Co-production equipment for preparing charcoal, gas and oil by utilizing various biomass materials and preparation method of charcoal, gas and oil

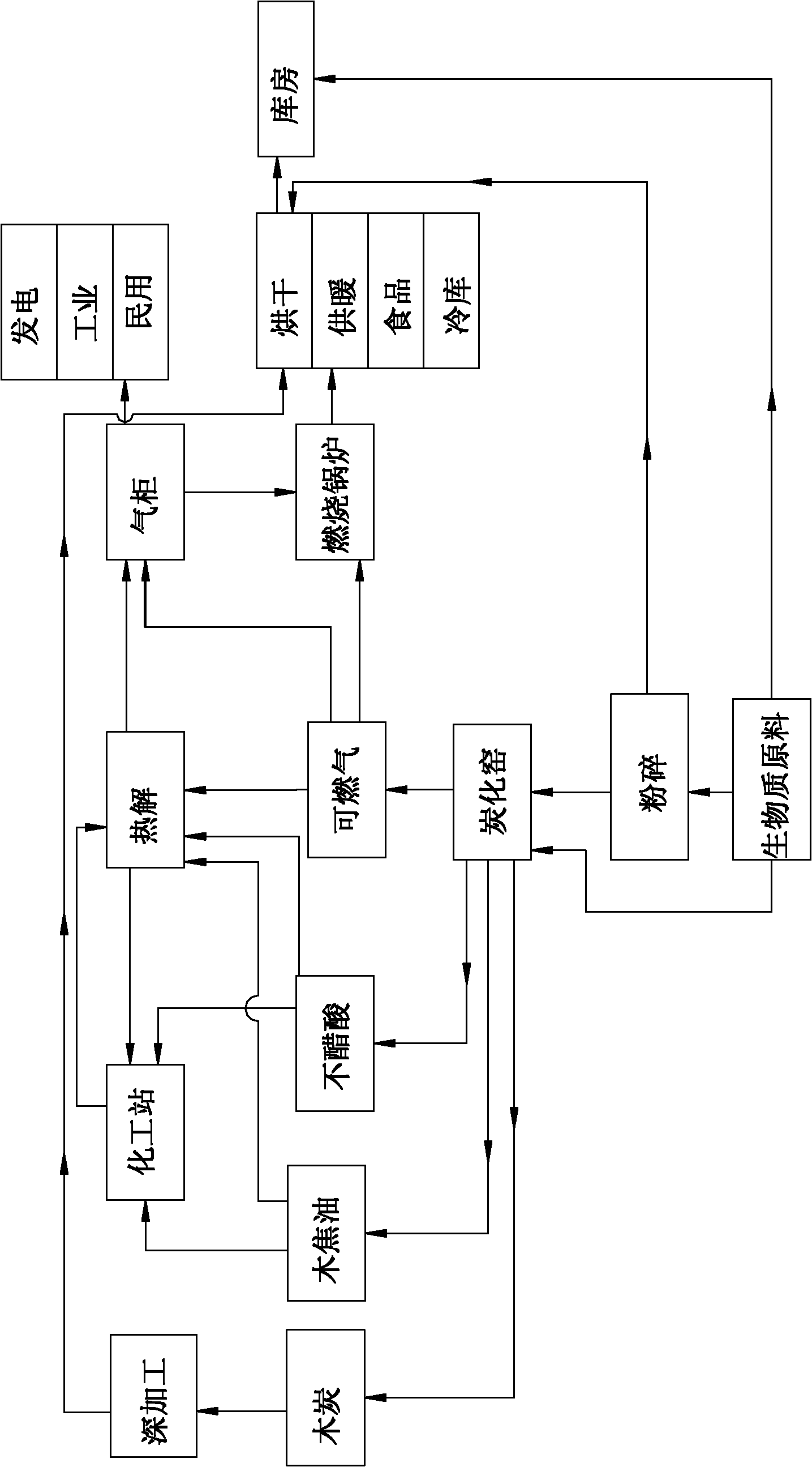

A technology of biomass raw materials and equipment, which is applied in the direction of biofuel, petroleum industry, special form of dry distillation, etc., can solve the problems of air pollution, loss of gasification function, and environmental pollution caused by smog, so as to promote the coordination of environmental protection and economy, and improve The effect of fully utilizing and shortening the process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

