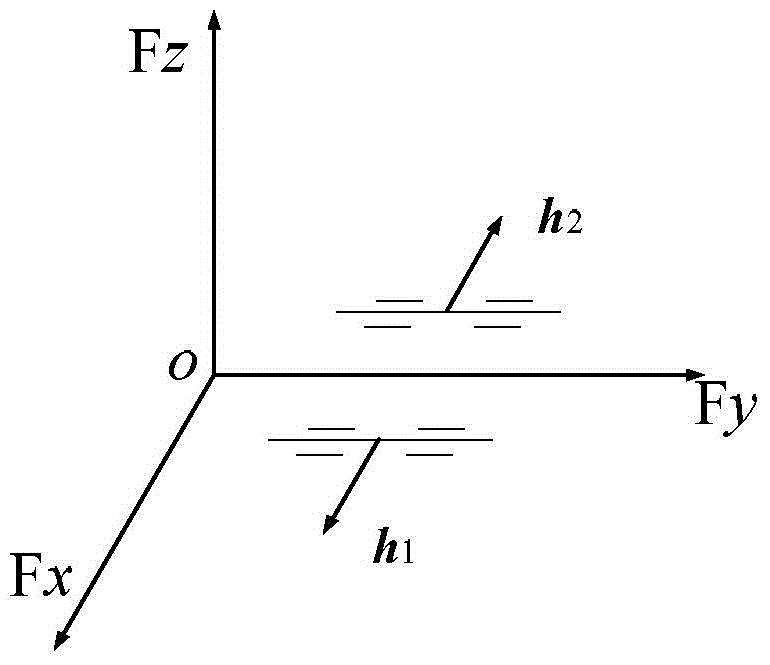

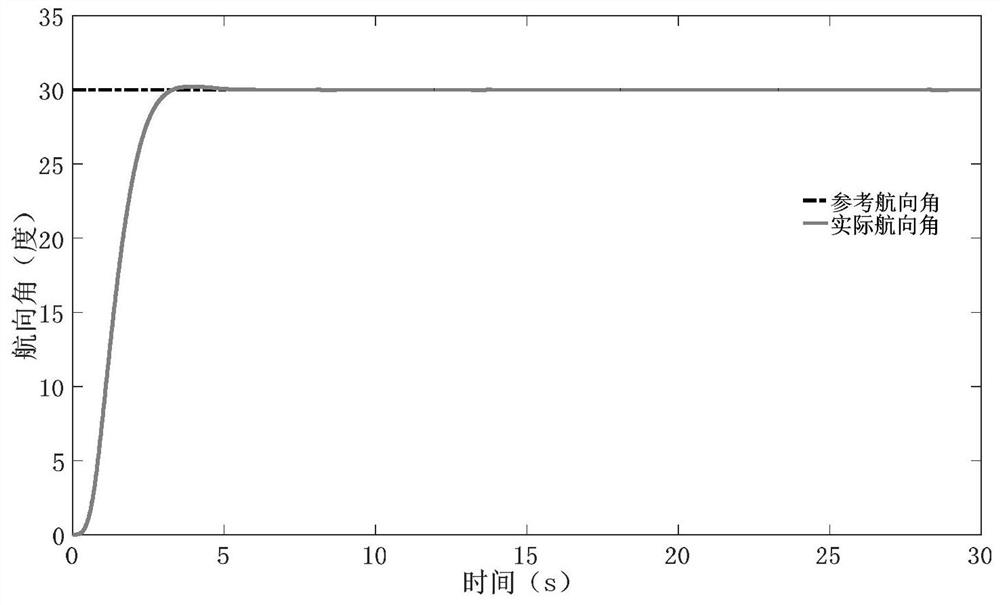

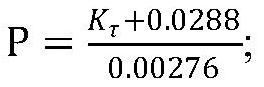

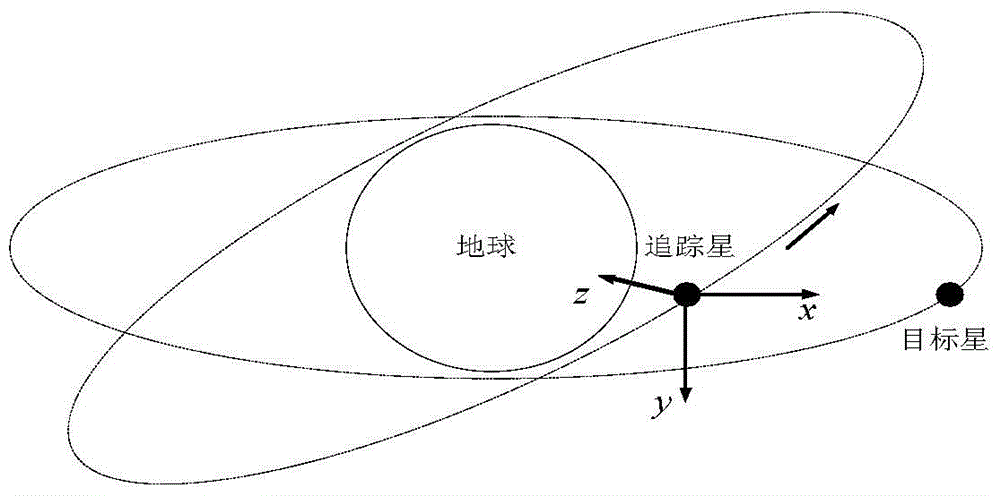

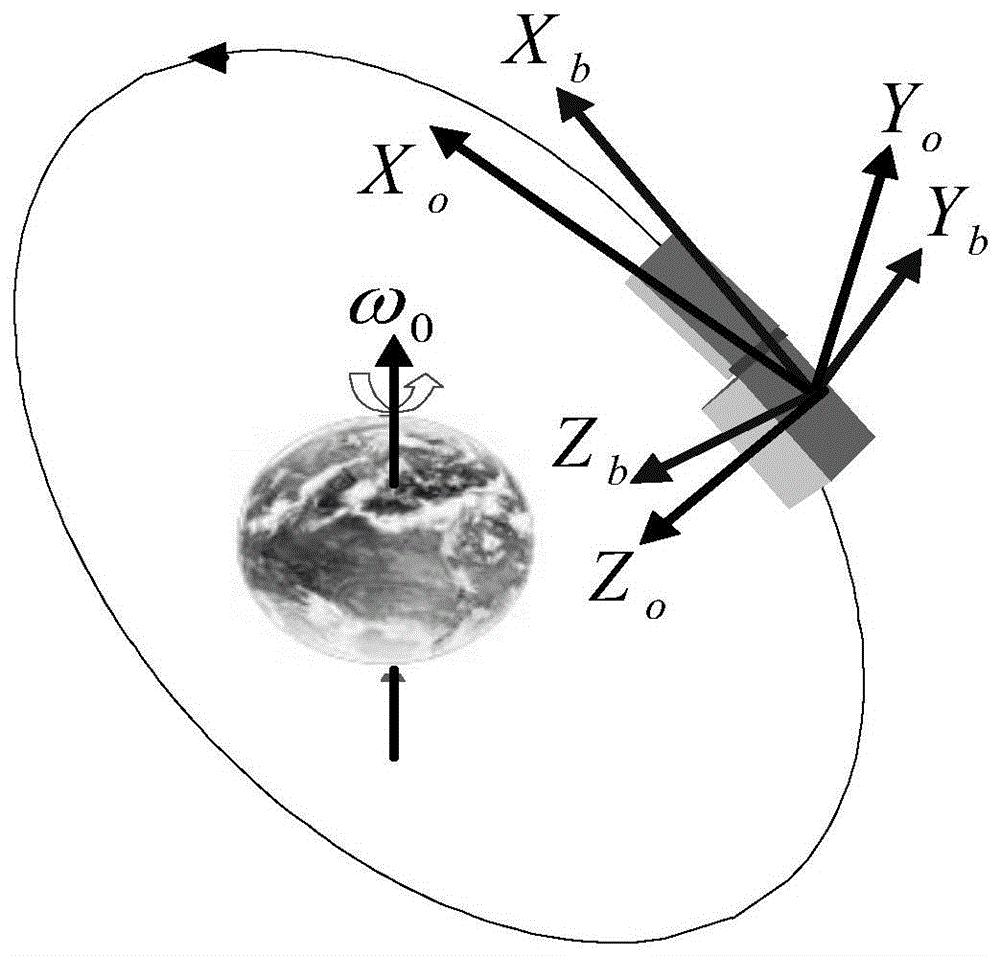

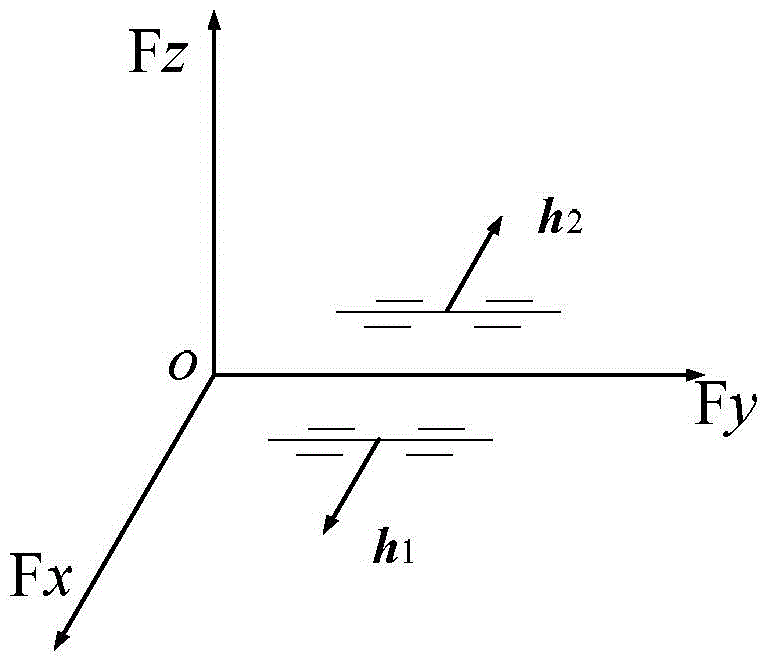

Feedforward PID (proportion, integration and differentiation) control based rapid high-precision relative pointing control method of noncoplanar rendezvous orbit

ActiveCN104570742ACompatible with practical engineering applicationsHigh practical application valueAttitude controlAdaptive controlKinematics equationsControl moment gyroscope

The invention relates to a rapid high-precision relative pointing control method of a noncoplanar rendezvous orbit, in particular to a feedforward PID (proportion, integration and differentiation) control based rapid high-precision relative pointing control method of the noncoplanar rendezvous orbit, and aims to solve the problem that rapid high-precision tracking-pointing control methods related to satellite attitudes under the noncoplanar rendezvous orbit do not exist in the prior art. The feedforward PID control based rapid high-precision relative pointing control method including adopting an Euler angle for attitude description of a spacecraft, creating dynamical and kinematical equations of the spacecraft, and acquiring an precise expected angle theta according to a noise-containing expected angle z by a Kalman filtering algorithm of a spaceborne computer; designing an attitude control law of each axis according to a formula of ; selecting two parallelly-placed single-frame control moment gyroscopes to control a yaw axis, and selecting two flywheels to control a rolling axis and a pitch axis respectively; calculating gyroscopic moment T and flywheel actual output moment uw to complete rapid high-precision relative pointing control of the noncoplanar rendezvous orbit. The feedforward PID control based rapid high-precision relative pointing control method is applicable to rapid high-precision relative pointing control of the noncoplanar rendezvous orbit.

Owner:HARBIN INST OF TECH

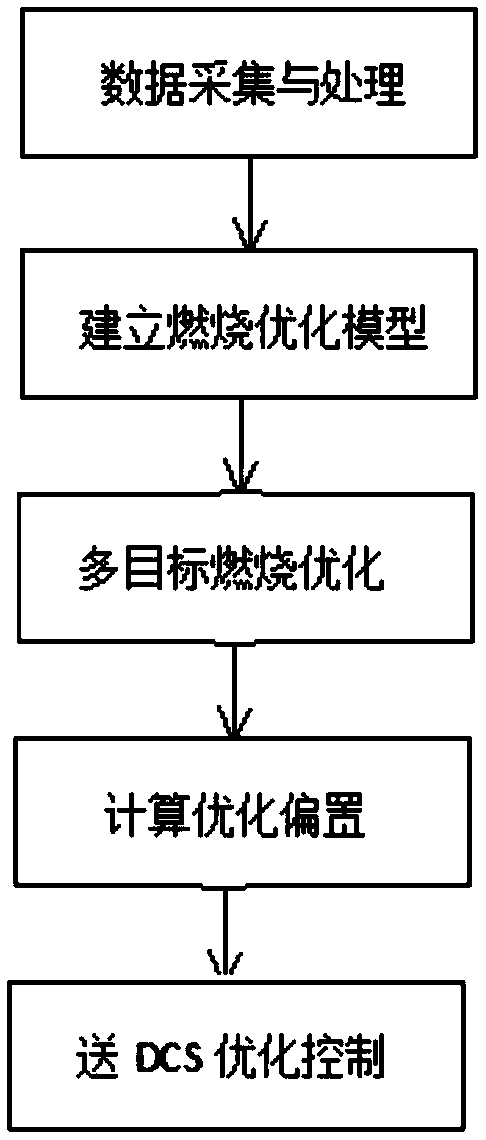

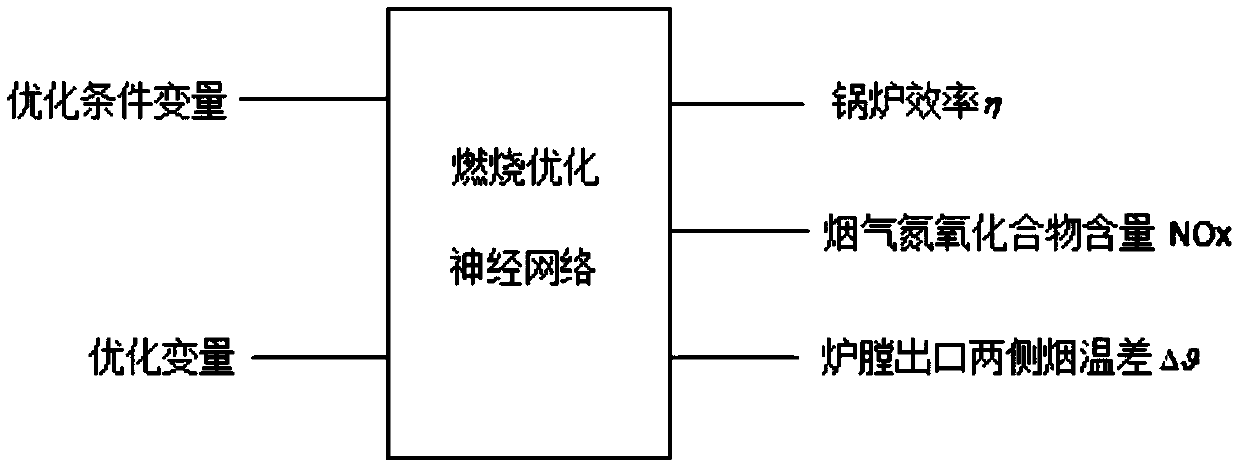

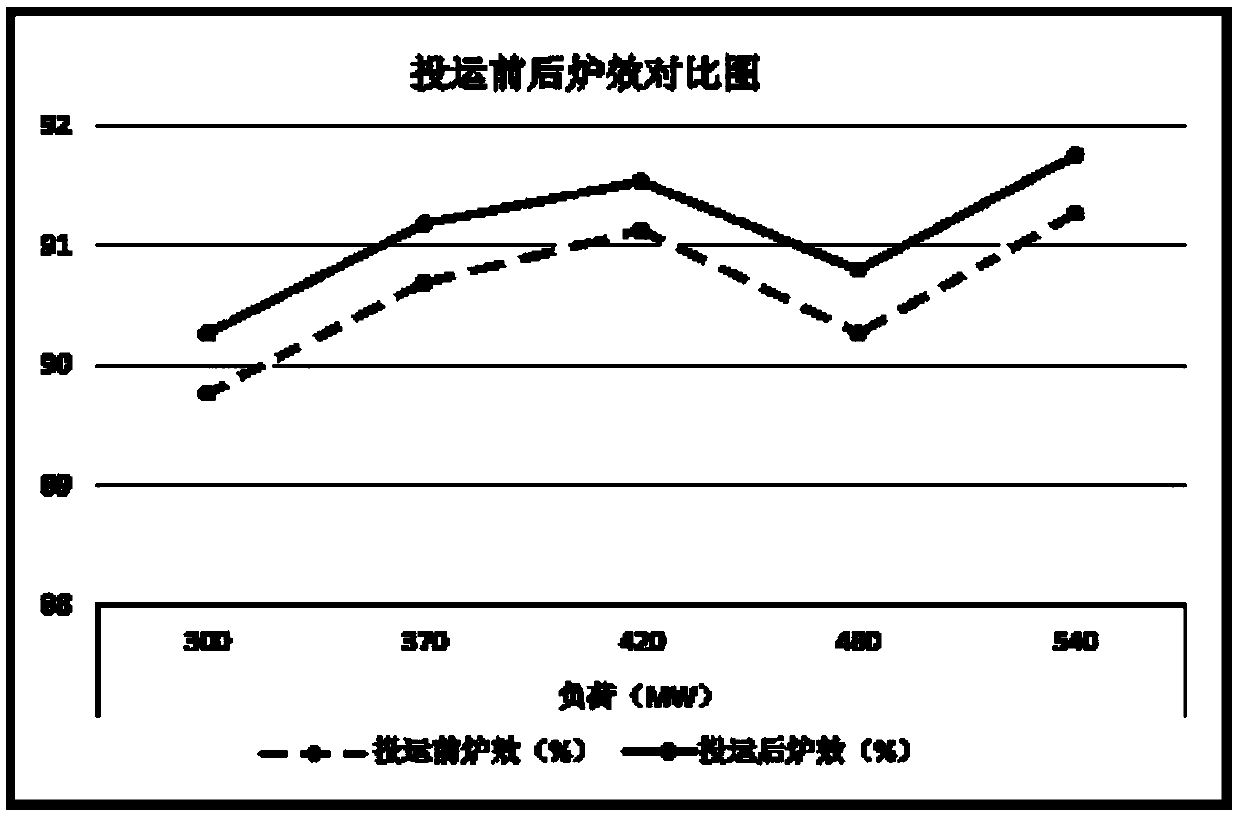

Optimal controlling method for boiler intelligent combustion based on big data

InactiveCN108644805AQuality improvementImprove convenienceCombustion regulationGenetic algorithmsClosed loopGenetic algorithm

The invention discloses an optimal controlling method for boiler intelligent combustion based on big data. The method comprises the following steps that firstly, the DCS data of a unit is collected and processed to form neural network training samples, and then a combustion optimization neural network model is established according to the training samples; then combustion parameters are optimizedby using multi-objective non-dominated fast sorting genetic algorithm (NSGA) according to the combustion optimization neural network model; and finally, optimization bias is calculated according to the optimized combustion parameters and sent to a DCS for realizing closed-loop optimization control. According to the optimal controlling method for boiler intelligent combustion based on big data, because the big data is adopted and the data of boiler ash blowing conditions is eliminated, the quality of the combustion optimization neural network model is improved; the optimization performance andoptimization effect are improved by adopting the multi-objective genetic algorithm optimize combustion parameters, and the optimal controlling method can adapt to the various optimization requirementsin practical application; and in addition to the boiler efficiency and the flue gas NOx emission of the optimizing objectives, the temperature difference index of smoke on both sides of a chamber outlet is further considered, and the optimal controlling method is more suitable for practical application of engineering.

