Patents

Literature

1733 results about "Electric capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Capacity, Electric, or Electrostatic. The relative capacity of a conductor or system to retain a charge of electricity with the production of a given difference of potential. The greater the charge for a given change of potential, or the less the change of potential for a given charge the greater the capacity.

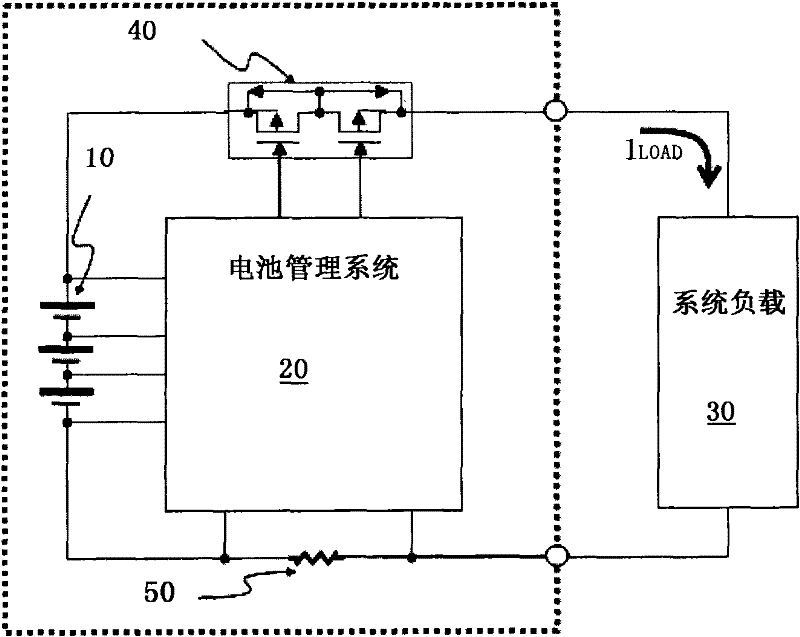

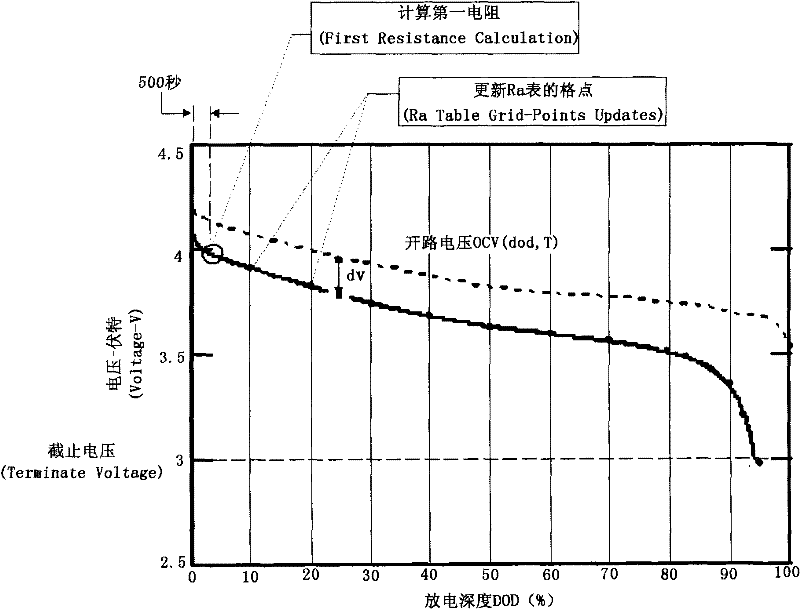

Method for predicting left capacity and health status of storage battery

InactiveCN102230953AAvoid the hassle of checking discharge testsImprove reliabilityElectrical testingBattery degradationElectrical battery

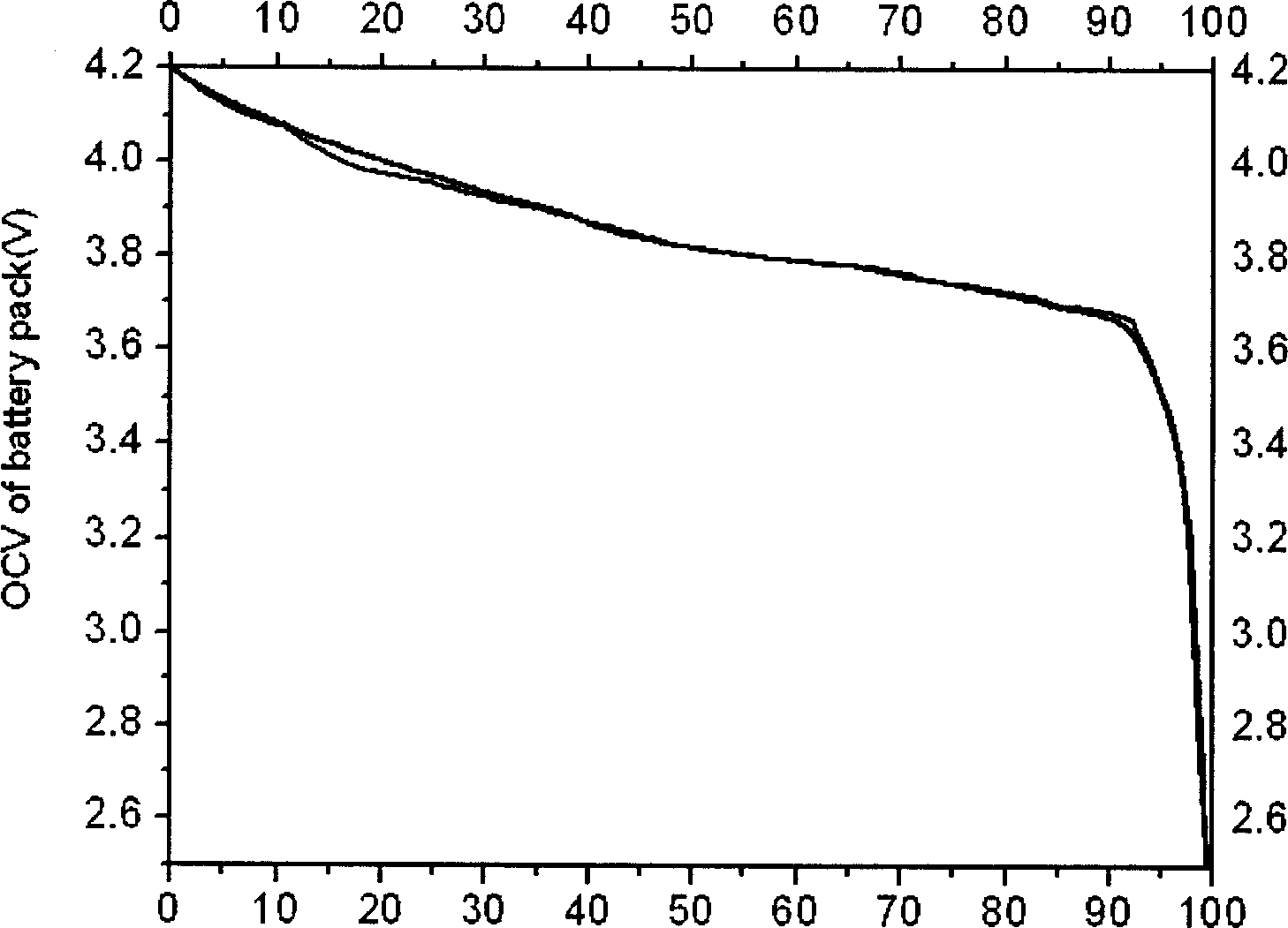

The invention discloses a method for predicting the left capacity and the health status of a storage battery. According to the invention, predicting the left capacity of the battery based on an ampere hour integration method and an open-circuit voltage method is realized, an adjustment is carried out based on discharge currents and ambient temperature, a self correction is carried out in a process of continuous driving and influences from cell agedness on electric capacity prediction are corrected. Based on the working characteristic of a vehicle cell, a cell failure determination mode based on a combination of open-circuit voltage and ampere hour integration is put forward and the trouble of carrying out a check discharge test towards the cell is avoided. Experiments show that in the case of vehicle power storage battery which is not at a float status in a long term, the capacity obtained from the method has a high reliability. The invention is directed to the social background that motor-assisted bicycles are frequently used at present while most users know little about the cell status and has great application significances.

Owner:JIANGNAN UNIV

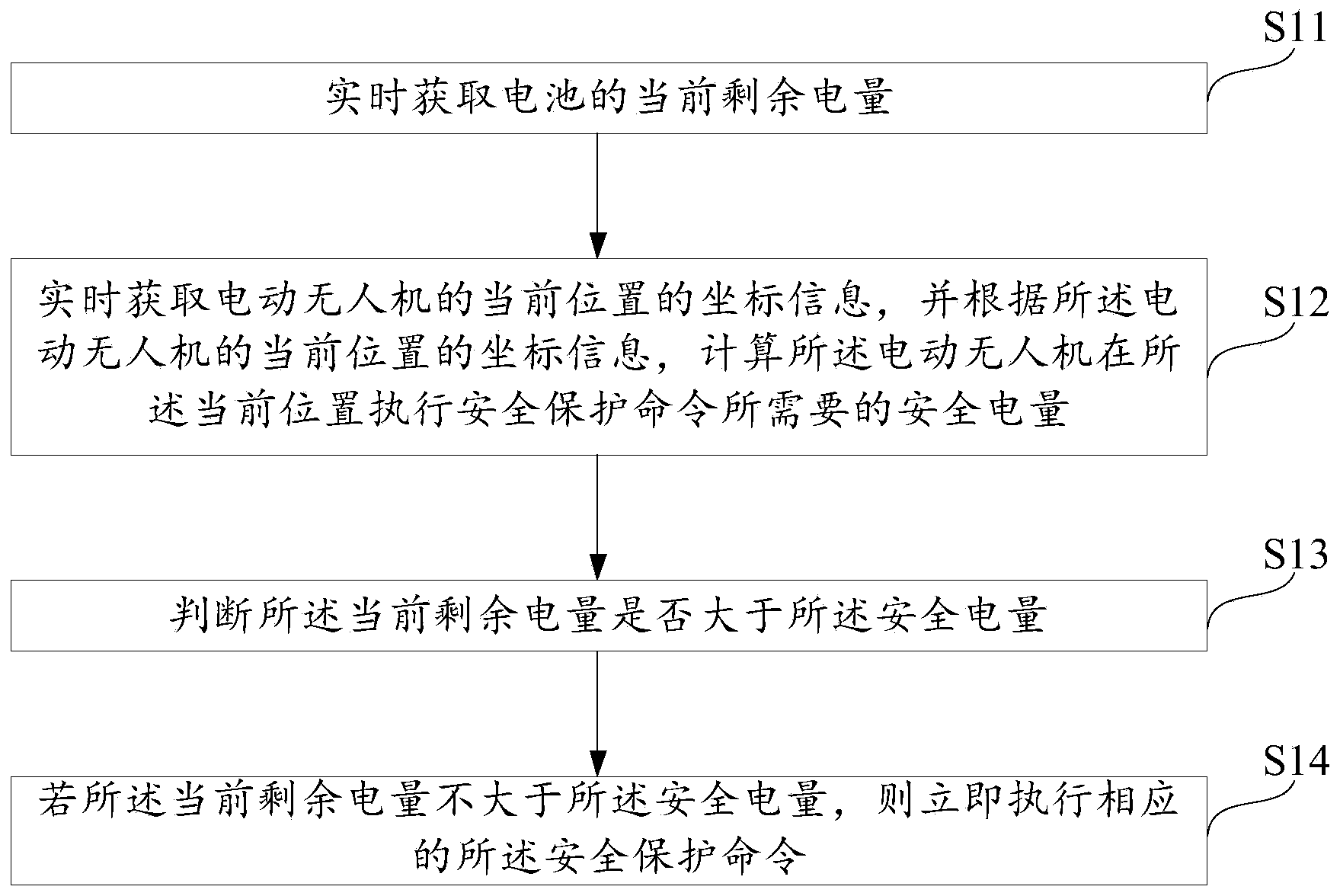

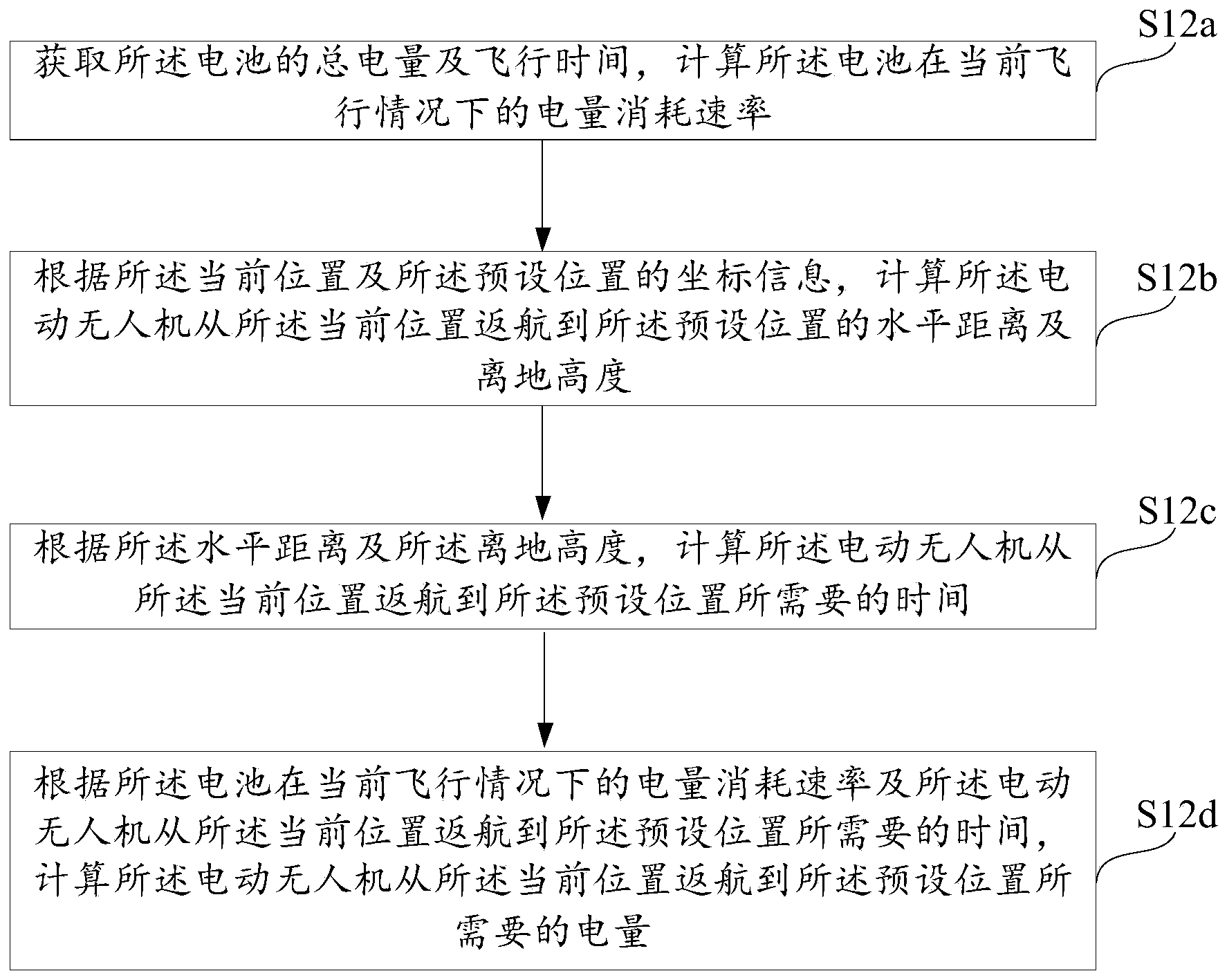

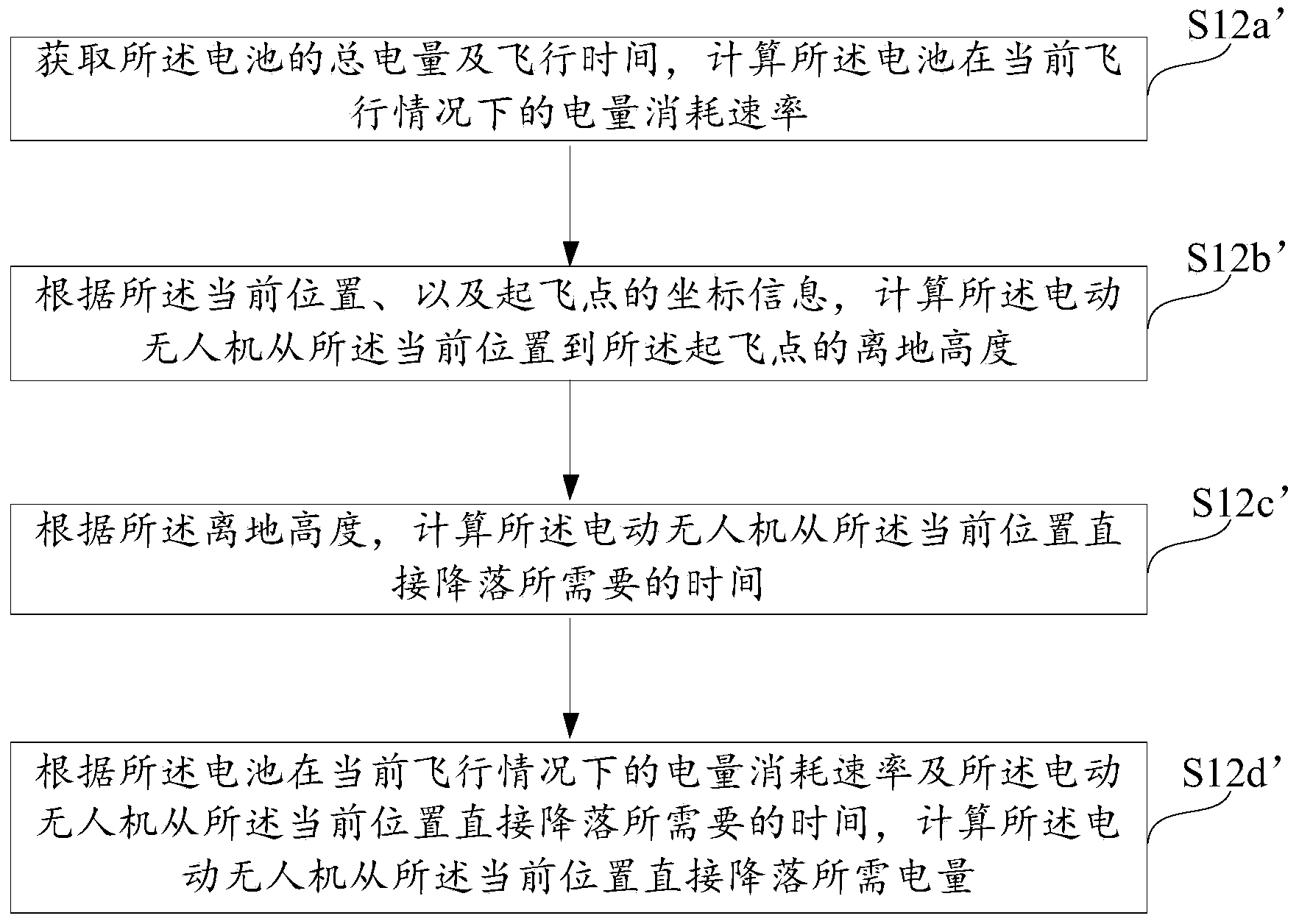

Electric unmanned aerial vehicle and intelligent electric quantity protection method

ActiveCN104166355AReal-time protectionAvoid accidentsProgramme controlControl safety arrangementsElectrical batteryElectric capacity

The invention discloses an intelligent electric quantity protection method of an electric unmanned aerial vehicle. The method comprises the following steps: obtaining a current remaining electric quantity of a battery in real time; obtaining coordinate information of a current position of an electric unmanned aerial vehicle in real time and calculating a security electric quantity needed for security protection command execution by the electric unmanned aerial vehicle at the current position according to the coordinate information of the current position of the electric unmanned aerial vehicle; determining whether the current remaining electric quantity is larger than the security electric quantity; and if not, executing a corresponding security protection command immediately. With the intelligent electric quantity protection method, the electric unmanned aerial vehicle can be protected effectively and intelligently in real time; an electric unmanned aerial vehicle accident caused by insufficient electric capacity can be avoided; and the battery utilization rate is also improved. In addition, the invention also provides an electric unmanned aerial vehicle using the intelligent electric quantity protection method.

