Patents

Literature

472 results about "Industrial material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

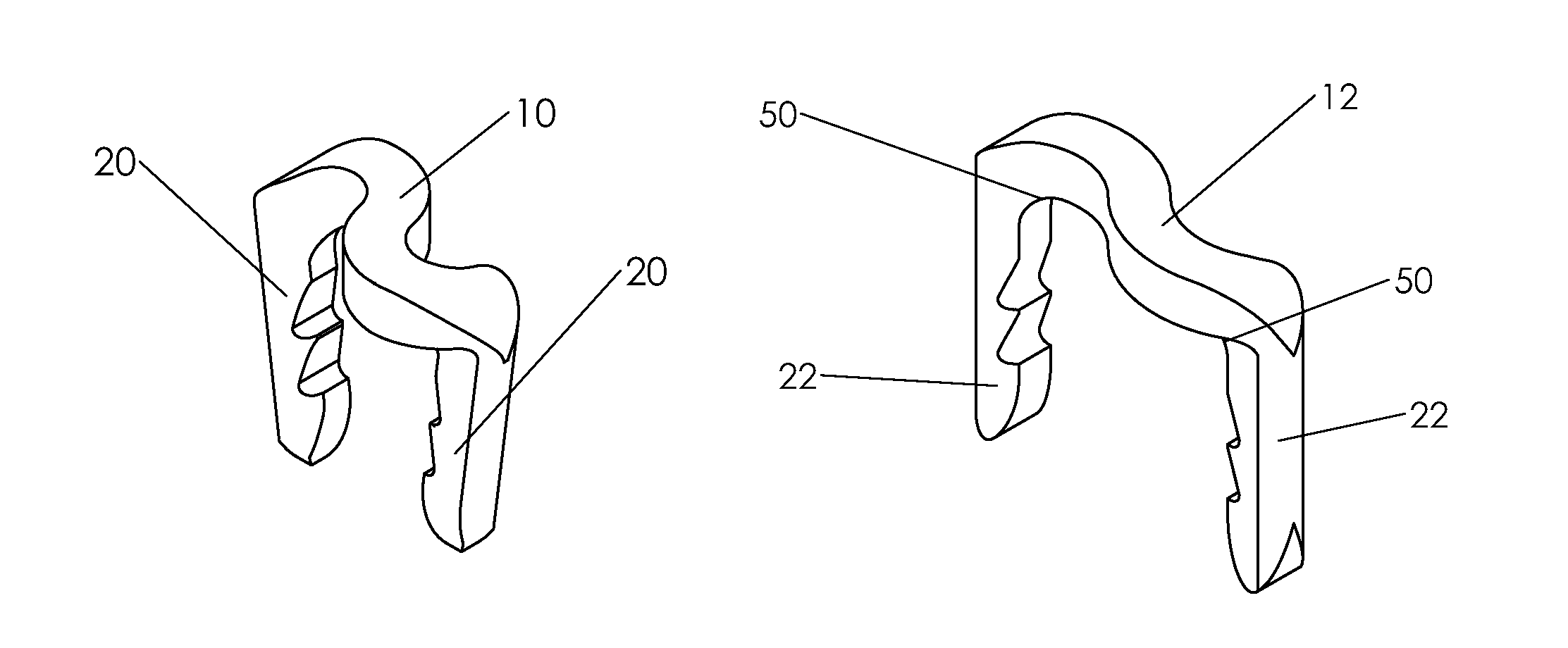

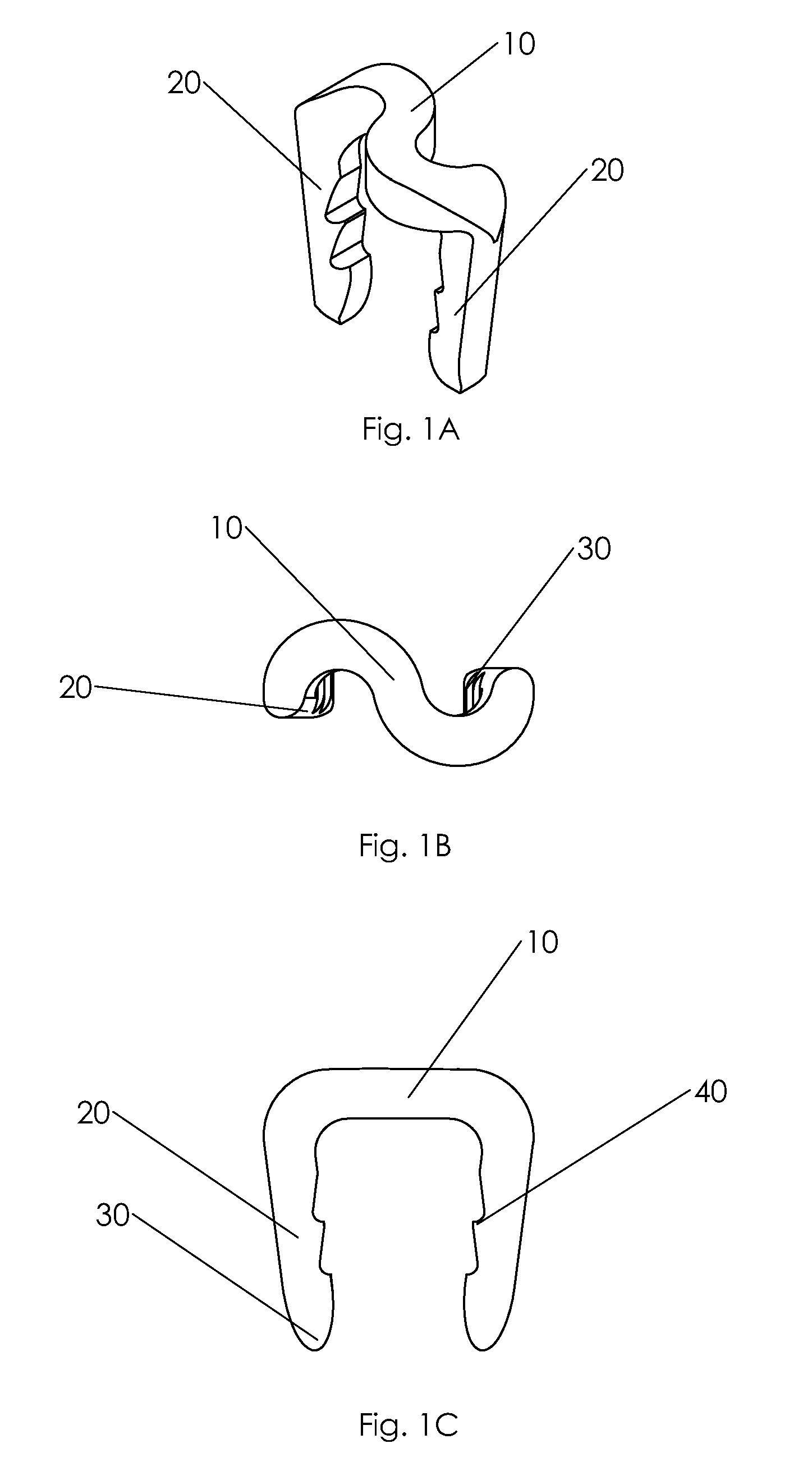

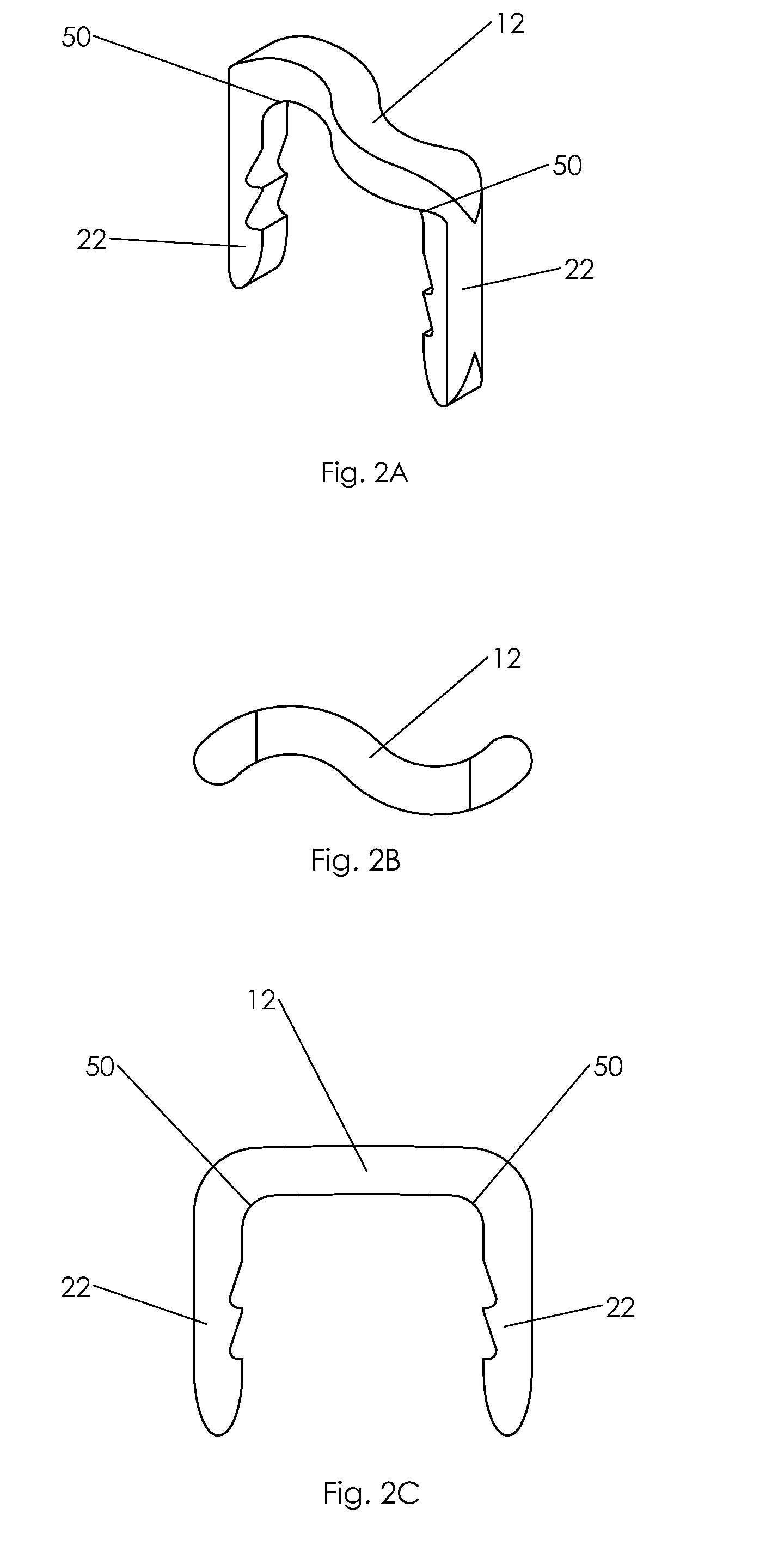

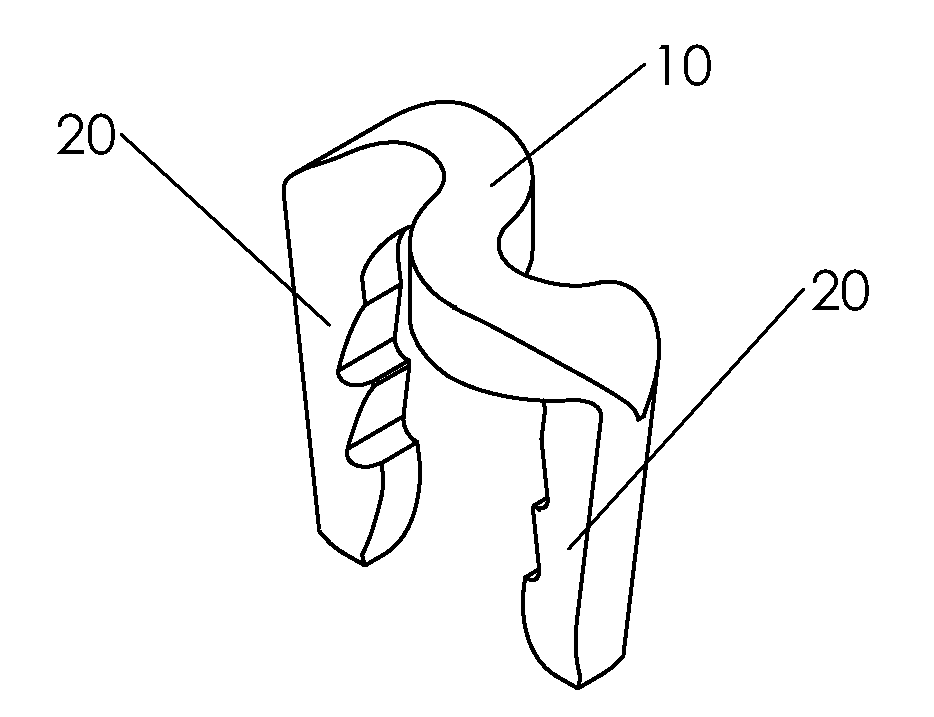

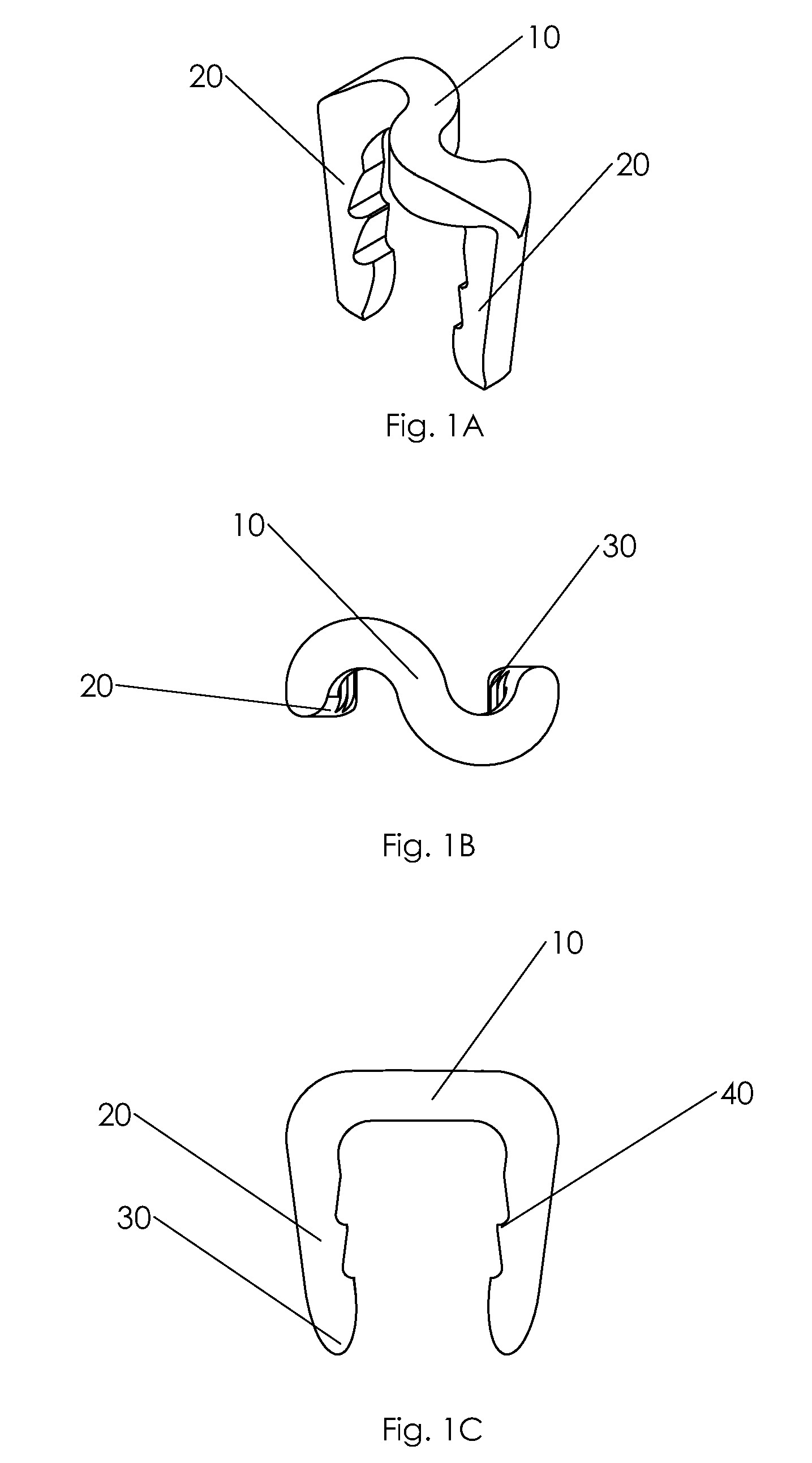

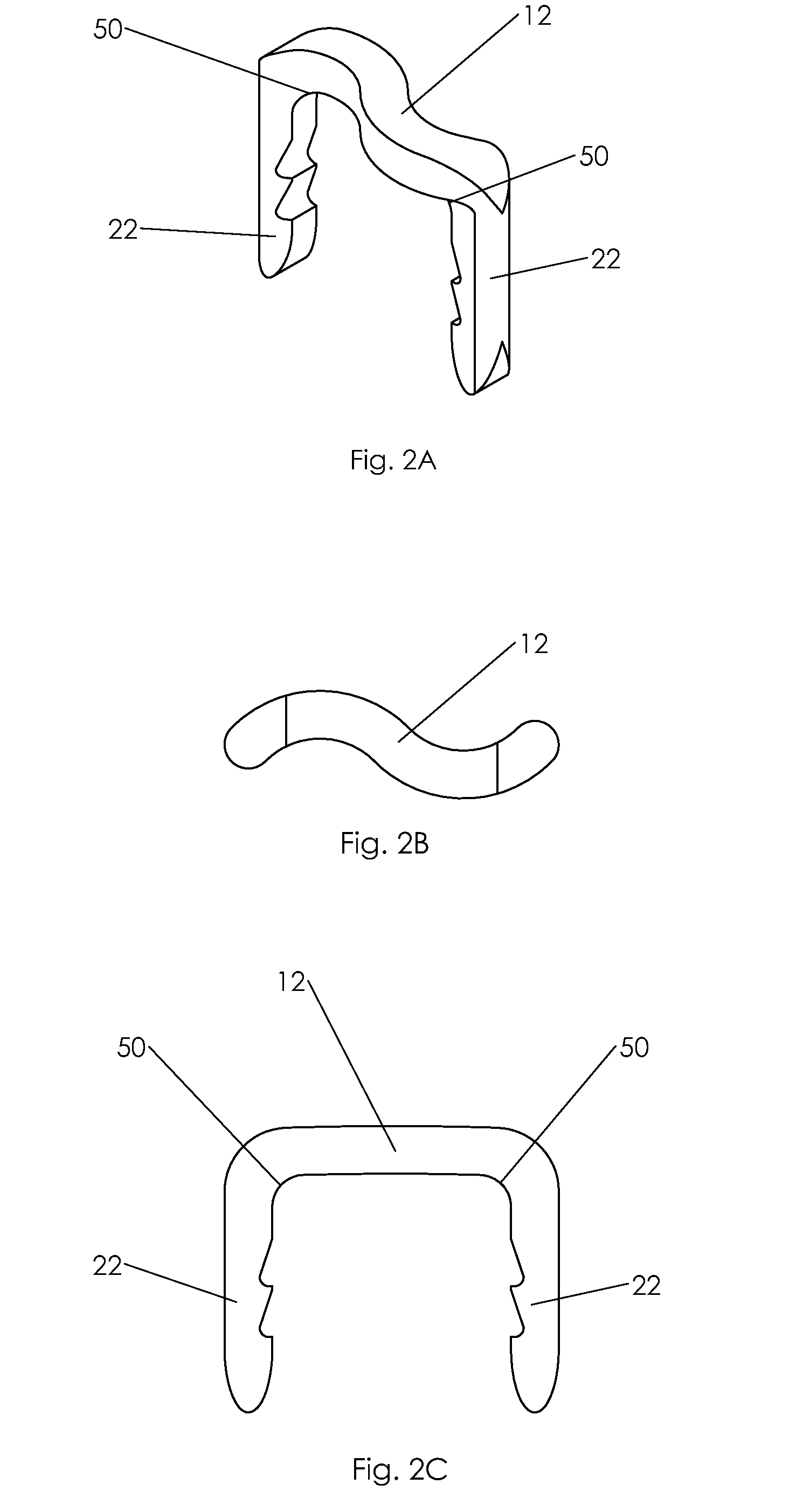

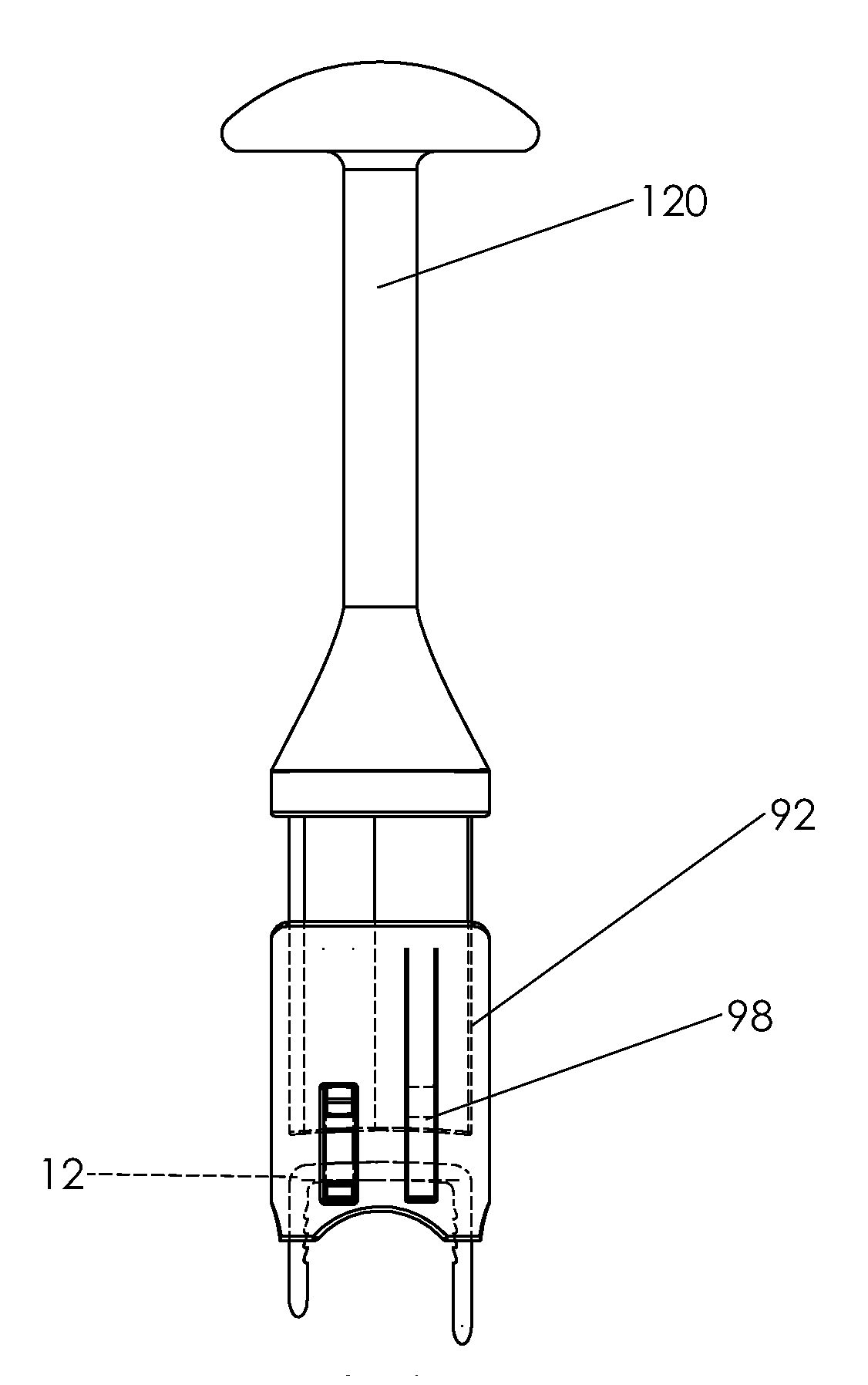

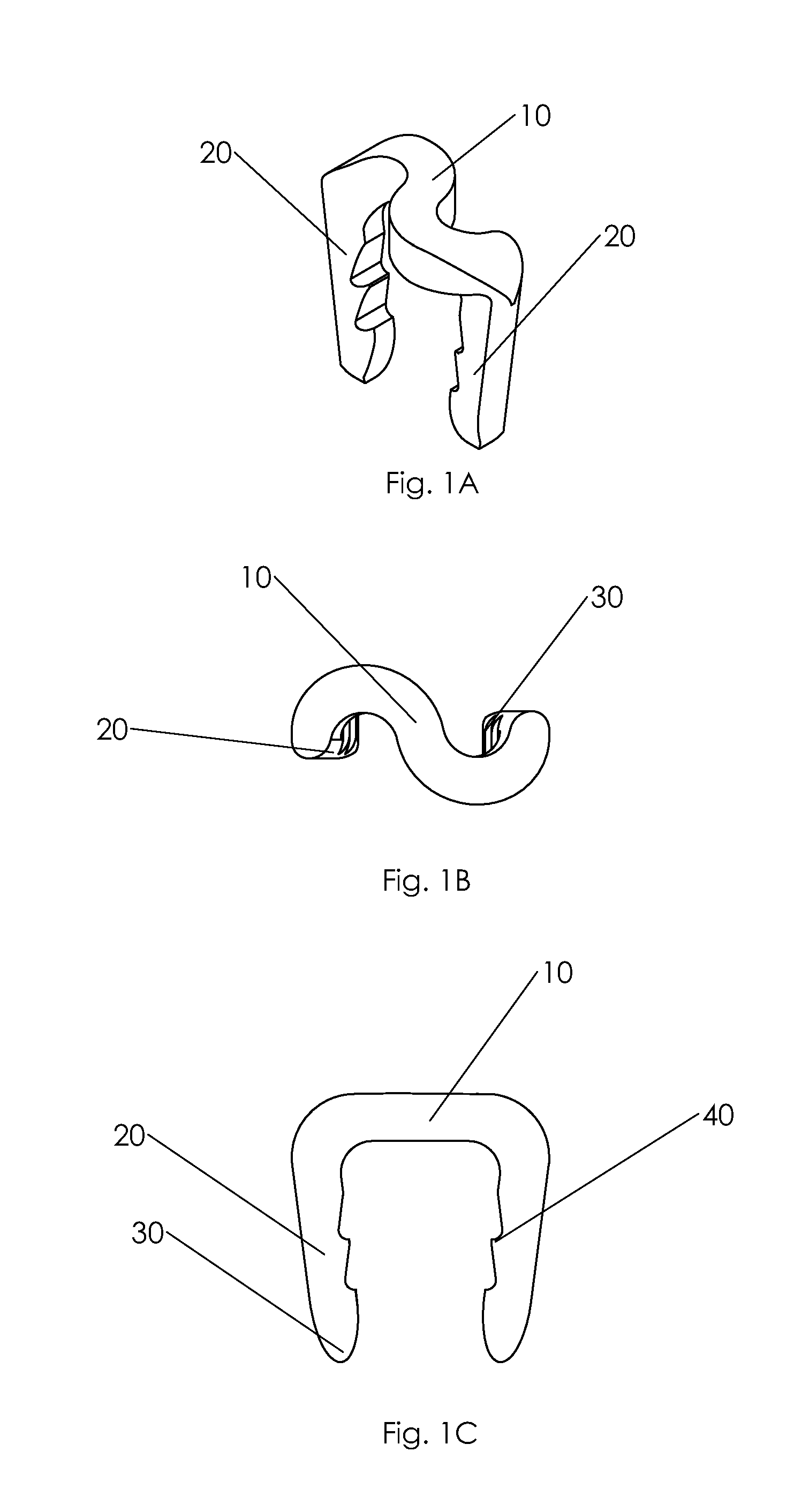

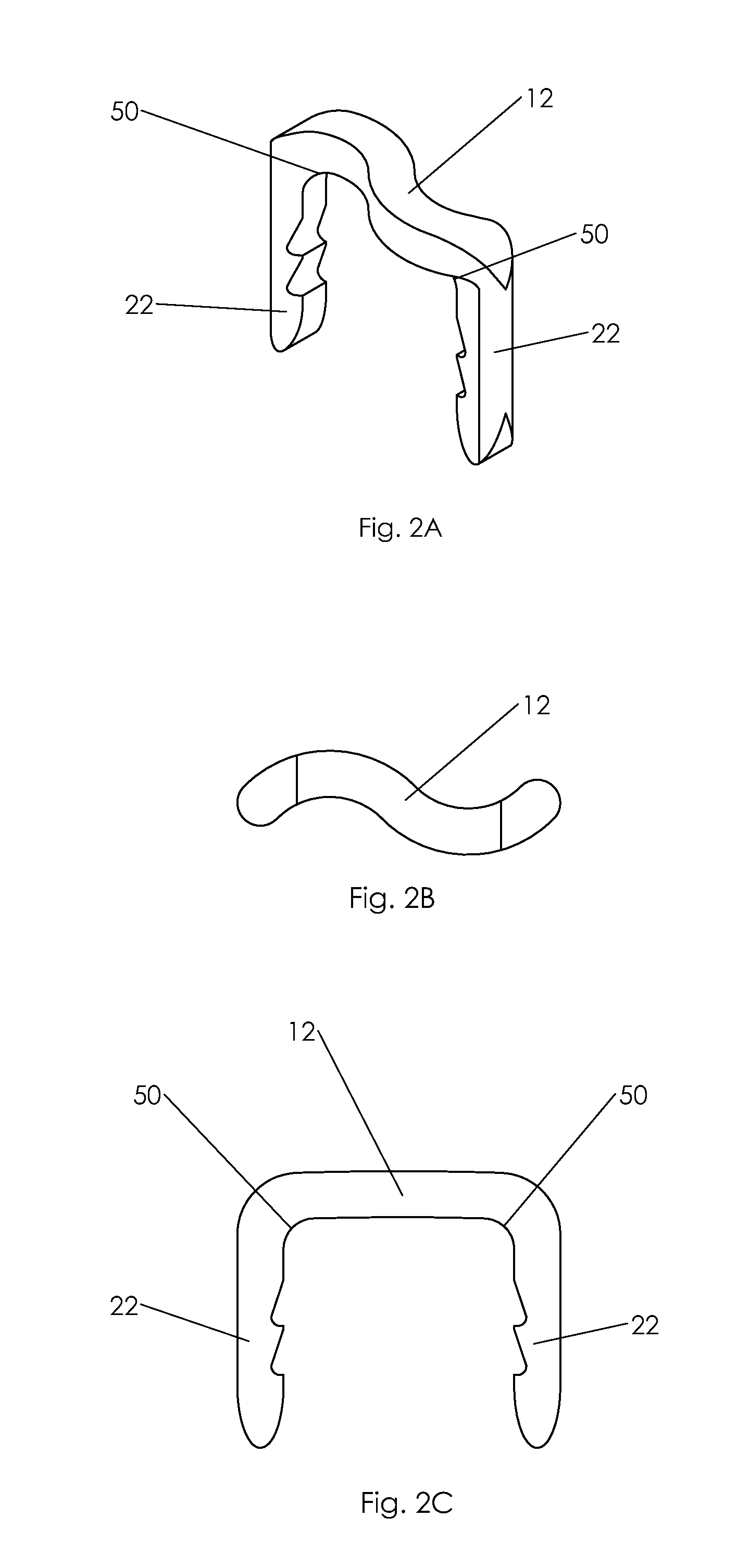

Bone staple, instrument and method of use and manufacturing

ActiveUS9017331B2Stores recoverable mechanical energyEasy to implantPinsInternal osteosythesisShape changeMechanical energy

Owner:FOX WILLIAM CASEY

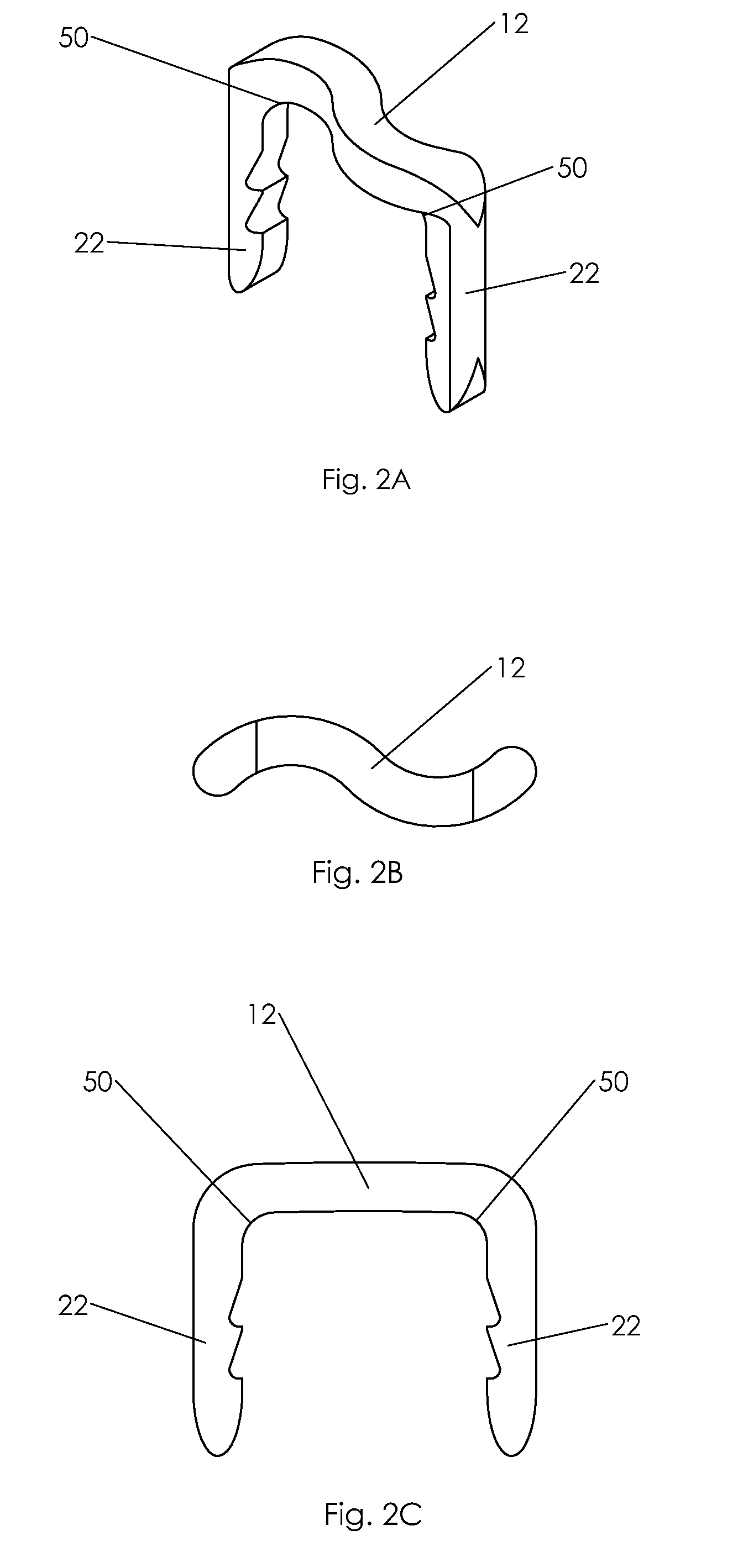

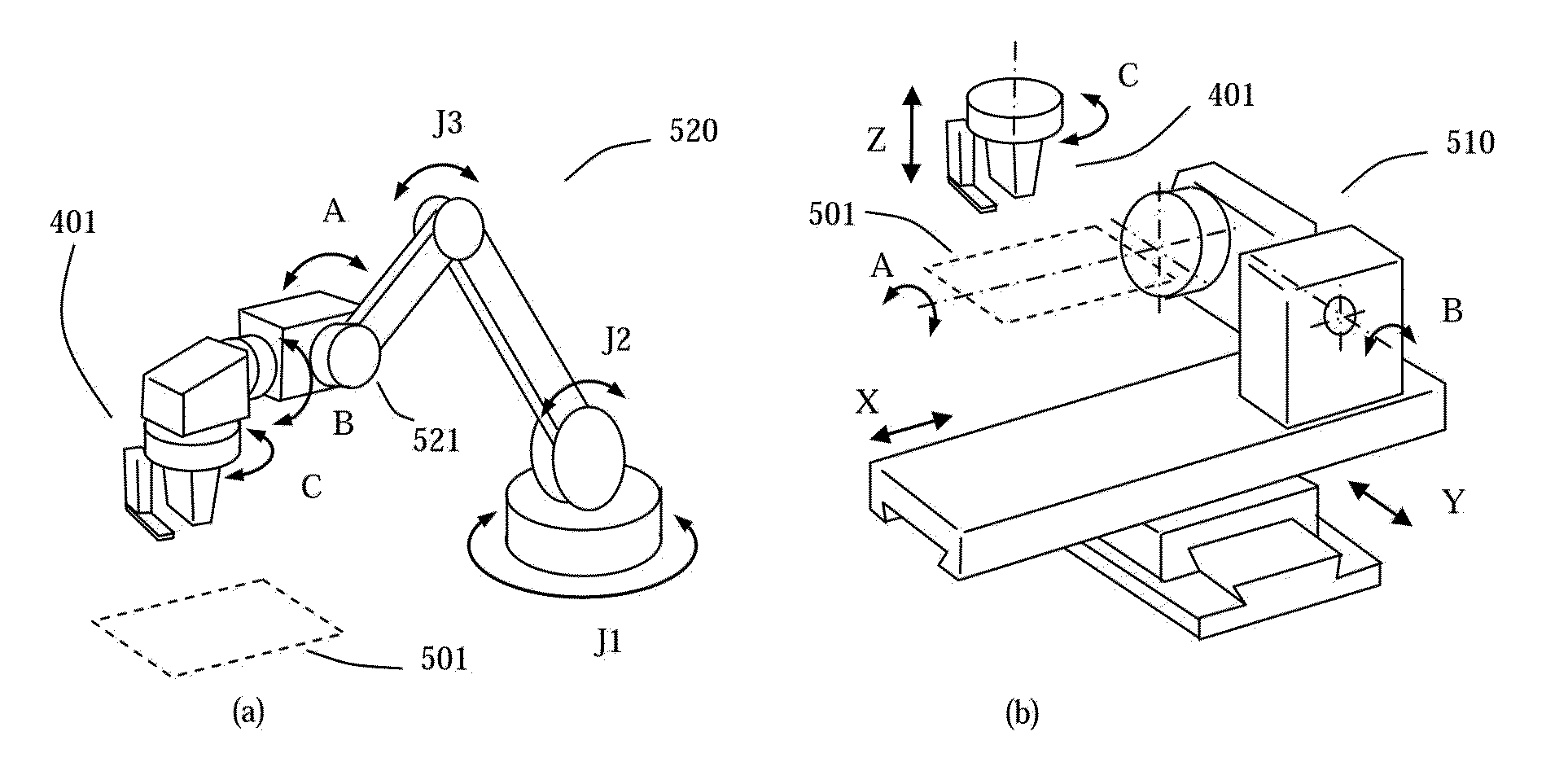

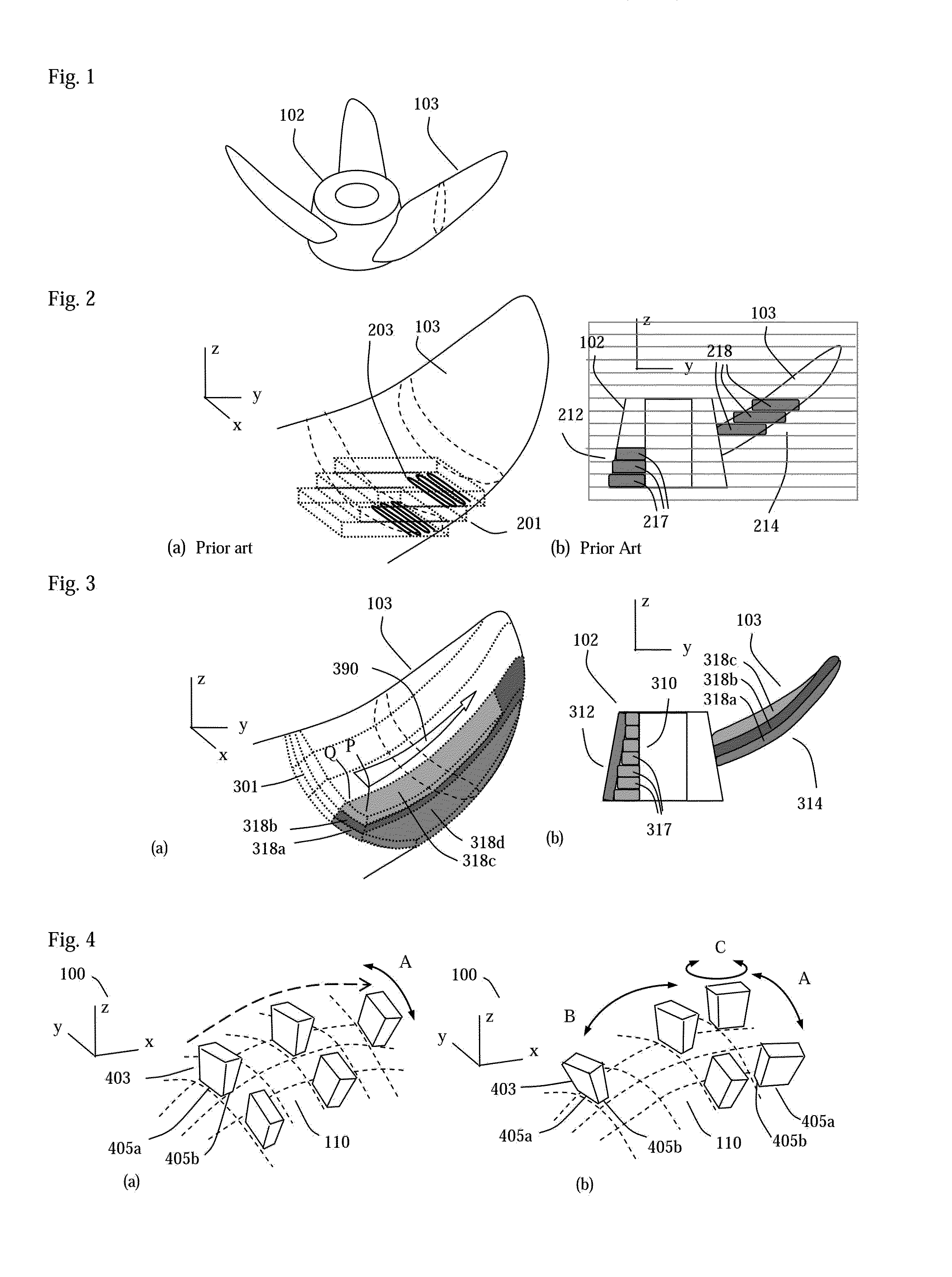

Flexible 3D Freeform Techniques

ActiveUS20160151833A1Improve manufacturing speedBuild fine and complexConfectioneryGlass forming apparatusEngineeringInjection molding machine

This invention relates to processes and systems of rapid prototyping and production. Its features includes flexible material deposition along tangential directions of surfaces of a part to be made, thereby eliminating stair-shape surface due to uniform horizontal layer deposition, increasing width of material deposition to increase build up rate, applying the principles of traditional forming / joining processes, such as casting, fusion welding, plastic extrusion and injection molding in the fabrication process so that various industrial materials can be processed, applying comparatively low cost heating sources, such as induction heating and arc-heating. Additional features include varying width and size of material deposition in accordance with geometry to be formed and applying a differential molding means for improved shape formation and surface finishing.

Owner:NATIONAL TSING HUA UNIVERSITY

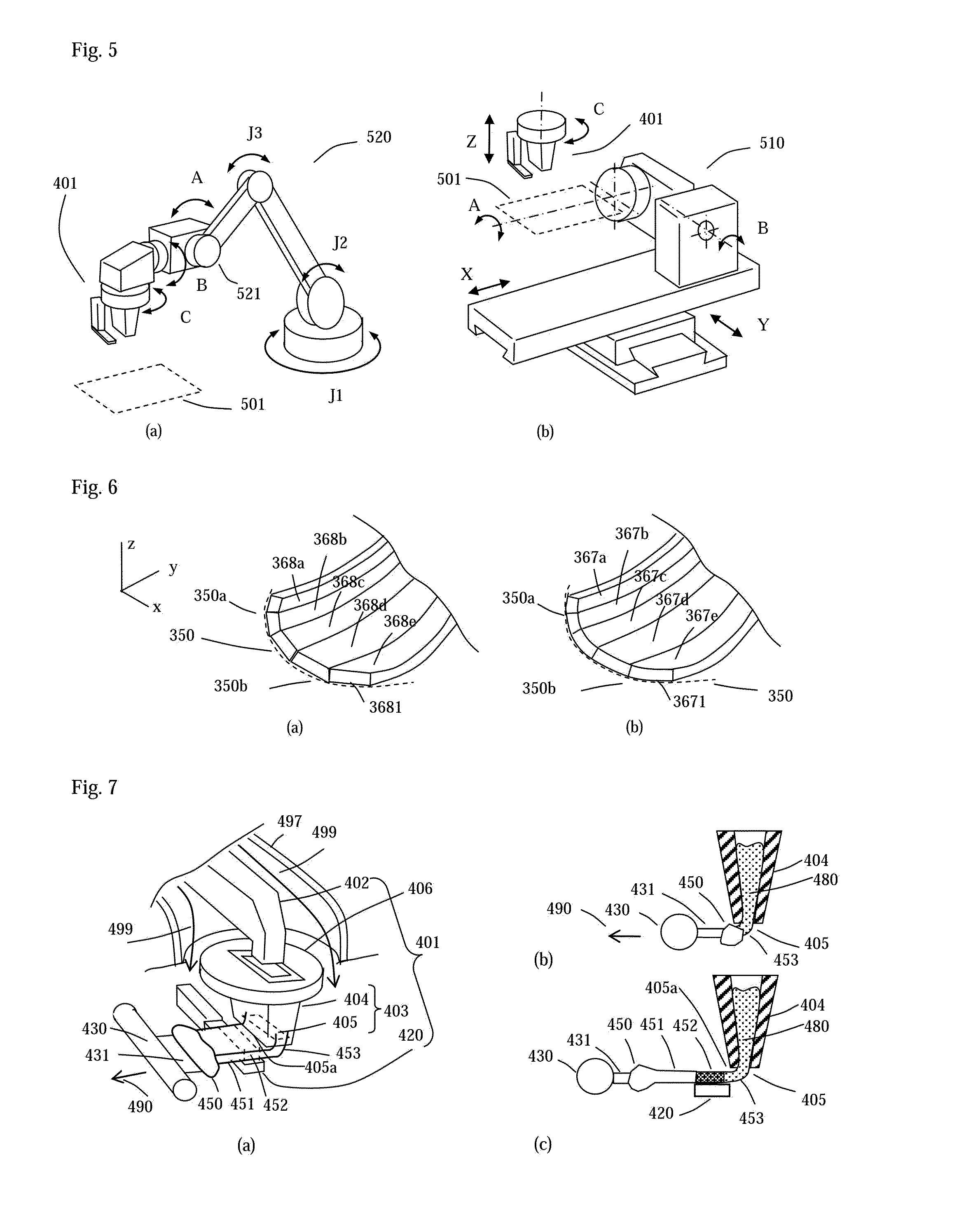

