Patents

Literature

336 results about "Boiler control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

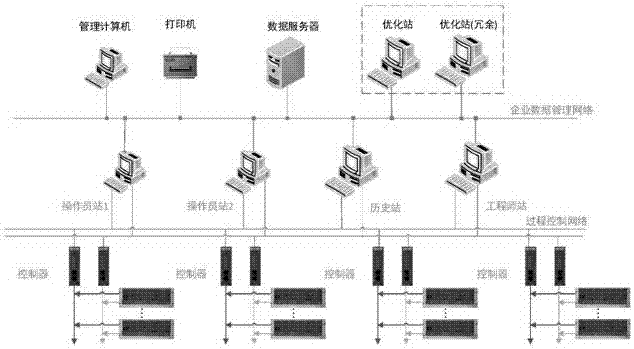

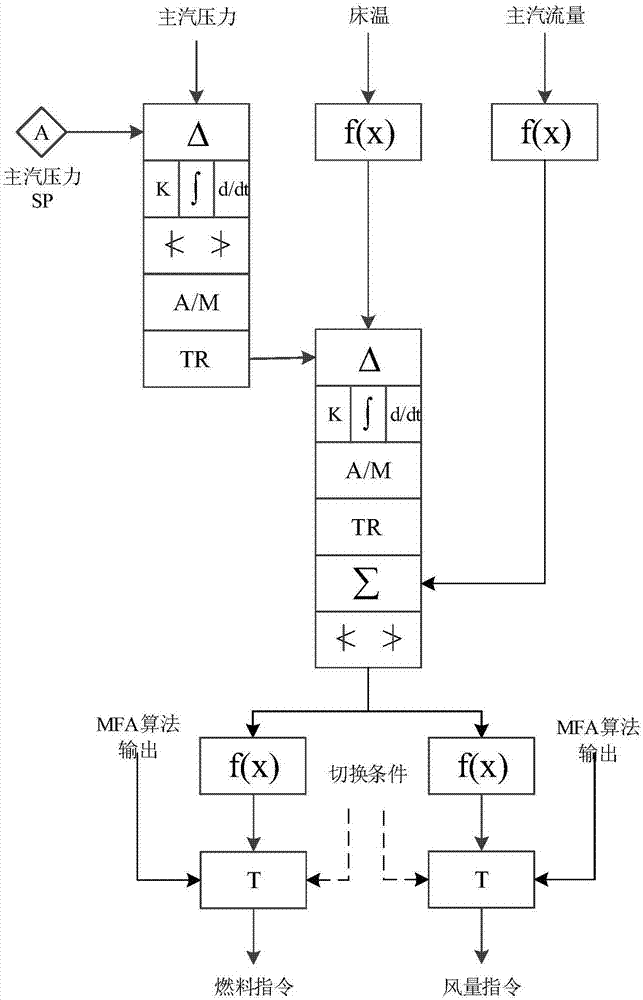

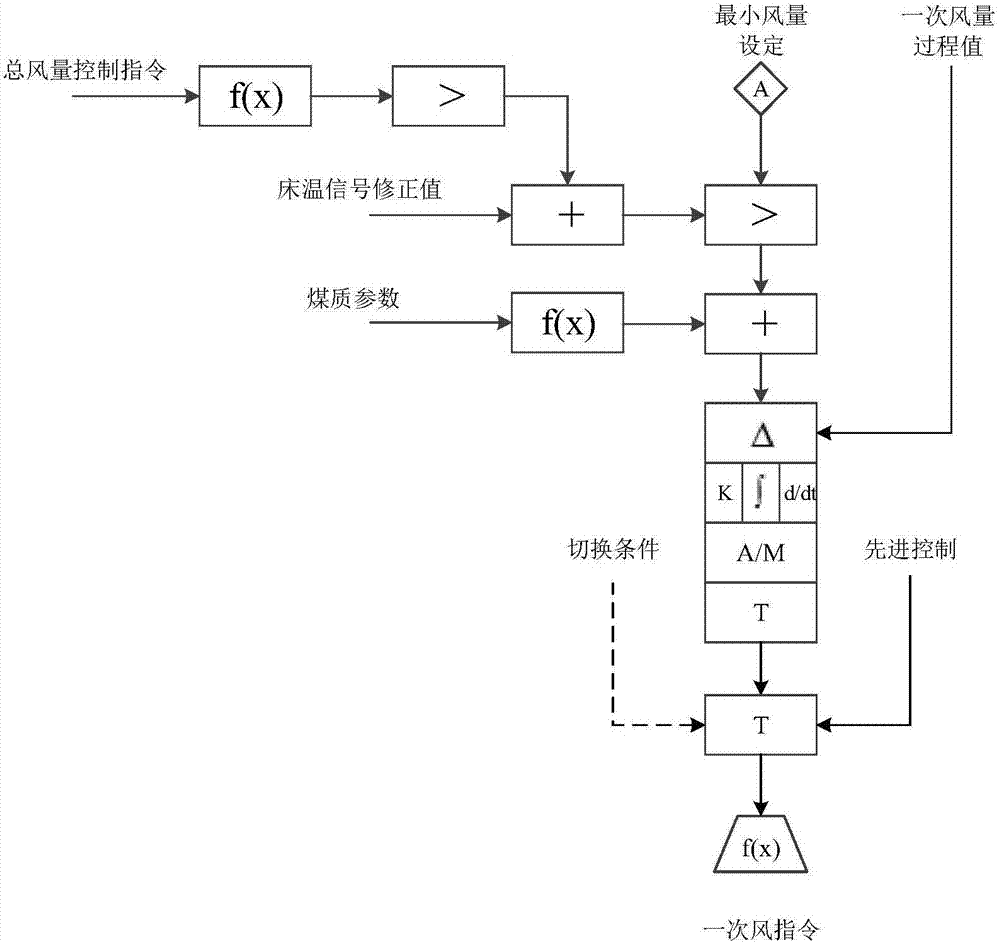

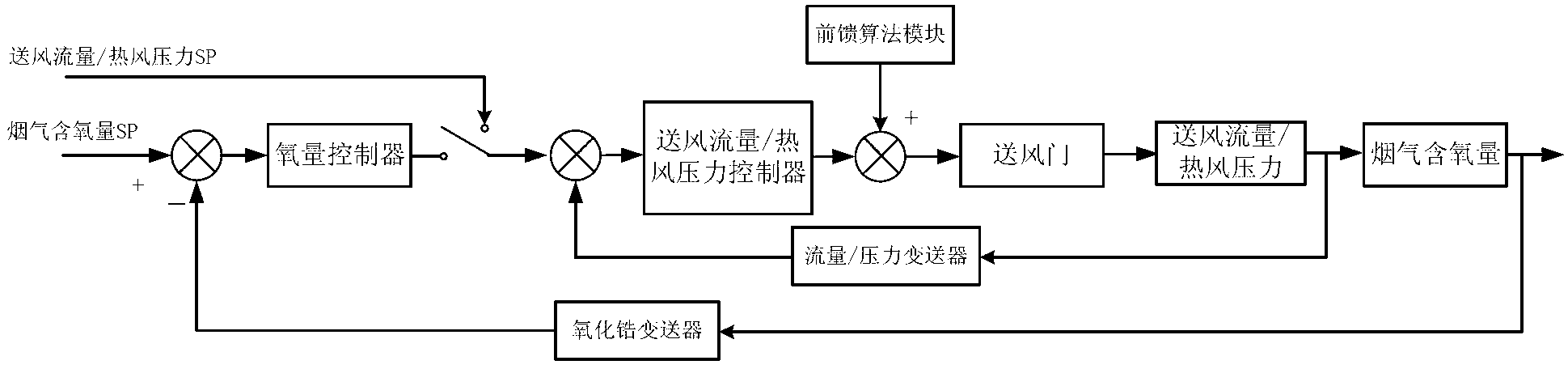

Fluidized bed boiler control and combustion optimization system

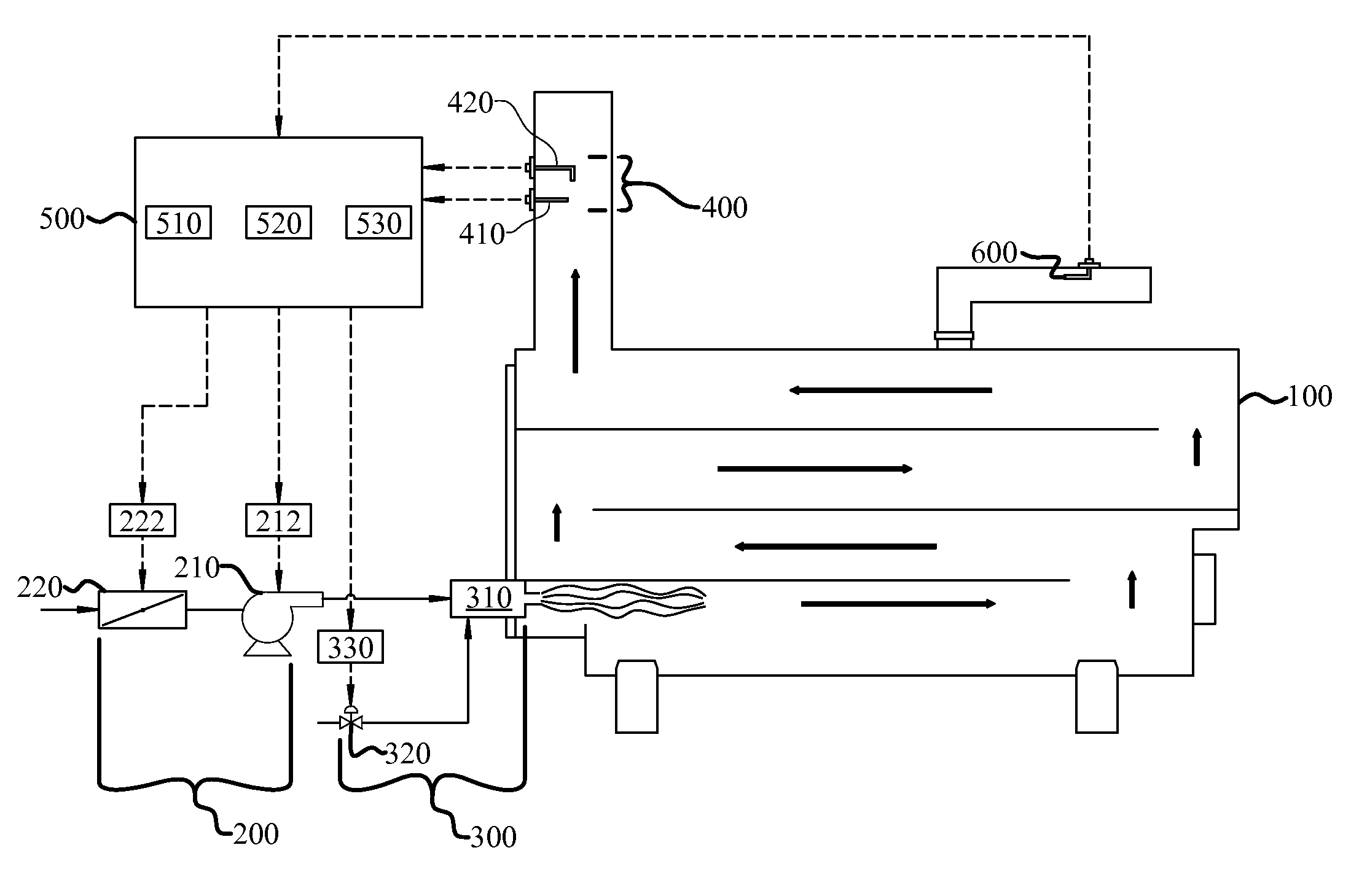

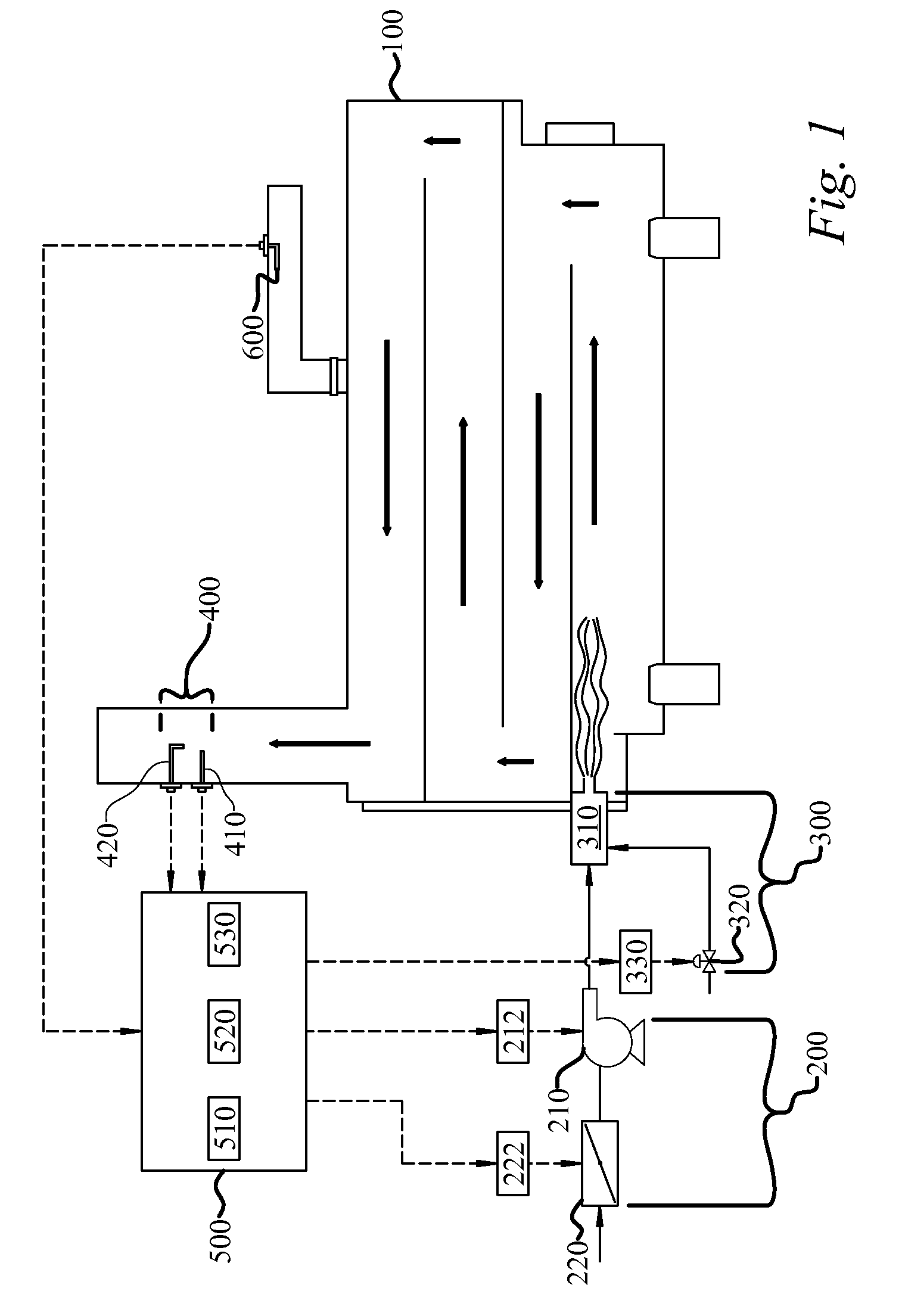

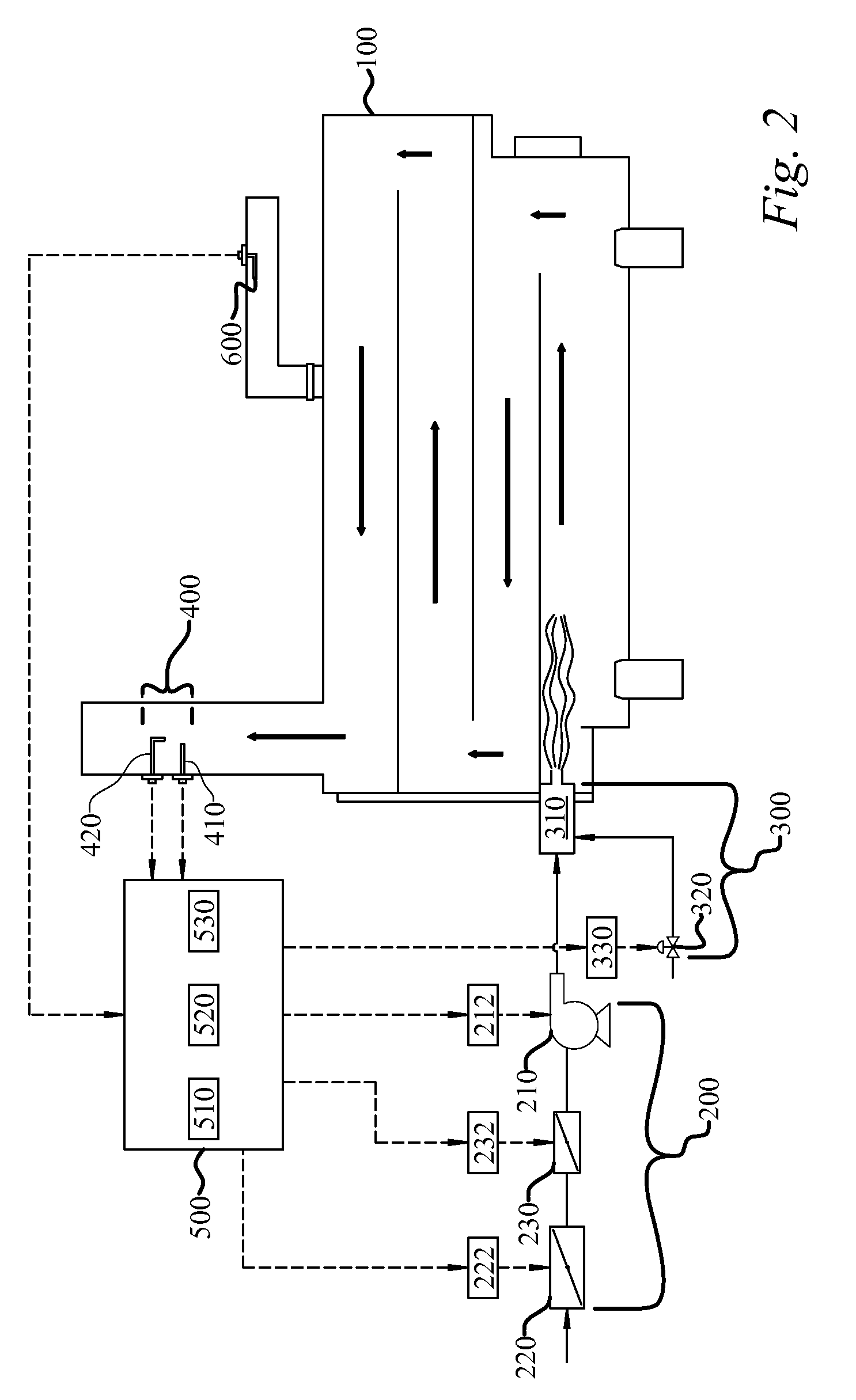

ActiveCN107023825AOptimize operating parametersImprove controlFluidized bed combustionApparatus for fluidised bed combustionFluidized bedOxygen content

The invention discloses a fluidized bed boiler control and combustion optimization system. The problem that a fluidized bed boiler system is not easy to control for a long time is solved. According to a method, a control strategy of combining an advanced control algorithm and a conventional control algorithm is adopted, and continuous, economical and stable operating of the boiler system is guaranteed; multivariable model-free adaptive control is adopted, and decoupling control of the fuel quantity and the air supply quantity over the bed temperature under the variable load work condition is achieved; and a nerual network technique is adopted for building a boiler combustion prediction model, online calculation of the boiler efficiency and NOX and SOX emissions is achieved, a multi-objective optimization function is constructed according to the prediction result, a combustion self-optimization algorithm is adopted, the flue gas oxygen content and the bed temperature are optimized constantly so as to adapt to work condition changes, and a fluidized bed boiler can operate in an optimal combustion area.

