Fossil power plant coordination control method based on multi-parameter prediction

A thermal power unit, coordinated control technology, applied in electric controllers, controllers with specific characteristics, etc., can solve problems such as regulation oscillation, low unit load rise and fall rate, unit peak regulation, and poor frequency regulation capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

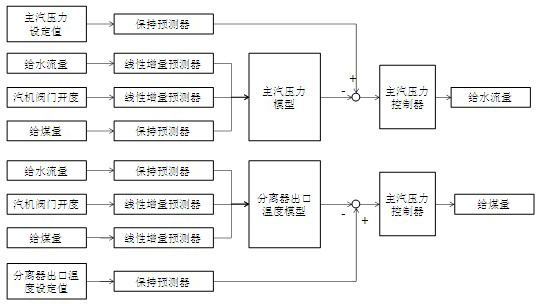

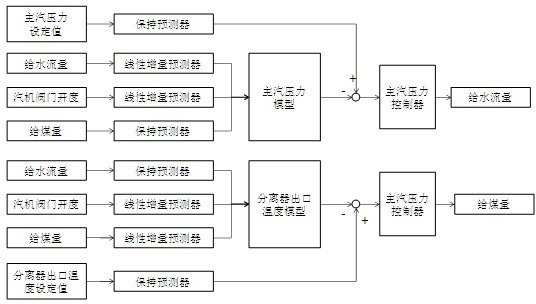

Image

Examples

Embodiment Construction

[0051] Concrete realization process of the present invention is as follows:

[0052] 1. Through field tests on thermal power units, the following data are obtained: water flow Fw, coal feed Fu, turbine valve opening Tm, main steam pressure Msp, separator outlet temperature Tsp, load Ne.

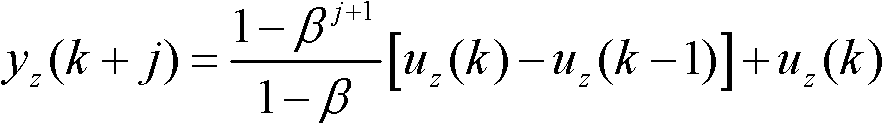

[0053] 2. Identify the mathematical model based on the acquired data, and use the transfer function model to identify the corresponding transfer function:

[0054]

[0055] in G fu ne = 2.2093 ( 1 + 400 s ) ( 1 + 800 s ) , G fw ne = 0.36741 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com