Patents

Literature

657results about How to "Realize resource reuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soil washing restoration system based on reduction concentration design concept and method thereof

ActiveCN104475441AShort stayImprove production efficiencyContaminated soil reclamationSoil washingCompound (substance)

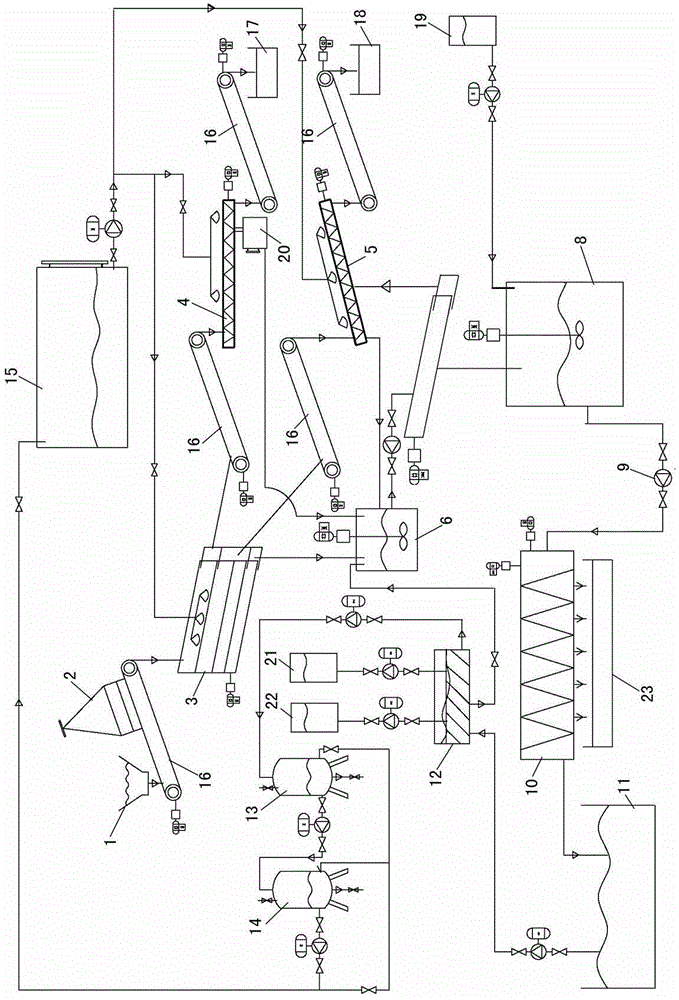

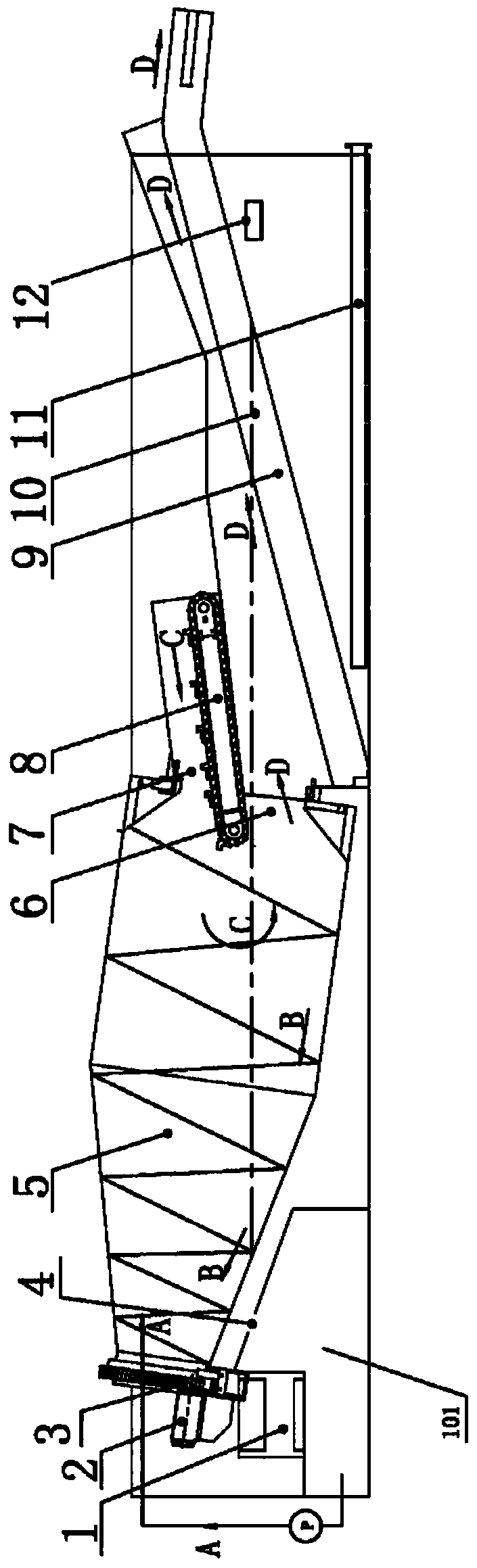

The invention discloses a soil washing restoration system based on a reduction concentration design concept and a method thereof. The washing restoration system comprises the following four module units which are sequentially connected with one another: a feeding and screening unit, an ore washing unit, a sludge dewatering unit and a tail-end sewage treatment recycling unit. The pollutants on the surface of coarse particles are eluted, transferred and concentrated into the filter-pressed mud cake by virtue of washing, so that pollutant-containing fine particles in contaminated soil can be effectively separated from crude particles such as gravel and grit. The repaired and discharged clean gravel and grit can be directly recycled to serve as building material. According to the system, purified water serves as a washing solution, so that secondary pollution caused by addition of a chemical washing agent is avoided, and the washing solution is treated by a tail-end sewage treatment system so as to be recycled. The reduction of remediation of contaminated soil is realized, the comprehensive repair cost is greatly reduced, the washed and discharged materials can be recycled, the contaminated soil is repaired, and a novel profit point is created.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

Method of providing service continuity between cellular communication and device-to-device communication

InactiveUS20140162633A1Realize resource reuseLow costConnection managementRadio transmissionComputer terminalBase station

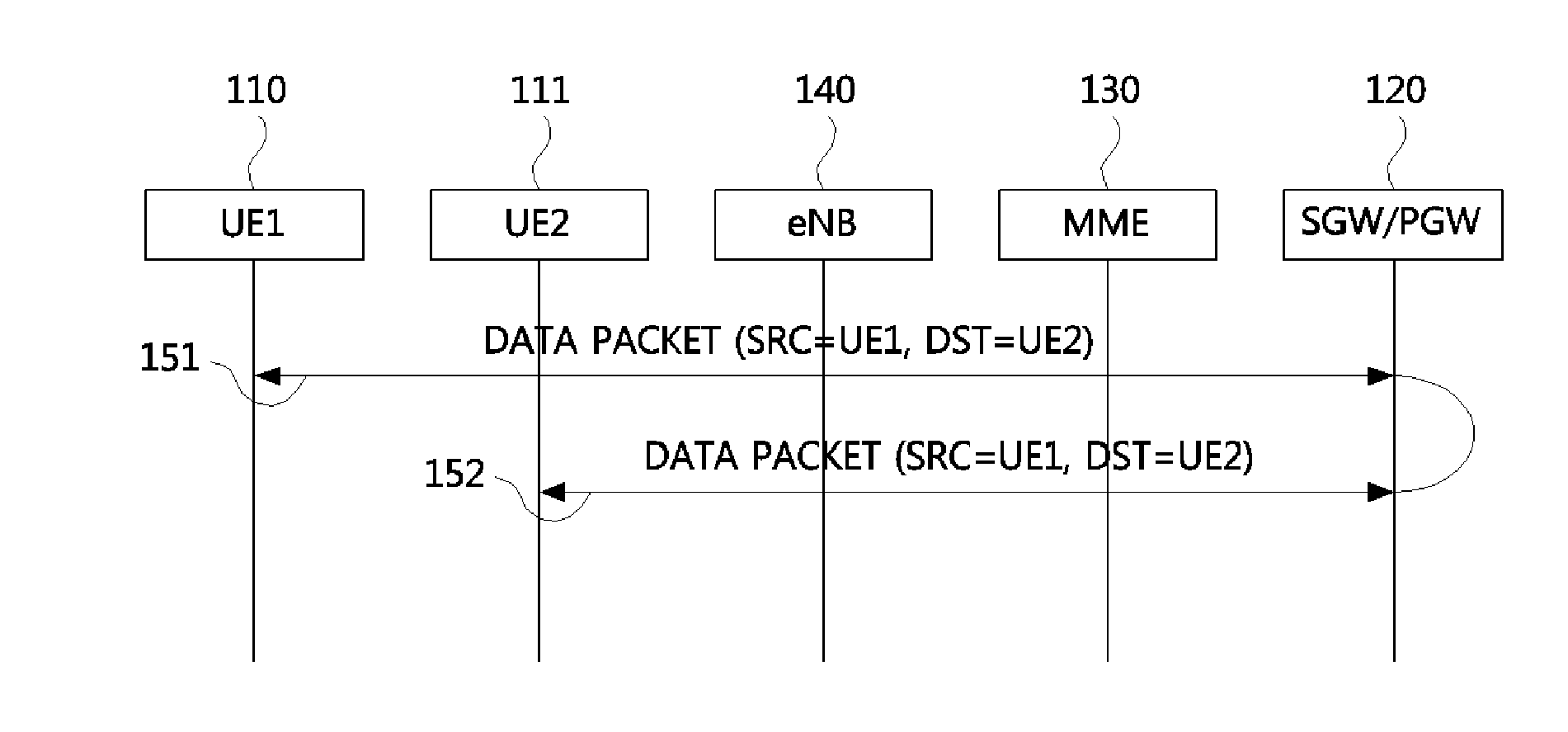

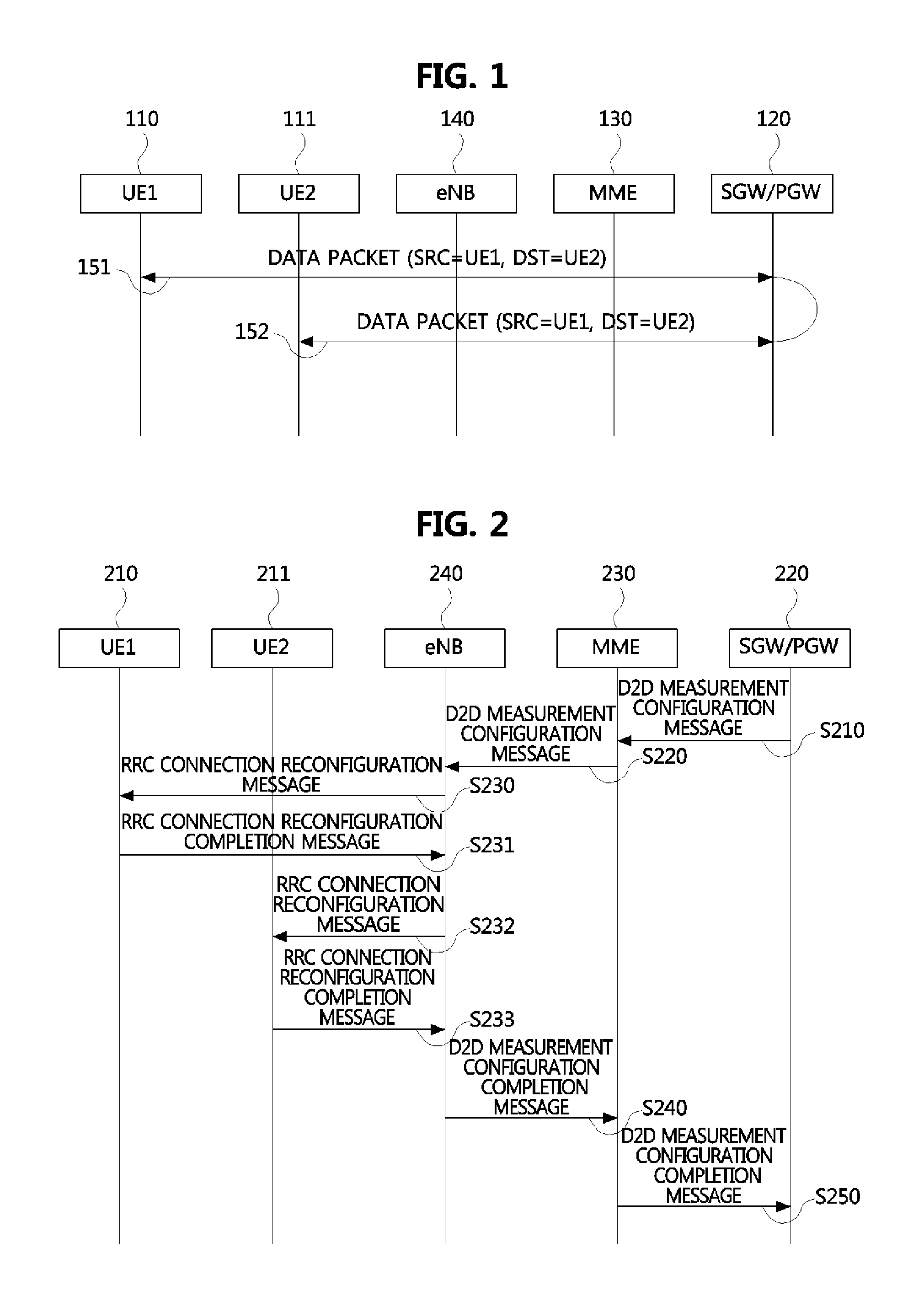

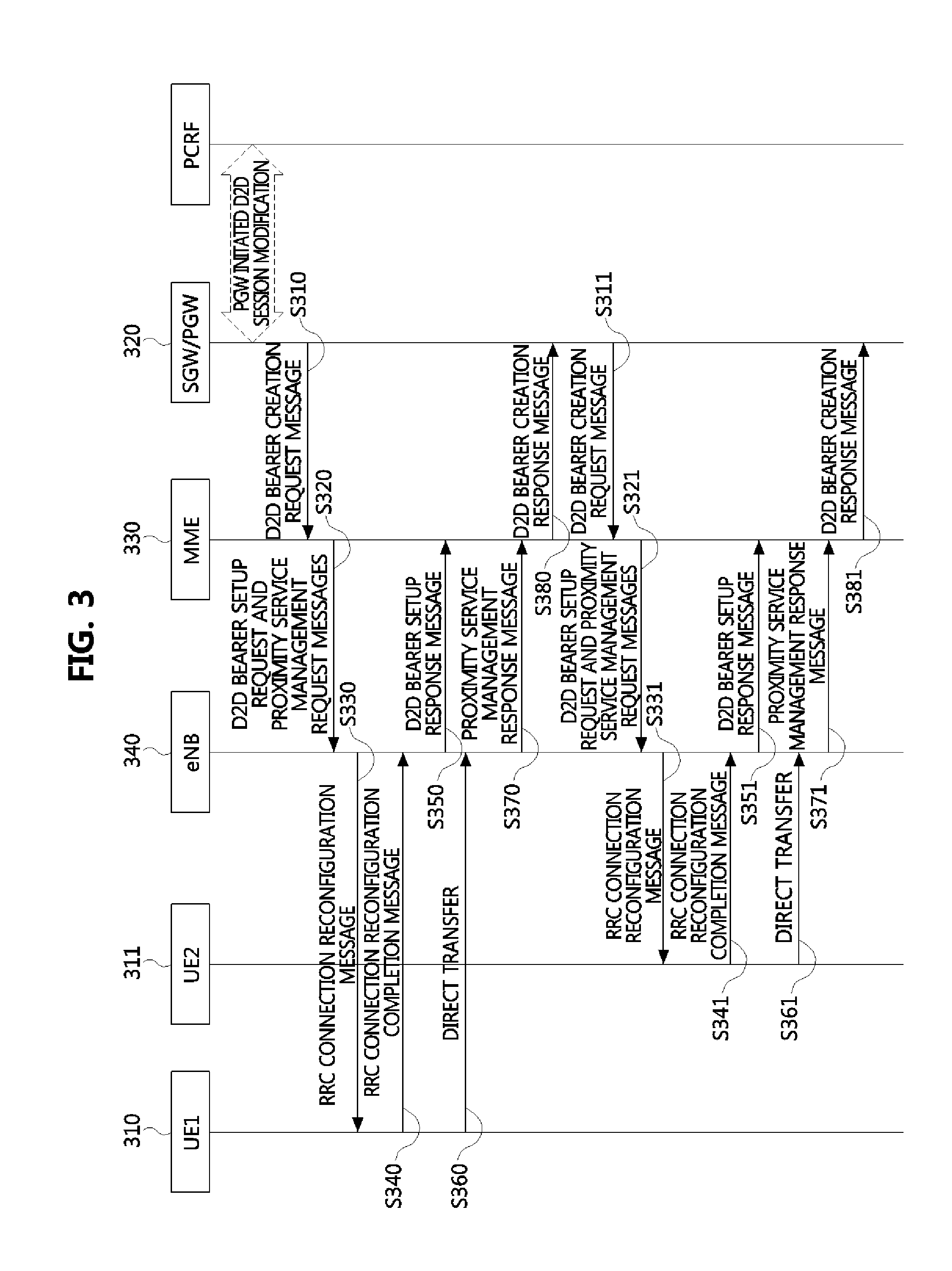

A method of providing service continuity between cellular communication and device-to-device communication is disclosed. A procedure for switching between cellular communication and device-to-device communication according to an example embodiment of the present invention may include transferring, by a gateway, a D2D bearer creation request message to an MME, transferring, by the MME, the D2D bearer creation request message to a base station, mapping, by the base station, D2D bearer QoS to D2D radio bearer QoS and transmitting an RRC connection reconfiguration message to terminals, receiving, by the base station, an RRC connection reconfiguration completion message indicating creation of a D2D radio bearer from the terminals, transmitting, by the base station, a D2D bearer creation response message indicating creation of a D2D bearer to the MME, and transferring, by the MME, the D2D bearer creation response message to the gateway.