Bone staple, instrument and method of use and manufacturing

ActiveUS20130030438A1Simple and reliable processLow costInternal osteosythesisPinsShape changeBone tissue

A new shape changing staple and instrument for the fixation of structures to include bone tissue and industrial materials. This new staple stores elastic mechanical energy to exert force on fixated structures to enhance their security and in bone affect its healing response. This staple once placed changes shape in response to geometric changes in the materials structure, including healing bone tissue. The staple is advanced over prior staples due to its: 1) method of operation, 2) high strength, 3) method of insertion, 4) compressive force temperature independence, 5) energy storing staple retention and delivery system, 6) compatibility with reusable or single use product configuration, 7) efficient and cost effective manufacturing methods, and 8) reduction in the steps required to place the device. In addition to the staple's industrial application an embodiment for use in the fixation of the musculoskeletal system is shown with staple, cartridge, and extrusion handle.

Owner:FOX WILLIAM CASEY

Polyamide

A polyamide characterized in that the polyamide is obtained by thermal polycondensation of (a) dicarboxylic acid components comprising 10 to 80% by mole in total carboxylic acid components of 1,4-cyclohexanedicarboxylic acid having a trans / cis molar ratio of 50 / 50 to 97 / 3 and (b) an aliphatic diamine component is disclosed. The alicyclic polyamide having 1,4-cyclohexanedicarboxylic acid in a backbone thereof as a dicarboxylic acid unit, which is suitable as materials for various uses such as automotive parts, electric / electronics parts, industrial materials, engineering materials and daily household goods, and superior in heat resistance, low water absorption, light resistance, moldability and light weight, as well as superior in toughness, chemical resistance and appearance, and molded articles thereof.

