Patents

Literature

592 results about "Boiler efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

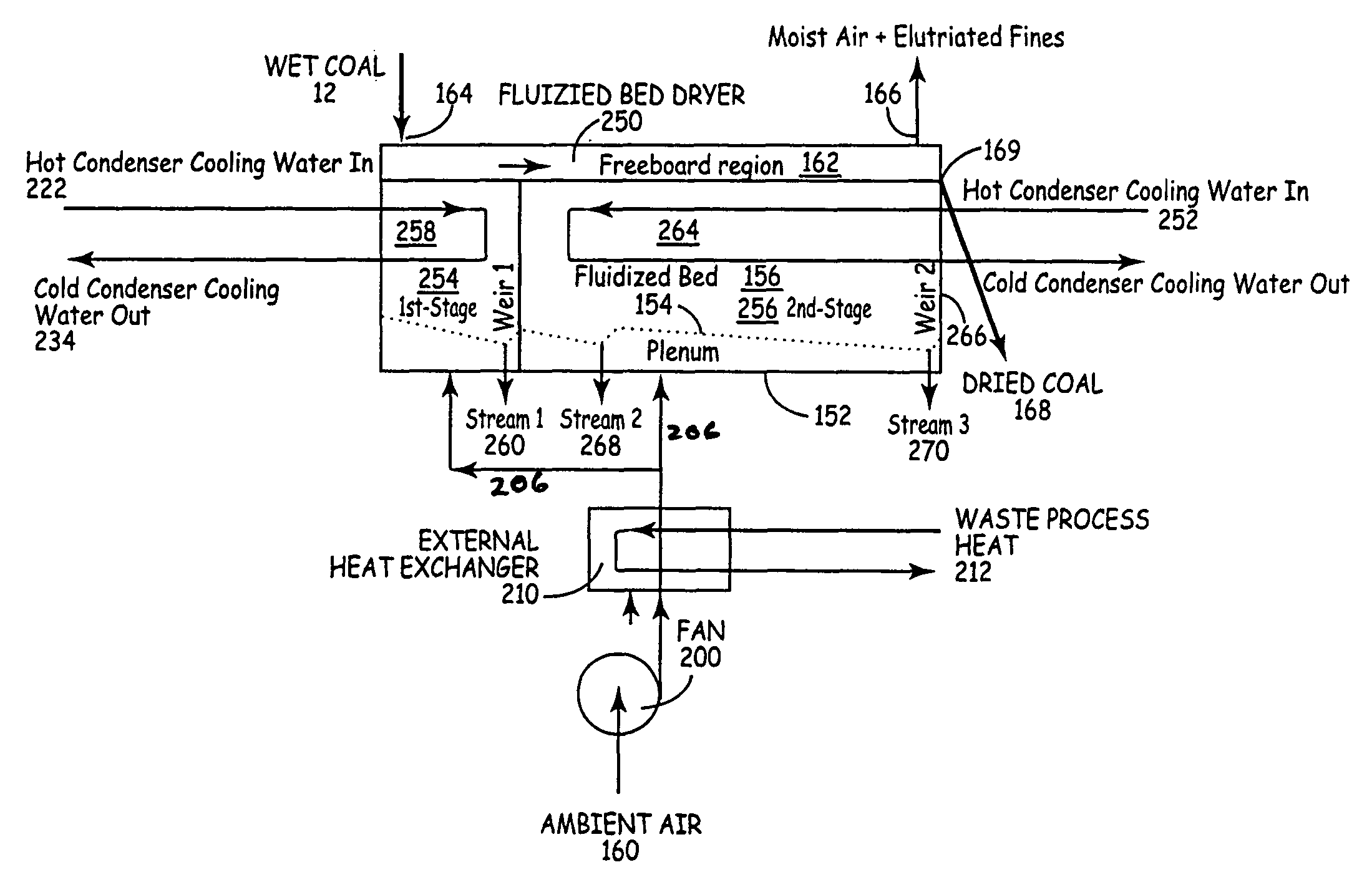

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS20080201980A1Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatSolid fuel pretreatmentParticulatesFluidized bed drying

