Patents

Literature

553 results about "Acidification - Treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon dioxide aerogel material and preparation method thereof

The invention relates to a silicon dioxide aerogel material and a preparation method thereof. The method comprises the following steps: by using water glass as silicon source, adding an acid-containing organic solvent free of chlorine ions and fluorine ions to generate a precipitate of sodium ions, potassium ions and other metal salt ions, filtering to remove the precipitate to obtain high-purity silica sol, carrying out a sol-gel process, aging, acidifying, modifying, and drying to obtain the silicon dioxide aerogel material. The acidification before modification enhances the surface reaction activity of the silicon gel, thereby obviously enhancing the modification effect and efficiency. The method has the advantages of low cost and simple and efficient technique, is beneficial to mass high-efficiency production, is free of chlorine ions and fluorine ions in the whole technical process, and enhances the equipment operation safety and reliability; and the product can be used for heat preservation and thermal insulation of nuclear power and liquefied natural gas equipment and pipelines with higher requirement for corrosion resistance, and can also be used for thermal insulation in the field of aerospace, petrochemical engineering, track transportation, ships, automobiles, construction and the like.

Owner:浙江圣润纳米科技有限公司

Method for preparing carbon nanofibers

InactiveCN101718011AIncreased interlaminar shear strengthImprove efficiencyCarbon fibresFibre chemical featuresIonElectrospinning

The invention relates to a method for preparing carbon nanofibers. The method comprises the following steps: taking a polyacrylonitrile solution or an acrylonitrile copolymer solution or melt as materials, preparing nanofibers by the electrostatic spinning or the airflow spray method, and then preparing the nanofibers into carbon nanofibers. The method is characterized in that the carbon nanofibers are acidified or electrochemically treated into carbon nanofibers containing oxygen or nitrogen functional groups. The acidifying process comprises the following steps of: placing the carbon nanofibers in a nitric acid solution with the mass concentration of 30-68% and treating for 1-10 hours at 10-50 DEG C; rinsing with deionized water and drying; thus, obtaining the carbon nanofibers containing carboxyl functional groups. The electrochemical treating process comprises the steps of: placing the carbon nanofibers in a nitric acid or phosphoric acid solution with the mass percentage concentration of 1-20% at 10-50 DEG C, or in ammonium carbonate or ammonium hydrogen carbonate, and treating with the apparent current density of 10-100A / m2 for 1-120 minutes to obtain the carbon nanofibers containing carboxyl or amino functional groups.

Owner:TIANJIN POLYTECHNIC UNIV

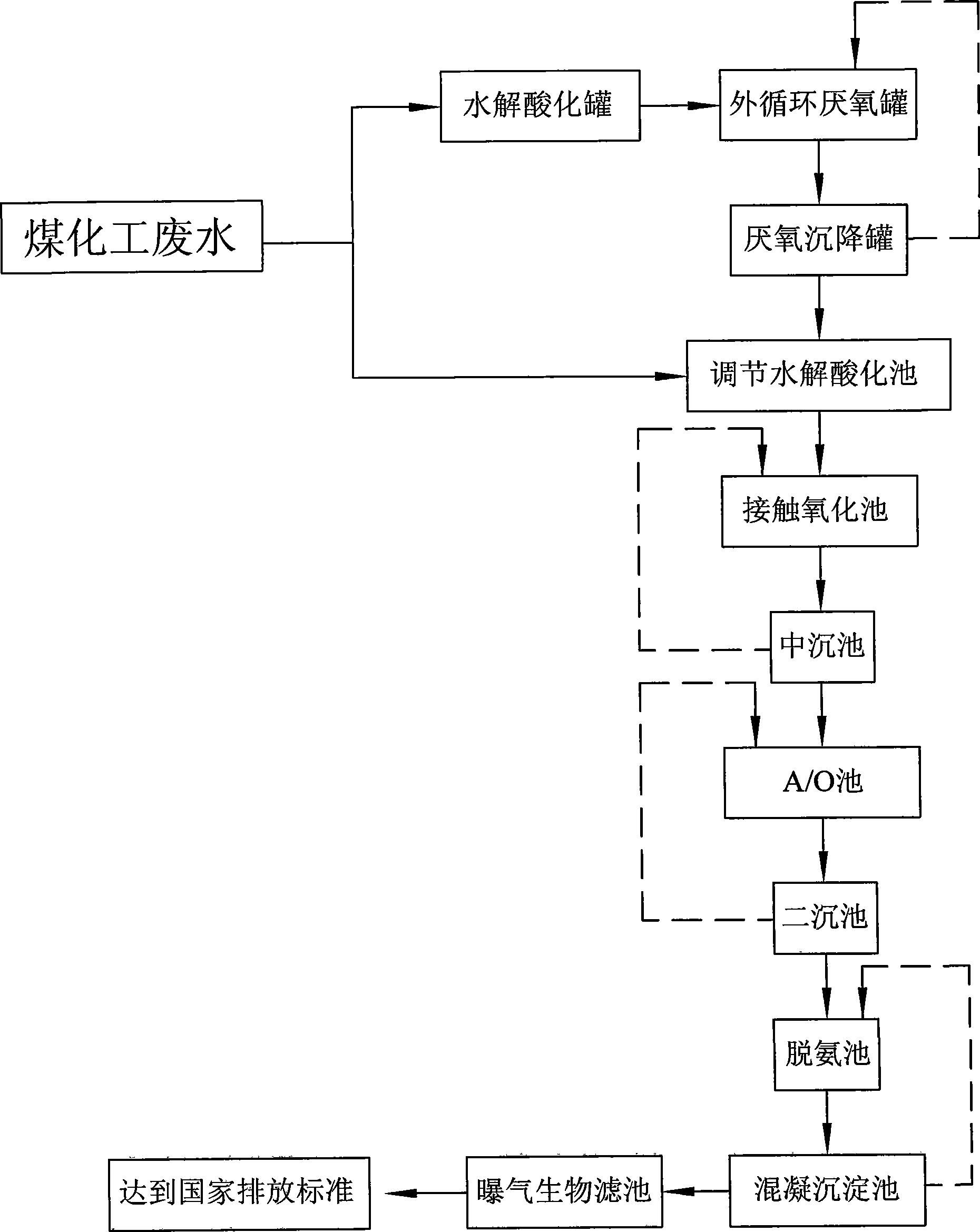

Coal chemical industry wastewater treating method

InactiveCN101503267AEasy to handleImprove the water effectWater contaminantsTreatment with aerobic and anaerobic processesOperational costsBiological filter

The invention relates to a coal chemical wastewater treatment method, in particular to a chemical wastewater treatment method. The invention aims to solve the problems of the chemical wastewater treatment method such as bad outlet water quality and high operational cost. The method comprises the following steps: pretreating coal chemical wastewater to be treated; then carrying out hydrolytic acidification treatment, external circulating anaerobic treatment, anaerobic sedimentation treatment, adjusting hydrolytic acidification treatment, contact oxidation treatment, sedimentation treatment, A / O treatment, sedimentation treatment, deamination treatment, coagulating sedimentation treatment and aeration biological filter tank treatment, wherein the temperature in an external circulating anaerobic tank is controlled within the scope of 32 to 35 DEG C; the hydraulic detention time is 24 to 36 h; the sludge concentration is controlled between 50 and 100 g / L; the volume load is 5 to 10 kg COD / m.d ; and the pH value is controlled between 7.0 and 7.5. The invention has the advantages of flexible operation, impact load resistance, low operating cost and good treatment effect; after the coal chemical wastewater is treated by the treatment method, the outlet water quality completely can achieve the wastewater comprehensive discharge standard regulated by the State.

Owner:HARBIN INST OF TECH

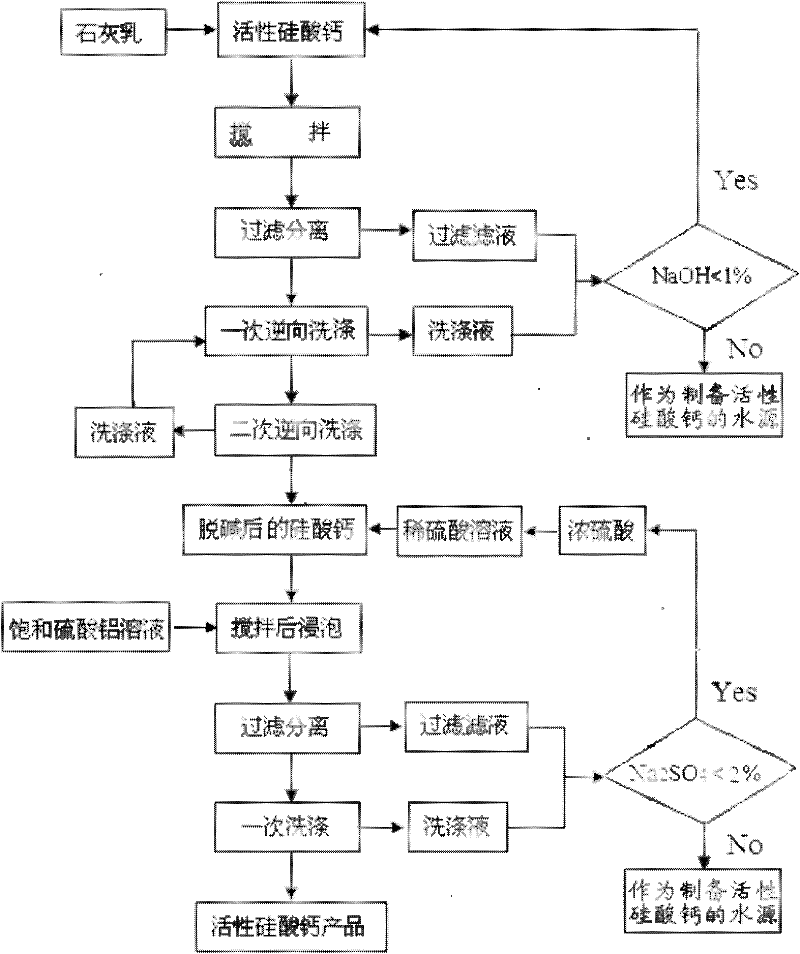

Method for lowering pH value of active calcium silicate

InactiveCN102190309AIncrease profitComply with environmental policyAlkaline-earth metal silicatesCalcium silicateDealkalization

The invention discloses a method for lowering the pH value of active calcium silicate. The method comprises the following steps of: adding lime milk to high-alkality active calcium silicate for dealkalization when the Na2O content (weight percent) in the high-alkality active calcium silicate is greater than or equal to 1%, and then carrying out acidification treatment; and directly carrying out acidification treatment on high-alkality active calcium silicate when the Na2O content (weight percent) in the high-alkality active calcium silicate is smaller than 1%. The invention overcomes the defects of the prior art, and realizes the advantages of wide raw material sources, low price, simple operation steps and low energy consumption. The pH value of high-alkality active calcium silicate treated by the method can be lowered to 8-10, thereby meeting the requirements on filler performance in the industries of plastic, rubber, paper making, paint and the like, and high-alkality active calcium silicate treated by the method can be used as a heat-insulation material.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

Method for preparing functional carbon nano-tube and application thereof

InactiveCN101104668AGood dispersionImprove performancePigment treatment with macromolecular organic compoundsModified carbonCarbon nanotube

The invention provides carbon nano tubes modified by polymers with maleic anhydride chain segments and a preparation method of the carbon nano tubes. The carbon nano tubes are processed in one-step acidification treatment with concentrated sulfuric acid and concentrated nitric acid, and then have reaction with thionyl chloride after being processed in two-step acidification treatment with concentrated sulfuric acid and hydrogen peroxide. The product obtained from the above process has reaction with dihydric alcohol to obtain the modified carbon nano tubes with hydroxyl. Then the carbon nano tubes modified by polymers with maleic anhydride chain segments are obtained by means of the polymerization reaction between the hydroxyl and the polymers with maleic anhydride chain segments. Thereby, the carbon nano tubes can disperse into the composite materials well, the compatibility of the carbon nano tubes with the other materials are improved, so that the carbon nano tubes can take the advantages maximally and realize the functional design and application.