Owner:ASAHI KASEI KK

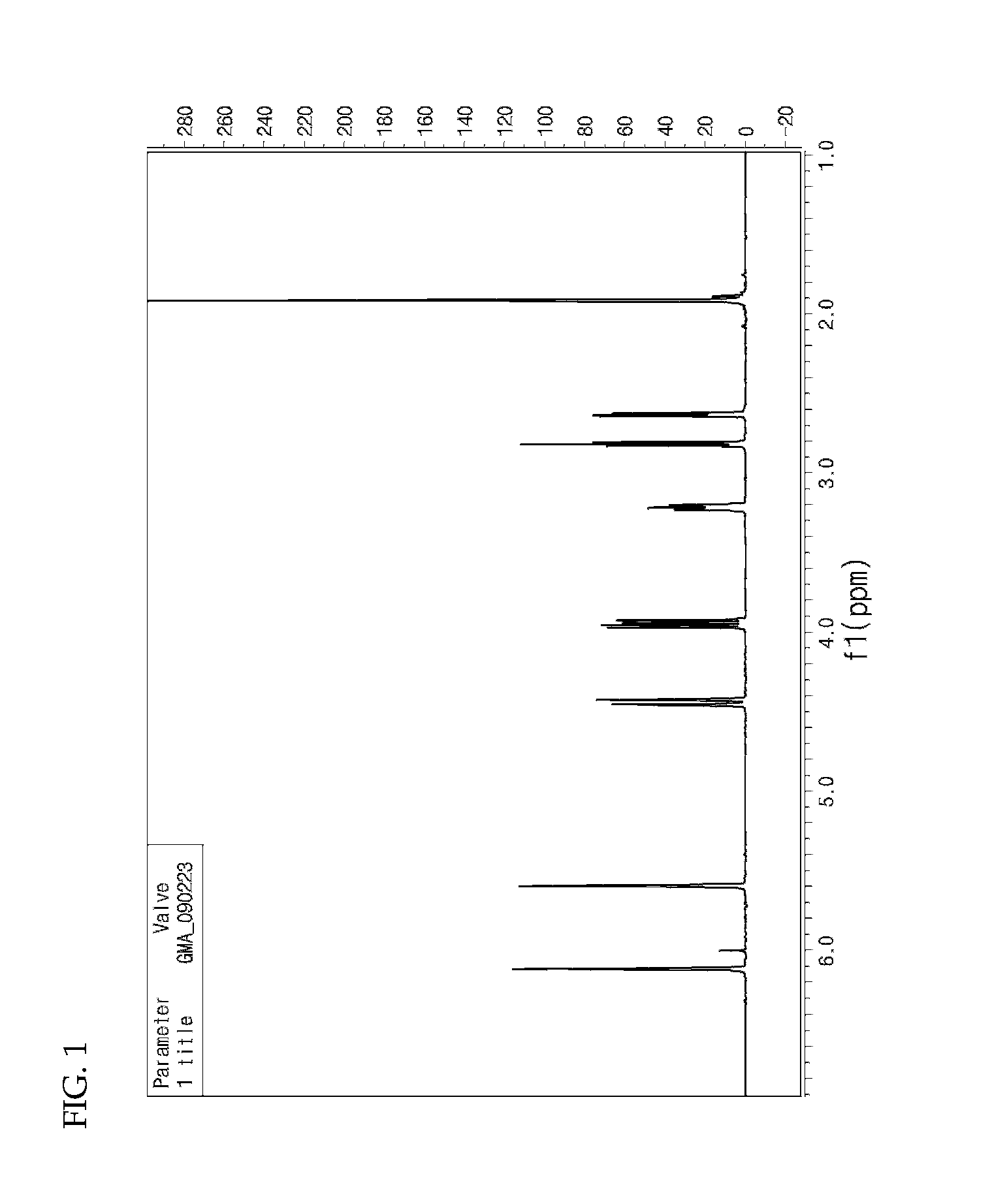

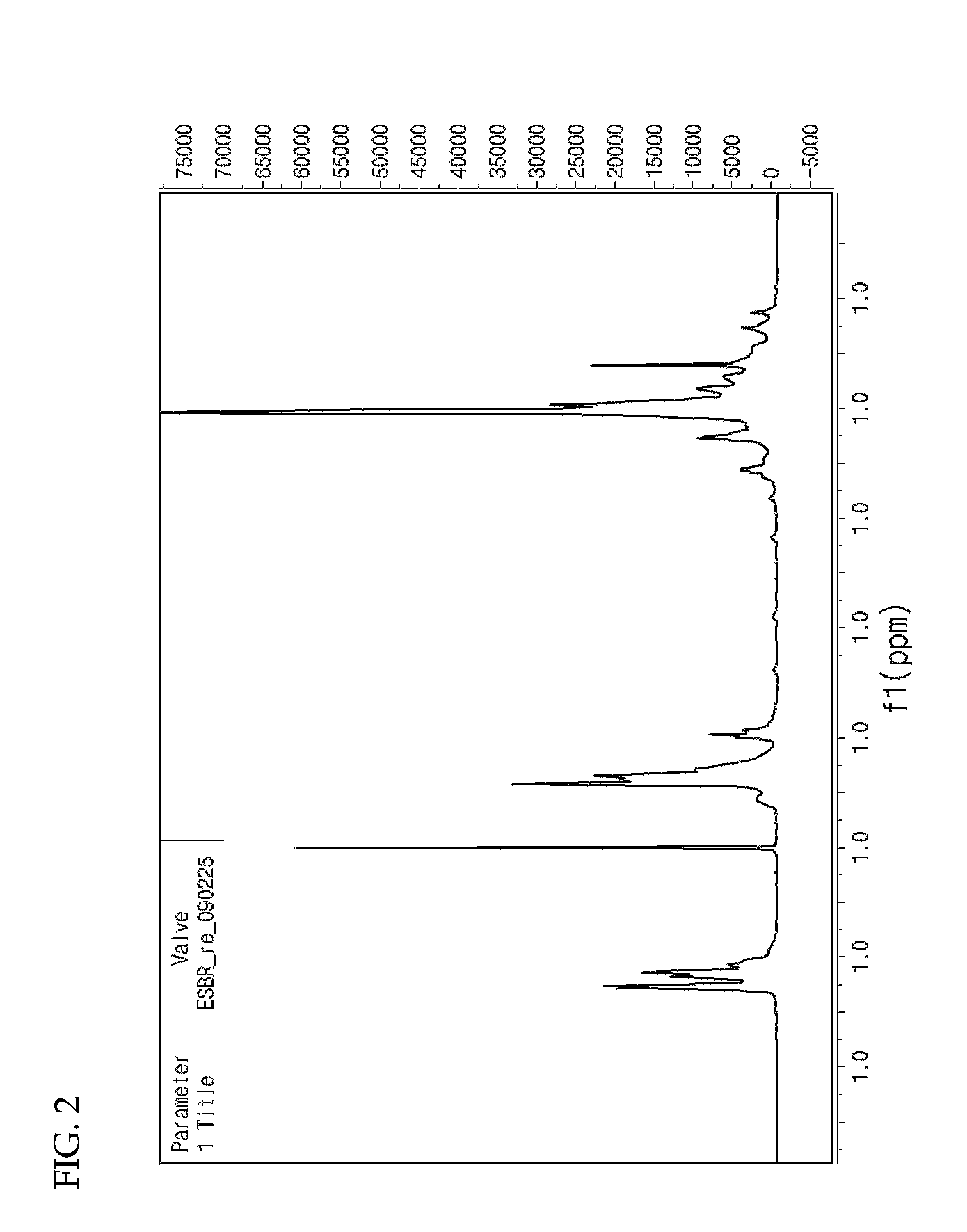

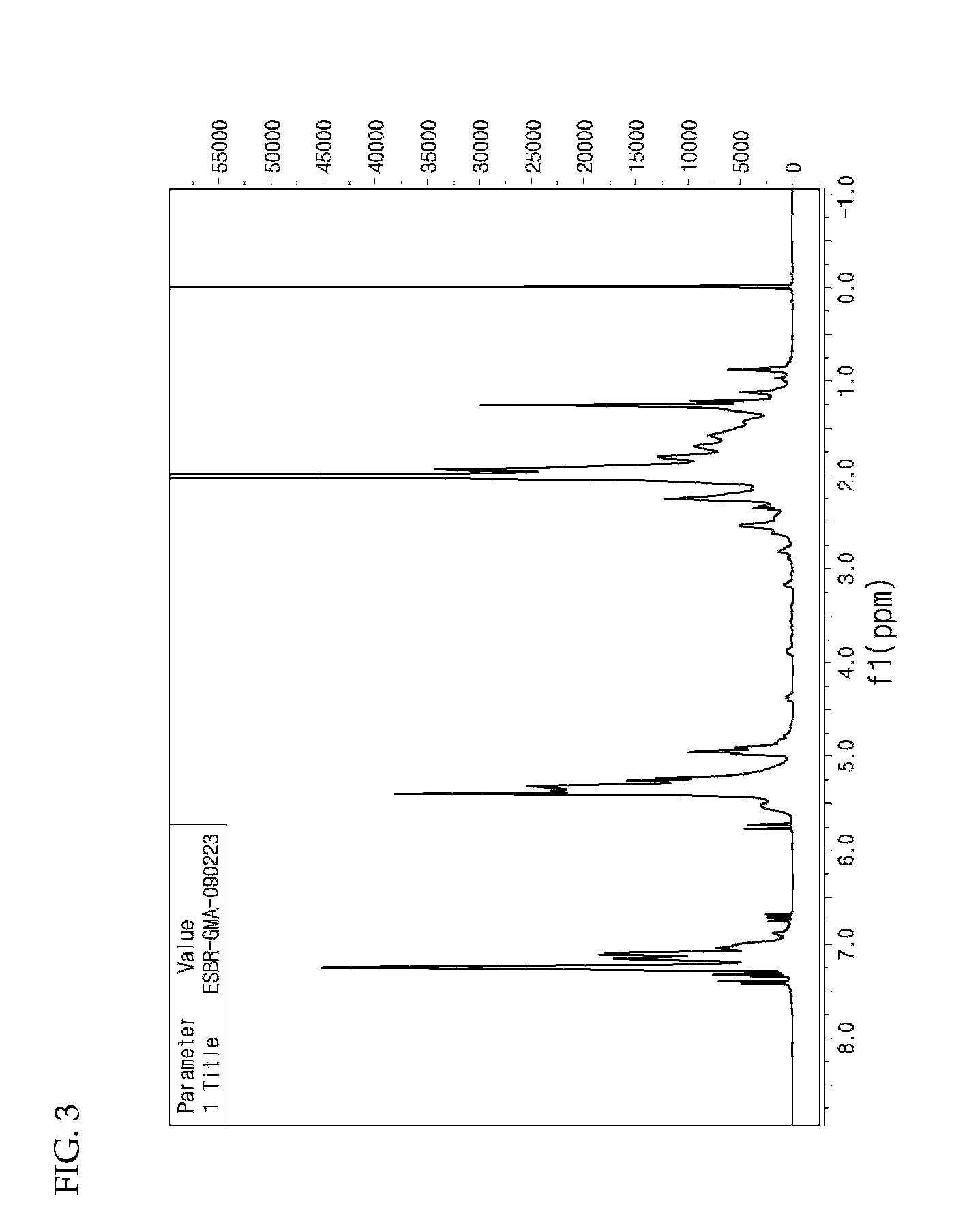

Functional styrene-butadiene copolymer

A functional styrene-butadiene copolymer is disclosed. More specifically, the copolymer is prepared by radical polymerization of a styrene monomer, a butadiene monomer and an epoxy acrylate monomer in an emulsion state and ring-opening of the resultant styrene-butadiene-epoxy acrylate copolymer. When blended with silica, the disclosed copolymer provides excellent wet stopping performance and superior wear resistance. Therefore, it can be usefully applied for industrial materials including fuel-efficient tires, snow tires, belts, hoses, etc.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

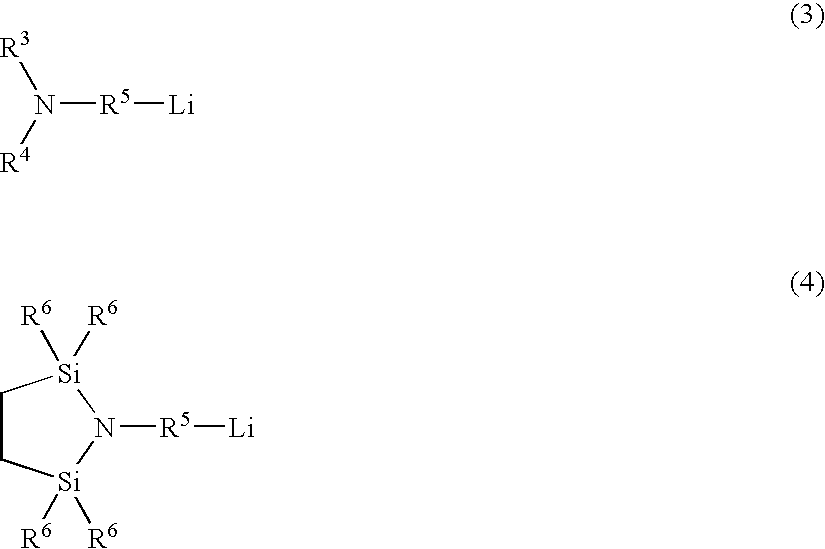

Polyolefin production catalyst and method of preparing polyolefins

InactiveUS6121182AHigh polymerization activityImprove rigidityOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePolyolefin

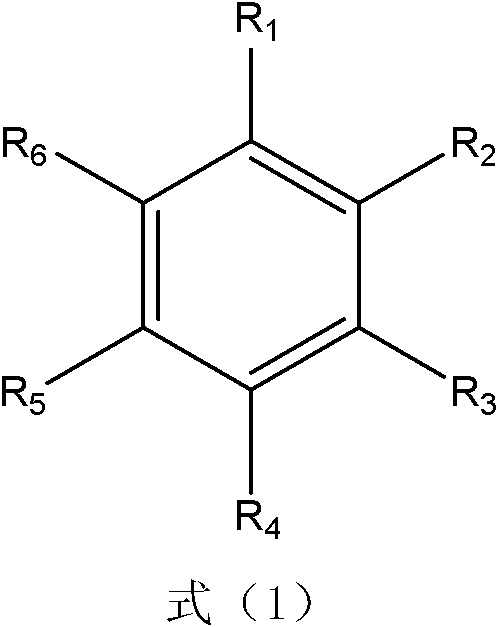

PCT No. PCT / JP97 / 01387 Sec. 371 Date Dec. 11, 1997 Sec. 102(e) Date Dec. 11, 1997 PCT Filed Apr. 22, 1997 PCT Pub. No. WO97 / 40075 PCT Pub. Date Oct. 30, 1997A catalyst component for polyolefin production catalysts comprising a metallocene compound represented by general formula (1) (symbols have the meanings as described in the specification), polyolefin production catalyst containing the component, and method for producing polyolefin with the catalyst are provided. Use of a catalyst containing the novel metallocene compound as a catalyst component of the invention in polymerization of alpha -olefin, particularly propylene, enables one to prepare high rigid, high melting point isotactic polypropylene useful as an industrial material for automobiles and the like, more specifically isotactic polypropylene having highly controlled stereoregulartity and regioregularity, particularly the one having a high regioregularity that has been difficult to achieve with conventional metallocene catalysts.

Owner:SUNALLOMER

Bone staple, instrument and method of use and manufacturing

ActiveUS20130030437A1Simple and reliable processLow costInternal osteosythesisJoint implantsShape changeMechanical energy

A new shape changing staple and instrument for the fixation of structures to include bone tissue and industrial materials. This new staple stores elastic mechanical energy to exert force on fixated structures to enhance their security and in bone affect its healing response. This staple once placed changes shape in response to geometric changes in the materials structure, including healing bone tissue. The staple is advanced over prior staples due to its: 1) method of operation, 2) high strength, 3) method of insertion, 4) compressive force temperature independence, 5) energy storing staple retention and delivery system, 6) compatibility with reusable or single use product configuration, 7) efficient and cost effective manufacturing methods, and 8) reduction in the steps required to place the device. In addition to the staple's industrial application an embodiment for use in the fixation of the musculoskeletal system is shown with staple, cartridge, and extrusion handle.

Owner:FOX WILLIAM CASEY

Method of producing a weld-cut sealing/heat-shrinkable packaging film formed of a polyethylene terephthalate-based block copolymer polyester

A PET-based polyester packaging film capable of weld-cut sealing and heat-shrinkage refers to a film obtained by biaxially orienting a material prepared through block copolymerization of a PET / PETG / polyester elastomer with an epoxy resin and a catalyst. This film eliminates the most serious weak points in physical properties of conventional PET films, and is useful for packaging of books, bottlesets, food containers, etc., for general packaging, packaging of industrial materials, and the like, and is further useful in the field of packing and packaging of daily commodities, civil engineering and construction members, electric and electronic members, and automobile vehicle members, etc. Moreover, this film can be produced through effective use of the huge amount of recycled PET bottles and inexpensive PET for fiber as a prepolymer, and thus is also highly beneficial socially. Still further, even if incinerated after use, this film produces a combustion heat value lower than that of a polyethylene or polypropylene. Thus, this film barely damages incinerators or the like, and emits no toxic gases.

Owner:NAKAMOTO PAKKUSU

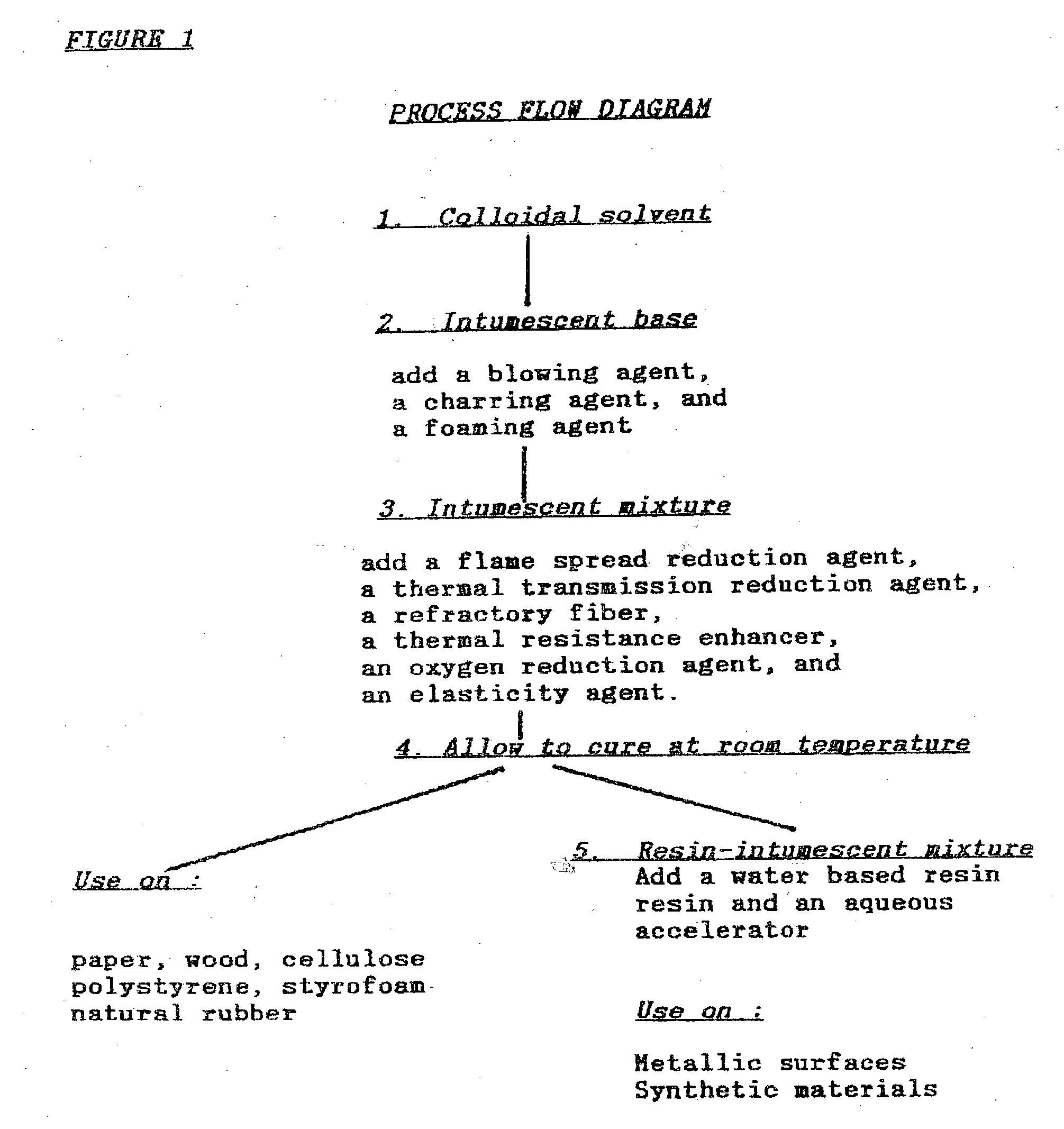

Flame inhibiting and retarding chemical compositions for general use on multiple solid surfaces

