Patents

Literature

75results about How to "Change adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing catalyst for treating high-concentration organic wastewater through catalytic oxidation

InactiveCN101601998AChange adsorptionIncrease the number ofWater contaminantsCatalyst activation/preparationHigh concentrationActivated carbon

The invention discloses a method for preparing a catalyst for treating high-concentration organic wastewater through catalytic oxidation, which comprises the following steps: 1) drying a cocoanut active charcoal at a temperature of between 100 and 120 DEG C for 8 to 15 hours, taking out and adding the cocoanut active charcoal into 2 to 10 percent sulfuric acid solution to perform soakage for 12 to 36 hours, adding the cocoanut active charcoal into a 1 to 10 percent oxydol solution to perform soakage for 12 to 36 hours, taking the cocoanut active charcoal out, and draying the cocoanut active charcoal in shade to obtain an activated charcoal for standby; and 2) soaking constant volume of the activated charcoal into transition metal salt solution for 12 to 36 hours, drying the activated charcoal at a temperature of between 100 and 120 DEG C for 8 to 15 hours, and calcining the activated charcoal at a temperature of between 300 and 650 DEG C for 3 to 8 hours to obtain the catalyst for treating the high-concentration organic wastewater through the catalytic oxidation. The service life of an active charcoal catalyst bed prepared by the method can reach over 0.5 to 1 year. After the treatment of the wastewater, compared with a Fenton reagent, the treatment efficiency of the catalyst is improved obviously, and the treatment cost is reduced by about 20 percent.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

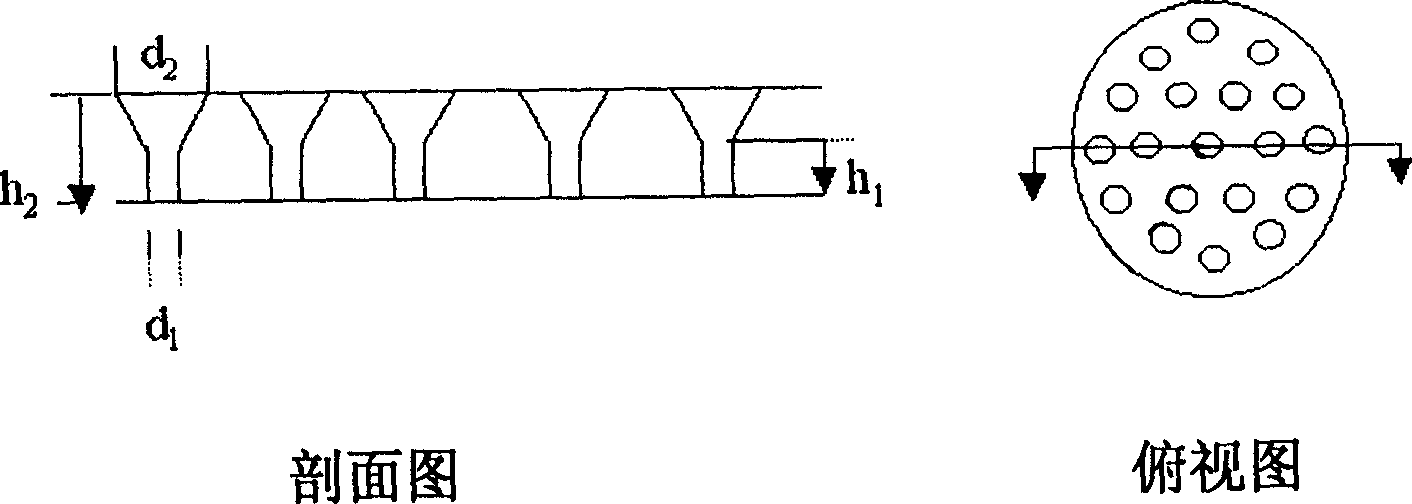

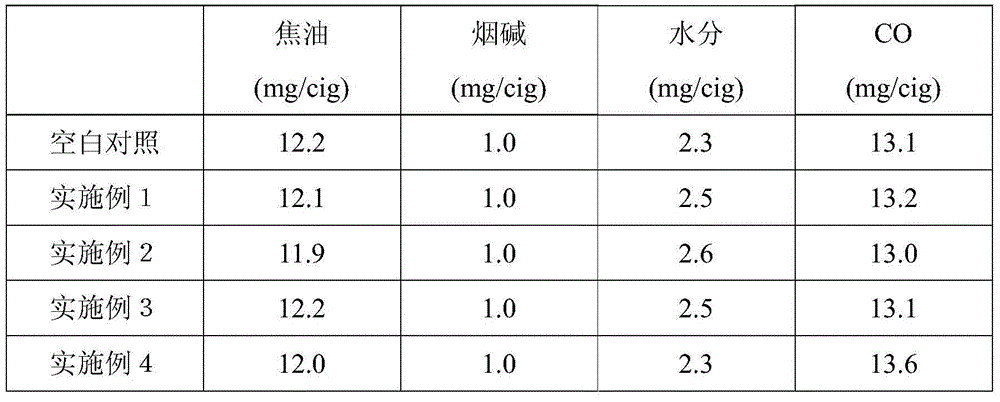

Cigarette with dobble-layer of cigarette paper

The present invention discloses cigarette with tobacco encircled with two, one inner and one outer, layers of cigarette paper. The inner layer of cigarette paper contains inorganic stuffing 20-40 wt%, combustion assistant 6-10 wt% and essence 12-18 wt%; and the outer layer of cigarette paper contains inorganic stuffing 25-35 wt% and combustion assistant 5-10 wt%. The said inorganic stuffing is calcium carbonate, magnesium hydroxide, magnesia, trihydroxyl aluminum or their mixture; the combustion assistant is the mixture of potassium citrate and sodium citrate with weight ratio between potassium ion and sodium ion of 2-4; and the essence is one of menthyl palmitate, vanillin, menthyl carbonate and beta-carotene. The present invention can reduce the side flow fume of cigarette, lower tar and reduce fragrance loss.

Owner:YUNNAN RES INST OF TOBACCO SCI

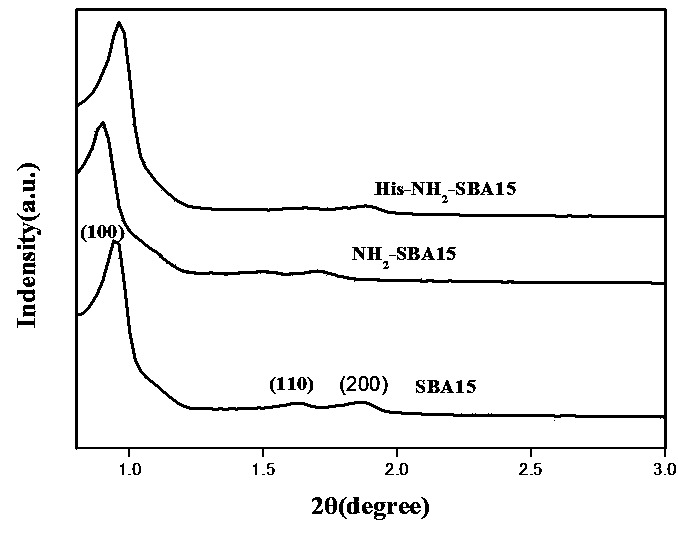

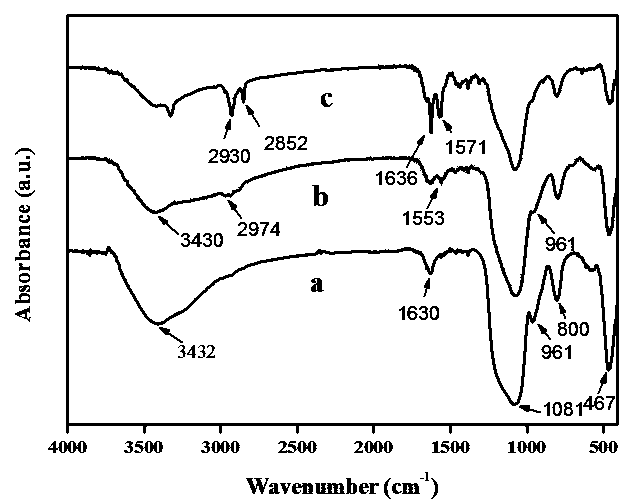

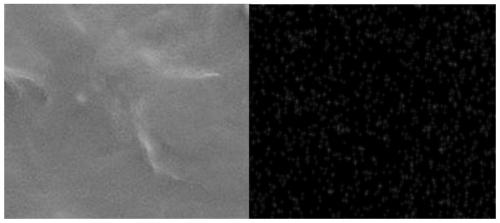

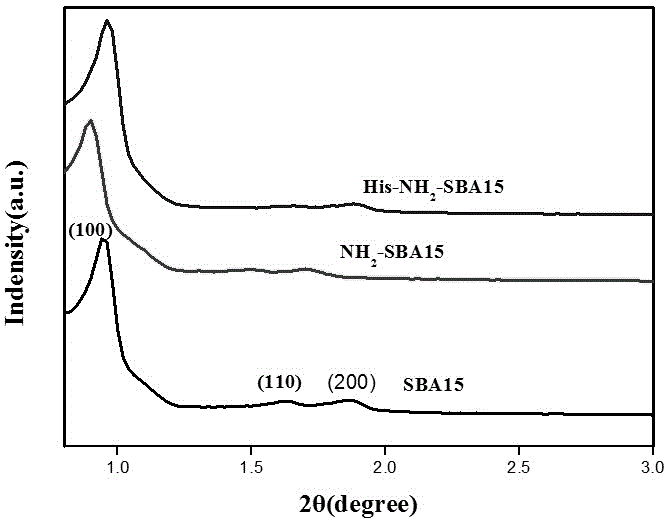

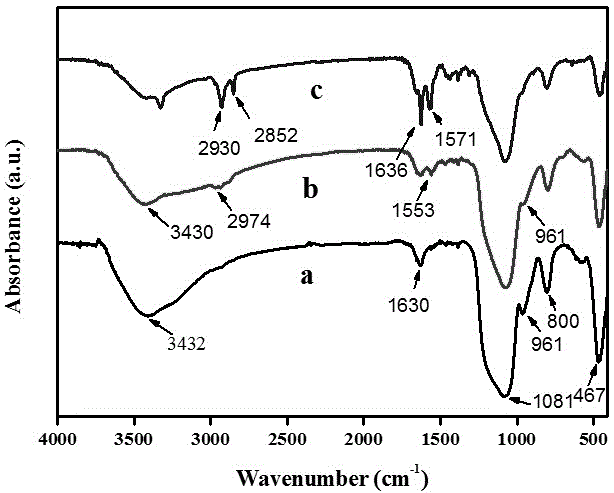

Preparation method and adsorption method of Ni<2+> adsorbent

ActiveCN104226238AChange adsorptionImprove adsorption capacityOther chemical processesSilicon compoundsSilicic acidSilanes

The invention discloses a preparation method and an adsorption method of a Ni<2+> adsorbent. The method comprises the following steps: (1) with tetraethoxysilane as a silicon source and triblock copolymer (P123, EO20PO70EO20) as a template agent, synthesizing a silica-based mesoporous material SBA-15, and modifying the inner surface of the silica-based mesoporous material SBA-15 with 3-aminopropyl triethoxy silane (APTES) through an alkyl coupling method to obtain an amino functionalized silica-based mesoporous material NH2-SBA-15; (2) grafting amino acid onto NH2-SBA-15 by a post-transplantation method to obtain the amino acid modified silica-based mesoporous material, namely, the adsorbent; (3) regulating the pH value of the adsorbent to 3-5 by virtue of a water solution containing Ni<2+>, and feeding the adsorbent to adsorb Ni<2+> in a water body, wherein the mass ratio of the adsorbent to Ni<2+> in the water body is 5:1 to 8:1, the adsorption temperature is 20-30 DEG.C, and the adsorption time is 10-30 minutes. The adsorbent preparation method is high in operability and good in reproducibility, the obtained amino acid modified silica-based mesoporous material has a good removal effect for heavy metal ions, Ni<2+>, in a water body, the equilibrium adsorption capacity of the adsorbent reaches up to 60mg.g<-1> above, and thus the actual application value of the adsorbent is good.

Owner:常熟紫金知识产权服务有限公司

Purifying method of epoxypropane

ActiveCN106117165AHas reversible ion exchange capabilityChange adsorptionOrganic chemistryFaujasite aluminosilicate zeolitePurification methodsGranularity

The invention discloses a purifying method of epoxypropane. In a fixed bed reaction device, liquid-phase epoxypropane containing aldehyde impurities enter a reaction bed layer of the fixed bed reaction device from bottom to top, a modified zealite sieve adsorbs the aldehyde impurities in epoxypropane at the temperature of 5-60 DEG C and the pressure intensity of 0.3-10.0 Mpa, and therefore purified epoxypropane is obtained; the modified zealite sieve adsorbing the aldehyde impurities recovers aldehyde substances after being purged by inert gas at high temperature so as to restore the adsorption performance. The method is a purifying method of epoxypropane containing the aldehyde impurities with granularity of 20-200 ppm; by means of the adsorption effect of the modified zealite sieve, the method can purify epoxypropane containing the aldehyde impurities with granularity of 20-200 ppm into an epoxypropane product containing aldehydes with granularity smaller than 10 ppm.

Owner:CHINA CATALYST HLDG CO LTD

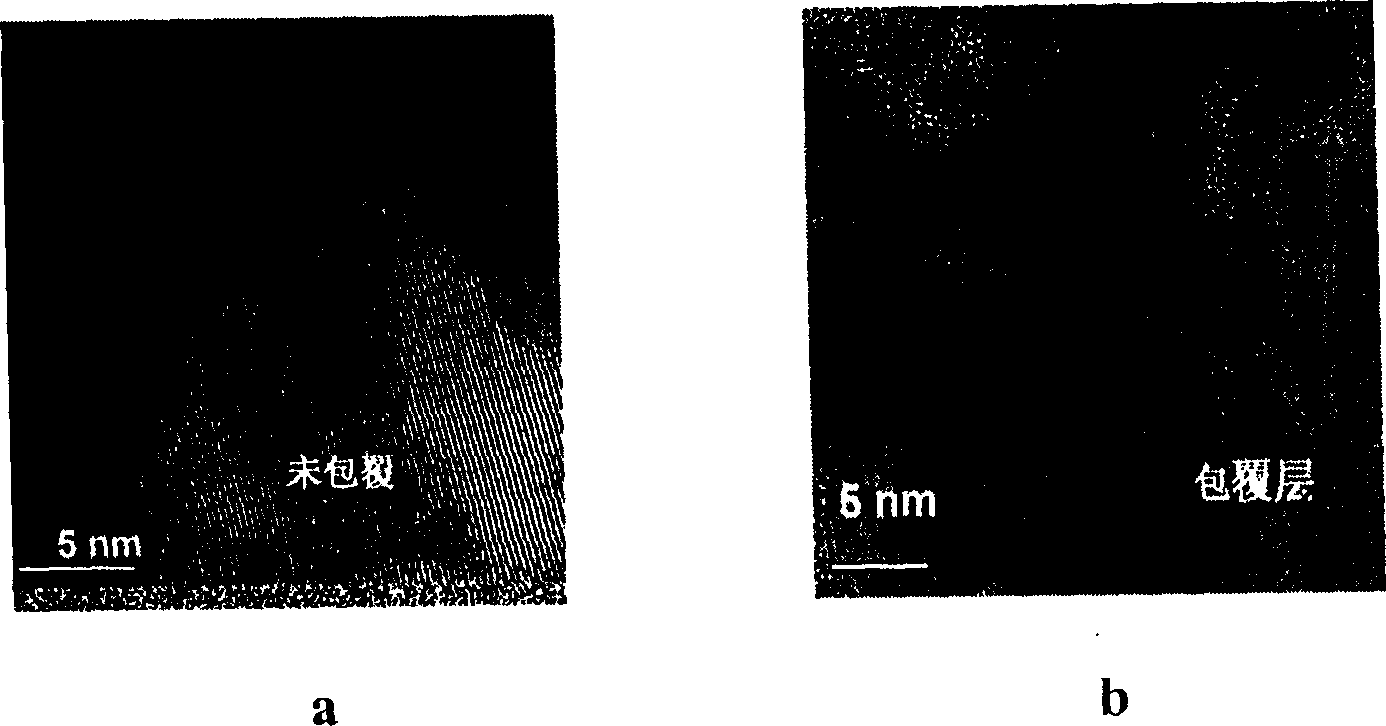

Nano particle surface physicochemical structure cutting and coating method

InactiveCN1488462AEasily brokenPromote infiltrationVacuum evaporation coatingSputtering coatingChemical structureSurface roughness

The invention is a cutting and coating method for surface physical and chemical structure of nano particles. Through confecting the radio frequency plasma to control pulse ratio, time, power, and furthermore control the kind, content, sediment layer thickness the coarse rate of packing film of functional group, it can cut and coat the special monomer molecular functional group film on the surface of the nano particles, and adjusts the thickness, surface coarse rate and so on, gets the coating film with special physical and chemical structure, changes the physical and chemical structure of nano particles.