Owner:TONGJI UNIV

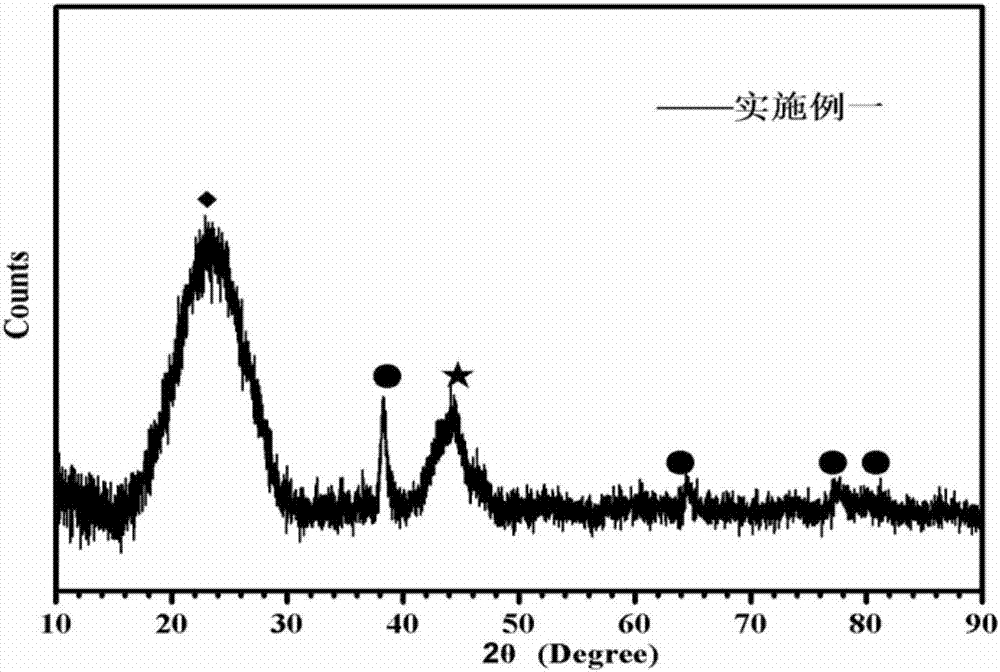

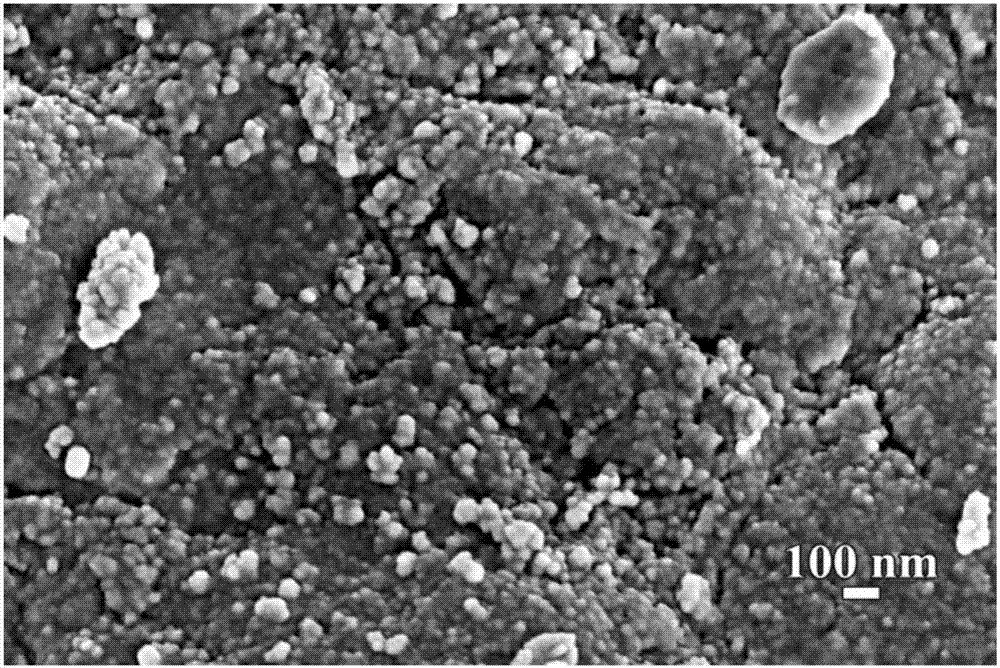

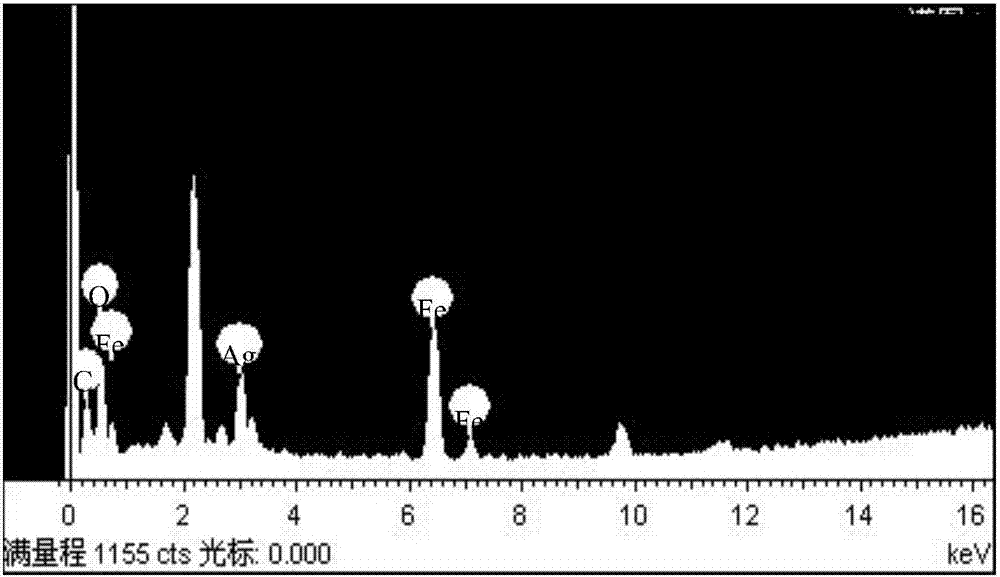

Composite material of nano zero-valent iron and silver metal cluster loaded on activated carbon and preparation method of composite material

InactiveCN106955667AHigh social and economic valueHuge specific surface areaOther chemical processesSpecific water treatment objectivesSolventActivated carbon

The invention relates to a composite material of nano zero-valent iron and a silver metal cluster loaded on activated carbon and a preparation method of the composite material. The method comprises the steps of firstly carrying out acidifying treatment on the activated carbon, cleaning and drying; secondly, adding polyethylene glycol to a mixed ferrous sulfate solution employing ethanol and water as mixed solvents, dissolving, adding NaOH to adjust the pH value; adding acidified activated carbon to the mixed solution, fully stirring and then adding a sodium borohydride solution to obtain nano zero-valent iron-loaded activated carbon; and finally washing the nano zero-valent iron-loaded activated carbon, and adding the nano zero-valent iron-loaded activated carbon to a silver salt solution as quickly as possible and reacting to obtain the material. The preparation method is simple in process, and simple in operation; and in a practical water purification application, various pollutants in drinking water are efficiently converted and degraded by combining the strong adsorption ability of the activated carbon and a micro-galvanic cell formed between iron and silver nanoparticles.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

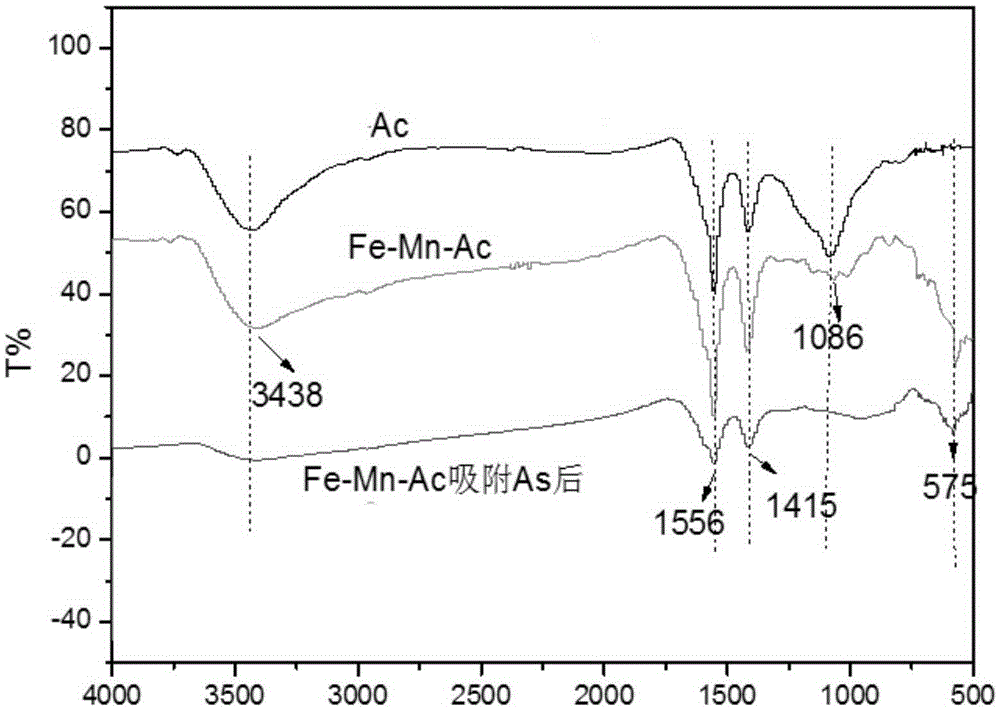

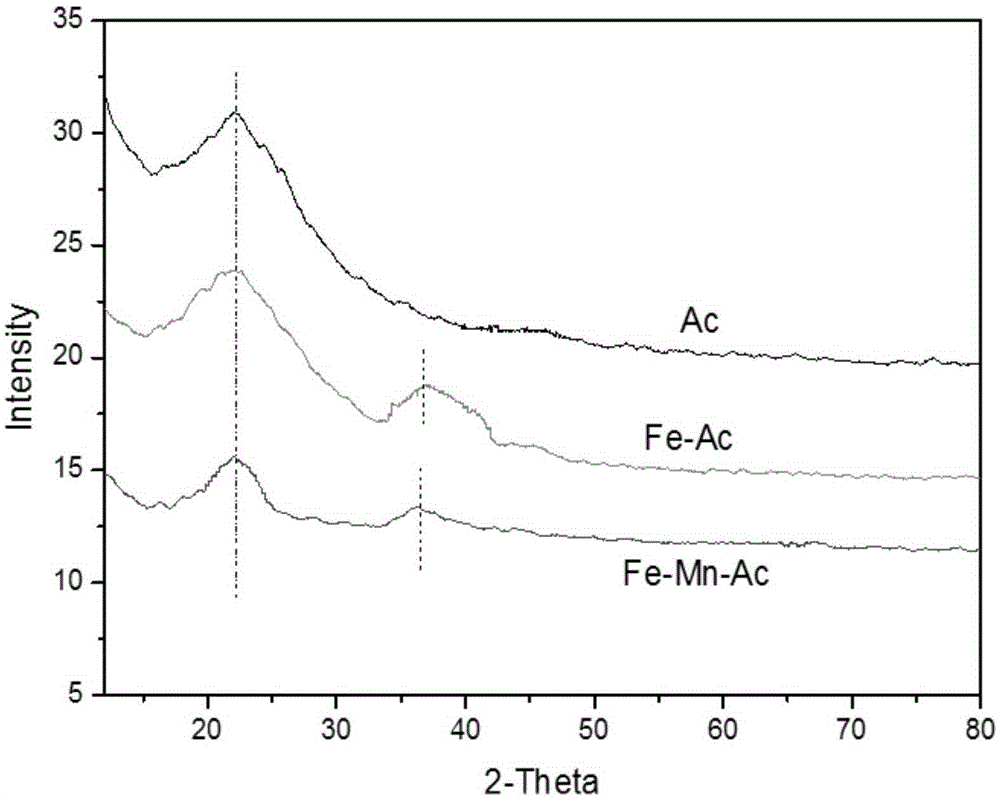

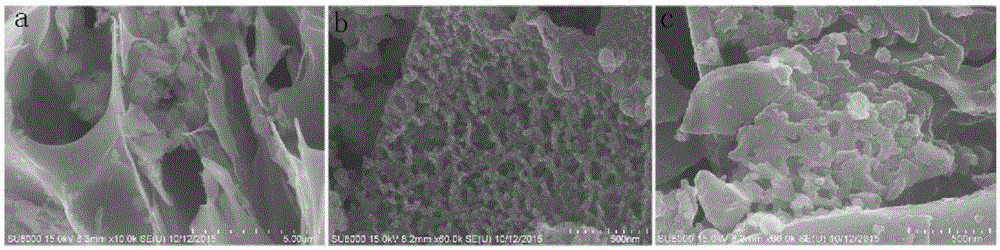

Ferromanganese modified straw active carbon adsorbent for As (III) adsorption, and applications thereof

ActiveCN105289493AHuge productionIncrease profitOther chemical processesWater/sewage treatment by sorptionActivated carbonSorbent

The present invention relates to a ferromanganese modified straw active carbon adsorbent for As (III) adsorption, and applications thereof. The technical scheme comprises: preparing straw into straw active carbon, adding to nitric acid, carrying out an acidification treatment to obtain acidified straw active carbon, adding the acidified straw active carbon to a metal iron salt and HCl mixing solution, carrying out a reaction at a room temperature for 22-24 h, heating to a temperature of 95-105 DEG C, carrying out a reaction for 6-7 h to obtain iron modified active carbon, mixing a metal manganese salt and the iron modified active carbon, carrying out a reaction at a temperature of 75-85 DEG C, adding a KMnO4 and KOH mixing aqueous solution, carrying out a reflux reaction at a temperature of 75-85 DEG C, and washing he product so as to obtain the target product. According to the present invention, with the ferromanganese modified straw active carbon adsorbent, the As (III) can be selectively recovered from the solution containing the As (III) ions and the impurity metal ions; and the ferromanganese modified straw active carbon adsorbent has advantages of low cost, high selectivity, high adsorption capacity, and the like.

Owner:LIAONING UNIVERSITY

Method for preparing macromolecule modified carbon nano-tube and application thereof

The present invention provides a macromolecule modified carbon nano-tube made by in situ polymerization and the related preparation method. Concentrated sulfuric acid and concentrated nitric acid are used for the first-step acidification treatment of the carbon nano-tube; then concentrated sulfuric acid and hydrogen peroxide are used for the second-step acidification treatment; afterward, the acidified carbon nano-tube reacts with dichloride sulfoxide and the product will then react with diol to produce a modified carbon nano-tube with hydroxyl; finally, the carbon nano-tube containing polymerizable double bonds is obtained after the pre-reaction between hydroxy and maleic anhydride. The carbon nano-tube containing polymerizable double bonds and maleic anhydride have in situ polymerization reaction with substances containing double bonds and then are connected on the external surface of the carbon nano-tube so that the carbon nano-tube can be well dispersed into composite materials to improve the compatibility between the carbon nano-tube and other materials in order to maximize the advantages of the carbon nano-tube and realize the functionalized design and application of the carbon nano-tube.

Owner:TONGJI UNIV

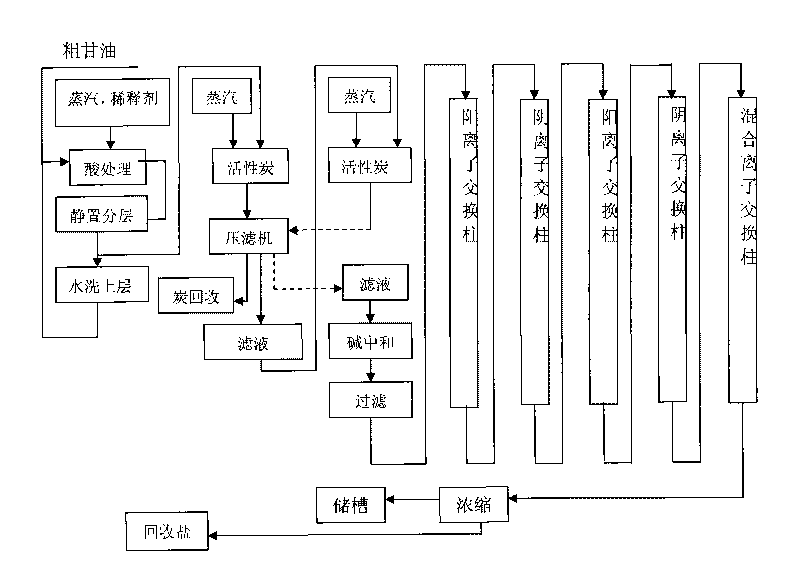

Refining production method of glycerin

InactiveCN101759526ALess investmentSave energyIon-exchange column/bed processesHydroxy compound separation/purificationTrans esterificationBiodiesel

The invention provides a refining production method of crude glycerin. Byproducts of grease ester exchange or hydrolyzation are used as ingredients, and byproducts of biodiesel can also be used as ingredients. The method comprises the following steps: acidizing treatment, decolourization, alkali return for neutralization, concentration for salt removal, ion exchange and concentration treatment, wherein the ion exchange step comprises the substep of sequentially using cations, anions, cations, anions and zwitterions to exchange resin posts in a mixed way, the operation temperature of the resin posts is controlled between 40 and 60 DEG C, the flow rate is 15 mL / min, and finally, the pure glycerin solution is collected. The process of the invention has the advantages of simple operation condition, low temperature, little pollution and high yield, and can avoid the deterioration of the glycerin at the high temperature, the yield is higher than 97 percent, and the product purity is higher than 99.2 percent. The invention also provides a multiplex mixed type anion-cation exchange resin post combination device applicable to the method.

