Mudstone hydrophobically modified grouting material and preparation method thereof

A grouting material and hydrophobic modification technology, which is applied in the field of underground engineering safety, can solve the problems of poor anti-hydrophobic performance of roadways, short effective time, and inability to change the adsorption characteristics of clay and mudstone, so as to enhance filling effect and improve fluidity. , The effect of enhancing the grouting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

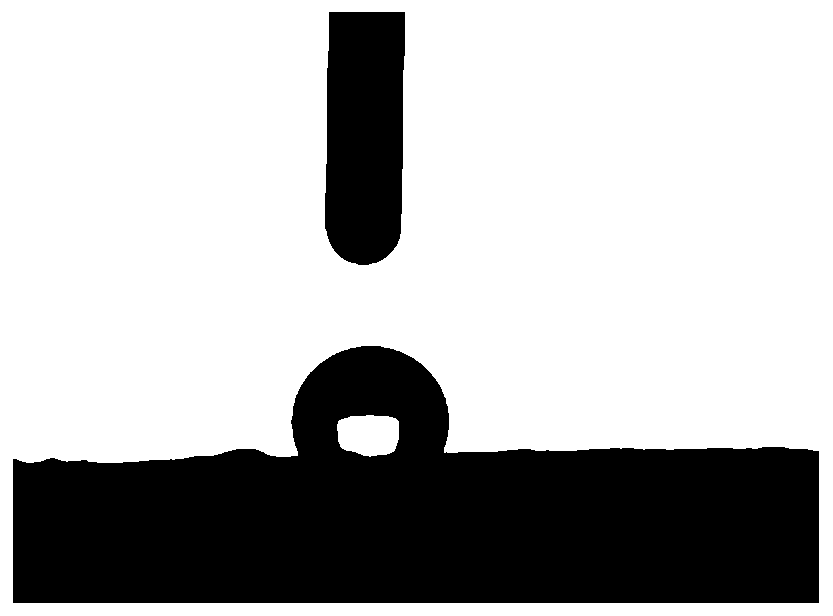

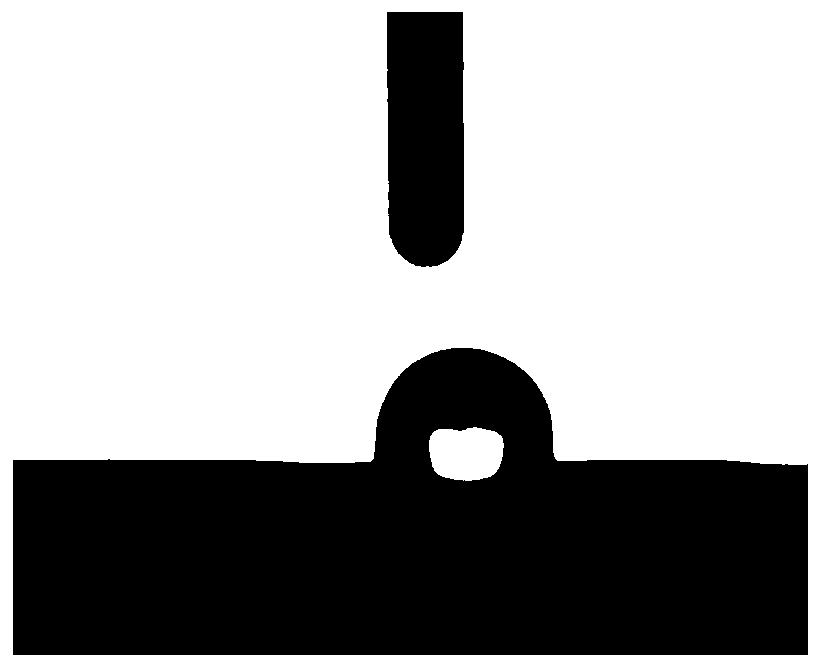

Image

Examples

preparation example Construction

[0051] The preparation method of described grouting modified material comprises the following steps:

[0052] Step 1. Take Portland cement, water-quenched slag powder, coal gangue micropowder, water reducing agent, surfactant solution and water glass solution according to the proportion by weight;

[0053] Step 2: firstly mix the ordinary portland cement, water-quenched slag and coal gangue micro-powder, and after stirring uniformly once, add water reducing agent, surfactant solution and water glass, after fully mixing, stir uniformly again, Obtain grouting material.

[0054] In the second step, the stirring speed is 180 r / min, the primary stirring time is 10-15 minutes, and the secondary stirring time is 2-4 minutes.

[0055] In the second step, the initial setting time of the grouting material is 266-364 minutes, and the final setting time is 397-495 minutes. The setting time test is detected according to GB / T 1346-2011.

[0056] In the second step, after the grouting mate...

Embodiment 1

[0067] A modified grouting material, which is made of the following proportions by weight: 40 parts of ordinary Portland cement, 5 parts of water-quenched slag powder, 20 parts of coal gangue micropowder, 2 parts of water reducer, and 60 parts of surfactant solution parts, 5 parts of water glass solution. The water-quenched slag powder is produced by blast furnace ironmaking, and is crushed and screened to make the particle size less than 400 mesh powder; the coal gangue powder is mixed with coal gangue and calcium oxide powder at a ratio of 2:1, calcined at 600°C for 40 minutes, and passed through Quenching and cooling in water, crushing and sieving into powders of three particle sizes of 40-100 mesh, 100-200 mesh and 200-400 mesh, mixed according to the ratio of 1:1:6, the water reducer is lignosulfonic acid Salt; the concentration of the water glass is 39Be, and the modulus is about 3.1; the surfactant solution is a mixed reaction of octadecenoic acid and sodium hydroxide a...

Embodiment 2

[0072] A modified grouting material, which is prepared by the following proportions by weight: 50 parts of ordinary portland cement, 8 parts of water-quenched slag powder, 18 parts of coal gangue micropowder, 3 parts of water reducing agent, and 70 parts of surfactant solution Parts, 6 parts of water glass solution. The water-quenched slag powder is produced by blast furnace ironmaking, and it is crushed and screened to make the particle size less than 400 mesh powder; the coal gangue powder is mixed with coal gangue and calcium oxide powder at a ratio of 2:1, calcined at 700 ° C for 60 minutes, and passed through Quenching and cooling in water, crushing and sieving into powders of three particle sizes of 40-100 mesh, 100-200 mesh and 200-400 mesh, mixed according to the ratio of 1:1:6, the water reducer is lignosulfonic acid Salt; the concentration of the water glass is 39Be, and the modulus is about 3.1; the surfactant solution is a mixed reaction of octadecenoic acid and so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com