Owner:ELECTRONICS & TELECOMM RES INST

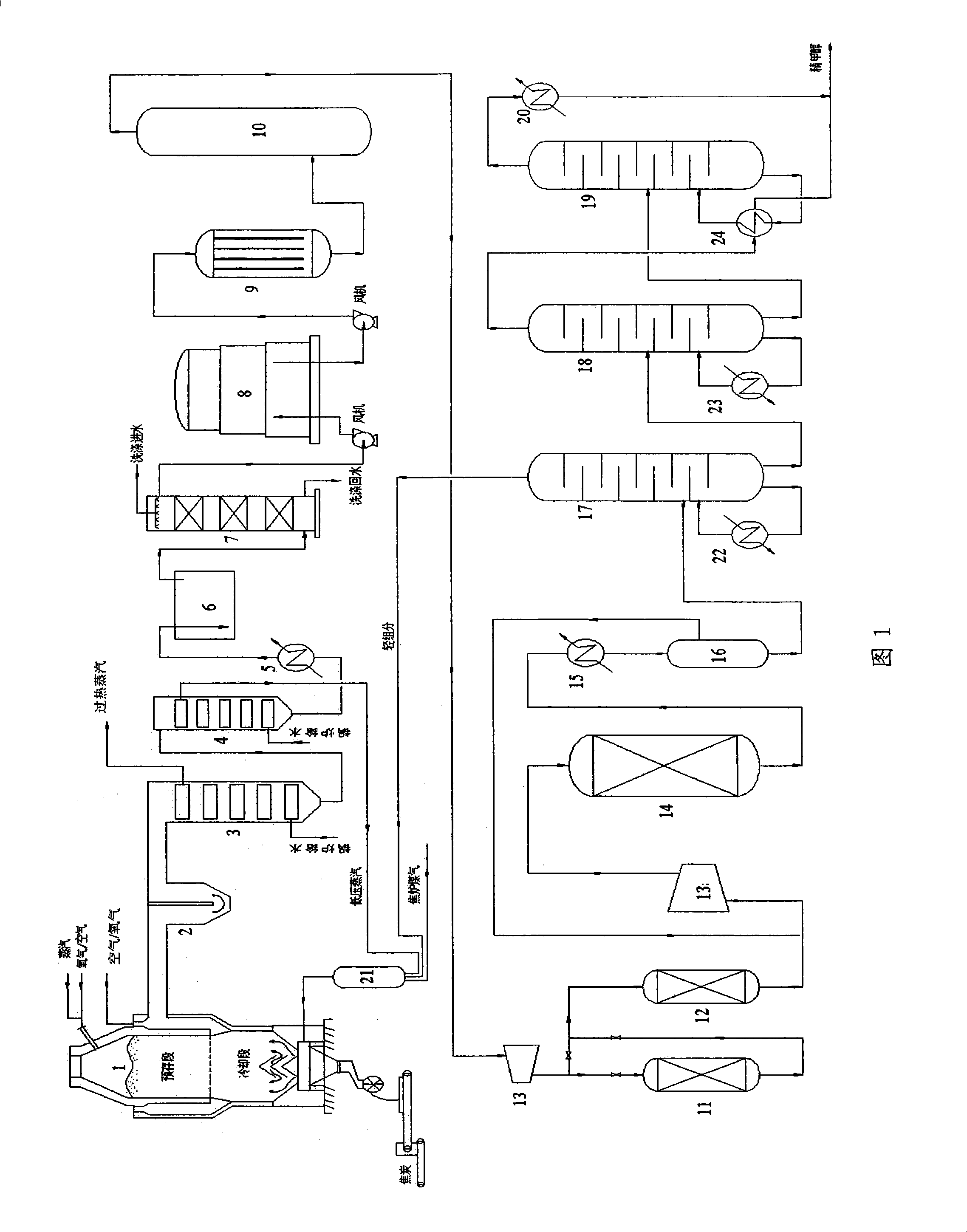

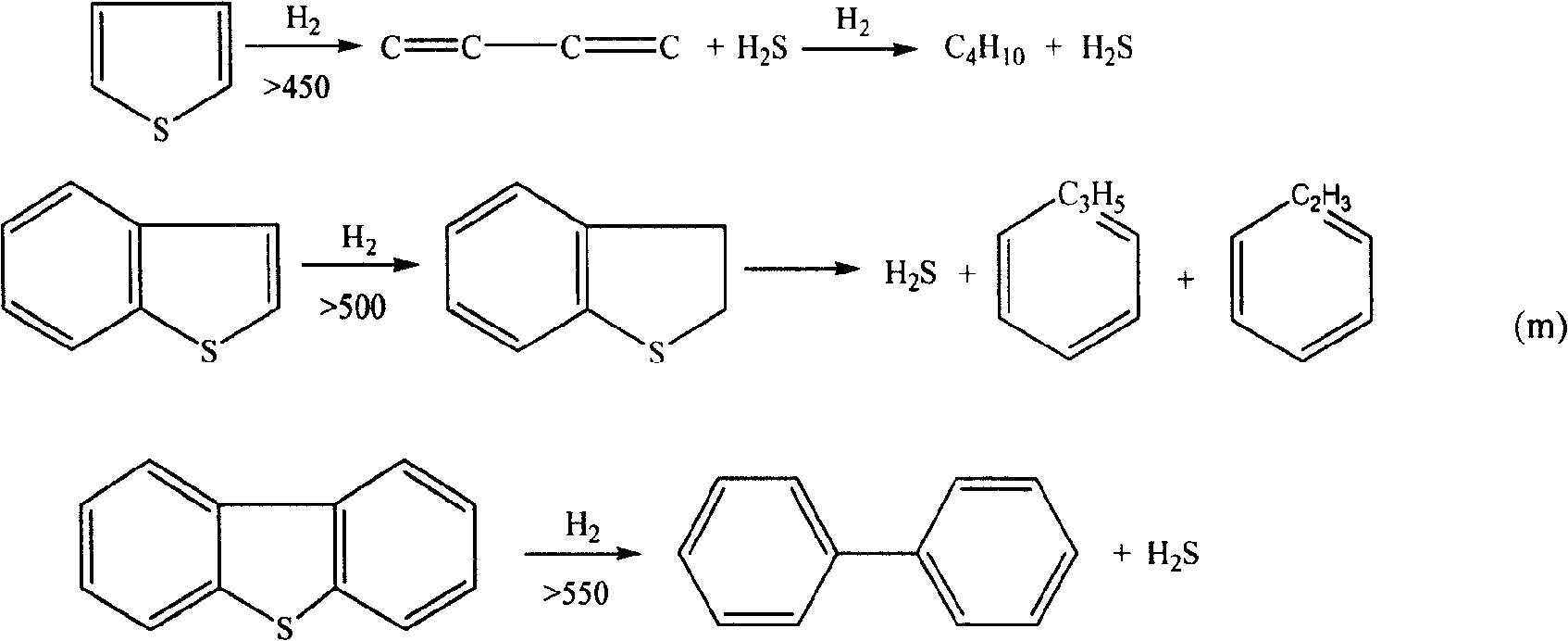

Integration process of coke dry quenching co-production synthesis gas and downstream products thereof of methanol

InactiveCN101289620AIncrease carbon to hydrogen ratioReduce sulfur contentCoke quenchingOrganic chemistryChemistrySensible heat

The invention discloses an integrated process of a dry quenching coke coproduction synthesis gas and the downstream product, methanol of the synthesis gas. The integrated process adopts the following steps that: low-pressure steam or the mixed gas of low-pressure steam and coke oven gas is used as cooling gas to absorb red coke sensible heat and to carry out water-gas reaction with red coke, thereby generating a synthesis gas; after dust removal, the synthesis gas is fed to a steam gas waste heat boiler and a low-pressure steam waste heat boiler to carry out heat recovery, and then is output; the steam gas waste heat boiler generates steam gas, while the low-pressure steam waste heat boiler generates low-pressure steam which is fed in a dry quenching coke oven as cooling gas; or the steam gas is used in a back pressure steam turbine to generate electricity, and the low-pressure steam left over after back pressure electricity generation is used as the cooling gas of dry quenching coke, thereby omitting the low-pressure steam waste heat boiler. Compared with the prior art, the integrated process combines the production of dry quenching coke and synthesis gas, and ensures that the dry quenching coke oven integrates the functions of quenching coke, conversion, gas making and coke desulfurization; meanwhile, methanol is made through making use of the synthesis gas generated during dry quenching coke.

Owner:YANTAI TONGYE CHEM TECH

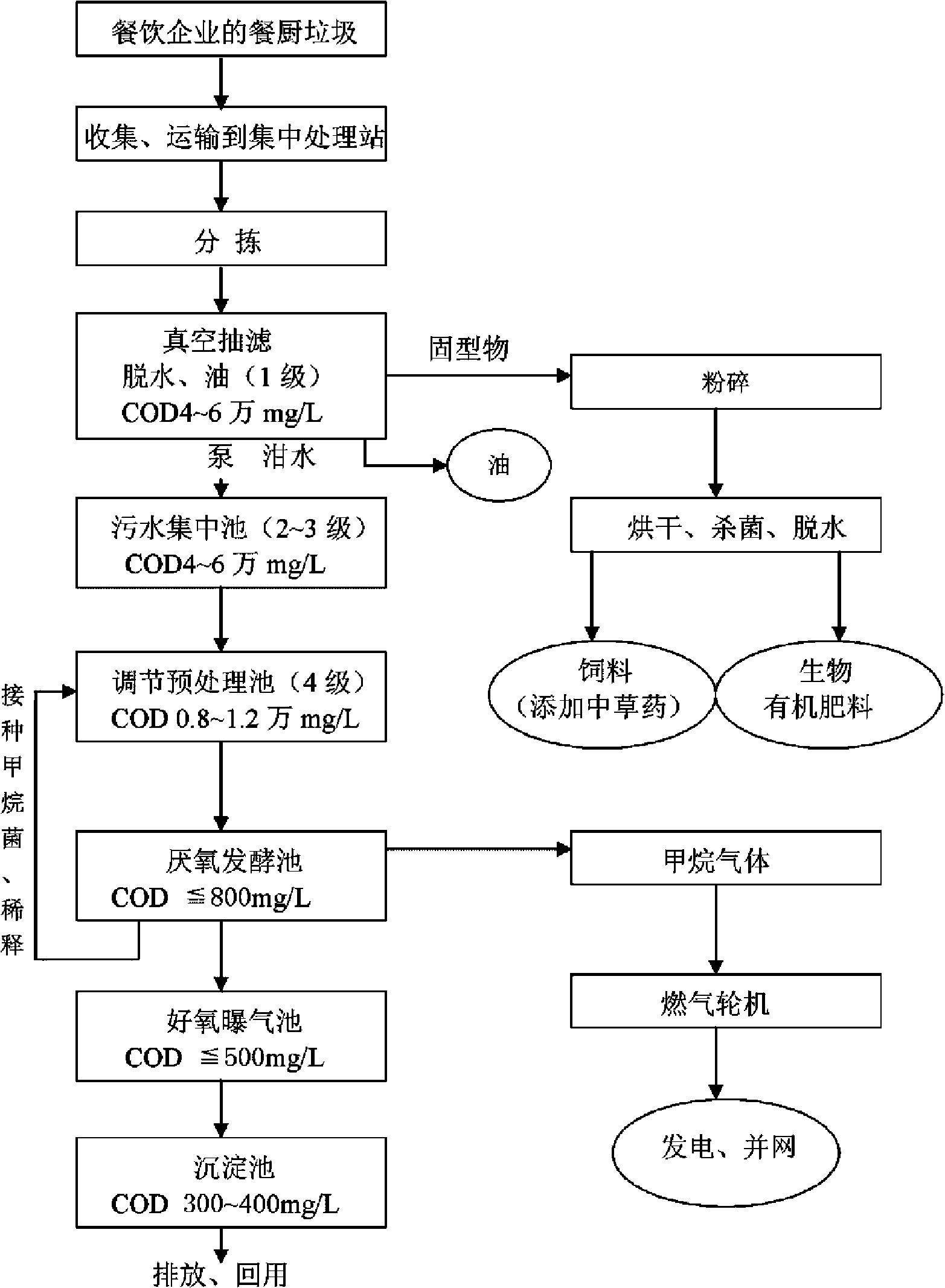

Processing method for changing restaurant and kitchen garbage into resource without environmental pollution

InactiveCN101274860AAvoid wastingEnergizeBio-organic fraction processingWaste processingThermal energyAnaerobic bacteria

The invention relates to a treating method for energy regeneration, resource recovery and pollution free of restaurant garbage, which comprises the steps that separated liquid material is pumped into a swage concentrating pool; then the concentrated liquid material is discharged into a regulating and pretreating pool, in which methane bacteria are inoculated; the pretreated liquid material is discharged into an anaerobic fermentation pool, in which anaerobic bacteria groups are added so that methane gas is generated and the overflowing liquid material from the anaerobic fermentation pool is led to enter an aerobic aerated pool for aerobic reaction; the liquid material after the aerobic reaction is discharged into a sedimentation tank for sedimentation. In the comprehensive utilization of 'swill', the disposing method of the invention carries out anaerobic fermentation and aerobic aerated biochemical treatment to transform part of the energy in the swill into bio-energy which is then transformed into heat energy and finally into electrical energy that is connected with power grid for use. The separated solid material is smashed, dried, sterilized, dehydrated and then added with Chinese herbal medicine to be processed into Chinese herbal medicine compound feeds and fertilizers; meanwhile, the treatment of energy regeneration, resource recovery and pollution free of restaurant garbage for restaurant garbage is realized.

