Method for preparing nano manganese dioxides with different appearances by hydrothermal synthesis process

A technology of nano-manganese dioxide and hydrothermal synthesis, applied in the direction of manganese oxide/manganese hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of inconvenient industrialization, complicated process, and only one product Dimensional nanomaterials and other issues, to achieve the effect of wide applicability, simple process, and controllable crystal shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

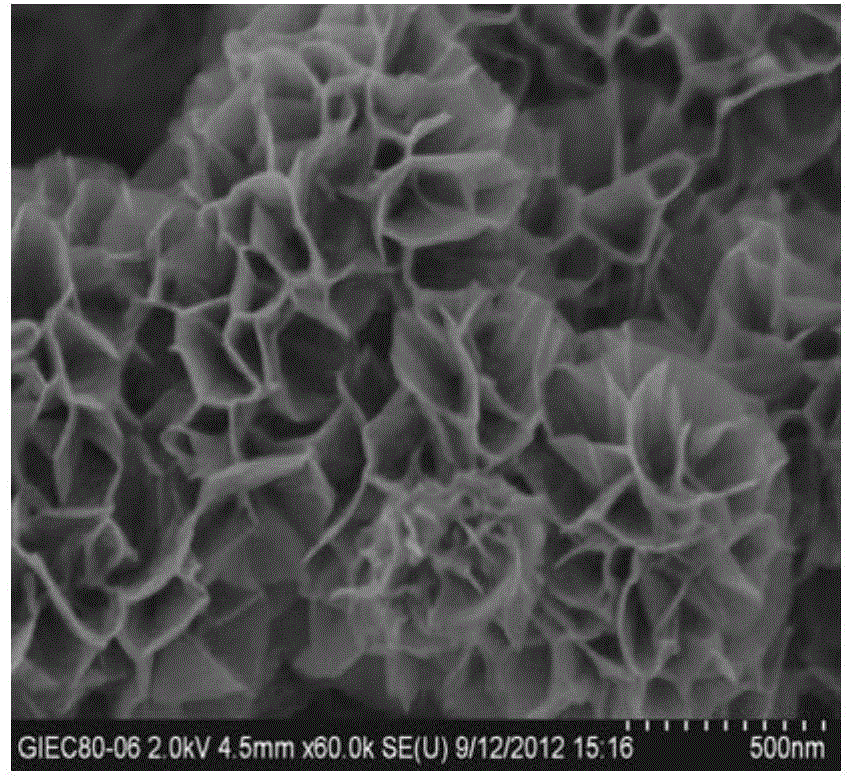

[0022] Add potassium permanganate to deionized water, stir to form a uniform solution of potassium permanganate with a concentration of 0.3 mol / L, then add manganese sulfate and stir to form a uniform mixed solution. The mass ratio of potassium permanganate to manganese sulfate It is 5:2, then transfer the above mixed solution to a high temperature and high pressure reactor with a polytetrafluoroethylene liner, react at 140℃ for 2 hours, then cool to room temperature, filter, and deionize Rinse with water to neutrality, and finally dry in the air at 100°C to obtain nano-manganese dioxide with different morphologies. Found by SEM (such as figure 1 As shown), the main morphology of the manganese dioxide obtained under this condition is nanoflowers, only 2%-8% of nanorods exist, and its specific surface area is about 65.7m 2 / g, and its electrochemical catalytic activity was detected by cyclic voltammetry, and it was found that an obvious peak appeared at -0.433V (such as Image 6 ...

