Thermal insulation system and construction method for type b liquid cargo tank of liquefied natural gas carrier

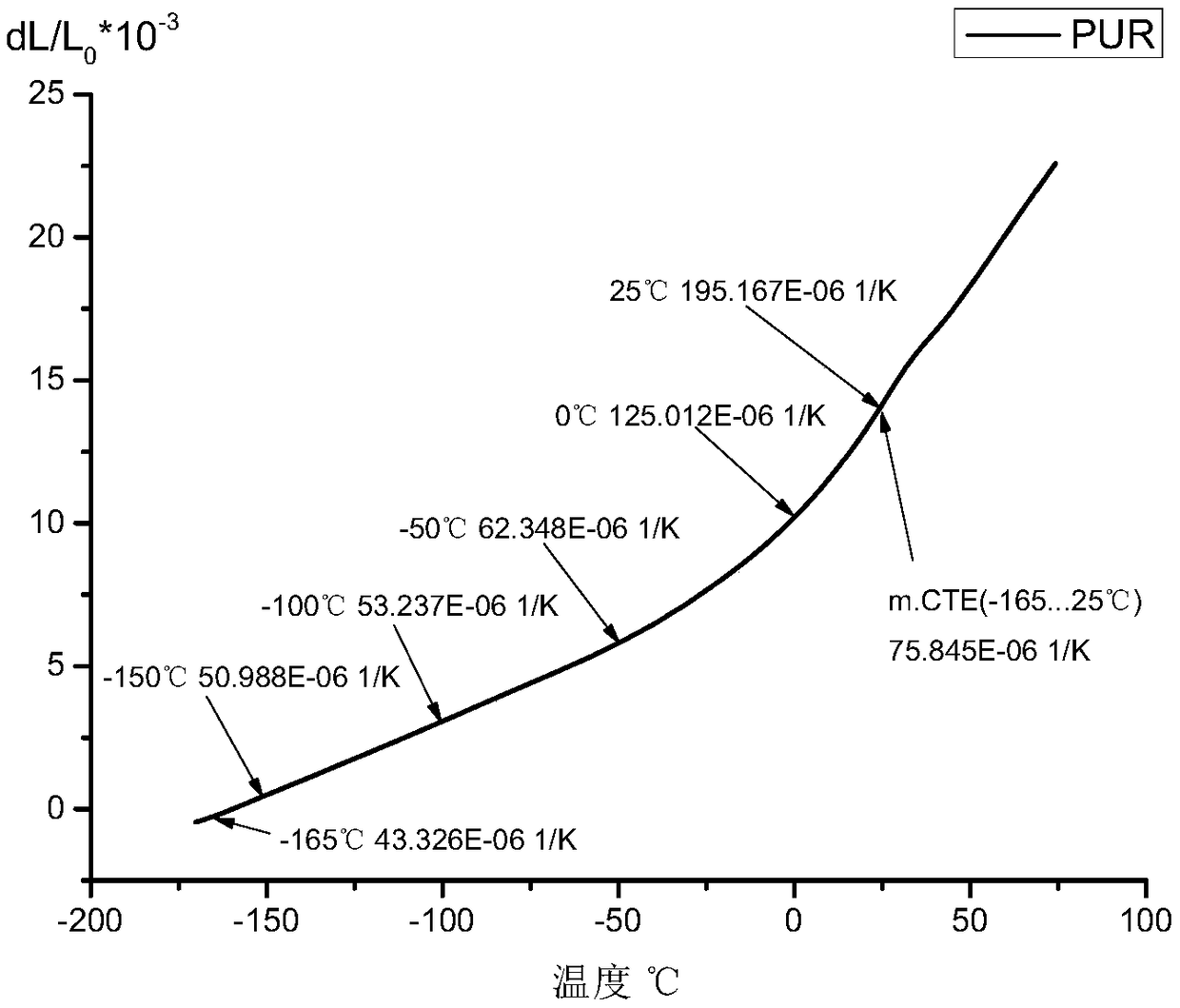

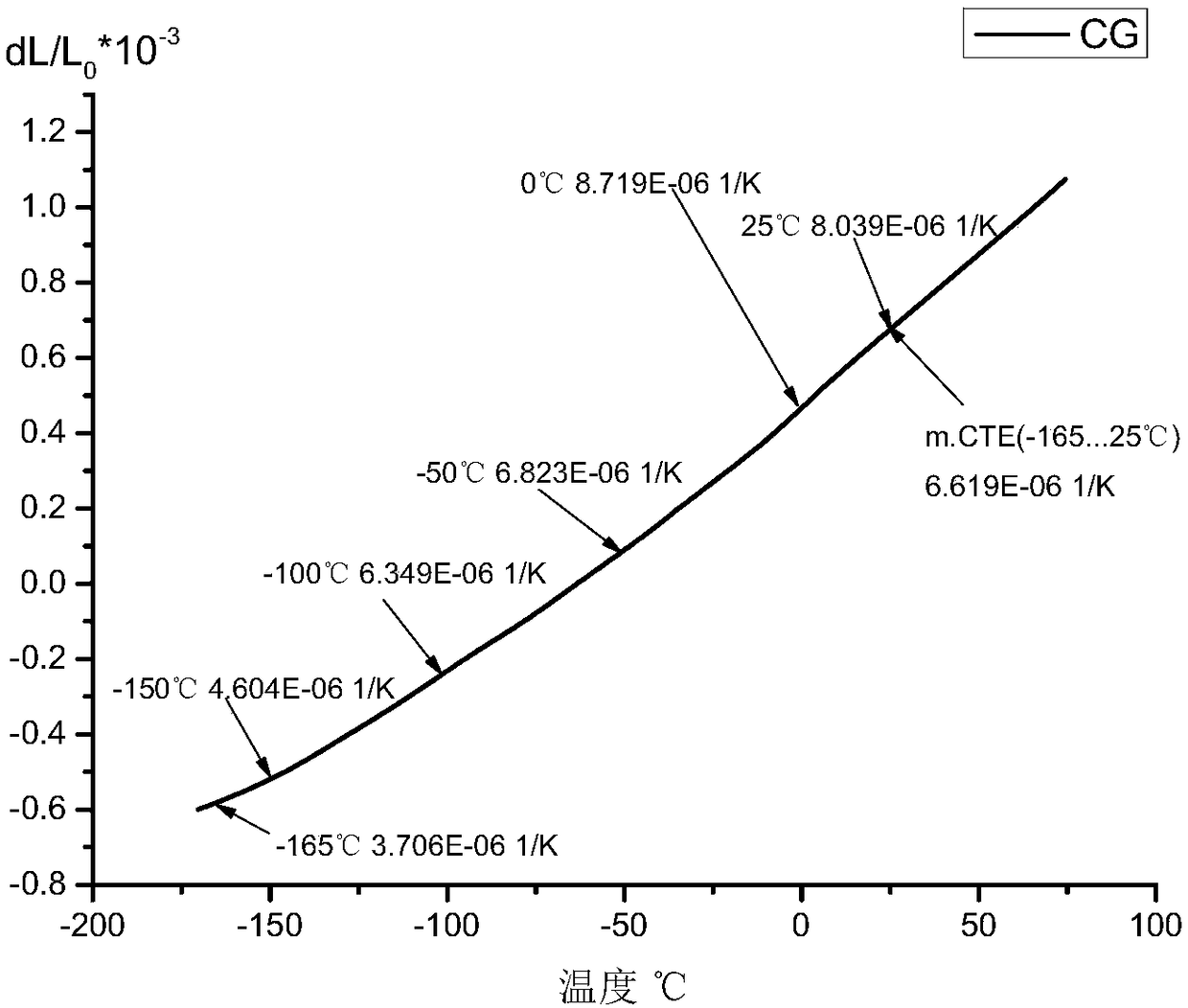

A technology for liquefied natural gas and liquid cargo tanks, which is applied to chemical instruments and methods, heat exchange equipment, and bulk cargo, and can solve problems such as damage to the insulation layer and large PUR thermal stress of the insulation board to improve insulation performance and safe use Wide temperature range and stable effect of thermal insulation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples of the present invention are described in detail below. The following examples are implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the embodiment.

