Red mud-based sewage treatment agent, preparation method thereof, red mud-based ceramsite concrete, and preparation method and application of concrete

A technology of sewage treatment agent and ceramsite concrete, which is applied in the field of resource utilization of red mud, can solve problems such as secondary pollution, and achieve the effects of reducing carbon emissions, low production costs, significant economic benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

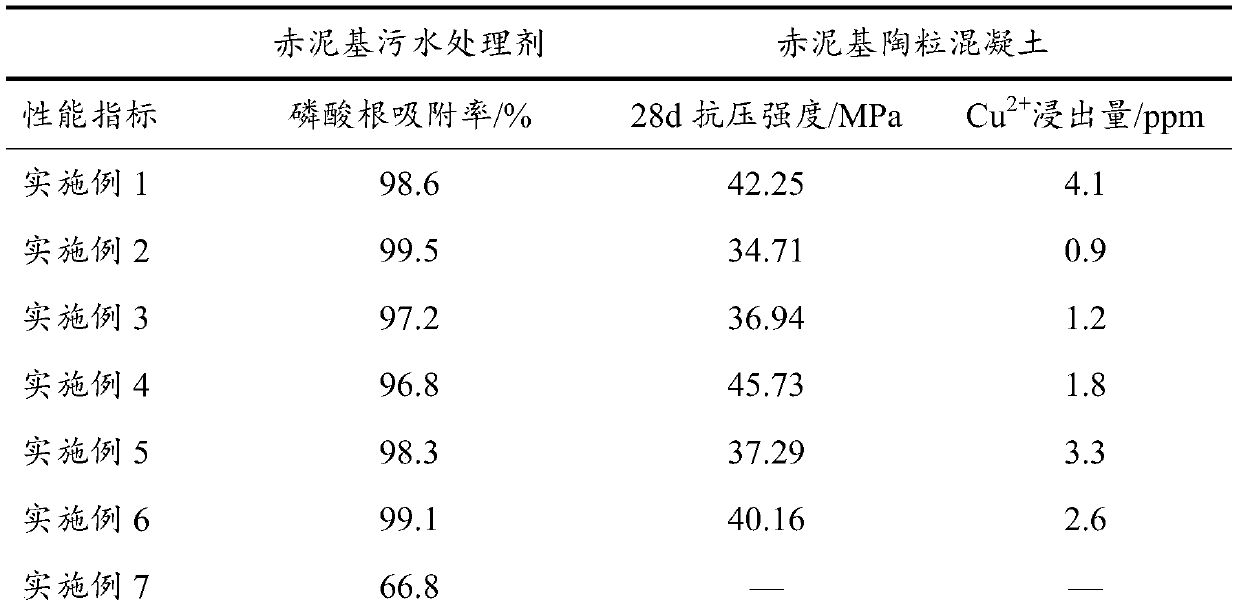

Examples

no. 1 example

[0062] 1, a kind of preparation method of red mud base sewage treatment agent, comprises the steps:

[0063] (1) In terms of mass percentage, dry red mud and blast furnace slag separately, grind them, and then pass through 400 sieves to obtain red mud fine powder and blast furnace slag fine powder, and mix the two fine powders at a mass ratio of 6:4 to obtain solid waste Complex.

[0064] (2) Use simulated industrial tail gas (mass concentration of carbon dioxide is about 16%) to acidify the solid waste complex in step (2) for 4.0 hours under the conditions of temperature 100°C, humidity 80%, and pressure 1.0MPa. After completion The solid waste complex is dried, ground, and passed through a 400-mesh sieve to obtain the modified solid waste complex.

[0065] (3) In terms of mass percentage, 90% of the modified solid waste complex of step (2), 0.4% polycarboxylate water reducer, 4.0% sodium silicate, 2.0% ultrafine zeolite (900 mesh), 3.6 Mix % hexadecyl ammonium bromide even...

no. 2 example

[0070] 1, a kind of preparation method of red mud base sewage treatment agent, comprises the steps:

[0071] (1) Red mud, coal gangue, and iron tailings are dried and ground respectively by mass percentage, and then passed through 400 sieves to obtain red mud fine powder, coal gangue fine powder, and iron tailing fine powder. The ratio of 6:3:1 is mixed to obtain solid waste complex.

[0072] (2) Utilize simulated industrial tail gas (mass concentration of carbon dioxide is about 16%) to acidify the solid waste compound in step (2) for 4 hours under the conditions of temperature 200°C, humidity 100%, and pressure 2.0MPa. The solid waste complex is dried, ground, and passed through a 400-mesh sieve to obtain a modified solid waste complex.

[0073] (3) In terms of mass percentage, 90% of the modified solid waste complex of step (2), 0.4% naphthalene-based water reducer, 4.0% sodium hydroxide, 2.0% ultrafine zeolite (900 mesh), 3.6% Sodium dodecyl sulfonate is mixed evenly, pu...

no. 3 example

[0078]1, a kind of preparation method of red mud base sewage treatment agent, comprises the steps:

[0079] (1) In terms of mass percentage, red mud and fly ash are dried and ground respectively, and then passed through 400 sieves to obtain red mud micropowder and fly ash micropowder, and the two kinds of micropowders are mixed in a mass ratio of 6:4 to obtain Solid waste compound.

[0080] (2) Utilize simulated industrial tail gas (mass concentration of carbon dioxide is about 16%) to acidify the solid waste compound in step (2) for 4 hours under the conditions of temperature 150°C, humidity 80%, and pressure 1.5MPa. The solid waste complex is dried, ground, and passed through a 400-mesh sieve to obtain a modified solid waste complex.

[0081] (3) In terms of mass percentage, 90% of the modified solid waste complex of step (2), 0.5% aliphatic water reducer, 3.0% potassium silicate, 1.0% ultrafine metal organic framework material (ZIFs, 800 mesh), 5.0% cetyl ammonium bromide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com