Owner:SZ DJI TECH CO LTD

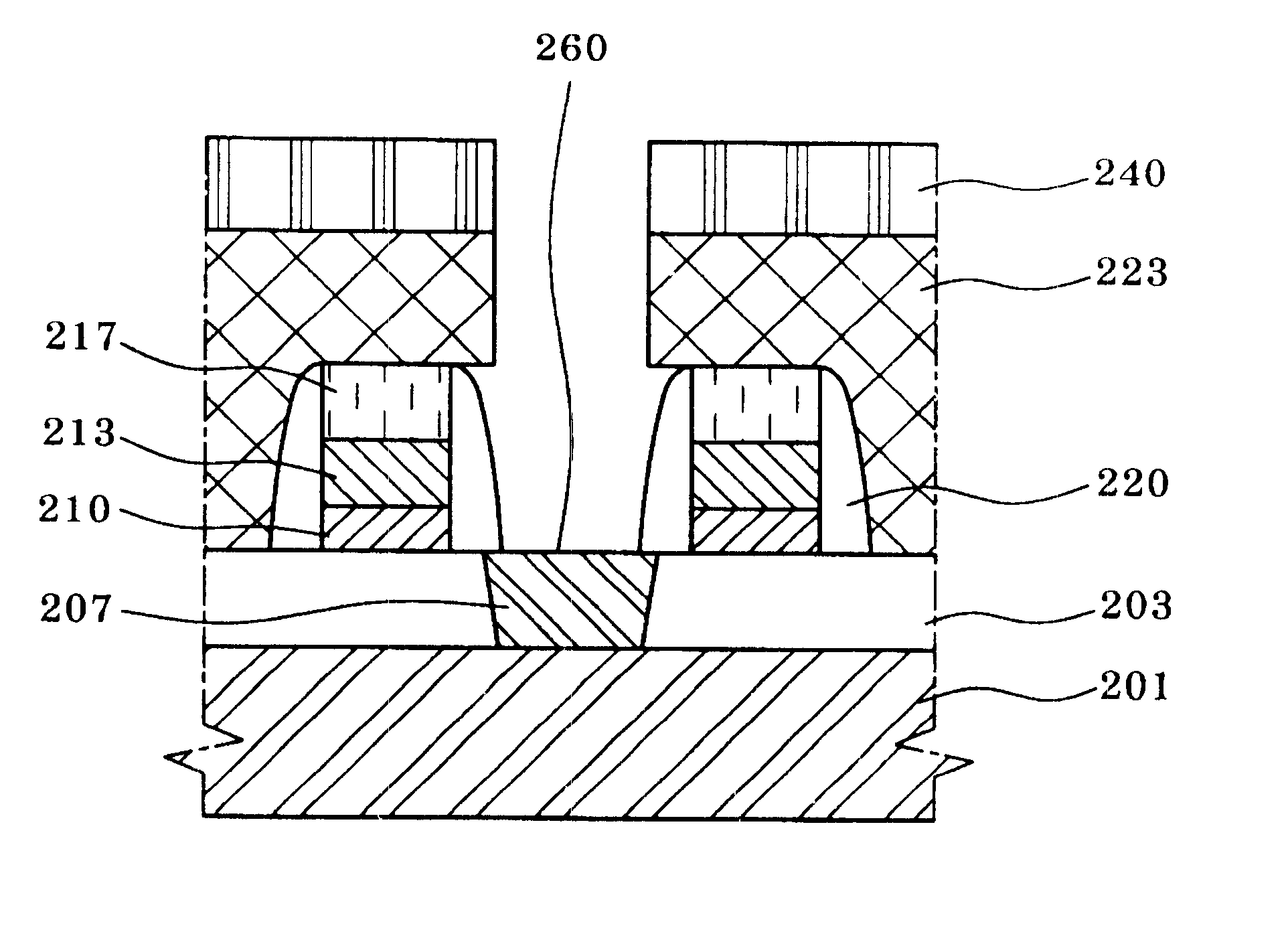

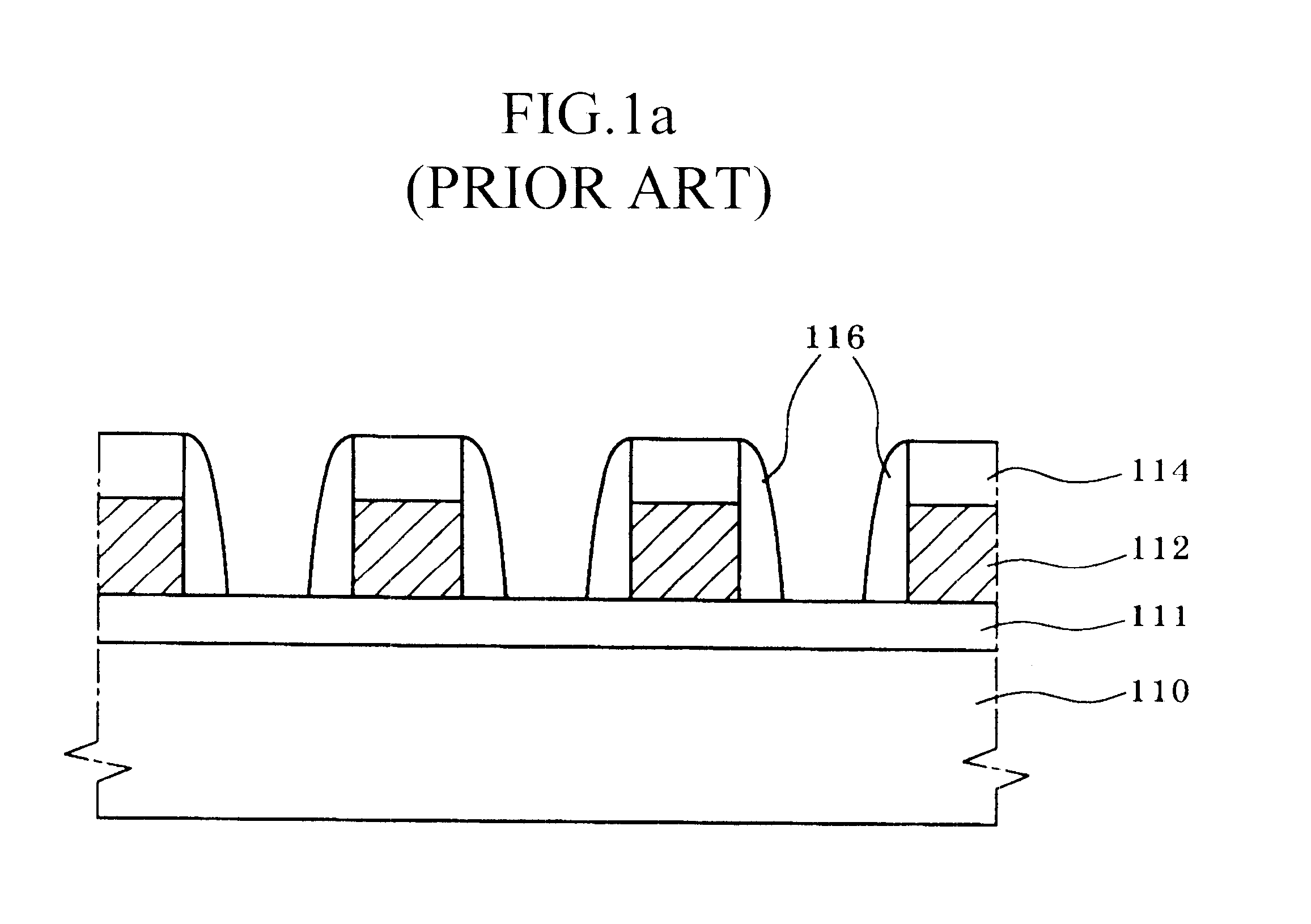

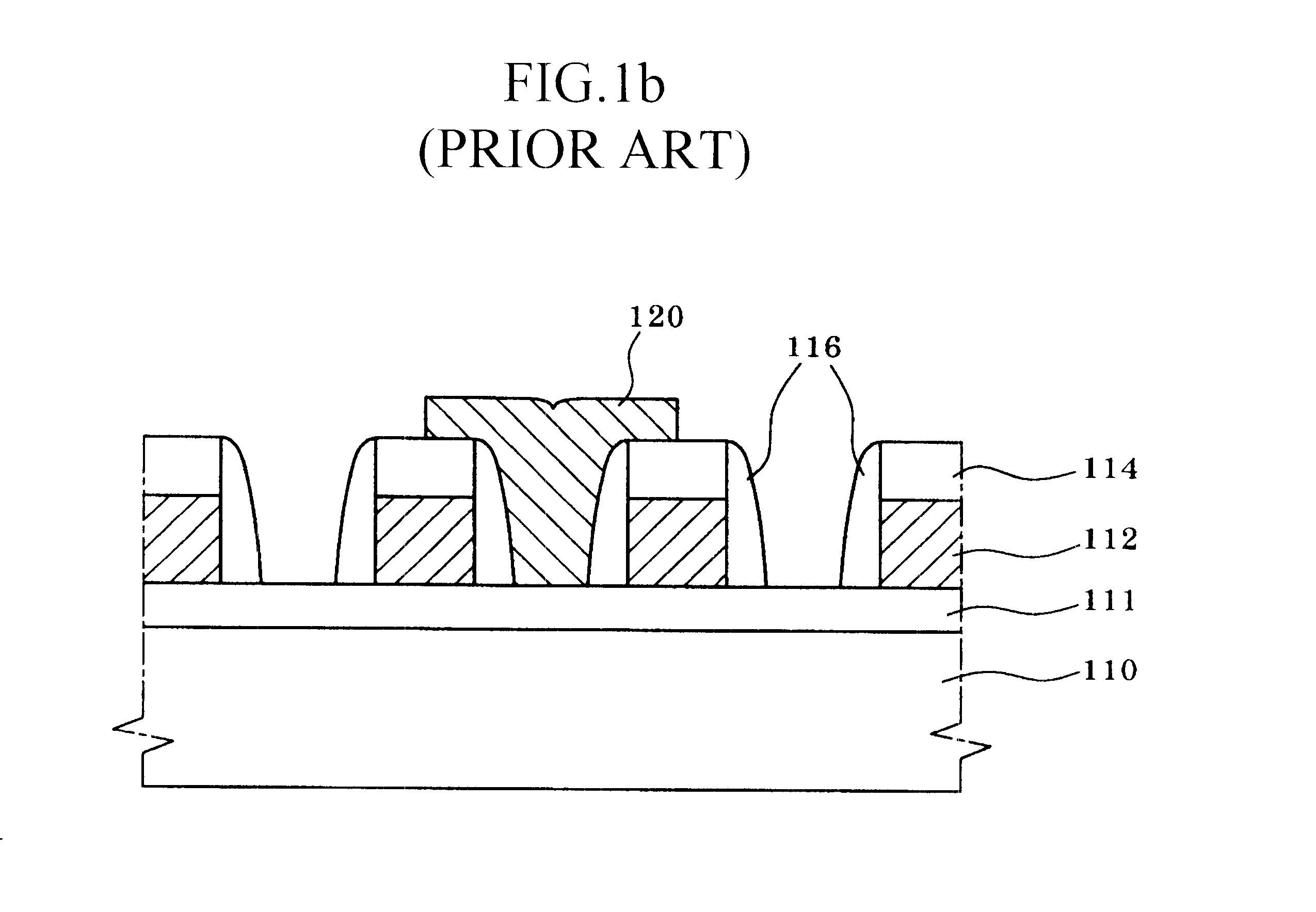

Electric double layer capacitor

InactiveUS6466429B1Lower internal resistanceInhibit sheddingHybrid capacitor electrolytesHybrid capacitor electrodesActivated carbonLead dioxide

The present invention is directed to a novel capacitor. The capacitor may be used in electric double layer capacitors. The capacitors include a polarizable electrode including activated carbon and a non-polarizable electrode including lead dioxide and lead sulfate. The capacitors of the present invention provide considerably higher electric capacity, higher durability, and low resistance, while maintaining high conductivity. Additionally, the electrodes may be produced more quickly and inexpensively.

Owner:WAINWRIGHT D WALKER

Novel carbon-sulfur compound for lithium-sulfur battery

InactiveCN101587951AIncrease profitIncrease specific energyCell electrodesSulfur compoundsElectric capacityInternal resistance

The invention relates to a novel carbon-sulfur compound for an anode material of a lithium-sulfur battery and a preparation method thereof. Sulfur is filled into a nano and micron hole of a matrix in an elementary substance way by taking a macroporous carbon material with high pore volume, electrical conductivity and specific surface area as the matrix, and the sulfur and carbon can also carry out combination reaction so as to prepare the novel carbon-sulfur compound of which the sulfur exists in one or more chemical states in a carbon material. The novel carbon-sulfur compound used as the anode material of the lithium-sulfur battery has the advantages that the high pore volume has large contained sulfur contents and can ensure high electric capacity; the small granularity of the sulfur can reduce a conductive distance between ions and electrons and increase the utilization ratio of the sulfur; and the adsorption characteristics of the high specific surface of the carbon material can inhibit a discharging intermediate product from dissolving and moving towards a cathode, reduce the self discharge, prevent a nonconductive discharging product, namely lithium sulfide from largely accumulating outside carbon particles and reduce internal resistance, therefore, the material can improve the specific energy, the specific power and the cycle performance of the lithium-sulfur battery.

Owner:NO 63971 TROOPS PLA

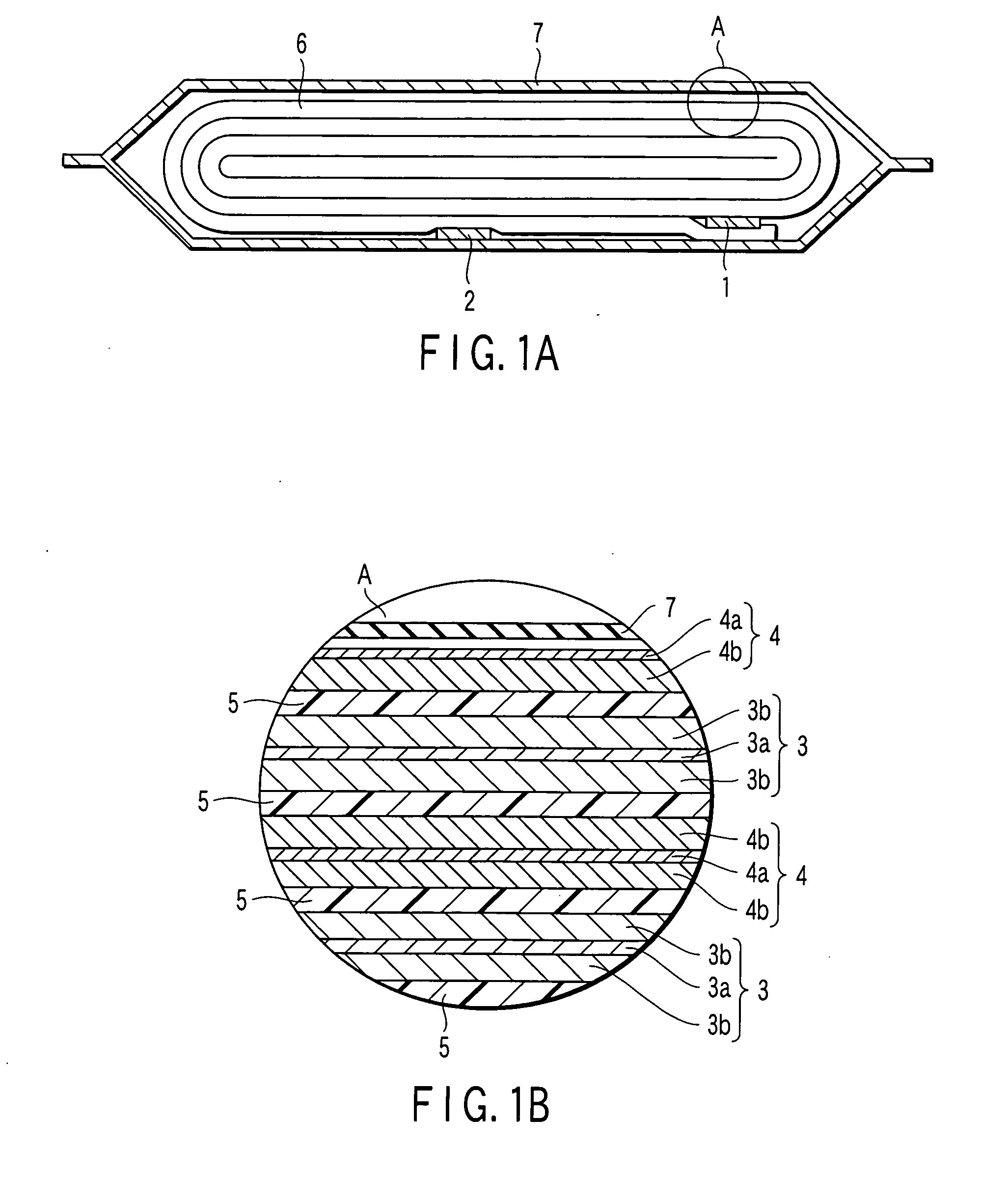

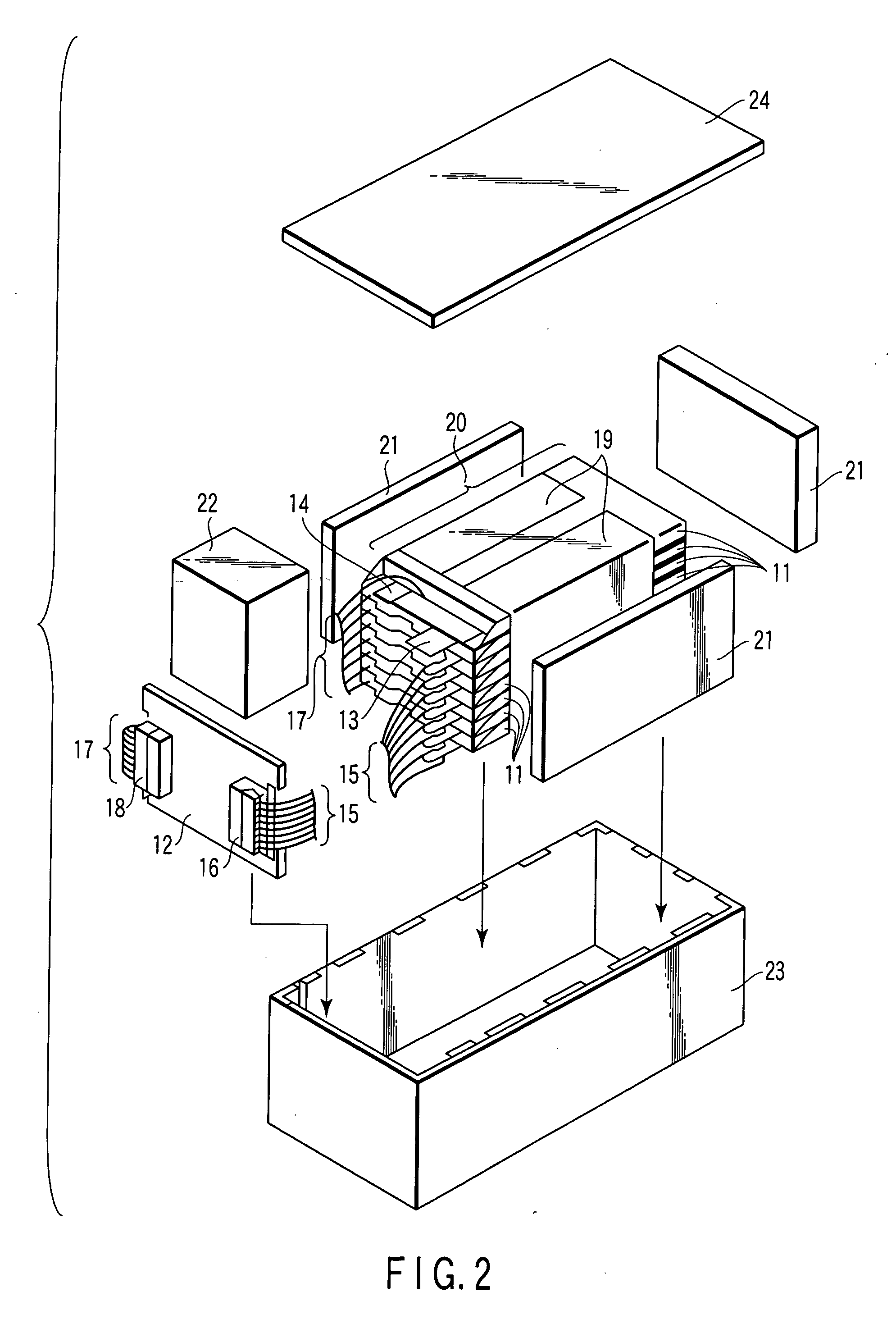

Battery pack and vehicle

ActiveUS20060216600A1Excellent in charge-discharge cycle characteristicFinal product manufactureCell lids/coversElectric capacitySpinel

A battery pack includes nonaqueous electrolyte batteries each comprising a positive electrode and a negative electrode. The positive electrode contains a lithium-transition metal oxide having a layered crystal structure. The negative electrode contains a lithium-titanium composite oxide having a spinel structure. And the positive electrodes and the negative electrodes satisfy the formula (1) given below: 1.02≦X≦2 (1) where X is a ratio of an available electric capacity of each of the negative electrodes at 25° C. to an available electric capacity of each of the positive electrodes at 25° C.

Owner:KK TOSHIBA

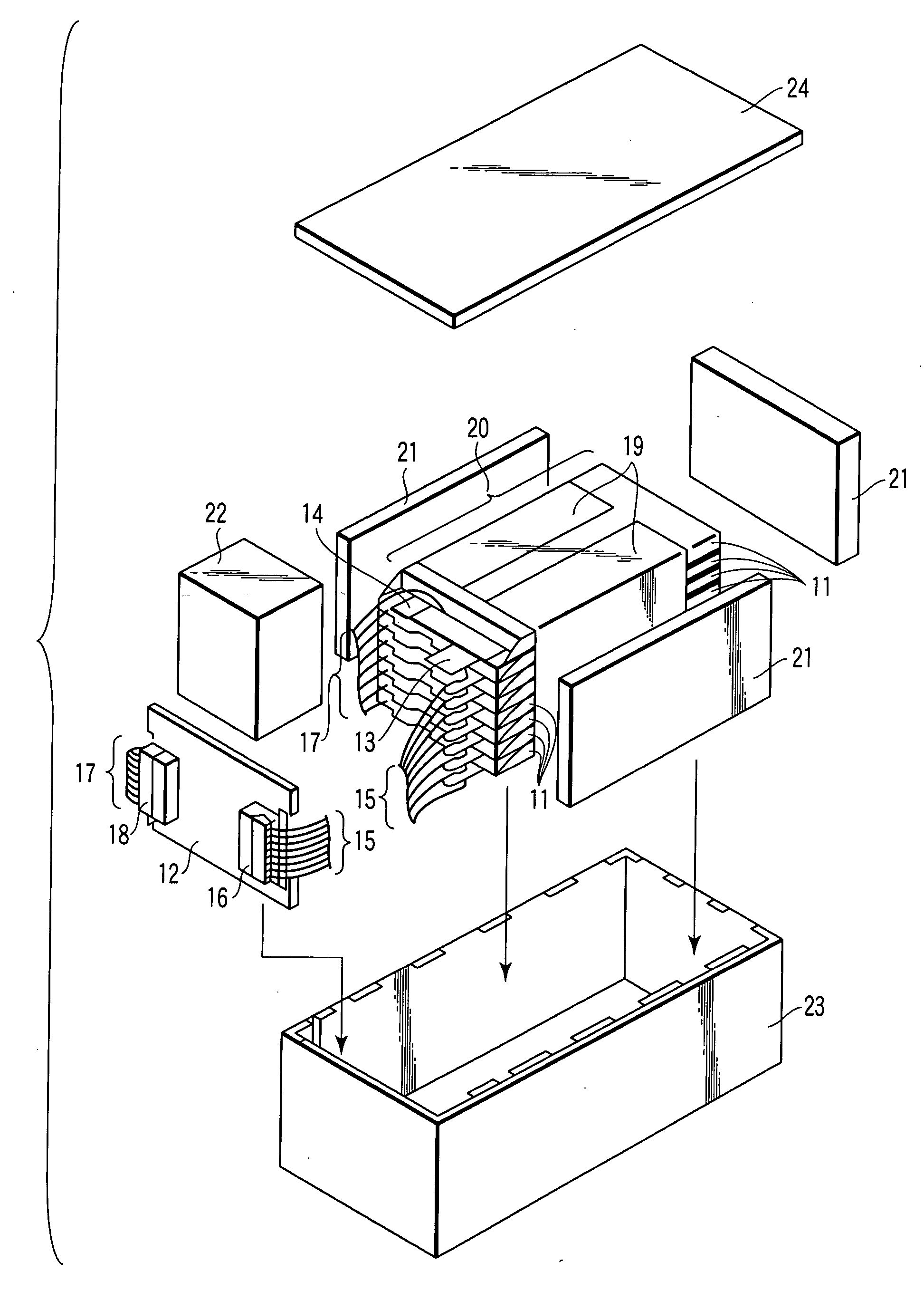

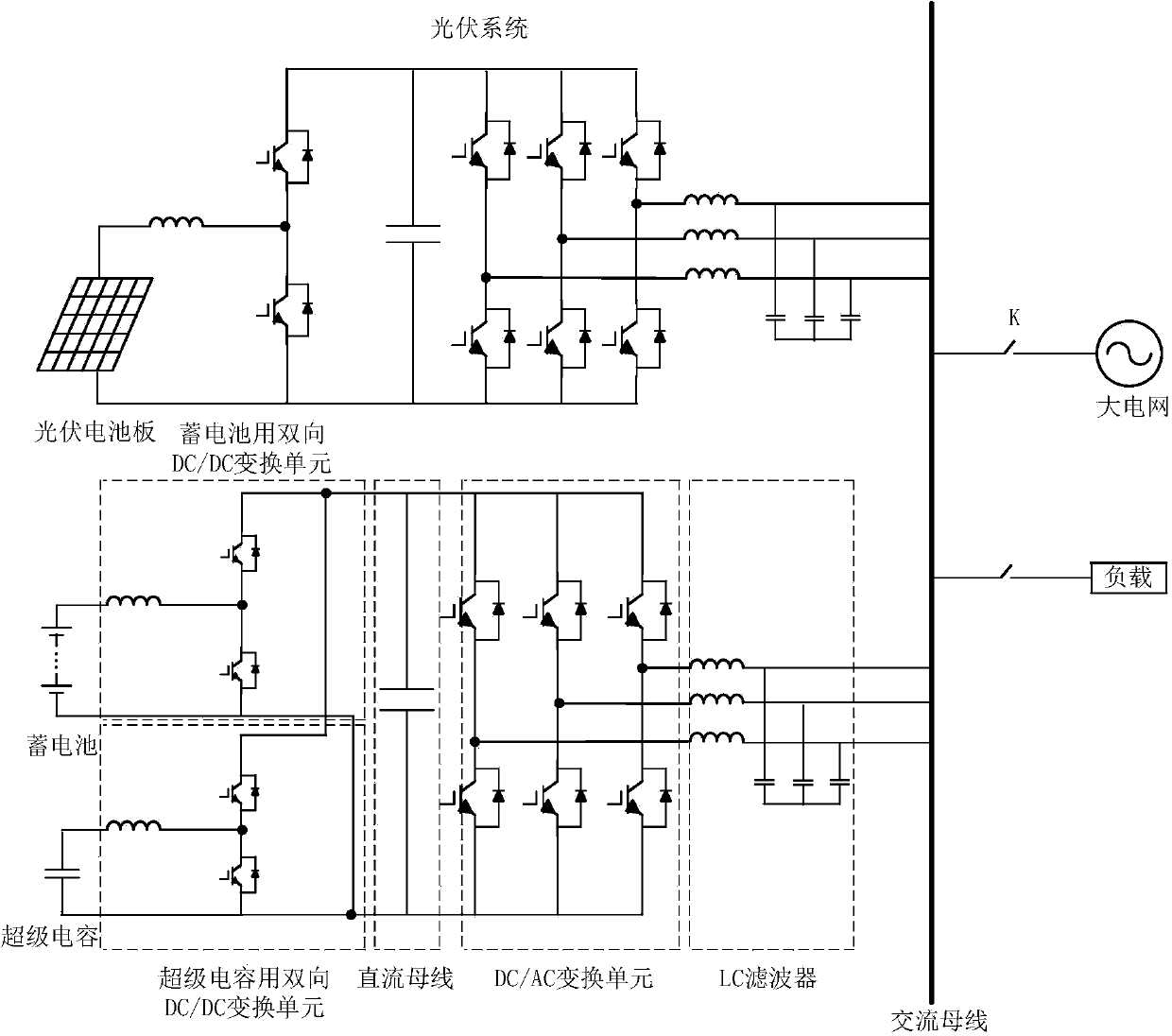

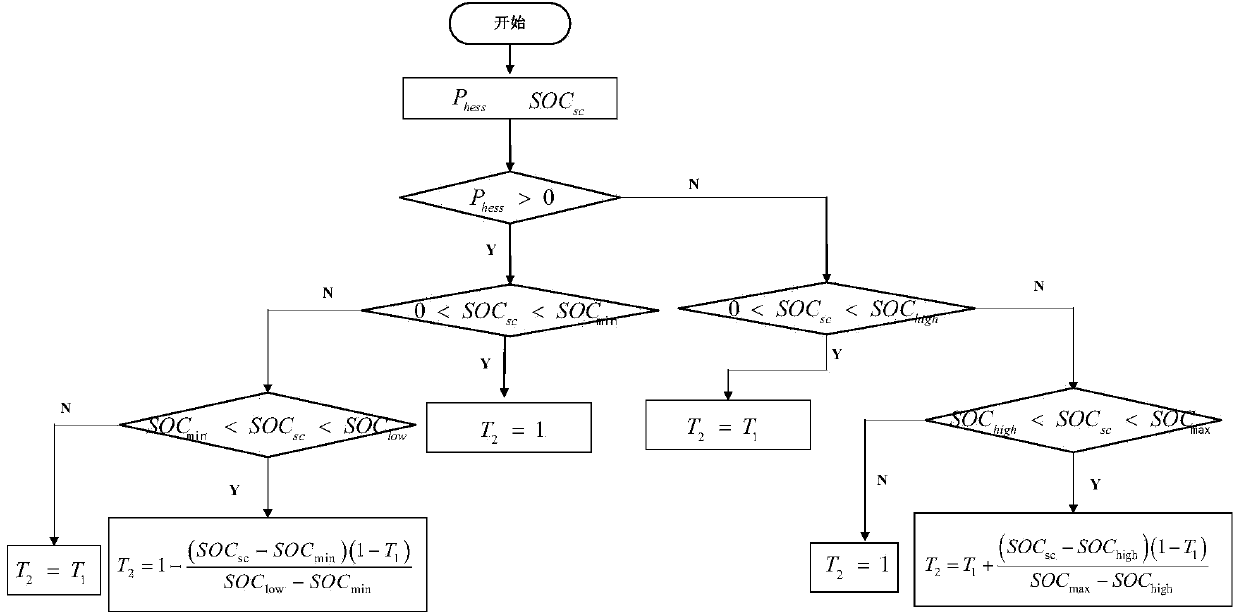

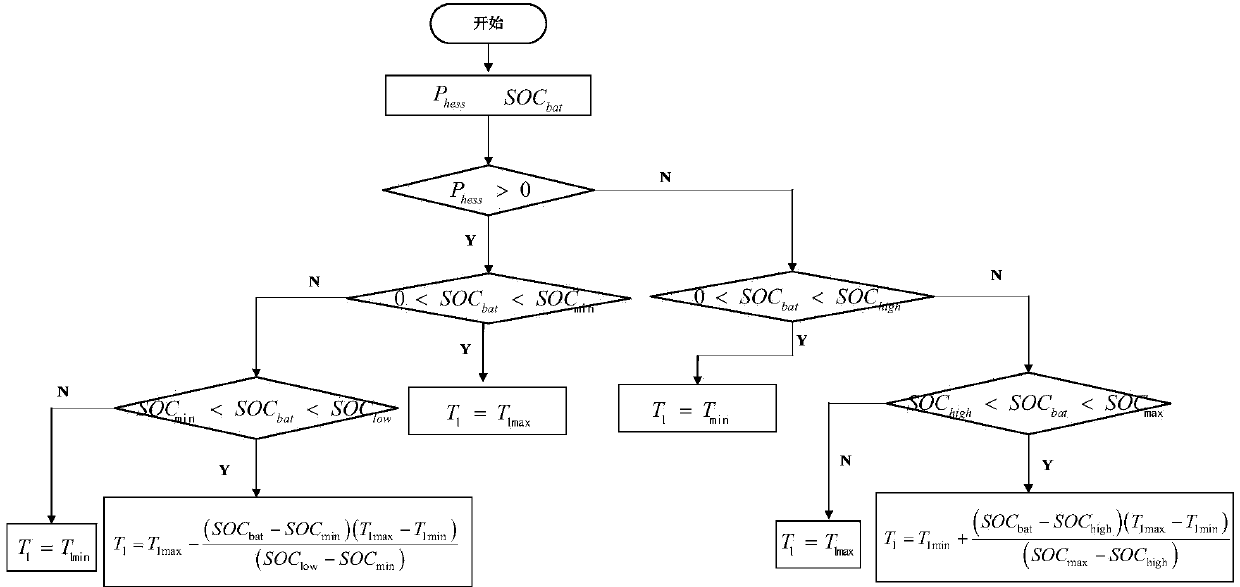

Co-scheduling strategy for multiple energy storage in distributed light storage micro-gird system