Owner:HUNAN ACAD OF FORESTRY

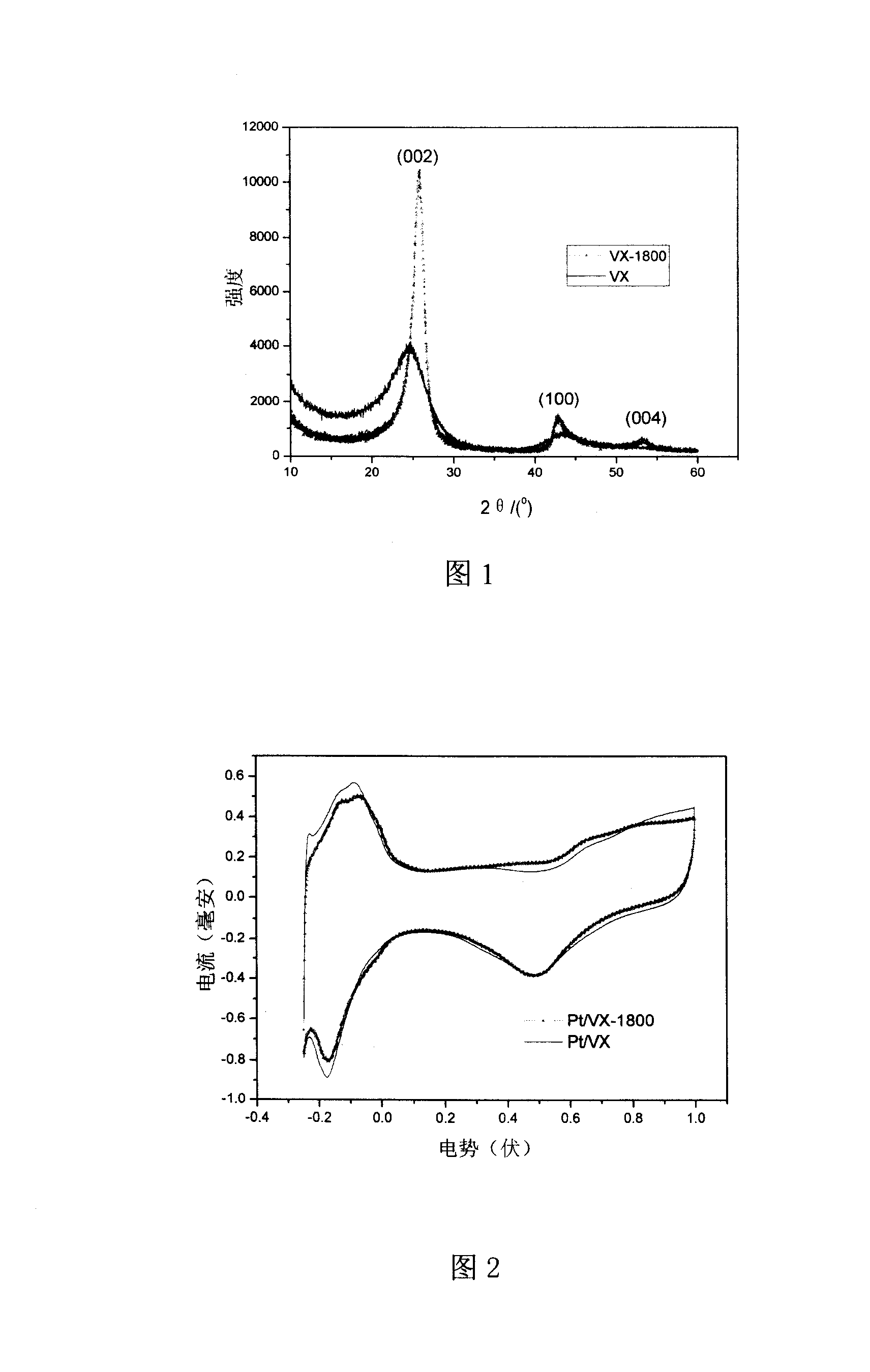

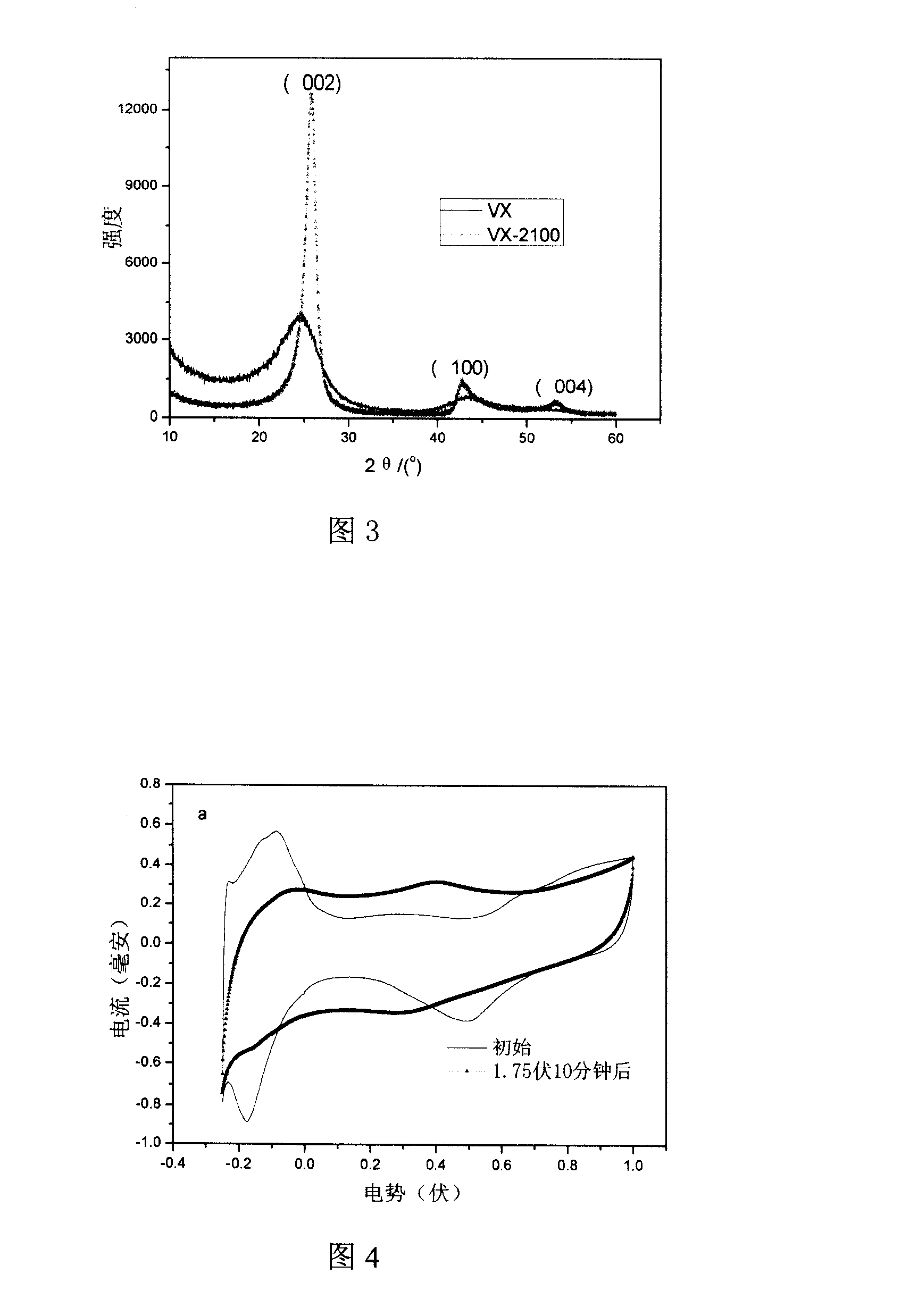

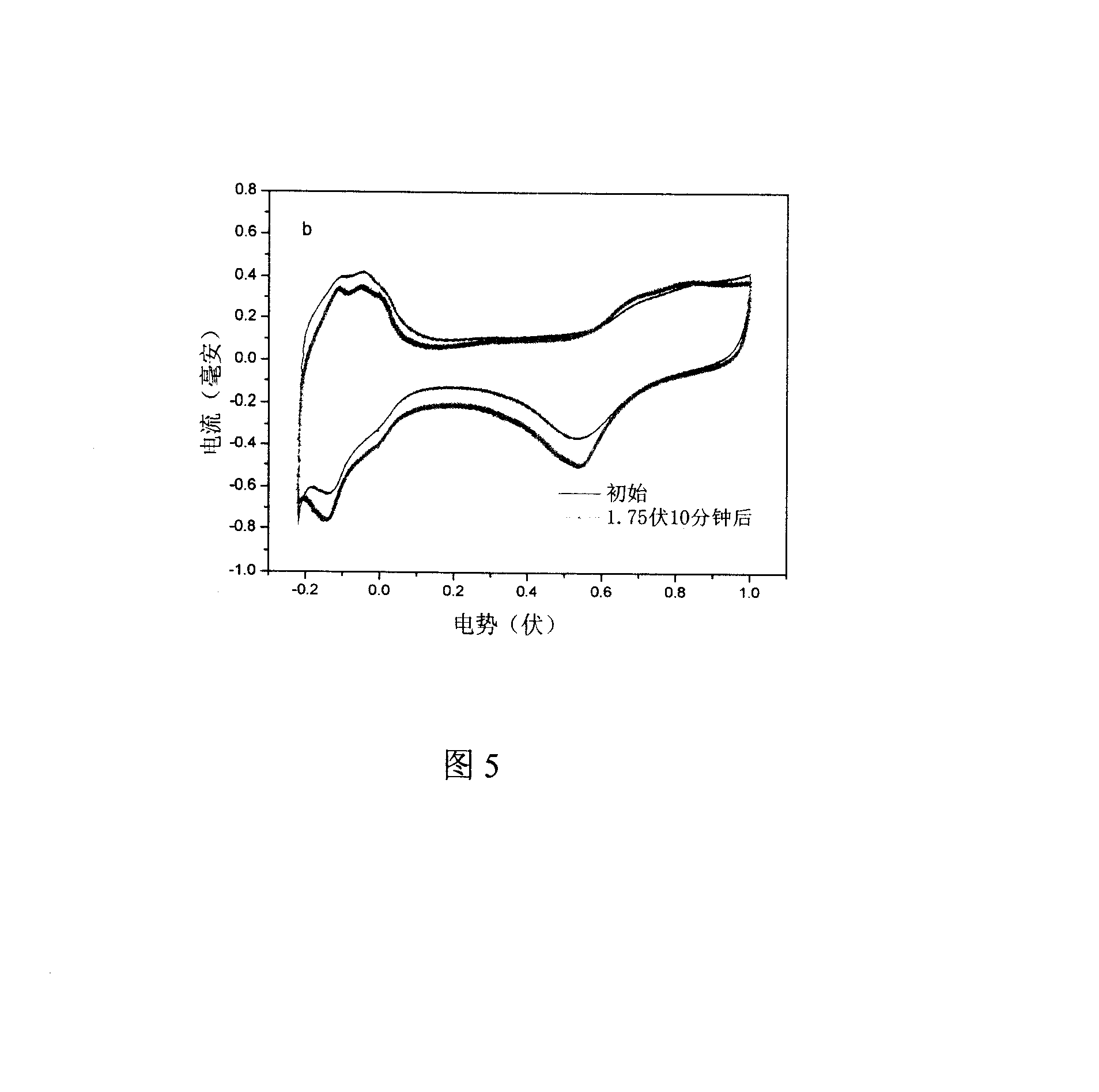

Method of increasing fuel cell catalyst stability

InactiveCN101229512AHigh degree of graphitizationImprove stabilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsFuel cellsHigh carbon

The invention discloses a technology used for improving the stability of catalysts in the fuel cell industry; in particular to a process for preparing novel catalysts through graphitize treatment of carbon carriers. The preparation process of the invention, under the protection of inert gas with high-purity, carries out high-temperature heat treatment to common commercial carbon carriers to cause carrier materials to be partially graphitized and eliminate partial impurities in the original supporters, thus improving the stable properties of the high carbon carriers. Furthermore, the graphitized materials are carried out acidification treatment and a direct-reduction process or an ethylene glycol reduction process is adopted to prepare the catalysts in order to improve the stability of fuel cell catalysts. The invention is characterized by new structure, simple technique conditions, lower cost, being relatively suitable for scale production, etc. Hence, the invention belongs to a method that integrates economical efficiency and practicability into a whole and improves the stability of the fuel cell catalysts.