Owner:NANJING GUITU TECH DEV

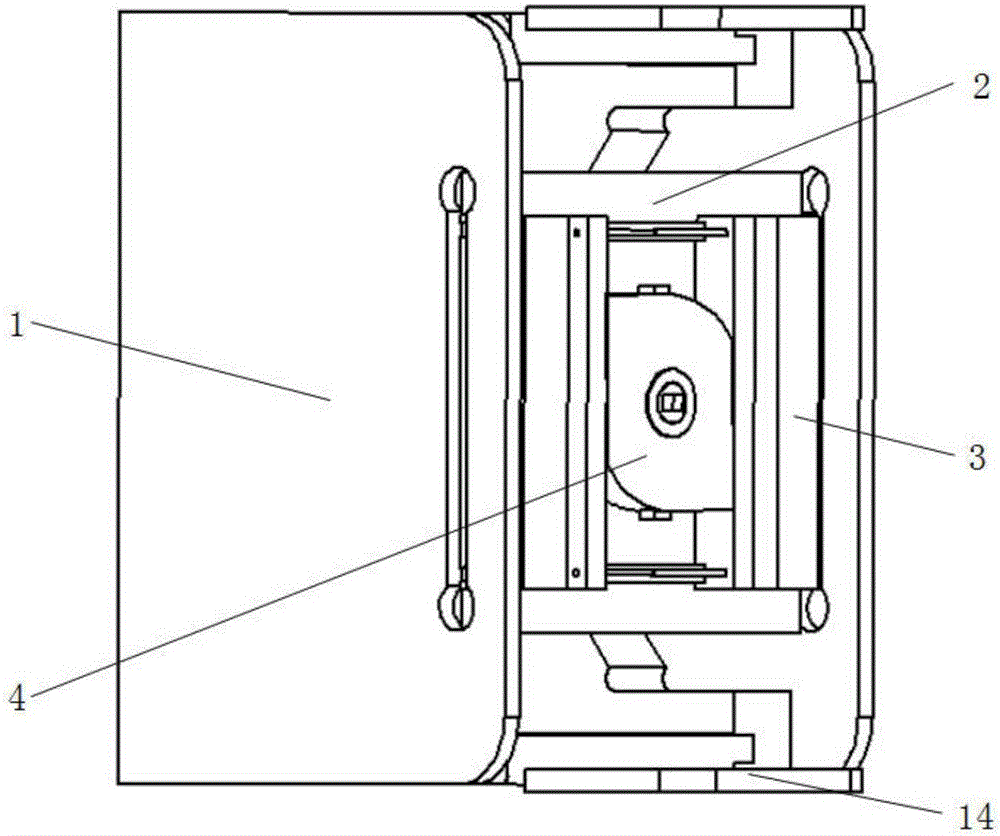

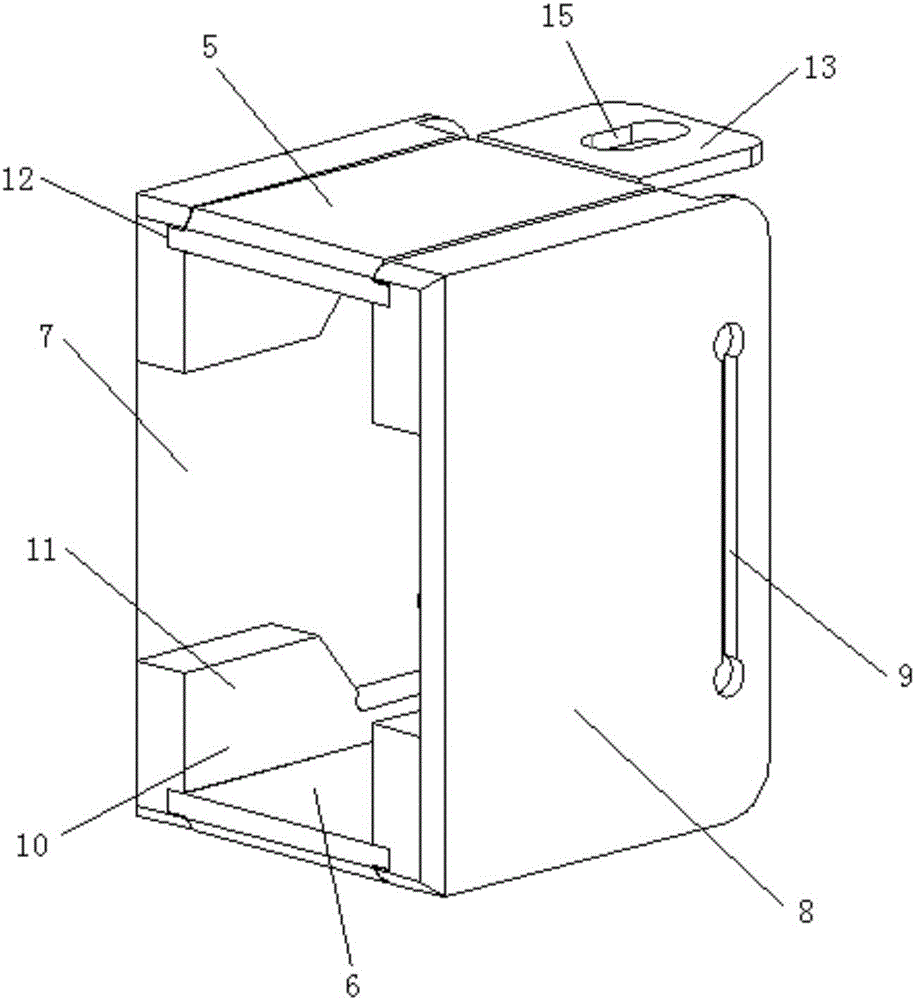

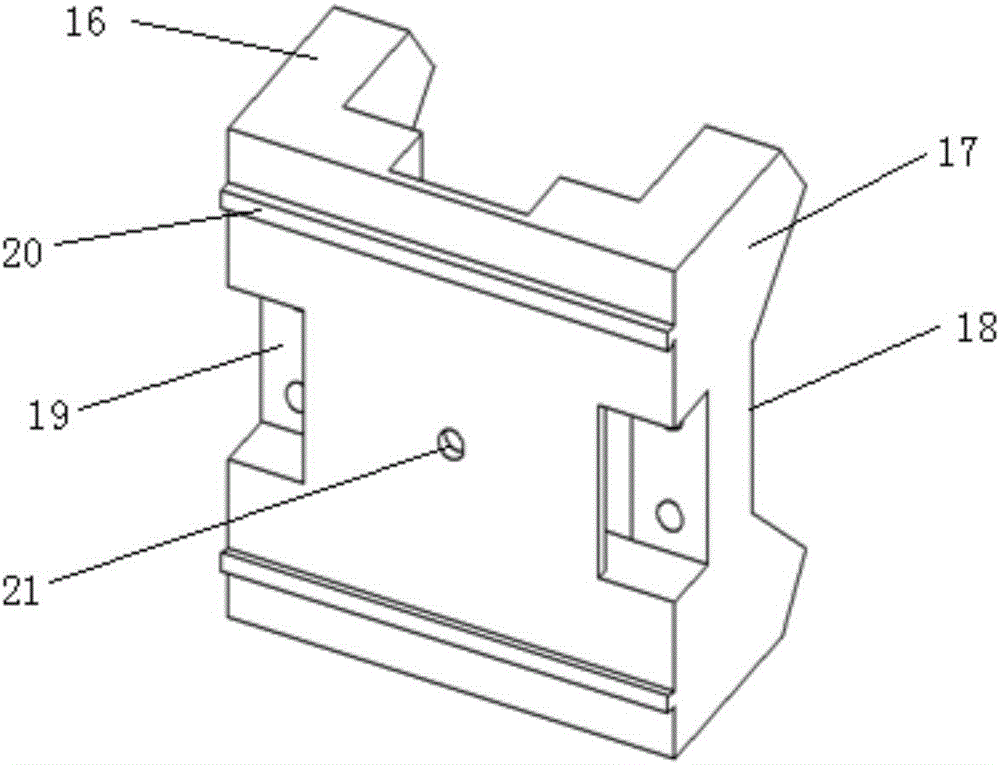

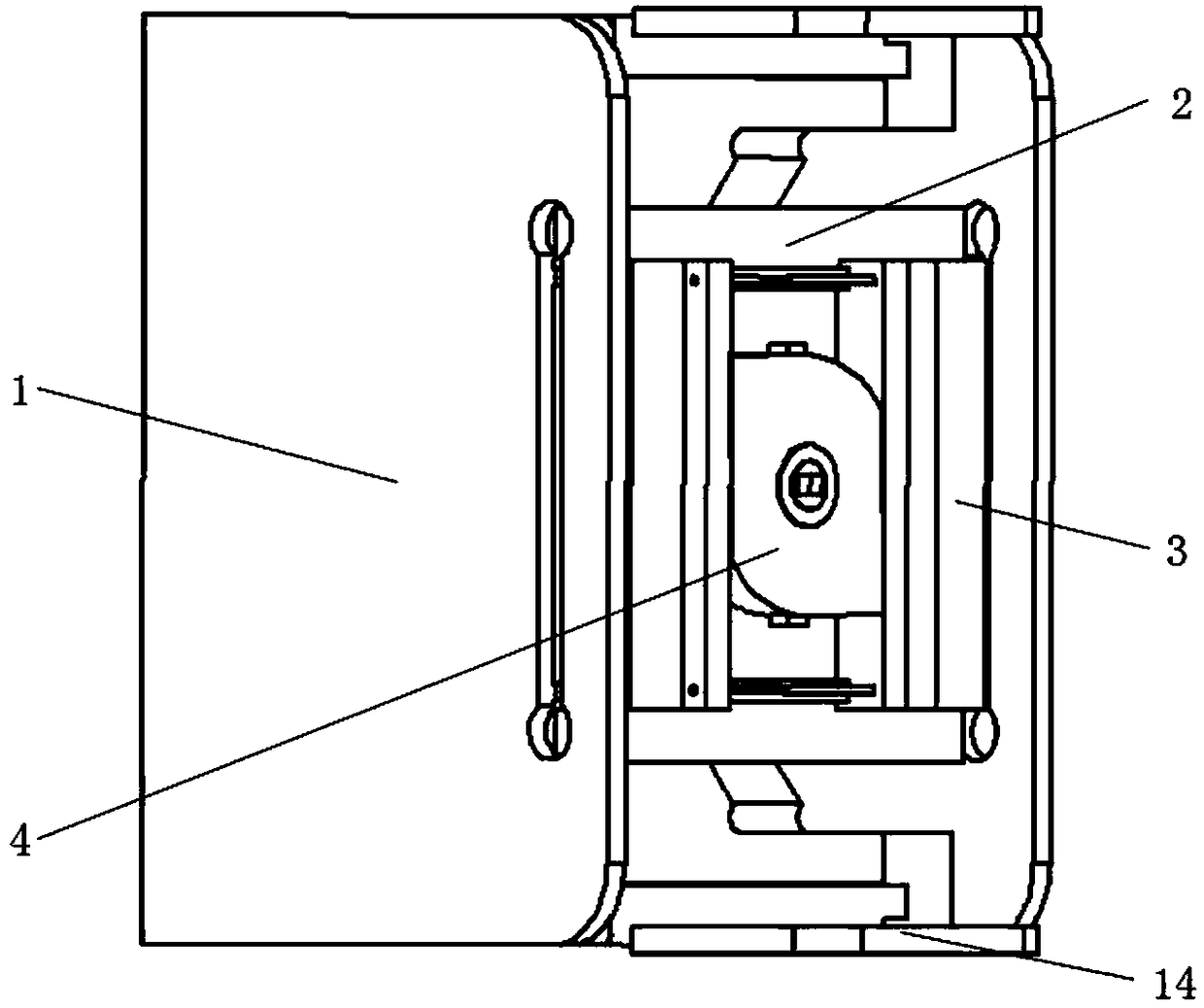

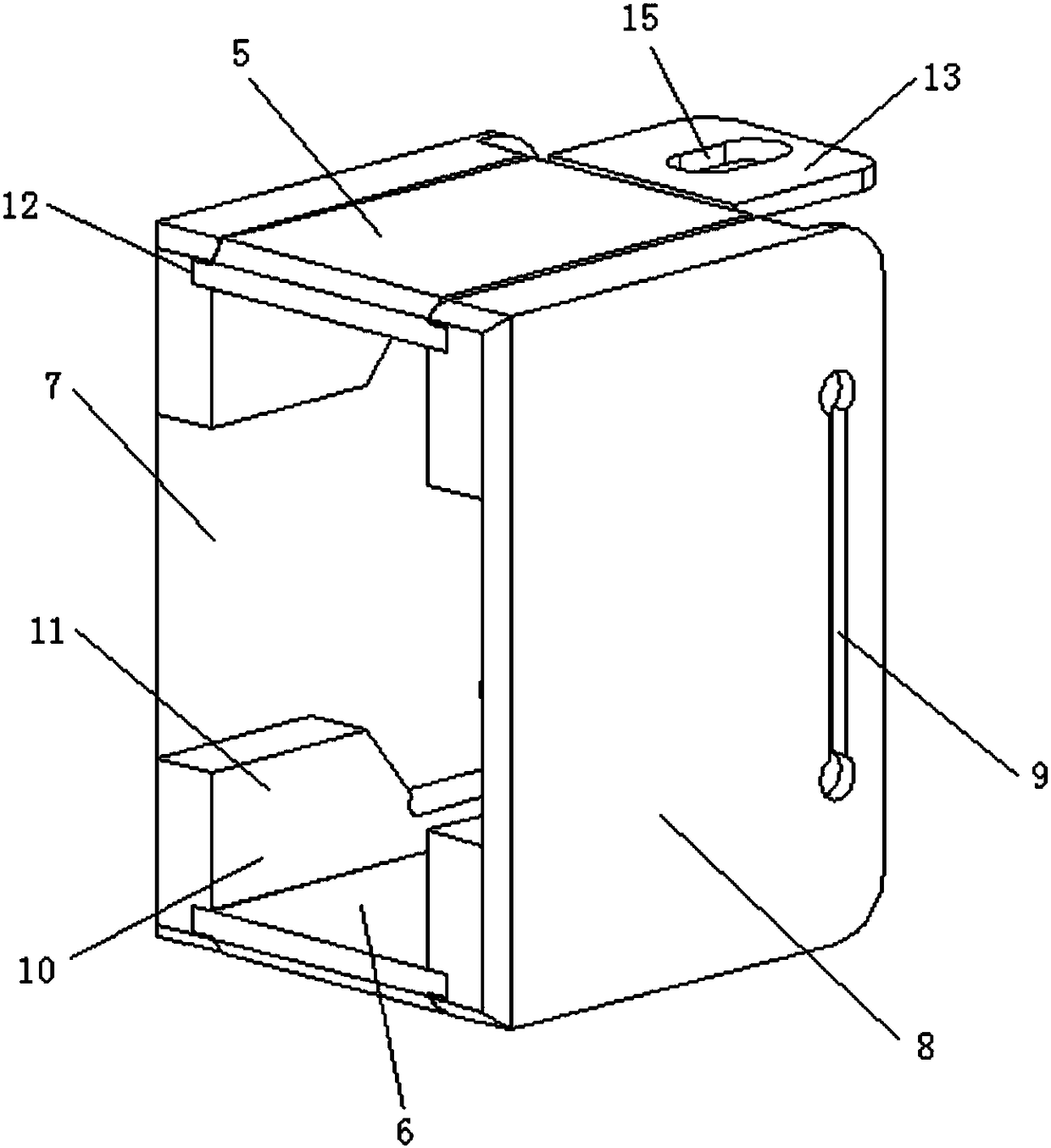

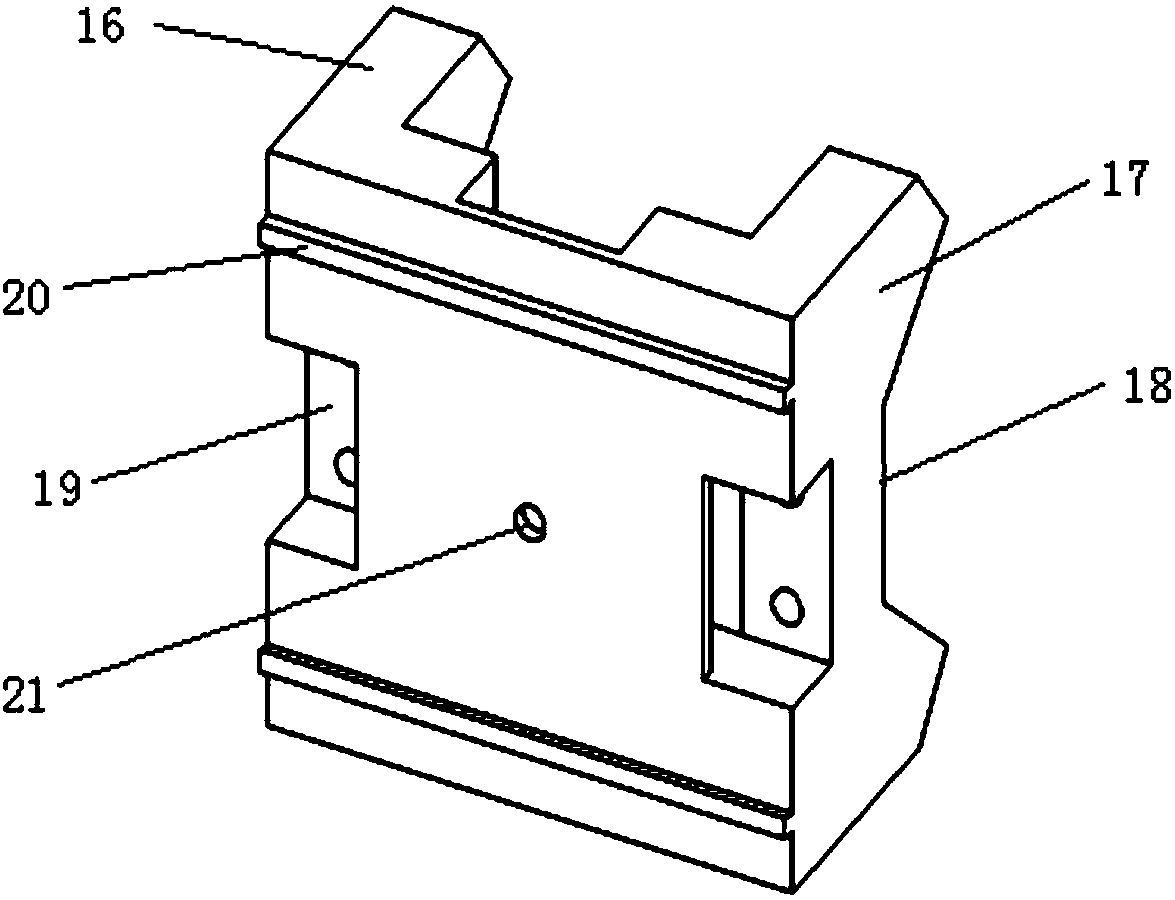

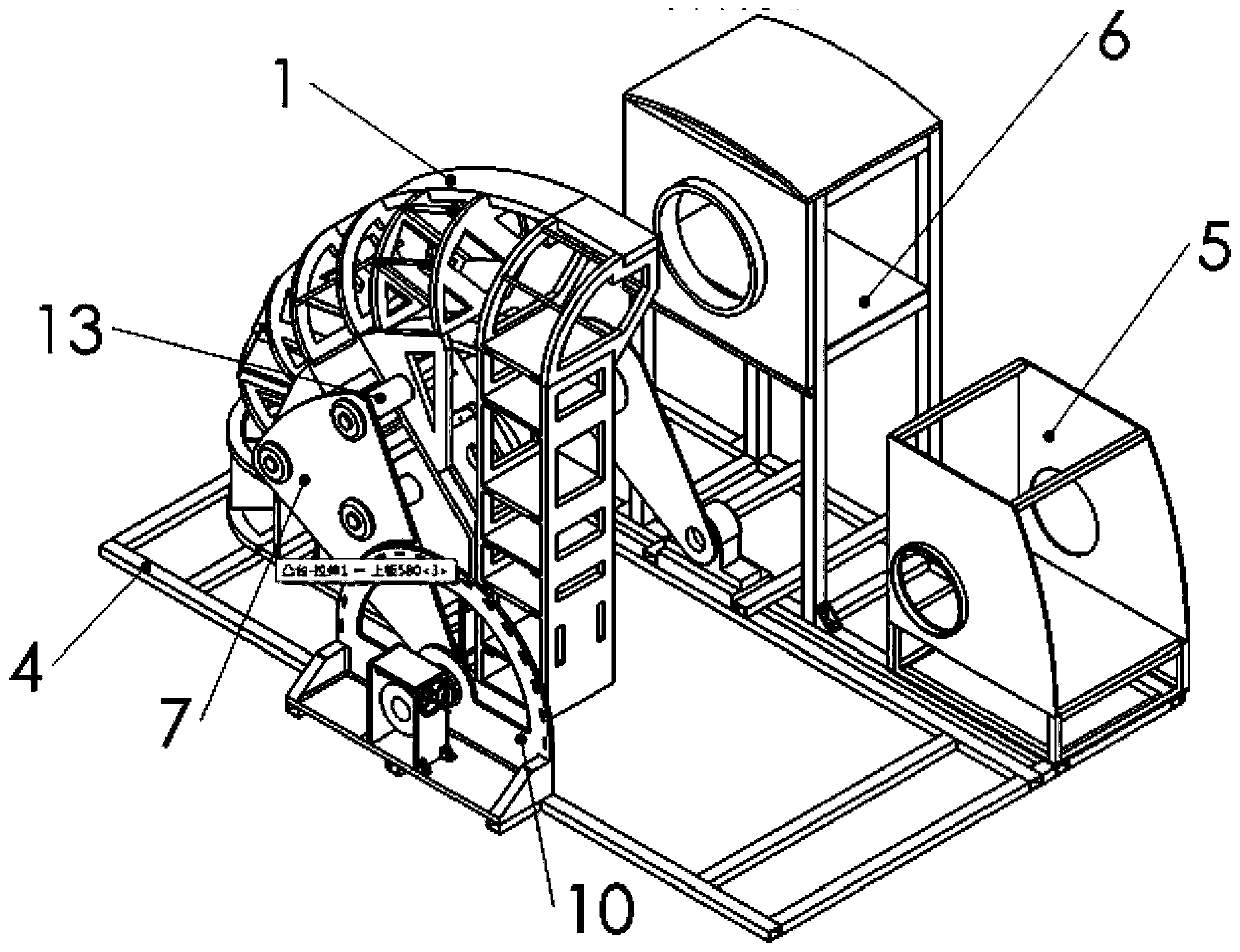

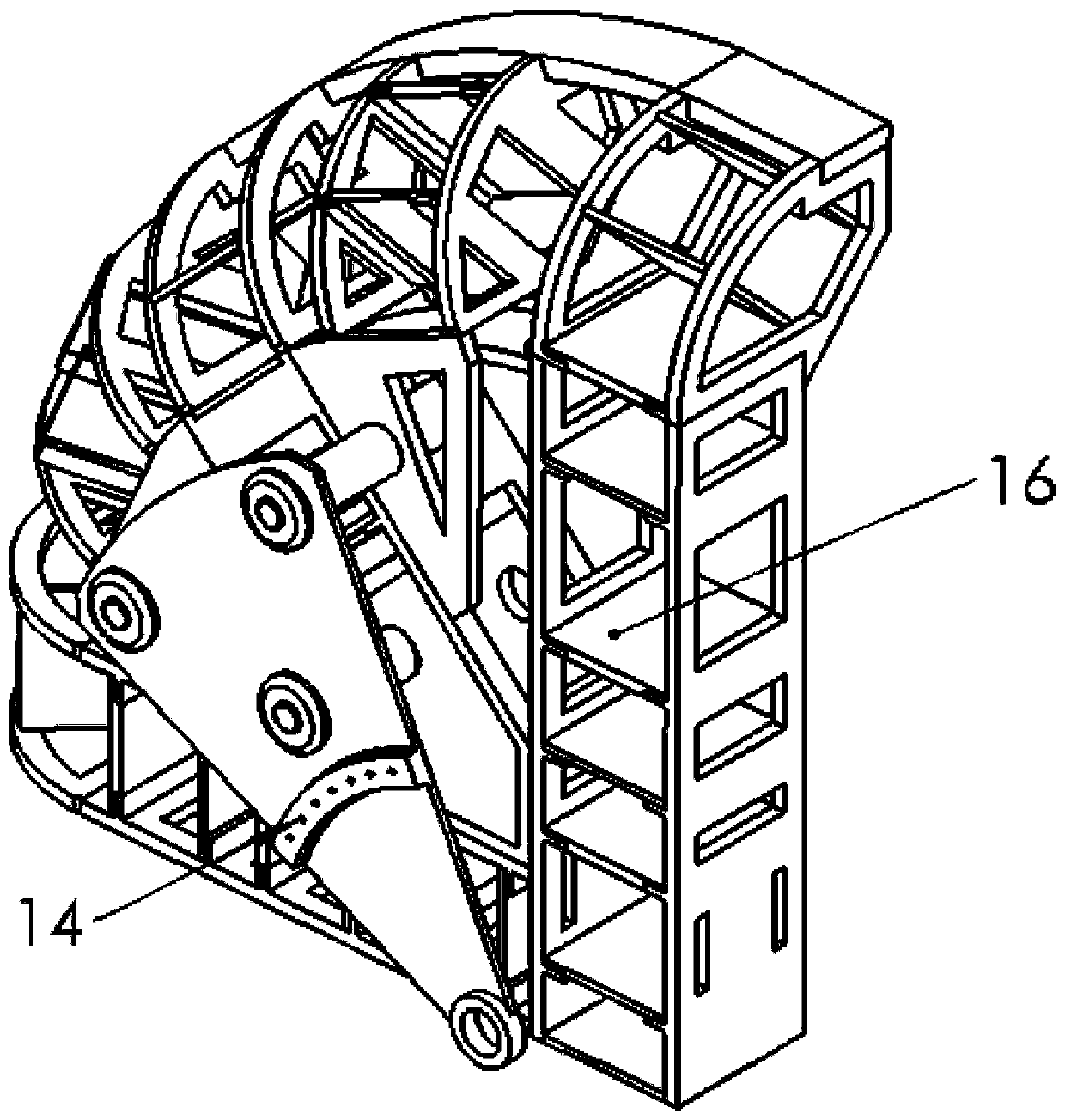

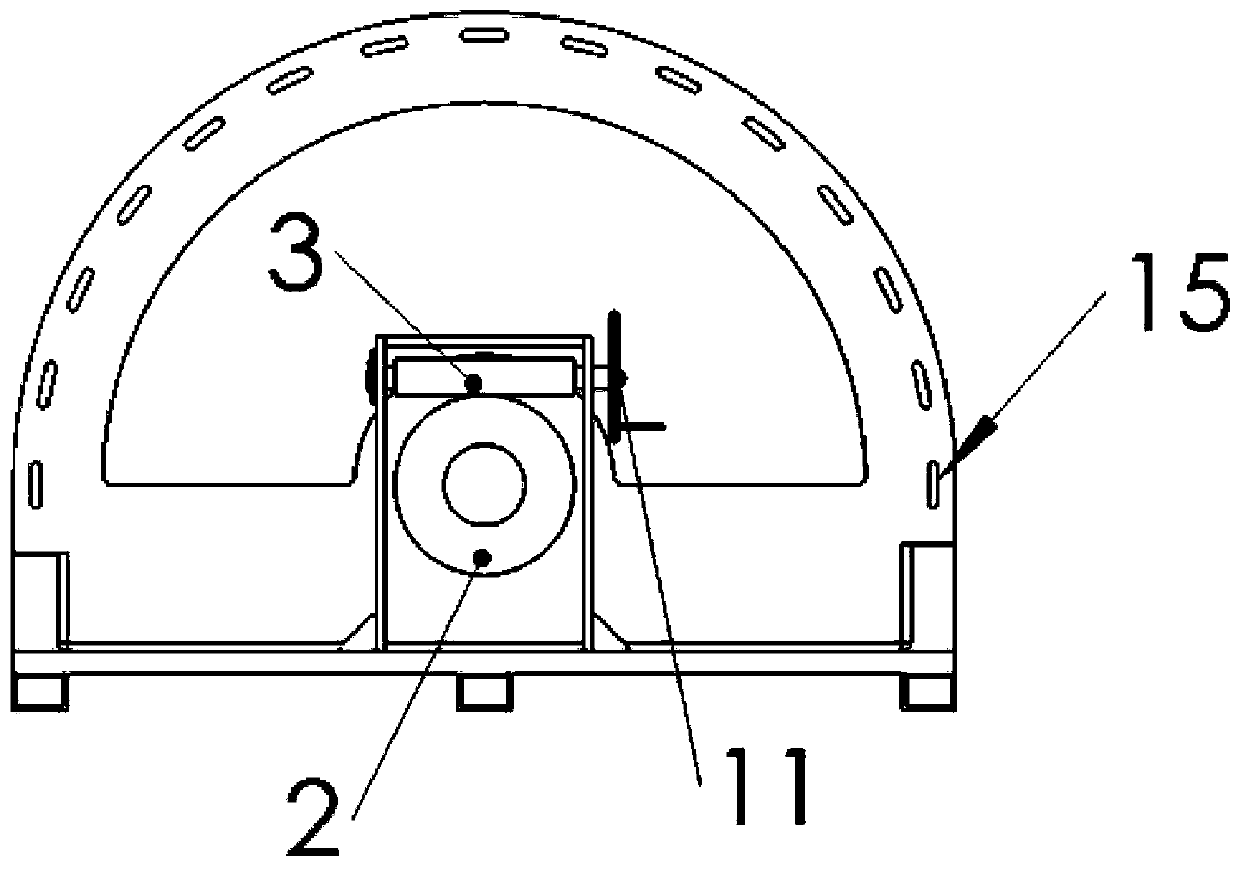

Disc hobbing cutter box mechanism of shield tunneling machine and application method thereof