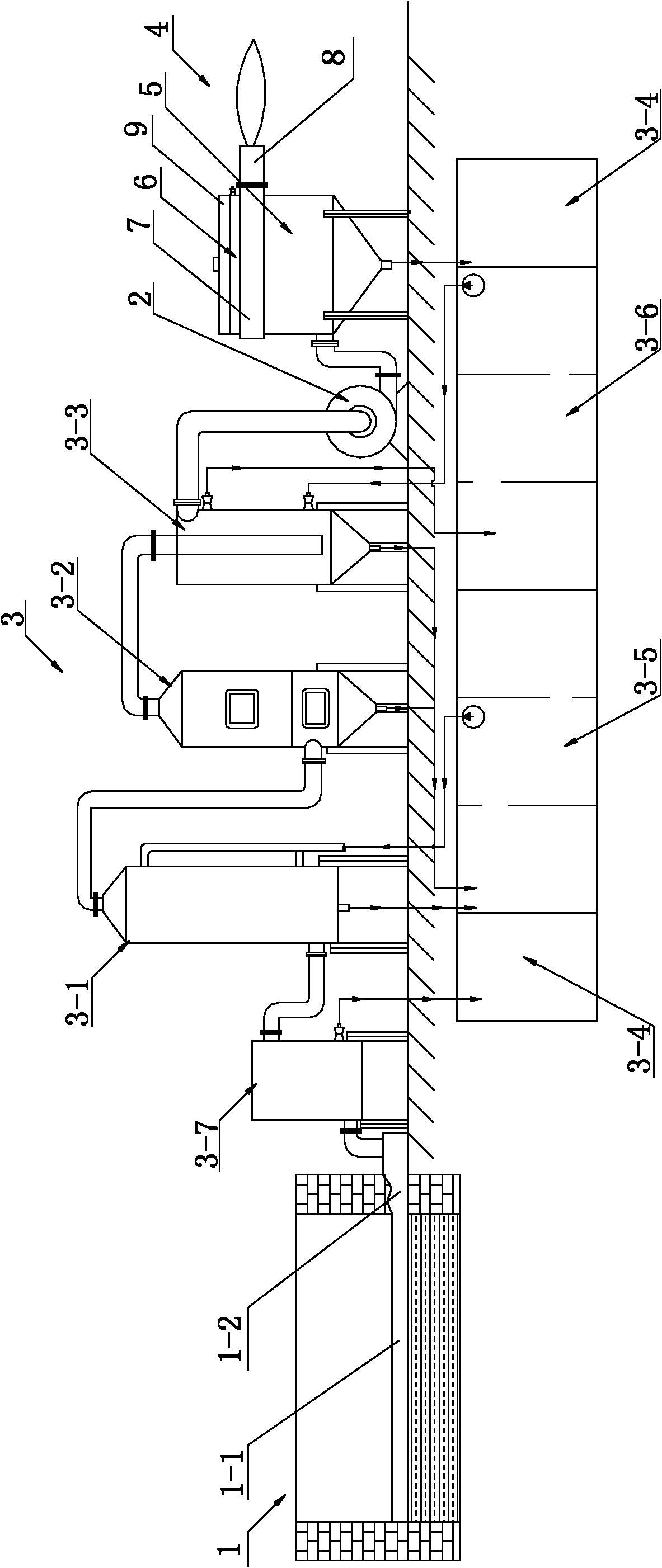

[0052] see figure 1 , a co-production equipment for preparing charcoal, gas and oil by using various biomass raw materials, including a carbonization kiln 1, an induced draft fan 2, a purification recovery device 3 and a tail gas treatment device 4, the carbonization kiln 1 adopts a pool structure, and the pool The bottom of the carbonization kiln is provided with an air duct 1-1, and the air duct 1-1 is connected to the air outlet 1-2 located on the side wall of the bottom of the carbonization kiln 1, and the air outlet 1-2 is connected to a larger filter located independently on the outside of the carbonization kiln. Particle filtration and purification pools 3-7, the filtration and purification pool 5 is filled with filtration and purification raw materials, this purification can be selected as raw materials with adsorption and filtration functions such as corn cob, coke, Pall ring slag, etc. according to the different biomass raw materials, and the filtration and purificati...