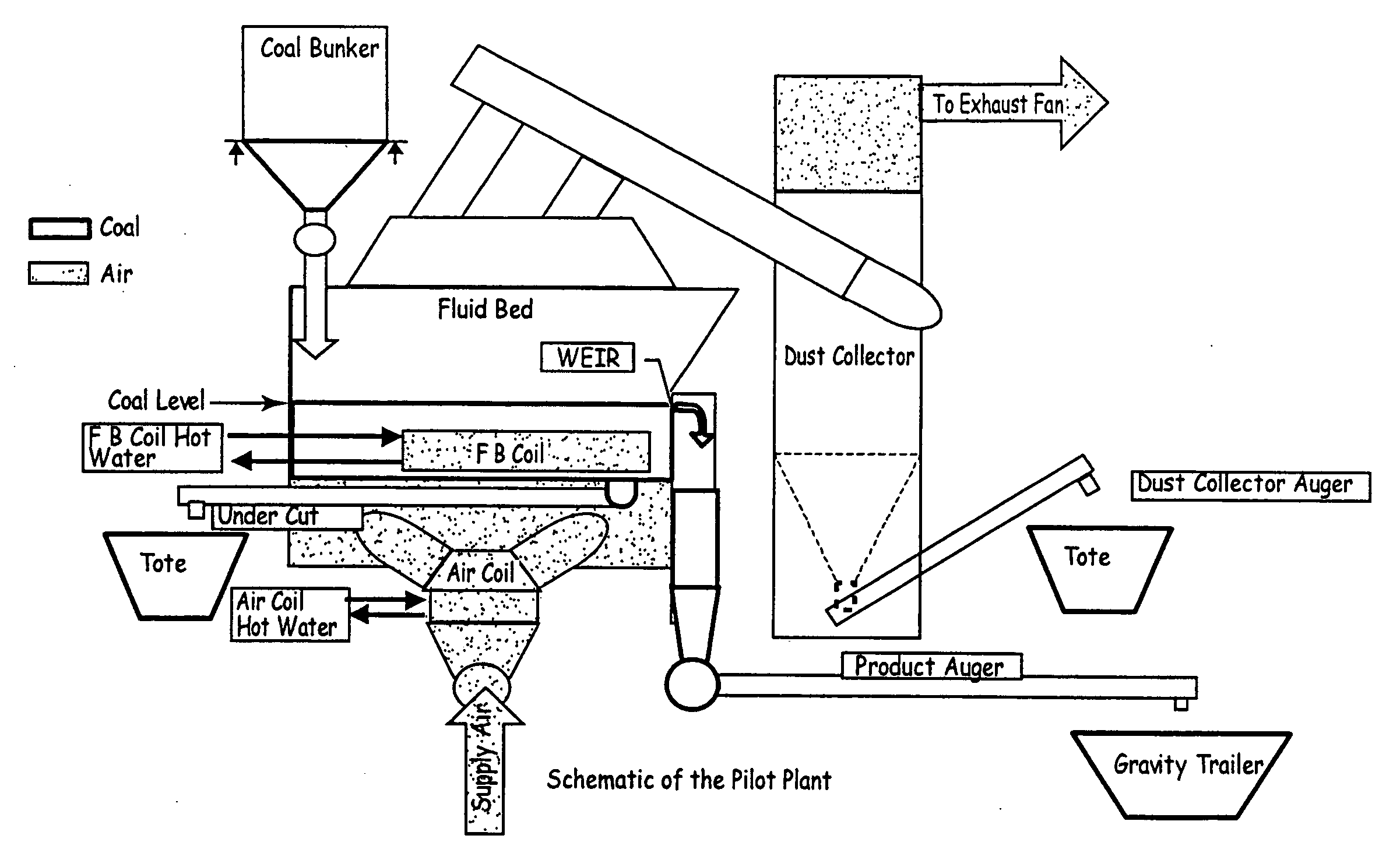

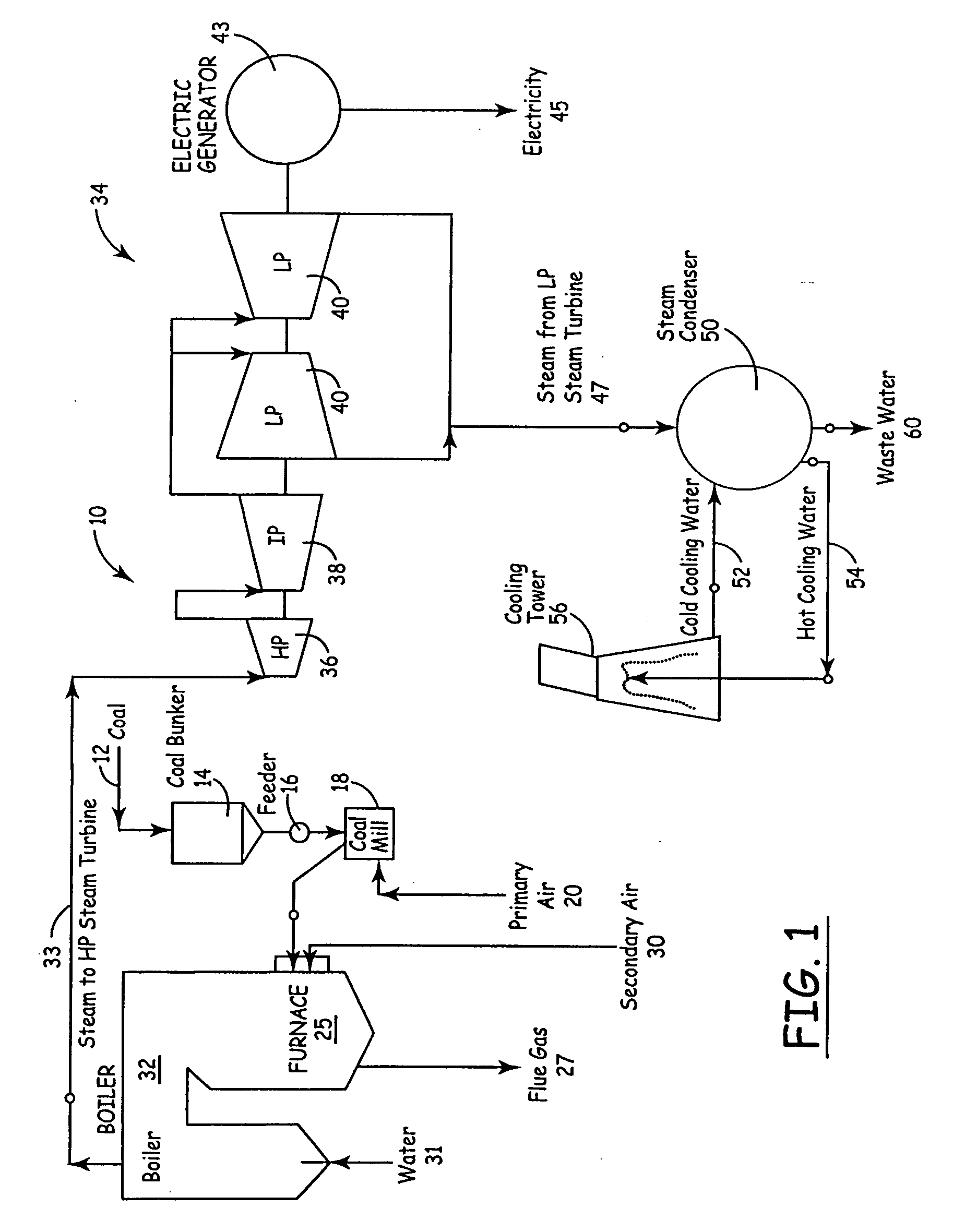

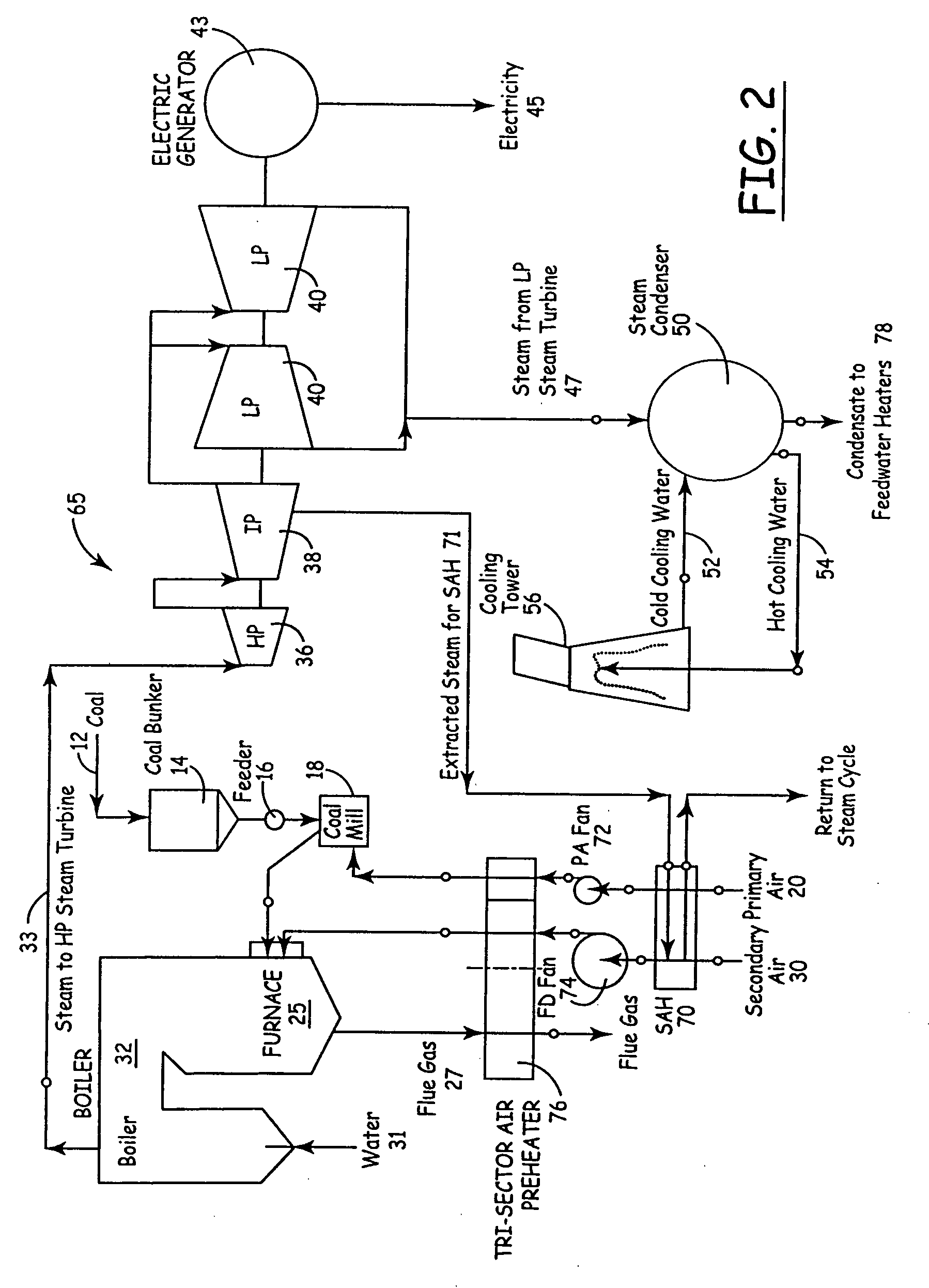

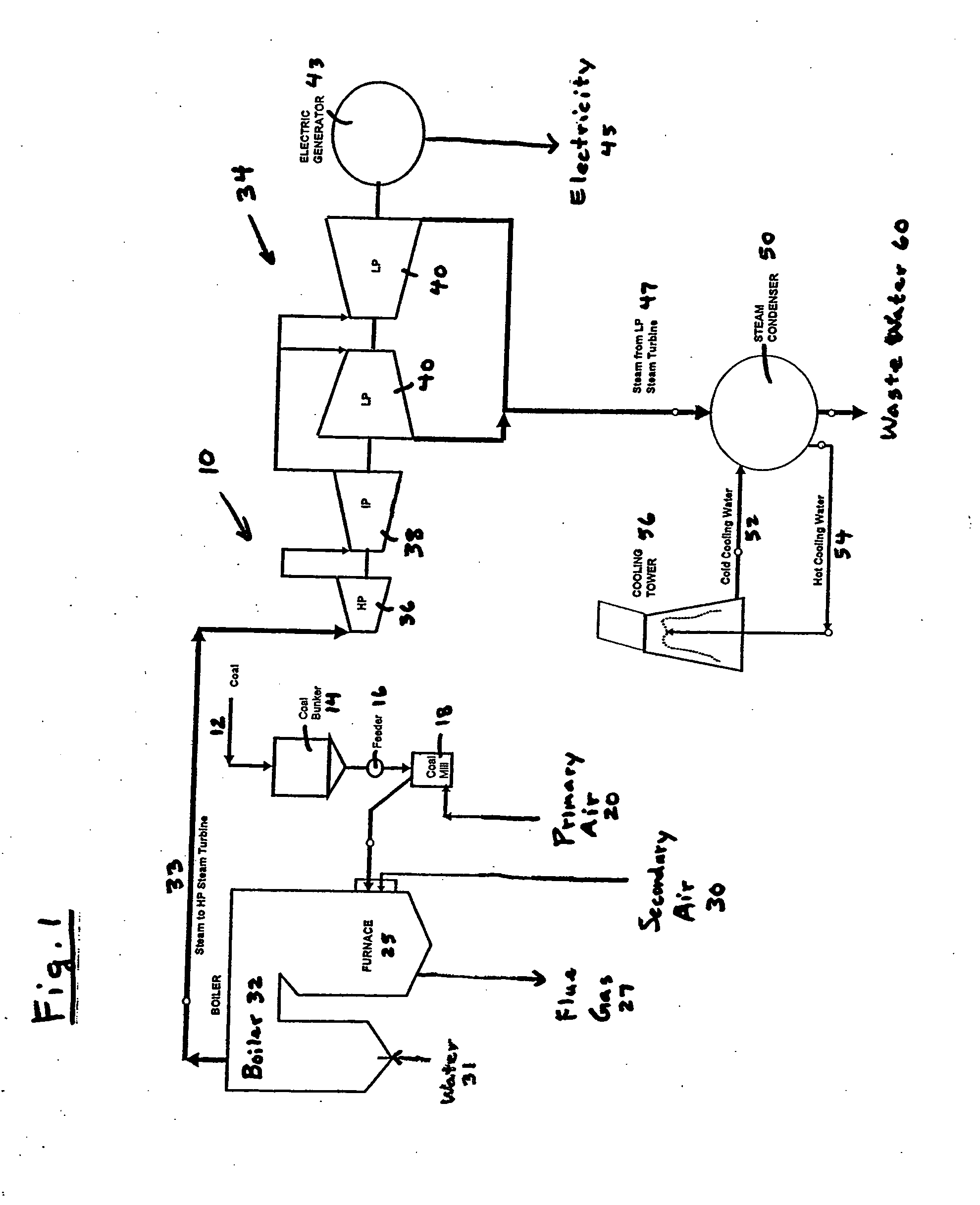

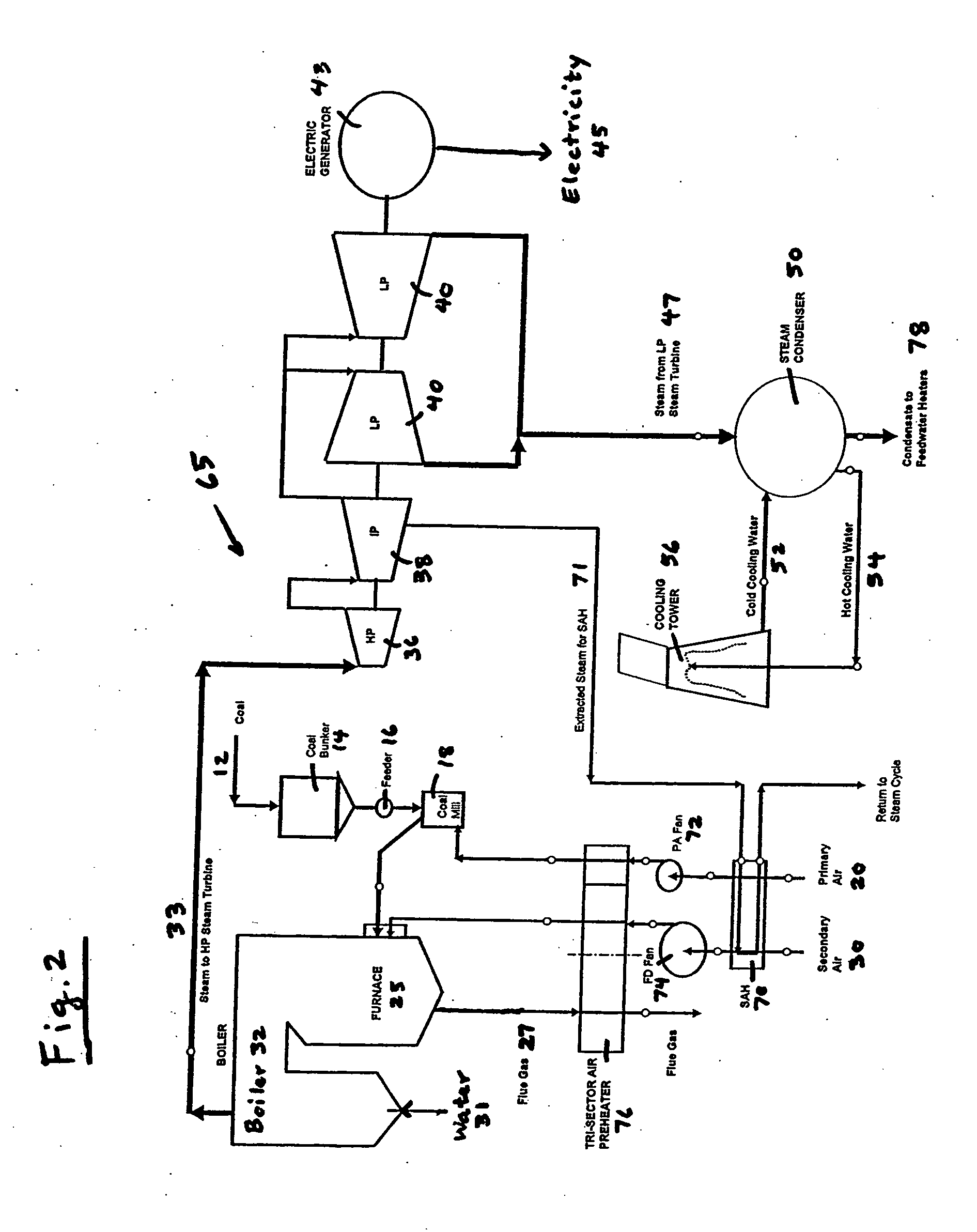

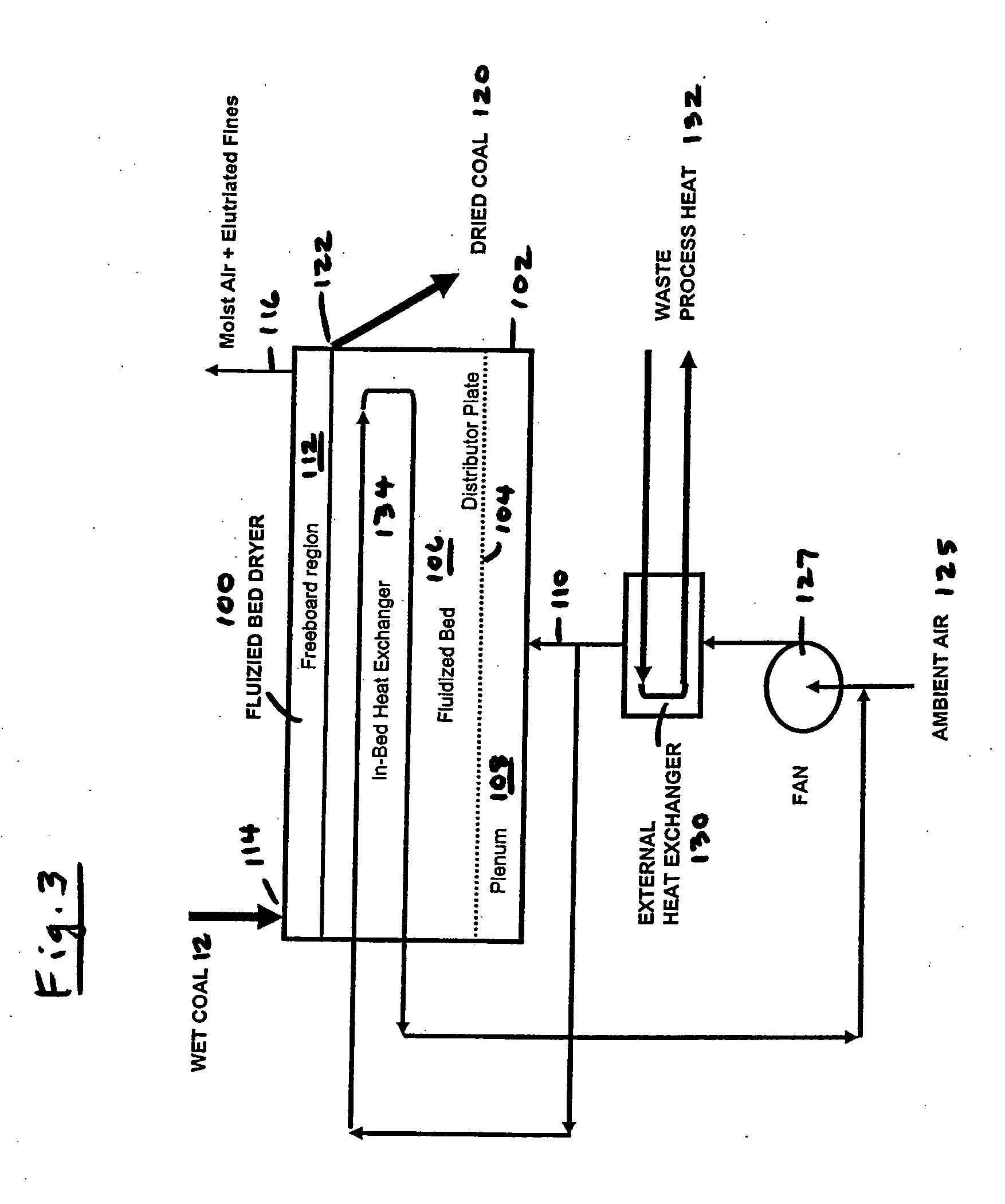

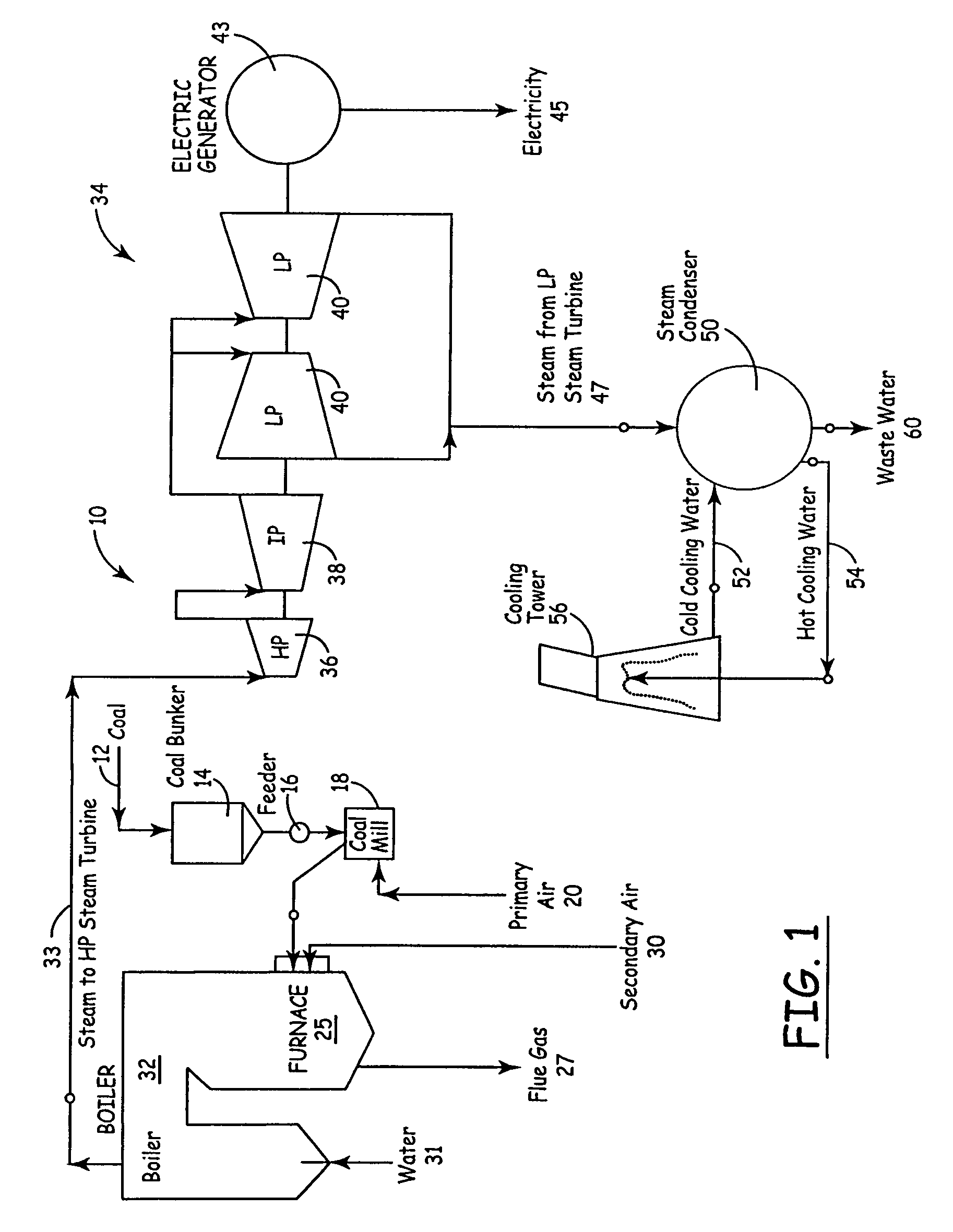

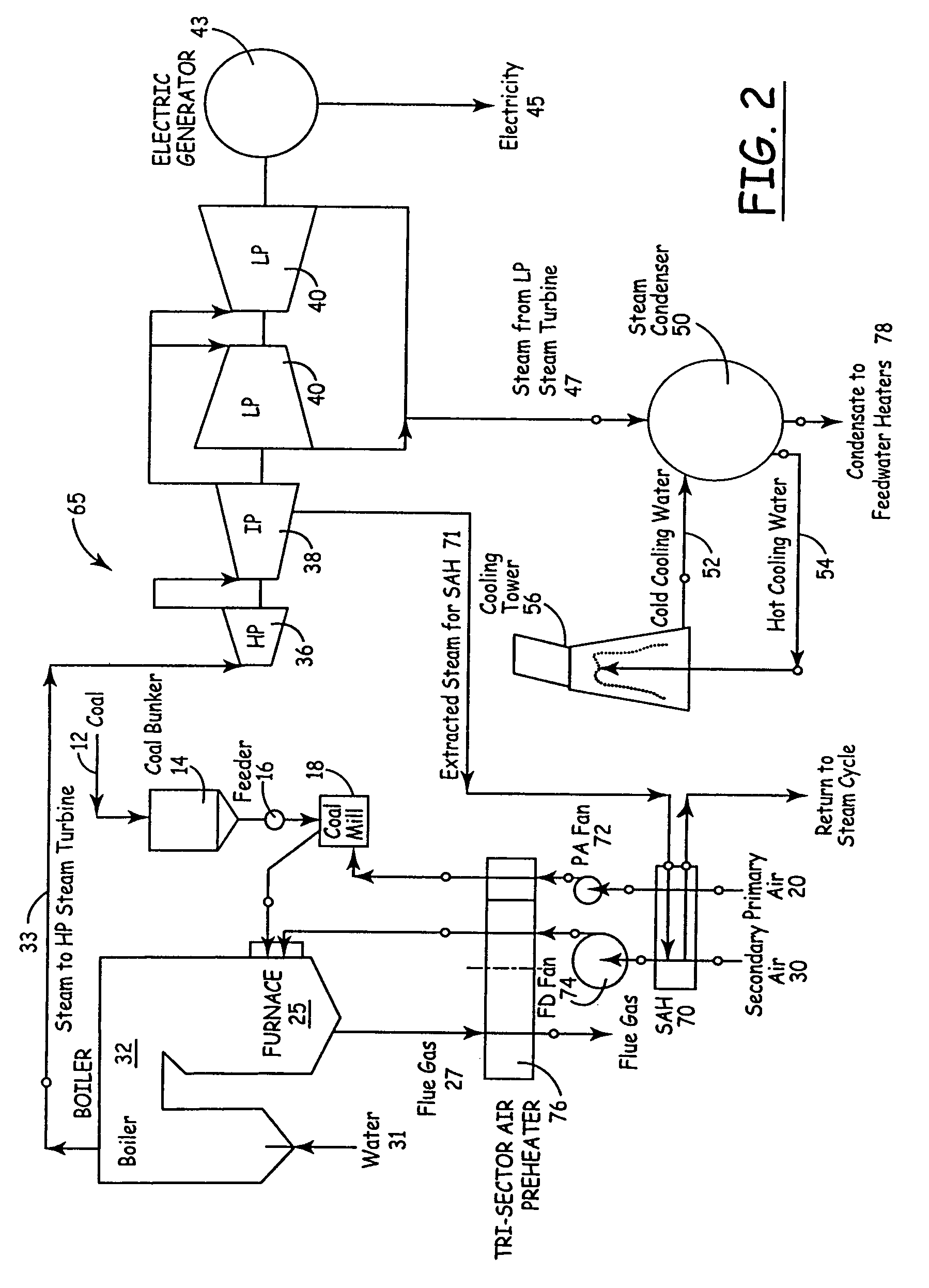

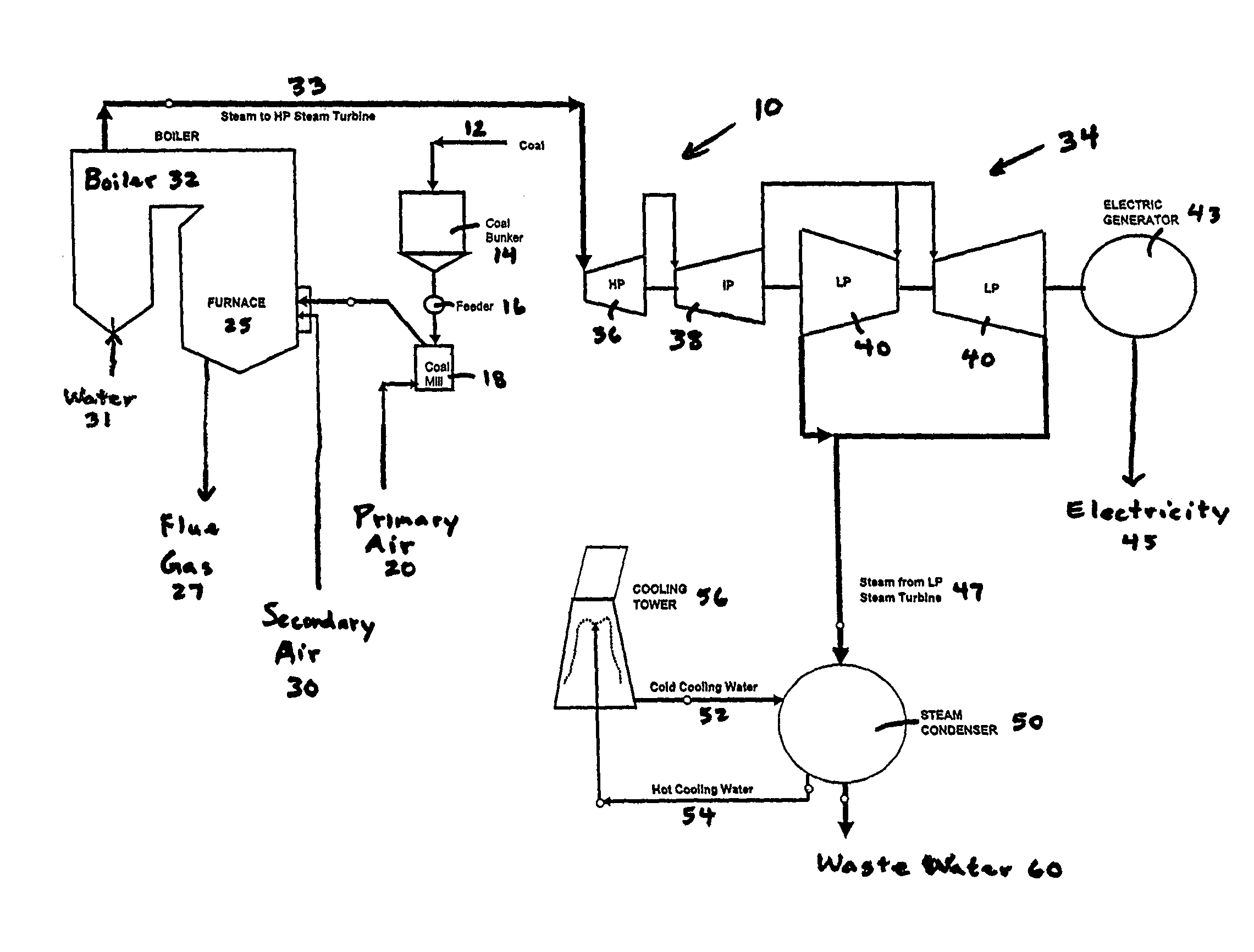

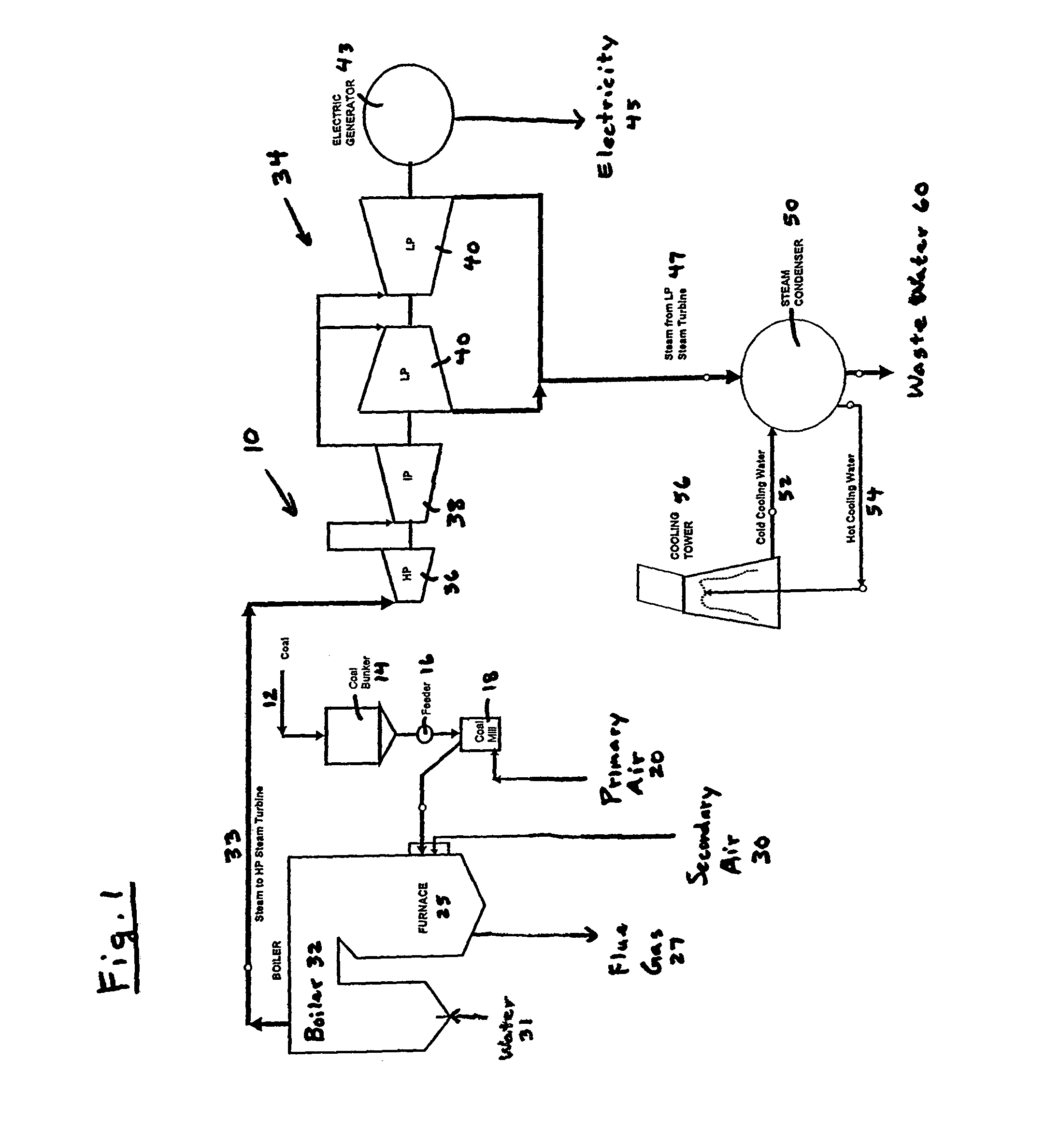

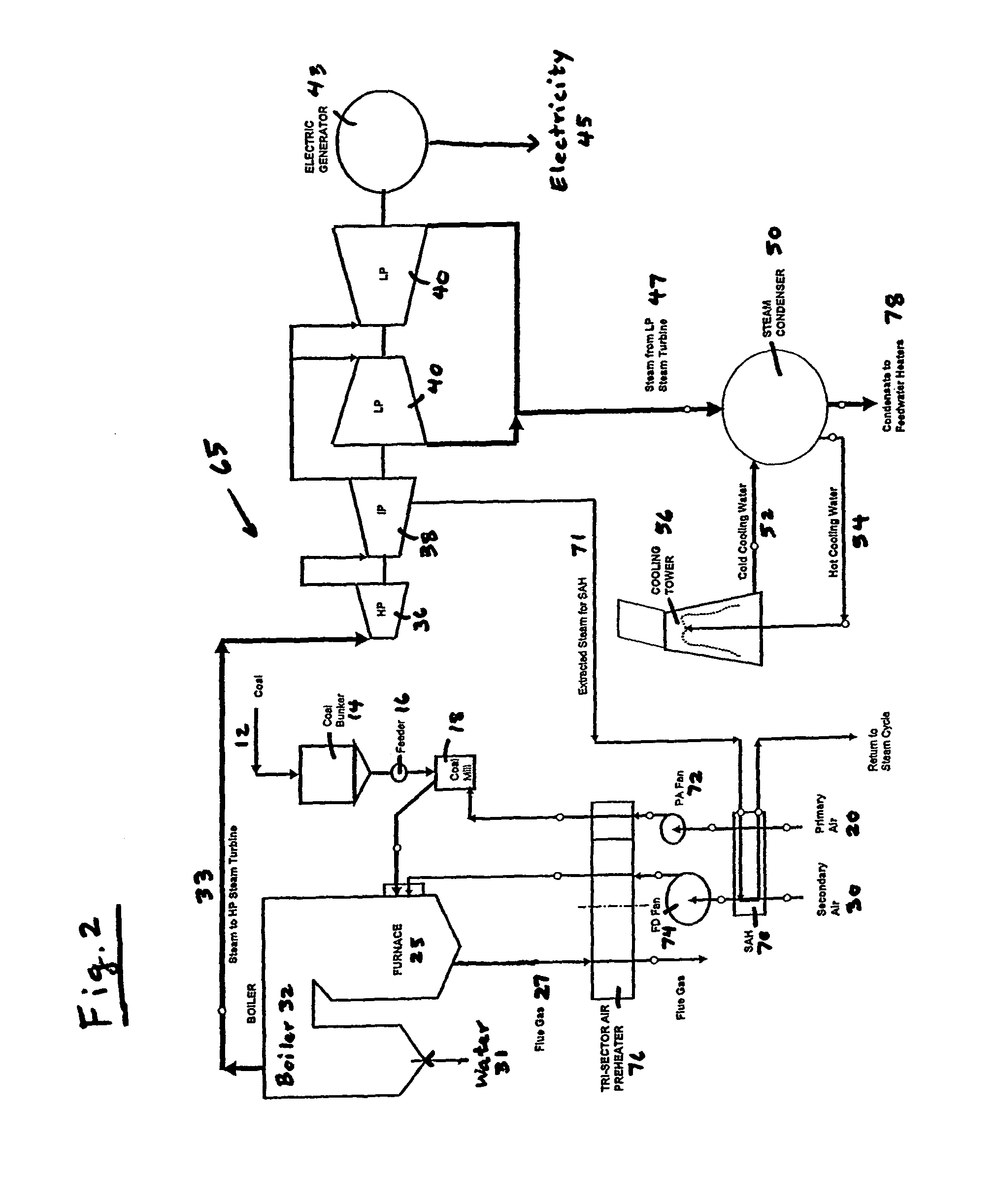

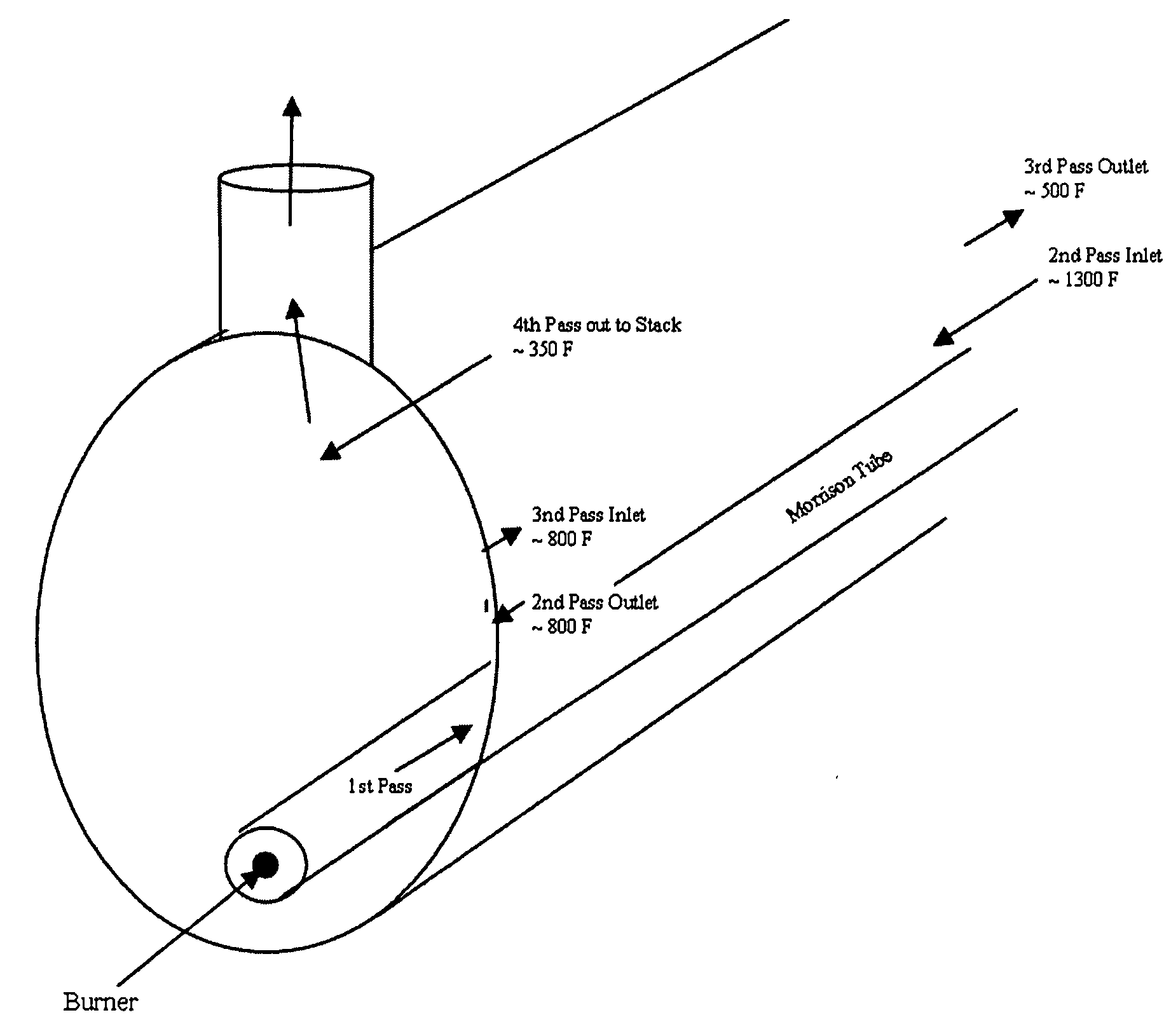

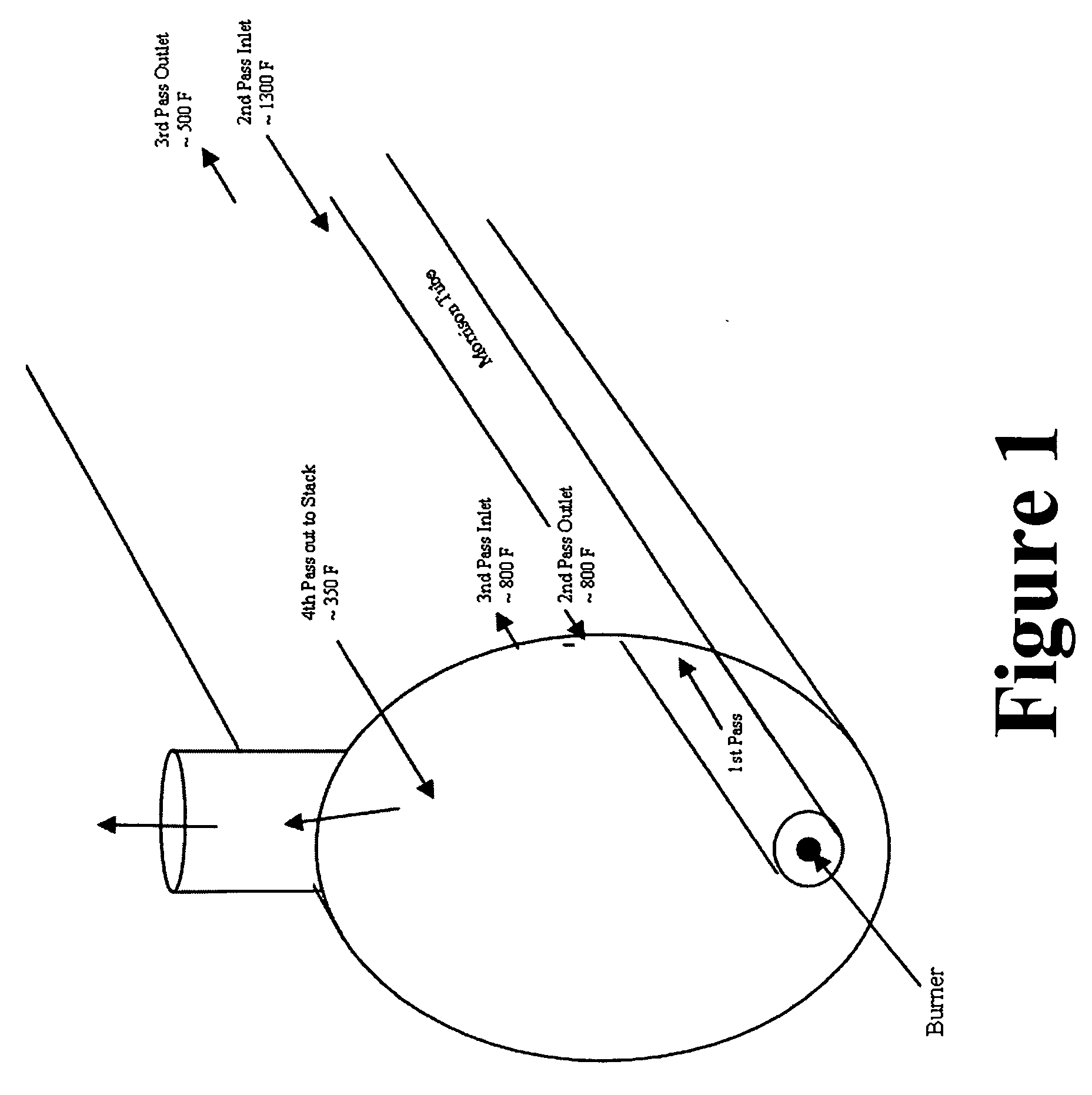

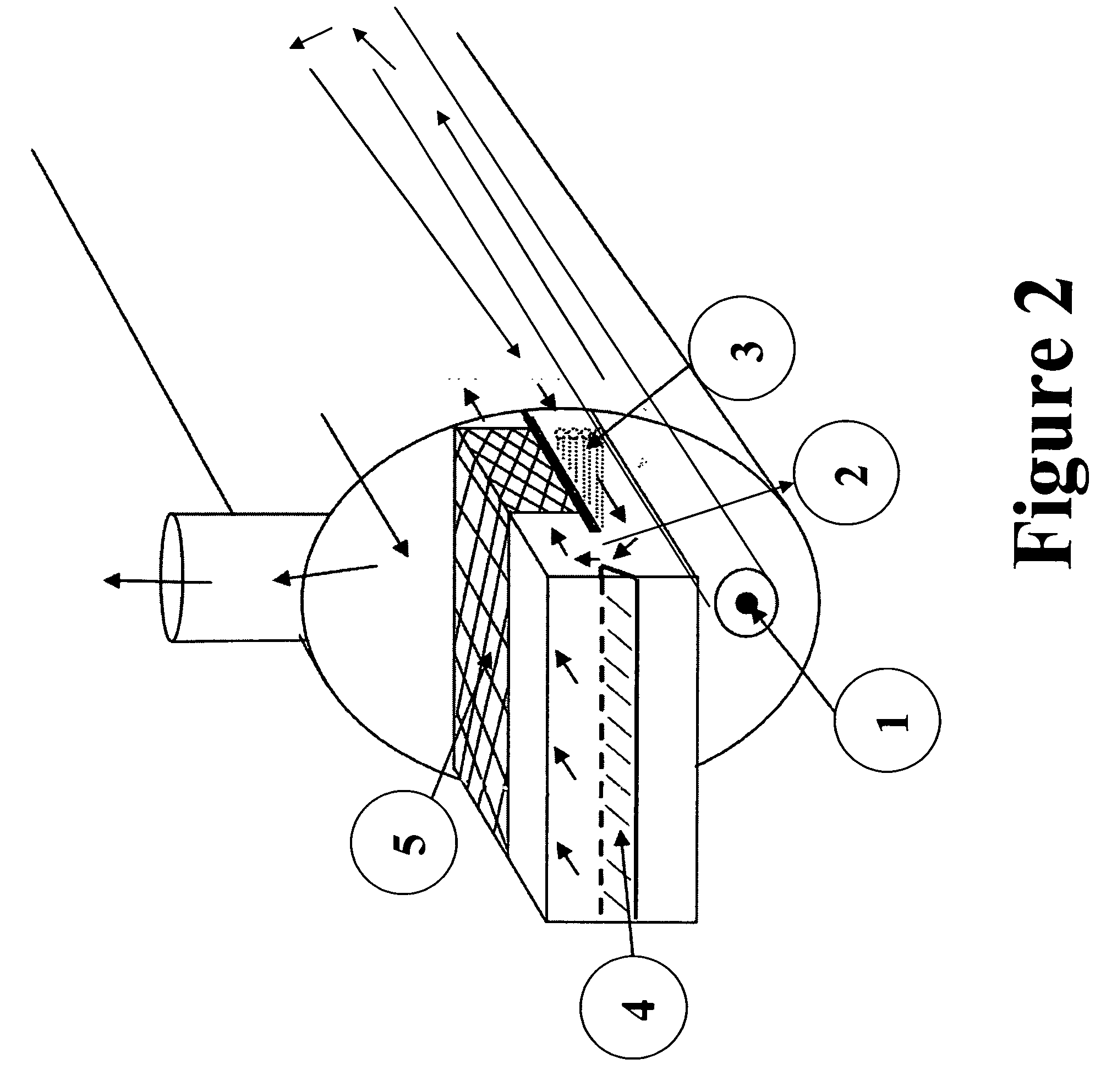

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

Method of enhancing the quality of high-moisture materials using system heat sources

ActiveUS20060075682A1Eliminates potential harmEmission reductionDrying solid materials with heatSolid fuelsFluidized bed dryingHeat flow