Owner:WUXI KELUN SCI & TECH DEV

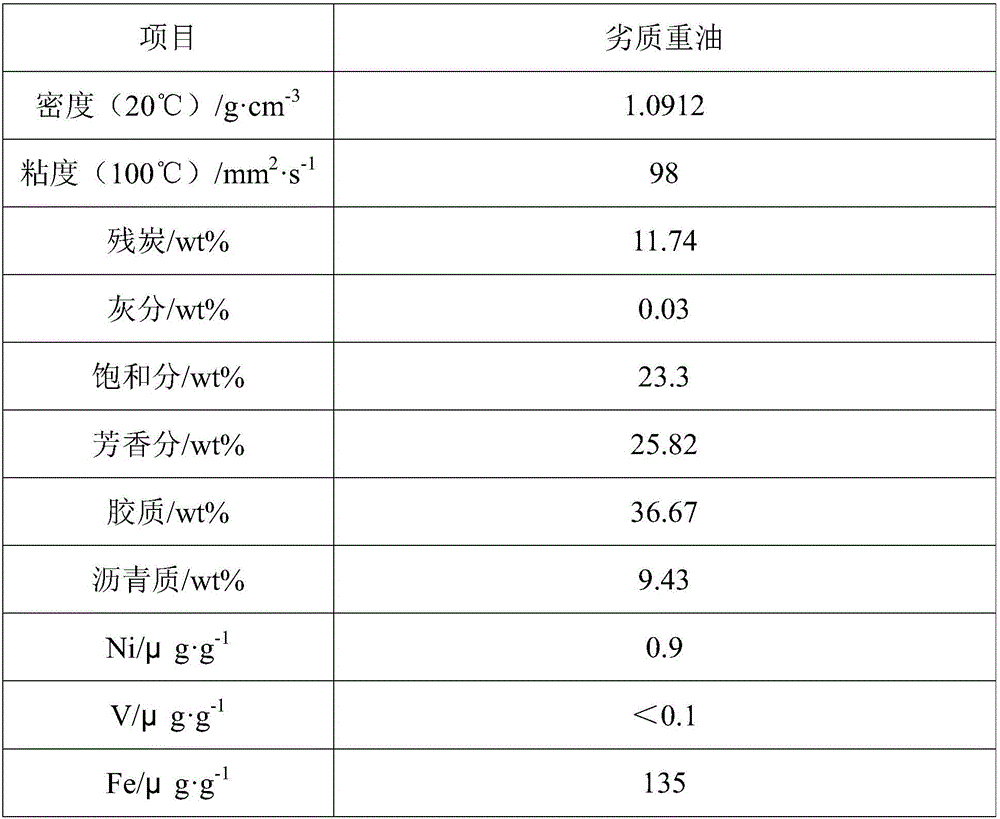

Oil-soluble catalyst and preparation method thereof

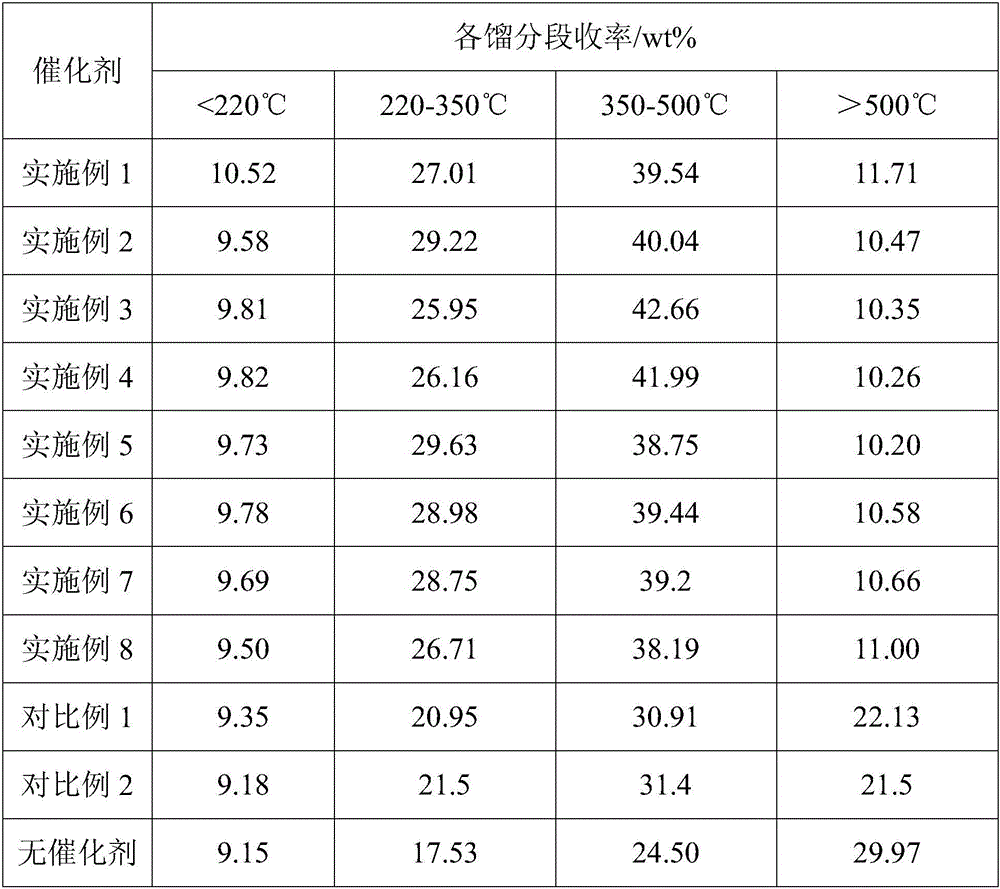

InactiveCN106391111AStrong hydrogenation activityAdd lessOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOrganic solventReaction temperature

The invention discloses an oil-soluble catalyst and a preparation method thereof. The oil-soluble catalyst comprises metal Mo and / or W in VIB group, and at least one of metal Fe, Co or Ni in VIII group. The total content of metals in VIB group and VIII group is 10-30wt%, and the mol ratio of the metal in VIB group and VIII group is 1:10-10:1. In the preparation process, organic solvents are not needed, the oil-soluble catalyst which contains high content of active metals is prepared at a lower reaction temperature. The catalyst has high hydrogenation activity and excellent catalysis performance, the catalyst is applied to a slurry bed hydrocracking process of inferior heavy oil, coke yield is substantially reduced, and conversion rate of inferior heavy oil and yield of light oil are improved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for preparing organic fertilizer by using aminonitrile waste liquid

InactiveCN101391911AReduce manufacturing costImprove economic efficiencyBio-organic fraction processingClimate change adaptationAmino nitrilesChemistry

The invention provides a method for preparing an organic fertilizer by utilizing amino-nitrile waste liquor, which comprises the steps: catalyst and dispersant are added in the associated amino-nitrile waste liquor generated in the preparation of iminodiacetonitrile, aminoacetonitrile, ammonium dinitrile and EDTW, and mixed for reaction at the temperature of 30 to 150 DEG C and the pressure of 0 to 1.0MPa, so as to obtain base fertilizer which is added with biological strains for fermentation of 7 to 15 days at the temperature of 10 to 60 DEG C after nutrient allocation; and then hydrolysis is carried out to the base fertilizer to obtain a raw fertilizer which is carried out with nutrient allocation, pelleting and drying to be prepared into the organic fertilizer. The method can reduce the treatment cost, effectively utilizes the resources of the water liquor, and prepare the organic fertilizer by utilizing the amino-nitrile waste liquor.

Owner:四川省天然气化工研究院

Special culture material formula capable of remarkably improving content of various amino acids in dictyophora fruit body and cultivation method

InactiveCN102557799ARealize resource reuseHigh in amino acidsHorticultureFertilizer mixturesEngineeringMonopotassium phosphate

The invention discloses a special culture material formula capable of remarkably improving content of various amino acids in dictyophora fruit body and a cultivation method. The special culture material formula is characterized by comprising the following raw materials in parts by weight: 20-30 parts of bamboo, 20-30 parts of wood chips or sawdust or roots of other trees, 20-30 parts of bagasse, 10-20 parts of chaff, 1-3 parts of urea (or 5-10 parts of ammonia bicarbonate), 0.3-0.5 parts of potassium dihydrogen phosphate, 0.2-0.3 parts of magnesium sulfate and 1.0-1.2 parts of calcium carbonate, wherein 20-40kg of swine waste is added into every 100kg of mixed cultivation material. The cultivation method comprises the following steps of: selection of a cultivation place, preparation of materials, stockpile fermentation, blanking and seeding, earthing, spawn running and harvesting. According to the invention, the content of various amino acids in dictyophora fruit body is remarkably improved, the discharge of pollutants in the pig industry can be reduced, the pollutants of the pig industry are reduced, and the resource recycling of the swine waste is realized.

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

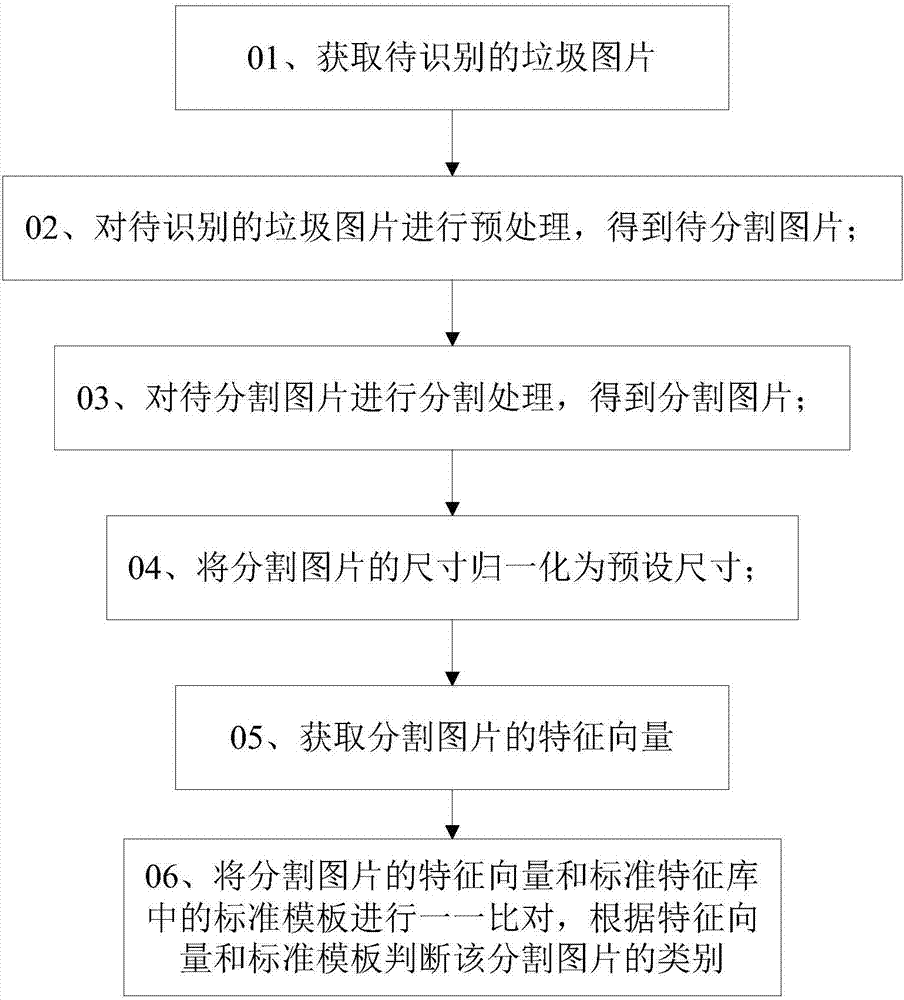

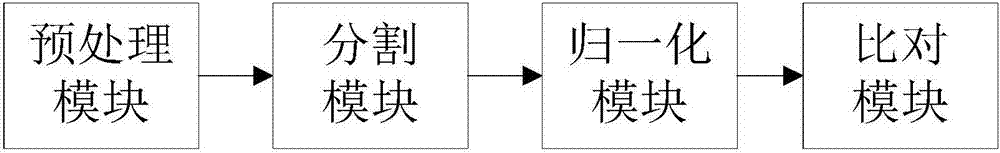

Garbage classification method, device and system based on image identification

ActiveCN107092914AEasy to classifyReduce workloadImage analysisCharacter and pattern recognitionFeature vectorClassification methods

The invention discloses a garbage classification method, device and system based on image identification. The method includes the steps of S1, pre-processing a garbage picture to be identified to obtain a picture to be segmented; S21, segmenting the picture to be segmented to obtain a plurality of sub pictures; S22, acquiring feature information of each sub picture, judging whether the feature information belongs to a preset threshold range, if so, judging the corresponding sub picture as a segmented picture, and if not, performing S23; S23, further segmenting the segmented picture for each sub picture; S3, normalizing the size of each segmented picture into a preset size; and S4, acquiring feature vectors of the segmented pictures, and judging the category of the segmented pictures according to the feature vectors and standard templates in a standard template library. The invention is advantageous in that garbage identification can be quickly performed through the image identification technique, people are assisted in quick garbage classification in daily life, and the workload for secondary garbage sorting is reduced.

Owner:GUANGDONG MATVIEW INTELLIGENT SCI & TECH CO LTD

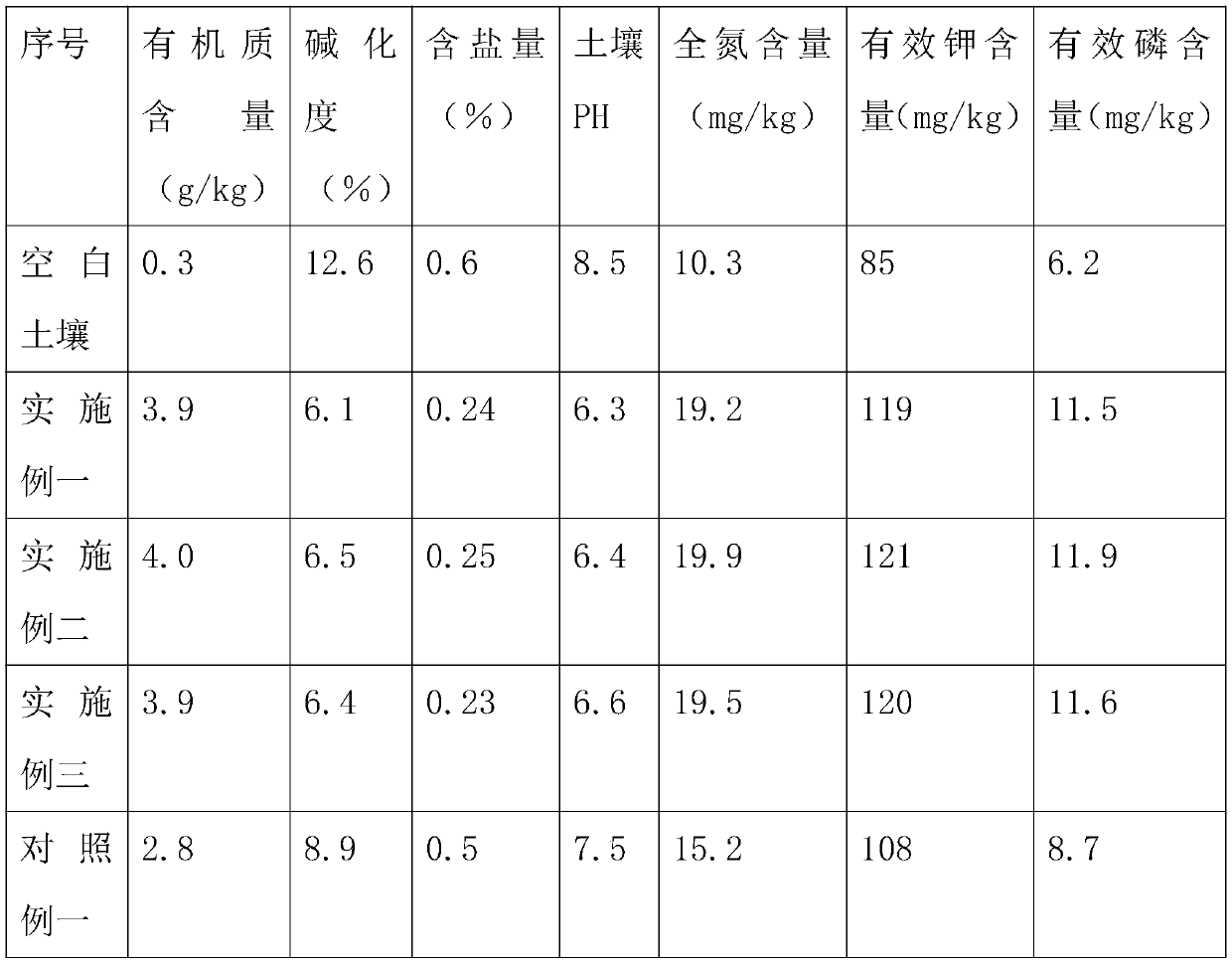

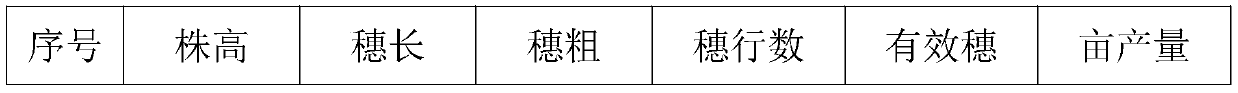

Saline-alkali soil improved microbial agent and preparation process thereof

InactiveCN110373207AImprove stabilityNot easy to influenceAgriculture tools and machinesOther chemical processesBacillus licheniformisAlkali soil

The invention discloses a saline-alkali soil improved microbial agent and a preparation process thereof, and belongs to the field of saline-alkali soil improvement. The saline-alkali soil improved microbial agent is prepared from the following raw materials in parts by weight: 140-180 parts of a composite microbial agent, 100-130 parts of biochar, 30-50 parts of humic acid, 5-10 parts of a trace element, 10-15 parts of a filler and 30-50 parts of superphosphate. Synergistic growth and reproduction in a saline-alkali soil environment is achieved by combining bacillus subtilis, bacillus licheniformis, bacillus laterosporus, Jingyang streptomyce and bacillus mucilaginosus in a specific ratio. The combination of the kinds of microbial agents can improve synergistic alkali-resistance, the saline-alkali soil improved microbial agent can ferment well in saline-alkali soil, the growth of plants on saline-alkali soil is supported, biochar made from crop straws can improve the soil, help the growth of the plants, increase agricultural productivity and purify water quality, and is lower in cost relative to peat, and the saline-alkali soil improved microbial agent is worthy of promoting.