Owner:SUNRISE POWER CO LTD

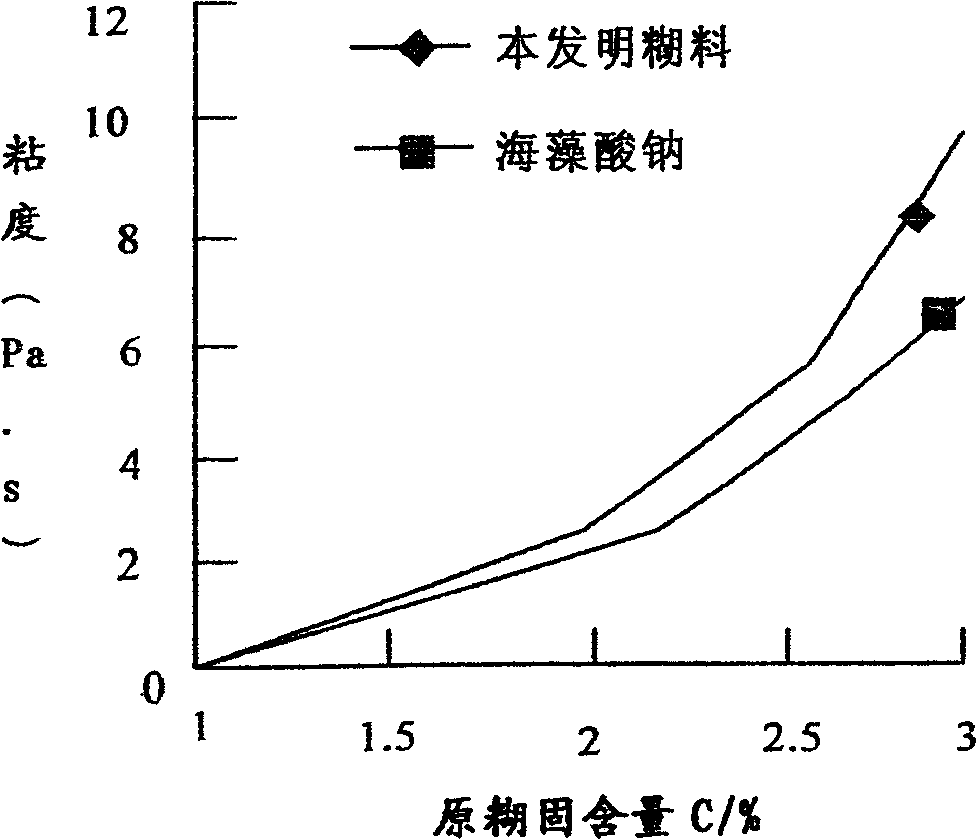

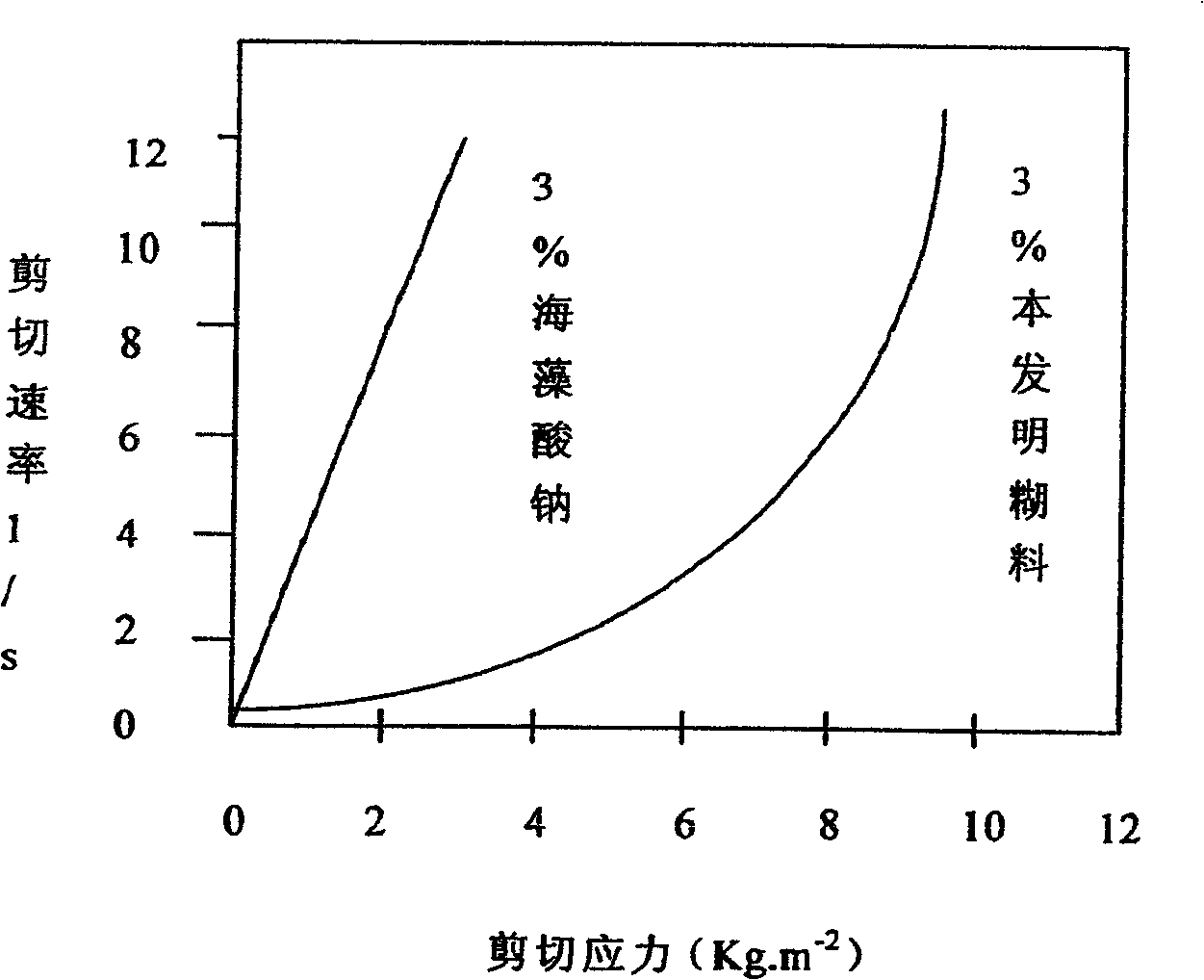

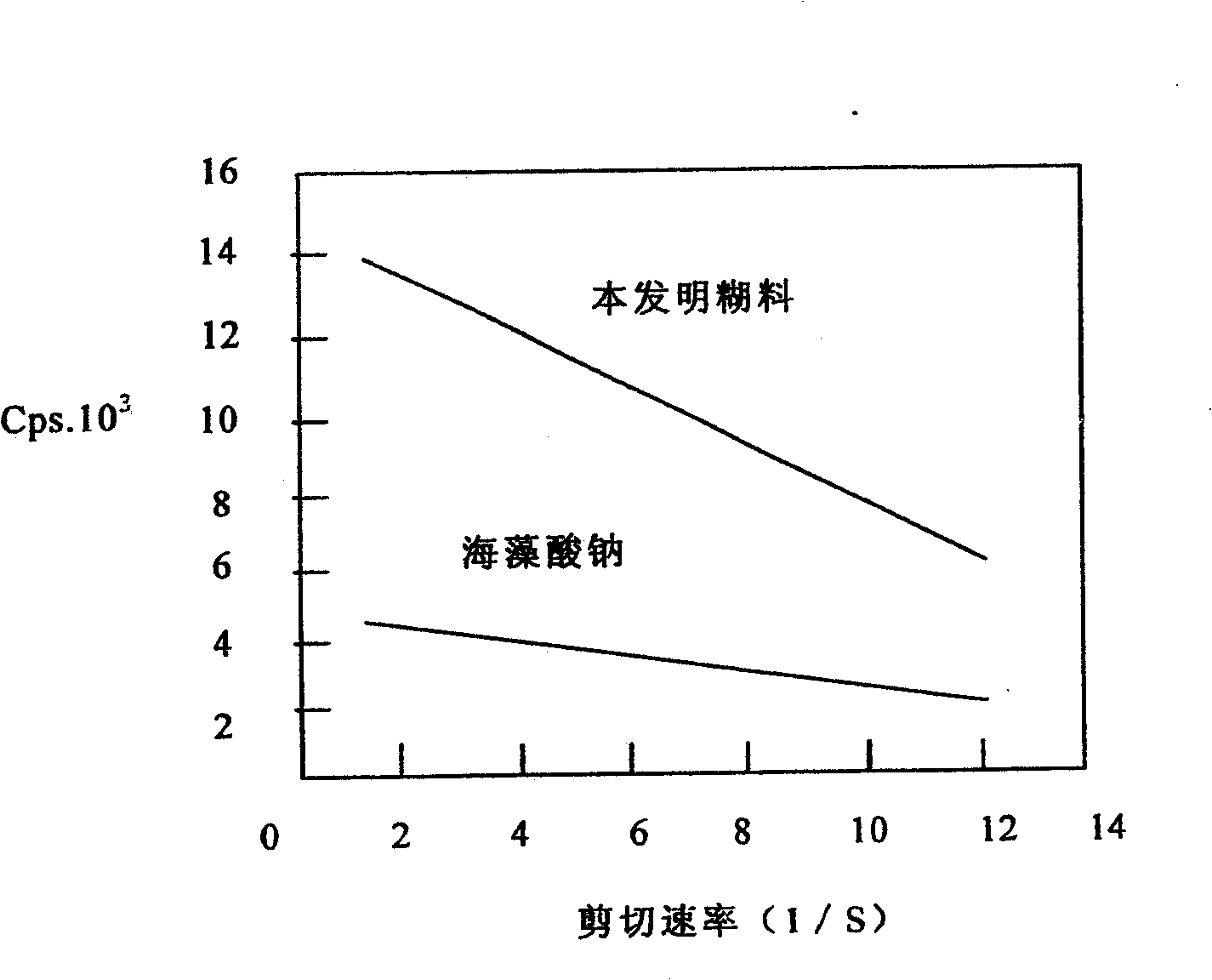

Complex printing gum for reactive dye and preparation method thereof

ActiveCN101314920AHigh structural viscosityImprove water retentionDyeing processCross-linkPotato starch

The invention relates to a paste applied during the printing process of active dyes of textiles and the preparation method thereof. The method comprises the steps as follows: subjecting wood pulp to acidification treatment, alkalization treatment, etherealization treatment and carboxylation treatment to obtain a component (A); subjecting potato starch to alkalization, cross-linking and grafting treatment, introducing sulfoethyl group, conducting etherealization treatment to obtain a component (B); taking kollidon as a component (C); and mixing the components (A), (B) and (C) at a ratio of 5:4:1. The paste as a novel printing paste can improve the printing performance, reduce the production cost and replace sodium alginate.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

Novel surrounding purifying material as well as preparation and use thereof

InactiveCN101347127AGood chemical stabilityImprove thermal stabilityBiocideDisinfectantsFiberPack material

Owner:SHANGHAI NORMAL UNIVERSITY

Red mud-based sewage treatment agent, preparation method thereof, red mud-based ceramsite concrete, and preparation method and application of concrete

PendingCN111217562AIncrease profitRealize large-scale utilizationOther chemical processesSilicon compoundsSlagRed mud

