Method for prolonging service life of cooling wall of schreyerite smelting blast furnace

A technology of cooling stave and vanadium titanite, applied in the direction of cooling device, etc., can solve problems such as endangering blast furnace production, and achieve the effect of reducing thermal stress changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

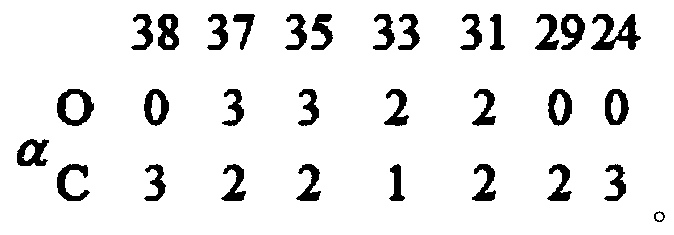

[0055] During the production process of the blast furnace, the material structure of the furnace is controlled according to 63wt% sinter + 31wt% pellet + 3wt% acidic oxidation pellet + 3wt% natural lump ore, and the overall water volume of medium pressure water is 6200m 3 / h, the overall water volume of high pressure water is 1030m 3 / h cooling parameters, the resulting product, the pig iron contains 0.27wt% Ti, the temperature of the molten iron is 1465°C, the binary alkalinity of the slag is 1.00, and the ratio of slag to iron is 585kg / t. The distribution matrix used is as follows:

[0056] cloth angle 37.5° 36.5° 34.5° 32.5° 30.5° 28.5° 23.5° Number of ore circles 0 2 3 3 2 0 0 Coke circle number 3 2 1 1 1 2 3

[0057] During the blast furnace production process, the water temperature difference of the stave is monitored. Once the temperature difference of the stave fluctuates abnormally (the fluctuation of the water temperature d...

Embodiment 2

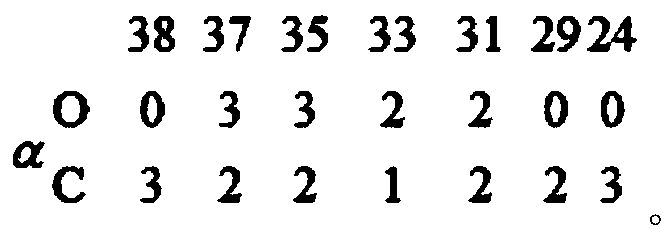

[0059] During the blast furnace production process, the material structure of the furnace is controlled according to 63wt% sinter + 31wt% pellets + 3wt% acidic oxidation pellets + 3wt% natural lump ore, the overall water of medium pressure water: 6500m 3 / h, the overall water volume of high pressure water is 1020m 3 Cooling parameters per hour, the resulting product, the pig iron contains 0.20wt% Ti, the temperature of the molten iron is 1448°C, the binary basicity of the slag is 1.01, and the slag-iron ratio is 577kg / t. The distribution matrix used is as follows:

[0060] cloth angle 37.5° 36.5° 34.5° 32.5° 30.5° 28.5° 23.5° Number of ore circles 0 2 3 3 2 0 0 Coke circle number 3 2 1 1 1 2 3

[0061] According to the detection method in Example 1, the service life of the blast furnace stave in the blast furnace smelting method provided in Example 2 of the present invention can reach 8 years.

Embodiment 3

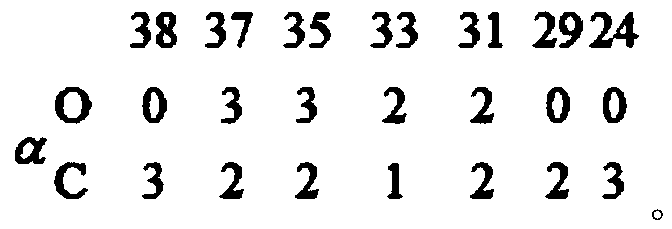

[0063] During the production process of the blast furnace, the material structure of the furnace is controlled according to 63wt% sinter + 31wt% pellet + 3wt% acidic oxidation pellet + 3wt% natural lump ore, and the overall water volume of medium pressure water is 6260m 3 / h, the overall water volume of high pressure water is 1050m 3 / h cooling parameters, the resulting product, the pig iron contains 0.23wt% Ti, the temperature of the molten iron is 1458°C, the binary alkalinity of the slag is 1.02, and the slag-iron ratio is 569kg / t. The distribution matrix used is as follows:

[0064] cloth angle 37.5° 36.5° 34.5° 32.5° 30.5° 28.5° 23.5° Number of ore circles 0 2 3 3 2 0 0 Coke circle number 3 2 1 1 1 2 3

[0065] According to the detection method in Example 1, the service life of the blast furnace stave in the blast furnace smelting method provided in Example 3 of the present invention can reach 8 years.

[0066] As can be seen f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com