Owner:苏州沣懿生物科技有限公司

Production method of ecotypic sintering ceramic colored permeable brick

InactiveCN105948707AEnsure porosityGood water permeabilityCeramic materials productionClaywaresBrickPrill

The invention belongs to the technical field of inorganic nonmetallic material, and relates to an ecotypic sintering ceramic colored permeable brick and a production method thereof. The method is characterized by including using the waste ceramic particles as a basic skeleton material, using the coarse particle size gradation as an internal layer skeleton material, using the fine particle size gradation as a surface layer skeleton material, adding proper amount of colorless and colored clear glaze fine powder, organic binder CMC, and water, and preparing the qualified ecotypic sintering ceramic colored permeable brick by performing the technologies such as preparation of materials, mixing, aging, secondary material distribution and pressing, drying, sintering and testing. The production method disclosed by the invention is suitable for industrial production of the permeable brick, and the prepared permeable brick has high water permeability, high compressive strength, rich colors, and good practical durability, and is widely used for ground laying of the outdoor public places such as large parking lot, square and city road, and artistic landscape.

Owner:宜兴友邦陶瓷有限公司

Production process for coloured polyester staple fibre

InactiveCN102517685ARealize resource reuseReduce manufacturing costArtificial filament heat treatmentMelt spinning methodsColour fastnessPolyester

The invention discloses a production process for coloured polyester staple fibre. In the production process, regenerative PET (Polyethylene Terephthalate) material is used as the raw material, and the finished product is acquired by pre-treating, rotary drum drying, melt spinning, cooling forming, winding, drafting, curling, oil applying, thermosetting and cutting-off in sequence, wherein the rotary drum drying comprises the steps of firstly drying the regenerative PET material for 7.5h-8.5h and then adding master batches with the final mass fraction of 2%-10%, and toner; the total drying time is 9.5h-10.5h; both the screw rod and the spinning beam of a screw extruder in the melt spinning step are at the temperature from 265 DEG C to 275 DEG C; spinneret plates are provided with 3500 bores having the diameter of 0.2mm and are arranged in 14 circles; cooling forming is realized through circular air blow, the temperature of the circular air is 22 DEG C to 26 DEG C, and the velocity of the circular air is 4.0m / s to 5.0m / s; the total draft multiple is 3.0-3.2 times; and the thermosetting temperature is 168 DEG C to 172 DEG C, and the thermosetting time is 13 minutes to 17 minutes. Theproduction process can save the cost and is helpful for environmental protection; the produced product has smaller linear density, higher colour fastness and smooth and comfortable hand feeling.

Owner:HANGZHOU BEST CHEM FIBER

Formula of special culture material capable of increasing content of each amino acid in grey mushroom fruiting body and culture method

InactiveCN102557800ARealize resource reuseHigh in amino acidsHorticultureFertilizer mixturesPig breedingMonopotassium phosphate

The invention relates to the formula of a special culture material capable of increasing the content of each amino acid in a grey mushroom fruiting body and a culture method. The formula provided by the invention is characterized in that the formula of the special culture material consists of the following raw materials in part by weight: 20 to 30 parts of straw, 20 to 30 parts of sawdust, 20 to 27 parts of cottonseed hull, 10 to 15 parts of bran, 0.3 to 0.5 part of monopotassium phosphate, 0.2 to 0.3 part of magnesium sulfate and 1.0 to 1.2 parts of calcium carbonate or calcium sulfate, wherein 10 to 30 kilos of pig excrement residues are added into 100 kilos of mixed culture material. According to the invention, the grey mushroom fruiting body has a round and attractive mushroom flower and greatly increases the content of each amino acid in the grey mushroom fruiting body, wherein the content of sulfur amino acid, branched chain amino acid, children amino acid, essential amino acid, flavor amino acid and sweet amino acid is greatly increased respectively. The grey mushroom fruiting body can increase the health-care medicinal function, increase the production additional value, reduce pollutants in the pig breeding industry and recycle the pig excrement residues.

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

Preparation method of composite adsorption purifying agent

InactiveCN103071455ASufficient sourceLow priceOther chemical processesWater/sewage treatment by sorptionActivated carbonPtru catalyst

The invention provides a preparation method of a composite adsorption purifying agent. The method comprises the following steps of: washing a dead catalyst with water to remove impurities, and drying at the temperature of 100-120 DEG C for three hours; introducing a protective gas, and raising the temperature to 700-900 DEG C by microwave heating; and stopping introducing the protective gas, simultaneously introducing activating gas for activating for 20-40 minutes, cooling to the room temperature, and drying to obtain the composite adsorption purifying agent. The composite adsorption purifying agent has the advantages of rich source, low price, great reduction in the production cost, protection of the environment, saving of resources and realization of recycling. A production method is simpler, is easy to operate, has low energy consumption, contributes to reducing the emission of pollutants in a production process and no secondary pollution. The reaction rate is increased, the reaction time is shortened, and the reaction cost is reduced. A produced ZnO / active carbon composite adsorption purifying agent has ideal effects on the degradation of organic dyes, treatment of heavy metal ions in waste water and photocatalysis sterilization, and plays an important role in comprehensively treating environmental pollution.

Owner:KUNMING UNIV OF SCI & TECH

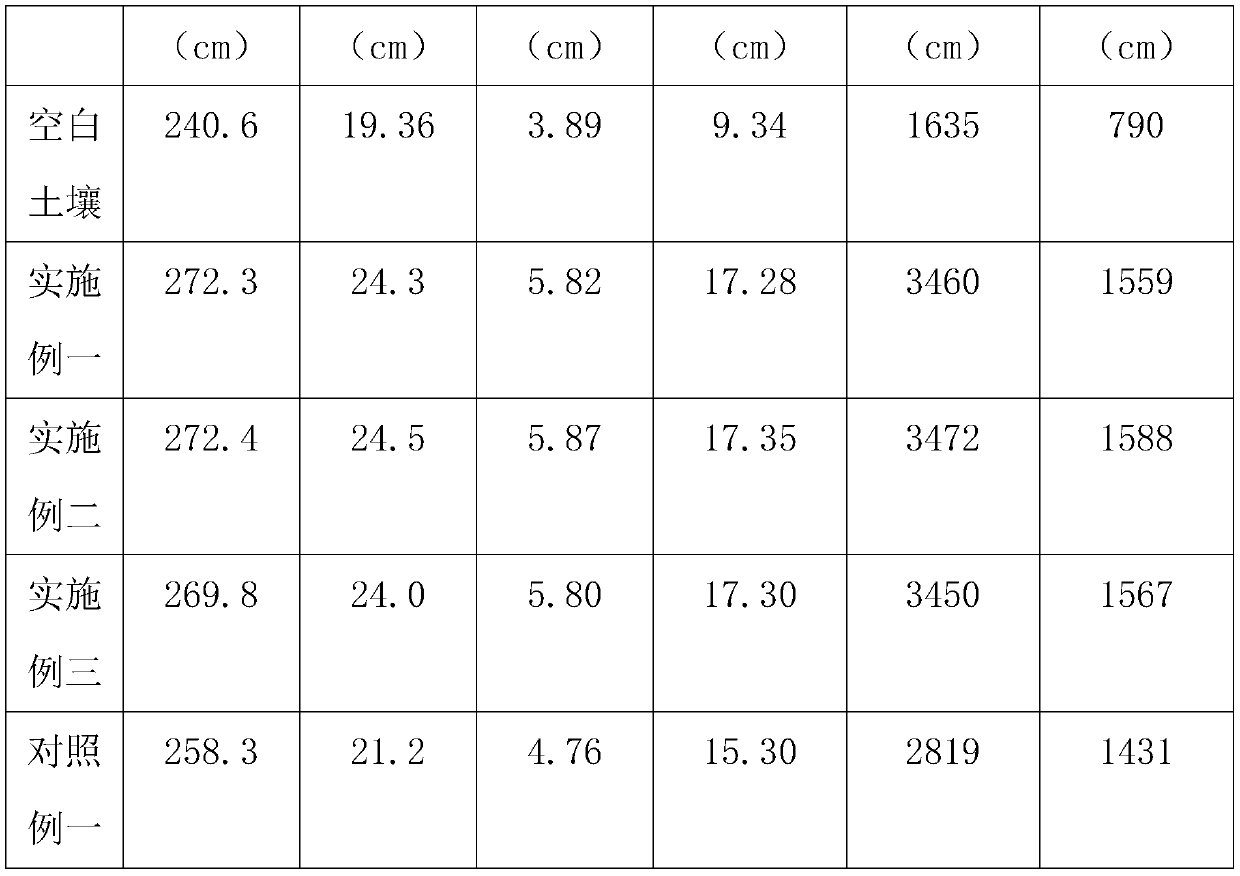

Treatment method of complexing nickel wastewater

InactiveCN106495377AReduce processing costsGuaranteed uptimeWater treatment compoundsWater contaminantsSulfate radicalsTherapeutic effect

The invention discloses a treatment method of complexing nickel wastewater. Compared with the prior art, Fe is loaded on granular active carbon, and a supported Fe2O3.FeO / GAC catalyst is prepared, a heterogeneously activated persulfate system generates sulfate radical free radicals with the strong oxidizing property to oxidize complex form heavy metals in the wastewater, by damaging the stable structure of complexing ions, the heavy metals are freed from complex, and the heavy metals are removed through a simple alkaline chemical precipitation method. The Fe2O3.FeO / GAC activated persulfate coupling system is established, the pH value of the wastewater is adjusted through the actual condition of the wastewater during wastewater treatment, a good treatment effect can be achieved, the catalyst still has good catalytic activity after being reused, and the wastewater treatment cost can be greatly reduced. A large amount of equipment investment and operating cost is not needed, materials are easy to take, and operation is simple. The active carbon carrier can be reused, resource reuse is achieved, and cost is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Household garbage treatment system and method

ActiveCN103706615AHigh degree of mechanizationRealize resource reuseSolid waste disposalOrganic matterCrusher

The invention provides a household garbage treatment system and method. The system comprises a crusher for crushing garbage, a water separation screening machine for classifying the garbage, an anaerobic fermentation tank for performing anaerobic fermentation on organic matters screened out by the water separation screening machine, and a fertilizer making machine for making fertilizers by using biogas residues output by the anaerobic fermentation tank. The system can automatically classify and treat the garbage in order to enhance the mechanical degree of household garbage treatment and realize the resource recycling.

Owner:BEIJING LANTIAN GAOZHAO ENVIRONMENTAL PROTECTION TECHN

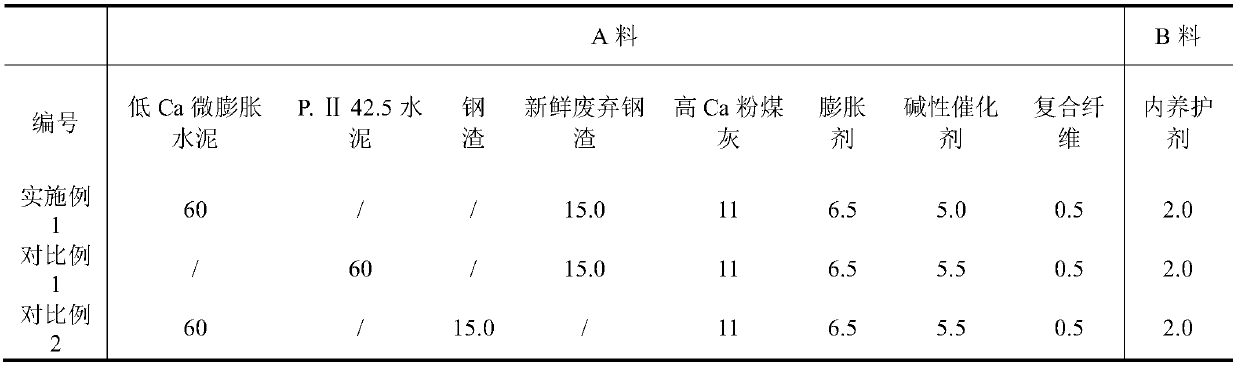

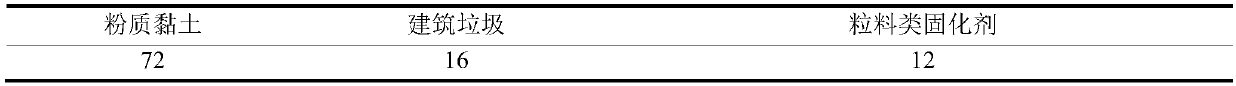

Granule curing agent and high-strength low-shrinkage cracking-resistance road surface base layer material prepared using same

ActiveCN109626892AReduce the plasticity indexLow water absorptionCement productionFiberCrack resistance

The invention discloses a granule curing agent and a high-strength low-shrinkage cracking-resistance road surface base layer material prepared using the same. The curing agent is a powder reagent which is prepared by taking low Ca micro-expansive cement, an alkaline catalyst, waste steel slags, high Ca powder coal ash, an expanding agent, an internal curing agent and composite fibers. The curing agent aims at solving the difficult problem of insufficient stable soil material mechanical performance and durability when curing soil exceeds a normal particular dimension; the high-strength low-shrinkage cracking-resistance road surface base layer material prepared using the granule curing agent has the advantages of excellent mechanical performance, stable water resistance and cracking resistance, durability and excellent energy-saving environmental-friendly characteristics, the cost of an engineering project can be effectively reduced, the material can be generally applied to the fields ofroad base layers, soft base treatment, ecological slope protection, dam anti-seepage walls, filling materials, building foundation treatment and the like, and the material has wide application prospects.

Owner:WUHAN MUNICIPAL CONSTR GROUP

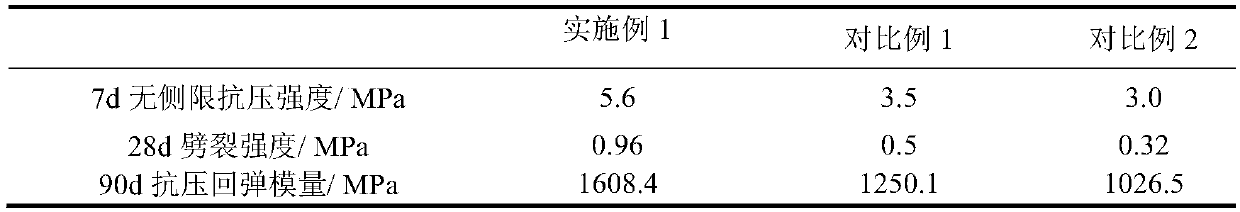

Technique for recycling ketazine-process hydrazine hydrate high-salt wastewater

ActiveCN104724871ASolve processing problemsReduce manufacturing costMultistage water/sewage treatmentNature of treatment waterDecompositionCatalytic oxidation

The invention discloses a technique for recycling ketazine-process hydrazine hydrate high-salt wastewater, which changes the solution idea that the ketazine-process hydrazine hydrate wastewater often adopts abundant oxidizers for oxidation treatment and then is discharged. The treatment technique based on air stripping oxidation and microwave catalytic oxidation is utilized to effectively perform oxidative decomposition and remove ammonia nitrogen and organic matters which can cause harm in wastewater in the diaphragm-process chlorine alkali production process, so that the treated wastewater can be recycled as a NaCl solution to be the diaphragm-process chlorine alkali production raw material, thereby implementing recycling of wastewater, lowering the diaphragm-process chlorine alkali production cost and achieving the treatment goal of zero wastewater discharge in deed.