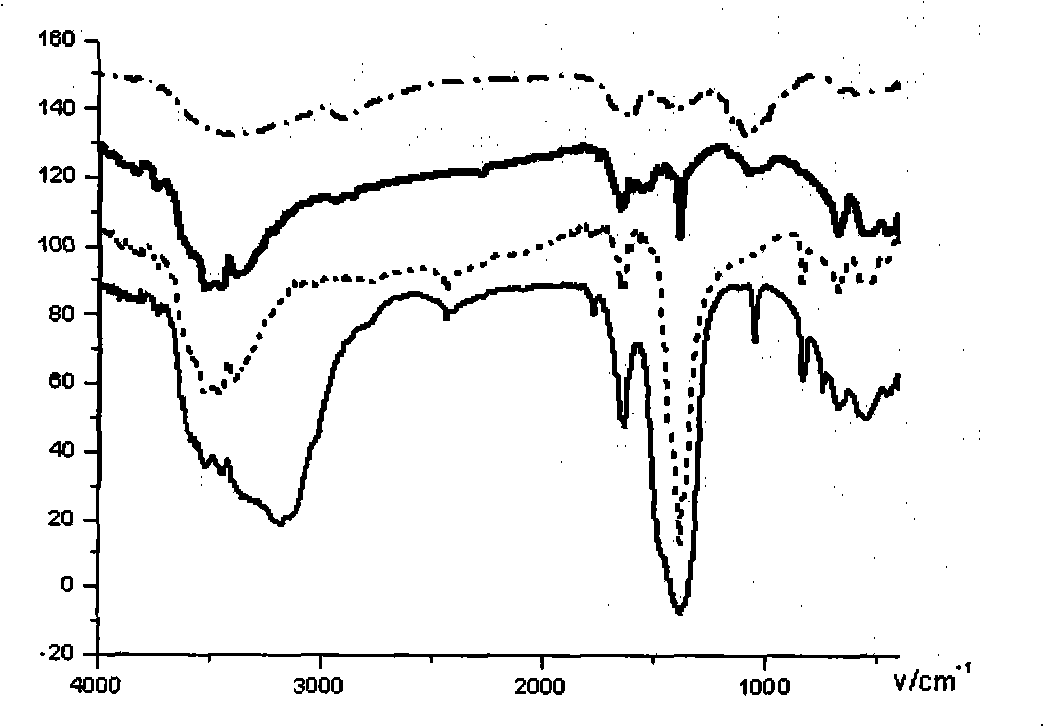

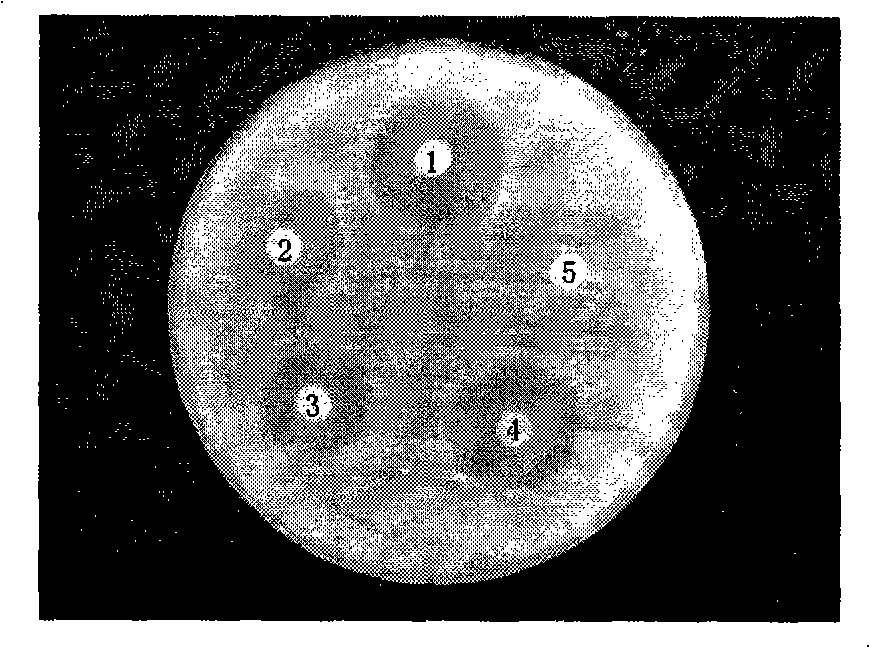

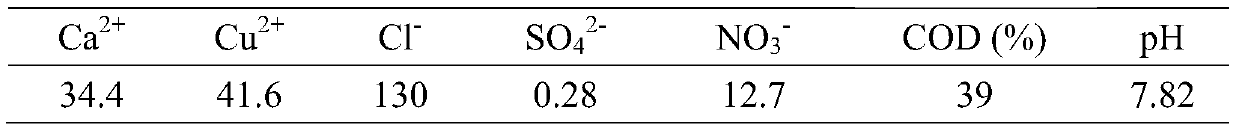

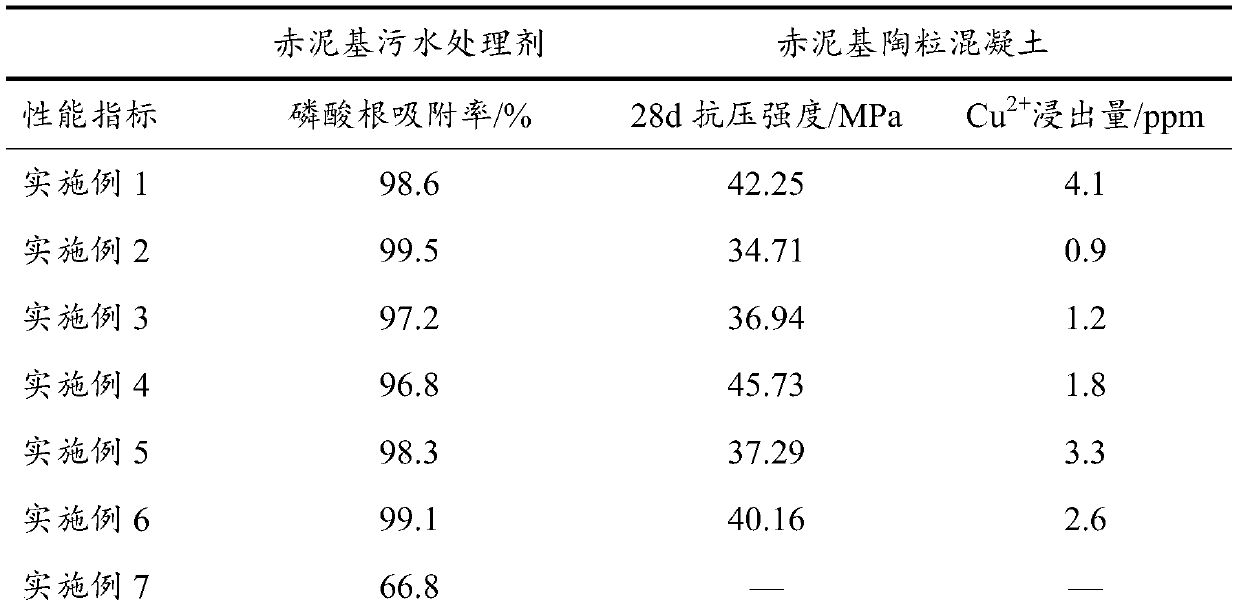

The invention relates to the technical field of red mud resource utilization, and especially relates to a red mud-based sewage treatment agent, a preparation method thereof, a red mud-based ceramsiteconcrete, and a preparation method and an application of the concrete. The red mud-based sewage treatment agent is prepared from 80-90% of an acidified solid waste complex, 2-15% of an alkali activator, 0-1.0% of a water reducing agent, 0.5-2.0% of an ultrafine additive and 1.0-5.0% of a treatment agent; and the solid waste complex comprises at least one of red mud powder, blast furnace slag powder, fly ash, coal gangue powder and iron tailing powder. The red mud is modified to prepare an intermediate, namely the red mud-based sewage treatment agent, and the red mud-based sewage treatment agent is used for adsorbing pollutants in sewage, and then used as a raw material again to prepare the final end product red mud-based ceramsite concrete, progressive comprehensive utilization of red mudis achieved, and adsorbed pollution factors can be fixedly sealed in the final end product, so the environmental friendliness of the final end product is guaranteed.

Owner:SHANDONG UNIV

Acidified attapulgite clay

The invention discloses acidified attapulgite clay, and the key points of the technical scheme are that: the acidified attapulgite clay comprises the ingredients of attapulgite clay, sulfuric acid, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methyl cellulose and sodium carbonate. A production method of the acidified attapulgite clay is as follows: acidified attapulgite clay ingredients are transported into a mill for milling powder, and the milled powder is the acidified attapulgite clay. Acidification treatment can remove impurities distributed in attapulgite clay pore channels, the pore channels are dredged, and the pore volume is increased. The acidified attapulgite clay can improve the adsorption property, decolorization rate, catalytic action, specific surface area and porosity of the attapulgite clay, colloid viscosity of the acidified attapulgite clay can be increased and the PH of the acidified attapulgite clay can be adjusted. The acidified attapulgite clay is applicable to the production of products of petroleum, chemical industry, medicines, building materials, plastics and other industry fields.

Owner:XUYI BOTU ATTAPULGITE CLAY HIGH TECH DEV

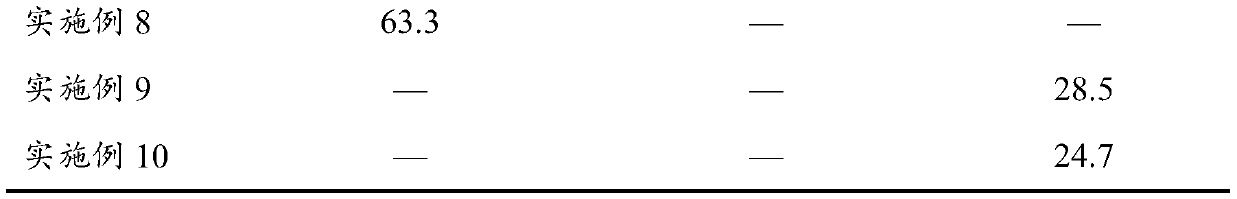

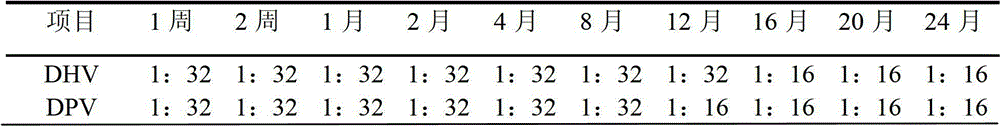

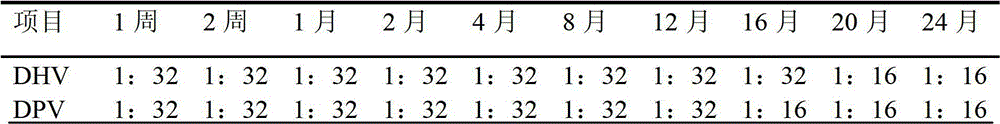

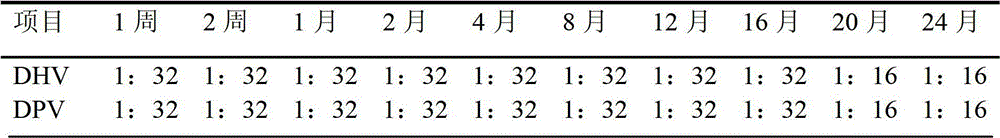

Dual hyper-immune egg yolk antibody injection for duck virus hepatitis and duck plague and preparation method thereof

InactiveCN102716485AHigh purityReduce lossesPharmaceutical delivery mechanismAntiviralsAntibodySide effect

The invention relates to a dual hyper-immune egg yolk antibody injection for duck virus hepatitis and duck plague and a preparation method of the injection. The preparation method comprises the following steps: separating strains to prepare a vaccine, immunizing healthy ducks to obtain eggs, and performing disinfection, acidification, octanoic acid treatment, refining extraction and purification, preparation and packaging on the eggs to obtain the dual hyper-immune egg yolk antibody injection for duck virus hepatitis and duck plague. The preparation method in the application has the characteristics that: the vaccine is prepared by firstly sampling and separating the viruses in a disease prevalence area and screening the virus strains wider in coverage; then hot and cold acidification treatments are carried out to obtain a clear crude egg yolk antibody solution, and this technology is not mentioned in the existing production; and then the egg yolk antibody solution is obtained after octanoic acid treatment, low-temperature high-speed centrifuge, microfiltration and ultrafiltration. The dual egg yolk antibody injection prepared by the method not only is different from those produced by other companies in preparation types, but also has other advantageous features in the production process such as low loss, high purity and high biological activity, and no clinical side effects are brought about.

Owner:ZHENGZHOU HOUYI PHARMA

Acid lixiviation based recycling treatment method of aluminum circulating coagulation sludge

InactiveCN102583951ALower Disposal CostsEasy to recycleSludge treatment by de-watering/drying/thickeningAluminium compoundsFlocculationChemical oxygen demand

The invention provides an acid lixiviation based recycling treatment method of aluminum circulating coagulation sludge. The method is characterized by comprising the following steps of: dehydrating sludge to reduce water content of the aluminum circulating coagulation sludge to be lower than 80%; drying and baking; carrying out acidifying treatment: adding mixture of water and acid to adjust pH value of sludge slurry to 3, controlling reaction temperature to be 38 DEG C and agitating sludge and acid in mixed liquid so that the sludge and the acid sufficiently contacts; separating and purifying; and finally, filtering, evaporating and crystallizing to obtain crystal aluminum salt with a flocculation effect. According to the acid lixiviation based recycling treatment method of the aluminum circulating coagulation sludge, a large part of water and aluminum in the sludge is converted into a flocculating agent and impurities are further removed by separating to purify the flocculating agent, thereby improving the recycling of an aluminum salt flocculating agent, greatly reducing sludge disposal cost and further reducing COD (Chemical Oxygen Demand), pH value, residual organic matters and chromaticity of the sludge wastewater; and therefore, the aim of recycling is realized, the subsequence biochemical treatment is easy to implement and the damage of wastewater discharging to the environment is reduced.

Owner:NANJING UNIV

Method for synthesizing granular beta molecular sieve with montmorillonoid

InactiveCN101723398AExpand the range of raw materialsLow costCrystalline aluminosilicate zeolitesMolecular sieveCore shell

The invention relates to a method for synthesizing a granular beta molecular sieve with montmorillonoid, comprising the following steps: acidification treatment and high-temperature roasting are carried out to the montmorillonoid, and the montmorillonoid which is acidified is soaked and heated by template agents, and then the montmorillonoid which is activated is used as raw material to provide total or partial aluminum source, and then the granular beta molecular sieve is prepared by adding template agents and carrying out hydrothermal crystallization; in the invention, the prepared beta molecular sieve grows on the surface of the montmorillonoid closely, so as to form a similar core-shell structure, and the catalytic reaction efficiency is improved by shortening the diffused route of reactants and product molecules in a molecular sieve crystal. The method not only expands the raw material range for synthesizing the beta molecular sieve, but also further reduces the preparation cost of the beta molecular sieve with a crystal seed method.

Owner:CHINA PETROLEUM & CHEM CORP +1

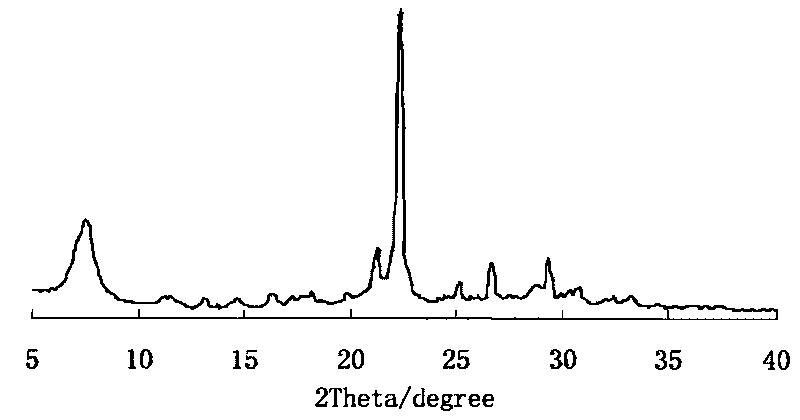

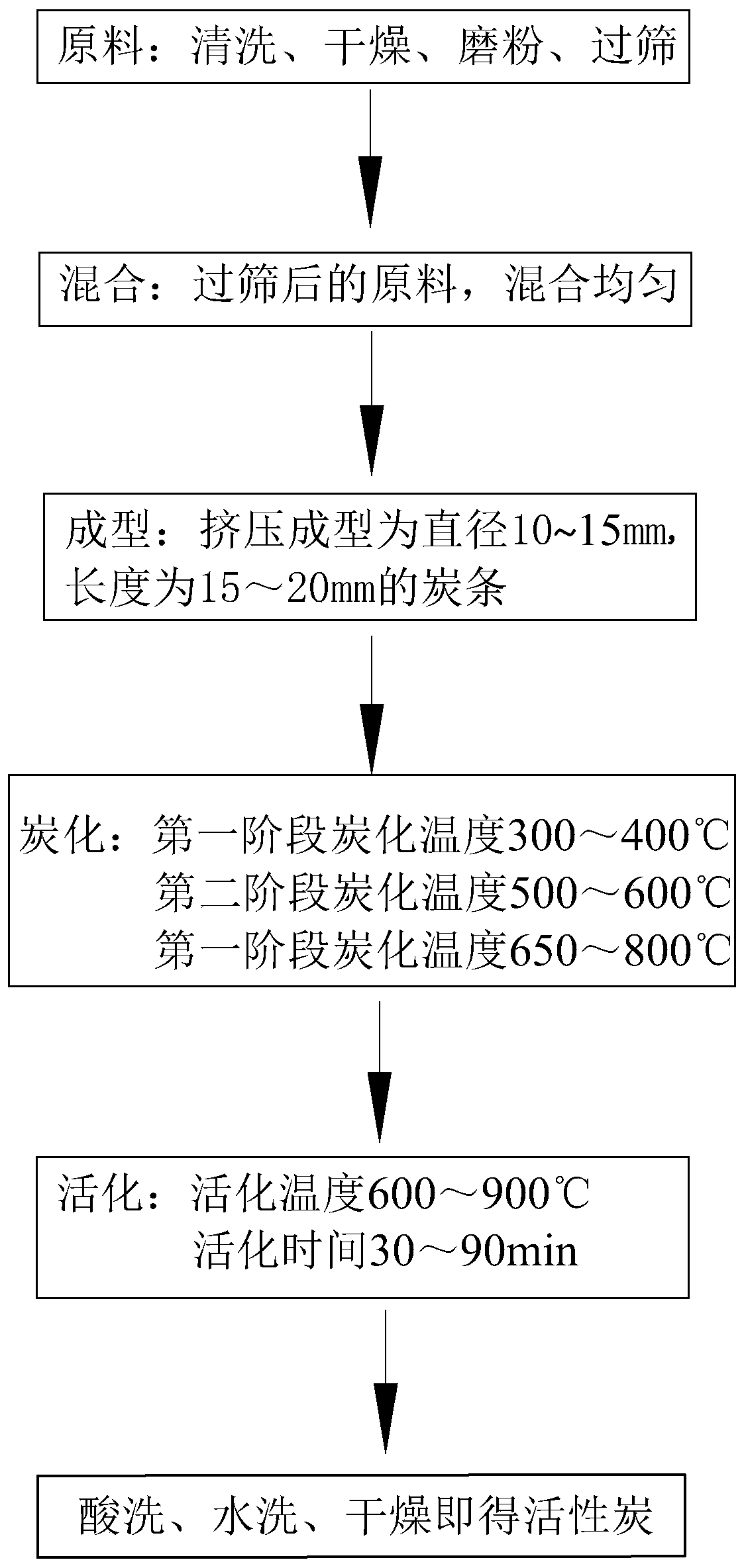

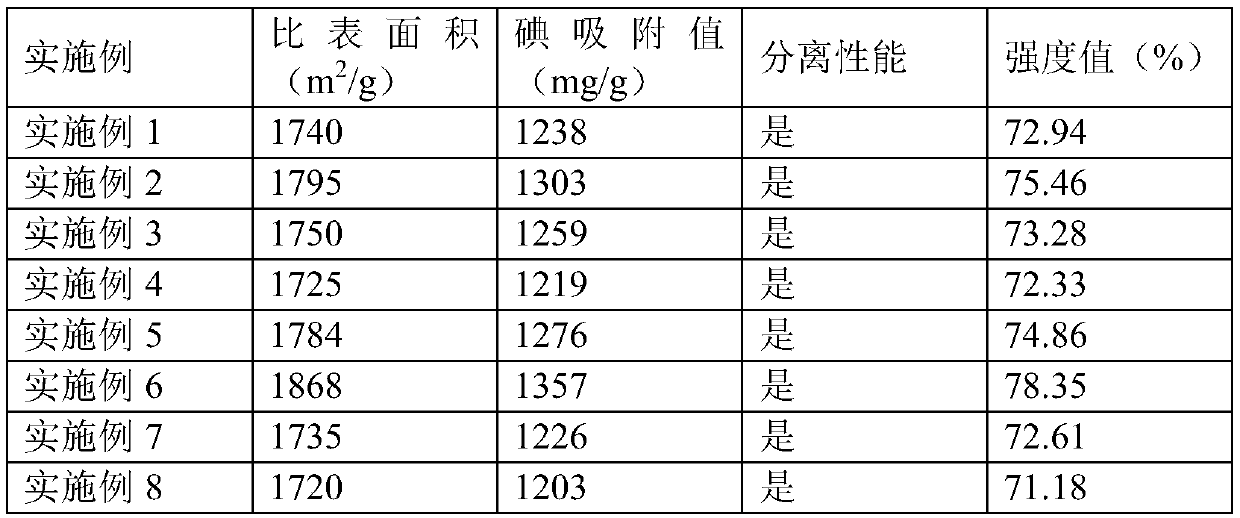

Preparation method of activated carbon

InactiveCN110182805ALarge specific surface areaImprove adsorption capacityCarbon compoundsActivated carbonClay minerals