Owner:XIAN IBL TECH DEV +1

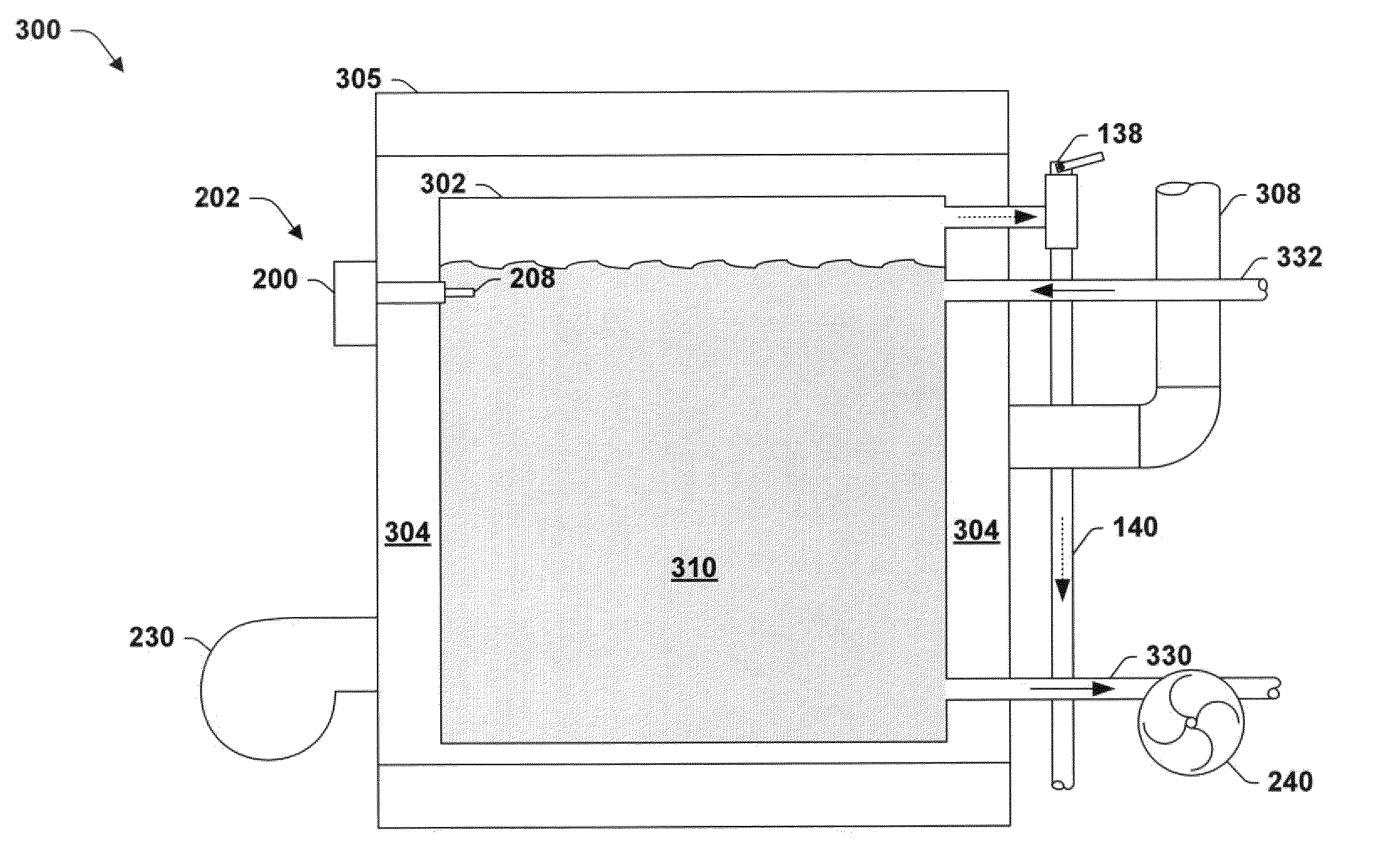

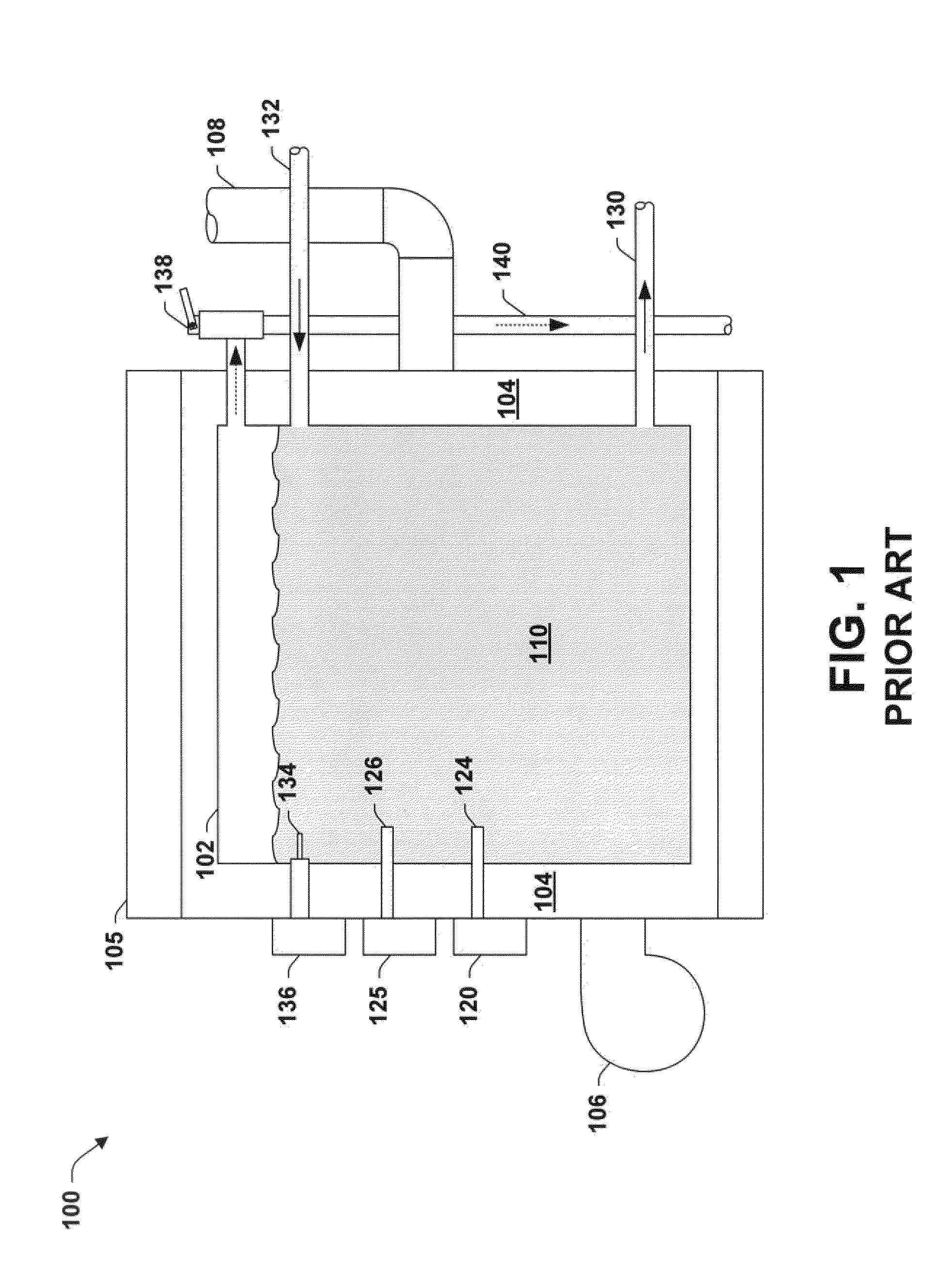

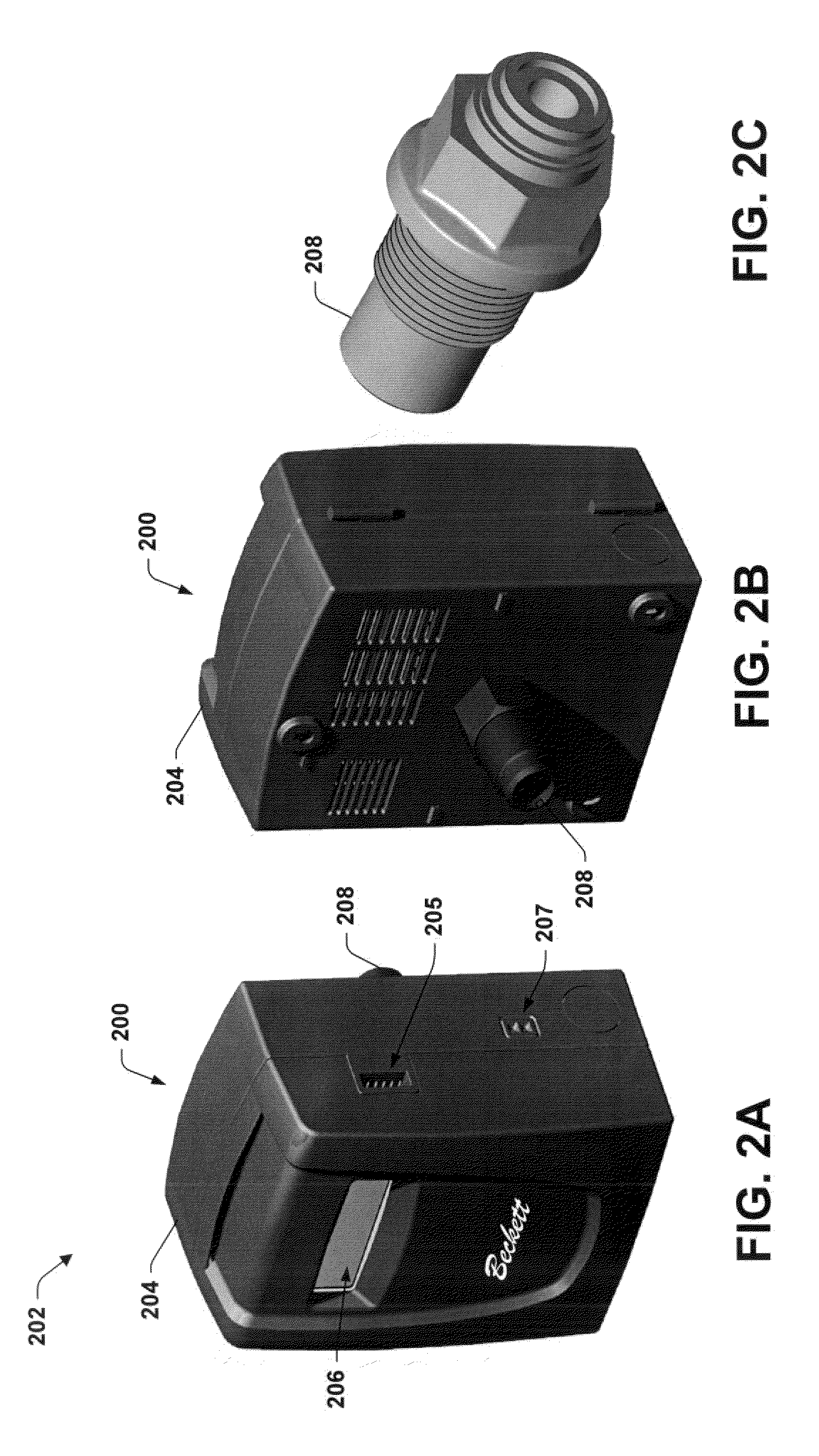

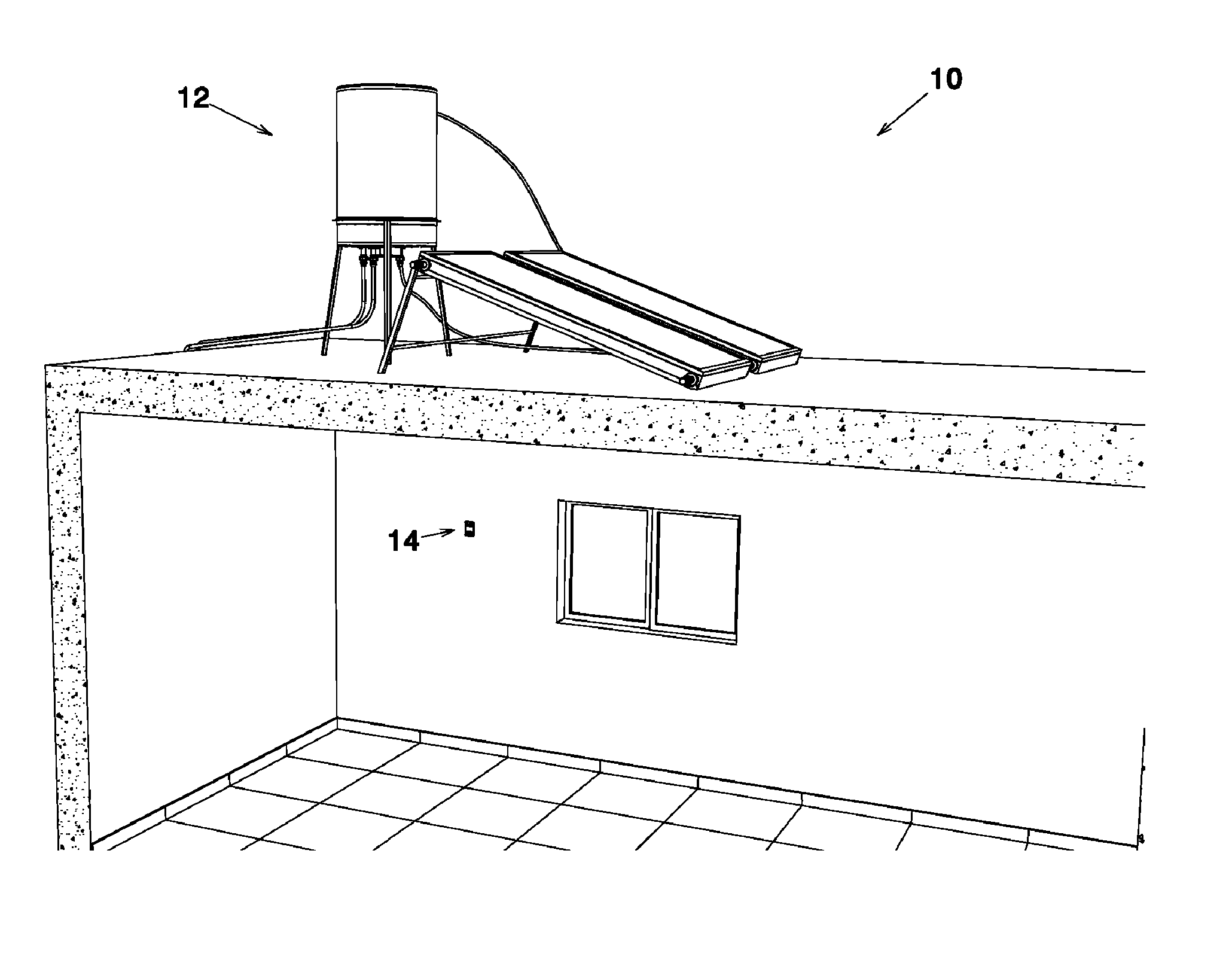

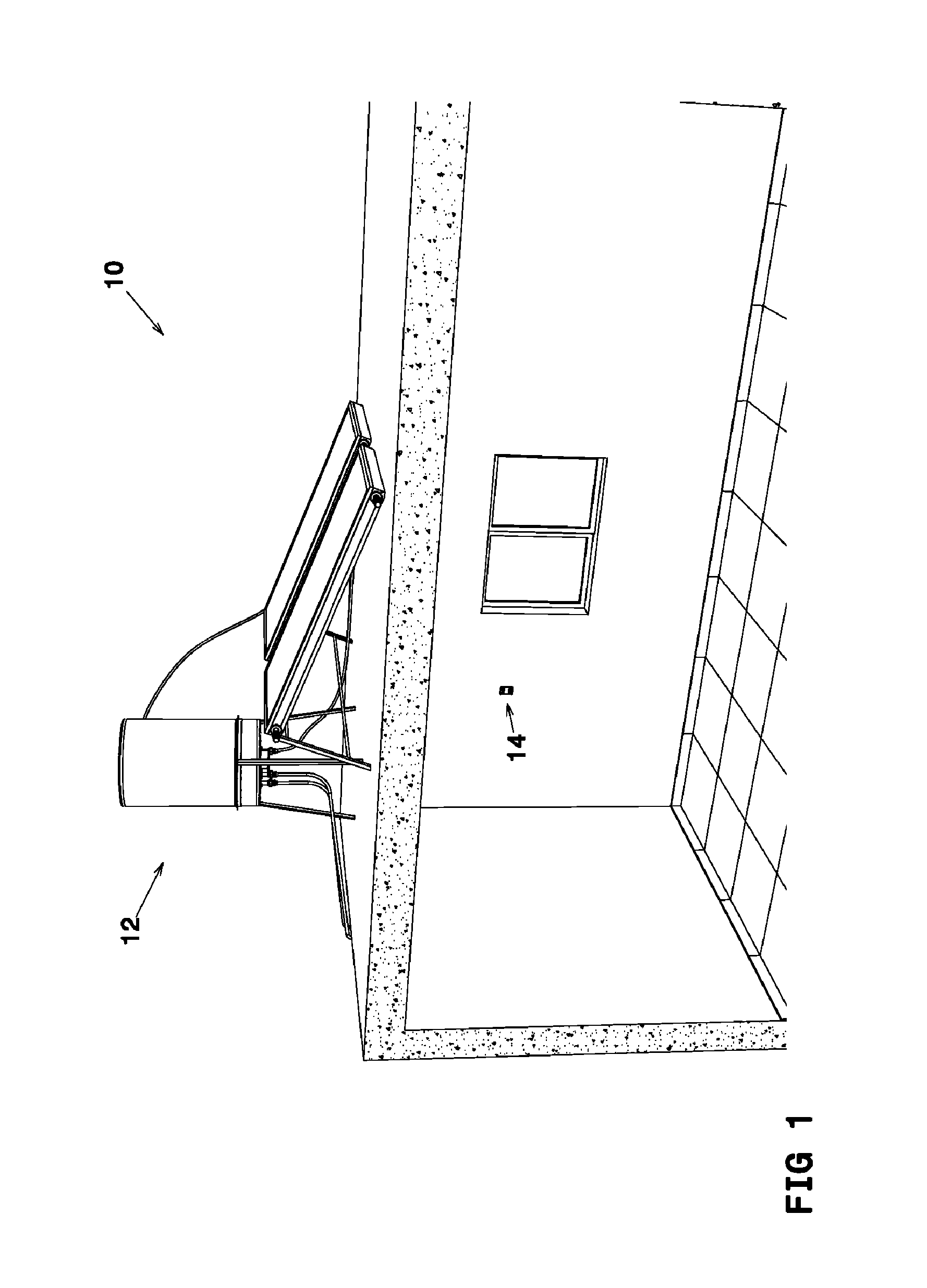

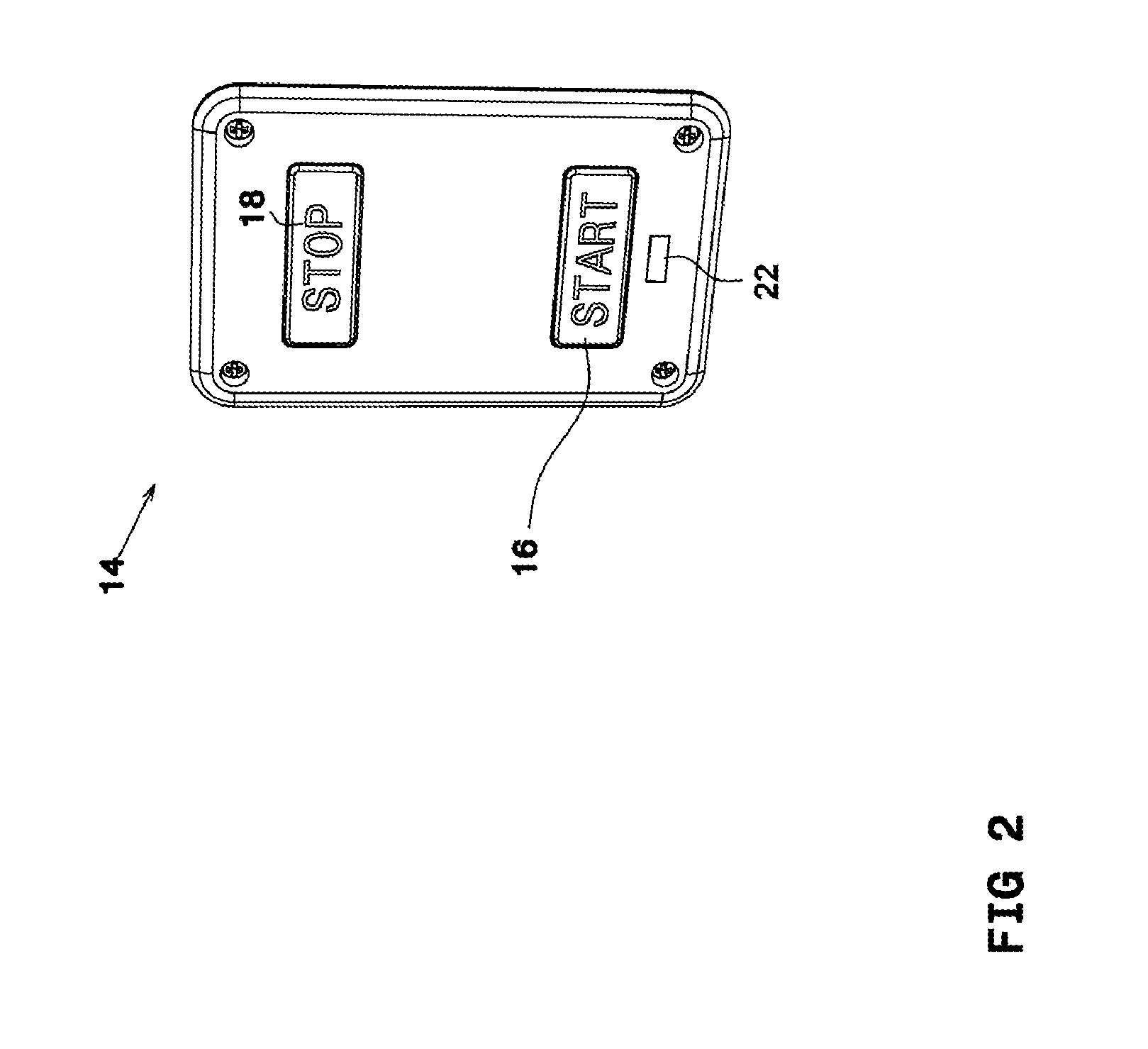

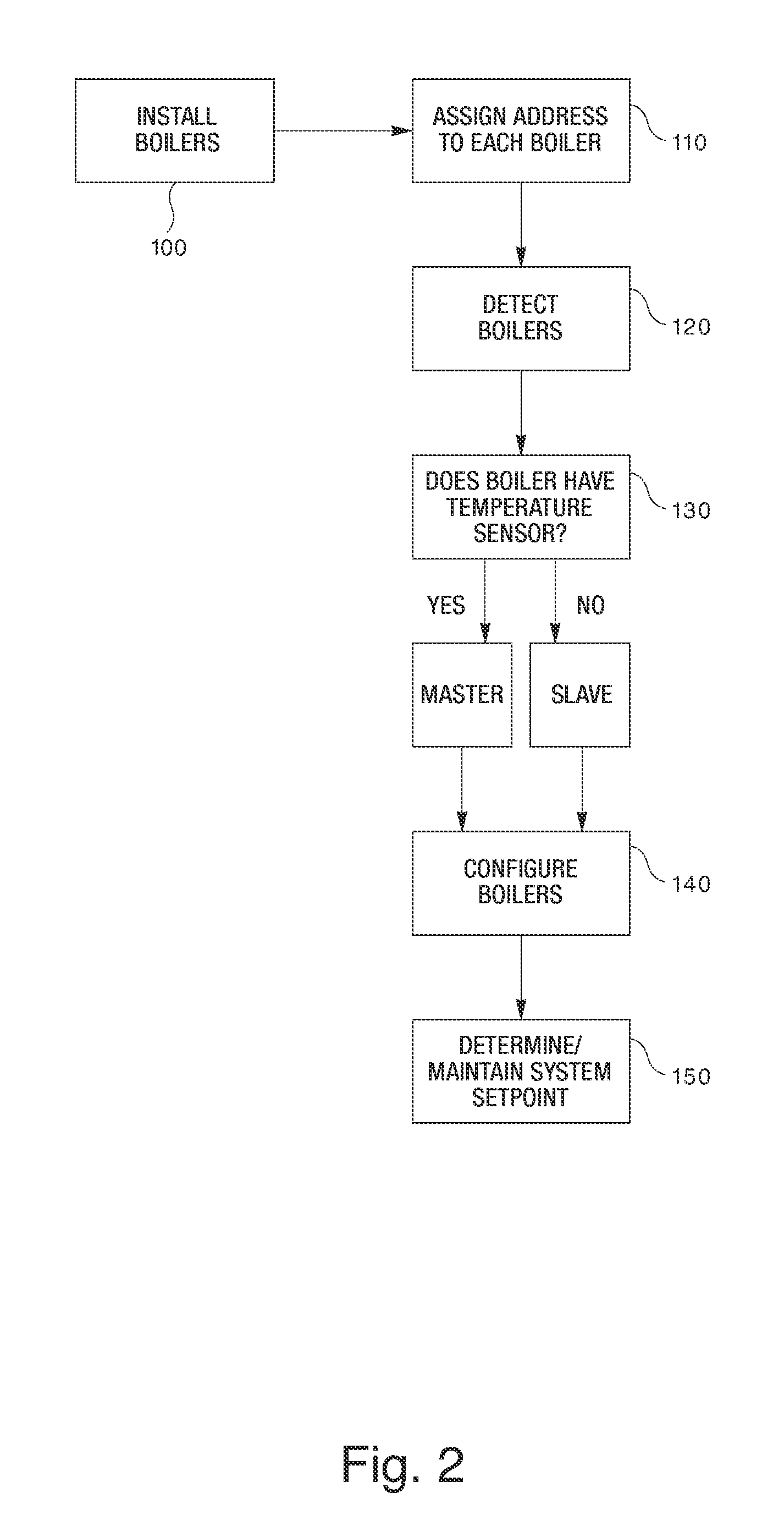

Sensor and boiler control system

InactiveUS20100280665A1Energy/fuel savingEliminate needSampled-variable control systemsSafety arrangmentsCombustorBoiler control

A system and method is presented for a boiler controller for a boiler system. The boiler controller comprises a sensor monitoring component, operably coupled to a temperature detector operable to measure a temperature of a medium within the boiler, and a pressure detector operable to measure a pressure of the medium. The boiler controller also comprises a burner controller coupled to a burner. The burner controller is operable to control the burner to heat the boiler based upon at least one of the temperature of the medium measured by the temperature detector compared to a range of temperature setpoints, results of an energy efficiency calculation, a presence of the medium, and the pressure of the medium.

Owner:R W BECKETT

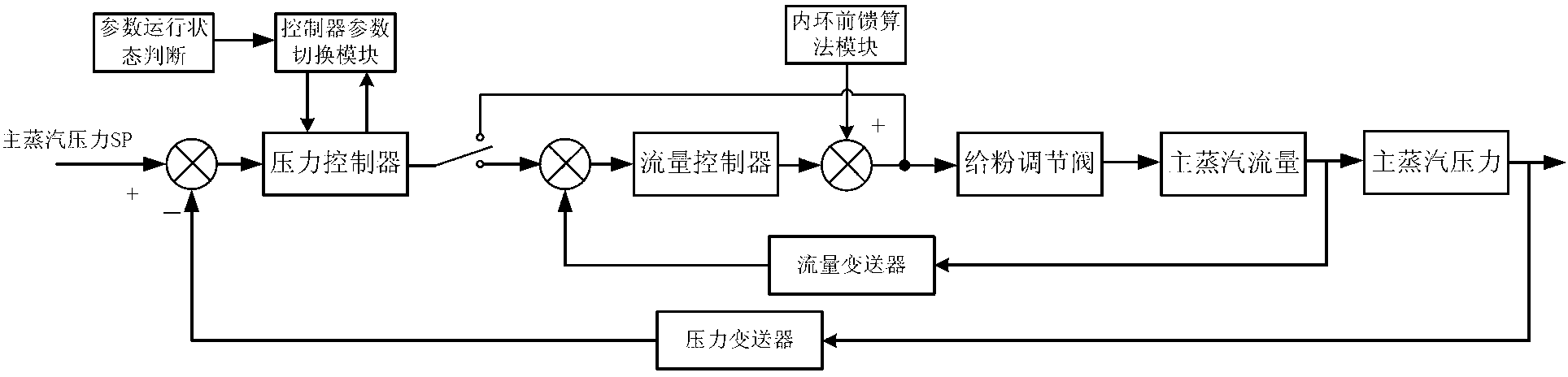

Boiler control and combustion optimization method

ActiveCN103322547AReduce labor intensityGuaranteed stabilityBoiler controlCombustion regulationCombustionEconomic benefits

The invention discloses a boiler control and combustion optimization method and solves the problem that the boiler system is difficult to control for a long time. The method includes the steps of 1, establishing a target function; 2, recording an optimized target function value and an operating parameter to be optimized when the boiler system stably operates; 3, adding a preset step value to the operating parameter to be optimized; 4, after the boiler system stabilizes and the target function increases, continuing to add a step value until the target function value decreases; if the target function value decreases, performing reverse step optimization, decreasing by one step value until the target function value increases, and confirming that the boiler system is in the optimal combustion area. The boiler control and combustion optimization method has the advantages that system stability is ensured, system performance is improved, labor intensity is reduced for workers, the system is integrally optimized, and economic benefit is high.

Owner:XIAN IBL TECH DEV

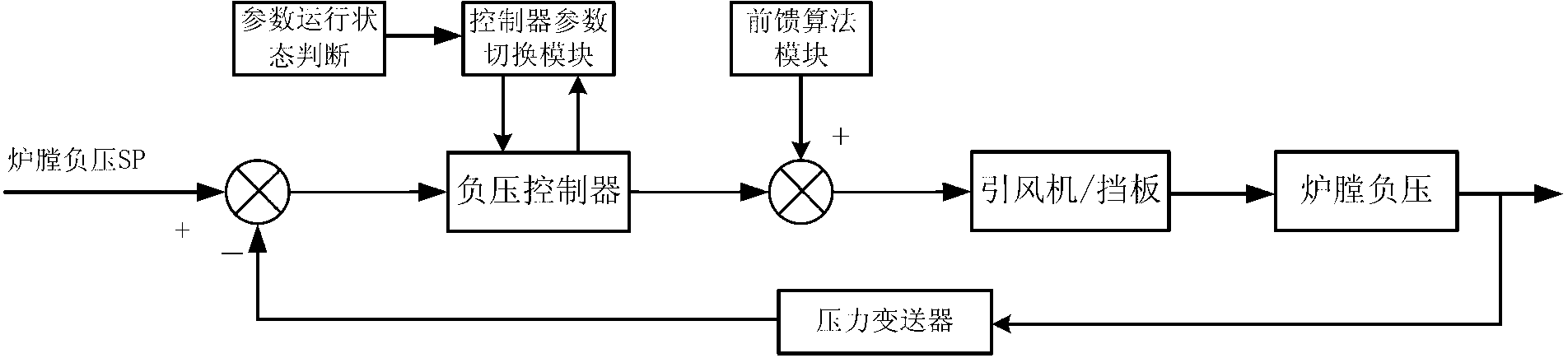

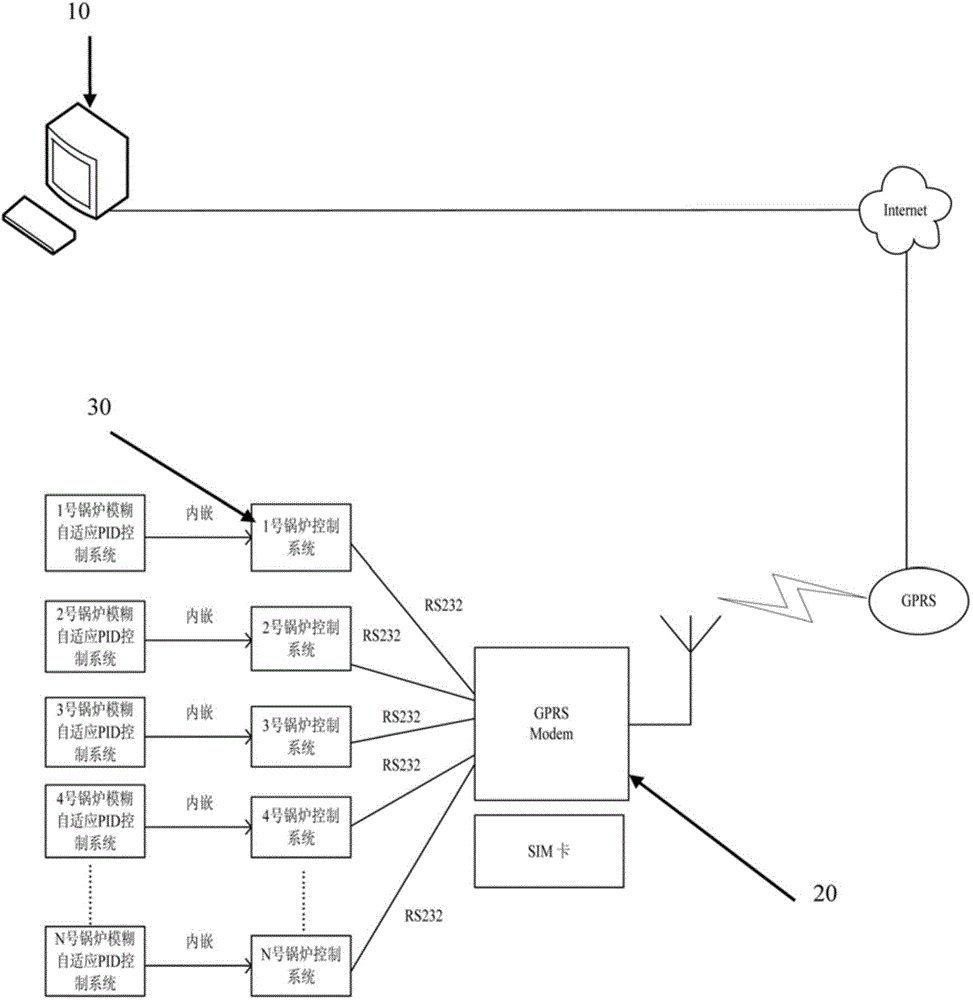

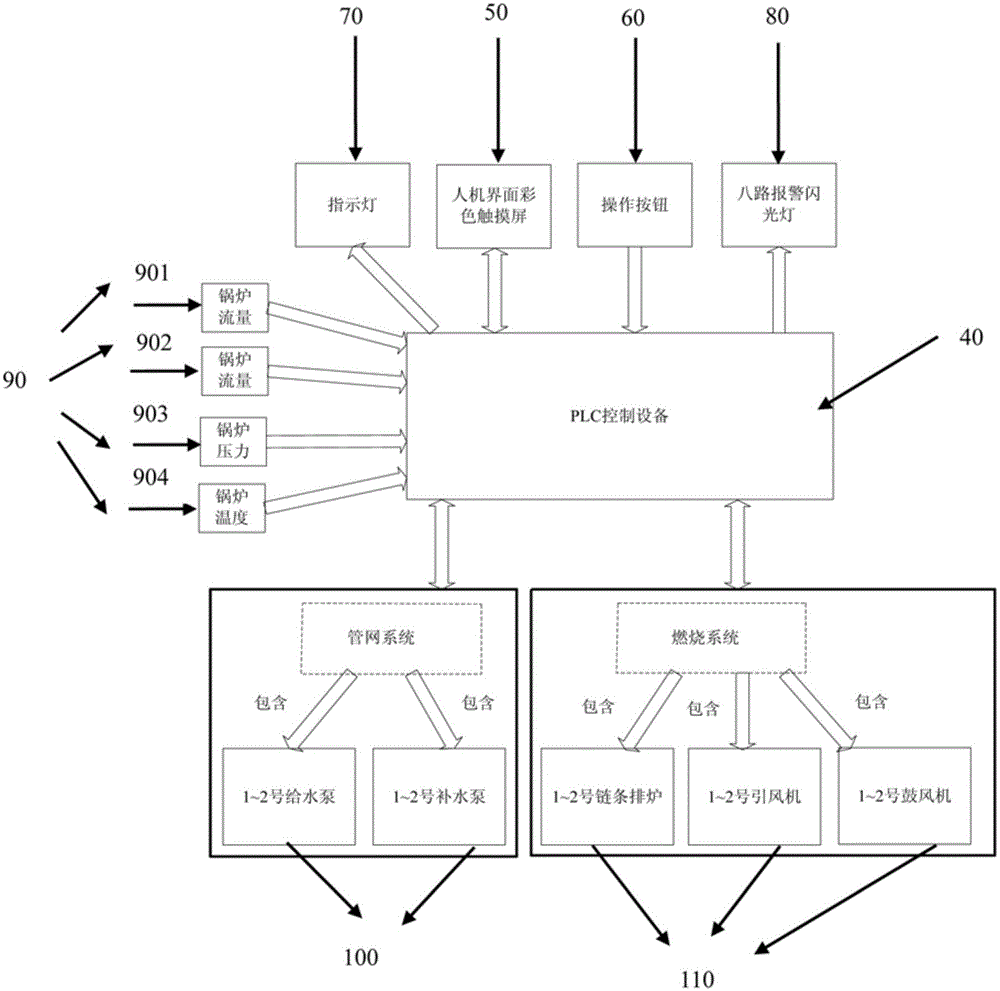

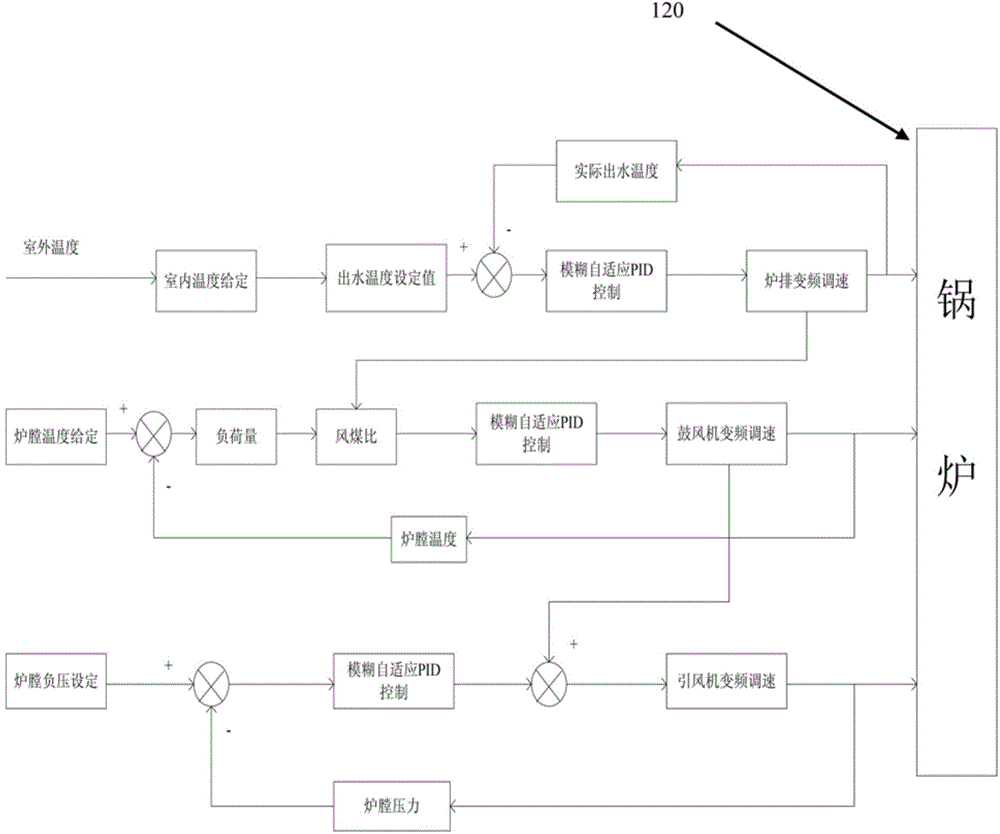

Boiler heating intelligent control system and method based on internet of things

ActiveCN104165412AReduce labor intensityImprove securityBoiler controlSpace heating and ventilation detailsHuman–machine interfaceThe Internet

The invention provides a boiler heating intelligent control system and method based on internet of things. The boiler heating intelligent control system comprises an internet of things remote monitoring terminal, a remote network communication connection device and a boiler control system. According to the boiler heating intelligent control system, an advanced internet of things mobile terminal is combined with a PLC industrial automatic technique, remote communication ability is achieved, and boilers in different places can be monitored uniformly. When no person is on site, the operation states of the boilers can be monitored in real time through the internet of things remote monitoring terminal, and production efficiency and safety of the boilers are improved; the operation state of a heating system is monitored through a man-machine interface colored touch screen, and automatic fault emergent processing capacity integrating interlocking and warning is achieved; a fuzzy self-adaptation PID controller is guided according to outdoor temperature, water return temperature and other actual work conditions, optimal frequency control is carried out on fire grate rotation speed, rotation speeds of a water feeding pump and a make-up pump and rotation speeds of an air blower and an induced draft fan, and the boiler heating system can operate intelligently, efficiently, stably and reliably.