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

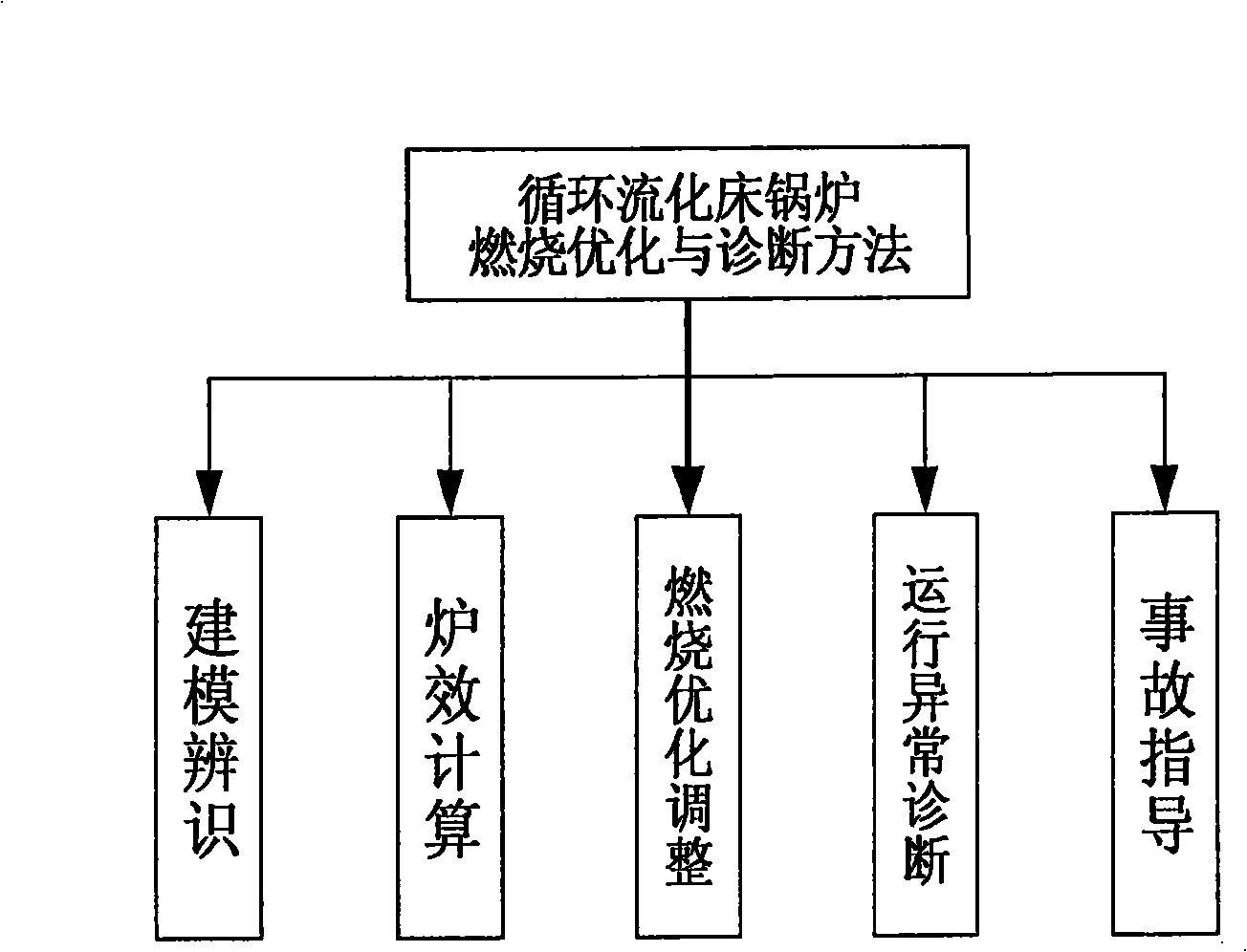

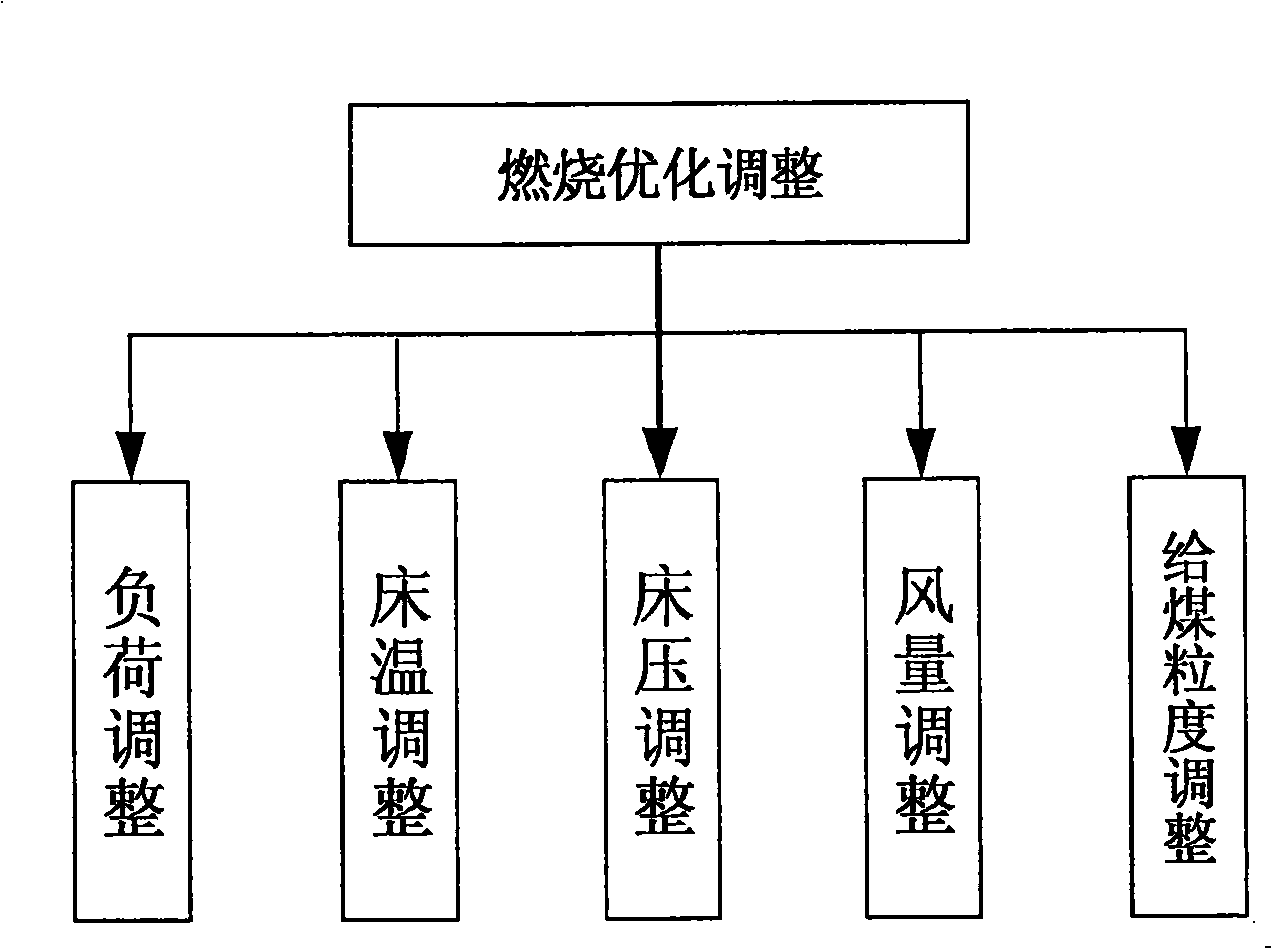

Method for optimizing and diagnosing circulating fluid bed boiler combustion

InactiveCN101329582AImprove economyFix security issuesElectric testing/monitoringAdaptive controlAir volumeEngineering

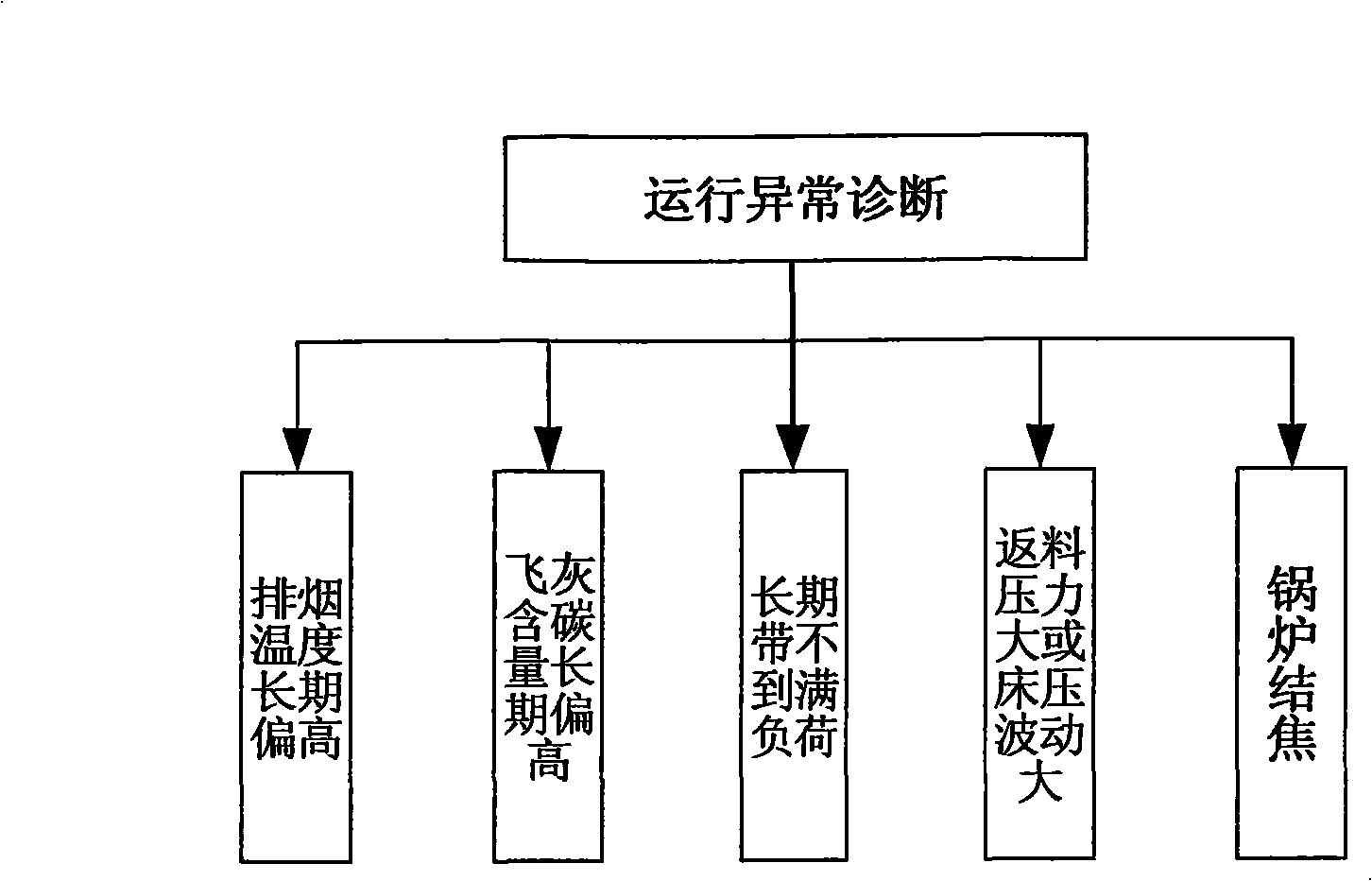

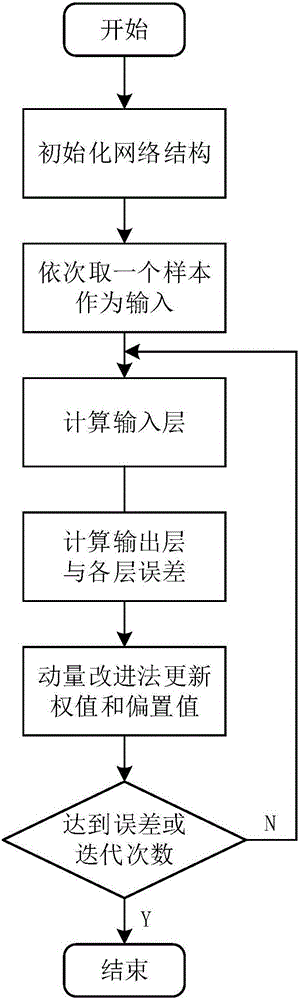

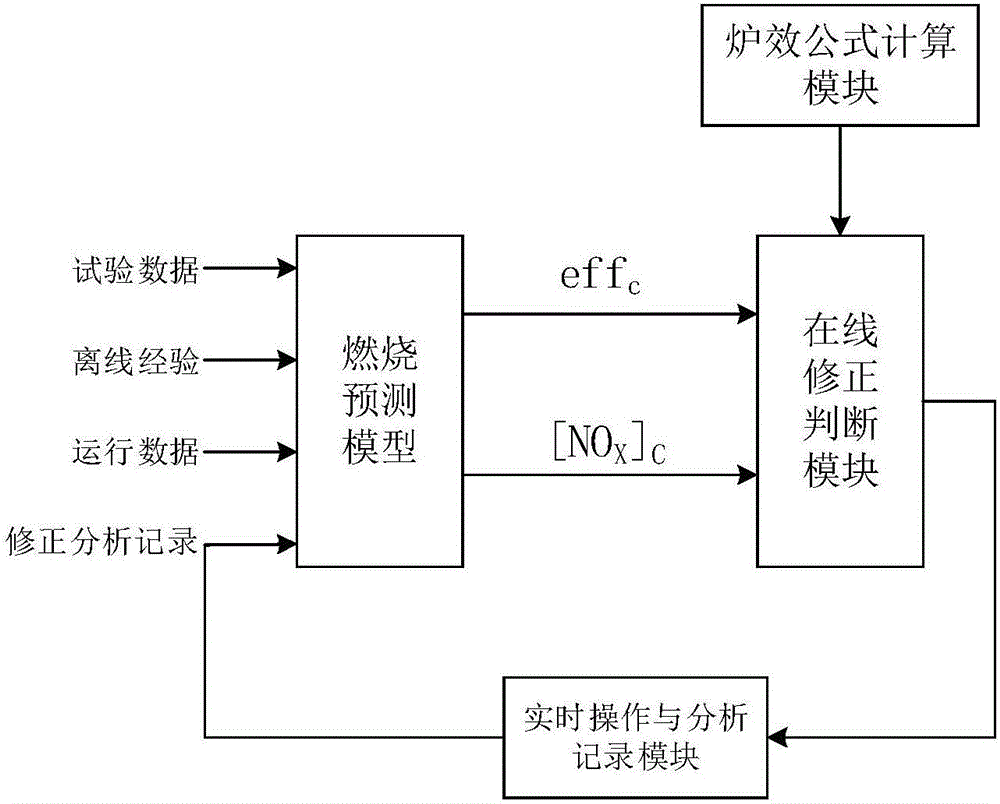

The invention relates to a circulating fluidized bed boiler combustion optimization and diagnosis method for acquiring and sorting out operation data such as bed temperature, bed pressure, load, efficiency, coal supply amount, limestone supply amount, primary air volume, primary wind pressure, upper secondary air volume and wind pressure, lower secondary air volume and wind pressure, oxygen content, induced air volume, slagging amount, NOx, Sox, etc., to build a neural network model as the basis for optimization adjustment and diagnosis. Field data of design value, measured value during operation, fuel chemistry assay value and etc. of the circulating fluidized bed boiler are utilized as the basis for optimization adjustment and diagnosis to calculate boiler efficiency as the basis for optimization adjustment and diagnosis; a judgment criterion for the optimization adjustment of combustion work condition is established and a corresponding solution is proposed, and therefore, optimization adjustment can be carried out when the circulating fluidized bed boiler deviates from the optimum combustion work condition; a judgment criterion for abnormal operation is established and a solution thereof is proposed; and therefore, problems which can not be solved after optimization adjustment can be diagnosed and analyzed. Common accident phenomena are summarized and processing strategies can be proposed, and therefore, guidance can be provided to accident handling.

Owner:SOUTHEAST UNIV

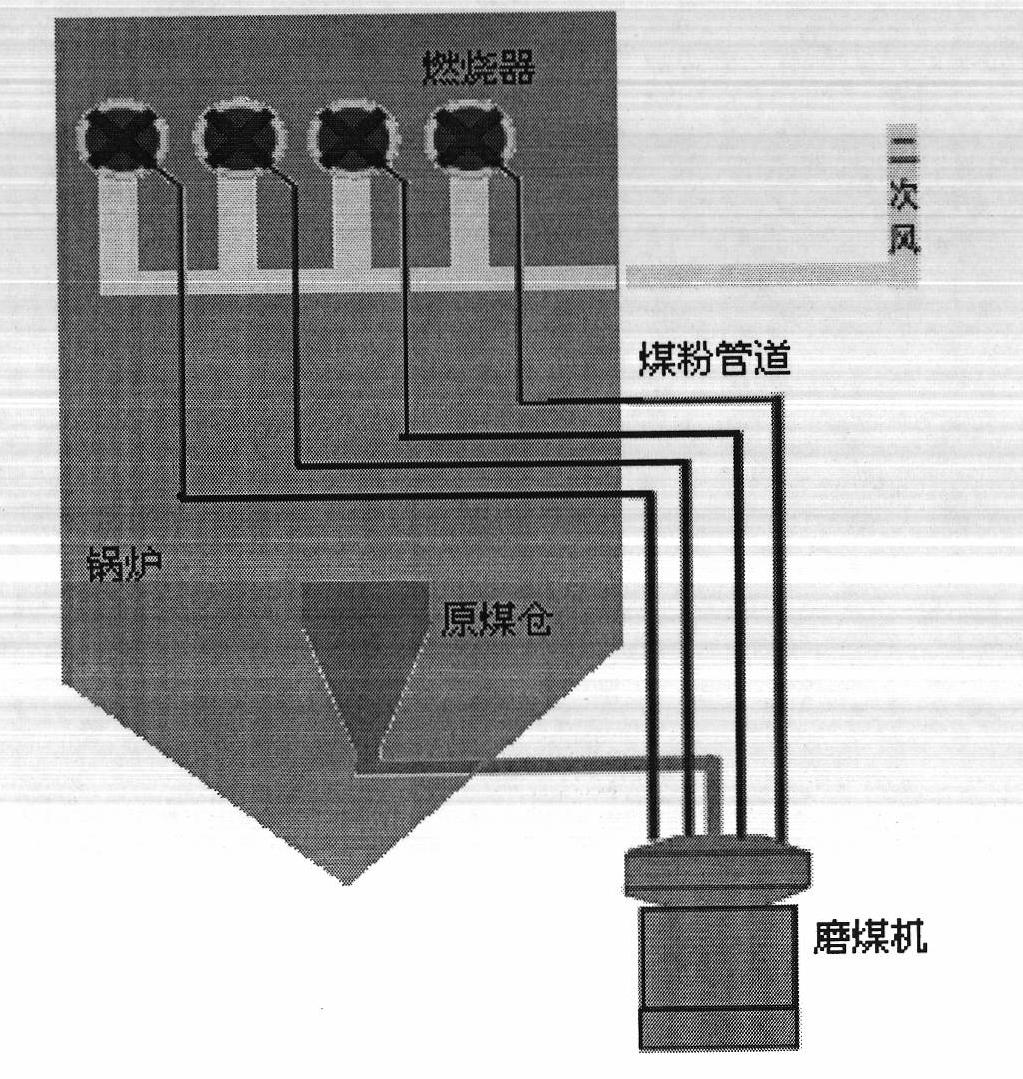

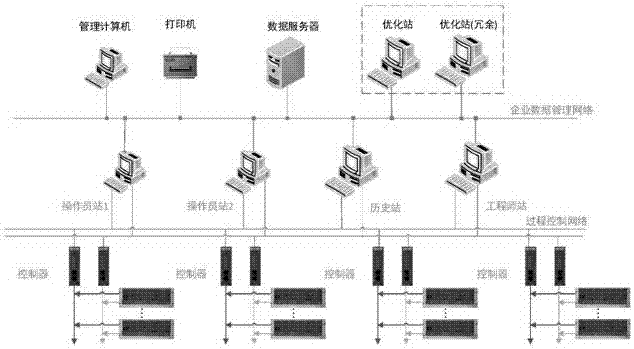

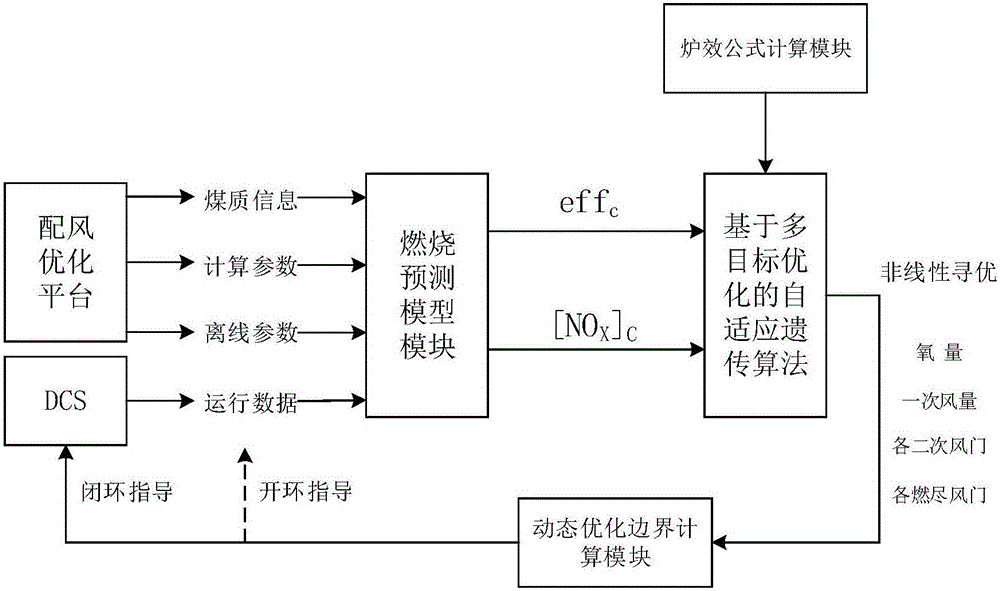

Large coal-fired unit online monitoring and optimal control system and implementation method thereof

InactiveCN103759290AImprove efficiencyHigh power consumptionBoiler controlCombustion regulationOptimal control systemProcess engineering

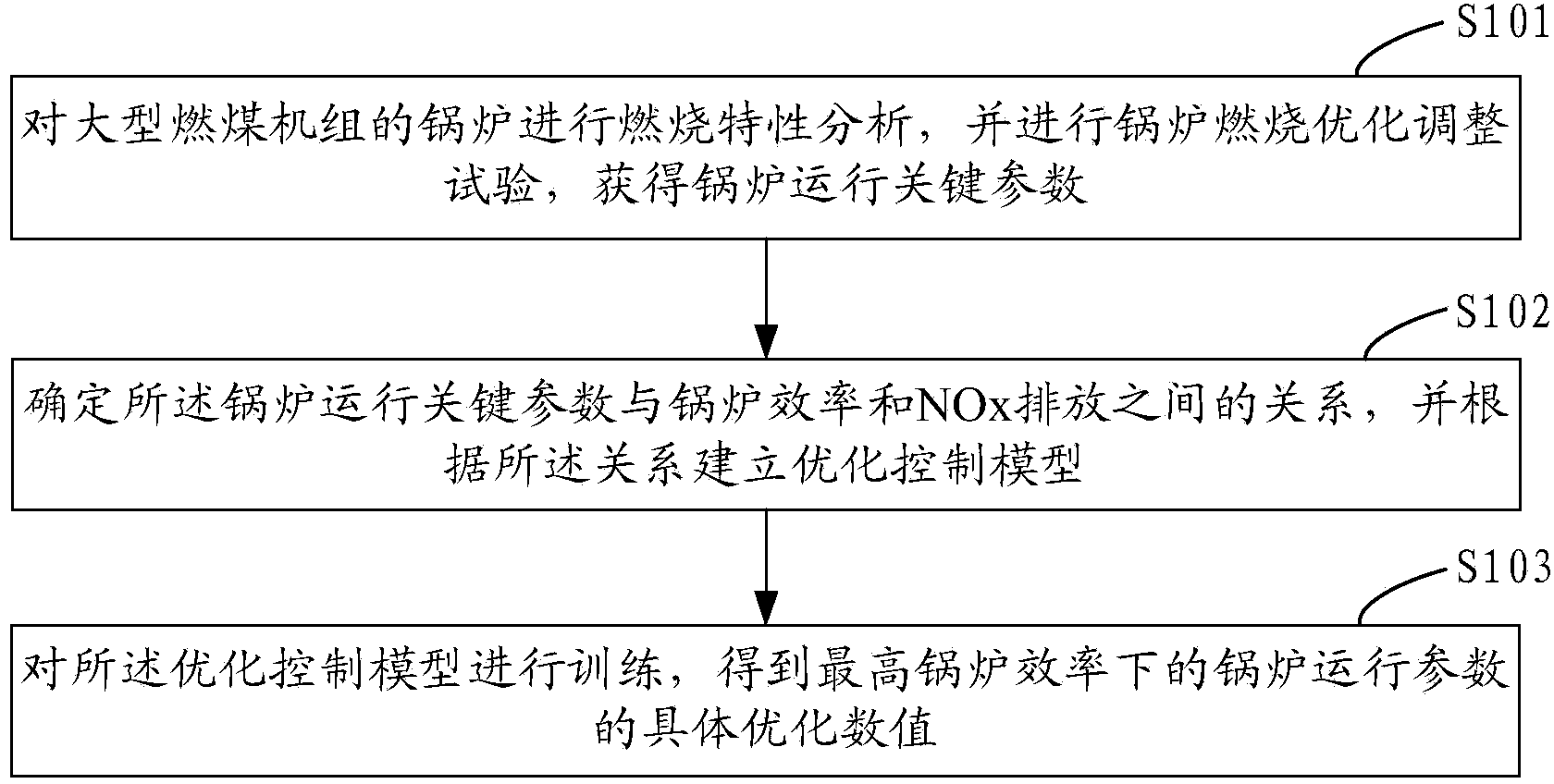

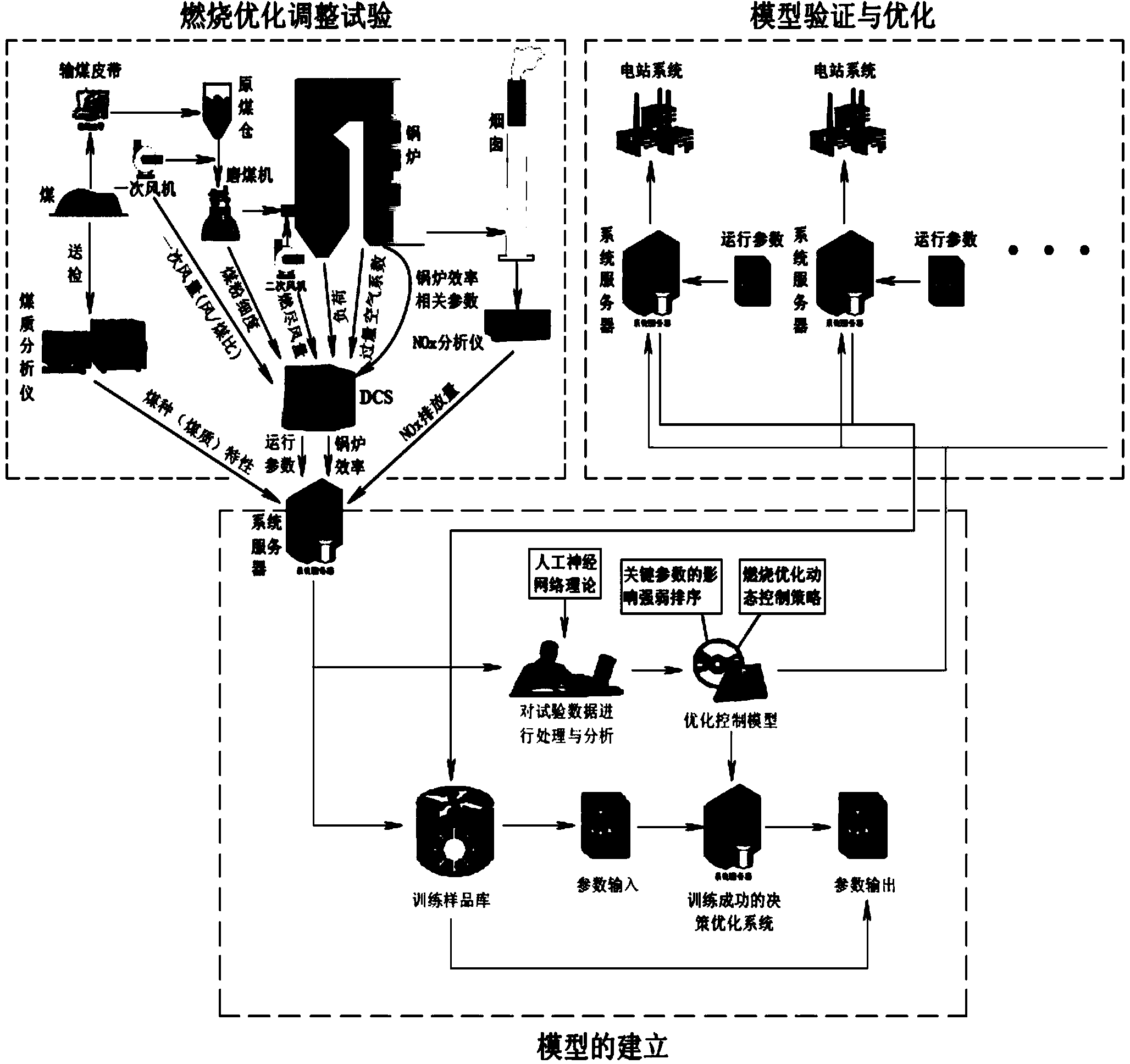

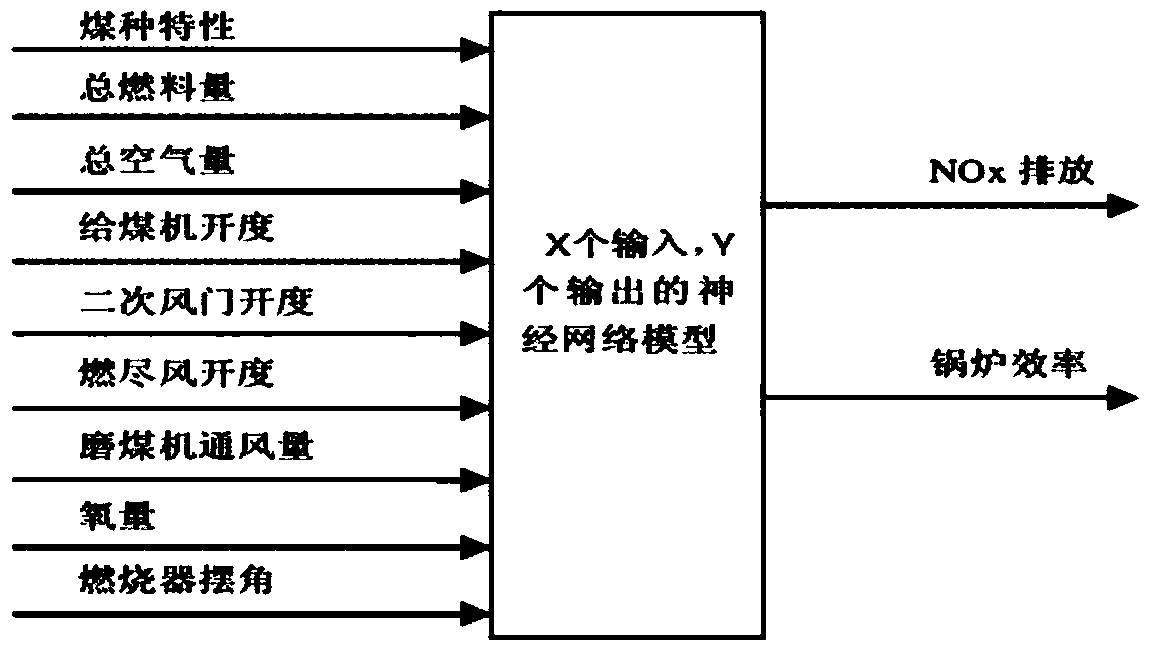

The invention provides a large coal-fired unit online monitoring and optimal control system and an implementation method thereof. The method includes the steps of analyzing combustion characteristics of a boiler of a large coal-fired unit, and performing boiler combustion optimization and adjustment test to acquire boiler operation key parameters; determining a relation of the boiler operation key parameters to boiler efficiency and NOx emission, and establishing an optimal control model according to the relation; training the optimal control model to obtain specific optimal values of boiler operation parameters under highest boiler efficiency. The large coal-fired unit online monitoring and optimal control system and the implementation method thereof have the advantages that boiler efficiency is improved on the premise of guaranteeing low NOx emission and operational economy of power plants is effectively improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