Owner:DONGHUA UNIV

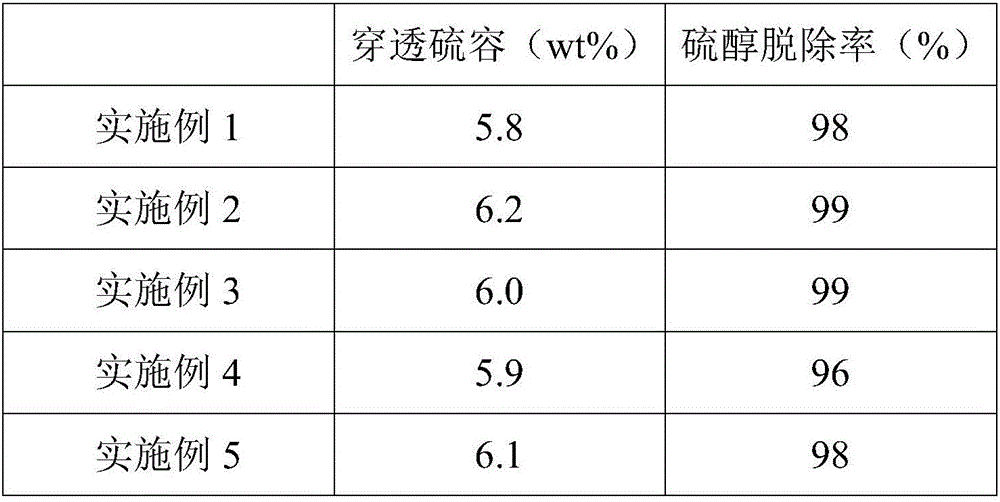

Mercaptan removal catalyst as well as preparation method and application thereof

ActiveCN106238091AEnhanced chemical adsorption capacityImprove adsorption capacityMolecular sieve catalystsGaseous fuelsRare-earth elementHeteropoly acid

The invention provides a mercaptan removal catalyst as well as a preparation method and application thereof. The catalyst comprises a carrier, an active component and an oxidizing auxiliary agent heteropoly acid, wherein the carrier is composed of alumina and a rare earth element-modified molecular sieve; the active component is one or more of group IA, IIA, IB, IIB, VIIB or VIII metal oxide. The catalyst provided by the invention can change a pore structure and the adsorption performance of the molecular sieve by modifying the molecular sieve, and enhance the chemical adsorption capacity of the catalyst carrier to the mercaptan so as to be more favorable for adsorbing the mercaptan; meanwhile, the catalyst provided by the invention oxidizes the mercaptan into corresponding disulfide by using the strong oxidizing property of the heteropoly acid and then is adsorbed by the composite carrier, thereby allowing the mercaptan removal catalyst provided by the invention to remove the mercaptan without hydrogenation while reducing the total sulfur content, and achieving the purpose of thoroughly and effectively removing the mercaptan.

Owner:SHENYANG SANJUKAITE CATALYST

Preparation method of sodium danshensu

ActiveCN1868994ASimple processQuality controllableCarboxylic compound separation/purificationChemistryCrystal

Owner:SHANDONG LUYE PHARMA CO LTD

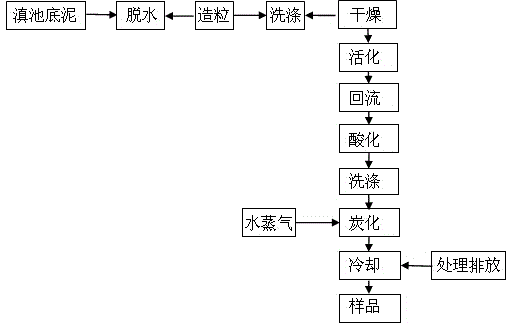

Method for preparing adsorbent by using bottom mud of Dian Lake and application thereof

InactiveCN104437374AChange surface electrical propertiesChange adsorptionOther chemical processesWater contaminantsSorbentCarbonization

The invention discloses a method for preparing adsorbent by using bottom mud of Dian Lake and application thereof, and belongs to the technical field of preparation of heavy metal adsorbents. The method comprises the following steps: soaking the bottom mud by distilled water, repeatedly washing and drying the bottom mud, adding a glutaraldehyde solution into the bottom mud to serve as an activator, adding the bottom mud into a polydimethyl diallylammonium chloride solution, putting in a water bath to carry out heating reflux, pouring the supernate and carrying out acidizing by hydrochloric acid, filtering and washing to neutral and drying to obtain initial samples, putting the samples in an electric furnace and carrying out high-temperature carbonization by taking vapor as protection gas, obtaining carbonized samples after cooling, repeatedly washing the samples to remove the impurities in the carbonized products until washing to neutral (pH>6.5), carrying out drying, grinding after cooling, and screening to obtain the samples according with adsorption. The method is simple in operation conditions, extremely high in adsorbent productivity; through combining the physical activation method and the chemical activation method, the activation effect is relatively good, the performance of the adsorbent is improved and the adsorption value of manganese is greater than 19mg / g.

Owner:KUNMING UNIV OF SCI & TECH

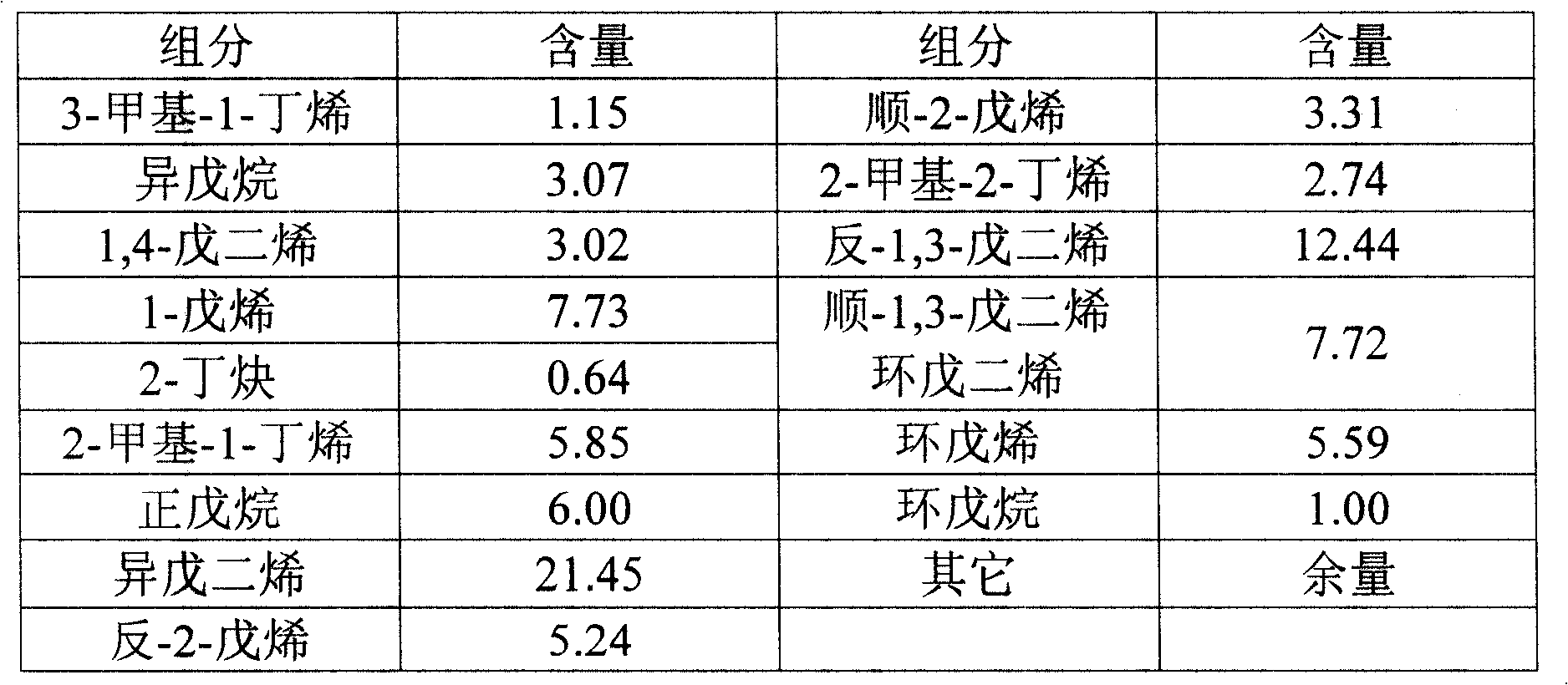

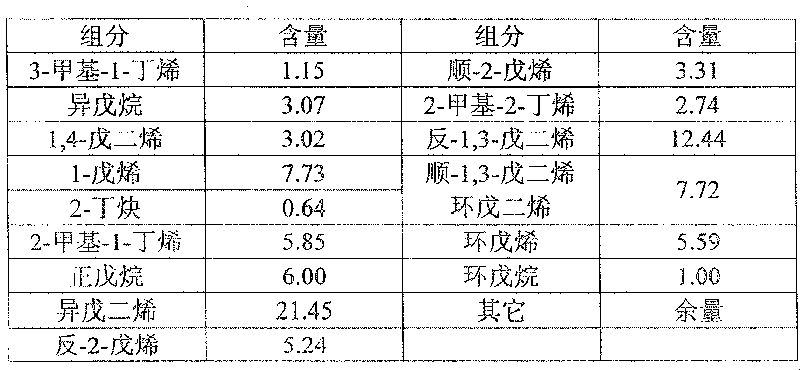

Cracking carbon five selective hydrogenation catalyst

ActiveCN101254465AHigh activityHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionStrontiumPotassium

The invention relates to a selective hydrogenation catalyst for C5 fraction cracking and belongs to the technology field of hydrogenation catalysts. In order to meet the urgent need of the selective hydrogenation catalysts for the C5 fraction cracking, the invention provides a catalyst for selective hydrogenation in the C5 fraction cracking, which contains the following components in the given mass percentages: Ni 10-35%, La 0.5-3%, Ag 0.3-3% and aluminum oxide carrier 59-89.2%, calculated on basis of the total mass of the catalyst. The catalyst can also contains K and / or Sr or Pb. The catalyst is used for selective hydrogenation in the C5 fraction cracking as well as hydrogenation in the C5 fraction cracking and excellent in conversion rate, selectivity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel sulfonation melamino-formaldehyde resin and preparation method thereof

The invention relates to the technical field of resin materials, in particular to a novel sulfonated melamine-formaldehyde resin and a preparation method thereof. The raw materials of the sulfonated melamine-formaldehyde resin include modified melamine, formaldehyde, sodium metabisulfite, sulfuric acid, saturated calcium hydroxide, sodium hydroxide and water. Melamine can be replaced by modified melamine. When melamine is modified with lauryl alcohol Jinxin, its molecular weight can be increased, its production cost can be reduced, and thus it can be mass-produced.