Owner:GANG HENRY

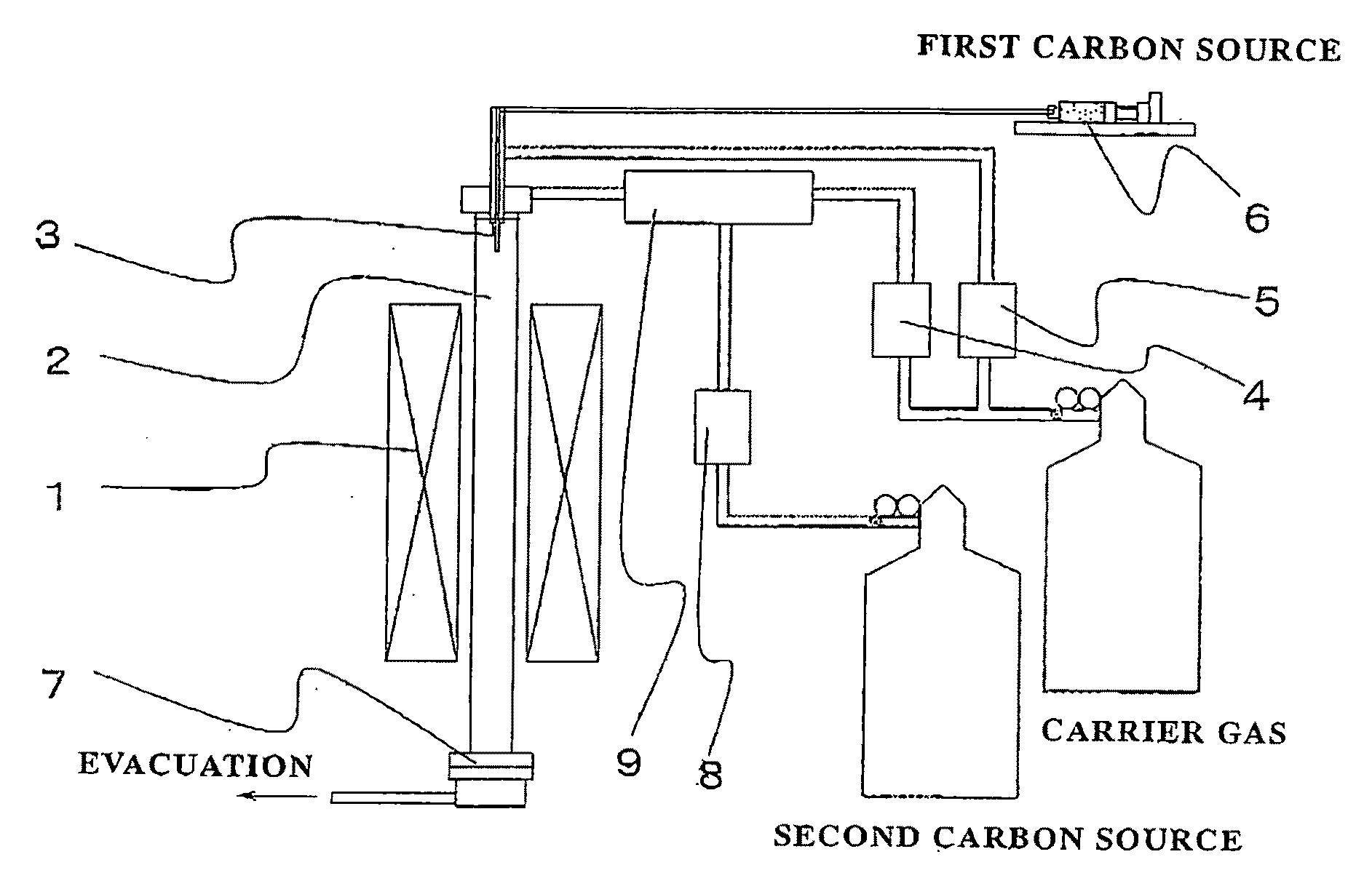

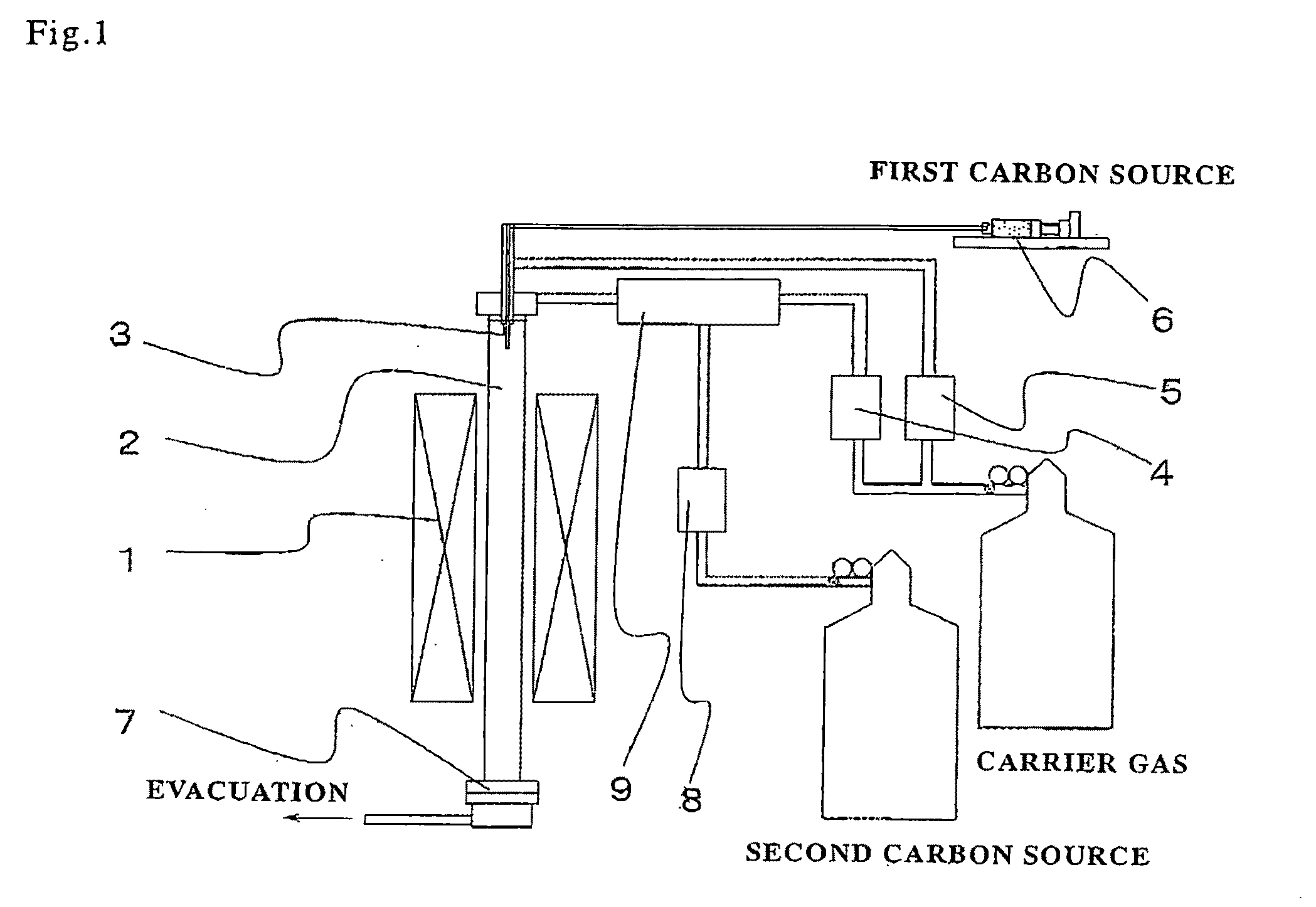

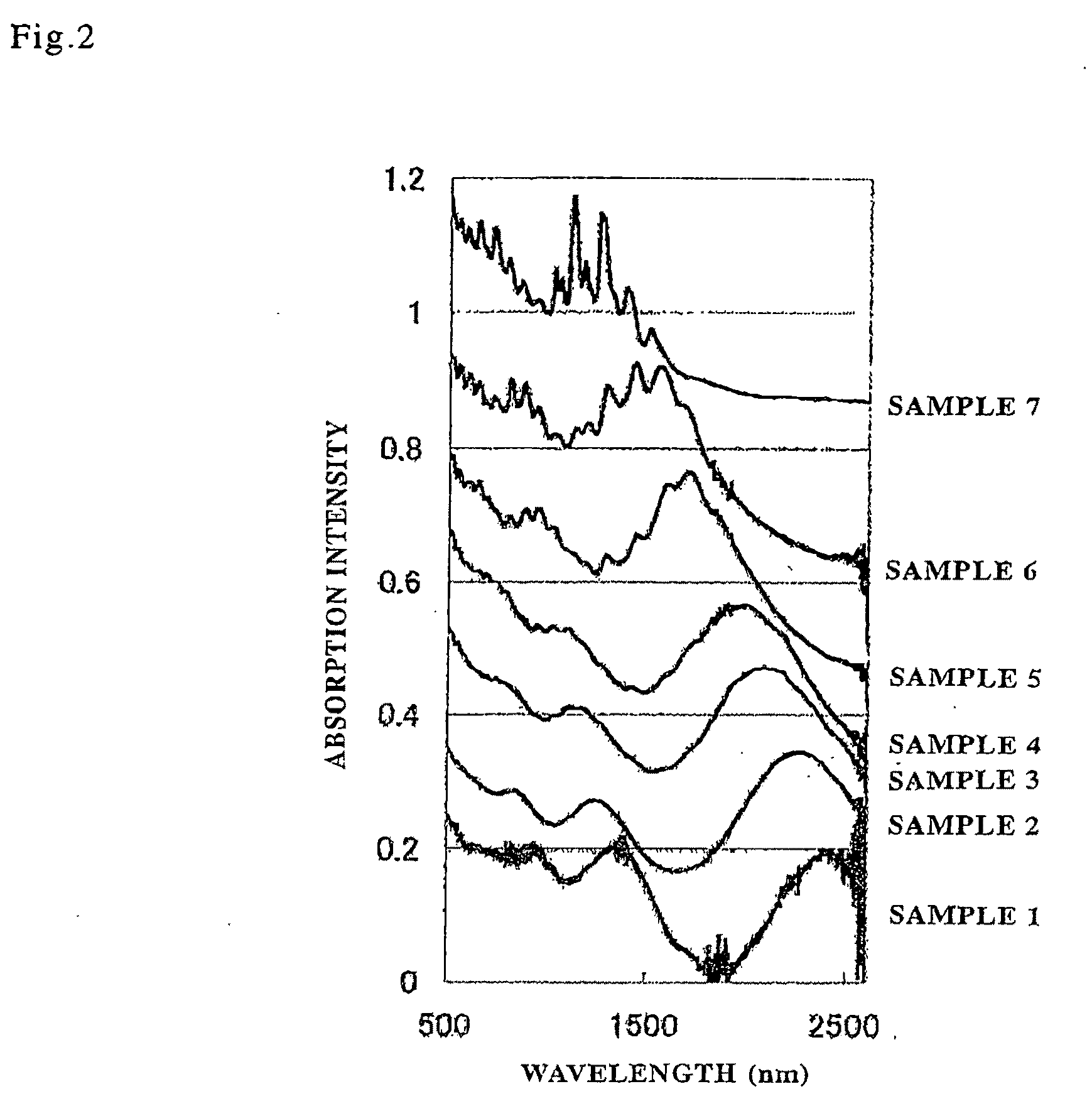

Single-Walled Carbon Nanotubes, Carbon Fiber Aggregate Containing the Single-Walled Carbon Nanotubes, and Method for Producing Those

InactiveUS20090186223A1High purityQuality improvementMaterial nanotechnologyFibre chemical featuresFiberCarbon fibers

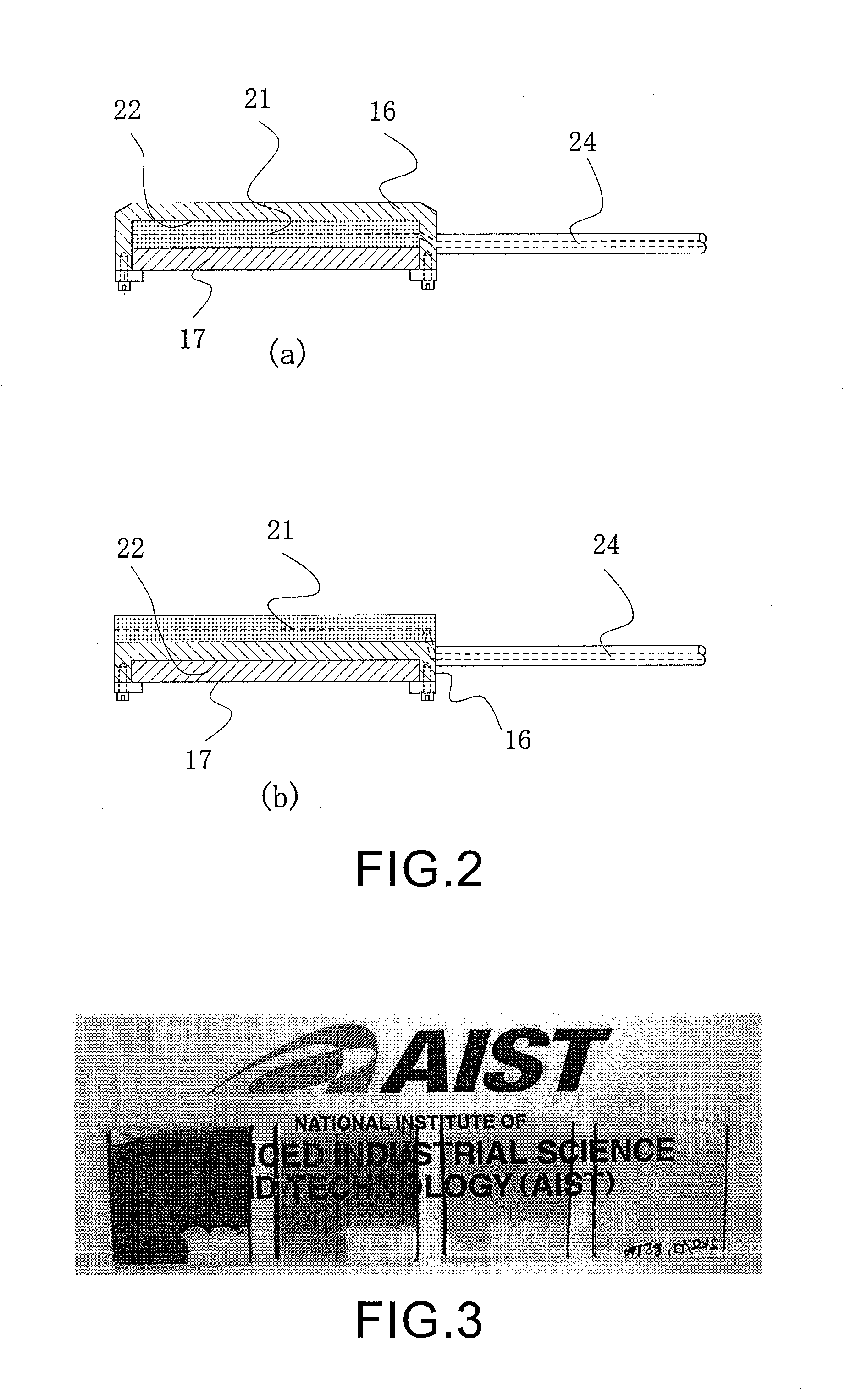

It relates to high purity single-walled carbon nanotubes having controlled diameter, useful as industrial materials, including high-strength carbon wire rods, particularly uniform single-walled carbon nanotubes having diameter fallen in a range of from 1.0 to 2.0 nm, and a method for producing the same efficiently, in large amount and inexpensively. The single-walled carbon nanotube obtained is characterized in that its diameter is fallen in a range of from 1.0 to 2.0 nm, and an intensity ratio IG / ID between G-band and D-band in a Raman spectrum is 200 or more. Furthermore, those single-walled carbon nanotubes are synthesized by a gas-phase flow CVD method that uses a saturated aliphatic hydrocarbon which is liquid at ordinary temperature as a first carbon source and an unsaturated aliphatic hydrocarbon which is gas at ordinary temperature as a second carbon source.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Bone staple, instrument and method of use and manufacturing

ActiveUS20130026207A1Simple and reliable processLow costSuture equipmentsStapling toolsShape changeBone tissue

A new shape changing staple and instrument for the fixation of structures to include bone tissue and industrial materials. This new staple stores elastic mechanical energy to exert force on fixated structures to enhance their security and in bone affect its healing response. This staple once placed changes shape in response to geometric changes in the materials structure, including healing bone tissue. The staple is advanced over prior staples due to its: 1) method of operation, 2) high strength, 3) method of insertion, 4) compressive force temperature independence, 5) energy storing staple retention and delivery system, 6) compatibility with reusable or single use product configuration, 7) efficient and cost effective manufacturing methods, and 8) reduction in the steps required to place the device. In addition to the staple's industrial application an embodiment for use in the fixation of the musculoskeletal system is shown with staple, cartridge, and extrusion handle.

Owner:FOX WILLIAM CASEY

Resin composition and molded product thereof

A resin composition includes: a resin component comprising 50 to 100 parts by mass of (i-1) a polylactic acid and 50 to 0 part by mass of (i-2) a polyolefin [the total of (i-1) and (i-2) is 100 parts by mass], and 1 to 100 parts by mass, per 100 parts by mass of the resin component, of (ii) a functional group-containing, hydrogenated, diene-based polymer containing at least one kind of functional group selected from the group consisting of carboxyl group, acid anhydride group, epoxy group, (meth)acryl group, amino group, alkoxysilyl group, hydroxyl group, isocyanate group and oxazoline group; and a molded article thereof. The resin composition and the molded article are superior in balance between tensile property or stiffness and impact resistance as well as in appearance when molded and, moreover, have biodegradability (disintegratability); and, therefore, can be used in various applications such as packaging materials, industrial materials, industrial products, containers, medical tools and the like.

Owner:JSR CORPORATIOON

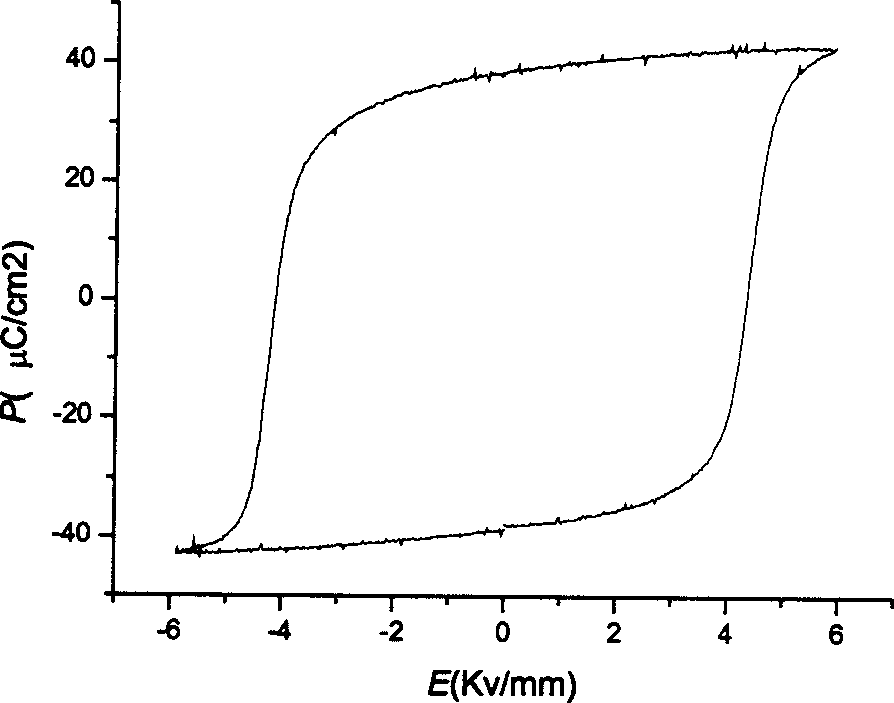

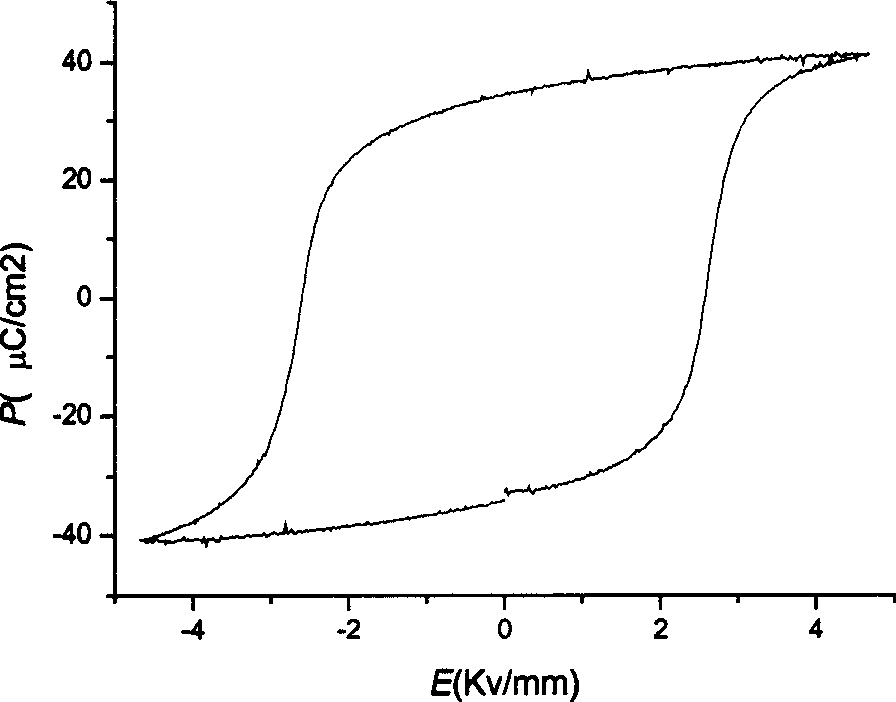

Multi constituent niobate lead-free piezoelectric ceramics

InactiveCN1511802AExcellent piezoelectric ferroelectric propertiesImprove processing stabilityCeramicsPiezoelectric/electrostrictive/magnetostrictive devicesCeramicRaw material

The present invention belongs to environment concordant piezoelectric ceramic. The lead-free piezoelectric ceramic of the present invention may be expressed in the general expression of (LixNayK1-x-y)(Nb1-zRz)O3+aLMnO3, where, x is 0-0.3, y 0-1, (x+y) is 0-1, z 0-0.4, a is the weight percentage of LMnO3, 0-15 wt%, R is Ta and / or Sb, L is RE element, such as Y, Er, Ho, Dy , Tm, etc. The piezoelectric ceramic has d33 up to 150 pC / N and kp up to 27.0 %, and may be prepared with industrial material and through traditional piezoelectric ceramic process.

Owner:SICHUAN UNIV

Method for forming carbon nanotube film, film-forming apparatus, and carbon nanotube film

InactiveUS20110014446A1Efficient mass productionLow costMaterial nanotechnologyCarbon compoundsGas phaseCarbon nanotube

A method and an apparatus for efficiently mass-producing a single-wall carbon nanotube (SWCNT) film are disclosed. The SWCNT film is useful as an industrial material, at low temperature and low cost. The method and apparatus are characterized in that carbon nano-tubes (CNTs) are synthesized from a raw material source through a gas-phase chemical vapor deposition (CVD) process, and the synthesized CNTs are directly deposited on a substrate in a chamber connected with a reaction tube, thereby forming a CNT film on the substrate.

Owner:NAT INST OF ADVANCED IND SCI & TECH

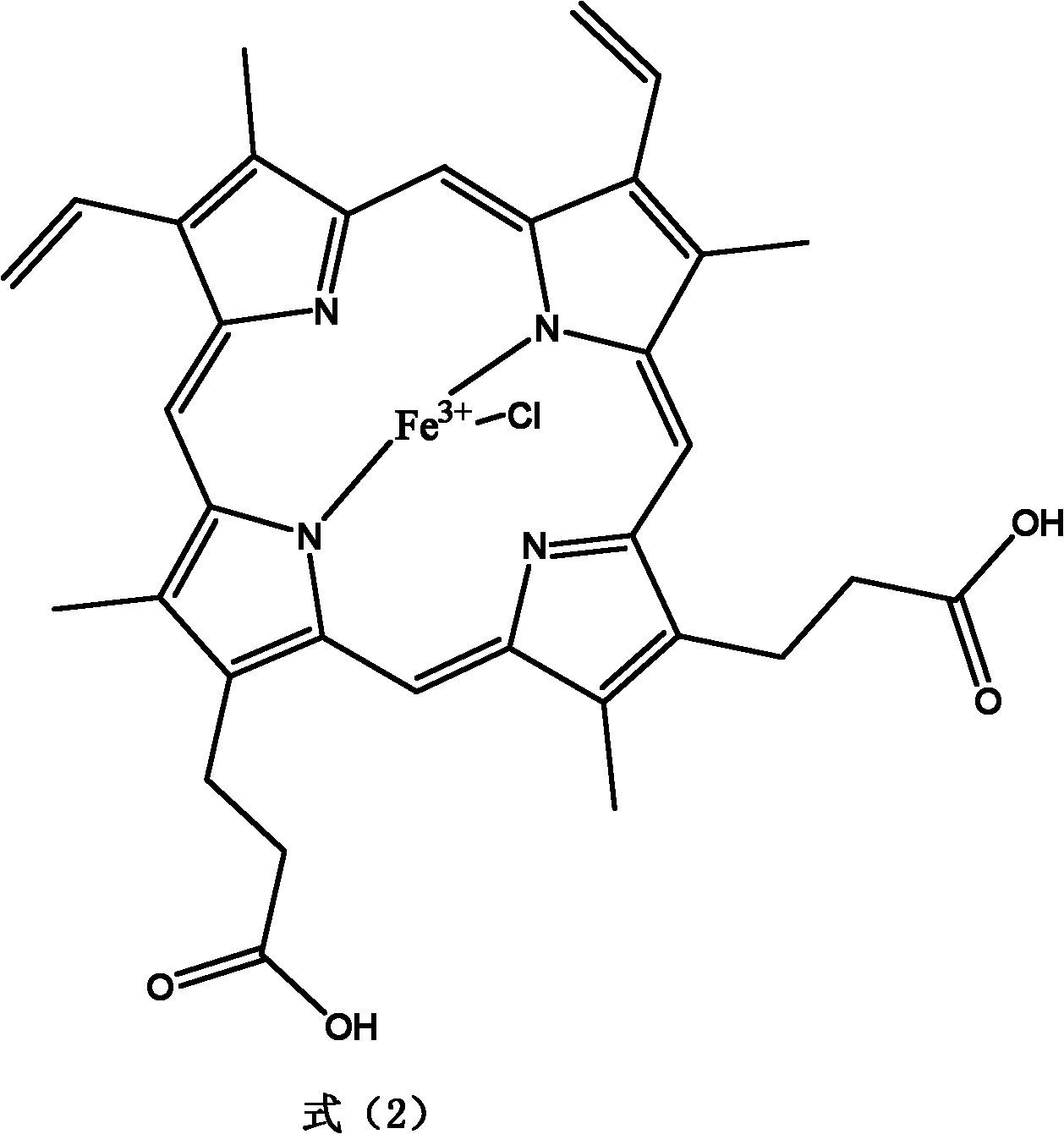

Method for preparing benzaldehyde or substituted benzaldehyde by catalytically oxidizing methylbenzene or substituted methylbenzene

ActiveCN102070382AReduce dosageSimple processOrganic compound preparationCarbonyl group formation/introductionBenzaldehydeCatalytic oxidation

The invention provides a method for preparing benzaldehyde or substituted benzaldehyde by catalytically oxidizing methylbenzene or substituted methylbenzene and relates to the field of chemical industrial material intermediates. The benzaldehyde or substituted benzaldehyde of a general formula (1) and relevant side products are prepared by using a substance containing ferroporphyrin, derivatives of the ferroporphyrin or relevant load as a catalyst, adding a proper cocatalyst according to requirements, and oxidizing methylbenzene or substituted methylbenzene by using oxygen-containing gases such as oxygen, air and the like. In the method, the reaction is performed at a certain temperature of between 25 and 250 DEG C and pressure of 0.1 to 2 MPa; the using amount of the catalyst is small, and is 1 ppm to 1 mass percent under a non-load condition and 0.1 to 10 mass percent under a load condition; and other solvents are not added, and if necessary, a certain amount of cocatalyst is added. The method has the characteristics of environmental friendliness and simple process.

Owner:SHANDONG YINGYANG FLAVORS & FRAGRANCES

Multi-component system nonleaded piezoelectric ceramic with good performance

InactiveCN1541976AExcellent piezoelectric ferroelectric propertiesImprove performanceCeramicsPiezoelectric/electrostrictive/magnetostrictive devicesRare earthPerovskite

The polycomponent lead-free piezoelectric ceramic composition with excellent performance is one perovskite type environment consistency piezoelectric ceramic composition. The composition has the general expression of (1-e-f-g)(Bi1-uLu)1-w(Na1-x-yKxLiy)wTiO3+eBaTiO3+fSrTiO3+gCaTiO3+aMalphaObeta, where x is 0-1, y 0-0.5, u 0-0.12, (x+y) 0-1, e 0-1, f 0-1, g 0-1, (e+f+g) 0-1, w 0.3-0.7, L is RE elements La, Ce, Pr, Nd, Sm, etc.; MalphaObeta is doping oxide(s) in the content an of 0-10 %; M is +1~+6 valent element capable of forming solid oxide, such as Na, K, Li, Zn, Cr, etc. with alpha and beta being atom number. The piezoelectric ceramic composition has d33 up to 200 pC / N, kp up to 36.0 % and stable technological process, may be produced via traditional piezoelectric ceramic preparation process and industrial material, and is practical.