InactiveCN104184159AKeep constantAc network load balancingPower oscillations reduction/preventionCapacitancePower grid

Provided is a co-scheduling strategy for multiple energy storage in a distributed light storage micro-gird system. The based multiple energy storage adopts a two-stage converter topology structure comprising a preceding-stage bidirectional DC / DC conversion unit and a back-stage DC / AC conversion unit. A bidirectional DC / DC conversion unit for a storage battery and a bidirectional DC / DC conversion unit for a super capacitor share a DC bus, and are connected with a load and a large power grid through the DC / AC conversion unit and via an LC filter. The co-scheduling method of a two-stage converter for multiple energy storage is characterized by when the distributed light storage micro-gird system is in a grid-connected mode, carrying out double filter control on the two-stage converter for multiple energy storage, controlling the energy-storage element to carry out smooth photovoltaic output power fluctuation, and carrying out adjustment on filtering parameters according to the charge state of the super capacitor and the charge state of a storage battery; and when the distributed light storage micro-gird system is in an off-grid state, controlling the energy-storage element to provide voltage and frequency support to the distributed light storage micro-gird system, the distributed light storage micro-gird system jointly providing power for the load, wherein the energy-storage element is the storage battery and the super capacitor.

Owner:GUANGDONG YUANJING ENERGY

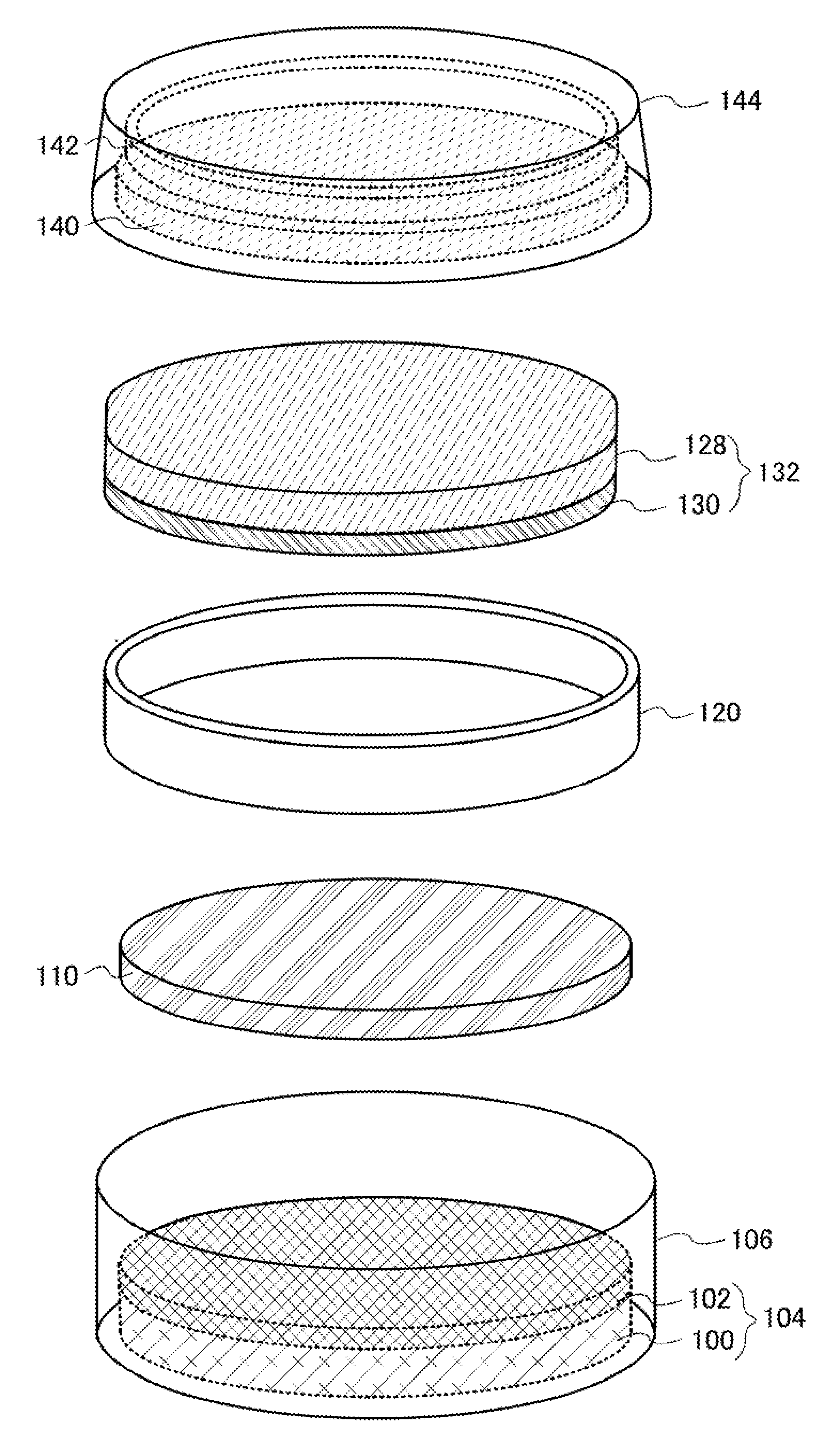

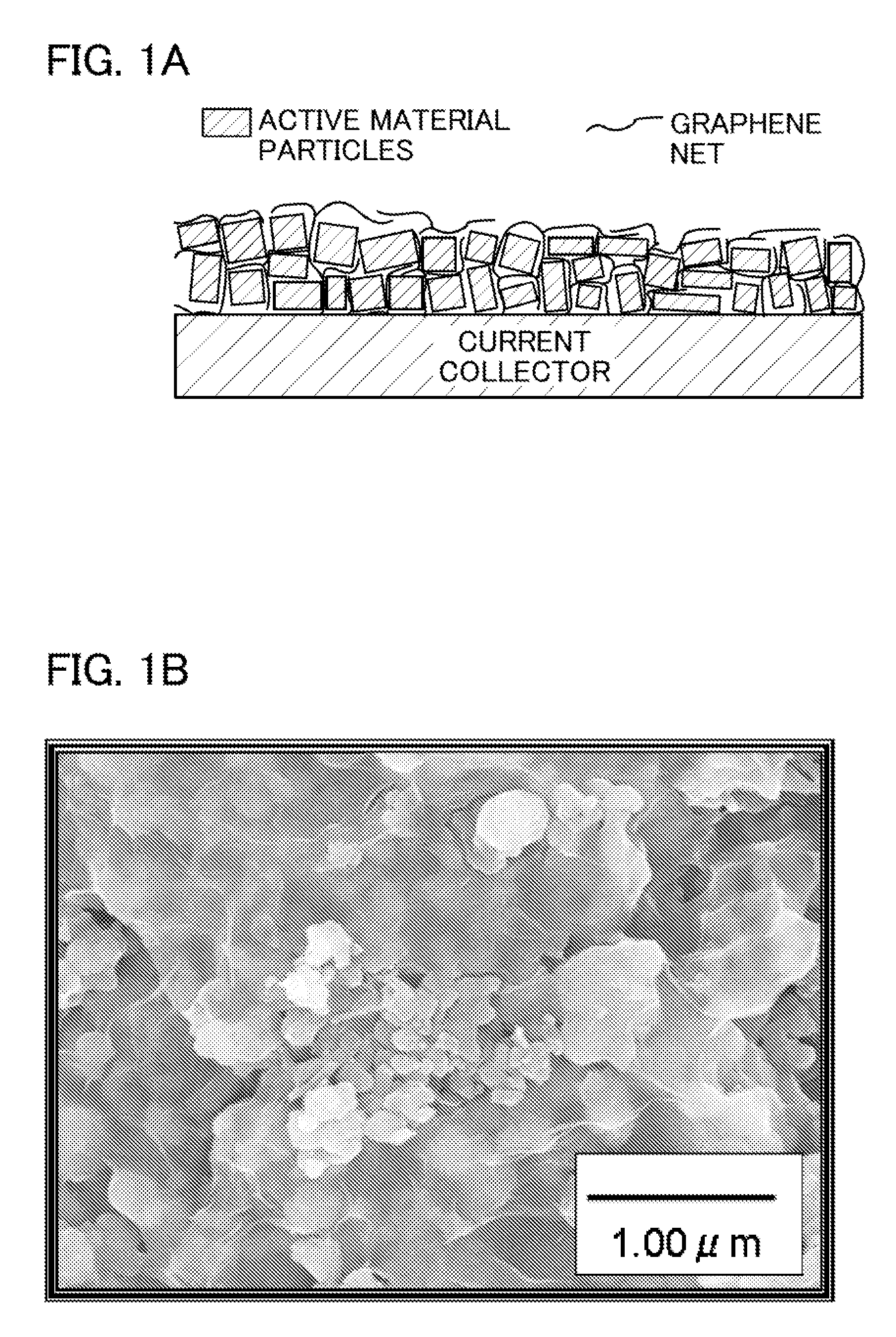

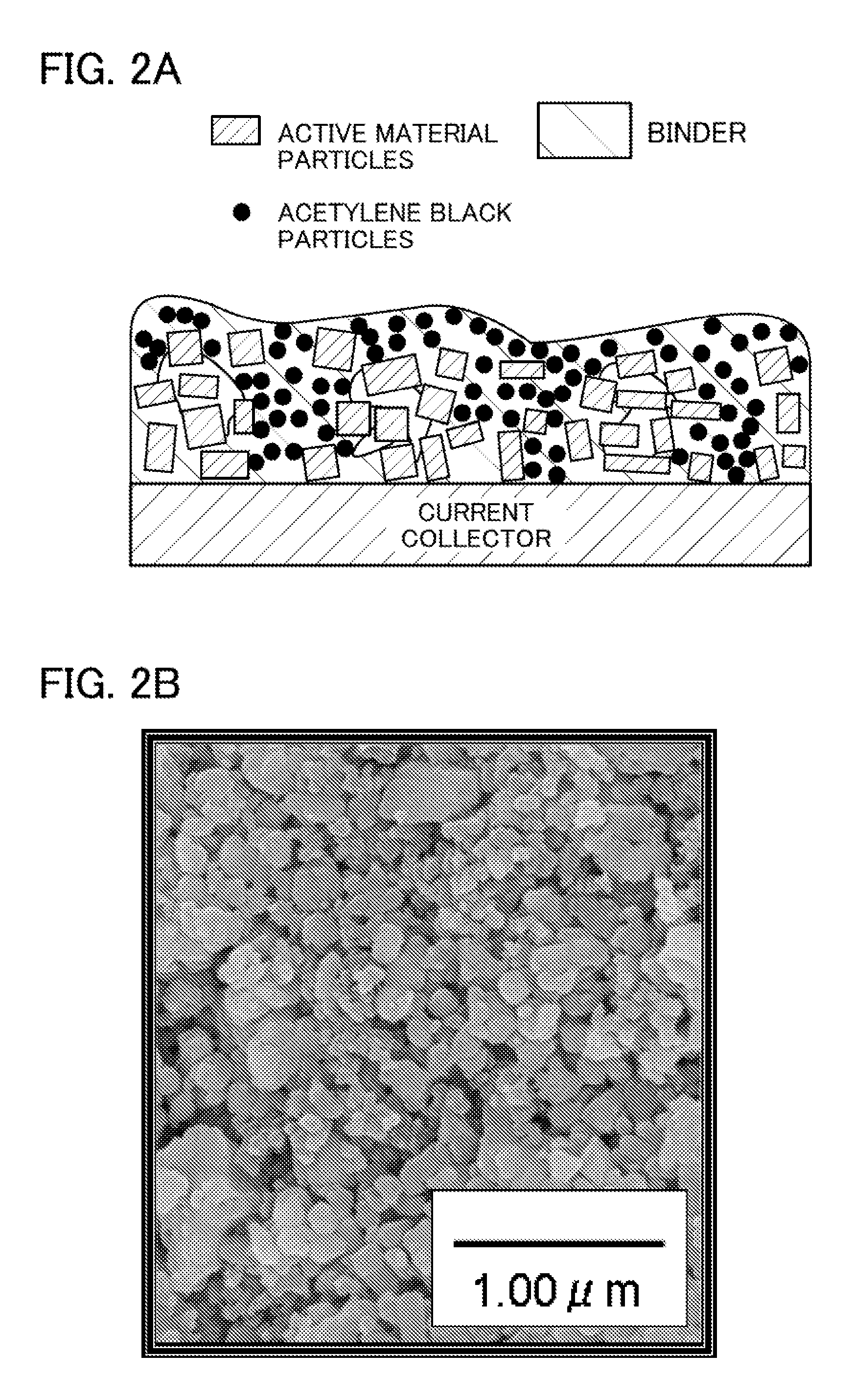

Method of manufacturing electrode

ActiveUS20120308891A1Large electric capacityExcellent electrical propertiesMaterial nanotechnologyElectrode thermal treatmentElectric capacityReducing atmosphere

To increase the conductivity and electric capacity of an electrode which includes active material particles and the like and is used in a battery, a graphene net including 1 to 100 graphene sheets is used instead of a conventionally used conduction auxiliary agent add binder. The graphene net which has a two-dimensional expansion and a three-dimensional structure is more likely to touch active material particles or another conduction auxiliary agent, thereby increasing the conductivity and the bonding strength between active material particles. This graphene net is obtained by mixing graphene oxide and active material particles and then heating the mixture in a vacuum or a reducing atmosphere.

Owner:SEMICON ENERGY LAB CO LTD

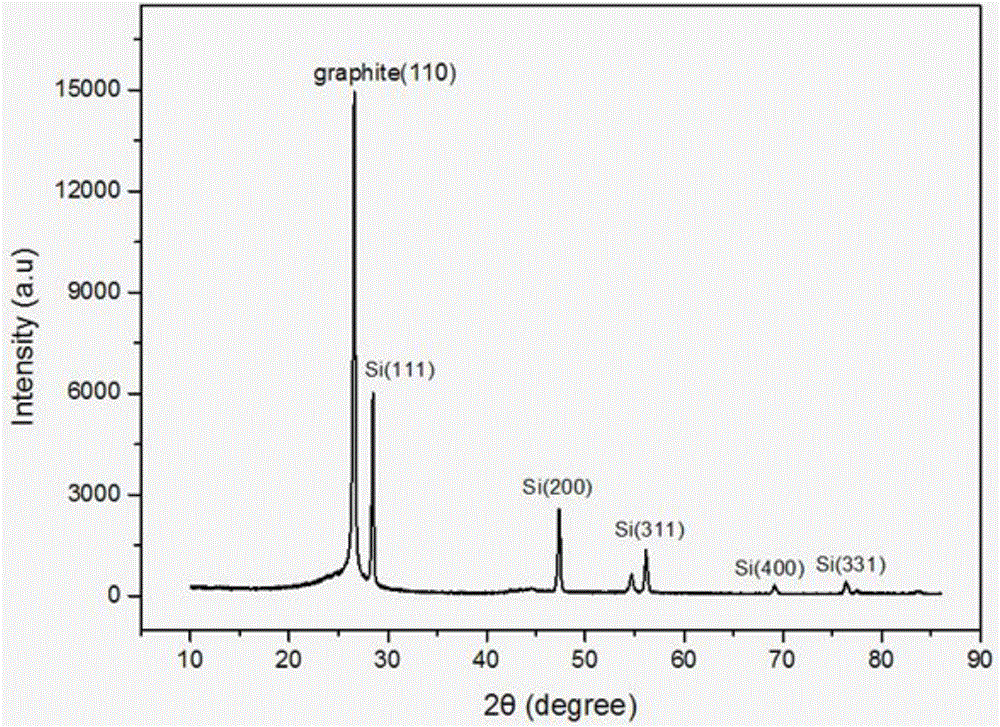

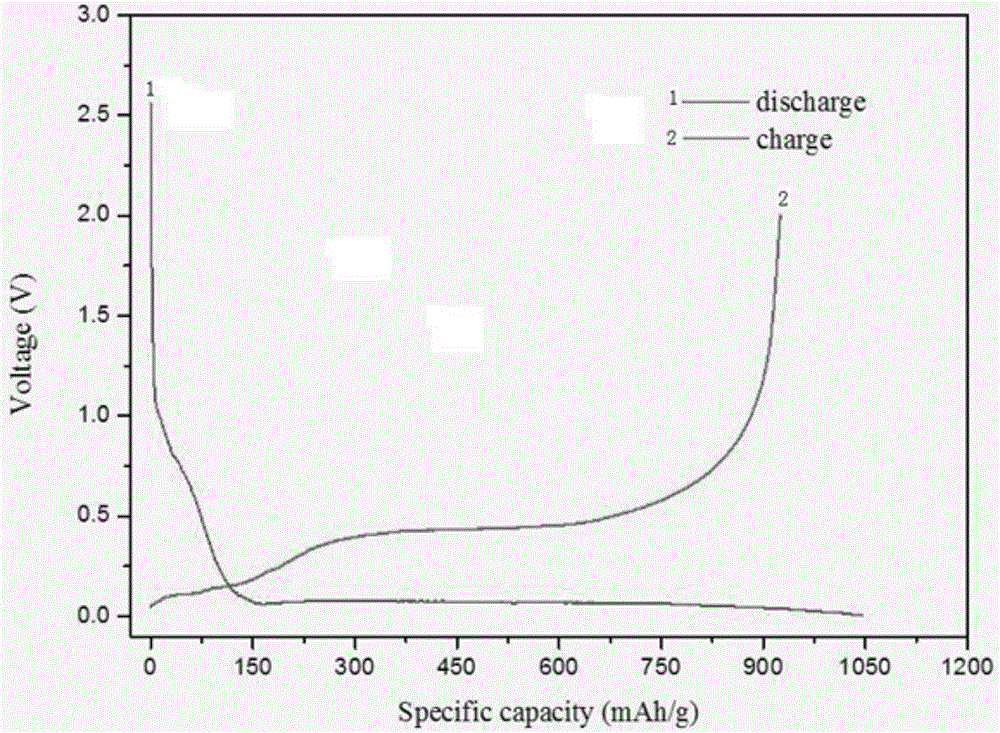

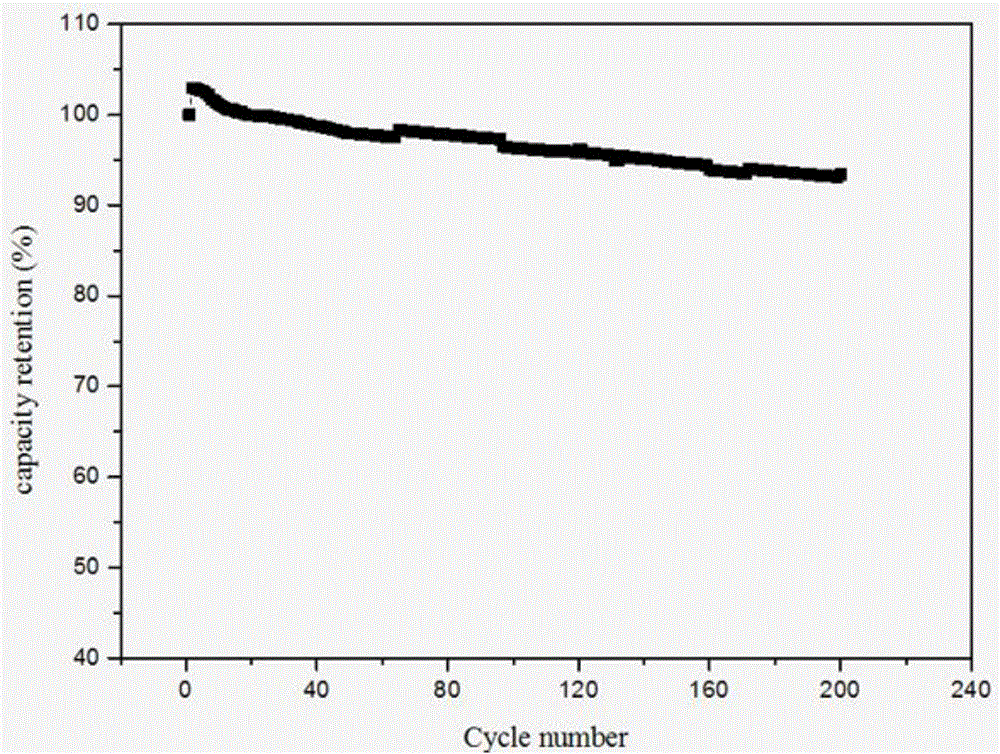

Silicon-carbon composite negative pole material preparation method and lithium ion battery

ActiveCN106257716AEvenly dispersedAvoid direct contactNegative electrodesSecondary cellsCarbon compositesElectric capacity

The invention relates to a silicon-carbon composite negative pole material preparation method and a lithium ion battery. The preparation method comprises putting nanometer silicon and graphite micro-powder into a ball mill, carrying out ball milling uniform dispersion in an organic solvent environment, carrying out vacuum drying, putting the dried mixture and asphalt into a cone-type mixer, carrying out coarse mixing, putting the mixed powder subjected to coarse mixing into a mechanical fusion machine, carrying out mechanical fusion, carrying out heat treatment in an inert gas protective atmosphere and carrying out cooling to obtain the silicon-carbon composite negative pole material. The preparation method carries out asphalt softening coating on nanometer silicon so that silicon particle and electrolyte direct contact is avoided, a capacity reduction rate is delayed, a lithium ion diffusion path is shortened, an electrode material electron conduction loss is avoided, and first charge-discharge efficiency, a charge-discharge electric capacity and cycle performances are improved. Before coating, nanometer silicon is dispersed through graphite micro-powder so that it is avoided that in asphalt coating, nanometer silicon aggregation causes local capacity excess and nanometer silicon is uniformly dispersed.

