Preparation and application of phosphorus-hybridized functional activated-carbon absorption material

A technology of activated carbon adsorption and functionalization, which is applied in the field of resource reuse and environmental new functional materials, can solve problems such as shortage of carbon sources in the production of activated carbon, and achieve the effects of low cost, high adsorption capacity and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

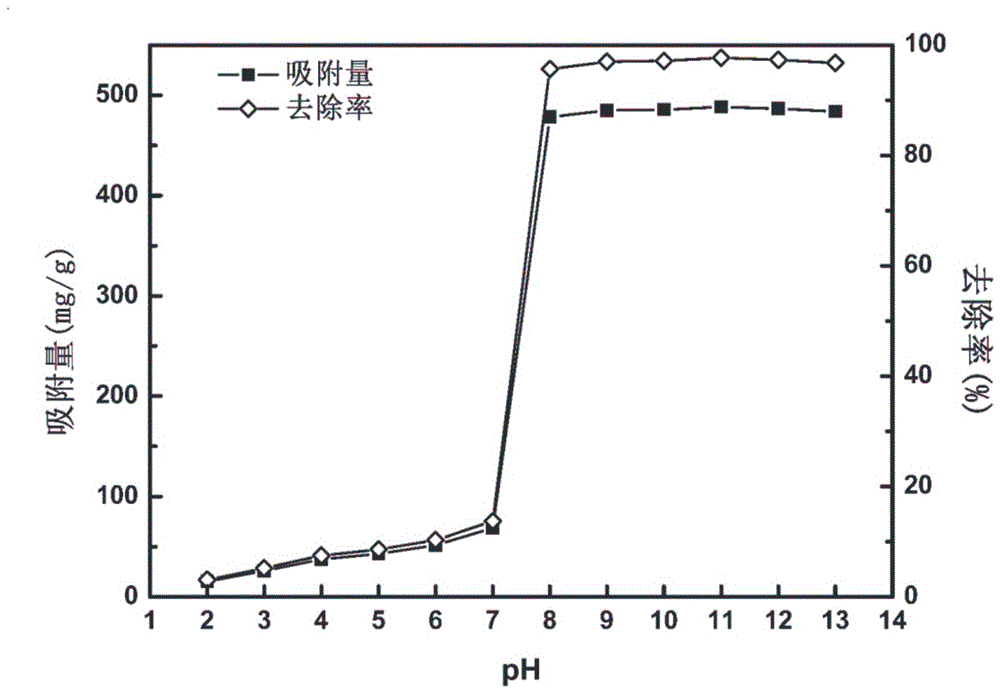

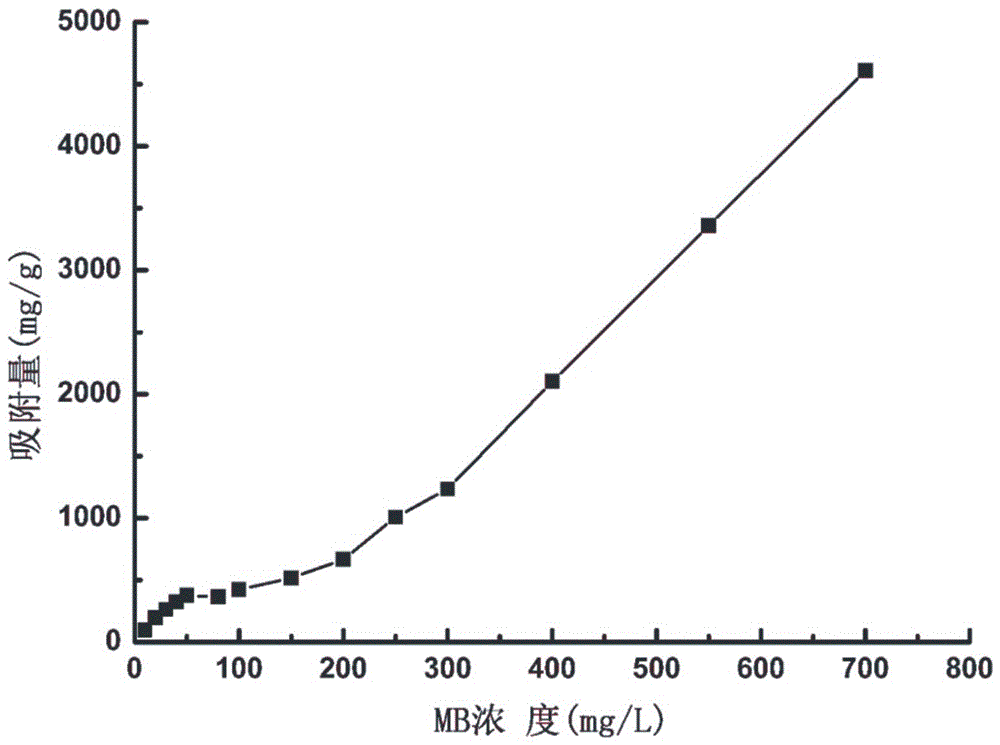

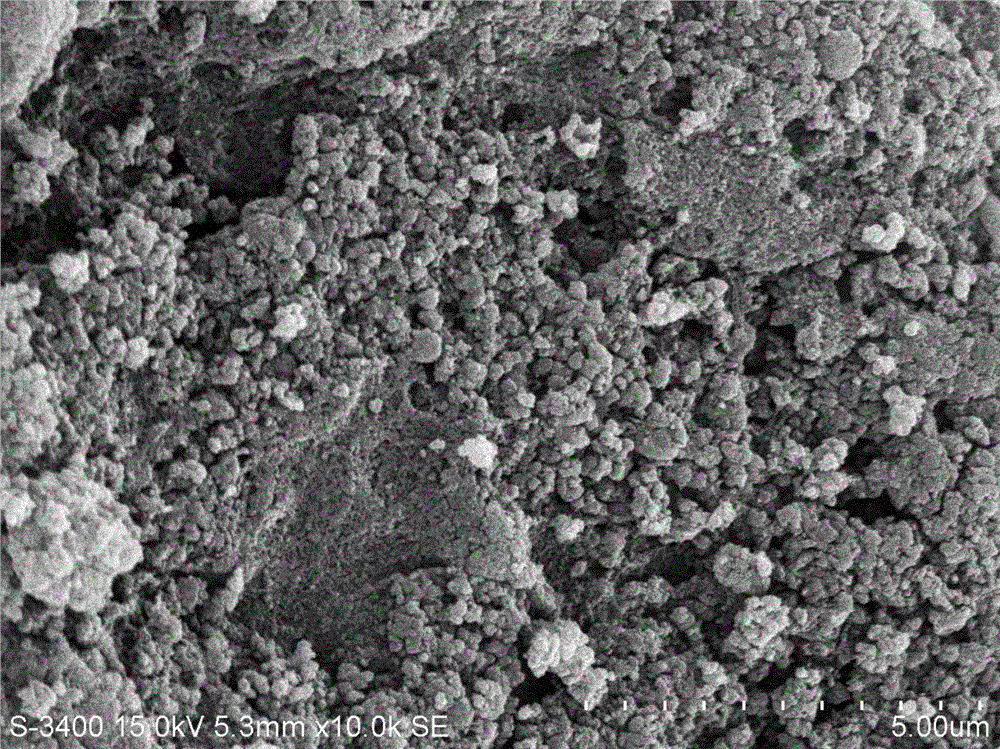

[0018] Preparation Example 1 of Phosphorized Functionalized Activated Carbon Adsorption Material: Soak 100 g of shrimp shells in 500 mL of 2.0 mol / L sodium hydroxide for 12 h, wash with deionized water until neutral and filter to obtain a flaky solid Soak in 300 mL of 2.0 mol / L hydrochloric acid solution, heat at 90°C for 4 h, wash with deionized water until neutral, filter and dry at 120°C for 24 h to obtain the precursor; soak the precursor After dissolving in 200 mL of 60% sulfuric acid at 90 °C for 6 h, the resulting suspension was settled, filtered, washed until neutral, and then dried for 24 h to obtain a black powder. The above black powder was immersed in 20 mL of concentrated phosphoric acid, placed in a muffle furnace, activated at 550 °C for 2 h to obtain the target product; then washed with deionized water until neutral, dried for 24 h, and ground to obtain Black phosphorylated activated carbon powder (PS-Ac).

[0019] Example 2 of methylene blue dye wastewater tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com