Owner:SHENYANG SHUNYI TECH

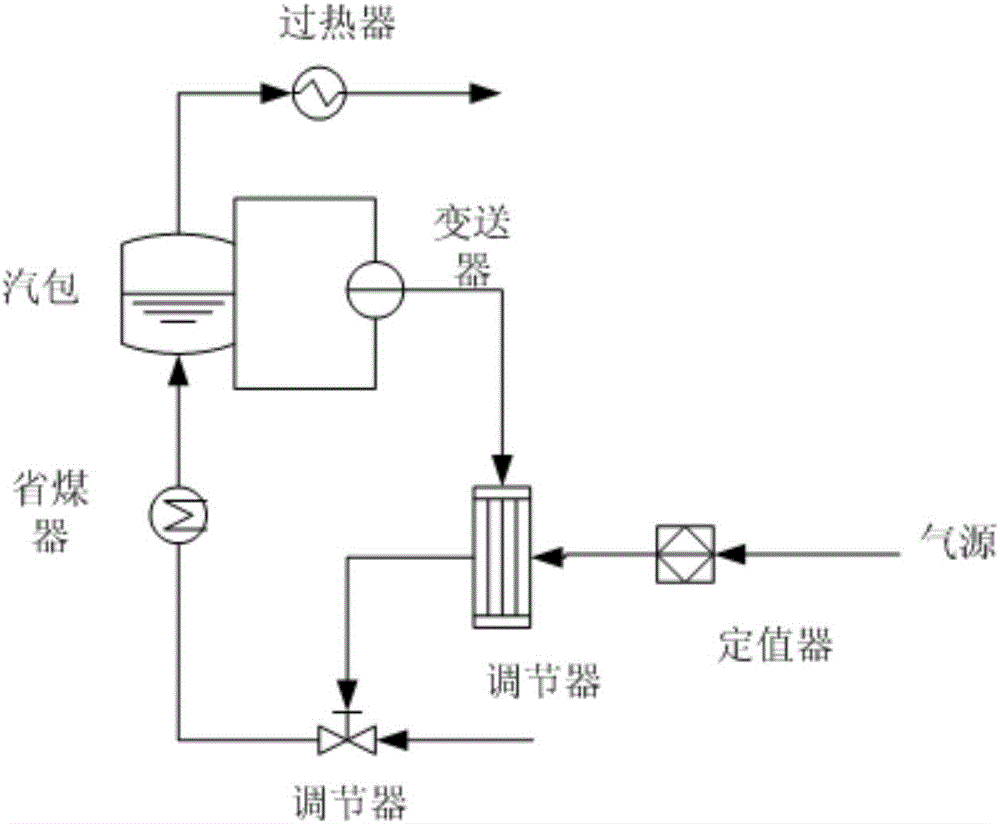

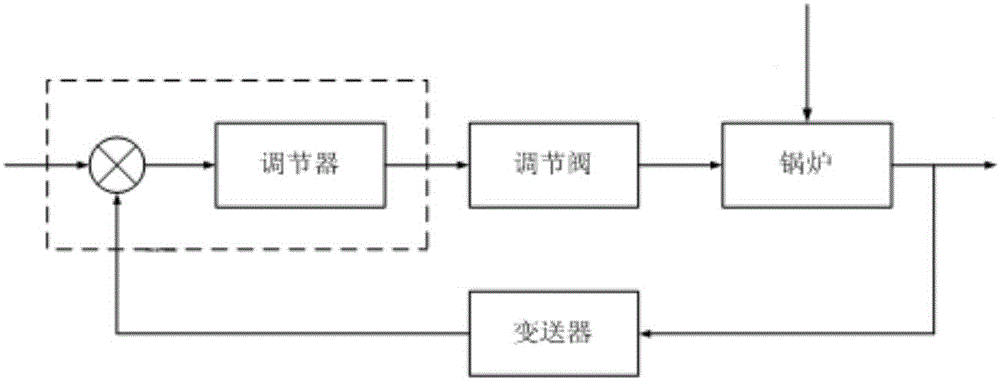

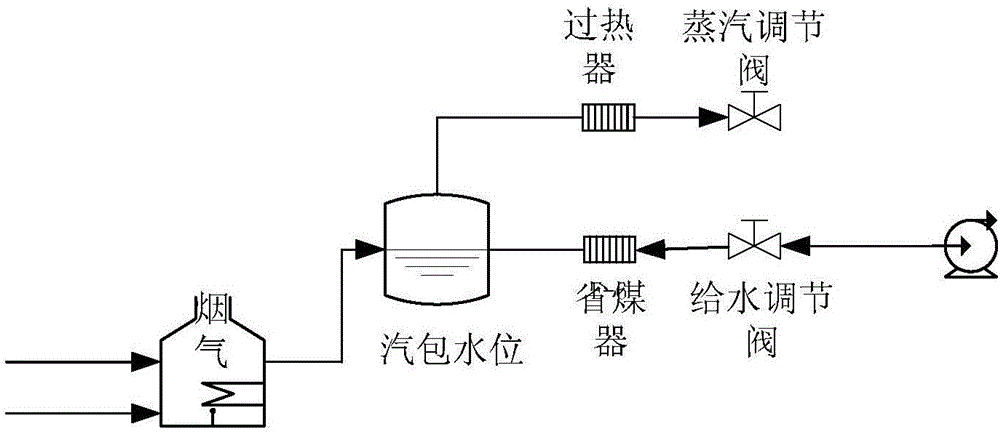

Liquid level control system and method of boiler

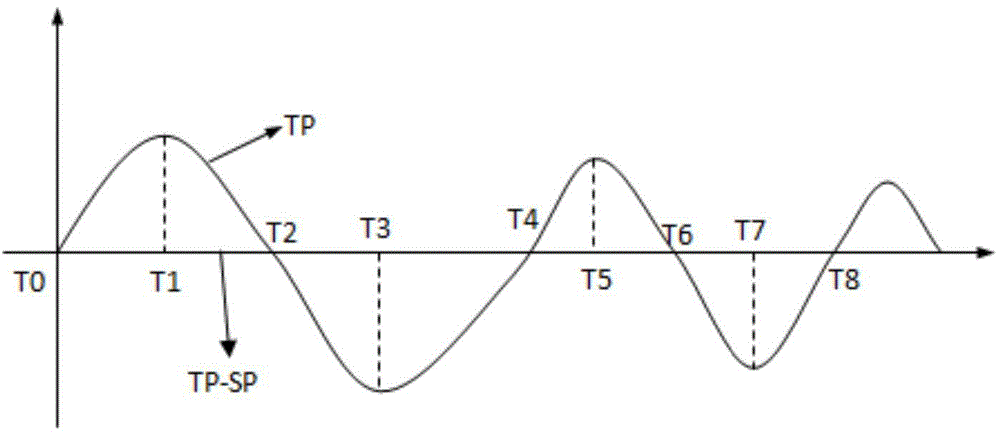

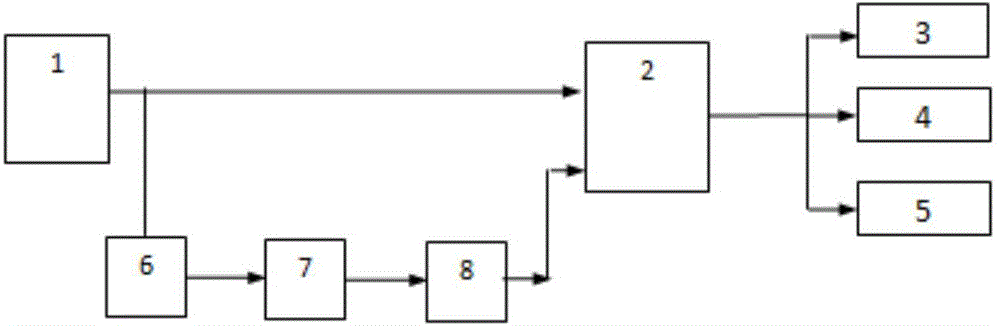

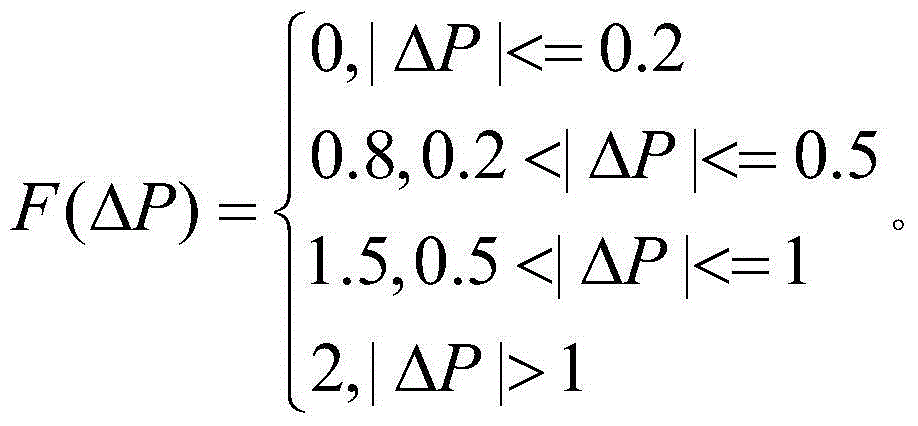

ActiveCN106642067AReal-time adjustment of running errorImprove adaptabilitySteam generation using hot heat carriersWater feed controlFuzzy control systemTime signal

The invention provides a liquid level control system and method of a boiler. The method comprises the steps that a real-time signal transmitted by a liquid level transmitter of the boiler is compared with a preset signal, and the operation errors of the boiler are determined; and the operation errors are subjected to repeated analog-digital conversion through a fuzzy controller so that the output quantity can be obtained, and the output quantity is used for controlling the opening degree of an adjusting valve so as to make sure that the liquid level of the boiler is within the preset range. Due to the fact that the real-time signal transmitted and detected by the transmitter is subjected to repeated fuzzy conversion through the fuzzy controller, the operation errors in the boilers can be adjusted in real time, the adaptability of the boiler control system to dynamic environment is improved, and the control effect of the boiler system is improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

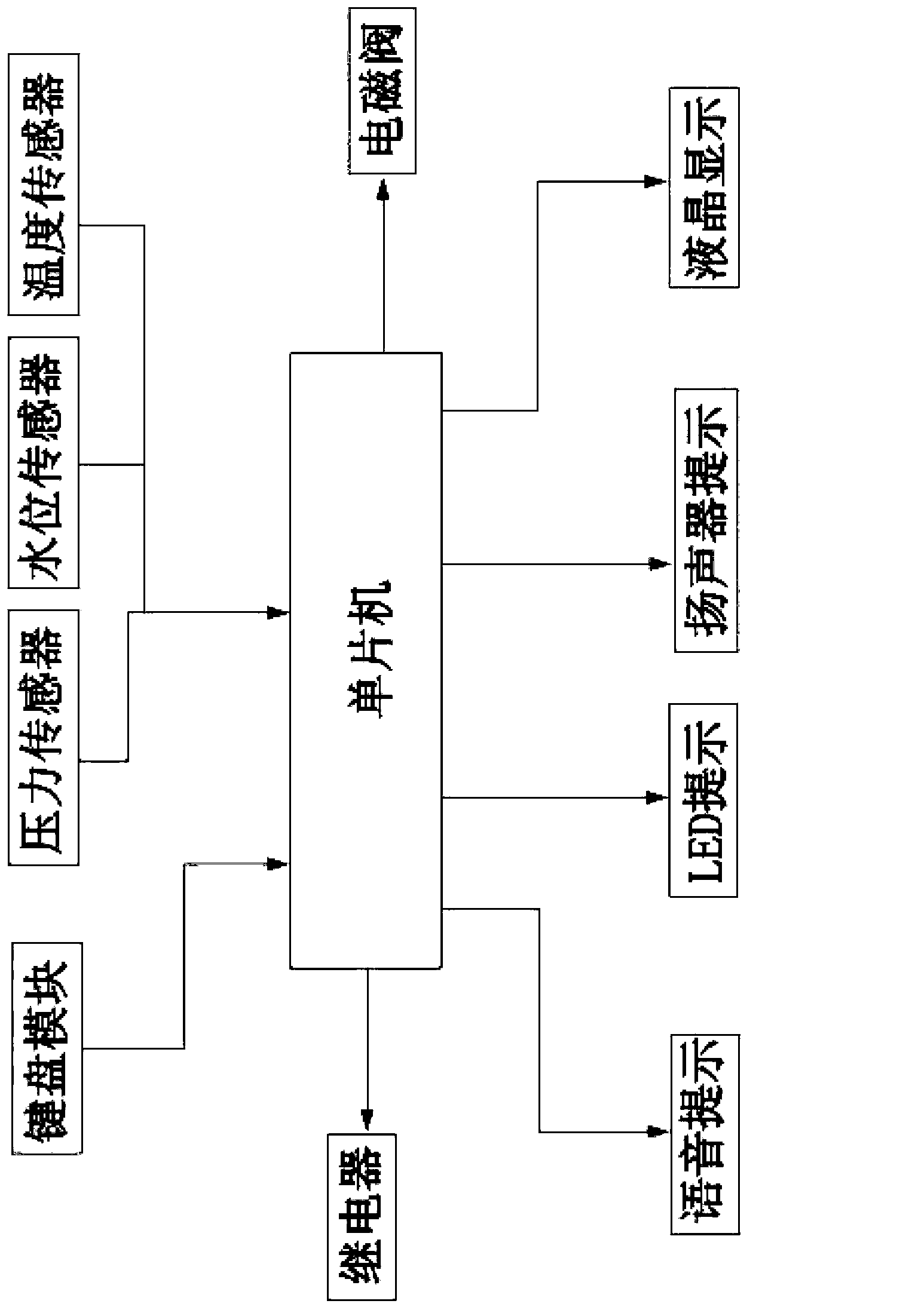

Intelligent boiler control system

InactiveCN103017134AImprove reliabilityImprove securityFluid heatersBoiler controlMicrocontrollerEngineering

The invention discloses an intelligent boiler control system, which comprises a controller, a keyboard module, a detection module, a failure processing module and an alarm prompting module, wherein the output end of the controller is further connected with a liquid crystal display. On the basis of a singlechip technology, a temperature sensor, a pressure sensor and a water level sensor are fully used for monitoring the temperature, pressure and water level of a boiler; when the boiler is in an unsafe state according to detection, the failure processing module is started automatically; an electromagnetic valve is used for controlling water feeding, a relay is used for controlling a blower, and the risks of water depletion, overpressure and over-temperature of the boiler are prompted and alarmed through voice prompts, LED (Light-Emitting Diode) prompts and a loudspeaker, so that the running reliability and safety of the boiler are effectively improved, the service life of the boiler is prolonged, and explosive incidents are reduced; and moreover, the intelligent boiler control system is low in production cost, and contributes to popularizing.

Owner:潘慧敏

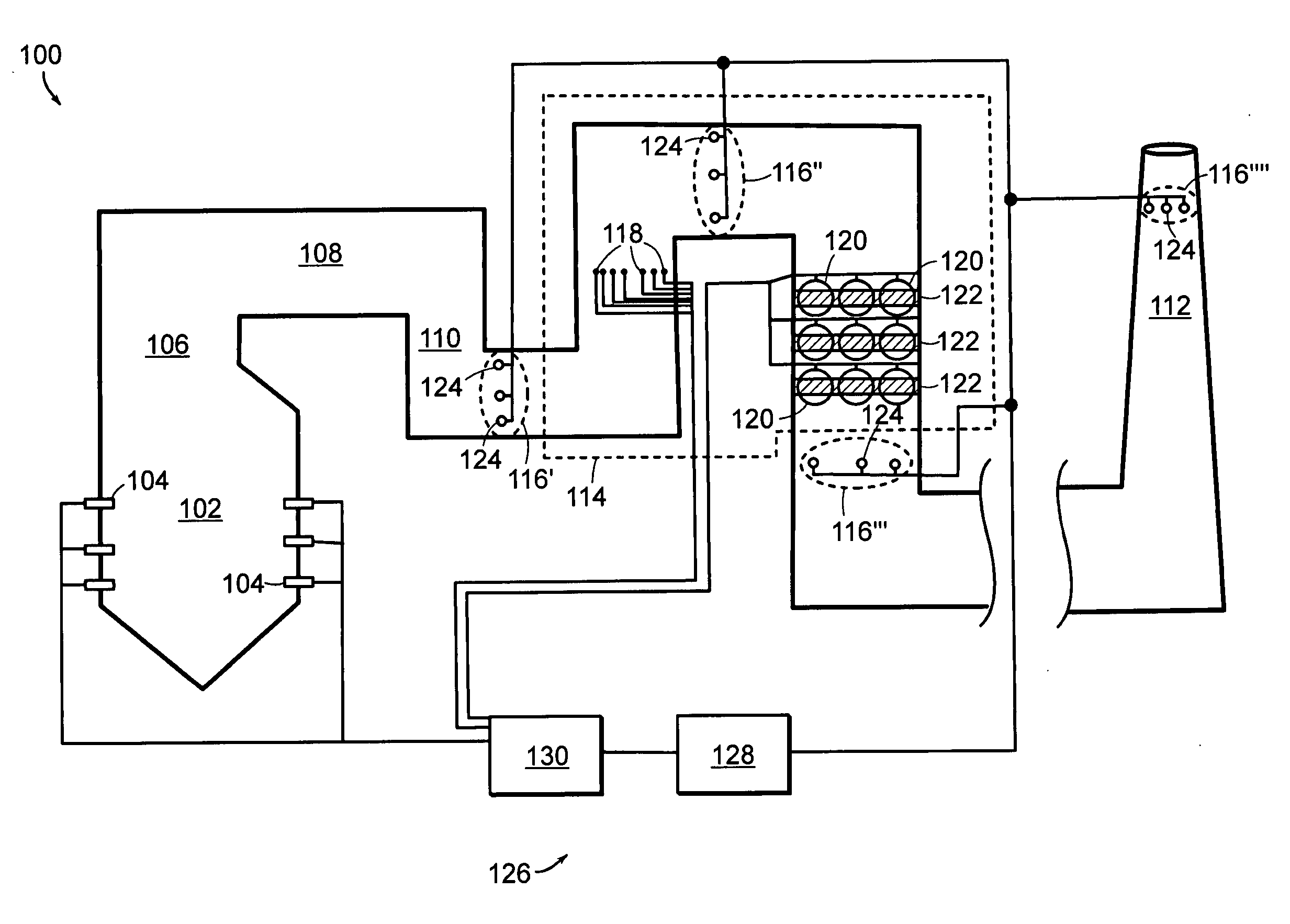

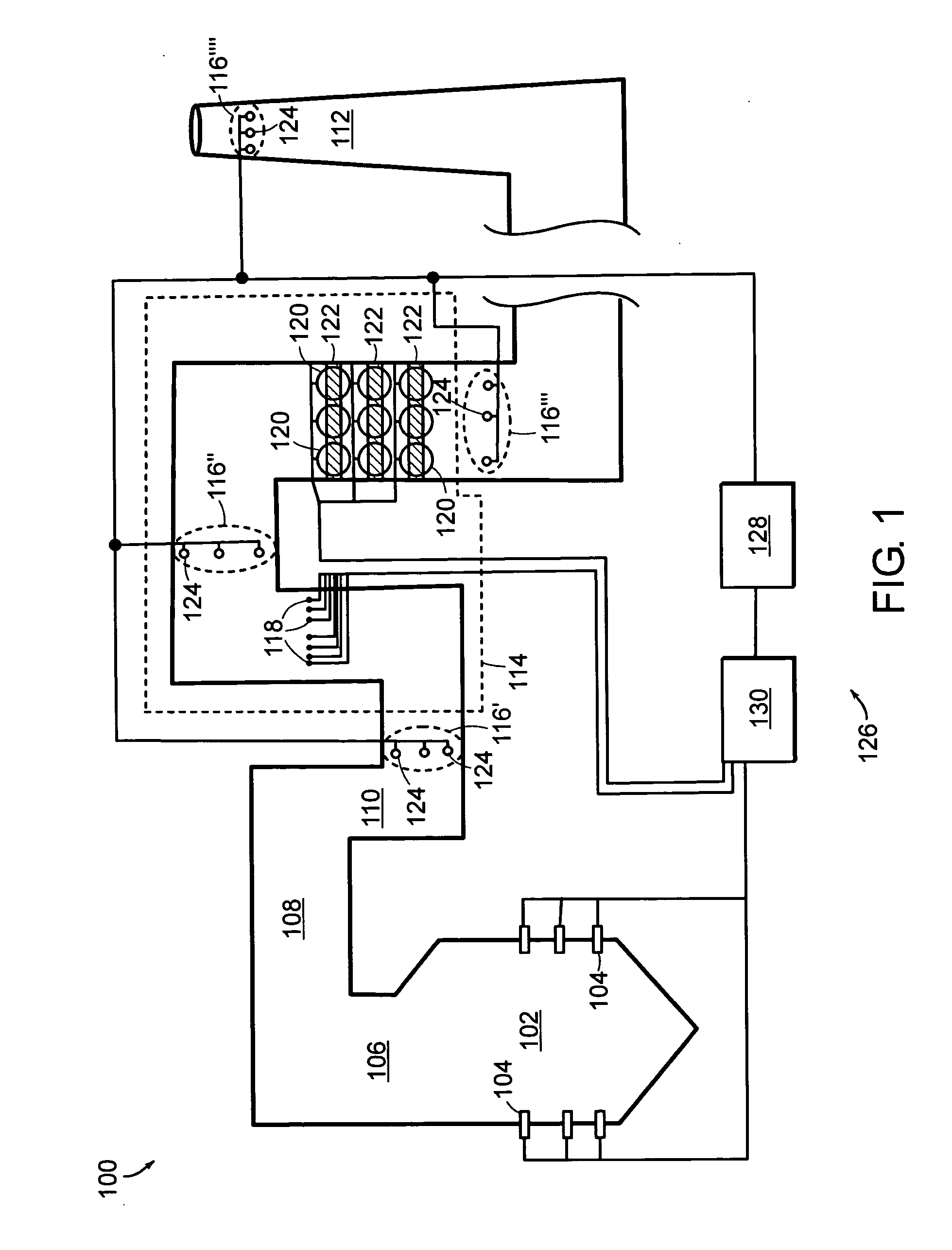

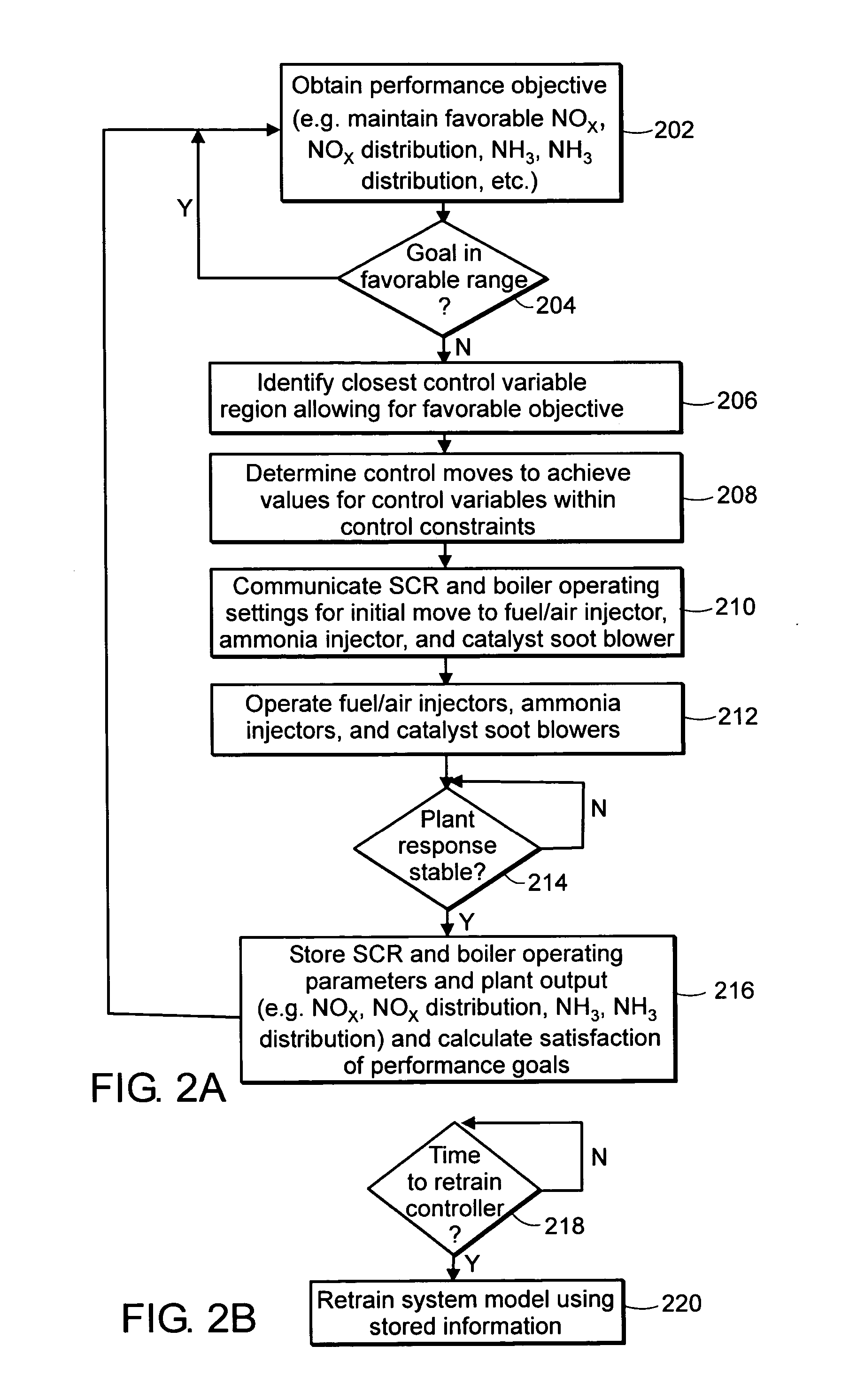

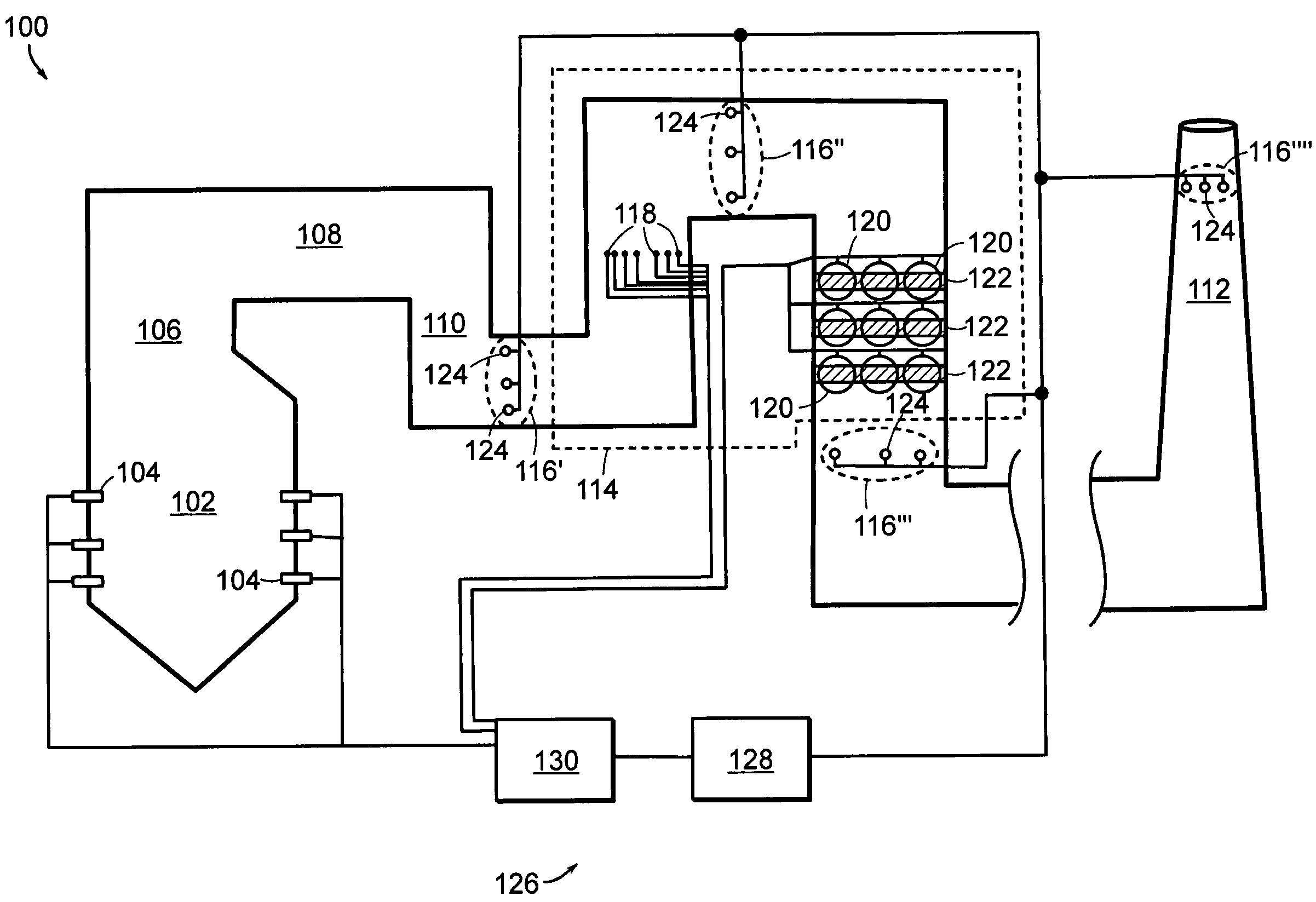

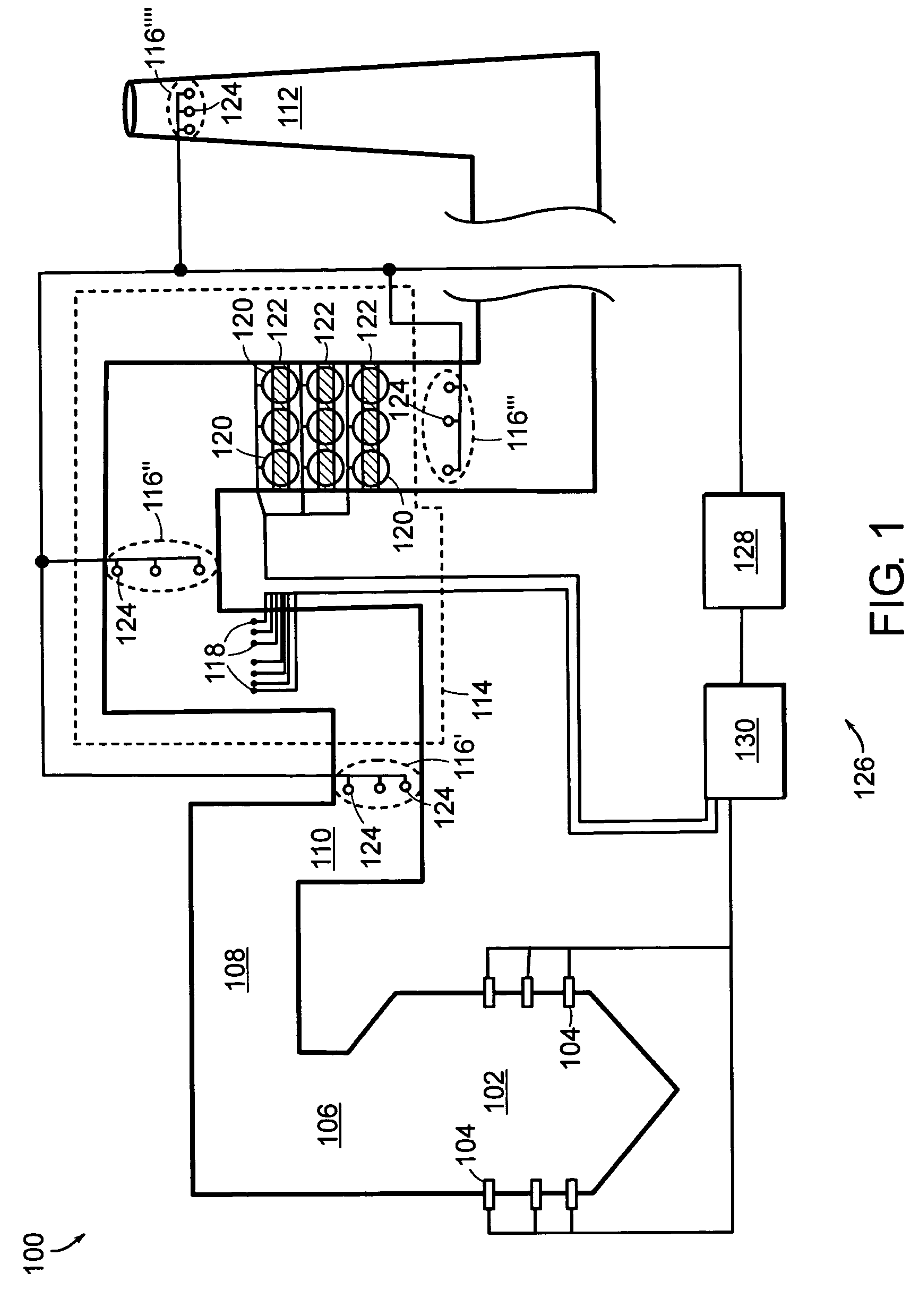

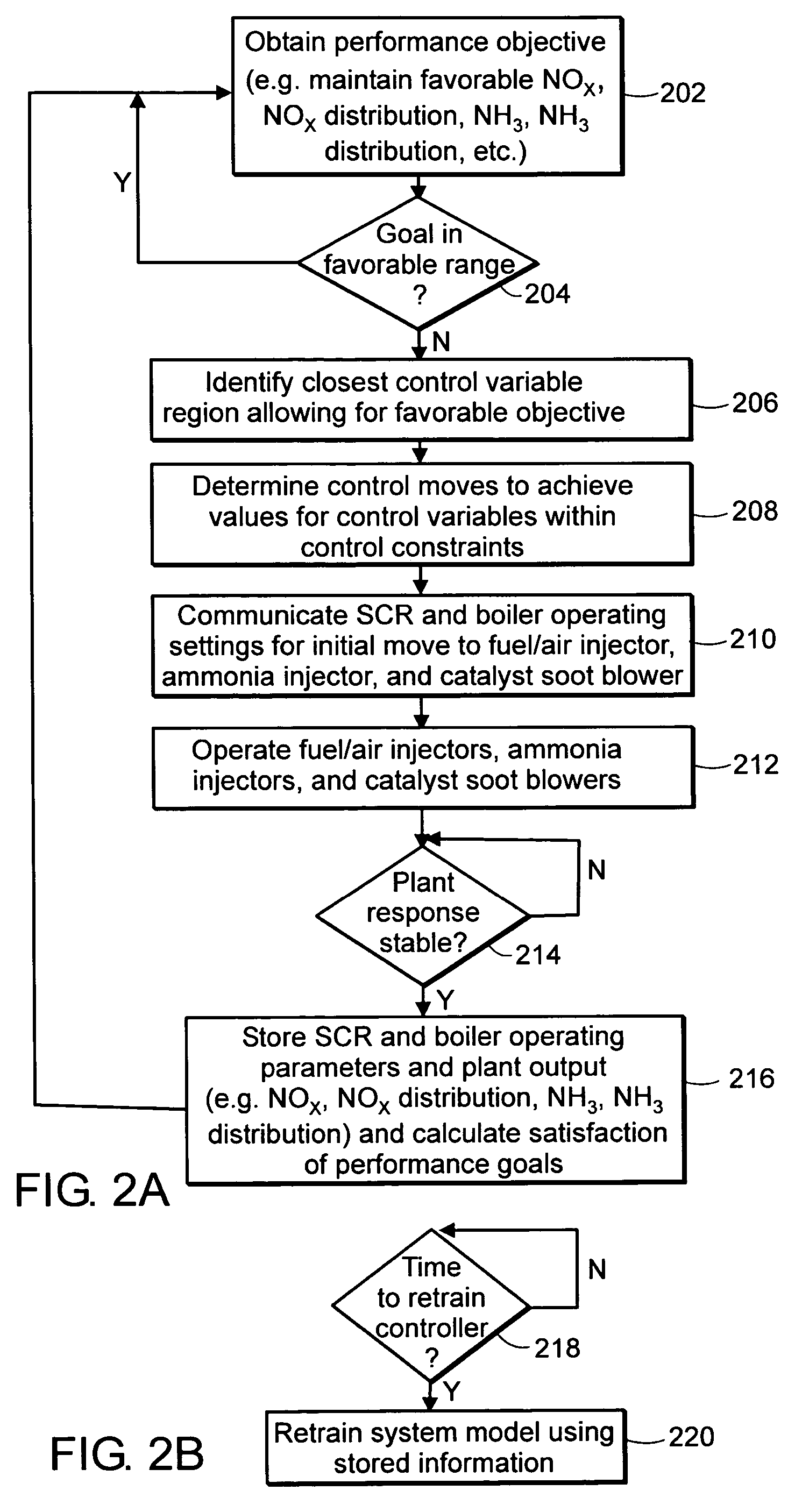

Method and system for SCR Optimization

ActiveUS20060042525A1Control performanceMechanical apparatusCombustion using liquid and pulverulent fuelData valueBoiler control