Owner:浙江超恒动力科技有限公司

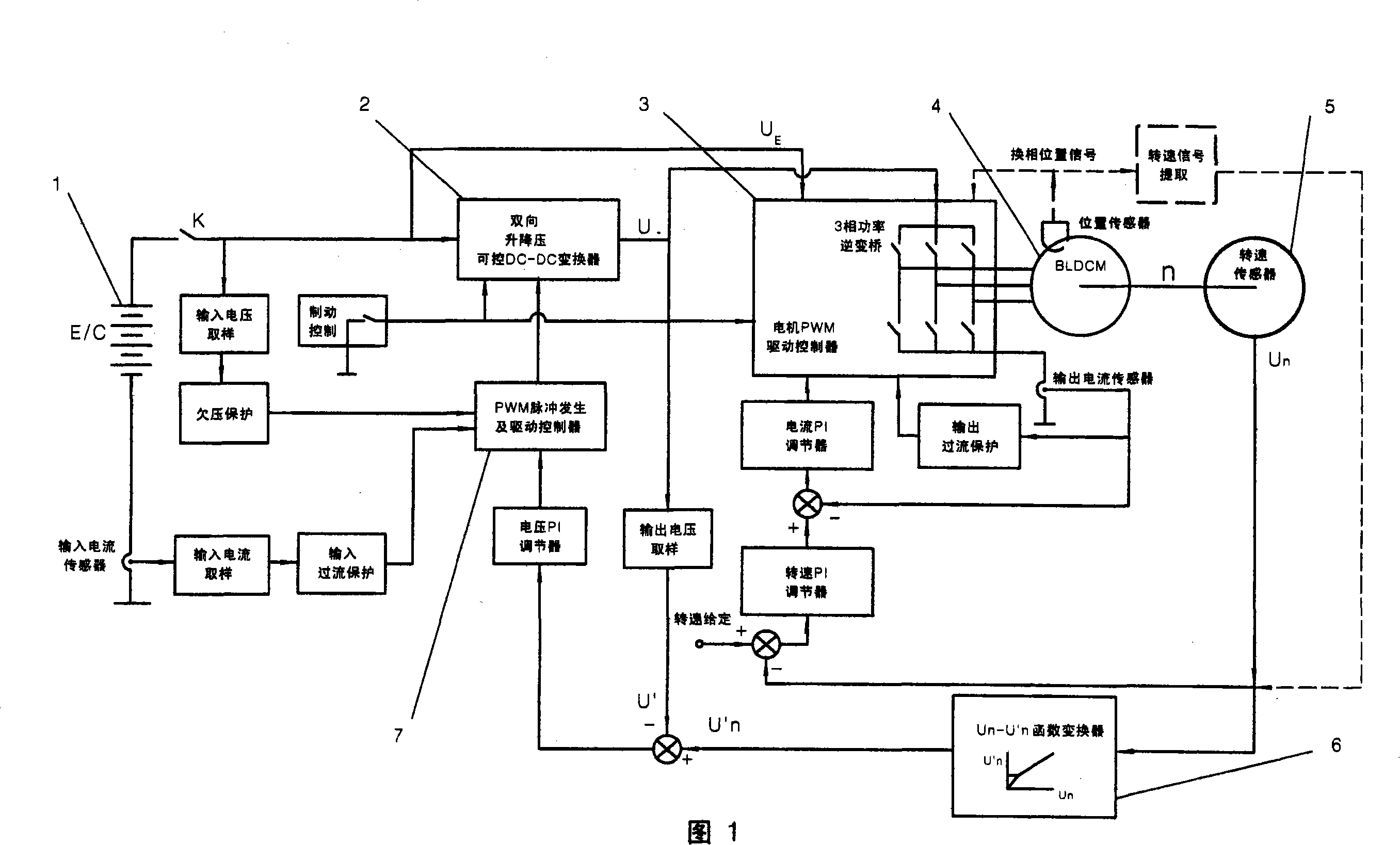

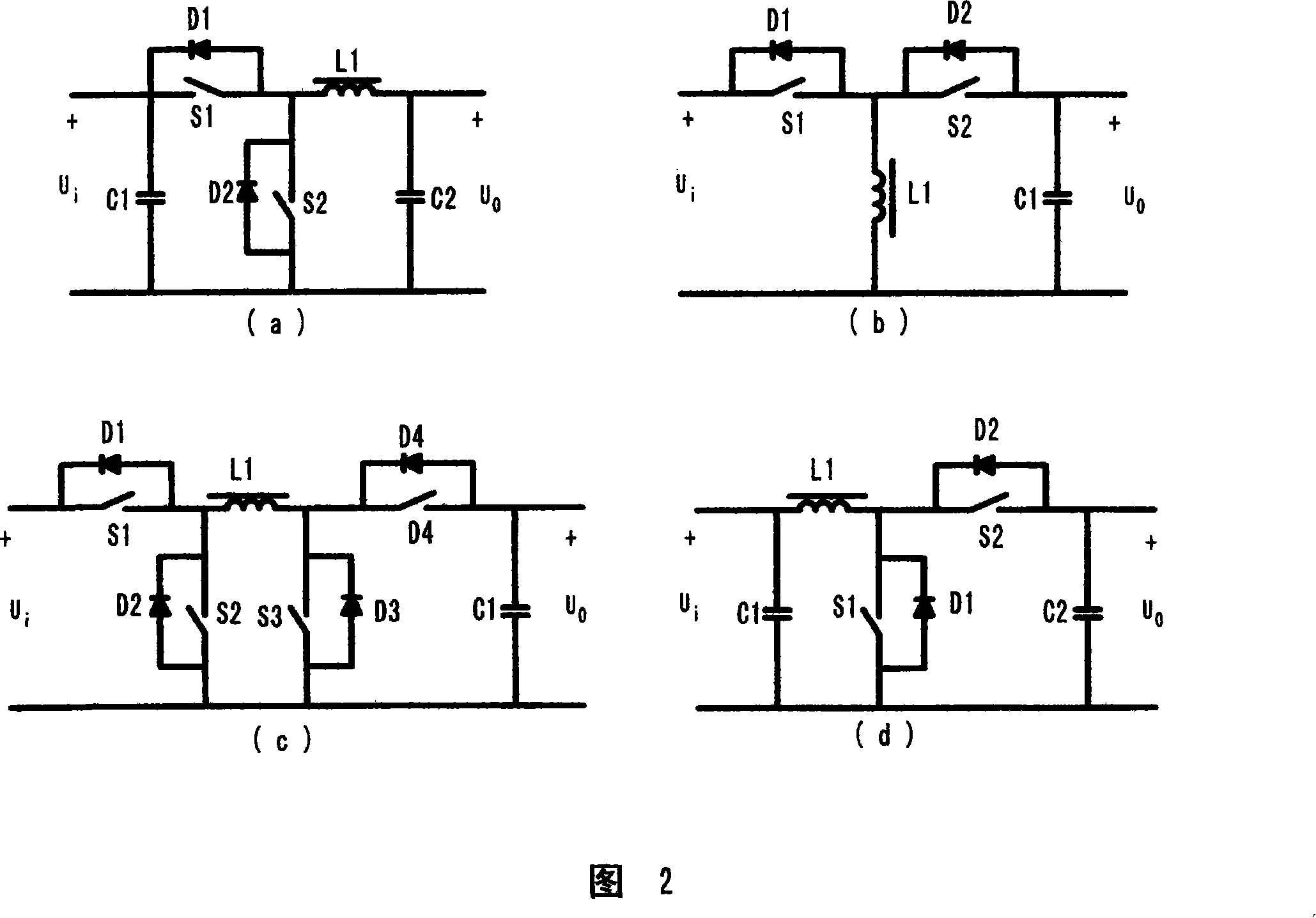

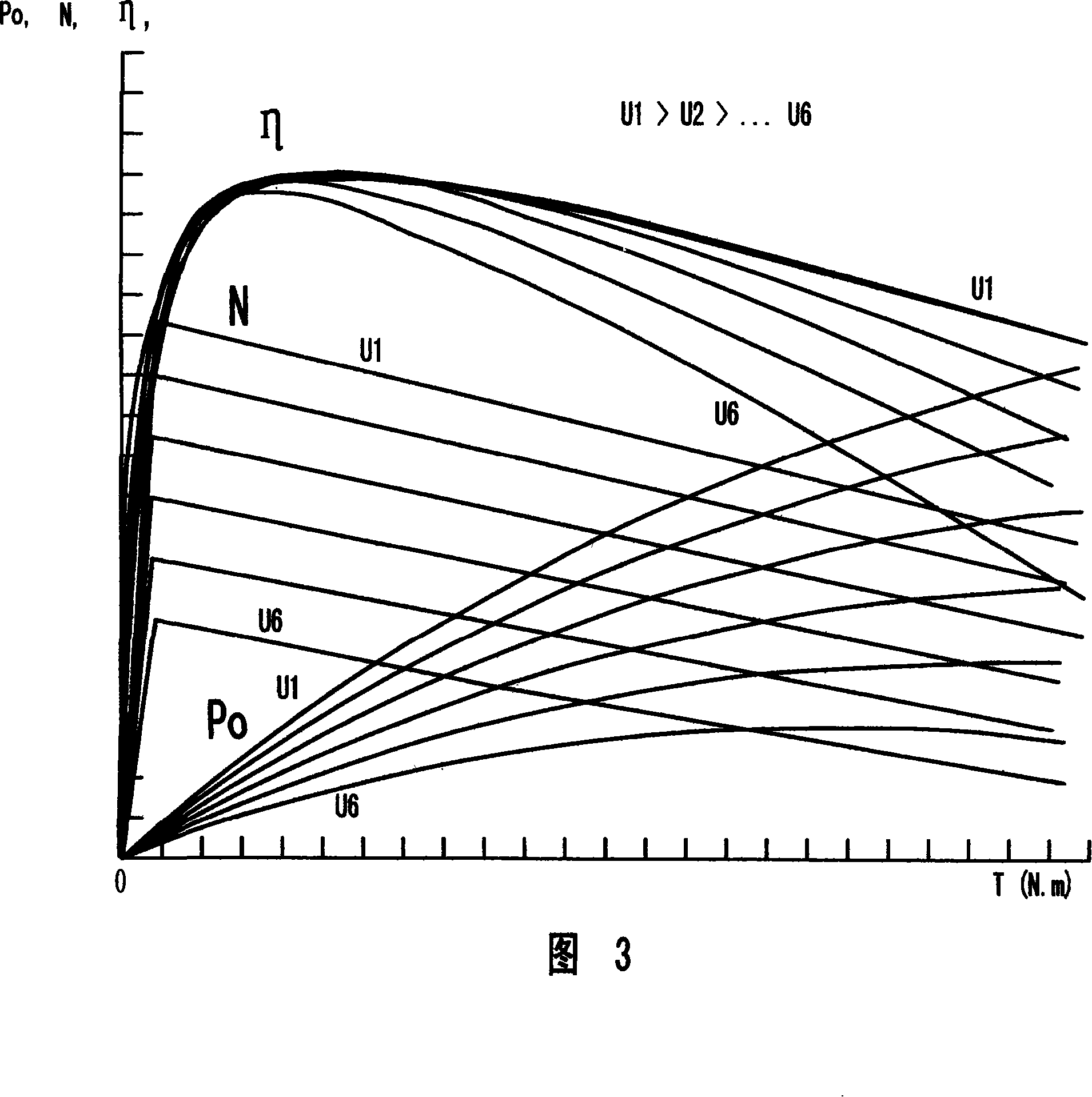

Permanent-magnet DC motor drive control system with approximate constant power pulling motor characteristics

InactiveCN101159422AIncreased complexityIncrease manufacturing costSingle motor speed/torque controlMechanical energy handlingCapacitanceBrushless motors

A permanent-magnetic DC motor bearing similar characteristics with the constant power pulling motor, in particular a new drive control system for brushless motor adopts new technologies of full electronic drive control and DC-DC transducer. The motor can generate great drive torque, i.e. high tractive force, climbing ability and better acceleration performance with low power consumption, and eliminate the needs for improvement to the motor structure, complication, high manufacture cost or weak magnetic control; the motor may further gain such performance as high speed, wide speed regulation and infinite variable speed under light load; the total voltage of the battery and the number of single series of connection can be reduced; controllable electric brake can be realized through fully utilizing the energy feedback during sliding and braking. The new system can significantly improve the kinetic performance, safety and reliability of electric vehicles and remarkably reduce operating costs, with ideal characteristics expected in various electric vehicles powered by rechargeable battery or / and super capacitance as well as significantly expanded work scope and capacity for conventional electrically driven system.

Owner:李平 +1

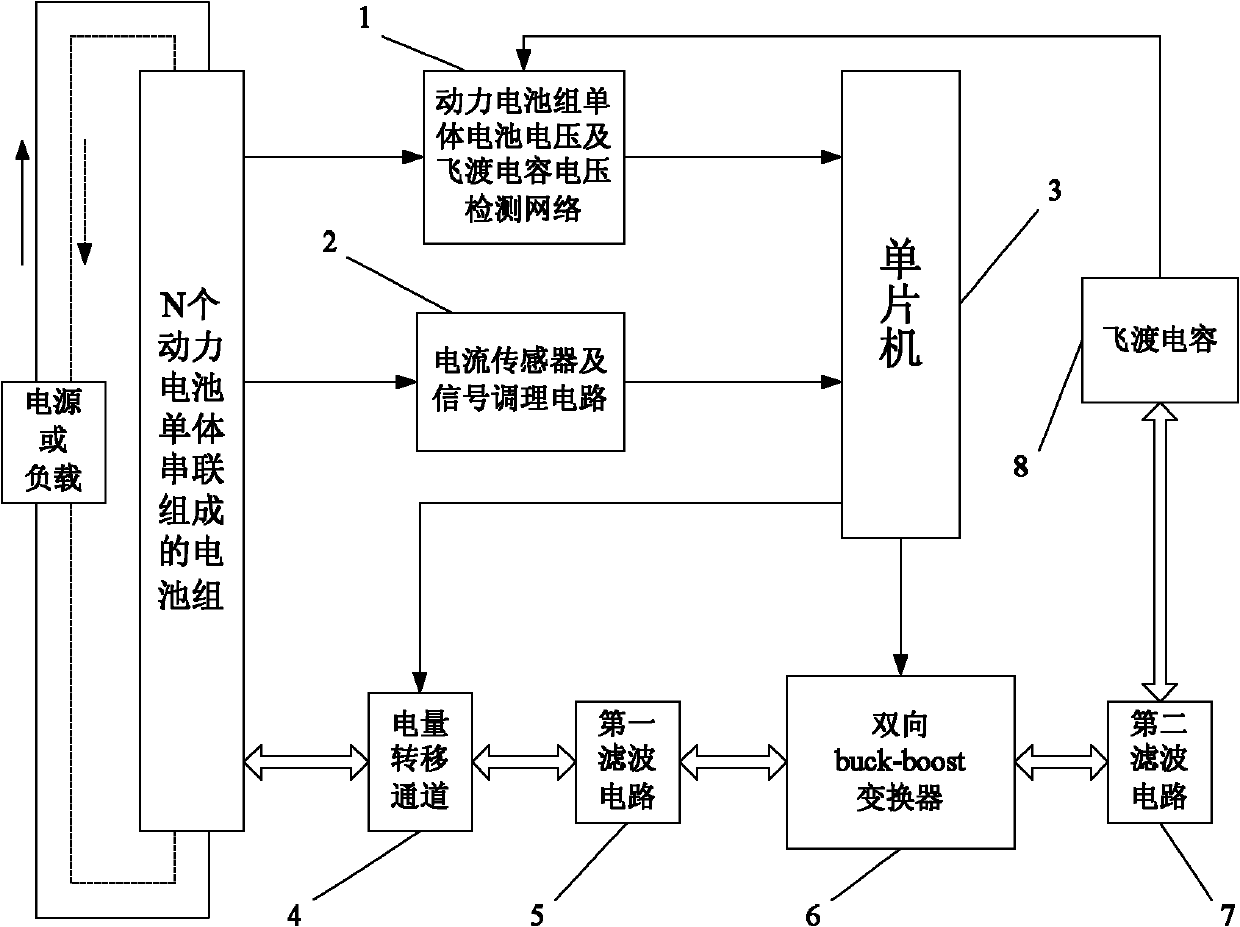

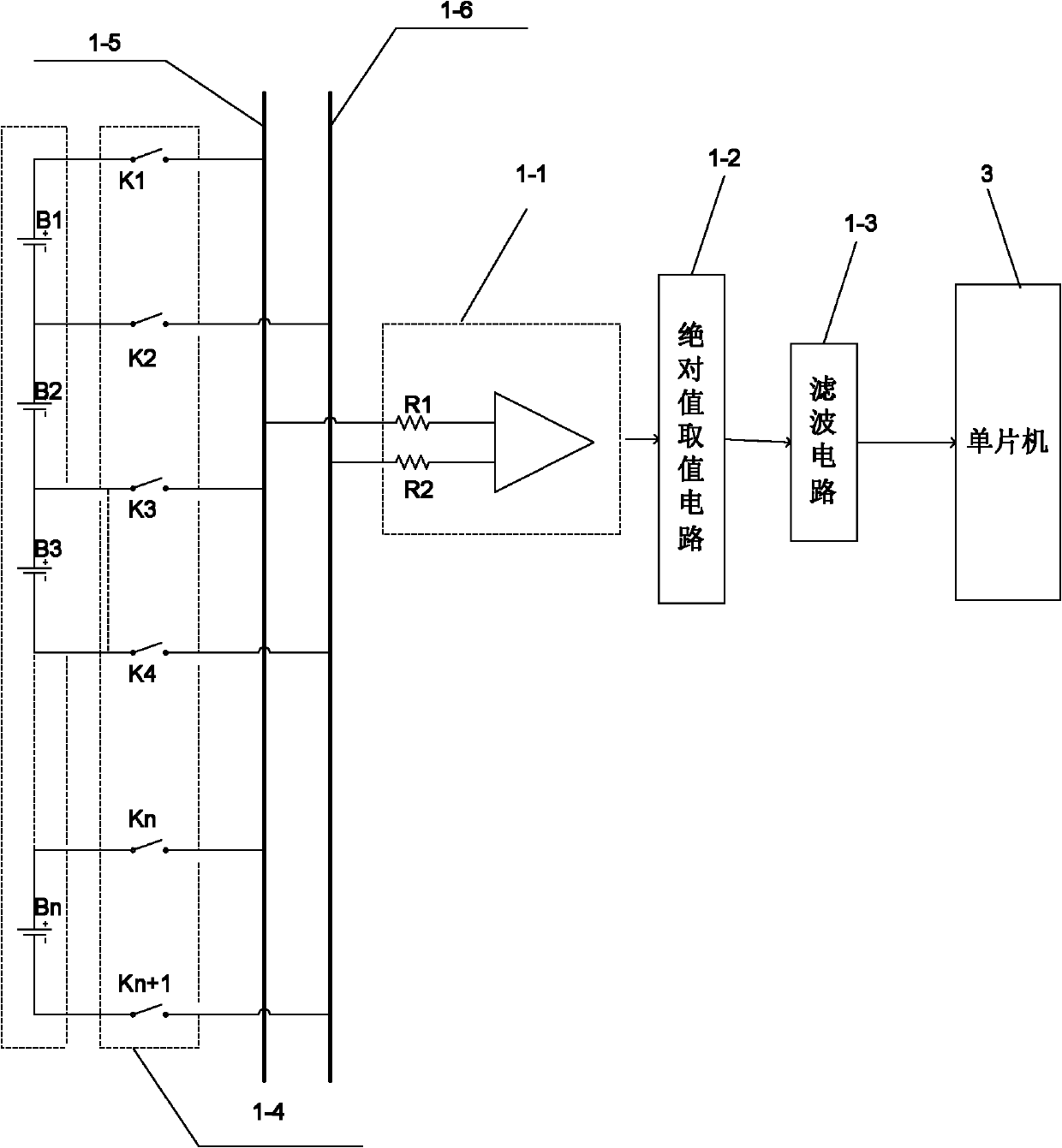

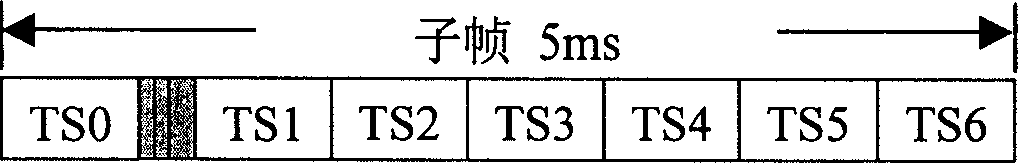

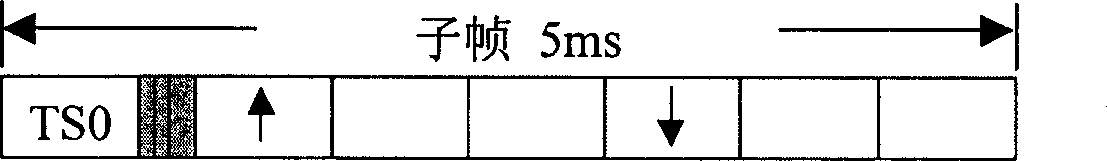

Energy transfer type power battery quick balancing system and control method

InactiveCN102170029AReduce consumptionReduce dependenceBatteries circuit arrangementsElectric powerElectrical batteryLow voltage

The invention relates to an energy transfer type power battery quick balancing system and a control method thereof. The invention relates to the battery voltage balancing system and further relates to the control method of battery pack quick balancing process, which solves the problem that a balanced battery single body and an energy storing element are impacted through pulse current by a currentbalancer in the prior art. The system comprises a power battery pack single body battery voltage and flying capacitor voltage detecting network, a current sensor and a signal modulating circuit, a single chip microcomputer, an electric power transfer channel, a first filter circuit, a two-way buck-boost converter, a second filter circuit and a flying capacitor. After starting to work, the system firstly detects the battery pack single body battery voltage, the flying capacitor voltage and the charging / discharging current; and if the dropout voltage between the highest voltage of the battery single body and the lowest voltage of the single body exceeds a set value, the balancing operation is started.

Owner:HARBIN INST OF TECH

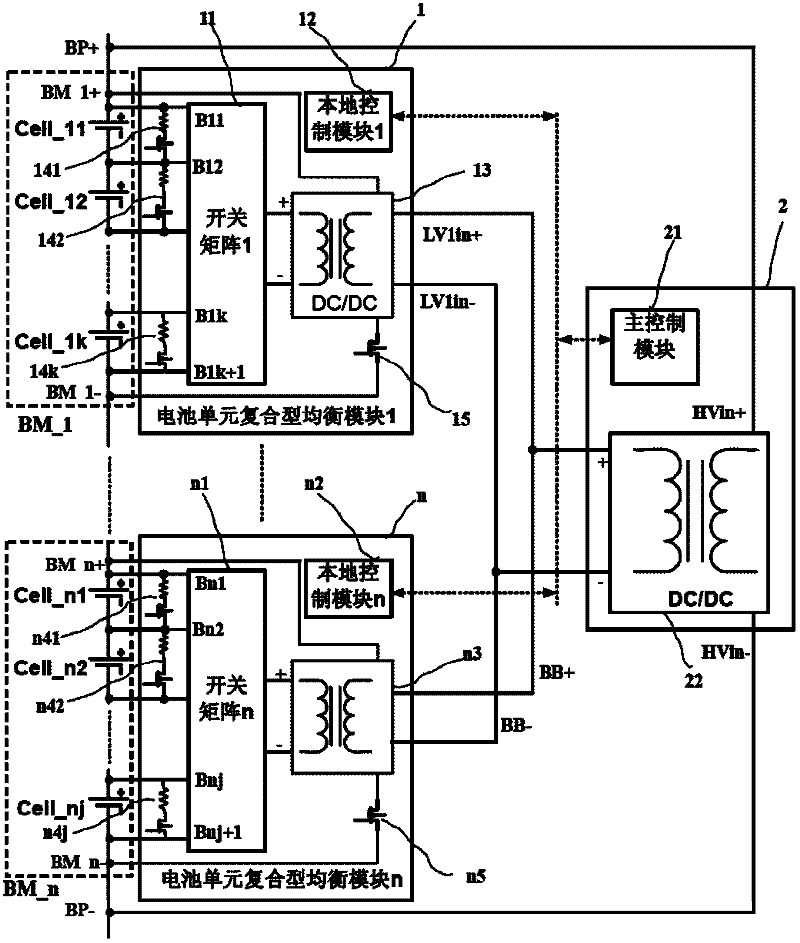

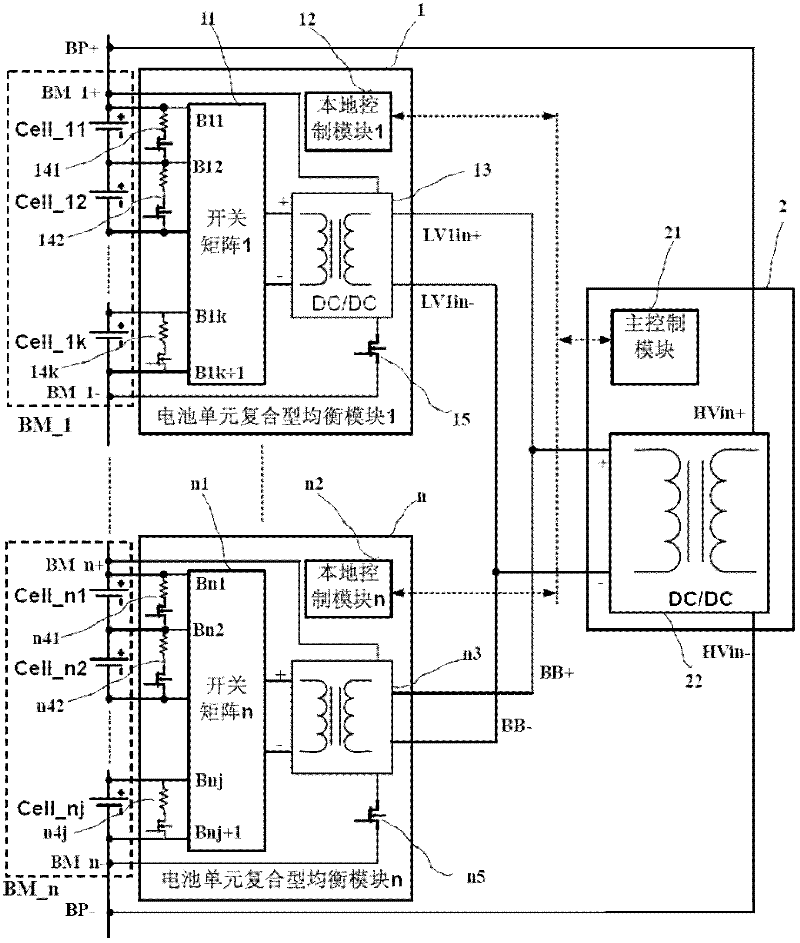

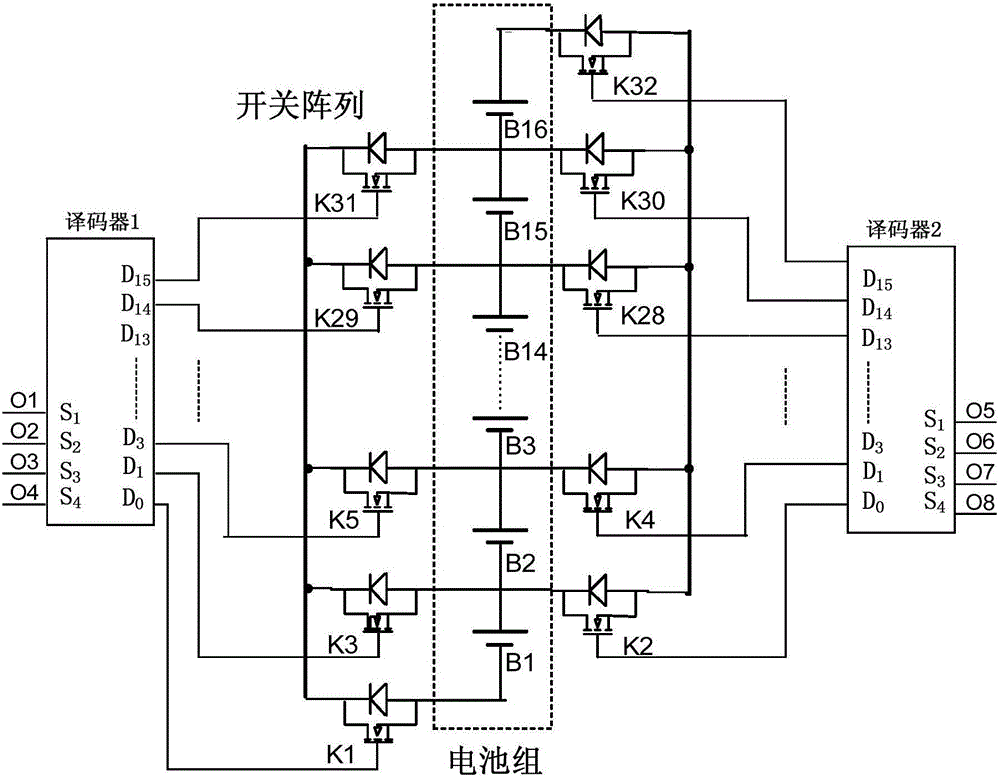

Charging and discharging compound type automatic equalizing circuit for serially-connected battery pack and equalizing method

