Patents

Literature

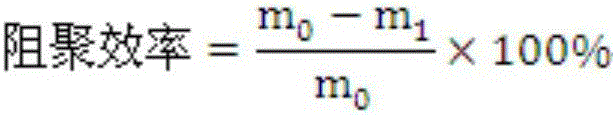

660results about How to "Reduce COD value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

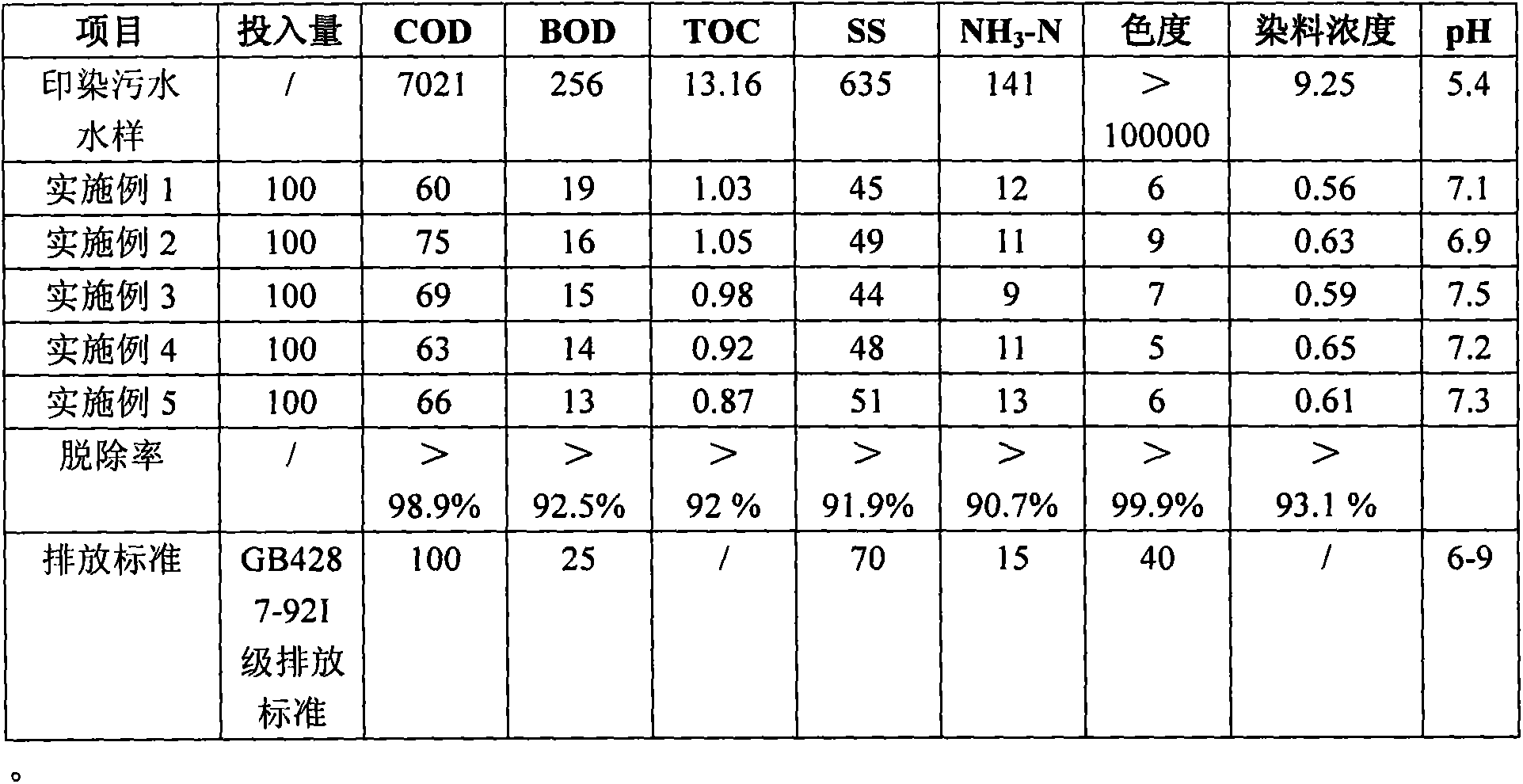

Dyeing wastewater treatment agent and preparation method thereof

InactiveCN103708593ASustainable processingHigh chromaWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionDyeing wastewaterPollution

The invention relates to the technical field of wastewater treatment, and particularly relates to a dyeing wastewater treatment agent and a preparation method thereof. The dyeing wastewater treatment agent comprises the following raw materials in parts by weight: 2-10 parts of ferrous sulfate, 20-30 parts of magnesium sulfate, 0.5-2 parts of polyacrylamide, 10-20 parts of iron nitrate, 1-5 parts of nickel nitrate, 40-60 parts of polyaluminum chloride, 10-20 parts of modified kieselguhr, 8-22 parts of meerschaum powder, 10-20 parts of crosslinked rectorite, 5-10 parts of chitosan-graphene composite material and 1-3 parts of graphene nano layer / MnO2 compound. The dyeing wastewater treatment agent provided by the invention has the advantages of convenient production method, low investment, quick effect taking and no secondary pollution.

Owner:HANDAN COLLEGE

Pre-treatment of cotton fabrics by rolling and piling up of enzyme

The invention provided a fore treatment process of the enzyme rolling pile for the fabric which belongs to the fore treatment process of the dyeing and finishing field. The process is: first to impregnate the fabric into the mixture of the alkali pectinase liquid, neutral proteinase liquid and xylanase liquid, then to keep the temperature, next to wash with the hot water (killing the enzyme) and the cool water last to blanch with the H2O2. The pectinase is produced by the Bacillus subtilis WSHB04-03. The process has many merits such as high efficiency, low work output and the energy conservation and so on.

