Elevator system and accumulator unit

A battery and discharge circuit technology, applied in electrical components, control systems, battery circuit devices, etc., can solve problems such as battery waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

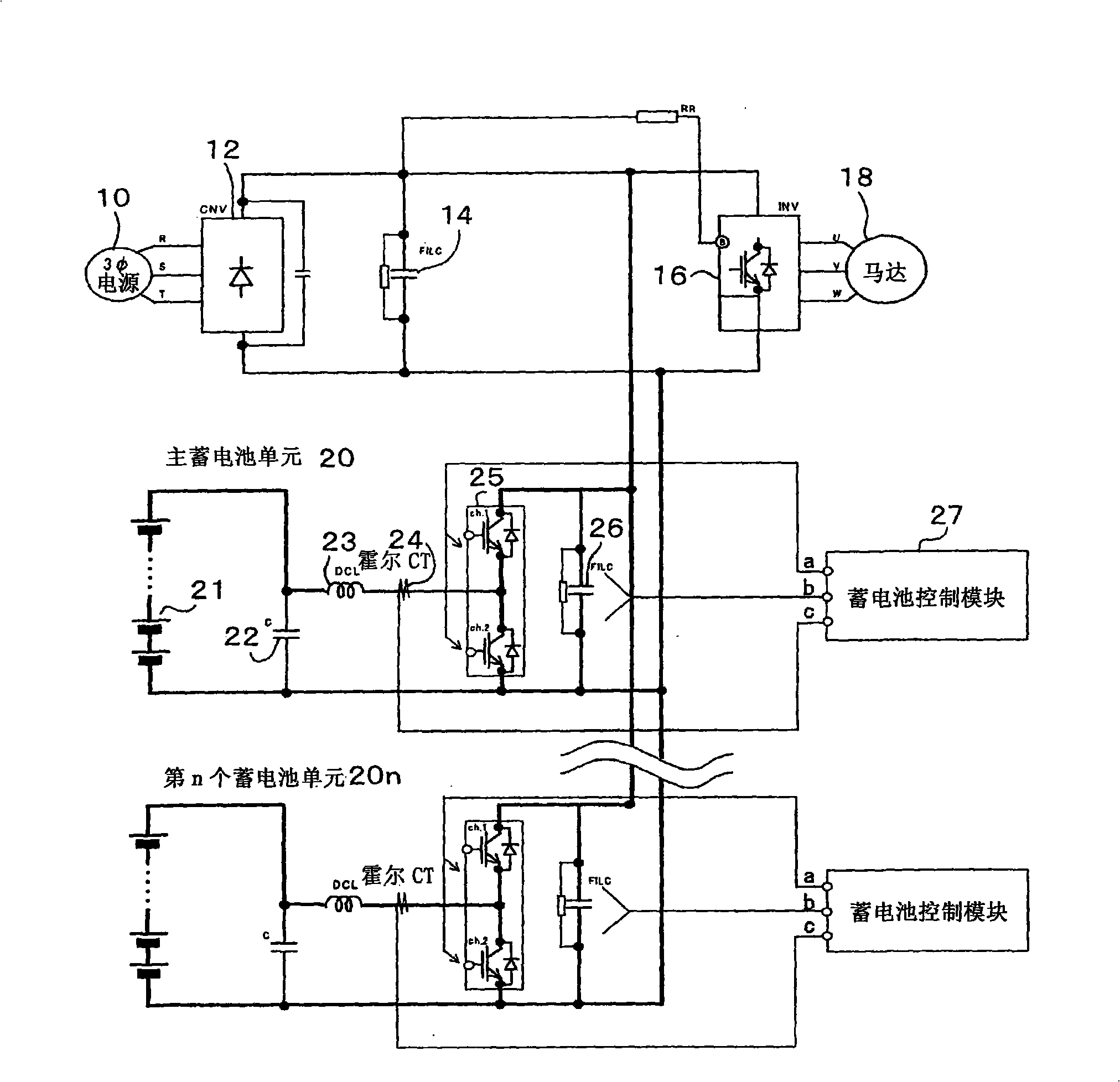

[0036] figure 1 It is a block diagram showing the system configuration of Embodiment 1 of an elevator system in which a plurality of storage battery units are connected in parallel according to the present invention.

[0037]The elevator system of Embodiment 1 has an inverter 12 that converts commercial AC power 10 into DC power, a smoothing capacitor 14, and an inverter that converts the DC power of the converter 12 into AC power with variable voltage and variable frequency and controls the elevator drive motor. inverter 16, and an unshown elevator control circuit that rectifies the commercial alternating current 10 and receives power to control the inverter 16. Among them, a plurality of storage battery units 20 connected in parallel and charged by the direct current of the converter 12 ˜20n have a storage battery charging / discharging circuit for charging the storage battery units 20˜20n when receiving the power supply of the AC power 10, and supplying DC power from the sto...