ActiveCN102420447AOvercome timeOvercome efficiencyBatteries circuit arrangementsSecondary cells charging/dischargingCapacitanceElectrical battery

The invention discloses a charging and discharging compound type automatic equalizing circuit for a serially-connected battery pack and an equalizing method. The charging and discharging compound type automatic equalizing circuit comprises n battery unit compound type equalizing modules which are set according to the number of battery units in the serially-connected battery pack, and a battery pack equalizing module which consists of a main control module and a high-voltage direct-current / direct-current (DCDC) module, wherein n is more than or equal to 1; the battery unit compound type equalizing modules correspond to a battery pack which consists of k serially connected battery units, wherein k is more than 1; and each battery unit compound type equalizing module consists of a switch matrix, a local control module, a low-voltage DCDC module, k discharging equalizing circuits and a mode control switch. The charging and discharging compound type automatic equalizing circuit for the serially-connected battery pack has the advantages of high reliability, low cost, small volume and light weight, has multiple functions, is easy for large-scale and industrial manufacturing and application, and can be used in the fields of electric automobiles, rail traffics, wind power generation and the like, which require serially-connected battery packs and capacitor sets.

Owner:杭州久翼智能科技有限公司

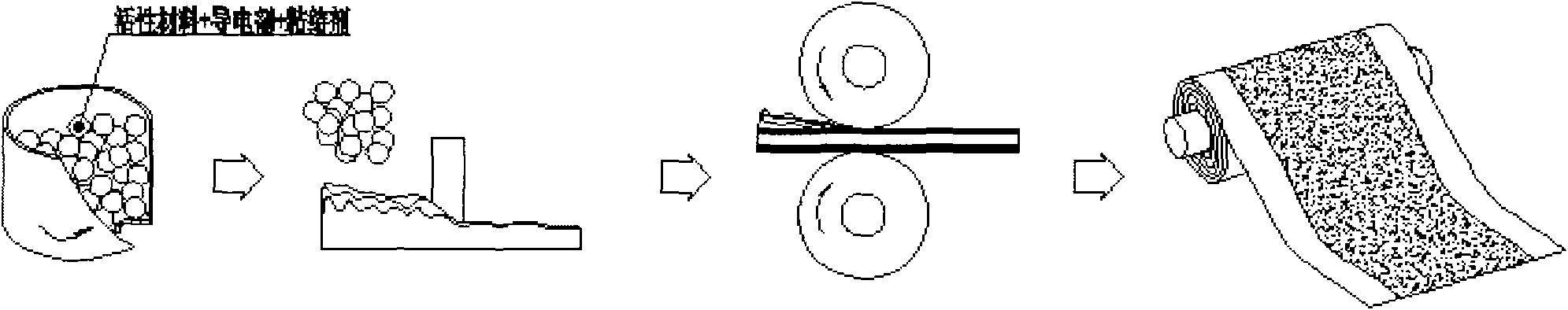

Preparation process of long-lived negative pole piece and capacitor battery using negative pole piece

ActiveCN101847513AIncrease energy densityImprove cycle lifeElectrode rolling/calenderingCapacitor and primary/secondary cellsHybrid typeElectrical battery

The invention relates to a preparation process of a long-lived negative pole piece and a capacitor battery using the negative pole piece. The preparation process of the long-lived negative pole piece comprises the following steps: mixing materials: mixing fast-storage lithium carbon and a binder, and adding a solvent; squeezing, squeezing the mixture by a roll squeezer to obtain a platy pole piece with a certain thickness; coating: mixing a conductive agent into a sizing agent, and coating the sizing agent on a negative current collector body; attaching the piece, squeezing and attaching the platy pole piece on negative current collector body coated with the sizing agent; and drying, grinding, cropping, and vacuum drying to prepare the negative pole piece. The invention adopts the process that the platy pole piece is firstly squeezed and then is attached on the negative current collector body, so that the negative pole piece has higher compaction density and longer cycle life. The organic hybrid super-capacitor battery prepared by the invention has the characteristics of high energy density (which can reach 45-80Wh / Kg) and high power density (which is higher than 4500W / Kg), can bewidely applicable to the fields such as electric vehicles, power tools, solar energy storage, wind energy storage, portable appliances and the like.

Owner:SHANGHAI AOWEI TECH DEV

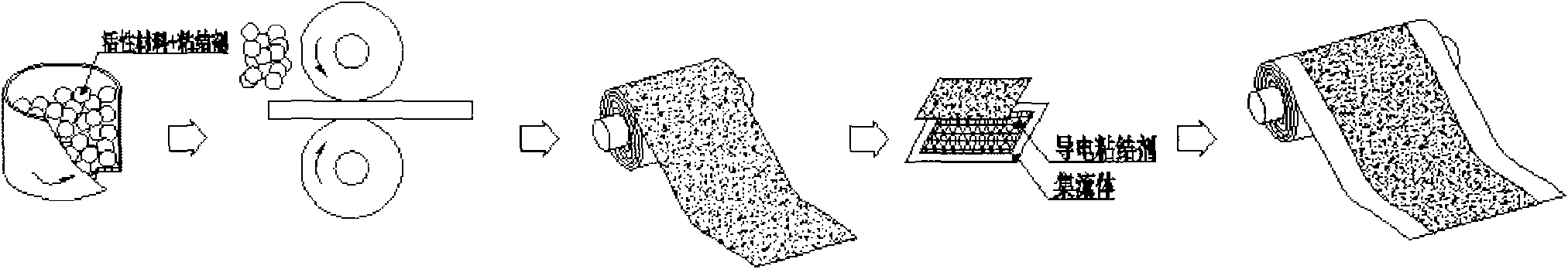

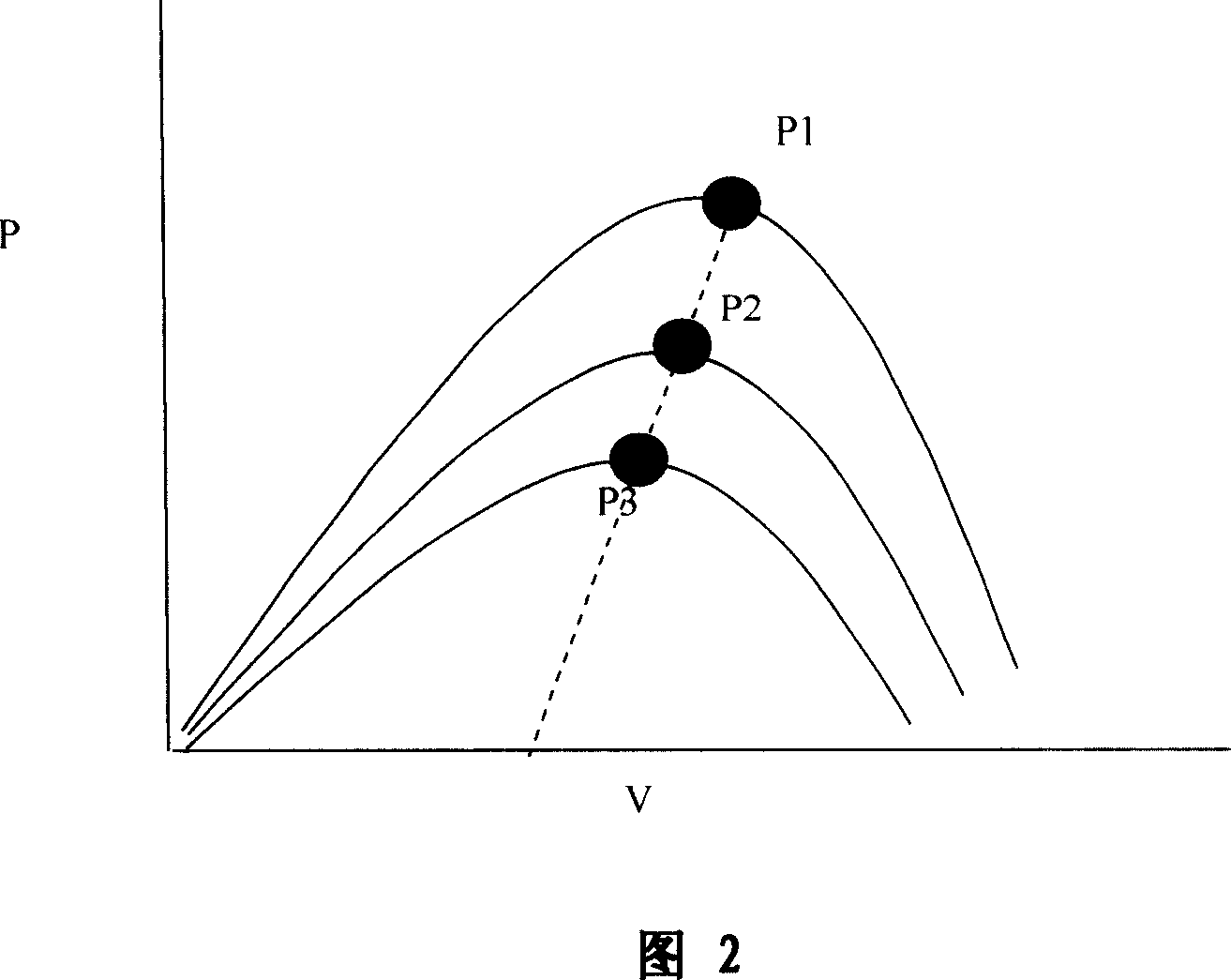

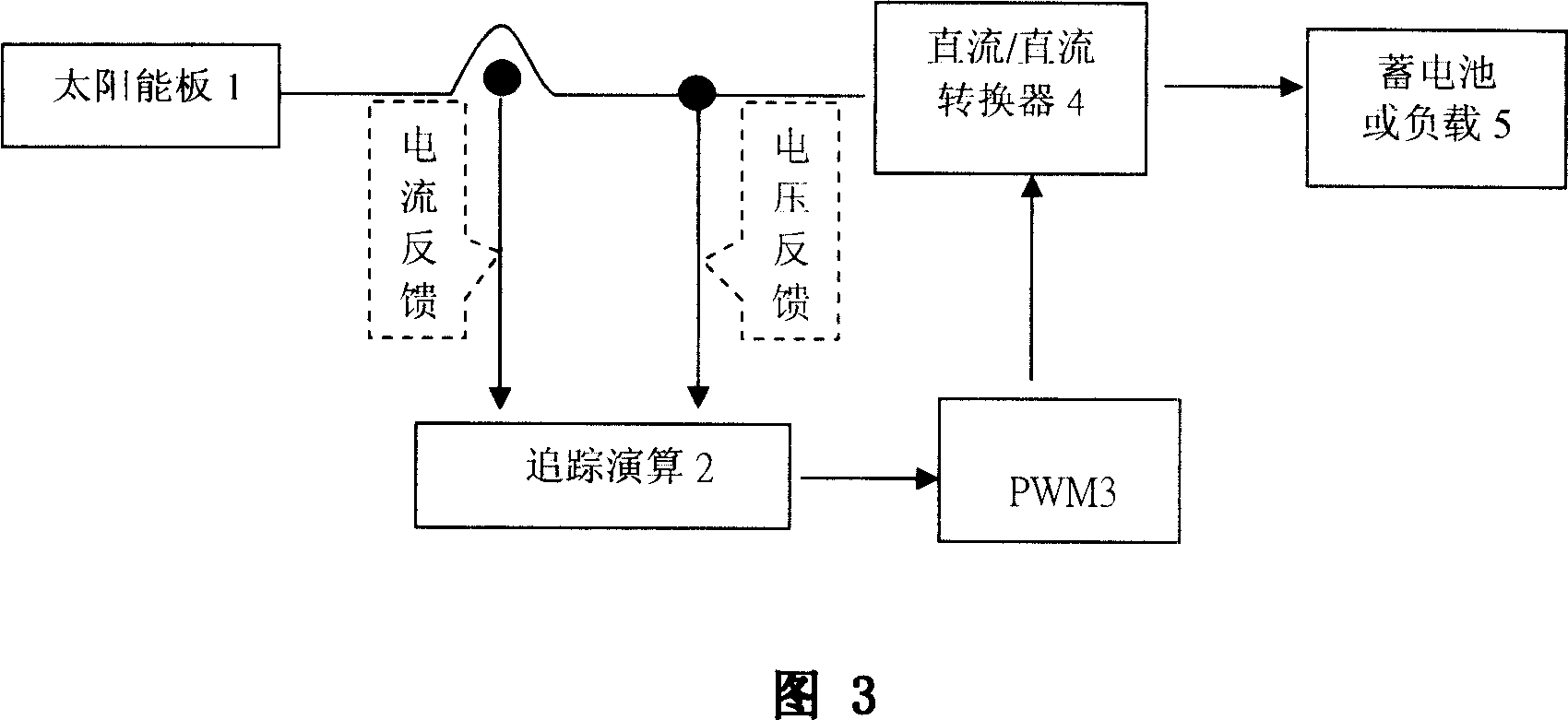

Maximum power tracing method for solar power system and solar power device

InactiveCN1949624AHigh energyThe method of maximum power tracking is simpleElectrical storage systemBatteries circuit arrangementsTraffic signalDynamic balance

The invention discloses a maximum power tracking method for a solar energy power supply system and the solar energy power supply unit thereof, relating to solar power generation technical field. And the method tracks the maximum power of the solar energy system by dynamic balancing. According to the method, it adds in intelligent charging-discharing mechanism to form an intelligent coordination solar energy device, comprising at least a solar panel, super capacitor, DC / DC buck-boost converter, pulse width modulation driver, storage battery, logic controller and load; and the method is characterized in that an instant power type super capacitor is connected between the solar panel and the DC / DC buck-boost converter to act as an energy dynamic balancer; it converts the electric energy produced by the solar panel into capacitor type electric energy to make the maximum power calculation, able to largely simplify calculation program, improving tracking calculation real-timeness and reliability and raising solar energy system efficiency. And the invention can be widely applied to solar LED lamps, and solar energy lamps, especially solar energy street lamps, solar traffic signal lamps, solar energy engineering lamps, etc.

Owner:孙民兴

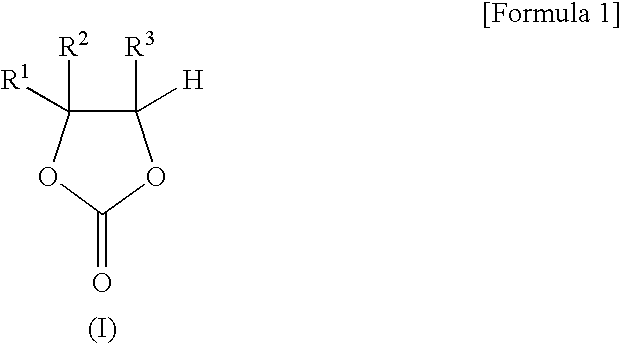

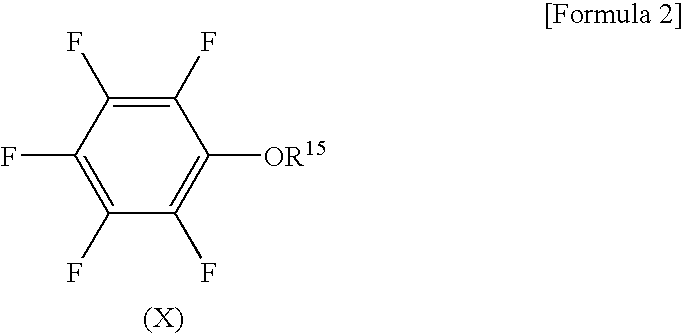

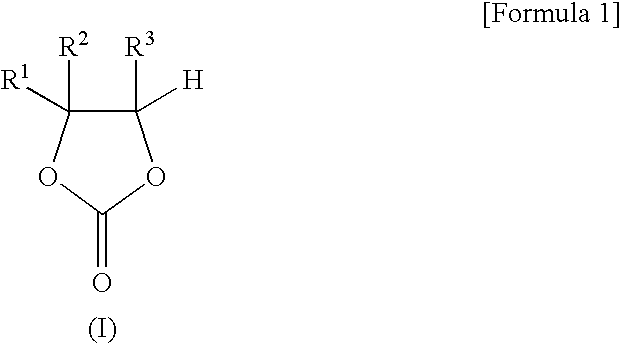

Nonaqueous electrolyte solution and lithium secondary battery using same

ActiveUS20090053598A1Improve featuresReduce generationElectrolytic capacitorsOrganic electrolyte cellsCapacitanceAryl

The present invention provides a nonaqueous electrolytic solution exhibiting excellent battery characteristics such as electrical capacity, cycle property and storage property and capable of maintaining the battery characteristics for a long tire, and a lithium secondary battery using the nonaqueous electrolytic solution.A nonaqueous electrolytic solution for a lithium secondary battery, in which an electrolyte salt is dissolved in a nonaqueous solvent, containing 0.1 to 10% by weight of an ethylene carbonate derivative represented by the general formula (I) shown below, and 0.01 to 10% by weight of (A) a triple bond-containing compound and / or (B) a pentafluorophenyloxy compound represented by the general formula (X) shown below:wherein R1 to R3 each independently represents a hydrogen atom, a halogen atom, an alkenyl group, an alkynyl group or an aryl group, provided that ethylene carbonate is excluded from the definition of the ethylene carbonate derivative,wherein R15 represents an alkylcarbonyl group, an alkoxycarbonyl group, an aryloxycarbonyl group or an alkanesulfonyl group.

Owner:MU IONIC SOLUTIONS CORP

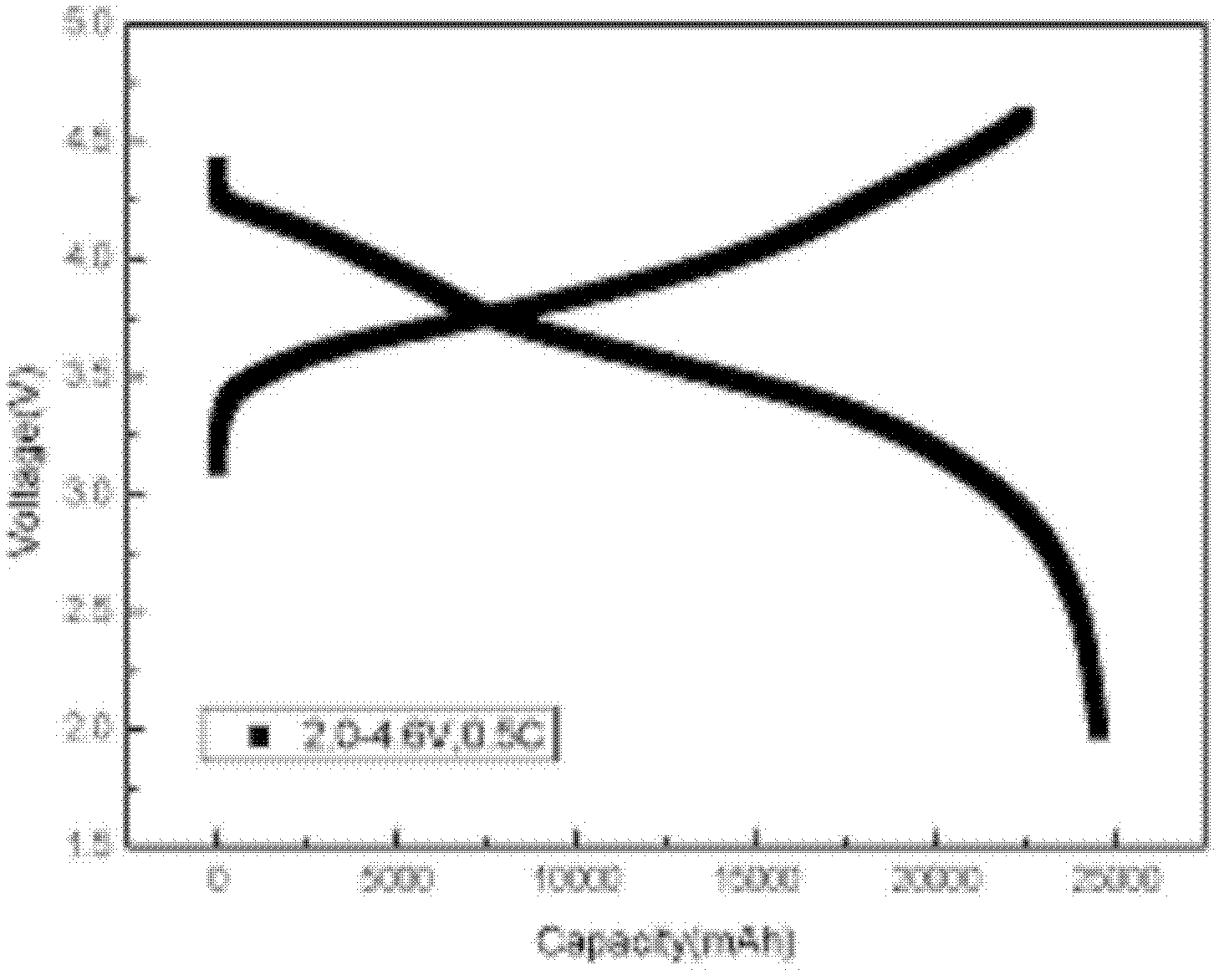

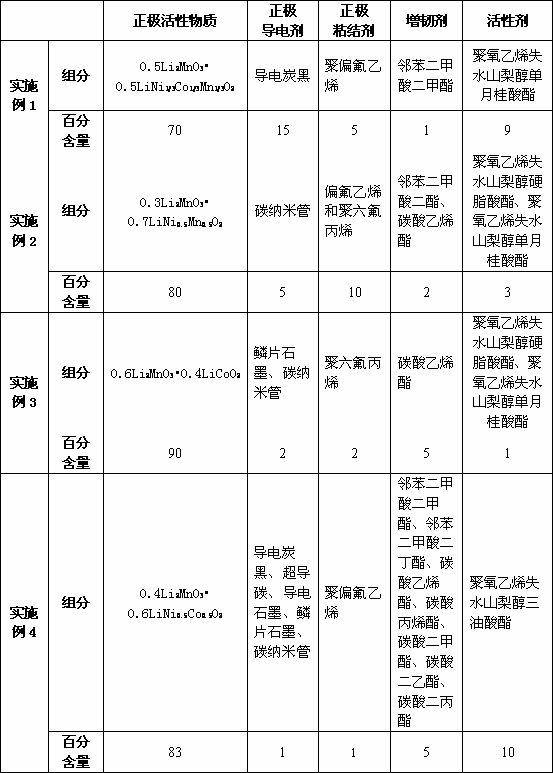

Lithium-rich manganese-based power battery and manufacturing method thereof

The invention discloses a lithium-rich manganese-based power battery which comprises a positive plate, a negative plate and a diaphragm, wherein the positive plate comprises a positive current collector and a positive pole material coated on the positive current collector, the negative plate comprises a negative current collector and a negative pole material coated on the negative current collector, the positive pole material comprises a positive pole active substance, a positive pole conductive agent and a positive pole binding agent, the positive pole material further comprises a toughener and an activating agent, the positive pole active substance is of lithium-rich manganese-based, and the general formula of the lithium-rich manganese-based power battery is xLi2MnO3.(1-x) LiYO2, wherein Y is one or more of Co, Mn, Ni and Cr, x is more than 0 and less than 1, and the compacted density and the electric capacity of the battery are high. The invention further discloses a preparation method of the lithium-rich manganese-based power battery, and the lithium-rich manganese-based power battery prepared by the preparation method disclosed by the invention has the advantages of high energy density, high discharge capacity and the like.