Owner:SICHUAN UNIV

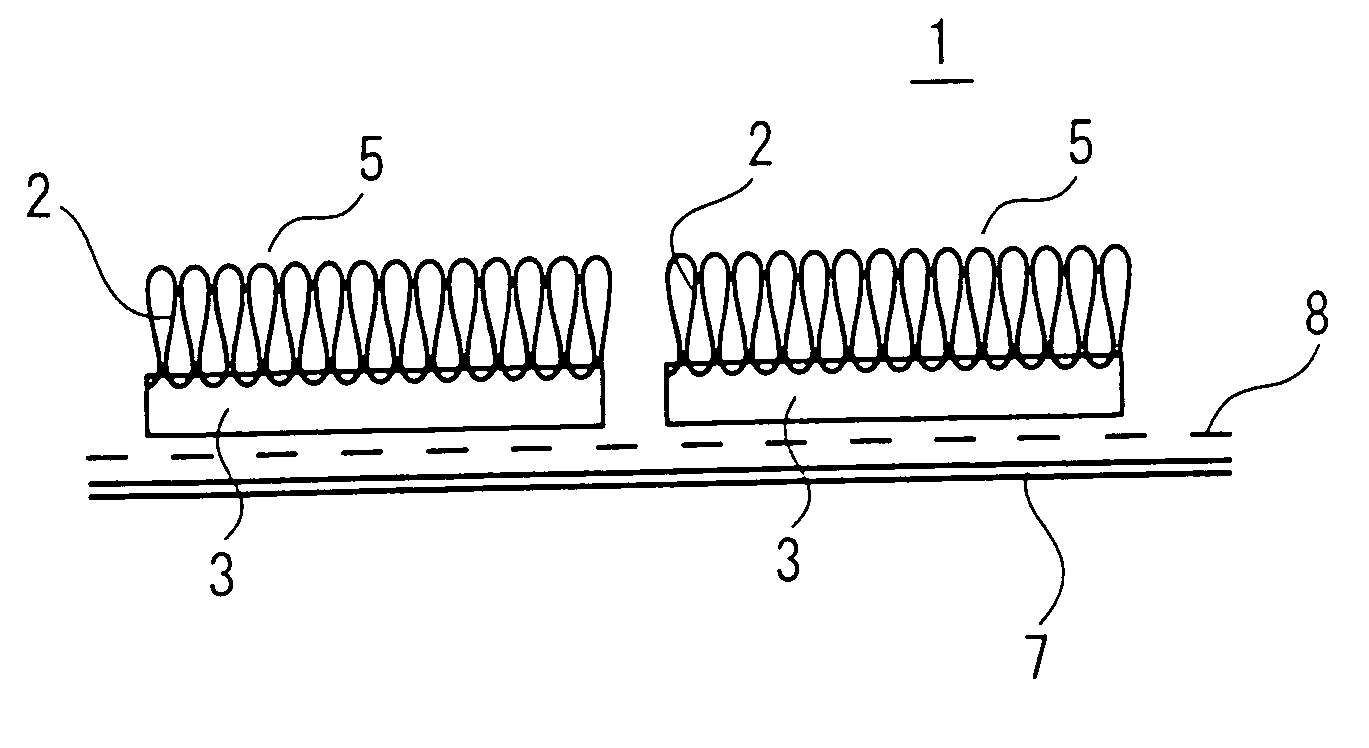

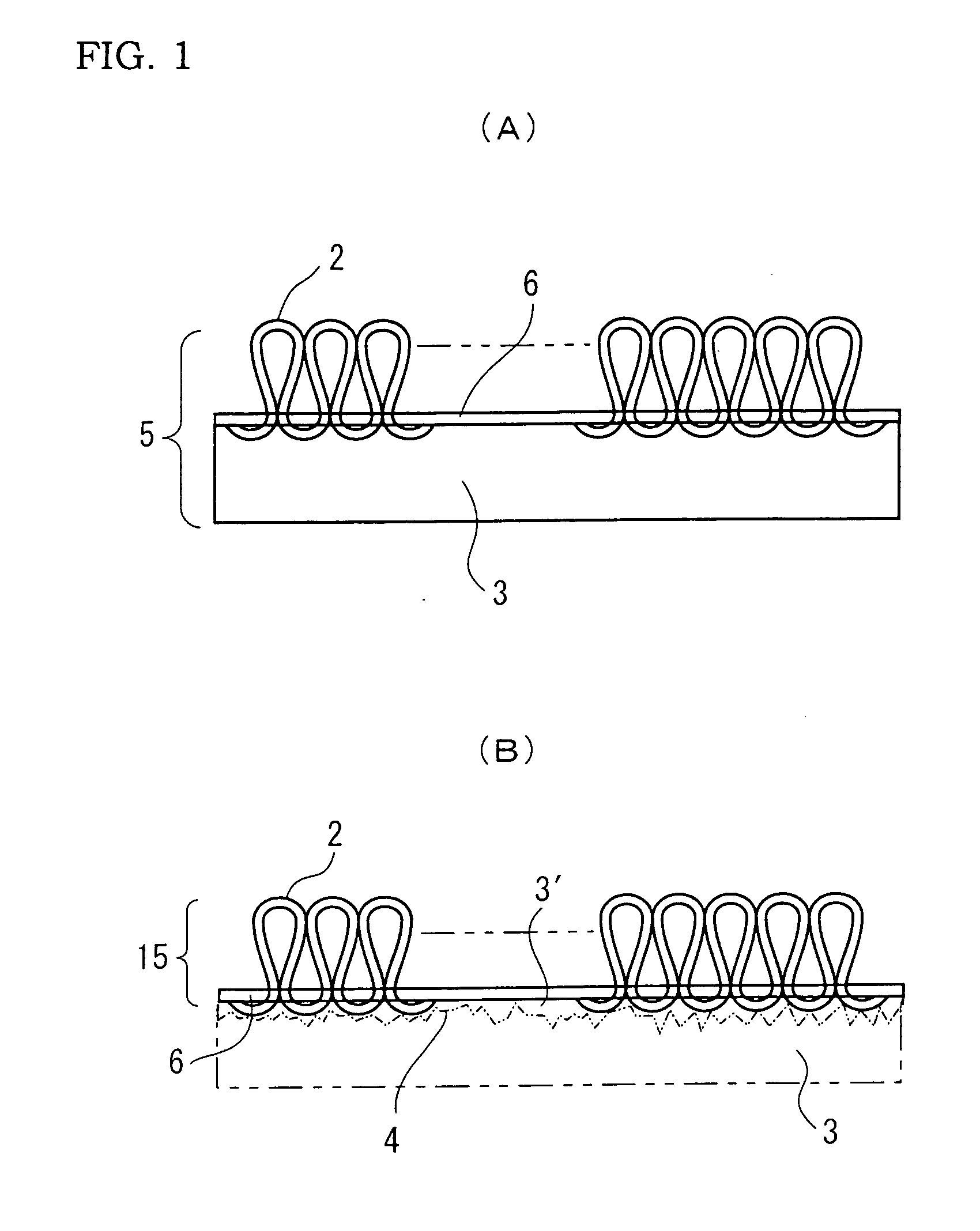

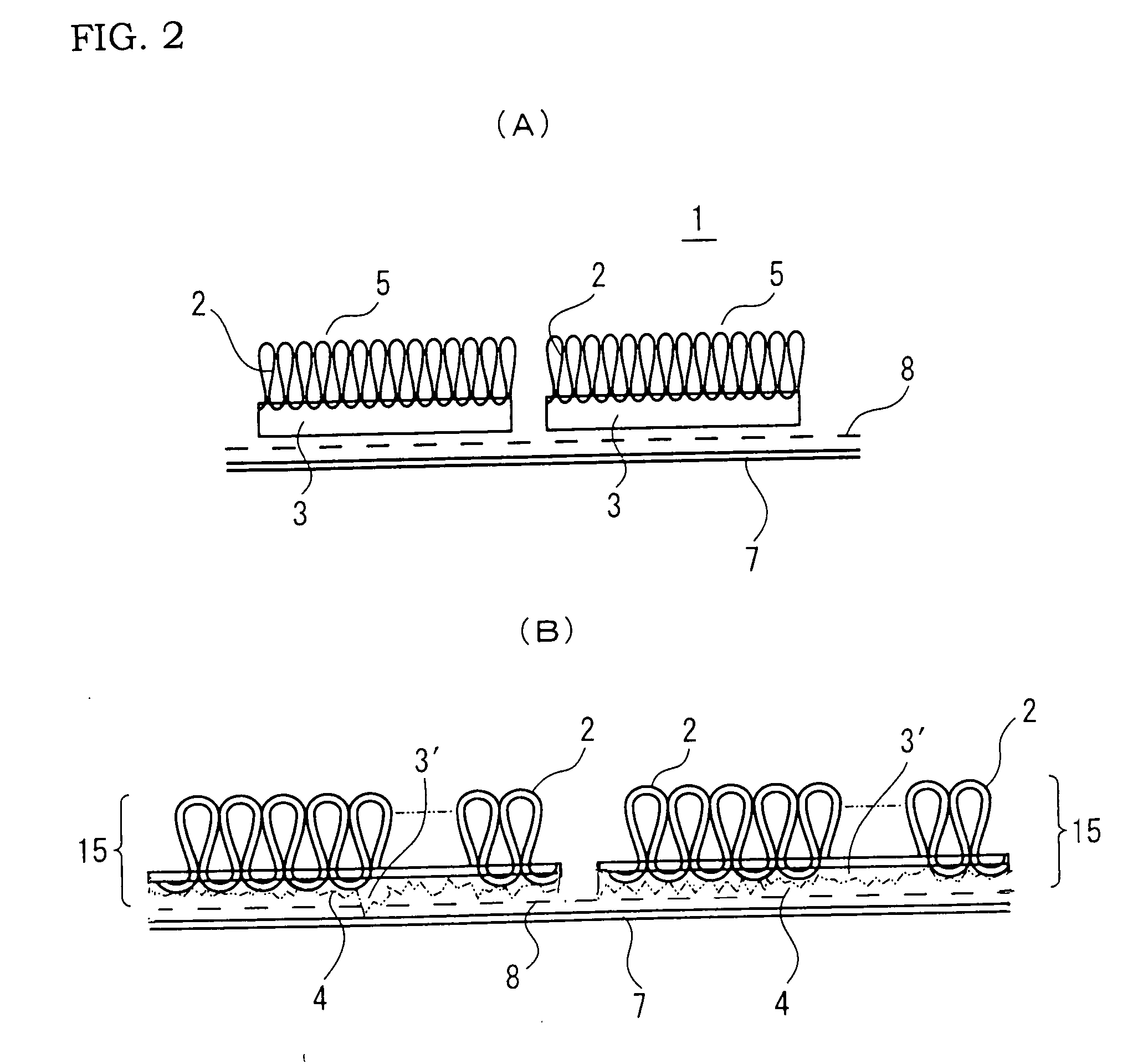

Sheet material, block-like sheet material, method of manufacturing sheet material and method of separating fiber-formed layer unit and backing layer from tile carpet and recovering the unit and the layer

InactiveUS20060147669A1Efficient separationReduce noiseAdhesivesThin material handlingFiberRecovery method

The present invention provides a effective recycling method for a fiber fabrication layer unit which has been separated and retrieved from a tile carpet and which comprising a fiber assembled layer to which a part of a backing layer being integrally contacted and also provide a method for producing a product to be recycled. And the method for effectively recycling the fiber fabrication layer unit comprises the steps of; applying a pressured shearing force to a surface of a backing layer of a tile carpet collected from the market before it is broken, so that at least a part of the backing layer is separated from a fiber assembled layer or from a rest of portion of the backing layer; separating the backing layer and the fiber fabrication layer unit including the fiber assembled layer from the tile carpet from each other; after that, gathering and connecting the tile carpets or the fiber fabrication layer units to each other with utilizing heat energy or suitable adhesive, to form a tile shaped block like sheet material or a longitudinal sheet material; and forming various kinds of industrial materials from these sheets.

Owner:TAJIMA

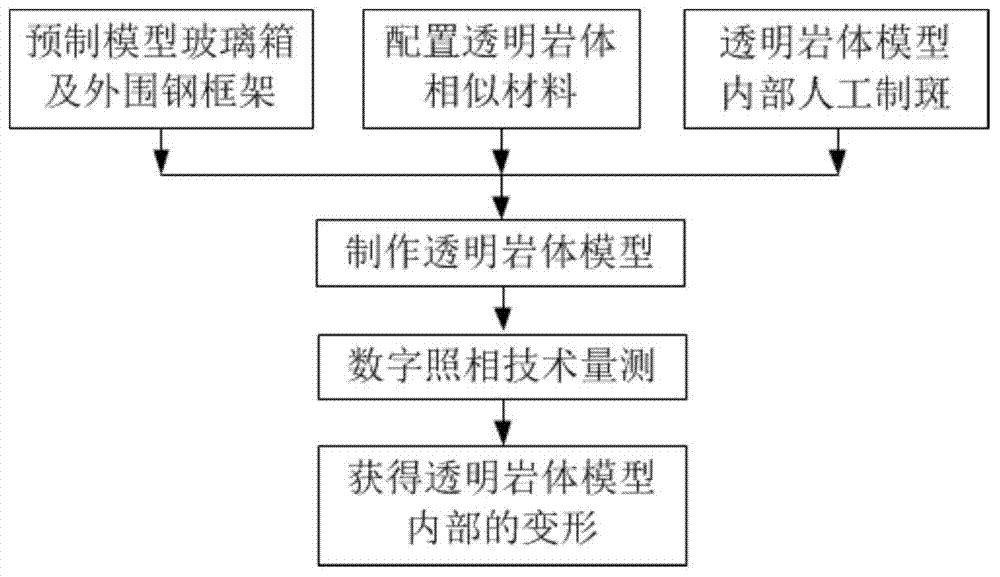

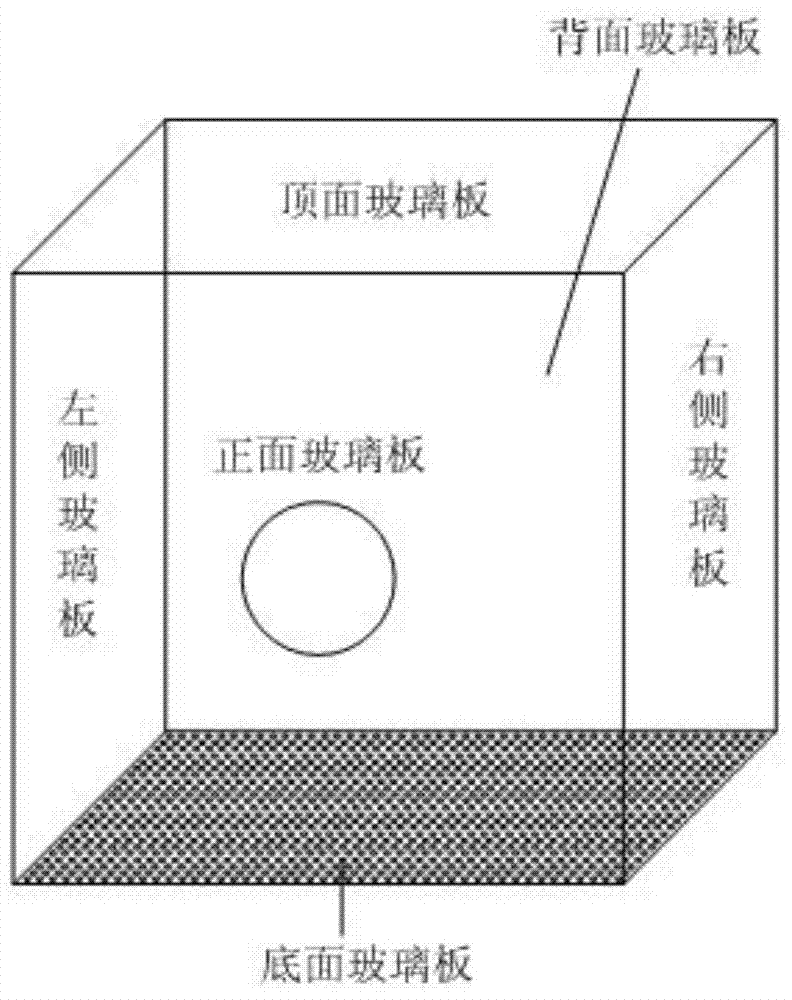

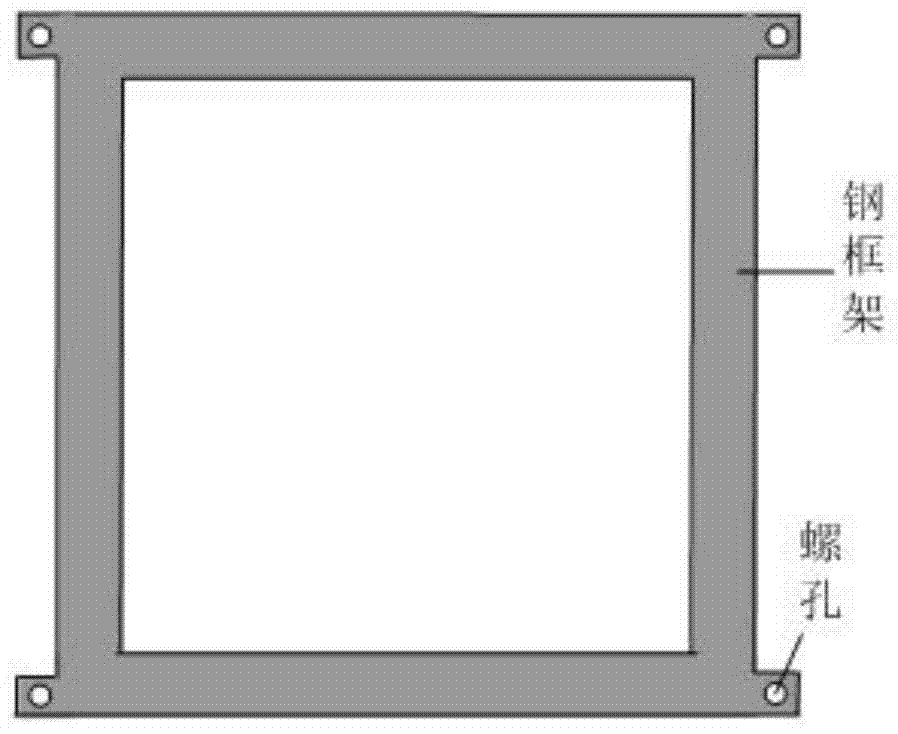

Physical testing method capable of directly observing internal deformation of rock mass model

InactiveCN104764745ASolve the problem that the deformation cannot be directly observedAchieve direct observationPreparing sample for investigationMaterial analysis by optical meansVacuum pumpingModel testing

The invention discloses a physical testing method capable of directly observing the internal deformation of a rock mass model, which belongs to a physical testing method for rock mass models. The method is implemented through mixing three industrial materials, i.e. silicon powder, liquid paraffin and n-tridecane at a mass ratio of 1:0. 836:0.702 so as to form a transparent rock mass similar material; then, pouring the transparent rock mass similar material into a rock mass model testing device for many times to carry out vacuum-pumping treatment, so that air in the similar material is discharged, and in the process of pouring for vacuum-pumping, regularly paving colored homogeneous silicon powder particles on several planes of the inside of a rock mass model so as to form artificial spot-making planes; and after a transparent rock mass model is completely manufactured, carrying out displacement tracking monitoring on artificial colored particles in the model in the process of testing by using a digital camera photogrammetry technology, so that rock mass deformation evolving data of each key part in the model is obtained. The method disclosed by the invention has the advantages that the direct observation on the internal deformation of a rock mass is realized; and the method can monitor full-field deformation, and is simple and flexible, economic in use, good in stability, and easy to promote.