Owner:SHENZHEN AIYIRUI TECH CO LTD

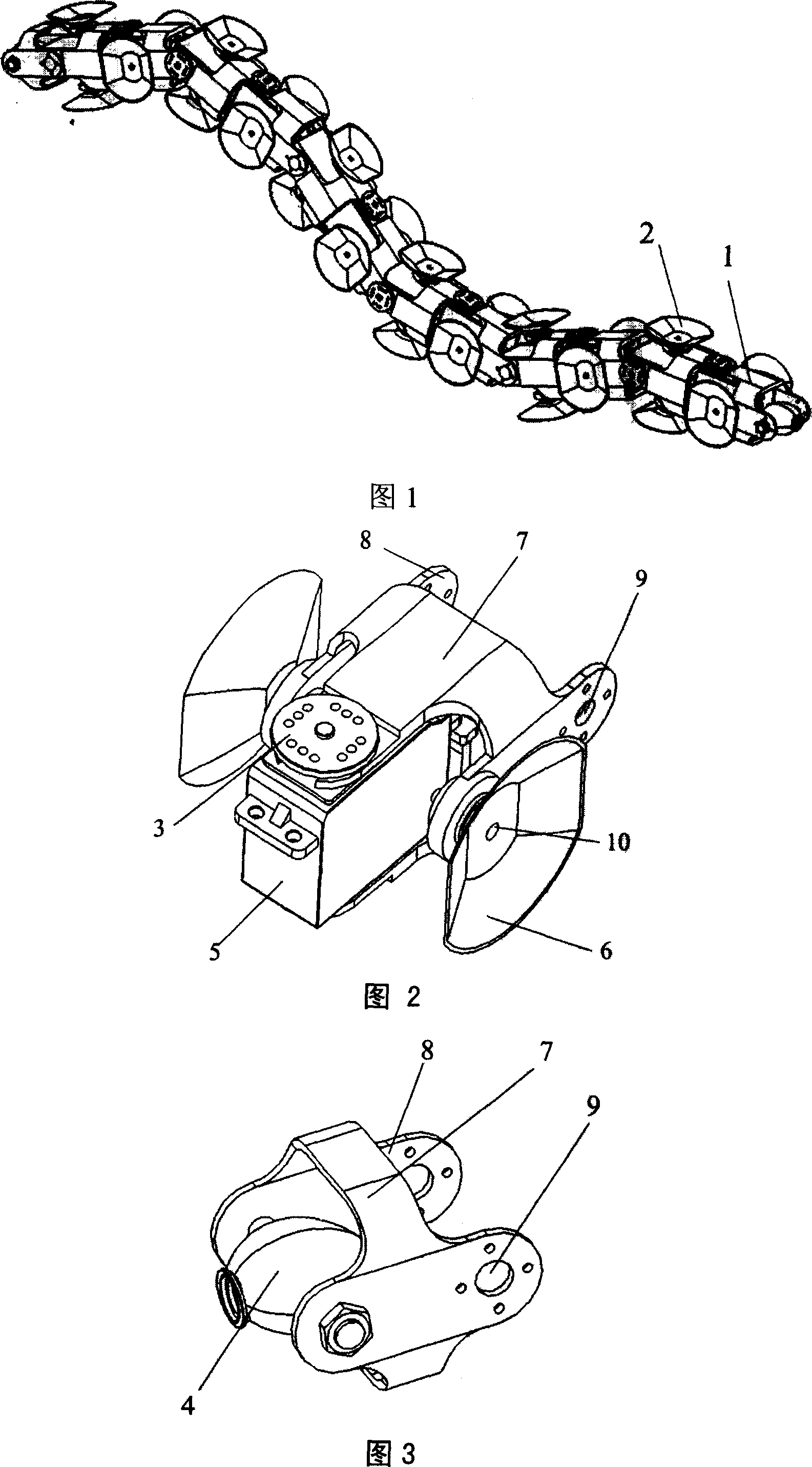

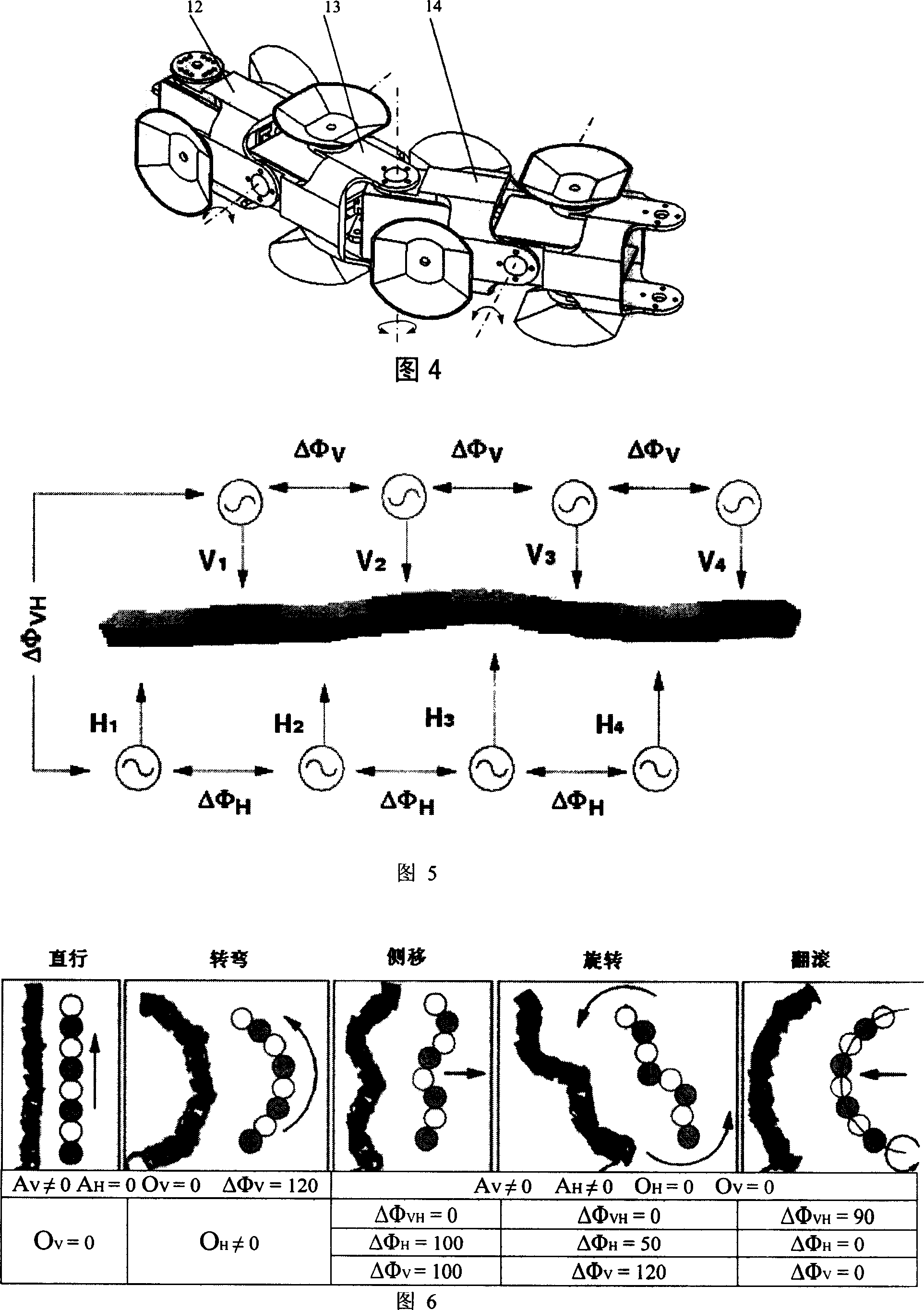

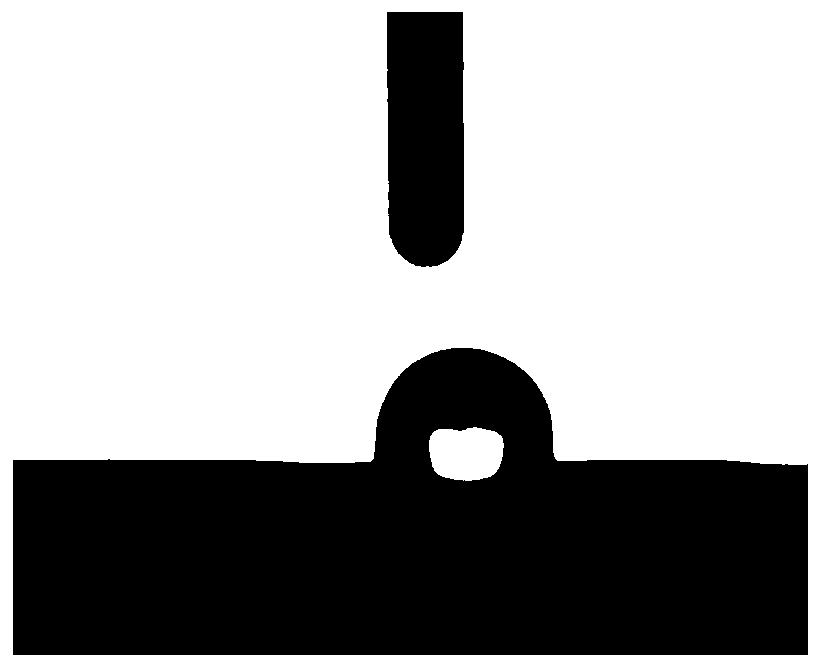

Bionic mechanical reptile

The bionic mechanical reptile consists of one head module and one tail module without autokinetic motion function and basic trunk modules with one rotating freedom. The present invention adopts automatic passive sucker adsorption, multiple sensor fusion, and central mode generator motion control algorithm. The present invention has the advantages of capacity of crawling in vertical and inclined wall of different materials, capacity of crossing obstacle and face-to-face converting, etc.

Owner:张厚祥

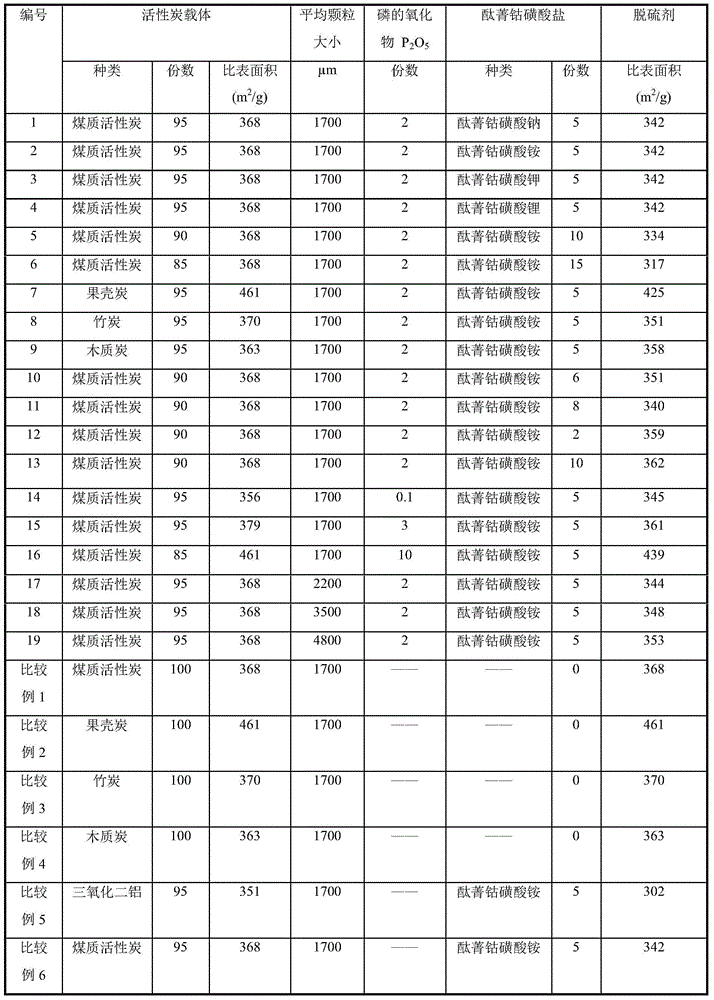

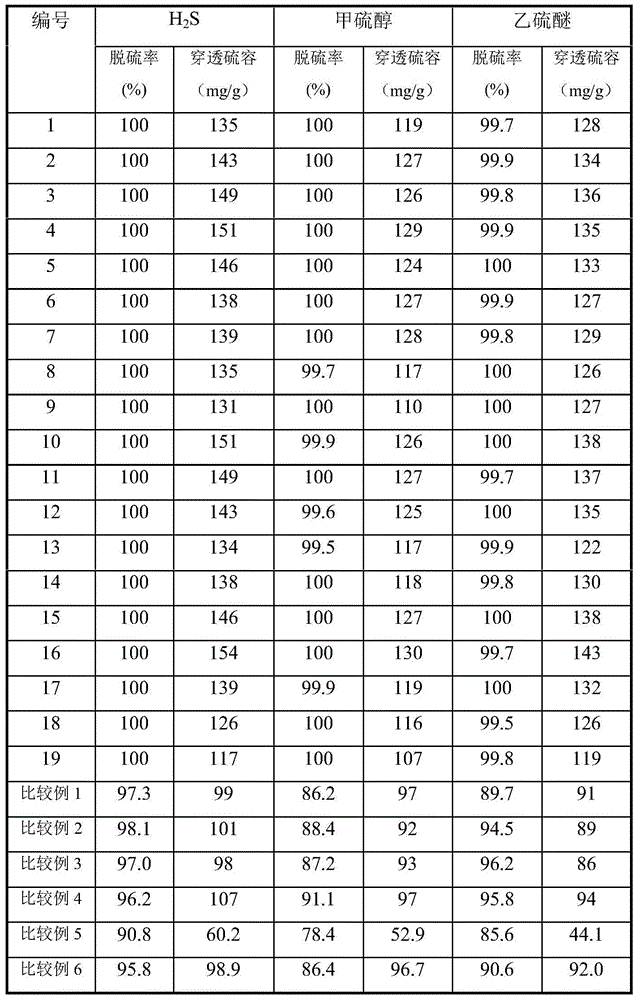

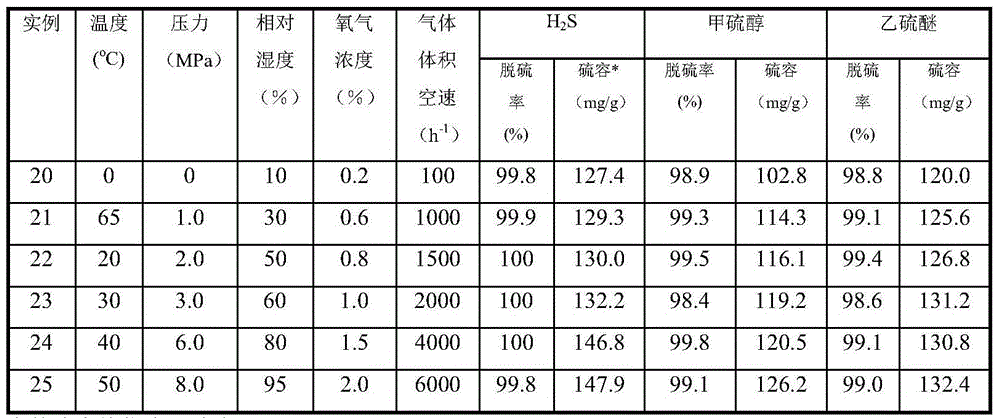

Active carbon desulphurization adsorbent loaded with cobalt phthalocyanine sulfonate and preparation method

ActiveCN105080488AHigh removal rateHigh breakthrough sulfur capacityIon-exchange process apparatusOther chemical processesActivated carbonSulfonate

The invention relates to a active carbon desulphurization adsorbent loaded with cobalt phthalocyanine sulfonate and a preparation method thereof, and mainly solves problems that sulfur removal rate is low, and breakthrough sulfur capacity of desulfurizer is low in existing gas adsorption, desulphurization and purification technology. In the invention cobalt phthalocyanine sulfonate is employed as active ingredient and a small amount of phosphor is added for modifying the active carbon. In this way, the solid adsorbent is obtained. The problems of low sulfur removal rate, etc. are solved. The desulphurization adsorbent of the invention can be used in adsorption and purification of gas materials for removal of sulfur-containing compound.

