Silicon carbide fiber solid fabric for in-situ growing carbon nano tubes, composite material and preparation method thereof

A silicon carbide fiber, carbon nanotube technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of easy delamination, low interlaminar shear strength, achieve good bonding, solve the problems of dispersion and orientation, Content controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

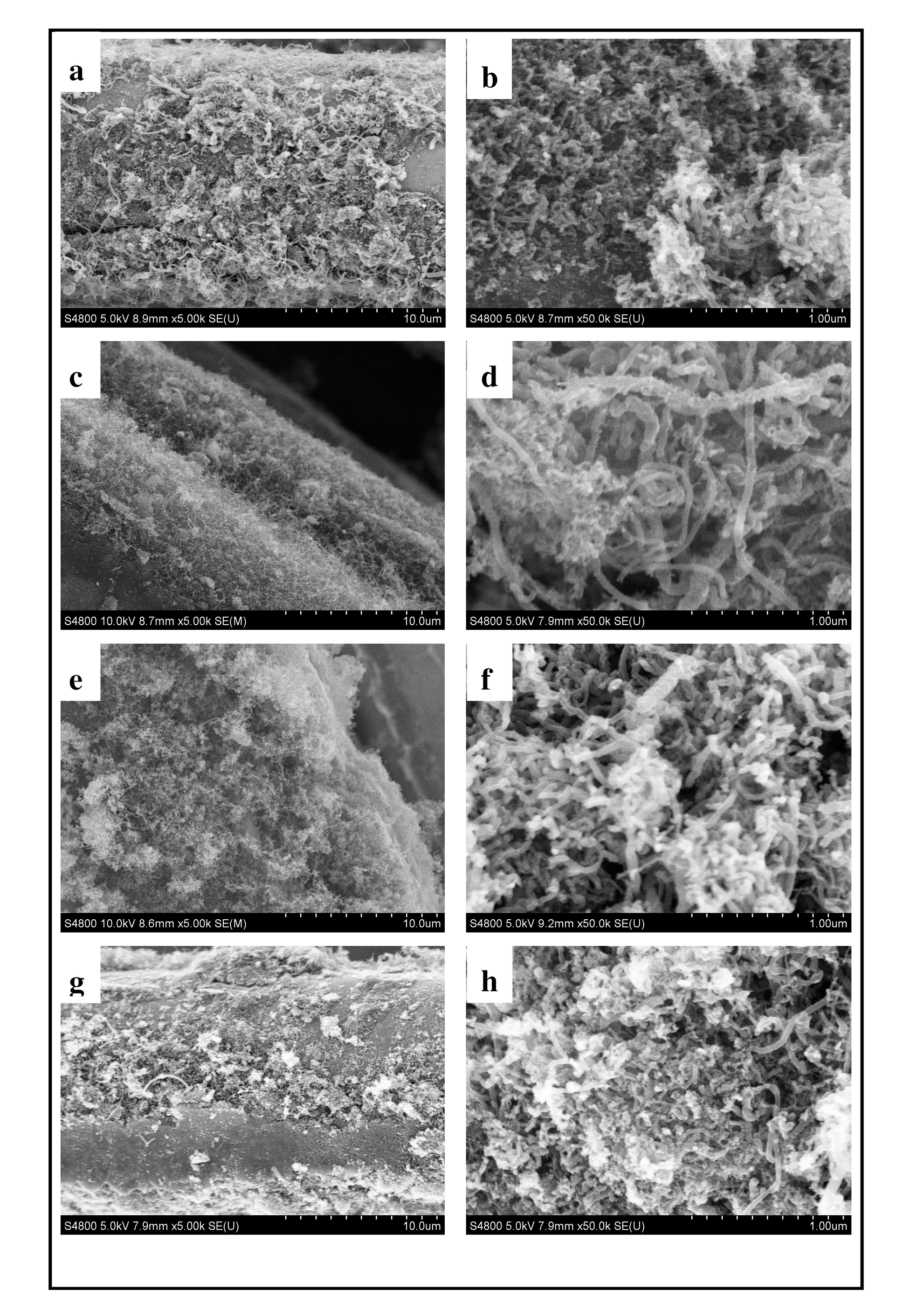

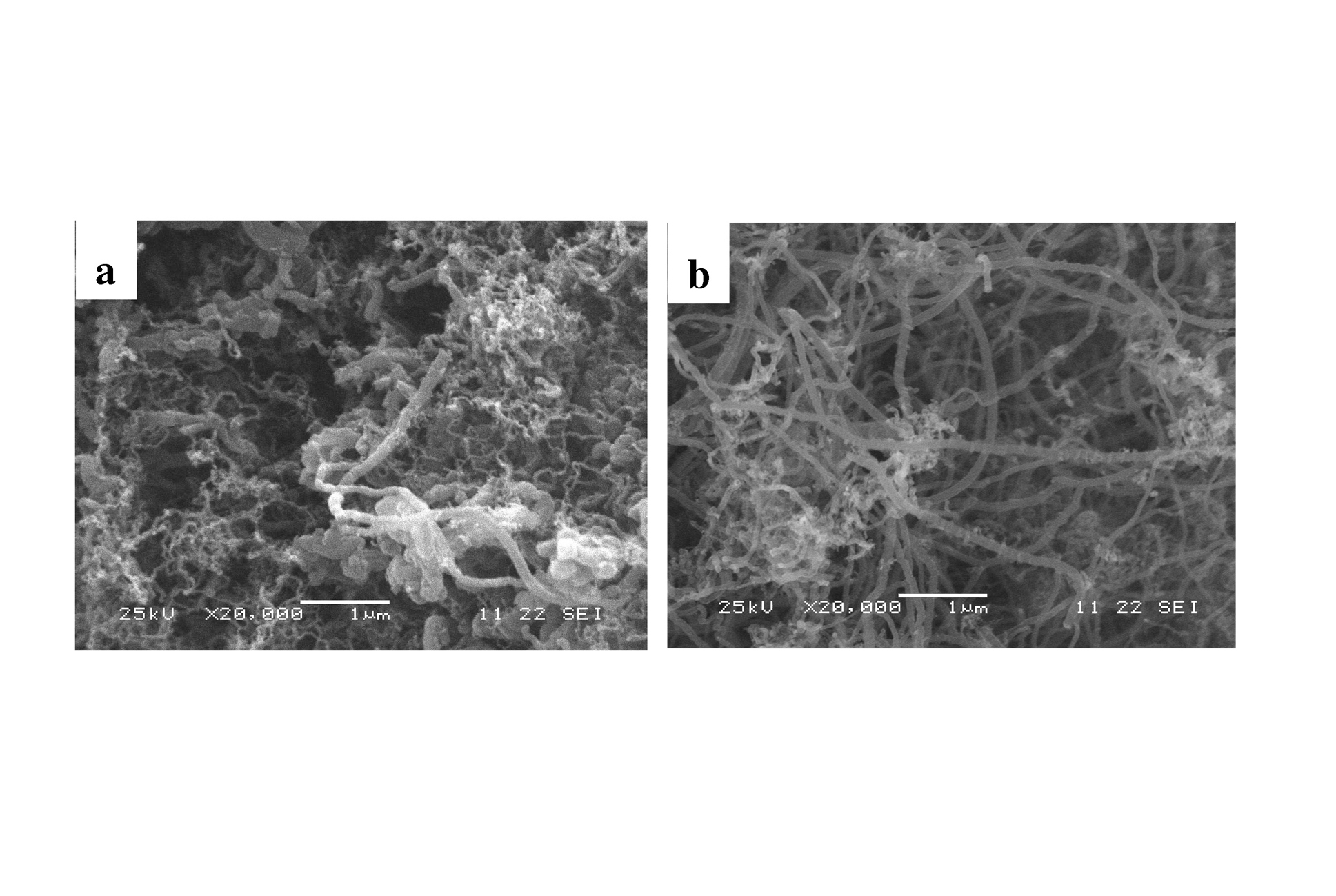

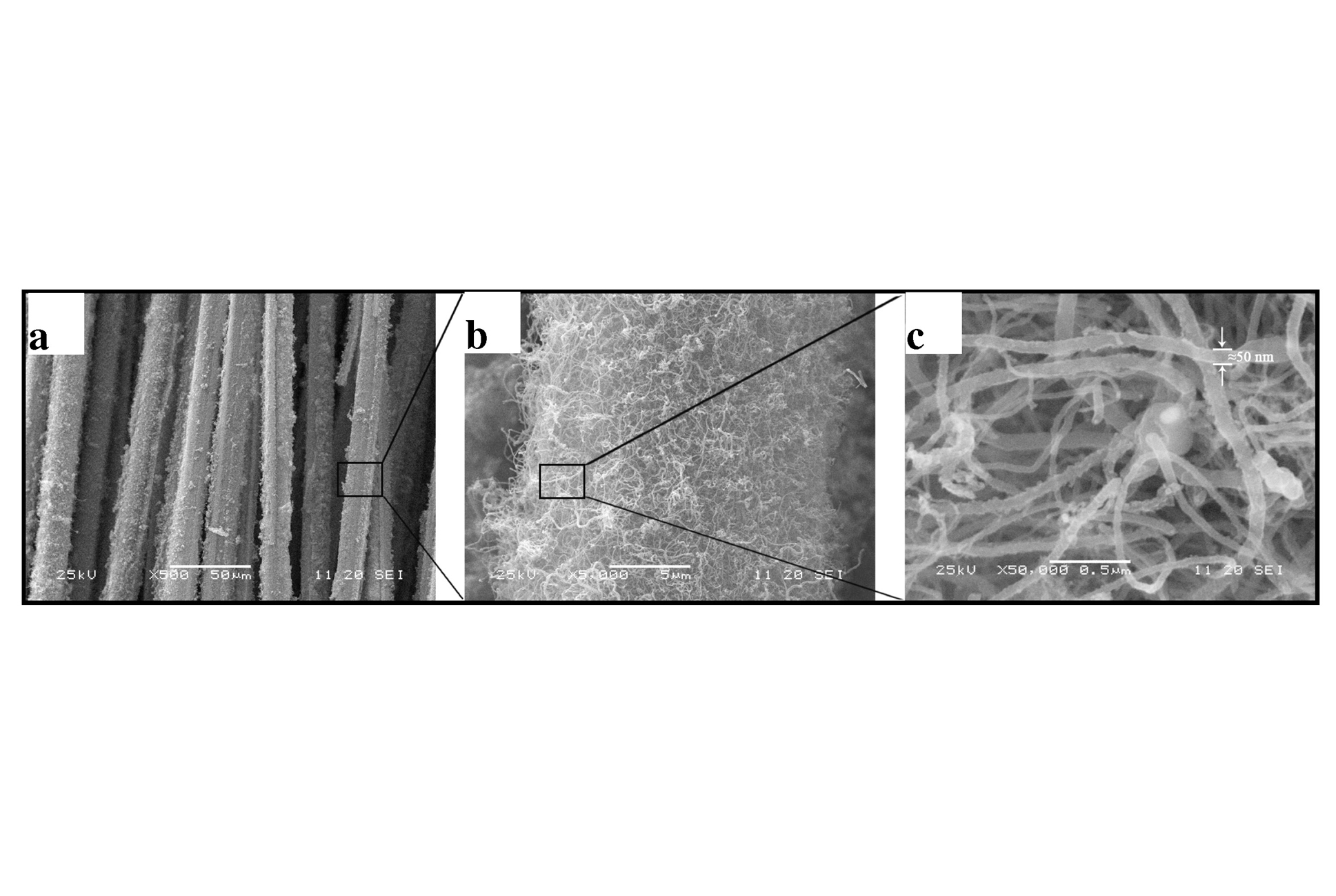

[0025] Such as figure 1 The silicon carbide fiber three-dimensional fabric with carbon nanotubes grown in situ of the present invention is shown, the silicon carbide fiber three-dimensional fabric is mainly woven from silicon carbide fibers, and the carbon nanotubes grown in situ are evenly distributed on the surface of the silicon carbide fibers , the carbon nanotubes are intertwined into a network structure. In this embodiment, the loading amount of carbon nanotubes is 4.1%-6.5%, the average length of carbon nanotubes is 3.8 μm, and the average diameter of carbon nanotubes is 50 nm-60 nm.

