Method for predicting fatigue life of wide-body mining vehicle frame

A technology for fatigue life prediction and mining vehicles, which is applied to instruments, electrical digital data processing, computer-aided design, etc., to achieve the effects of low cost, strong practicability, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0037] Example

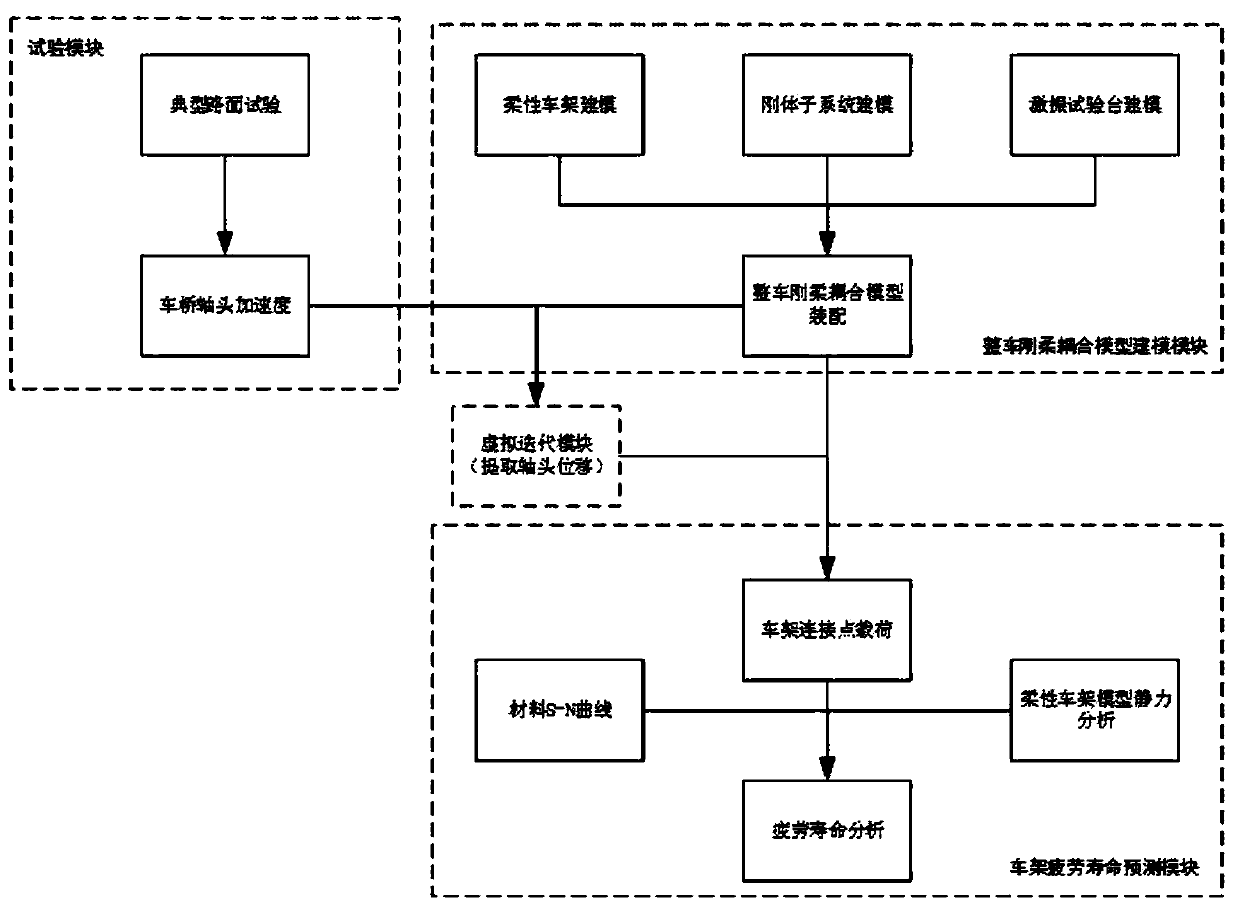

[0038] Refer to figure 1 , A system for predicting the fatigue life of a wide-body mining vehicle frame includes a test module, a rigid-flexible coupling model modeling module for the vehicle, a virtual iteration module, and a frame fatigue life prediction module.