Embodiment 2

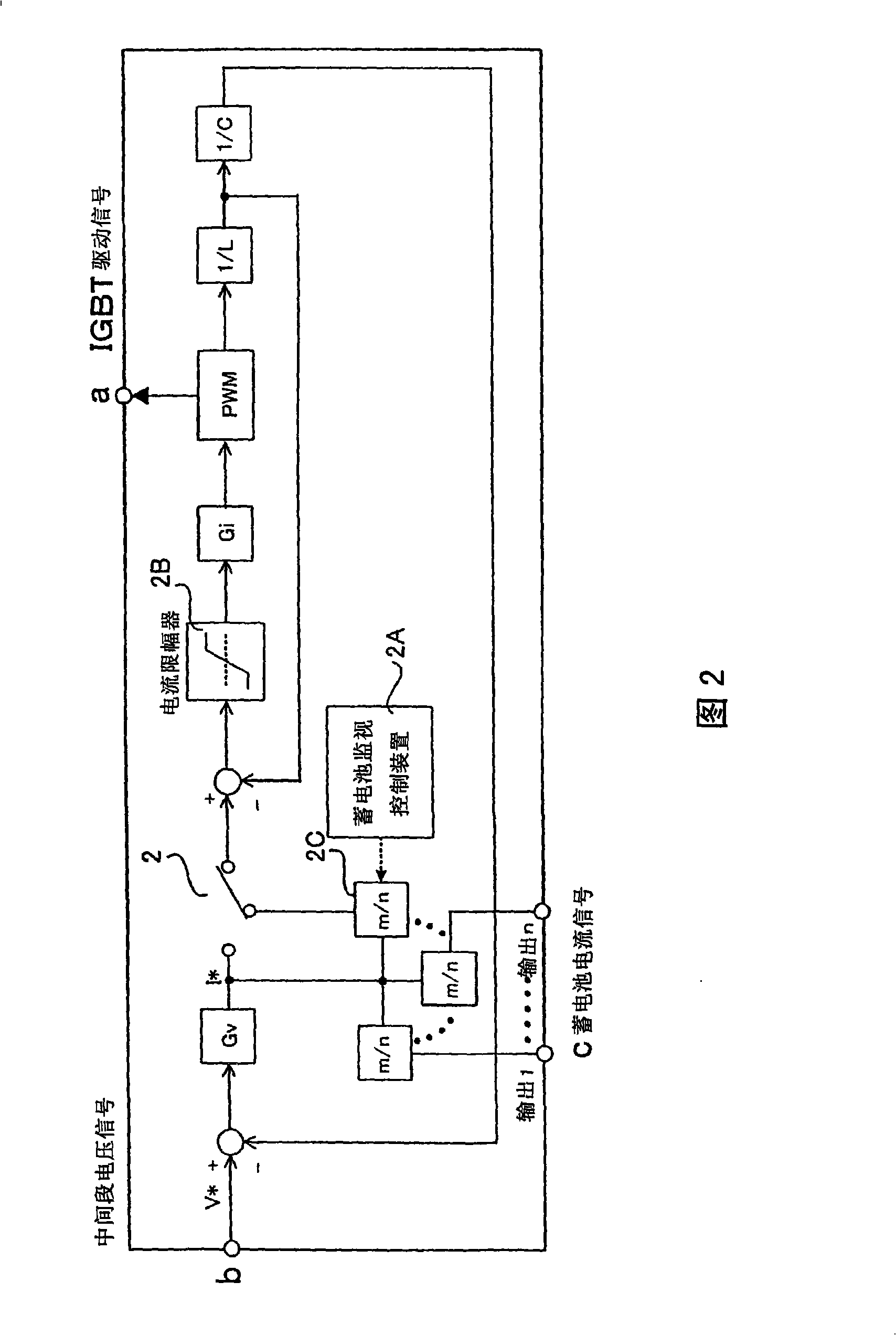

[0053] The elevator system of Embodiment 2 has an inverter 12 that converts commercial AC power 10 into DC power, a smoothing capacitor 14, and an inverter that converts the DC power of the converter 12 into AC power with variable voltage and variable frequency and controls an elevator drive motor 18. Inverter 16, and an unshown elevator control circuit that rectifies the commercial alternating current 10 and then receives power to control the inverter 16. Among them, a plurality of storage batteries connected in parallel and charged by the direct current of the converter 12 The units 20 to 20n have an elevator control circuit that charges the storage battery units 20 to 20n when receiving the power supply of the AC power 10, and charges the battery units 20 to 20n from the storage battery units 20 to 20n to the inverter 16 and the elevator control circuit (not shown) when the AC power 10 is cut off. The storage battery charging / discharging circuits 23-26 supplying direct curre...

