Ferromanganese modified straw active carbon adsorbent for As (III) adsorption, and applications thereof

A straw activated carbon and adsorbent technology, which is applied in the direction of adsorption of water/sewage treatment, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of unusable arsenic-containing waste residue, difficult treatment, secondary pollution, etc., and achieve The effect of rich raw materials, simple operation method and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

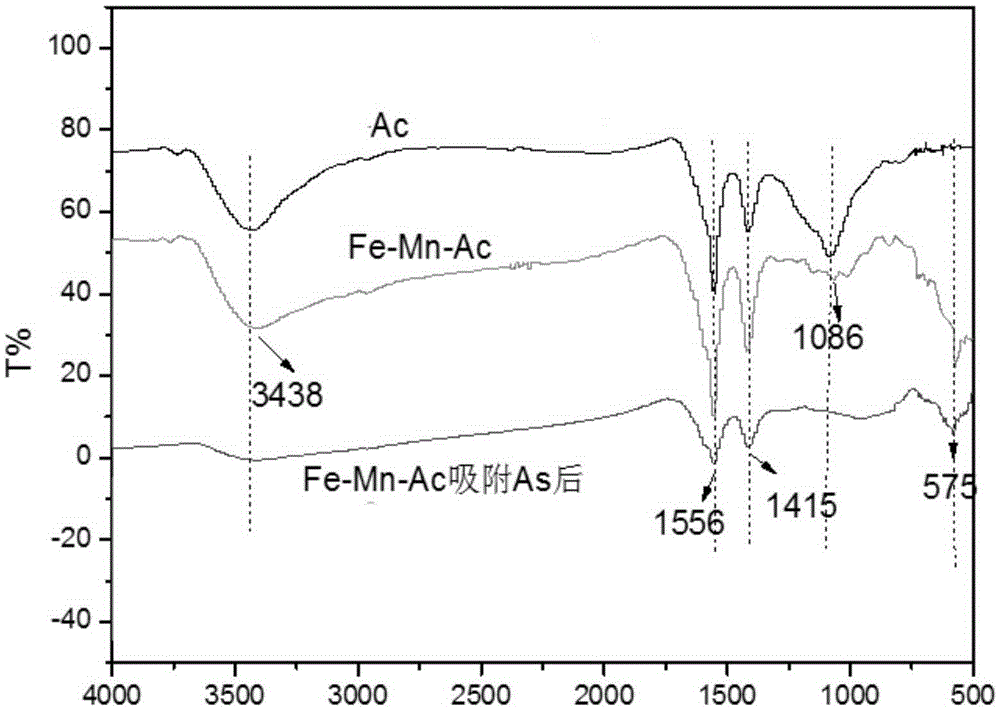

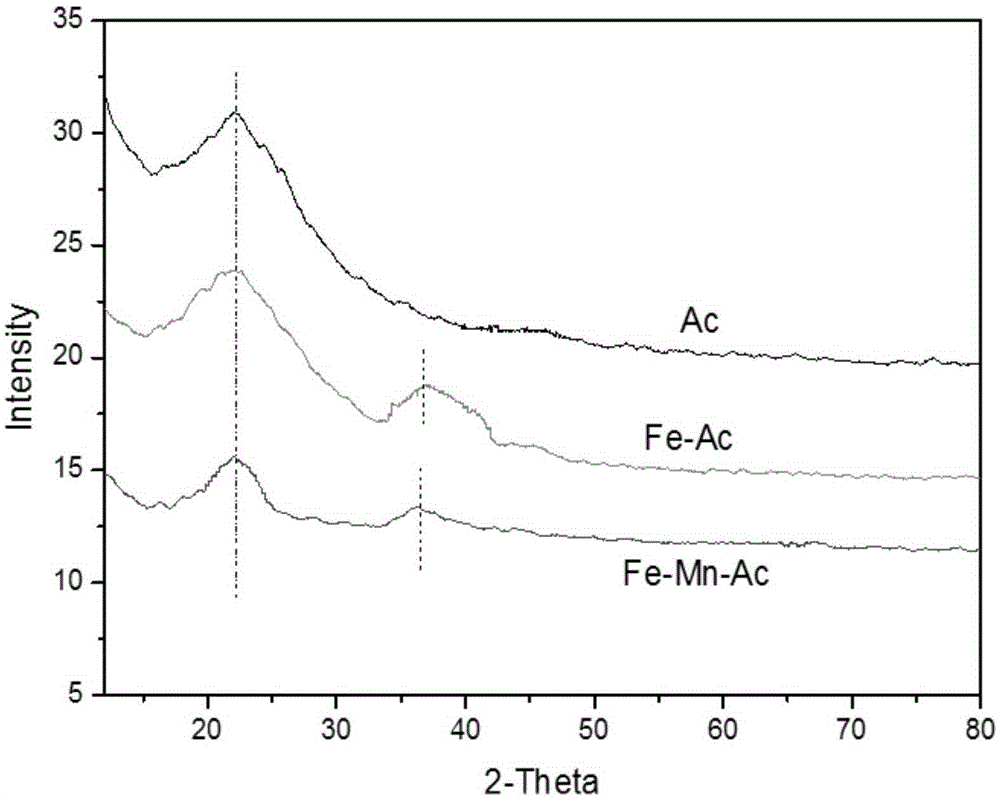

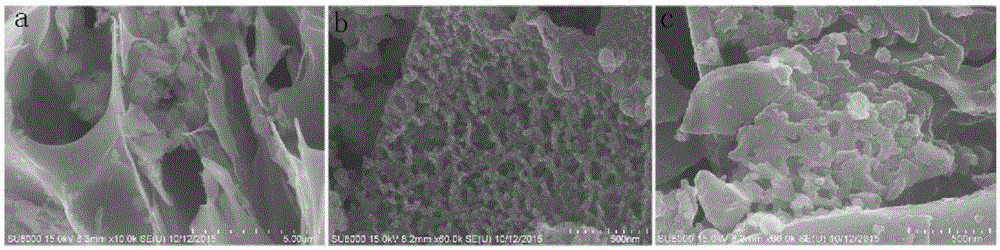

[0030] Example 1 A kind of straw activated carbon adsorbent (Fe-Mn-Ac) modified by iron and manganese for As(Ⅲ) adsorption

[0031] (1) The preparation method is as follows

[0032] 1) Preparation of straw activated carbon (Ac): Grind the straw into powder, put it into a tube furnace, raise the temperature to 350 °C at a rate of 10 °C / min, keep it in the tube furnace for 2 hours, cool down to room temperature, and take out , add 0.5mol·L according to the ratio of solid to liquid 1:3 -1 KOH, stirred for 30min, then dried in a vacuum drying oven at 80°C for 2.5h; then put it into a tube furnace, heated to 800°C at a speed of 15°C / min, in the tube furnace Keep it for 1h, cool down to room temperature, take it out, add 30ml of 5% HCl and stir for 30min, wash with water until neutral, filter, and dry at 50°C in a drying oven to obtain straw activated carbon (Ac).