Owner:CHINA PETROLEUM & CHEM CORP +1

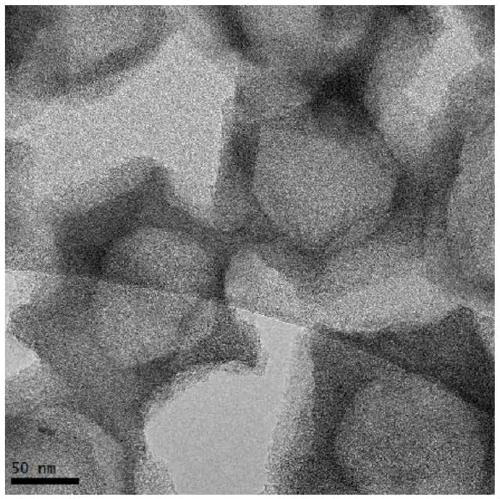

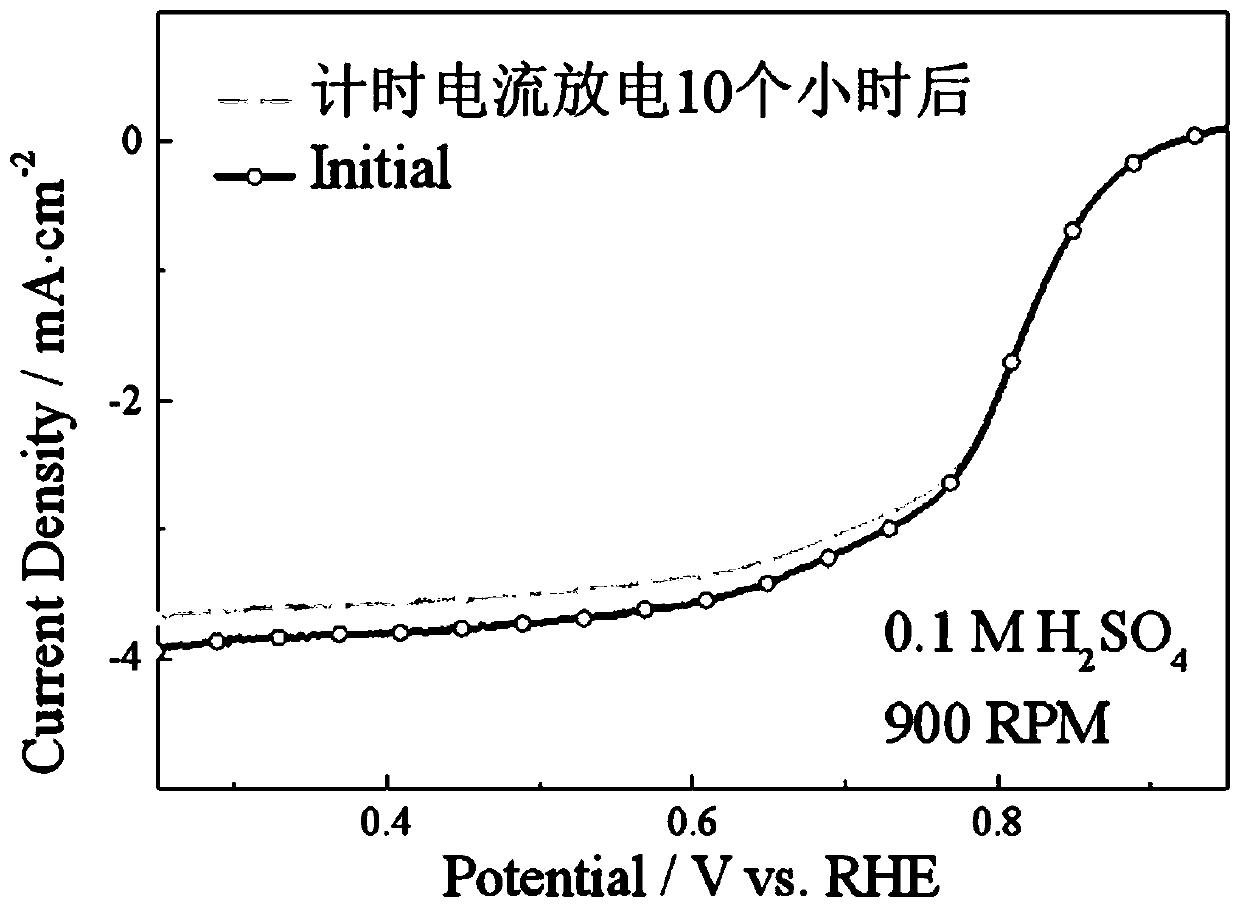

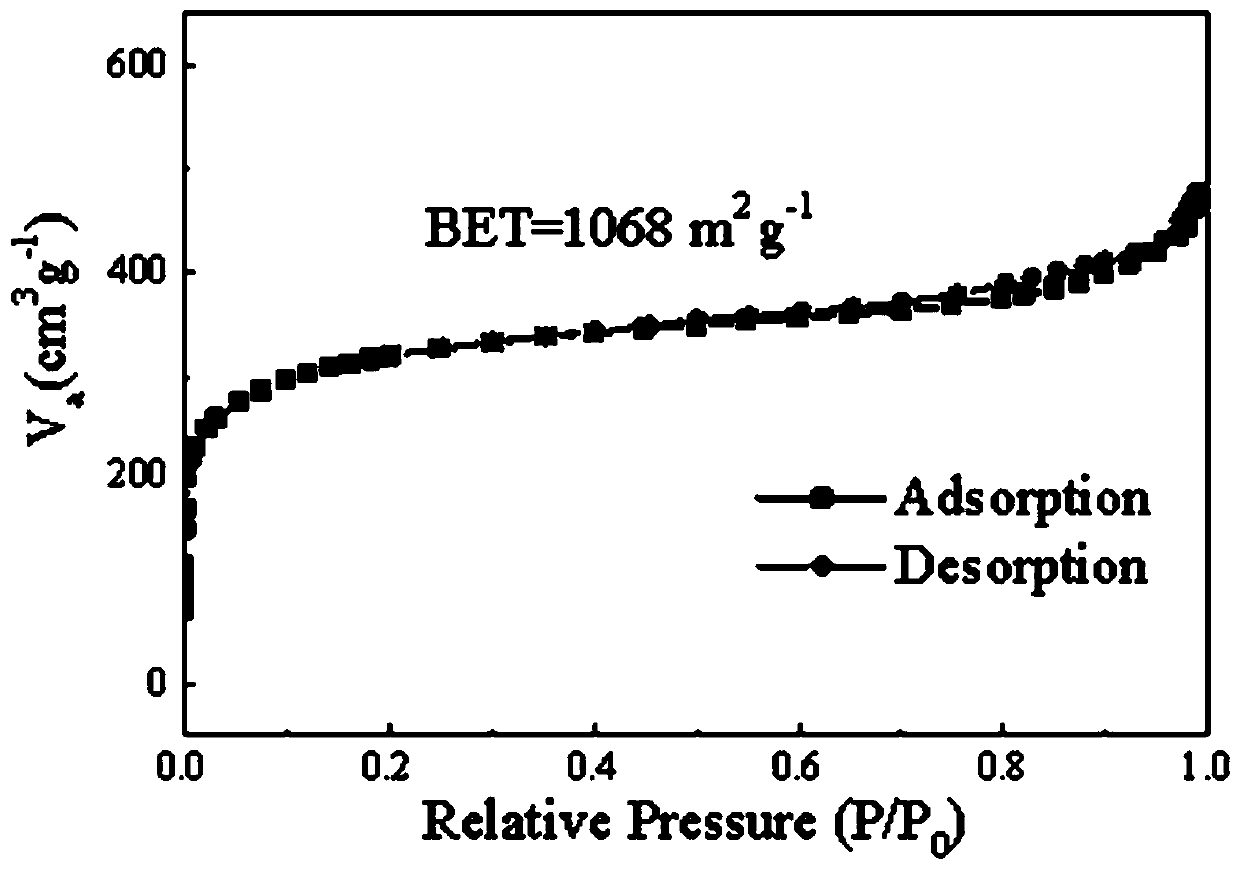

Sulfur-containing non-noble metal salt doped hollow nanometer metal organic framework material, and preparation method and application thereof

ActiveCN111138675ALarge specific surface areaImprove power densityMaterial nanotechnologyCell electrodesPtru catalystMetal-organic framework

The invention discloses a sulfur-containing non-noble metal salt doped hollow nanometer metal organic framework material, and a preparation method and an application thereof. The preparation method comprises the following preparation steps: 1) preparation of a metal organic framework material precursor; 2) preparation of a sulfur-containing non-noble metal salt solution; 3) doping of a sulfur-containing non-noble metal salt solution; and 4) pyrolysis preparation of the sulfur-containing non-noble metal salt doped hollow nanometer metal organic framework material. According to the invention, the process flow is simple; the reaction process is easy to be controlled; a template does not need to be introduced in the preparation process; and by introduction of sulfur-containing non-noble metalsalt doping as an excellent cocatalyst, the sulfur-containing non-noble metal salt is highly dispersed in micropores of an original single-crystal metal organic framework structure, and original metalconnecting elements are replaced in the pyrolysis process, so the electronic state and the adsorption property of the surfaces of noble metal particles are changed, and the purpose of improving the catalytic performance is achieved.

Owner:XI AN JIAOTONG UNIV

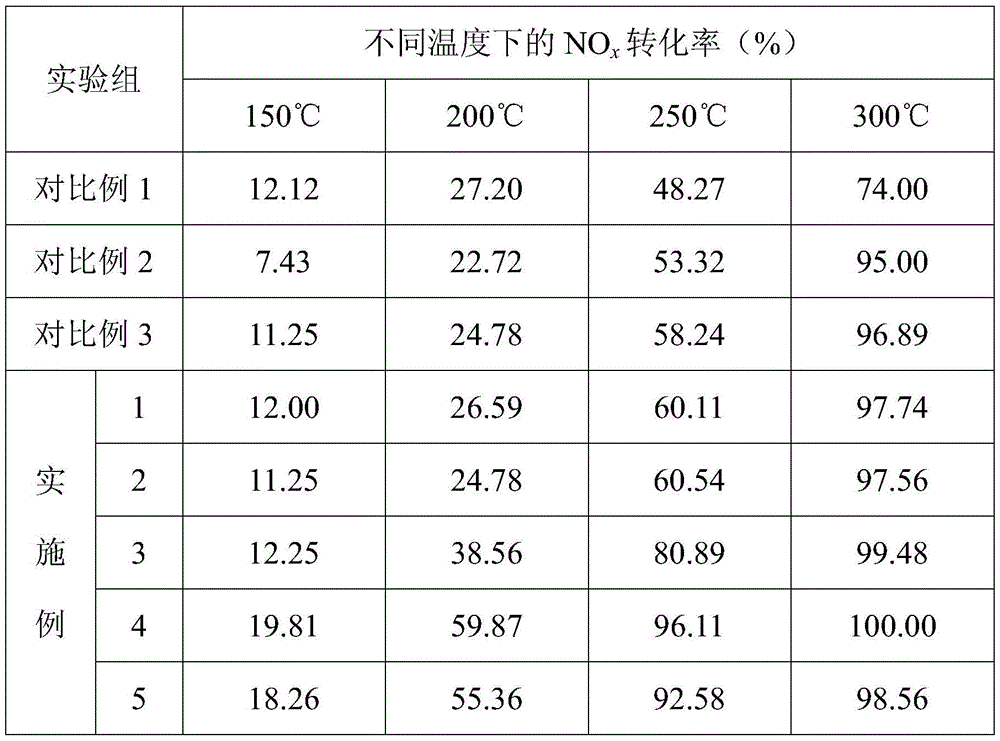

Cerium-tin-zirconium composite oxide catalyst, and preparation method and use thereof

InactiveCN105664912AGood catalytic activityWide temperature window rangeGas treatmentHeterogenous catalyst chemical elementsComposite oxideChemical composition

The invention relates to a cerium-tin-zirconium composite oxide catalyst, a preparation method and an application thereof. The catalyst has the following chemical composition: CeSn a Zr 2 o x , a ranges from 0 to 2.0 and does not include 0. The addition of Sn promotes the synergy between Sn, Ce, and Zr, changes the adsorption performance of the catalyst to the reactants, and makes the redox process of the catalyst easier to complete, thereby increasing the NO x removal efficiency. The CeSn a Zr 2 o x The catalyst activity is significantly improved, and the temperature window is also significantly widened. The cerium-tin-zirconium composite oxide catalyst has excellent NH 3 - SCR activity.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

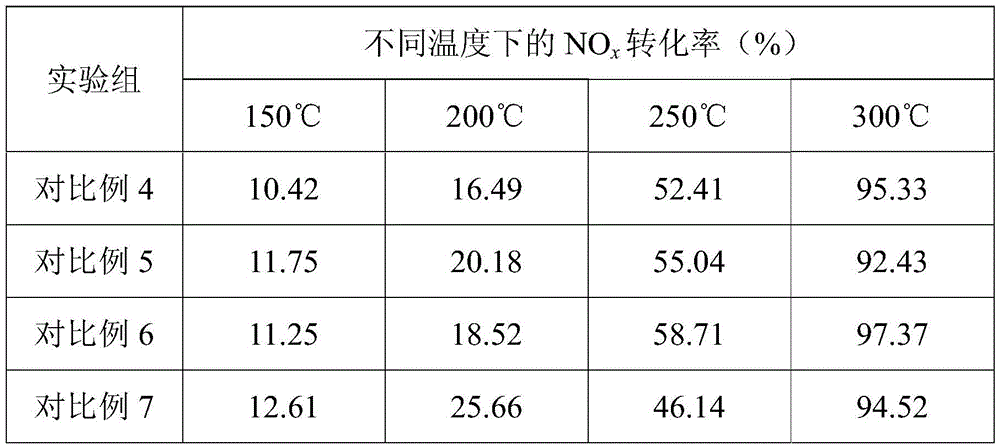

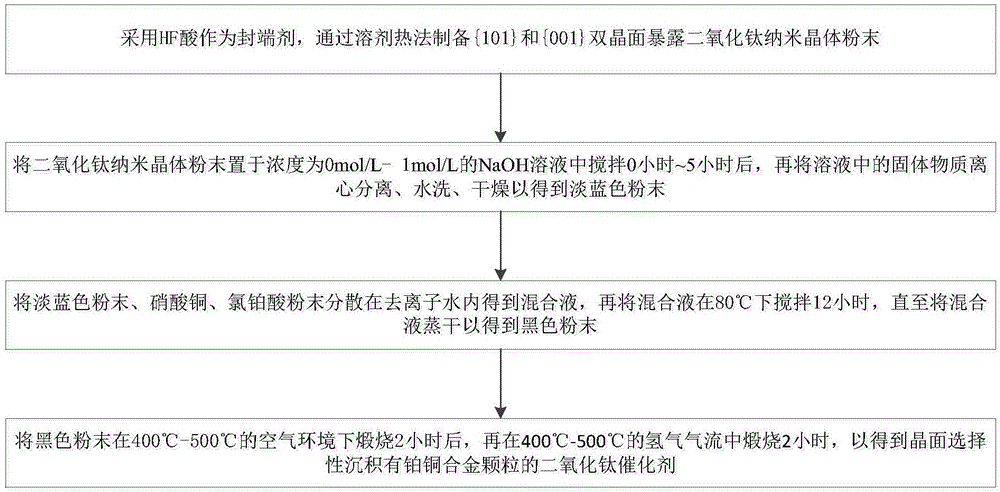

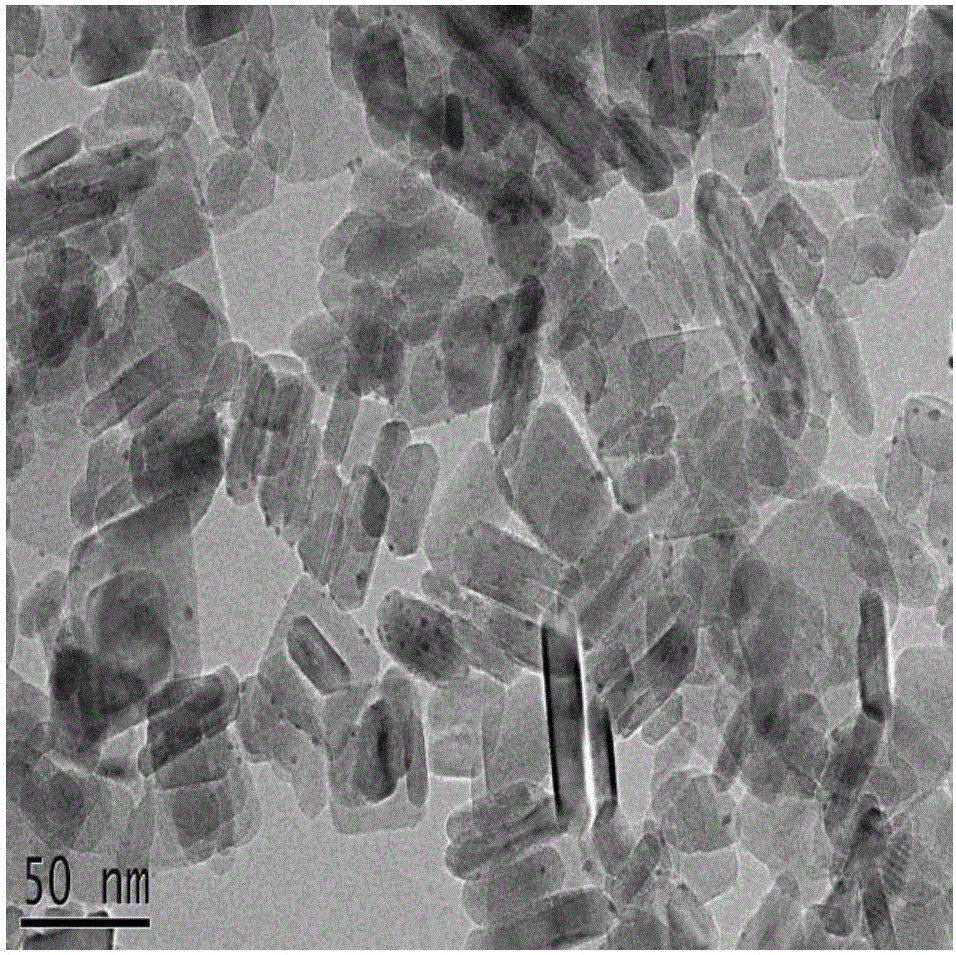

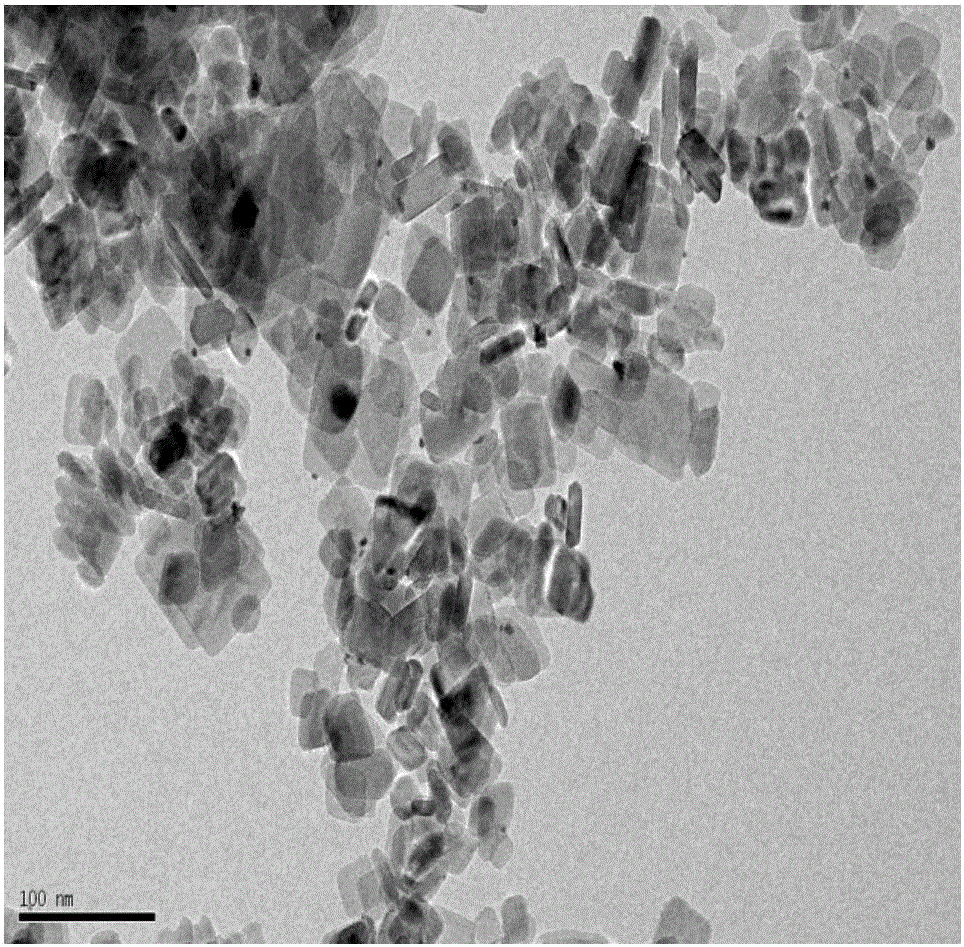

Method for preparing titanium dioxide catalyst with selectively deposited platinoid alloy granule

ActiveCN106807399AChange adsorptionFew types of substancesGas treatmentDispersed particle separationIonSolvent

The invention belongs to the technical field of materials and environments, and discloses a method for preparing a titanium dioxide catalyst with selectively deposited platinoid alloy granules. The method comprises the following steps: by adopting HF (Hydrofluoric Acid) as an end-capping reagent, preparing {101} and {001} double-crystal surface exposed titanium dioxide crystal powder by using a solvent thermal method; putting the titanium dioxide crystal powder into a 0-10mol / L sodium hydroxide solution, stirring for 0-5 hours, and performing centrifugal separation and water washing drying on solid substances in the solution so as to obtain light blue powder; dispersing the light blue powder, copper nitrate and chloroplatinic acid powder in deionized water so as to obtain a mixed liquid, stirring the mixed liquid for 12 hours at a temperature of 80 DEG C, and performing evaporation drying till black powder is prepared; calcining the black powder in an air environment, and calcining in hydrogen flow, so as to obtain the titanium dioxide catalyst with the selectively deposited platinoid alloy granules.