Owner:WANXIANG 123 CO LTD

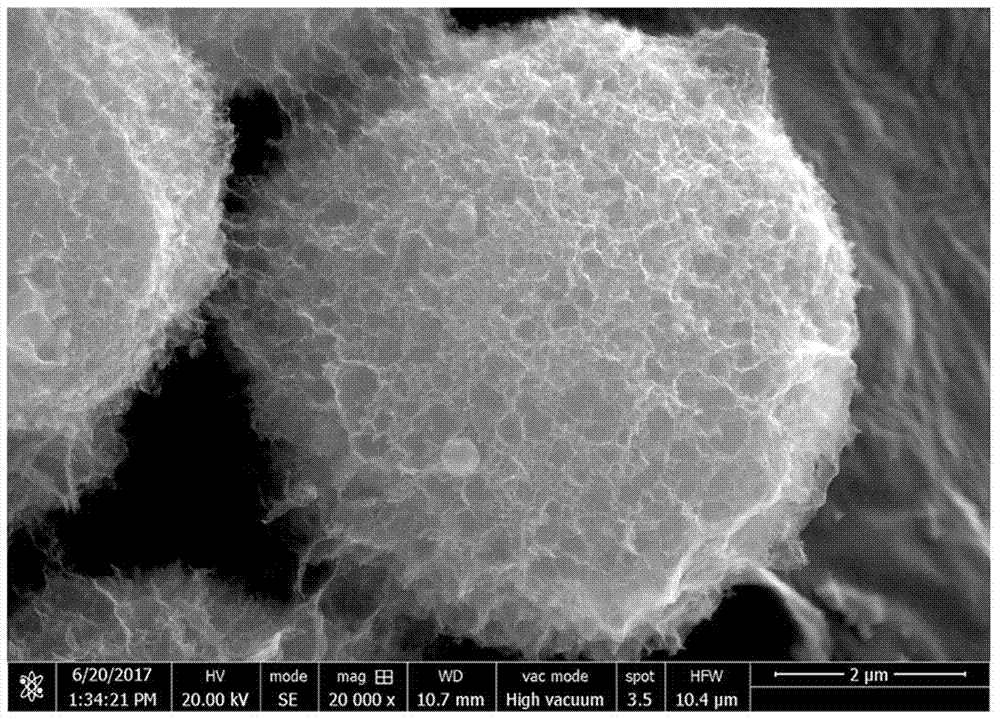

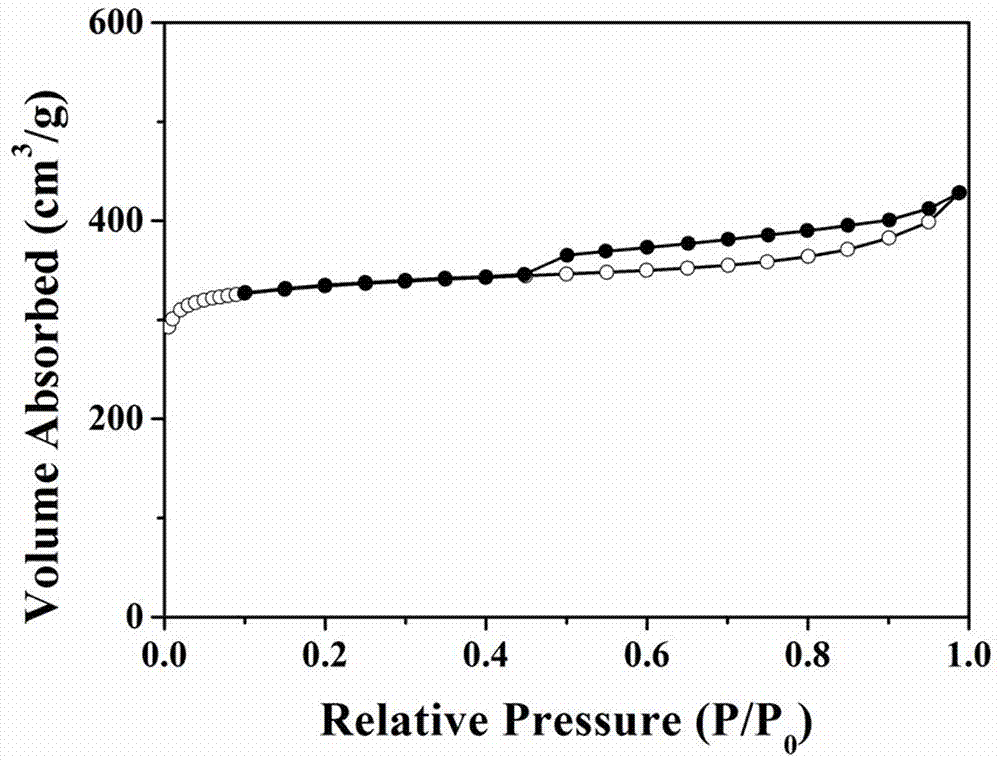

Preparation method for nitrogen-doped nuclear shell hollow carbon

The invention belongs to the technical field of carbon material manufacturing processes and relates to a preparation method method based on preparing nitrogen-doped nuclear shell hollow carbon. The preparation method is characterized in that silicon dioxide balls are utilized as formworks, after the surfaces of the silicon dioxide balls are wrapped with phenolic resin, multilayer wrapping with mesoporous silicon dioxide and nitrogen-containing polymers is conducted, core-shell structures are formed, the calcination is controlled, pomegranate-shaped core-shell materials are formed, cores are made of nano-scale hollow fractional porous carbon, and shells are made of nitrogen-doped ultrathin mesoporous carbon. By means of the preparation method, the fractional open-framework structure, the nano-scale particle size, the high electrical conductivity and the high wetability are achieved, the method is simple, the process is easy to control, and the preparation method can be widely applied to the electrochemistry fields such as supercapacitors, capatitive type desalination and lithium ion batteries.

Owner:SHANGHAI UNIV

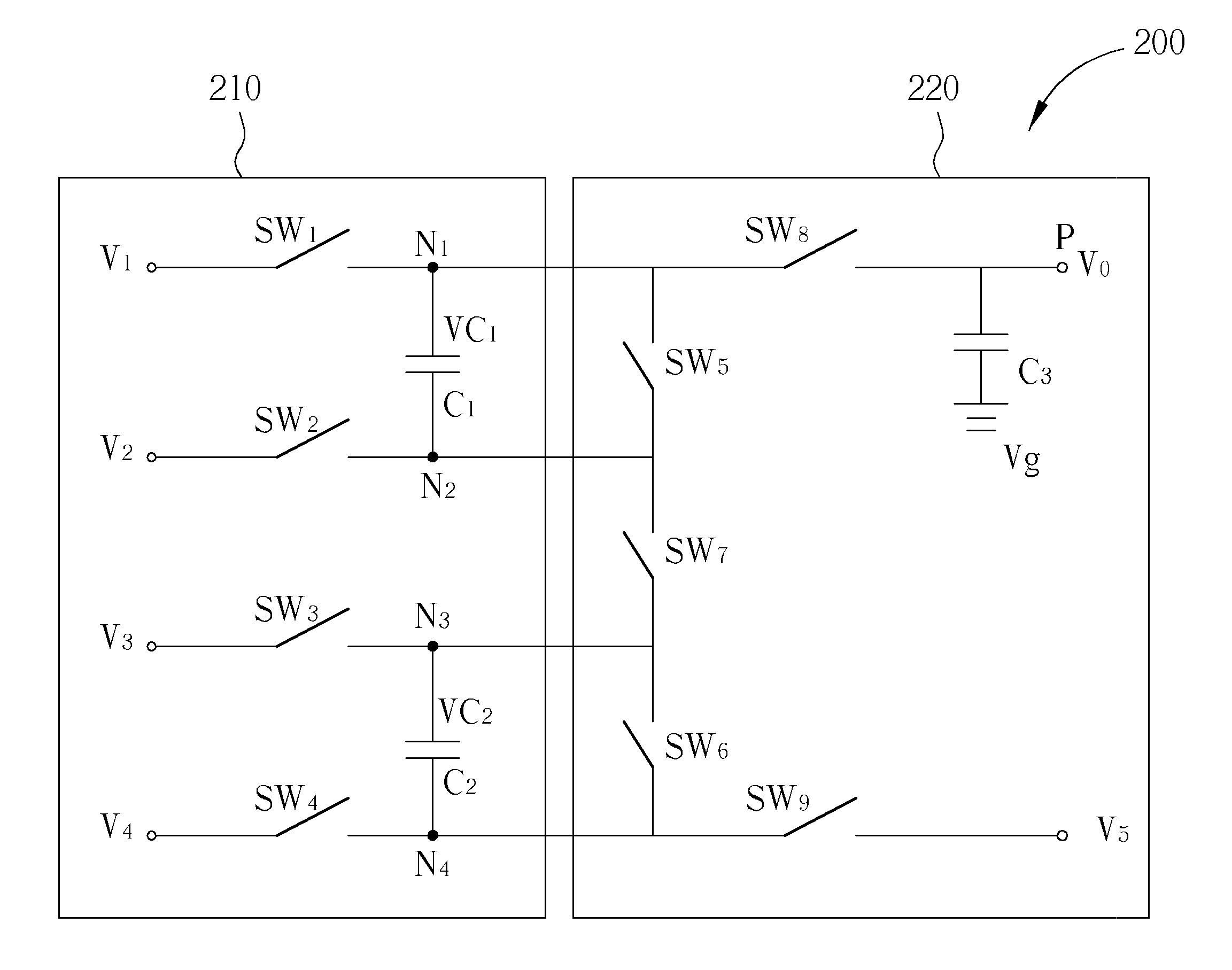

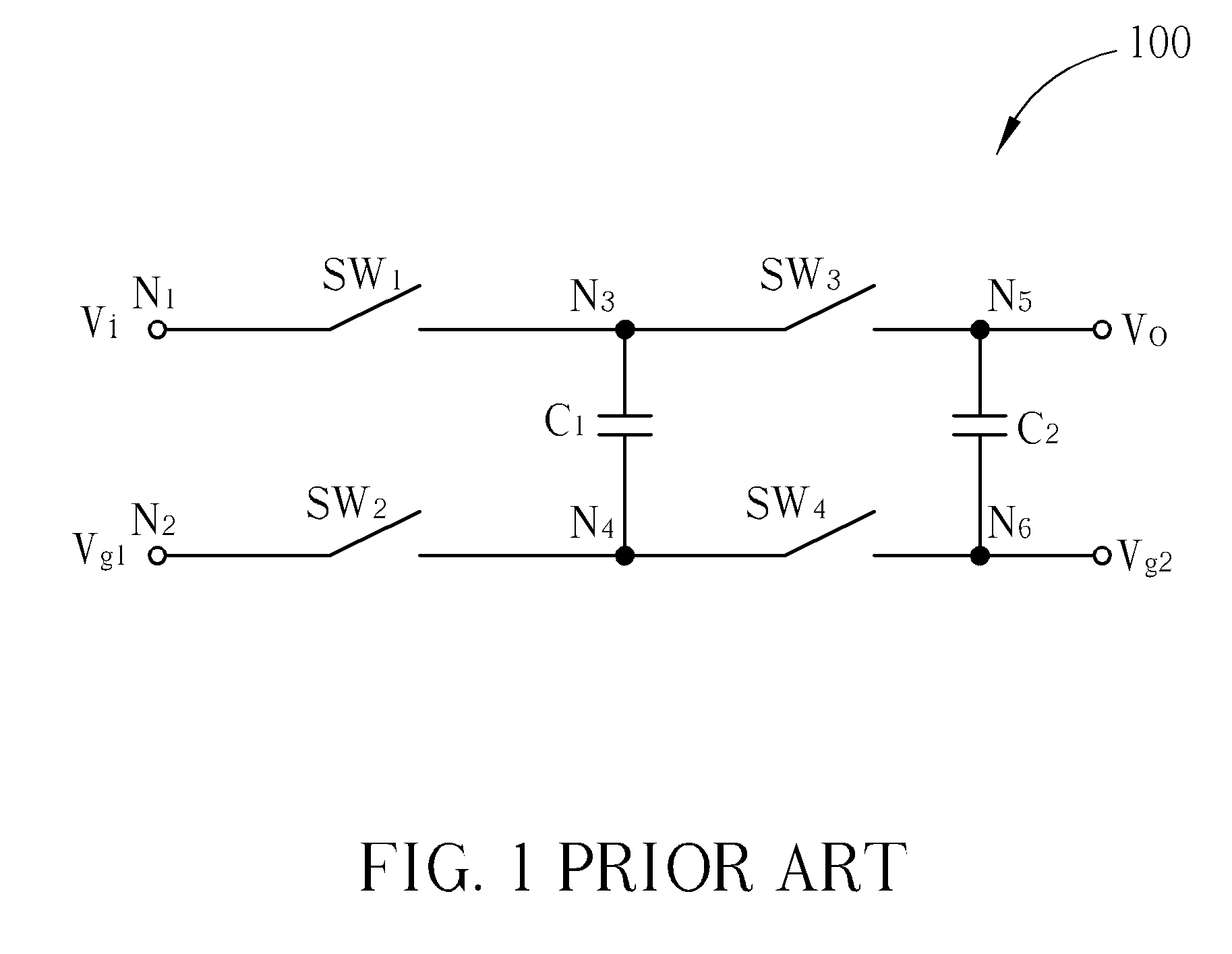

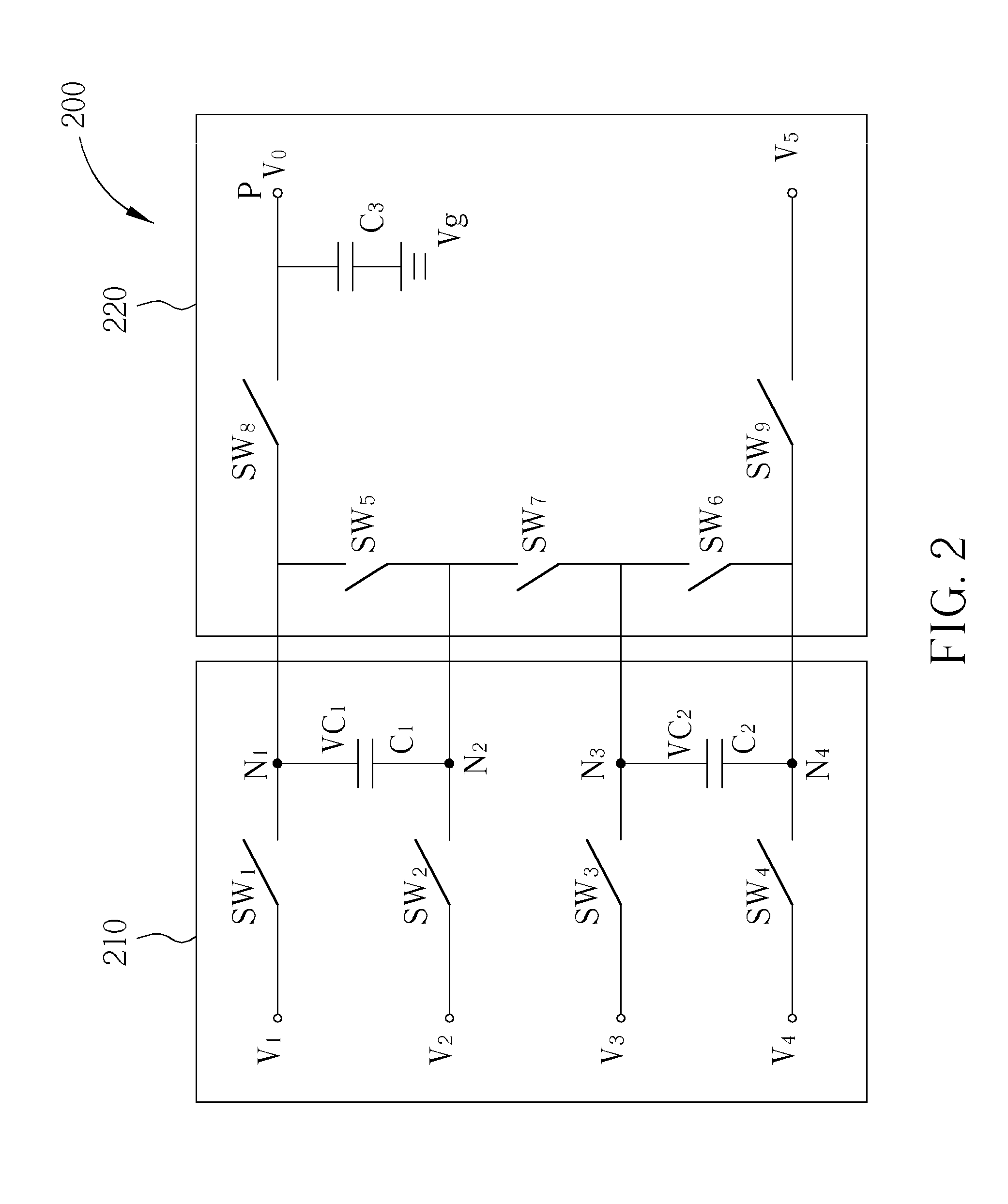

Convertible charge-pump circuit

ActiveUS20100085786A1Ac-dc conversionApparatus without intermediate ac conversionCharge pumpElectric potential

A convertible charge-pump circuit includes: a charging circuit having a plurality of charging capacitors and a pumping circuit having an output port coupled to a pumping capacitor. The charging circuit is configured for charging the charging capacitors to store a plurality of potential differences, respectively, when the convertible charge-pump circuit is in a charging phase. The pumping circuit is configured for selecting at least one charging capacitor from the charging capacitors charged in the charging phase to generate an output voltage level at the output port according to a potential difference stored in the selected charging capacitor when the convertible charge-pump circuit is in a pumping phase.

Owner:HIMAX TECH LTD

Electrode slurry preparing method

InactiveCN101132062AUniform and stable dispersionGood dispersionElectrode manufacturing processesElectric capacityInternal resistance

This inventive electrode slurry comprising: binder, conductive agent, electrode active substance and solvent are mixed evenly by agitating. Said conductive agent in the form of conductive system is mixed with the binder, electrode active substance and solvent. Said conductive system comprises conducting agent and conductive dispersion medium, said conducting agent having D50 size of 200-3000 nanometer. The slurry thus prepared has advantages of: excellent electric capacity of electrode active substance, slow rate of decay of electric capacity, stable discharging platform, stable internal resistance.

Owner:BYD CO LTD

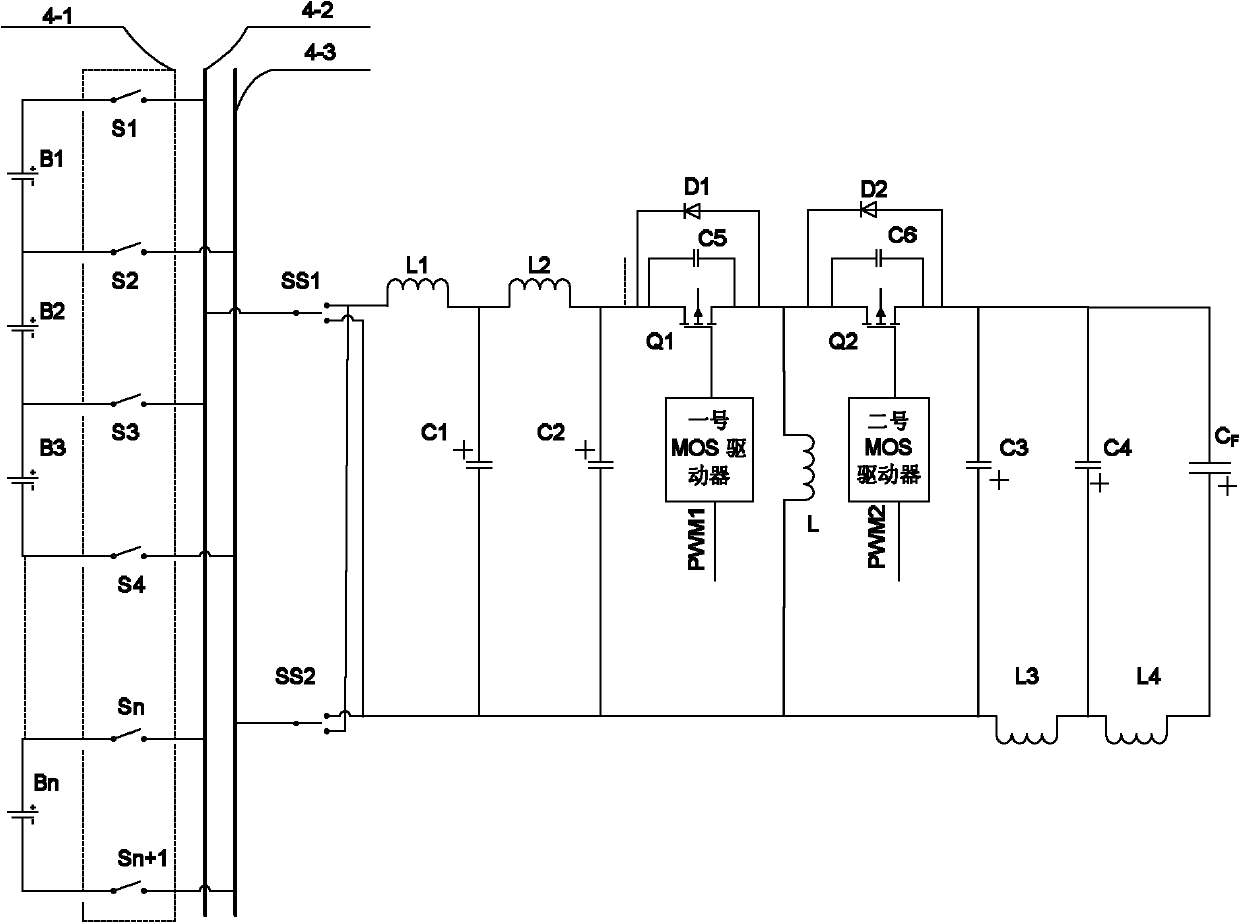

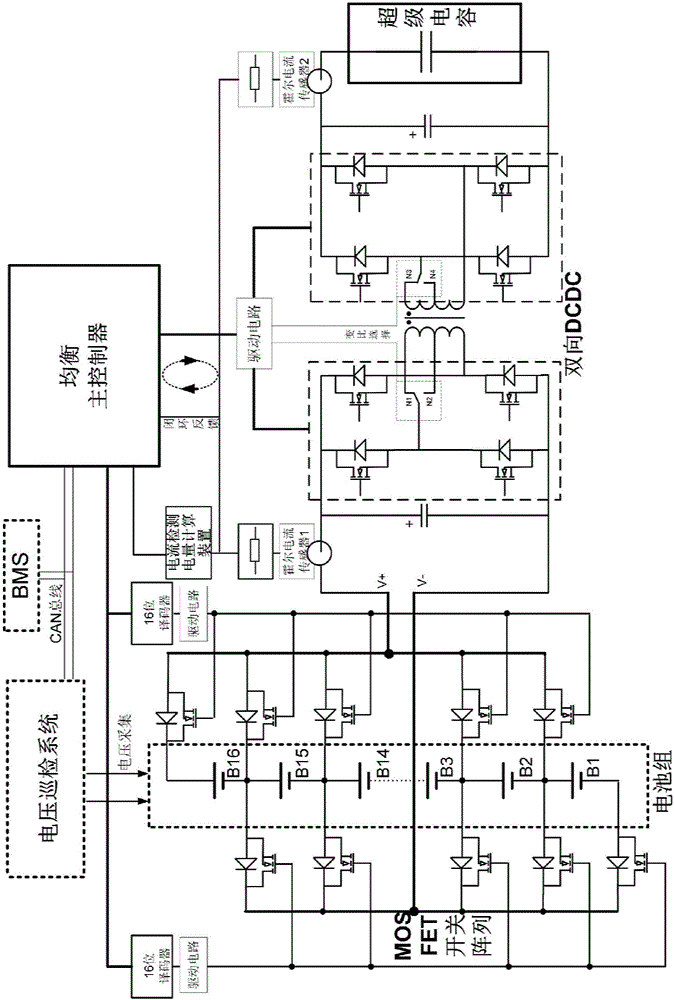

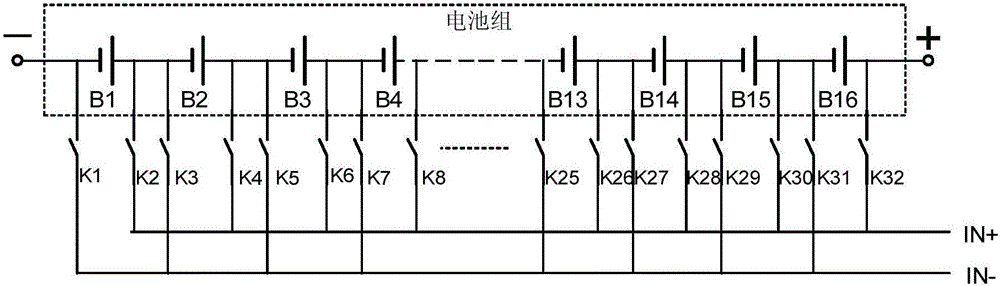

Super-capacitor energy storage and transfer-based active equalization system and method for lithium battery pack

ActiveCN105939034AGuarantee the demand for high power and high currentAchieve interlockCharge equalisation circuitSecondary cells charging/dischargingCapacitanceElectrical battery

The invention provides a super-capacitor energy storage and transfer-based active equalization system and method for a lithium battery pack. The active equalization system comprises an equalization main controller, a switch array, a two-way DC / DC, a super-capacitor, a current detection and power calculation device, a 16-bit decoder and a drive circuit, wherein the equalization main controller obtains a single battery voltage inspection value as an equalization state basis and any to-be-equalized battery is gated by the switch array to be connected to an equalization bus; the preceding stage of the full-bridge two-way DC / DC with an adjustable ratio is connected with the equalization bus and the backward stage is connected with the super-capacitor; the power of the equalization loss is calculated through the current detection and power calculation device; the equalization main controller achieves charging for the super-capacitor by a high-power battery through the two-way DC / DC; and the super-capacitor stores the power and then discharges a low-power battery through the two-way DC / DC until the equalization state. The power is stored and transferred through the super-capacitor; active equalization for the lithium battery pack is achieved; and the super-capacitor energy storage and transfer-based active equalization system has an important significance for prolonging of the lifetime of the lithium battery pack.