Owner:CHINA UNIV OF MINING & TECH

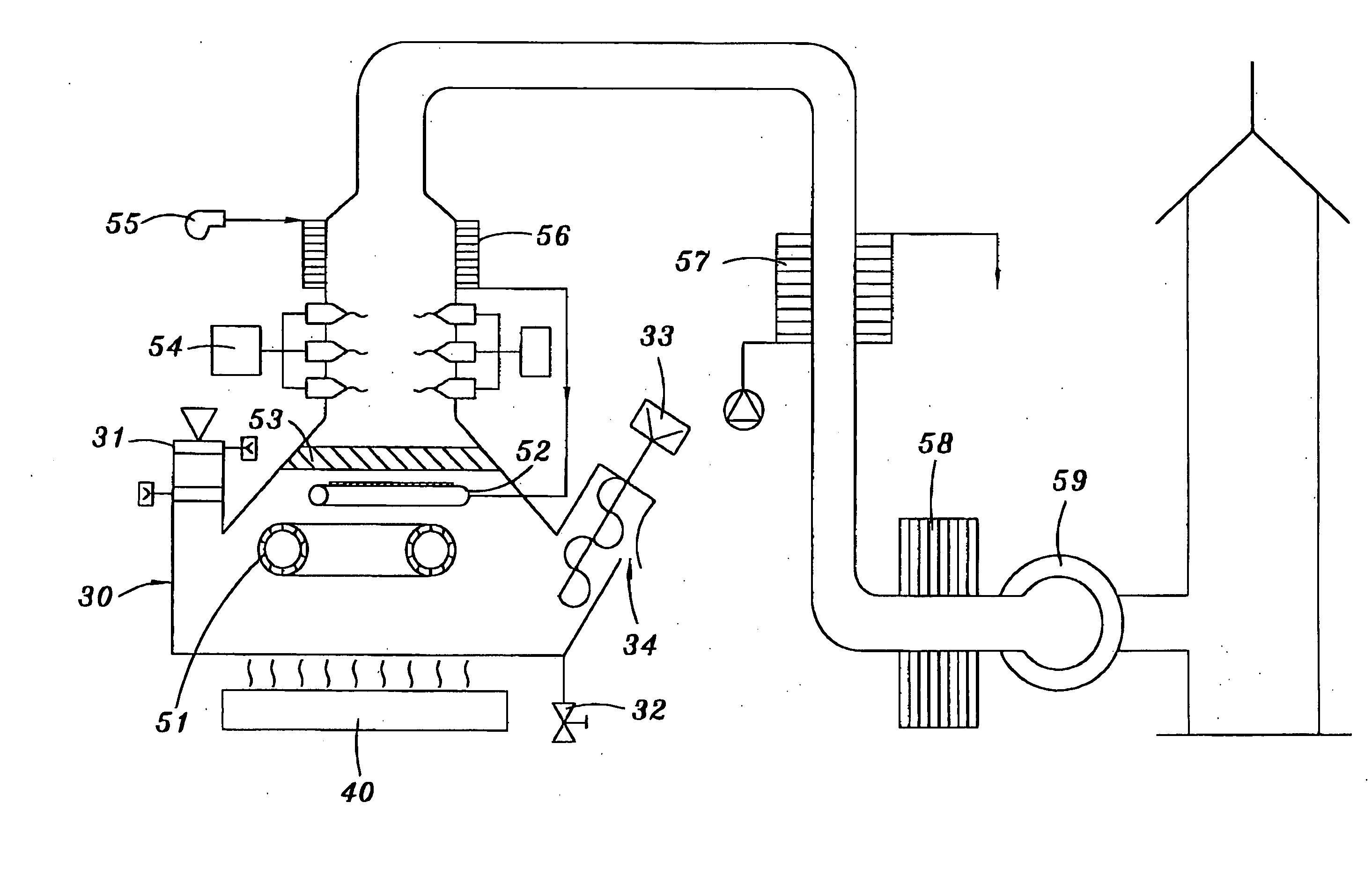

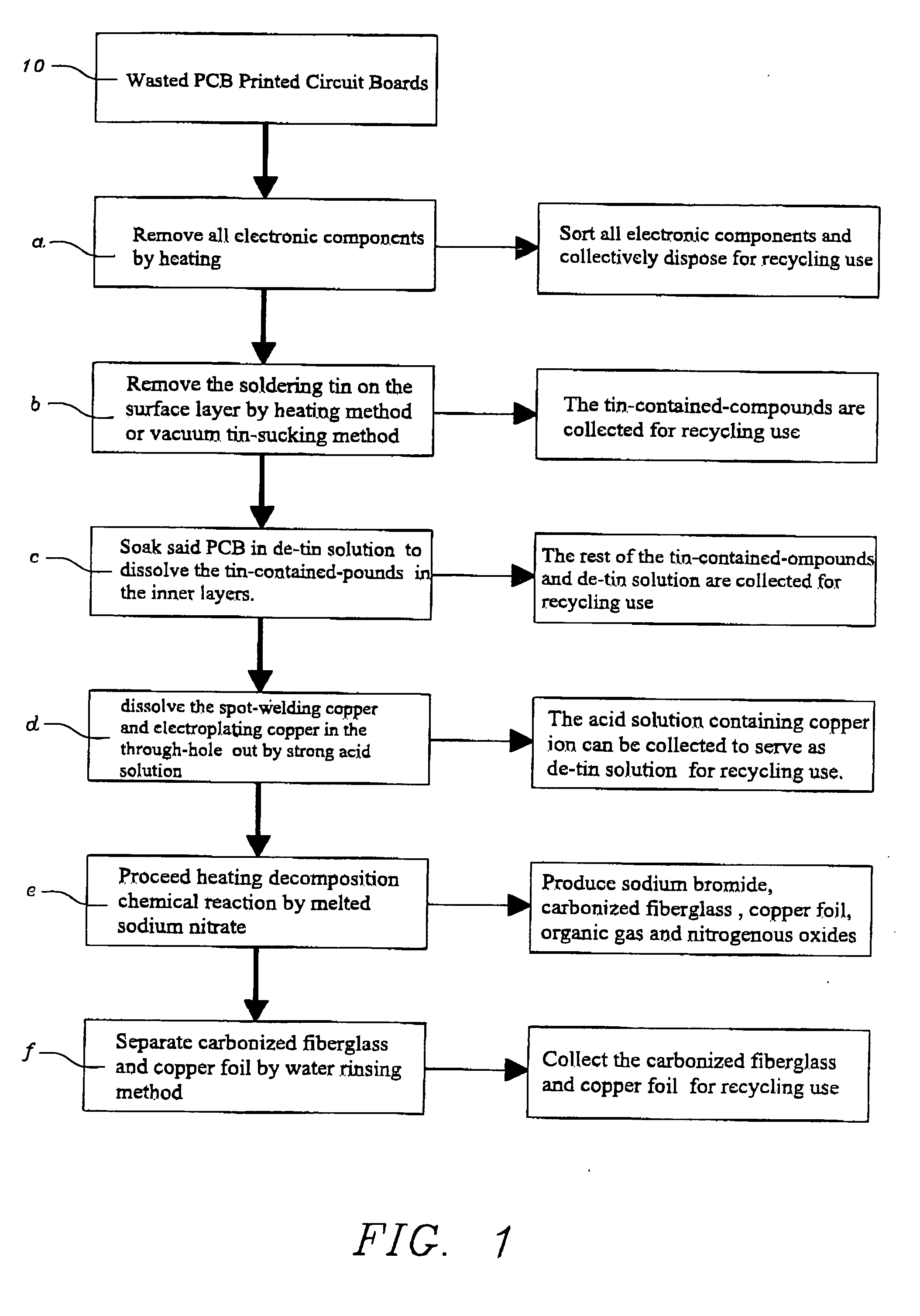

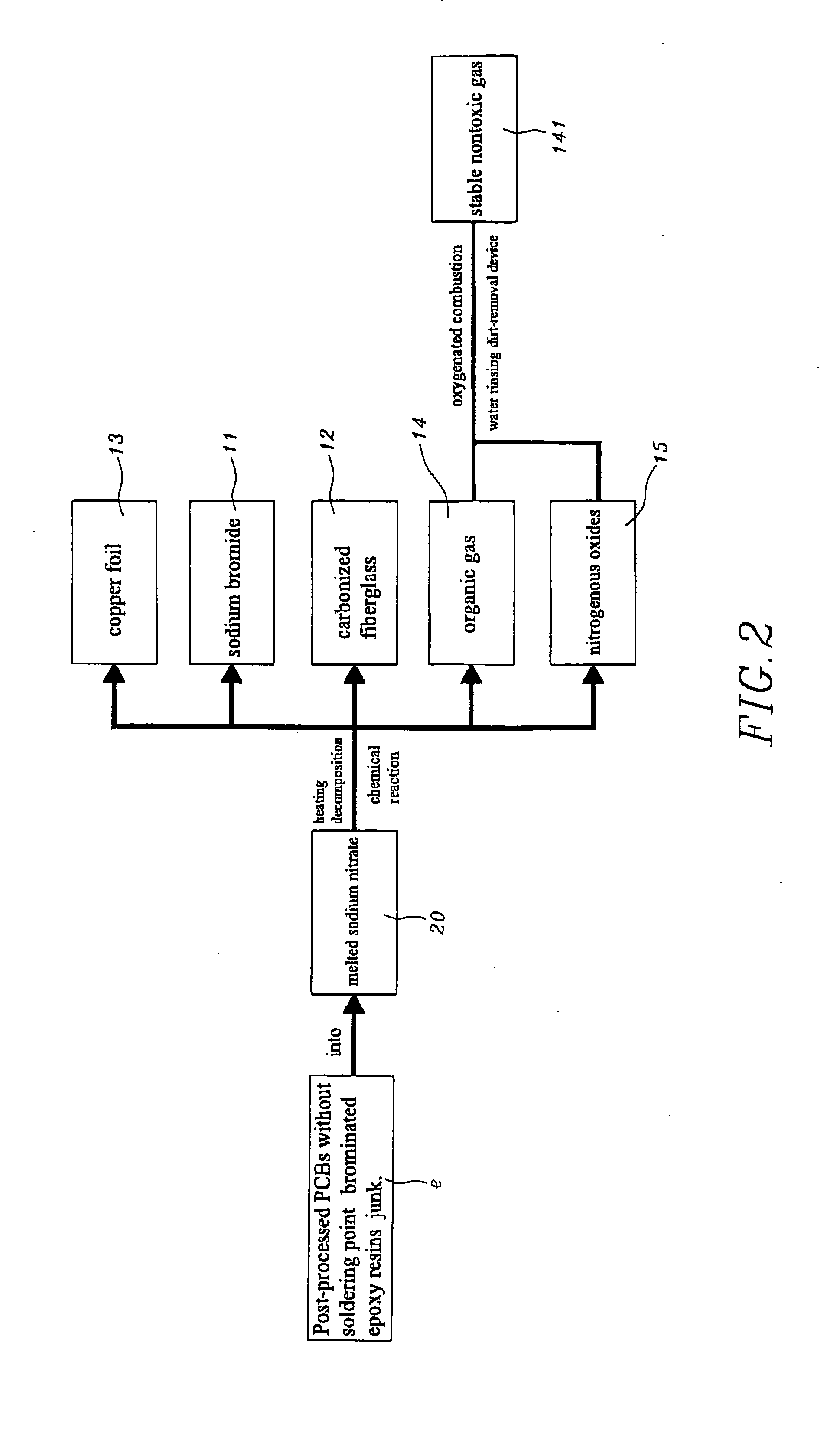

Method of recycling wasted printed-circuit-board

InactiveUS20070169330A1Final product manufactureTransportation and packagingRecovery methodGlass fiber

The present invention relates to a “method of recycling wasted printed-circuit-board”, which takes advantage of the characteristics of the PCB so as to dispose different recycling material in stage manner, so that different metals remaining on said PCB are sorted out step by step; Thereby, the bromide and the fiberglass of importance in the resins are collected and converted into variety of industrial materials as resource for recycling use in order to prevent said wasted PCB from spoiling the natural environment after recycling use.

Owner:WU HSIEH SEN

Separation method for agriculture and forestry biomass components

ActiveCN102101915AComplete molecular structureHigh yieldPaper material treatmentBulk chemical productionChemical productsSolvent

The invention discloses a separation method for agriculture and forestry biomass components. The separation method is to obtain cellulose, hemicelluloses and lignin, which have relatively complete molecular structure, by separating the agriculture and forestry biomass components step by step with a precipitator after cell walls dissolve completely. In the separation process, the operation is simple, the efficiency is high, the yields of the separated components are high, the used solvent and ionic liquid can be recovered and reused, and cost is saved. The separation method can provide a reliable theoretical basis for producing new industrial materials and biomass chemical products by using agriculture and forestry biomass as the raw material and provide a technical support for the development and utilization of renewable resources such as the agriculture and forestry biomass.

Owner:SOUTH CHINA UNIV OF TECH

Biaxially stretched laminated polyester film and polyester film for covering

InactiveUS20060073317A1Synthetic resin layered productsThin material handlingPolyesterBreaking strength

A biaxially stretched laminated polyester film having tensile break strengths in the machine and transverse directions of 40 to 200 MPa, and satisfying at least one of the following items: (1) wetting tension of at least one side of the film is not less than 48 mN / m; (2) surface resistivity of at least one side of the film is not more than 5×1012 Ω / □; and (3) a barrier layer is provided on at least one side of the film. Such a film is suited for use as a composing material of packages for industrial materials, medicines, hygienic materials, foods, etc., and is also suited as a packaging material which excels in printing ink adhesion and also has excellent laminating compatibility with other materials, antistatic gas barrier properties and hand cutting quality. The present invention also pertains to a biaxially stretched laminated polyester film whose tensile break strength in the machine and transverse directions is 41 to 170 MPa, and such a film can be suitably used as a covering of receptacles of the type which is ripped off in use, such as a covering of press-through packages for medicines such as tablets and capsules, various kinds of foods, industrial parts, etc., and a covering of the cup-type drink containers of which the content is sucked through a straw thrust into the container by breaking through the cover.

Owner:MITSUBISHI POLYESTER FILM

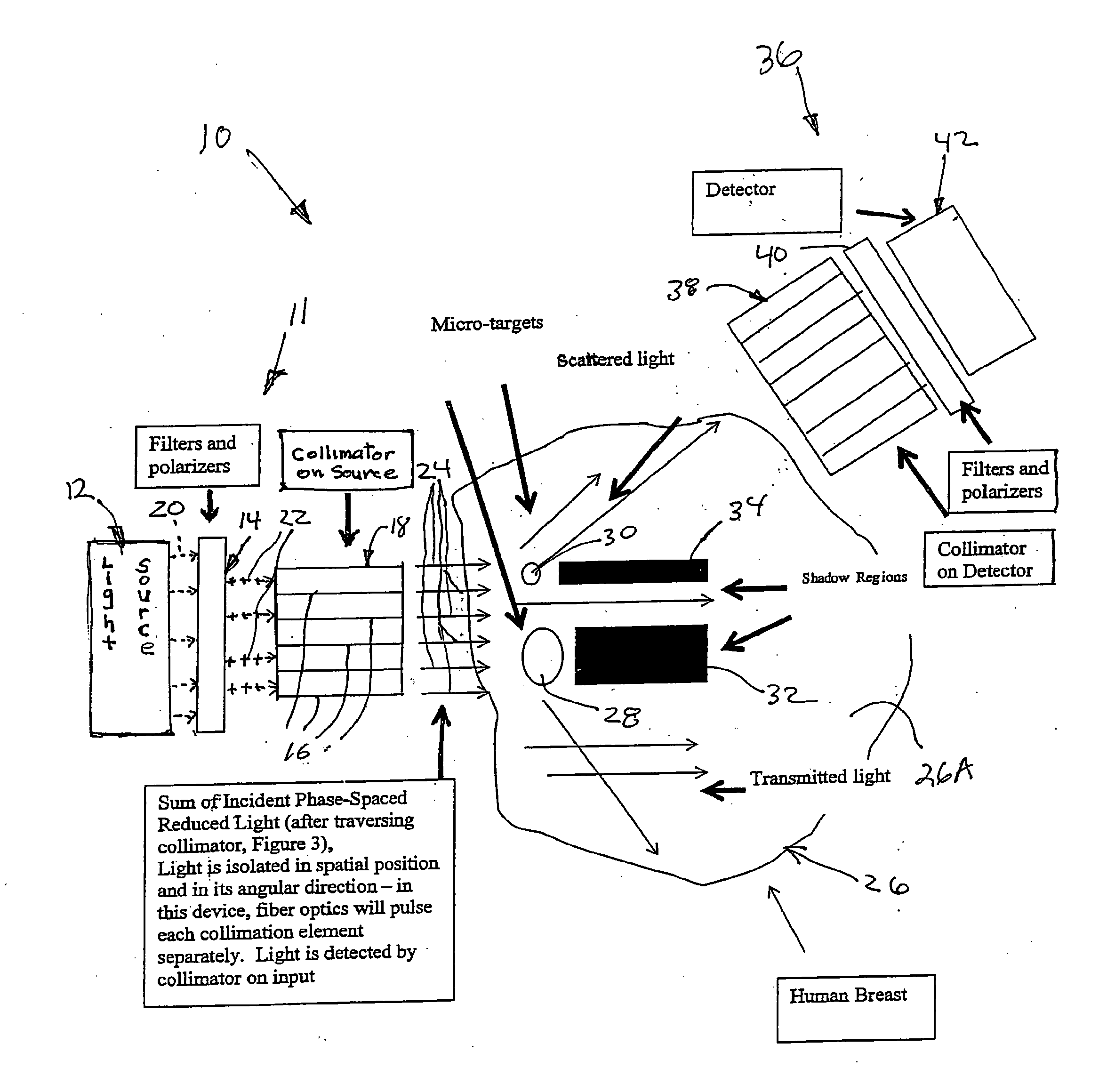

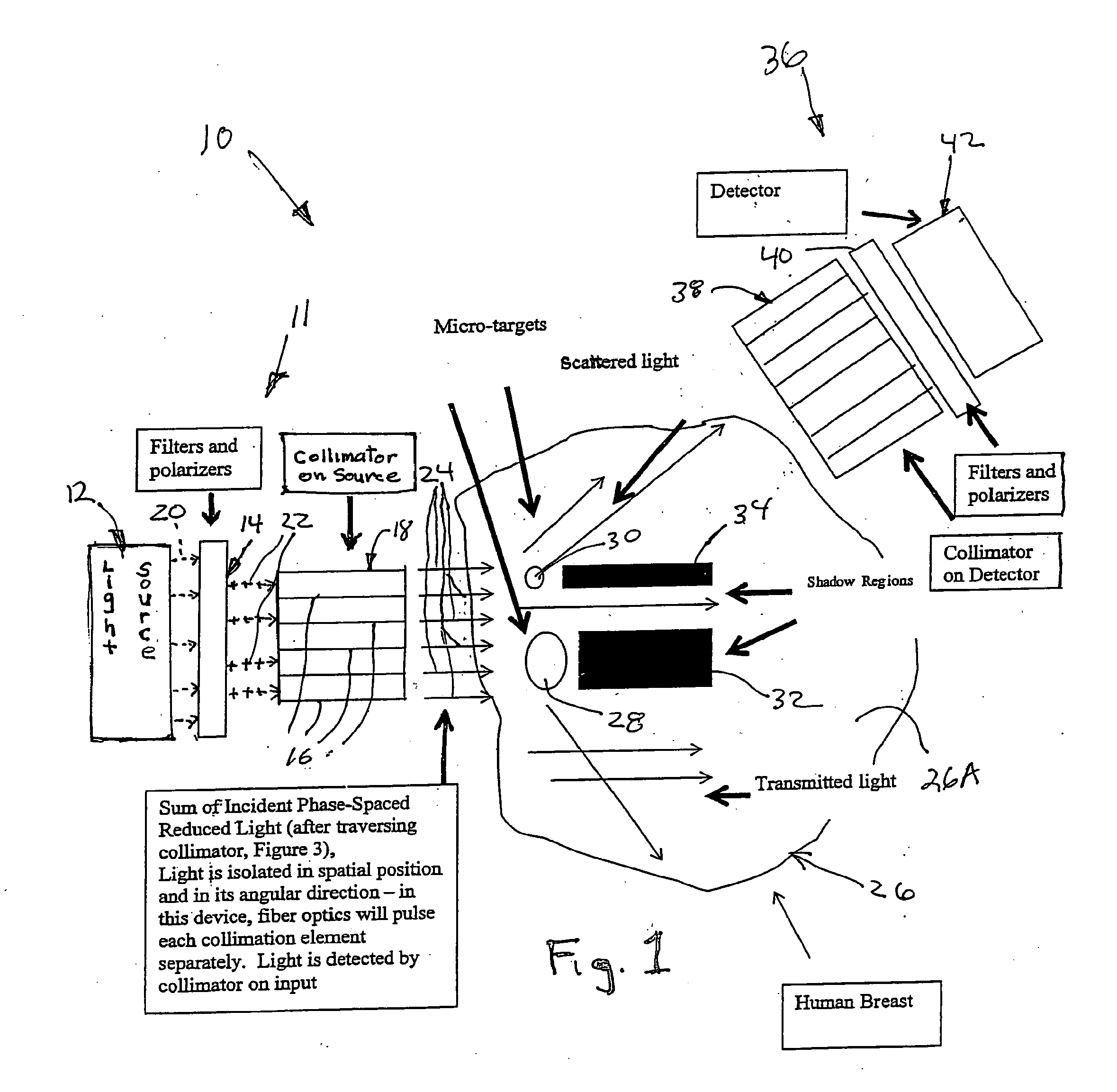

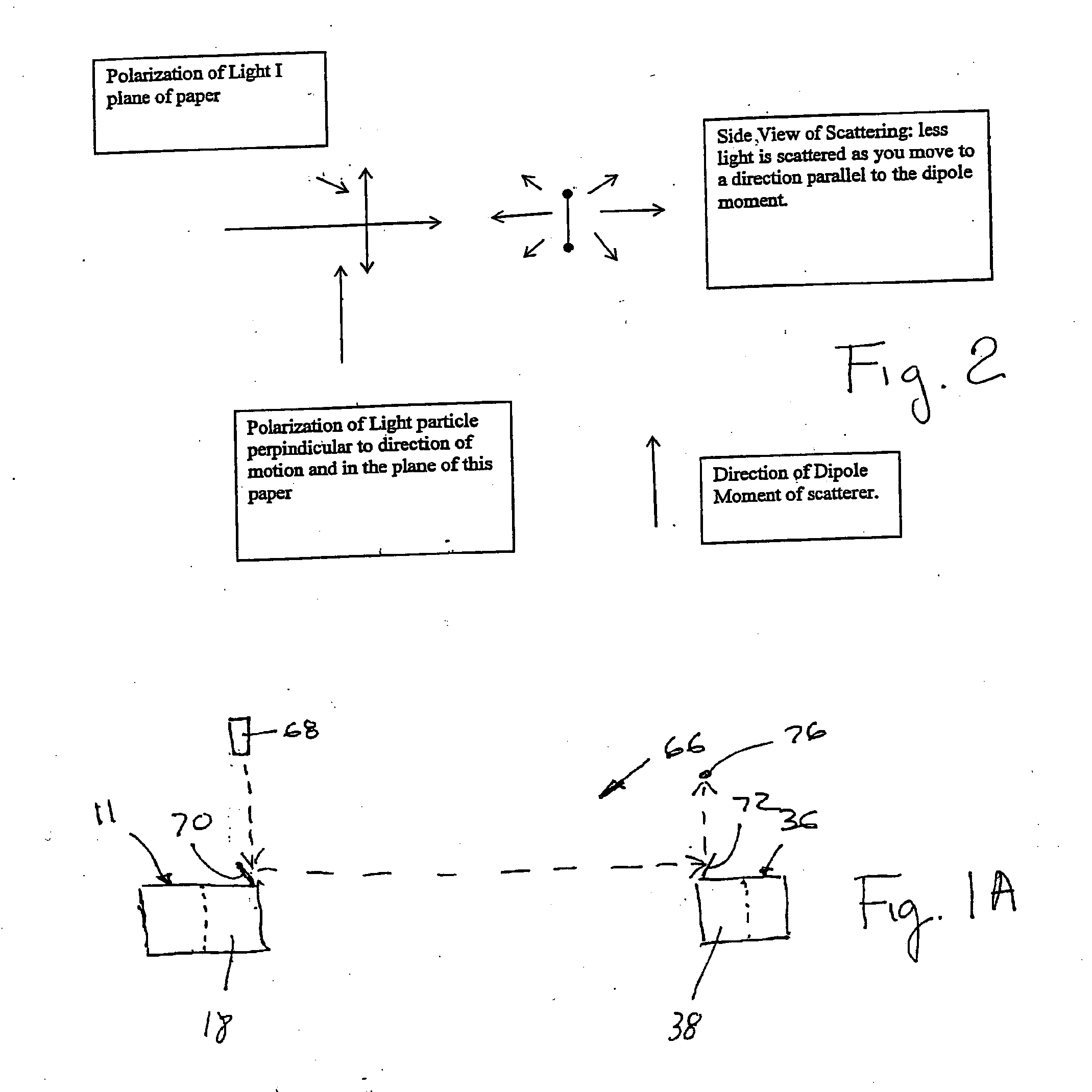

Apparatus and method for phase-space reduction for imaging of fluorescing, scattering and/or absorbing structures

InactiveUS20120059254A1Ease of use and safetyMaximum safetyEndoscopesLuminescent dosimetersInfraredFluorescence

A method and apparatus are disclosed for utilizing light, including ultraviolet, optical and / or infrared, for detecting a body in an object, such as biomaterial or tissue, animal and / or human tissue. The body or object may be made fluorescent by the use of dyes or agent. Light is used to illuminate the body and object and the scattered light, fluorescent and / or emitted light, reflected light and transmitted light are detected and used to reconstruct the body and / or object using an iterative analysis. Further, the method and apparatus may be extended to endoscopic applications to make subcutaneous images of internal tissue above, on, in or beyond endoscopic pathways such as esophagus, stomach, colon, bronchial tubes and / or other openings, cavities and spaces animate or inanimate, and in man-made or industrial materials as carbon / resin structures.