Methods and systems are provided for controlling SCR performance in a boiler. The boiler includes one or more generally cross sectional areas. Each cross sectional area can be characterized by one or more profiles of one or more conditions affecting SCR performance and be associated with one or more adjustable desired profiles of the one or more conditions during the operation of the boiler. The performance of the boiler can be characterized by boiler performance parameters. A system in accordance with one or more embodiments of the invention can include a controller input for receiving a performance goal for the boiler corresponding to at least one of the boiler performance parameters and for receiving data values corresponding to boiler control variables and to the boiler performance parameters. The boiler control variables include one or more current profiles of the one or more conditions. The system also includes a system model that relates one or more profiles of the one or more conditions in the boiler to the boiler performance parameters. The system also includes an indirect controller that determines one or more desired profiles of the one or more conditions to satisfy the performance goal for the boiler. The indirect controller uses the system model, the received data values and the received performance goal to determine the one or more desired profiles of the one or more conditions. The system model also includes a controller output that outputs the one or more desired profiles of the one or more conditions.

Owner:GENERAL ELECTRIC CO

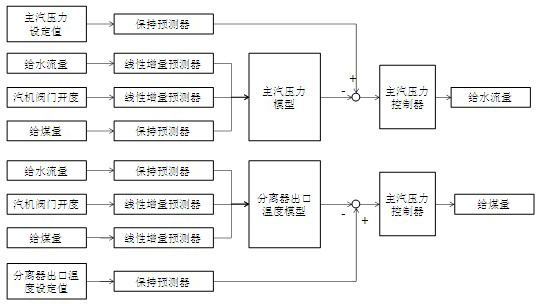

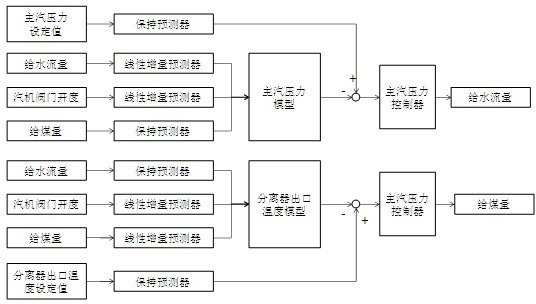

Fossil power plant coordination control method based on multi-parameter prediction

InactiveCN102608911AReduce thermal stress changesFast temperature responseControllers with particular characteristicsResponse processTemperature control

The invention discloses a fossil power plant coordination control method based on multi-parameter prediction. Aiming at the characteristics that a boiler controlled object is lagged, slow in response process and the like, feedwater flow, coal supply quantity and steam turbine valve opening are estimated reasonably, deviation of main steam pressure and separator outlet temperature is predicted, and a main steam pressure control loop and a separator outlet temperature control loop are respectively formed, and are coordinated with a load control loop so as to form a fossil power plant coordination control system. Control quality of the fossil power plant coordination control system is effectively improved, main steam pressure fluctuation during load change is suppressed effectively while the load change is responded fast, deviation between main steam pressure and a setting value is reduced, the separator outlet temperature fluctuation is suppressed, and the situation that the separator outlet temperature is over high is reduced. Besides, the stability of a boiler control system and the operation efficiency of a unit are improved.

Owner:SOUTHEAST UNIV

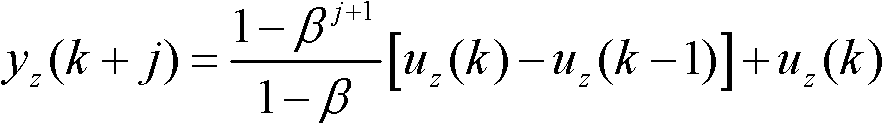

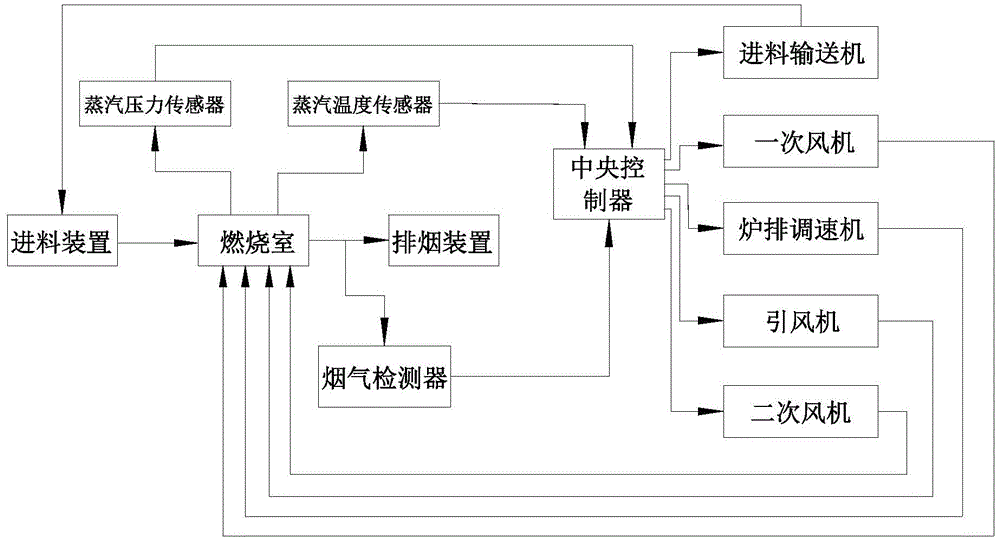

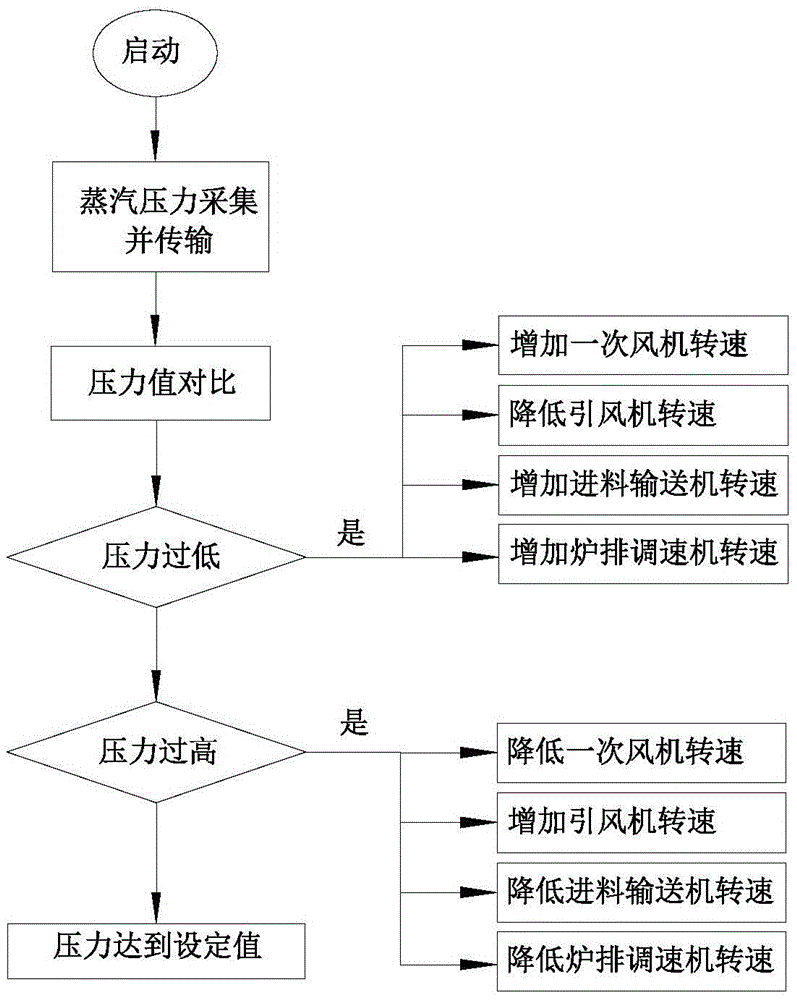

Boiler automatic control system and method

InactiveCN105465822ARealize multiple controlEfficient combustion stateFuel supply regulationSmoke detectorsAutomatic control

The invention belongs to the technical field of boiler control systems, and discloses a boiler automatic control system and method. The control system comprises a feeding device, a combustion chamber, a smoke exhaust device, a steam pressure sensor, a steam temperature sensor, a smoke detector, a central control unit, a feeding conveyor, an air blower, a grate speed adjusting machine and an induced draft fan. The control method comprises the steps of feeding, pressure and temperature detecting, smoke detecting and combustion control. According to the boiler automatic control system and the automatic control method, detection of smoke is introduced into the control system, multiple control over feeding and combusting of fuel can be achieved, generation of atmospheric pollutants is effectively reduced, and the fuel can be in the efficient combustion state.

Owner:SHENZHEN YTXNY ENVIRONMENTAL PROTECTION & TECH CO LTD

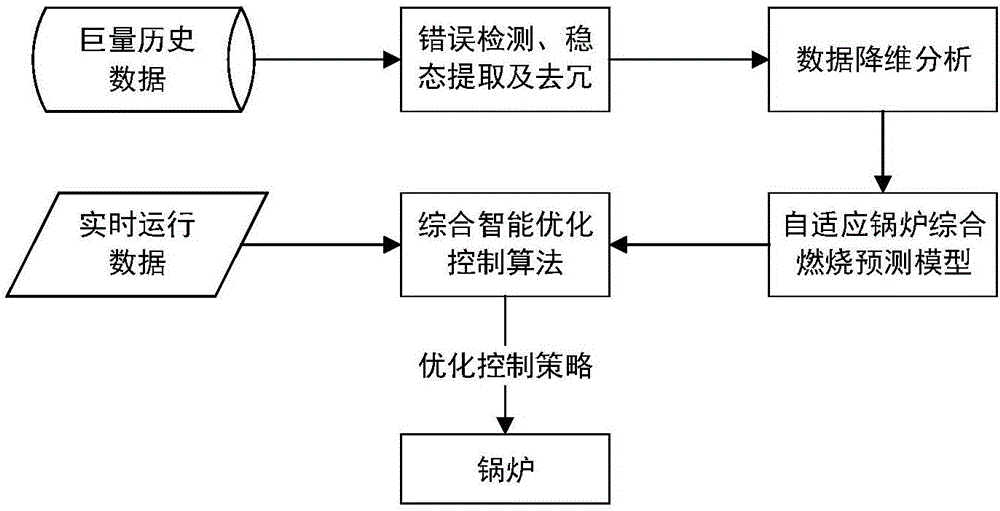

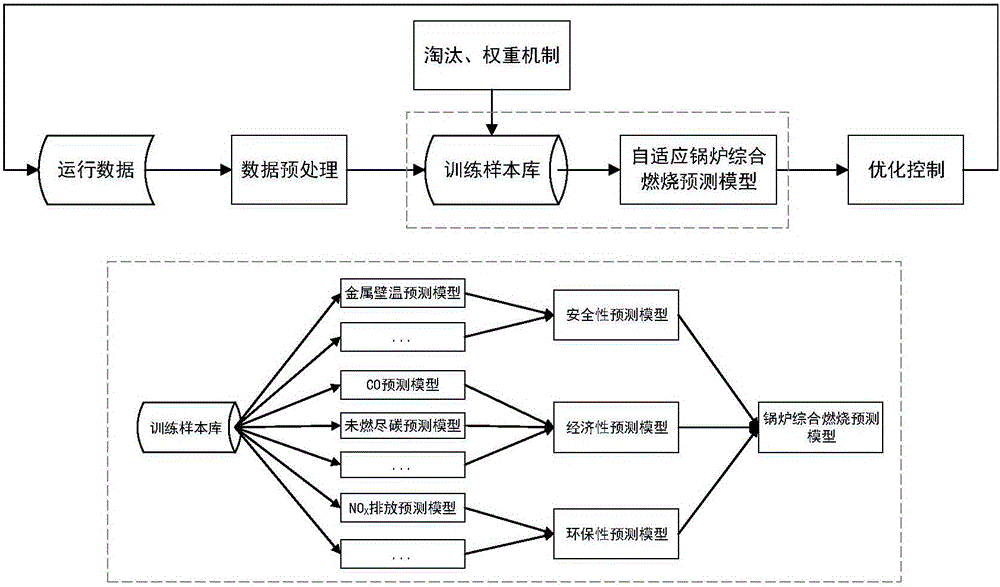

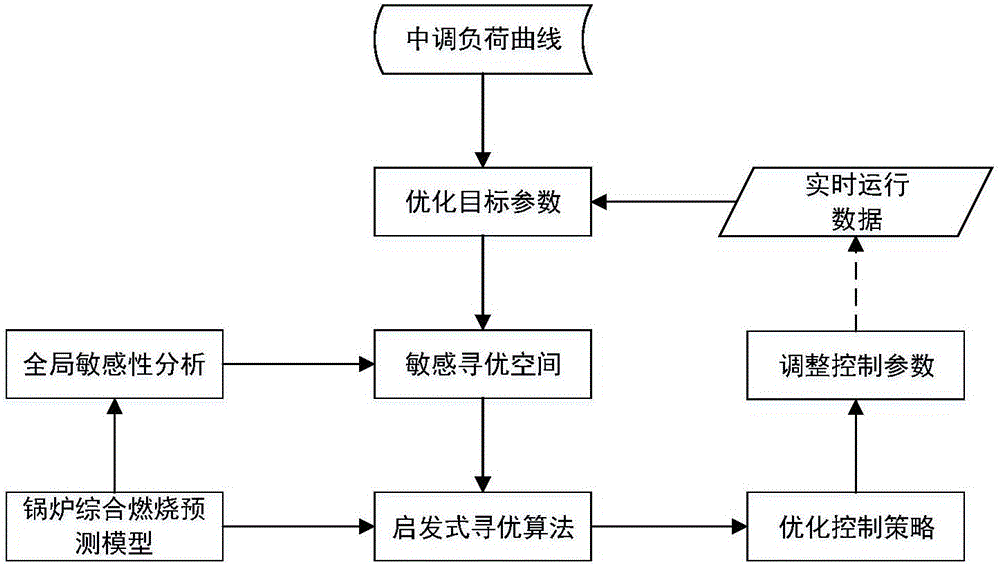

Power plant boiler combustion intelligent control method

ActiveCN105974793ALower acquisition costsImprove generalization abilityAdaptive controlCombustionComputer science

The invention discloses a power plant boiler combustion intelligent control method. The method comprises the following steps: (1) historical operation data are fused; (2) the historical operation data after fusion are traversed, error detection is carried out, error data are eliminated, steady-state operation condition data are screened, certain operation condition data in the steady-state operation condition data are removed, and the remaining steady-state operation condition data serve as training samples; (3) a training sample library is built, coal quality characteristic parameters and boiler control parameters serve as input parameters, combustion effect parameters serve as output parameters, and a boiler integrated combustion prediction model is built; and (4) global sensitivity analysis is carried out on the boiler combustion effect parameters, sensitive boiler control parameters in the boiler combustion effect parameters and a sensitive interval are obtained, a heuristic optimization algorithm is then adopted to realize optimization of the boiler control parameters, and thus, intelligent optimization control on the boiler is realized. Modeling is carried out based on the rich historical operation data of the power plant boiler, and the practicability is good.

Owner:HUAZHONG UNIV OF SCI & TECH

Electric boiler control system

Owner:COHEN KLOD

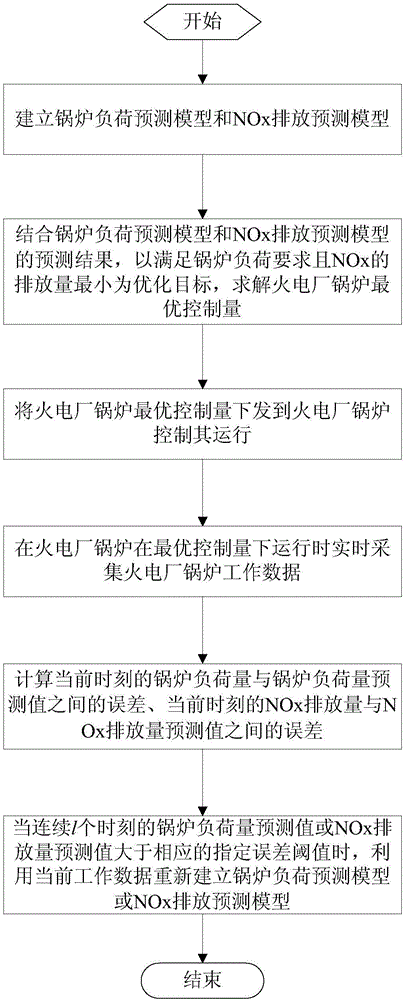

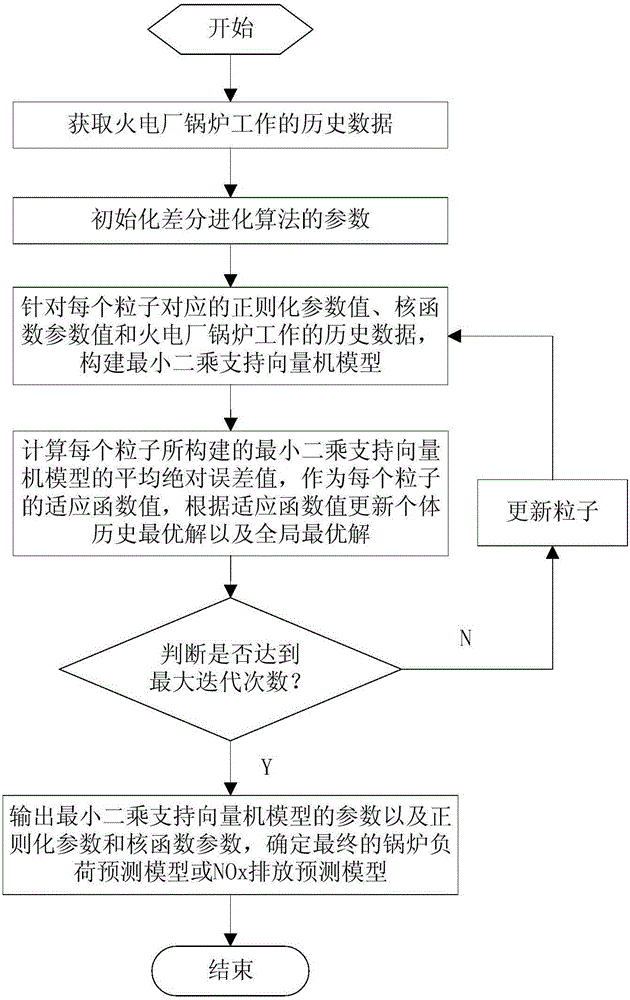

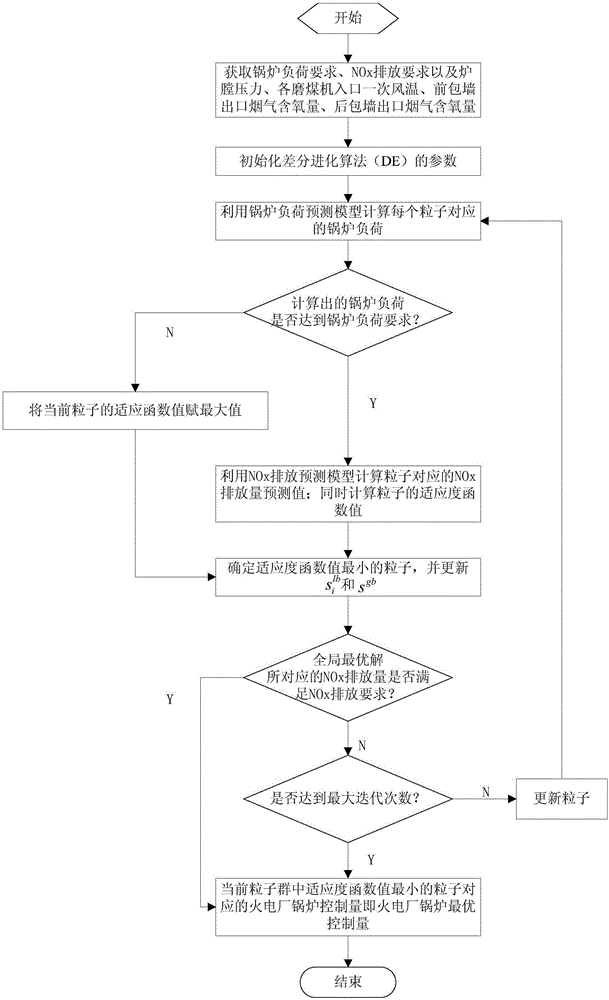

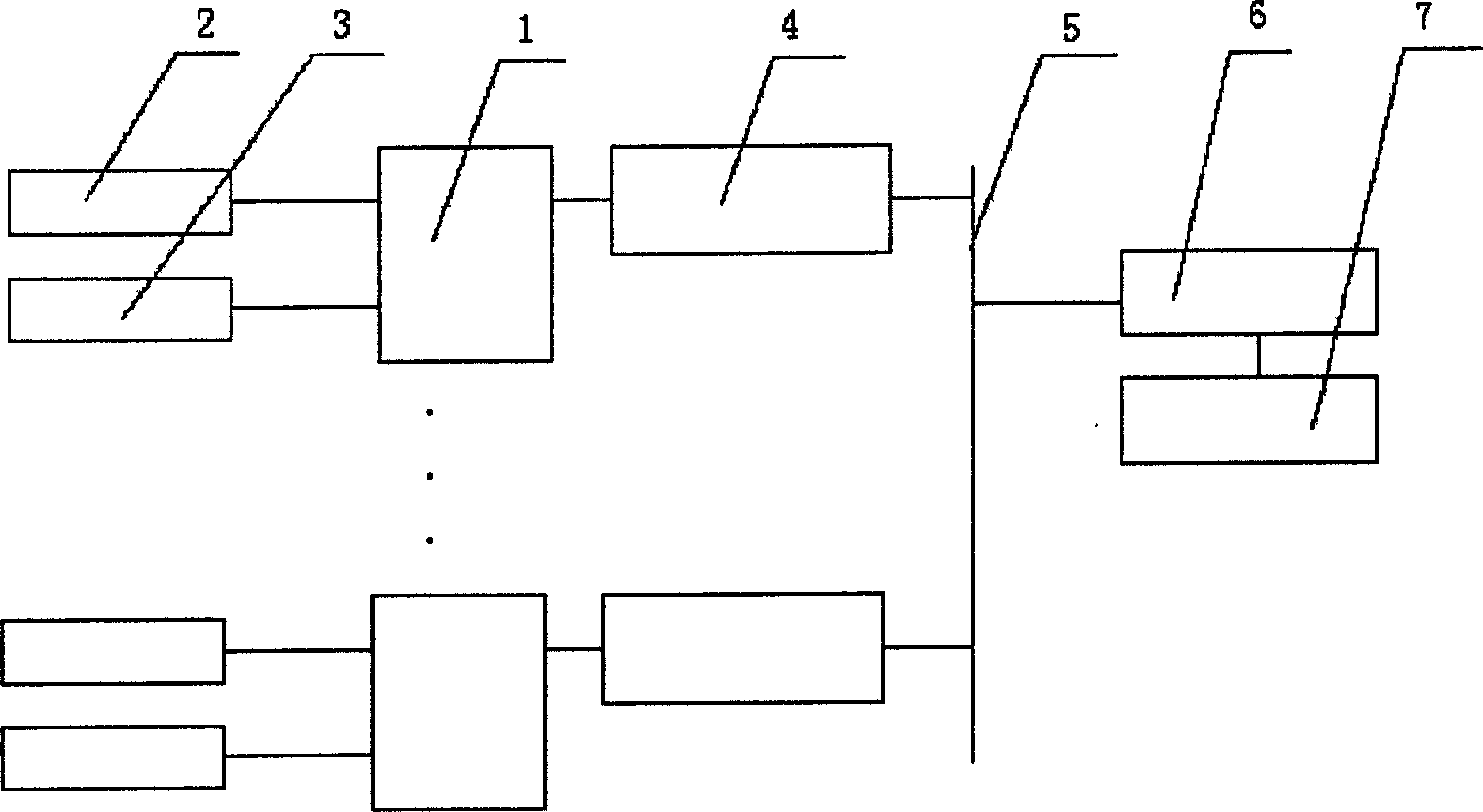

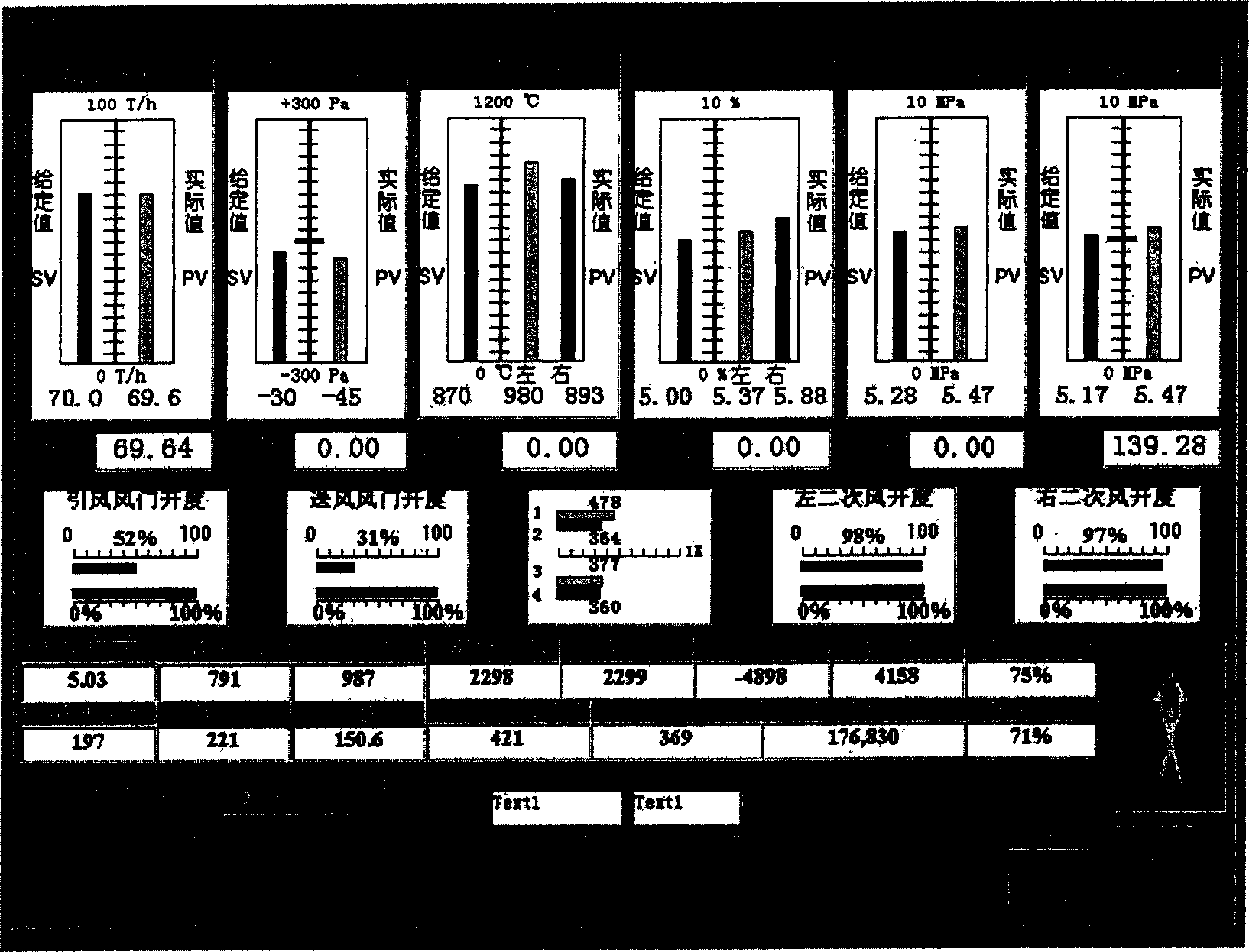

Thermal power plant boiler NOx emission control method under variable-load working conditions

ActiveCN106500128AEmission reductionMeet production requirementsCombustion regulationLoad forecastingEngineering

The invention provides a thermal power plant boiler NOx emission control method under variable-load working conditions. The method comprises the steps of (1) establishing a boiler load prediction model and an NOx emission prediction model; (2) solving the optimum control quantity of a thermal power plant boiler according to prediction results of the boiler load prediction model and the NOx emission prediction model in order to meet the requirement for boiler load and achieve an optimized target of minimizing NOx emissions; and (3) issuing the optimum control quantity of the thermal power plant boiler to the thermal power plant boiler so as to control operation of the thermal power plant boiler. In order to meet the requirements for low NOx emissions of a thermal power plant and control operation parameters reasonably, the control parameters of the minimum NOx emissions can be obtained while the thermal power plant boiler load is guaranteed, so that the power generation efficiency is improved, NOx emissions are reduced, and the production requirements are met.