Owner:SUZHOU JUZHI TONGCHUANG ENVIRONMENTAL PROTECTION TECH

Production method of polyaluminium chloride

InactiveCN101928031ARealize resource reuseReduce dependenceAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideWater discharge

The invention relates to a production method of polyaluminium chloride. The mixture of coal ash and bauxite is added into a kettle; industrial hydrochloric acid and acidic waste water are added, and then cosolvent is added; the mixture is heated and stirred under the sealing condition; after heated to 80-120 DEG C, the mixture reacts for 1.5-4 hours; after reaction ends, the obtained mixture is filtered; the filtrate is heated, and polymerizer is added; temperature is controlled to 80-120 DEG C; polymerization reaction is carried out for 1-3 hours to obtain the liquid polyaluminium chloride product; and after dried, the solid polyaluminium chloride is obtained. The invention uses coal ash to partially replace bauxite; acidic waste water is added so that cost is saved, the obtained product has good flocculation effect, and heavy metal content reaches the standard. The waste slag produced in the production process of the invention has small specific resistance, is easy to filter and can save energy. The invention aims to recycle the coal ash, provides raw material for preparing water treatment agent, solves the problem of environment pollution caused by waste water discharge and obtains the purpose of recycling comprehensive utilization of resource.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES +1

Treatment method of oil-containing sludge

InactiveCN108314290AHigh surface tension reduction abilityStrong flocculationDewatering/demulsification with chemical meansSludge treatment by de-watering/drying/thickeningAlkylphenolOil sludge

The invention discloses a treatment method of oil-containing sludge and belongs to the field of environmental engineering. The treatment method comprises the following steps of: introducing the oil-containing sludge into a separating groove, discharging into a deemulsifying groove for deemulsification after initially separating, and carrying out oil-water-sludge separation on deemulsified productsin an oil-sludge separating device; recovering dirt oil at the upper part, settling sludge-water mixture at the lower part, recovering clear liquor, and carrying out coagulation treatment, settling separation, mechanical dewatering, sludge drying and sludge incineration treatment in sequence on the sludge-water mixture at the bottom part and residual active sludge. Composite deemulsifying agentspreferred by the invention include a polyethylene polyamine blocked polyether deemulsifying agent, a silicon-containing deemulsifying agent, a phenolic-resin deemulsifying agent, an alkylphenol polyoxyethylene ether deemulsifying agent, a polyphosphoester deemulsifying agent or a polyaluminium-chloride deemulsifying agent. The deemulsifying method disclosed by the invention has the beneficial effects that the safe and environment-friendly effects are achieved, the water content of oil sludge can be reduced, most crude oil in the oil sludge can be recovered, and the difficulty of the followingtreatment of the sludge can be reduced.

Owner:YANGZHOU DAYANG WATER SUPPLY EQUIP

Method for producing ferric salt-series purifiers by recycling and comprehensive utilizing stainless steel waste etching solution

InactiveCN102992513ASimple technical processEasy to operateMultistage water/sewage treatmentIron halidesEtchingChromium

The invention relates to a method for producing ferric salt-series purifiers by recycling and comprehensive utilizing a stainless steel waste etching solution, which is developed for overcoming the defects of high production cost, halfway separation and complicated operation existing in the traditional stainless steel waste etching solution regeneration and nickel recovery technology. The method comprises the following steps of: firstly performing component analysis on the waste etching solution, additionally adding a certain amount of ferrous sulfate heptahydrate crystal according to the contents of nickel and chromium, and then oxidizing by using ozone; when Fe<2+> in a mixture is all oxidized to Fe<3+>, moving the mixture to a crystallization kettle, and adding hydrochloric acid to regulate pH value; forming hydrated sulfate and chlorate crystallized substances containing nickel and chromium ions by controlling the crystallization temperature and time, stirring speed and pH value; performing solid-liquid seperation on the crystallized substances, and then performing secondary crystallization when the contents of nickel and chromium in a filtrate are proper until the contents of the nickel and chromium in the filtrate are less than 100PPM; obtaining ferric chloride as a chemical component of the filtrate after separation, and producing other ferric salt-series purifiers by adjusting the amounts of ferrous sulfate and the hydrochloric acid.