Owner:JIANGNAN UNIV

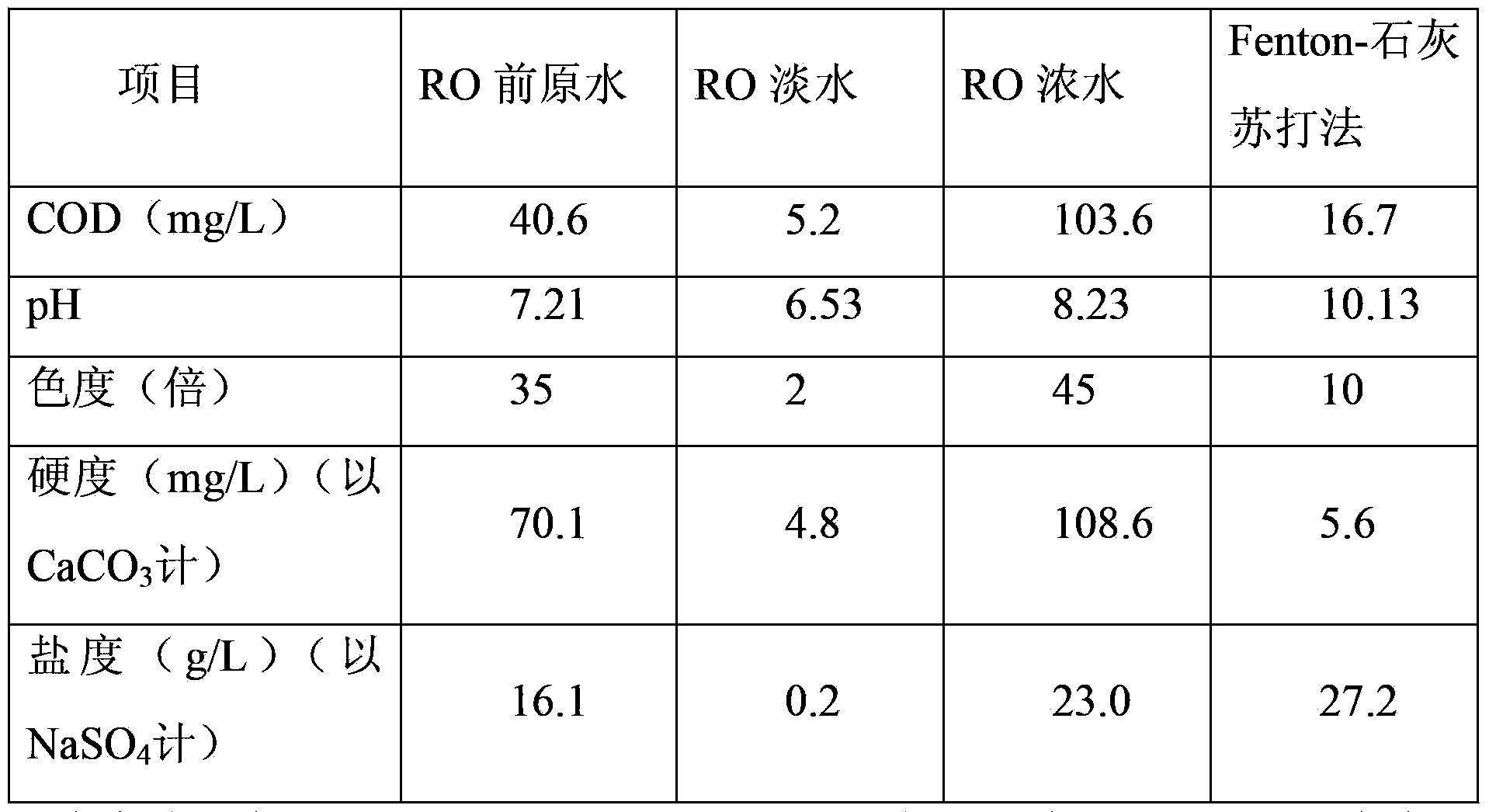

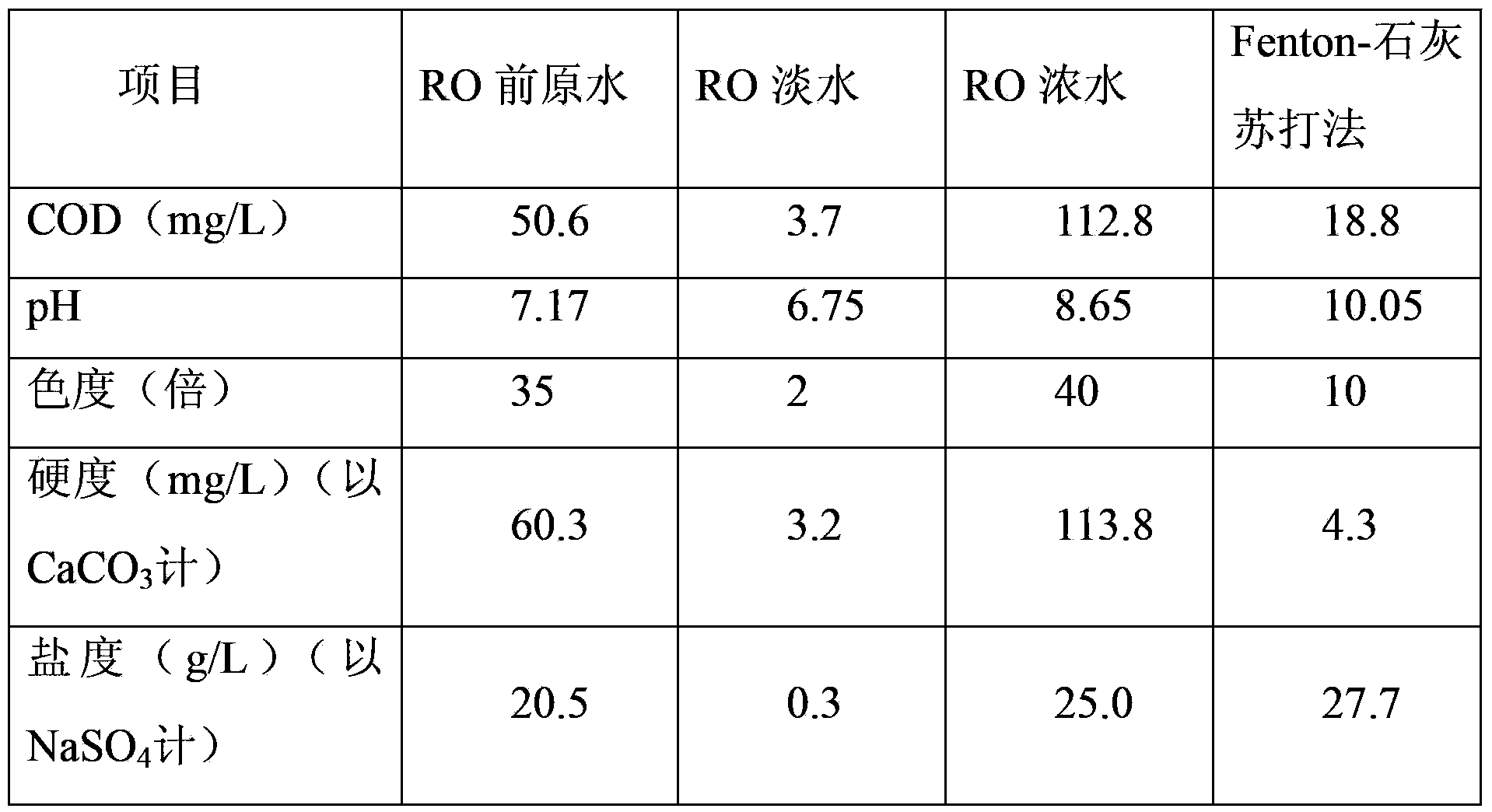

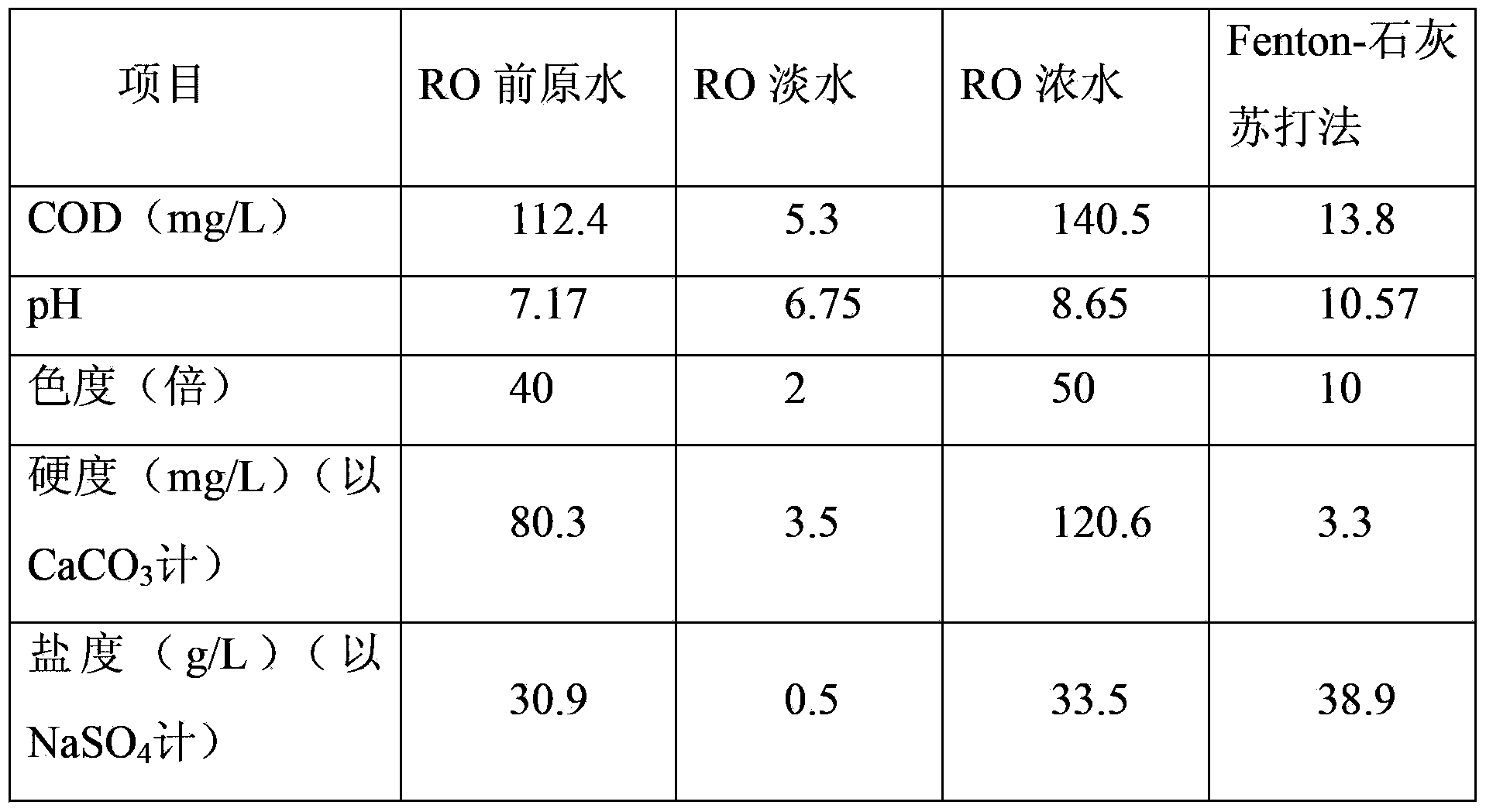

Treatment method for realizing zero emission of printing and dyeing wastewater

ActiveCN103359878AReduce energy consumptionNo secondary pollutionMultistage water/sewage treatmentWaste water treatment from textile industryEcological environmentUltrafiltration

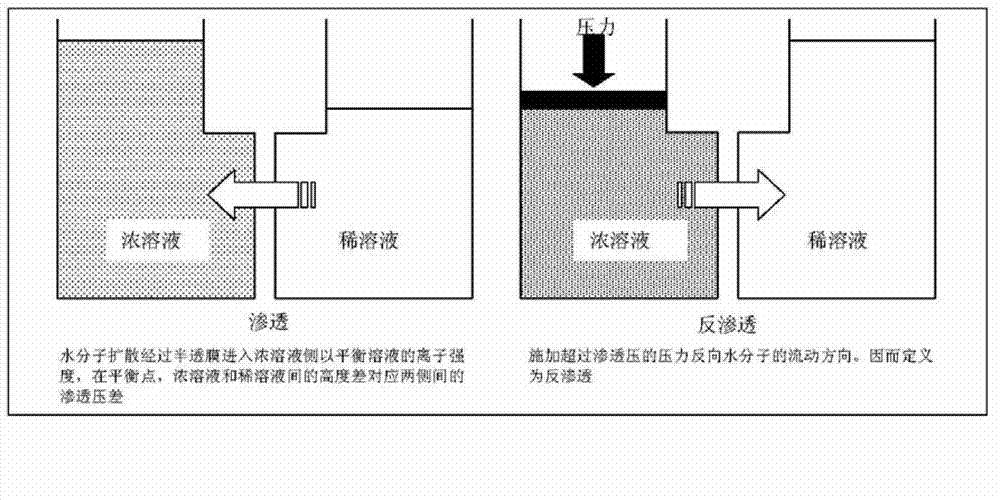

The invention discloses a treatment method for realizing zero emission of printing and dyeing wastewater. The treatment method comprises the following steps: performing physicochemical and biochemical treatments on printing and dyeing wastewater stoste; performing such advanced treatments on the discharged water as sand filtration, ultrafiltration and security filtration, and then, conveying the discharged water into a nanofiltration or reverse osmosis membrane treatment system to perform membrane treatment, thus obtaining fresh water and concentrated water through the membrane treatment, wherein the fresh water is low-COD and low-hardness ionized water and is used as process water to be directly recycled in dyeing procedure, boiler water addition, general washing or circulating cooling water. The concentrated water is high-salinity and high-hardness wastewater containing organic pollutants, the concentrated water is treated by a Fenton oxidation coupling lime soda method, the concentrated water becomes low-COD and low-hardness water with high salinity, and salt is directly added in the concentrated water according to dyeing process requirements so as to recycle the concentrated water in the dyeing procedure. The treatment method provided by the invention can be used for completely recycling the treated wastewater to realize zero emission of printing and dyeing enterprises and save the cost, and the treatment method is free of secondary pollution, thereby protecting the ecological environment and recycling the printing and dyeing wastewater.