Owner:HUAZHONG UNIV OF SCI & TECH

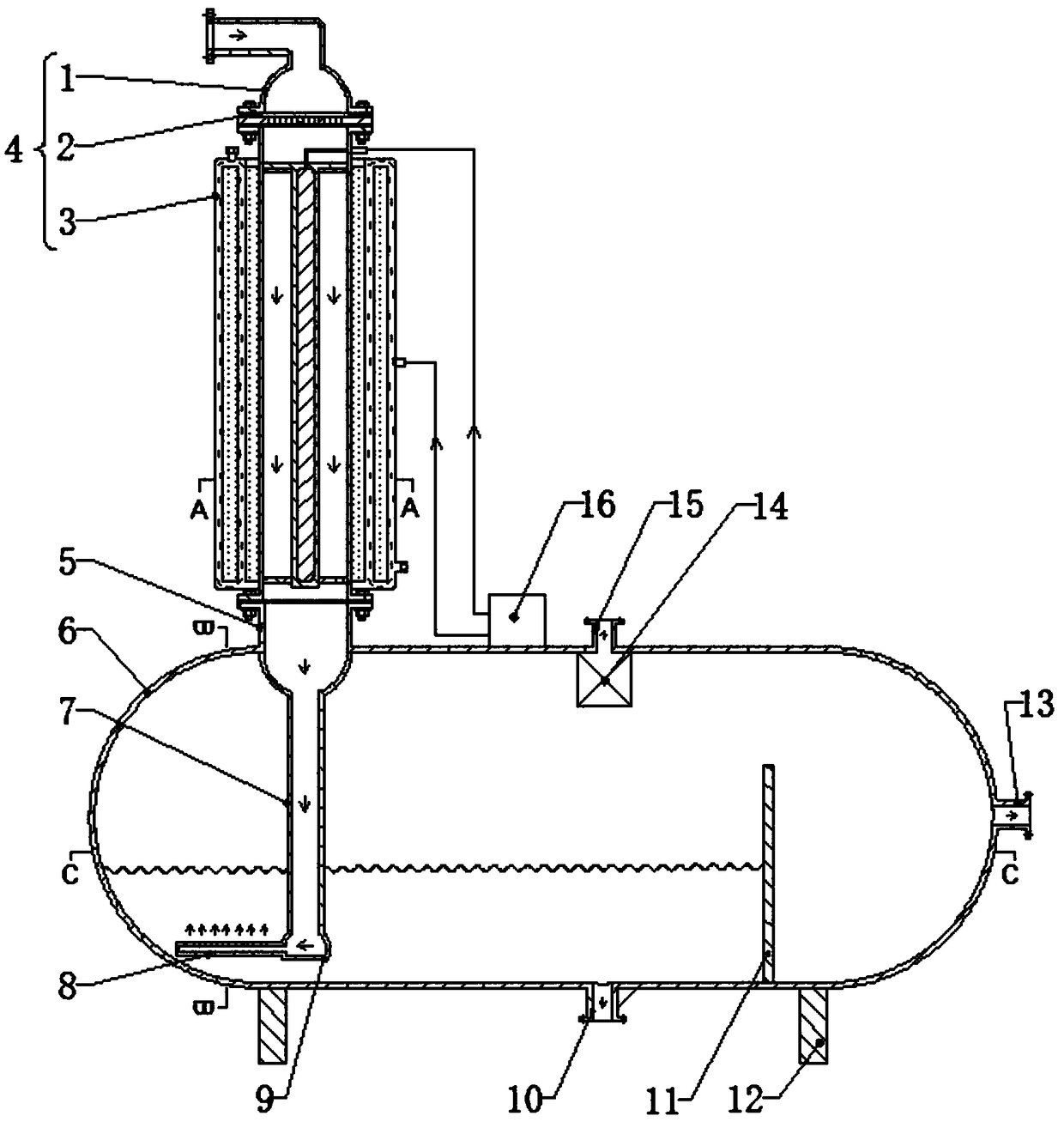

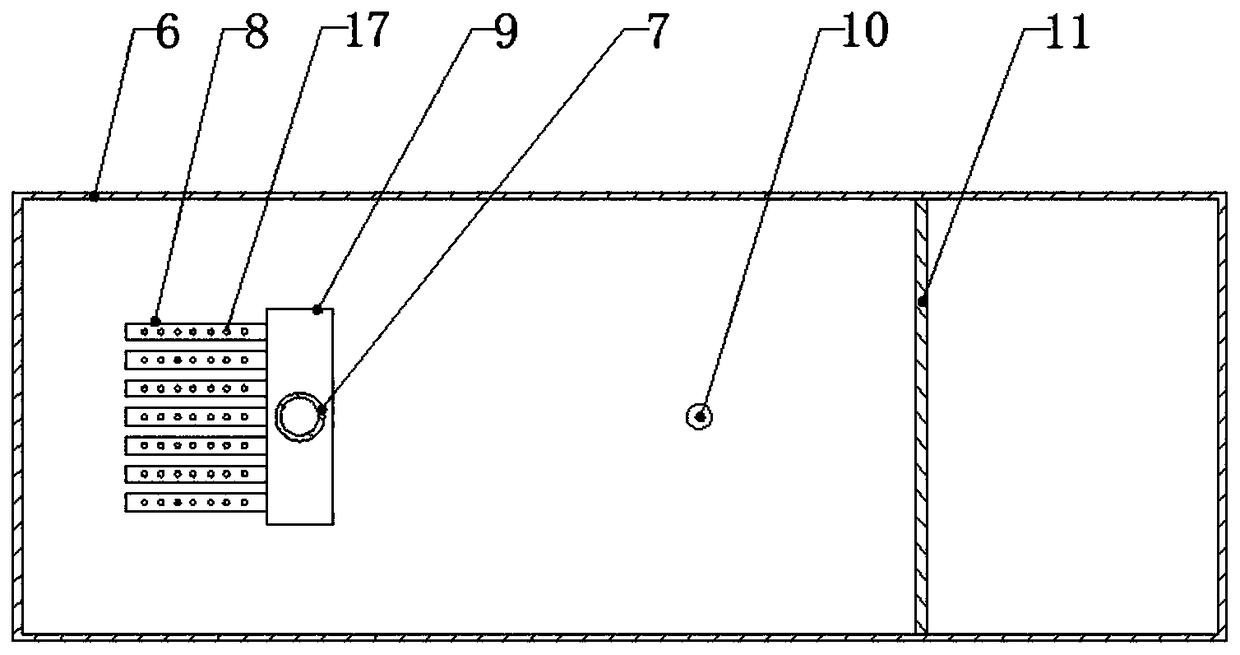

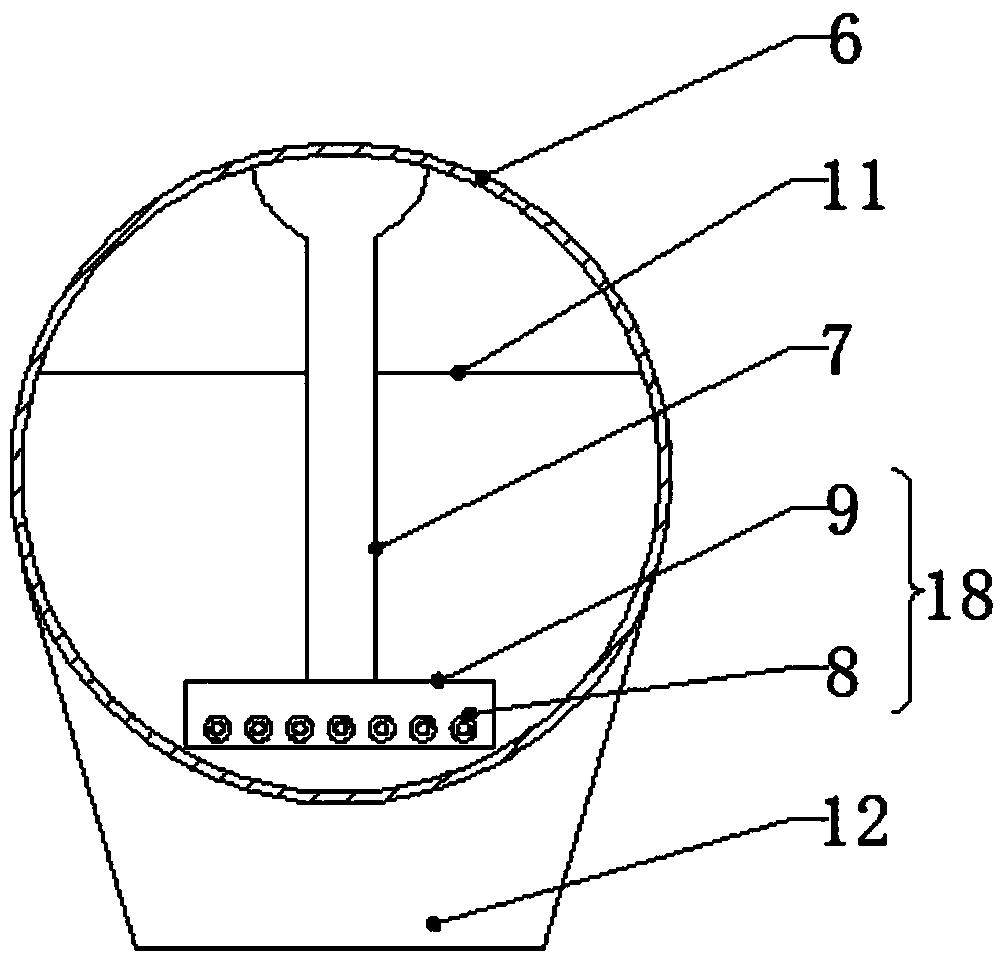

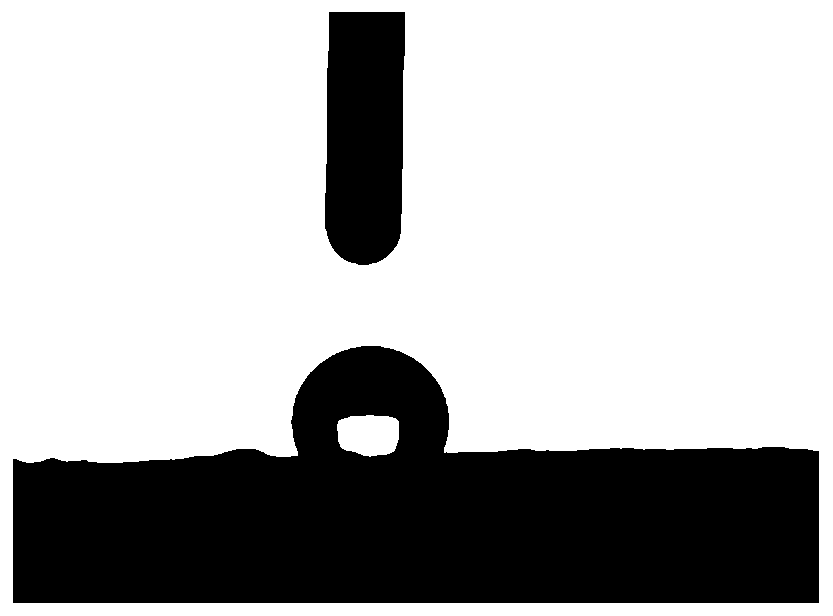

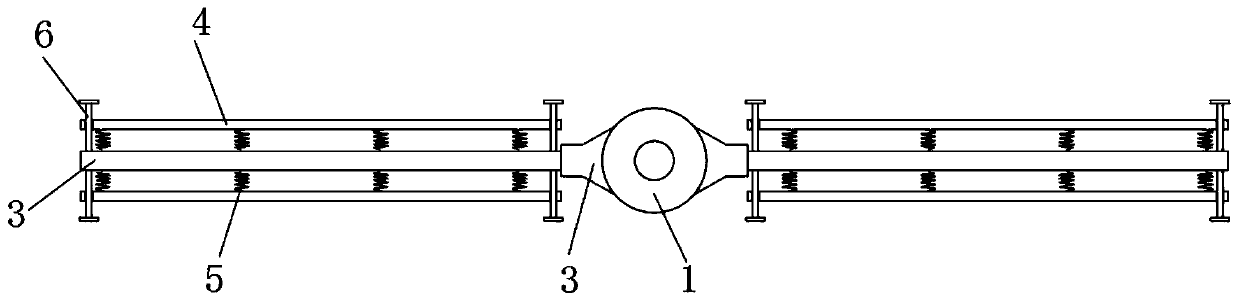

Oil-water separation system with efficient electromagnetic synchronous cooperation

ActiveCN108658181ASimple separation processWide range of moisture contentFatty/oily/floating substances removal devicesWater/sewage treatment by magnetic/electric fieldsVena contracta diameterEngineering

The invention relates to an oil-water separation system with efficient electromagnetic synchronous cooperation, comprising a reinforced coalescing device and a precipitating separating device and characterized in that a drain pipe liquid distributor is arranged at the inner bottom of the precipitating separating device, the reinforced coalescing device is provided with an electromagnetic coalescing component, a liquid-distributing orifice plate is arranged between an inlet head and the electromagnetic coalescing device, the electromagnetic coalescing component includes an electric field generating component and a magnetic field exciting component which are in coaxial distribution; an electric field and a magnetic field are orthogonally distributed to arrive at synchronous cooperation. Theelectric field generating component includes a grounding external electrode and an axial electrode coated with an insulating sleeve, allowing electric field intensity to be increased to 350 kV / m; themagnetic field exciting component includes outer and inner coils coaxially and hermetically sleeving the external electrode, the outer coil is greater than the inner coil in the number of turns, and the outer coil and the inner coil are contained in a self-circulating cooling sleeve. The oil-water separation system has the advantages that oil-water separation efficiency is significantly improved,oil-water separation range is significantly widened, the system is capable of treating oil-water emulsions having a water content of up to 40%, and therefore, the system is widely applicable to efficient and stable equipment and facilities for oil-water separation on land and sea.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Mudstone hydrophobically modified grouting material and preparation method thereof

The invention discloses a mudstone hydrophobically modified grouting material and a preparation method thereof, and belongs to the technical field of underground engineering safety. The hydrophobically modified grouting material is prepared from, by weight, 40-50 parts of ordinary Portland cement, 5-10 parts of water-quenched slag, 10-20 parts of coal gangue powder, 2-3 parts of a water reducing agent, 50-70 parts of a surfactant solution and 5-8 parts of water glass. All the components are mixed in sequence to prepare the grouting material. The grouting material can enhance the water resistance of mudstone surrounding rock, reduce the water absorption expansion of the surrounding rock, improve the filling effect and enhance the compression resistance, and meanwhile, the influence of industrial solid wastes on the environment is reduced by utilizing the water-quenched slag and the coal gangue powder.