Owner:天津市聚鑫源水处理技术开发有限公司

Intelligentized organic waste integrated processing device and process

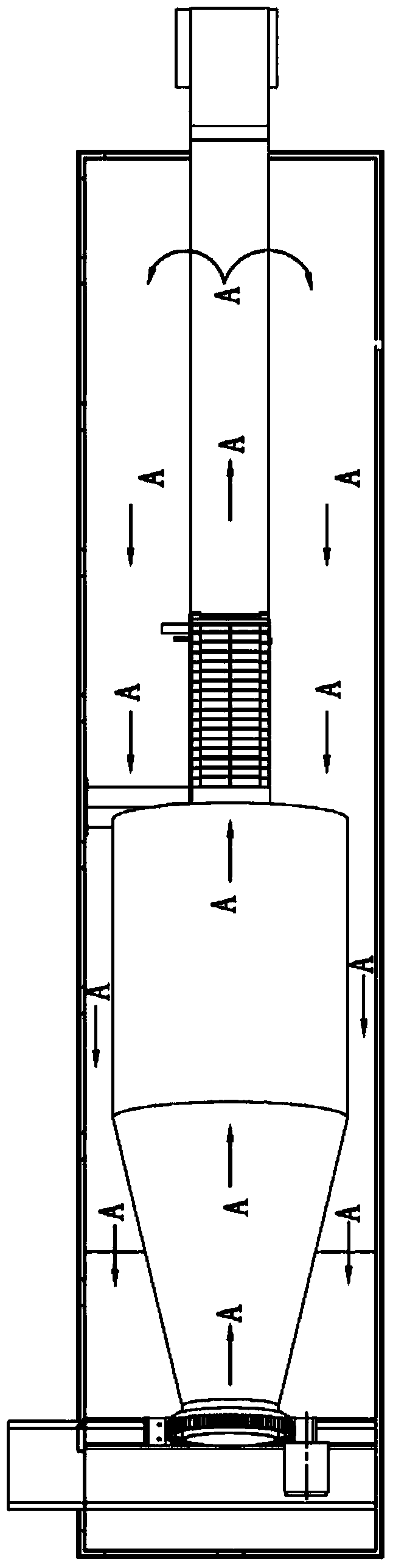

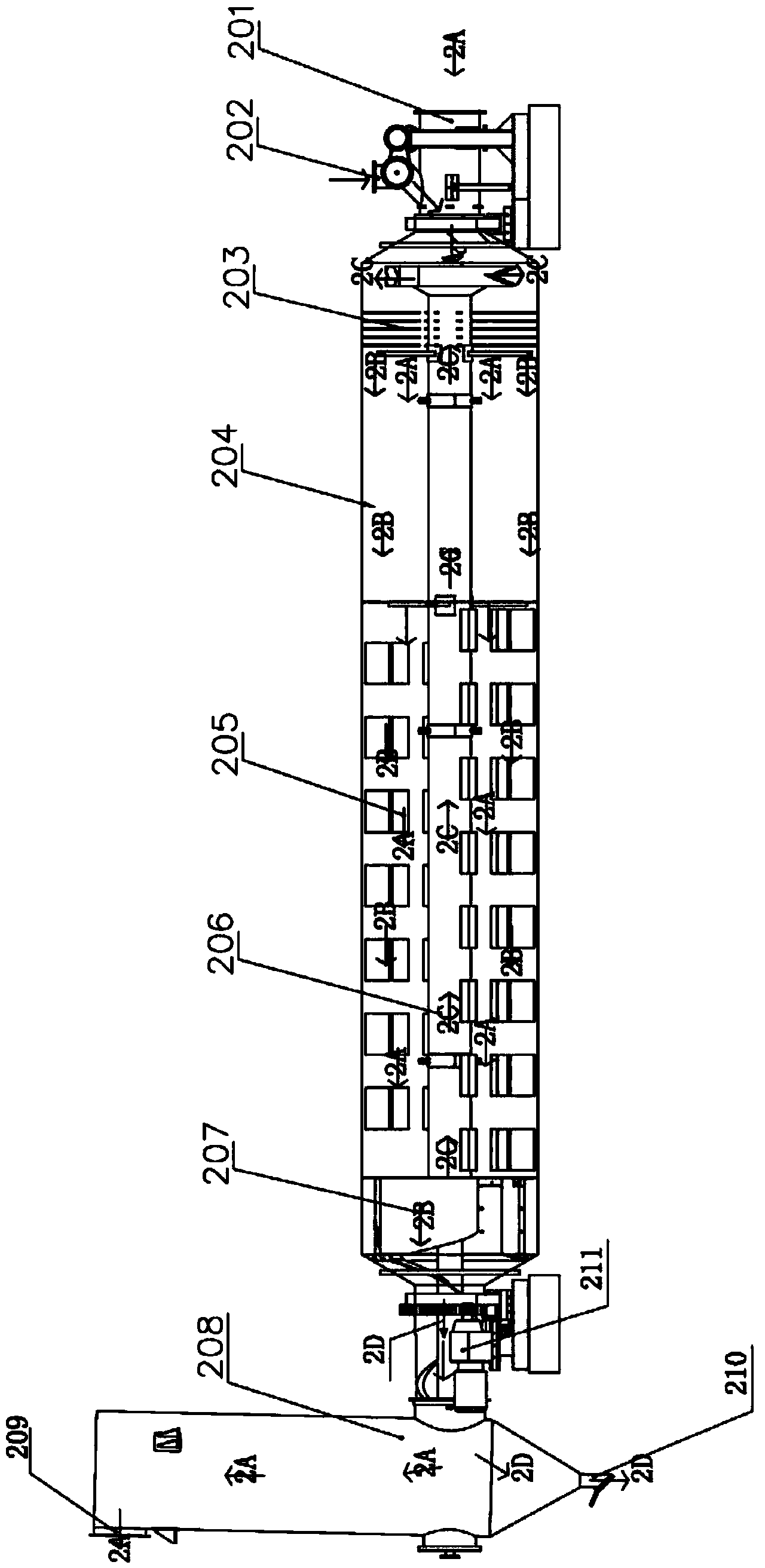

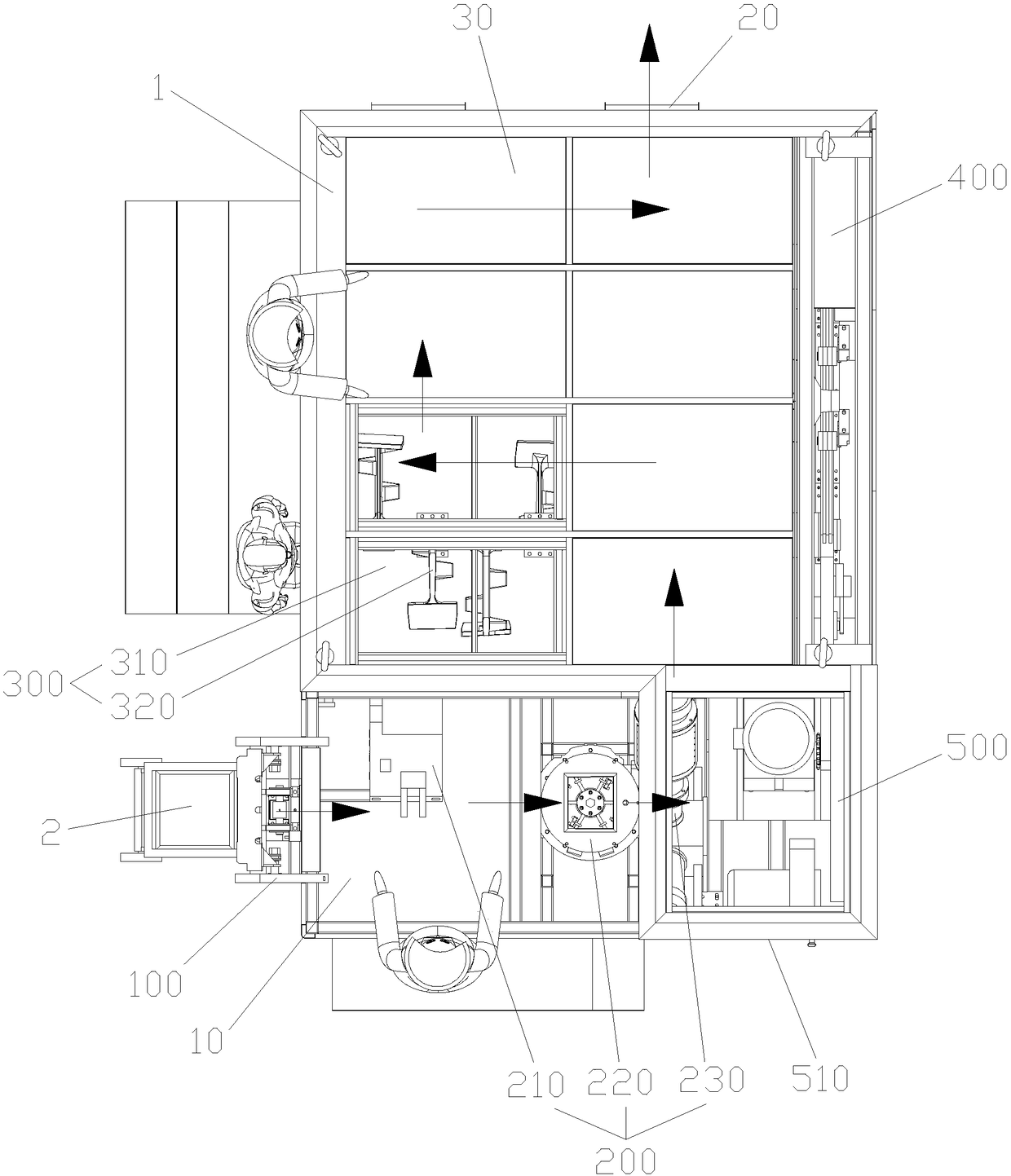

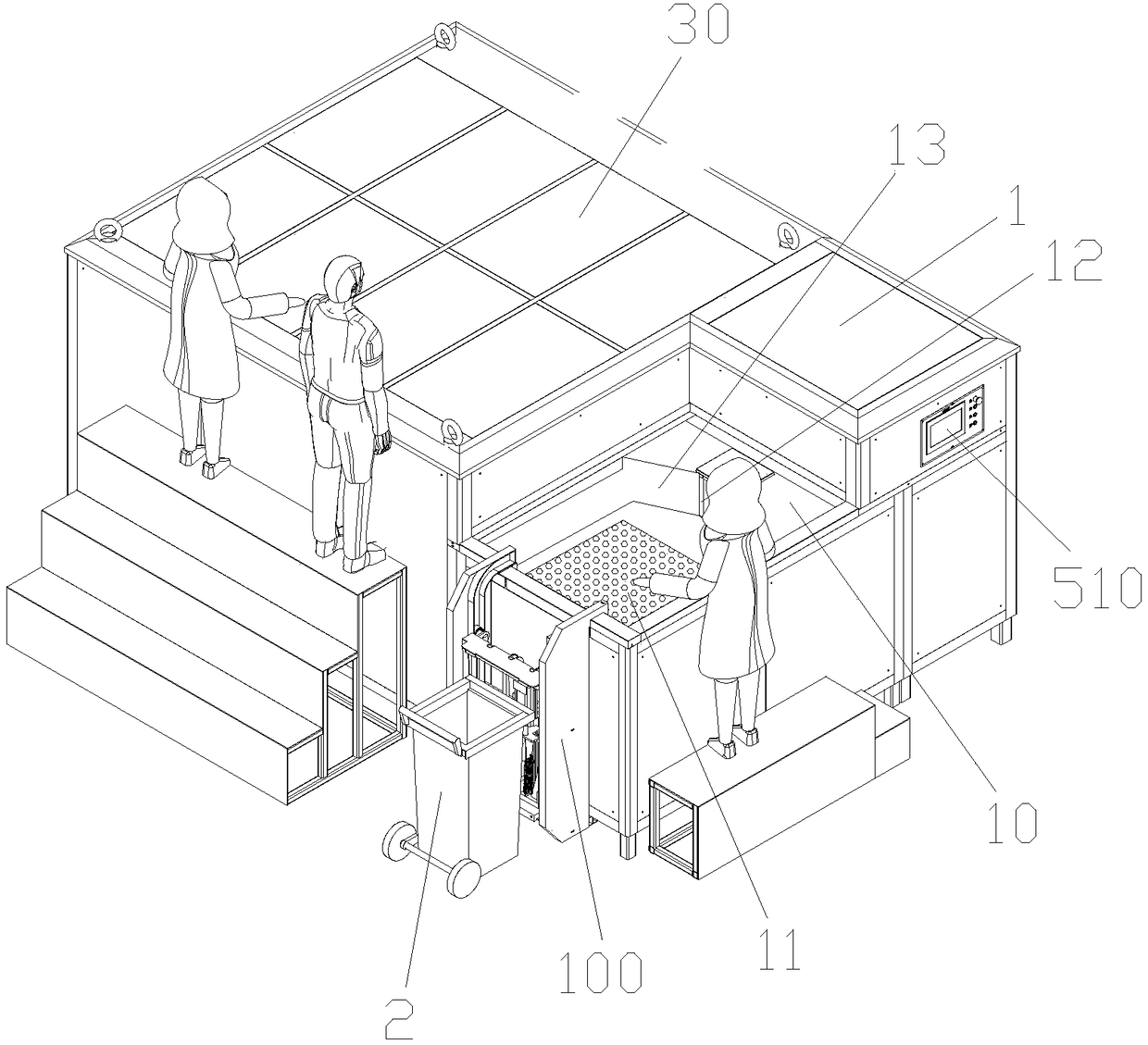

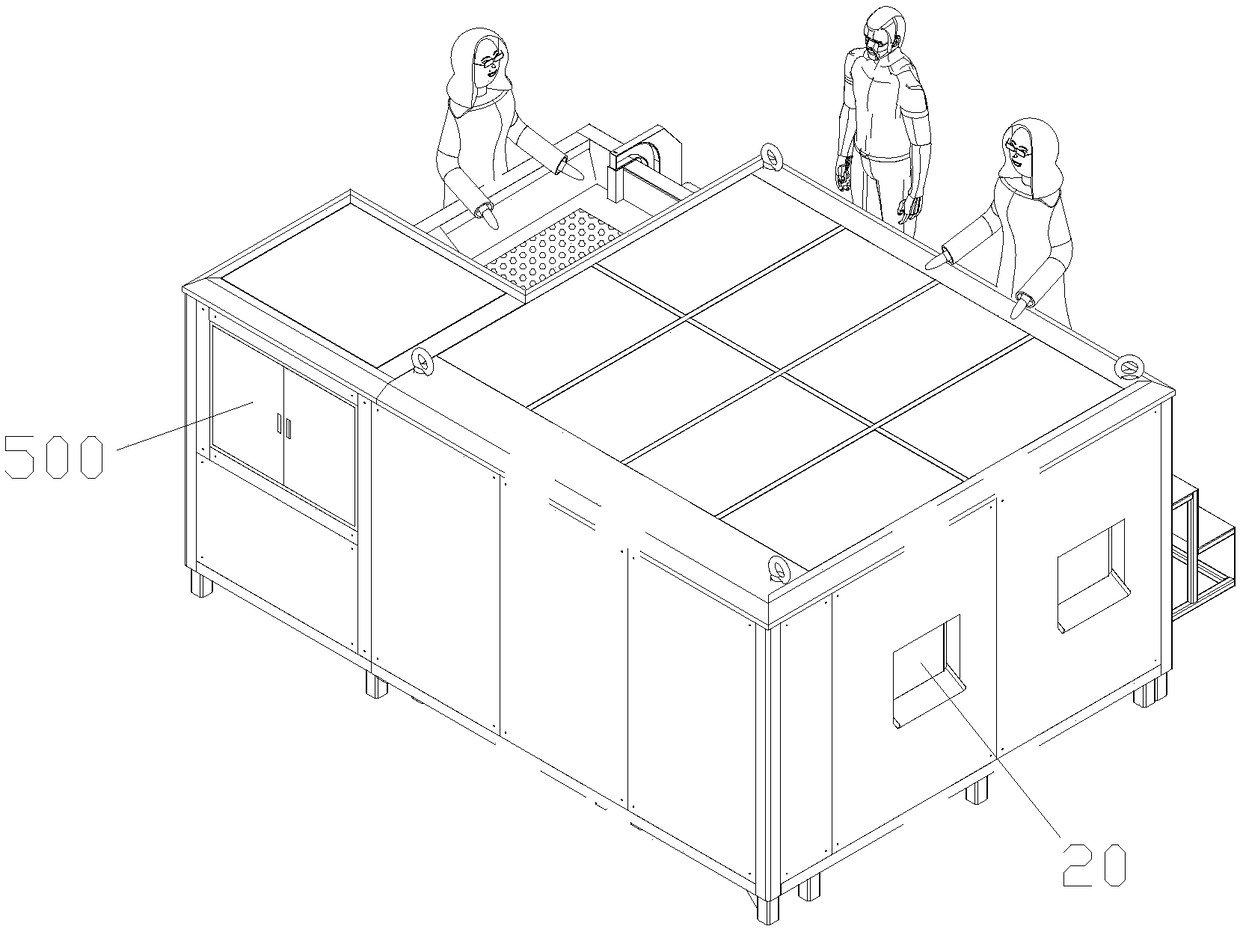

ActiveCN108326010ACompact structureReduce volumeBio-organic fraction processingSolid waste disposalTreatment targetsMan machine

The invention relates to an intelligentized organic waste integrated processing device and process. The device includes an outer shell and an elevator. The interior of the outer shell is integrally provided with a preprocessing device, a stirring fermenting device and a deodorizing device. The outer shell is provided with a sorting operation platform; the elevator is arranged on the outer side ofthe outer shell and is located by the side of the sorting operation platform; the bottom of the sorting operation platform is provided with a filter screen plate, and the side part of the sorting operation platform is provided with an organic waste outlet. The preprocessing device includes an oil-water separator, a crusher and a squeezer. The stirring fermenting device includes at least one fermentation chamber, and a discharge port of the squeezer is led to the fermentation chamber; the interior of the outer shell is also provided with a control device; the control device is electrically connected with the elevator, the oil-water separator, the crusher, the squeezer, the stirring and fermenting device and the deodorizing device, and is also electrically connected with a man-machine operation interface. The intelligent organic waste integrated processing device and process can realize the harmless, decrement and resourceful treatment targets of organic waste.

Owner:福建省劲牛重工发展有限公司

Method for regenerating used oil by adopting antibiotic waste mushroom dreg biomass charcoal

InactiveCN103923734AHigh specific surface areaGood adsorption performanceOther chemical processesLubricant compositionActivated carbonBiomass

The invention relates to a method of regenerating used oil by adopting antibiotic waste mushroom dreg biomass charcoal. The method comprises the following steps: 1) sterilizing and dehydrating antibiotic waste mushroom dregs to prepare waste mushroom dreg biomass charcoal or biomass active charcoal; 2) standing and layering the used oil, removing water at the lower layer and then filtering out solids and suspended solids to obtain the treated used oil; and 3) adding the used oil into the waste mushroom dreg biomass charcoal or biomass active charcoal, heating for reaction, and settling and carrying out suction filtering to obtain the regenerated oil. The method provided by the invention has the advantages that the biomass charcoal or biomass active charcoal prepared by antibiotic waste mushroom dregs has high specific surface area and good adsorptive property, solves the problem in disposal of waste mushroom dregs and realizes recycling of resources; a good decolorising agent is developed for the used oil, and the transmittance of the regenerated oil can reach 45-85%; recycle, reduction and harmless treatment of waste mushroom dregs and used oil are realized, so that the method has remarkable economical and social values.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Treatment process of high-slag-content and water-containing sump oil

ActiveCN105419856AHigh recovery rateImprove dehydration rateDewatering/demulsification with chemical meansCavitationSlag

The invention relates to a treatment process of high-slag-content and water-containing sump oil and relates to the technical field of separation and treatment of slag-containing and water-containing sump oil. Firstly, the sump oil is washed with alkali liquor, emulsification systems of a W / O type and an O / W / O type in the sump oil are subjected to phase inversion to form emulsion of an O / W type, the viscosity of the high-slag-content and water-containing sump oil and the interfacial tension of the emulsion systems can be effectively reduced due to formation of the emulsion of the O / W type, and therefore mass transfer of a subsequent demulsifying agent is facilitated, and the demulsifying effect of the subsequent demulsifying agent fully acts. Then, sulfuric acid is added and made to react with sodium naphthenate, sodium naphthenate is reduced into naphthenic acid without the emulsifying effect, and therefore the emulsifying effect of sodium naphthenate is eliminated. Next, a demulsifying agent of a compound type and a flocculating agent are sequentially added, and further flocculating setting separation happens to part of dross remaining in an oil layer. Finally, the sump oil is treated through the acoustic cavitation effect of ultrasonic waves, the mechanical vibration effect and the heat treatment effect, water and slag are further removed, and crude oil is recycled.

Owner:YANGZHOU UNIV

Environmental-friendly tourmaline composite home decoration material and preparation method thereof

ActiveCN104386982AChanging the Potential Threat QuestionPlay the environmentSolid waste managementOxygen ionsFar infrared

The invention discloses an environmental-friendly tourmaline composite home decoration material. The environmental-friendly tourmaline composite home decoration material comprises the following raw materials in parts by weight: 2-20 parts of tourmaline powder, 20-80 parts of slag, 2-10 parts of activated carbon, 5-40 parts of a binding agent, 1-40 parts of an accessory and 0.1-0.3 part of an air entraining agent. The invention further discloses a preparation method of the material. By mainly utilizing various excellent characteristics of tourmaline, the prepared home decoration material has functions of releasing negative oxygen ions and emitting a far infrared ray, the problem of potential threats to a human body caused by an existing home decoration material is greatly changed, a great number of negative oxygen ions can be released, formaldehyde, peculiar smells and the like can be absorbed, dust and other small molecule compounds in air can be adsorbed, and the effects of purifying indoor environment and killing and inhibiting bacteria are achieved; moreover, a main body part is prepared by using the flag and Portland cement, and the material is low in price, easy to obtain, high in mechanical strength, light in weight, reusable, wide in application prospect and suitable for popularization and application.

Owner:CHENGDU SHANGKE KITCHEN EQUIP

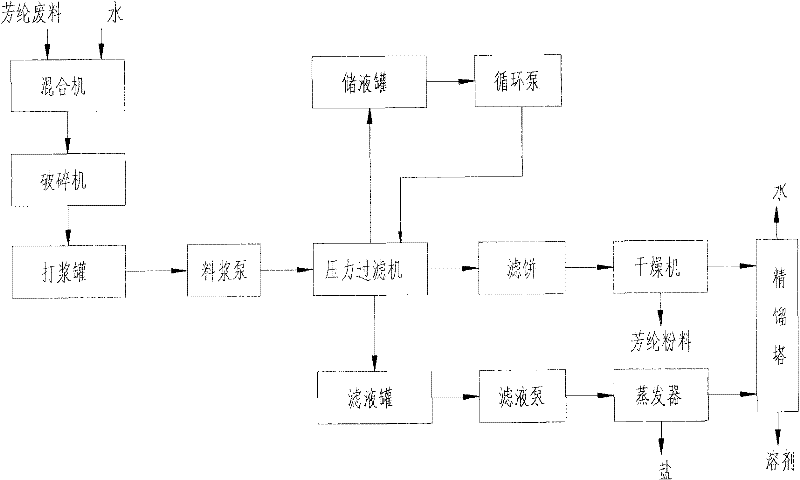

Solvent recovery process for para-aramid waste

The invention relates to a para-aramid waste material solvent recovery process. The process is characterized by: mixing para-aramid waste material and water; conveying the resulting mixture to a crusher to carry out crushing; conveying the crushed mixture to a beating tank to obtain slurry of the para-aramid; conveying the slurry of the para-aramid to a pressure filter through a slurry pump to carry out washing and filtering, wherein the washing water is stored in a liquid storage tank and then is beaten into the pressure filter through a recirculating pump to be recycled; conveying the resulting filtrate from the pressure filter to a evaporator through a filtrate pump to carry out evaporation to obtain a salt and other by-products, conveying the resulting filter cake from the pressure filter to a drier to carry out drying to obtain a solid powder material; conveying the solvent tail gas evaporated from the evaporator and the drier to a rectification tower to carry out separation and recovery. The invention provides a process method for the recovery of the solvent through carrying out crushing, pressure filtering, evaporation, drying and rectification for the para-aramid waste material. With the present invention, cycling utilizations of the N-methylpyrrolidone (NMP) and the pyridine are effectively raised during the para-aramid production process; the production cost is reduced; resource reutilization is realized; the pollution is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +2

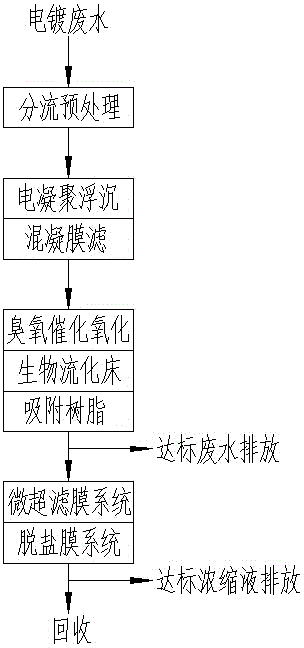

Processing method for performing standard treatment on electroplating wastewater and recycling heavy metal in water

InactiveCN104671611AAvoid secondary pollutionHigh recovery rateWaste water treatment from metallurgical processMultistage water/sewage treatmentHigh concentrationElectricity

The invention discloses a processing method for performing standard treatment on the electroplating wastewater and recycling a heavy metal in the water. The processing method comprises a split-flow pretreatment step and additionally comprises the following steps: (a) removing and recycling the heavy metal: removing the heavy metal in the electroplating wastewater split-flow pretreated by an electrocoagulation float-down method and a coagulation film filtering method, and recycling the heavy metal reaction product in the electroplating wastewater; (b) removing the residual difficultly-decomposed organic matters: removing the residual difficultly-decomposed organic matters in the electroplating wastewater of step (a) in which plenty of heavy metals are removed and recycled by an oxidizing technology, a biological fluidizing technology and an absorbing technology, and further enriching the low-concentration electroplating wastewater, separating the standard effluent which can be directly discharged, and rinsing to generate the high-concentration electroplating wastewater; and (c) standard treating the condensed effluent: desalting the enriched high-concentration electroplating wastewater in step (b) by a limit integrated membrane system, and separating the standard concentrated solution which can be directly discharged and the standard recovery solution which can be directly standardized and recycled.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