The invention discloses a disc hobbing cutter box mechanism of a shield tunneling machine and an application method thereof. The disc hobbing cutter box mechanism comprises a box body and a rotation mechanism, wherein a hobbing cutter installing mechanism is arranged in the box body, one side of the hobbing cutter installing mechanism is fixedly connected with a hobbing cutter, and the rotation mechanism is installed on the other side of the hobbing cutter installing mechanism; the rotation mechanism comprises a rotation mechanism installing block and a rotation box installed on the rotation mechanism installing block. A cutter box is simple in structure and easy to machine, and meets strength requirements. The cutter box is structurally integrated and free of any independent small part, and operation by a robot is convenient. When the disc hobbing cutter box mechanism is used in cooperation with a manipulator, torque generated in the rotation process of the rotation mechanism on the cutter box can be transmitted to the box body through mechanical fingers, and a mechanical arm does not need to bear the torque. A bevel arranged on a left baffle and a bevel arranged on a right baffle of the rotation mechanism installing block can prevent the left baffle and the right baffle from getting stuck in the box body. The rotation mechanism is installed behind the hobbing cutter installing mechanism, and the hobbing cutter is prevented from being scratched by falling rock-soil in the rock-soil cutting process.

Owner:NORTHEASTERN UNIV LIAONING

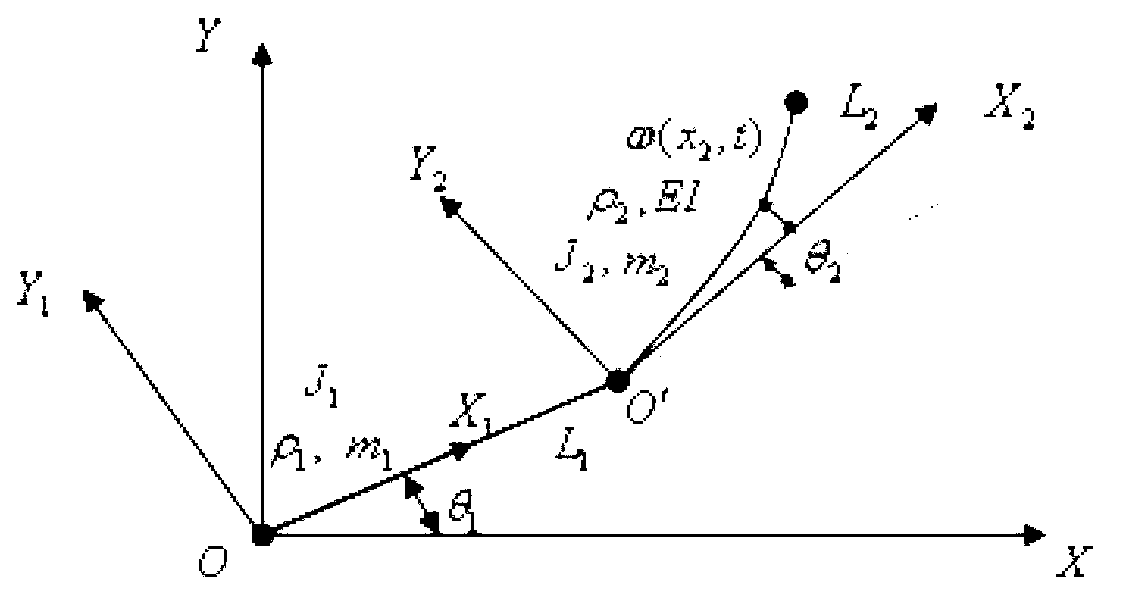

High-order nonsingular terminal slip mode control method for two-stage magnetic head positioning system

InactiveCN103077729ACompatible with practical engineering applicationsIncrease Servo BandwidthMaintaining head carrier alignmentHard disc driveLyapunov stability

The invention discloses a high-order nonsingular terminal slip mode control method applied to a two-stage magnetic head positioning system of a hard drive. The method comprises the following steps of: establishing a kinetic model of a flexible access arm system under the consideration of a flexible mode and the uncertainty of model parameters; and putting forward a three-order nonsingular terminal slip mode control method for permodeing one-time low-pass filtration on a control signal to effectively weaken the phenomenon of buffeting. In the method, a Lagrange method and an assumed mode method are used for deriving a dynamical equation of a flexible access arm two-stage system, and an output redefinition method is adopted for decomposing the flexible two-stage system into an input-output subsystem and an internal subsystem. Specific to the input-output subsystem in combination with two-order nonsingular terminal slip mode control and linear slip mode control, a three-order nonsingular terminal slip mode controller is designed, the converging characteristic of the system within limited time is proved through a Lyapunov stability theory, and the effectiveness of the method is verified by emulating with Matlab / Simulink software.

Owner:XIDIAN UNIV

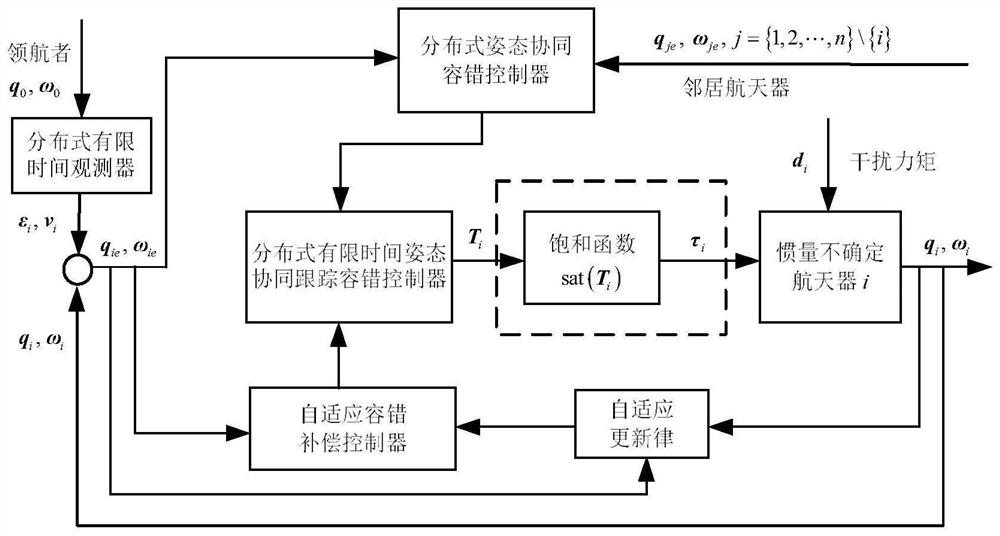

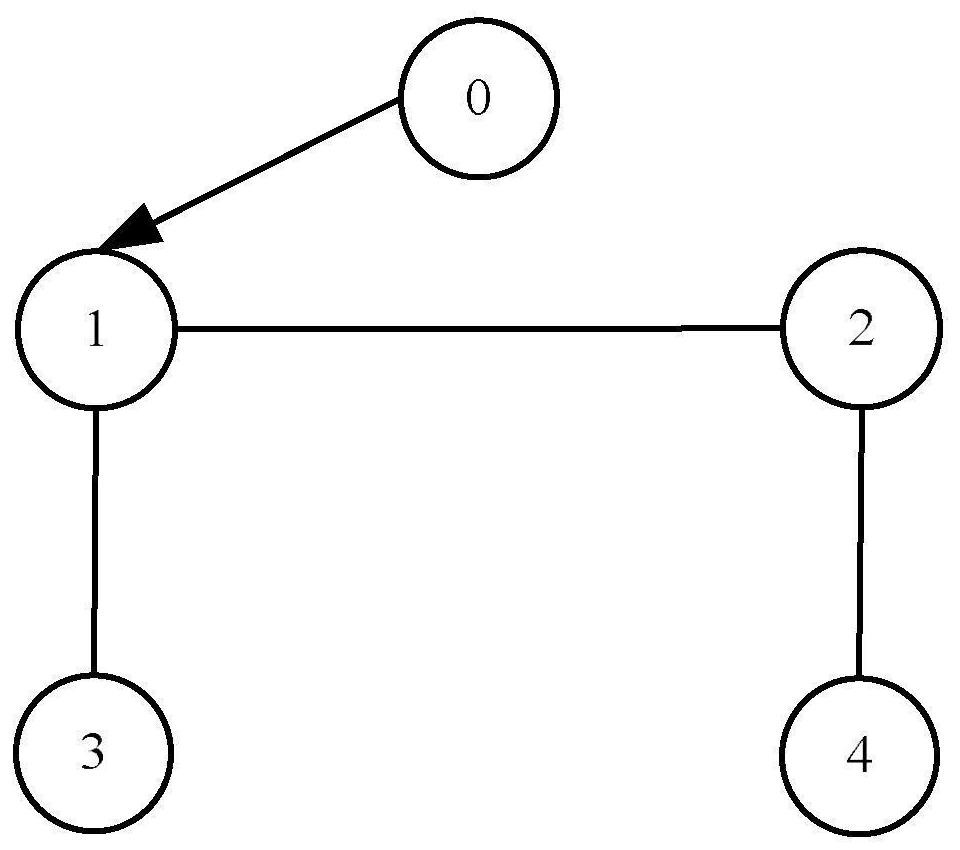

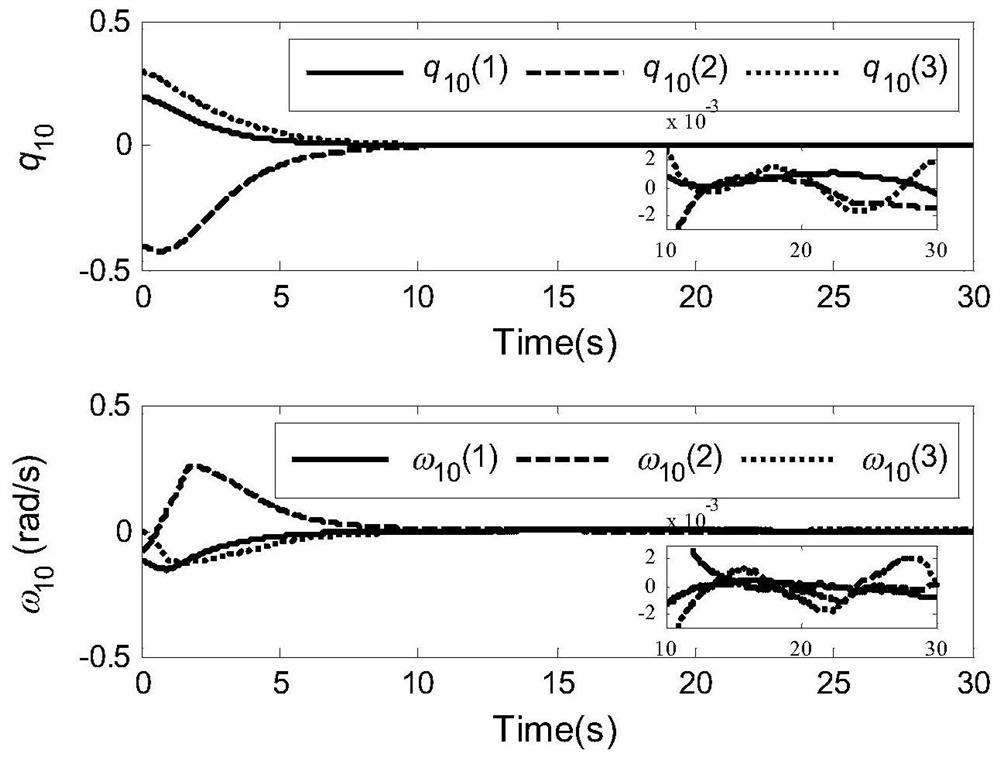

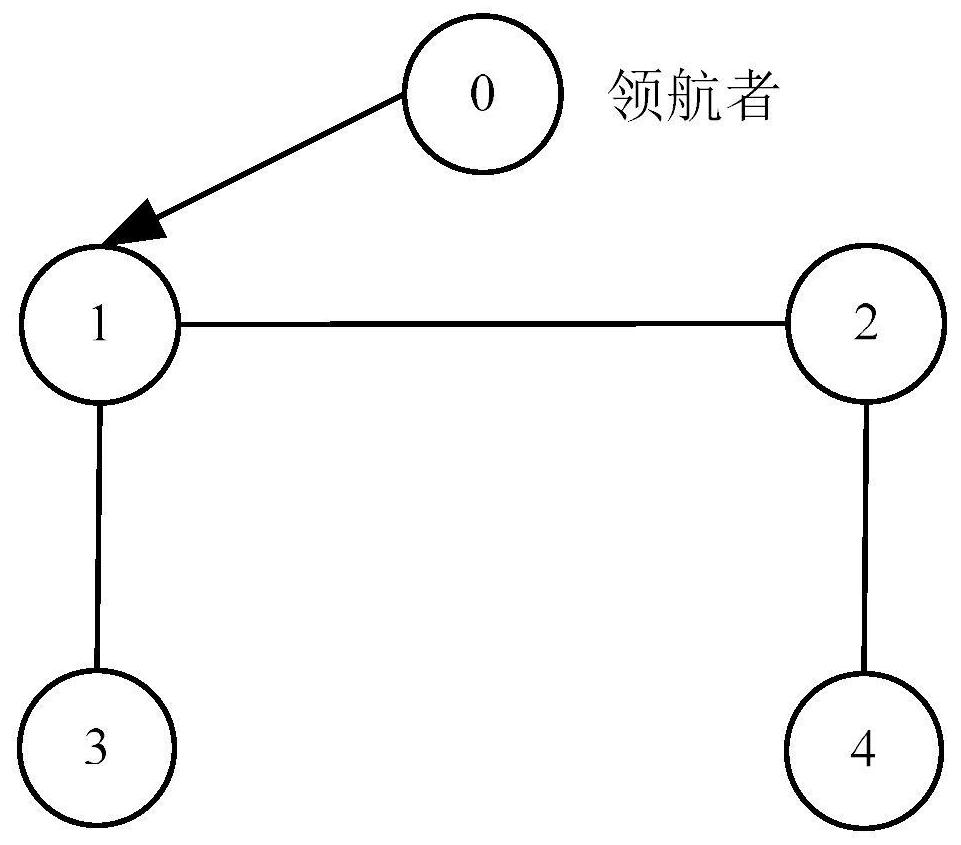

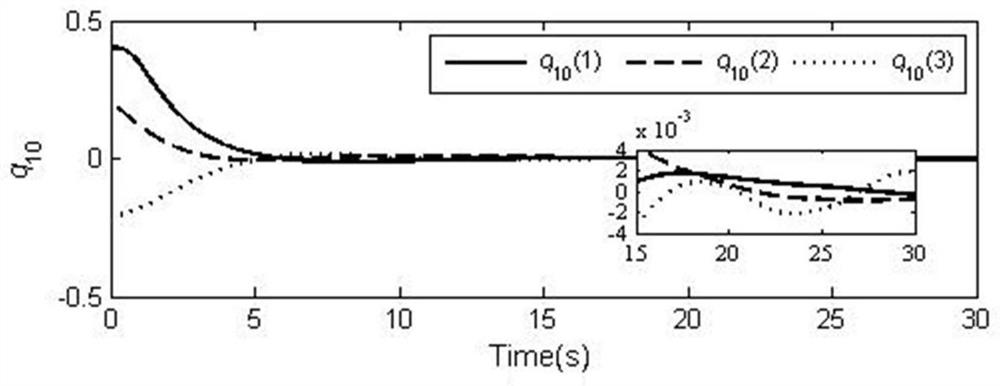

Input-limited finite time attitude cooperative tracking fault-tolerant control method

InactiveCN112357119AReduce occupancyShort collaboration timeCosmonautic vehiclesSpacecraft guiding apparatusInterference (communication)Communication bandwidth

The invention discloses an input-limited finite time attitude cooperative tracking fault-tolerant control method, and belongs to the technical field of multi-spacecraft formation flight. In order to reduce communication paths and avoid resource waste, a communication topological structure which has less communication traffic, comprises a directed spanning tree taking a navigator as a root node andonly has a part of followers capable of obtaining navigator information is adopted among spacecraft formation members. In order to enable a following spacecraft which cannot obtain pilot informationto obtain reference information, a distributed finite time state observer is designed to observe the pilot information. Considering communication bandwidth limitation, actuator fault and saturation, system uncertainty and external interference, based on a finite time algorithm, a redundant fault-tolerant algorithm, an adaptive algorithm and a saturation function, a finite time attitude cooperativetracking fault-tolerant control strategy is perfected, and the robustness and practicability of the control system are further improved.

Owner:YANCHENG INST OF TECH

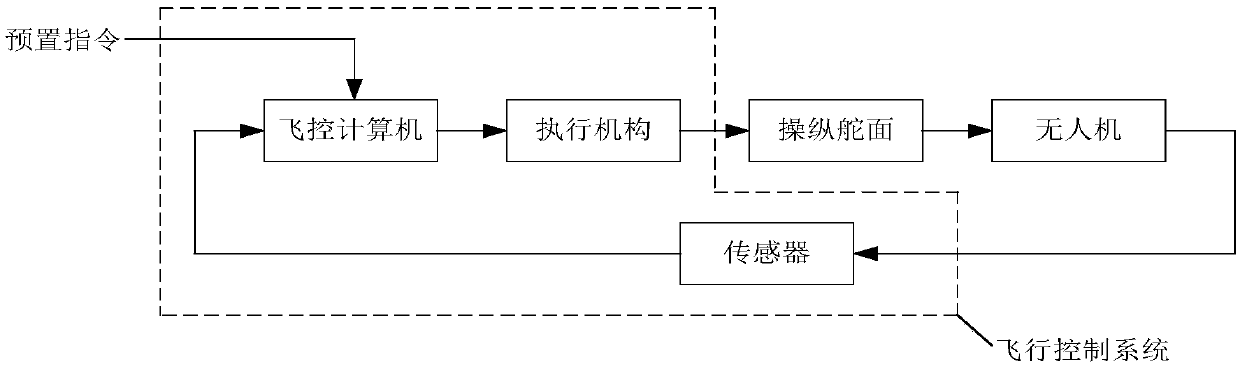

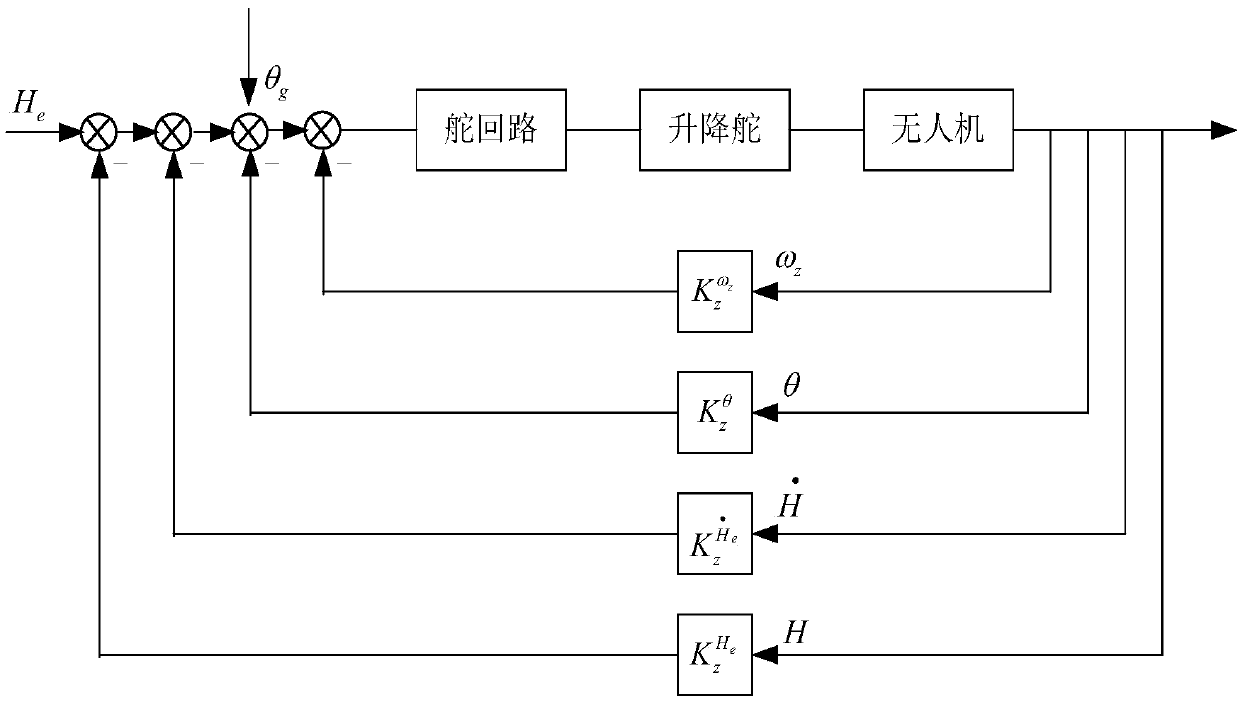

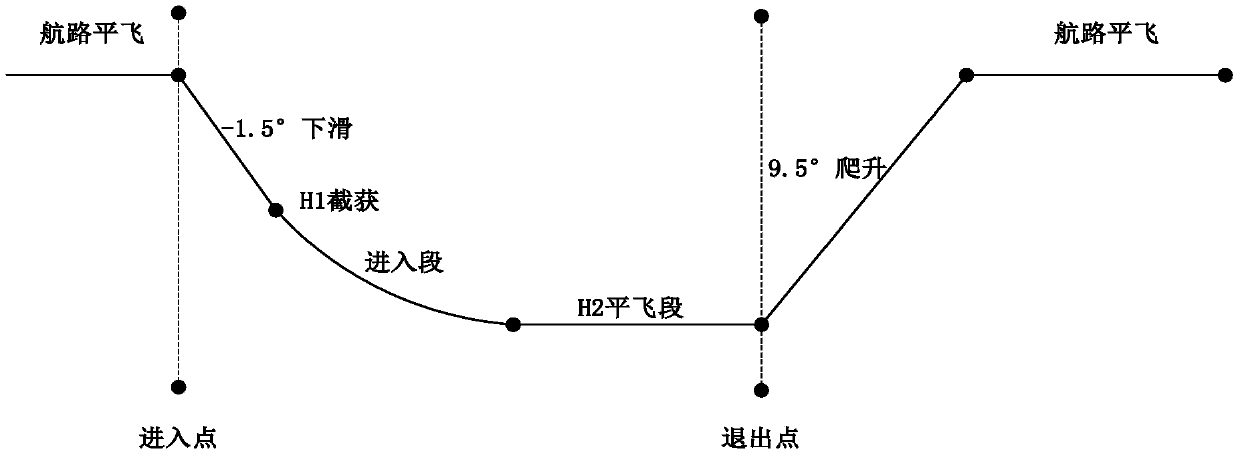

Segmentation-based super-low altitude flight control method for pilotless aircraft