Owner:NORTHEAST DIANLI UNIVERSITY

Intelligent control system for boiler and its multiple type of coal control method

InactiveCN1587820ACost-effective controlThe output data parameters are stable and accurateCombustion regulationAir volumeData acquisition

Boiler intelligent control system and its multi-kind coal controlling means belong to the computer management and control technical field, comprising data collection system, intelligent controller and warning system, industrial control computer,, data communication network, long-distance monitoring service, real-time Ethernet interface, data management system and different kinds of coal burning calculation and management system, especially real-time Ethernet interface and 'fixed furnace / movable furnace model have solved data transmission and multi- furnace teamwork problem; the multi-kind coal controlling means is, after entering the chosen kind of coal, the system will automatically choose its neuronic network or calculate the first wind rate, the second wind rate and fuel quantity with different load, build the initial neuronic network and learn online, realizing the boiler controlled automatically, changing and satisfying manufacturing parameter requirement also, adding long-distance monitoring service, increasing production management level.

Owner:DALIAN UNIV OF TECH

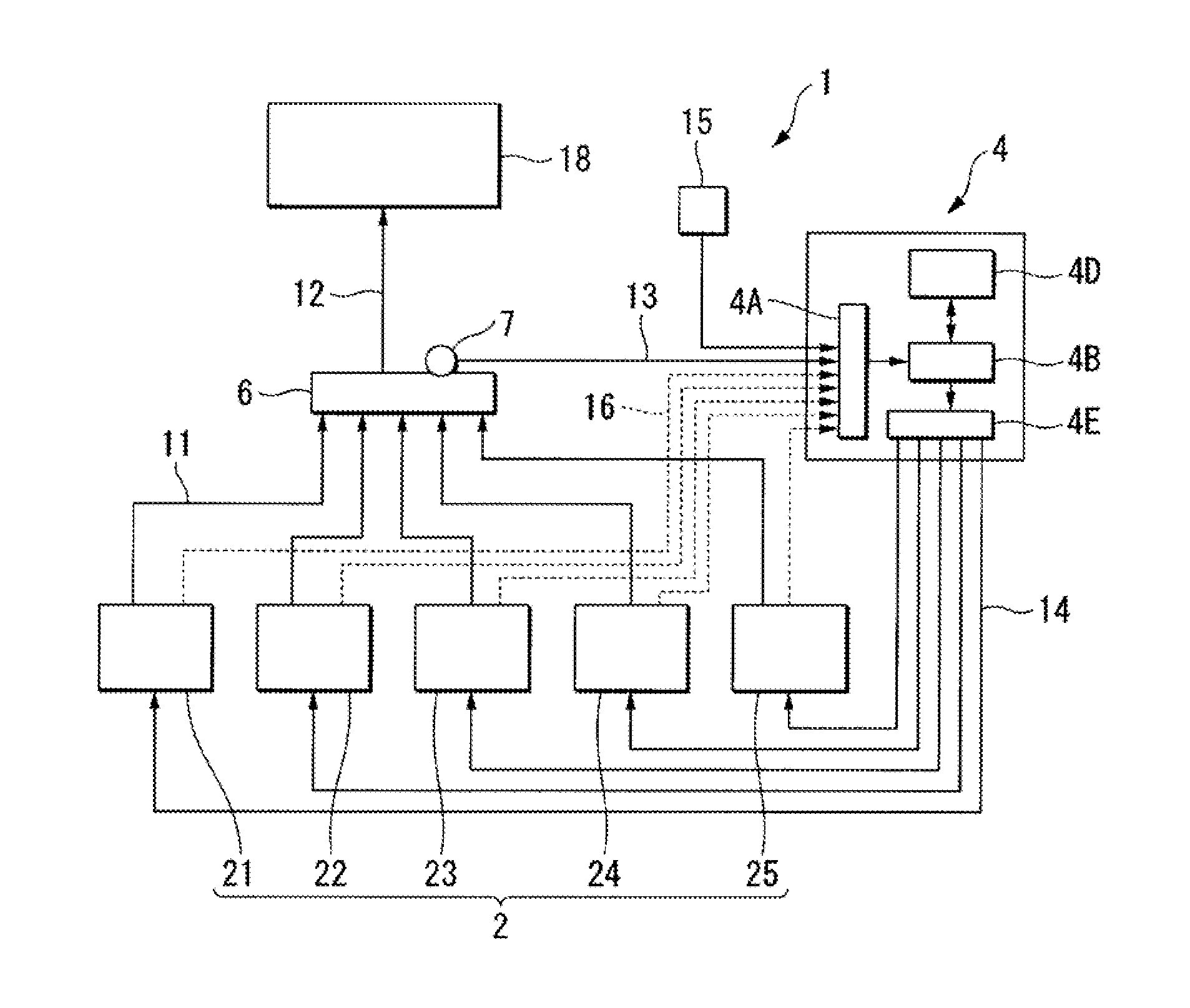

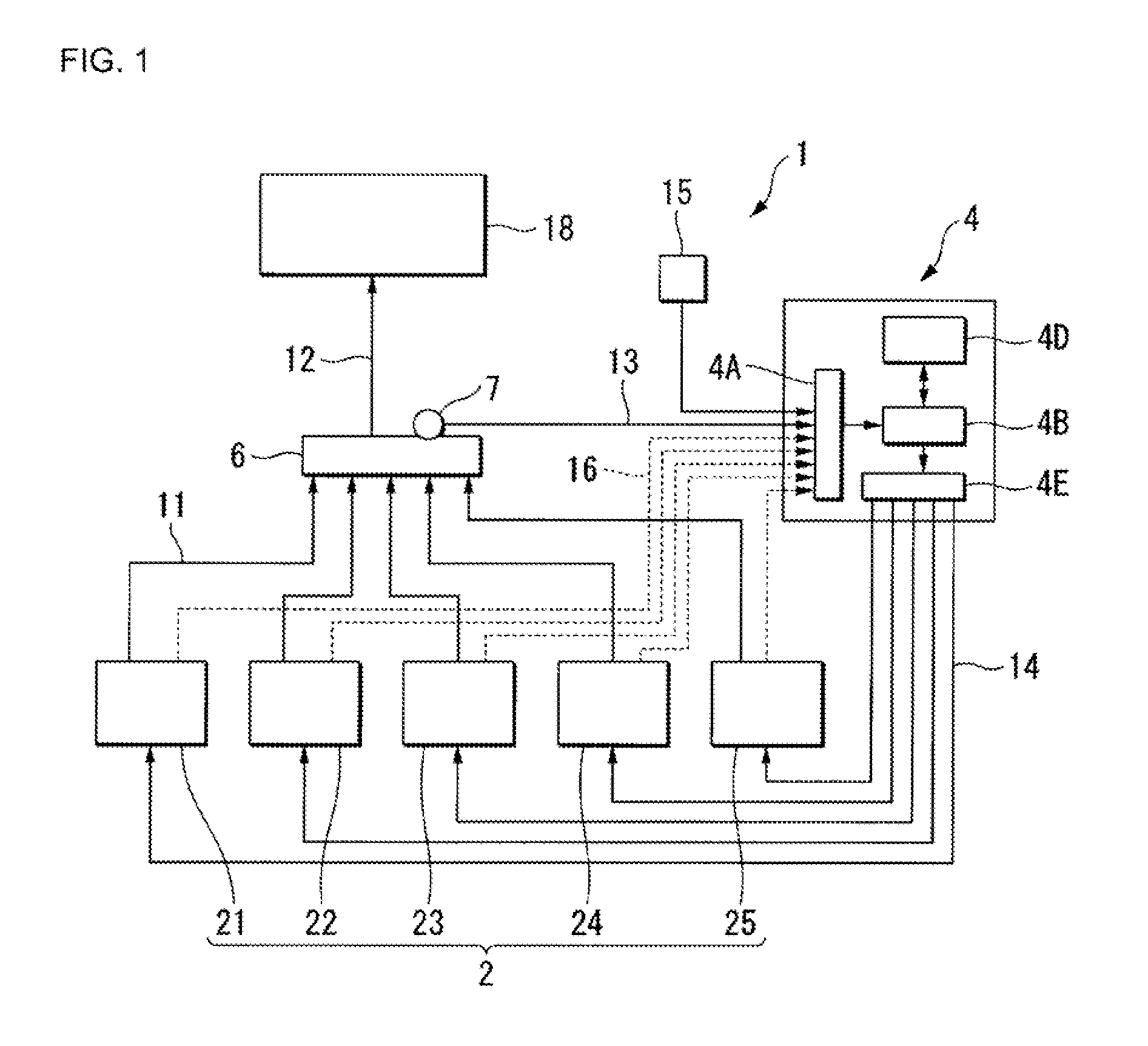

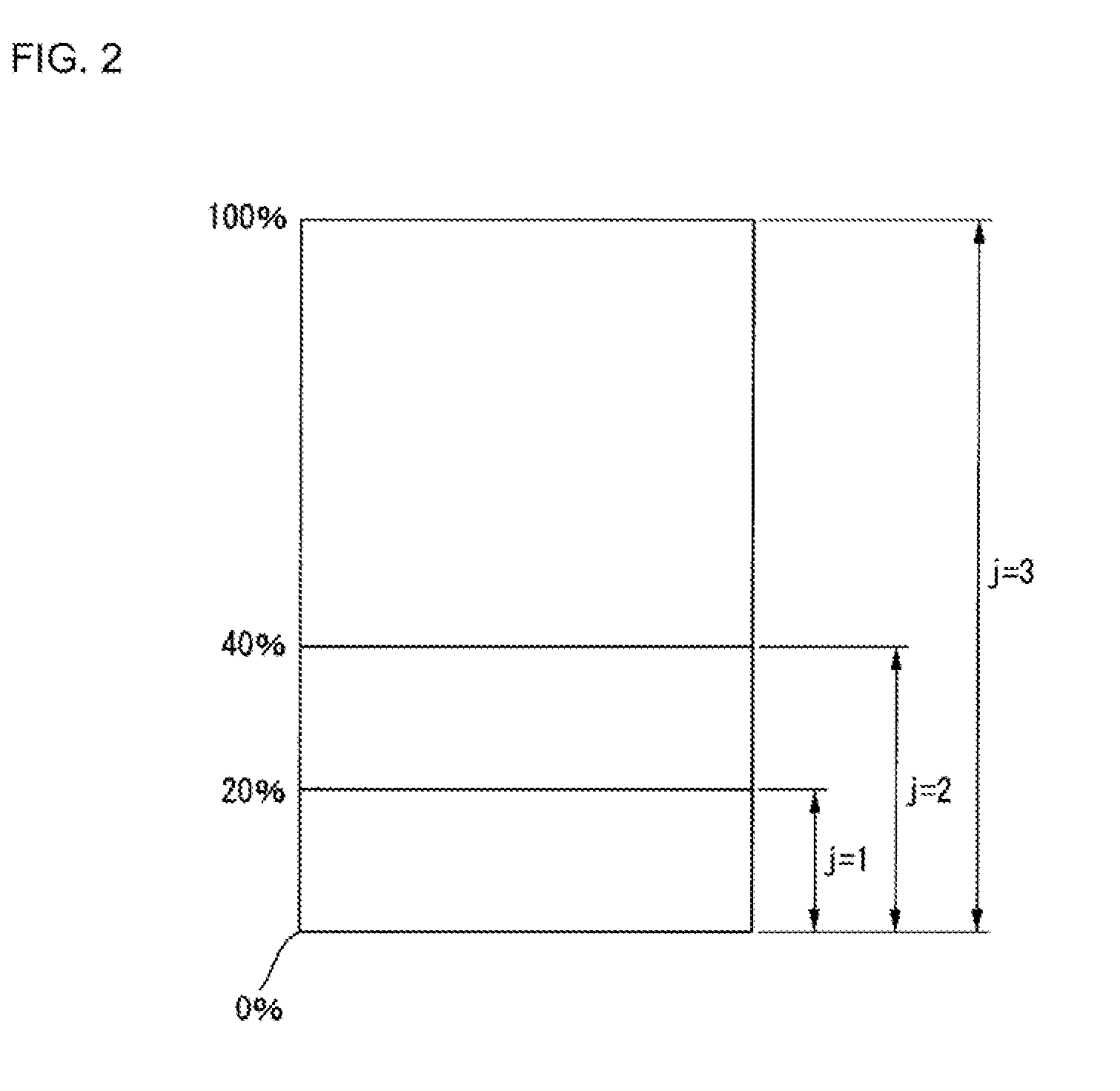

Control program, controller, and boiler system

ActiveUS20110162593A1Reduce necessityInhibit start-and-stop lossSampled-variable control systemsComputer controlControl subjectsCombustion

The present invention relates to a control program, a controller, and a boiler system that are related to a boiler group including a plurality of boilers controlled in combustion at stepwise combustion positions. It is well suitable, in a control program for conducting control on a boiler system that includes a boiler group having a plurality of boilers which can be controlled in combustion quantity at stepwise combustion positions and in which at least one of the combustion positions is assumed to be a high-efficiency combustion position and that is configured to be controlled in combustion based on an increase / decrease in desired loads, that in the case of increasing a quantity of combustion in the boiler group, after a high-efficiency combustion shift signal that makes the shift to the high-efficiency combustion position is output to all of the boilers subject to high-efficiency control by which control is conducted on the basis of combustion at the high-efficiency combustion position, a control signal may be output that makes the shift to a higher combustion position than the high-efficiency combustion positions for any one of the high-efficiency control subject boilers.

Owner:MIURA COMPANY LIMITED

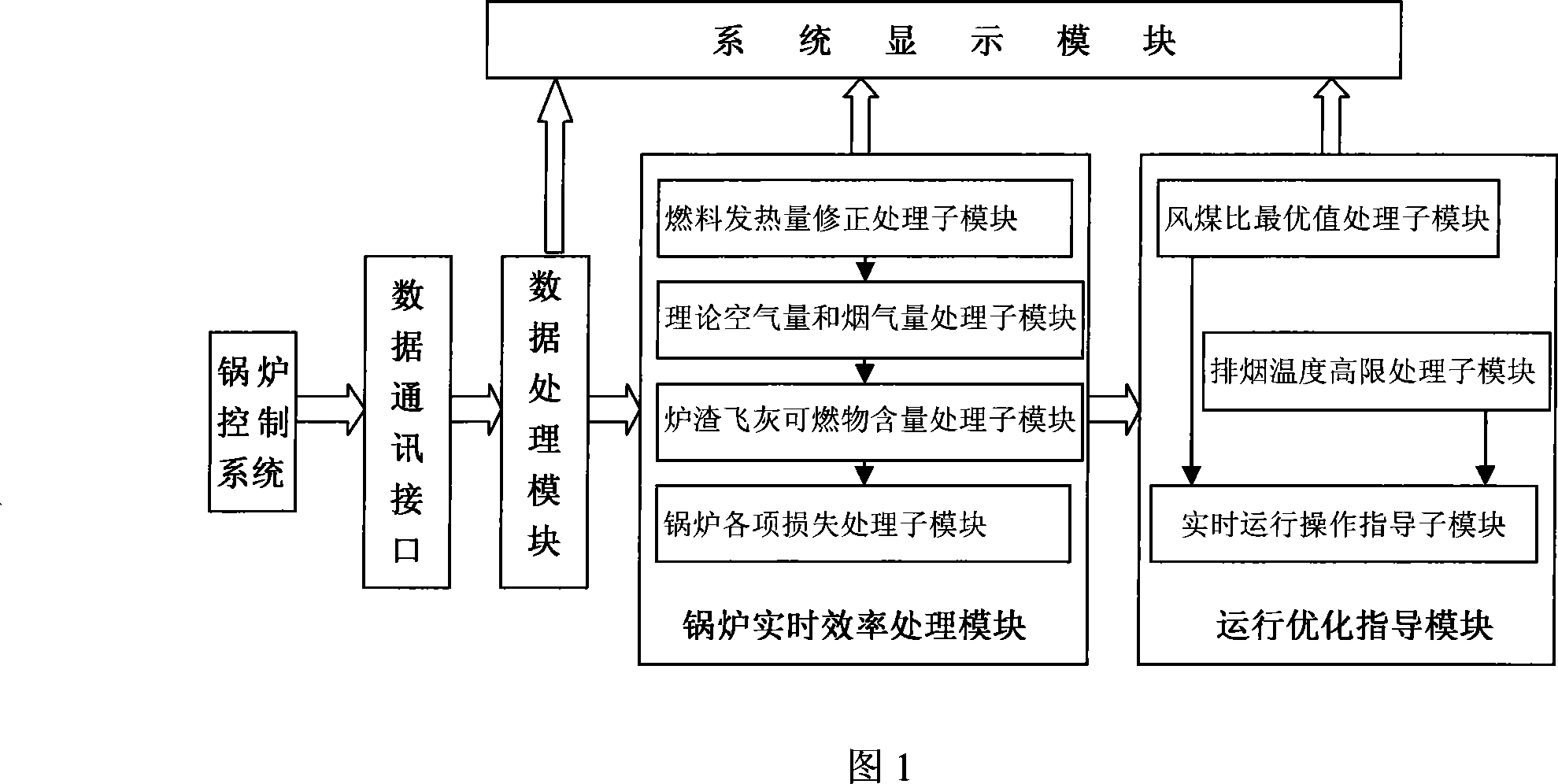

Optimizing and guiding system for coal-burned industrial boiler operation

A coal-fired industrial boiler operating optimizing and guiding system in the field of energy-saving technology is provided, which comprises: a data communicating interface, a data processing module, a system display module, a boiler real-time efficiency processing module and an operation optimize and guide module; wherein, the data communicating interface accepts real-time operating data from a boiler control system and transfers to the data processing module which can check and filter the data received; the boiler real-time efficiency processing module processes and achieves the heat lose of boiler smoke discharge and incomplete physical burning and boiler real-time efficiency and then transfers to the operating optimize and guide module and the system display module to compare the upper limit value with the lower limit value of real-time air coal and the best air coal of the boiler; meanwhile, compare the temperature high limit of smoke discharged surveyed with that of the boiler and transfer the result to the system display module as well as send out operating and guide operational command; the system display module is responsible for displaying data. The invention is able to improve the efficiency of boiler.

Owner:SHANGHAI JIAO TONG UNIV +1

Boiler control system

ActiveUS20090223466A1Reducing “ hunting ”Effective controlSampled-variable control systemsBoiler controlCombustionFlue gas

A boiler control system for efficiently controlling the operation of a packaged boiler is provided. The system includes a combustion air control system, a fuel control system, a flue gas sensing system, and a boiler controller. The boiler controller is in operative communication with the combustion air control system, fuel control system, and the flue gas sensing system. Based upon a system demand, the boiler controller controls coarse-level operation of the combustion air control system and the fuel control system. The flue gas sensing system includes an oxygen sensor and a flue gas differential sensor that senses a change in a characteristic of the flue gas. When the flue gas differential sensor senses a change in the flue gas characteristic that meets a flue gas differential setpoint, the boiler controller controls fine-level operation of the combustion air control system to efficiently control the amount of oxygen in the flue gas.

Owner:KNORR JR WARREN G

Control system and method for improving the rapid boiler adjusting capability of unit generating set

ActiveCN104932566ASafe and stable operationPrevent vibration and divergenceFluid pressure control using electric meansEngineeringPid regulator

The invention discloses a control system and method for improving the rapid boiler adjusting capability of a unit generating set. The system comprises a deviation sampling module, an automatic boiler pressure PID regulator, an integrated calculation module, a feedforward generation module and a feedforward output amplitude limit module, one input signal of the automatic boiler pressure PID regulator is a signal directly from the deviation sampling module, the other input signal of the automatic boiler pressure PID regulator is a signal which is processed by the integrated calculation module, the feedforward generation module and the feedforward output amplitude limit module, and the output end of the automatic boiler pressure PID regulator is connected with a boiler control system. The control system of the invention can solve the problem that the working condition is instable for a long time due to wide fluctuation of the main vapor pressure of the set when the set adjusts the load rapidly, prevents the operational pressure of the set from oscillation and divergency, and ensures that the power generating set runs safely and stably.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

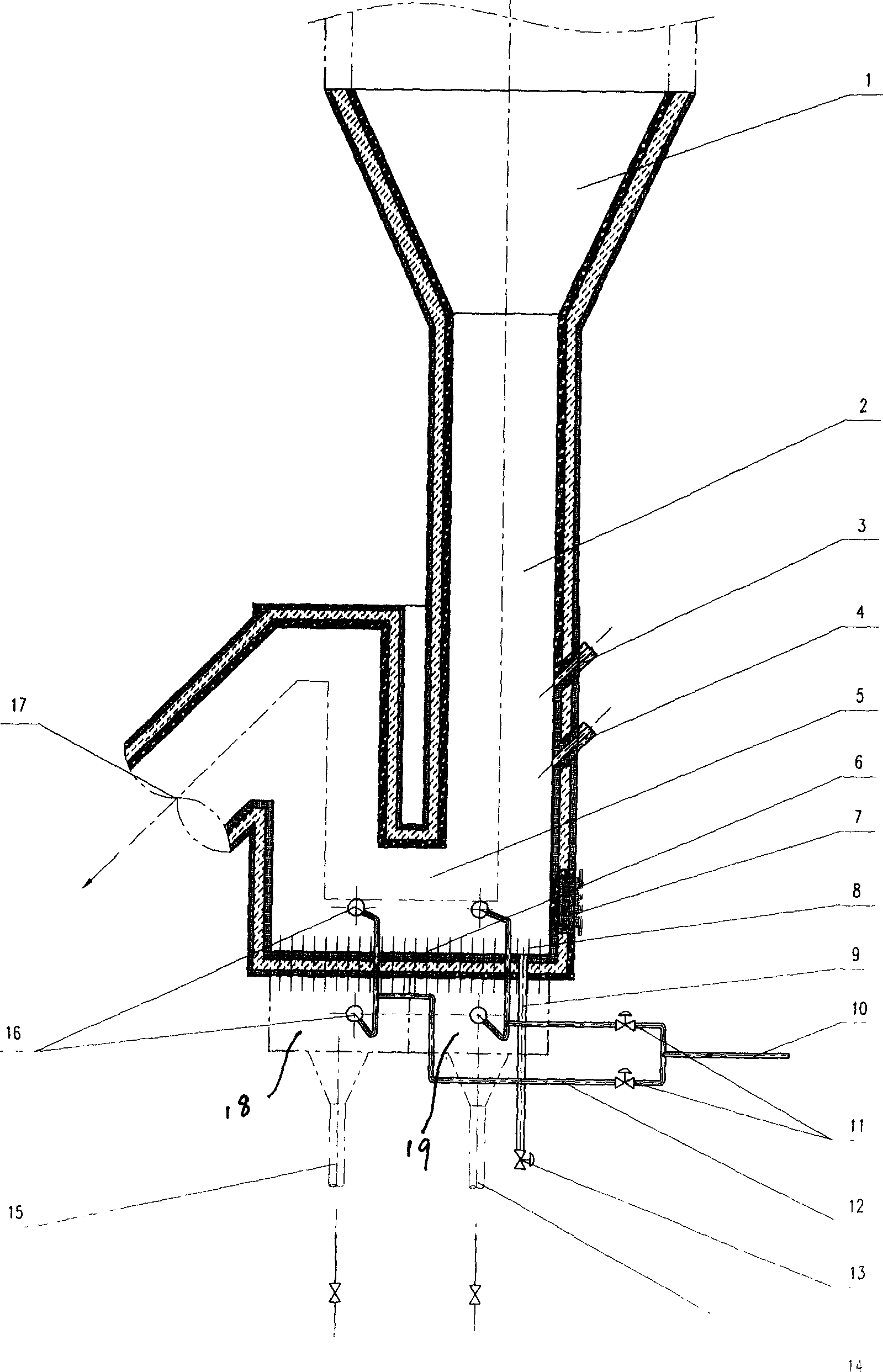

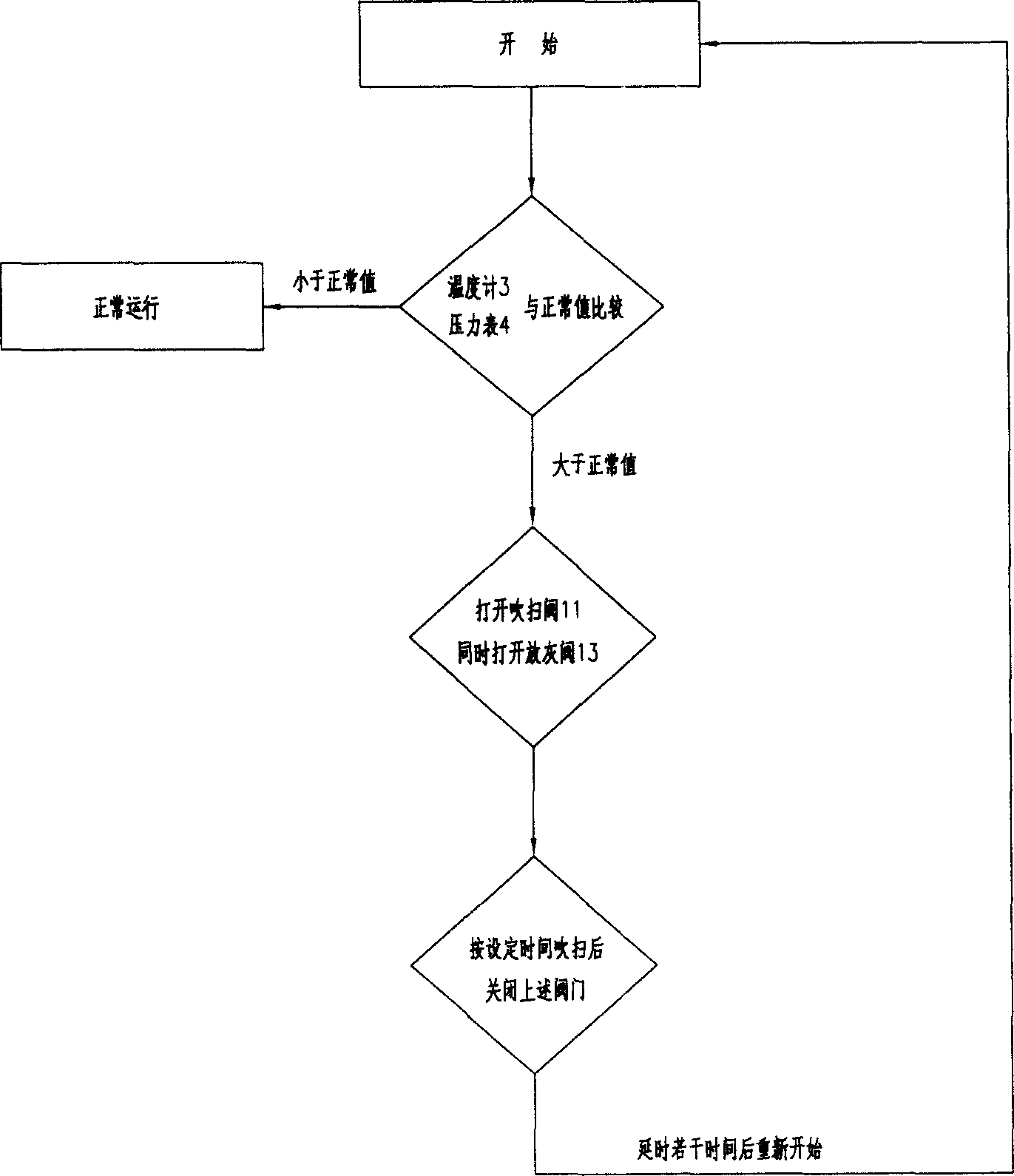

High pressure air clearing method for treating fault of feedback appts. of circulation fluidized bed boiler

InactiveCN1563791AQuickly deal with blockage problemsFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

The present invention relates to boiler controlling technology, and is especially the high pressure blast sweeping method for fast treating product returning device jamming accident in circular fluidized bed boiler. According to the design scheme the present invention provides, high pressure blast pipe is connected in the product returning device, and in case of abnormal temperature and pressure inside the product returning device, the control valve in high pressure blast pipe is opened and high pressure blast is utilized in blowing off the slag block deposited into the grid plate in the product returning device to restore the normal work state of the product returning devie. The high pressure blast pipe is connected to the grid plate and the high pressure blast sweeps upwards from the wind cowl on the grid plate. The present invention utilizes available high pressure medium in boilr for fast treating product returning device jamming via simple sweeping.