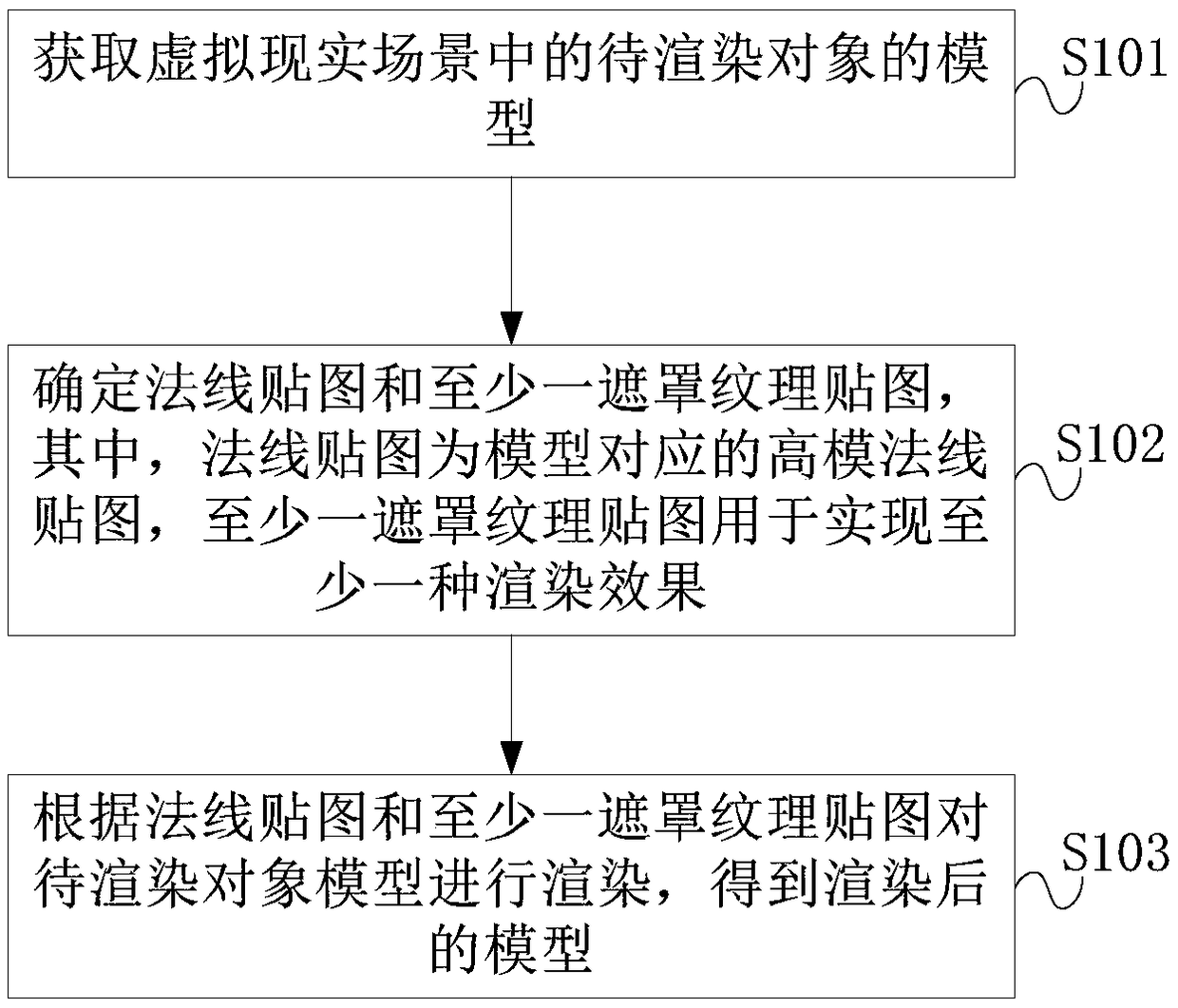

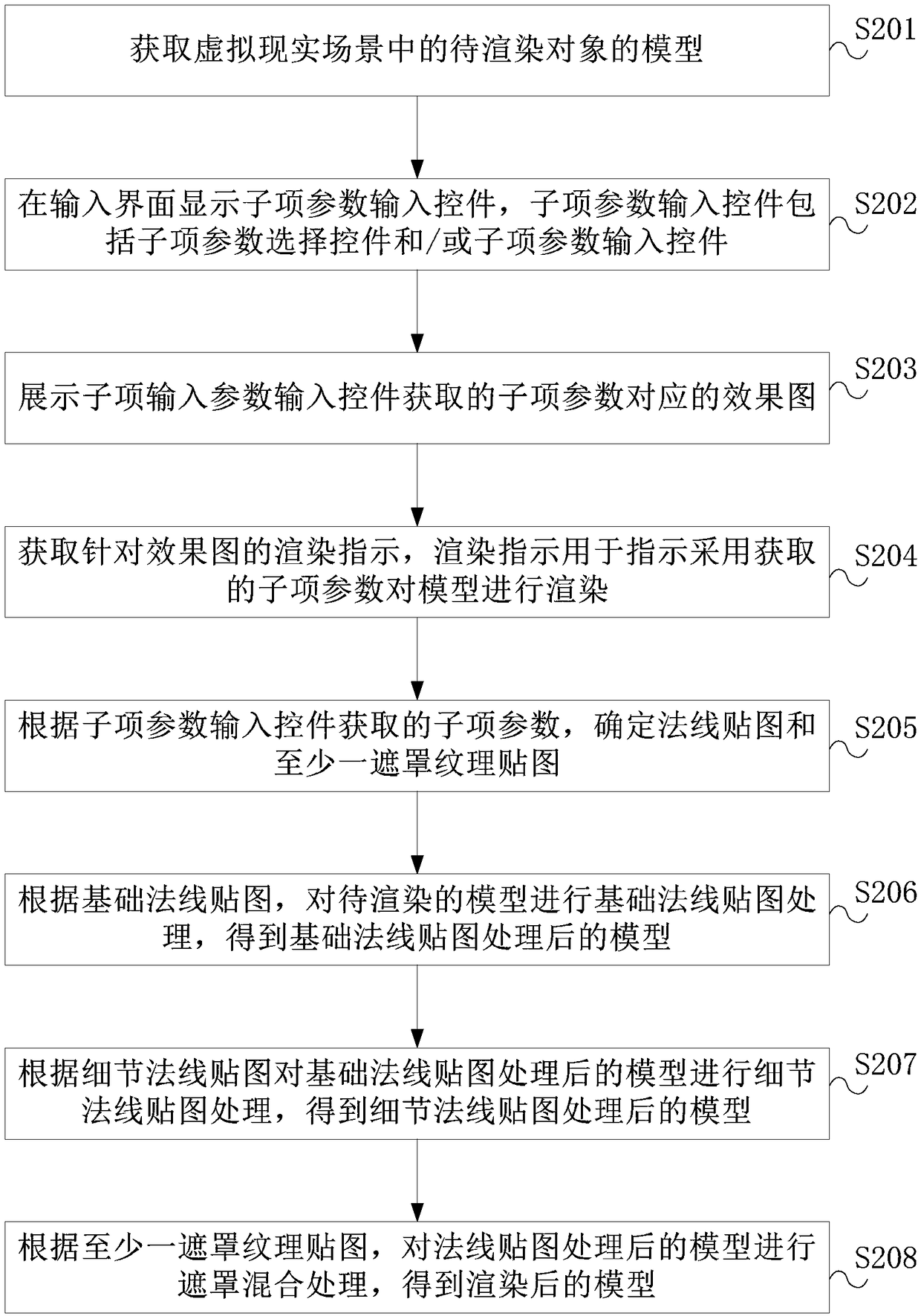

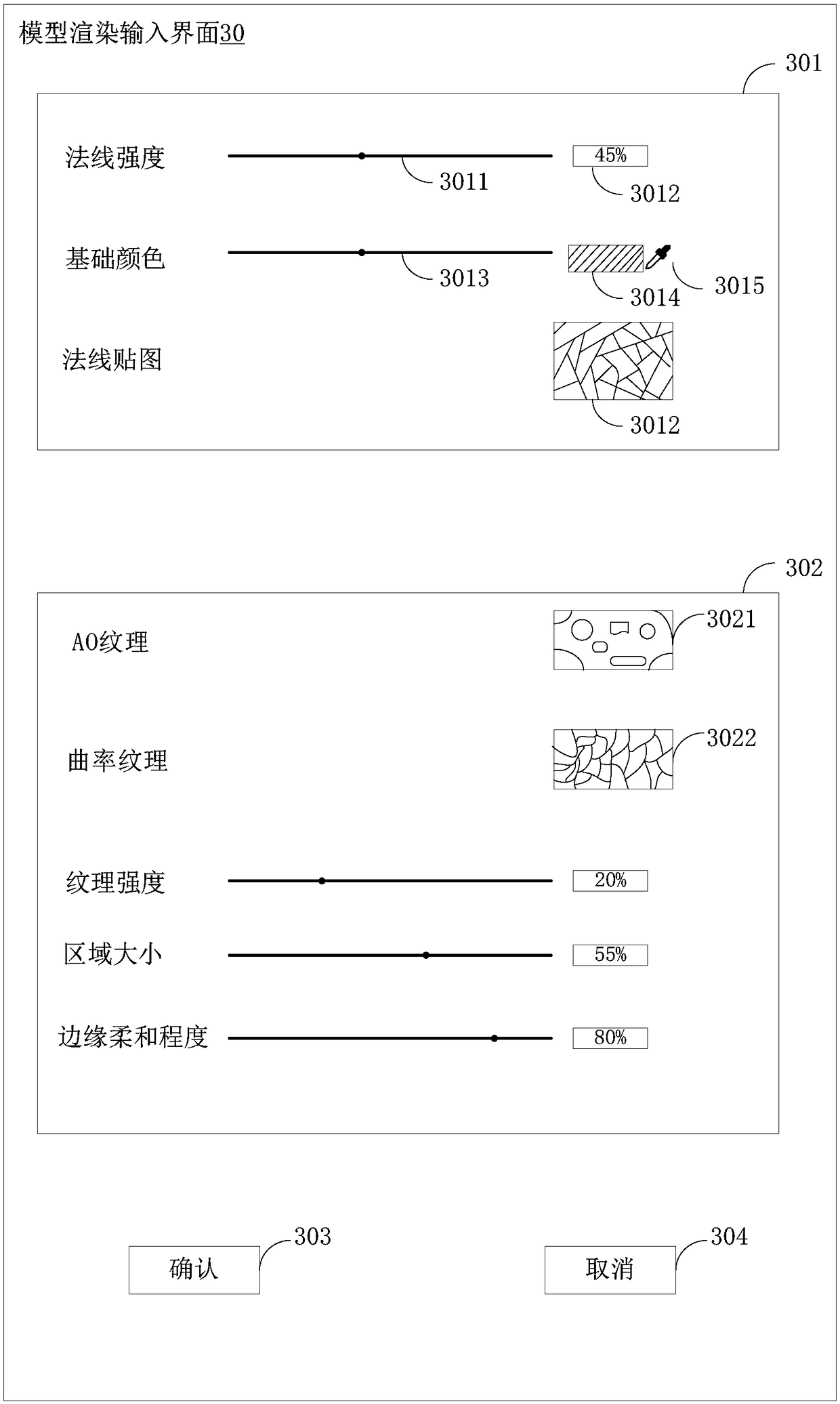

Virtual reality model rendering method and device

PendingCN109377546ARealize resource reuseReduce manufacturing cost3D-image renderingEnergy efficient computingComputer graphics (images)Normal mapping

The embodiment of the invention provides a virtual reality model rendering method and a device. The method comprises the following steps of: acquiring an object model to be rendered in a virtual reality scene. A normal map and at least one mask texture map are determined, wherein the normal map is a high-modulus normal map corresponding to the model, and at least one mask texture map is used for realizing at least one rendering effect. At least one mask texture map and a normal texture map are use for rendering that object model to be render to obtain the rendered model. The embodiment of theinvention enables the same model to be applied to different scenes, thereby realizing the resource reuse of the model and saving the production cost of the game.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

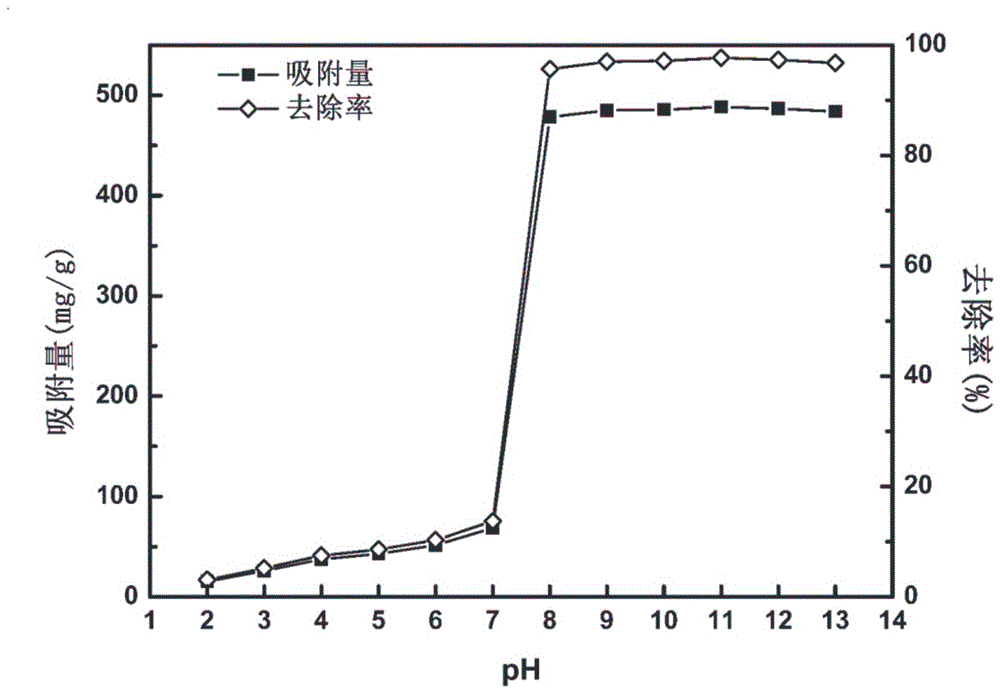

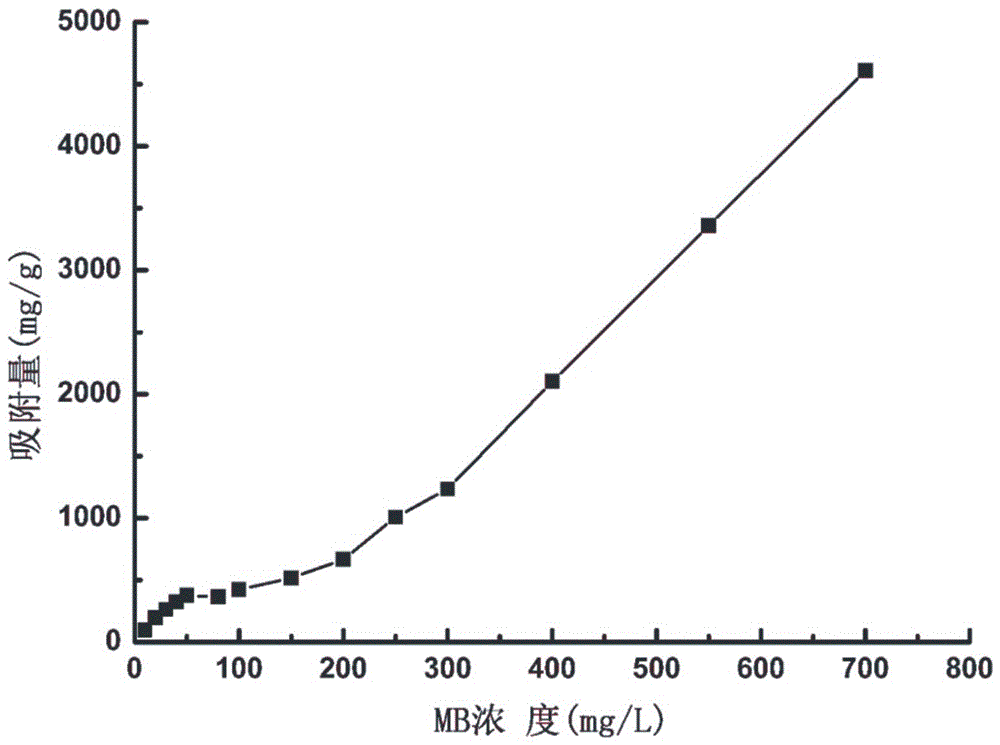

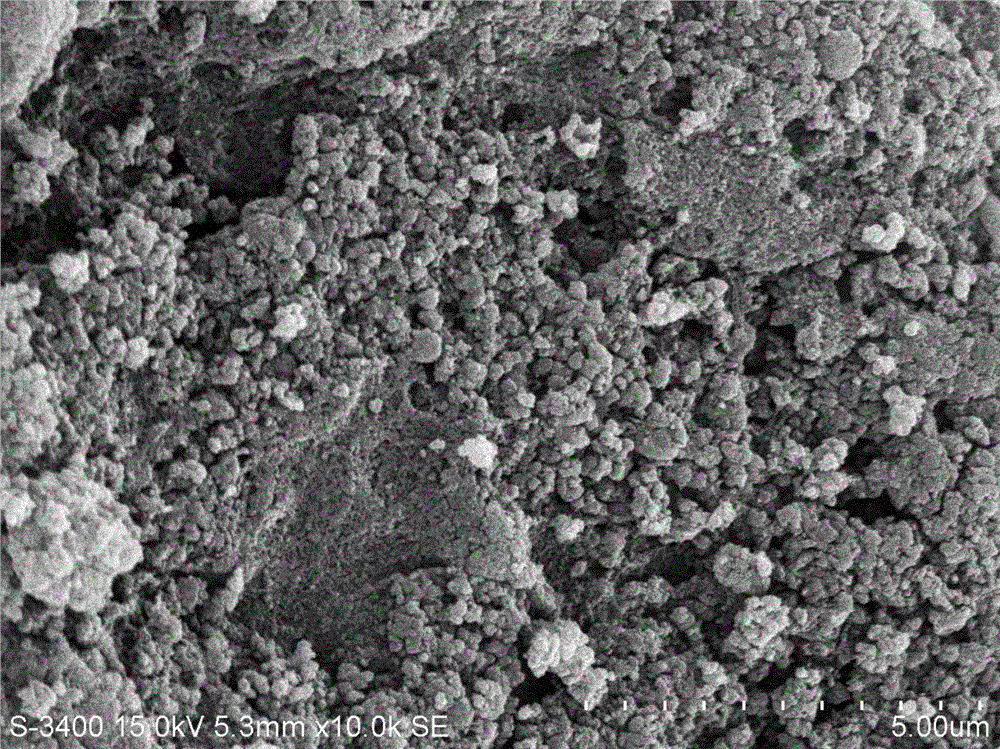

Preparation and application of phosphorus-hybridized functional activated-carbon absorption material