ActiveCN109542111AReduced rangeCompatible with practical engineering applicationsAttitude controlPosition/course control in three dimensionsUncrewed vehicleLow altitude

The invention discloses a segmentation-based super-low altitude flight control method for a pilotless aircraft. The method comprises the steps of: judging the flight mode of the pilotless aircraft according to a preset flight mode judging condition of the pilotless aircraft, wherein the flight mode is divided into super-low altitude flight mode, super-low altitude level-off flight mode, and super-low altitude quitting flight mode; determining the longitudinal segmented flight control strategy of the pilotless aircraft in the super-low altitude flight mode according to the judgment result, anddesigning the longitudinal segmented control law of the pilotless aircraft; and refining specific control logic and control law parameters. According to the segmentation-based super-low altitude flight control method for the pilotless aircraft, the pilotless aircraft can enters super-low altitude flight mode in a relatively stable posture under a small disturbance environment; the flight range isshortened, and the oil consumption is reduced; and after the pilotless aircraft quits the super-low altitude flight, the pilotless aircraft can climb at the maximum dynamic pressure with an allowed overload, and then enters a second super-low altitude flight or returns.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +2

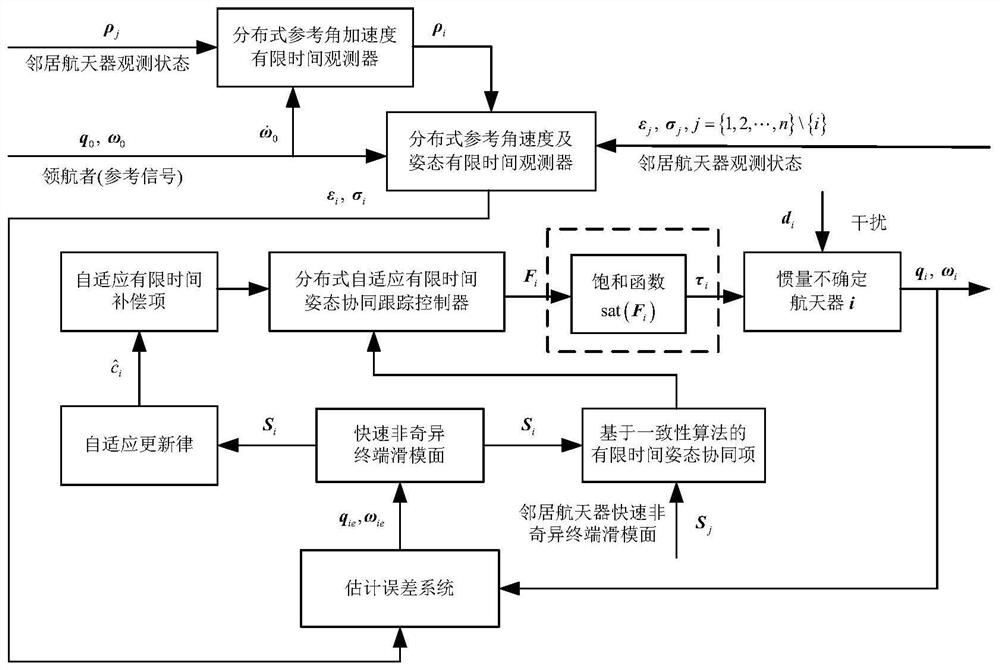

Attitude cooperative tracking control method for distributed spacecraft

ActiveCN111752292AReduce occupancyShort collaboration timeAttitude controlPosition/course control in three dimensionsSelf adaptiveRapid convergence

The invention discloses an attitude cooperative tracking control method for a distributed spacecraft, and relates to the technical field of spacecraft formation flight. A communication topological structure which has few communication paths and only enables a part of followers to obtain pilot information is adopted among spacecraft formation members, and in order to obtain the pilot information, adistributed finite time state observer is designed to observe the pilot information; a rapid nonsingular terminal sliding mode control algorithm is adopted to enable the attitude of a formation spacecraft to be rapidly coordinated and tracked, a saturation function is input to limit the amplitude of a control moment, and a self-adaptive algorithm is adopted to perform self-adaptive compensation on inertia change and external disturbance. A distributed spacecraft formation adaptive finite time attitude cooperative tracking control method is designed. According to the method, the considerationof communication resources, input saturation, rapid convergence, external interference and inertia uncertainty is more perfect, the formation spacecraft attitude cooperative tracking error system canbe rapidly converged, and the robustness and practicability of the system are improved.

Owner:YANCHENG INST OF TECH

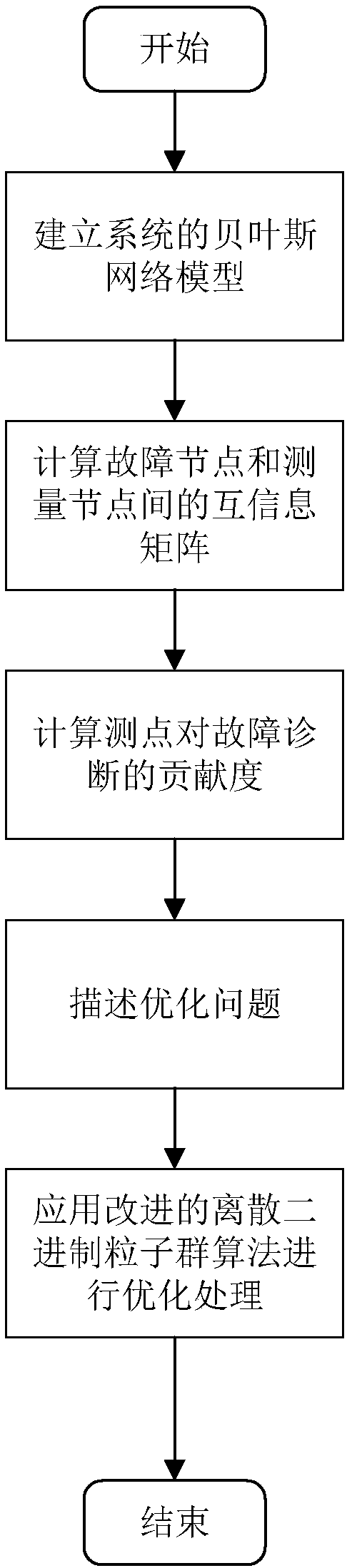

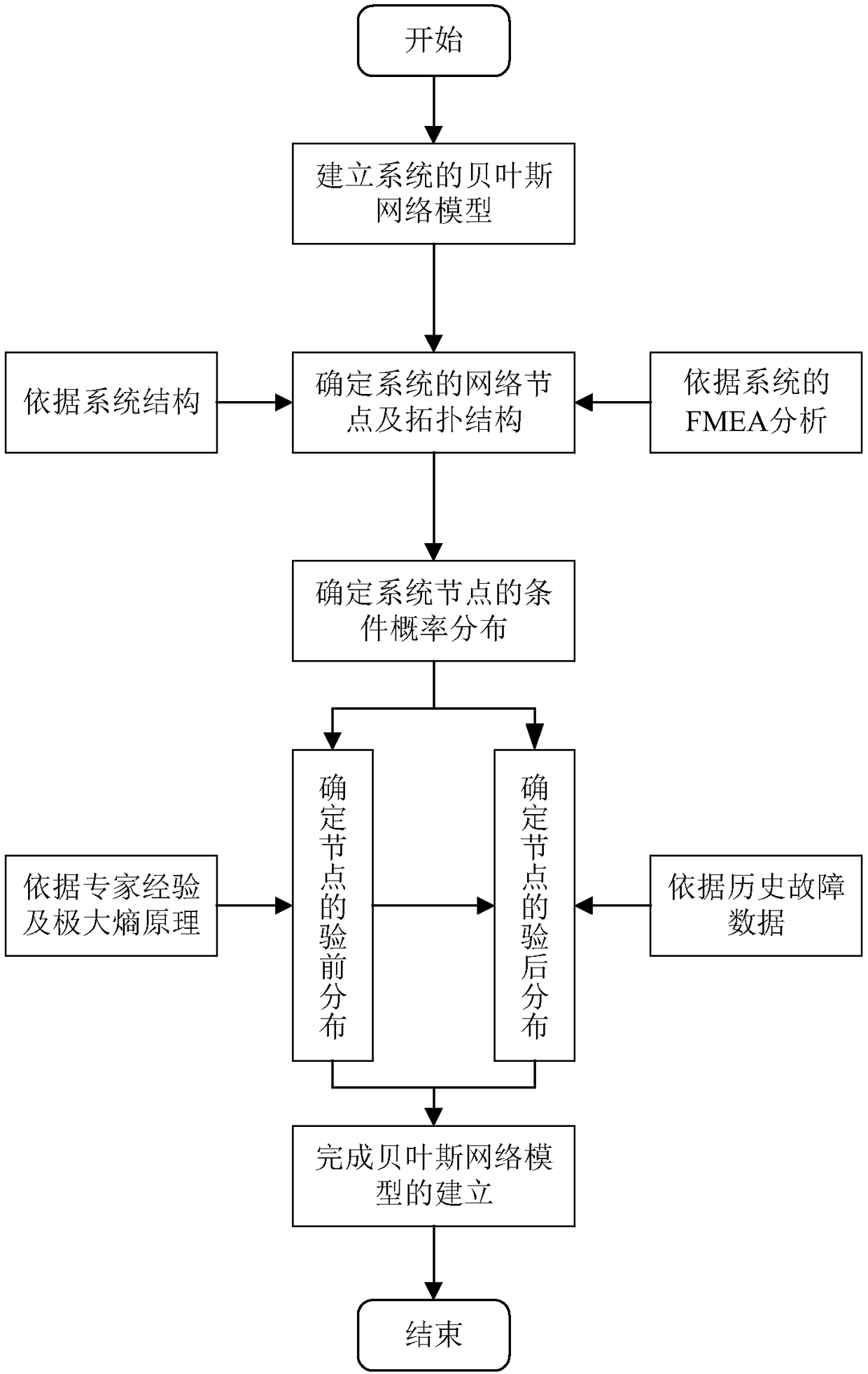

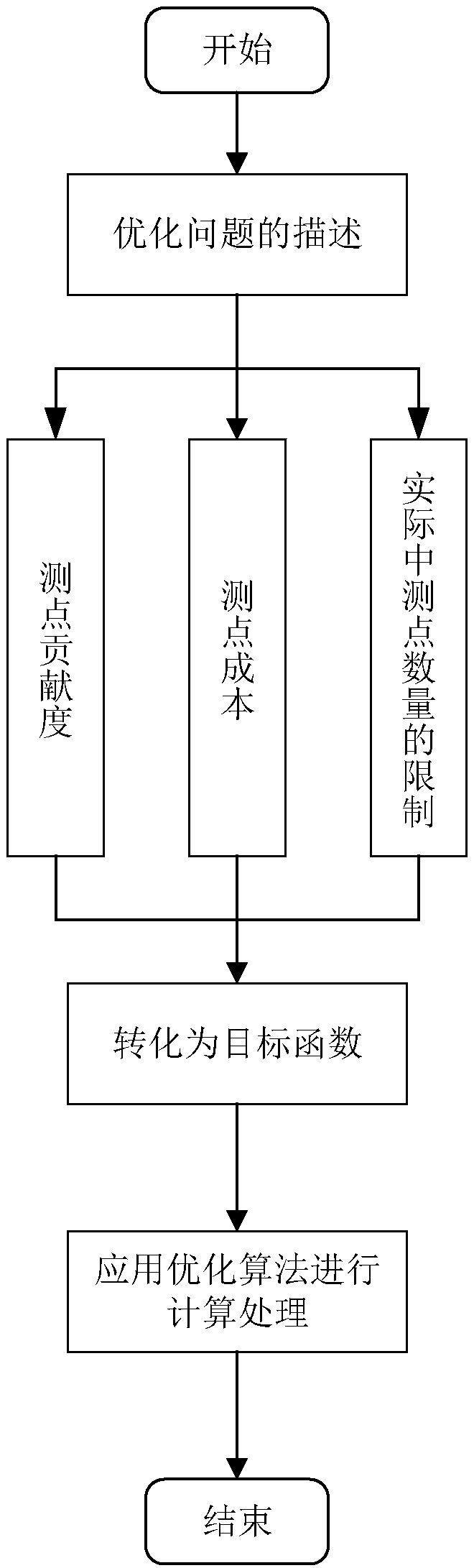

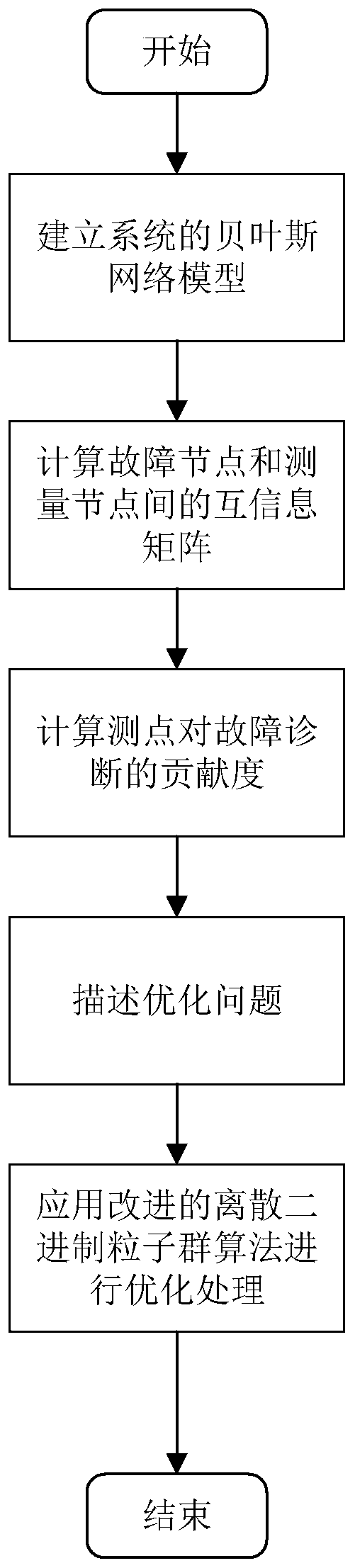

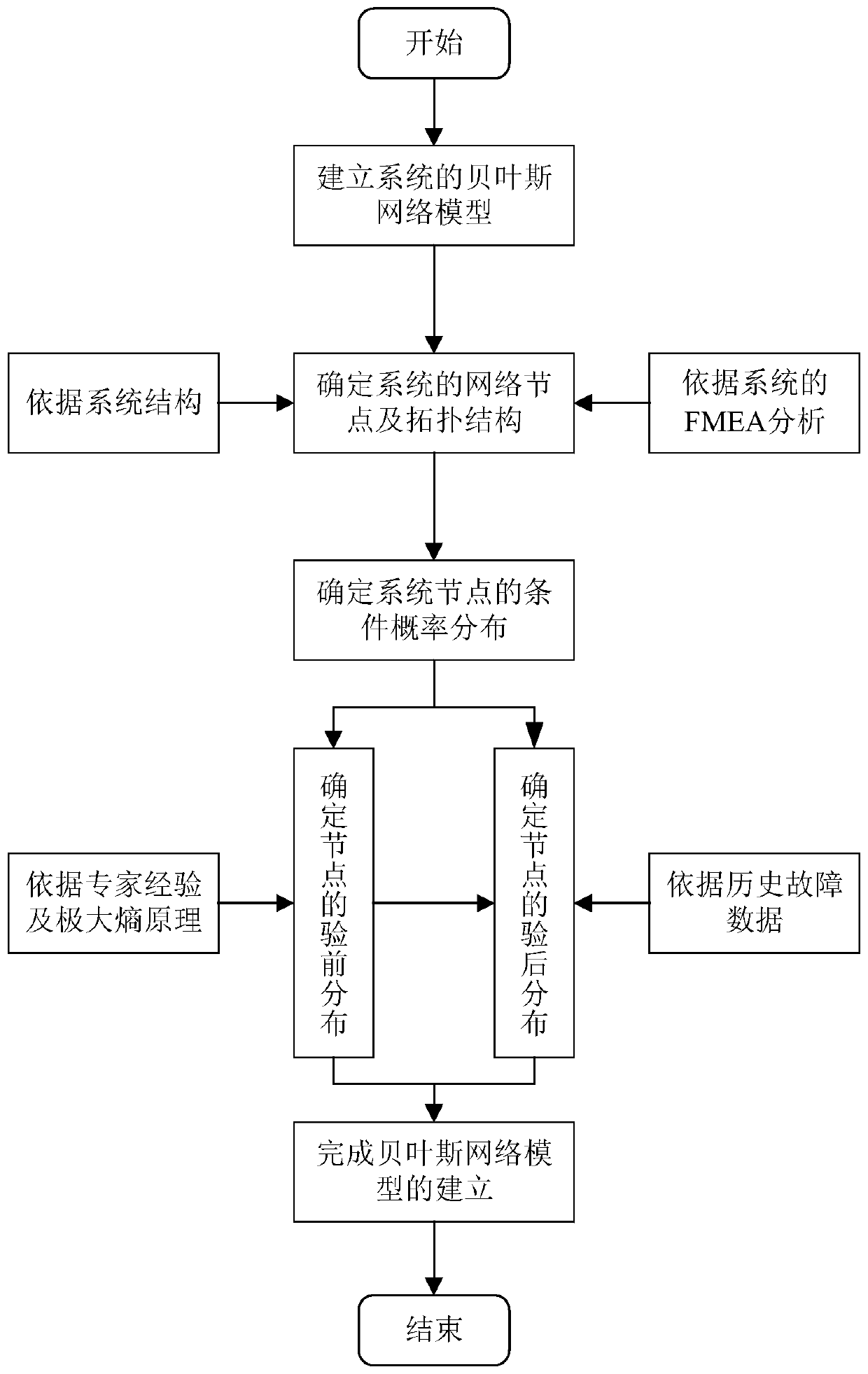

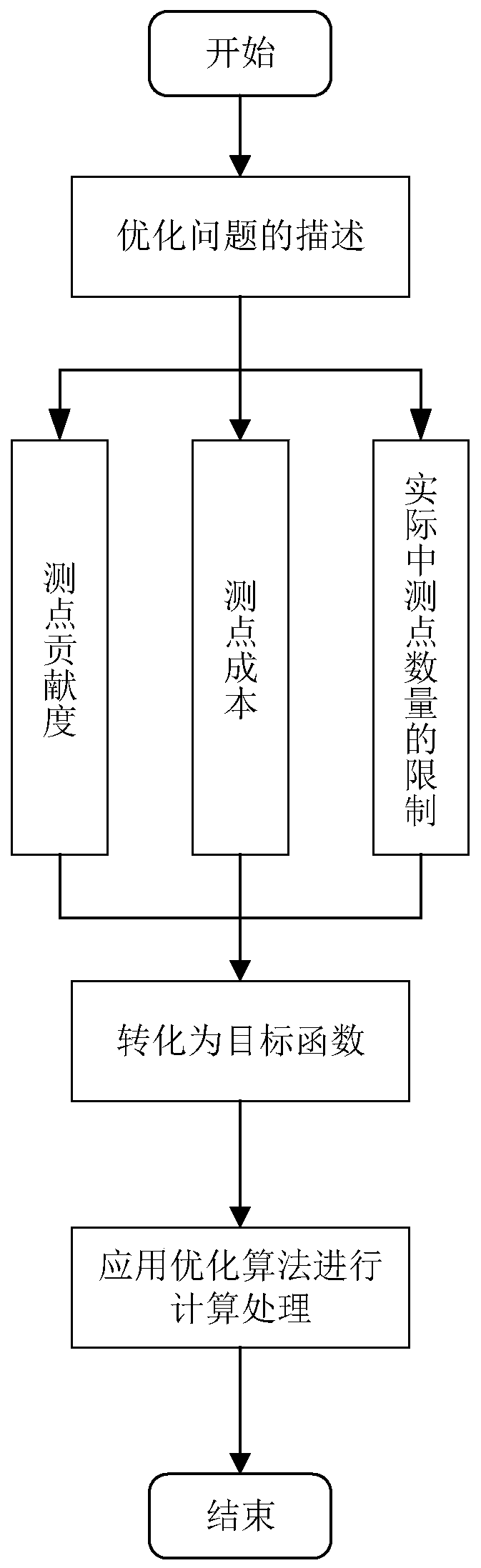

Bayesian network-based system measurement node optimization configuration method

ActiveCN108134680ACompatible with practical engineering applicationsBest measurement node configuration schemeData switching networksMeasurement costNetwork model

The invention relates to a Bayesian network-based system measurement node optimization configuration method. According to the method, a bayesian network model of a system is established. According tothebayesian network model, a mutual information matrix between a fault node and a measuring node is calculated. According to the mutual information matrix between the fault node and the measuring node, the contribution degree of the measuring point to the diagnosis of the fault node is calculated, and a comprehensive diagnosis capability index is determined. According to the contribution degree ofthe measuring point to the diagnosis of the fault node, the cost of the measuring point and the number limit of the measuring point, an optimization problem is described. Based on the improved discrete binary particle swarm algorithm, the optimization treatment is carried out. Finally, the optimized configuration result of the measuring pointis obtained. According to the invention, the optimization configuration problem of a sensor under the constraint condition is considered, so that the method is more suitable for practical engineering application. Meanwhile, the fault diagnosis capabilityand the measurement cost problem of the measuring point are considered at the same time, and the optimization treatment is carried out based on the improved optimization algorithm. As a result, an optimal measuring node configuration scheme of the system is found.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

