Optimizing and guiding system for coal-burned industrial boiler operation

A technology for operation optimization and industrial boilers, which is applied in the system field of energy-saving technology, can solve the problems of difficult determination of benchmark values, real-time efficiency processing fuel correction of coal-fired boilers, and poor operability of coal-fired boilers, etc., to achieve energy saving Fuel, improvement of boiler operation efficiency, effect of improvement of boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

[0024] This embodiment is applied to a 20t / h coal-fired industrial boiler, and the annual coal consumption of the boiler is about 20,000 tons.

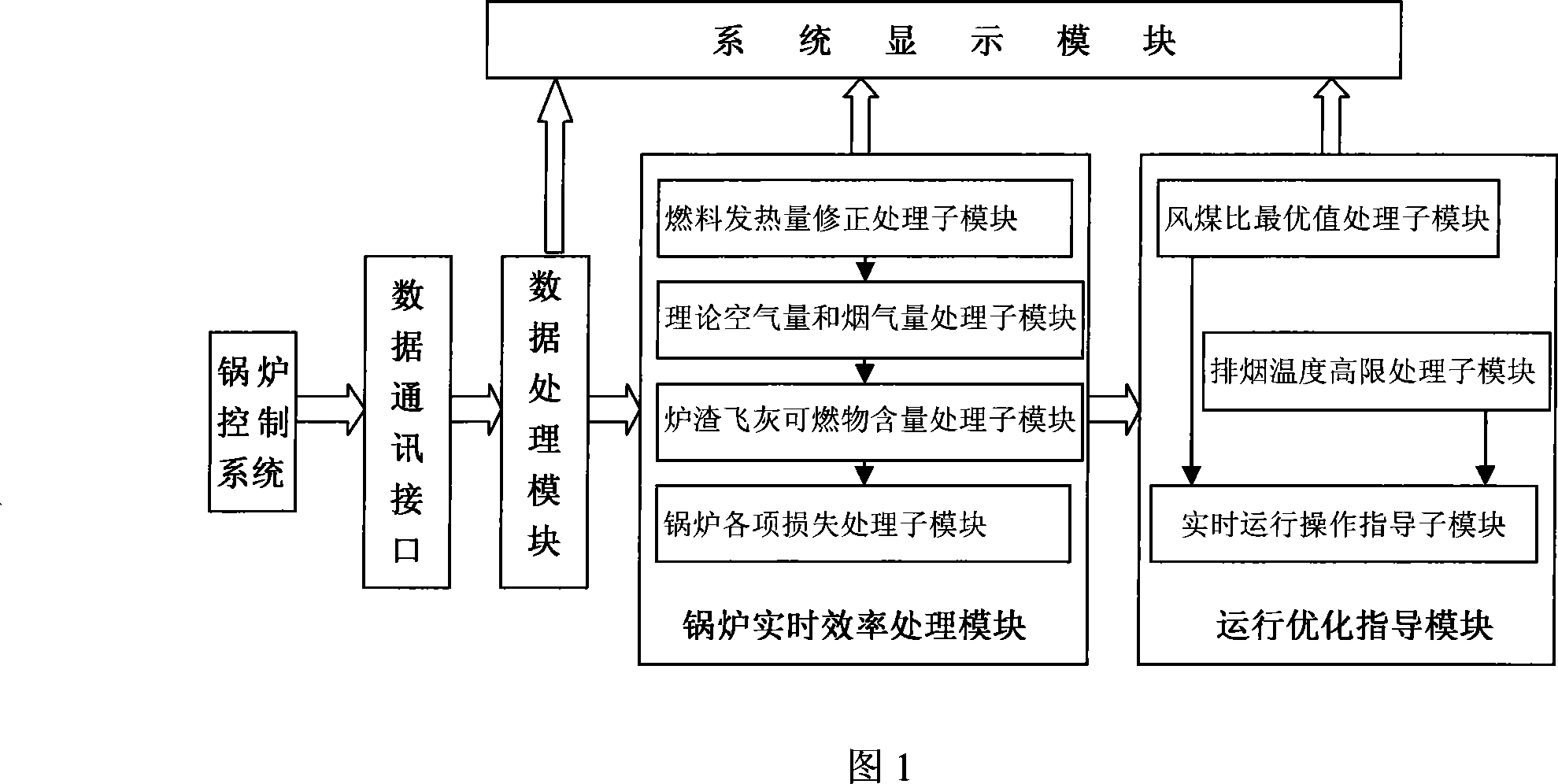

[0025] As shown in Figure 1, this embodiment includes five modules: data communication interface, data processing module, system display module, boiler real-time efficiency processing module and operation optimization guidance module,

[0026] Among them: the data communication interface is connected with the data interface of the boiler control system, and receives real-time operation data from the boiler control system. An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com