Owner:WUXI HUAGUANG BOILER

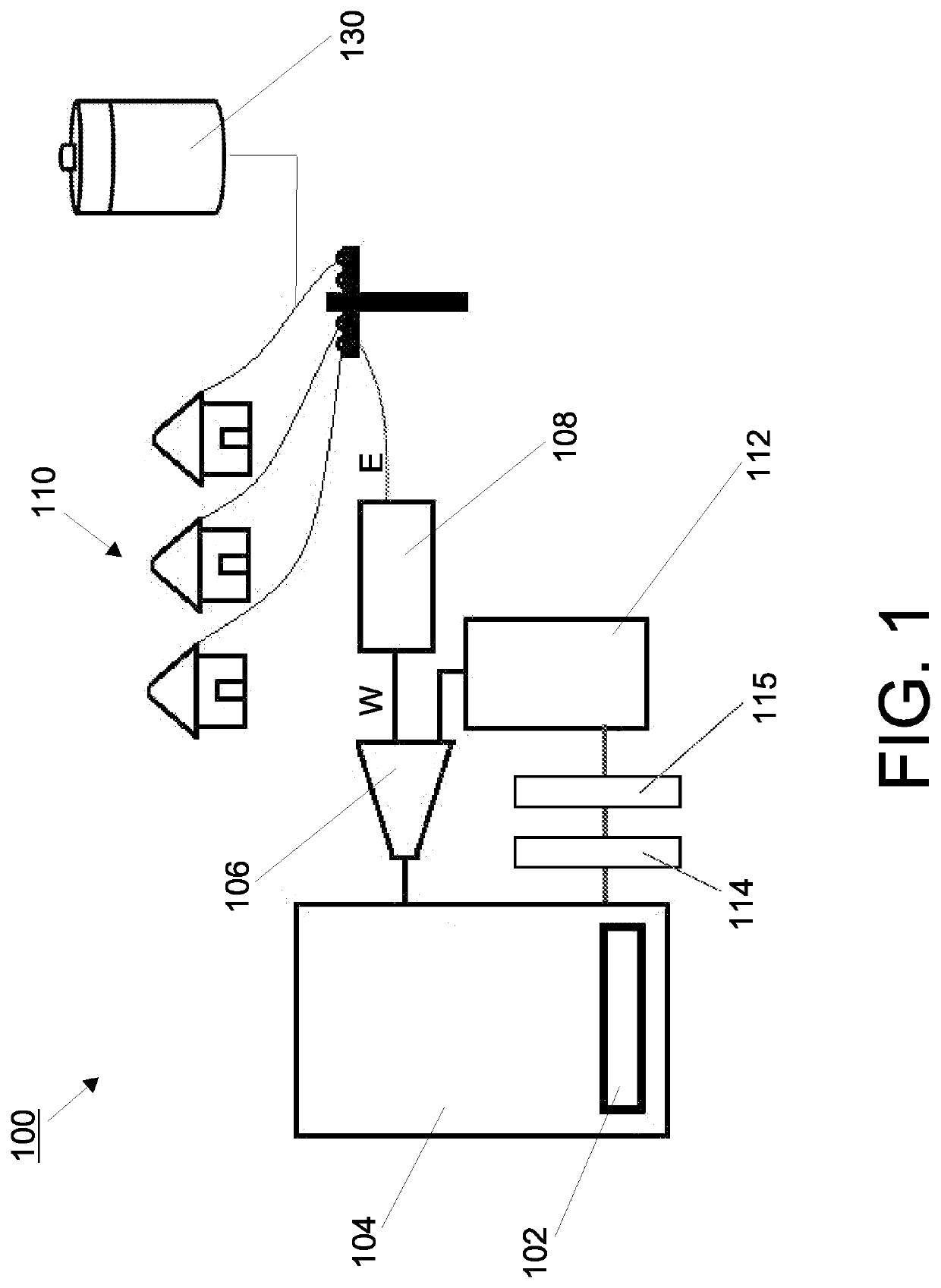

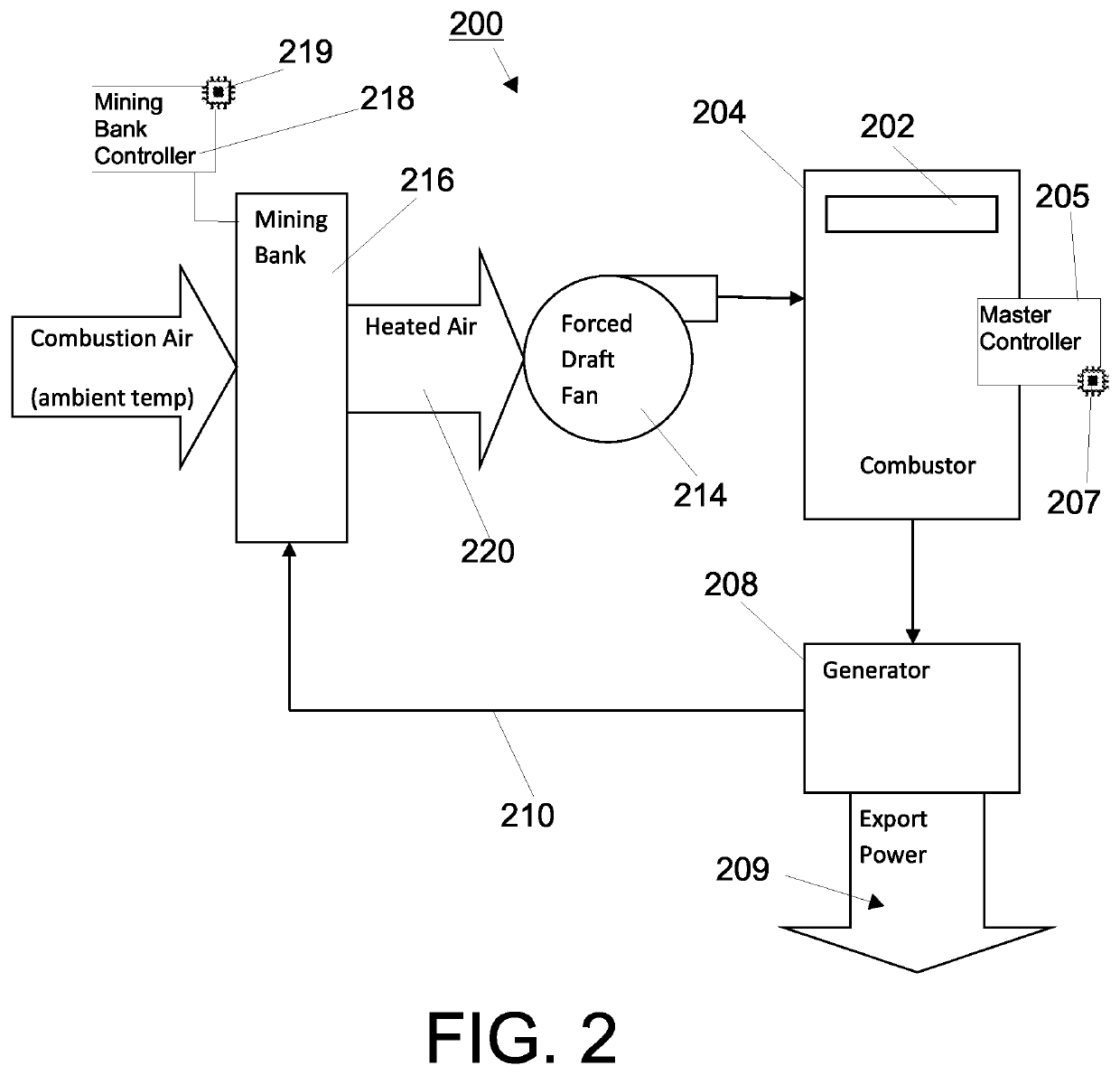

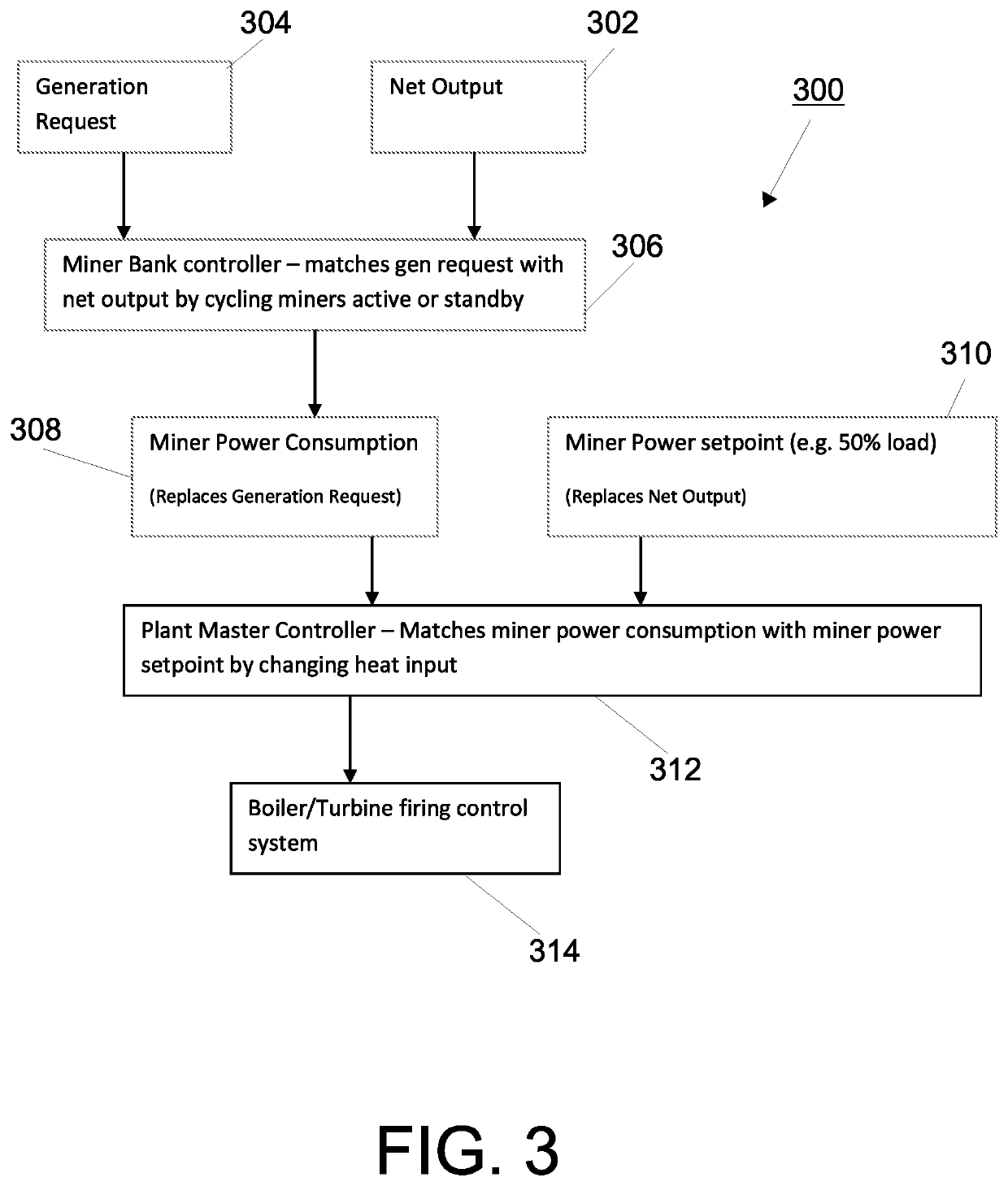

Integrating blockchain mining with boiler controls to create a hybrid power generator

ActiveUS20210175710A1Reduce power consumptionIncrease power outputGeneration forecast in ac networkEncryption apparatus with shift registers/memoriesBrayton cyclePower station

Owner:Q POWER LLC

Method and system for SCR optimization

Methods and systems are provided for controlling SCR performance in a boiler. The boiler includes one or more generally cross sectional areas. Each cross sectional area can be characterized by one or more profiles of one or more conditions affecting SCR performance and be associated with one or more adjustable desired profiles of the one or more conditions during the operation of the boiler. The performance of the boiler can be characterized by boiler performance parameters. A system in accordance with one or more embodiments of the invention can include a controller input for receiving a performance goal for the boiler corresponding to at least one of the boiler performance parameters and for receiving data values corresponding to boiler control variables and to the boiler performance parameters. The boiler control variables include one or more current profiles of the one or more conditions. The system also includes a system model that relates one or more profiles of the one or more conditions in the boiler to the boiler performance parameters. The system also includes an indirect controller that determines one or more desired profiles of the one or more conditions to satisfy the performance goal for the boiler. The indirect controller uses the system model, the received data values and the received performance goal to determine the one or more desired profiles of the one or more conditions. The system model also includes a controller output that outputs the one or more desired profiles of the one or more conditions.

Owner:GENERAL ELECTRIC CO

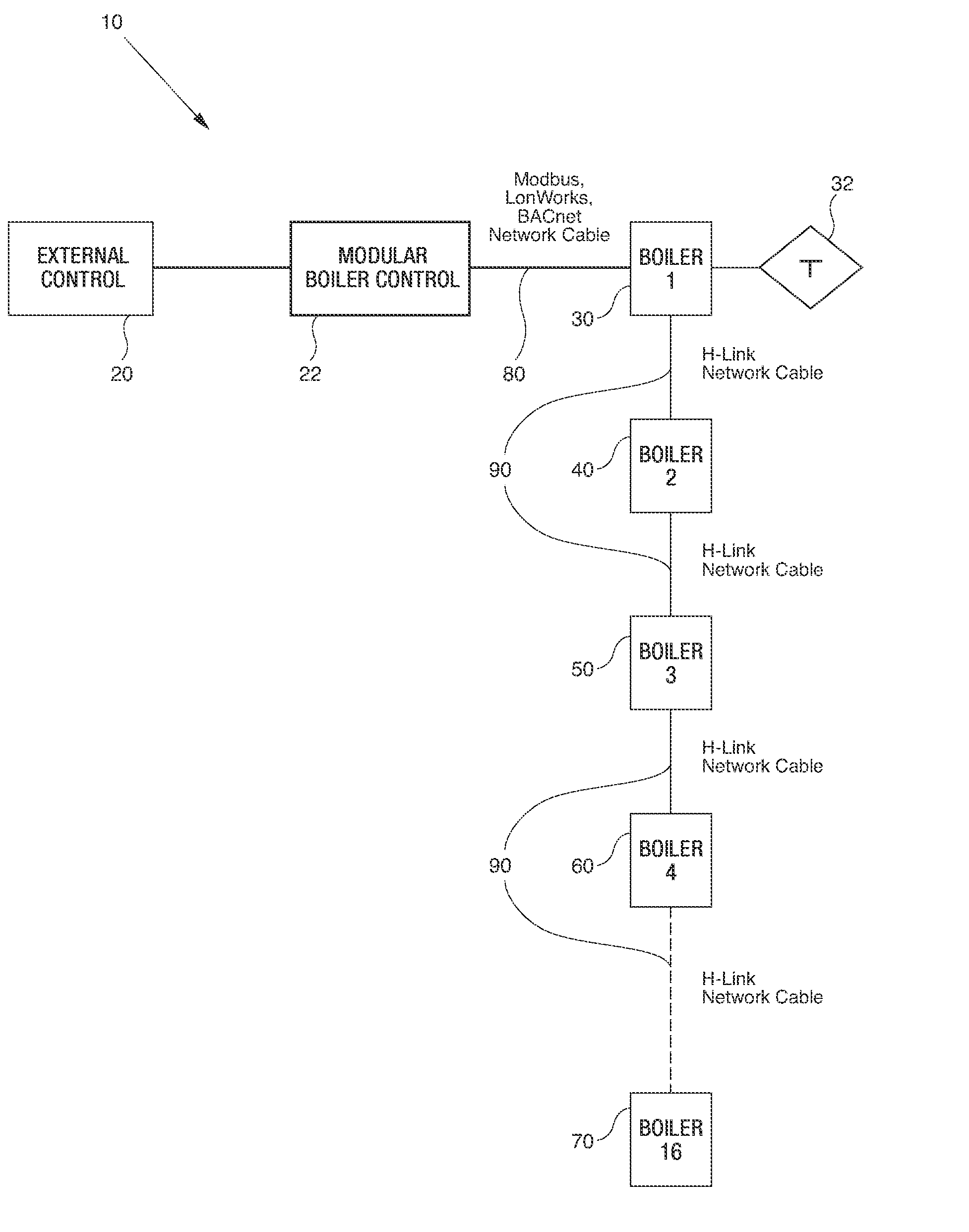

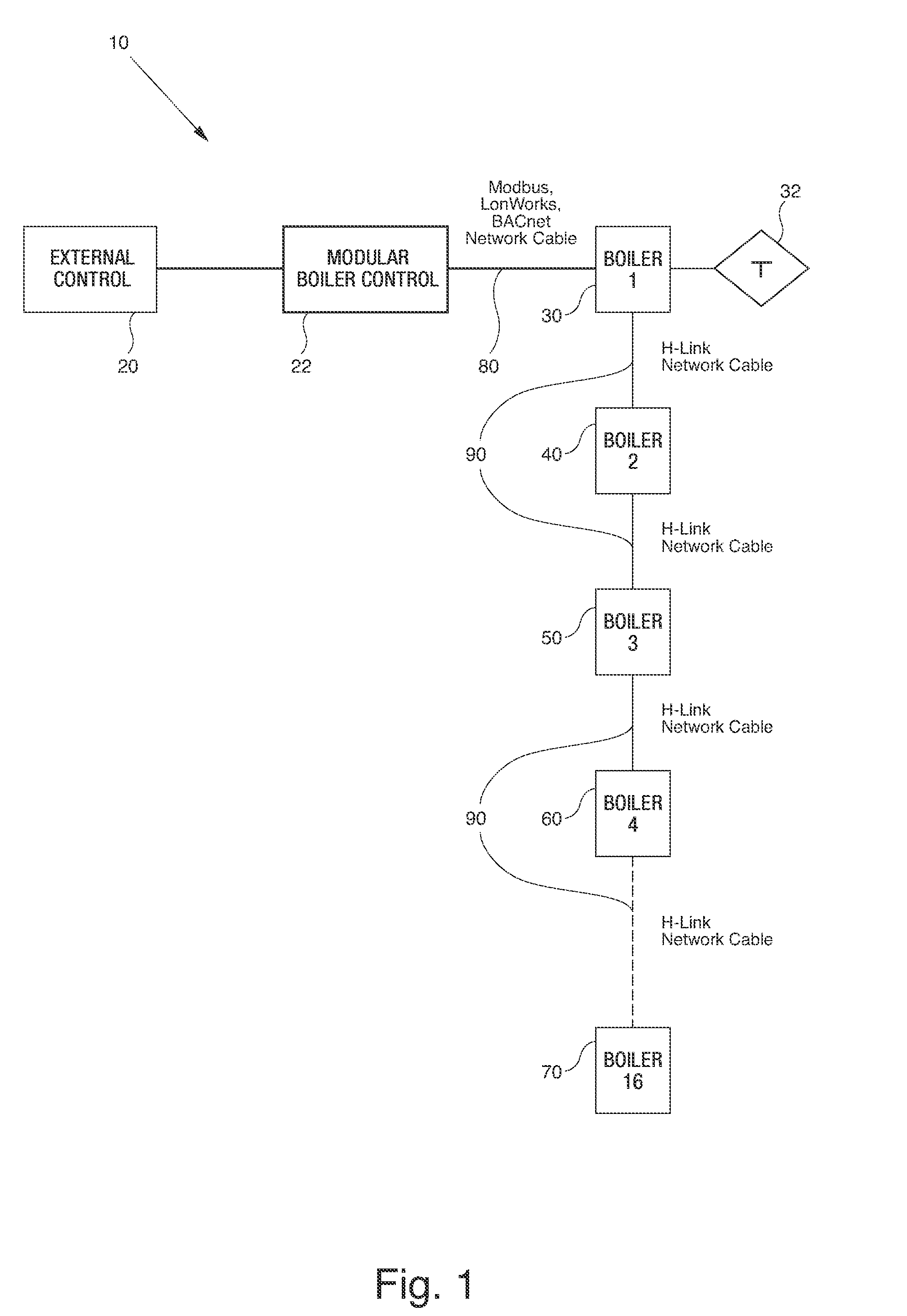

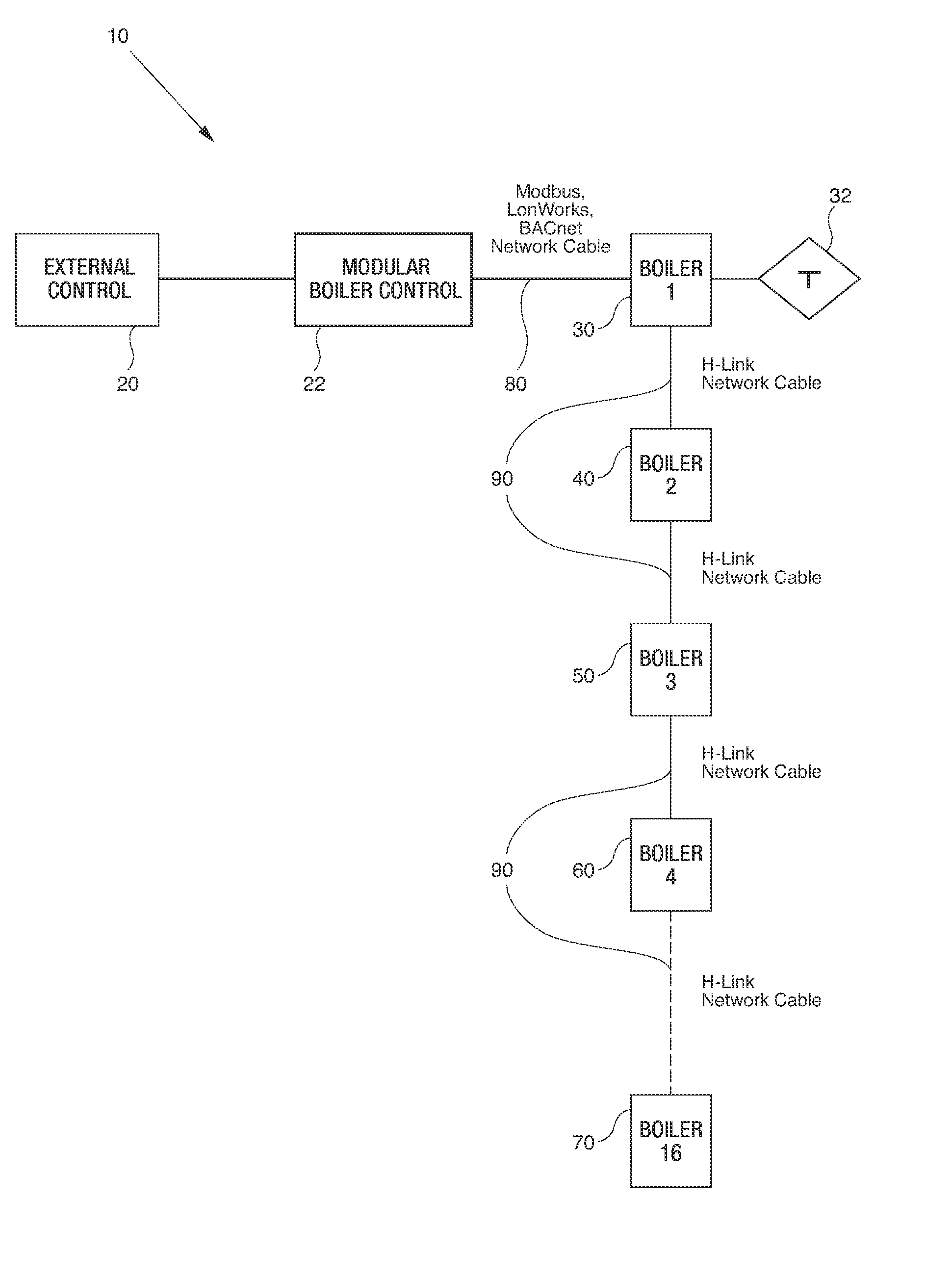

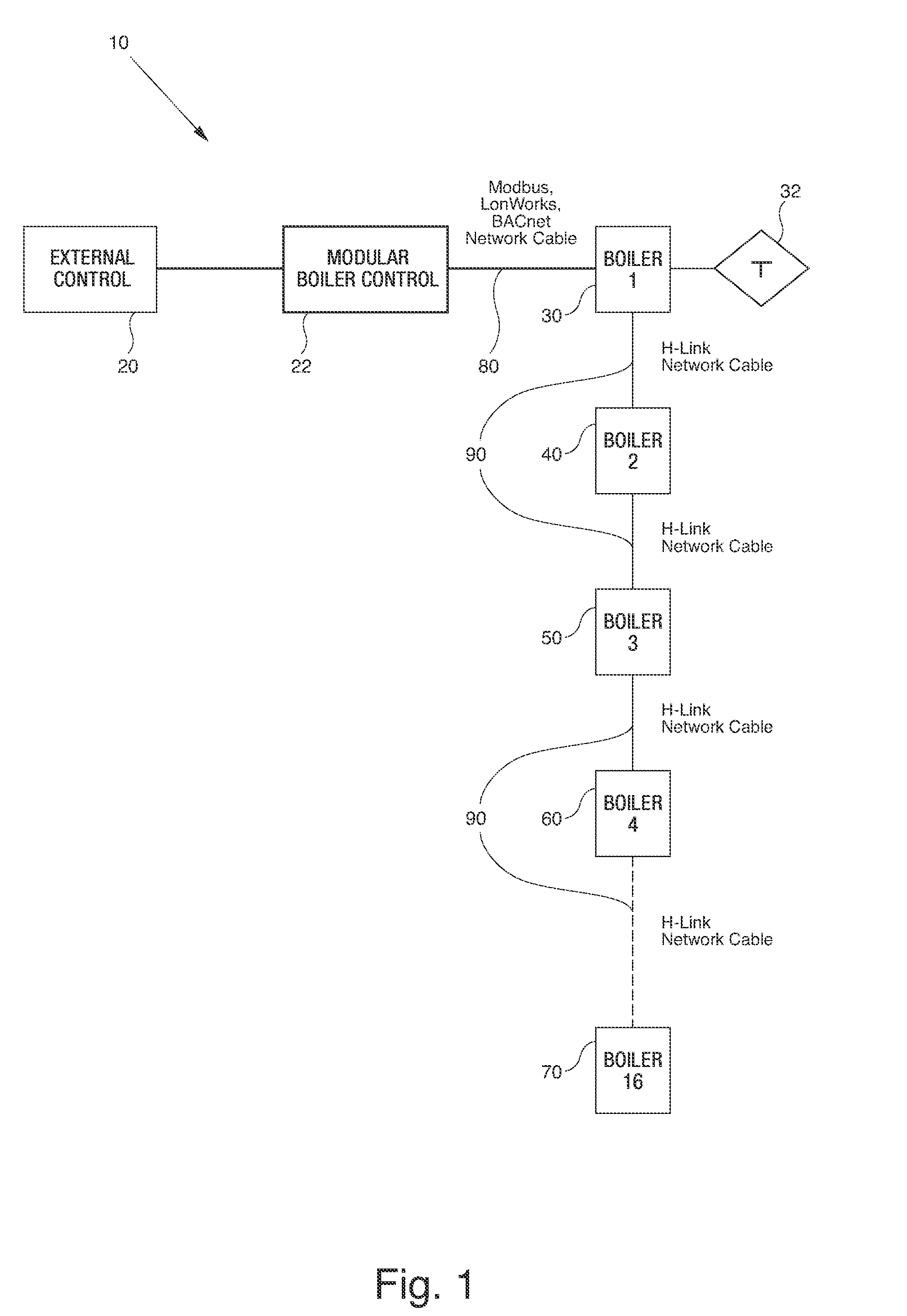

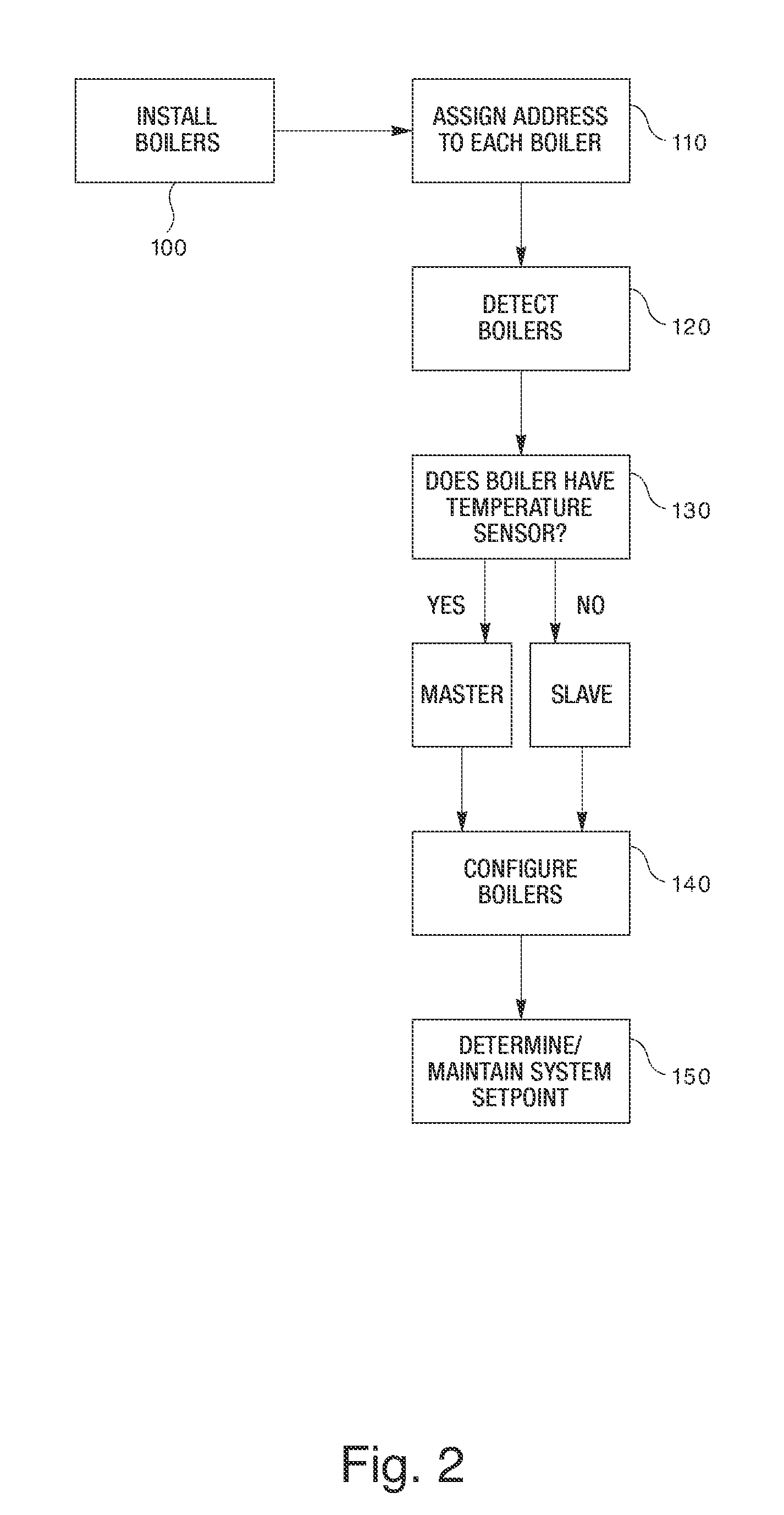

Modular boiler control

ActiveUS20070295830A1Low costEasy to addSpace heating and ventilationTemperatue controlControl theoryBoiler control

A modular boiler system includes a boiler control, a first boiler in operative connection with the boiler control, and a temperature sensor in operative connection with the first boiler. The system also features at least one secondary boiler in operative connection with the master boiler. The boiler control is operatively connected to only the first boiler and it enables the first boiler to control a boiler parameter of the first boiler and the at least one secondary boiler.