Embodiment 2

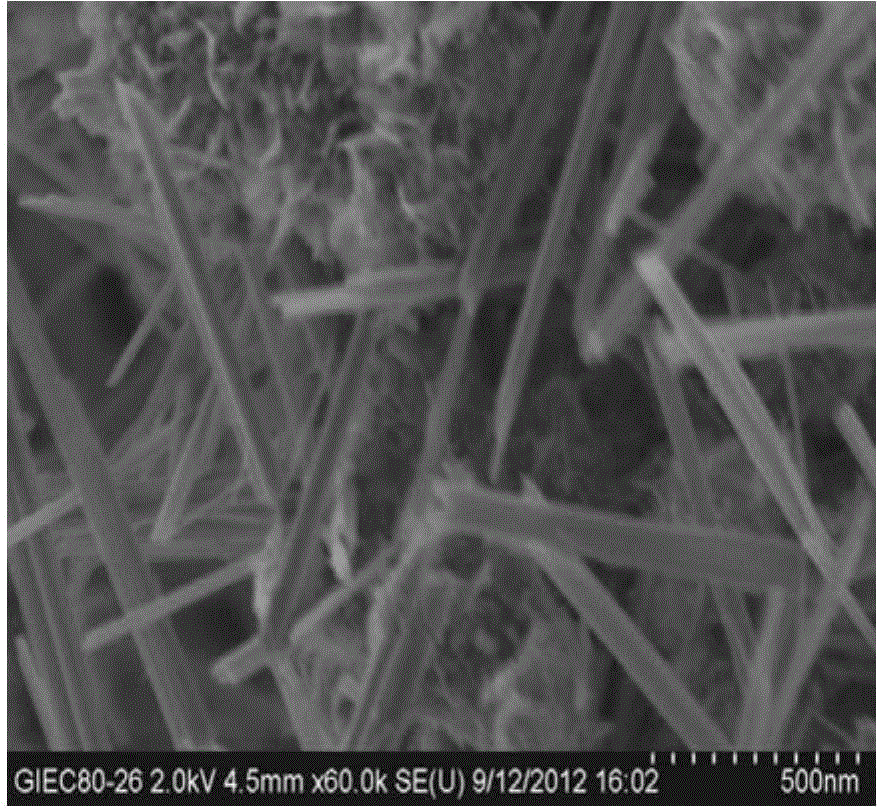

[0024] The method is the same as that in Example 1, except that the reaction was carried out at 140°C for 8 hours. Found by SEM (such as figure 2 As shown), the main morphology of the manganese dioxide obtained under this condition is still nanoflowers, but the nanorod-like structure increases, accounting for 20% to 30%, and its specific surface area is about 111.9m 2 / g, and the peak of its electrochemical activity appears at -0.385V (such as Image 6 As shown), compared with the material obtained with a synthesis time of 2h, the peak position becomes positive and the catalytic activity is enhanced. When this nano-manganese dioxide is used as a cathode catalyst for microbial fuel cells, such as Figure 5 As shown, the stable output voltage of the battery can reach 0.42V.

Embodiment 3

[0025] Example 3 A method for preparing nano-manganese dioxide with different morphologies by hydrothermal synthesis

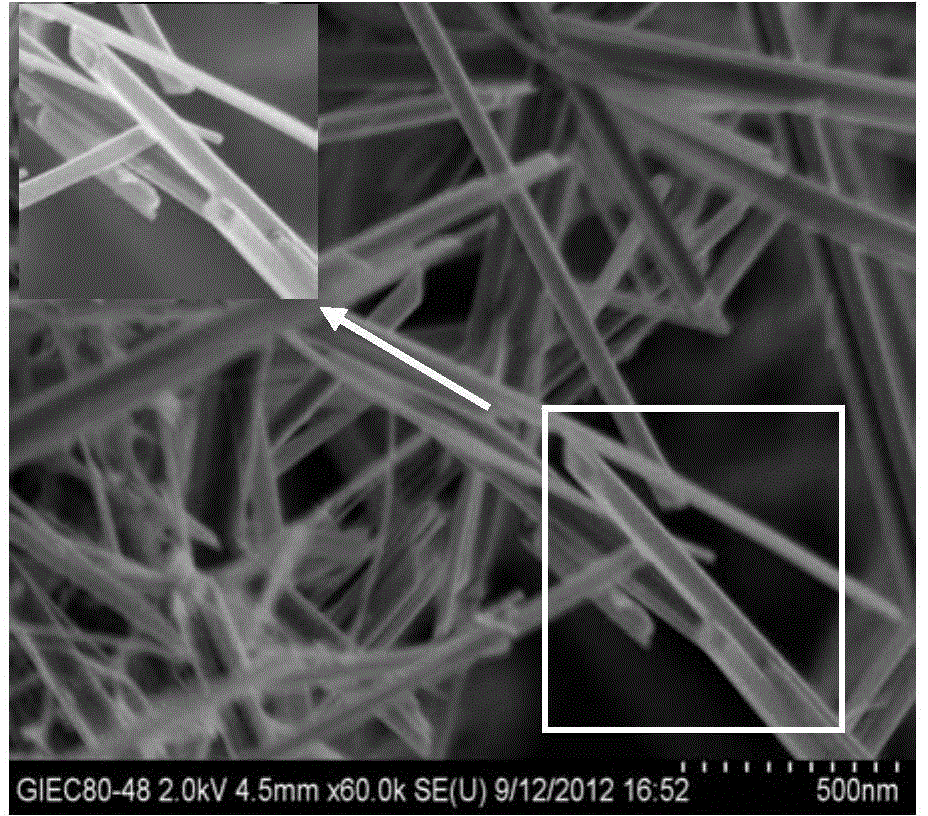

[0026] The method is the same as in Example 1, except that it was reacted for 12 hours at a temperature of 140°C. It was found by SEM that the manganese dioxide obtained under this condition showed no nano-flowers, mainly nano-rods, of which nano-rods accounted for 60%~ 70%; the rest is nanotube morphology, and its specific surface area is about 160.2m 2 / g, and the peak value of its electrochemical activity becomes more positive and appears at -0.308V (such as Image 6 Shown), indicating that its catalytic activity is further enhanced compared with the material obtained with a synthesis time of 8 hours. When this nano-manganese dioxide is used as a cathode catalyst for microbial fuel cells, such as Figure 5 As shown, the stable output voltage of the battery can reach 0.48V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com