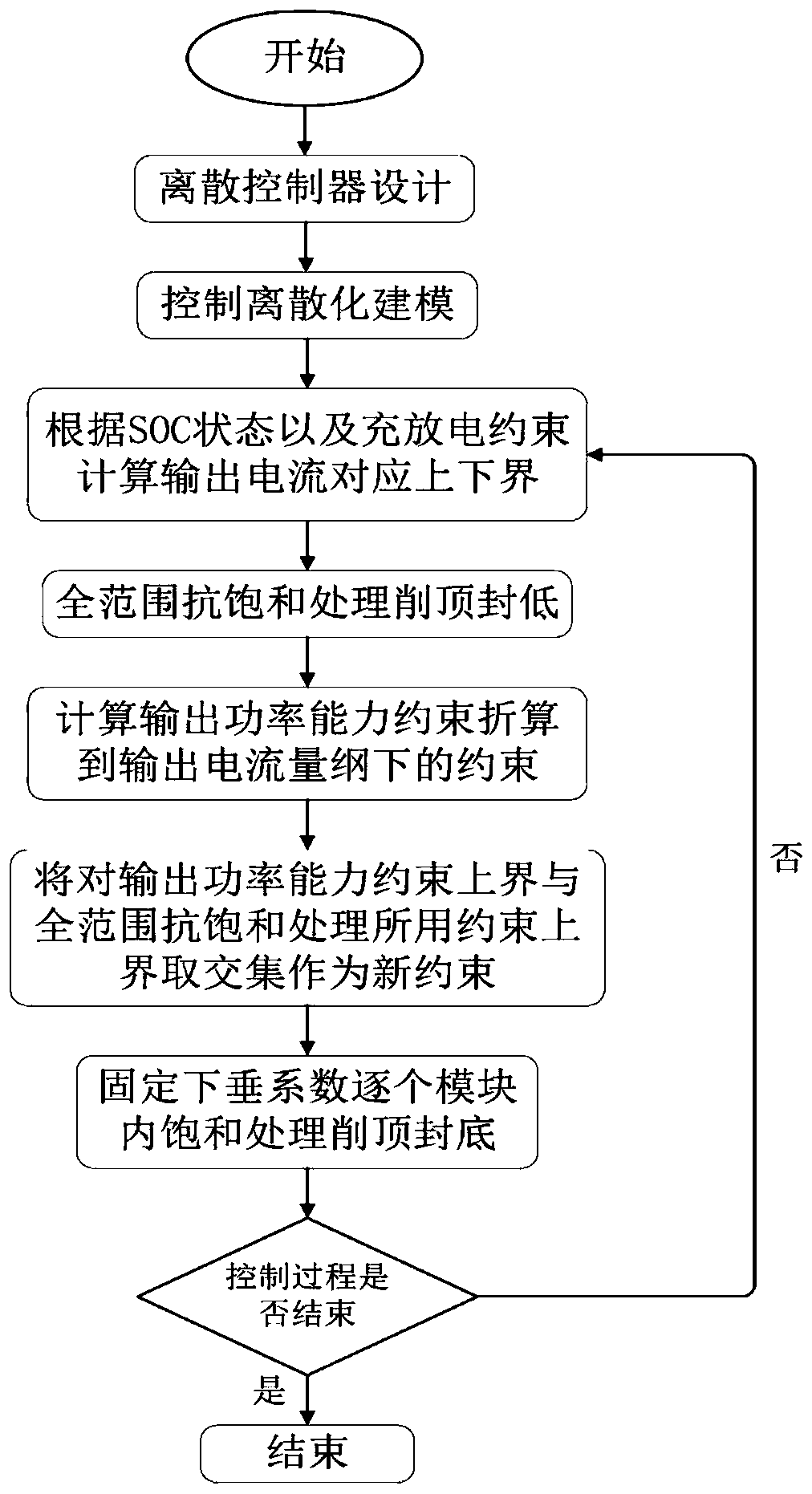

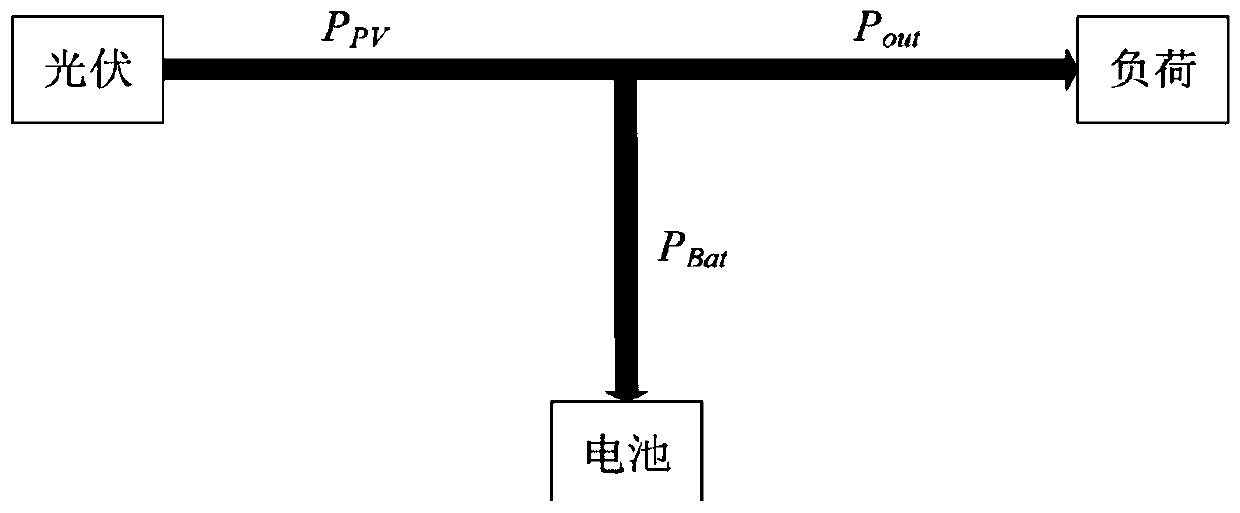

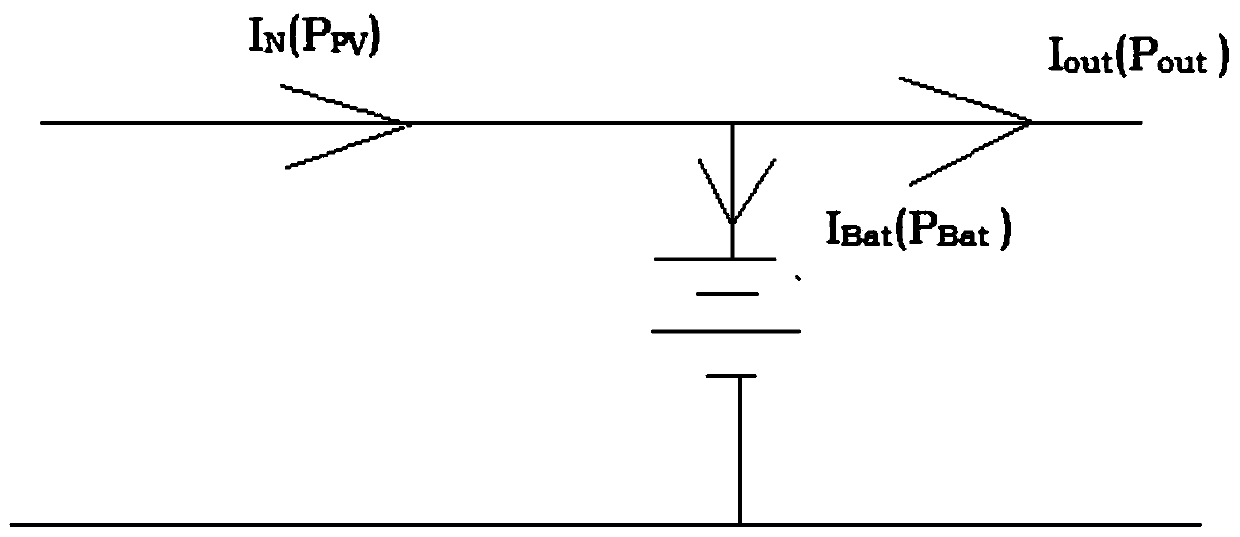

Discrete power generation, energy storage and power supply system cooperative control method

ActiveCN110994686ASimulation is accurateFacilitate reasoning and analysisSingle network parallel feeding arrangementsAc network load balancingControl theoryReliability engineering

The invention discloses a discrete power generation, energy storage and power supply system cooperative control method, and belongs to the technical field of power generation system management and control. The method is characterized by comprising the following steps of: 1, designing a discrete controller; and 2, carrying out anti-saturation treatment. In the voltage conversion process, the duty ratio is smaller than 100%, and a soft constraint is added to limit the output capability adjustment range of the system. Constraints considered in the design of the control method comprise the following steps: a, constraining of the charging and discharging current of the battery; b, limitation based on SOC (state of charge); c, constraining of the output capability; and d, constraining of the droop coefficient. By the adoption of the technical scheme, the method is mainly applied to hardware control over a power generation-energy storage-power supply system, the operation efficiency of an energy system can be improved, and it is guaranteed that the energy system stably and normally works in the state.

Owner:中电科蓝天科技股份有限公司

Method of optimal configuration of superconducting fault current limiter based on sensitivity technology

InactiveCN102738780BReliable startPractical applicationEmergency protective arrangements for limiting excess voltage/currentSuperconductor elements usageMulti objective optimization algorithmDecision maker

The invention discloses a method of optimal configuration of a plurality of superconducting fault current limiter based on a sensitivity technology, which comprises the steps of: calculating the three-phase short-circuit current of all nodes in a whole system, and finding b nodes with the short-circuit current exceeding the standard value; determining braches for installation and reliable startup of the SFCLs (superconducting fault current limiter) according to startup conditions of the SFCLs; calculating the sensitivity of self-impedance of each station with the short-circuit current exceeding the standard value, sequencing the stations in a sensitivity descending order, and taking the top a branches as candidate braches for installation of the SFCLs; and taking c candidate braches as optimal branches for a multi-objective optimization algorithm NSGA-II (non-dominated sorting genetic algorithm-II) in next step, determining a scheme with the optimal installation positions of the SFCLs, the number of SFCLs to be installed and the impedance, thereby realizing global optimum configuration. By adopting the method, the search space to be understood is reduced greatly, the speed of calculation is increased, and optimization results are more suitable for actual applications. Meanwhile, the problem of weight selection resulting from conversion of multi-objective optimization to single-objective optimization can be avoided, and a decision-maker can make final decisions according to actual engineering needs.

Owner:HOHAI UNIV

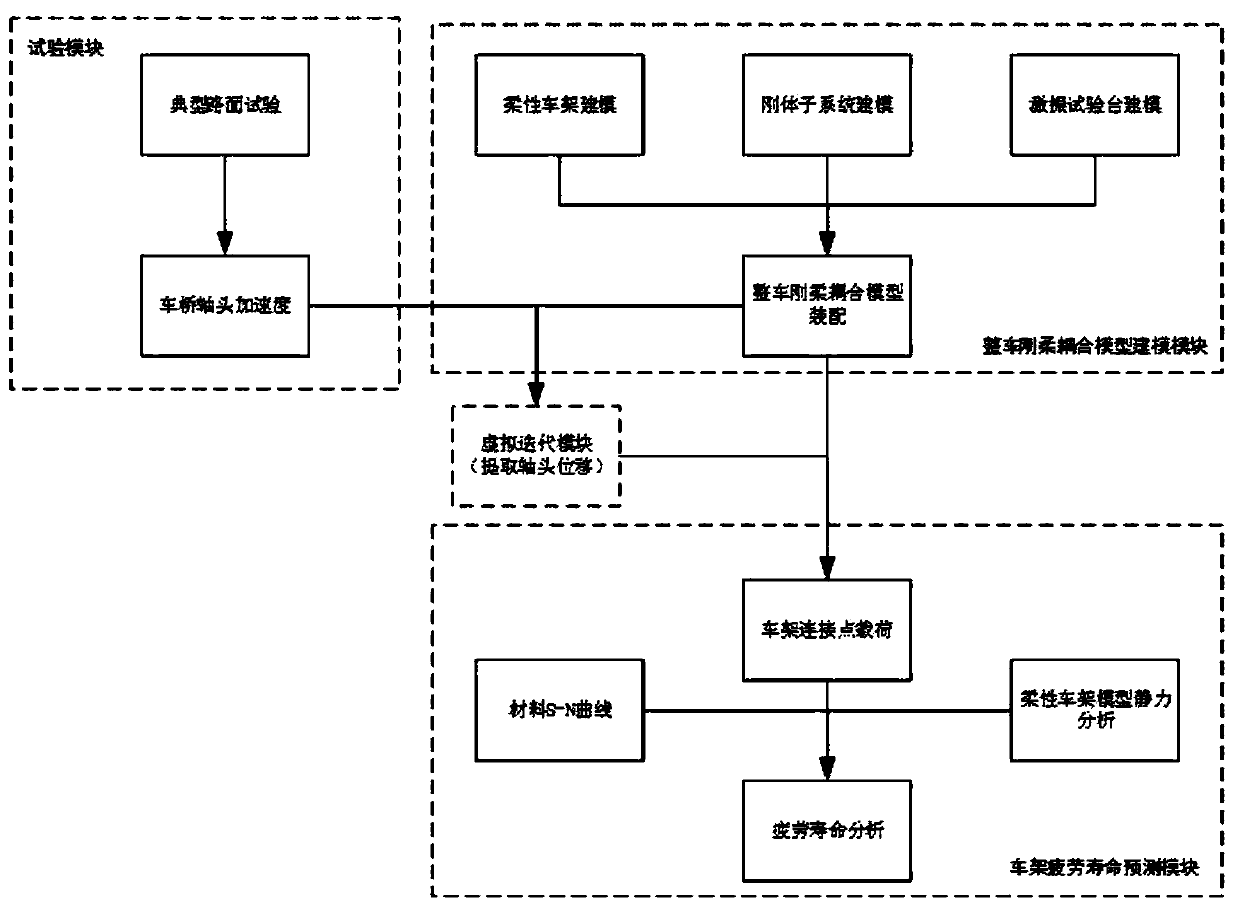

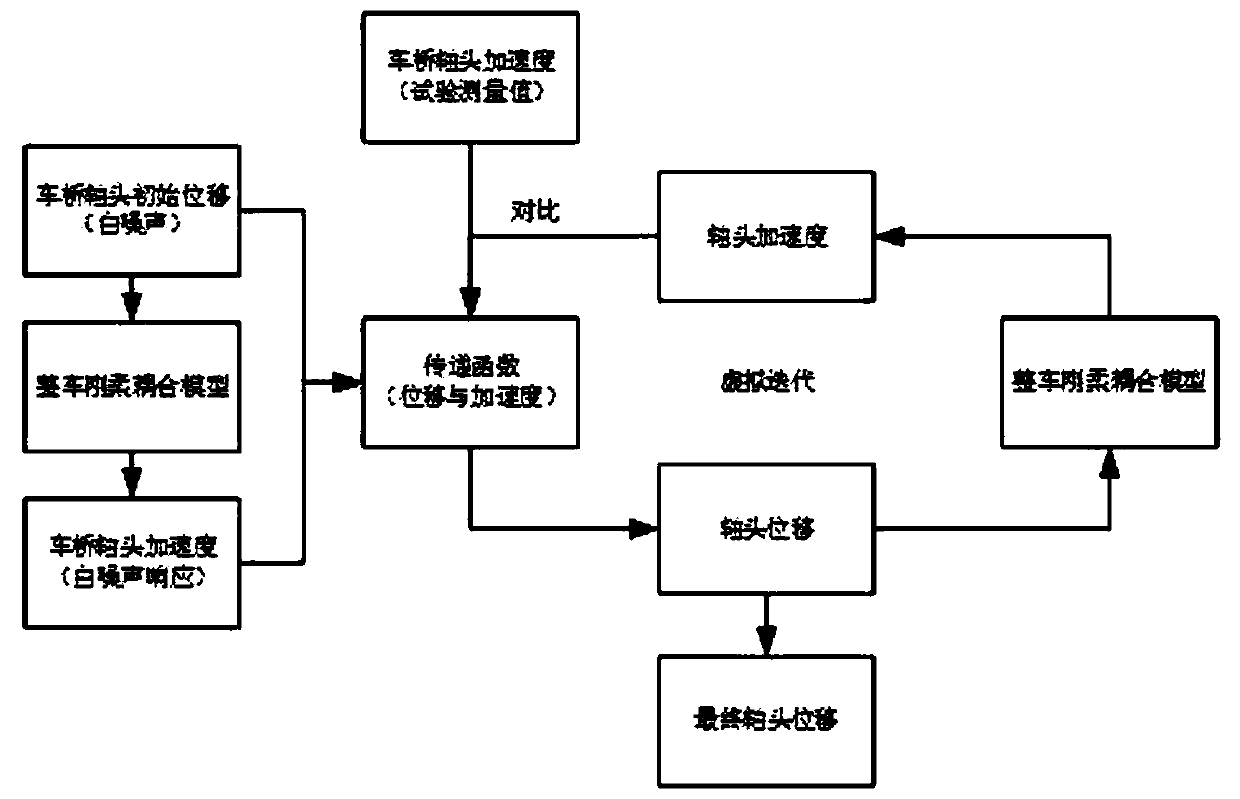

Method for predicting fatigue life of wide-body mining vehicle frame

PendingCN111241724AImprove efficiencyLow costDesign optimisation/simulationSustainable transportationVehicle frameStatic simulation

Owner:SANY HEAVY EQUIP

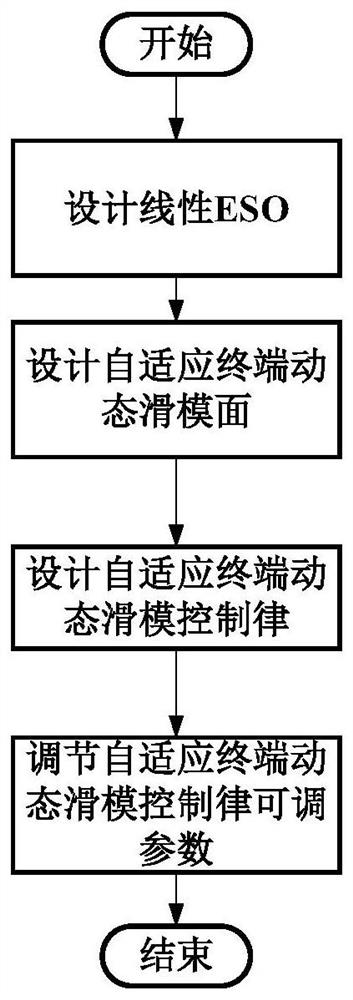

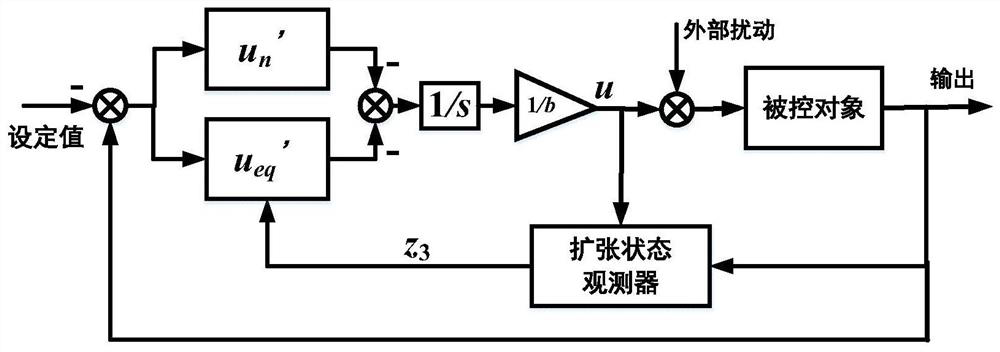

Adaptive terminal dynamic sliding mode control method based on active disturbance rejection

ActiveCN111856941ASolve the problem that the upper bound of disturbance information is difficult to obtainReduce buffetingTotal factory controlAdaptive controlControl engineeringControl theory

The invention discloses an adaptive terminal dynamic sliding mode control method based on active disturbance rejection. ESO is introduced, the ESO can estimate the state and the total disturbance of the system in real time only according to input and output information of a controlled object, more model information is provided for the design of sliding mode control, the total disturbance of the system is estimated in real time by using ESO, the total disturbance is compensated through a control law, the control gain can be reduced, and the control energy consumption can be reduced. In addition, the control precision can be improved by adding the information of the total disturbance into the design of the controller. In combination with a dynamic sliding mode control idea, the buffeting problem existing in traditional sliding mode control can be reduced to a great extent; in combination with a terminal sliding mode control idea, it can be ensured that the state of the controlled objectconverges to a balance point within limited time; actual conditions are fully considered, the upper bound of unknown part information of the system does not need to be acquired in advance by designingadaptive gain, and the problem that the upper bound of disturbance information in an actual system is difficult to acquire is solved.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

