Treatment method of complexing nickel wastewater

A treatment method and technology for nickel wastewater, which is applied in special compound water treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of narrow light absorption range of photocatalyst, inability to meet the standard stably, low adsorption rate, etc., and achieve resource The effect of reusing, increasing the number of reuses, and facilitating the collection of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

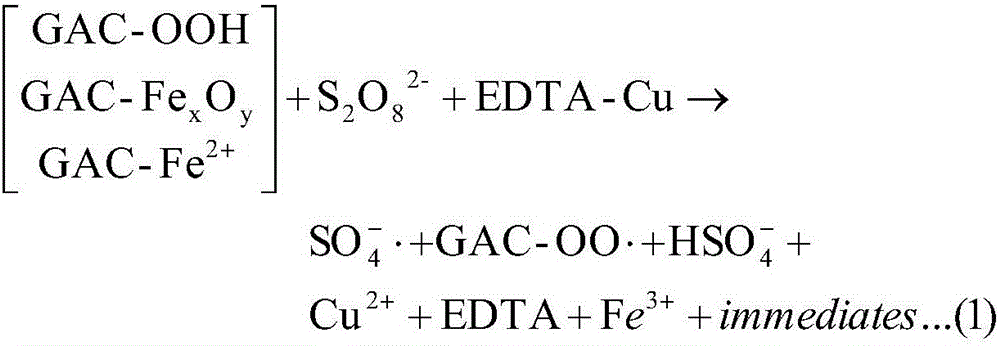

Method used

Image

Examples

Embodiment 1

[0039] A treatment method for complexed nickel waste water, comprising the following steps:

[0040] 1) Use commercially available general-purpose granular activated carbon (through a 20-40 mesh sieve), whose parameters are: methylene blue adsorption value ≥ 120mg / g, specific surface area > 800m 2 / g, put granular activated carbon in deionized water, heat and boil in an electric furnace for 40min, wash with ultrapure water, and dry in a vacuum oven at 105°C overnight; add 3mmol NH 4 Fe(SO 4 ) 2 12H 2 O was dissolved in 40ml of deionized water, then 3ml of cyclohexylamine was added dropwise and vigorously stirred at 120r / min for 20 minutes, then the colloidal mixture and 2g of activated carbon passing through a 20-mesh sieve were mixed and added to a 60ml polytetrafluoroethylene reactor , and cooled at room temperature after reacting at 150°C for 12 hours. The final sample was washed 5 times with deionized water and ethanol, and dried in a vacuum oven at 60°C for 6 hours to...

Embodiment 2

[0044] A treatment method for complexed nickel waste water, comprising the following steps:

[0045] 1) Use commercially available general-purpose granular activated carbon (through a 20-40 mesh sieve), whose parameters are methylene blue adsorption value ≥ 120mg / g specific surface area > 800m 2 / g, the granular activated carbon was heated and boiled in an electric furnace for 40min, washed with ultrapure water, and dried overnight in a vacuum oven at 105°C; 3mmol NH 4 Fe(SO 4 ) 2 12H 2 O was dissolved in 50ml of deionized water, then 3ml of cyclohexylamine was added dropwise and vigorously stirred for 25 minutes, then the colloidal mixture was mixed with 2g of activated carbon crossing a 20-mesh sieve, added to a 60ml polytetrafluoroethylene reactor, and heated at 150 After reacting at ℃ for 10 hours, it was cooled at room temperature. The final sample was washed 4 times with deionized water and ethanol, and dried in a vacuum oven at 60°C for 6 hours to prepare Fe 2 o 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com