[0039] The test module is mainly used to extract the acceleration signal on the axle head of the wide-body mining vehicle axle.

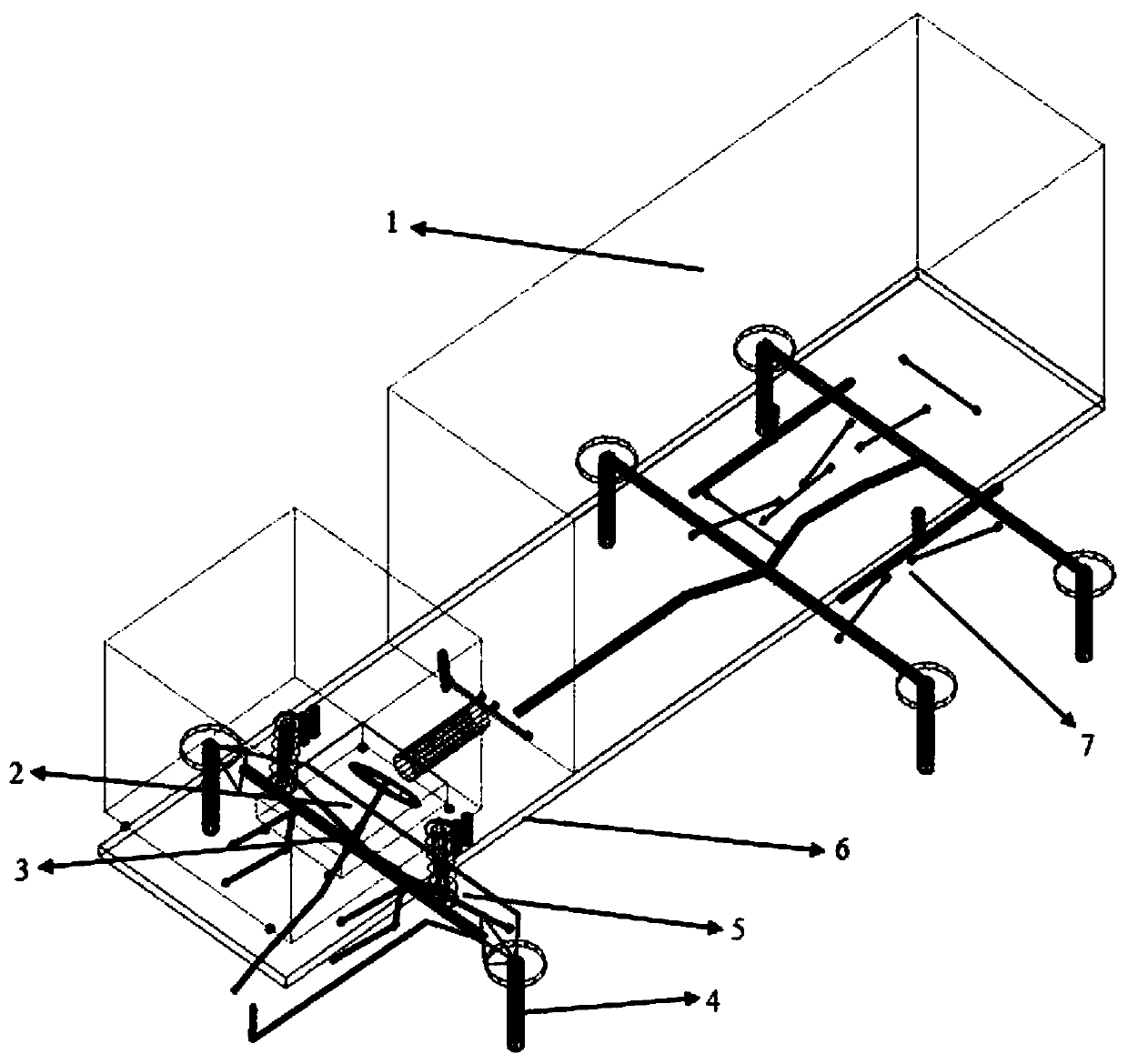

[0040] Refer to figure 2 For the multi-rigid body dynamics model of the whole vehicle, the rigid body of the frame needs to be replaced with the flexible body of the frame later. The vehicle rigid-flexible coupling model modeling module is used to establish