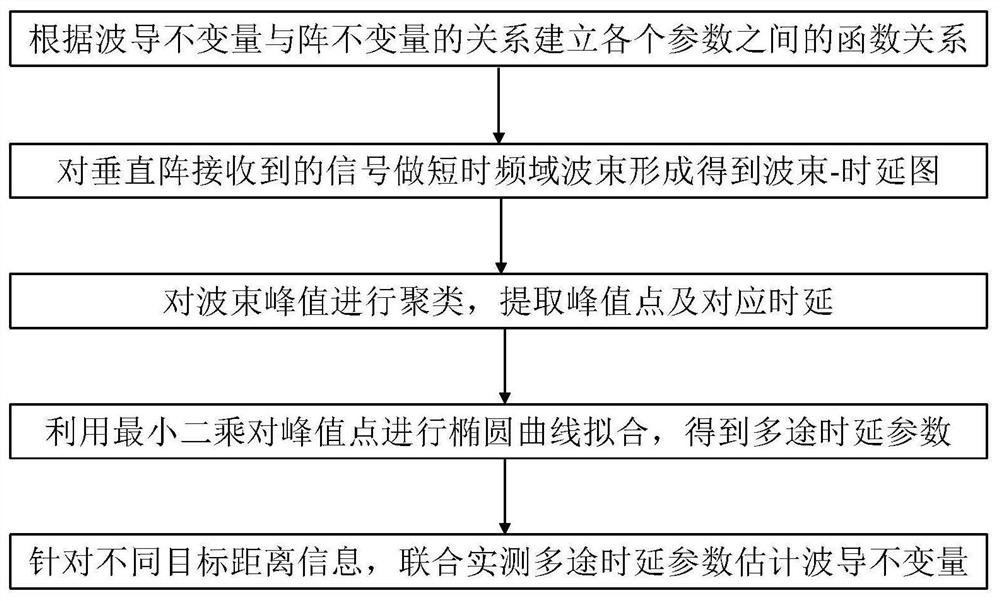

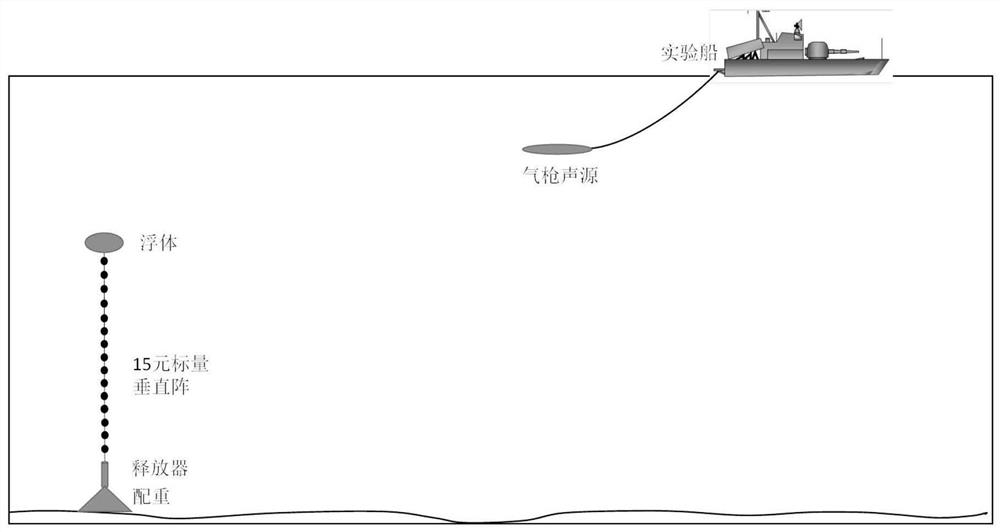

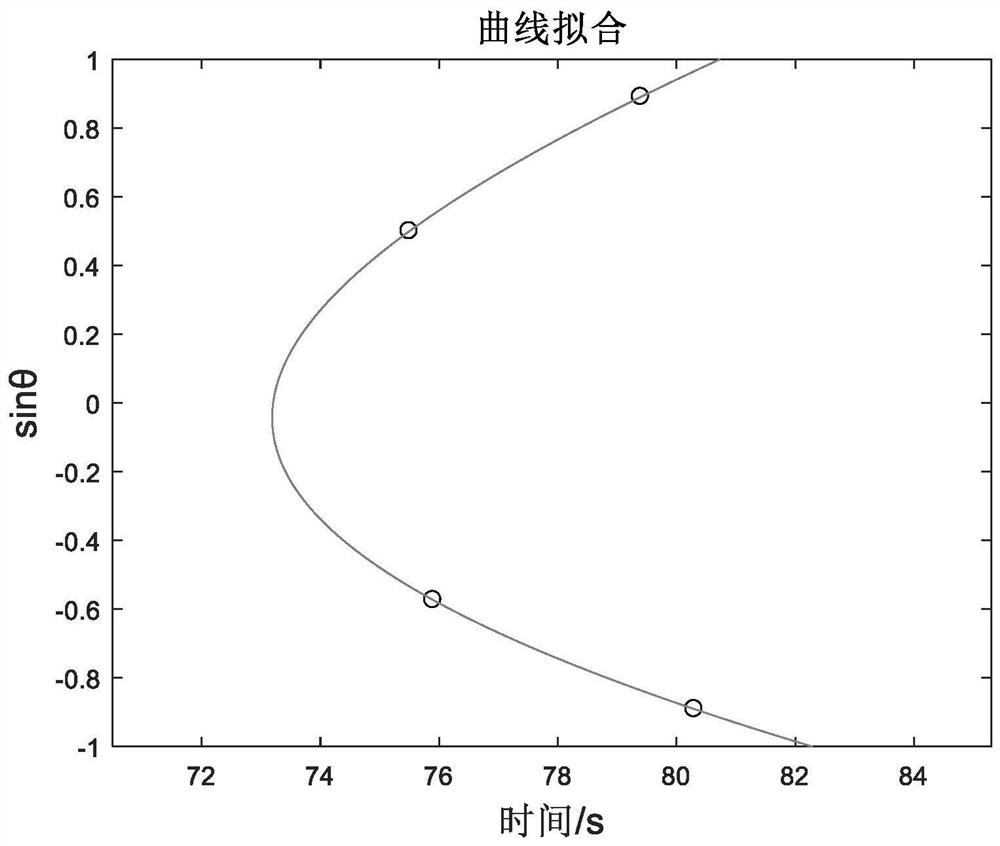

Waveguide invariant estimation method based on deep sea vertical array

PendingCN113671507ASimple methodReduce dependenceAcoustic wave reradiationHydrophone arrayVertical array

The invention discloses a waveguide invariant estimation method based on a deep sea vertical array, which relates to the technical field of underwater acoustic parameter estimation, can estimate waveguide invariants under two conditions of known and unknown target distances, and is simple and convenient. The waveguide invariant estimation method is characterized by comprising the following steps of: S1, establishing a function relationship among a waveguide invariant beta, a multipath time delay parameter bv, a signal arrival glancing angle theta, an arrival time delay t and a target distance R; S2, utilizing a target radiation sound signal received by a vertical hydrophone array deployed at a deep sea bottom, and carrying out short-time frequency domain beam forming processing on the target radiation sound signal to obtain a beam time delay diagram; S3, carrying out clustering on the wave beam time delay diagram and extracting a wave beam peak point and a corresponding time delay value; S4, carrying out curve fitting by using a least square method aiming at the head of the extracted wave beam peak so as to solve multipath time delay parameters; and S5, aiming at different target distance prior information, combining actual measurement multipath time delay parameters to estimate waveguide invariants.

Owner:NAT INNOVATION INST OF DEFENSE TECH PLA ACAD OF MILITARY SCI

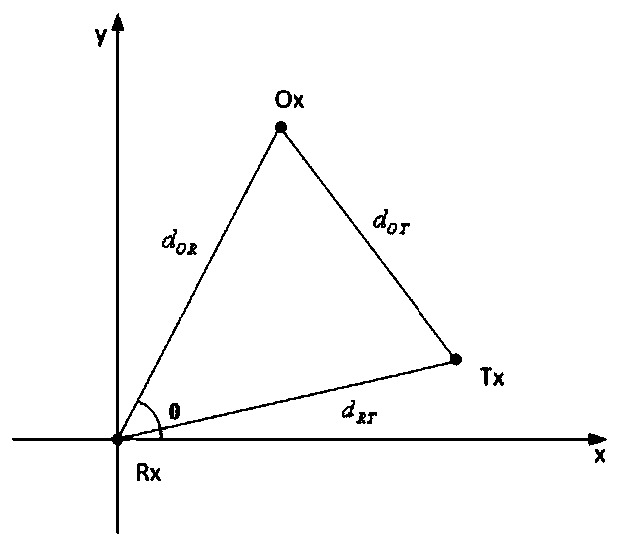

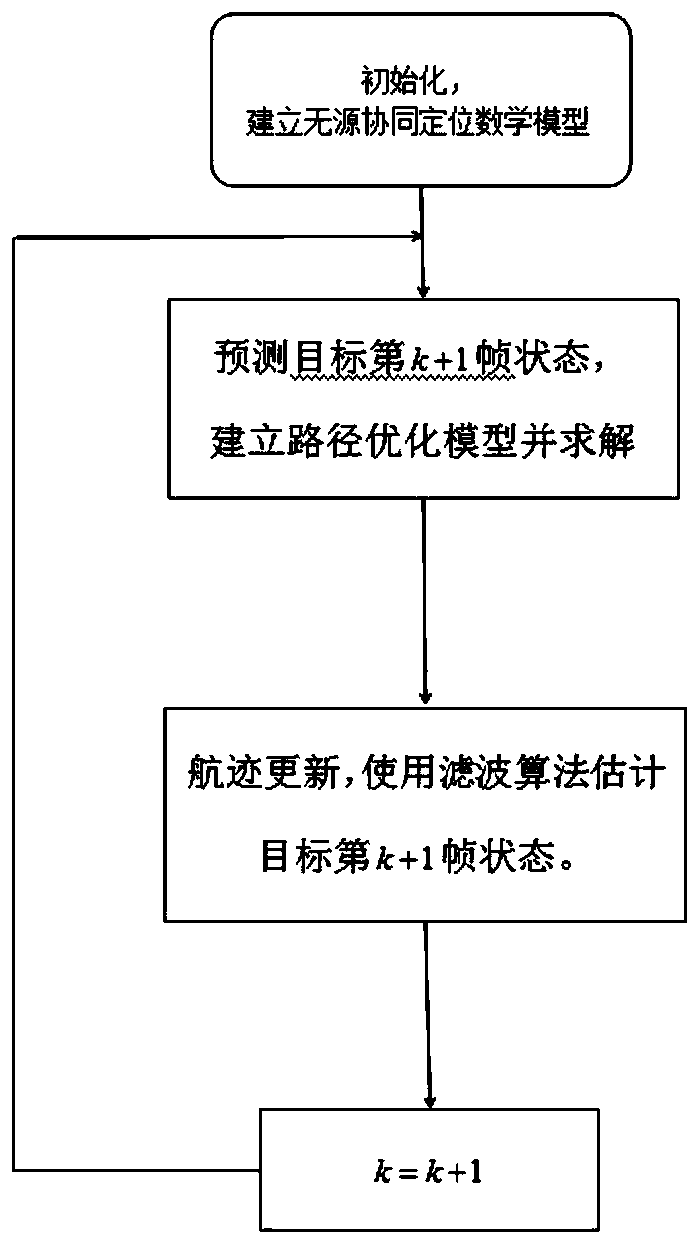

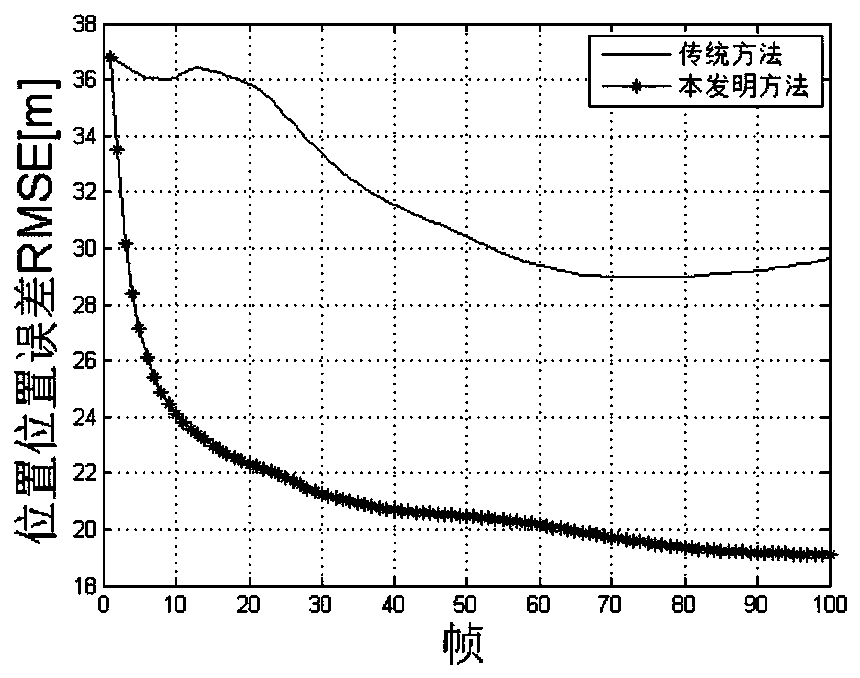

Amplitude information based path optimization method for receiving station under clutter condition

ActiveCN110412531AHigh precisionImprove real-time performanceWave based measurement systemsMathematical modelFilter algorithm

The invention discloses an amplitude information based path optimization method for a receiving station under a clutter condition. A mathematical model of a passive coordinated positioning system including the receiving station and an external radiation source is established. A target state is predicted, and a path optimization model is established and solved. A track is updated, and a filtering algorithm is used to estimate the target state; The updated target state and a covariance are returned to the path optimization model for prediction, and k=k+1 till that sampling is ended. Compared with the prior art that amplitude information is added to measurement, the clutter condition is taken into consideration, the method satisfies practical engineering application more, and the computational complexity is reduced by taking PCRLB as an optimization index. The target positioning tracking precision and instantaneity of the passive coordinated positioning system can be improved.

Owner:河北凯通信息技术服务有限公司

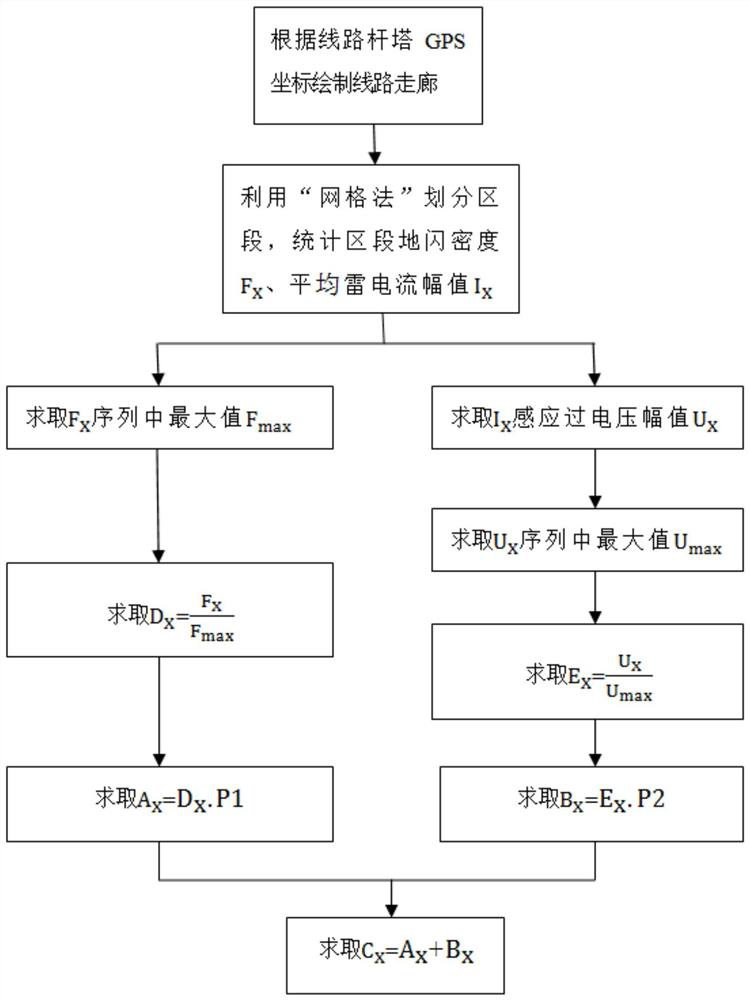

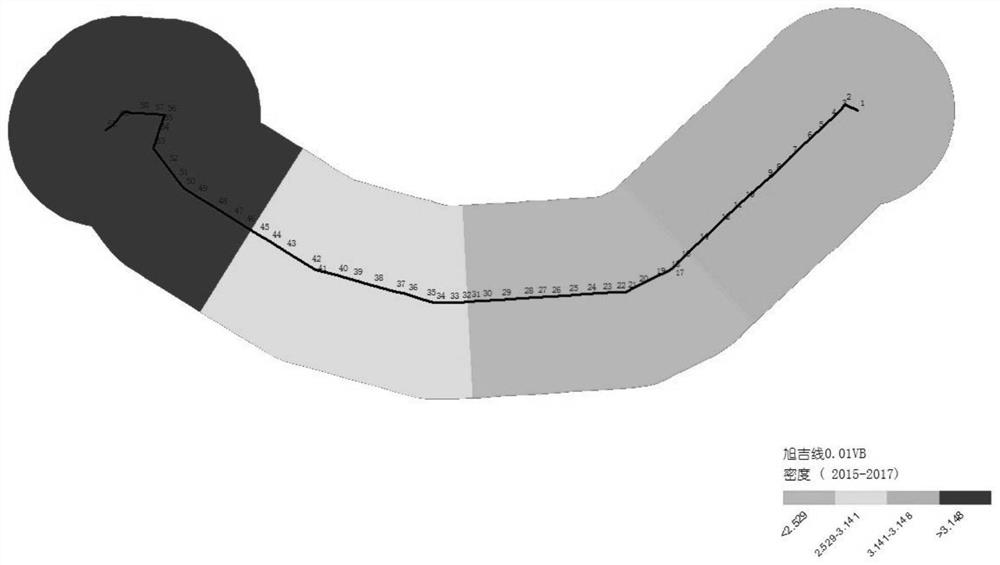

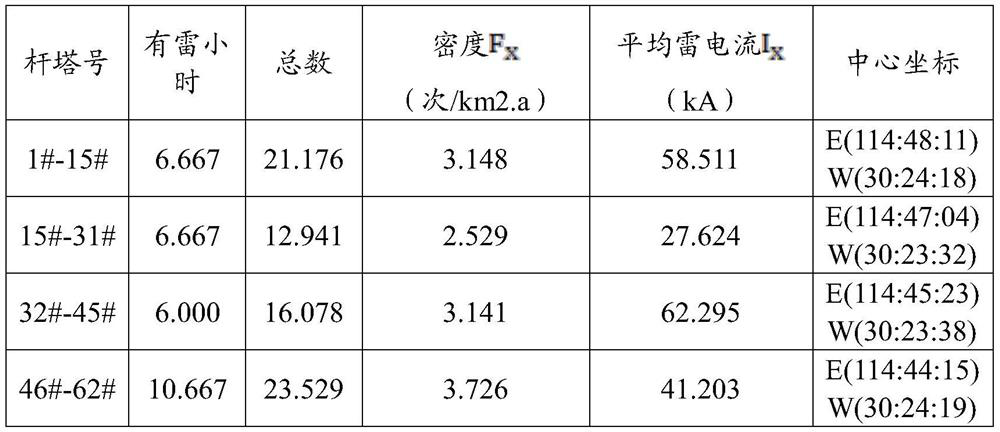

A Risk Assessment Method for the Relative Value of Lightning Parameters of Distribution Network Lines

ActiveCN109064057BReflect the concept of lightning protectionCompatible with practical engineering applicationsResourcesOvervoltageRisk level

The invention provides a risk assessment method for relative values of lightning parameters of distribution network lines, and relates to the technical field of lightning protection for overhead lines of power system distribution networks. This method comprehensively evaluates the risk level of towers in a specific distribution network line by introducing lightning activity parameters such as the relative value of ground flash density and the relative value of lightning current amplitude induced overvoltage, and accurately finds out the towers with a relatively high level of lightning risk in a specific line. Protection is carried out in order to meet the goal of lightning damage control for distribution network lines in different regions.

Owner:STATE GRID HUBEI ELECTRIC POWER RES INST +3

A knife box mechanism of a disc-shaped hob of a shield machine and its use method

Owner:NORTHEASTERN UNIV LIAONING

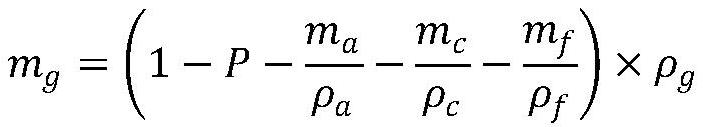

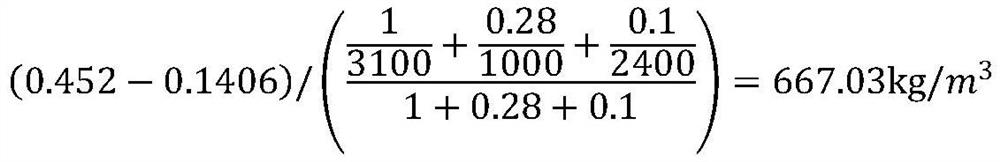

A design method for the mix ratio of recycled permeable bricks based on the target permeability coefficient

ActiveCN109711634BGuaranteed work performanceThe basis for the design is clearMolecular entity identificationForecastingBrickSlurry

The invention discloses a recycled water permeable brick mix proportion design method based on a target water permeable coefficient, a skeleton model of a water permeable brick is fully considered, askeleton is built with recycled aggregate, aggregate gaps are filled with target pores, water, fly ash and cement, and meanwhile, the working performance of slurry under different porosities is ensured by adjusting the mixing amount of a water reducing agent. The method can determine the mix proportion of the regenerated water permeable bricks according to different water permeable coefficient requirements, is clear and clear in design idea and simple and convenient to operate, and better conforms to practical engineering application. Meanwhile, the recycled aggregate with the particle size of4.75-9.5 mm is adopted according to the mixing ratio, the requirements for water permeability and strength can be met, the utilization range of the recycled aggregate is widened, the raw materials are easy to obtain, and the cost is low. According to the invention, cement, water and fly ash are used as main bodies of the cementing material, and the difference between the density of the cement andthe density of the fly ash are fully considered, so that the water permeability coefficient of the regenerated water-permeable brick can be more accurately obtained according to the target water permeability coefficient.