Owner:SOUTH CHINA UNIV OF TECH

Full-cotton woven fabric bioenzyme continuous destarch ungumming-bathing pretreatment process

The invention is a kind of fore process of biology enzyme continuous desizing, refinery-washing method for cotton textile, which belongs to textile front process field in printing and dyeing industry. It solves the problem that the water and electricity are consumed in a large amount, and goes against with the environment protection, the process reaches the best process effect. The process carries on boiled water heat process to cotton textile, and then through impregnating biology enzyme liquid, steamed biology enzyme desizing, refinery process water cleaning, then through impregnating hydrogen dioxide bleaching liquid, steaming bleaching process, water cleaning etc. processes. By using the process, the fore process effect is good, the desizing effect is good, the white rate is high, and it has good humidification, small harm to fiber, high quality, soft, the method process the colourity, pH value, COD value to degree far lower than the current process, it reduces the bear of waste water processing, it is advantage to protect the environment, the efficiency is high, the low labour intensity, energy saving, and water saving.

Owner:JIANGNAN UNIV

Dyeing wastewater treating agent and manufacturing method thereof

InactiveCN105152296AReduce COD valueGood processing effectWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationChemistryTreatment effect

The invention discloses a dyeing wastewater treating agent and a manufacturing method thereof. The dyeing wastewater treating agent is prepared from the following raw materials in parts by mass: 70-100 parts of diatomite, 40-70 parts of attapulgite, 90-120 parts of modified starch, 15-40 parts of acrylamide, 2-10 parts of ferrous sulfate, 20-30 parts of magnesium sulfate, 10-25 parts of meerschaum powder, 10-20 parts of crosslinked rectorite, 0.5-2 parts of polyacrylamide, 20-30 parts of cationic monomer, 0.17-0.21 part of initiator and 0.09-0.1 part of crosslinking agent. The treating agent can perform the flocculating settling purification and disinfection functions on the dyeing wastewater, has the characteristics of wide raw material sources, lower cost and favorable treatment effect, and is convenient for popularization and application.

Owner:杨洋

Cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics

InactiveCN102191692AReduce dosageReduce wasted waterBiochemical fibre treatmentDry-cleaning apparatus for textilesElectricityChemical oxygen demand

The invention relates to a cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics, comprising the following steps: (1) preparing a biological compound enzyme preparation, a biological enzyme synergist and a non-ionic surfactant into an enzyme working solution, wherein the pH of a processing bath is 6-7.5; padding the fabrics into the working solution; carrying out heat preservation; (2) washing the processed fabrics with cold water; padding the fabrics into a hydrogen peroxide bleaching solution containing the controlled decomposition additive of hydrogen peroxide; and steaming, washing with water and drying to obtain the finished products. In the method, high-density strong base is not required to serve as a scouring agent, thepH value of pretreatment waste water is 7-8, the chromaticity is low, the COD (Chemical Oxygen Demand) value is lowered by 30% compared with that of the traditional alkali kiering pretreatment technology, the water is saved by 10-30%, and the steam and electricity can be saved by 20%. The indexes (whiteness, capillary effect, water absorption, cotton seed hull strainaway rate, desizing rate, strong force and the like) of the processed cotton and cotton-type fabric all reach the quality indexes of a semi-product, cotton seed hulls can be completely removed, and the fabrics have vivid color andgood levelling property after being dyed.

Owner:DONGHUA UNIV

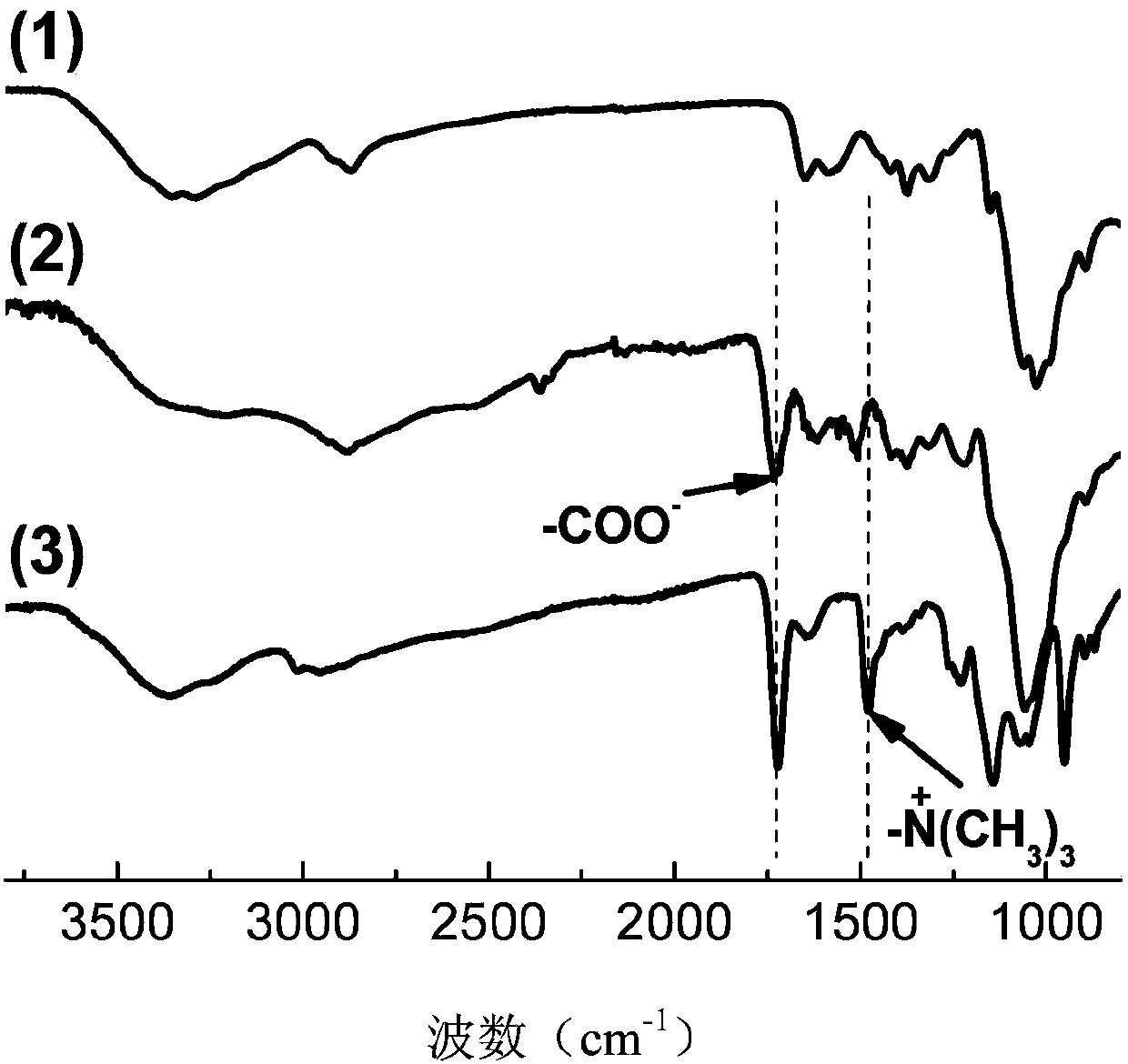

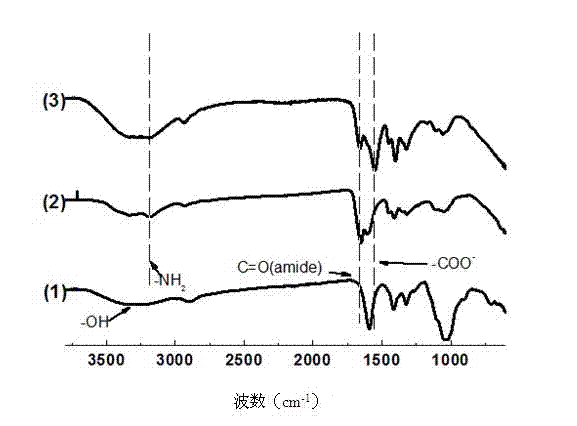

Chemical bond connected strong cationic grafted amphoteric chitosan flocculant and preparation method thereof

InactiveCN103387279AImprove solubilityGood flocculation effectWater/sewage treatment by flocculation/precipitationChemical oxygen demandCarboxylic acid

The invention relates to a chemical bond connected strong cationic grafted amphoteric chitosan flocculant which is obtained by grafting strong cationic monomers to amphoteric carboxymethyl chitosan in an acidic condition through copolymerization. The chemical bond connected strong cationic grafted amphoteric chitosan flocculant is in such a structure as follows: in the chemical bond connected strong cationic grafted amphoteric chitosan flocculant, degree of substitution of a carboxylic acid group is 5-90%, methylacryloyl oxyethyl trimethyl ammonium chloride is a strong cationic monomer, and polymethylacryloyl oxyethyl trimethyl ammonium chloride accounts for 5-80% by mass of the chemical bond connected strong cationic grafted amphoteric chitosan flocculant. The flocculant provided by the invention has amphoteric characteristics, so that not only is the flocculant property improved, but also the dissolving property is improved. The raw material chitosan is wide in source, natural, non-toxic and degradable. The flocculant has multiple functions of good flocculation effect, metal ion absorption, bacteriostasis, deodorization, decoloration, and effective reduction of COD (Chemical Oxygen Demand) value and the like.

Owner:NANJING UNIV

Extract technology of semi-manganese oxide ore

The invention provides a new method for extracting a semi-manganese oxide ore to prepare a manganese sulfate solution, belonging to the technical field of manganese ore extraction. The method comprises the following steps: crushing the semi-manganese oxide ore; adding cassava alcohol waste water in a reactor, then adding the semi-manganese oxide ore and sulfuric acid, and adjusting the ore pulp liquid-to-solid ratio to be 3:1-5:1 with water; and stirring at 70-98 DEG C for reaction for 1-6h to obtain the reaction lixivium, wherein the leaching rate of manganese is more than 90%. In the invention, the trade waste, i.e. cassava alcohol waste water is taken as a reducing agent, so that the method changes waste into treasures, has double benefits of environmental protection and economy, and has mild process condition and simple edulcoration process.

