A design method for the mix ratio of recycled permeable bricks based on the target permeability coefficient

A technology of mix ratio design and water permeability coefficient, which is applied in calculation, data processing application, prediction, etc., can solve problems such as difficult strength and water permeability balance, complex design process of mix ratio, etc., to ensure water permeability and strength requirements, and easy to operate , design based on clear and definite effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

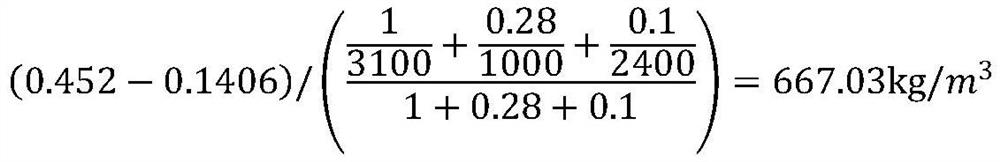

[0038] Prepare raw materials:

[0039] Cement: ordinary Portland cement of grade 42.5 with a density of 3100kg / m 3 ;

[0040] Fly ash: secondary fly ash with a density of 2400kg / m 3 ;

[0041] Water reducing agent: HSC polycarboxylate high performance water reducing agent, water reducing rate 30%, specific gravity 1.07, solid content 40%;

[0042] Recycled aggregate: crushed particle size is 5~9.5mm, bulk density is 1362kg / m 3 , Apparent density 2485kg / m 3 , porosity 45.2%;

[0043] Three types of recycled permeable bricks with different target water permeability coefficients were selected, the water-cement ratio was determined to be 0.28 by trial mixing, and the fly ash content was set to 10%. During the preparation process, the fluidity of each group was controlled by adjusting the amount of water reducing agent.

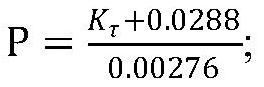

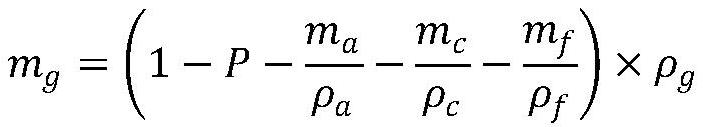

[0044] Taking the target water permeability coefficient of 0.01 as an example, the calculation method of the distribution ratio of each group is given.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com