Optimal controlling method for boiler intelligent combustion based on big data

A combustion optimization and control method technology, applied in the direction of combustion control, genetic models, genetic rules, etc., can solve problems such as wrong models, insufficient "quantity", increased NOx emissions, etc., to improve optimization performance, optimization effect, and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to describe the technical solutions disclosed in the present invention in detail, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

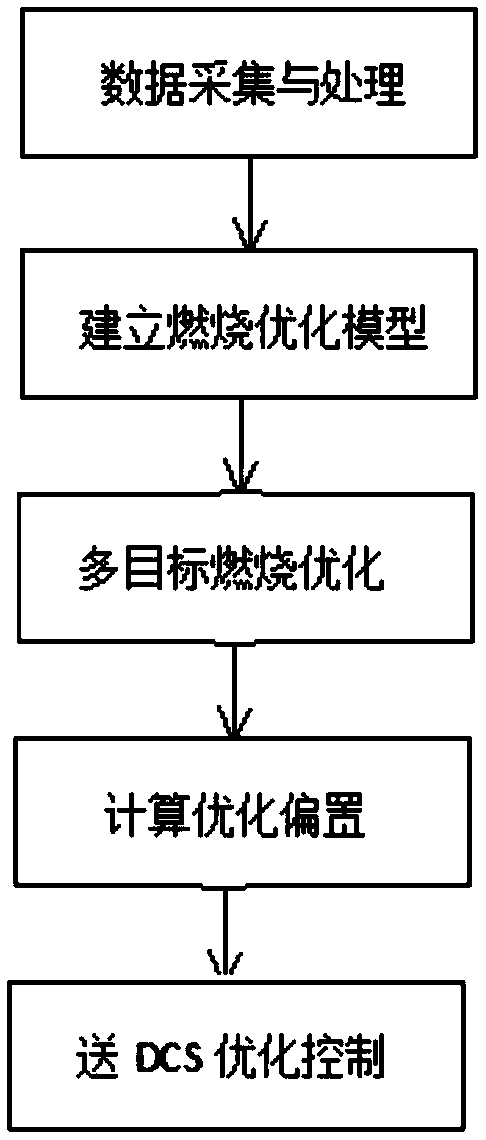

[0039] refer to figure 1 As shown, the steps of the boiler intelligent combustion optimization control method based on big data provided by the present invention are as follows:

[0040] (1) Collect DCS data of the unit, and process and form neural network training samples;

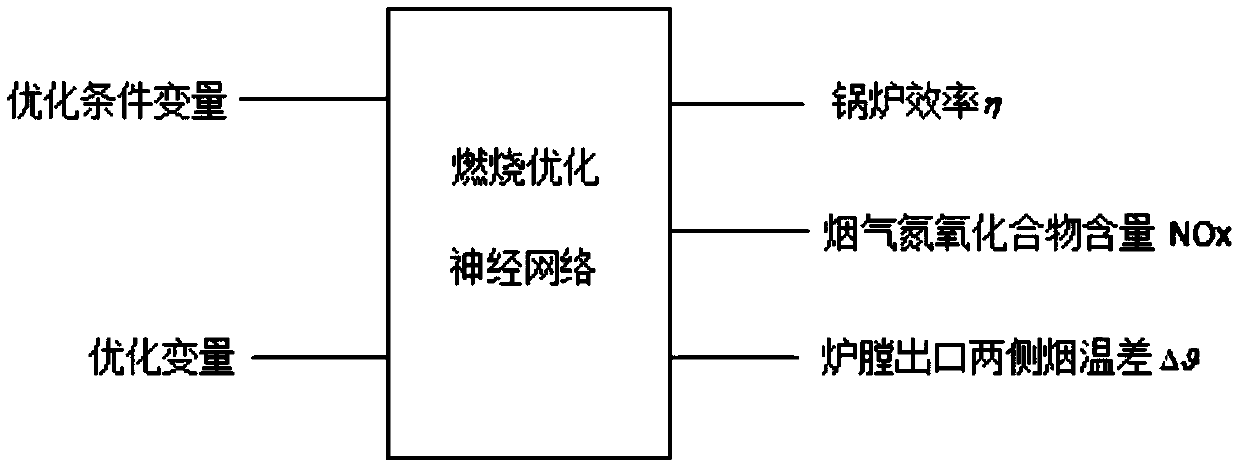

[0041] (2) Establish a combustion optimization neural network model according to the training samples;

[0042] (3) According to the combustion optimization neural network model, a multi-objective genetic algorithm is used to optimize the combustion parameters;

[0043] (4) Calculate the optimal bias according to the optimized combustion parameters, and send it to DCS to realize closed-loop optimal control.

[0044] The steps of the present invention will be described in detail b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com