Owner:GUANGXI UNIV

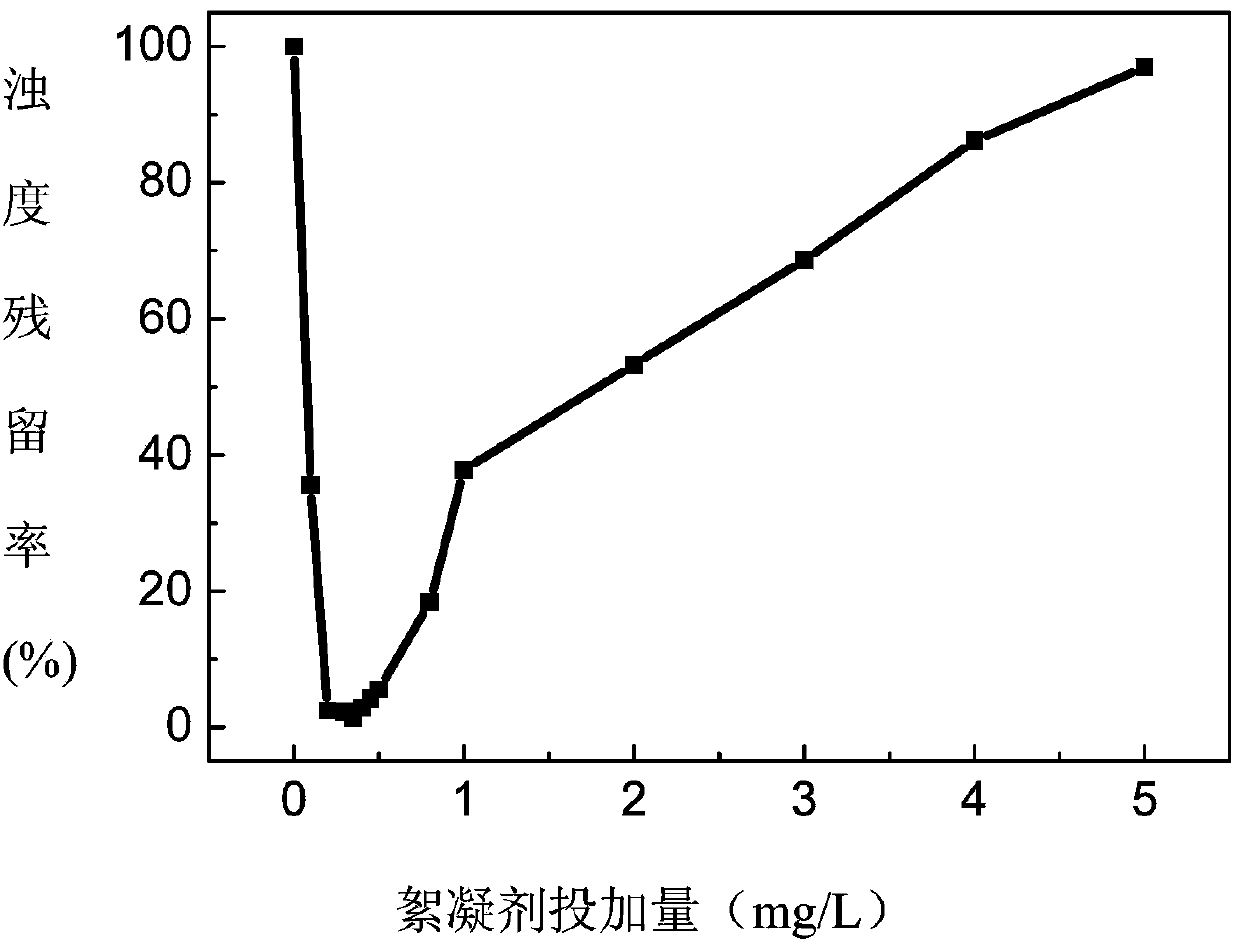

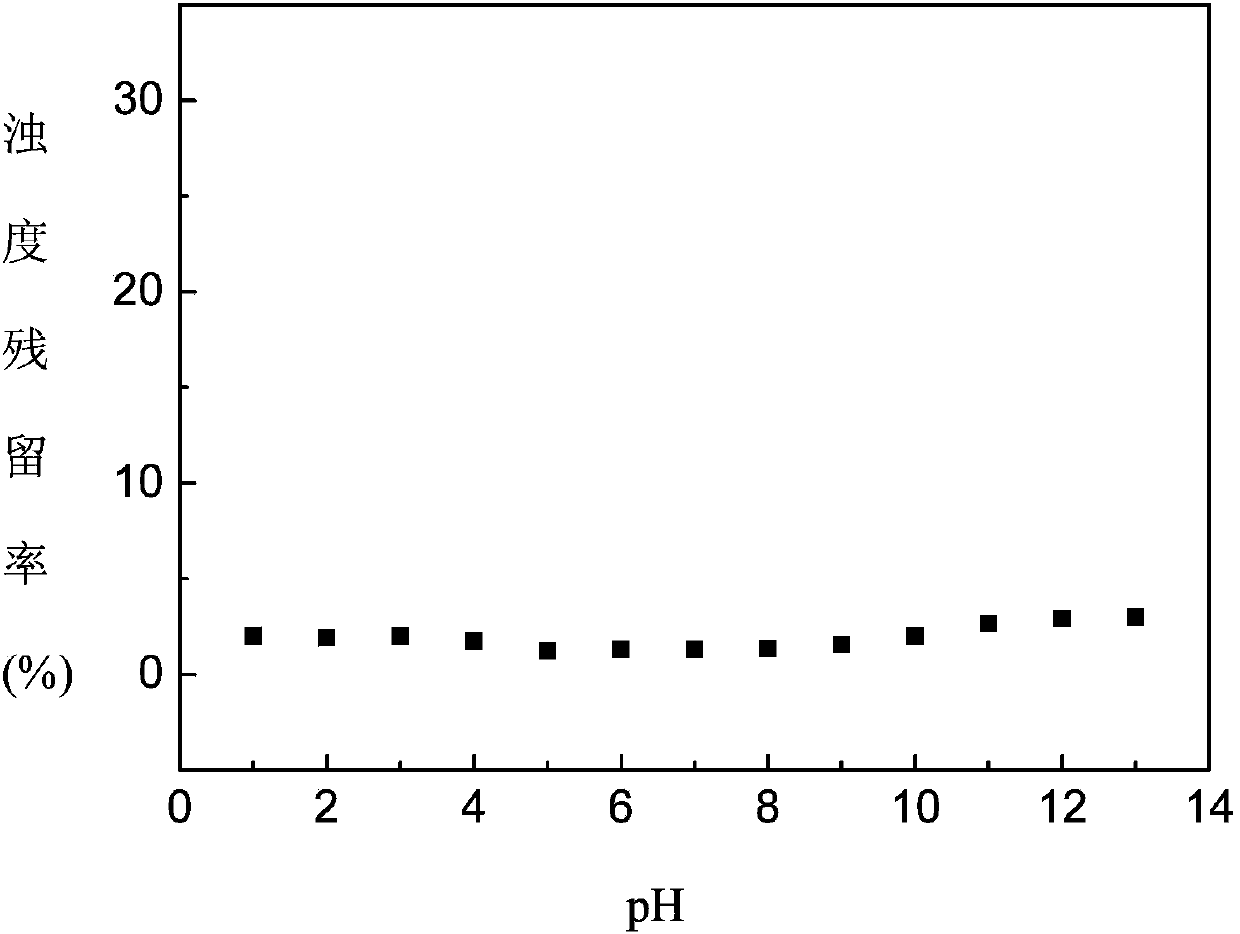

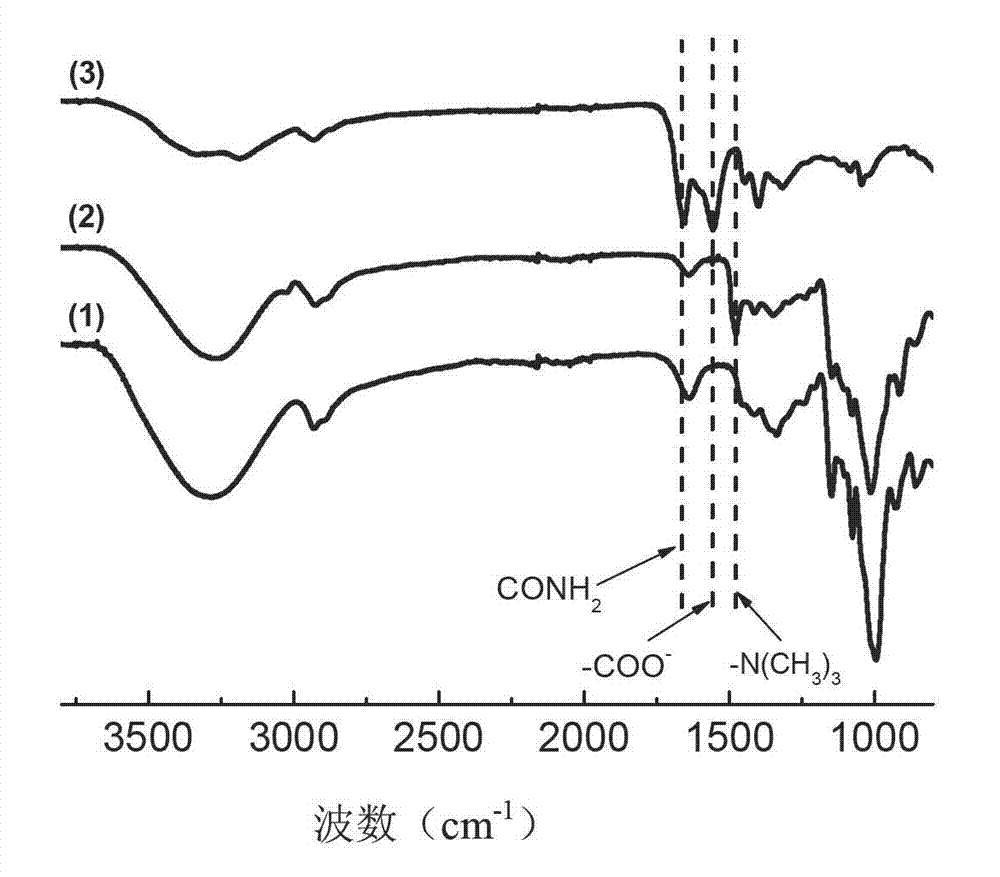

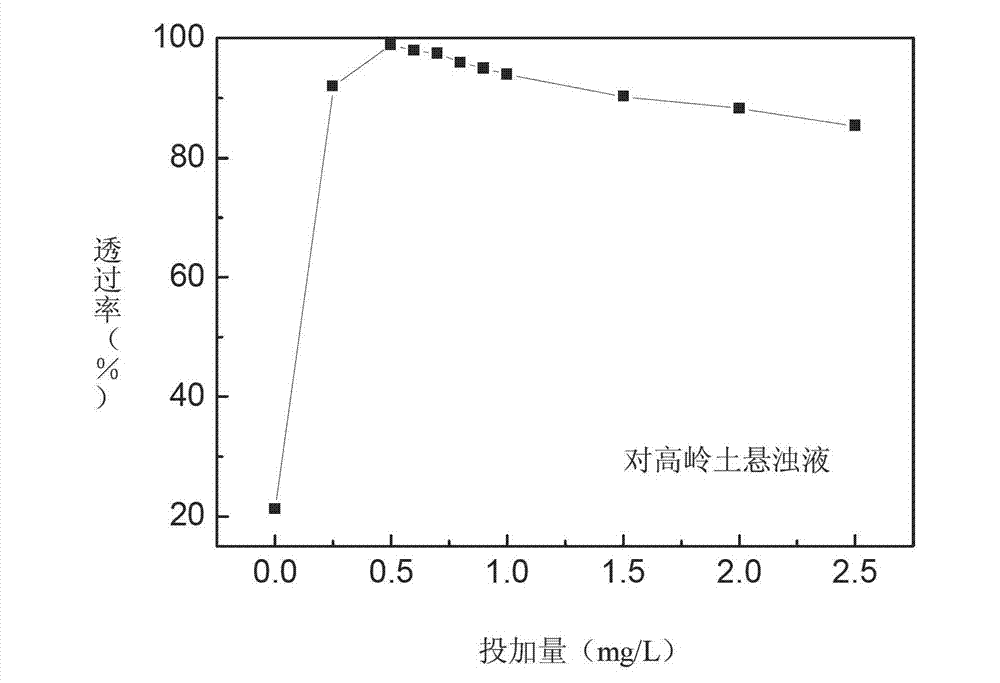

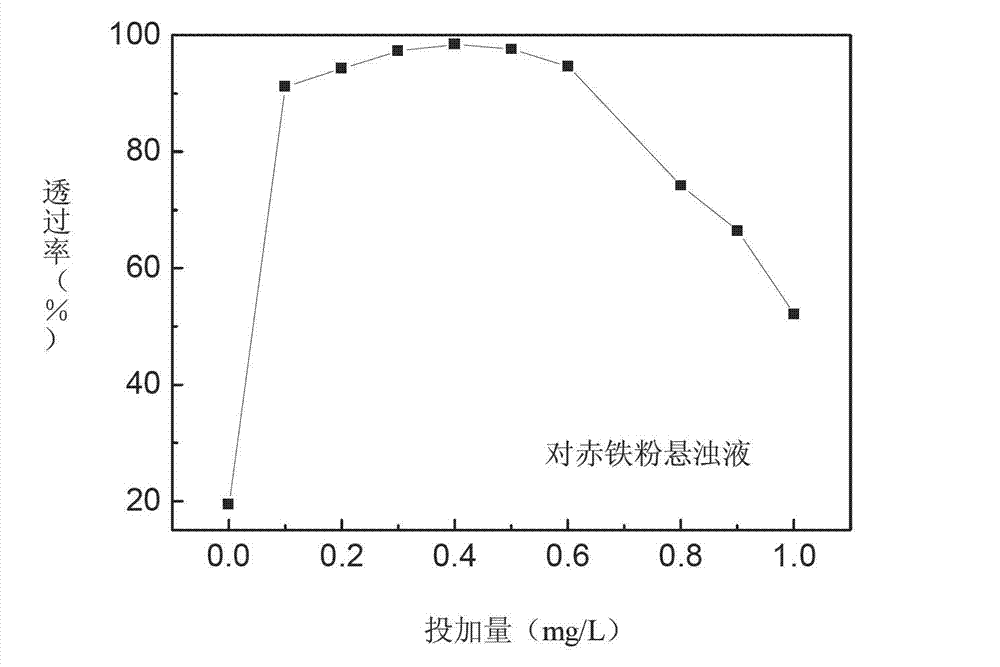

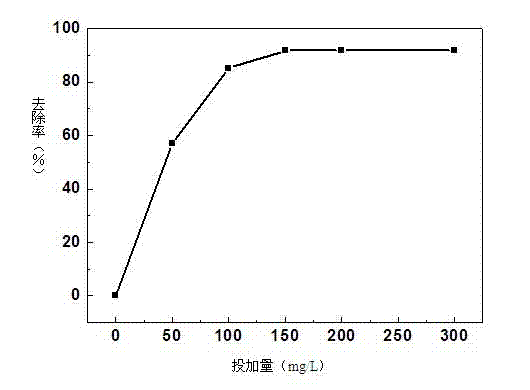

Preparation method of grafted amphoteric starch flocculants

InactiveCN103087265AImprove solubilityGood flocculation effectWater/sewage treatment by flocculation/precipitationFlocculationSalt resistance

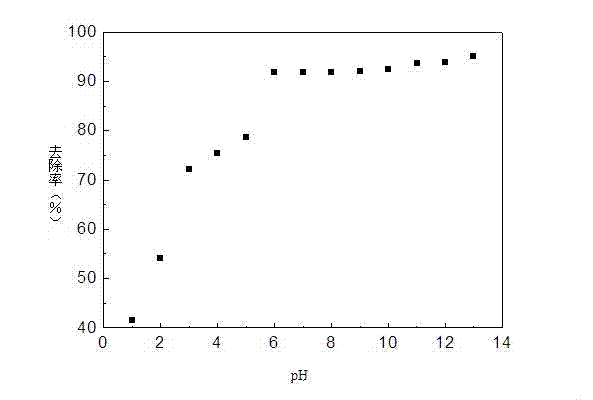

The invention discloses a preparation method of grafted amphoteric starch flocculants, which is implemented by carrying out graft copolymerization on cationic starches, acrylamide and an acrylic acid so as to obtain a grafted amphoteric starch flocculant, and the grafted amphoteric starch flocculant has the following structure shown in the abstract. The method disclosed by the invention has the following advantages that because a molecular chain is rich in anion-cation groups and has amphoteric characteristics, not only is the flocculation property of materials improved, and also the dissolving property of starches is improved; high polymer materials are wide in resource and low in cost, so that the grafted amphoteric starch flocculant has a high performance price ratio; starches have biodegradability and are non-toxic, so that starches do not produce secondary pollution to water bodies; the grafted amphoteric starch flocculant has various good effects such as flocculation, metal ion adsorption, bacteriostasis, deodorization, decoloring, and capability of effectively reducing the COD value; the grafted amphoteric starch flocculant has a characteristic of high efficiency, and is low in putting amount, and the putting amount is generally 0.1-10mg / L; and the the grafted amphoteric starch flocculant is suitable for treating water bodies with different charges, good in salt resistance and wide in applied pH range, and can be applied when the pH value is 1-12.