Owner:LIFAN WANG +4

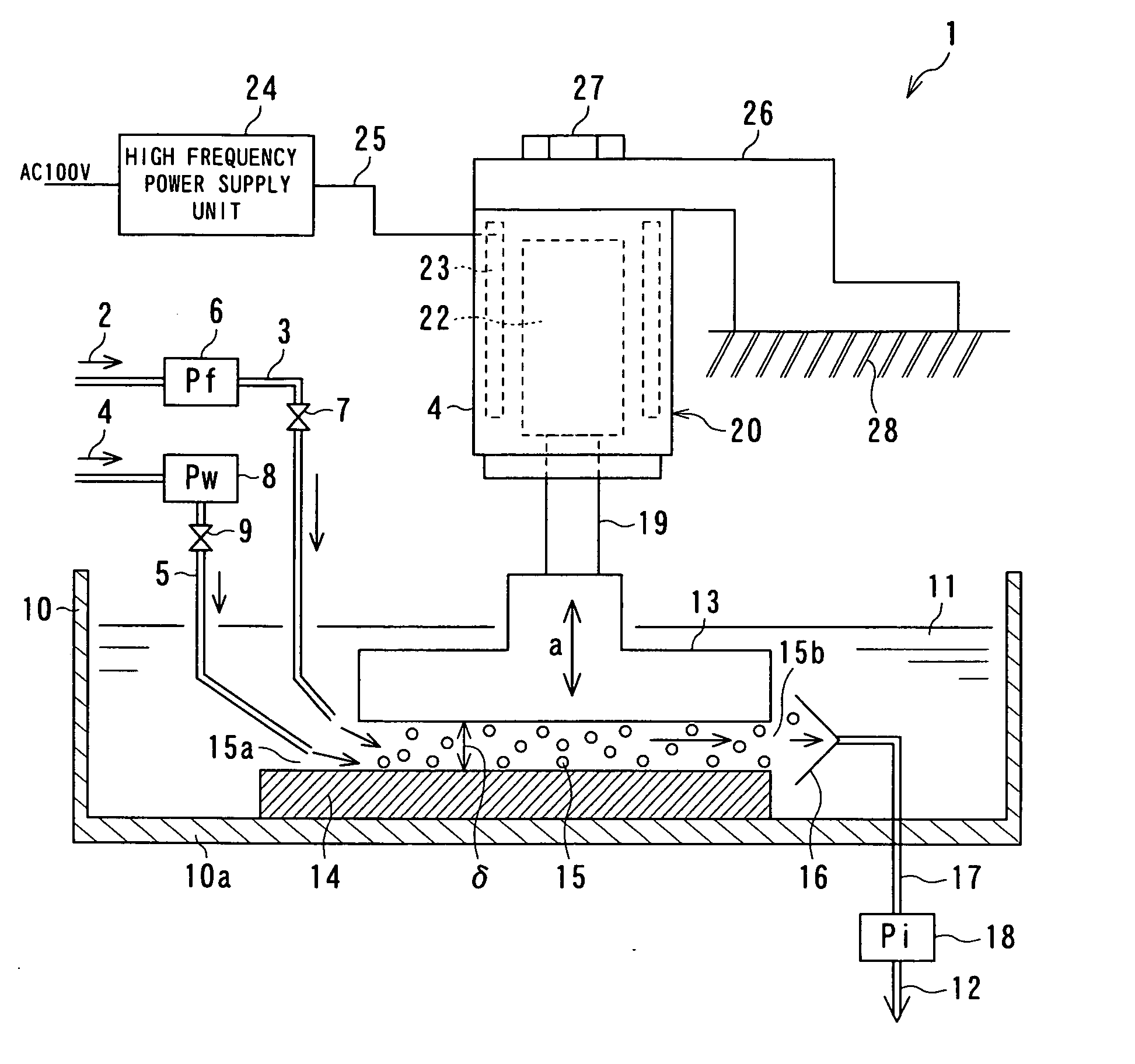

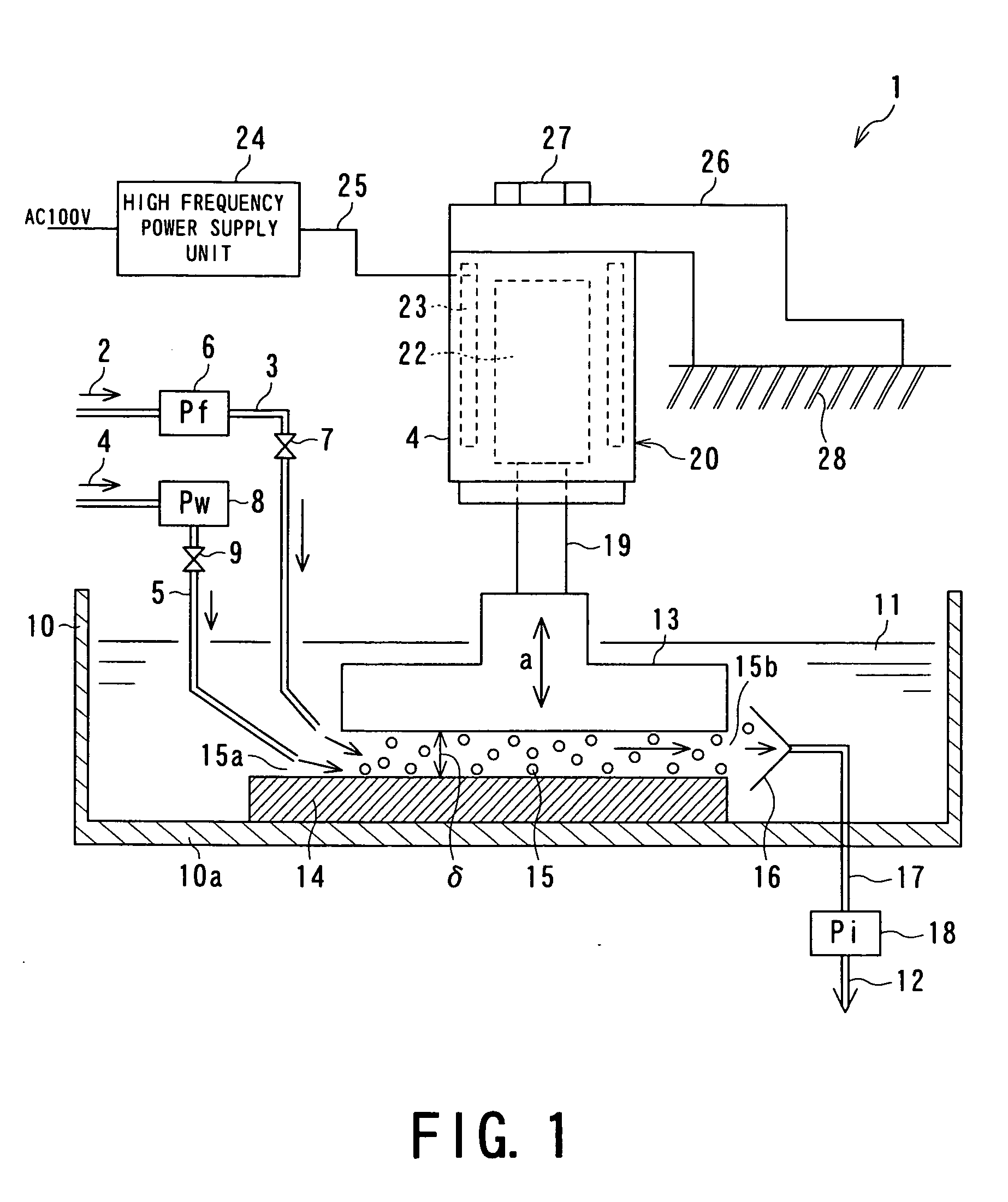

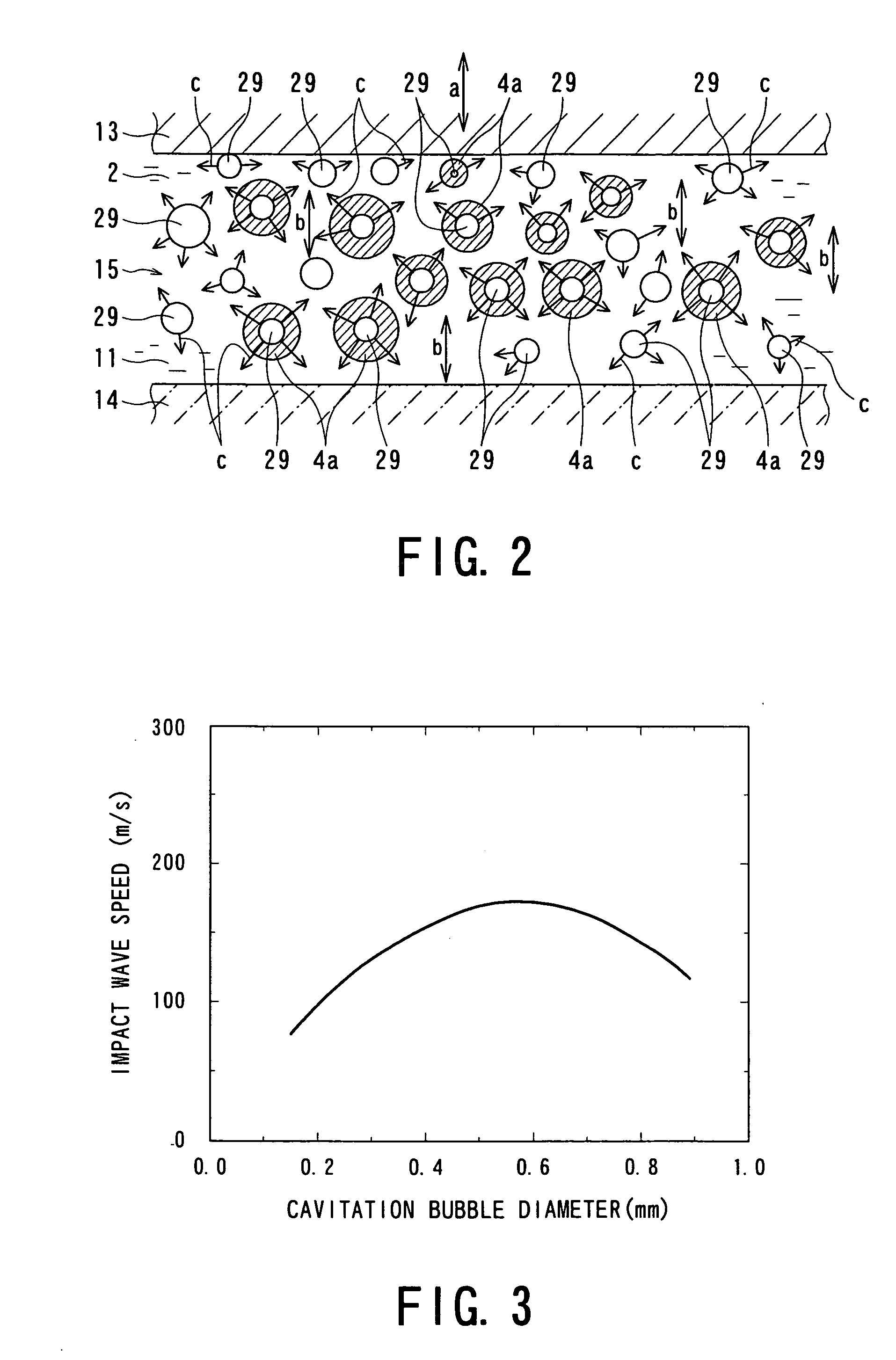

Liquid mixing apparatus and method of liquid mixing

InactiveUS20050270896A1Extremely-high cavitation effectHigh mixture densityShaking/oscillating/vibrating mixersInternal combustion piston enginesEmulsionCavitation

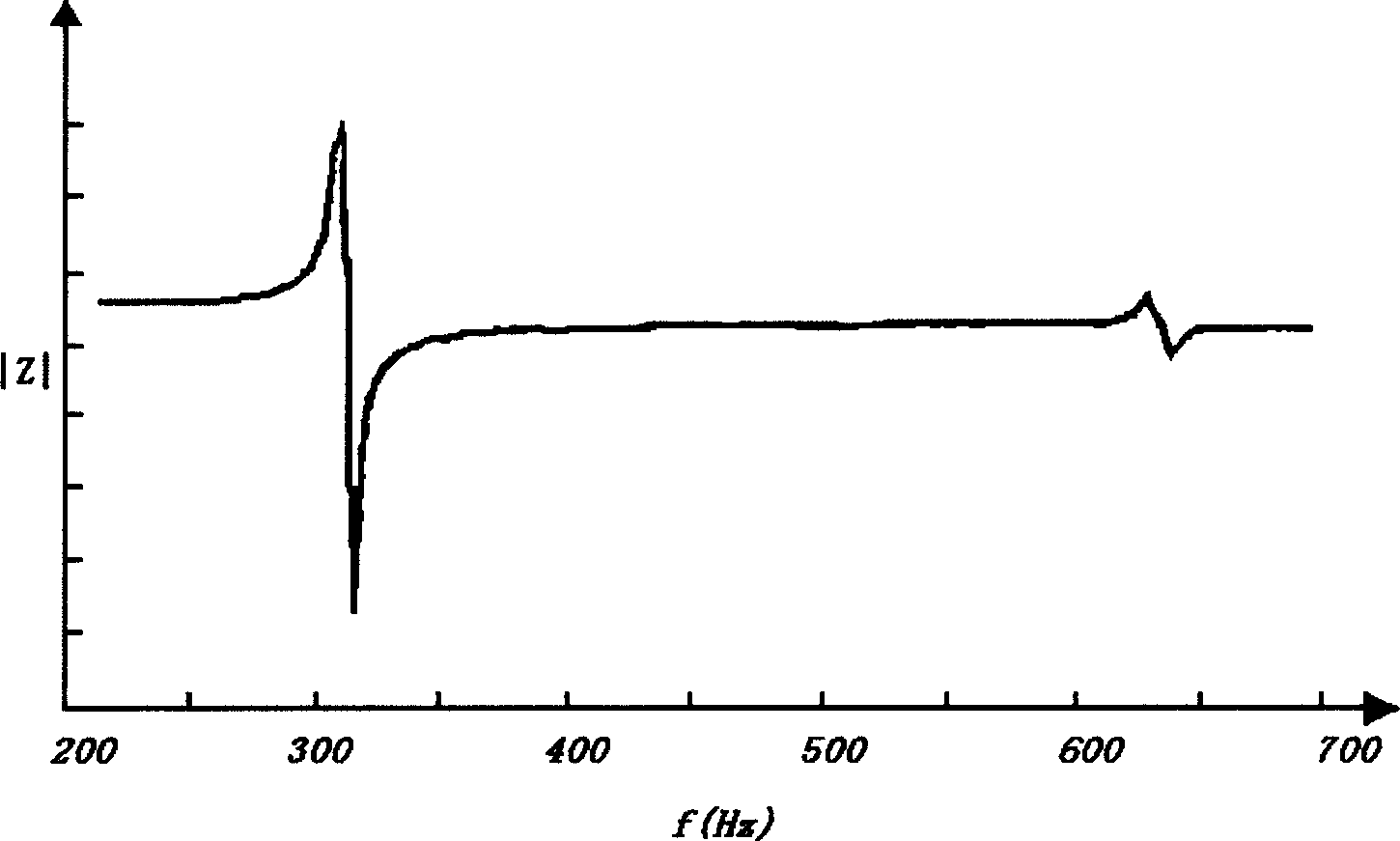

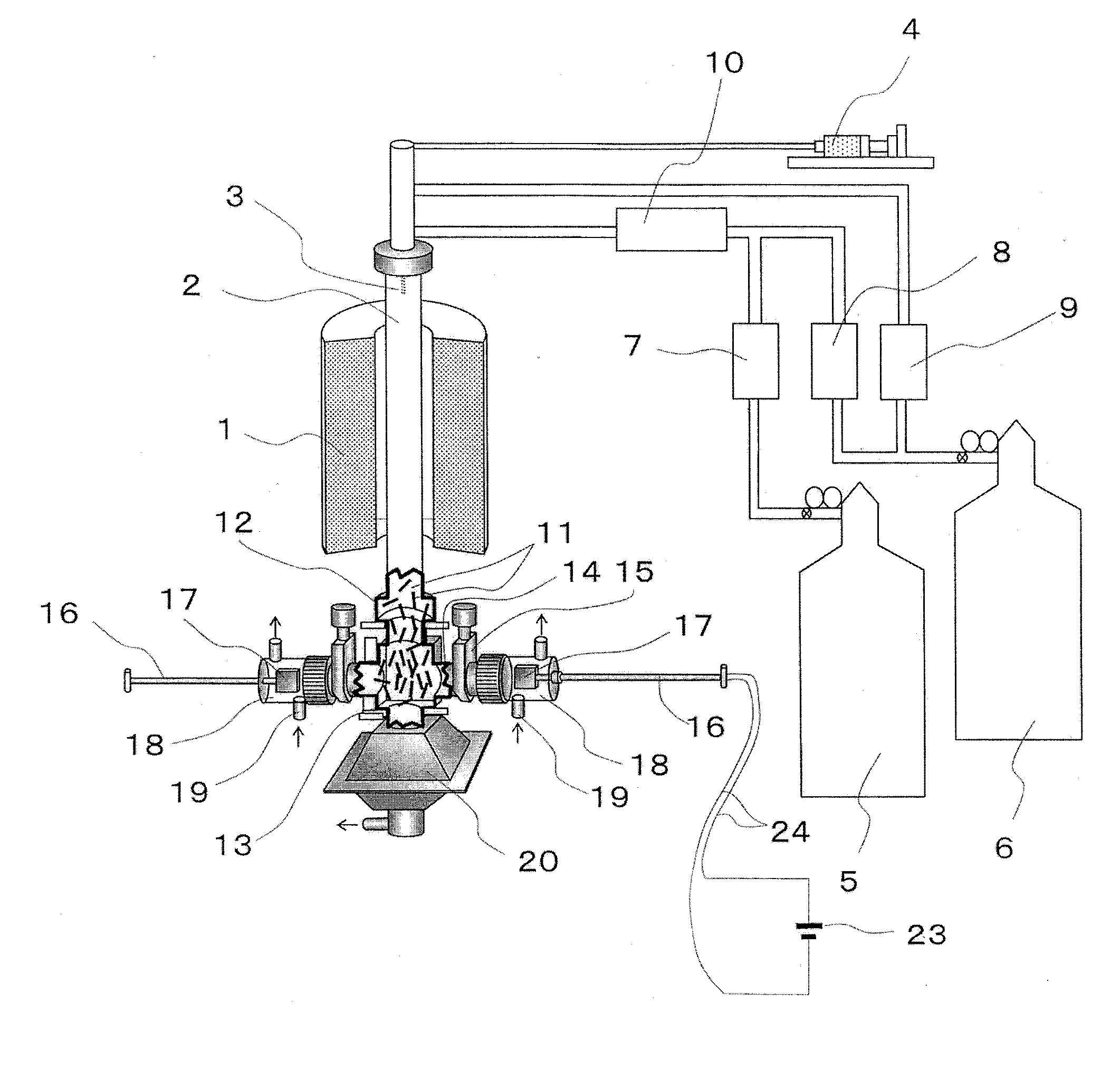

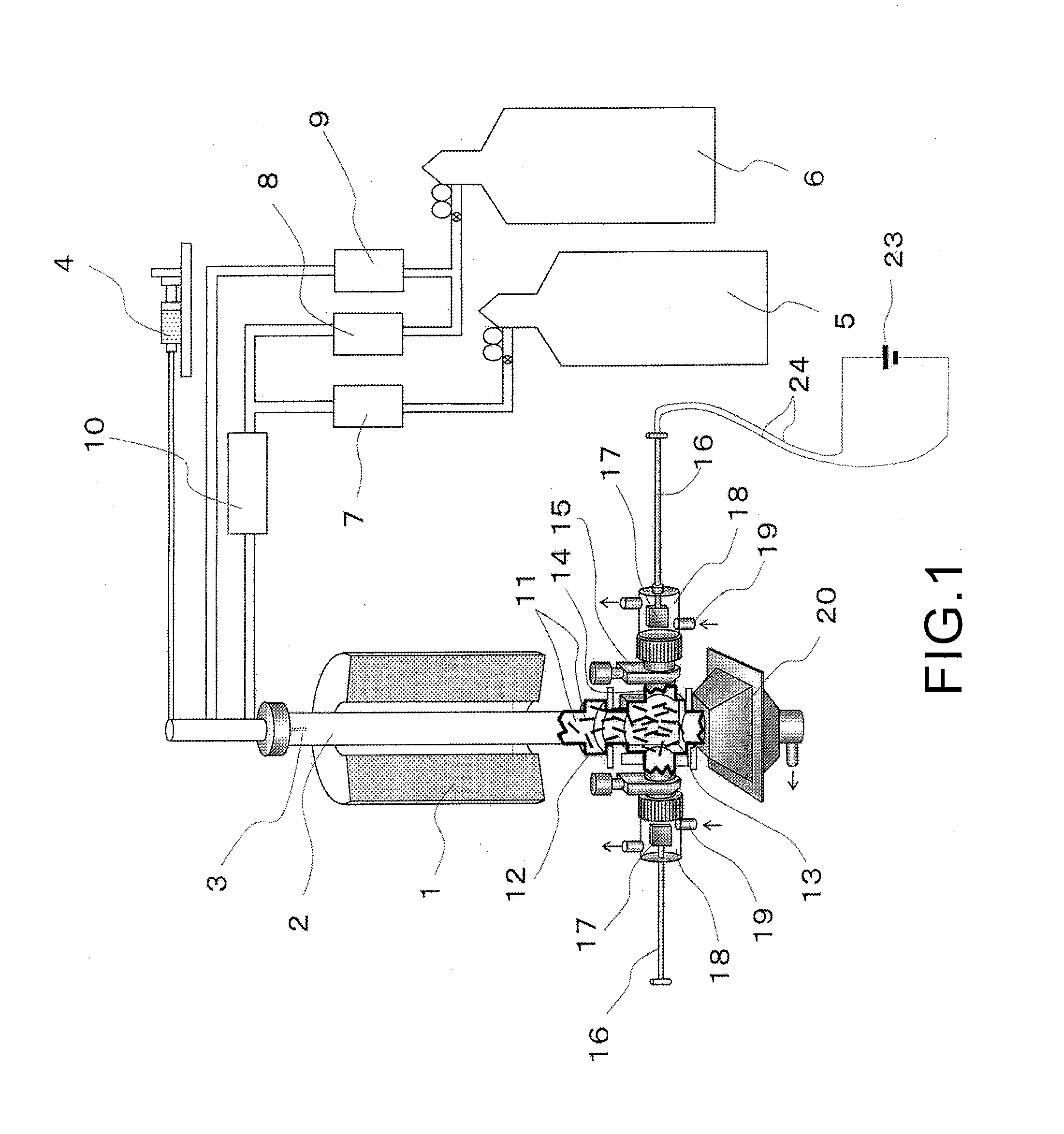

An apparatus includes a vessel 10 for storing a liquid mixture 11 containing a liquid fuel 2 and an incompatible liquid 4 such as water or for allowing the liquid mixture 11 to flow therethrough, a vibrator 13 having at least one portion making contact with the liquid mixture in the vessel, a vibration generator 20 for vibrating the vibrator at high frequency, and a reflector 14 spaced from the vibrator 13 at a small distance. The incompatible liquid 4 is dispersed in and mixed with the fuel 2 by vibrating the vibrator at high frequency, whereby an emulsion fuel 12 having an ultra fine particle size and high mixture density is produced. According to the above configuration, cavitation can be extremely efficiently generated. The following technique is disclosed: a technique for producing various types of liquid mixture having an ultra fine particle size using the cavitation efficiently. In particular, the following mixture can be produced in a short time with high efficiency: a liquid mixture, such as an emulsion fuel, a liquid industrial material, a food product, a cosmetic product, or a drug product, having an ultra fine particle size, high mixture density, and high quality. If the liquid mixture is stored over a long period of time, liquid components thereof are hardly separated from each other.

Owner:TOSHIBA PLANT SYSTEMS & SERVICES

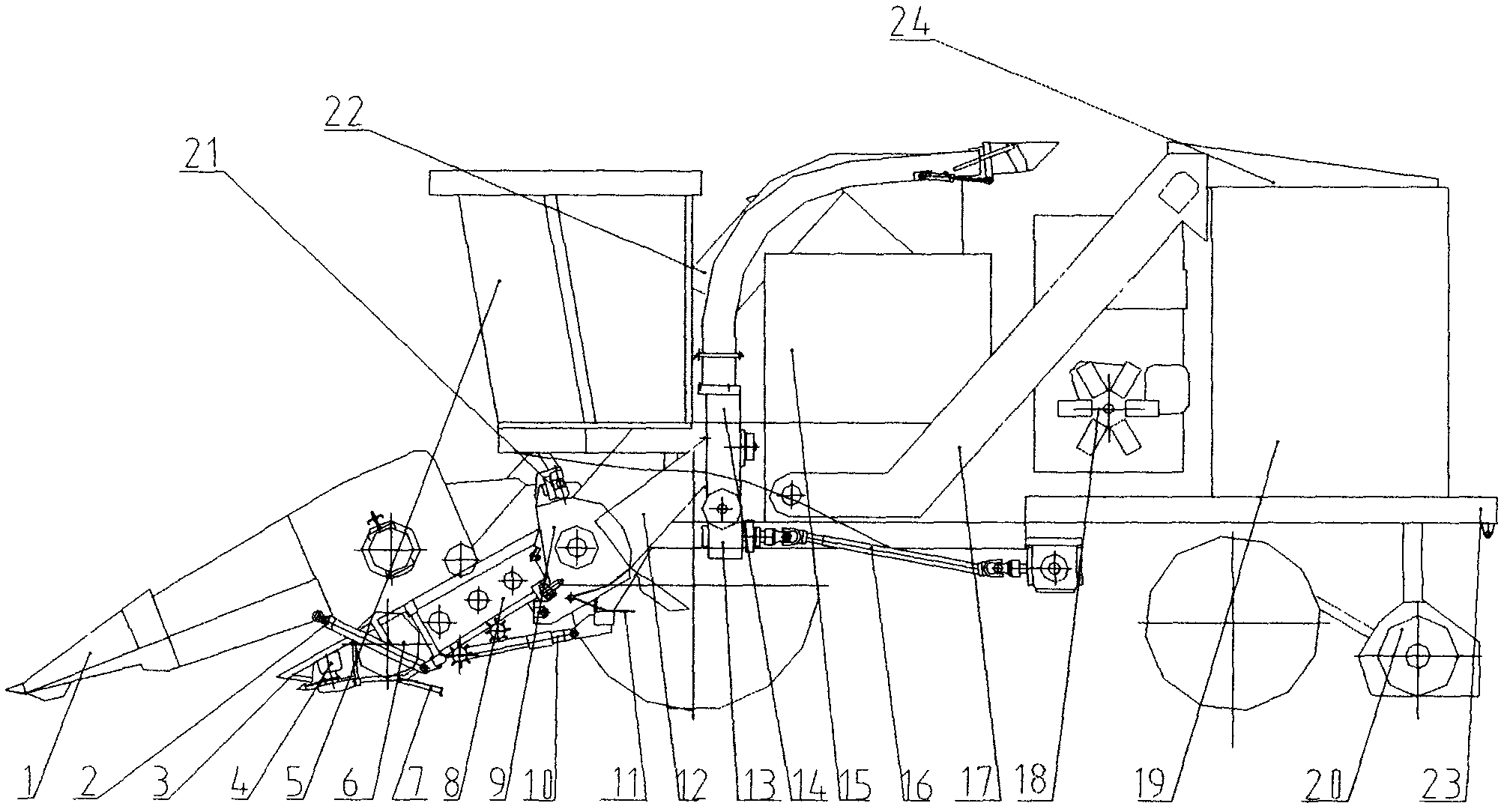

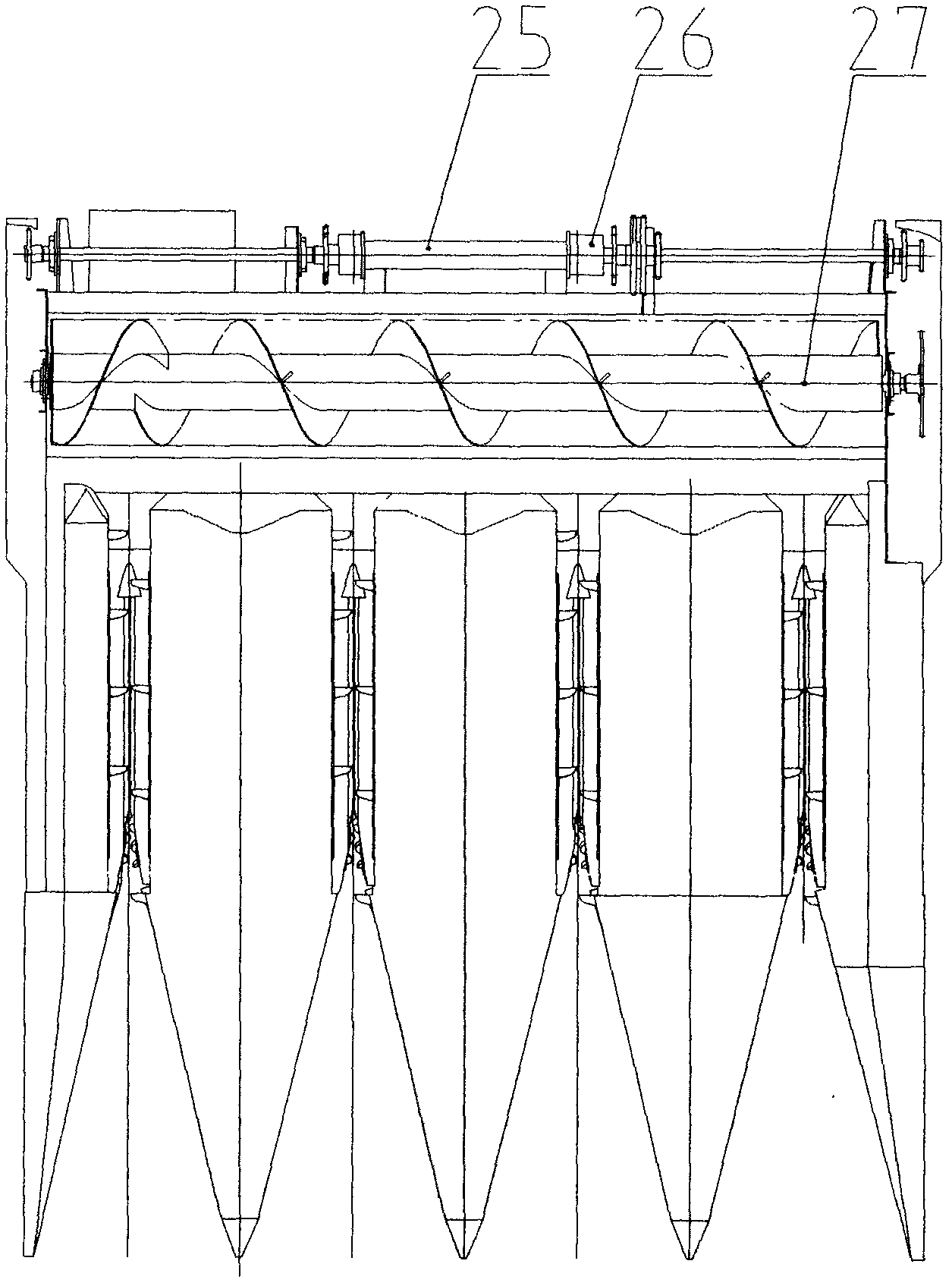

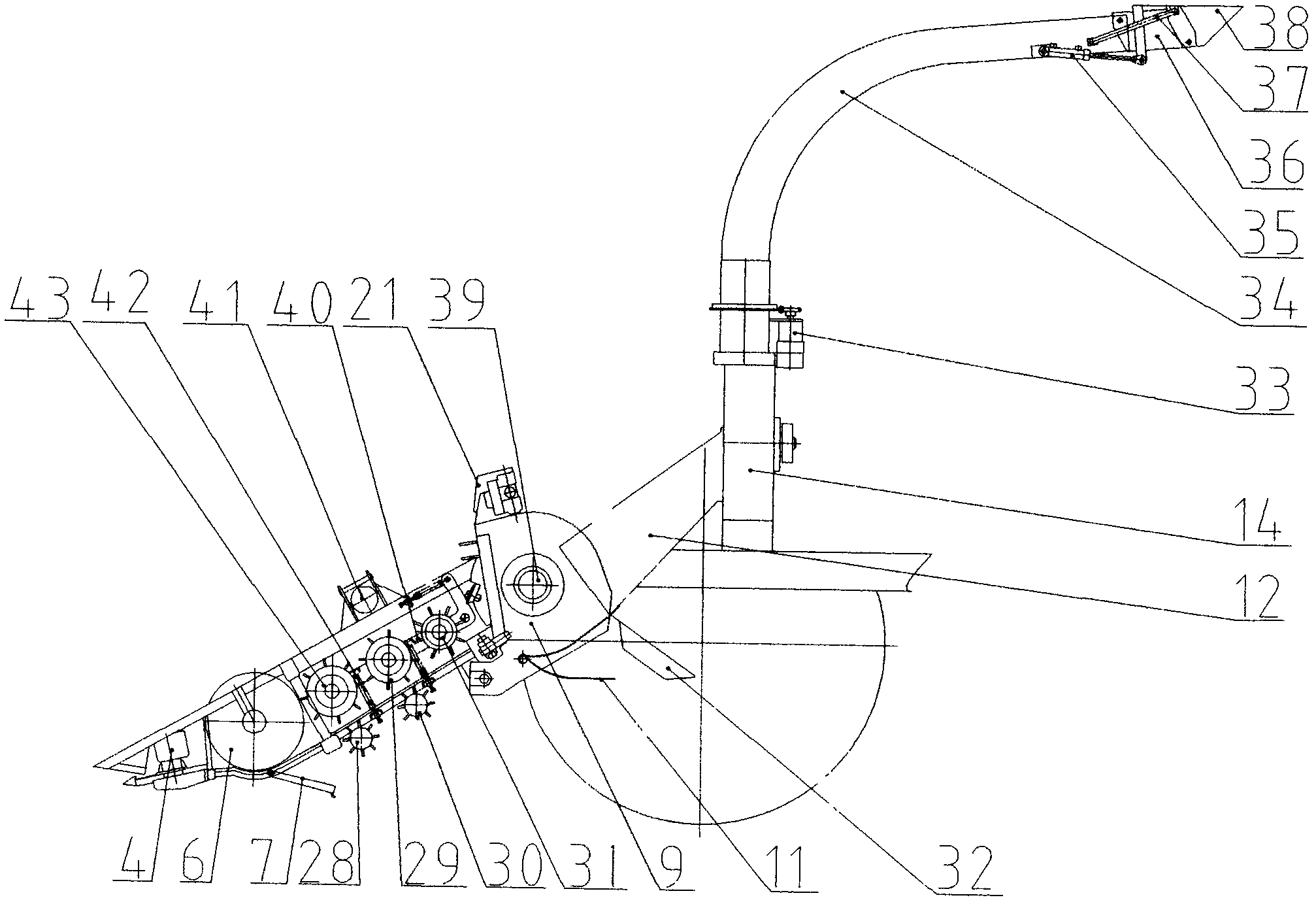

Corn combine harvester for both ears and stalks

InactiveCN102523827AStrong pulling powerPull the stem quicklyMowersThreshersEngineeringCombine harvester