The invention relates to a preparation method of activated carbon. The preparation method comprises the following steps: step 1, cleaning, drying and crushing biomass raw materials, screening with a 60-mesh sieve for standby application, and acidizing the crushed biomass raw materials; step 2, performing flotation treatment on coal slime until the ash content is not greater than 25%, and then drying, crushing and screening with a 200-mesh sieve to obtain coal slime powder for standby application; step 3, weighing the following materials in parts by mass: 10-15 parts of wood flour, 10-15 partsof clay minerals, 30-40 parts of acidified biomass powder prepared in the step 1 and 45-60 parts of coal slime powder prepared in the step 2, and uniformly mixing and stirring to obtain a mixed raw material; step 4, molding the mixed raw material; step 5, carbonizing; step 6, activating; and step 7, pickling activated and molded particles prepared in the step 6, washing with water to neutrality, and drying to obtain molded activated carbon. The preparation method provided by the invention can prepare activated carbon which is easy to be molded, not easy to loosen in structure and convenient tobe separated after adsorption and saturation.

Owner:合肥煜创碳业有限公司

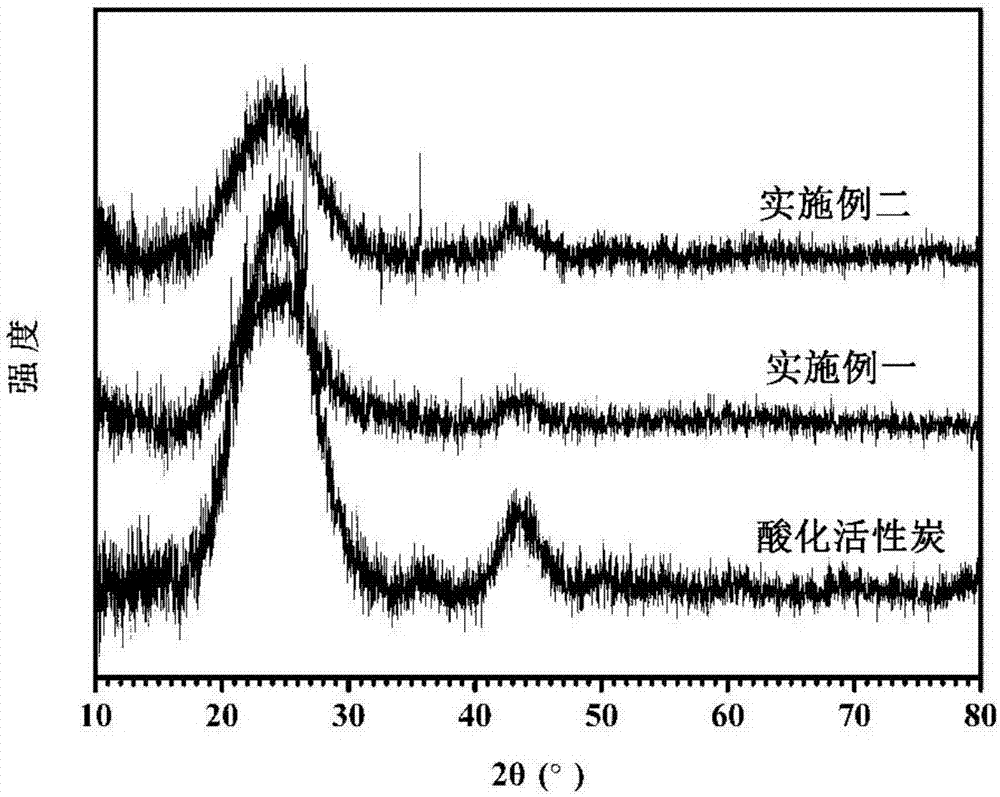

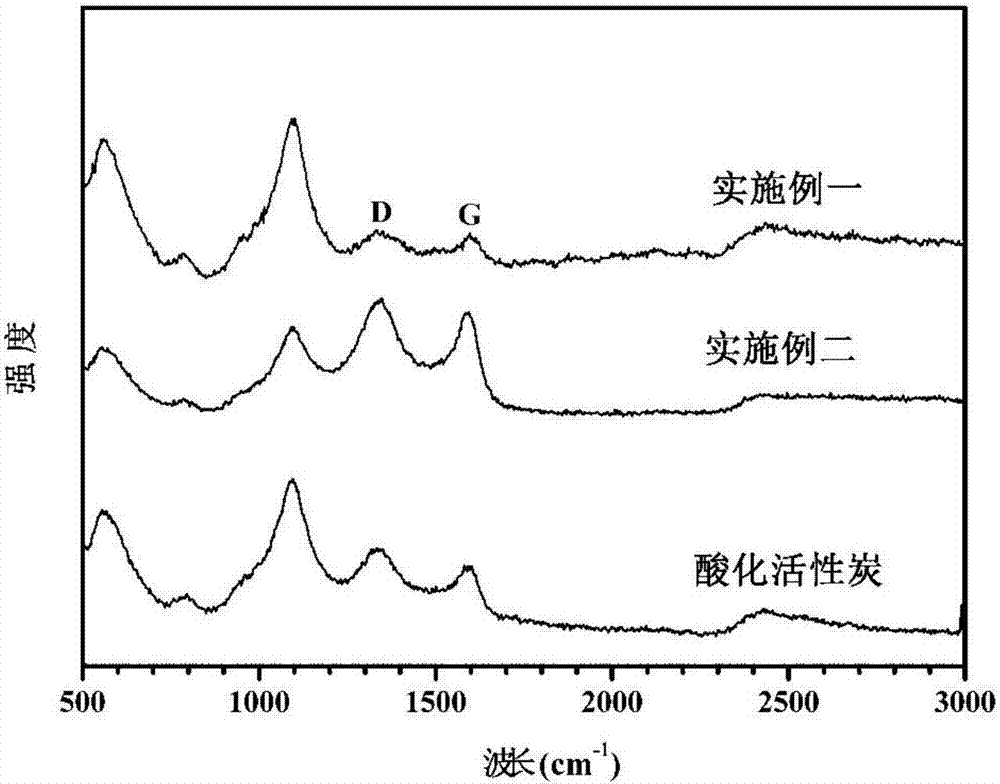

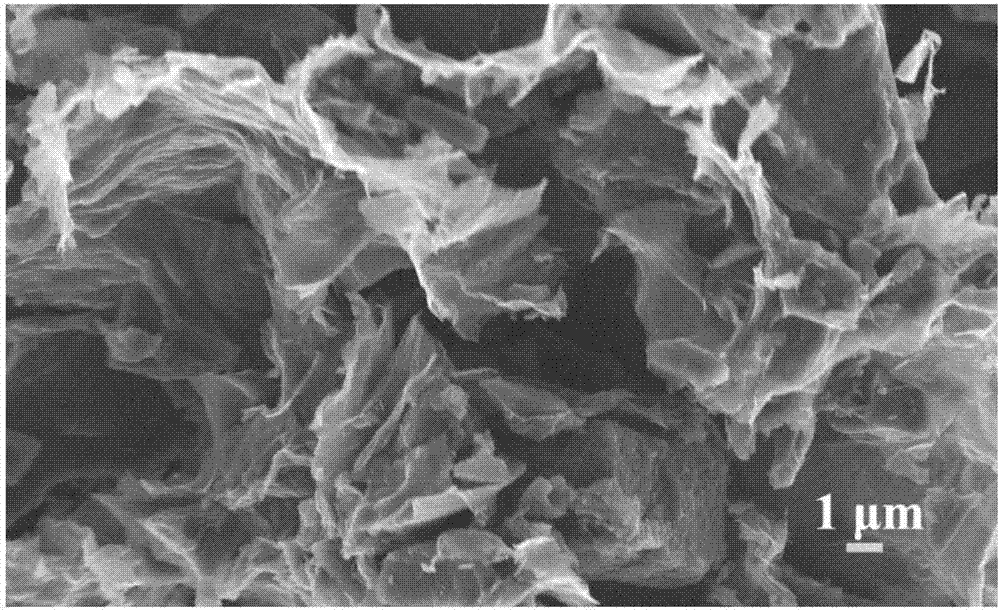

Graphene-loaded activated carbon composite material and preparation method thereof

ActiveCN107055532ALow commercial valueImprove conductivityHybrid capacitor electrodesGrapheneWater bathsActivated carbon

The invention relates to a graphene-loaded activated carbon composite material and a preparation method thereof. The preparation process of the material comprises the following steps of crushing activated carbon to be 1,000 meshes, carrying out acidification treatment on the activated carbon, and then cleanly washing and drying the activated carbon; carrying out ultrasonic treatment on a graphene oxide solution, so as to form a homogeneous solution; afterwards, immerging the acidified activated carbon into the solution, sufficiently agitating an obtained first mixture, then adding an ethylenediamine solution into the obtained first mixture, making an obtained second mixture react at a temperature of 80 DEG C in a water bath, and after a reaction is terminated, subjecting graphene loaded activated carbon to dialysis treatment; finally, washing and filtering the graphene-loaded activated carbon, and subjecting the graphene-loaded activated carbon to vacuum drying, so that the material is made. The method provided by the invention is simple in technique, and is simple and convenient to operate; by utilizing the excellent electric conduction performance of graphene, the graphene-loaded activated carbon composite material which is higher in conductivity and lower in cost is prepared; not only is the agglomeration phenomenon, which is generated due to surface electrostatic action, of the graphene overcome, but also the self electric conduction performance of the activated carbon is promoted; the conductivity of the composite material is increased by approximately 100 times.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