Owner:NANJING UNIV

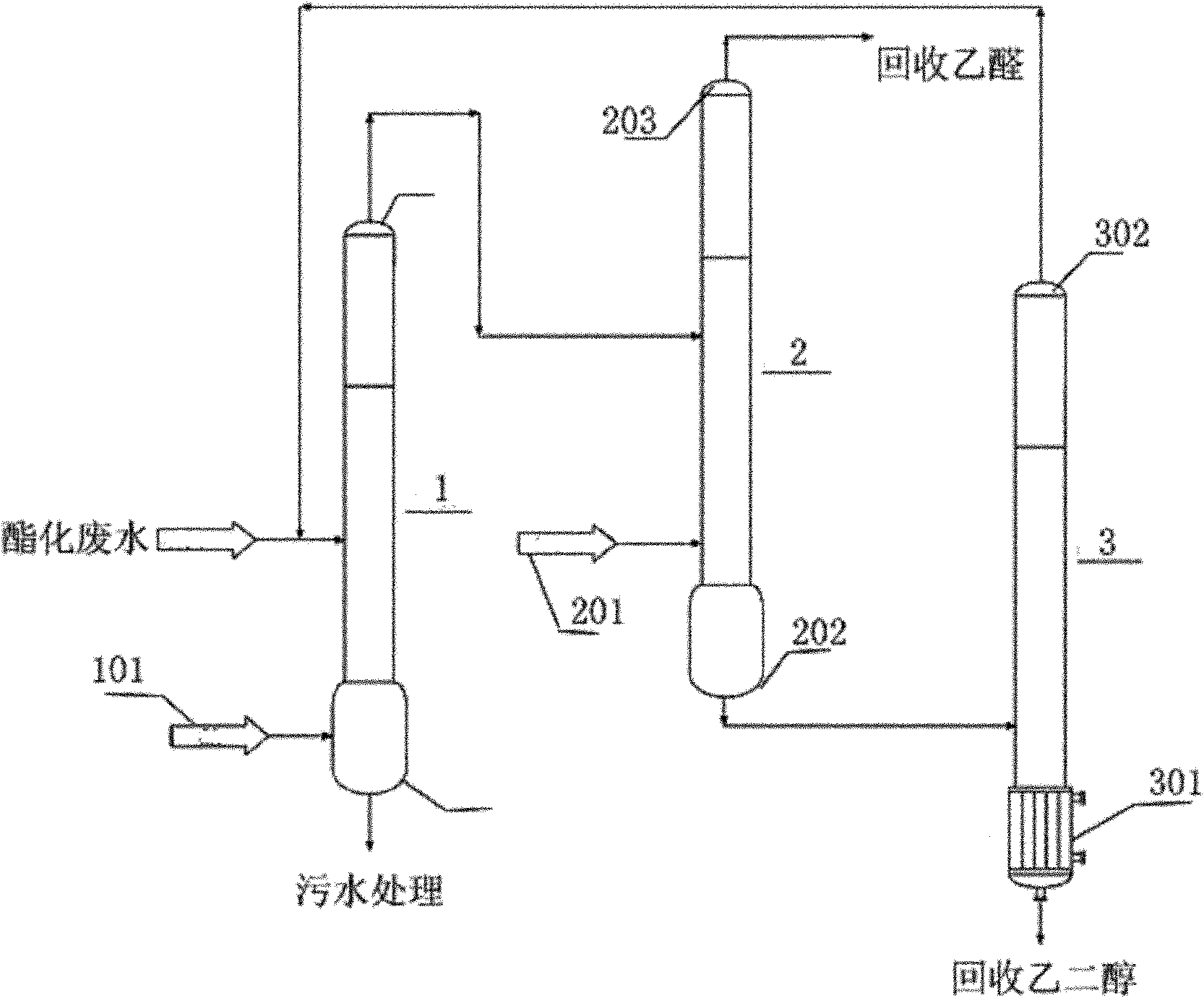

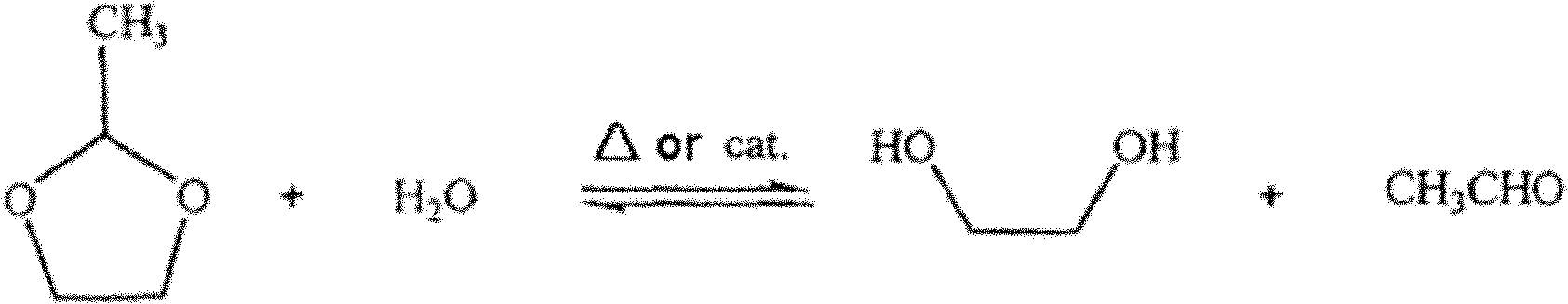

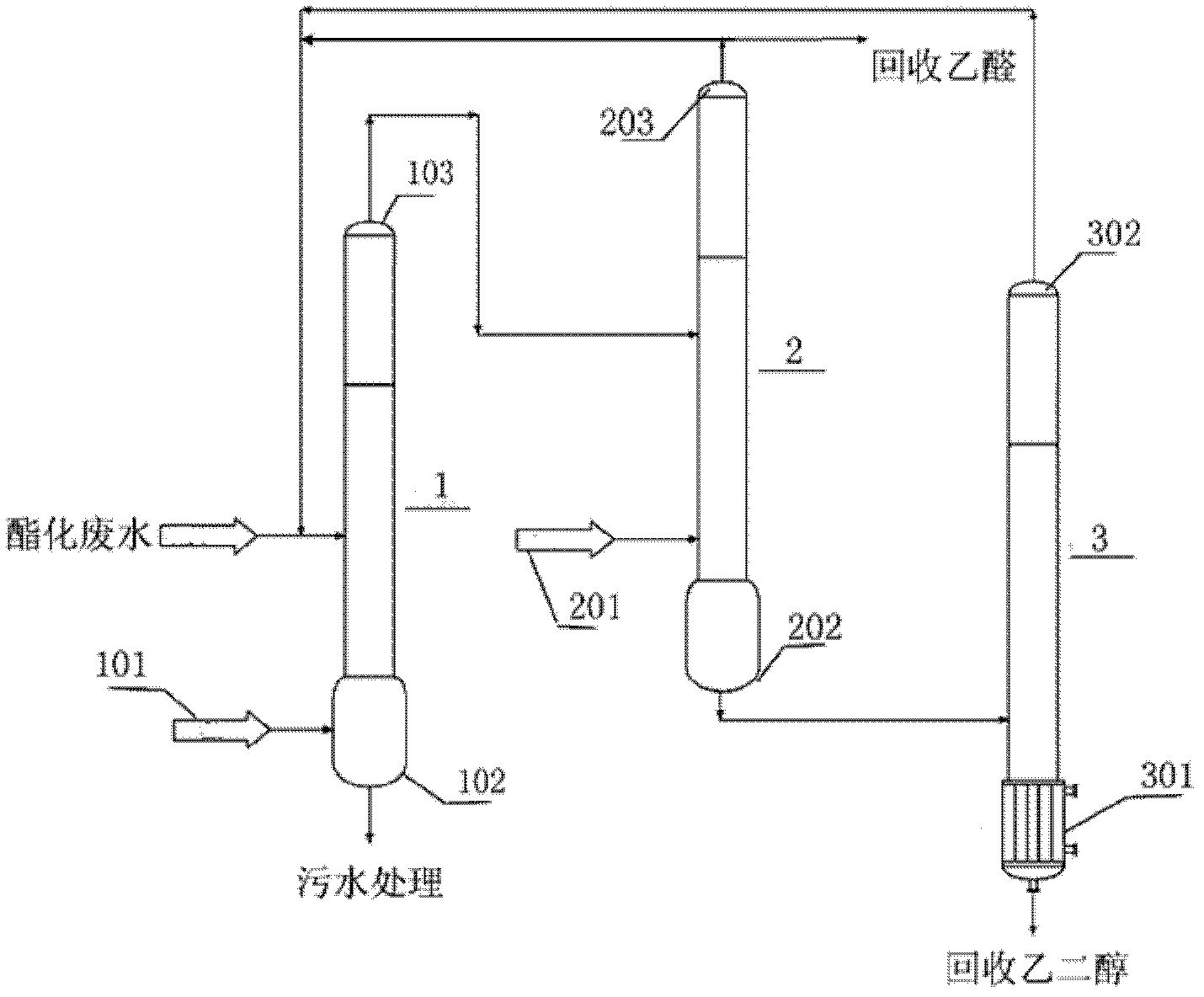

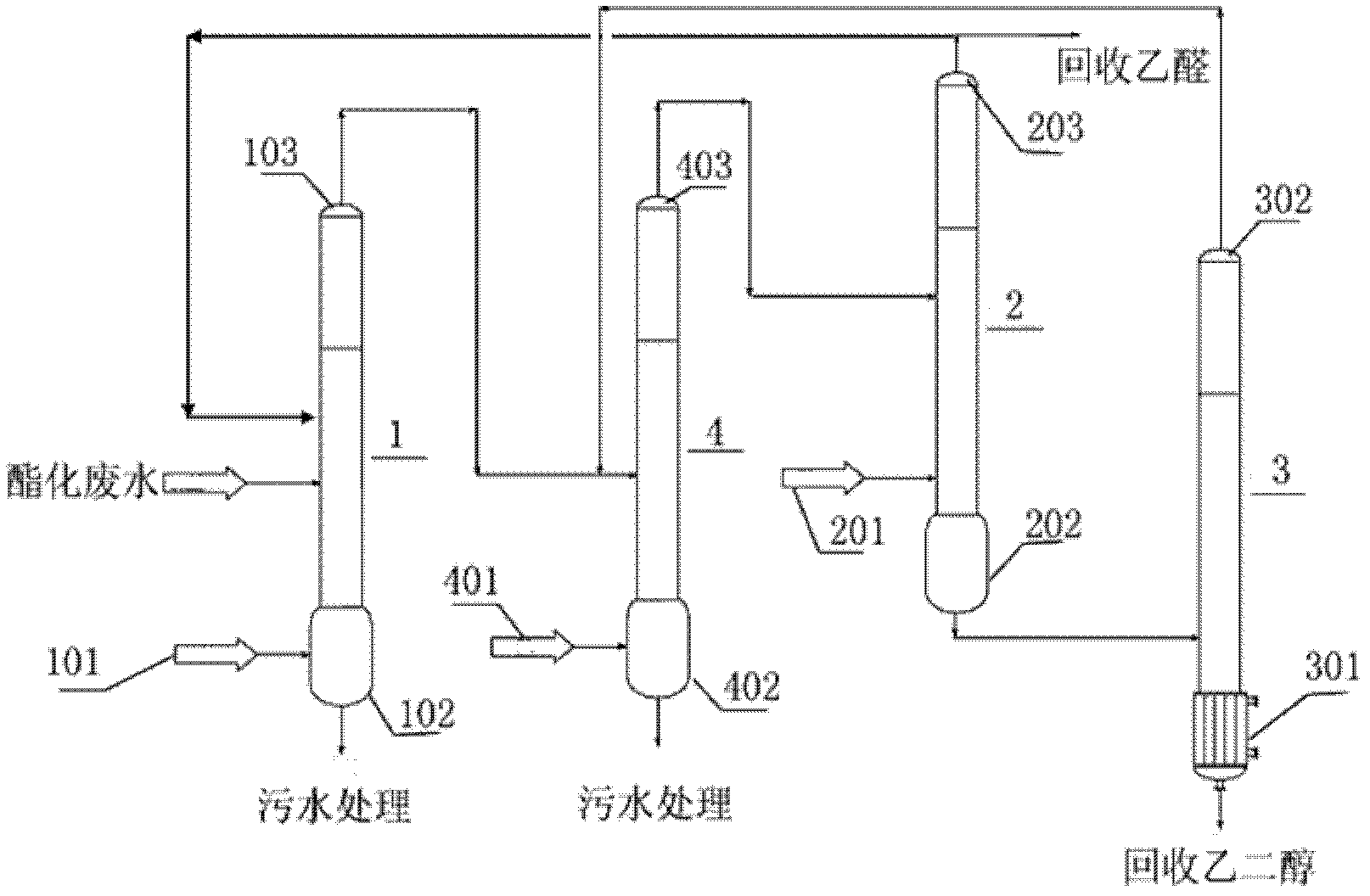

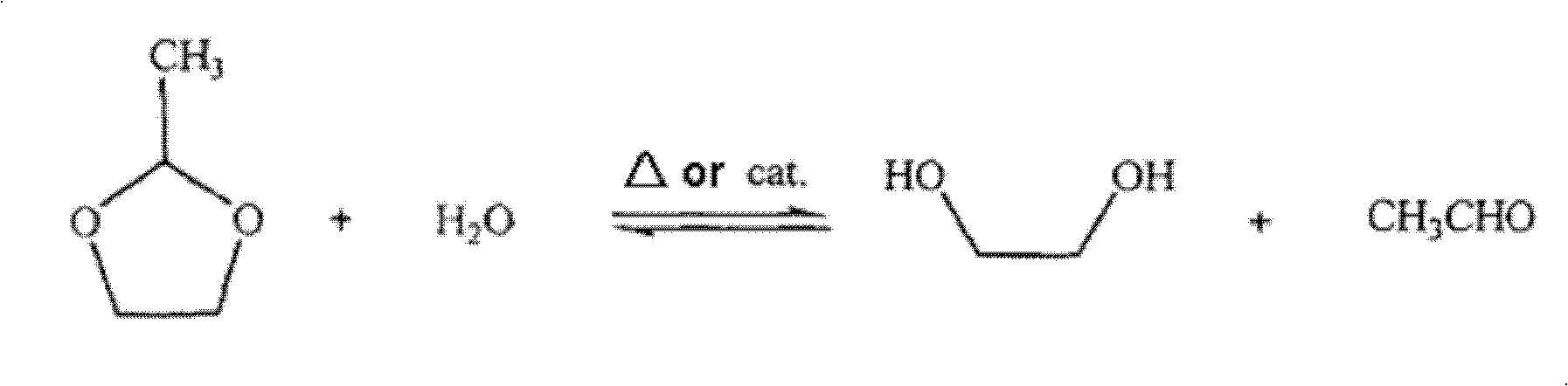

Method for recycling ethylene glycol and acetaldehyde from polyester waste water

ActiveCN102126926AReduce COD valueFix security issuesMultistage water/sewage treatmentWater/sewage treatment by degassingPolyesterDistillation

The invention discloses a method for recycling ethylene glycol and acetaldehyde from polyester waste water. The method is implemented by the following steps of: (1) introducing esterification waste water into a stripping tower for treating and directly introducing organic matter gas and water vapor collected from a tower top into an acetaldehyde rectifying tower; (2) treating in the acetaldehyde rectifying tower, collecting high-purity acetaldehyde from the tower top and introducing waste water collected from a tower bottom into an ethylene glycol distillation tower; and (3) treating in the ethylene glycol distillation tower, collecting a high-purity ethylene glycol solution from the tower bottom and introducing waste gas and water vapor produced on the tower top into the stripping tower for cyclic treatment. In the method, acetaldehyde and ethylene glycol are continuously collected, so that hydrolysis of byproduct of 2-methyl-1,3-dioxolane in the esterification waste water is continuously performed positively and negatively, acetaldehyde with the concentration of over 95 percent and ethylene glycol with the concentration of over 70 percent are obtained at the end of treatment, and the 2-methyl-1,3-dioxolane is fully hydrolyzed.

Owner:SHANGHAI JUYOU CHEM ENG +1

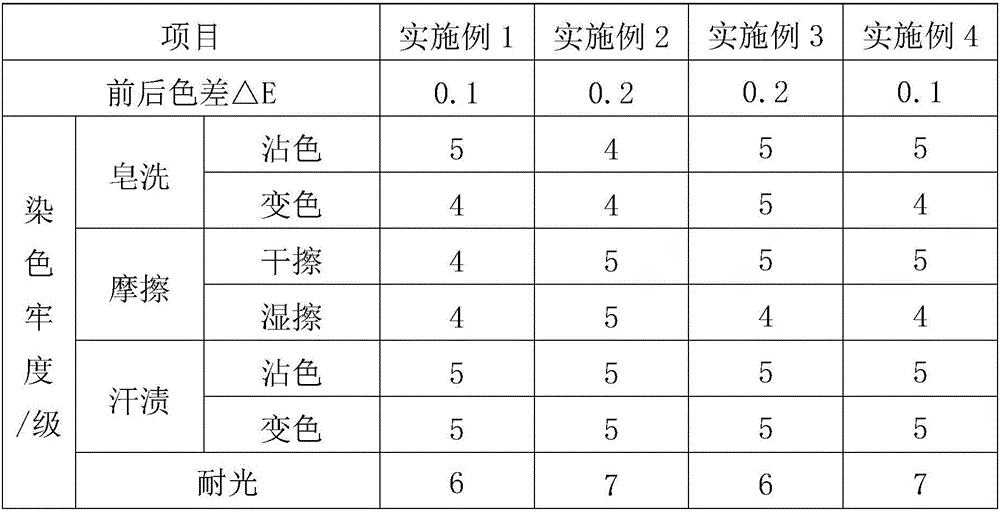

Dispersion-reduction dyeing process for cotton-polyester blended fabric

ActiveCN106087463AImprove reducibilityImprove dyeing effectSucessive textile treatmentsDyeing processDisperse dyeVat dye

The invention discloses a dispersion-reduction dyeing process for a cotton-polyester blended fabric. The dispersion-reduction dyeing process comprises a disperse dyestuff treating procedure and a vat dye treating procedure which are successively carried out. The disperse dyestuff treating procedure comprises dyeing, reduction cleaning, washing and pickling; the vat dye treating procedure comprises dip padding with a vat dye suspension, dip padding with a reducing solution, steaming, oxidation, soaping, hot washing and drying; in the disperse dyestuff treating procedure, a disperse dyestuff microcapsule method is used for dyeing; and in the vat dyestuff treating procedure, vat dye wet rapid-steaming pad dyeing process is employed. The dispersion-reduction dyeing process for the cotton-polyester blended fabric has the advantages of good level dyeing effect, small chromatic aberration and high color fastness, and is simple in process.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

High-yield low-pollution preparation method for minced fish products

The invention provides a high-yield low-pollution preparation method for minced fish products, which belongs to the technical field of aquatic food processing. A main preparation process of the method comprises the steps of removing offal, heads and tails of silver carps, grass carp and other freshwater fishes and obtaining minced fish products through fish collection, rinsing, seasoning, mincing, molding and heating. Aiming at the problems of severe protein loss, low product yield, high content of soluble protein and high COD in rinsing wastewater, and the like in the conventional water rinsing process, the method adopts a novel control acid-base rinsing method, precipitates protein at isoelectric points, and then further recover the protein in wastewater through ultrafiltration membrane, so that the minced fish products prepared have the characteristics of high protein content, high production yield, low environmental pollution and the like. In addition, compared with the products of the conventional water rinsing method, the products of the invention have no significant difference in color, texture, gel properties, sensory property, flavor, storage stability and other characters.

Owner:JIANGNAN UNIV

