Silicon-carbon composite negative pole material preparation method and lithium ion battery

A negative electrode material, silicon-carbon composite technology, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of difficult control of hollow inner diameter, brittle PVC coating layer, unfavorable long-term cycle, etc., to reduce the surface active points of particles , uniform dispersion, and the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

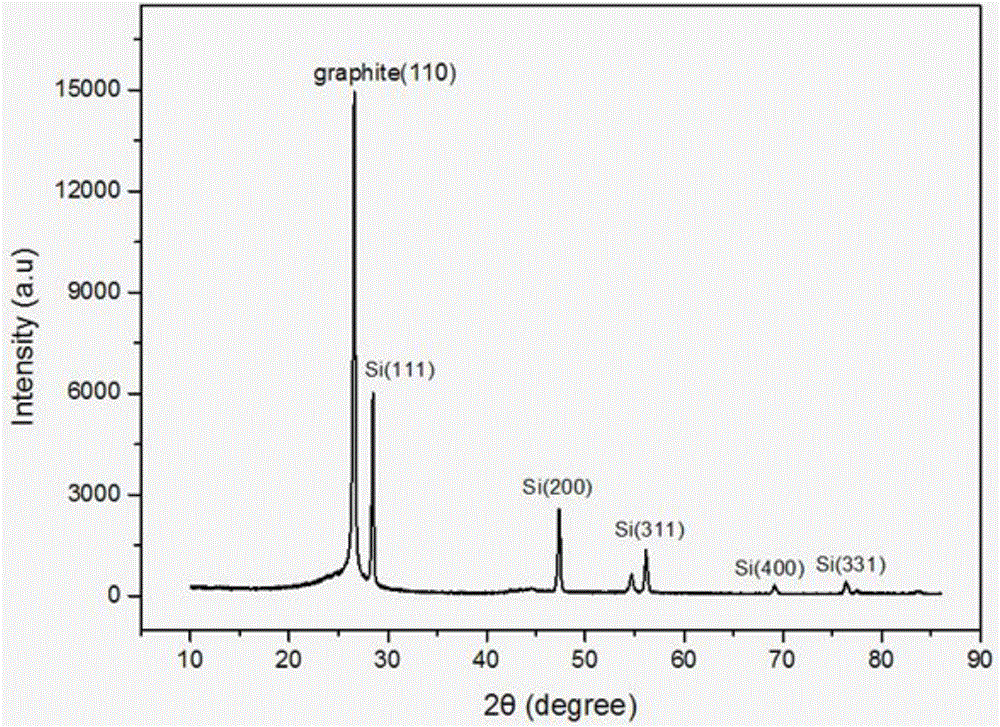

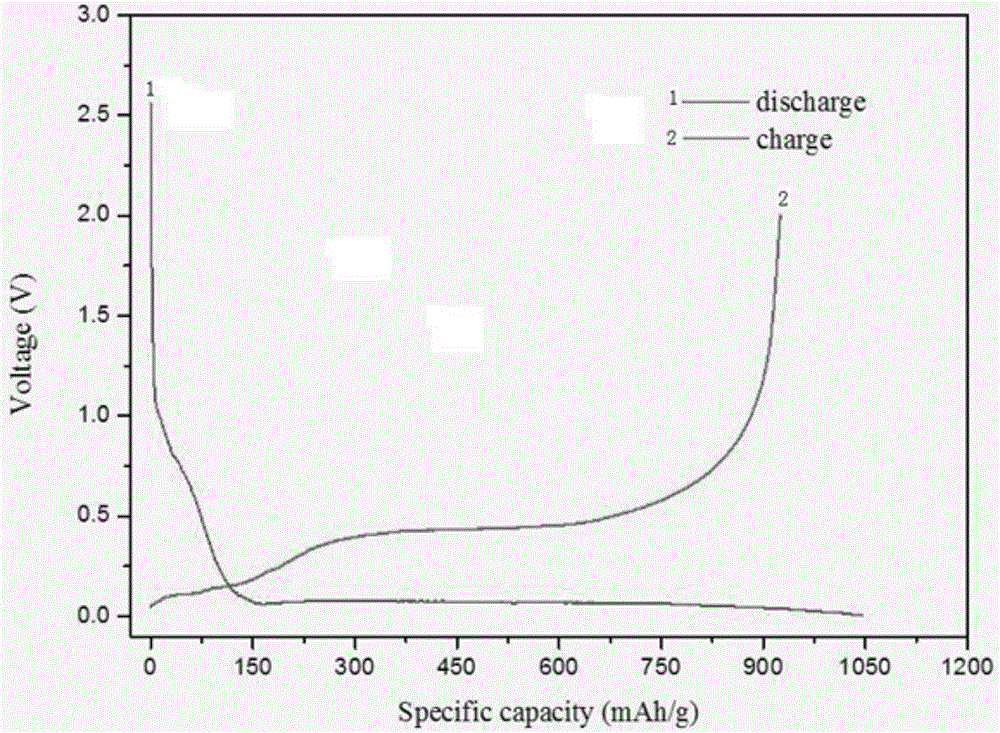

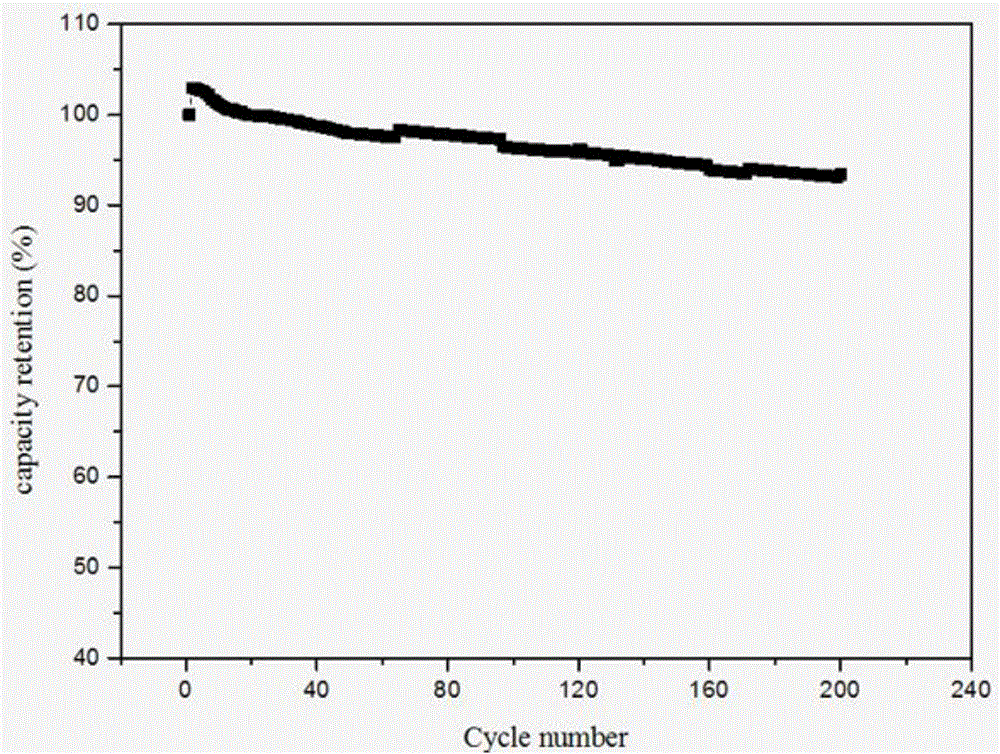

[0030] A method for preparing a silicon-carbon composite negative electrode material, comprising the following steps:

[0031] A: Ultrasonic disperse 120g of spherical graphite in 100ml of absolute ethanol, then add 40g of nano-silicon into the graphite dispersion, use a planetary ball mill for 7 hours, the speed of the ball mill is 250r / min, and then place it in a vacuum drying oven at 80°C for vacuum drying 3h;

[0032] Before nano-silicon is ball-milled, first add silicon powder to 10 times its mass of sodium hydroxide solution with a concentration of 10wt%, and after the dispersion is uniform, heat it to 120°C under reduced pressure, keep warm and decompose for 7 hours; Add the powder to 10 times the mass of ethanol solution with a concentration of 75wt%, heat it to 85°C and keep it warm for 4h, filter again, beat until the pulp has a beating degree of 15°SR, and then refine to a pulp The degree of beating is 20°SR. After beating, the silicon powder obtained by washing wi...

Embodiment 2

[0036] A method for preparing a silicon-carbon composite negative electrode material, comprising the following steps:

[0037] A: Ultrasonic disperse 120g of spherical graphite in 100ml of absolute ethanol, then add 15g of silicon powder into the graphite dispersion, use a planetary ball mill for 7 hours, the speed of the ball mill is 250r / min, and then place it in a vacuum drying oven at 80°C for vacuum drying 3h; before the nano-silicon is ball-milled, add silicon powder to 12 times the mass of the sodium hydroxide solution with a concentration of 12wt%, and after the dispersion is uniform, heat it to 130°C under reduced pressure, keep warm and decompose for 8h; filter after decompression to obtain Add silicon powder to 12 times its mass in an ethanol solution with a concentration of 80wt%, heat it to 90°C and keep it warm for 5h, filter again, beat until the slurry has a beating degree of 16°SR, and then refine to The beating degree of the slurry is 22°SR. After beating, th...

Embodiment 3

[0041] A method for preparing a silicon-carbon composite negative electrode material, comprising the following steps:

[0042] A: Ultrasonic disperse 80g of spherical graphite in 100ml of absolute ethanol, then add 10g of silicon powder into the graphite dispersion, use a planetary ball mill for 3 hours, and the speed of the ball mill is 250r / min, and then place it in a vacuum drying oven at 80°C for vacuum drying 3h; before the nano-silicon is ball-milled, add silicon powder to 12 times the mass of the sodium hydroxide solution with a concentration of 12wt%, and after the dispersion is uniform, heat it to 130°C under reduced pressure, keep warm and decompose for 8h; filter after decompression to obtain Add silicon powder to 12 times its mass in an ethanol solution with a concentration of 80wt%, heat it to 90°C and keep it warm for 5h, filter again, beat until the slurry has a beating degree of 16°SR, and then refine to The beating degree of the slurry is 22°SR. After beating,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com