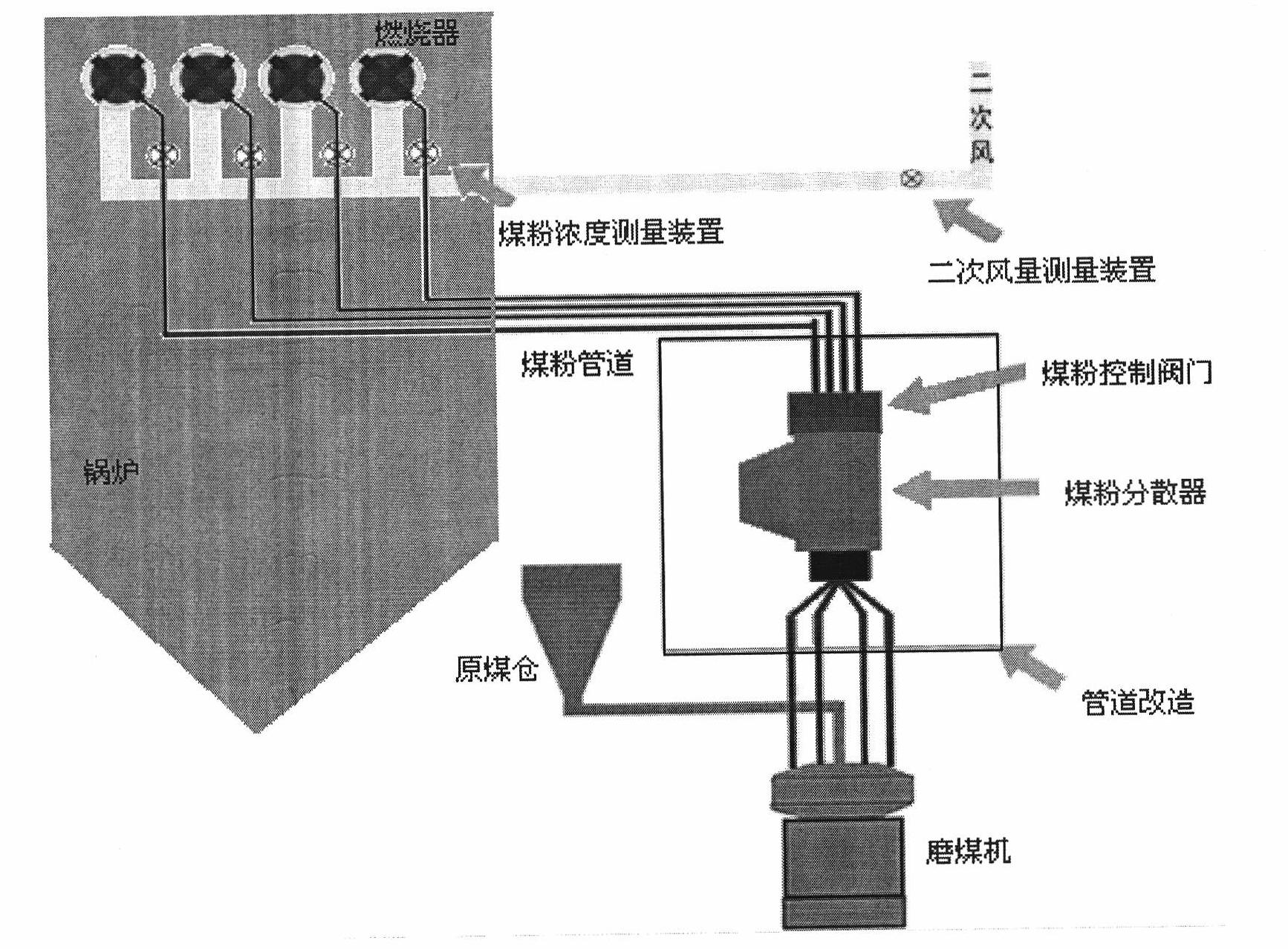

Boiler combustion optimizing control system and optimizing control method based on accurate measurement system

ActiveCN102032590AEmission reductionReduce coal consumptionCombustion regulationMathematical modelControl system

The invention discloses a boiler combustion optimizing control system and a boiler combustion optimizing control method. The method comprises the following steps of: on the basis of the equilibrium distribution and transformation for coal powder in a fire coal unit, accurately measuring parameters such as wind, powder, ash and the like by using a measuring device; analyzing a history behaviour of operation by the deep analysis and digging of data by using the acquired real-time history data of a boiler and taking the work condition optimization as a basic optimizing method; establishing mathematical models among operation parameter, status input parameter and parameters such as boiler efficiency, NOx and the like in the combustion process to obtain a unit operation mode knowledge base; performing the whole plant energy-saving and emission-reducing comprehensive assessment and diagnosis; analyzing the unit operation potential; and providing a knowledge base and a rule for optimizing operation; optimizing boiler combustion parameter configuration aiming at different combustion indexes or an index combination to realize the optimization of multiple optimizing objects and propose an energy-saving and emission-reducing implementation scheme and measurement in a classification mode. The method not only can realize closed-loop optimizing control but also can realize on-line optimizing guide.

Owner:BEIJING HUADIAN TIANREN ELECTRIC POWER CONTROL TECH

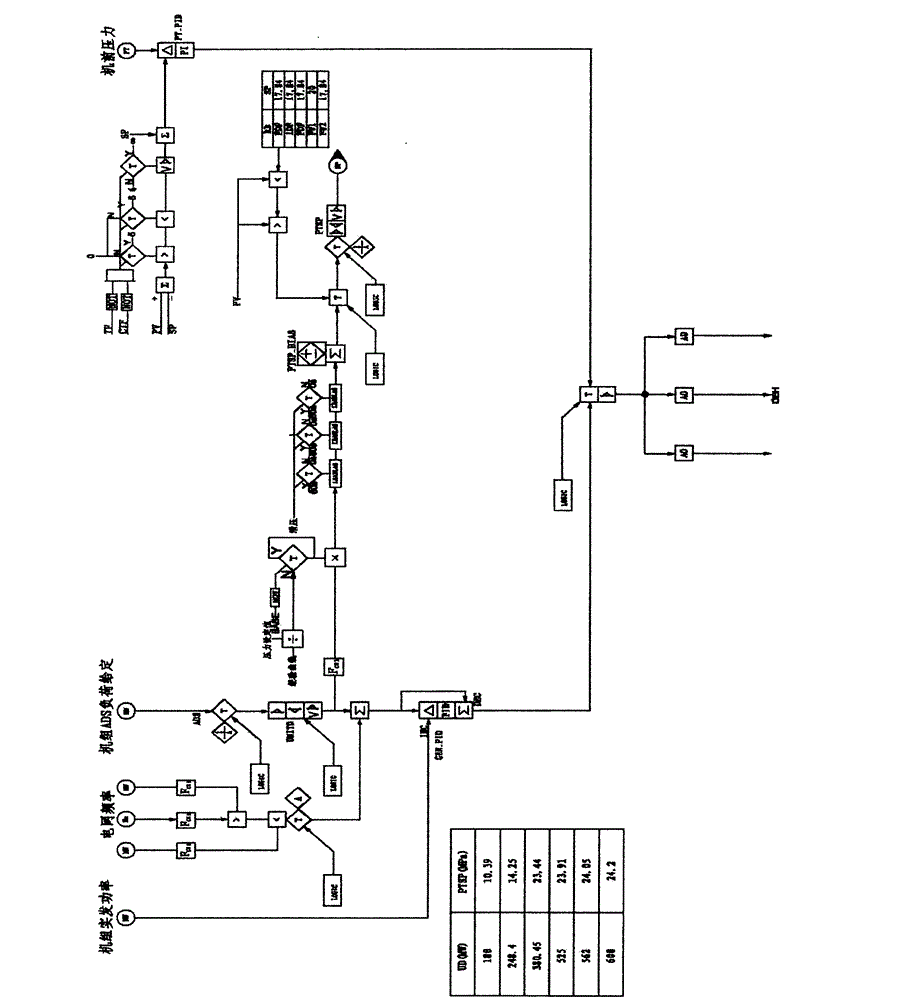

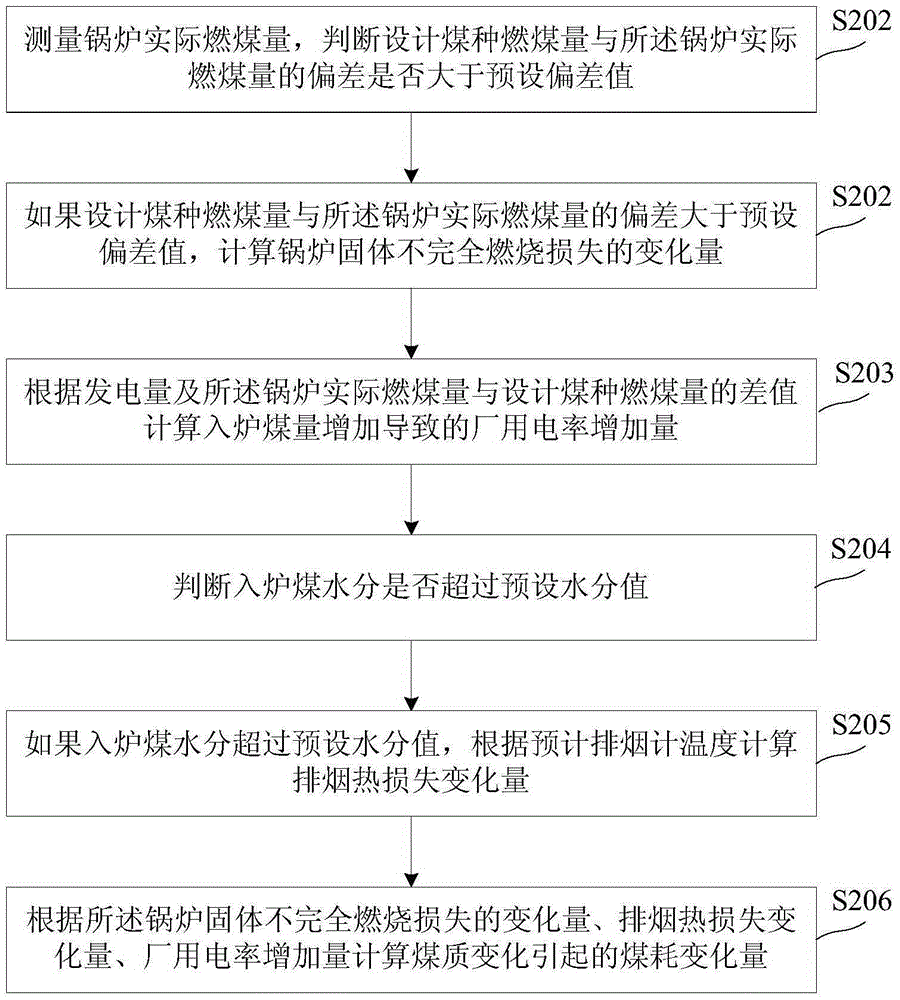

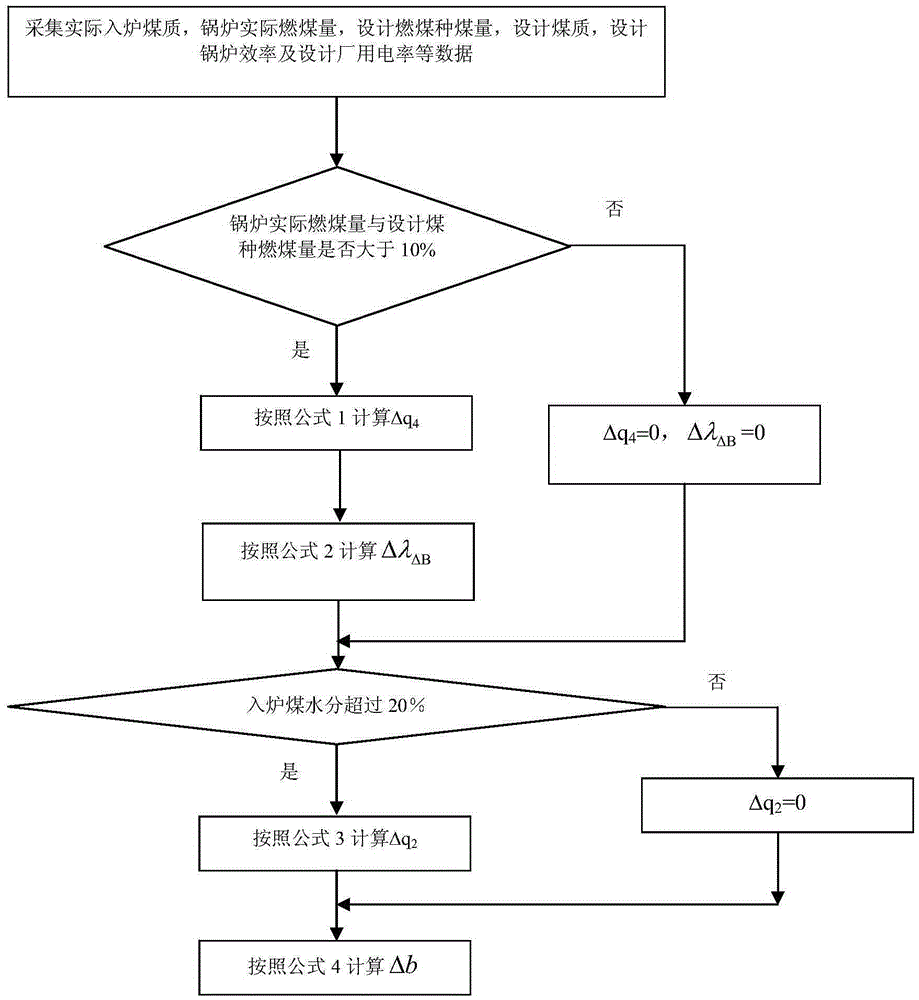

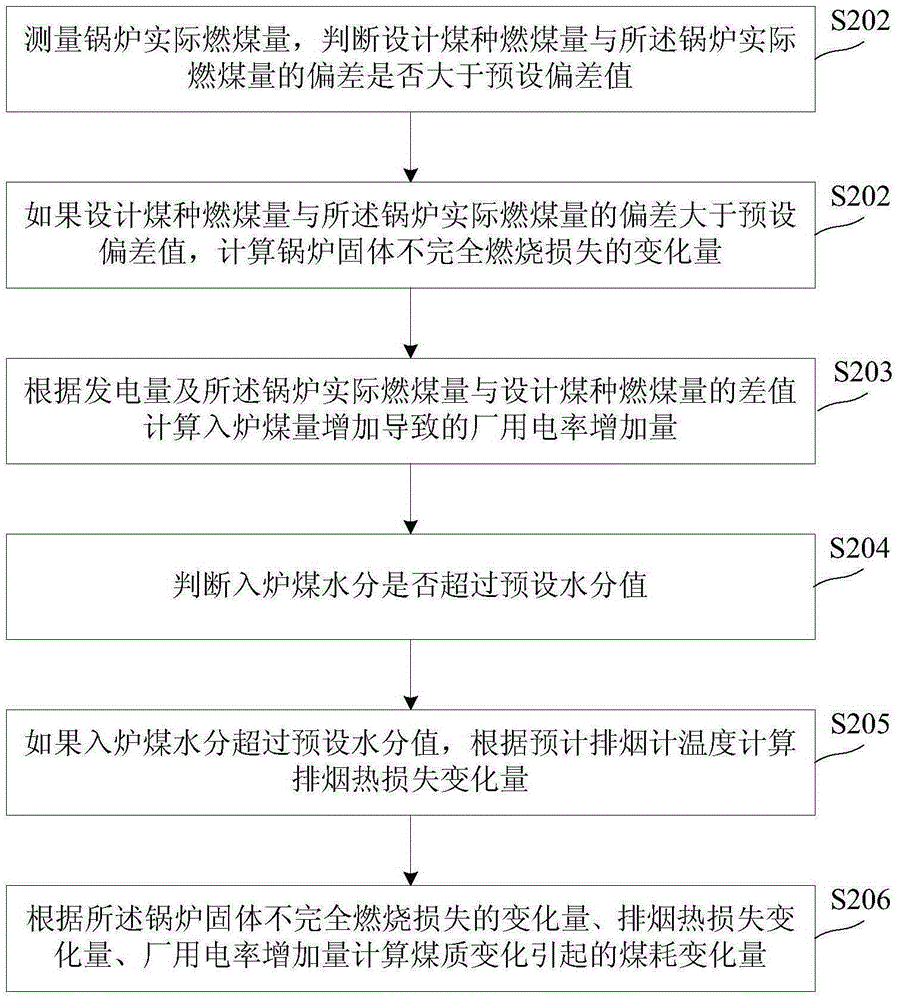

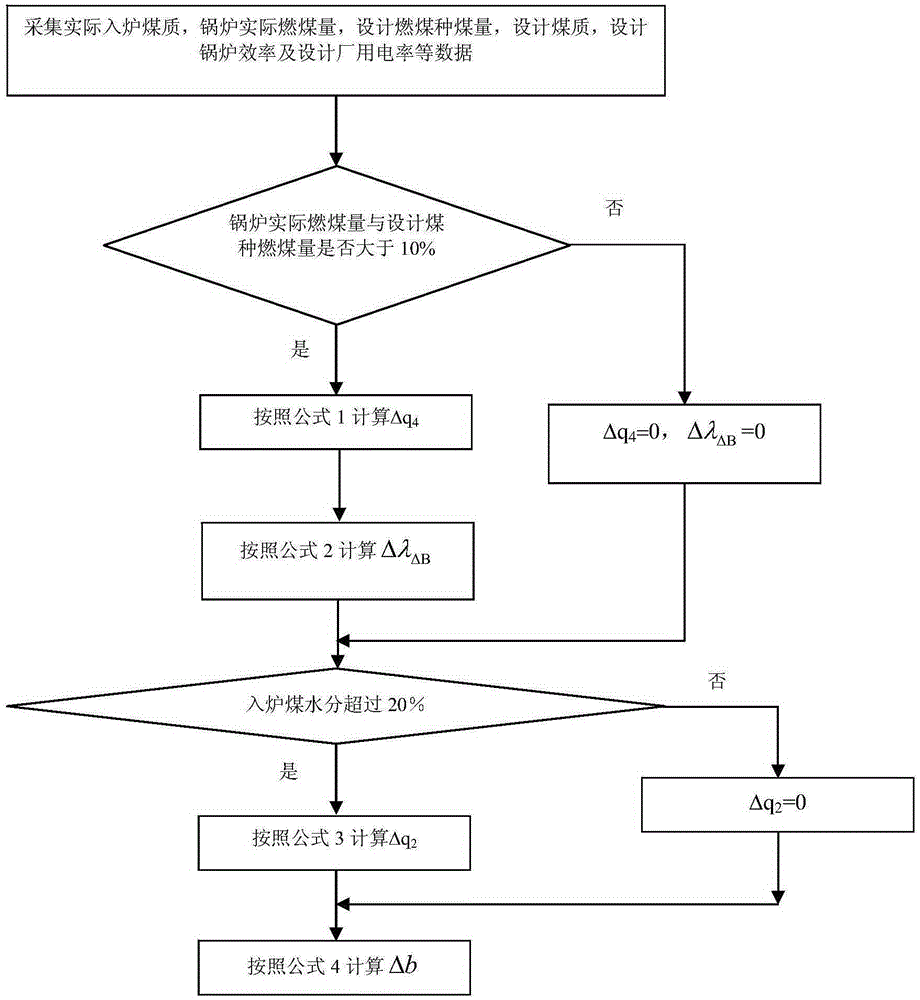

Method for coordinating and controlling quality change of coal in supercritical once-through boiler unit

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER

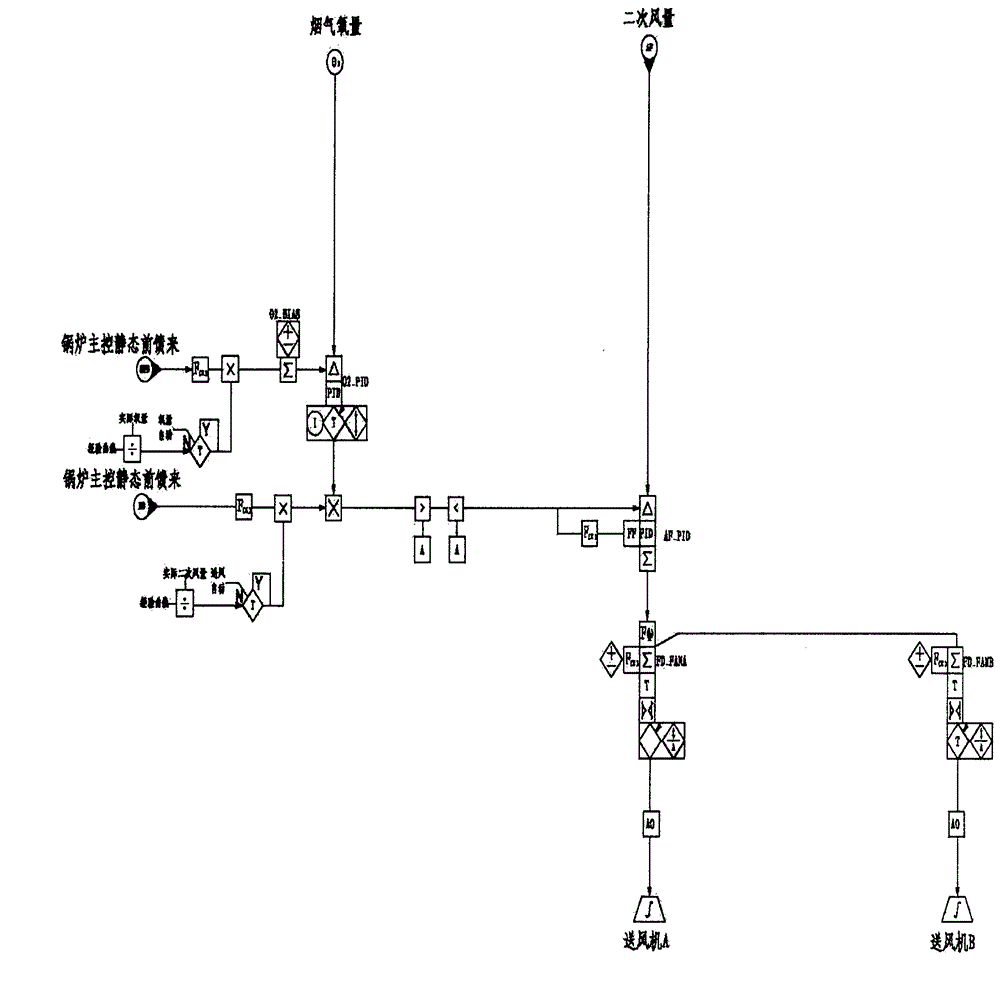

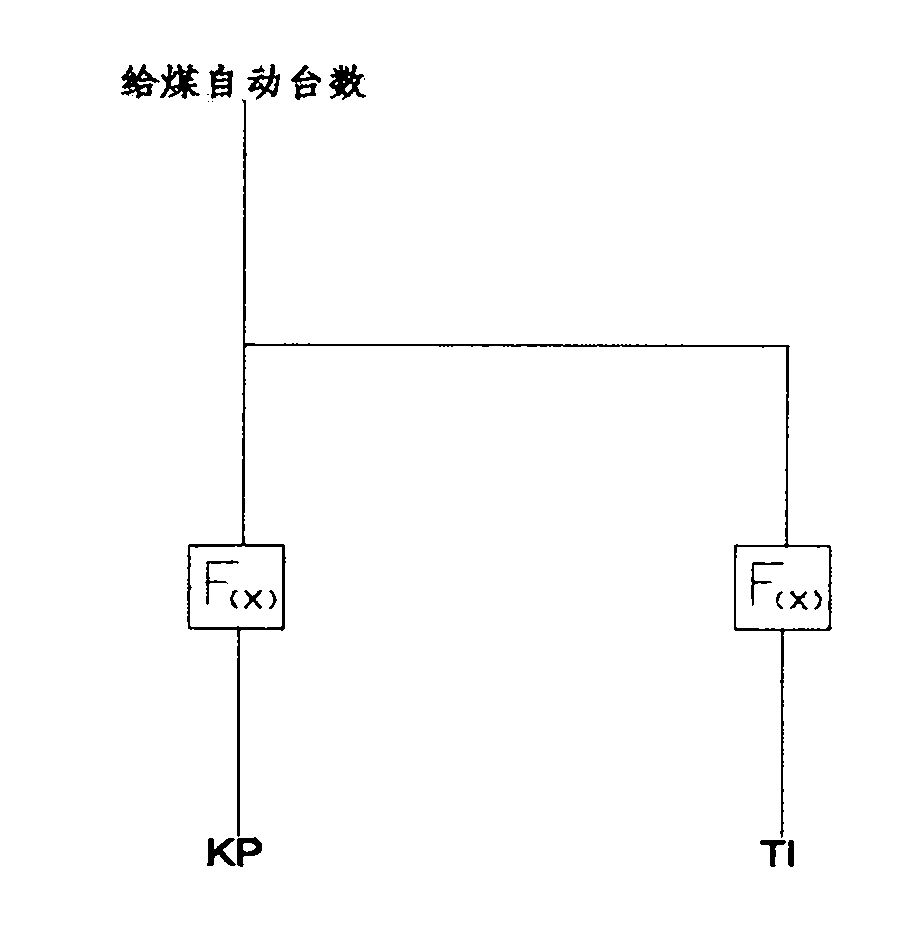

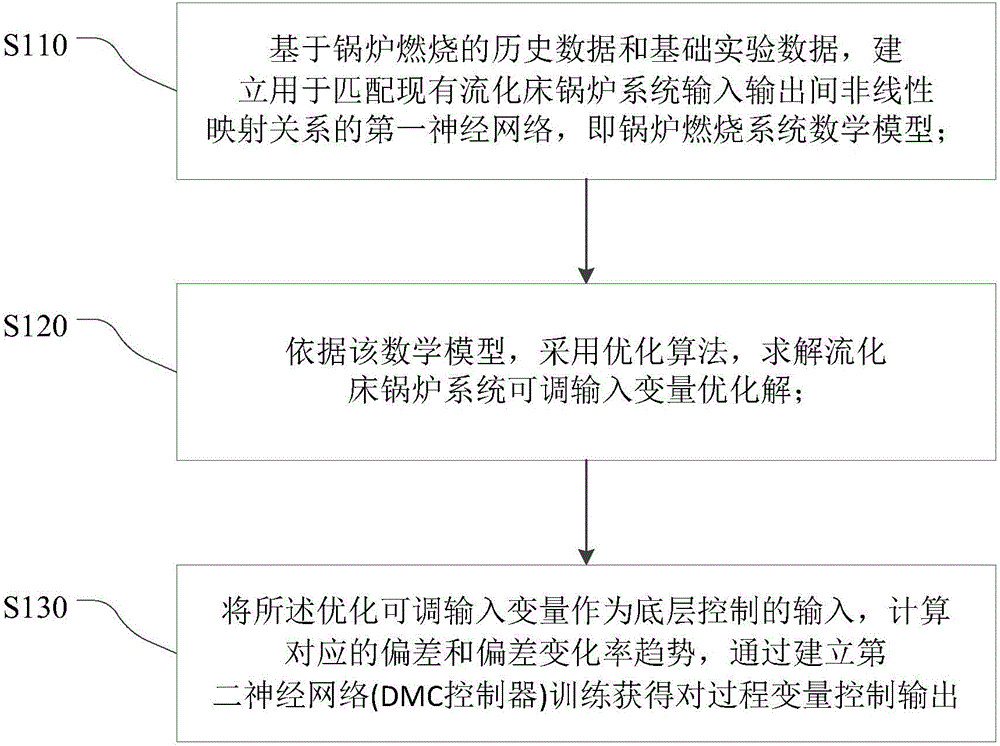

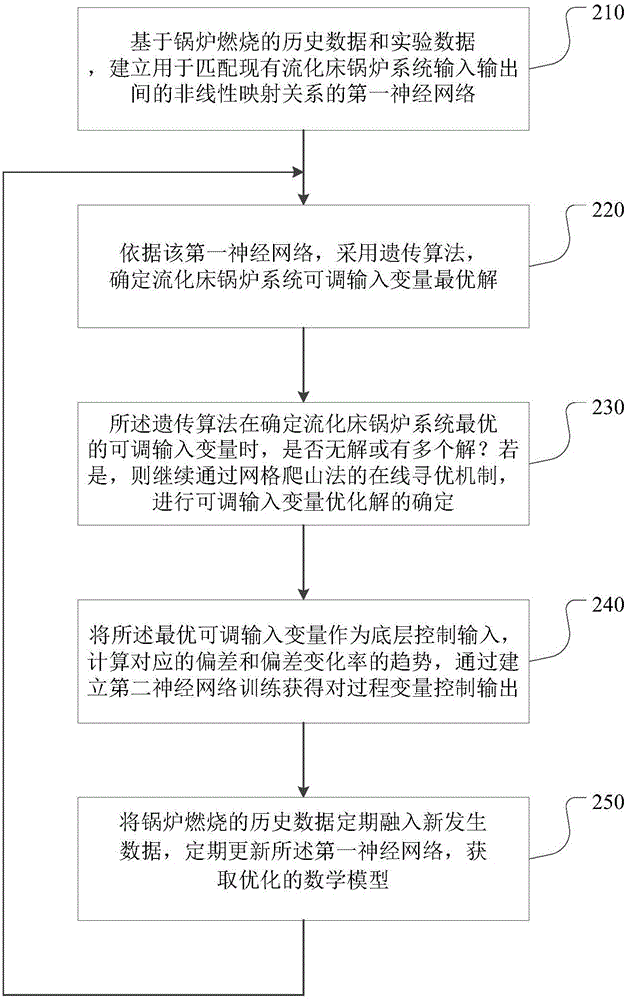

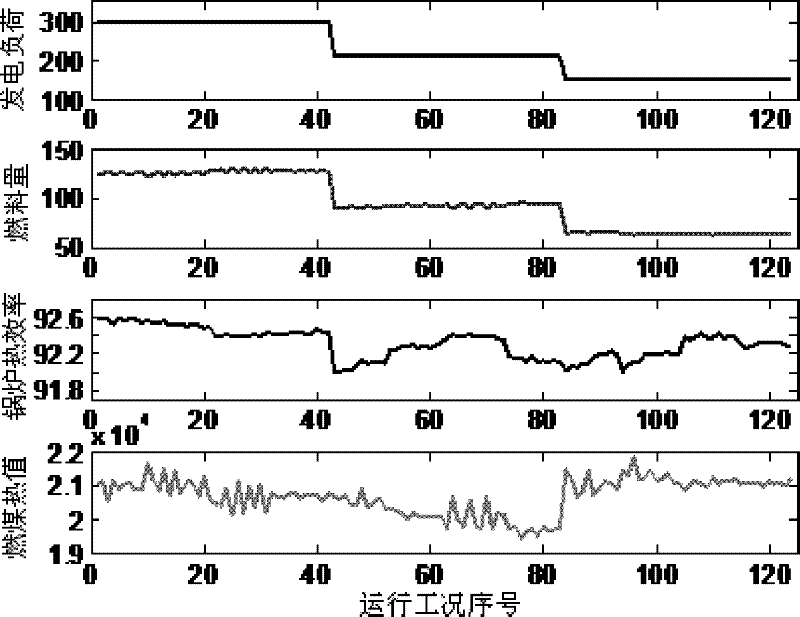

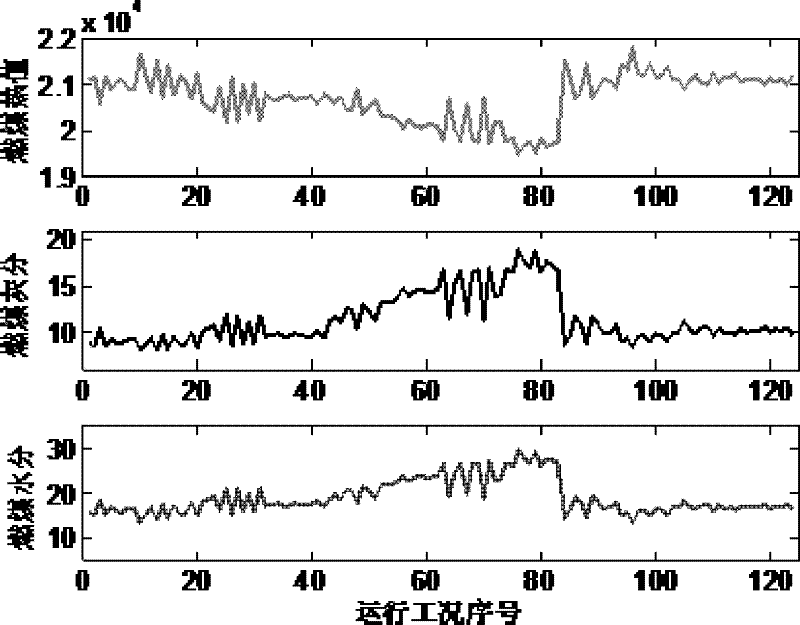

Method and system for optimizing and controlling combustion performance of circulating fluidized bed boiler in real time

ActiveCN105020705AGuaranteed uptimeImprove performanceFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

The invention provides a method and system for optimizing and controlling combustion performance of a circulating fluidized bed boiler in real time. The method for optimizing and controlling combustion performance of the circulating fluidized bed boiler in real time includes the steps that based on historical data of combustion of the boiler, a first neural network used for being matched with a nonlinear mapping relation between the input and the output of an existing fluidized bed boiler system is established; according to the first neural network, the adjustable input variable of the input of the fluidized bed boiler system is determined; and the adjustable input variable serves as the bottom layer control input, the trends of corresponding deviation and the deviation change rate are calculated, and a second neural network is established for training and acquiring the process variable control output. By the adoption of the method and system, the boiler efficiency is improved, the power supply coal consumption is lowered, coking and slag bonding are prevented or treated, NOx emission is reduced, and the safety, the reliability and the economical efficiency of operation of the boiler are further improved.