Owner:ZHEJIANG UNIV +1

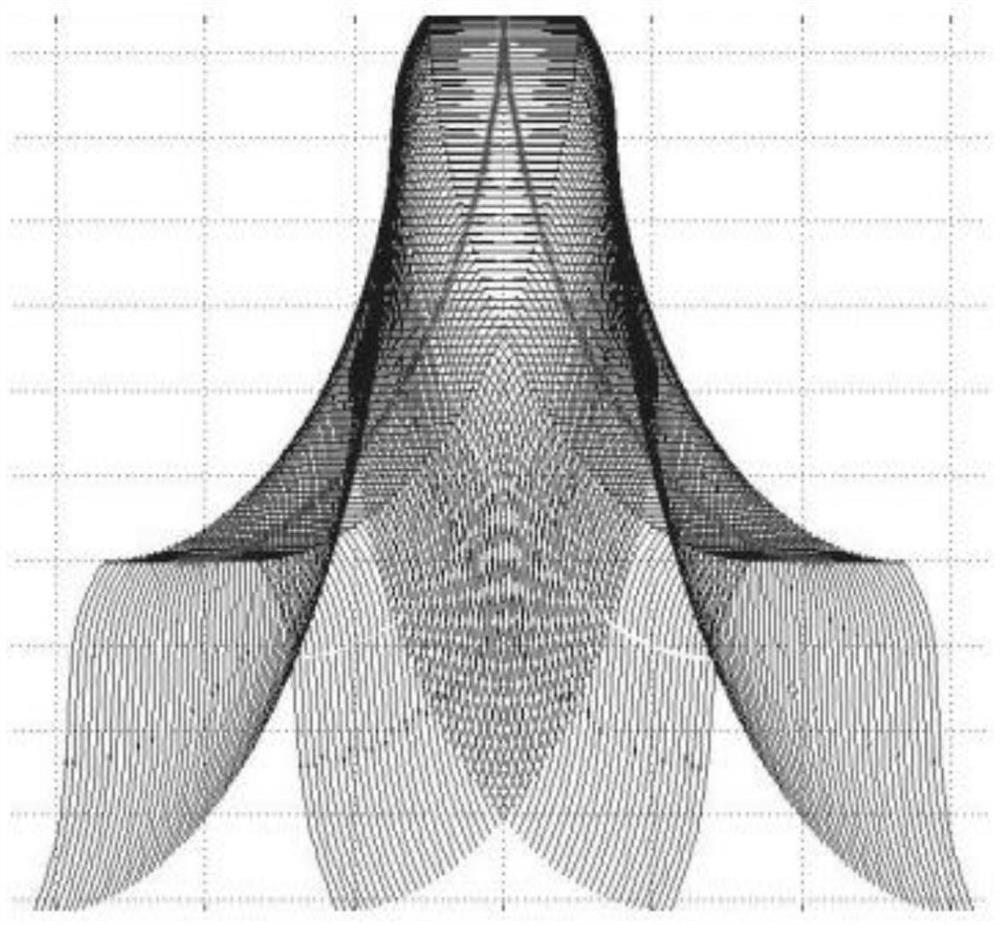

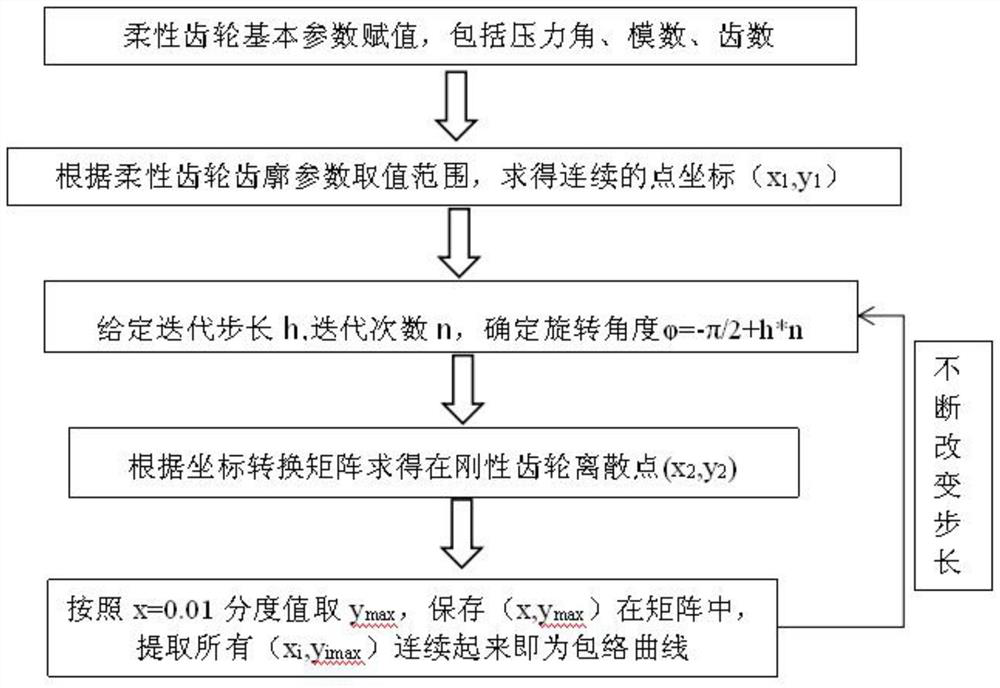

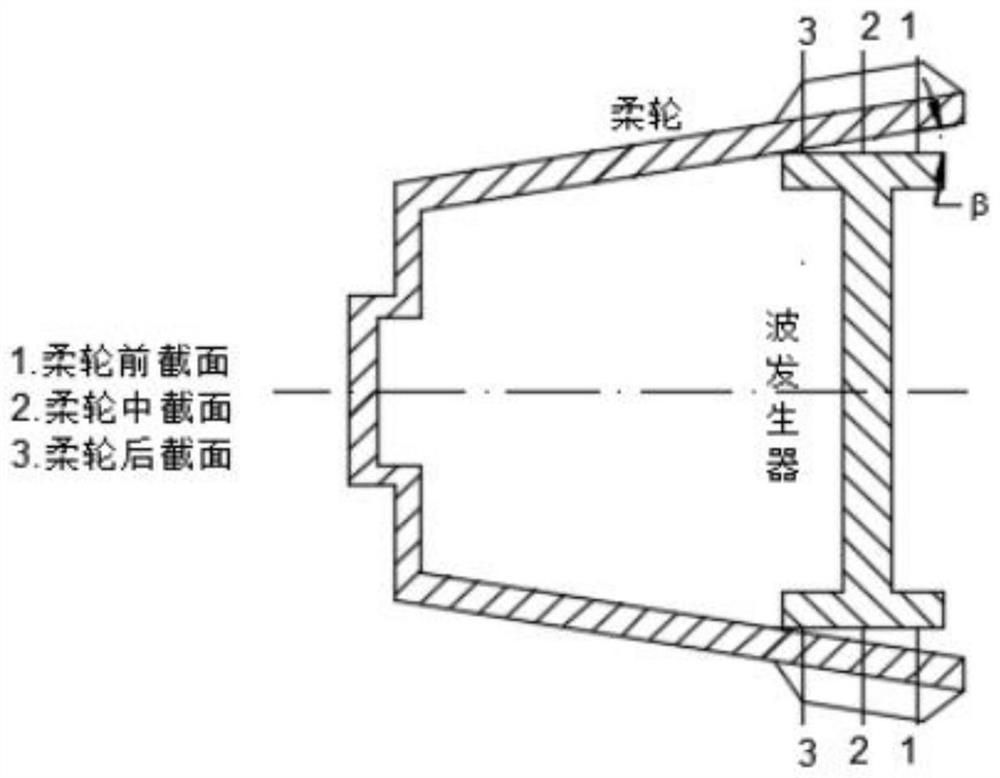

A design method of harmonic gear device

The invention discloses a design method of a harmonic gear device, and designs the harmonic gear device comprising a rigid gear and a flexible gear and the rigid gear and the flexible gear capable ofrealizing space engagement. The design method comprises the following steps: (1) in a direction perpendicular to the axis of the flexible gear, front, middle and back sections of the flexible gear areselected; (2) a discrete point of a tooth profile of each section of the rigid gear is obtained through an envelope method based on a simulation motion trajectory of the flexible gear; and (3) a complete tooth profile of the rigid gear is obtained according to the obtained discrete points of the tooth profiles of the three sections of the rigid gear. The design method prevents defects in the conjugate profile design through single-section motion or adjustment of flexible gear structure in a traditional design method, and is more accordant with actual working conditions of a harmonic gear transmission device; and the designed rigid gear device is high in overlap ratio, stable in transmission and capable of effectively improving the transmission efficiency.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

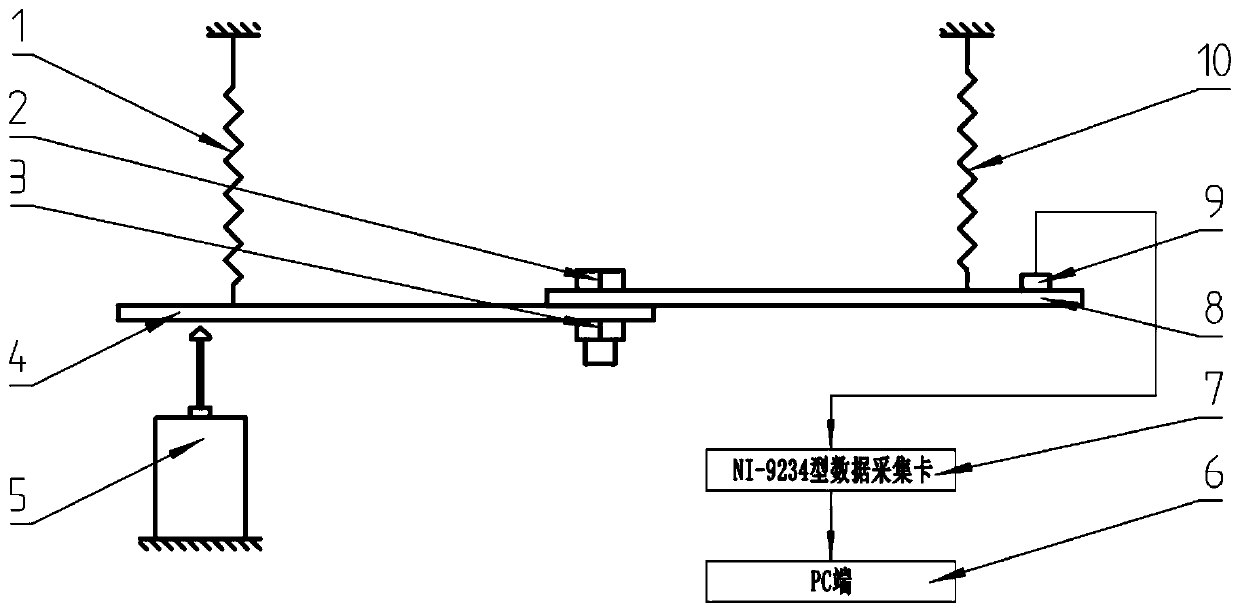

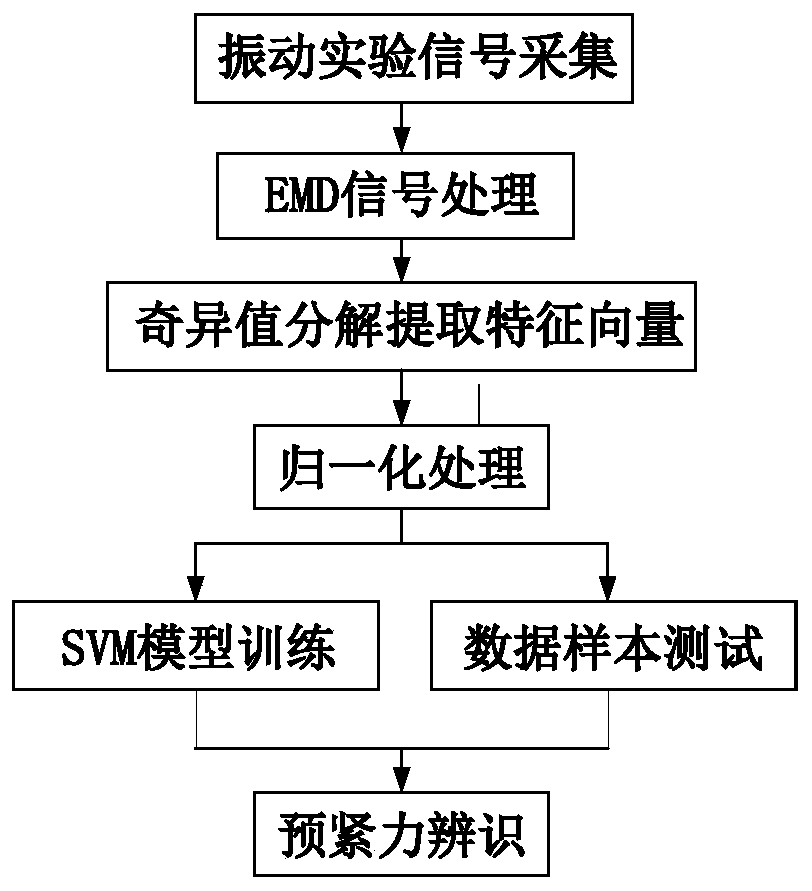

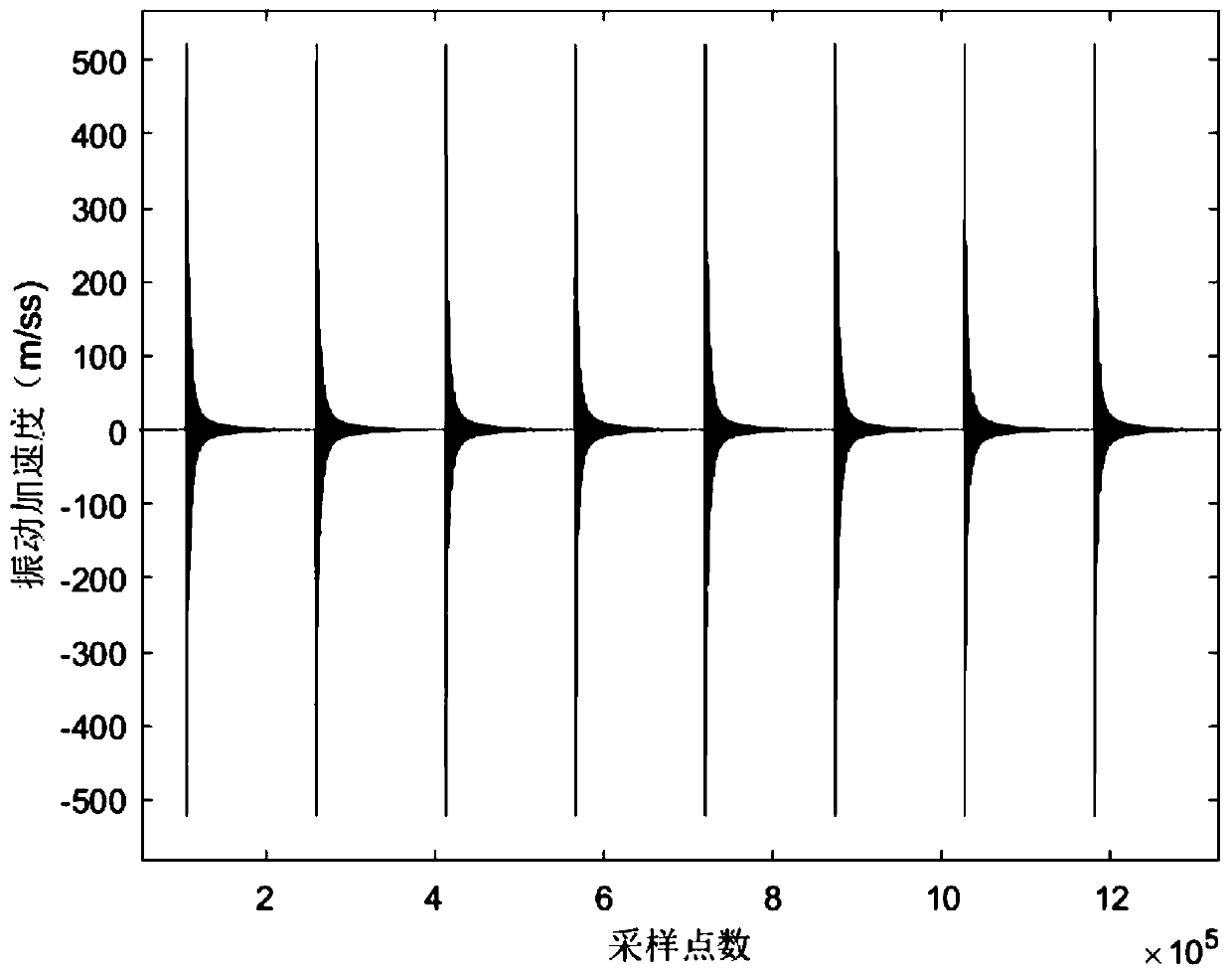

A Bolt Preload Identification Method Based on Singular Value Decomposition and Support Vector Machine

ActiveCN110487499BCompatible with practical engineering applicationsPreserve characteristic signal componentsMeasurement of torque/twisting force while tighteningVibration testingSingular value decompositionFeature Dimension

The invention provides a bolt pre-tightening force identification method based on singular value decomposition and a support vector machine, and belongs to the technical field of vibration signal fault detection. The invention provides a bolt pre-tightening force measuring method based on a vibration signal in order to solve the problems that the pre-tightening force of a bolt is reduced and eventhe bolt is separated and falls off due to the fact that mechanical environments such as impact and vibration generated in the operation process of mechanical equipment. The method comprises the stepsof collecting an impact vibration signal of a single bolt connecting beam in a free state through DASP modal analysis software; carrying out empirical mode decomposition and reconstruction on the experimental data to remove noise and trend terms; carrying out feature dimension reduction by combining singular value decomposition, and extracting a vibration signal feature vector; and taking the vibration signal feature vector as an input feature, performing classifier model training through the support vector machine, and finally realizing pre-tightening force identification of the bolt connecting structure by using the trained classifier.

Owner:DALIAN UNIV OF TECH

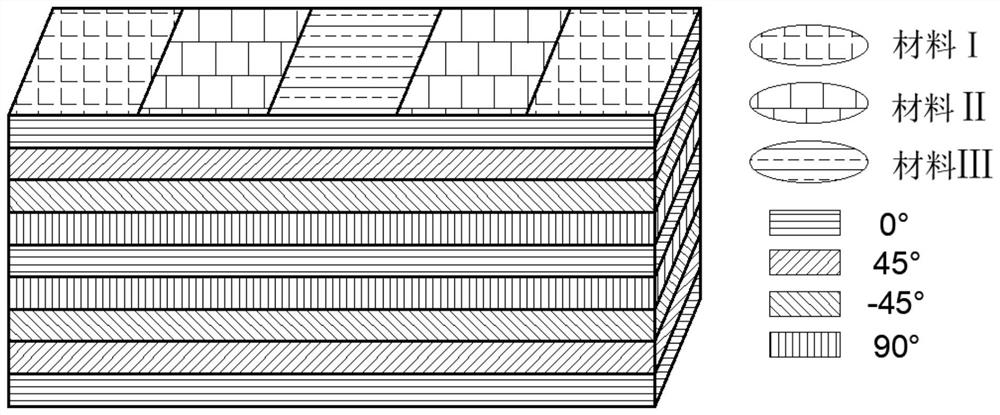

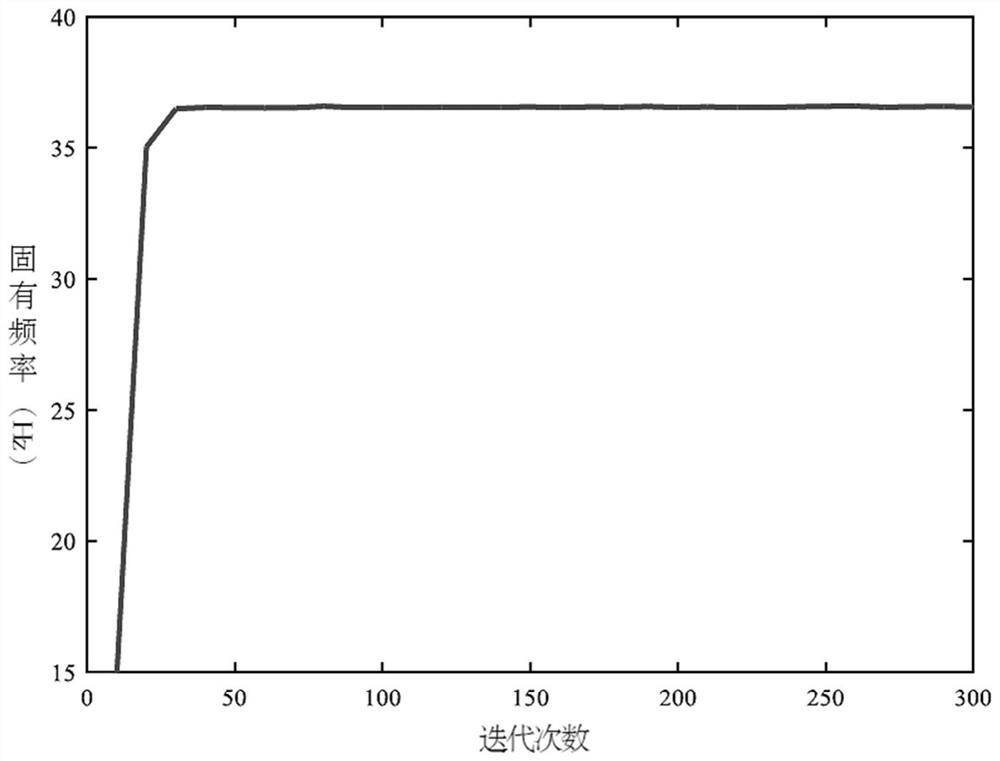

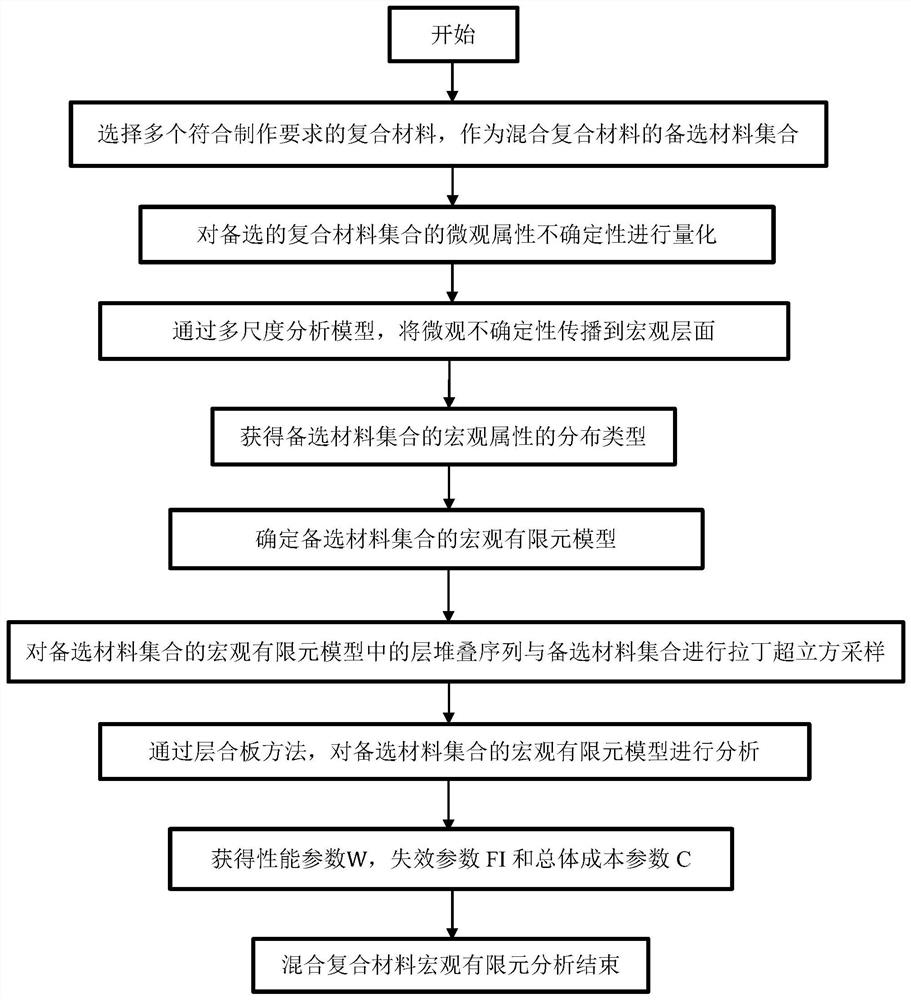

Mixed composite material layering method considering multi-scale uncertainty

PendingCN112464541AAccurate analysisCompatible with practical engineering applicationsDesign optimisation/simulationNeural architecturesElement modelMacroscopic scale

The invention discloses a mixed composite material layering method considering multi-scale uncertainty. The method comprises the steps of selecting an alternative material set, obtaining the microscopic attributes of the alternative material set, and obtaining the distribution type of macroscopic attributes of the alternative material set through a multi-scale analysis model; determining a macroscopic finite element model of the alternative material set by utilizing the macroscopic attributes and the distribution types of the macroscopic attributes; constructing a neural network model of the microscopic attributes of the alternative material set and the mixed composite material parameters, calculating a mean square error MSE for the trained neural network model, and judging the accuracy ofthe trained neural network model according to the mean square error MSE; and optimizing the selection of the alternative material set and the selection of the layer stacking sequence by using a genetic algorithm. According to the method, multiple optimization algorithms are used, so that the burden of designers and computers is greatly reduced, the calculation speed is greatly increased, the optimization accuracy is also improved, Meanwhile the method is more suitable for engineering practical application.

Owner:ZHEJIANG UNIV OF TECH

Calibrating method based on fixed parameters and variable parameters for three-dimensional scanning system

InactiveCN100461220CCompatible with practical engineering applicationsCalibration Distortion CoefficientImage analysisModel parametersVisual perception

A calibration method based on fixed and variable parameters in three-dimensional scanning system relates to the camera model parameter calibration in the visual system including the following steps: (1) fixed parameters calibration is primarily to acquire coordinates of sampling points on circular contour and heart in image coordinates through image processing techniques, and then use n sampling points to get aspect ratio through least squares method, (2) after obtaining the fixed parameters, it uses the image coordinates of image midpoint and the corresponding space coordinates of world midpoint to demarcate the initial value of variable parameters for the camera, including the equivalent focal length, main point coordinates, axis tilt factor, distortion factor and external parameters, (3) after demarcation, it takes fixed parameters as a constraint for nonlinear optimization objective function to establish a binding target function and get the optimal solution of variable parameters through the nonlinear optimization method.