Low-alkali pretreatment method for in-situ catalytic degradation of impurities in cotton and cotton fabrics

InactiveCN102978960AStrong process adaptabilityGood energy saving and emission reduction effectBiochemical fibre treatmentBleaching apparatusElectricityPretreatment method

The invention relates to a low-alkali pretreatment method for the in-situ catalytic degradation of impurities in cotton and cotton fabrics, which comprises the following steps: (1) preparing a biological compound enzyme preparation, a biological enzyme synergist and a nonionic surfactant into enzyme working fluid; padding a fabric in the enzyme working fluid; and carrying out heat preservation on the fabric; and (2) directly padding the treated fabric into hydrogen peroxide bleaching liquid containing a hydrogen peroxide controlled decomposing additive, and then steaming, washing and drying the fabric. According to the invention, sizes and impurities are subjected to in-situ catalytic degradation in fabrication processing, therefore, an effect of ultrahigh-concentration wastewater treatment is achieved, fabrics are easy to wash, the washing temperature and washing frequency are reduced, more than 25% of water is saved, more than 30% of steam is saved, and more than 10% of electricity is saved. The COD (chemical oxygen demand) value is reduced by more than 30% in comparison with that of a traditional alkali scouring process, the B / C value of pretreated wastewater is about 0.4, and the biodegradability is improved. All indexes (such as whiteness, capillary effect, cottonseed hull removal rate, desizing ratio, strength, and the like) of treated cotton and cotton fabrics meets the quality requirements of semi-finished products.

Owner:DONGHUA UNIV

Hydrolysis graft strengthened anionic carboxymethyl cellulose flocculating agent and preparation method thereof

InactiveCN103172790AHigh molecular weightEnhanced bonding and bridging flocculationWater/sewage treatment by flocculation/precipitationSodium carboxymethylcellulosePolyacrylamide

The invention discloses a hydrolysis graft strengthened anionic carboxymethyl cellulose flocculating agent. The hydrolysis graft strengthened anionic carboxymethyl cellulose flocculating agent is characterized by being obtained by carrying out hydrolysis reaction onto graft carboxymethyl cellulose under alkali condition, wherein the hydrolysis graft strengthened anionic carboxymethyl cellulose flocculating agent has the structure shown in the specification; the mass of polyacrylamide is 5%-65% of that of the hydrolysis graft strengthened anionic carboxymethyl cellulose flocculating agent; and the mass of the polyacrylic acid is 5%-70% of the that of the hydrolysis graft strengthened anionic carboxymethyl cellulose flocculating agent. The hydrolysis graft strengthened anionic carboxymethyl cellulose flocculating agent disclosed by the invention has the triple characteristic of carboxymethyl anionic group, polyacrylamide and polyacrylic acid. Moreover, the carboxymethyl anionic group, polyacrylamide and polyacrylic acid are linked by chemical bonds, so that the molecular weight of carboxymethyl cellulose is improved and the bonding and bridging flocculation is enhanced. Besides, the soluble pH range of the hydrolysis graft strengthened anionic carboxymethyl cellulose flocculating agent is expanded due to the existence of the grafting chain, and therefore, the pH sensitivity of the flocculation effect of carboxymethyl cellulose is effectively restrained.

Owner:NANJING UNIV

Coking wastewater treatment system and coking wastewater treatment method

InactiveCN103112991AGood processing effectReduce COD valueWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentTreatment effectCoal tar

The invention discloses a coking wastewater treatment system. The system comprises coking wastewater coal car treatment equipment, coking wastewater oxidization and biochemical treatment equipment, and coking wastewater deep treatment equipment, wherein the coking wastewater coal car treatment equipment is used for removing coal tar from the coking wastewater; and the coking wastewater deep treatment equipment is used for deeply treating the coking wastewater. The coking wastewater treatment system has good treatment effect. The invention further provides a coking wastewater treatment method.