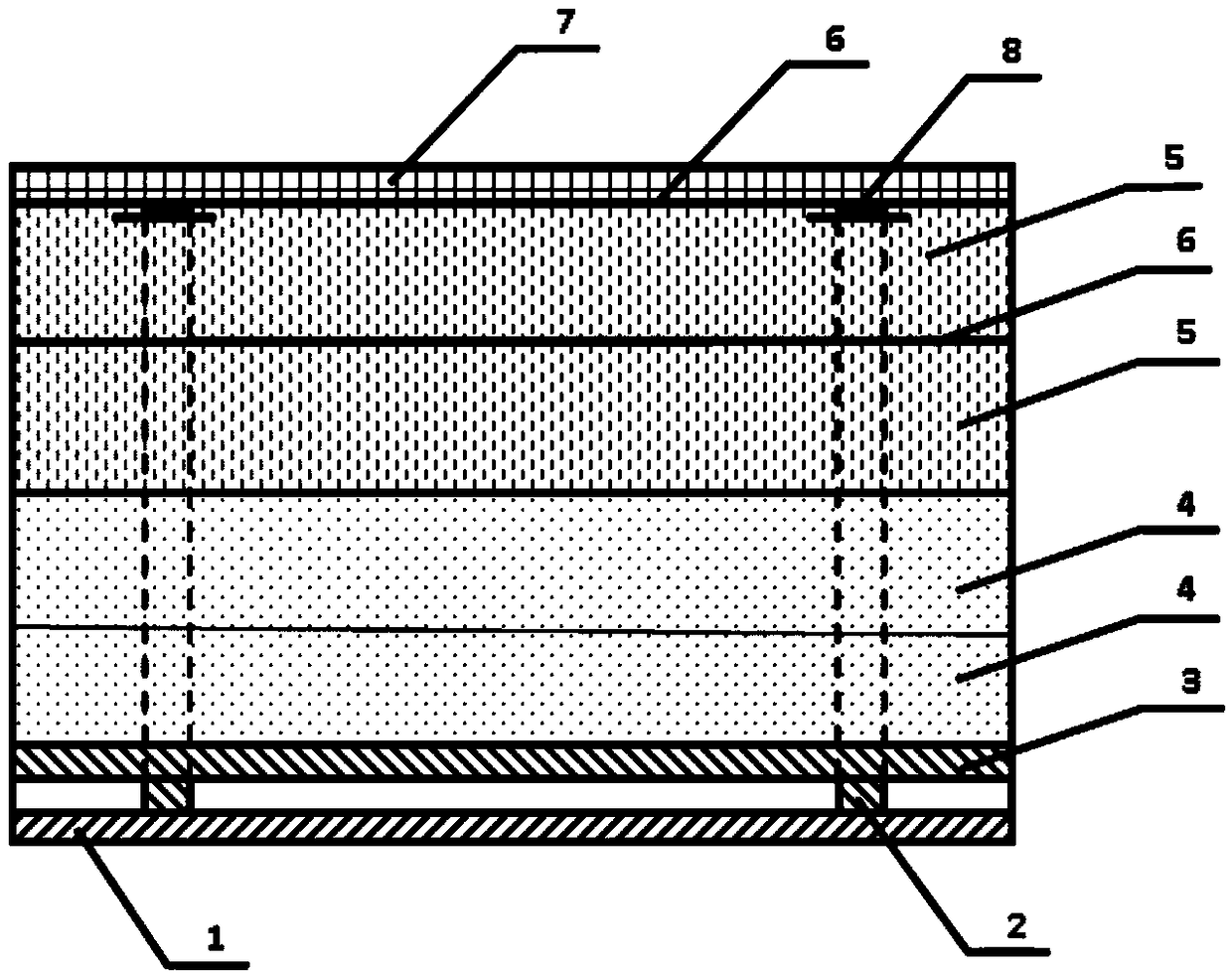

[0031] Such as image 3 and Figure 4 As shown, in a preferred embodiment of the present invention, the thermal insulation system of the cargo tank of an LNG carrier includes a main barrier wall 1, a thermal insulation layer and a protective layer 7, and the thermal insulation layer includes a secondary barrier wall 3, a thermal insulation board and a water blocking layer 6. The heat insulation board is sandwiched between the secondary barrier wall 3 and the protective layer 7 , and the protective layer 7 covers the outer surface of the water blocking layer 4 .

[0032] The main screen wall 1 is made of 9%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com