Embodiment 3

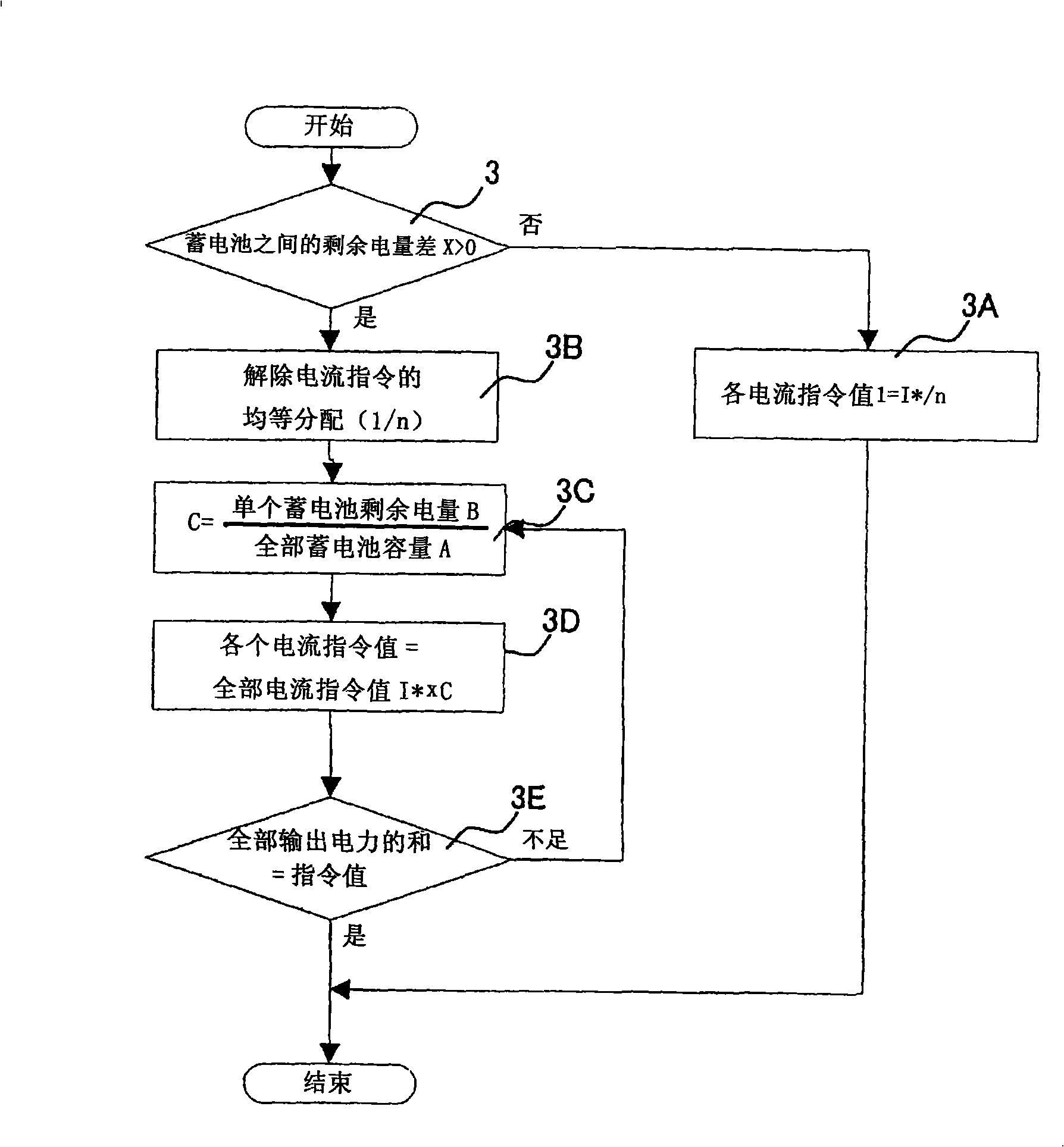

[0057] The elevator system of Embodiment 3 has an inverter 12 that converts commercial AC power 10 into DC power, a smoothing capacitor 14, and an inverter that converts the DC power of the converter 12 into AC power with variable voltage and variable frequency and controls the elevator drive motor. inverter 16, and rectifies the commercial alternating current 10 and then receives power supply to control the inverter 16. An elevator control circuit not shown in the figure is further provided with multiple inverters connected in parallel and charged by the direct current of the converter 12. battery units 20-20n, the elevator control circuit has: battery charging / discharging circuits 23-26, which are respectively set corresponding to the battery units 20, and charge the battery units 20-20n when receiving the power supply of the alternating current 10, and When the AC power 10 is disconnected, DC power is supplied from the storage battery units 20 to 20n to the inverter 16 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com