the vehicle rigid-flexible coupling model for subsequent virtual iteration and extraction of the load of the frame connection point. Based on the theory of multi-body dynamics and modal synthesis method, three models of the frame flexible body, rigid body subsystem, and excitation test bench are established.

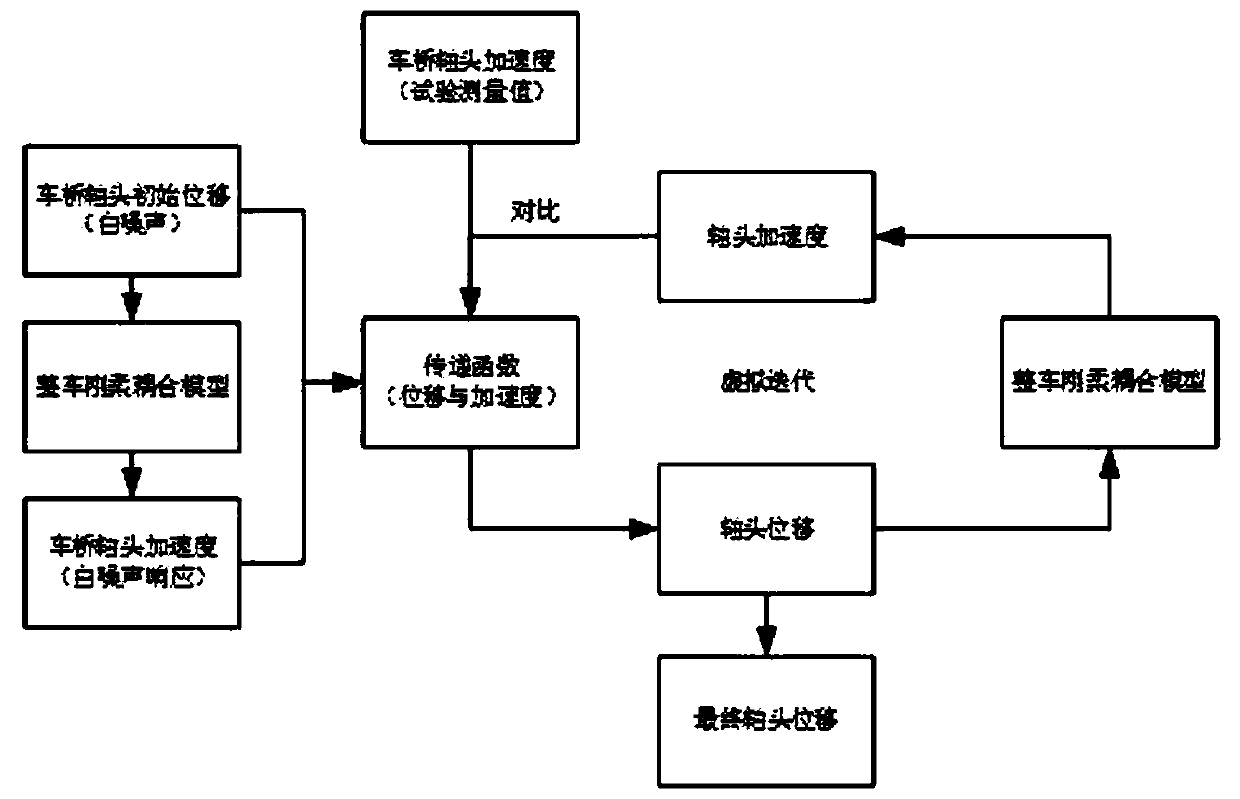

[0041] Refer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com