Owner:WESTCAST

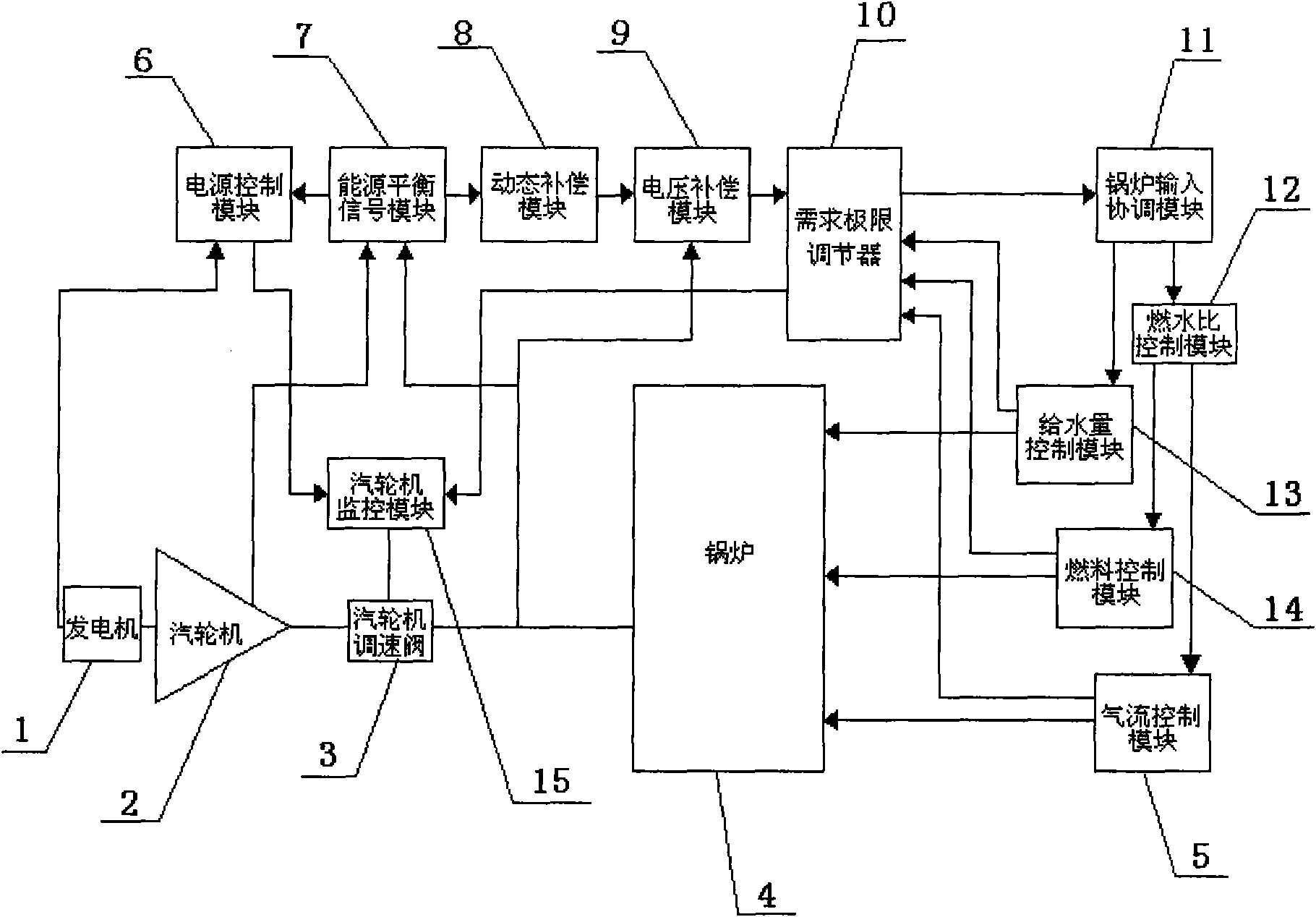

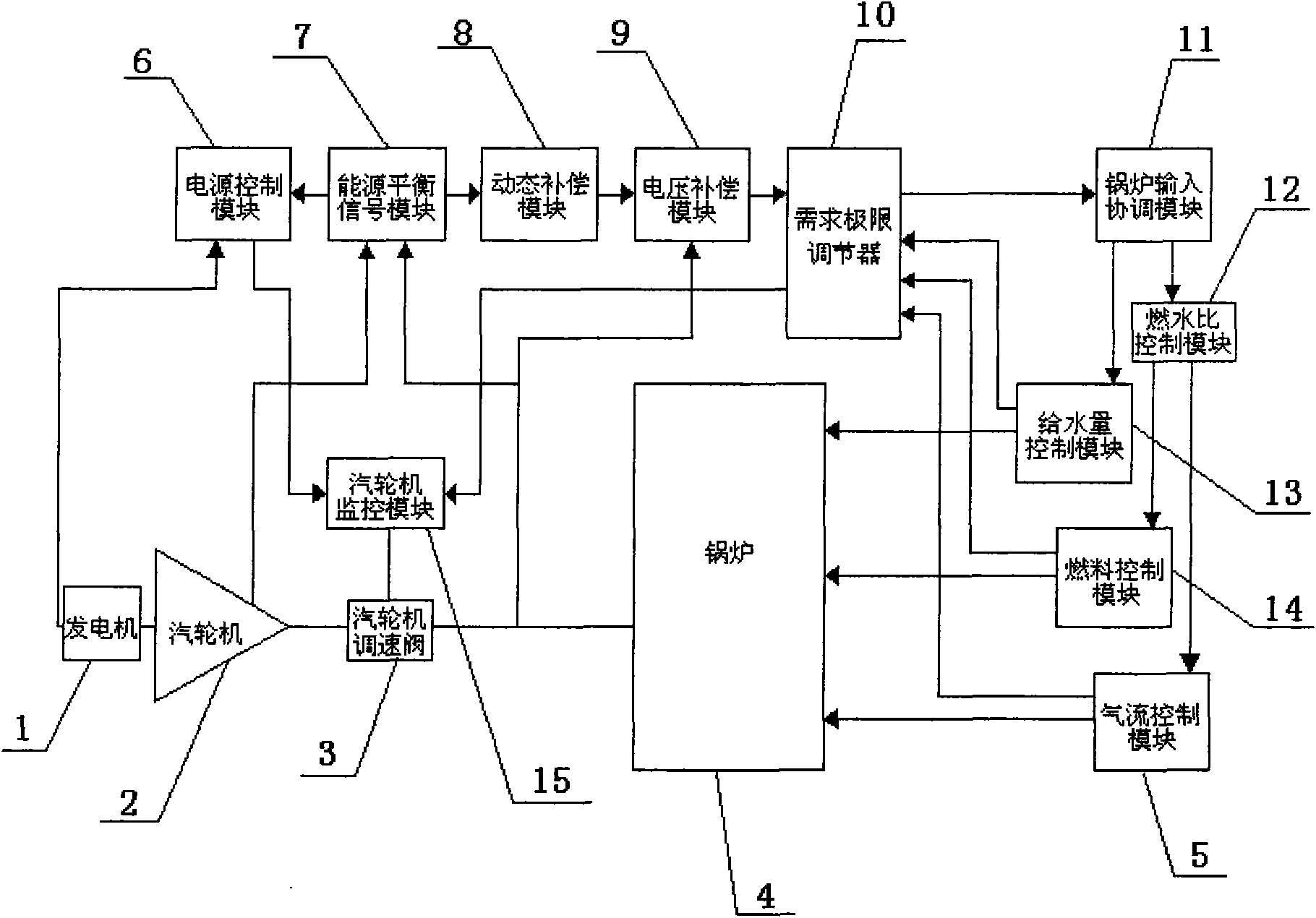

Direct energy balance and coordination control system for supercritical thermal power generating unit

The invention discloses a direct energy balance and coordination control system for a supercritical thermal power generating unit. Direct energy balance and coordination control starts changing in load from the maximum speed, power generation control and boiler control are decoupled completely, and procedural randomness of overburnt or underburnt is minimized. The direct energy balance and coordination control system for the supercritical thermal power generating unit is realized by the following technical scheme that a boiler receives the input signals of a water feed control module, a fuel control module and an air flow control module and provides output signals to an energy balance signal module and a voltage compensation module; a demand limit regulator receives the input signals of the voltage compensation module, the water feed control module, the fuel control module and the air flow control module and provides output signals to a turbine monitoring module and a boiler input coordination module; and the energy balance signal module receives the input signal of a turbine and provides output signals to a power source control module and a dynamic compensation module.

Owner:SHANGHAI ELECTRICGROUP CORP

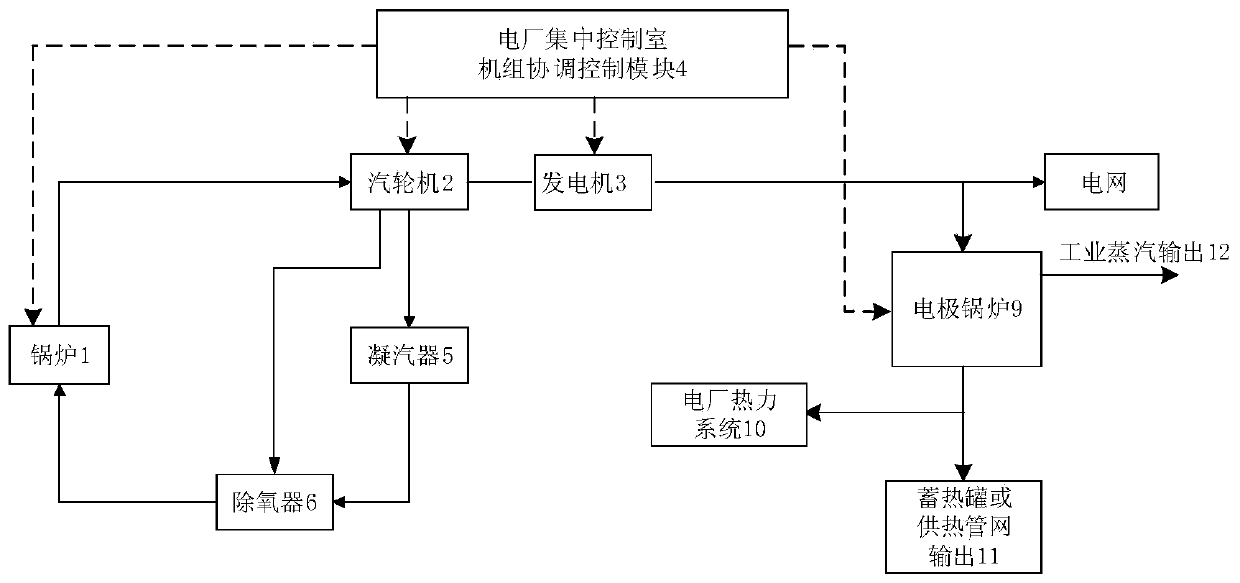

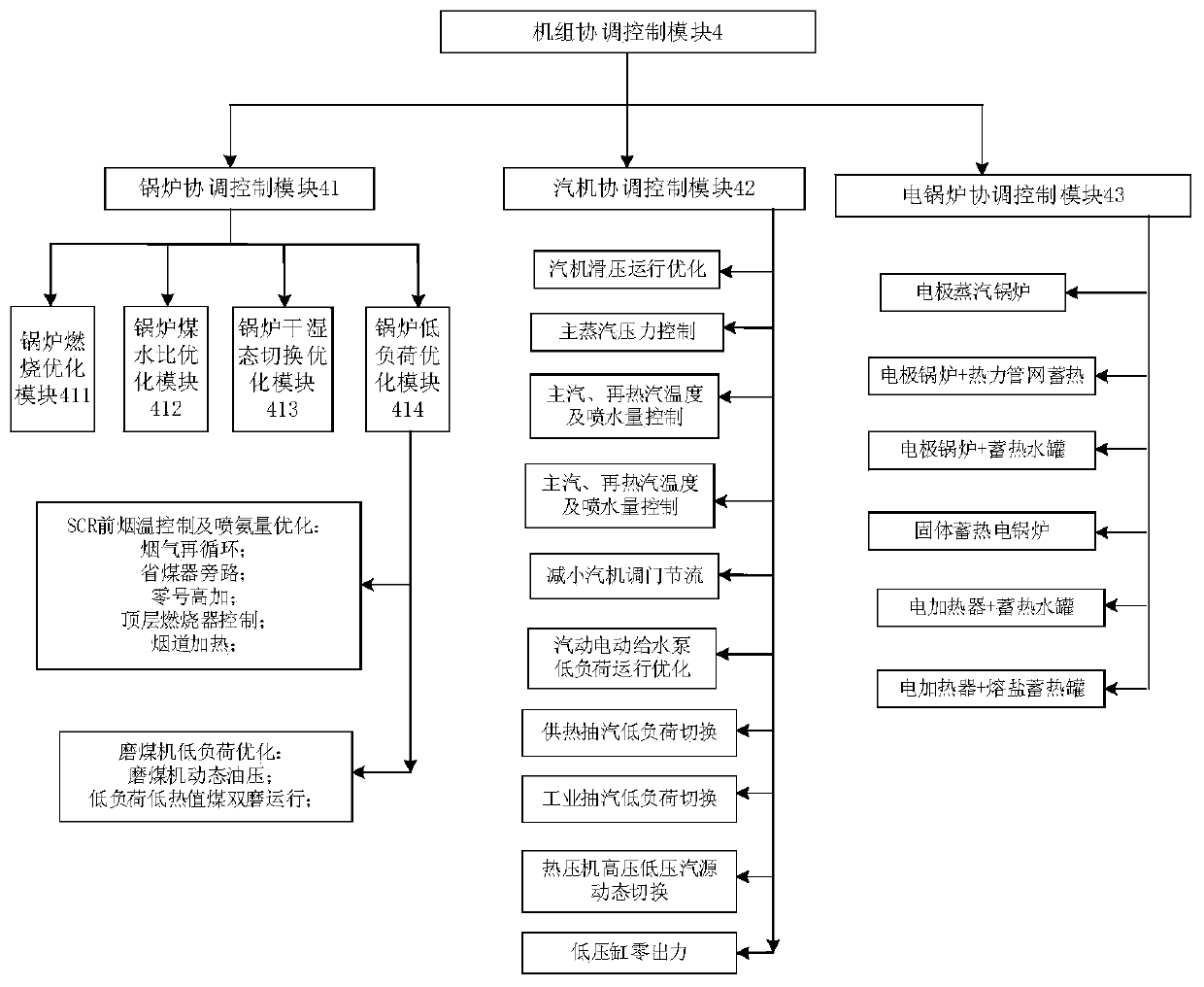

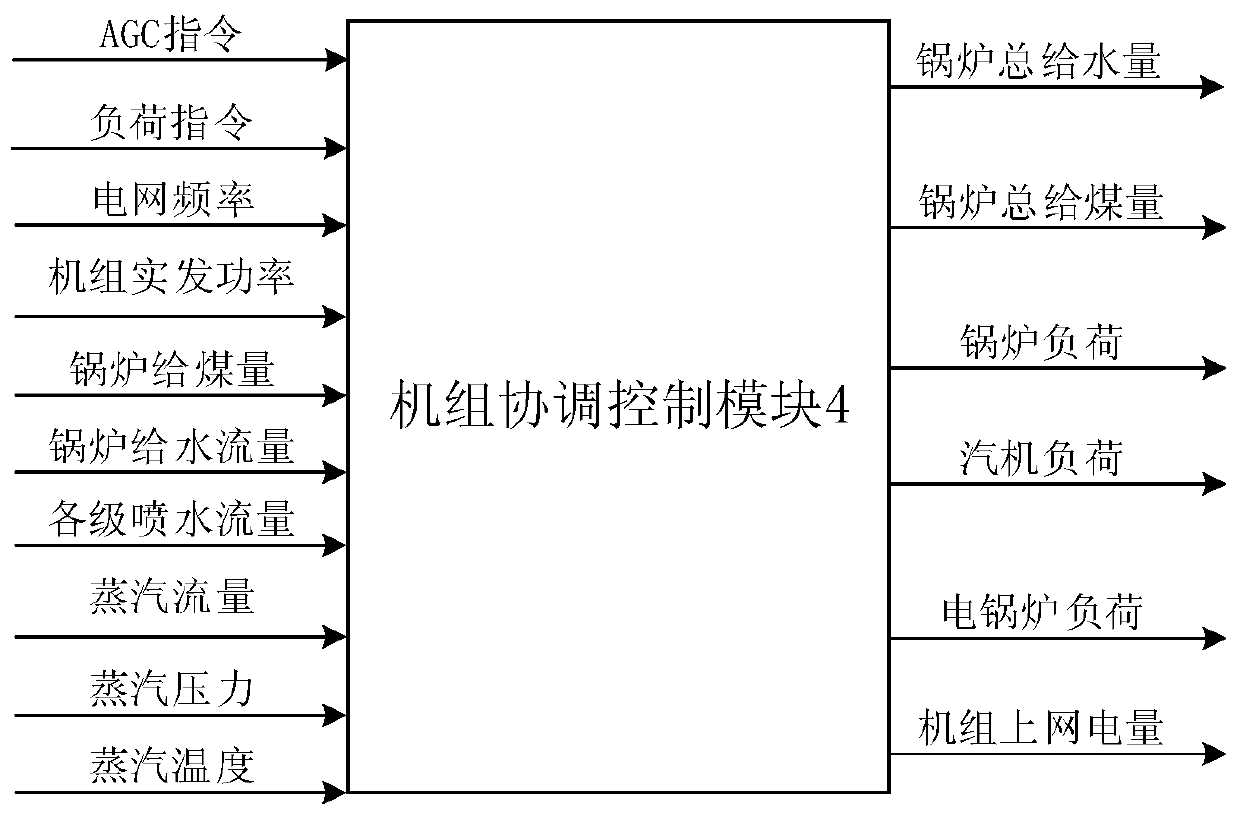

Coordinated control type peak and frequency regulation system and equipment of thermal power generating unit, and method thereof

ActiveCN110531719ACapacity setting reducedLess investmentTotal factory controlProgramme total factory controlEngineeringControl room

The invention relates to a coordinated control type peak and frequency regulation system and equipment of a thermal power generating unit, and a method thereof. The system comprises a unit coordination control module 4 and an electric boiler 9. The unit coordination control module 4 includes a boiler coordination control module, a steam turbine coordination control module and an electric boiler control module. The coordinated control type peak regulation and frequency modulation equipment comprises a hardware part and a software part. The unit coordinated control module 4 is integrated in a thermal power unit central control room control cabinet and is in communication connection with various operating parameter sensors and controllers of an original CCS and AGC control systems, a boiler,a steam turbine, a generator and an electric boiler. Therefore, the flexible peak and frequency modulation of the thermal power generating unit can be realized by using a coordinated control method.

Owner:HEPU ENERGY ENVIRONMENTAL TECHNOLOGY CO LTD

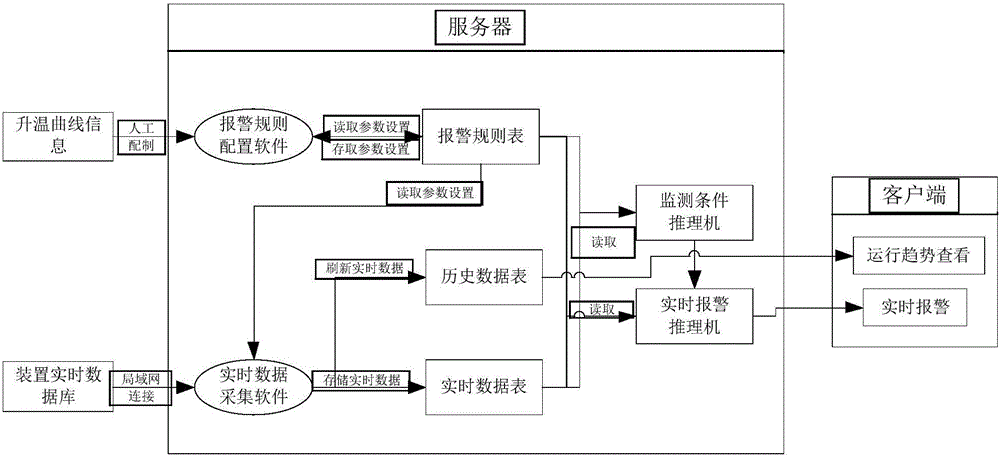

Monitoring and alarming system for temperature rise of oven of heating furnace

InactiveCN106094684AOvercoming excessive heatingOvercoming slow heatingProgramme controlComputer controlReal-time dataEngineering

The invention discloses a monitoring and alarming system for a temperature rise of an oven of a heating furnace. A temperature rise curve module is used for carrying out configuration on a temperature rise curve of an oven by alarm rule configuration software to form an alarm rule base, and an alarm rule table module stores parameter setting; a device real-time database module stores real-time data of needed monitoring parameters collection of a boiler control system or enterprise database into parameter historical data tables in a time sequence; the real-time parameter obtained by refreshing are provided for a real-time alarming unit; and then on the basis of connection of an operation trend module of a client and a real-time data acquisition unit, a current temperature rise curve operation state of the oven is checked, and whether alarming needs to be carried out is selected according to parameters in the historical table based on connection of an alarm implementation module of the client and the real-time alarming unit. According to the invention, the system collects the operation data and carries out real-time reasoning; and when a temperature offset occurs, alarming prompting is carried out.

Owner:CHINA PETROLEUM & CHEM CORP +1

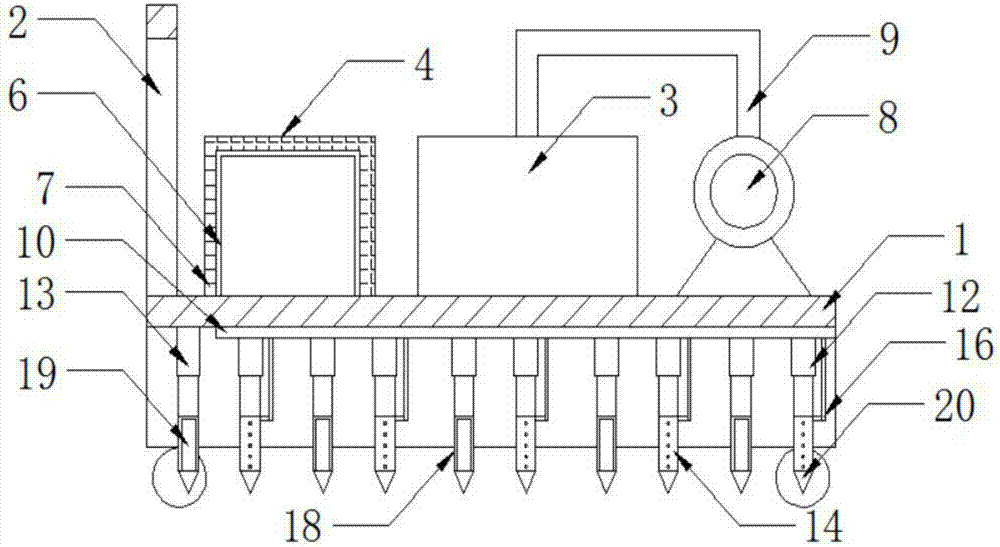

Novel high temperature insect killing device for vegetable planting

PendingCN107372446AAvoid harmIncrease humidityInsect catchers and killersElectrical batteryAgricultural engineering

The invention discloses a novel high temperature insect killing device for vegetable planting. The novel high temperature insect killing device comprises a fixed base, a push rod is fixedly arranged at one side of the top of the fixed base, a steam boiler is fixedly installed in the middle of the top of the fixed rod, a battery cover is fixedly arranged at one side of the steam boiler, a switch panel is fixedly installed at the lateral of the battery cover, a steam boiler control switch, a steam pump control switch, a first electric telescopic rod control switch, a second electric telescopic control switch and an electric heating rod control switch are arranged at the surface of the switch panel separately, and a storage battery is fixedly installed inside the battery cover. According to the novel high temperature insect killing device for vegetable planting, a first fixing pipe and a second fixing pipe are fixedly connected to the bottom of the first electric telescopic rod and the second electric telescopic rod, through an iron cone head both in threaded connection with the bottoms of the first fixing pipe and the second fixing pipe, the first fixing pipe and the second fixing pipe are inserted inside soil, high temperature insect killing deep in the soil is achieved, and the situation that pests deep in the soil cannot be killed when high temperature pest killing is conducted on the surface of the soil is avoided.