Owner:INNER MONGOLIA RUITE TECH

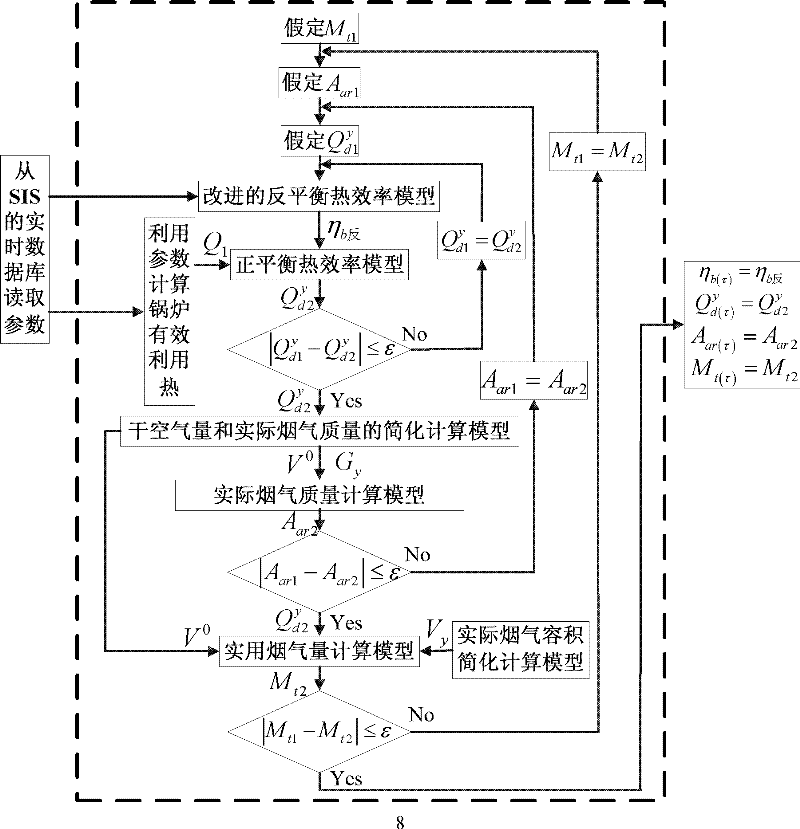

Synchronous reckoning method of utility boiler efficiency and coal heat value as well as ash content and moisture content

InactiveCN102494714AVerify correctnessImprove calculation accuracyStructural/machines measurementSteam pressureEvaporation

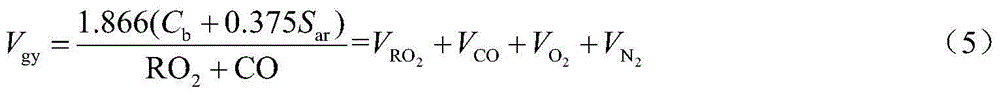

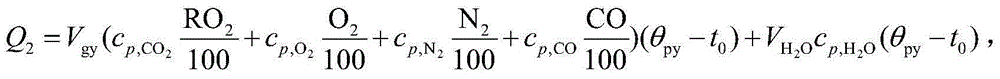

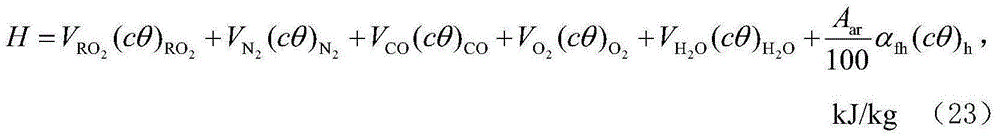

The invention relates to a synchronous reckoning method of utility boiler efficiency and coal heat value as well as ash content and moisture content, wherein air supply temperature, smoke exhaust temperature, smoke exhaust oxygen content, carbon content in fly ash, boiler-fed fuel content, boiler evaporation amount, assembly electric generating load, main steam pressure temperature, reheated steam inlet / outlet pressure temperature, water supply pressure temperature and flow rate, steam drum pressure, reheater temperature lowering water jet amount and steam extraction pressure temperature of each heater of high pressure cylinder are read through a plant-level supervisory information system (SIS) of a thermal power plant; and the parameters as the water temperature and drainage temperature of the inlet / outlets of different-level heaters of the high pressure cylinder are synchronously reckoned by hypothesizing the initial values of the coal heat value, the coal ash content and the coal moisture content, utilizing a boiler anti-balance heat efficiency model, a dry air amount required for theoretical combustion and actual smoke quality simplified calculating model, an actual smoke quality calculating model, an actual smoke volume calculating model, an actual smoke amount calculating model, a boiler positive-balance heat efficiency model and a boiler effective utilized heat model, and establishing prediction and rectification methods.

Owner:SOUTHEAST UNIV

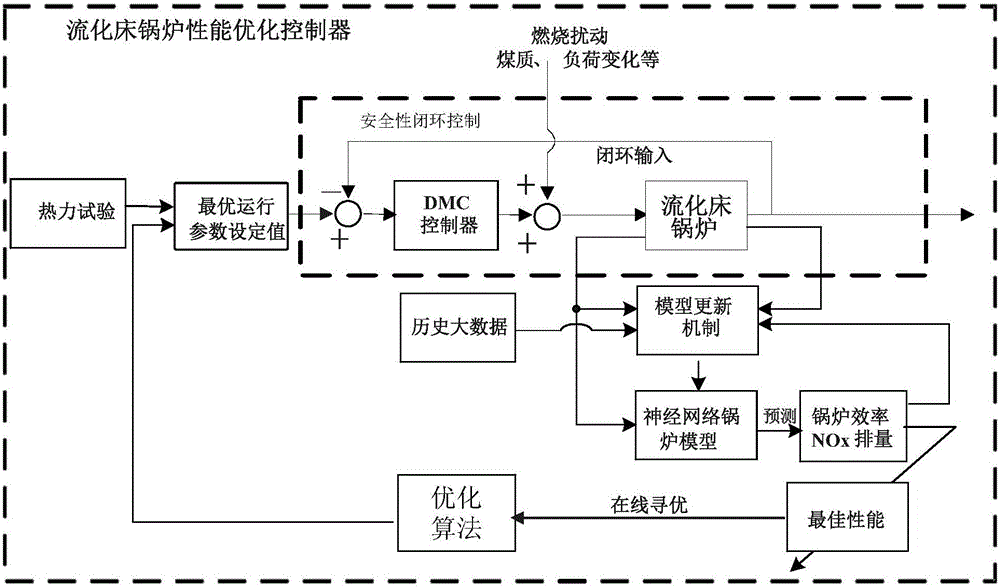

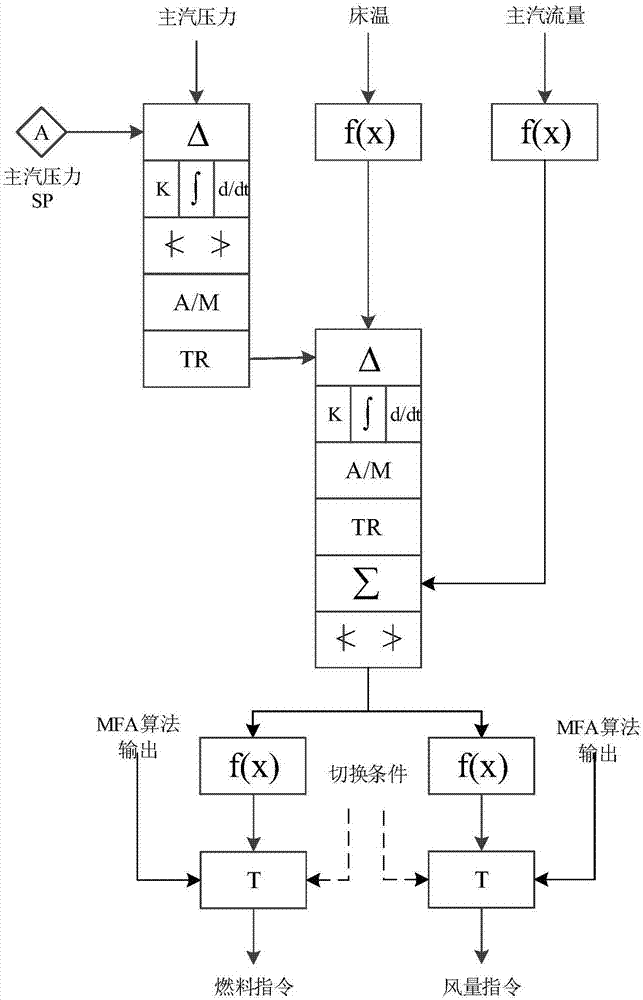

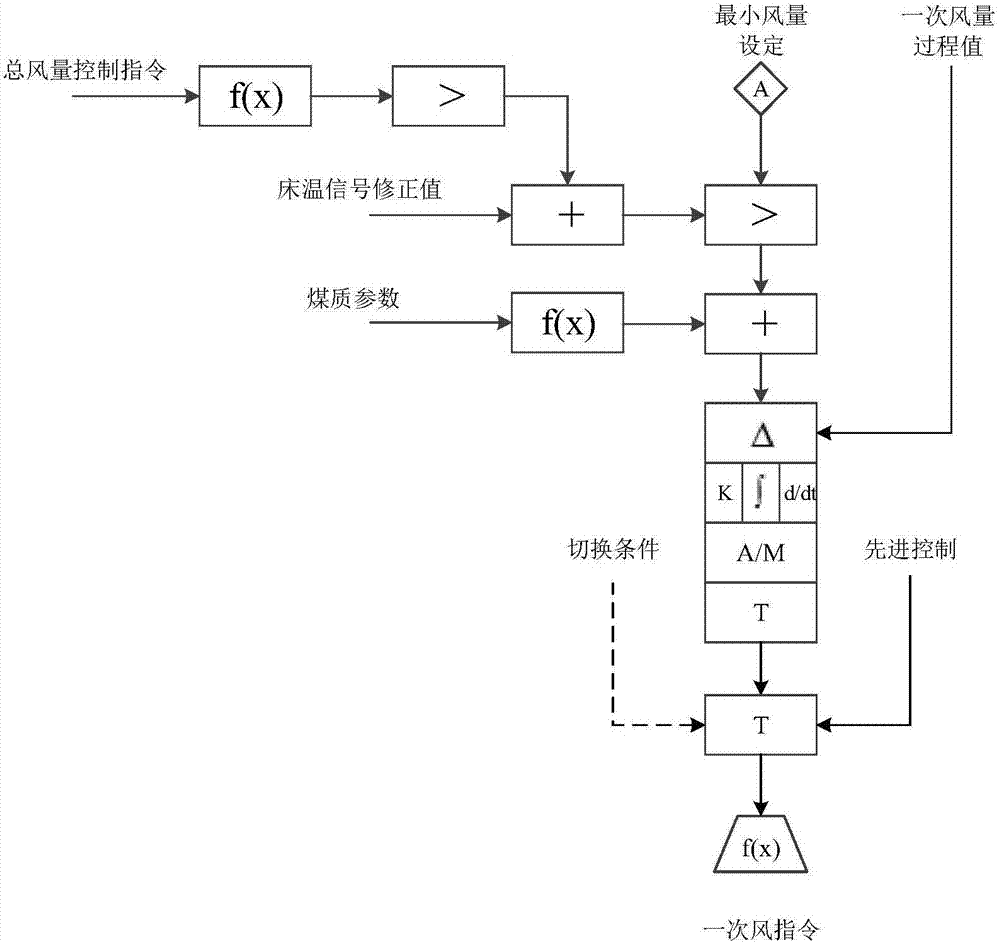

Fluidized bed boiler control and combustion optimization system

ActiveCN107023825AOptimize operating parametersImprove controlFluidized bed combustionApparatus for fluidised bed combustionFluidized bedOxygen content

The invention discloses a fluidized bed boiler control and combustion optimization system. The problem that a fluidized bed boiler system is not easy to control for a long time is solved. According to a method, a control strategy of combining an advanced control algorithm and a conventional control algorithm is adopted, and continuous, economical and stable operating of the boiler system is guaranteed; multivariable model-free adaptive control is adopted, and decoupling control of the fuel quantity and the air supply quantity over the bed temperature under the variable load work condition is achieved; and a nerual network technique is adopted for building a boiler combustion prediction model, online calculation of the boiler efficiency and NOX and SOX emissions is achieved, a multi-objective optimization function is constructed according to the prediction result, a combustion self-optimization algorithm is adopted, the flue gas oxygen content and the bed temperature are optimized constantly so as to adapt to work condition changes, and a fluidized bed boiler can operate in an optimal combustion area.

Owner:XIAN IBL TECH DEV +1

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS8062410B2Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatGas current separationParticulatesFluidized bed drying

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

Boiler combustion optimization air distribution method based on online model prediction

Provided is a boiler combustion optimization air distribution method based on online model prediction. The method includes: constructing a boiler combustion optimization air distribution model by employing an improved BP neural network algorithm and model online update calculation; and performing optimization calculation on parameters such as the optimal oxygen amount, the primary air amount, each secondary air door and a burnout air door etc. with the combination of an adaptive genetic algorithm and dynamic optimization boundary so that a multi-target function constructed by the boiler efficiency and the pollutant discharge capacity reaches the optimal combustion range.

Owner:XIAN IBL TECH DEV

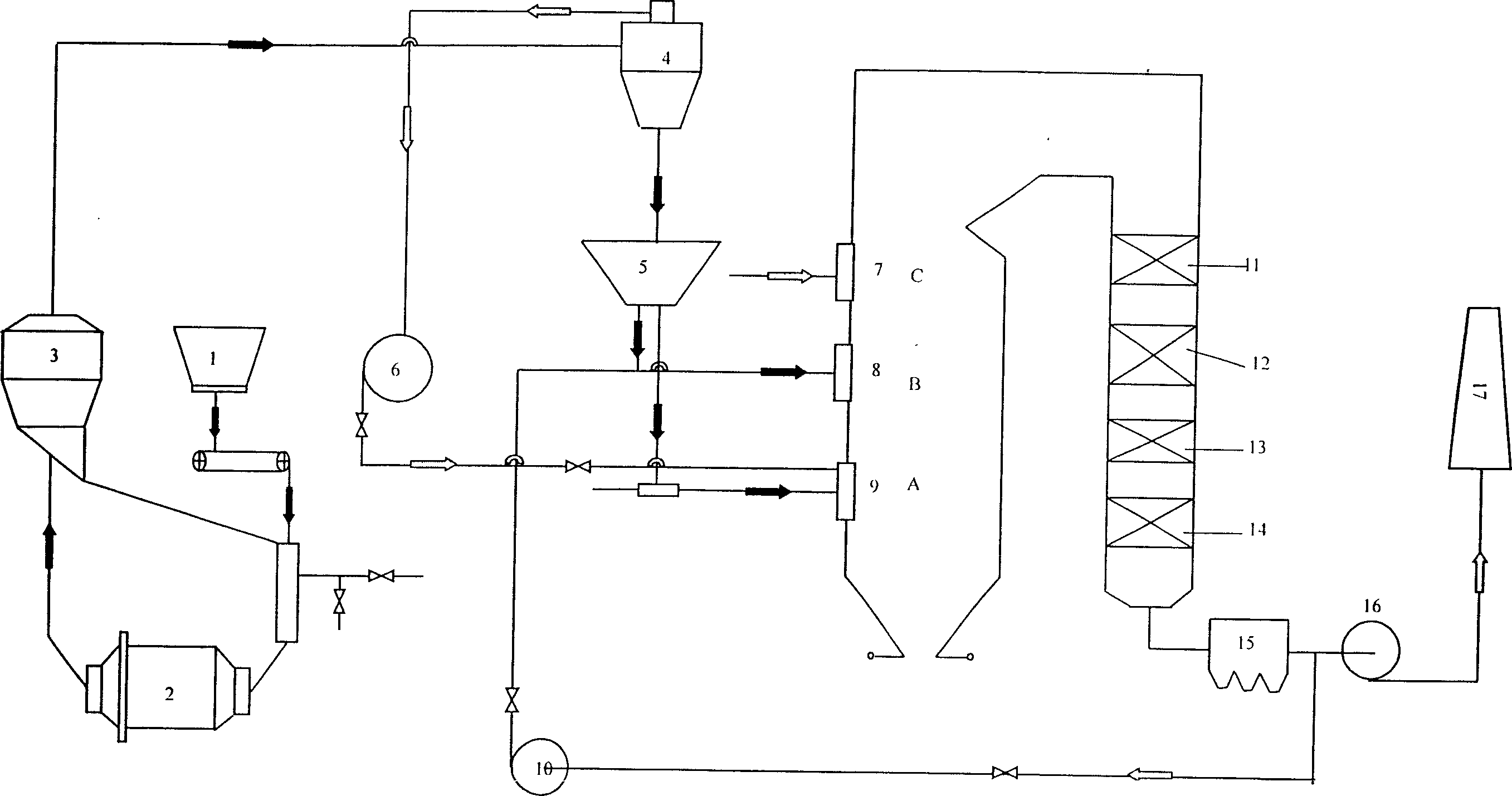

Fine coal powder recombustion denitrificating method

InactiveCN1587802AReduce initial investment costLow running costSolid fuel combustionCombustion apparatusCombustorNitrogen

The invention discloses a method and device for using tiny coal powder as reiguition fuel to reduce the NOX, which belongs to coal powder cleaning and combusting field. The method is: uses separator of raw and tiny coal powder to decrease the thin rate of all coal powder and improve the homogeneity, and uses part of tiny coal powder as reiguition fuel, extracts part of smoke form the tail smoke channel and then transmits the reiguition fuel into the reacting area, the NOX generated in the primary combustion area into N2; pours in part of combustion air from the top of the reacting area, ensures the coal powder combustion safety. The invention can decrease the discharge of nitrogen-oxygen material for 60% based on guaranteeing the boiler efficiency. In order to realize the technology, the primary combustor on the furnace is arranged with a reiguition fuel, burned wind aperture, and assembled with advanced raw powder separator and smoke extracting and transmitting system. The method in the invention has high denitration efficiency, it does not affect the combustion efficiency, the structure is reasonable, the investment is little, and the running cost is low.

Owner:XIAN THERMAL POWER RES INST CO LTD

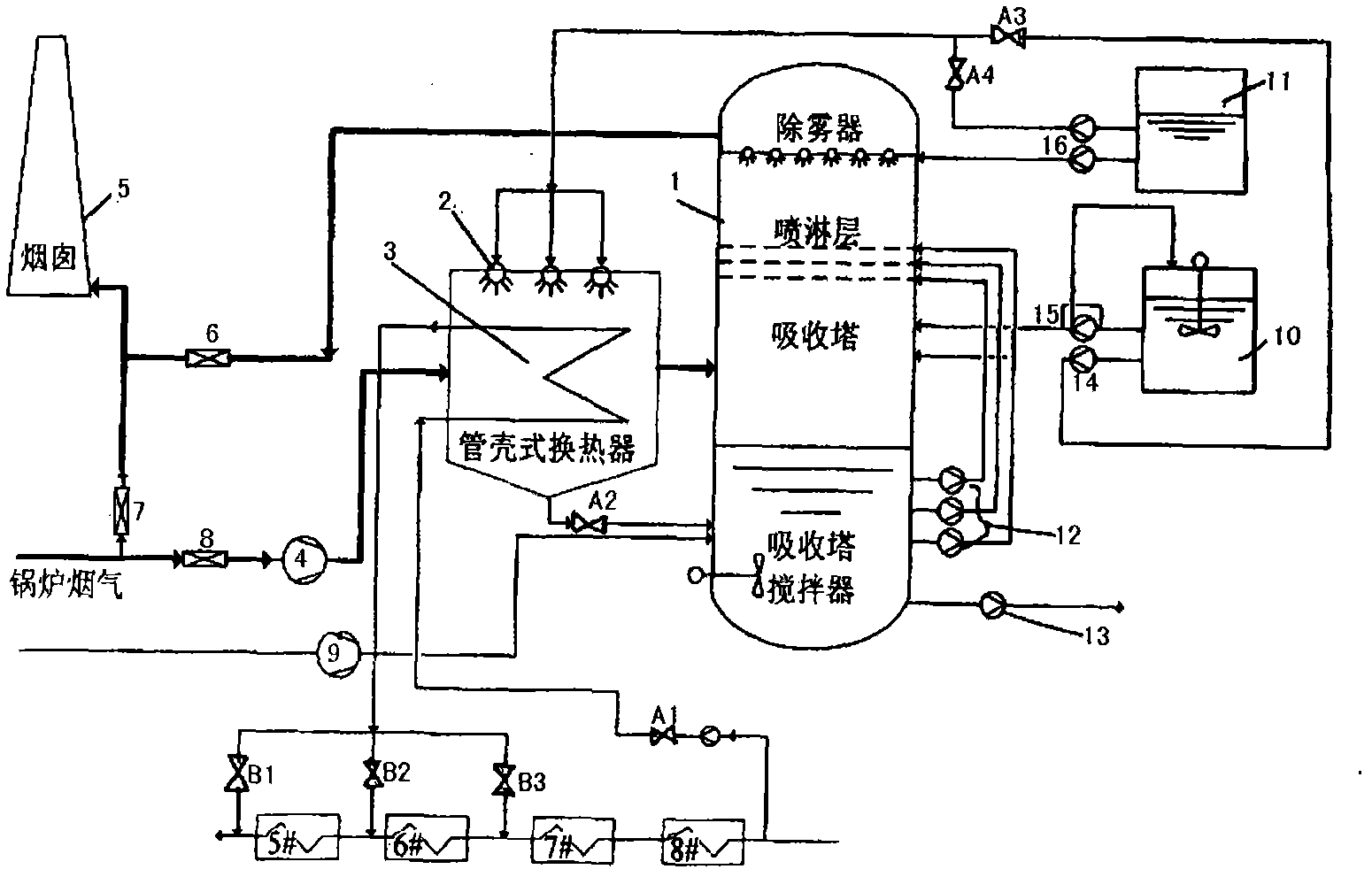

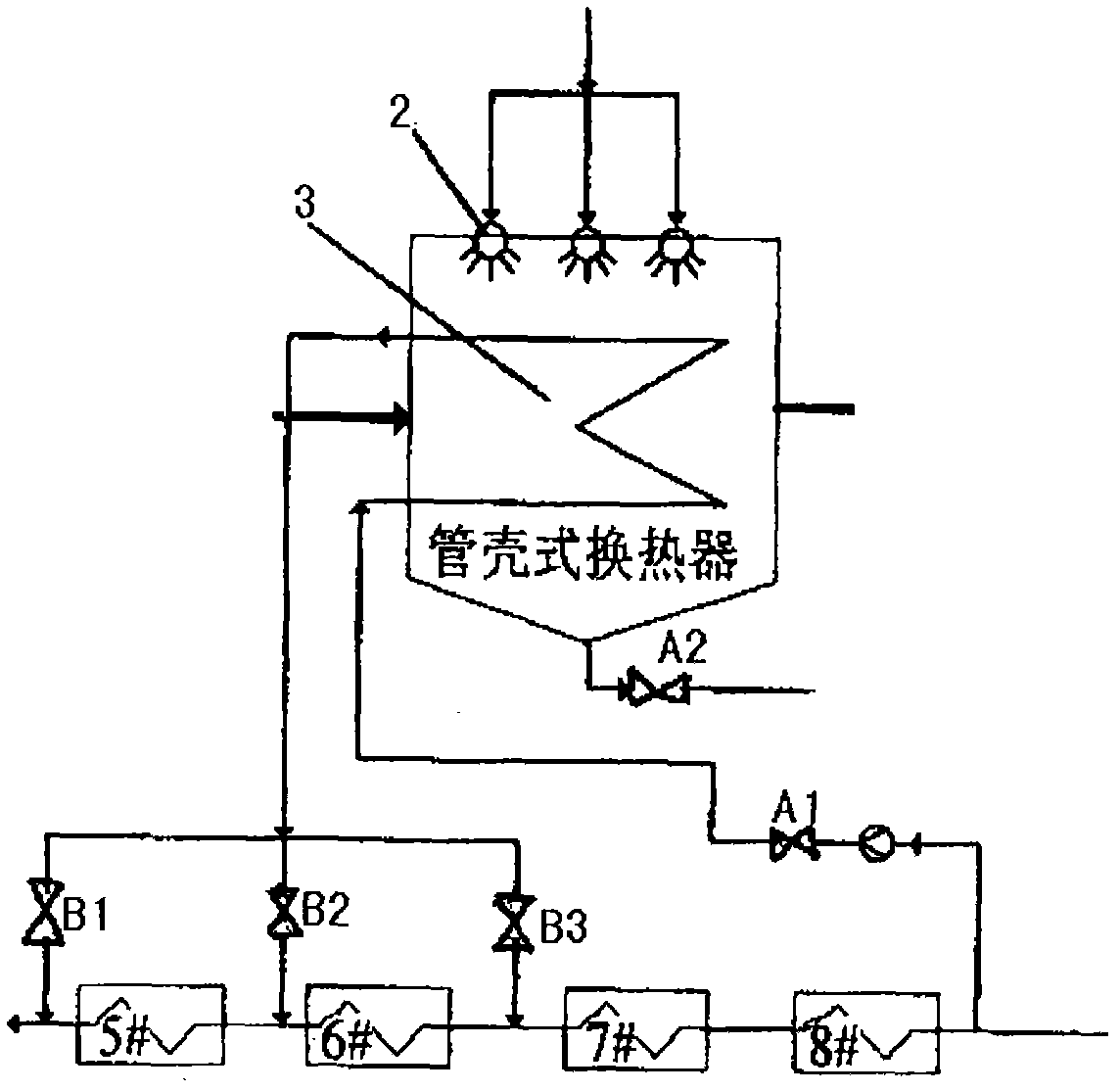

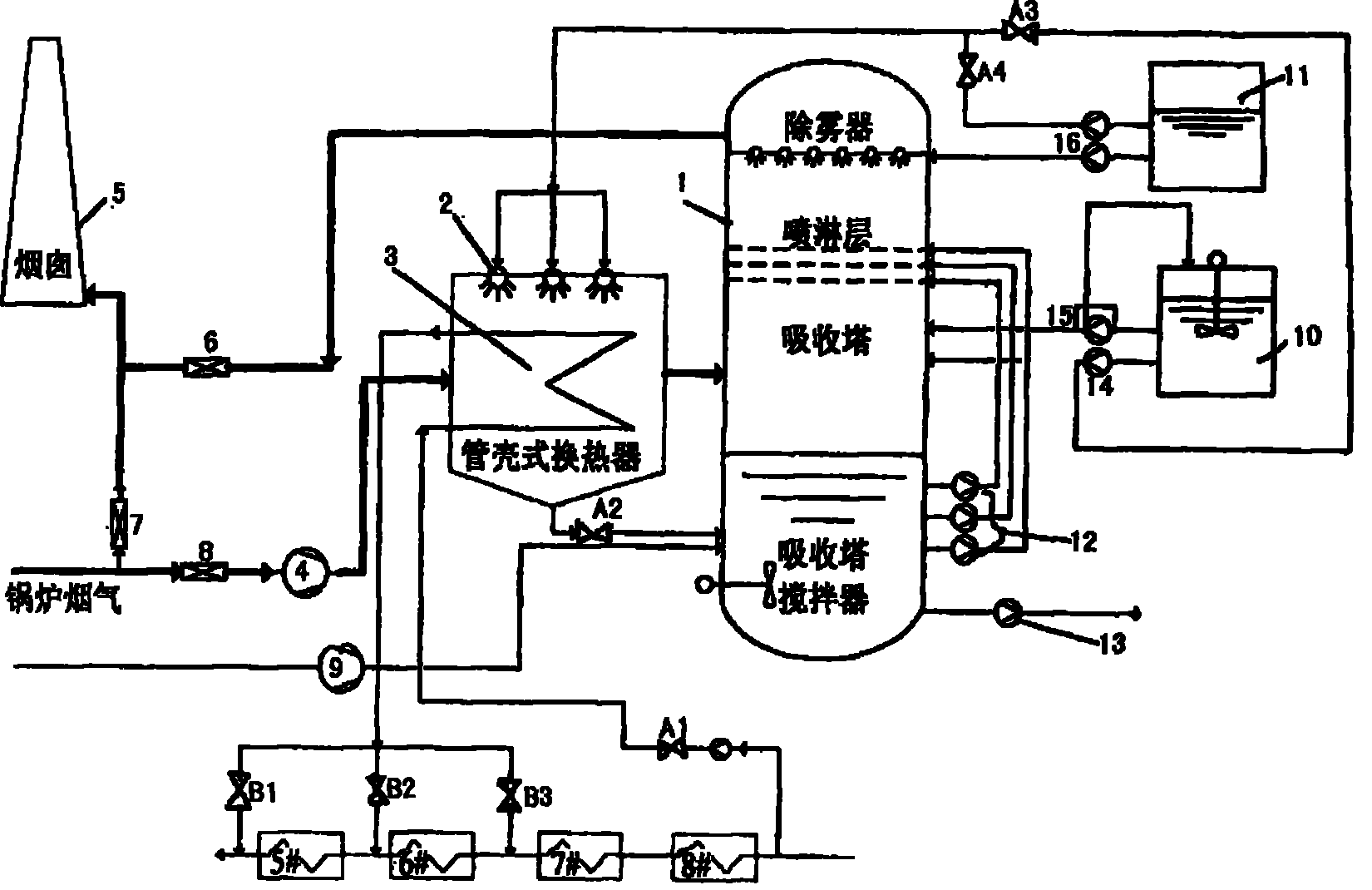

Integrated system for utilizing residual heat of boiler smoke and removing sulfur