Embodiment 2

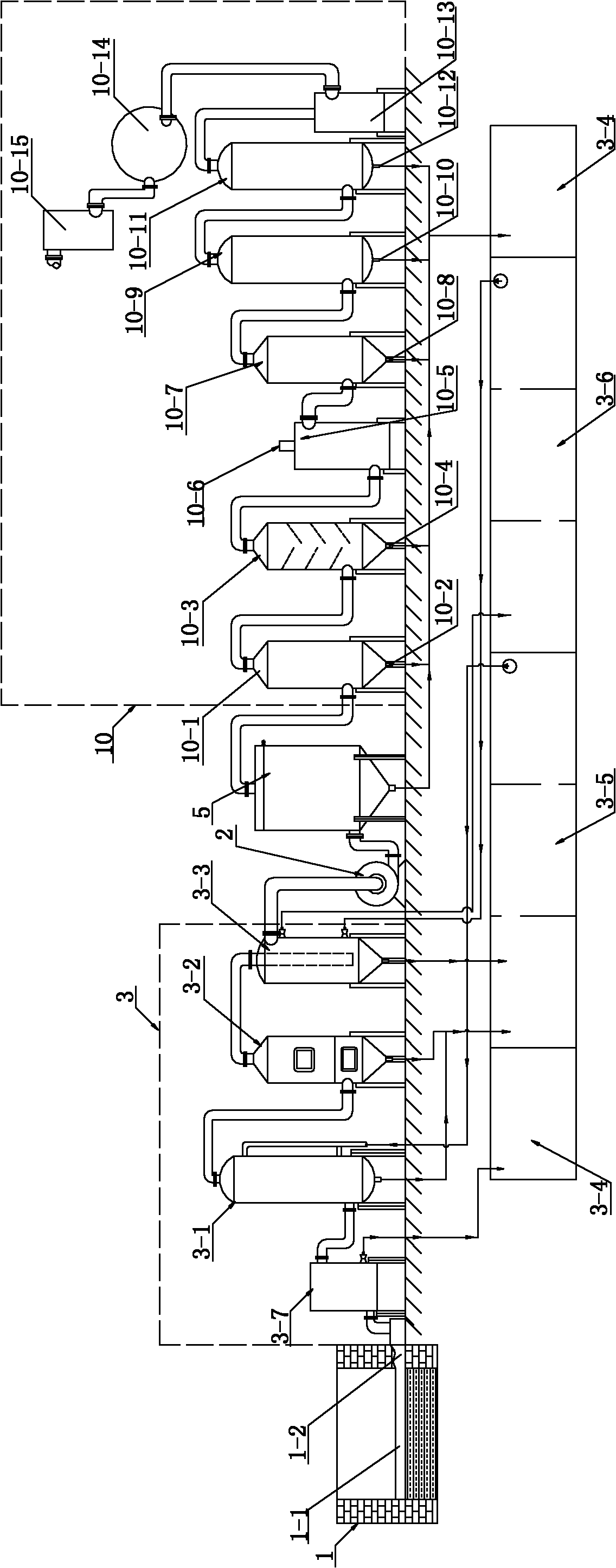

[0055] see figure 2 , Other structures in this example are the same as in Example 1, the difference is that the exhaust gas treatment device 4 adopts a purification recovery device 10, and the induced draft fan adopts a Roots blower in this exhaust gas treatment method. The purification and recovery device 10 mainly includes a gas-liquid filter 10-1 connected to the gas-phase separator 5. The gas-liquid filter 10-1 is provided with a filter cavity divided by a grate plate, and the filter cavity is filled with coke. The gas-liquid filter 10-1 The bottom of the bottom is provided with collector 10-2, and collector connects wood tar recovery tank 3-4; The gas outlet of described gas-liquid filter 10-1 is connected gas-liquid separator 10-3 by pipeline, and described gas-liquid separator 10-3 The two sides of the inner wall are crossed with cover plates, and the bottom of the gas-liquid separator is provided with a collector 10-4, and the collector 10-4 is connected to the wood a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com