The invention relates to agricultural machinery, in particular to a multifunctional corn combine harvester for both ears and stalks, which comprises a header including an upper layer and a lower layer. The upper header is an ear picking table, and the lower header is a stalk header. The corn combine harvester for both ears and stalks further comprises an ear harvesting collection box device, a stalk crushing device, a stalk thrower, a stalk baler, an intermediate drive device and a stalk stubble cleaning and returning device mounted on the rear lower portion of a frame and the like. Compared with the prior art, the corn combine harvester for both ears and stalks has the advantages that the functions of corn ear picking, husking and collection, stalk laying, stalk crushing and returning, stalk crushing for feed or industrial materials, and stalk stubble cleaning and returning are achieved on the corn combine harvester, the requirements of different users in different areas can be met, operation functions and cross-area operational adaptability of the corn combine harvester are improved greatly, comprehensive usability of corn stalks is improved greatly.

Owner:SHANDONG AGRI MACHINERY RES INST

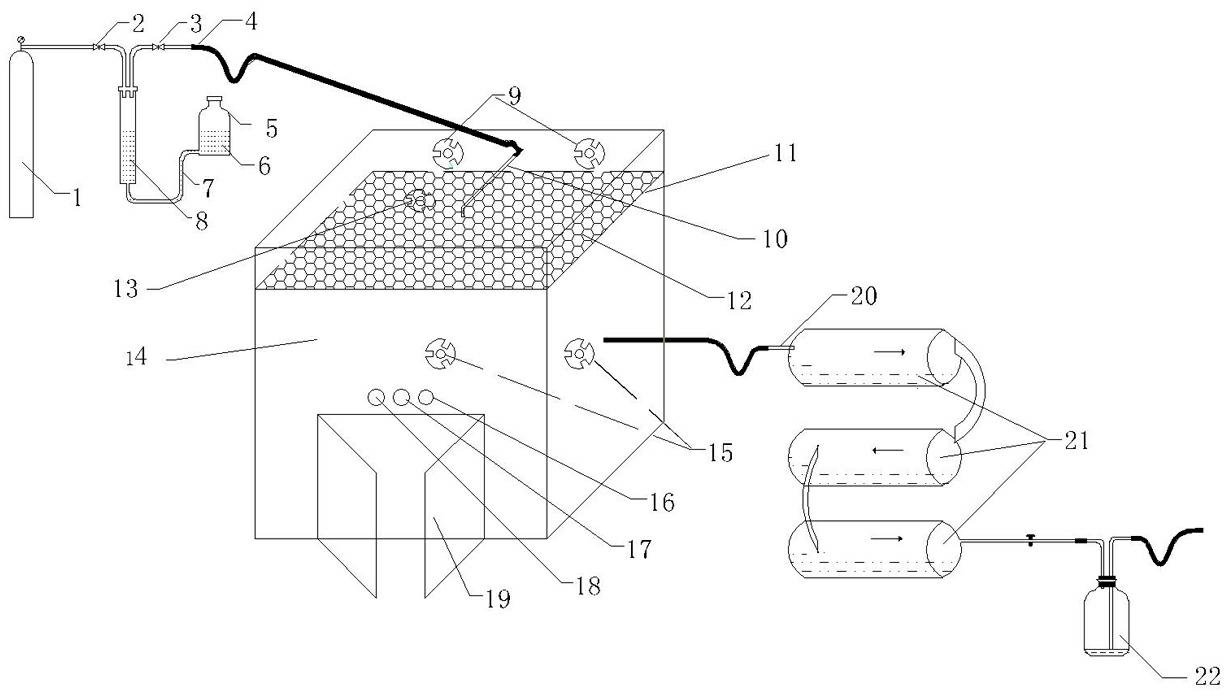

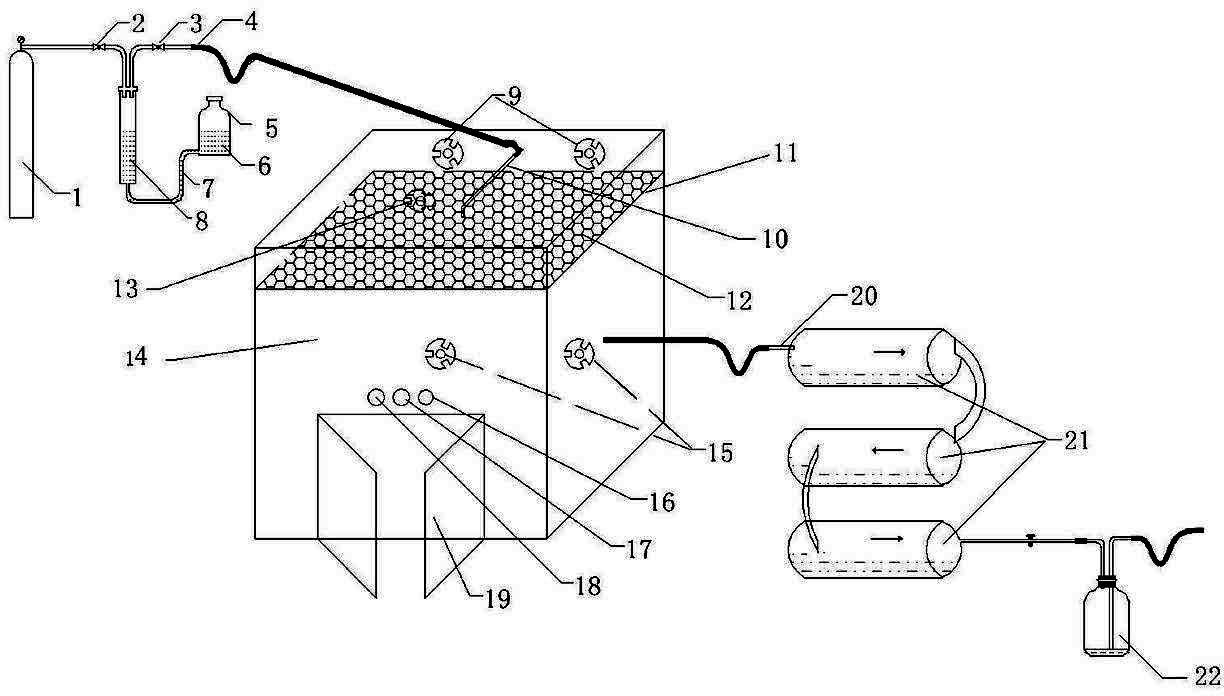

Simple dynamic sulfur dioxide gas toxicant exposure experimental device

InactiveCN102172336AAchieving decompression earlyQuantitative control in advancePreparing sample for investigationBiological testingToxic gasToxicant

The invention provides a simple dynamic sulfur dioxide gas toxicant exposure experimental device. The device consists of a gas decompression dosing device, a dynamic gas toxicant exposure cabinet / chamber and a waste gas absorption and discharge device, wherein the gas decompression dosing device has functions of directly decompressing and quantifying high-purity sulfur dioxide gas, thus omitting assembly of a special decompression gauge and a flow gauge and realizing quantitative control on toxic gas in advance; the dynamic gas exposure cabinet / chamber ensures that a simulated toxicant exposure environment is closer to a natural exposure environment and concentration of the toxic gas is uniform and accurate and can be regulated and controlled in real time; and the discharged gas meets thesafe discharge standard through the waste gas absorption and discharge device. The overall device has the advantages that operation method is simple, the manufacturing expense is low, and the continuous long-time toxicant exposure can be realized, thus solving the difficulty of continuous dynamic toxic gas exposure for a large number of animals, and realizing sulfur dioxide fumigation for variousfood and industrial materials and the like.

Owner:SHANXI AGRI UNIV

Sodium bismuth titanate base nonleaded piezoelectric ceramic

InactiveCN1541977AExcellent piezoelectric ferroelectric propertiesImprove performanceCeramicsPiezoelectric/electrostrictive/magnetostrictive devicesSodium titanateOxygen

The lead-free bismuth sodium titanate piezoelectric ceramic composition is one perovskite type environment consistency piezoelectric ceramic composition. The composition has the general expression of (1-x-y-z)Bi1-wNawTiO3+xBi0.5K0.5TiO3+yBaTiO3+zSrTiO3+aMalphaObeta, where x is 0-1, y 0-1, z 0-1, (x+y+z) 0-1, w 0.3-0.7; MalphaObeta is doping oxide(s) in the content an of 0-10 %; M is +1~+6 valent element capable of forming solid oxide, such as Na, K, Li, Al, Cu, etc. with alpha and beta being atom number. The piezoelectric ceramic composition has d33 up to 190 pC / N, kp up to 24.0 % and stable technological process, may be produced via traditional piezoelectric ceramic preparation process and industrial material, and is practical.

Owner:SICHUAN UNIV

High-strength low-absorption cement base plate slurry and method for making same

The present invention belongs to the building material technology field, in particular to relate to a cement base plate material with high-intension and low water-absorbing capacity and the corresponding preparation method. The mortar material uses a technical process of a self-compact active powder concrete to be cast into a plate with the thickness from several mm to more than 10mm. The present invention is made of cement, silicon ash, quartz powder, sand, water reducer, crack-proof agent and water according to the weight ratio. The present invention uses the new type water reducer and the rational weight ratio to decrease the water consumption and to make the flow expanding degree for the prepared cast mortar up to 255mm (flow degree of the mortar desk, sectioned cone circular mould, not being vibrated); and then the present invention can cast the plate with the required thickness directly without needing vacuum dehydration and pressure. The prepared plate is compact, with the water-absorbing capacity less than 2 percent that is far lower than that of each fibre strengthened cement plate in the prior market (about 20 percent). The folding strength can be adjusted by changing the content of the strengthened fibre, which can be up to 15-25MPa. The materials used in the present invention all are common industrial materials; so the present invention can simplify the manufacturing process, decrease the manufacturing cost greatly and enhance the product quality. The present invention can be widely used.

Owner:广东利盈投资集团有限公司

Method for preparing formic acid, methanol and methane by using metal hydro-thermal to reduce CO2

InactiveCN101265148ARealize resourcesReduce operating energy consumptionHydrocarbon from carbon oxidesOrganic compound preparationReaction temperaturePollution

Owner:TONGJI UNIV

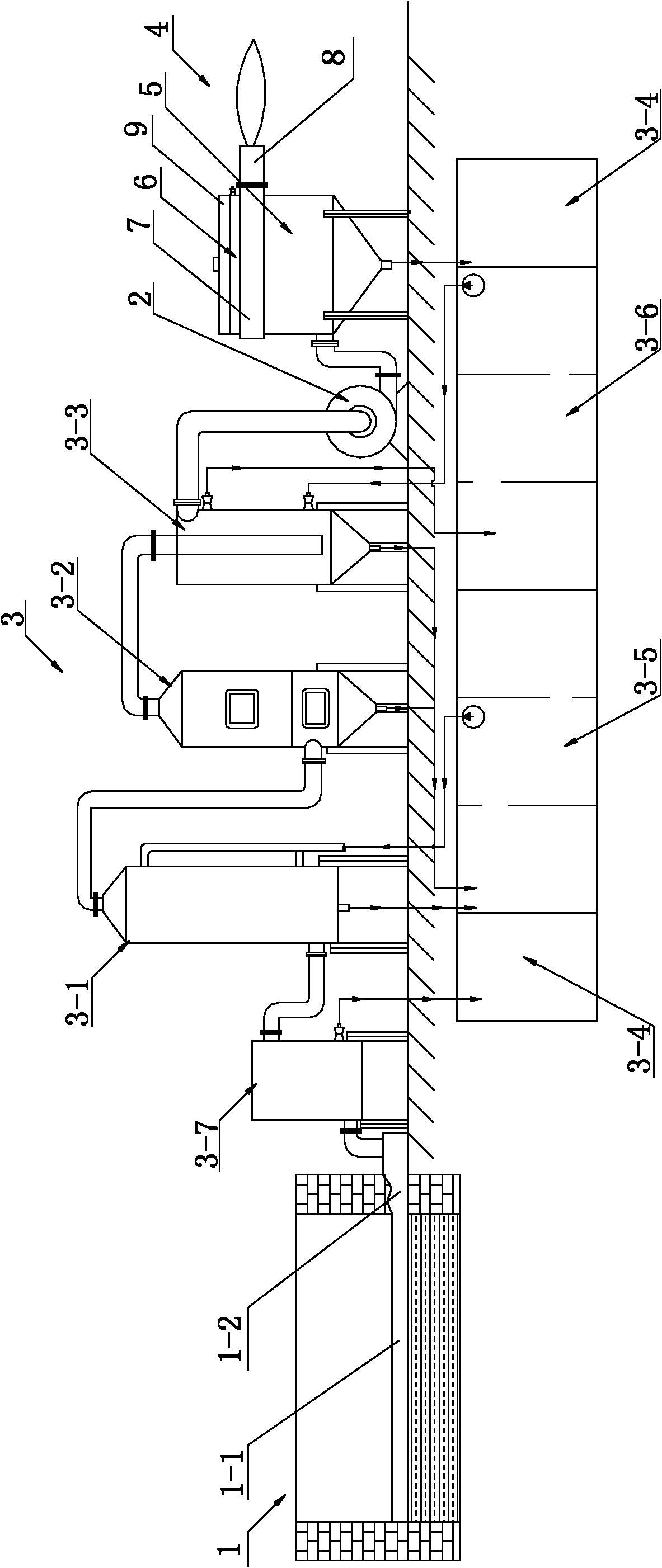

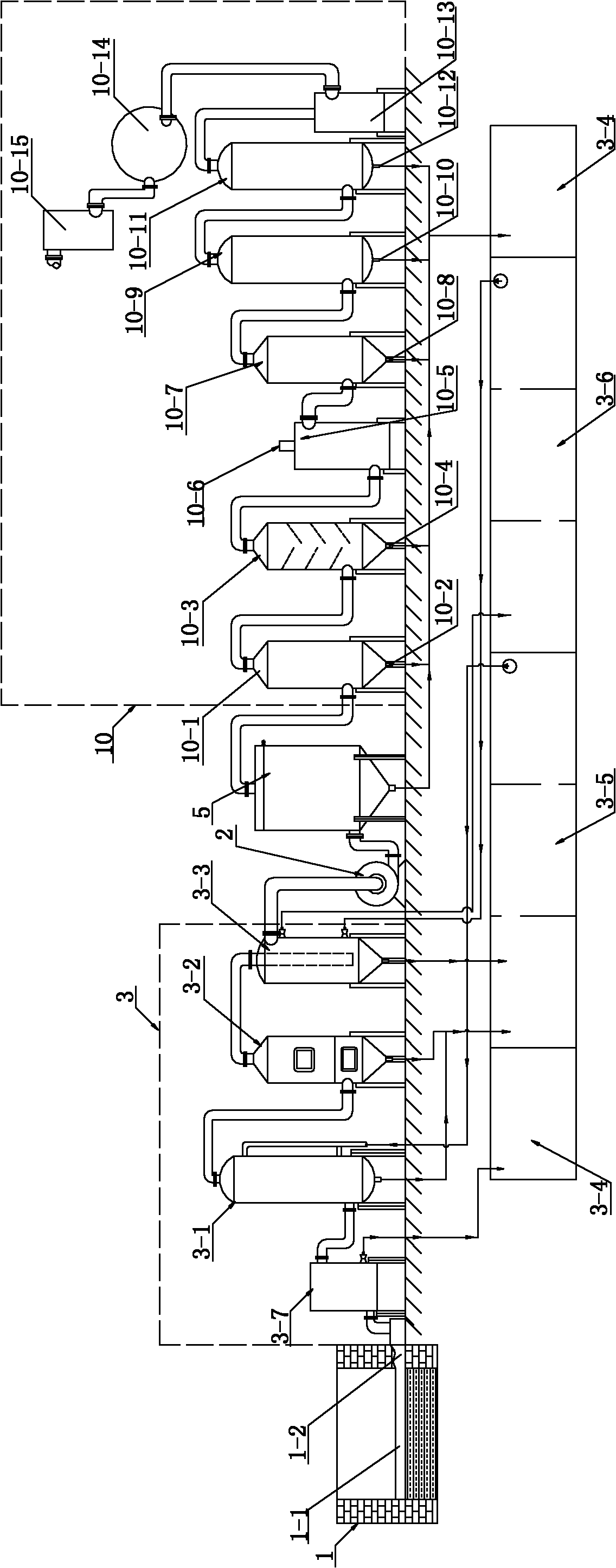

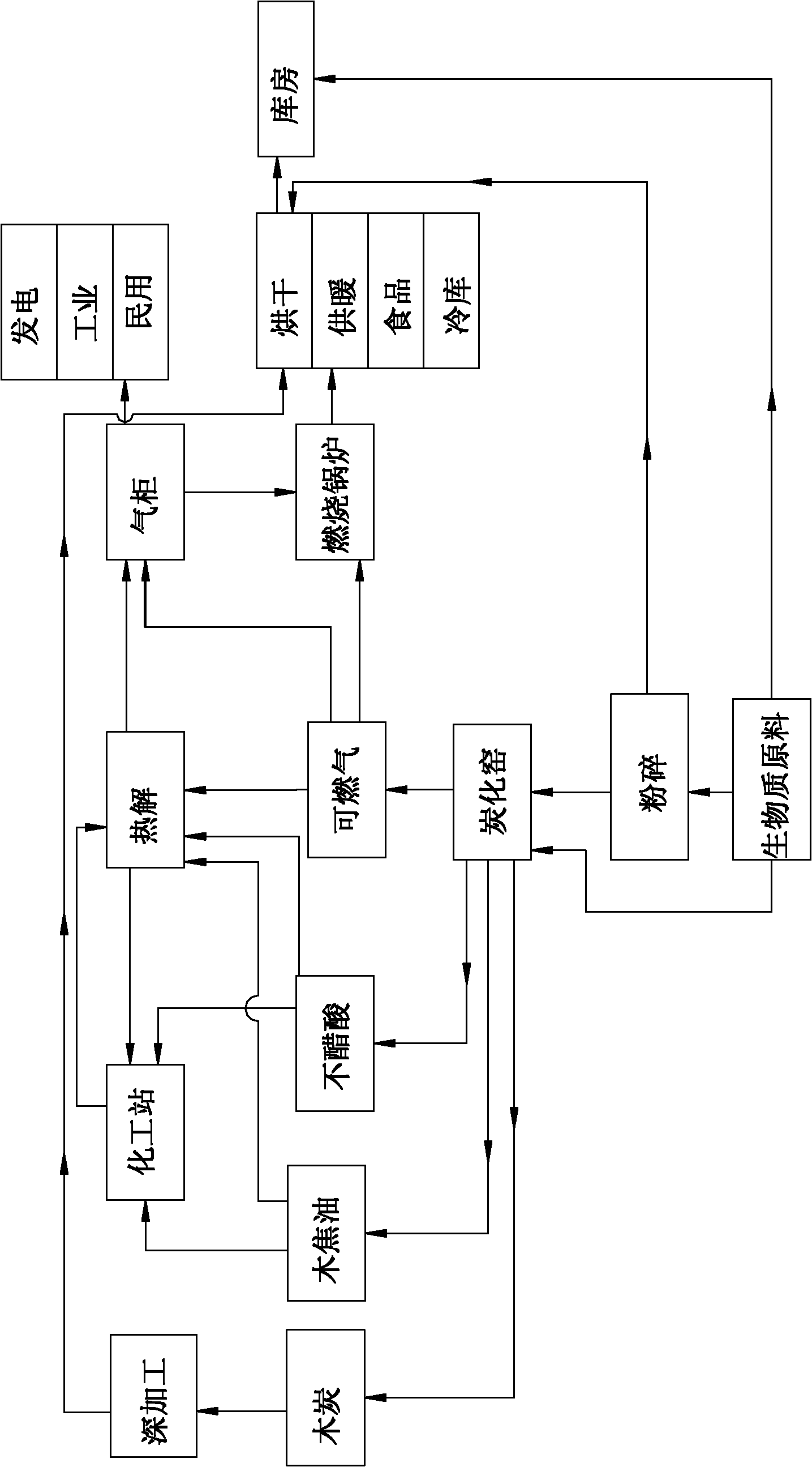

Co-production equipment for preparing charcoal, gas and oil by utilizing various biomass materials and preparation method of charcoal, gas and oil

InactiveCN102020999AShort processing cycleIncrease productionBiofuelsSpecial form destructive distillationGas phaseEngineering

The invention relates to co-production equipment for preparing charcoal, gas and oil by utilizing various biomass materials and a preparation method of the charcoal, gas and oil. The co-production equipment comprises a charring kiln, an induced draft fan, a purifying and recovering device and a tail gas treating device and is characterized in that the charring kiln is in a pool type structure andis connected with a filtering and purifying pool which is connected with the purifying and recovering device; and the purifying and recovering device is connected with the induced draft fan which is connected with a gas-phase separator connected with the tail gas treating device. The preparation method for preparing the charcoal, gas and oil by utilizing the biomass materials is as follows: putting the biomass materials into the charring kiln, covering a layer of crushed aggregates on the surface of the biomass materials, after igniting, controlling oxygen content by utilizing the duration ofstarting and stopping time of the induced draft fan, charring and adding the biomass materials simultaneously, and repeating the steps for 8-10 hours to finishing the charring of the biomass materials. By utilizing the invention, various materials can be mixed together for burning, dry distillation and charring, the situation of single utilization of the biomass materials is changed, and the utilization range of the biomass materials is expanded; in addition, compared with the traditional method, the production cycle is shortened, the yield and the quality are improved and other industrial materials also can be obtained.

Owner:天津市泽尔思生物碳宝科技有限公司 +1

Self-compacting active powder concrete and method for making same

InactiveCN101139190AImprove liquidityNo need to vibrateSolid waste managementPortland cementCompressive strength

The present invention belongs to the building material technology field, in particular to relate to a self-compact active powder concrete and the corresponding preparation method. The self-compact active powder concrete is made of cement, silicon ash, quartz powder, sand, water reducer and water according to the weight ratio. The cement is one of Portland cement or the common silicate; the water reducer is poly carboxylate water reducer. The present invention uses the new type water reducer to make the flow expanding degree for the active powder concrete up to 255mm; and moreover the age losing for the flow degree is much smaller; the flow degree within 2 hours is not changeable basically; so the present invention can enhance the convenience performance for the construction. The compression strength in 28d maintaining reaches up to 100Mpa; the compression strength in 90 DEG C and 3d water maintenance reaches up to 150Mpa. The materials used in the present invention all are the common industrial materials, so the present invention can decrease the manufacturing cost greatly and is convenient to be widely used. The present invention is of simple preparation method and wide application.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com