Boiler combustion optimization air distribution method based on online model prediction

A technology for boiler combustion and model prediction, applied in genetic models, predictions, genetic laws, etc., can solve the problems of inability to automatically adjust, unable to meet the long-term optimization of air distribution adjustment, and difficult to guarantee the accuracy of the model.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

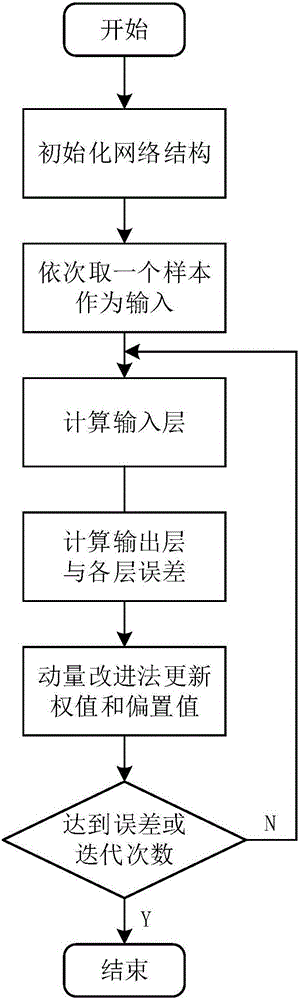

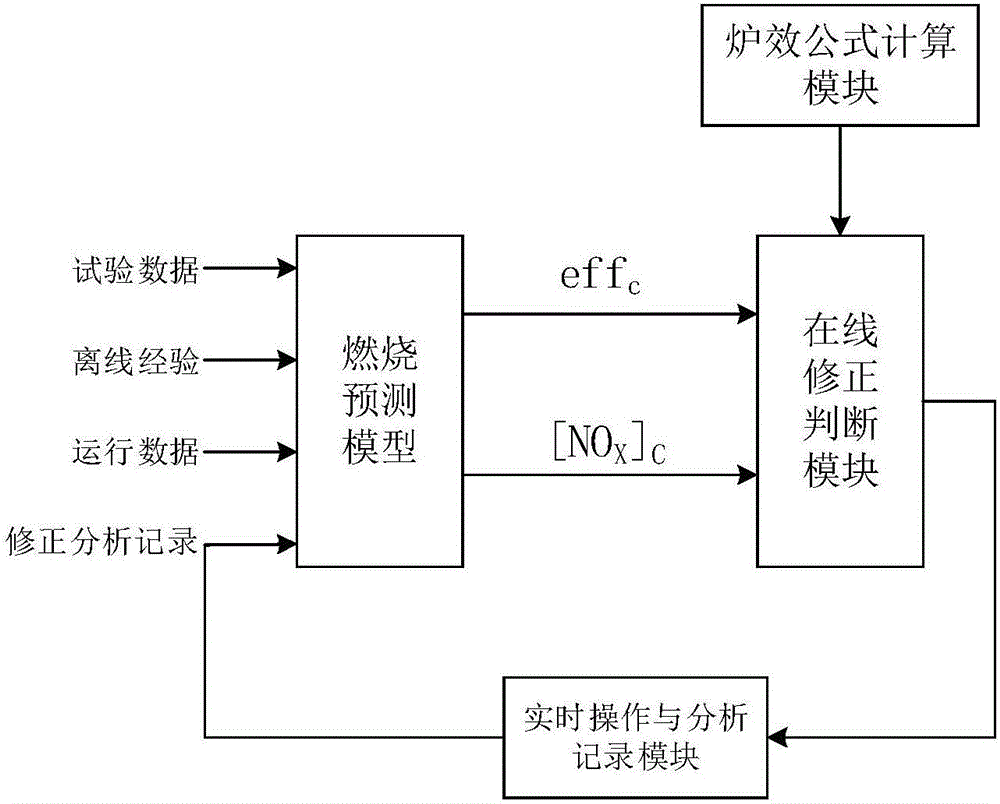

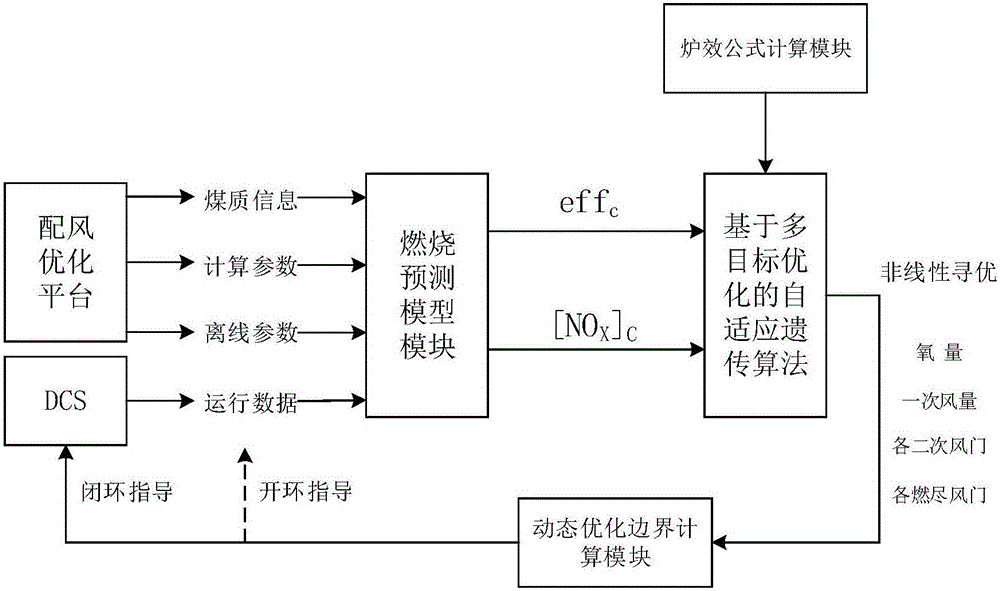

Method used

Image

Examples

Embodiment 1

[0107] Unit #1 of the first phase of a certain power plant is a 500MW coal-fired thermal power generation unit. Desulfurization and denitrification systems have been added to it, and low NOx systems have been replaced. X After the burner, the combustion situation of the boiler has changed a lot. In particular, the transformation of the air distribution of the burner enables the fuel to be burned step by step in the furnace and realizes the reduction of NO X the goal of. However, this layered air distribution method puts forward new requirements for unit combustion, control of secondary air baffles on each layer, total air volume and furnace oxygen control, etc., and is directly related to the safety, stability and economy of unit operation. sex. Therefore, the secondary air distribution optimization combustion system of the #1 and #2 unit boilers has been researched and transformed. In the original DCS——ABB Composer system, two new combustion optimization stations are added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com