Owner:WUHAN UNIV OF TECH

Resource recycling method of waste battery cathode materials

InactiveCN106328927ALow costIncrease capacityCell electrodesWaste accumulators reclaimingRecovery methodElectric capacity

The invention relates to a resource recycling method of waste battery cathode materials. The resource recycling method comprises the following steps: performing high-temperature calcinating to the waste battery cathode materials so as to separate active powder in the cathode materials from aluminum foil; dissolving the obtained active powder into acid solution, and then filtering to obtain filtrate; determining the concentration of metal ions in the filtrate, and correspondingly supplementing nickel and / or cobalt and / or manganese ions into the solution, so that the molar concentration ratio of nickel, cobalt and manganese ions is 1:1:1; adding sodium hydroxide into the prepared nickel, cobalt and manganese mixture solution, and heating to lead the nickel, cobalt and manganese ions to be co-precipitated, then filtering the precipitate and washing and drying to obtain a nickel-cobalt-manganese precursor; adding sodium carbonate into the filtrate obtained in the step IV, and reacting to obtain lithium carbonate precipitate, filtering, washing and drying the lithium carbonate precipitate, to obtain lithium carbonate powder; and mixing the nickel-cobalt-manganese precursor with the lithium carbonate powder, and calcinating to obtain the lithium nickel cobalt manganese cathode materials. A ternary cathode material is prepared by resource recycling ofvarious battery materials, and batteries produced from the ternary cathode material are lower in cost, higher in electric capacity and better in performance compared with single cobalt-lithium batteries, manganese-lithium batteries and nickel-lithium batteries.

Owner:王剑

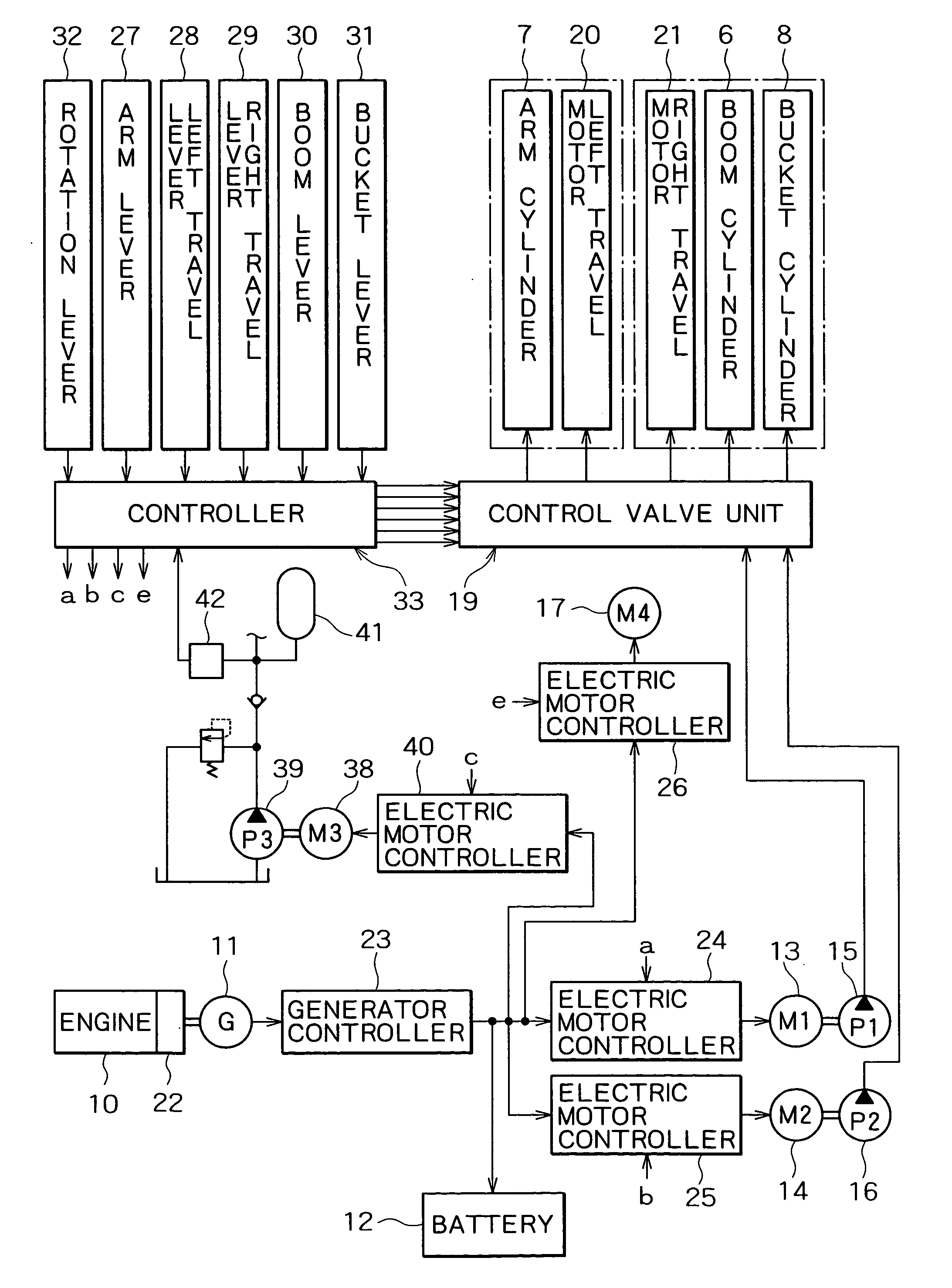

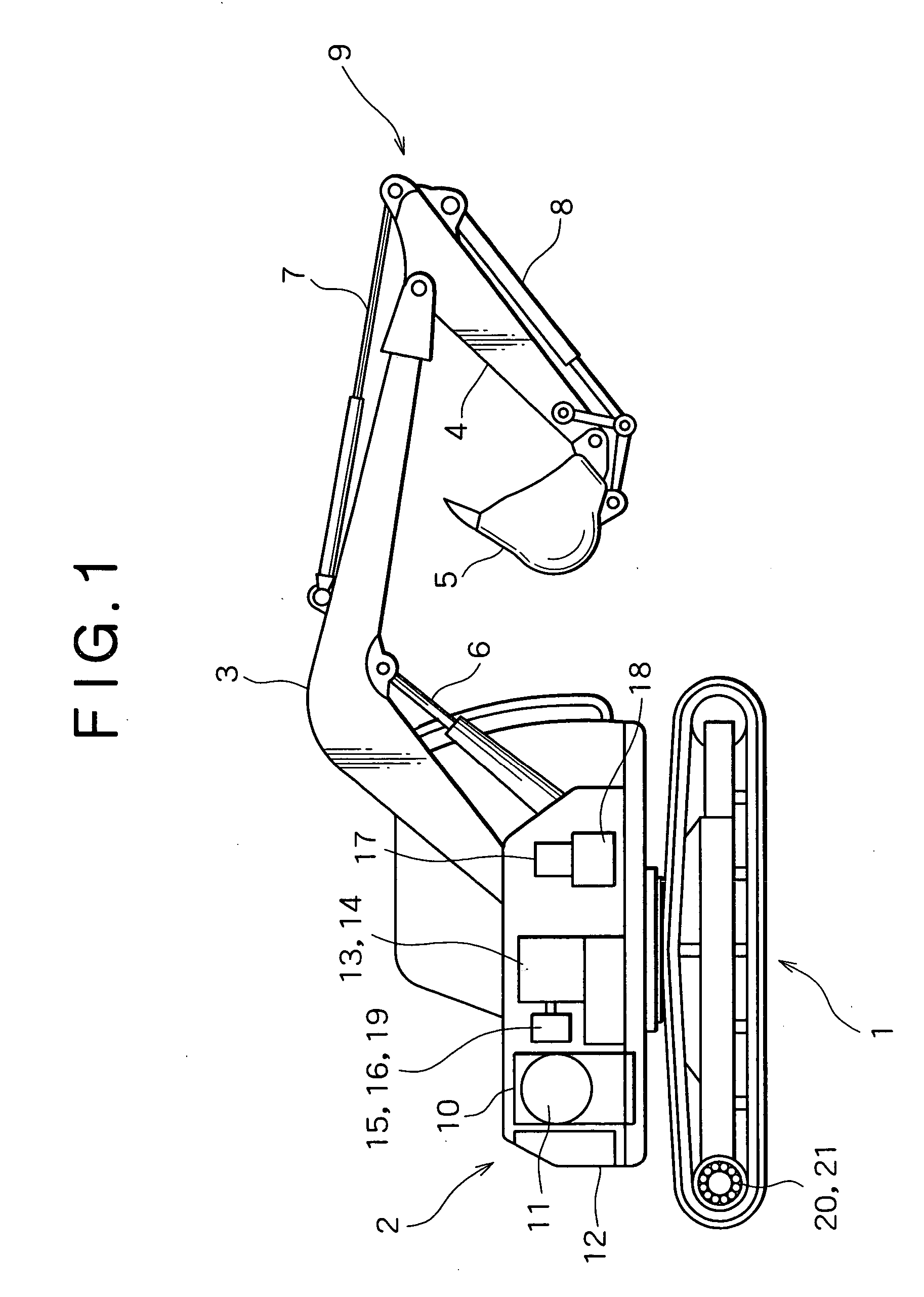

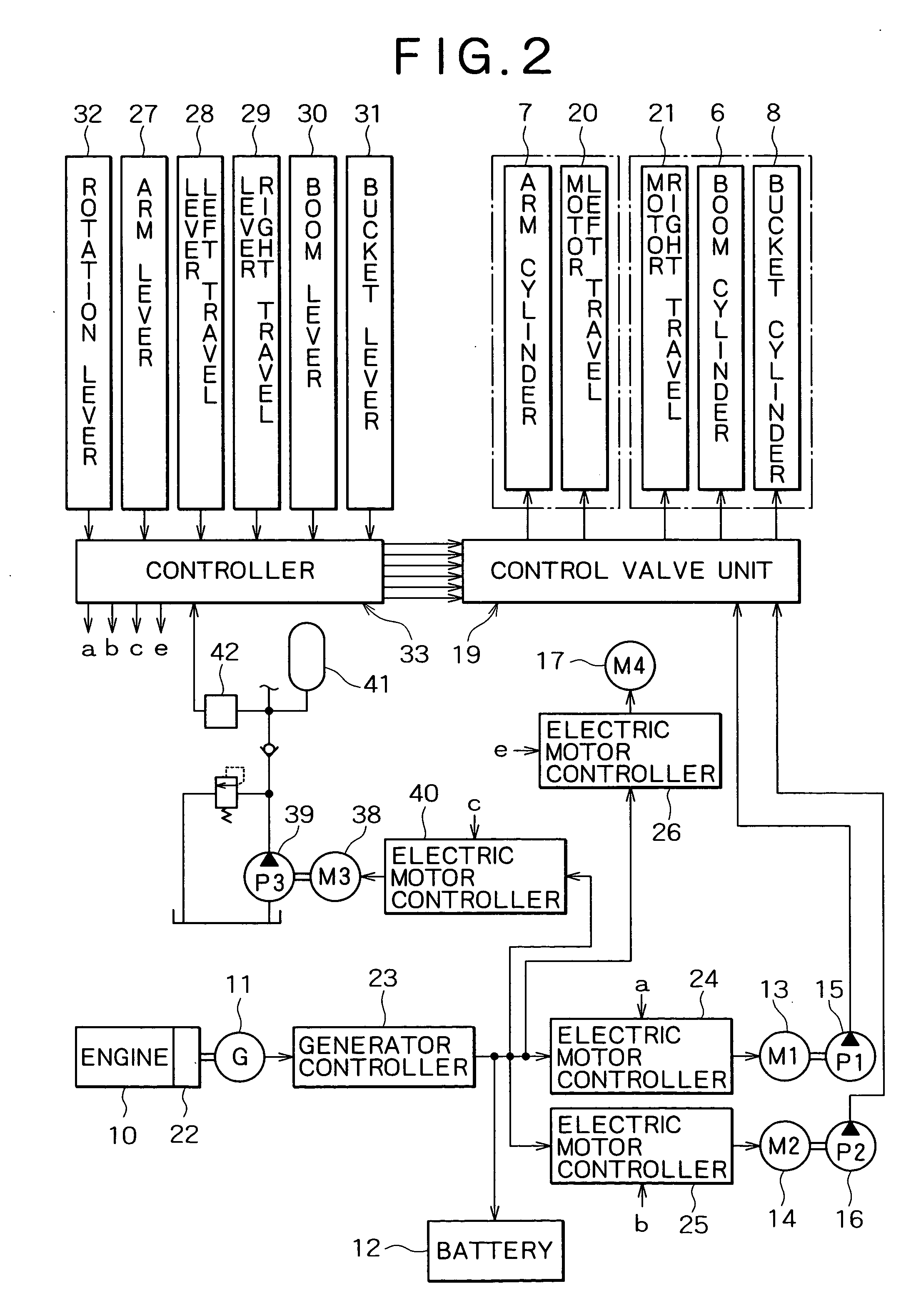

Actuator driving device of working machine

InactiveUS20050001567A1Setting space is limitedIncrease the areaMultiple dynamo-motor startersServomotorsCapacitanceControl power

A device, mounted on a hydraulic excavator, for allowing each of first and second electric motors (13), (14) to generate power by using electric power supplied from a power supply having a predetermined capacity, and actuating a boom cylinder (6), an arm cylinder (7), etc. using the generated power. The device is characterized by comprising electric motor controllers (24), (25), etc. for respectively controlling power that is generated by the electric motors (13), (14) so that, in machine-operation, powers generated by the electric motors (13), (14) may be equal to or less than predetermined rated outputs, and that the total amount of powers generated simultaneously by the electric motors (13), (14) may correspond to the maximum capacity of the power supply, so as to prolong the time of use with high thrust and high torque without increasing the capacitors of the electric motors (13), (14) and power supply.

Owner:KOBELCO CONSTR MASCH CO LTD

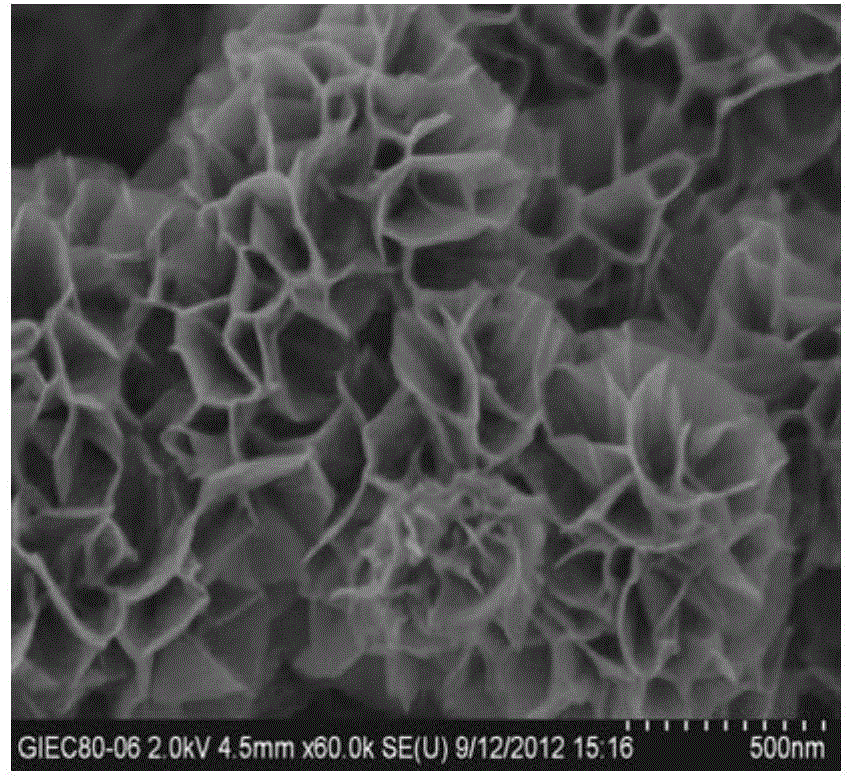

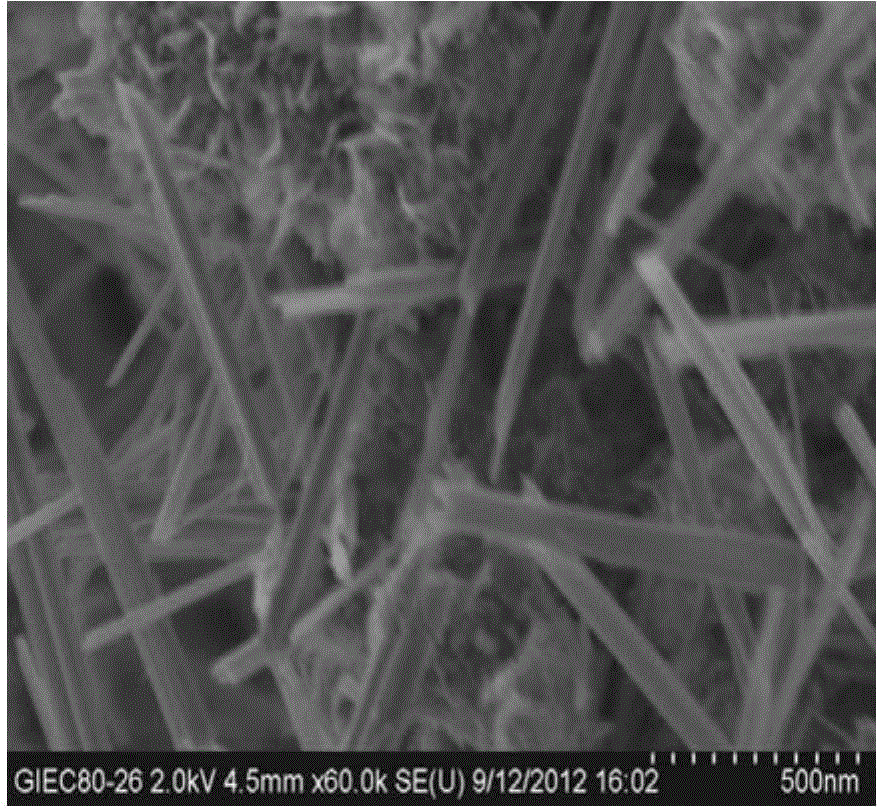

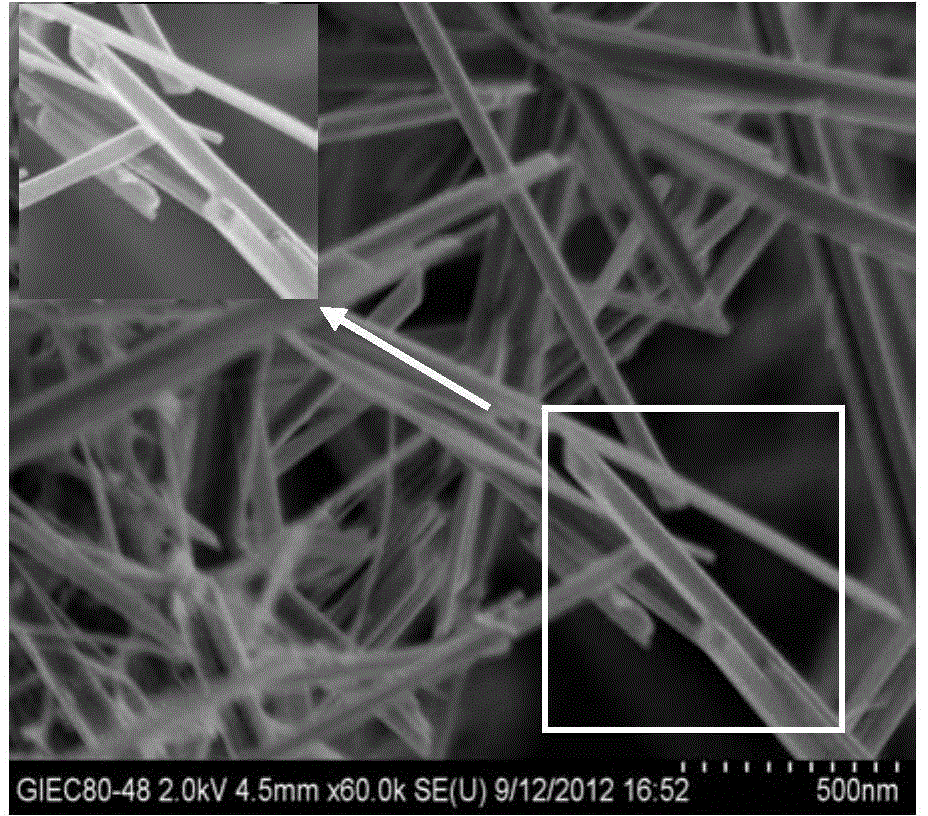

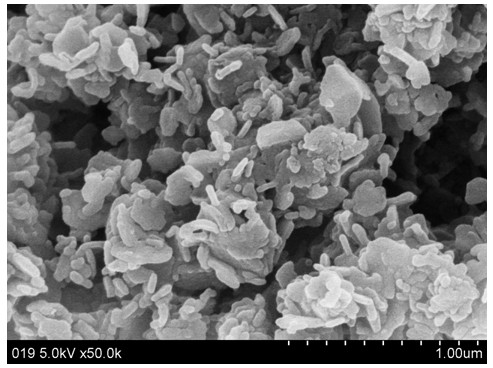

Method for preparing nano manganese dioxides with different appearances by hydrothermal synthesis process

ActiveCN103553137AHigh catalytic electrochemical activityLow costMaterial nanotechnologyManganese oxides/hydroxidesElectric capacityManganese

The invention discloses a method for preparing nano manganese dioxides with different appearances by adjusting the reaction time only under exactly same other conditions. The method comprises the following steps of adding potassium permanganate into deionized water, and stirring to form a uniform solution in which the concentration of potassium permanganate is 0.3mol / L; then adding manganese sulfate, wherein the mass ratio of potassium permanganate to manganese sulfate is 5:2; then transferring the solution into a high-temperature high-pressure reaction kettle of which the inner container is a polytetrafluoroethylene inner container; reacting for 1-18 hours at 140 DEG C; cooling, filtering, flushing and finally drying to obtain a target product. In the method disclosed by the invention, the process is simple, the cost is relatively low, the reaction conditions are mild, and the appearance of the crystal form is controllable; the obtained product has stable quality, relatively high catalytic electrochemical activity, wide applicability and the like, and can be widely applied to lithium ion batteries, molecular sieves, catalysts, super capacitors and the like as well as the basic study of related fields.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

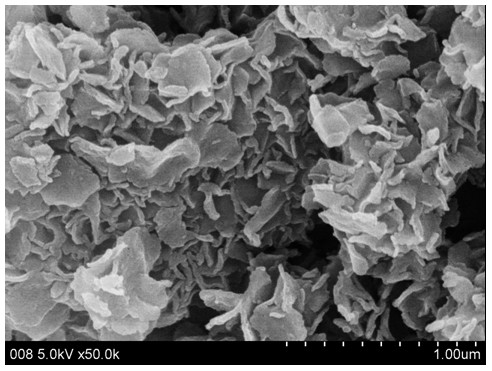

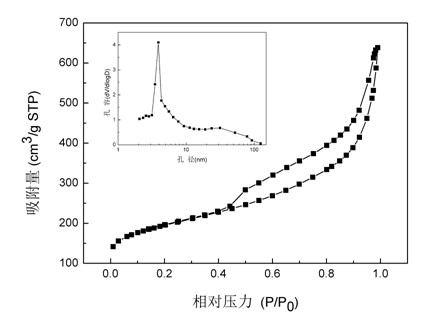

Preparation method of mesoporous carbon nanosheet and application of mesoporous carbon nanosheet as electrode material of super capacitor

ActiveCN102682928AImprove electrochemical performanceImproved magnification performanceElectrolytic capacitorsHybrid capacitor electrodesPolyethylene oxideElectric capacity

The invention relates to preparation of a mesoporous carbon nanosheet and application of the mesoporous carbon nanosheet as an electrode material in a super capacitor. According to the method, a porous magnesium oxide nanosheet is used as a template, dopamine is used as a carbon precursor, a carbon source is uniformly coated on the surface of the magnesium oxide nanosheet to form a complex, the complex is carbonized at a high temperature, and the magnesium oxide of the template is removed with excess sulfuric acid solution to obtain a two-dimensional carbon nanosheet. Triblock copolymer PEO-PPO-PEO (Polyethylene Oxide-Polyphenylene Oxide-Polyethylene Oxide) added in a preparation process is used as a structure directing agent to form a mesoporous structure, so that the specific surface area and the pore capacity of the carbon nanosheet are improved and transmission and diffusion of electrolyte ions are facilitated to improve the electric capacity of the material. The coating thickness of the carbon source on the surface of the template can be effectively controlled by adjusting the mass ratio of the template to the carbon source and the polymerization reaction time of the dopamine, and correspondingly the carbon nanosheets with different thicknesses are obtained, so that the electrochemical performance of the carbon nanosheet is affected.