InactiveCN105944672ATurn waste into treasureRealize resource reuseOther chemical processesWater contaminantsActivated carbonO-Phosphoric Acid

The invention relates to preparation and application of a phosphorus-hybridized functional activated-carbon absorption material. A phosphorus-hybridized functional activated-carbon absorption material is prepared by using shrimp shells as the basic raw material and using phosphoric acid low-temperature calcination for modification. A preparation method of the phosphorus-hybridized functional activated-carbon absorption material specifically includes: sequentially processing the shrimp shells with sodium hydroxide and hydrochloric acid in a pre-soaking manner, and drying to obtain precursor; crushing the precursor, using sulfuric acid with the mass fraction being about 60% to perform heating treatment, settling obtained suspension, filtering, washing until the suspension is neutral, and drying to obtain black powder; using concentrated phosphoric acid to perform calcination and activation treatment, washing until the solution is neutral, and drying to obtain phosphorus-hybridized activated carbon. The phosphorus-hybridized activated-carbon absorption material prepared by the method has the advantages that the phosphorus-hybridized activated-carbon absorption material is large in specific surface area (561m<2> / g) and good in absorption performance, and the cationic dye (methylene blue (MB)) absorption value of the phosphorus-hybridized activated-carbon absorption material reaches up to 4610mg / g and is much higher than that of other reported absorbents; in addition, the phosphorus-hybridized activated-carbon absorption material is wide in raw material source and low in cost, and resource recycling and environment protection are achieved.

Owner:EAST CHINA UNIV OF SCI & TECH

Biodegradable resin composition

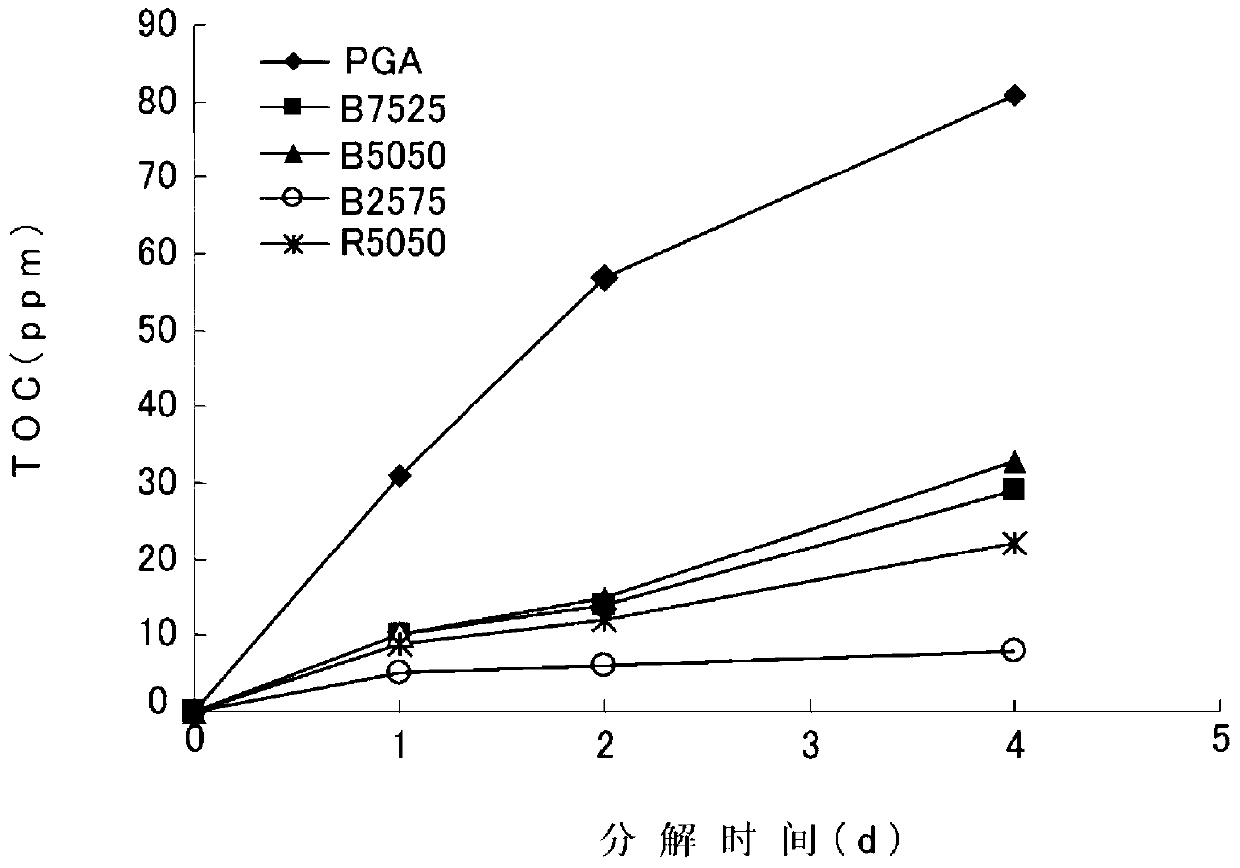

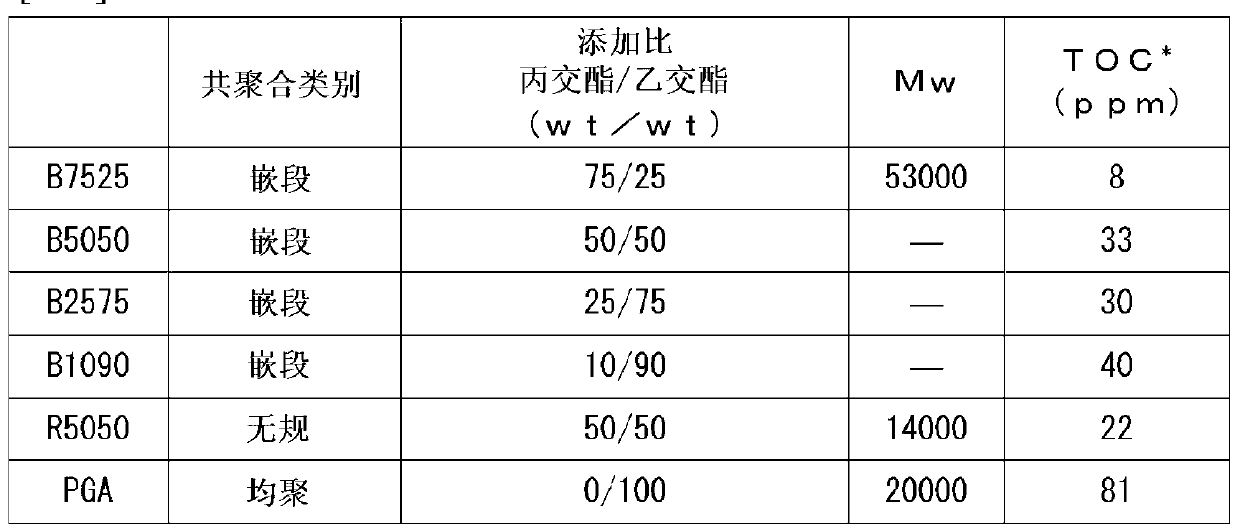

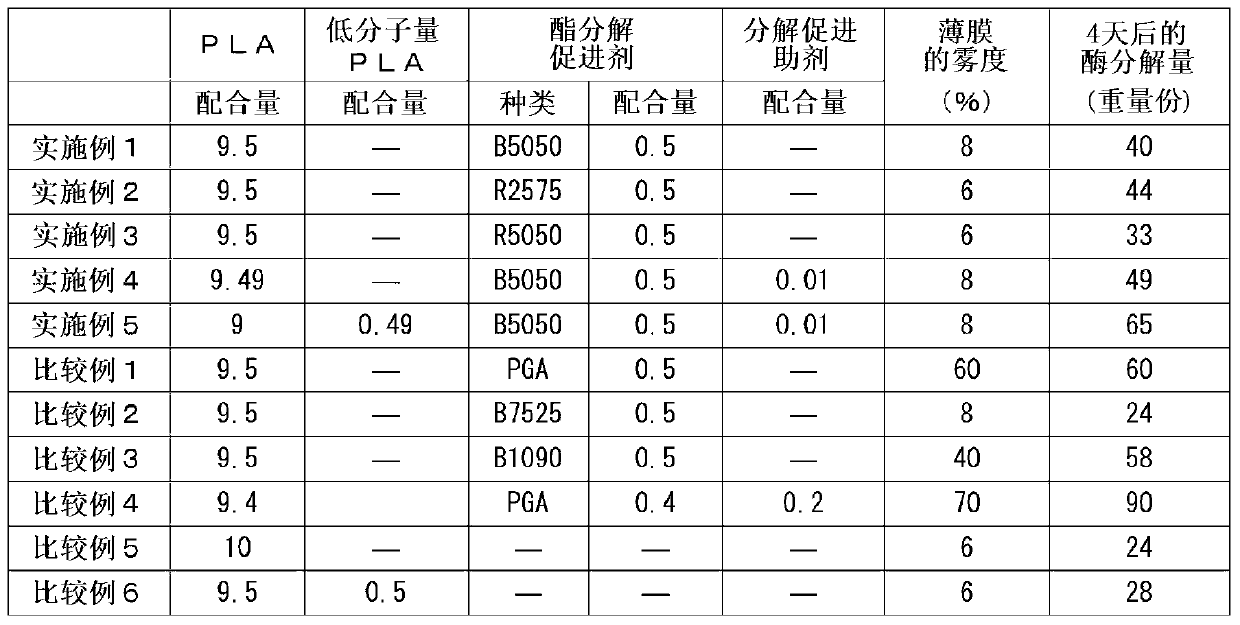

The present invention is a biodegradable resin composition which contains a hardly hydrolyzable biodegradable resin (A) and an ester degradation accelerator (B), and is characterized in that a copolyester, which contains a hardly hydrolyzable polyester segment (X) and a readily hydrolyzable polyester segment (Y) at a weight ratio such that 75 / 25 < X / Y < 10 / 90, is blended as the ester degradation accelerator (B). The biodegradable resin composition of the present invention has excellent biodegradability and excellent transparency.

Owner:TOYO SEIKAN GRP HLDG LTD

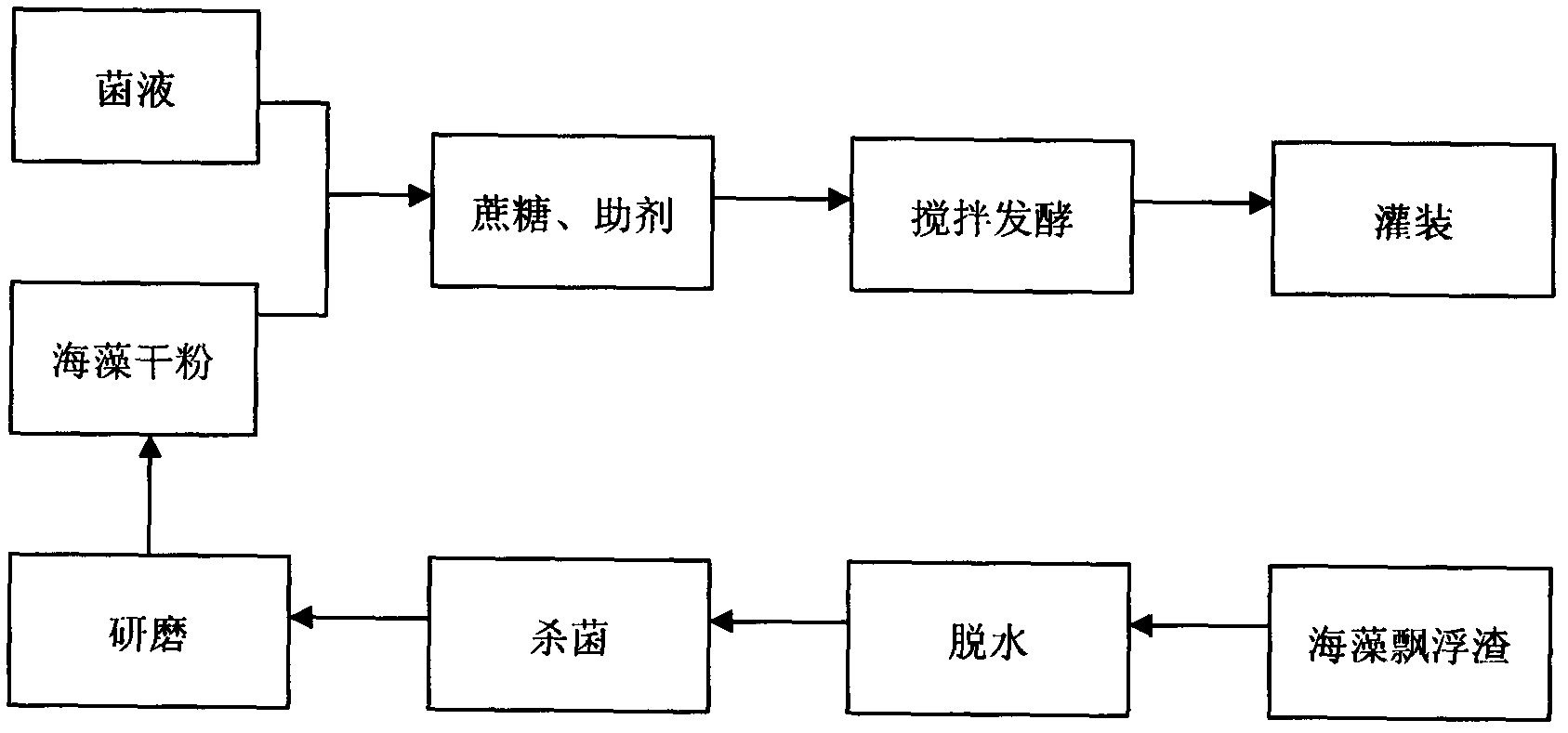

Formula for producing compound microbial fertilizer by use of algae and preparation method

The invention discloses a formula for producing a compound microbial fertilizer by use of algae and a preparation method. The formula is characterized by comprising 20% of algae dry powder, 5% of zymocyte liquid, 2% of auxiliary, 3% of sucrose and 70% of clean water, and the components are mixed and fermented into liquid; and a preparation method of the algae dry powder comprises the following steps of: dehydrating the algae floating slag, sterilizing and grinding into algae dry powder. By sufficiently utilizing the algae floating slag, environmental protection is facilitated, resource reuse is realized, waste is turned into wealth, and the preparation technology is simplified; superfine algae powder is fermented to prepare liquid, the solubility is high, the fertilizer is easily absorbed by plant, and the output of unit area is increased; since the pH value is 5.5-8.5, improvement of the soil structure is facilitated; and by applying efficient algae leaf fertilizer, the stress resistance of fruits and vegetables is enhanced, the quality of the fruits and vegetables is improved, and agricultural production is facilitated.

Owner:上海中意农业科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com