[0026]The silicon carbide fiber three-dimensional fabric with carbon nanotubes grown in situ in this embodiment is prepared by the following steps:

[0027] (1) Pretreatment of silicon carbide fiber three-dimensional fabric: put the prefabricated three-dimensional four-way three-dimensional fabric of domestic KD-1 silicon carbide fiber in a muffle furnace, heat it in the air to 400°C, ke...

Embodiment 2

[0032] like figure 2 The silicon carbide fiber three-dimensional fabric with carbon nanotubes grown in situ of the present invention is shown, the silicon carbide fiber three-dimensional fabric is mainly woven from silicon carbide fibers, and the carbon nanotubes grown in situ are evenly distributed on the surface of the silicon carbide fibers , the carbon nanotubes are intertwined into a network structure. In this embodiment, the loading amount of carbon nanotubes is 4.94%, the average length of carbon nanotubes is 4 μm, and the average diameter of carbon nanotubes is 50 nm to 60 nm.

[0033] The silicon carbide fiber three-dimensional fabric with carbon nanotubes grown in situ in this embodiment is prepared by the following steps:

[0034] (1) Pretreatment of silicon carbide fiber three-dimensional fabric: put the prefabricated three-dimensional four-way three-dimensional fabric of domestic KD-1 silicon carbide fiber in a muffle furnace, heat it in the air to 400°C, keep i...

Embodiment 3

[0039] A silicon carbide fiber three-dimensional fabric with carbon nanotubes grown in situ according to the present invention, the silicon carbide fiber three-dimensional fabric is mainly woven from silicon carbide fibers, and the carbon nanotubes grown in situ are evenly distributed on the surface of the silicon carbide fibers, The carbon nanotubes are intertwined into a network structure. In this embodiment, the loading amount of carbon nanotubes is 10.8%, the average length of carbon nanotubes is 4.2 μm, and the average diameter of carbon nanotubes is 50 nm to 60 nm.

[0040] The silicon carbide fiber three-dimensional fabric with carbon nanotubes grown in situ in this embodiment is prepared by the following steps:

[0041] (1) Pretreatment of silicon carbide fiber three-dimensional fabric: put the prefabricated three-dimensional four-way three-dimensional fabric of domestic KD-1 silicon carbide fiber in a muffle furnace, heat it in the air to 400°C, keep it warm for 1 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com