InactiveCN102087021AImprove efficiencyReduce the temperatureDispersed particle separationEnergy industrySlurryIntegrated systems

The invention relates to an integrated system for utilizing residual heat of boiler smoke and removing sulfur. A tubular heat exchanger is used as a heat exchange main body of the system and is arranged on a tail flue between a booster fan and a desulfurization absorber, wherein the tubular heat exchanger is connected to a condensed water heating system; sets of nozzles are arranged in the heat exchanger for intermittently washing the inner tube wall of the heat exchanger and the wall of the flue; the processing water from a desulfurization system or limestone size or the mixture of the processing water and the limestone size are used as washing fluid for washing the walls; and the washing fluid is recovered and reused by returning to the desulfurization absorber after gathering on the bottom of the heat exchanger. By using the integrated system provided by the invention, the temperature of the smoke on the tail part of the boiler can be reduced to 50-70DEG C, thereby recovering the residual heat of boiler smoke and increasing the boiler efficiency. Meanwhile, the smoke within the temperature range which enters into the absorber of the desulfurization system on the tail part still meets the requirement of the temperature for desulfurization reaction, and the water consumption for desulfurization is reduced by 50-80%. Without designing a single size preparation and sewage treatment process, the water-saving and energy-saving properties, the anticorrosion property and reuse of the whole system are finally realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

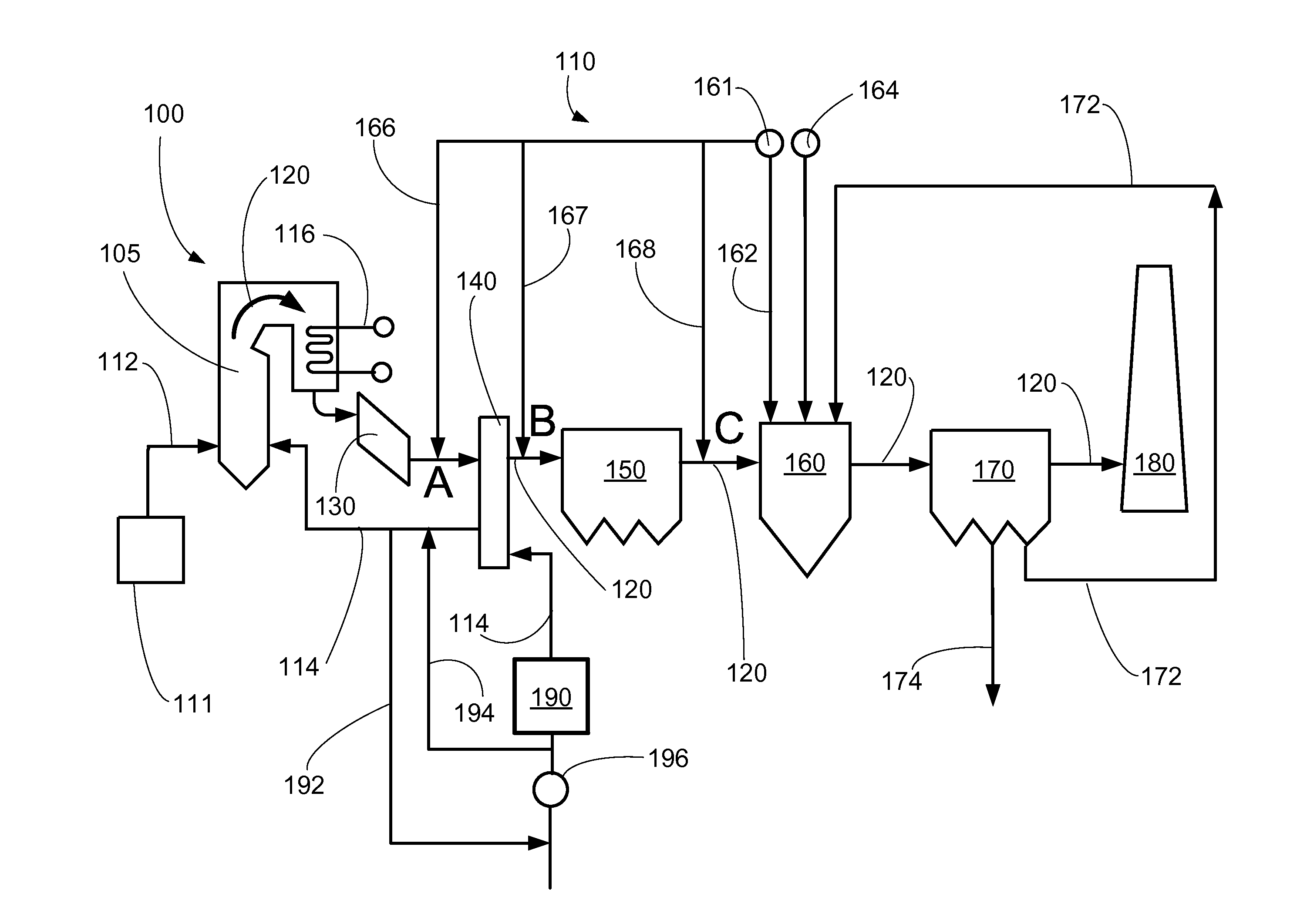

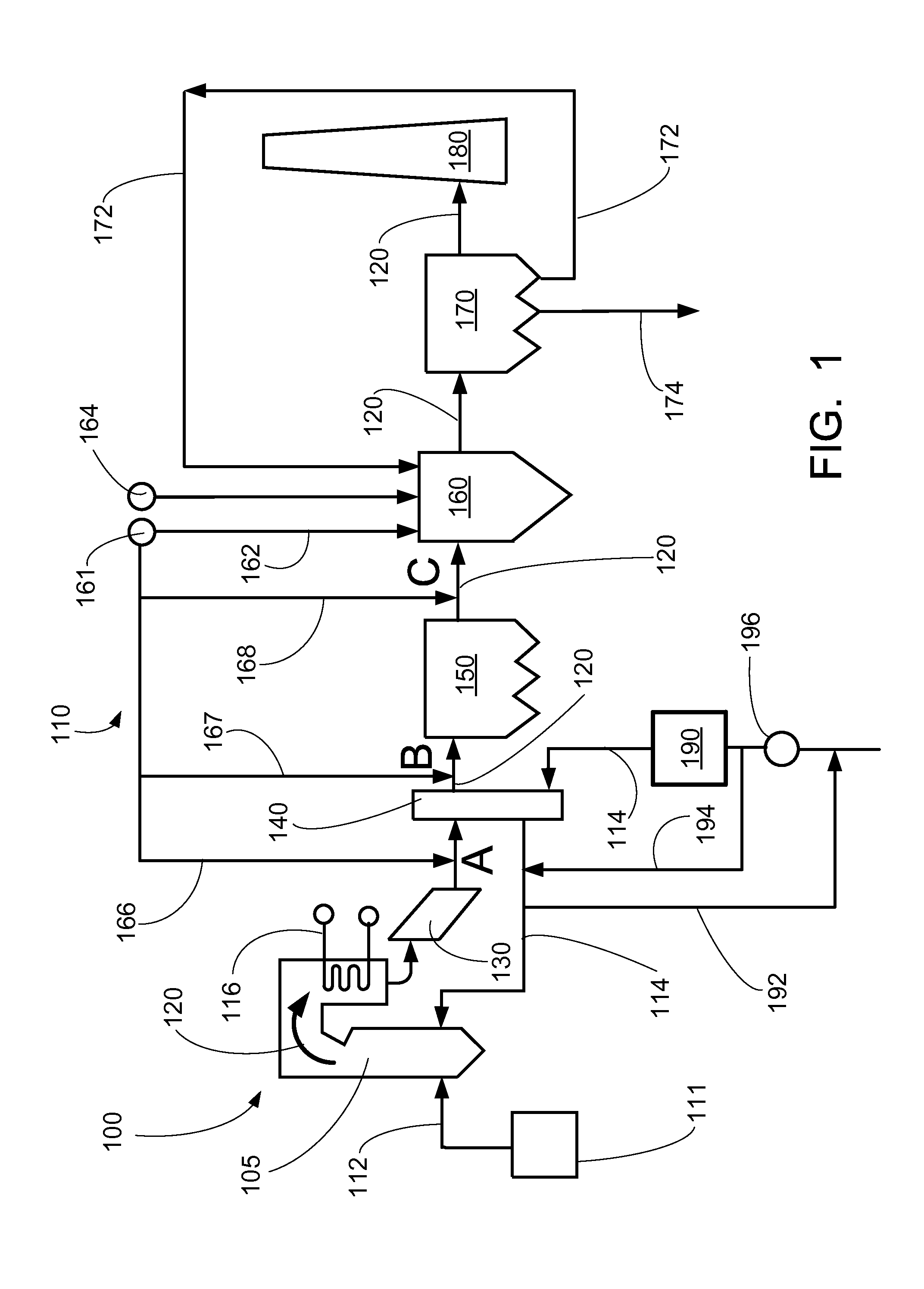

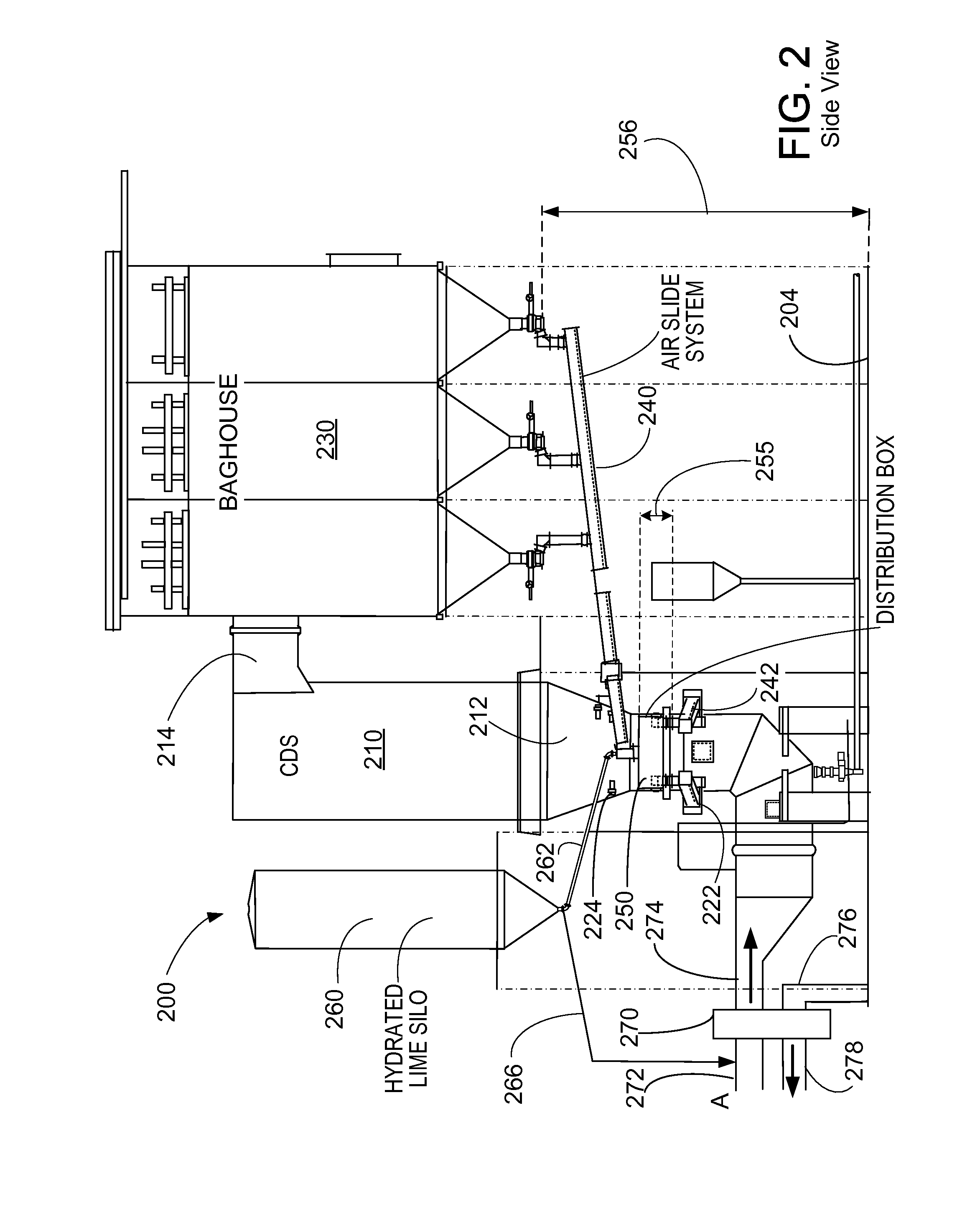

Integrated sorbent injection and flue gas desulfurization system

ActiveUS20150139882A1Operational securityLowering of average gas temperatureCombination devicesGas treatmentThermal energySorbent

An integrated sorbent injection, heat recovery, and flue gas desulfurization system is disclosed. A dry sorbent is injected into the flue gas upstream of the air heater. This reduces the acid dew point temperature, permitting additional heat energy to be captured when the flue gas passes through the air heater. The flue gas then passes through a desulfurization unit and through a baghouse, where solids are captured. The capture of additional heat energy permits the overall boiler efficiency to be increased while safely operating at a lower flue gas temperature. The integrated system consumes no greater quantity of sorbent than conventional methods but provides the benefit of improved plant heat rate.

Owner:THE BABCOCK & WILCOX CO

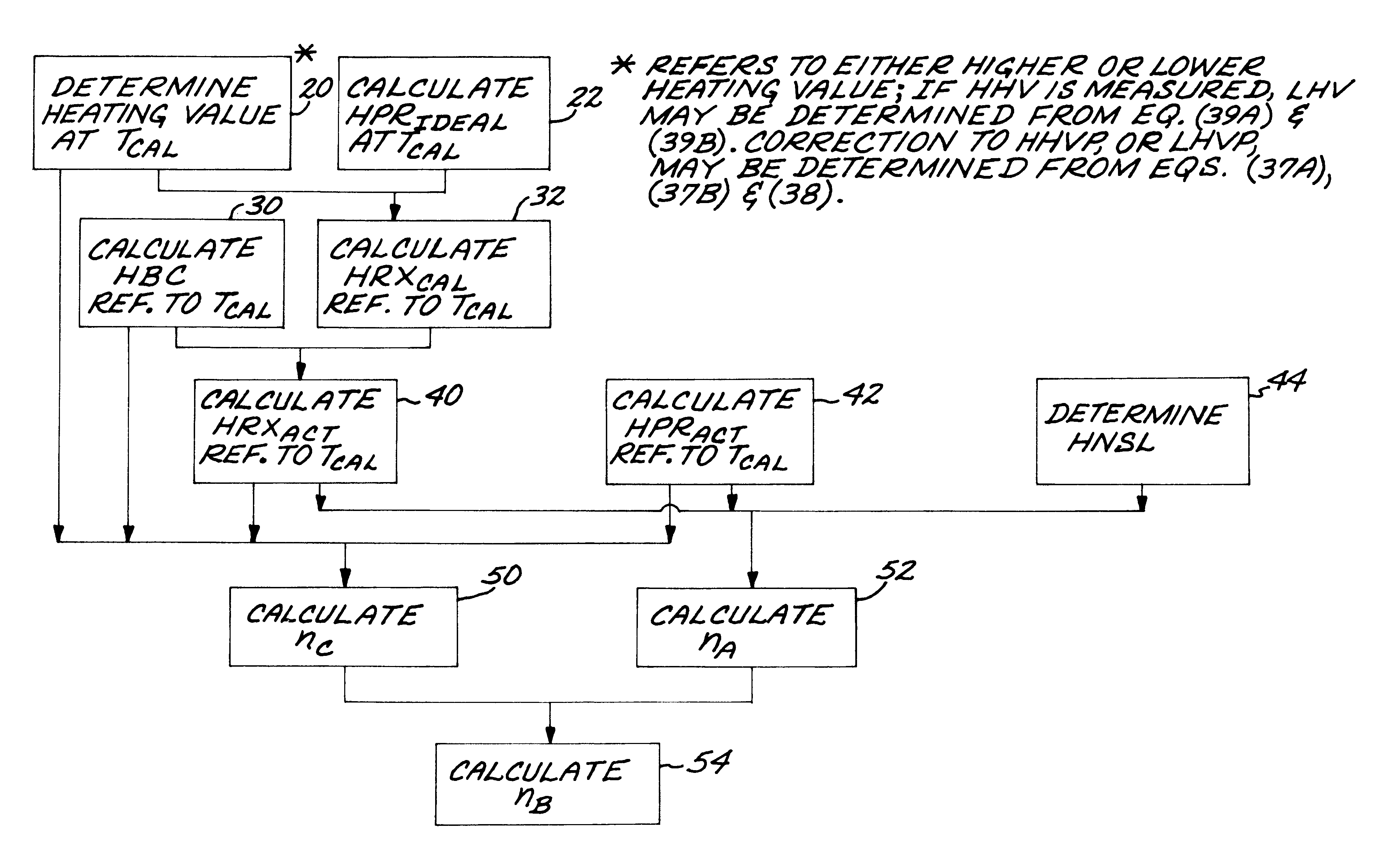

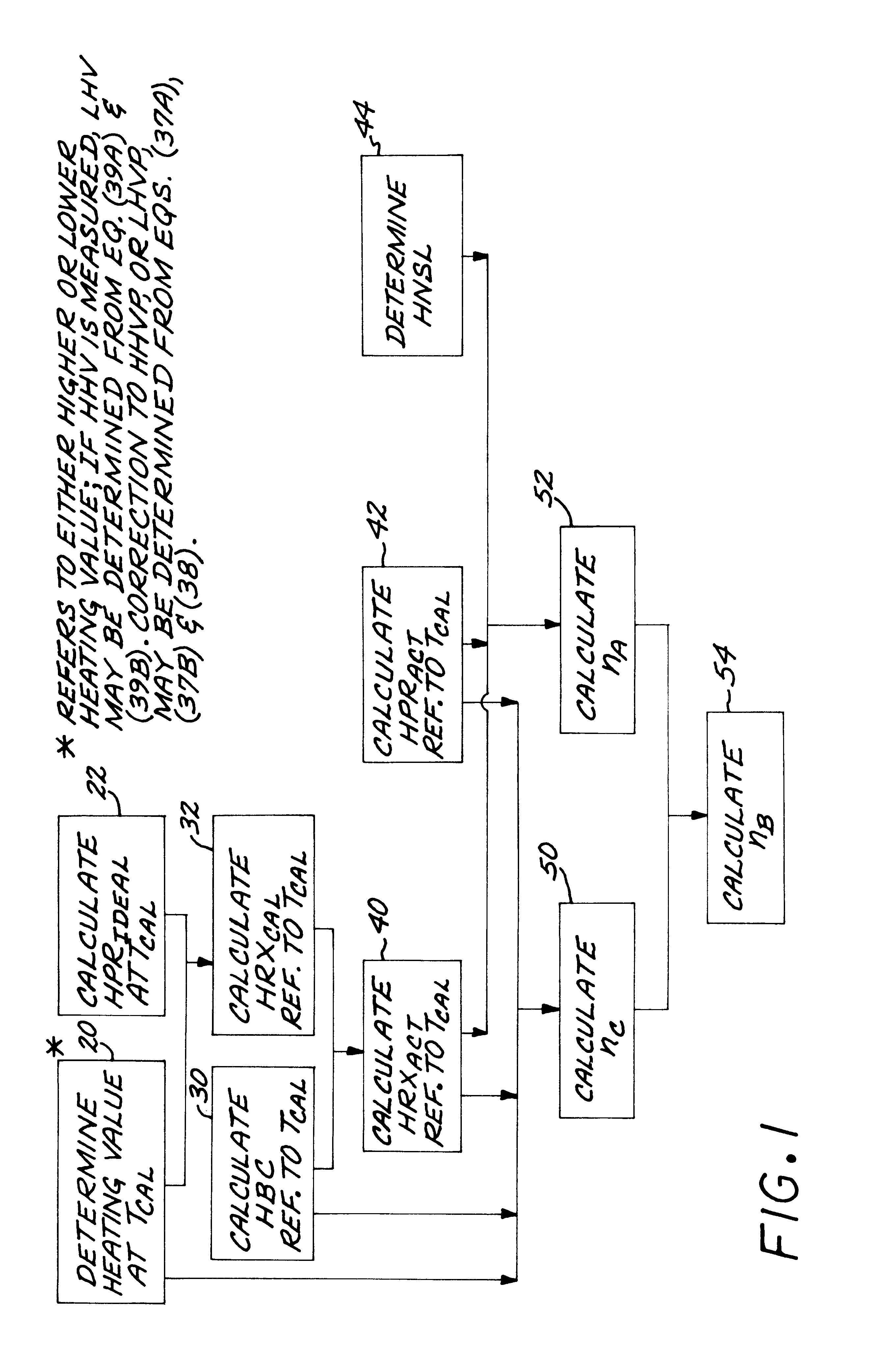

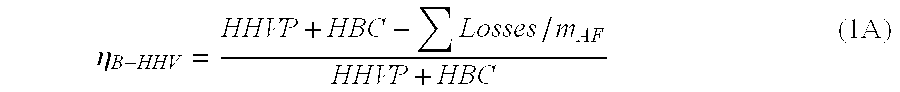

Input/loss method for determining boiler efficiency of a fossil-fired system

InactiveUS6584429B1Consistently appliedSampled-variable control systemsFuel supply regulationEngineeringBoiler efficiency

The operation of a fossil-fueled thermal system is quantified by obtaining an unusually accurate boiler efficiency. Such a boiler efficiency is dependent on the calorimetric temperature at which the fuel's heating value is determined. This dependency affects the major thermodynamic terms comprising boiler efficiency.

Owner:EXERGETIC SYST

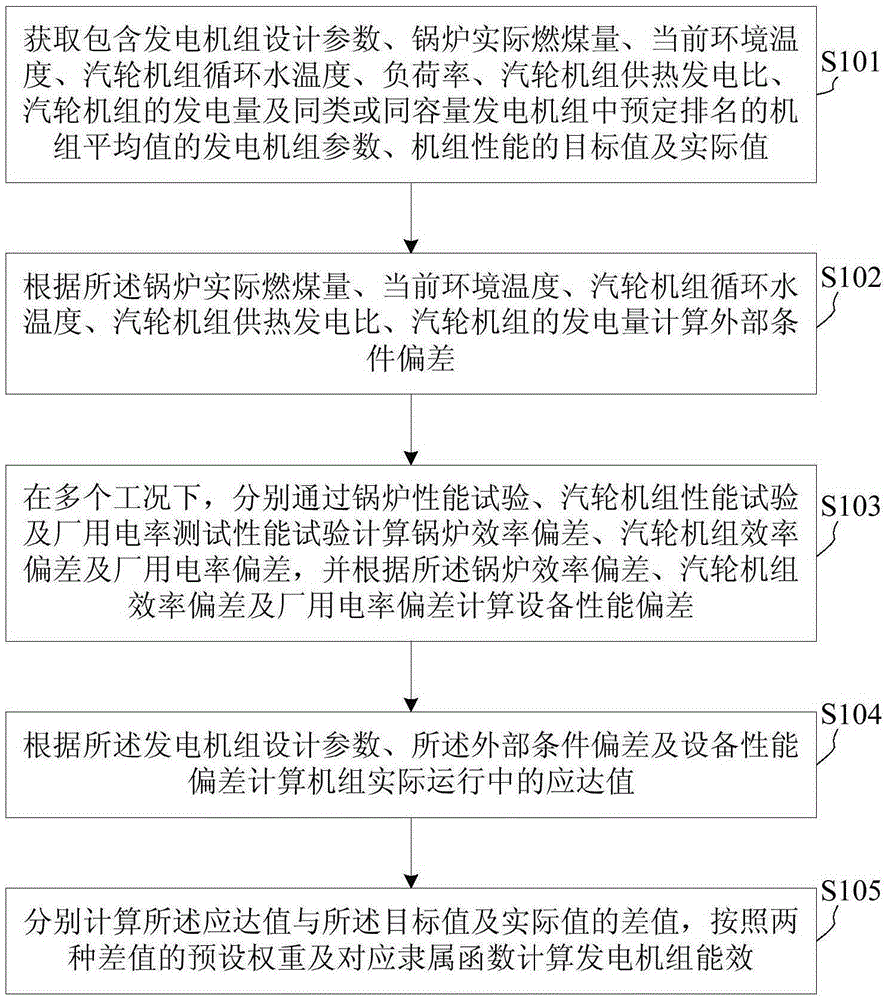

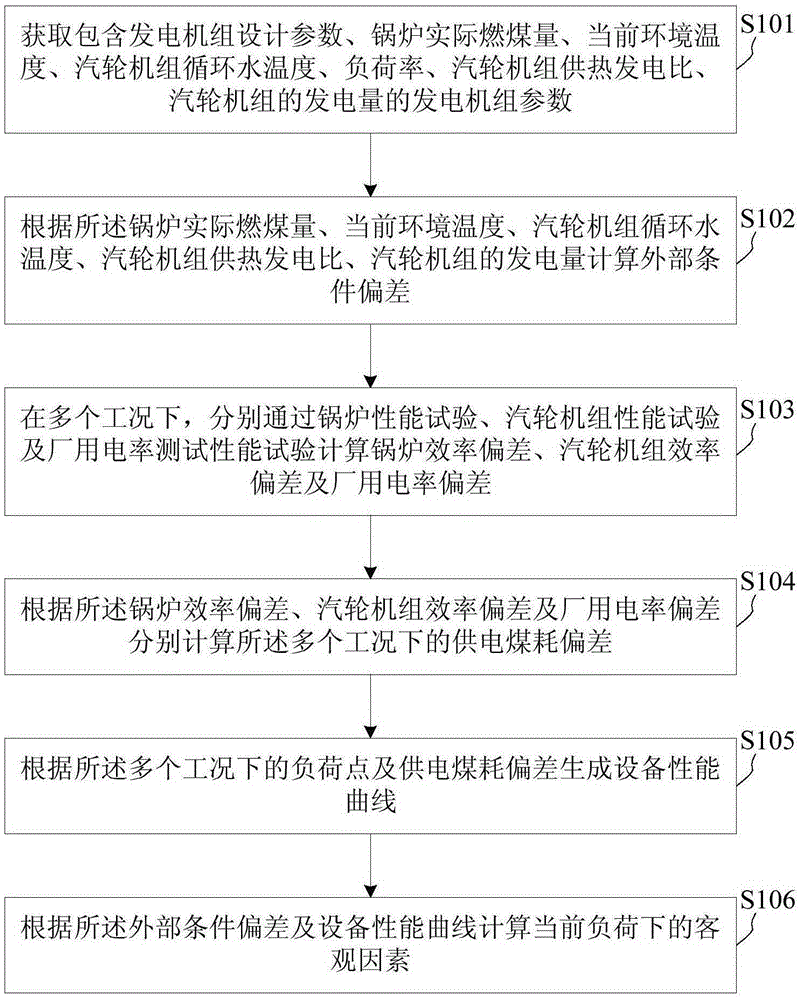

Energy efficiency analysis method of generator set

ActiveCN105224735ASolve the problem of the calculation method of the influence of heat consumptionConvenient researchSpecial data processing applicationsSimulationAnalysis method

The invention provides an energy efficiency analysis method of a generator set. The method comprises: acquiring generator set parameters, set performance target value and actual values; calculating external condition deviations according to boiler actual coal consumption, current environment temperature, turboset circulating water temperature, turboset heat-supply power generation ratio and turboset power generation capacity of the generator set parameters; respectively calculating a boiler efficiency deviation, a turboset efficiency deviation and a station service power consumption rate deviation through a boiler performance test, a turboset performance test and station service power consumption rate testing performance test under multiple working conditions, and calculating a device performance deviation according to the boiler efficiency deviation, the turboset efficiency deviation and the station service power consumption rate deviation; calculating expected values of set actual operation according to generator set design parameters, the external condition deviations and the device performance deviation; and respectively calculating difference values between the expected values and the target values and difference values between the expected values and the actual values, and calculating generator set energy efficiency according to preset weights and corresponding membership functions of the two types of difference values.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

Method of enhancing the quality of high-moisture materials using system heat sources

ActiveUS8579999B2Improve efficiencyIncrease heatDrying solid materials with heatSolid fuelsFluidized bed dryingMoisture

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

Boiler efficiency self-correction computing method based on flue gas testing

ActiveCN104699937ARealize online self-calibrationLearn about healthSpecial data processing applicationsInternet networkData platform

The invention discloses a boiler efficiency self-correction computing method based on flue gas testing. The boiler efficiency self-correction computing method comprises the following steps: (1) transmitting all primary measurement signals of a unit to a built data platform through Internet network in real time, carrying out online monitoring, and processing the data on the platform to obtain and compute parameters required by the boiler efficiency; (2) conducting online flue gas testing, transmitting the data signals to the data platform through the Internet network in real time, and processing the data; (3) meanwhile, from the aspect of positive balance and negative balance, regarding the acquired primary measurement values, secondary parameters obtained by computing the primary measurement values and parameters obtained by the field flue gas testing as known quantities, and establishing a boiler efficiency real-time monitoring mathematical model. The method is simple, convenient, feasible and suitable for variable coal quality operation conditions, and realizes real-time online measurement and self-correction of boiler thermal efficiency, fire coal analysis, fire coal calorific value and various heat losses of the boiler.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD

Method for calculating coal elements and industrial components in real time

The invention discloses a method for calculating coal elements and industrial components in real time, which comprises the following steps of: acquiring the boiler total heat absorption capacity by utilizing the existing calculation results and acquired real-time data; calculating a real-time calorific value of coal as fired by utilizing the real-time coal supply; and calculating elements, moisture and ash of the actual coal as fired in real time by utilizing designed coal elements and industrial components. The coal parameter acquired by the method can also be used for calculating boiler efficiency and coal consumption of thermal power units in real time.