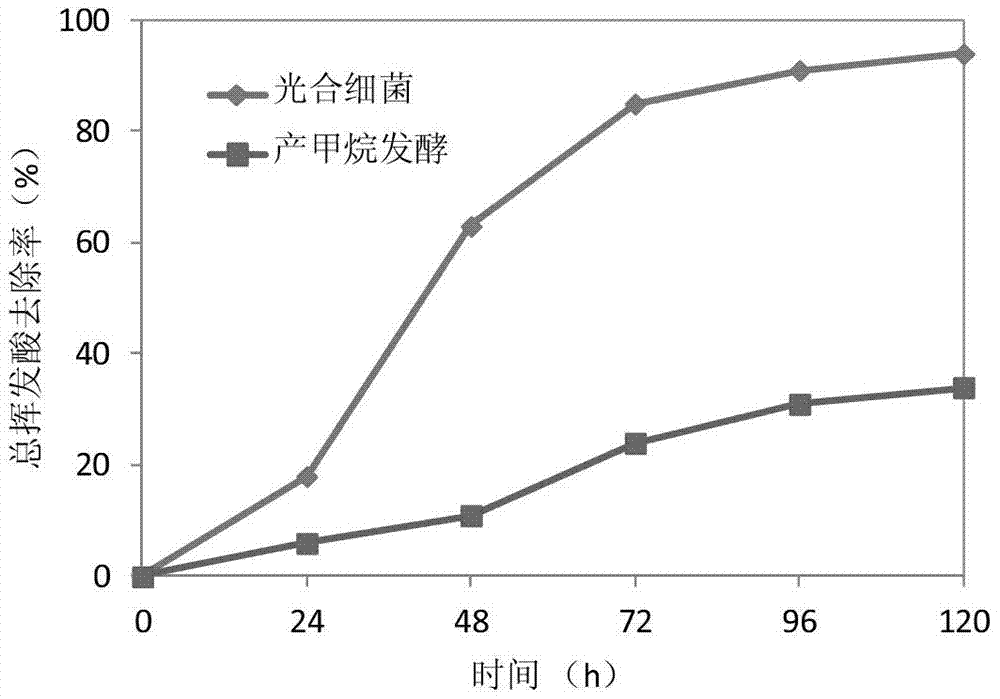

Treatment and recycling of kitchen wastes

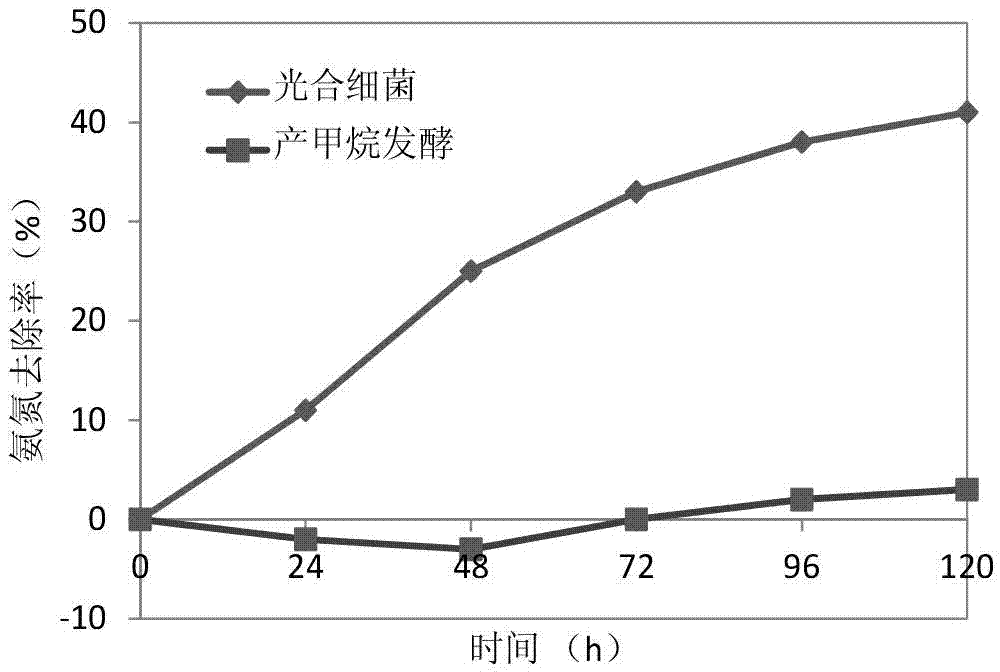

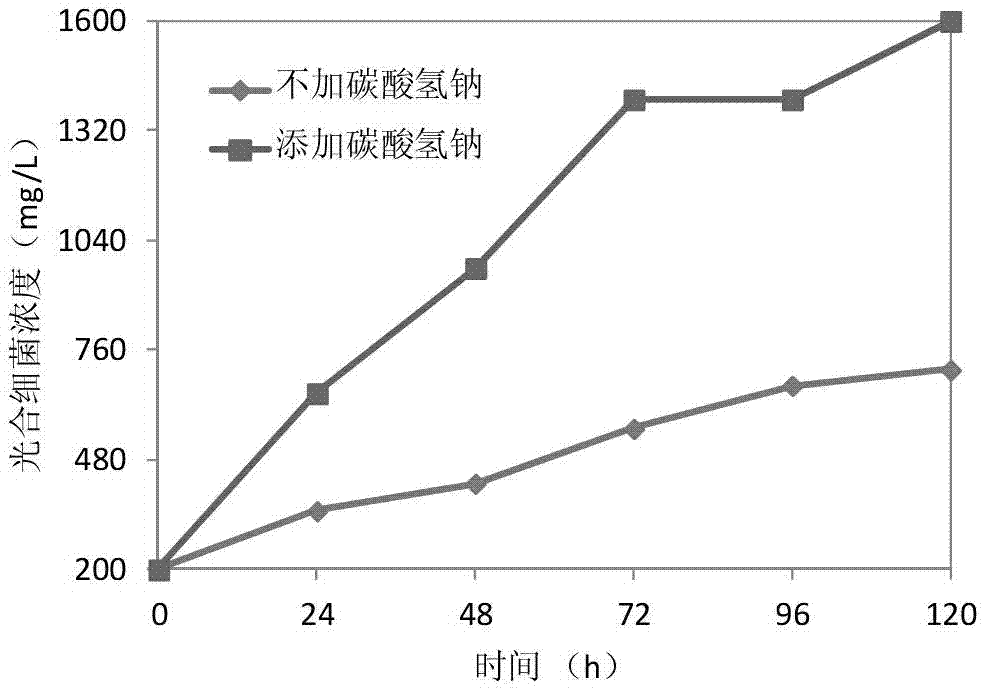

InactiveCN103084377AImprove processing efficiencyRealize resourcesBacteriaSolid waste disposalPretreatment methodVolatile fatty acids

The invention relates to a method for treating kitchen wastes by utilizing photosynthetic bacteria and recycling the kitchen wastes. The method particularly comprises a kitchen waste pretreating method which includes carrying out hydrolysis acidification treatment on the kitchen wastes until the concentration of volatile fatty acid is up to be 5000-15000mg / L to obtain hydrolysis acidification liquid, performing solid and liquid separation on the hydrolysis acidification liquid, adjusting the pH value of the liquid to be 6.5-7.5 to obtain a pretreated material, and a method for culturing the photosynthetic bacteria by using the pretreated material, which comprises the following steps of: inoculating 100-1000mg / L of a photosynthetic bacteria flora in the pretreated material and culturing the photosynthetic bacteria flora for 3-5 days under conditions that the illuminance is 1500-5000lux, the temperature is 25-35 DEG C and the dissolved oxygen concentration is 0-0.8mg / L. A product obtained by using the method can be used for preparing feed additives, water purification agents, ecological organic fertilizers or aquaculture baits. The method is strong in poison resistance capability for treating the kitchen wastes, good in denitrification and high in organic matter removal capability.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

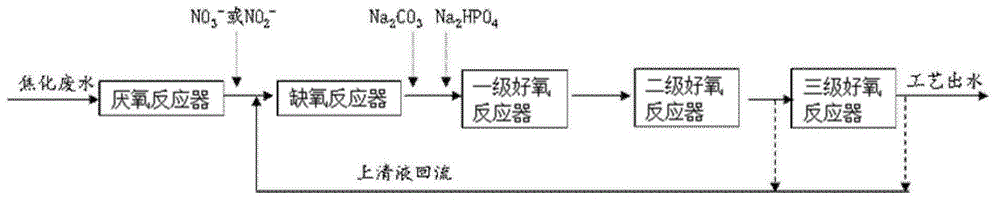

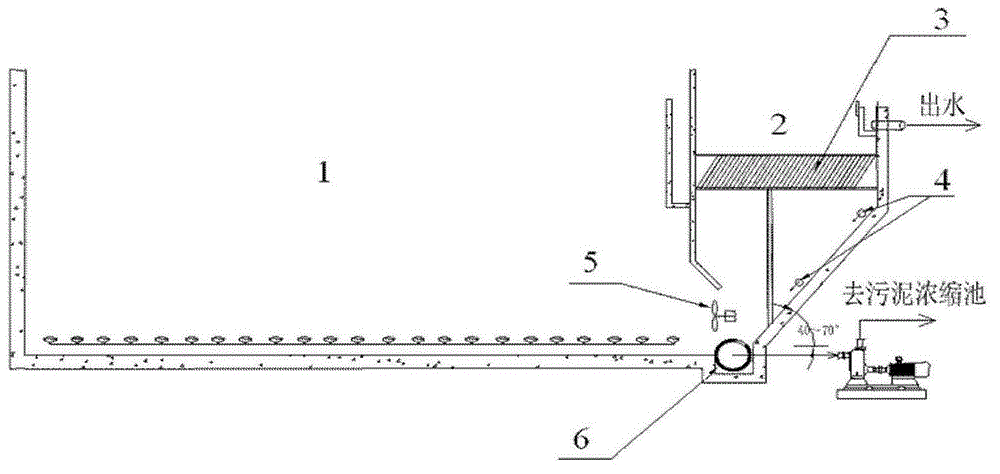

Biological treatment method, biological treatment system and bioreactor of coal chemical wastewater

ActiveCN102874927AHigh N/C valueIncrease concentrationTreatment with aerobic and anaerobic processesAnaerobic reactorOxygen

The invention relates to a biological treatment method of coal chemical wastewater, which adopts a biological reaction-muddy water separation integrated bioreactor. The method comprises the following steps of: sequentially feeding materialized and pre-treated coal chemical wastewater into an anaerobic bioreactor, an anoxic bioreactor, a first-stage aerobiotic bioreactor, a second-stage aerobiotic bioreactor and a third-stage aerobiotic bioreactor, selecting each aerobiotic bioreactor to discharge water and inflow into the anoxic bioreactor; and carrying out anaerobic acidification treatment by the anaerobic reactor, reinforcing a biological denitrification reaction in the anoxic reactor to remove non-gradable organic matters, completely decarbonizing by the first-stage aerobiotic bioreactor, and realizing the short-course nitratlon reaction and the whole-course nitratlon reaction by the second-stage aerobiotic bioreactor and the third-stage aerobiotic bioreactor, wherein the sludge concentration in the reactor can be guaranteed to be greater than 8mg / L due to the biological reaction-muddy water separation integrated bioreactor, the sludge age is greater than 60 days, the specific strains can be preferably cultured, and the function realization of a novel method can be guaranteed. The coal chemical wastewater is treated by the method, so that the discharged water can reach the requirement of the national wastewater comprehensive discharge standard.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

Graphene powder material with three-dimensional structure and optimized production method

The invention discloses an optimized production method of a graphene powder material with a three-dimensional structure. The optimized production method comprises the following operation steps: (1) performing sensitizing treatment on a polymer, wherein the sensitizing treatment is alkalinization treatment, acidification treatment, metal ion exchange and hole making treatment sequentially performedon a raw material; (2) performing drying treatment on the raw material sensitized in the step (1); (3) performing high-temperature cracking treatment on the raw material dried in the step (2); (4) performing disintegrating treatment on a sample after the high temperature cracking treatment in the step (3); (5) performing metal recycling treatment on the sample disintegrated in the step (4). The optimized production method disclosed by the invention has the benefits that grinding and crushing are not required in the whole process of preparing the graphene powder material with the three-dimensional structure, a complicated preparation process in the graphene preparation process by a traditional catalytic cracking method is optimized, the production process is simplified, and the productioncost is reduced.

Owner:GUANGXI UNIV

Method for treating arsenic-containing wastewater

InactiveCN102476836AHigh removal rateRaw materials are easy to getWater/sewage treatment by sorptionHydration reactionMagnetite

The invention discloses a method for treating arsenic-containing wastewater, belonging to the technical field of sewage treatment in environmental protection. The method provided by the invention sequentially comprises the following steps of: (1) immersing crushed magnetite powder of 40-100 meshes or magnetite grains with the grain diameter of 5-7 mm in water with the pH value of 7.5-9.5 at a constant temperature of 50-80 DEG C for 5-7 days, and then separating, and drying and activating the immersed magnetite powder or magnetite grains at a temperature of 110 DEG C for 1.5 hours to obtain activated magnetite; (2) acidifying the activated magnetite by using a hydrochloric acid solution with the concentration of 0.1 mol / L and carrying out alkaline washing on the acidified activated magnetite by using sodium hydroxide with the concentration of 2.0 mol / L, and then immersing the alkaline-washed magnetite into an organic amine solution for 12-24 hours; (3) adding 50-100 mg of the activated and modified magnetite powder into 30-800 mL of the arsenic-containing wastewater and stirring for 2.5-3.5 hours; and (4) depositing the stirred mixed liquid and then separating. According to the method disclosed by the invention, amorphous ferric oxide hydrate is generated by hydrolyzing mineral substances including the magnetite and the like, and the amorphous ferric oxide hydrate is aminated in the organic amine solution to form active sites for adsorbing the arsenic after the acidification and the alkaline washing of the amorphous ferric oxide hydrate; the arsenic is easy to combine with an amino so as to be firmly adsorbed on the surface of the magnetite, and the removing rate of the arsenic in the wastewater reaches up to more than 99.9%; and the adsorbed magnetite can be repeatedly utilized after being acidified.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

Method for preparing functional carbon nano-tube and application thereof

InactiveCN101104511AGood dispersionHigh reactivityPigment treatment with non-polymer organic compoundsChemical reactionModified carbon

The present invention provides a functionalized carbon nano-tube with polymerizable double bond and the related preparation method. Concentrated sulfuric acid and concentrated nitric acid are used for the first-step acidification treatment of the carbon nano-tube; then concentrated sulfuric acid and hydrogen peroxide are used for the second-step acidification treatment; afterward, the acidified carbon nano-tube reacts with dichloride sulfoxide and the product will then react with diol to produce a modified carbon nano-tube with hydroxyl; finally, the carbon nano-tube with polymerizable double bond is obtained after the reaction between hydroxy and maleic anhydride. The carbon nano-tube with polymerizable double bond can react further with other substances containing double bonds, therefore, the carbon nano-tube can be used as an important intermediate; other substances will be connected on the external surface of the carbon nano-tube through chemical reactions to realize the functionalized design and application of the carbon nano-tube.

Owner:TONGJI UNIV

Method for preparing adsorbent by using bottom mud of Dian Lake and application thereof

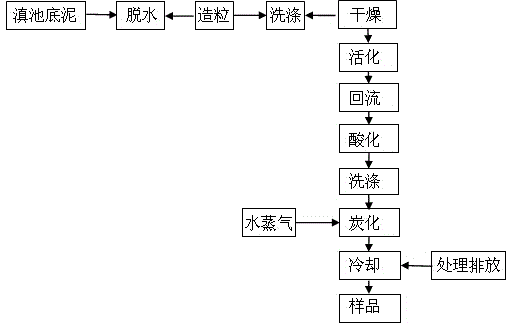

InactiveCN104437374AChange surface electrical propertiesChange adsorptionOther chemical processesWater contaminantsSorbentCarbonization

The invention discloses a method for preparing adsorbent by using bottom mud of Dian Lake and application thereof, and belongs to the technical field of preparation of heavy metal adsorbents. The method comprises the following steps: soaking the bottom mud by distilled water, repeatedly washing and drying the bottom mud, adding a glutaraldehyde solution into the bottom mud to serve as an activator, adding the bottom mud into a polydimethyl diallylammonium chloride solution, putting in a water bath to carry out heating reflux, pouring the supernate and carrying out acidizing by hydrochloric acid, filtering and washing to neutral and drying to obtain initial samples, putting the samples in an electric furnace and carrying out high-temperature carbonization by taking vapor as protection gas, obtaining carbonized samples after cooling, repeatedly washing the samples to remove the impurities in the carbonized products until washing to neutral (pH>6.5), carrying out drying, grinding after cooling, and screening to obtain the samples according with adsorption. The method is simple in operation conditions, extremely high in adsorbent productivity; through combining the physical activation method and the chemical activation method, the activation effect is relatively good, the performance of the adsorbent is improved and the adsorption value of manganese is greater than 19mg / g.