[0033] 2) Acidification of straw activated carbon: add 2 g of straw activated carbon (Ac) to 100 mL of 68% nitric ac...

Embodiment 2

[0043] The comparison of embodiment 2 Fe-Mn-Ac adsorbent and Fe-Ac adsorbent to As(Ⅲ) adsorption performance

[0044] (1) React 10 mg of Fe-Mn-Ac adsorbent with 10 mL of 20 ppm As(Ⅲ) solution at different pH (pH=3, 4, 6, 8, 9, 10, 11, 12); Shake at 180r / min at 30°C for 24h.

[0045] (2) Comparative test

[0046] 10 mg of adsorbent Fe-Ac was reacted with 10 mL of 20 ppm As(III) solution at different pH (pH=3, 4, 6, 8, 9, 10, 11, 12). Shake it at 180r / min in a shaking box at 30°C for 24h.

[0047] The adsorption rate was measured as Figure 4 ,Depend on Figure 4 It can be seen that the comparison of Fe-Mn-Ac adsorbent with Fe-Ac adsorbent shows that Fe-Mn-Ac adsorbent has a maximum adsorption rate of 85% for As(Ⅲ) at pH=3, while Fe- When Ac is at pH=9, the maximum adsorption rate of As(Ⅲ) is only 57%. Therefore, Fe-Mn-Ac adsorbent can be used to extract As(Ⅲ) in As(Ⅲ) waste liquid under the condition of pH=3.

Embodiment 3

[0048] Example 3 Application of iron-manganese modified activated carbon adsorbent to the separation and enrichment of As(Ⅲ)

[0049] Take 200ppm As(Ⅲ) solution, adjust the pH of the solution to pH=3, add 200 mg of Fe-Mn-Ac adsorbent to 200 mL of As(Ⅲ) solution, shake for 24 hours, and remove As(Ⅲ) in the solution Adsorption, after filtration, the adsorbent loaded with As(Ⅲ) was eluted with 0.05% NaOH solution, and the calculated recovery rate was 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com