Owner:南通鑫唐纺织印染有限公司 +1

A Method for Optimal Configuration of System Measurement Nodes Based on Bayesian Network

ActiveCN108134680BCompatible with practical engineering applicationsBest measurement node configuration schemeData switching networksMeasurement costNetwork model

The invention relates to a Bayesian network-based system measurement node optimization configuration method. According to the method, a bayesian network model of a system is established. According tothebayesian network model, a mutual information matrix between a fault node and a measuring node is calculated. According to the mutual information matrix between the fault node and the measuring node, the contribution degree of the measuring point to the diagnosis of the fault node is calculated, and a comprehensive diagnosis capability index is determined. According to the contribution degree ofthe measuring point to the diagnosis of the fault node, the cost of the measuring point and the number limit of the measuring point, an optimization problem is described. Based on the improved discrete binary particle swarm algorithm, the optimization treatment is carried out. Finally, the optimized configuration result of the measuring pointis obtained. According to the invention, the optimization configuration problem of a sensor under the constraint condition is considered, so that the method is more suitable for practical engineering application. Meanwhile, the fault diagnosis capabilityand the measurement cost problem of the measuring point are considered at the same time, and the optimization treatment is carried out based on the improved optimization algorithm. As a result, an optimal measuring node configuration scheme of the system is found.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

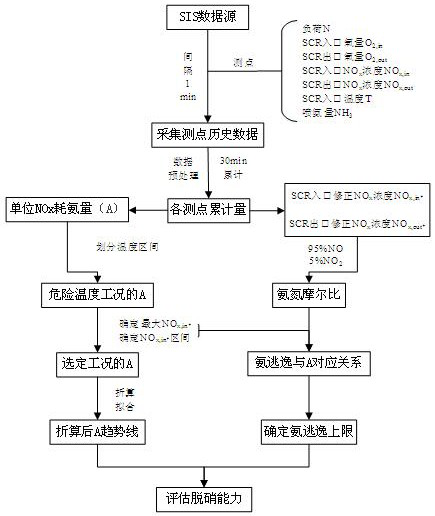

A method for evaluating the denitrification capacity of scr reactor

ActiveCN109493250BGive full play to the advantagesMeet engineering needsData processing applicationsDesign optimisation/simulationData sourceEngineering

The invention discloses a method for evaluating the denitrification ability of an SCR reactor, which comprises the following steps: obtaining historical data of each measuring point of the unit from a data source, performing data preprocessing, correcting the oxygen amount at the outlet and inlet NOx concentrations, and calculating the denitration capacity. In addition to the amount of ammonia consumed per unit of NOx, the working conditions of temperature and outlet NOx concentration are divided and typical working conditions are selected, and the ammonia consumption curve of removing unit NOx is fitted and converted accordingly. The upper limit is determined by the relationship between the amount of ammonia and the slip rate of ammonia, and the denitrification capability of the SCR reactor is evaluated in combination with the slope of the trend line and the upper limit. The method for evaluating the denitrification capability of the SCR reactor provided by the invention can realize steady-state tracking and self-adaptive correction calculation.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH +1

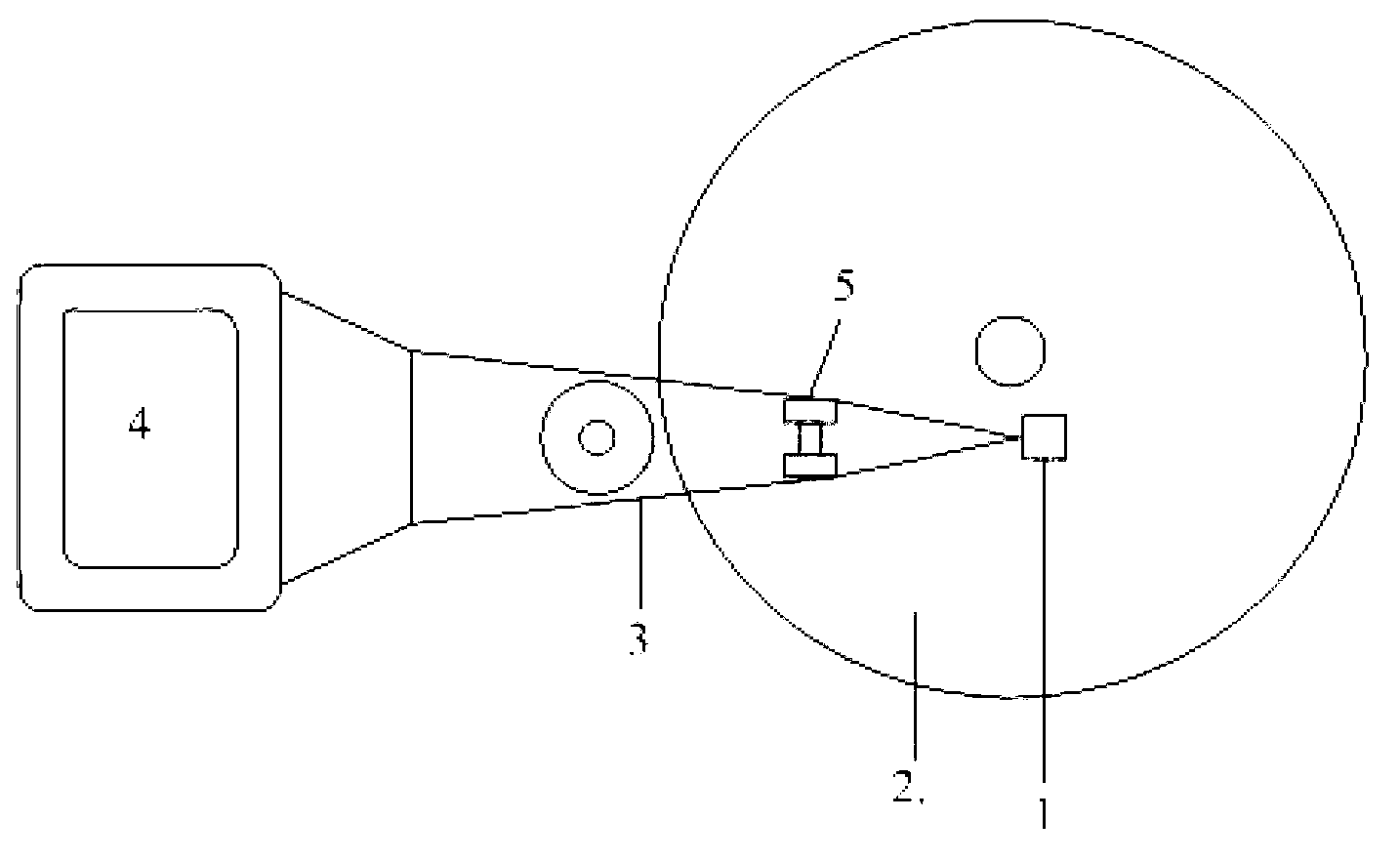

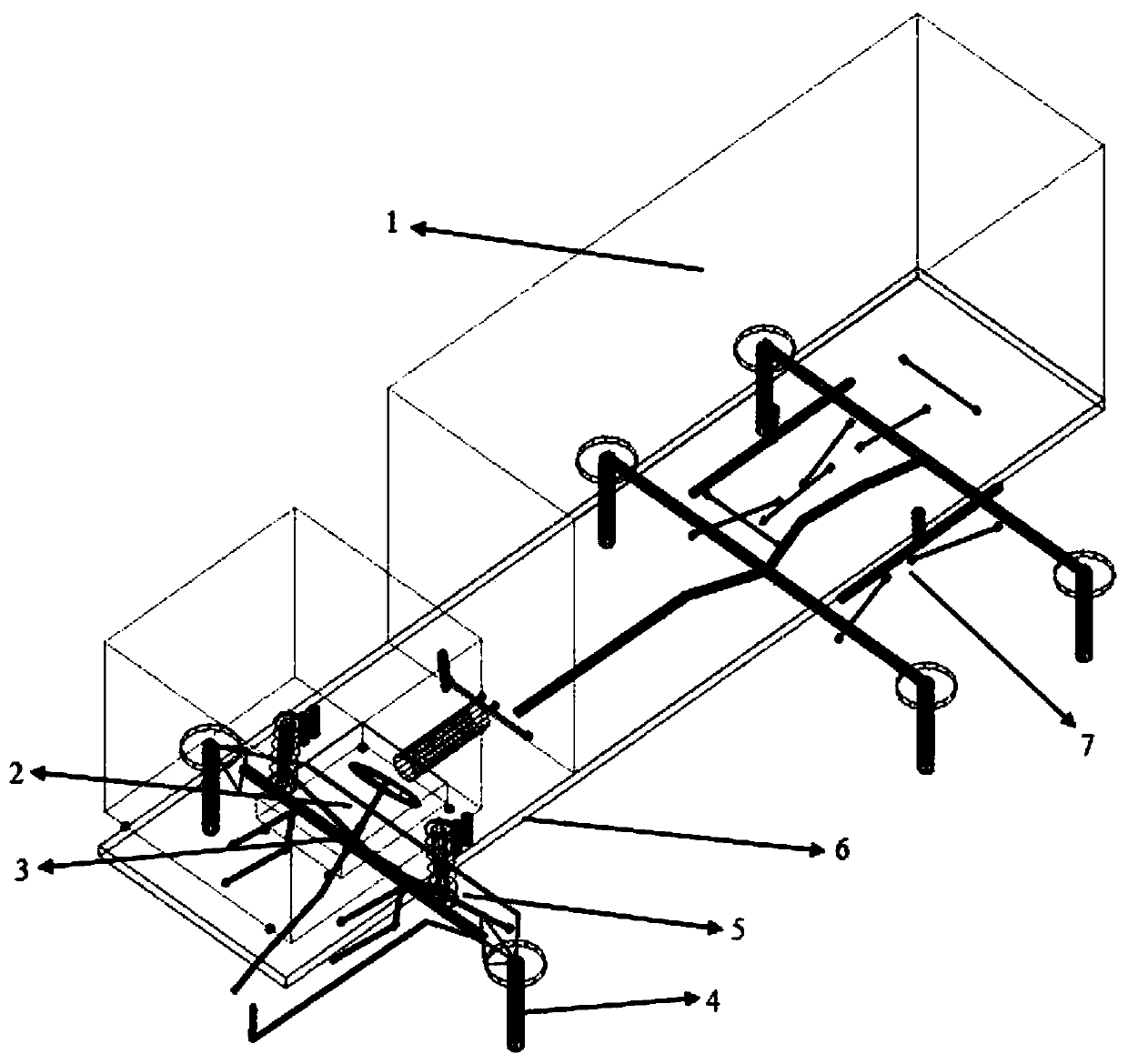

A simulation test bench for shield machine cutter head and its use method

The invention relates to a simulation test bench for a shield machine cutterhead and a method of using it, which includes: a cutterhead, a worm gear structure, a base, a tool storage bin and a manipulator installation bin, wherein the cutterhead is rotated and installed on the base through a mounting plate. , the tool storage bin and the manipulator installation bin are both installed on the base. The worm gear structure is installed on the edge of the base and one side of the 1 / 4 cutterhead surface. In the worm gear structure, the worm gear shaft and the axis of the mounting plate are coaxially fixed together. , a handwheel is provided on the worm gear structure, and the handwheel is fixedly connected to the worm in the worm gear structure in the axial direction; the method is: fixing the hob cutter box; rotating the cutterhead; fixing the cutterhead; installing the tool changing robot; simulation To change the tool, input the position information to the tool changing robot to verify its trajectory planning and movement accuracy. The simulation test bench of the present invention adopts an integrated worm gear structure to avoid the appearance of separate small parts, facilitates installation and operation, has a simple structure, is easy to process, meets strength requirements, and is consistent with actual engineering applications.

Owner:NORTHEASTERN UNIV LIAONING

Fast and high-precision relative pointing control method based on feed-forward pid control for crossing fast-changing tracks on different planes

ActiveCN104570742BCompatible with practical engineering applicationsHigh practical application valueAttitude controlAdaptive controlKinematics equationsGyroscopic moment

The invention relates to a rapid high-precision relative pointing control method of a noncoplanar rendezvous orbit, in particular to a feedforward PID (proportion, integration and differentiation) control based rapid high-precision relative pointing control method of the noncoplanar rendezvous orbit, and aims to solve the problem that rapid high-precision tracking-pointing control methods related to satellite attitudes under the noncoplanar rendezvous orbit do not exist in the prior art. The feedforward PID control based rapid high-precision relative pointing control method including adopting an Euler angle for attitude description of a spacecraft, creating dynamical and kinematical equations of the spacecraft, and acquiring an precise expected angle theta according to a noise-containing expected angle z by a Kalman filtering algorithm of a spaceborne computer; designing an attitude control law of each axis according to a formula of ; selecting two parallelly-placed single-frame control moment gyroscopes to control a yaw axis, and selecting two flywheels to control a rolling axis and a pitch axis respectively; calculating gyroscopic moment T and flywheel actual output moment uw to complete rapid high-precision relative pointing control of the noncoplanar rendezvous orbit. The feedforward PID control based rapid high-precision relative pointing control method is applicable to rapid high-precision relative pointing control of the noncoplanar rendezvous orbit.

Owner:HARBIN INST OF TECH

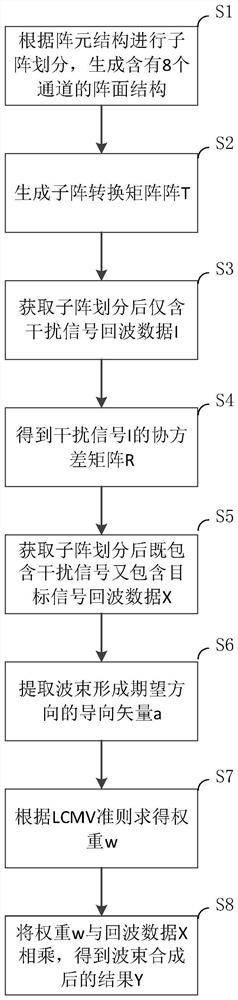

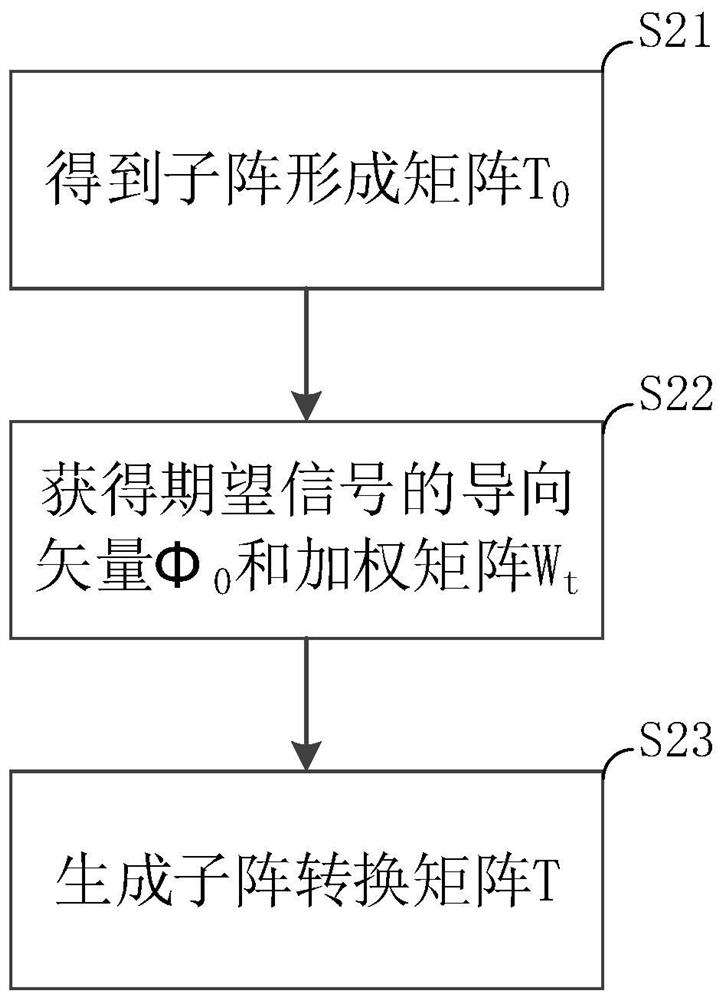

Multi-channel adaptive beam forming method based on LCMV criterion

ActiveCN114142900AImprove real-time performanceAdaptive beamforming method fastSpatial transmit diversityHigh level techniquesInterference resistanceAlgorithm

The invention provides a multi-channel adaptive beam forming method based on an LCMV criterion, is suitable for radar communication sidelobe anti-interference application, and belongs to the field of array signal processing. Compared with a traditional beam forming algorithm, the method has the advantages that sub-array division is carried out on the array plane according to the actual array plane structure and engineering requirements of the radar, the multi-channel signal model is generated, adaptive beam forming is carried out by using the LCMV criterion, and the method is high in real-time performance and easy to implement. Compared with a traditional beam forming algorithm, the method has the advantages that the operation speed is higher under the multi-channel condition.

Owner:BEIJING RES INST OF TELEMETRY +1

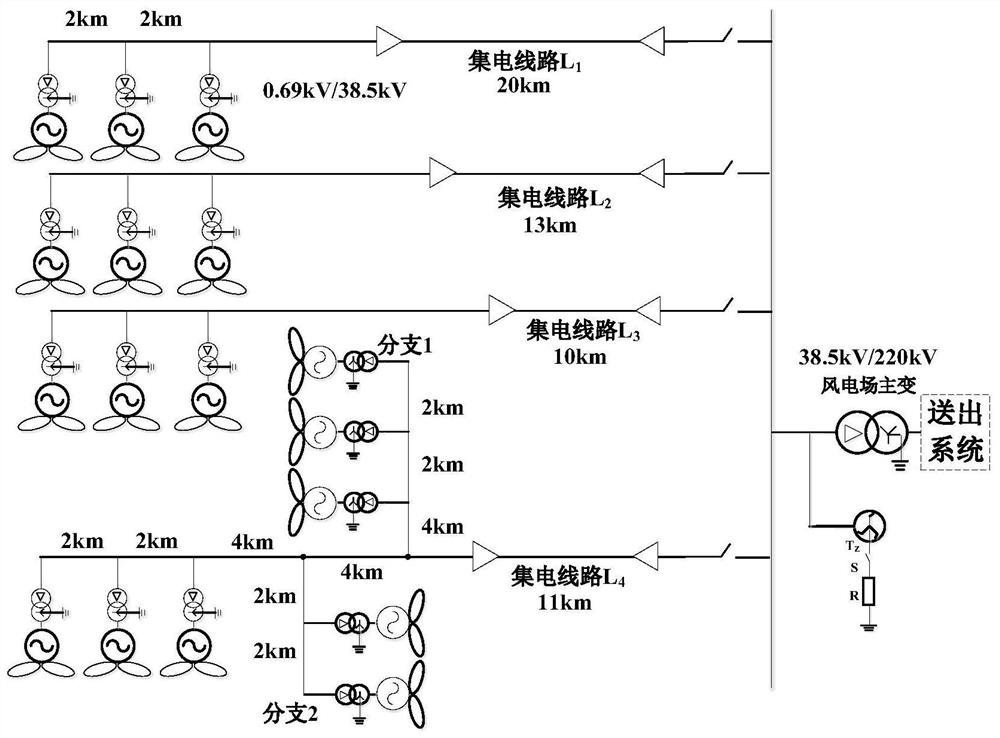

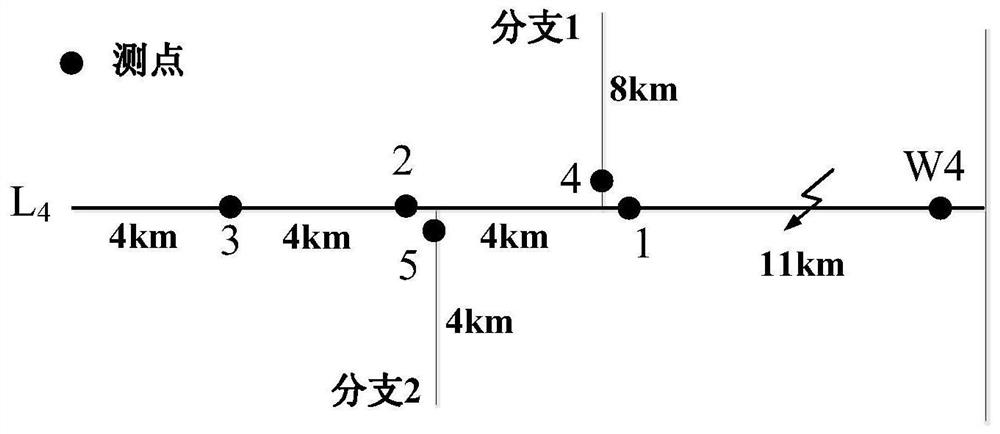

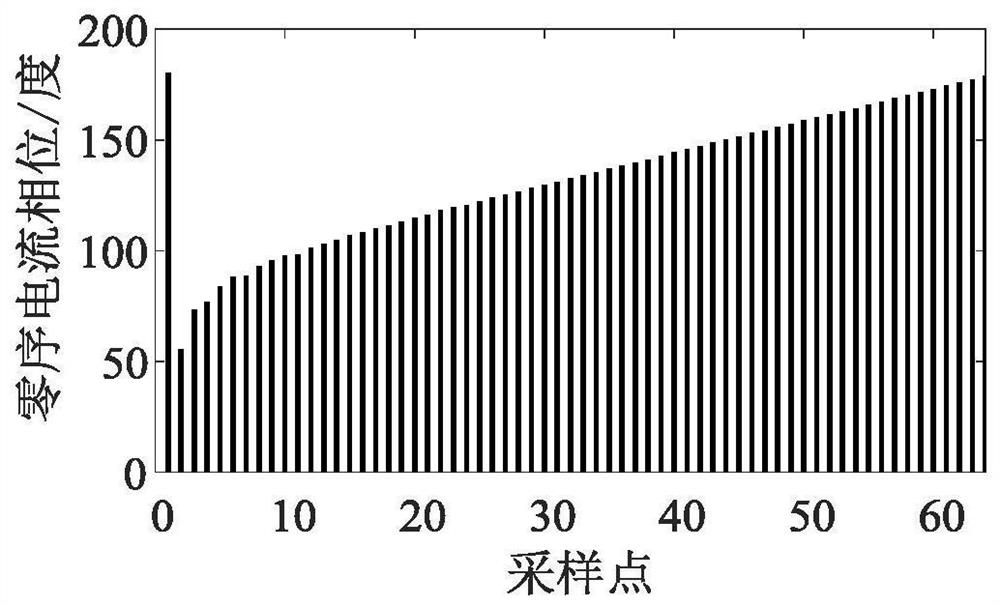

A Method for Identifying Fault Sections and Fault Branches of Collecting Lines in Wind Farms

ActiveCN112083284BThe principle is simpleCompatible with practical engineering applicationsVoltage-current phase angleFault location by conductor typesElectric power systemControl theory

The invention relates to a method for identifying a fault section and a fault branch of a collector line of a wind farm, and belongs to the technical field of electric power system relay protection. Firstly, the zero-sequence current data of one cycle after the fault of each measuring point on the collector line is extracted, and the Hanning window function is selected to add a window to it, and the zero-sequence current sequence value after windowing is calculated. FFT transforms the zero-sequence current sequence values after windowing at each measuring point to obtain the transformed zero-sequence current sequence values, and calculates the zero-sequence current fault component phase spectrum and its phase spectrum mean value of two adjacent measuring points. If the two adjacent measurement points are on the main line, judge whether the section is faulty according to the faulty section identification criterion; Whether the branch is faulty. The invention only adopts the zero-sequence current construction criterion of the wind farm collector line to identify fault sections and branches, the principle is simple, and it is suitable for practical application in engineering.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com