Owner:池州市恒森生态农业有限公司

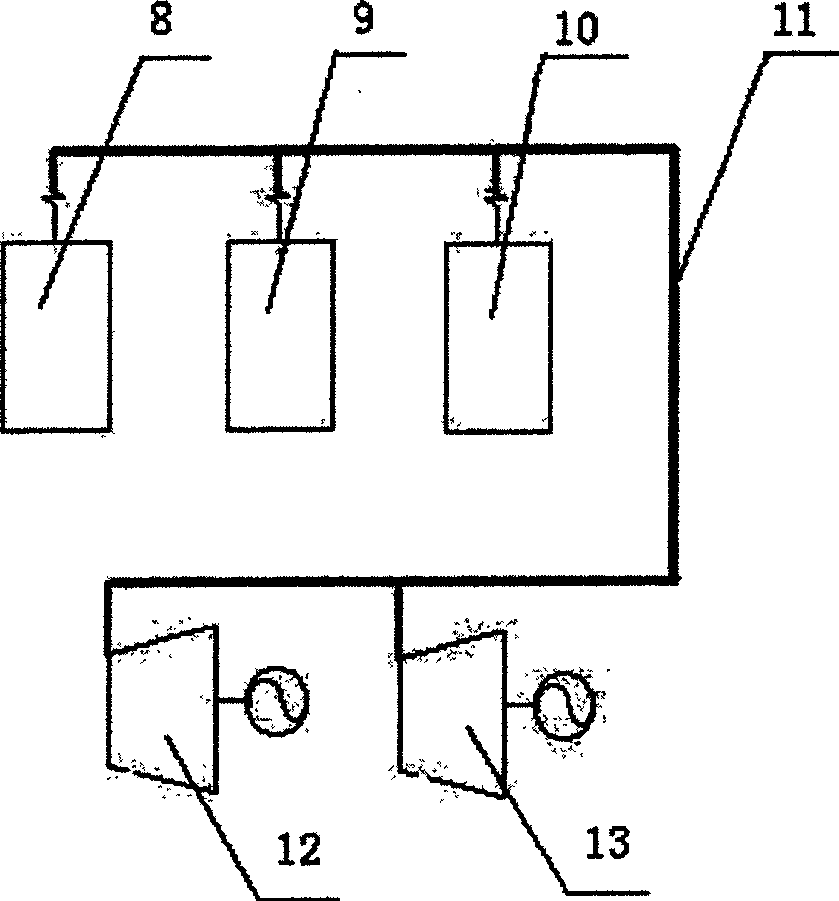

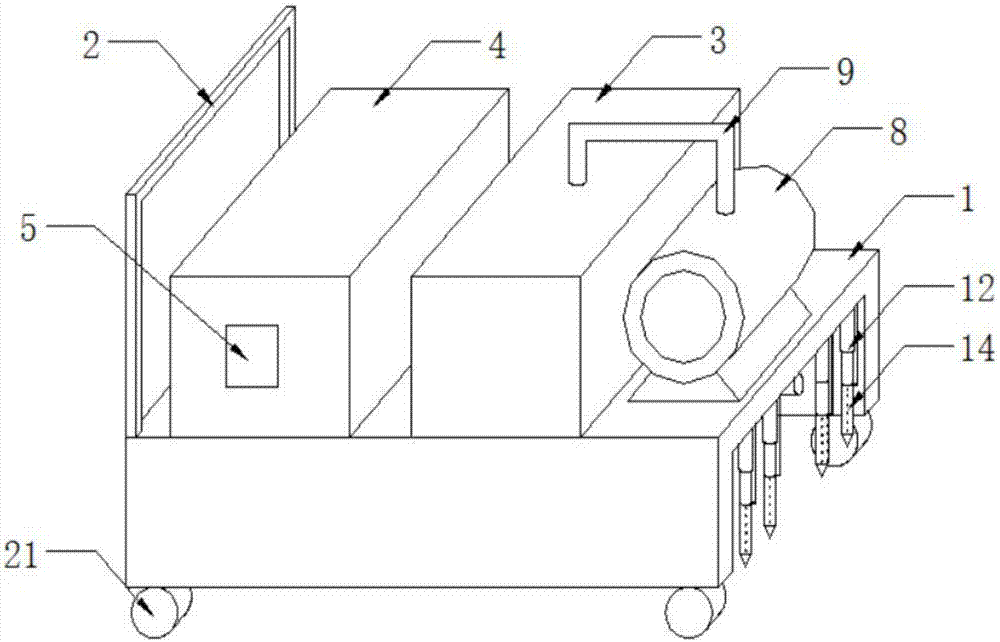

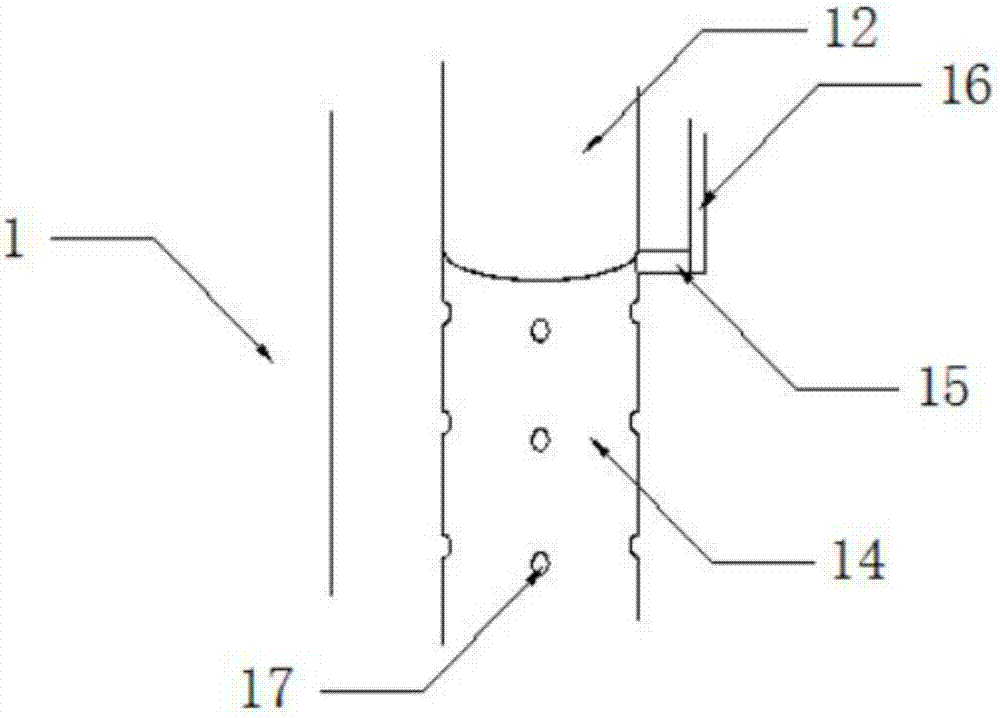

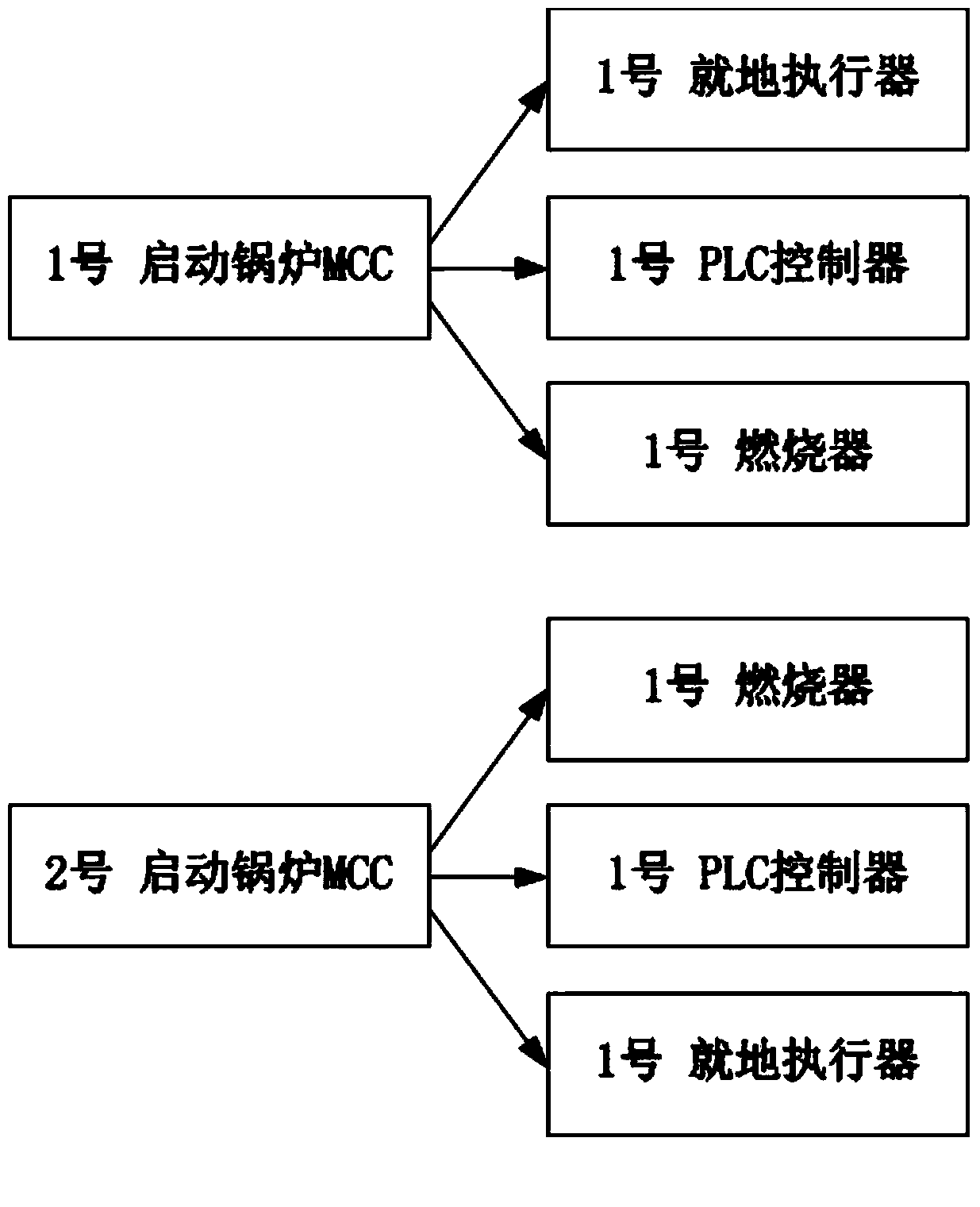

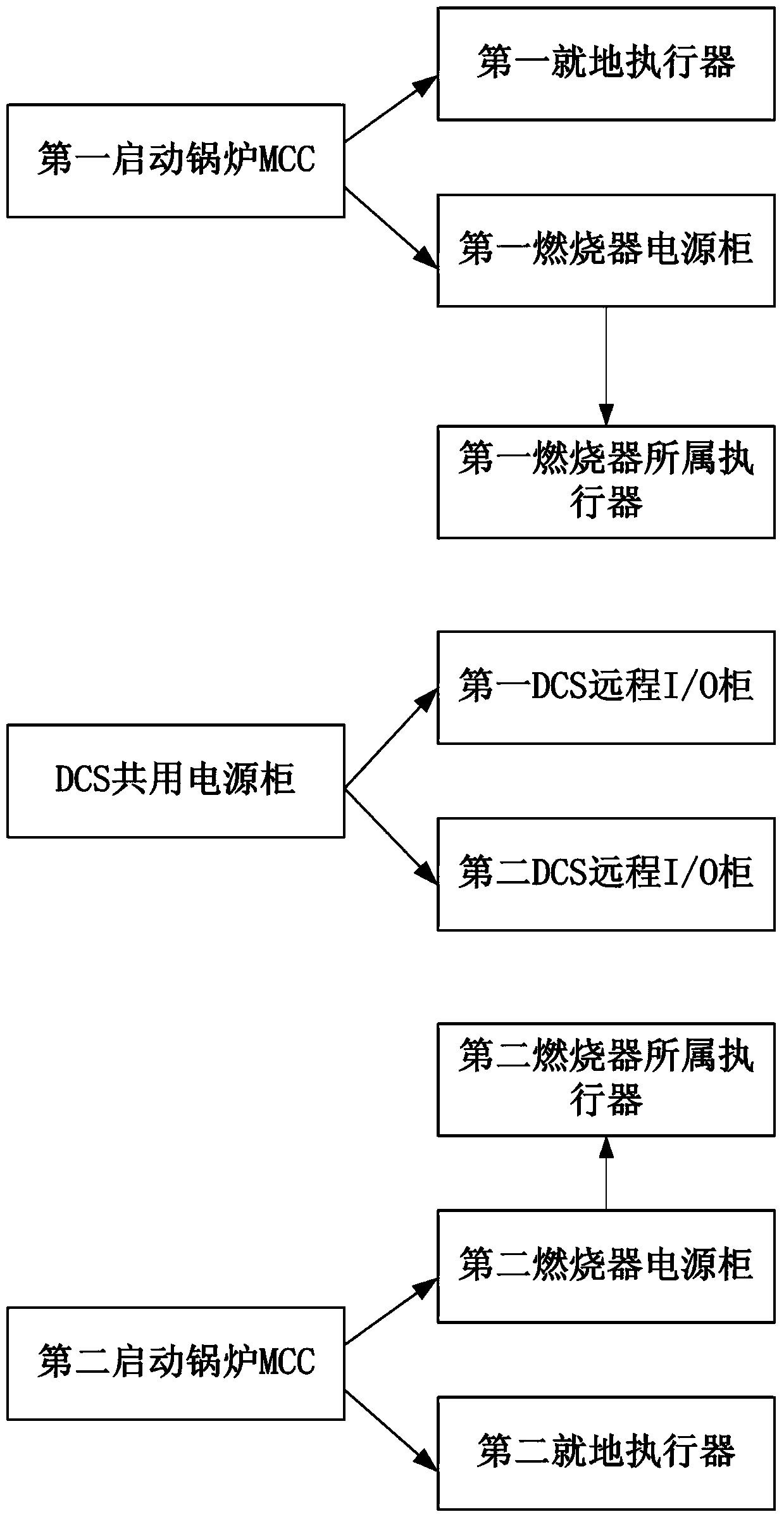

Startup boiler control system

ActiveCN104049622AHigh degree of automationImprove centralized control operationTotal factory controlProgramme total factory controlCombustorActuator

The invention relates to a startup boiler control system. The startup boiler control system comprises a power supply system. The power supply system comprises a first startup boiler MCC, a second startup boiler MCC and a DCS common power supply cabinet. The first startup boiler MCC supplies power to an on-site actuator which a first startup boiler belongs to and a first combustor power supply cabinet respectively. The second startup boiler MCC supplies power to an on-site actuator which a second startup boiler belongs to and a second combustor power supply cabinet respectively. The DCS common power supply cabinet supplies power to a first DCS remote I / O cabinet and a second DCS remote I / O cabinet respectively. The first combustor power supply cabinet supplies power to an actuator which a first combustor belongs to. The second combustor power supply cabinet supplies power to an actuator which a second combustor belongs to. Through the startup boiler control system, a circuit can be simplified, and reliability can be improved.

Owner:浙江大唐国际绍兴江滨热电有限责任公司

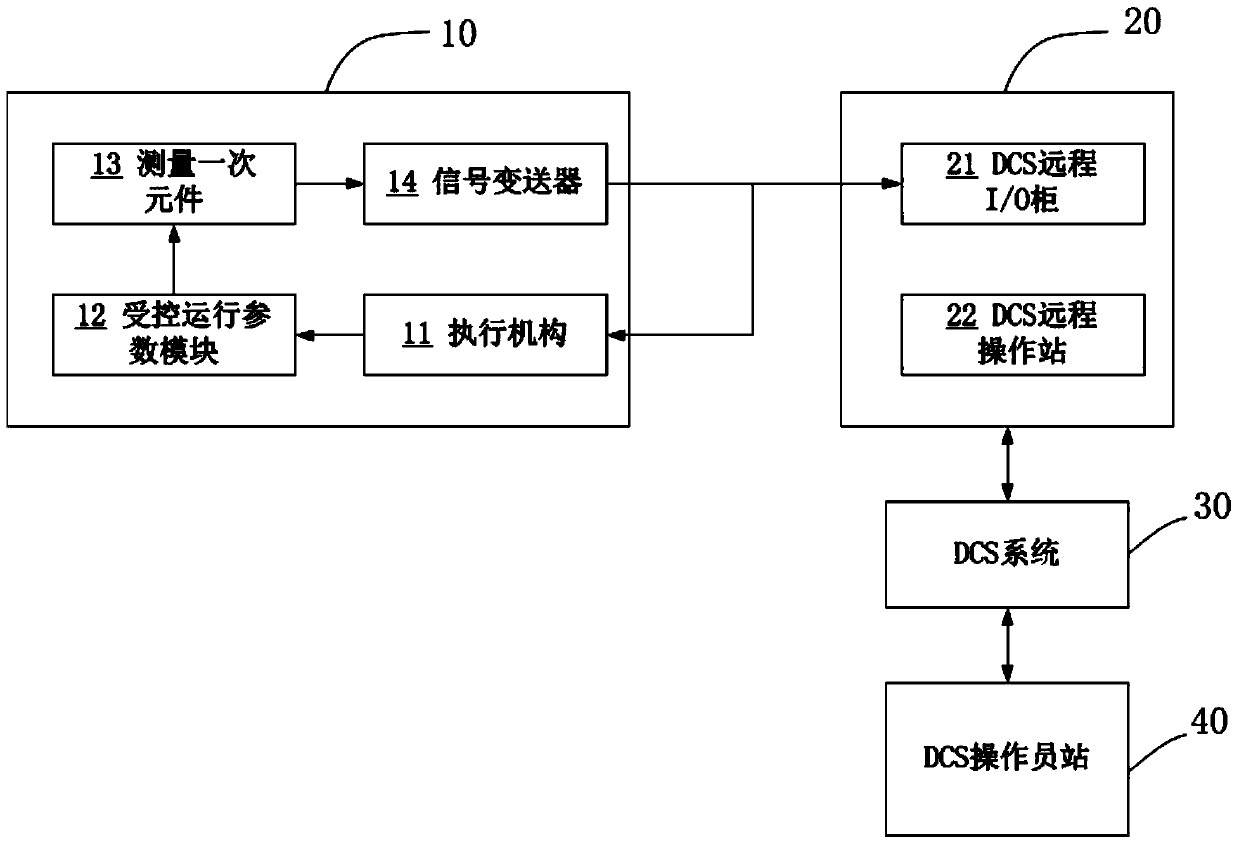

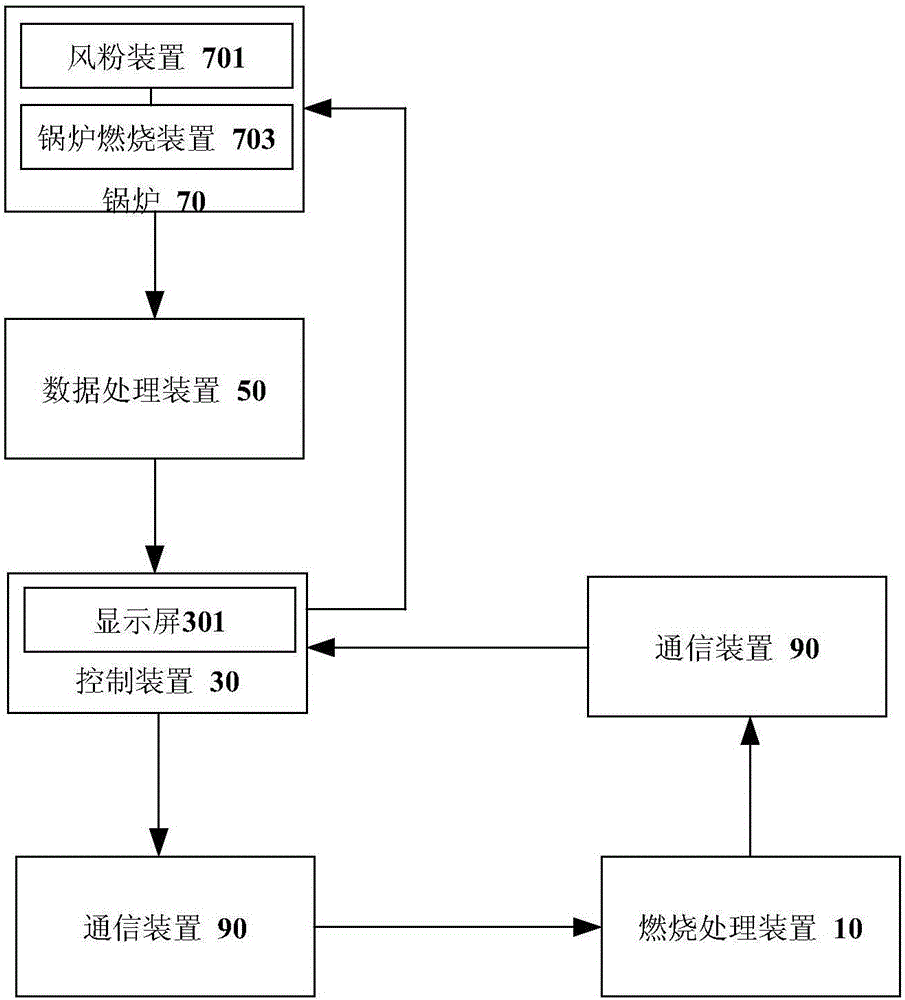

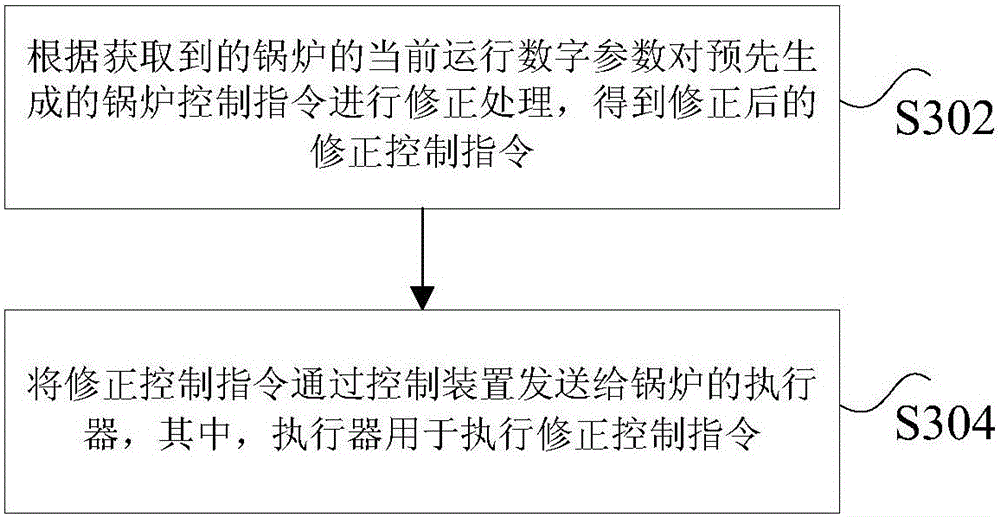

Boiler combustion control system, method and device

The invention discloses a boiler combustion control system, method and device. The control system comprises a combustion treatment device and a control device; the combustion treatment device is used for conducting correction treatment on a boiler control command generated in advance according to obtained currently run digital parameters of a boiler, and a corrected correction control command is obtained; the control device is connected with the combustion treatment device and used for receiving the correction control command and sends the correction control command to an actuator of the boiler, wherein the actuator is used for carrying out the correction control command. According to the boiler combustion control system, method and device, the technical problem that the running performance of an existing boiler which acts based on a DCS is poor is solved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

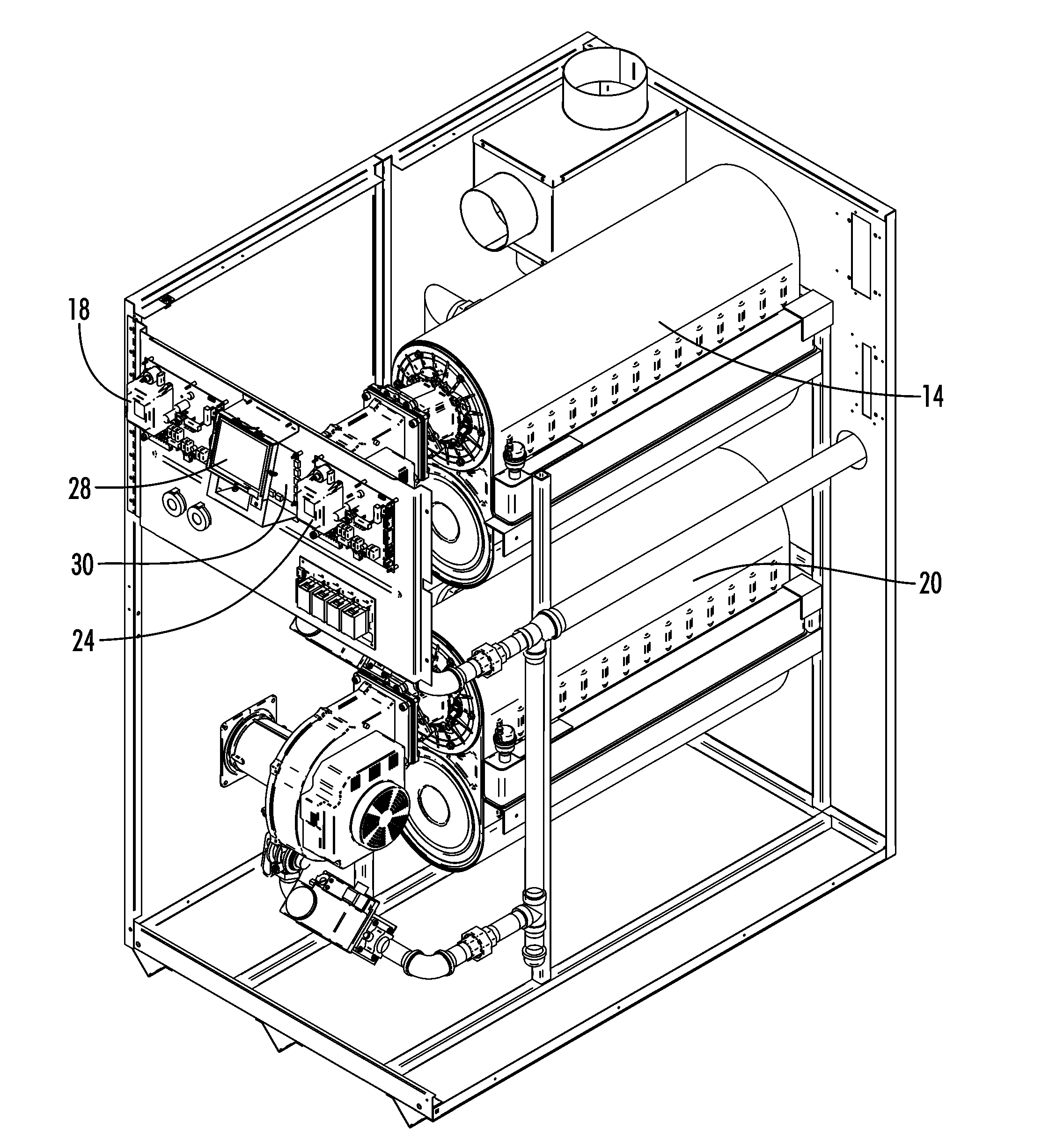

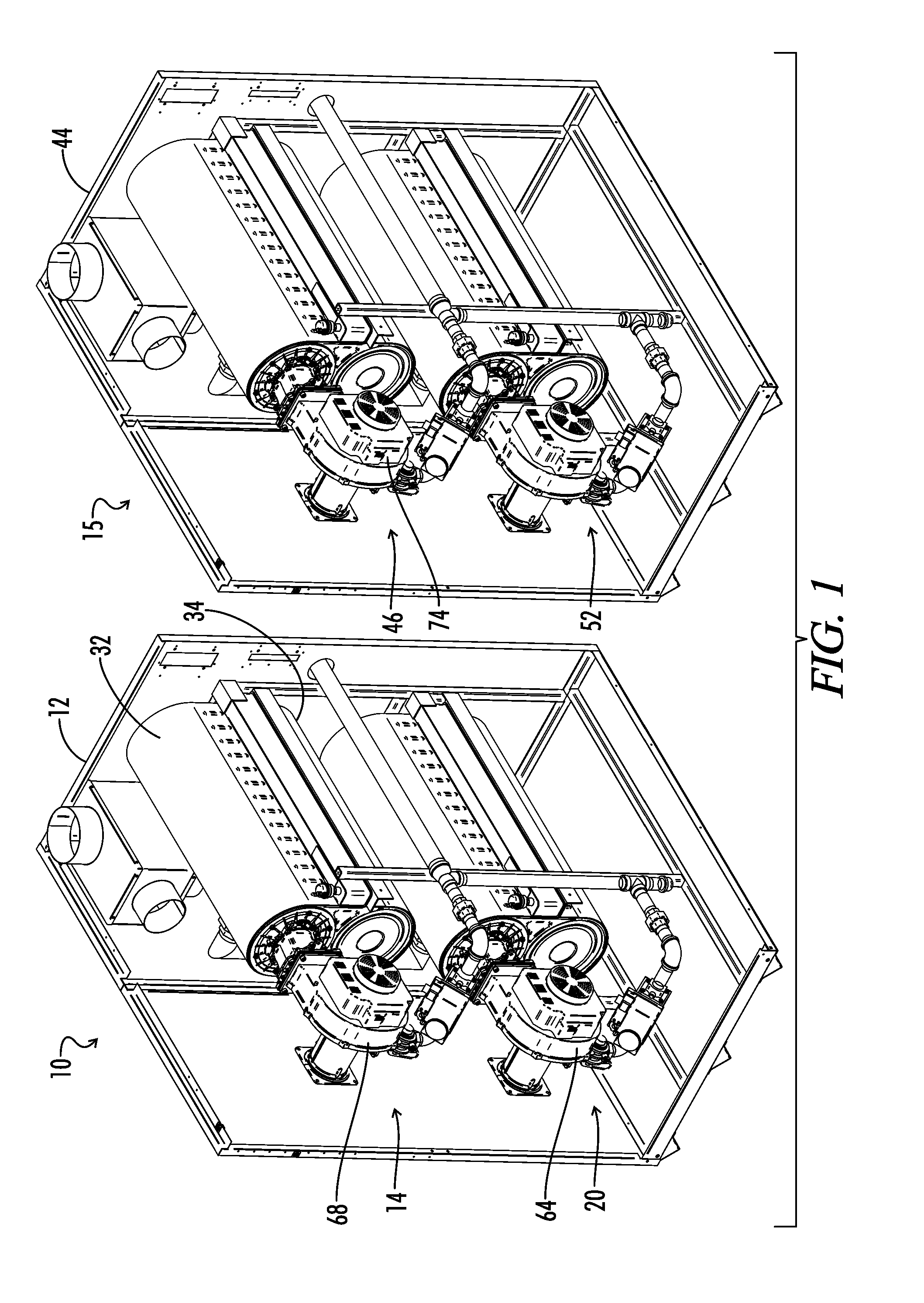

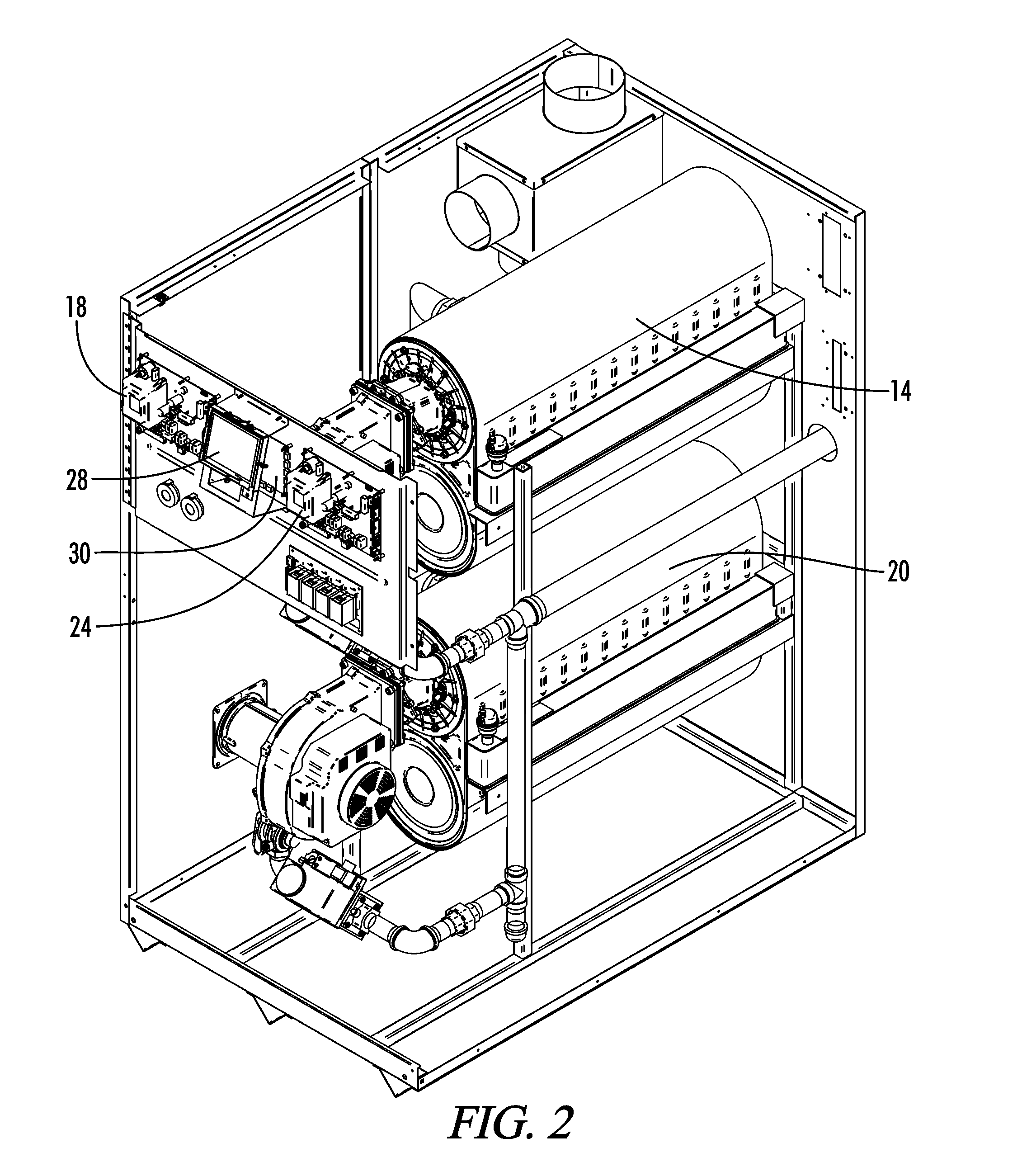

Control System For A Boiler Assembly

ActiveUS20130126627A1Modulated outputMinimize occurrenceBoiler flue tubes/fire tubesBoiler controlEngineeringControl theory

A control system for managing and interfacing a plurality of water heaters, e.g. boilers. The control system includes a first boiler unit controlled by a first boiler control unit and a second boiler unit controlled by a second boiler control unit. The first boiler control unit is operable to coordinate the operation of the first and second boiler units in response to changes in output demand. The flues of the first and second boiler units are connected to a common flue. The control system further includes an interface and an interface control system. The interface control system communicates requests from the interface, to report and / or alter the operating parameters of the first and second boiler units, to the first and second boiler control units and communicates the request outcome(s) back to the interface.

Owner:LOCHINVAR

Modular boiler control

ActiveUS7735459B2Low costEvenly distribute runtime among the boilersSpace heating and ventilationTemperatue controlControl theoryBoiler control

Owner:WESTCAST

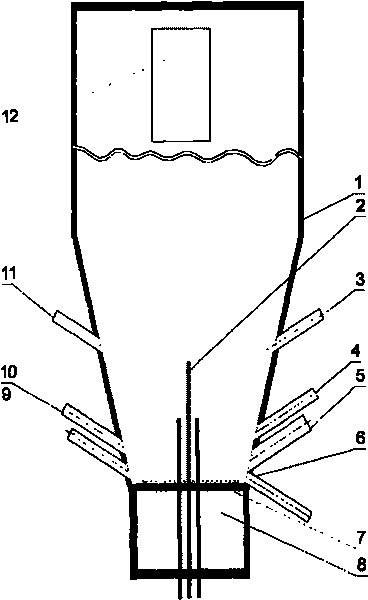

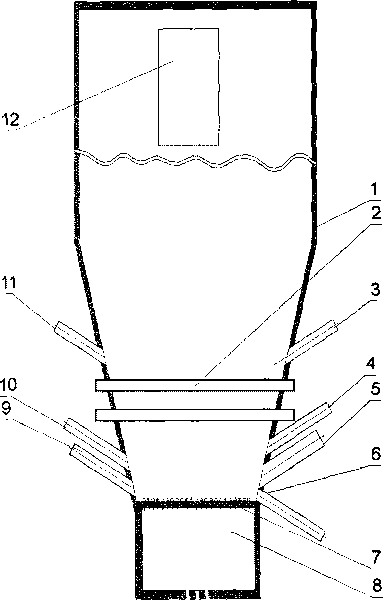

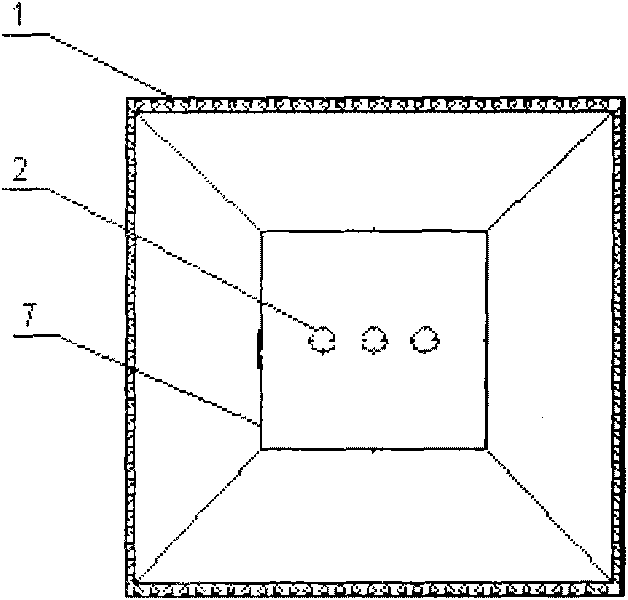

Circulating fluidized bed boiler combusting low calorific value gas fuel

InactiveCN101725962AWell mixedReduce generationFluidized bed combustionApparatus for fluidised bed combustionHigh concentrationSlag

The invention discloses a circulating fluidized bed boiler combusting low calorific value gas fuel. Partial or entire exhaust gas is sent into a hearth through an air distribution plate, horizontally or vertically arranged hearth center fuel gas feeding pipes and an external fuel gas feeding pipe at the peripheral wall of the hearth ; partial or entire air is sent into the hearth through an air chamber on the air distribution plate, and the residual air is sent into the hearth through the peripheral wall of the hearth; and an external heat source is utilized to heat inert materials (coal slag or sand and the like) in the hearth, and then the exhaust gas and the air are mixed uniformly by utilizing the thermal storage of high-concentration materials at the lower part of the hearth and the kinetic energy of fluidized materials, and are heated to an ignition temperature to be combusted. The boiler controls the production of NOx through low-temperature combustion when realizing the combustion of the low calorific value gas fuel that a low calorific value is between 200 and 2,500kJ / Nm3, and can realize the standard discharge of pollutants.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com