Owner:LIAONING TECHNICAL UNIVERSITY

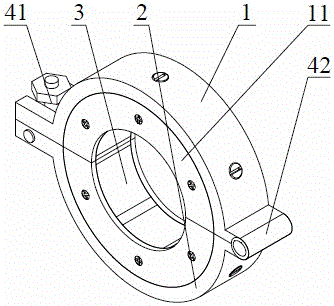

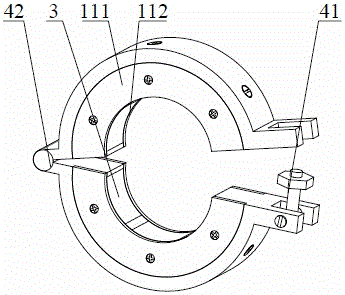

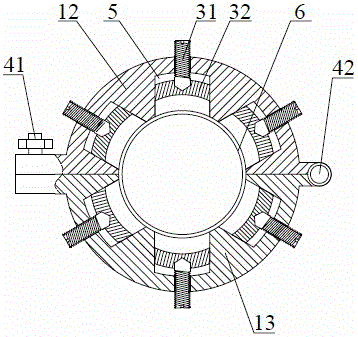

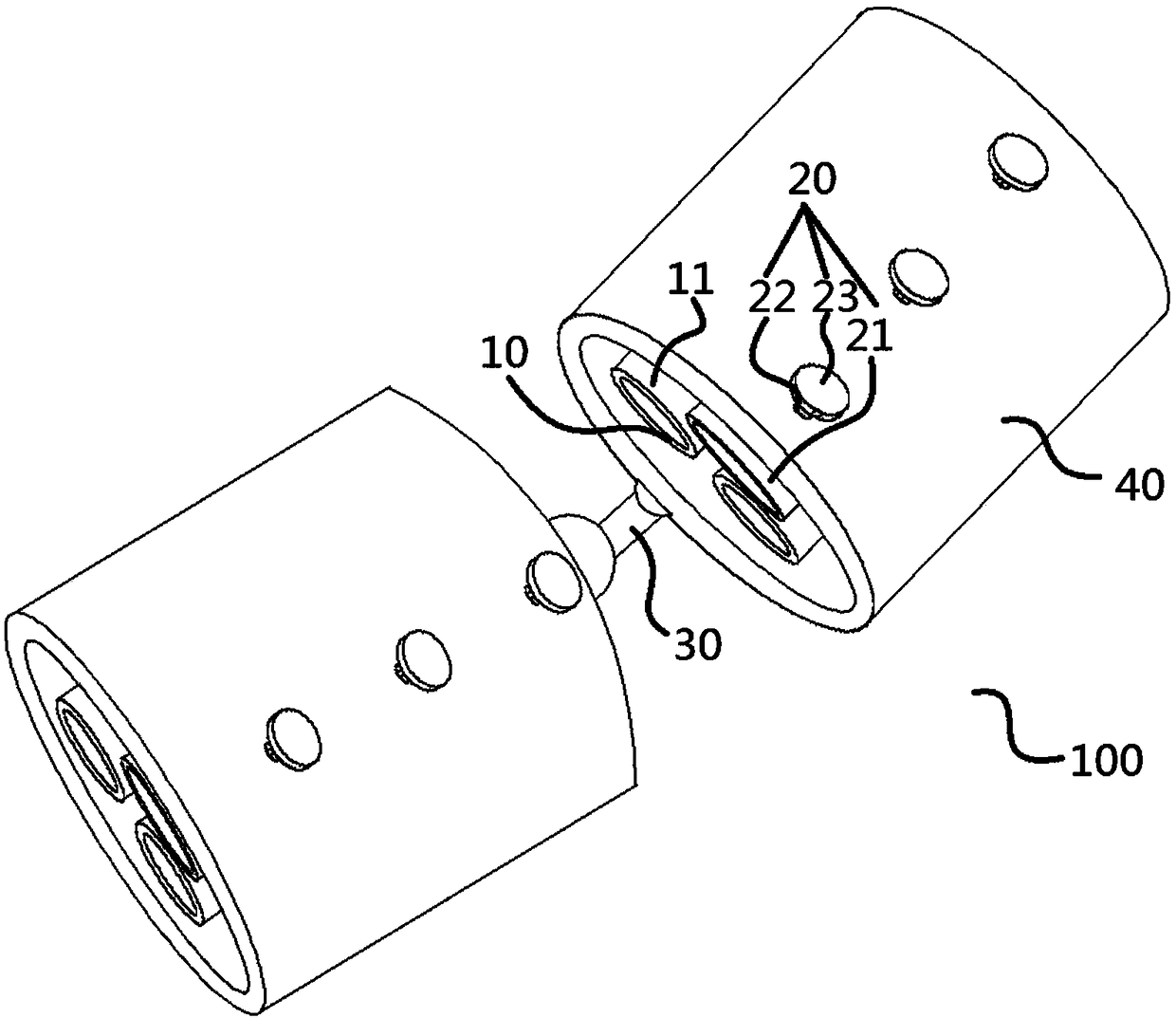

Clamping tool with magnetism and monitoring device adopting clamping tool

ActiveCN105728189AAvoid enteringThe size of the adsorption force is adjustableMagnetic separationMetal impuritiesMechanical engineering

The invention relates to a mechanical part installed on a liquid passing pipeline, in particular to a clamping tool with the magnetism and a monitoring device adopting the clamping tool. The clamping tool comprises a clamping part matched with a pipeline, the clamping part is provided with at least one sliding groove, and magnetic devices used for attracting metal impurities in the pipeline are arranged in the sliding grooves and can slide along the sliding grooves. When the clamping part clamps the pipeline, the magnetic devices on the clamping part can attract the metal impurities in the pipeline, therefore, the metal impurities are accumulated at the position, corresponding to the clamping range of the clamping part, of the pipeline, it is guaranteed that liquid passing through the clamping range of the clamping part does not contain the metal impurities any more, the metal impurities are prevented from entering the monitoring device which utilizes the magnetic principle and is arranged on the pipeline, and therefore accurate working of the monitoring device is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

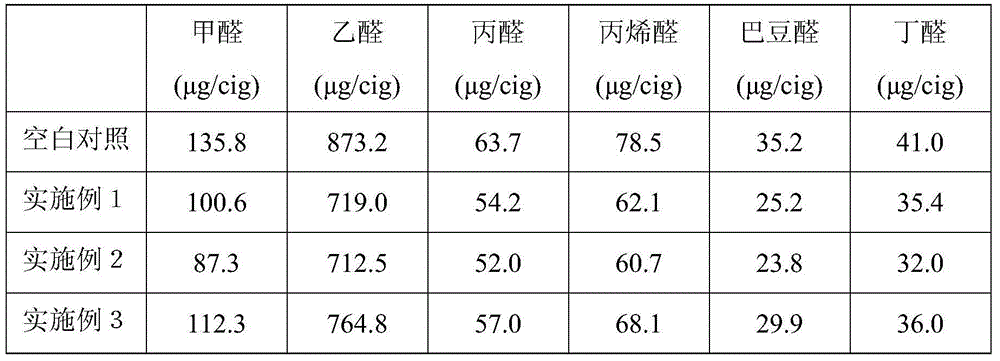

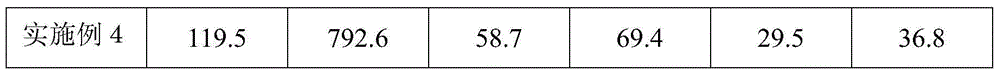

Cigarette filter tip additive removing aldehydes in cigarette mainstream smoke and preparation method and application thereof

ActiveCN104432507AWide variety of sourcesChange surface structureTobacco smoke filtersAdhesive materialsCigarette filter

The invention discloses a cigarette filter tip additive removing aldehydes in the cigarette mainstream smoke and a preparation method and application thereof. The cigarette filter tip additive is a compound material composed of tobacco material particles, carbon material and adhesive material in an adhered manner. The cigarette filter tip additive added into a cigarette filter tip is capable of reducing the aldehydes in the cigarette mainstream smoke effectively and selectively, and the cigarette taste is not influenced; the preparation method of the cigarette filter tip additive is easy and fast to implement, the cost is low, and the industrial production can be met.

Owner:CHINA TOBACCO HUNAN INDAL CORP

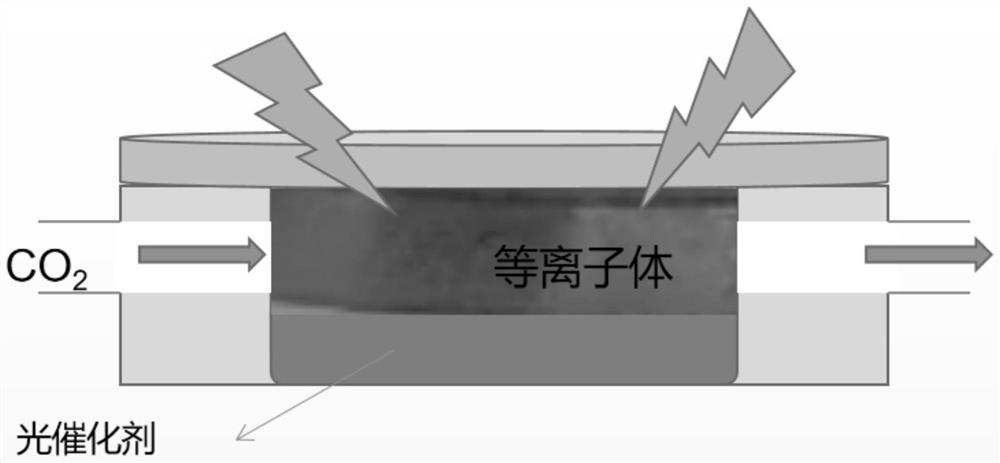

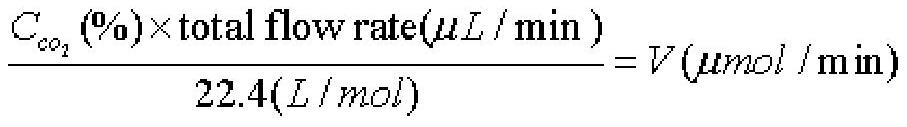

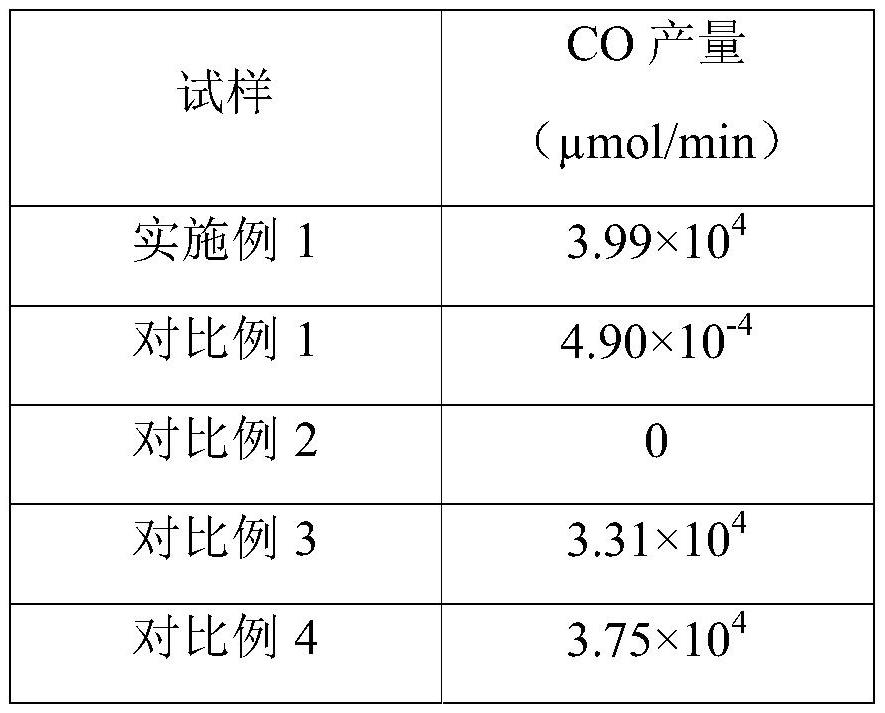

Method for synergistically converting carbon dioxide through plasma and photocatalyst

PendingCN113975946AEvenly distributedImprove efficiencyGas treatmentDispersed particle separationPhoto catalysisChemical engineering

The invention relates to a method for synergistically converting carbon dioxide through plasma and a photocatalyst, and belongs to the field of comprehensive utilization of carbon dioxide. The method mainly comprises the following steps: adding 0.01 g of a photocatalyst into a plasma catalysis device with a plasma power supply power of 60W, introducing CO2 at a flow rate of 50 mL / min, and carrying out plasma discharge reaction for 10 minutes to reduce CO2 into CO. The method has the advantages of being simple in process, easy and convenient to operate, low in cost and beneficial to industrial production.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

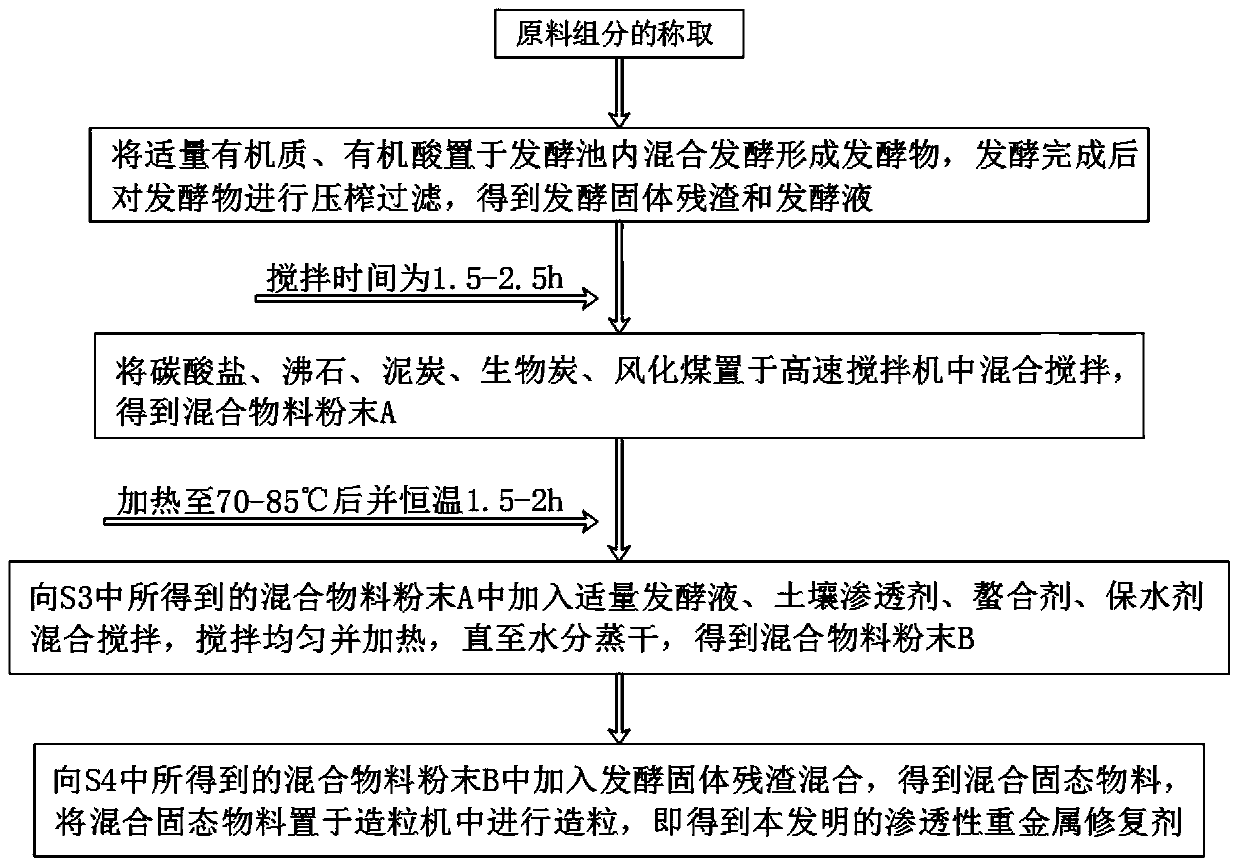

Self-permeating type soil heavy metal repair agent and preparation method thereof

InactiveCN110591719AGood physical propertiesImprove fat retention capacityAgriculture tools and machinesRotary stirring mixersFood chainIon exchange

The invention discloses a self-permeating type soil heavy metal repair agent and a preparation method thereof, and belongs to the technical field of repair agent preparation. According to the self-permeating type soil heavy metal repair agent and the preparation method thereof, organic matter is mixed with a base material of organic acid, the promoting property of the repair agent on growth and development of plants is effectively improved, physical properties of repaired soil are improved, activities of microorganisms and soil organisms are promoted, nutrient elements in the soil are promotedto be decomposed, and meanwhile, air permeability, permeability and adsorbability of the soil are changed; by addition of mineral improvers such as zeolite, peat, charcoal, weathered coal and the like, on one hand, reaction performance such as adsorption, ion exchange and the like of heavy metal elements is improved, heavy metal pollutants such as cadmium, chromium, lead and the like in soil canbe cured and passivated, bio-availability of the heavy metal pollutants and mobility in soil are reduced, risks that the pollutants are absorbed by crops and transferred to food chains are reduced, and on the other hand, physical and chemical properties of the soil are improved.

