Preparation process of long-lived negative pole piece and capacitor battery using negative pole piece

A preparation process and technology of capacitor batteries, which are applied to capacitor electrodes, capacitor half-cells, primary or secondary half-cells, hybrid capacitor electrodes, etc., can solve cycle life constraints, pole piece compaction density limitations, and unsatisfactory energy density and other issues to achieve the effect of high energy density and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

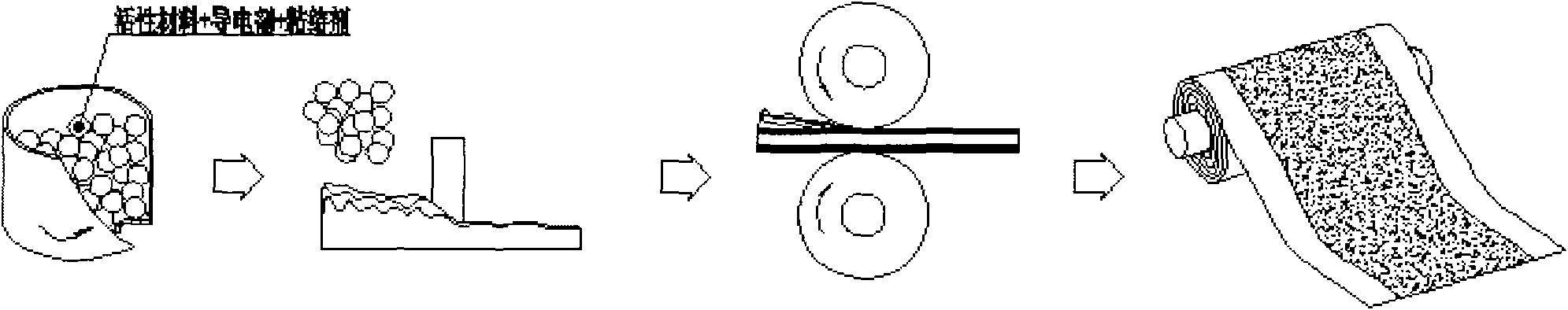

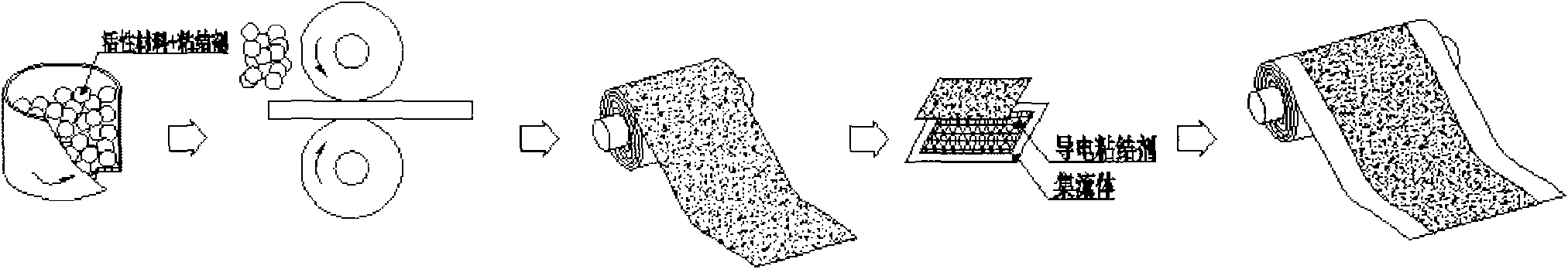

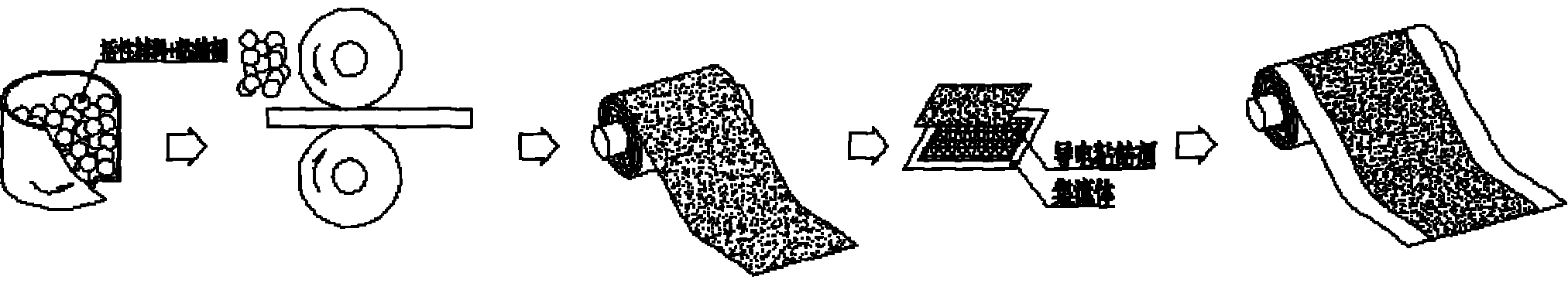

Method used

Image

Examples

Embodiment 1

[0057] The making of positive plate: the LiNi that total amount is 500g 1 / 3 co 1 / 3 mn 1 / 3 o 2 , activated carbon, graphite powder, and PVDF are mixed in a mass ratio of 75:15:5:5, adjusted to a slurry with NMP, and then coated on a 20 μm aluminum foil (the coating weight gain is: 240g / m 2 ), dried (110-120°C), rolled, and cut into pieces (size: 37.5*59.5mm 2 ), 24h vacuum drying (120 ~ 130 ℃) to make a positive sheet.

[0058] The making of negative plate: the hard carbon that total amount is 500g, PVDF are mixed by mass ratio as 90: 10, adjust into slurry with NMP, then coat on the copper foil of 16 μ m (coating gain is: 120g / m 2 ), after drying (110~120℃), rolling (compaction density is 0.96g / cm 3 ), cut pieces (size: 37.5*59.5mm 2 ), 24h vacuum drying (120 ~ 130 ℃) to make negative electrode sheet. Use polyethylene polypropylene three-layer composite microporous membrane as the diaphragm, put the pole piece into the 38*61*32 aluminum shell and laminate it into a batt...

Embodiment 2