Owner:KUNMING UNIV OF SCI & TECH

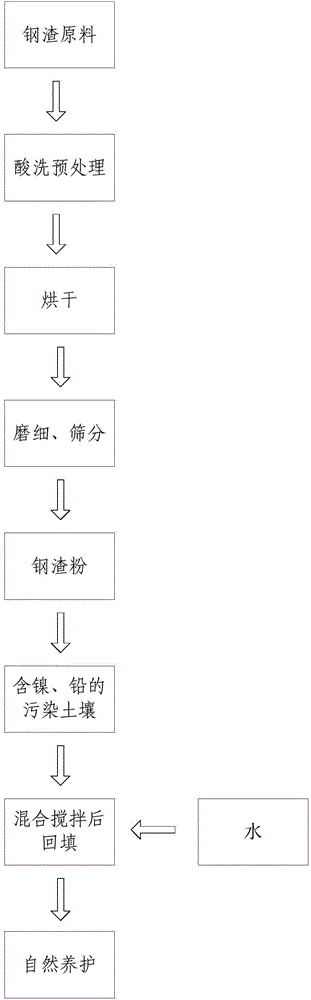

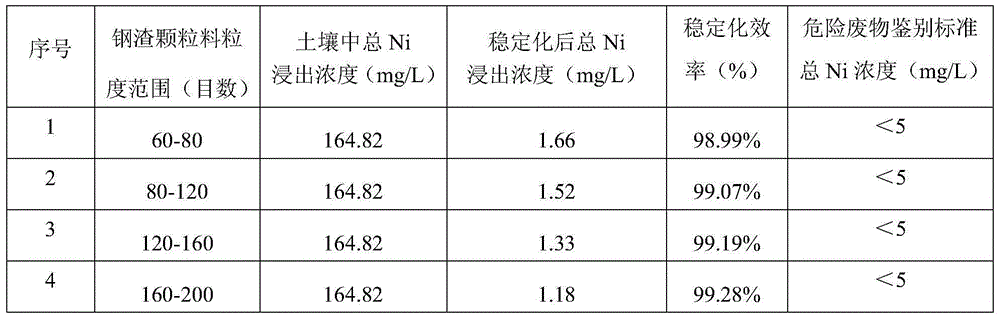

Treatment method of Ni and Pb contaminated soil remediation

The invention provides a treatment method of Ni and Pb contaminated soil remediation. The treatment method comprises the following steps: (1) carrying out acid pickling pretreatment on taken steel slag raw materials, and then taking out, and drying for later use; (2) grinding and sieving the spare steel slag raw material to obtain steel slag granules; and (3) adding the steel slag granules into nickel and lead-containing contaminated soil, adding water and mixing and stirring, and then backfilling the processed soil to original contaminated sites, and naturally curing. According to the treatment method of Ni and Pb contaminated soil remediation provided by the invention, after a small amount of steel slag raw material is subjected to acid pickling treatment, the porosity can be increased and the opportunity of contact between a medicament and a pollutant is improved; meanwhile, the steel slag granules used as a loose and porous silicate-containing substance with a large specific surface area and heavy metals generate ion exchange, surface coordination and co-precipitation and other effects to reduce the effectiveness of the heavy metals in soil together. The method has the advantages of simple process, low cost, good stability, and good economic, social and environmental benefits, and capability of turning waste into treasure.

Owner:SHANGHAI MCC ENVIRONMENTAL ENG TECH CO LTD +1

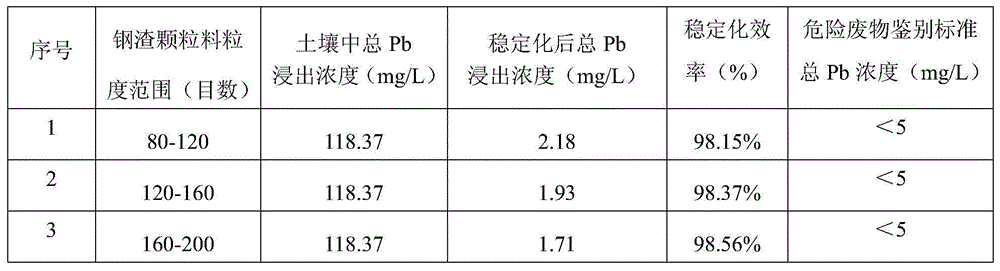

Uranium-containing wastewater treatment method

ActiveCN108257706AAvoid affecting adsorptionAvoid pollutionRadioactive decontaminationParticulatesDesorption

The invention belongs to nuclear fuel circulation technologies, and specifically discloses a uranium-containing wastewater treatment method. The treatment method is characterized in that firstly uranium-containing wastewater is subjected to pre-filtration, and followed by acidification treatment and alkalization treatment; and after being filtered again, the wastewater is subjected to silica gel adsorption uranium removing, after the wastewater reaches standards, deep treatment is performed, and if the wastewater does not reach the standards, deep treatment is performed after silica gel desorption. According to the treatment method, particulate matters in the wastewater are removed through pre-filtration firstly, thereby avoiding high temperature acidification making the uranium concentration of the wastewater increased to bring critical safety problems; with the help of the high temperature acidification, acid gases are driven off, and organic matters are destroyed, thereby avoiding affecting the adsorption of the silica gel on uranium; after the acidification, ammonia water, sodium hydroxide or the like is added to precipitate most of the uranium in the wastewater, thereby reducing the uranium concentration in the wastewater, and the precipitated wastewater is subjected to two stage filtration to make most of uranium-containing particles intercepted, thereby avoiding the uranium-containing particles polluting the silica gel, and improving the service life and the adsorption effect of the silica gel.

Owner:CNNC JIANZHONG NUCLEAR FUEL

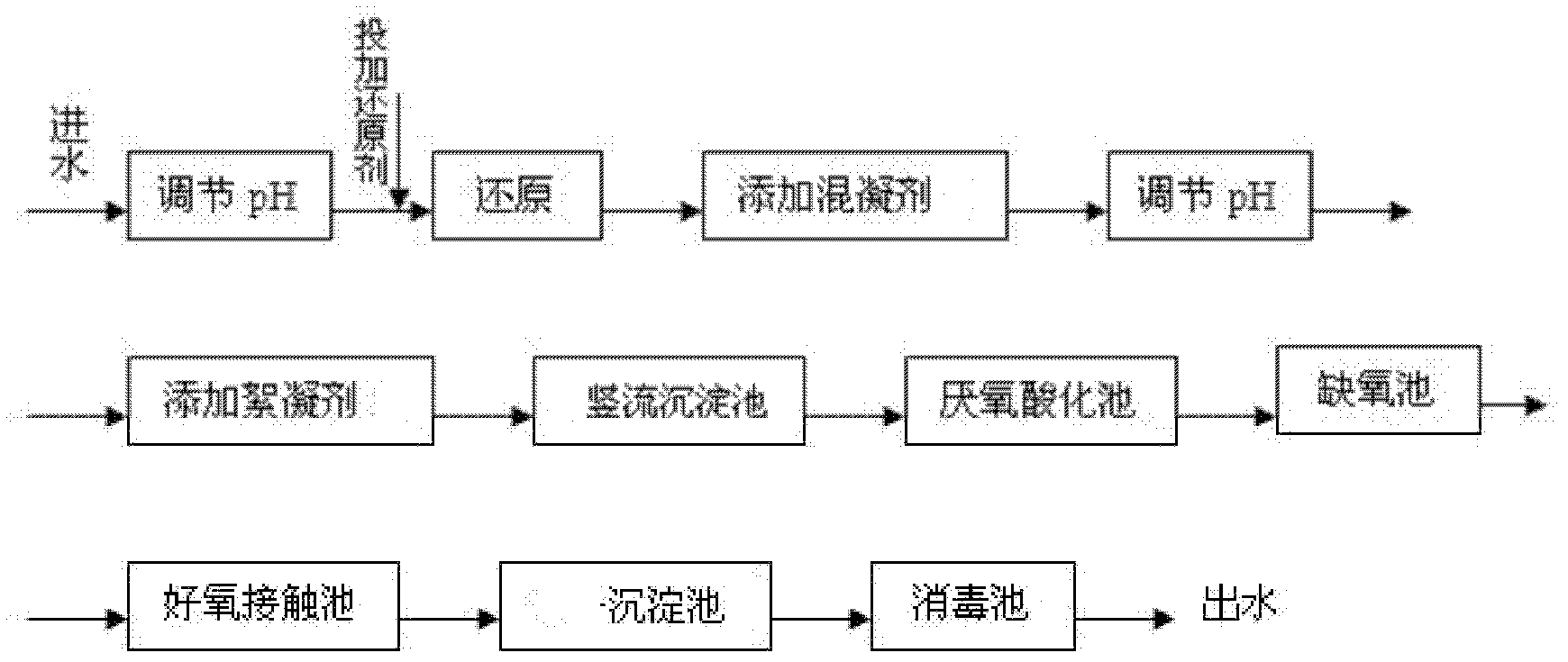

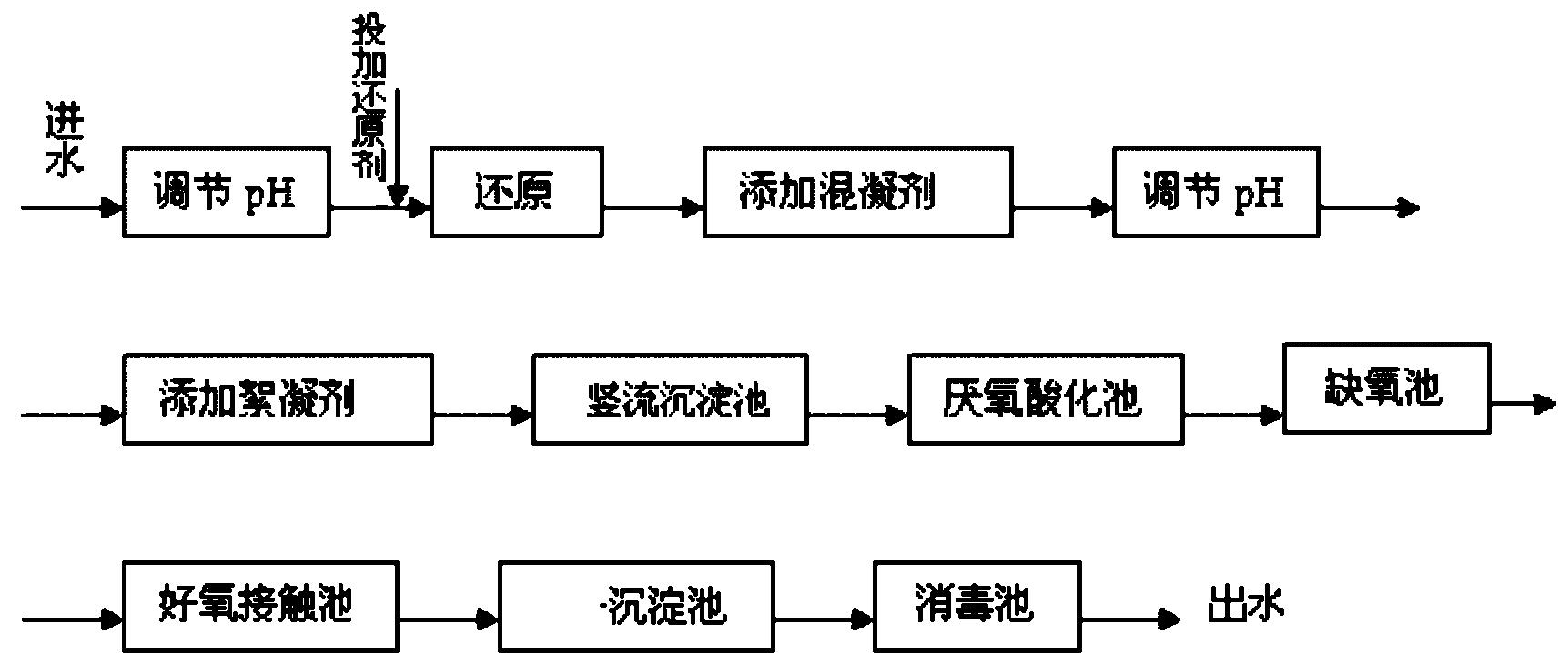

Treatment method of chromium-containing high concentration organic wastewater

ActiveCN102616980AWater contaminantsMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention discloses a treatment method of chromium-containing high concentration organic wastewater. The method comprises: first adjusting the pH value of chromium-containing high concentration organic wastewater to 3-4, and then adding a reducing agent to reduce Cr<6+>; conducting continuous aeration stirring reaction; then under the conditions of aeration stirring, adding a coagulant, and carrying out continuous aeration stirring, adjusting the pH value to about 8, and then adding a flocculant; then bringing the treated wastewater into a vertical flow sedimentation tank for sedimentation; introducing the effluent water from the vertical flow sedimentation tank into an anaerobic acidification tank for anaerobic acidification treatment; letting the effluent water from the anaerobic acidification tank enter an anoxic tank for anoxic treatment; making the effluent water from the anoxic tank enter an aerobic tank for aerobic treatment; bringing the effluent water from the aerobic tank into a sedimentation tank for sedimentation; and leading the effluent water from the sedimentation tank into a disinfection tank for disinfection treatment, and carrying out up-to-standard dischargeon the disinfected effluent water. Employment of the treatment method provided in the invention to treat chromium-containing high concentration organic wastewater can make the total chromium, hexavalent chromium, and COD (chemical oxygen demand) respectively above the B standard of the first level in the ''Discharge standards of pollutants for municipal wastewater treatment plants''(GB18918-2002).

Owner:SHANGHAI JIHUI REMONDIS ENVIRONMENT PROTECTION TECH DEV

Air purification material capable of removing formaldehyde, acetaldehyde, acetic acid and ammonia and preparation method of air purification material

ActiveCN105148856AImprove adsorption capacityGood removal effectOther chemical processesDispersed particle separationHydroxylamineAir cleaning

The invention discloses an air purification material capable of removing formaldehyde, acetaldehyde, acetic acid and ammonia and a preparation method of the air purification material. The preparation method comprises: performing acidizing treatment, washing and drying of an air purification material carrier to prepare an acidized air purification material carrier; mixing water, hydroxylammonium chloride, hexamethylene tetramine, chitosan, and orotic acid according to a mass ratio of 10:0.5-1.0:0.2-0.4:0.05-0.12:0.1-0.3 to prepare a mixed solution; and soaking the acidized air purification material carrier into the mixed solution for reaction, and drying the obtained product after reaction to obtain the air purification material. The air purification material provided in the invention has an excellent adsorption effect on formaldehyde, particularly has a preferable removal effect on low-concentration formaldehyde, and further has an excellent removal effect on acetaldehyde, acetic acid and ammonia. The air purification material is convenient to use, simple in preparation process, and good in practicality.

Owner:安徽泽汶环保科技有限公司

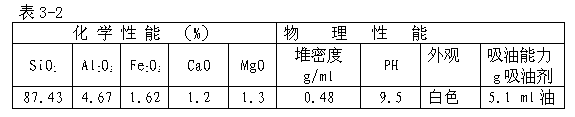

Oil absorbent prepared from low grade diatomite and preparation method thereof

InactiveCN103252209AGood compatibilityGood dispersionFatty/oily/floating substances removal devicesOther chemical processesVolumetric Mass DensityPollution

The invention relates to a preparation method of an oil absorbent, in particular to a method for preparing the oil absorbent from low grade diatomite. The preparation method comprises the following 9 steps of: low grade diatomite raw material selection, crushing, acidification treatment, washing, drying, adding of the assistant (3%-5%) Na2Cl (industrial salt) and mixing, roasting at 750-850DEG C, breaking winnowing, and adding of the silane coupling agent KH-550 (gamma-aminopropyl triethoxysilane, Nanjing Union silicon Chemical Co., LTD. 5%-7%) to conduct modification treatment, thus obtaining the particle and powder diatomite oil absorbent. The oil absorbent has simple and easy preparation method, wide raw material sources and low cost, solves the current solid waste pollution problem of low grade diatomite, opens up a new way for low grade diatomite application, and realizes recycling of waste materials. The oil absorbent has good selectivity, strong absorptivity up to 500% of its own weight, rapid oil absorption speed, small oil absorbent stacking density, a melting point of 1450DEG C, and a high use temperature, and can float on the water surface before and after oil absorption, thus being convenient for recovery and post-treatment.

Owner:任象玉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com