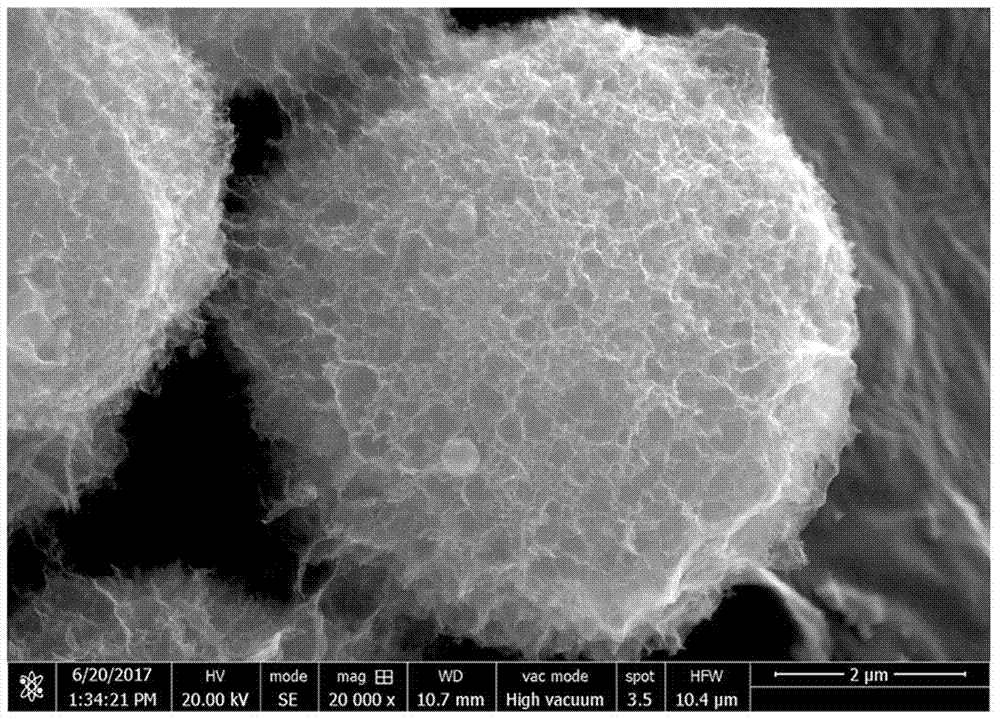

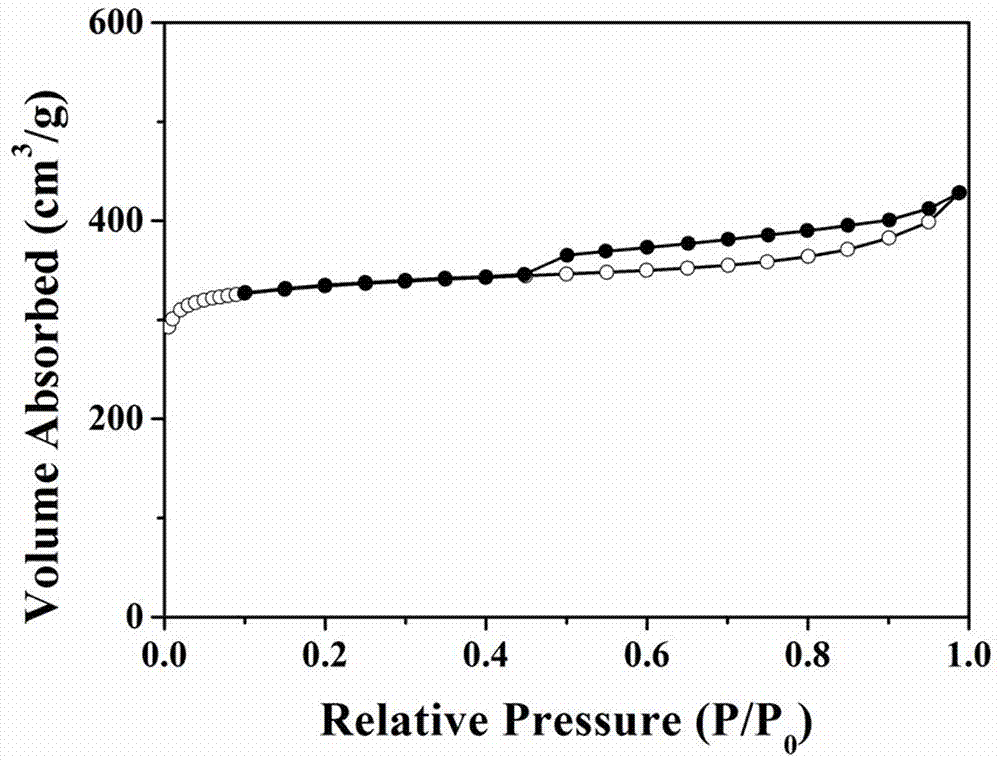

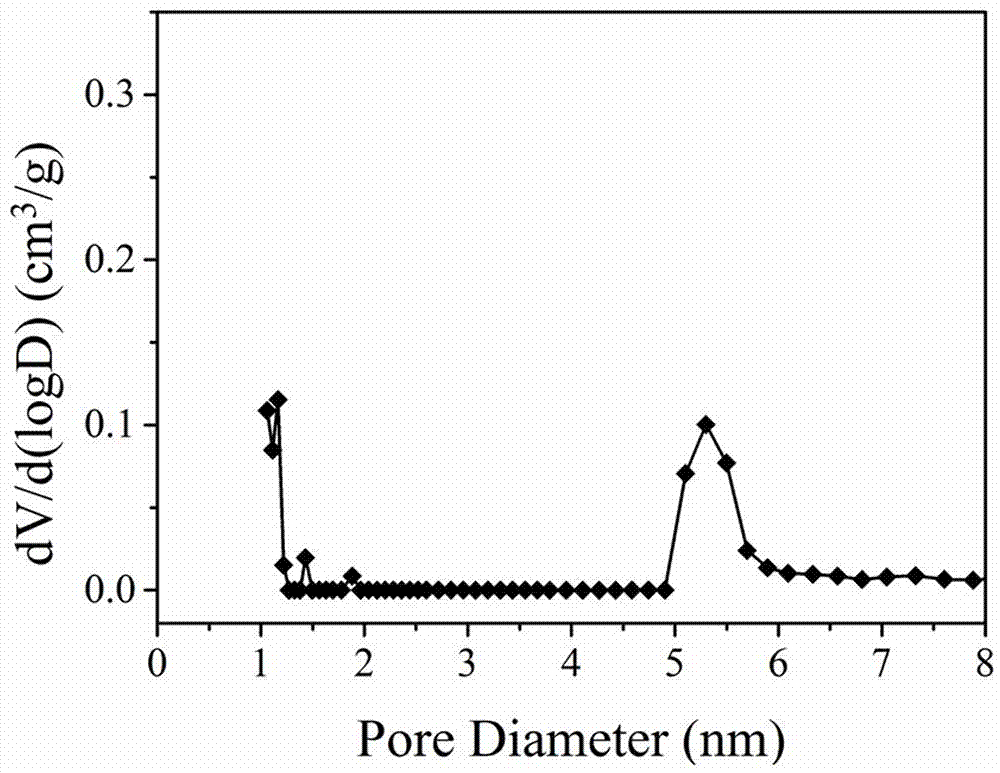

Nitrogen-doped grading porous carbon microspheres, and preparation method and application thereof

A hierarchical porous, nitrogen-doped technology, applied in the field of porous materials, can solve the problems of complex preparation process, difficulty in large-scale production, difficult standardization, etc., to achieve the effect of improving specific capacity, increasing utilization rate, and reducing transmission resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The preparation method of nitrogen-doped hierarchical porous carbon microspheres with a mass ratio of glucose to DTPA of 4:2 is as follows:

[0040] Step 1) Preparation of nitrogen-containing precursors, 4 g of glucose and 2 g of DTPA were added to deionized water and stirred evenly, and then placed in a reaction kettle for 6 h at 180 °C, and then the product was filtered, washed, and dried to obtain Nitrogen precursors;

[0041] Step 2) Carbonization and activation of nitrogen-containing precursors, mix nitrogen-containing precursors and KOH at a mass ratio of 1.0:2.0, soak in deionized water and stir, put them in a blast drying oven to dry, and then calcinate at 700 °C under nitrogen protection 2 h, after cooling down, take out the roasted sample and grind it;

[0042] Step 3) Post-treatment of nitrogen-doped hierarchical porous carbon microspheres, the above samples were washed with 1 M HCl solution, vacuum filtered, washed with deionized water until neutral, dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com