[0060] The making of positive plate: the LiNi that total amount is 500g 1 / 3 co 1 / 3 mn 1 / 3 o 2 , activated carbon, graphite powder, and PVDF are mixed in a mass ratio of 75:15:5:5, adjusted into a slurry with NMP, and then coated on a 20 μm aluminum foil (the coating weight gain is: 240g / m 2 ), dried (110-120°C), rolled, and cut into pieces (size: 37.5*59.5mm 2 ), 24h vacuum drying (120 ~ 130 ℃) to make a positive sheet.

[0061] Production of the negative electrode sheet: mix a total amount of 500g of hard carbon and PTFE at a mass ratio of 90:10, make a slurry with deionized water, stir until it becomes a paste, and press it with a roller press to obtain a sheet of a certain thickness Shaped pole piece, the compaction density is 1.35, the conductive agent Super-P is adjusted into a slurry, and then a layer of conductive agent is coated on the negative electrode collector, and finally the pole piece is attached to the negative electrode collector coated with a layer of con...

Embodiment 3

[0063] The making of positive plate: the LiMn that total amount is 500g2 o 4 , activated carbon, graphite powder, and PVDF are mixed in a mass ratio of 75:15:5:5, adjusted to a slurry with NMP, and then coated on a 20 μm aluminum foil (the coating weight gain is: 300g / m 2 ), dried (110-120°C), rolled, and cut into pieces (size: 37.5*59.5mm 2 ), 24h vacuum drying (120 ~ 130 ℃) to make a positive sheet.

[0064] The making of negative plate: the hard carbon that total amount is 500g, PVDF are mixed by mass ratio as 90: 10, adjust into slurry with NMP, then coat on the copper foil of 16 μ m (coating gain is: 120g / m 2 ), after drying (110~120℃), rolling (compaction density is 0.96g / cm 3 ), cut pieces (size: 37.5*59.5mm 2 ), 24h vacuum drying (120 ~ 130 ℃) to make negative electrode sheet. Use polyethylene polypropylene three-layer composite microporous membrane as the diaphragm, put the pole piece into the 38*61*32 aluminum shell and laminate it into a battery cell, with a tig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com