Owner:XIAN THERMAL POWER RES INST CO LTD

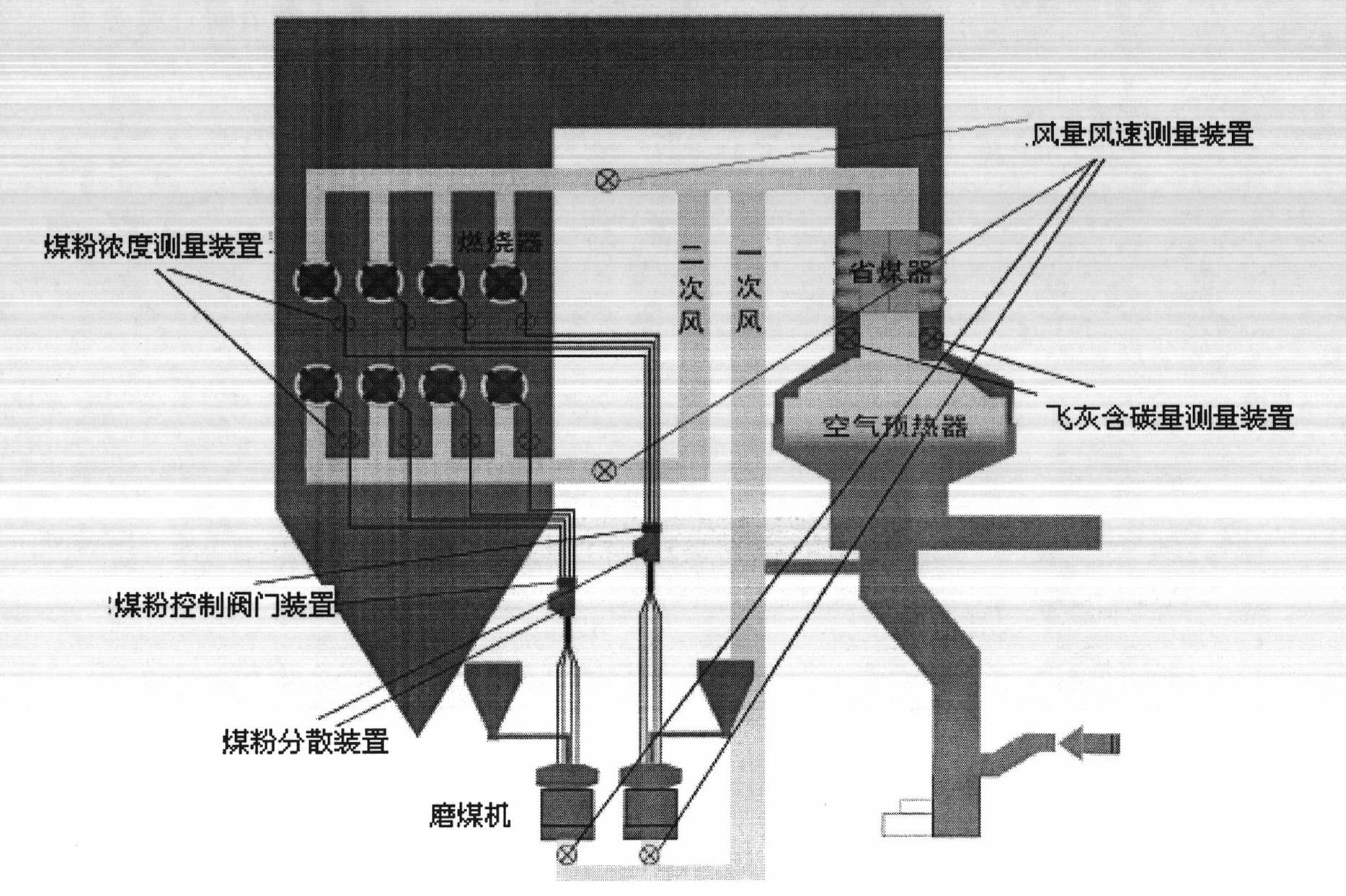

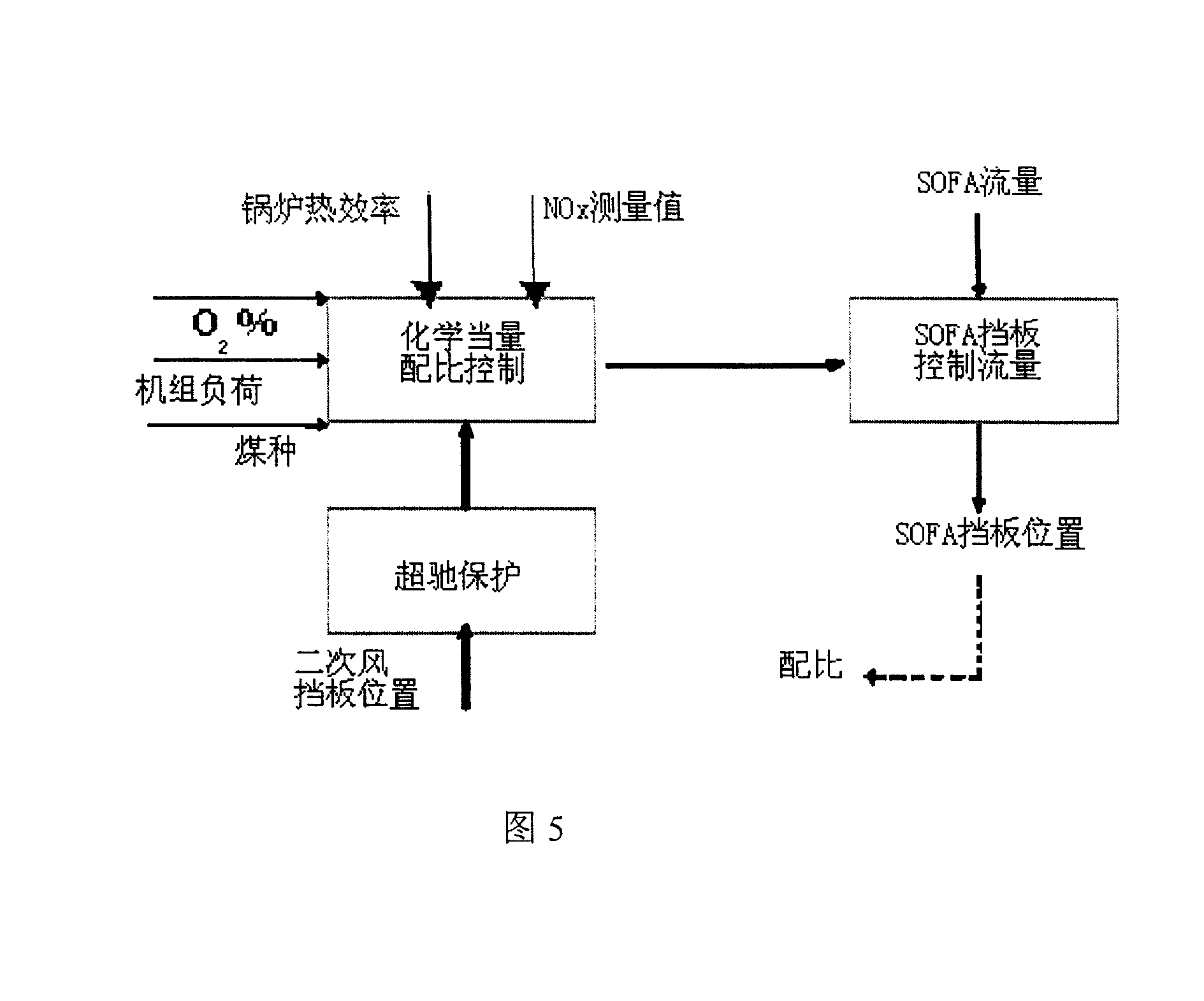

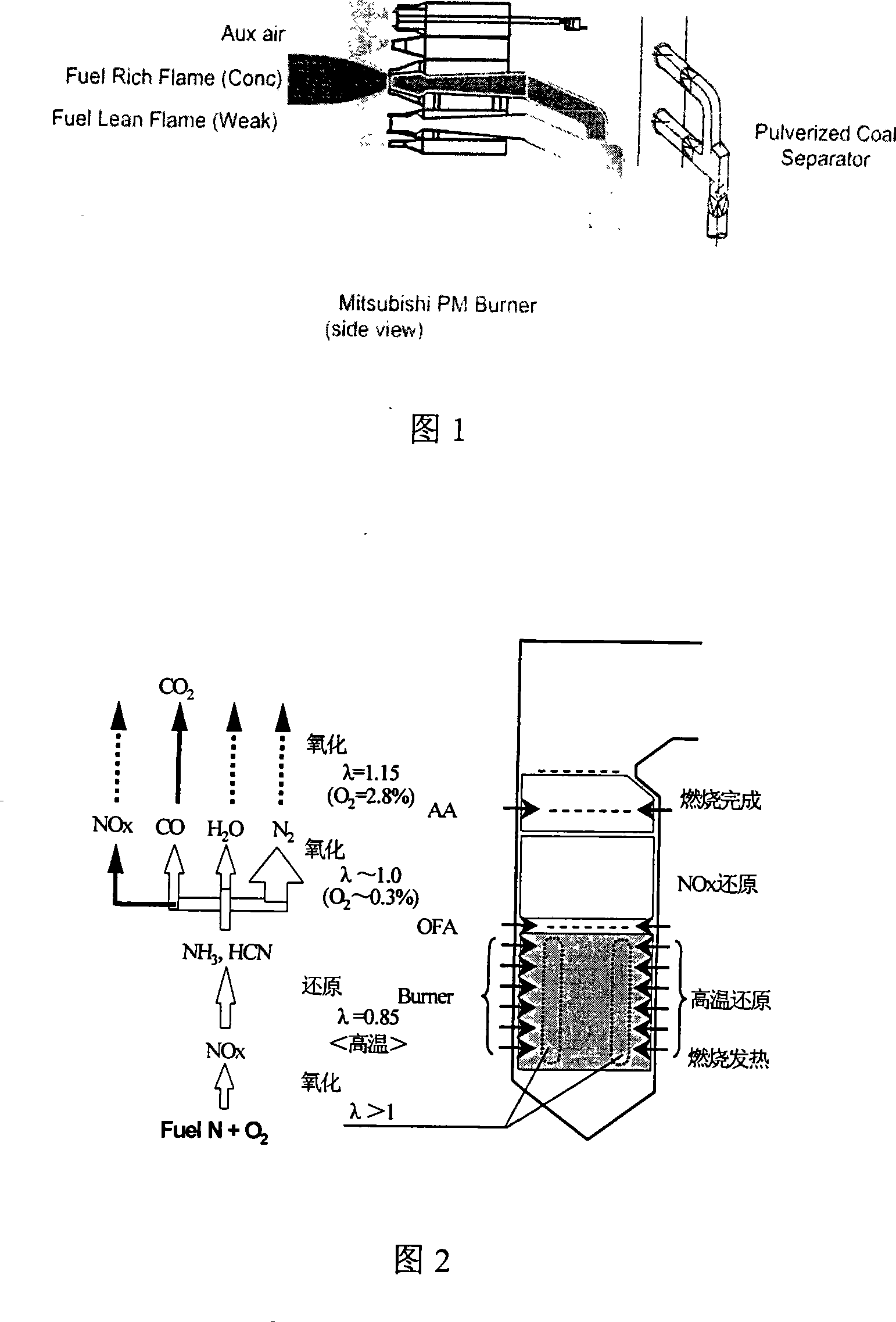

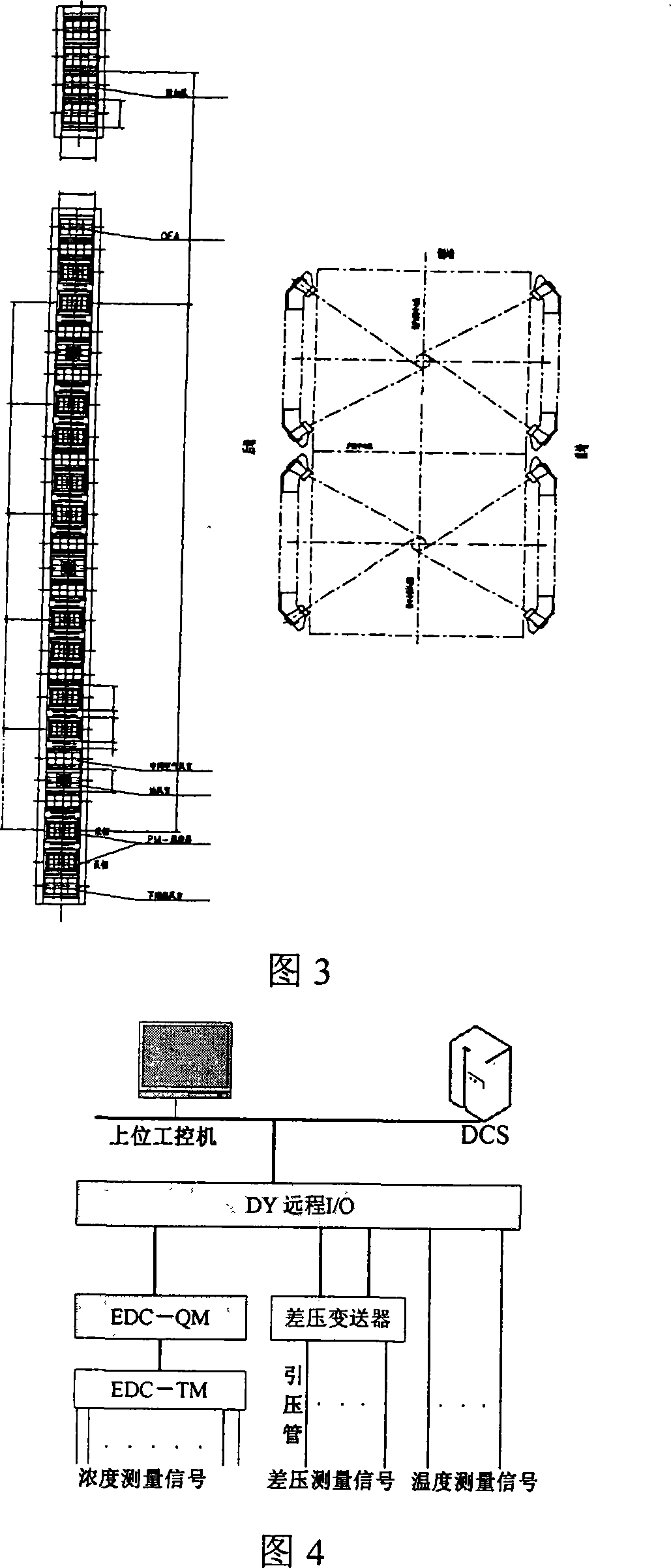

Power boiler low NOx combustion method and control system based on wind powder closed-loop control

The present invention discloses a power station boiler low NOx combustion method based on wind powder closed loop control and a boiler primary air wind powder closed loop control system. The method is as follows: the main burner region excessive air coefficient is controlled below 1.0; the deficient air at the upper side of a hearth is supplemented by an SOFA nozzle at AA interval; a function f(Q)=f(N,D) is used to compare NOx actual measured value with target value, wherein N is coal type, D is load and Q is graded air amount; after adjusted by PID, the deviation of the comparison is used as a correcting factor to be overlapped with the coal type-load-graded air amount function f(Q) for adjusting the mixture ratio between the SOFA air amount and the secondary air amount of the combustion region. The system comprises a first signal measuring part, a signal acquiring part, a data processing part and a feedback part. With the closed loop control system, the method ensures, in different working conditions, the even distribution of the first air wind powder of each layer and perfect mixture ratio between the SOFA air amount and the secondary air amount of the combustion region, so that the method realizes the optimized control target of reducing the discharging of boiler contamination NOx and improving boiler efficiency.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Analysis method for objective factor affecting generator set energy efficiency

ActiveCN105303032ASolve the problem of the calculation method of the influence of heat consumptionConvenient researchSpecial data processing applicationsCurrent loadAnalysis method

An analysis method for objective factor affecting generator set energy efficiency comprises the following steps of acquiring generator set parameters including generator set design parameters, boiler practical coal combustion amount, current environment temperature, turboset circulating water temperature, load rate, turboset heat supplying and generating ratio and turboset generation amount, calculating external condition deviation according to the boiler practical coal combustion amount, current environment temperature, turboset circulating water temperature, load rate, turboset heat supplying and generating ratio and turboset generation amount, calculating boiler efficiency deviation, turboset efficiency deviation and station service power consumption rate deviation according to a boiler performance test, a turboset performance test and a station service power consumption rate test under multi-work conditions, calculating net coal consumption rate deviation of the multi-work conditions according to the boiler efficiency deviation, turboset efficiency deviation and station service power consumption rate deviation, generating equipment performance curve according to multi-load points and net coal consumption rate deviation, and calculating objective factors of the current load according to external condition deviation and the equipment performance curve.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

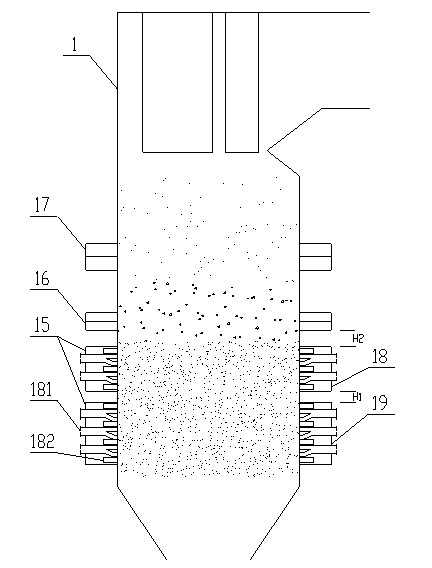

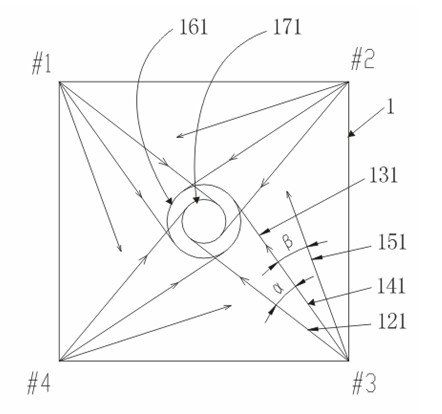

Combustion device for tangentially fired boiler and ultralow NOx combustion method employing same

ActiveCN102563624ALow efficiencyReduce mixCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsCombustor

The utility model discloses a combustion device for a tangentially fired boiler and an ultralow NOx combustion method employing same. A high-position burner, a low-position burner and a main burner are arranged on a hearth from top to bottom; the space between the low-position burner and the main burner is H2, the main burner comprises dense-dilute primary air pulverized coal burners and secondary air pulverized coal burners arranged at the upper parts and the lower parts of the dense-dilute primary air pulverized coal burners, wherein the secondary air pulverized coal burners correspond to secondary air nozzles, the dense-dilute primary air pulverized coal burners are bifurcated pipes, light-phase primary air nozzles and dense-phase primary air nozzles are arranged at the front ends of the bifurcated pipes respectively, and middle secondary air nozzles are arranged between the light-phase primary air nozzles and the dense-phase primary air nozzles; and the main burner comprises an upper group of burners and a lower group of burners, and the space between the upper group of burners and the lower group of burners is H1. The characteristic of divided layer blowing in the horizontal direction is reflected, mixing the secondary air is delayed, the purpose of supplying air on the same layer by grading is achieved, mixing O2 is delayed, the production of NOx is inhibited, and the efficiency of the boiler is ensured not to be reduced.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Emission control system internal to a boiler

InactiveUS20080317652A1Reduce back pressureReduce harmful emissionsNitrous oxide captureCombination devicesControl systemEngineering

Owner:CATALYTIC SOLUTIONS INC

Device and method for mixed smoke evaporation to dryness of desulfuration wastewater

ActiveCN105692745AAvoid wall stickingGuaranteed service lifeWater contaminantsWater/sewage treatmentAir preheaterWastewater

The invention relates to a device and method for mixed smoke evaporation to dryness of desulfuration wastewater. The wall attaching phenomenon or the flue blocking phenomenon exists in an existing mode of boiler smoke evaporation to dryness of desulfuration wastewater, and the desulfuration efficiency is low. The device comprises a mixed gas evaporation to dryness desulfuration part and a gas tempering desulfuration part. The mixed gas evaporation to dryness desulfuration part comprises a drying tower, a wastewater preprocessing pipeline and a mixed gas pipeline. The drying tower is communicated with a flue main pipe through a tail gas pipe. The mixed gas pipeline comprises a main pipe, a first branch pipe and a second branch pipe which is communicated with external air and flows through an air preheater. Smoke and heated external air are mixed and sent into the drying tower so that evaporation to dryness can be conducted on desulfuration wastewater. The wall attaching phenomenon during mixed smoke evaporation to dryness of desulfuration wastewater is effectively solved, the service life of the drying tower is ensured,the influences of external air to boiler efficiency can be effectively reduced,the desulfuration efficiency is effectively improved, the desulfuration wastewater volume can be decreased, the workloads of evaporation work are relieved, and the heat loss for evaporation of desulfuration wastewater is reduced.

Owner:ZHEJIANG ZHENENG TECHN RES INST +1

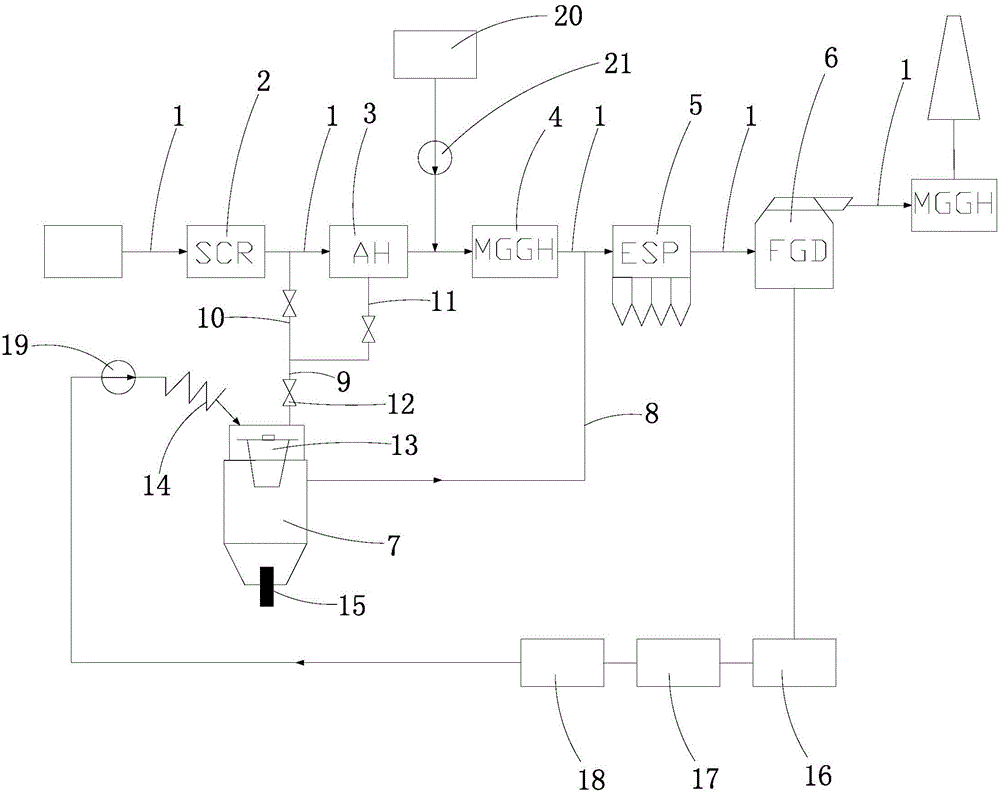

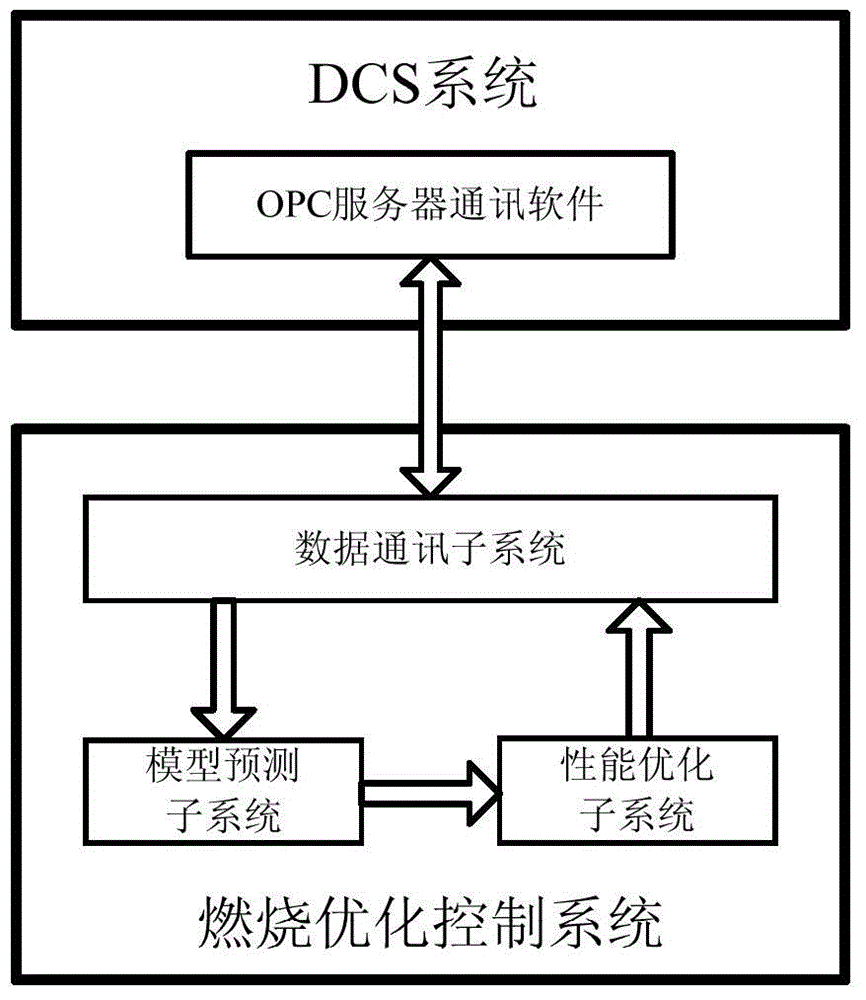

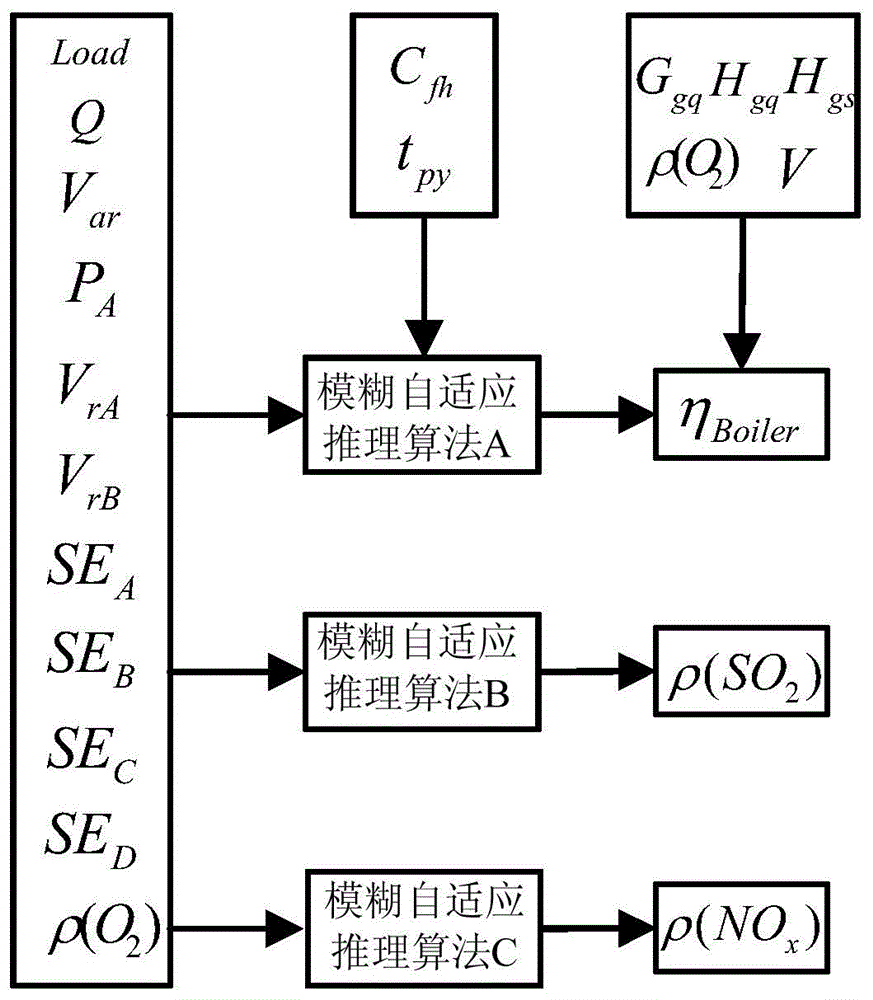

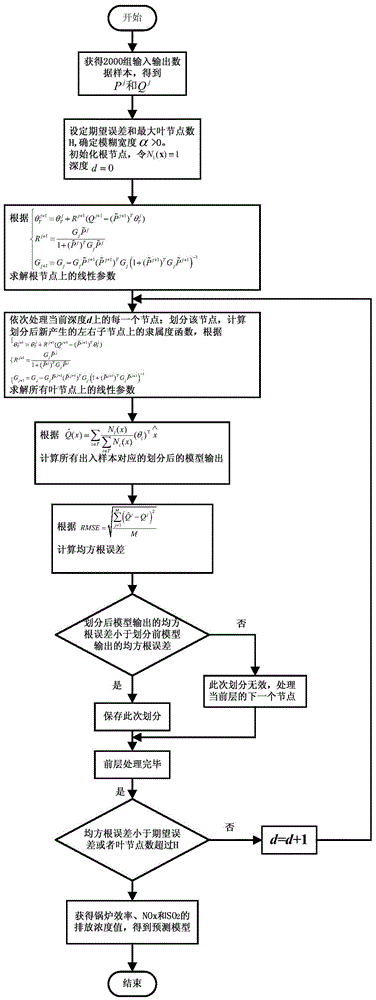

Circulating fluidized bedboiler combustion optimizing control method based on fuzzy adaptive inference