Owner:杨涛

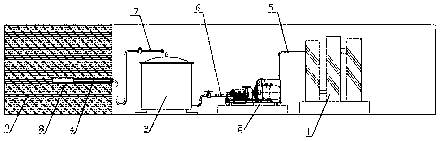

Device and method for transforming physical characteristics of coal seam through downhole heat injection

The invention provides a device and method for transforming physical characteristics of a coal seam through downhole heat injection, and relates to coal mining technologies. According to the device and method for transforming the physical characteristics of the coal seam through downhole heat injection, the technical problem that rock burst or outburst of coal and gas easily occurs during coal roadway tunneling is solved. According to the device and method for transforming the physical characteristics of the coal seam through downhole heat injection, a coal seam heating system is composed of acoal mine neutral water purifier-softener, a high pressure water pump, an electric heater, a heat injection pipeline and a heat injection drilling hole; water is injected into the electric heater through the high pressure water pump after being processed through the purifying-softener, the water is heated by the electric heater in the high-pressure state, and the generated superheated water is injected into the coal seam along a hole sealing pipe of the heat injection pipeline and the heat injection drilling hole; after water enters the coal seam, part of water is converted into water vapor along with reduction of pressure, and the superheated water and the water vapor is subjected to seepage along cracks of the coal seam and heat the coal seam; and the water after heat is released flowsinto a pumping and mining drilling hole and is discharged from the coal seam. After the coal seam is heated for a period of time, the physical characteristics such as adsorption, the strength and thespontaneous combustion point of coal can be changed in a short time, and rock burst or outburst of coal and gas during coal roadway tunneling is effectively prevented.

Owner:TAIYUAN UNIV OF TECH

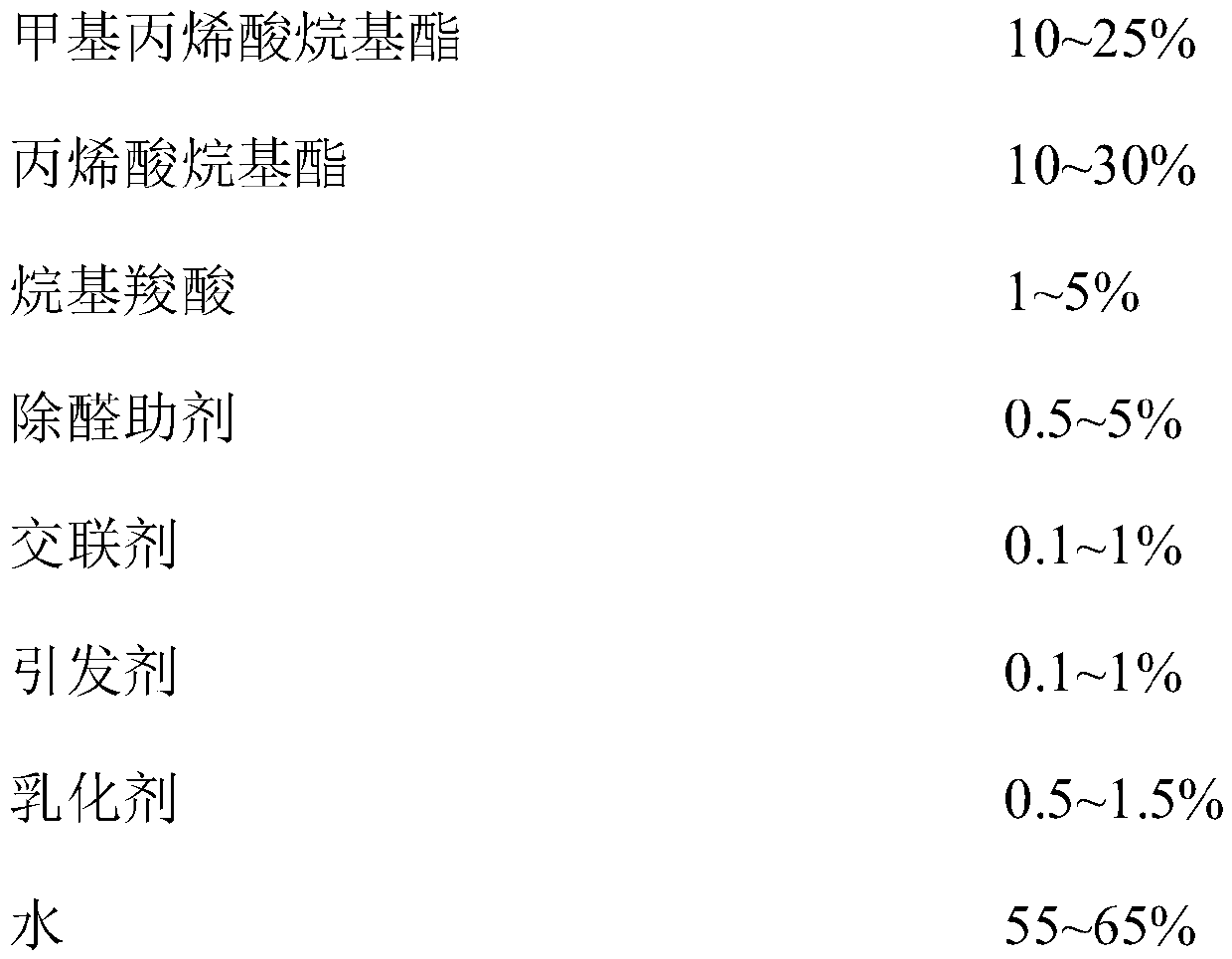

Waterborne acrylic resin capable of absorbing and degrading formaldehyde and preparation method thereof

PendingCN110204645AChange adsorptionDisadvantages of changing photocatalytic degradationFunctional monomerEmulsion

The invention discloses waterborne acrylic resin capable of absorbing and degrading formaldehyde. The waterborne acrylic resin capable of absorbing and degrading formaldehyde is prepared by physicallymixing waterborne acrylic acid emulsion prepared by alkyl methacrylate, alkyl acrylate, alkyl carboxylic acid, a crosslinking agent, an initiator and an emulsifier with an aldehyde auxiliary agent. The invention also discloses a preparation method of the waterborne acrylic resin capable of absorbing and degrading formaldehyde. A cross-linking type functional monomer with internal plasticization is introduced into the emulsion of the invention. The prepared emulsion has good film forming property, can be used for preparing waterborne acrylic acid paint for chemically absorbing and degrading formaldehyde and can meet the requirements of functional paint, and a formed film has high density and hardness.

Owner:KUNMING UNIV OF SCI & TECH

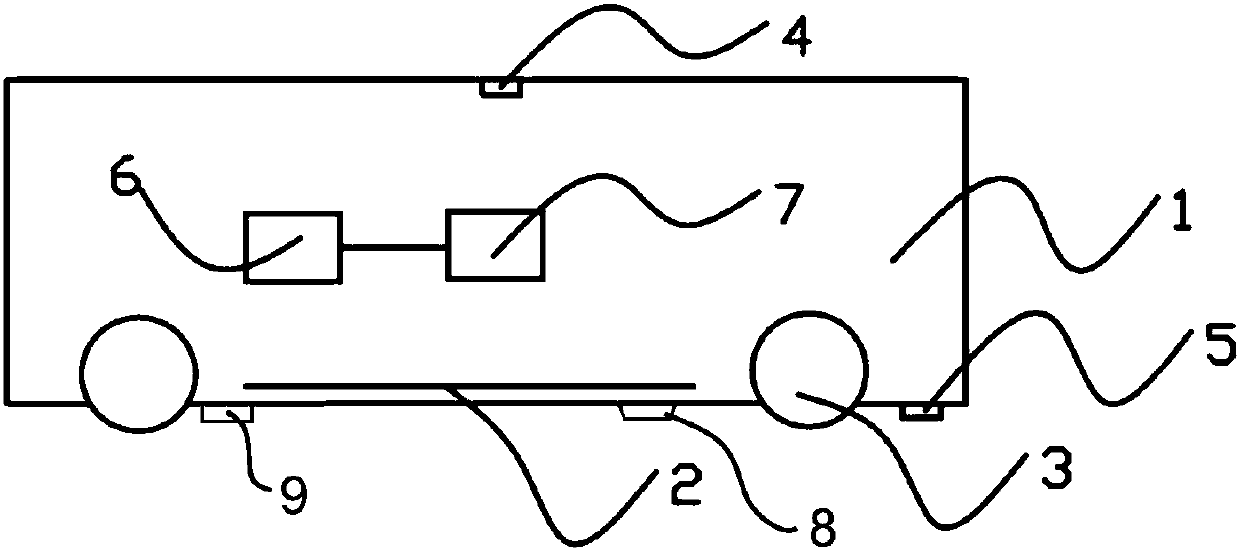

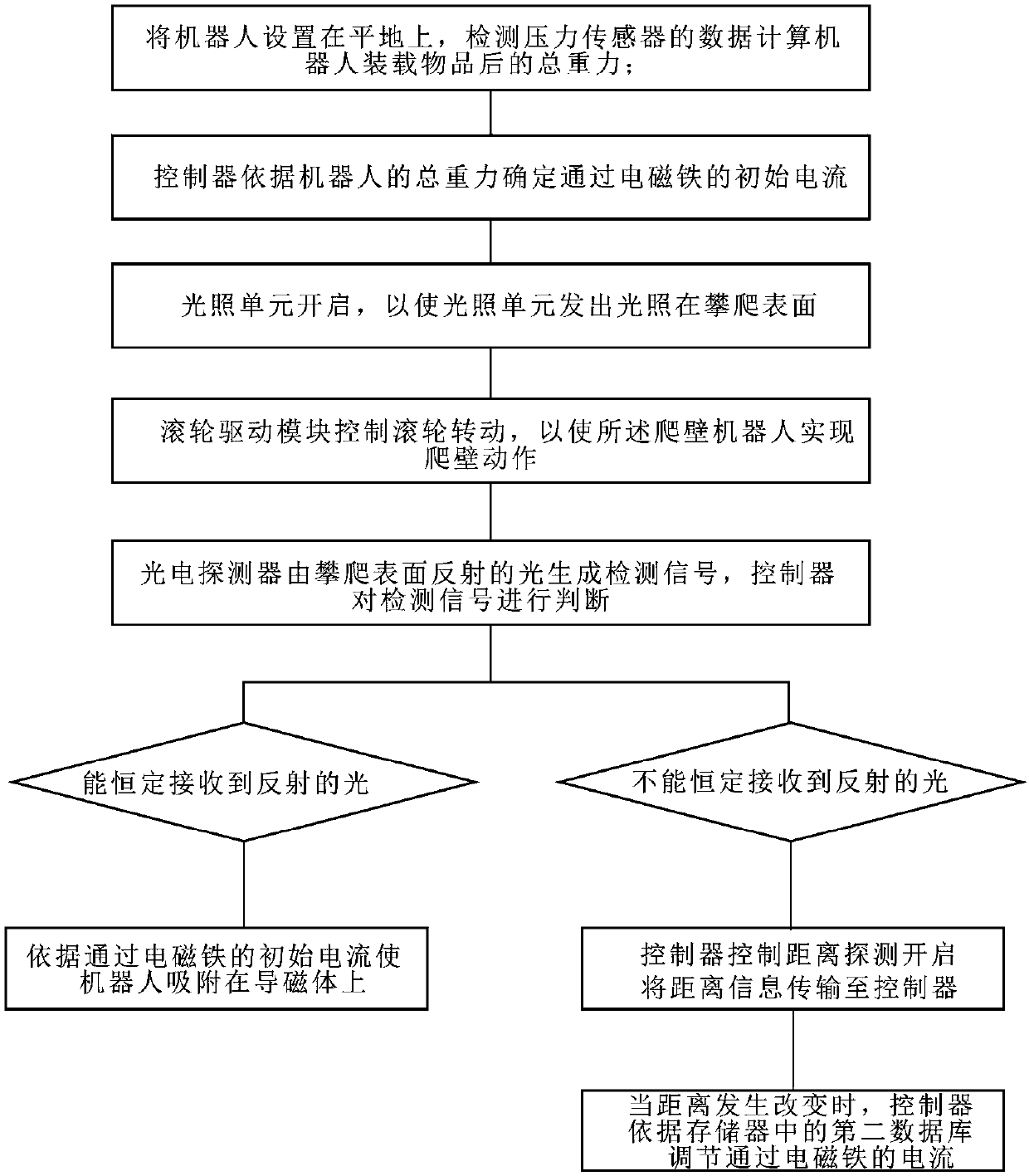

Wall-climbing robot and working method thereof

InactiveCN110065547APrevent fallingStable jobWelding/cutting auxillary devicesAuxillary welding devicesControl theoryDistance sensors

The invention relates to a wall-climbing robot and a working method thereof. The wall-climbing robot comprises a body, an electromagnet arranged at the bottom of the body, rolling wheels used for driving the body to move, and a controller suitable for controlling the electromagnet to be attracted to the surface of a magnetizer and controlling the rolling wheels to rotate through a rolling wheel driving module, so that the wall-climbing robot can realize wall climbing action. According to the wall-climbing robot, the total load after loading of objects is calculated firstly, then the working current of the electromagnet is determined according to the total load, then a climbing surface is subjected to roughness detection, a distance sensor is selectively started, and therefore the robot works more stably, and energy waste is avoided.

Owner:NANJING ROBOTICS RES INST CO LTD

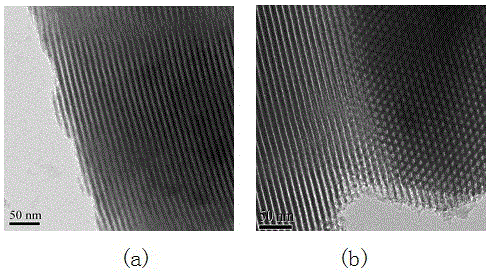

ni 2+ Preparation of Adsorbent and Its Adsorption Method

ActiveCN104226238BChange adsorptionImprove adsorption capacityOther chemical processesSilicon compoundsSilicic acidSilanes

The invention discloses the preparation and adsorption method of Ni2+ adsorbent, which comprises the following steps: (1) using tetraethyl orthosilicate as silicon source and three-block copolymer (P123, EO20PO70EO20) as template to synthesize silicon-based media Pore material SBA-15, and then modified 3-aminopropyltriethoxysilane (APTES) to the inner surface of silicon-based mesoporous material SBA-15 by alkyl coupling method to obtain amino-functionalized silicon-based mesoporous Material NH2‑SBA‑15; (2) Amino acids were grafted onto NH2‑SBA‑15 by the post-grafting method to obtain silicon-based mesoporous materials modified by amino acids, that is, adsorbents; (3) Ni2+-containing aqueous solution, adjusted When the pH value reaches 3~5, put in the adsorbent to absorb Ni2+ in the water body, the mass ratio of the adsorbent to the Ni2+ in the water body is 5:1~8:1, the adsorption temperature is 20~30°C, and the adsorption time is 10~30 min. The preparation method of the adsorbent of the present invention has strong operability and good reproducibility, and the obtained amino acid-modified silicon-based mesoporous material has a good removal effect on heavy metal ions Ni2+ in water, and the equilibrium adsorption capacity reaches 60 mg·g-1 Above, the practical application value is good.

Owner:常熟紫金知识产权服务有限公司

Preparation method of beef proteins with high adsorption property to flavor components

The invention discloses a preparation method of beef proteins with high adsorption property to flavor components. The method comprises the following steps: (1) removing impurities from fresh beef, dicing and mincing; (2) degreasing beef samples to obtain crude beef proteins; (3) performing pulse microwave treatment on the extracted crude beef proteins, wherein the output power of the pulse microwaves is 20-500W, the microwave output duty ratio is 5-60%, the pulse width is 10-100ms, the frequency is 2400-2500MHz, the phase is 0-180 degrees, and the pulse microwave treatment time is 5-100seconds; and (4) performing vacuum freeze drying, grinding into powder, and screening, thereby obtaining the beef proteins with high adsorption property to flavor components. According to the beef proteins prepared by the method disclosed by the invention, the adsorption capacity of flavoring compounds can be wholly improved by 20-50%.

