Dual-clutch structure

A technology of dual clutches and clutches, which is applied to control devices, transportation and packaging, and vehicle components, can solve the problems of increasing the axial length of dual clutches, affecting the spatial layout of the vehicle, and complicated manufacturing processes, so as to facilitate space layout, Eliminate adverse effects and reduce production and assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

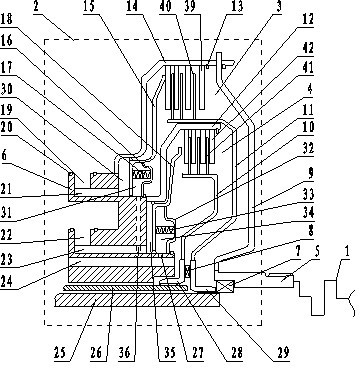

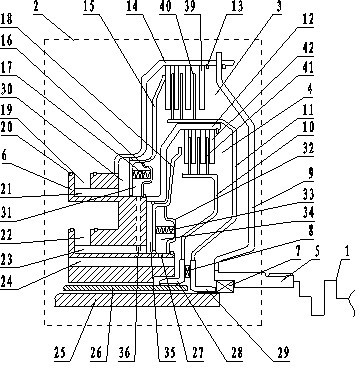

[0016] Referring to Fig. 1, the present invention comprises input shaft 5, clutch front cover 9, main hub 6, outer clutch 3, inner clutch 4, output shaft one 25 and output shaft two 26 in the composition of the present invention, and one end of said input shaft 5 is connected with the engine shaft , the other end is connected with the clutch front cover 9, the clutch front cover 9 is assembled with the outer clutch element, the main hub 6 is an integral structure, and is sleeved on the outside of the output shaft two 26 in a clearance fit manner, the outer clutch 3 And inner clutch 4 is installed on the corresponding element of main wheel hub, described output shaft one 25 is fitted with outer clutch element, and described output shaft two 26 is fitted with inner clutch element.

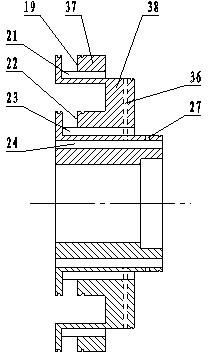

[0017] see figure 1 , figure 2 The main hub 6 in the composition of the present invention is axially provided with a clutch cooling oil passage 24, radially provided with an outer clutch cooling oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com