InactiveCN104613468AEmission reductionMeet the requirements of environmental regulationsFluidized bed combustionApparatus for fluidised bed combustionControl layerPower station

The invention discloses a circulating fluidized bedboiler combustion optimizing control method based on fuzzy adaptive inference, and belongs to the technical field of circulating fluidized bed combustion. A circulating fluidized bedboiler combustion optimizing control system comprises a data communication subsystem, a model prediction subsystem and a performance optimization subsystem, wherein the data communication subsystem is in data interaction with OPC server communication software of a DCS; the model prediction subsystem is connected with the data communication subsystem; the performance optimization subsystem is respectively connected with the model prediction subsystem and the data communication subsystem; a boiler efficiency and SO2 and NOx discharge model is established through fuzzy adaptive inference algorithms, the running working condition of a circulating fluidized bedboiler is optimized by selecting a fruit fly optimization algorithm with an optimum reserved strategy, optimal set values of operating variables are provided for a power station DCS basic control layer, and high-efficiency and low-pollutant discharge running of the circulating fluidized bedboiler is realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

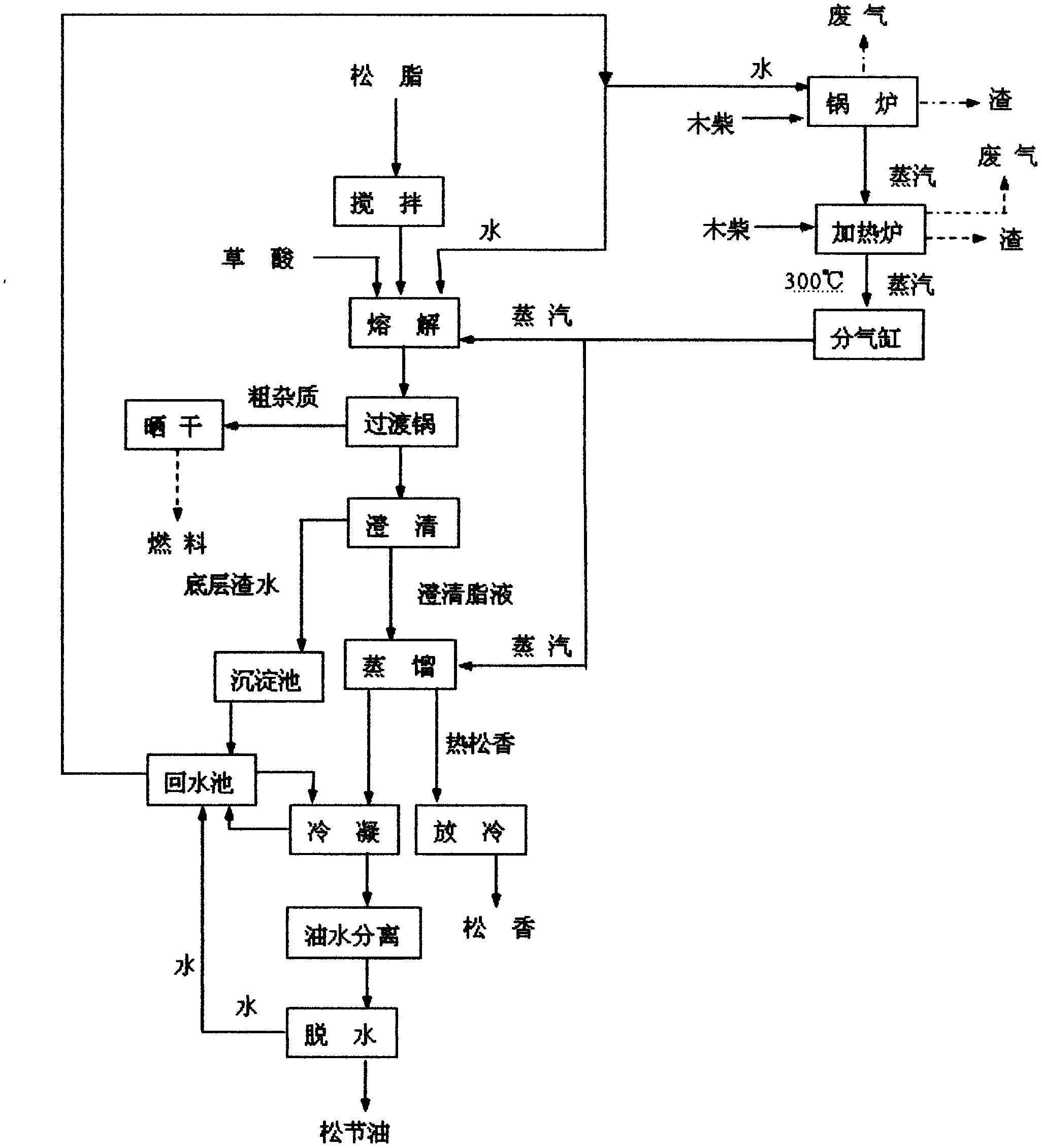

Rosin production technology process

InactiveCN104342034AImprove melting abilityThere will be no meltingChemical industryTurpentine spiritsSteam pressureTurpentine

The invention discloses a rosin production technology process. The process comprises the following steps: conveying turpentine to a melting boiler, adding water, turpentine oil, and oxalic acid, wherein the weight ratio of turpentine to water to turpentine oil is 2-4:1-2:1, and the oxalic acid accounts for 0.1 to 0.3% of the turpentine weight; heating the boiler to melt the mixture in the boiler; transferring the melt mixture to a transition boiler; introducing the melt mixture into a clarifying boiler after precipitation in the transition boiler, then transferring the liquid to a steaming boiler to carry out steaming, wherein during the steaming process, water and turpentine oil are continuously steamed out from the liquid. The provided rosin production technology process has the following advantages: the turpentine is fully stirred before melting so as to grind the turpentine, thus the turpentine melting effect is improved, at the same time the phenomenon that some turpentine is not melted during the melting process is avoided, and thus the yield is increased; moreover, the metling is reduced, the energy consumption is reduced, and the rosin color will not turn darker; the condensed hot water can be directly applied to the boiler so as to reduce the temperature difference between the inlet water and outlet water, the boiler efficiency is improved, the steam pressure is more stable, and more energy is saved.

Owner:琼中森富松香加工厂有限公司

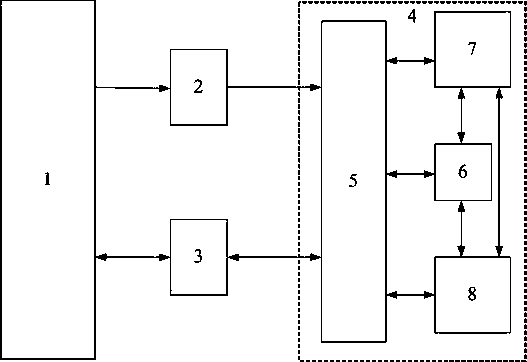

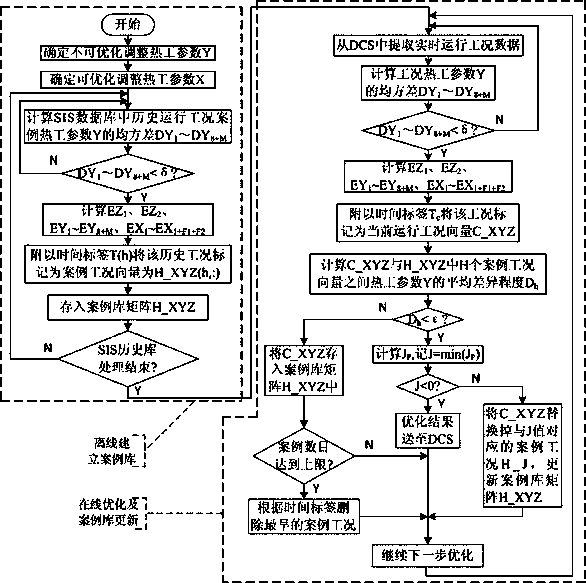

Power station boiler combustion optimization method based on data driven case matching

InactiveCN103838216AImprove efficiencyEmission reductionTotal factory controlProgramme total factory controlPattern matchingLoad following power plant

The invention discloses a power station boiler combustion optimization method based on data driven case matching. The method comprises the steps that (1) a thermal parameter Y=[Y1, Y2, ..., Y8+M] which is relevant to boiler efficiency Z1 and nitrogen oxide Z2 and cannot be optimized and adjusted is determined; (2) a thermal parameter M=[X1, X2, ..., X1+F1+F2] which is relevant to the boiler efficiency Z1 and the nitrogen oxide Z2 and can be optimized and adjusted is determined; (3) operation cases are extracted from a historical database of a monitor information system SIS, so that a case library matrix H_XYZ is formed; (4) real-time operation data are extracted from a real-time collection DCS, and a current operating condition vector C_XYZ is judged; (5) pattern matching is carried out on the C_XYZ and the H_XYZ, and boiler combustion is optimized and adjusted or the H_XYZ is updated according to the pattern matching result; (6) the step 4 and the step 5 are executed again, and it is maintained that the operating state is optimal. The power station boiler combustion optimization method based on data driven case matching has the advantage of solving the optimal value selection problem of adjustable thermal parameters which are relevant to the boiler efficiency and nitrogen oxide emission within a unit operating full load range in a thermal power generating unit boiler combustion system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for optimizing load distribution of boiler

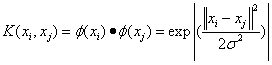

ActiveCN102799778AImprove combustion efficiencySpecial data processing applicationsSupport vector machineParallel computing

The invention relates to a method for optimizing a load distribution of a boiler. At present, the concept of load distribution optimization has not been provided. The method comprises the steps of respectively acquiring load and boiler efficiency data corresponding to the load in the production process of boilers in the production unit of the number of boilers of n (n is greater than 1), establishing a database, modeling each boiler by using a support vector machine method, establishing the model between the load of each boiler and the combustion efficiency, establishing n models, and optimizing the load configuration of each boiler by using a genetic optimization algorithm and combining the boiler load and the combustion efficiency model. By the method, the load of boilers can be distributed through optimization in case that the total load is certain, and the total combustion efficiency is improved.

Owner:夏津会盟建设工程有限公司

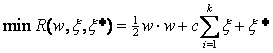

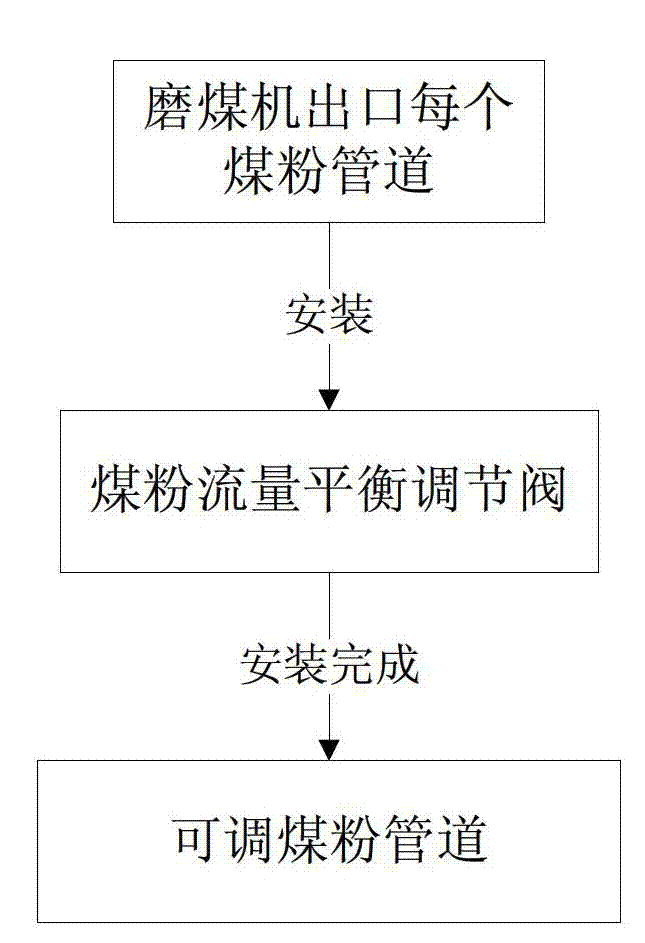

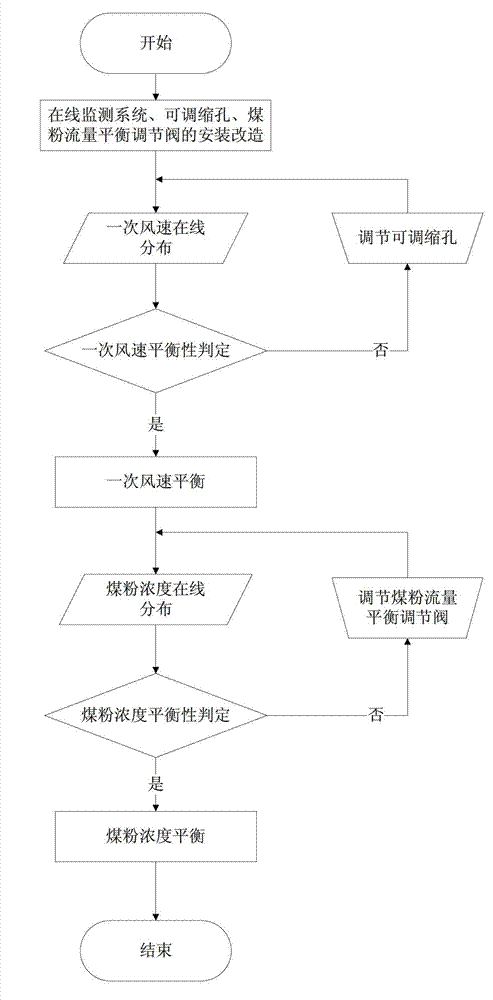

On-line coal powder pipeline wind-powder leveling method

ActiveCN102853447AUniform concentrationWind speed distribution deviation reducedFuel supply regulationEngineeringTwo parameter

The invention discloses an on-line coal powder pipeline wind-powder leveling method for monitoring two parameters including the concentration and the flow speed of coal powder, and the leveling of primary wind speed and coal powder concentration adopts a comprehensive regulating scheme according to the monitored result. The regulating sequence is that the gradual leveling is carried out on the primary wind speed firstly, and on the basis, the coal powder concentration leveling is carried out. The on-line wind-powder leveling of the coal powder pipeline is the comprehensive leveling by using the combination of cod state and hot state environments of a machine set, and the great deviation caused by the leveling through the unitary cold state is remedied; the regulation of the primary wind speed is realized through adjustable contracted holes, and on the basis of monitored data, the contracted holes are regulated step by step by gradually reducing the aperture from 100% until the primary wind speed is balanced; and after the primary wind speed is leveled, the coal powder concentration is leveled through a coal powder pipe balanced valve. According to the method, the wind-powder distribution balancing property can be optimized effectively, the secondary wind optimization configuration can be matched, the boiler efficiency is improved, and the emission of NOx is lowered.

Owner:BEIJING HUADIAN TIANREN ELECTRIC POWER CONTROL TECH

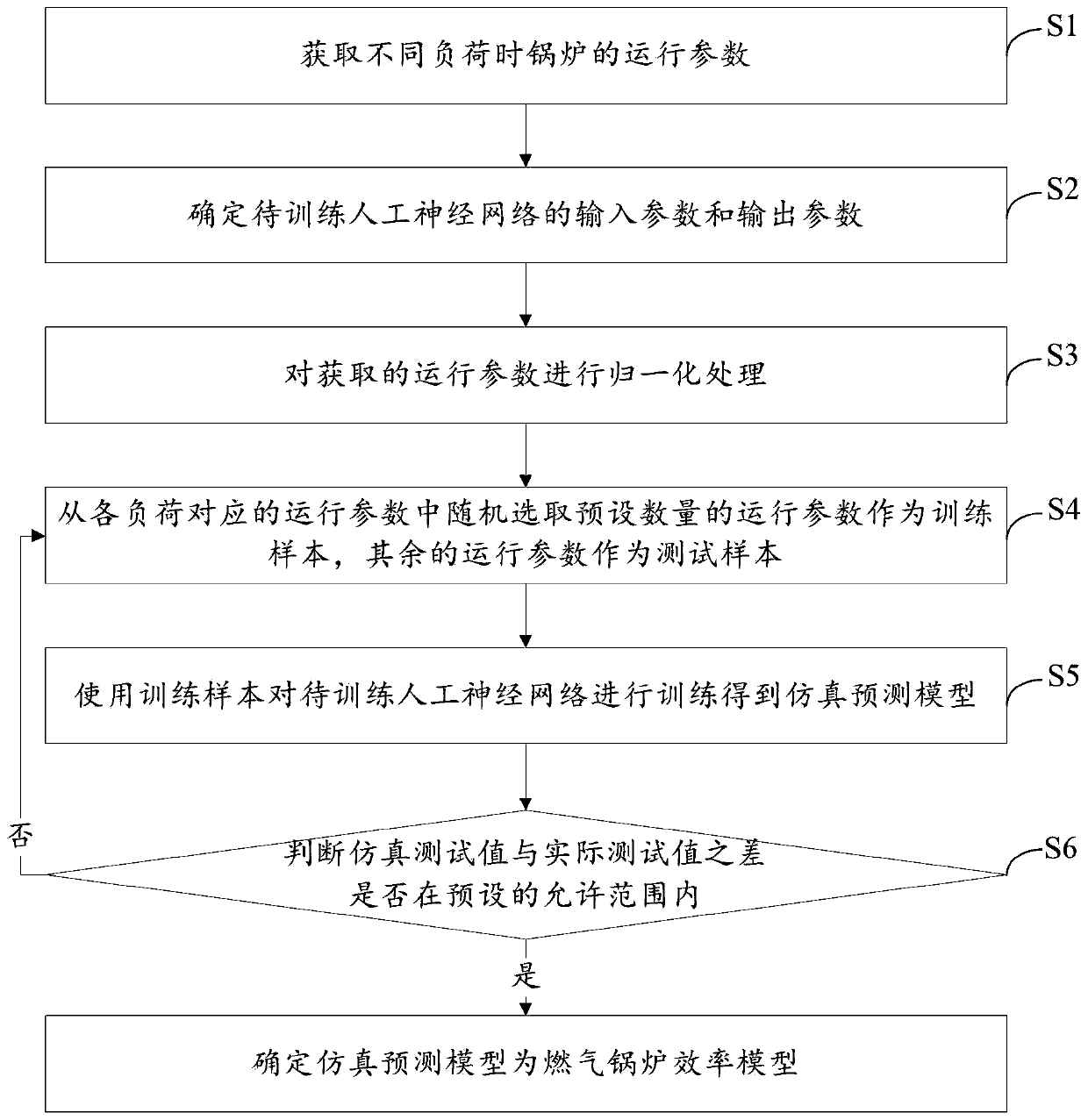

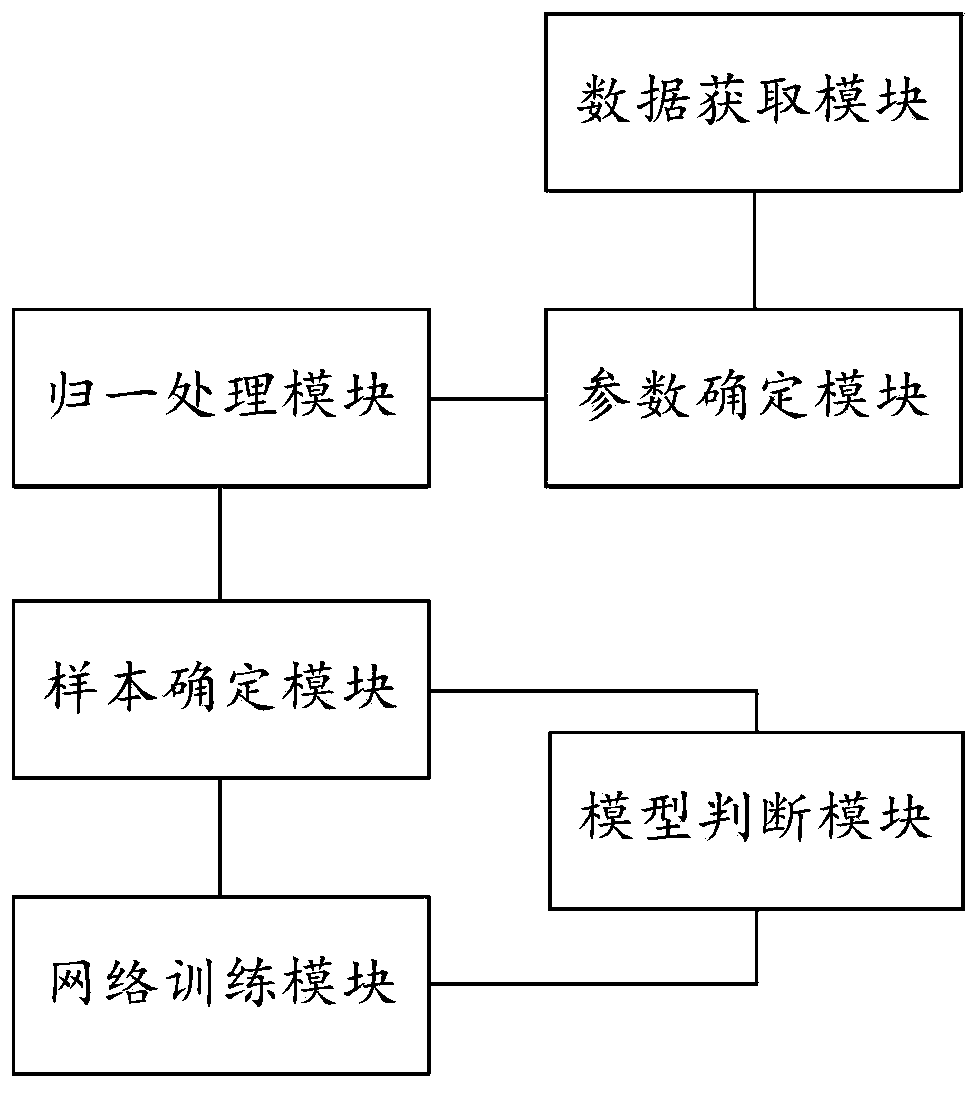

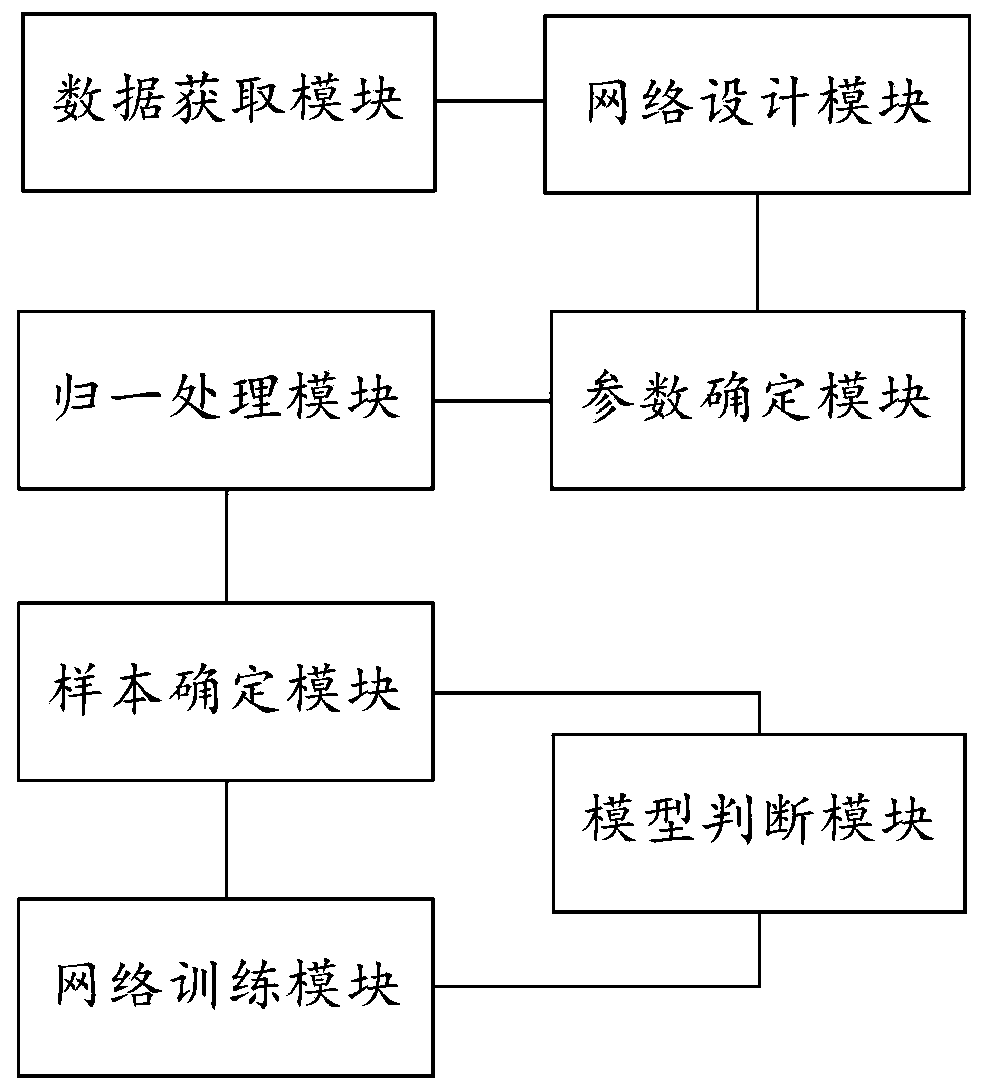

Method and device for determining efficiency of gas-fired boiler

PendingCN109858136AOptimized combustion efficiencyUnrestricted Field Test ConditionsBoiler controlNeural architecturesTest sampleEngineering

The invention discloses a method and device for determining the efficiency of a gas-fired boiler. The method comprises the steps that S1,obtaining operating parameters of the boiler under different loads; s2, determining input and output parameters of the artificial neural network; s3, carrying out normalization processing; s4, determining a to-be-trained artificial neural network; s5, selecting apreset number of operating parameters from the operating parameters corresponding to each load as training samples, and taking the rest operating parameters as test samples; s6, training the to-be-trained artificial neural network by using the training sample to obtain a simulation prediction model; and S7, substituting the test sample into the simulation prediction model to obtain a simulation test value, judging whether the difference between the simulation test value and an actual test value is within a preset allowable range or not, if yes, determining the simulation prediction model as agas boiler efficiency model, and otherwise, executing S5. According to the method, the boiler combustion efficiency model is established through the artificial neural network, so that a basis is provided for optimization and improvement of the combustion efficiency of the gas-fired boiler.

Owner:XINAO SHUNENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com