Owner:SOUTH CHINA UNIV OF TECH

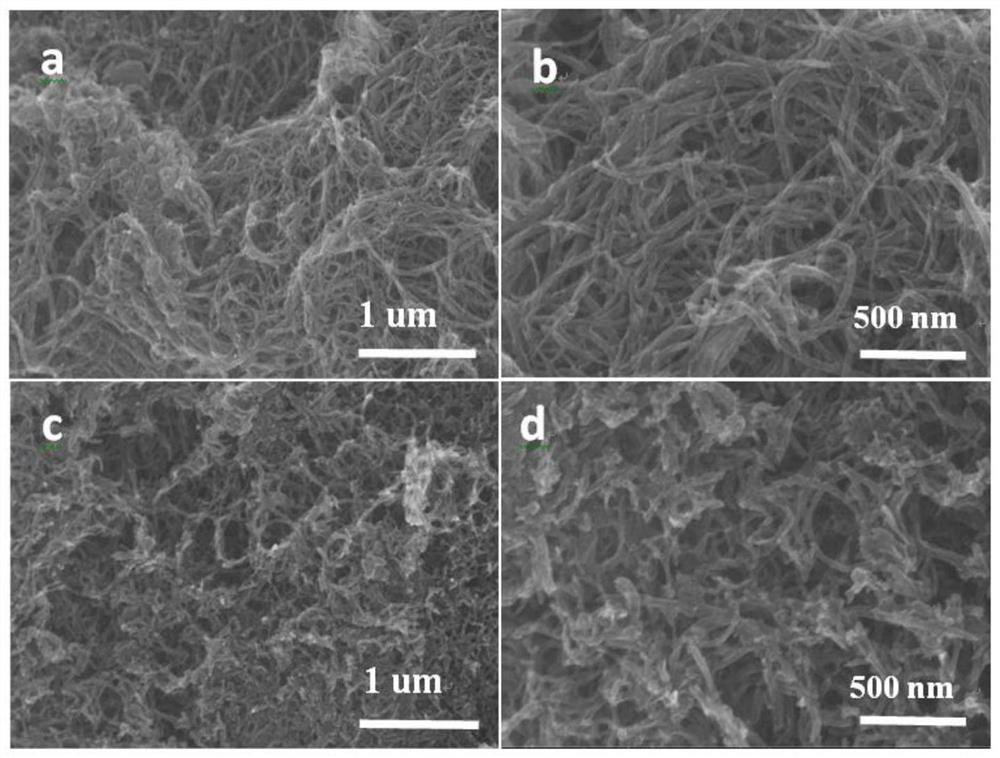

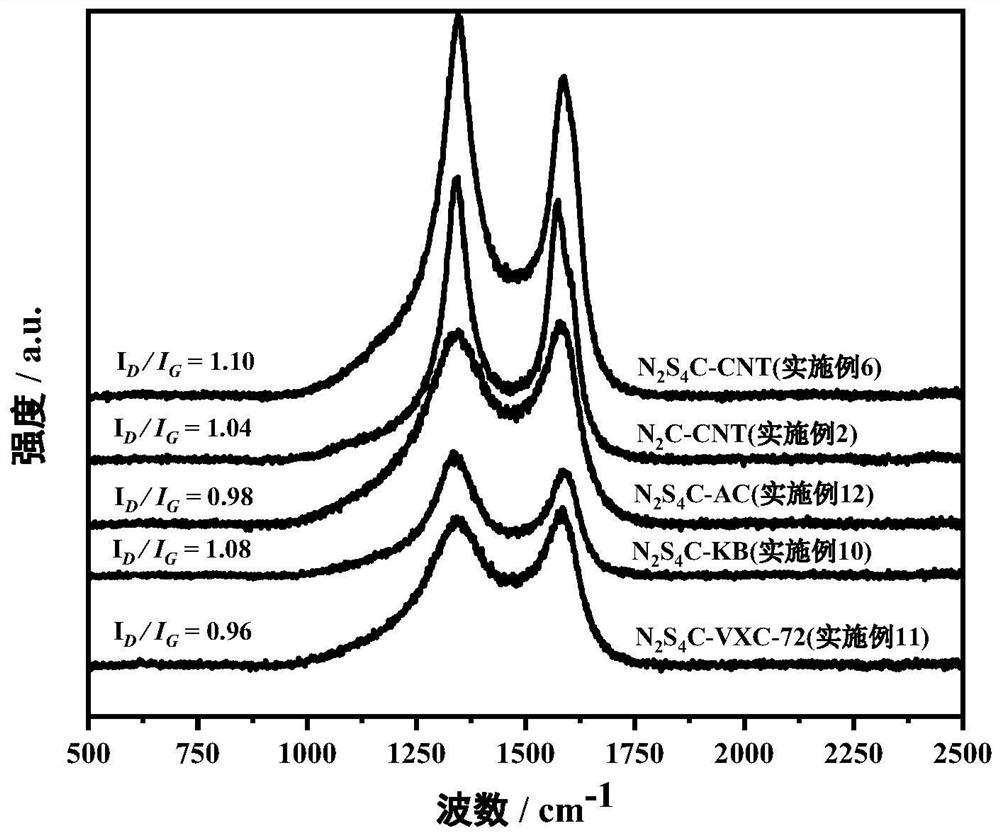

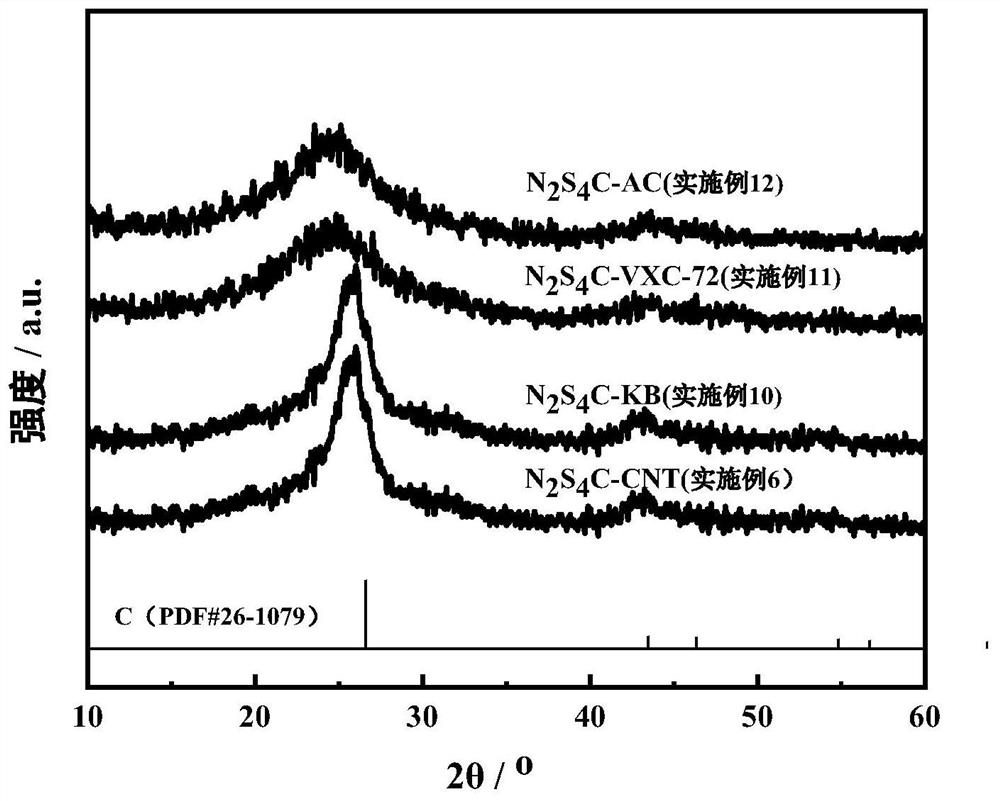

N, S co-doped porous carbon coated carbon nanotube bifunctional oxygen electrode catalyst and preparation method thereof

ActiveCN112221527AHigh ORRHigh activityPhysical/chemical process catalystsPtru catalystPorous carbon

The invention discloses an N, S co-doped porous carbon coated carbon nanotube bifunctional oxygen electrode catalyst and a preparation method thereof, and belongs to the technical field of energy materials and electrochemistry. The preparation method comprises the following steps of: dispersing a polysulfide precursor into a solvent, transferring an obtained mixture into a reaction container, andreacting at 50-300 DEG C to obtain a polysulfide precursor material; preparing a precursor of the N, S co-doped porous carbon coated CNT catalyst; and finally, putting the obtained NSC-CNT-Px materialinto a reaction furnace, heating to 600-1200 DEG C, and carrying out heat treatment to obtain the N, S co-doped porous carbon coated CNT catalyst. The catalyst prepared by the invention has a large number of pores and a high specific surface area, is beneficial to improving the ORR / OER catalytic activity of a material, is simple in preparation process, is green and pollution-free, is easy for large-scale production, and is beneficial to large-scale application.

Owner:DALIAN UNIV OF TECH

Cracking carbon five selective hydrogenation catalyst

ActiveCN101254465BEnhanced interactionStrong interactionMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionPotassiumStrontium

The invention relates to a selective hydrogenation catalyst for C5 cracking and belongs to the technology field of hydrogenation catalysts. In order to meet the urgent need of the selective hydrogenation catalysts for the C5 cracking, the invention provides a catalyst for selective hydrogenation in the C5 cracking, which contains the following components in the given mass percentages: Ni 10-35%, La 0.5-3%, Ag 0.3-3% and aluminum oxide carrier 59-89.2%, calculated on basis of the total mass of the catalyst. The catalyst can also contain K and / or Sr or Pb. The catalyst is used for selective hydrogenation in the C5 cracking as well as hydrogenation in the C5 cracking and excellent in conversion rate, selectivity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-direction flexible manipulator

The invention provides a multi-direction flexible manipulator. The multi-direction flexible manipulator comprises at least one adsorption assembly for generating adsorption force and at least two direction control assemblies. The adjacent direction control assemblies are movably connected; the adsorption assemblies and the direction control assemblies are connected; each direction control assemblycomprises at least two first pipes, and first fluids are arranged in the first pipes; and the first fluids in the adjacent first pipes are different in volume. According to the multi-direction flexible manipulator, through the structure that the adsorption assemblies and the direction control assemblies are combined, objects can be efficiently grasped, meanwhile, multiple degrees of freedom are achieved, multi-direction adjusting can be achieved, and the multi-direction flexible manipulator has the advantages that the structure is simple, and operation is convenient.

Owner:佛山市奥耶克思机械设备有限公司

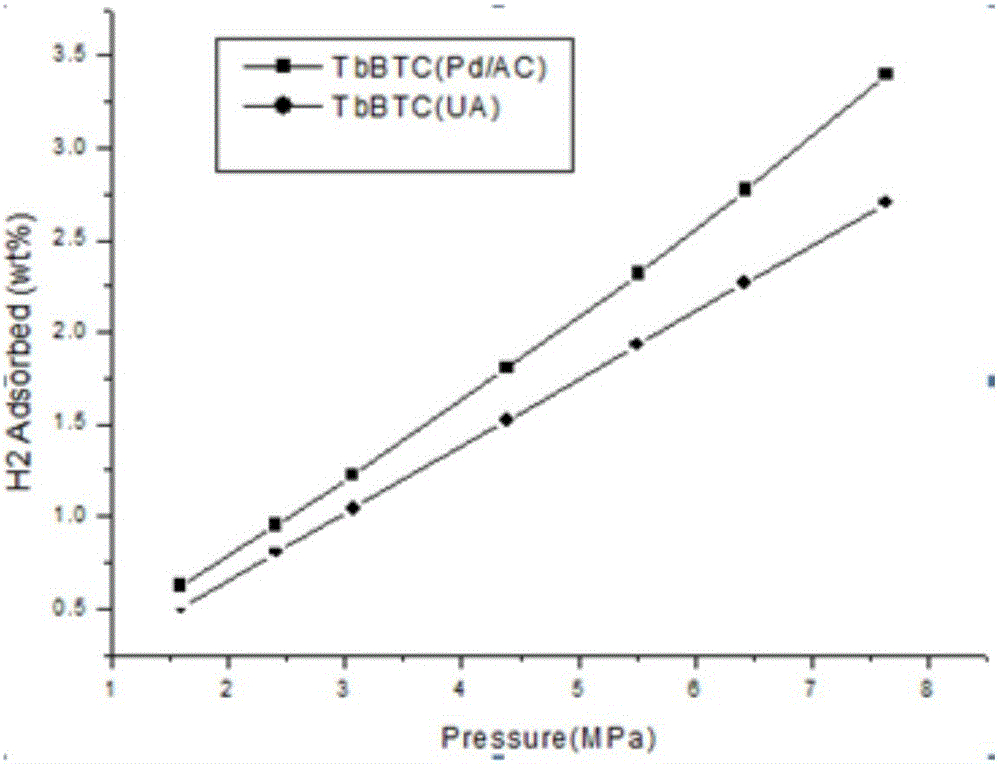

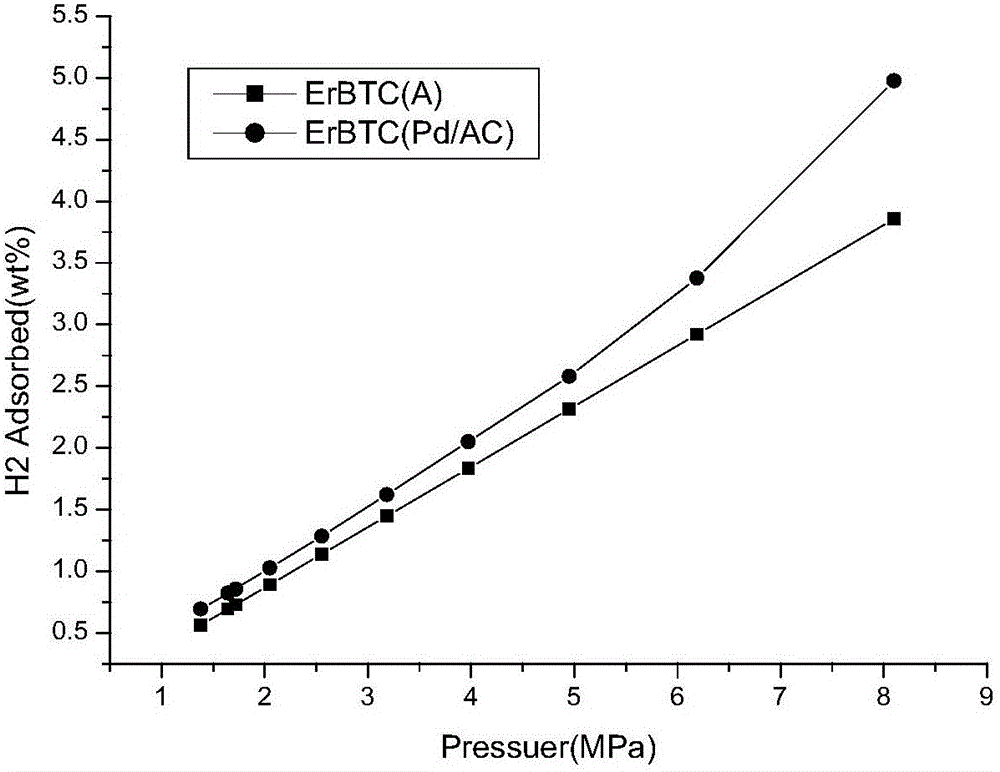

Modified lanthanide-series-metal organic framework material and preparation method thereof

InactiveCN106040179AChange the adsorption processImprove hydrogen storage capacity at room temperatureHydrogenOther chemical processesMetal-organic frameworkLanthanide

The invention provides a modified lanthanide-series-metal organic framework material and a preparation method thereof. The modified lanthanide-series-metal organic framework material comprises a lanthanide-series-metal organic framework material and a palladium catalyst, wherein the palladium catalyst accounts for 0.1-1% of the total mass of the raw materials when being counted by palladium. The modified lanthanide-series-metal organic framework material has the advantages that the palladium is introduced into the metal organic framework of the modified lanthanide-series-metal organic framework material, the absorption process of hydrogen in the framework is changed, and room-temperature hydrogen storage quantity is increased.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com