Energy-saving gas replacement method for low-temperature liquid tank car

A cryogenic liquid and tank car technology, which is applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., and can solve problems such as complex operation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

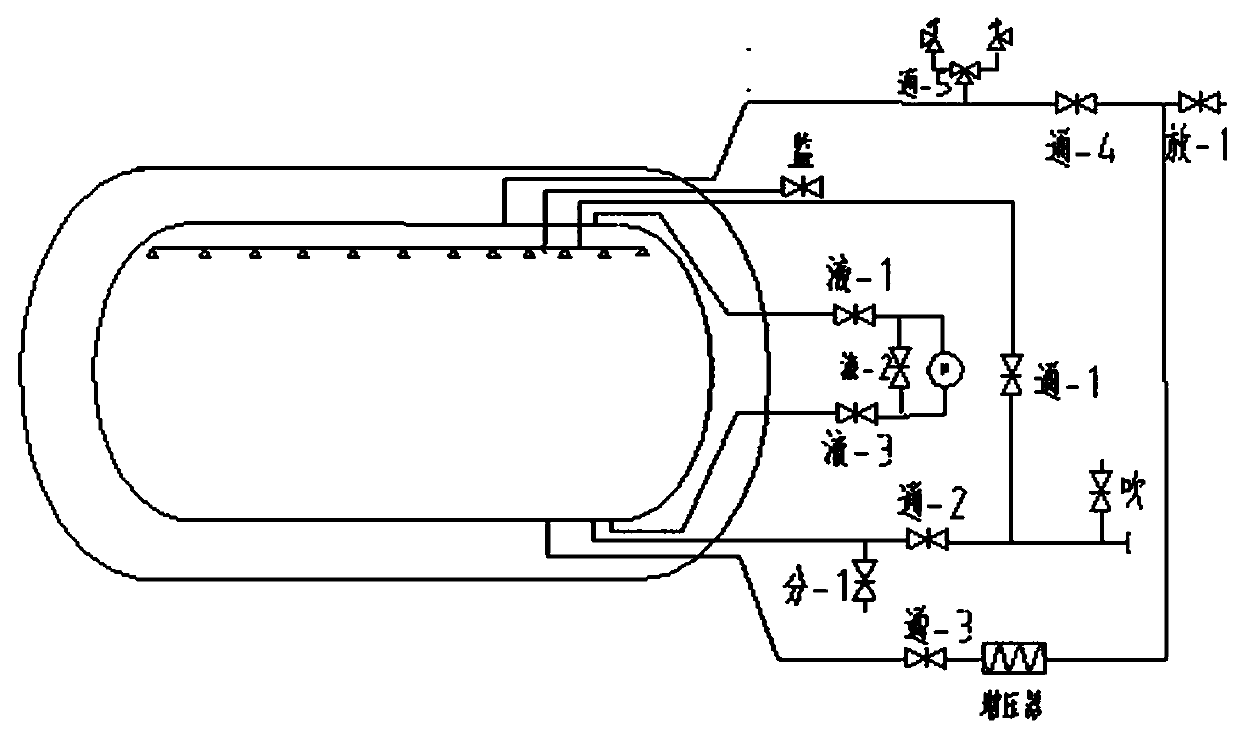

[0008] An energy-saving replacement method for gas in a low-temperature liquid tank car, such as figure 1 As shown, the tank truck storage tank uses gas energy-saving to replace the operation method: 1. Move the installation position of the supercharger outlet valve "Tong-4" to the three-way safety valve "Tong-5" and the vent valve "Tong-1" pipeline 2. The first three steps are the same as the "1~3" replacement method in the prior art; 3. According to the type of low-temperature liquid medium to be filled, return the low-temperature oxygen and nitrogen to the inlet of the main heat exchanger of the air separation unit. , or the low-temperature process argon gas at the outlet of the crude argon tower is connected to the tank car through the filling hose, so that the corresponding low-temperature gas is filled into the storage tank through the top inlet (discharge) liquid valve "Tong-1", and the inlet of the supercharger is opened The valve "tong-3" and the vent valve "release-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com