Owner:EAST CHINA UNIV OF SCI & TECH

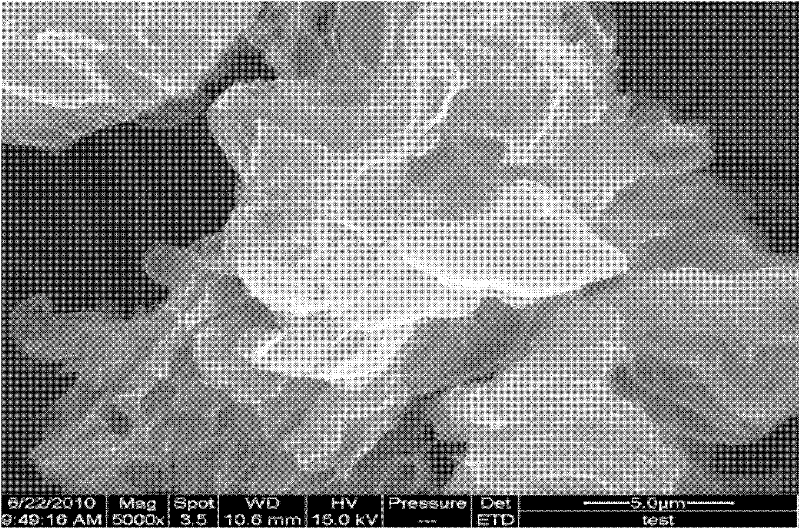

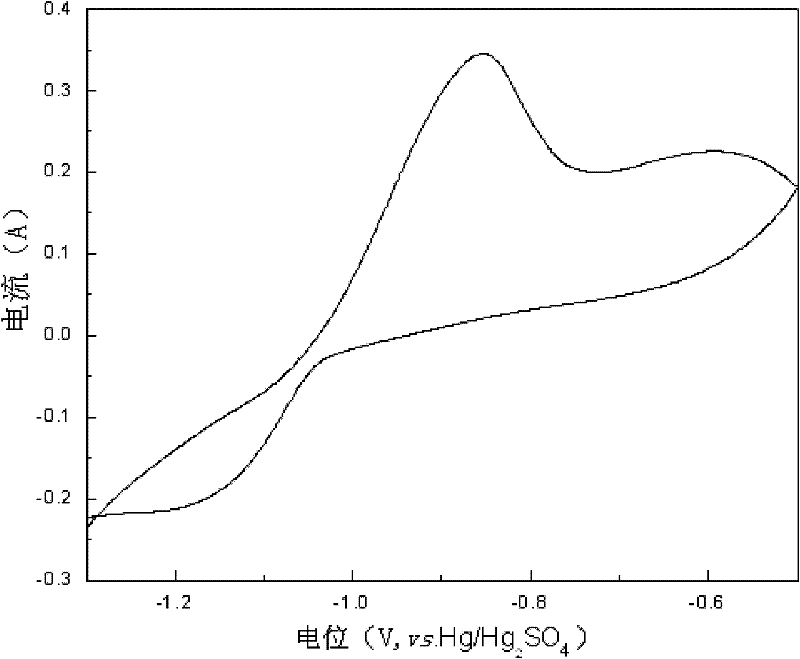

Lead sulfate-graphene composite electrode material and lead-acid battery negative electrode lead paste containing same

InactiveCN102201575AIncrease contact areaLower hydrogen evolution potentialCell electrodesCapacitanceGraphene

The invention relates to an electrode material and a lead-acid battery negative electrode lead paste containing the same, in particular to a lead sulfate-graphene composite electrode material and a lead-acid battery negative electrode lead paste containing the same, solving the problems of the traditional electric vehicles and energy-storage lead-acid battery, such as poor high rate discharging cycling performance of the negative electrode and short service life. In the lead sulfate-graphene composite electrode material, lead sulfate is loaded on graphene, wherein the weight ratio of lead sulfate to graphene is (0.1-10):1. The mass of the composite electrode material in the lead-acid battery negative electrode lead paste is 0.1% to 10% of the mass of lead powder. The composite electrode material has reversible oxidation-reduction performance and capacitance performance, and can reduce the hydrogen-evolving potential of graphene, thereby providing more lead sulfate growth points for the lead-acid negative electrode, suppressing the sulfation of the negative electrode of a lead-acid battery in the high rate charging-discharging process, and prolonging the service life of the lead-acid super battery. With the first pulse discharging cycling frequency of more than 6,000 times, the negative electrode lead paste is suitable for the negative electrode material of electric vehicles and energy-storage lead-acid batteries.

Owner:HARBIN INST OF TECH

Method for measuring mobile communication terminal battery electricity quantity

InactiveCN1889736AAvoid damagePrevent abnormal shutdownElectrical testingSecondary cellsElectrical batteryElectric capacity

A method for measuring electric capacity of battery on mobile communication terminal includes selecting different chance to measure voltage of battery when mobile communication terminal is on standby state or on communication state then confirming electric capacity of battery on mobile communication terminal according to condition of measuring out voltage of battery on mobile communication terminal.

Owner:ST ERICSSON SEMICON BEIJING

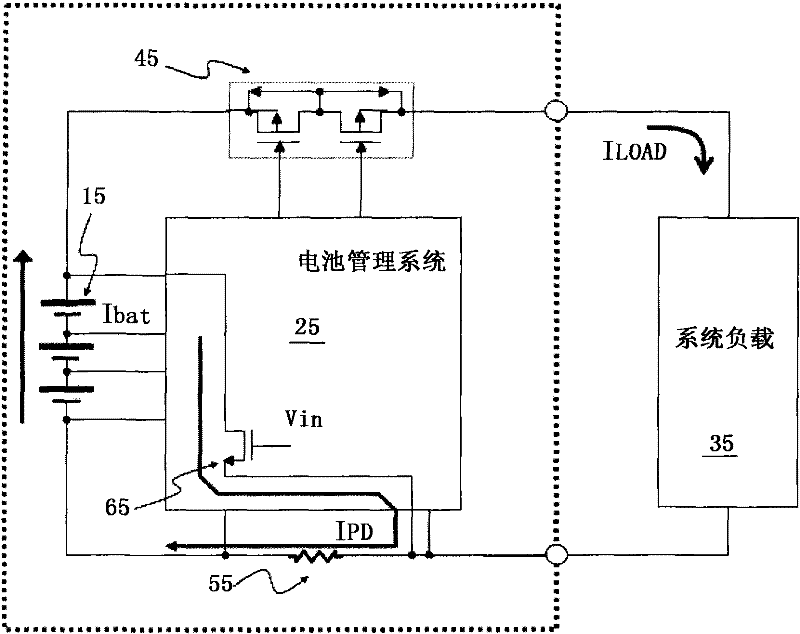

Method for measuring direct current internal resistance, full charge capacity and remaining power of battery pack

InactiveCN102207541AImprove consistencyAccurate estimateElectrical testingElectric capacityInternal resistance

The invention provides a method for measuring direct current internal resistance, full charge capacity and remaining power of a battery pack. The method comprises the following step of building a discharge circuit in a battery module, wherein the discharge circuit can be controlled by a switch, and discharge current of a lithium battery is a fixed value in a certain period of time, and is not changed with a system load. The electric capacity of the lithium battery can be easily and precisely derived from the obtained direct current internal resistance.

Owner:NEOTEC SEMICON

Modified activated carbon for capacitor electrodes and method of fabrication thereof

A novel electrode and method of making the same. The electrode includes activated carbon that has been modified by treatment with an alkali solution and an acid, such as nitric acid, and then washed and dried. The carbon may then be annealed. The method of modifying the activated carbon helps produce an electrode with considerably higher electric capacity and stable electric characteristics. Additionally, the electrodes may be produced more quickly and inexpensively and, therefore, permits their production of electrodes that are used for superconductors.

Owner:WAINWRIGHT D WALKER

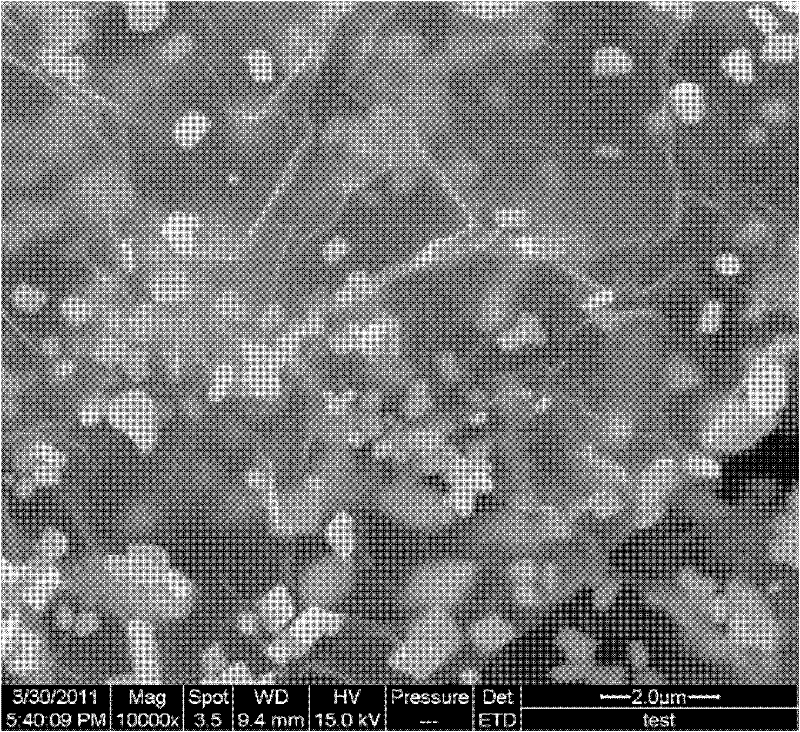

Nitrogen-doped grading porous carbon microspheres, and preparation method and application thereof

InactiveCN107572523AIncrease profitReduce transmission resistanceHybrid capacitor electrodesCell electrodesElectric capacityPorous carbon

The invention discloses nitrogen-doped grading porous carbon microspheres. The nitrogen-doped grading porous carbon microspheres are prepared by performing hydrothermal reaction on glucose and a nitrogen-containing compound and then performing activation, wherein the specific surface area is high and is 1160 to 1791 m<2> / 1, the pore diameter is distributed uniformly and the micropore content is high. The preparation method comprises the following steps: 1) preparing a nitrogen-containing precursor, adding the glucose and the nitrogen-containing compound into water, stirring uniformly, reacting, filtering, washing and drying to obtain the nitrogen-containing precursor; 2) carbonizing and activating the nitrogen-containing precursor, mixing the nitrogen-containing precursor and an alkaline inorganic matter, soaking into water, stirring and drying, and calcining and activating to obtain the nitrogen-doped modified grading porous carbon microspheres; and 3) performing aftertreatment on thenitrogen-doped modified grading porous carbon microspheres, soaking the nitrogen-doped modified grading porous carbon microspheres in a hydrochloric acid solution, washing, filtering, drying and grinding. When the nitrogen-doped grading porous carbon microspheres serve as supercapacitor electrode materials, the specific electric capacity is 248 to 407 F / g. The nitrogen-doped grading porous carbonmicrospheres have an application prospect in the fields of supercapacitors, lithium ion batteries and electric catalysis.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Soluble carbon nanometer pipe absocped with polyelectrolyte on surface and its preparation method

InactiveCN100999314AImprove machinabilitySimple and fast operationNanostructure manufacturePolyelectrolyteElectricity

This invention discloses a water-soluble carbon nanometer tube that superficially adsorbs polyelectrolyte and its preparation method. Process nanometer tube, make its surface have active group, display electro-negativity'alternatively adsorb electrolytic which has positive / negative charge by LBL, and make water-soluble carbon nanometer tube of superficial adsorbing single / multilayer polyelectrolyte. This invention is simple to operate, of no pollution; the product show good dissolving dispersibility in water, which can be used as superordinary aquosity additive, and provide excellent machinery, light, electricity, and magnetic function for water-soluble organic giant molecule basal body. And inlet different functional group through polyelectrolyte, make function pattern carbon nanometer tube. Thus, it has extensive application prospect in stuff science and organic medicine field of preparing nanometer ware, transmitter, and super electric capacity.

Owner:EAST CHINA UNIV OF SCI & TECH

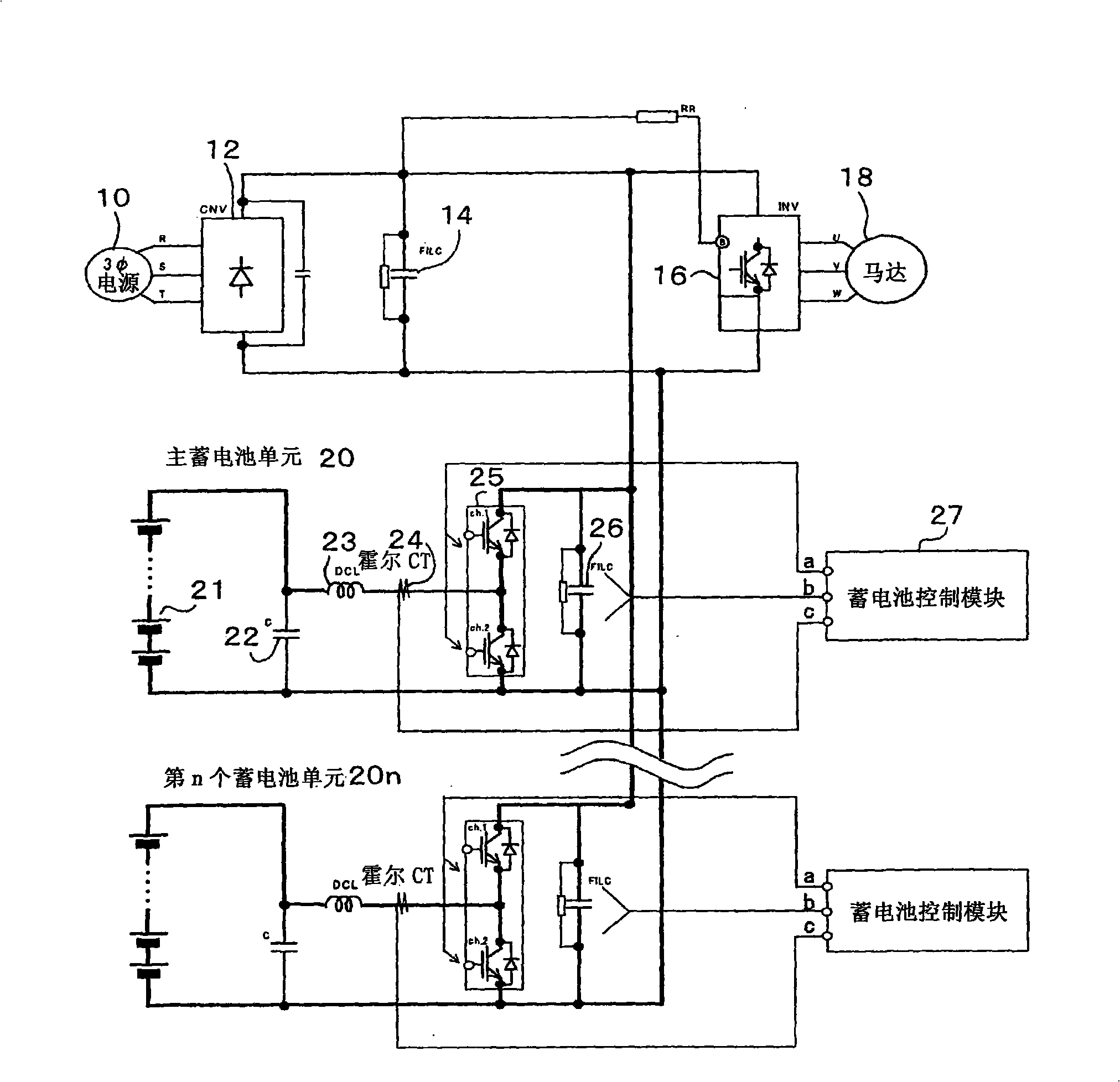

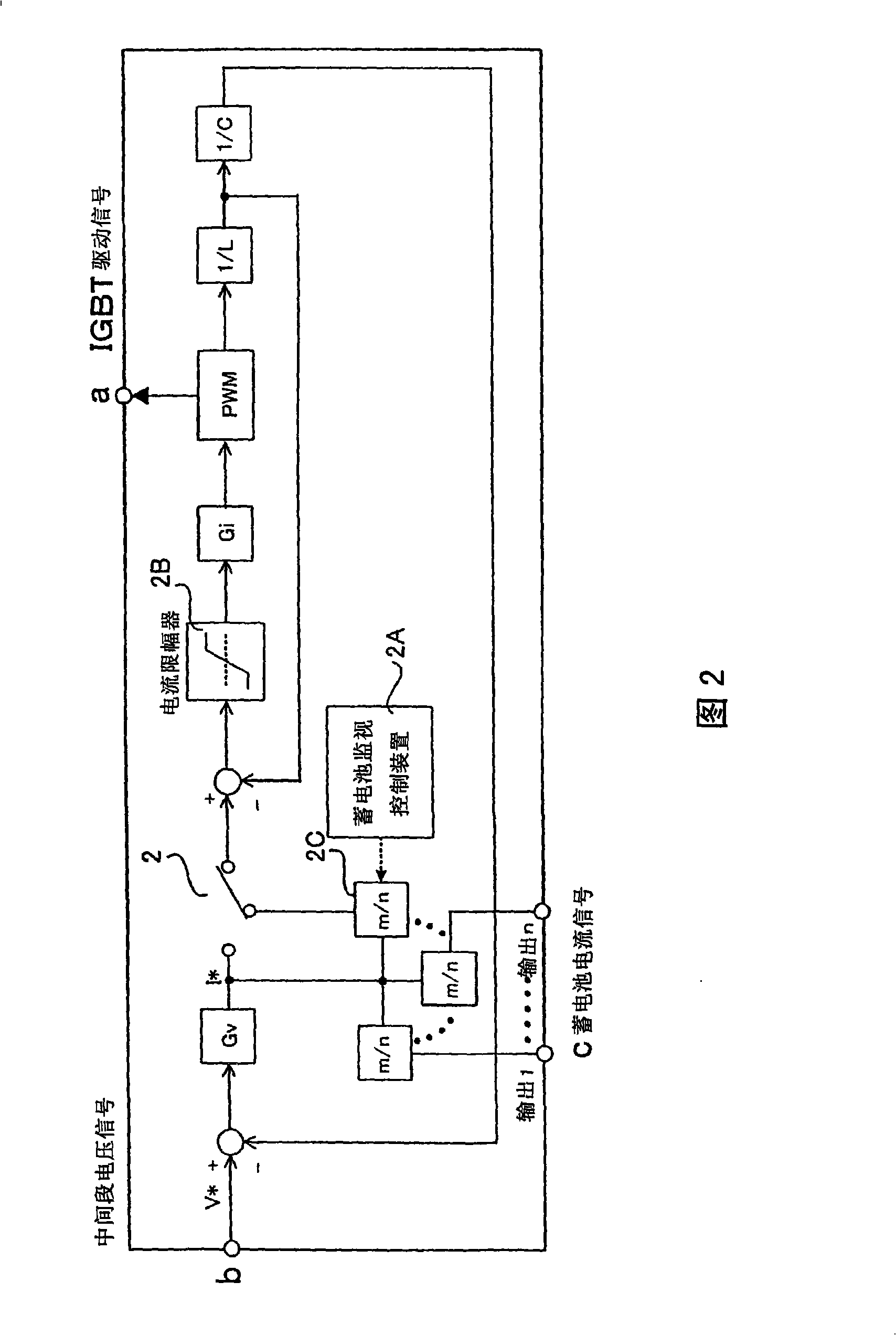

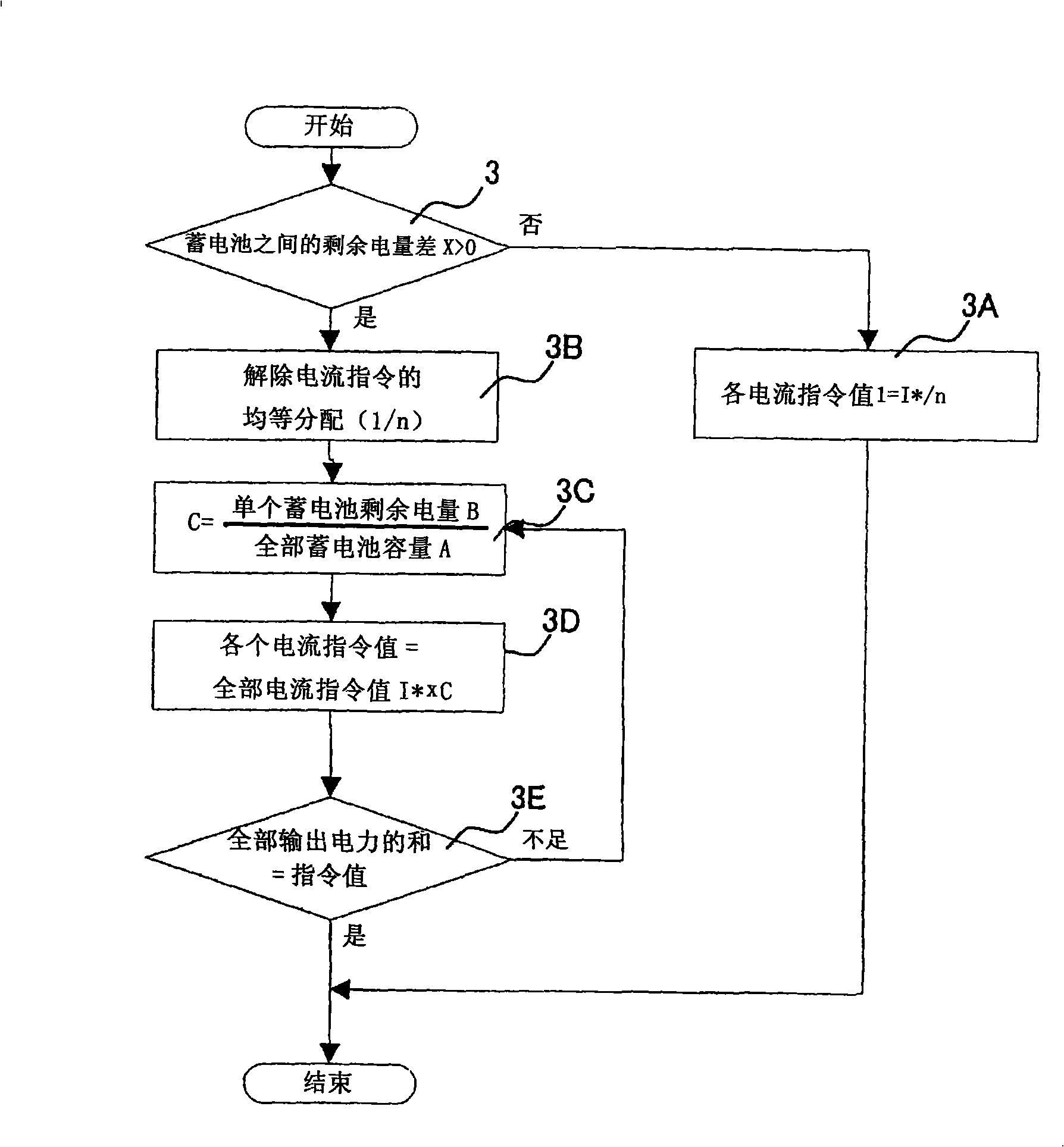

Elevator system and accumulator unit

InactiveCN101409526ATake advantage ofBatteries circuit arrangementsAC motor controlElectric capacityAlternating current

The invention provides an elevator system which is provided with a device which can monitor the residual electric capacity of all batteries, correctly distributing the charging / discharging currents according to the quantity of batteries connected in parallel, and always sufficiently utilizes all batteries. The elevator system is provided with a plurality of battery cells which are charged by direct current of a converter, a battery discharging / charging circuit which charges the battery cell when the power is supplied by alternative current and a battery charging / discharging circuit which supplies direct current from the battery cell to an inverter and an elevator control circuit when the alternative current is turned off, and a battery control module which is provided with a device which can detect the quantity of parallel connected battery cells, a device which calculates the average charging current / upper limit discharging current of the battery cell according to the quantity of the detected battery cell, and a device which rectifies and arranges the charging / discharging current of all battery cells according to the discharged / charged quantity of all battery cells detected by the battery charging / discharging circuit and the average charging current / upper limit discharging current.

Owner:HITACHI LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com