Owner:深圳力合环保技术有限公司

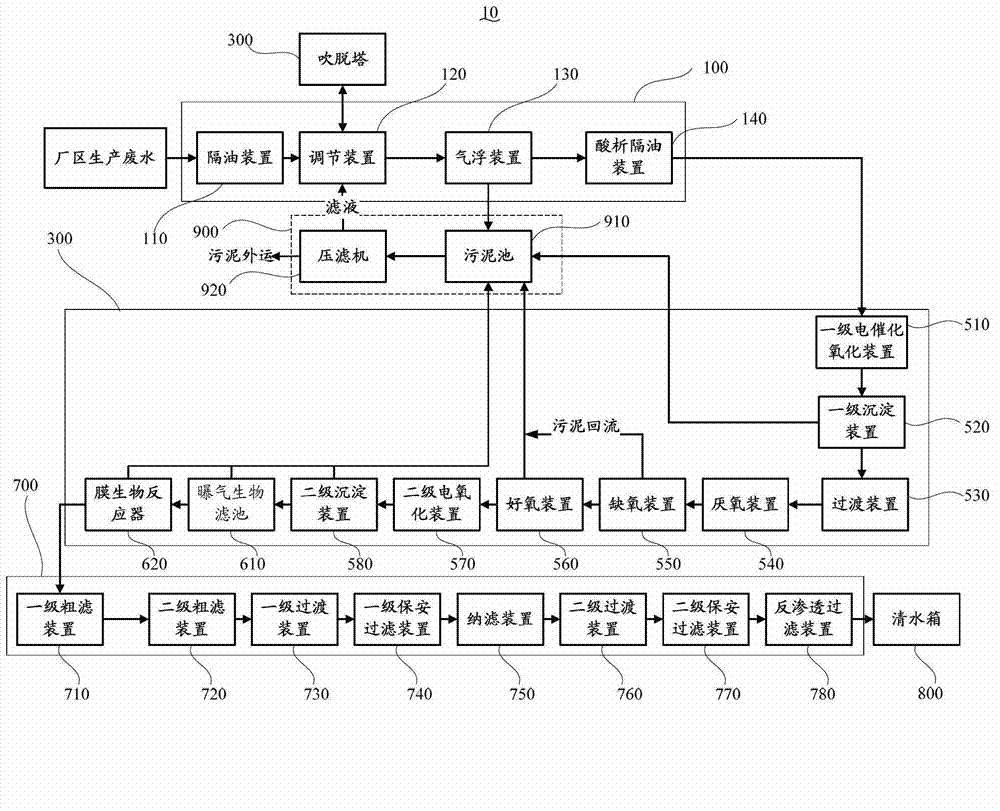

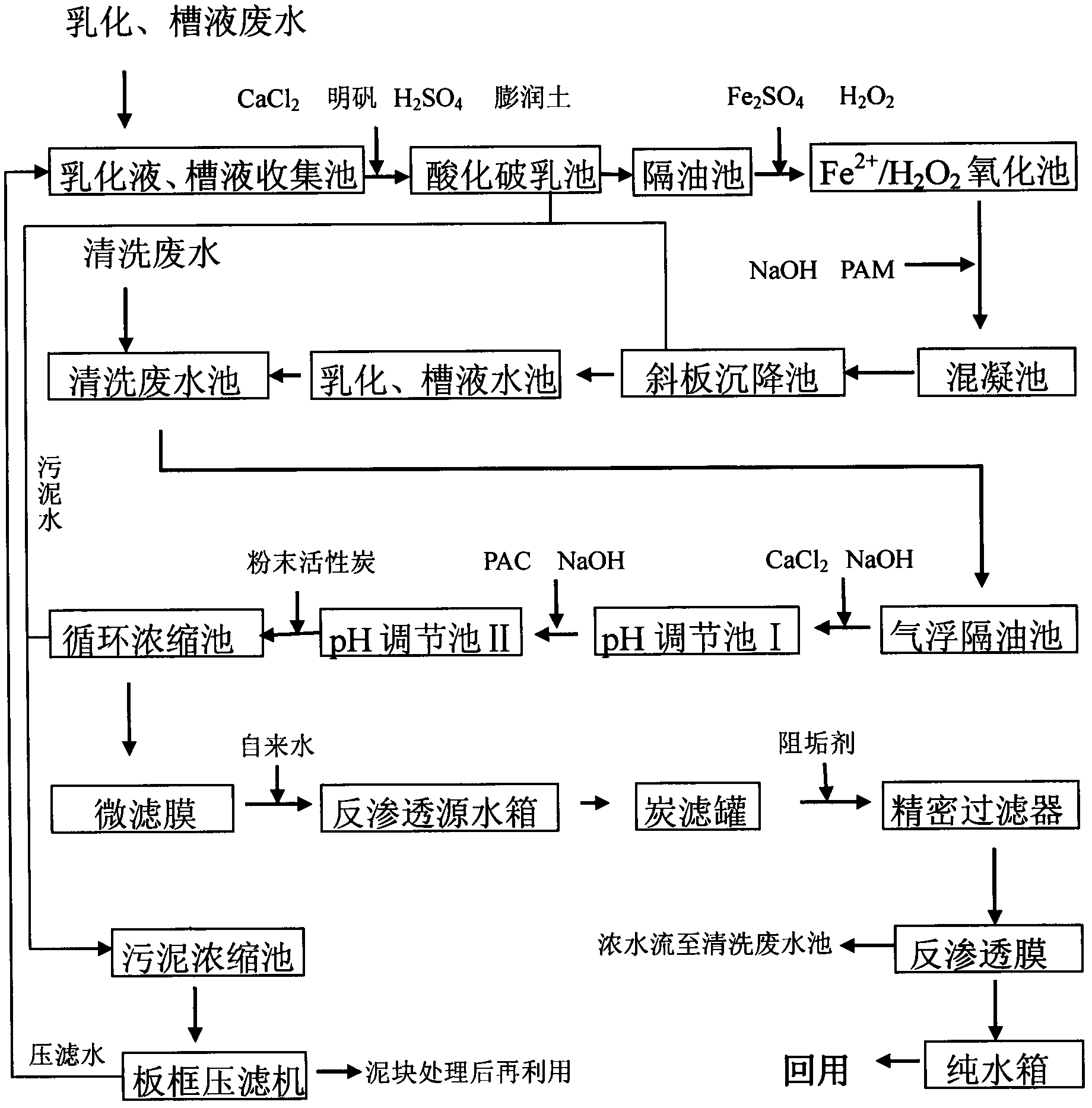

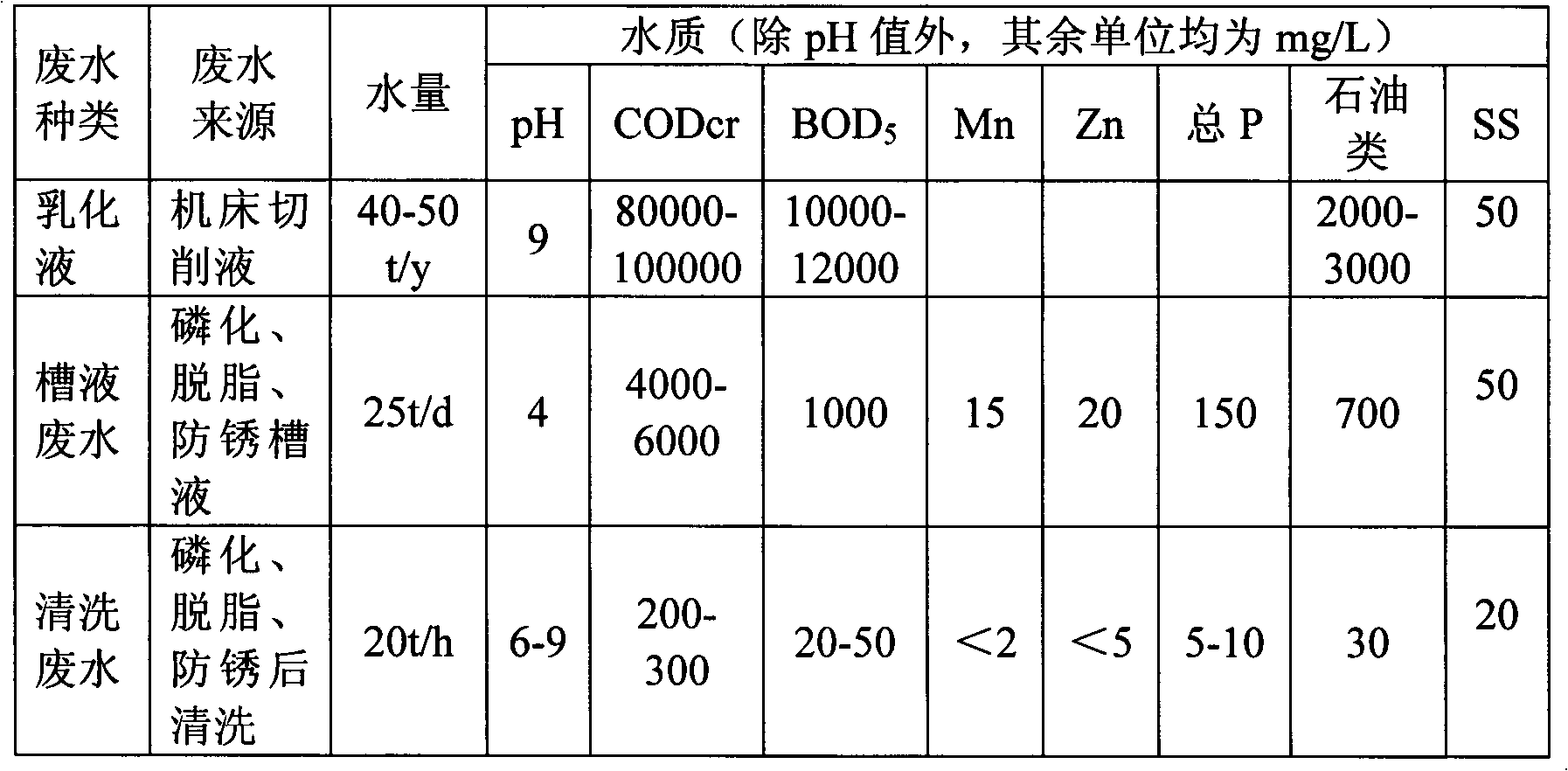

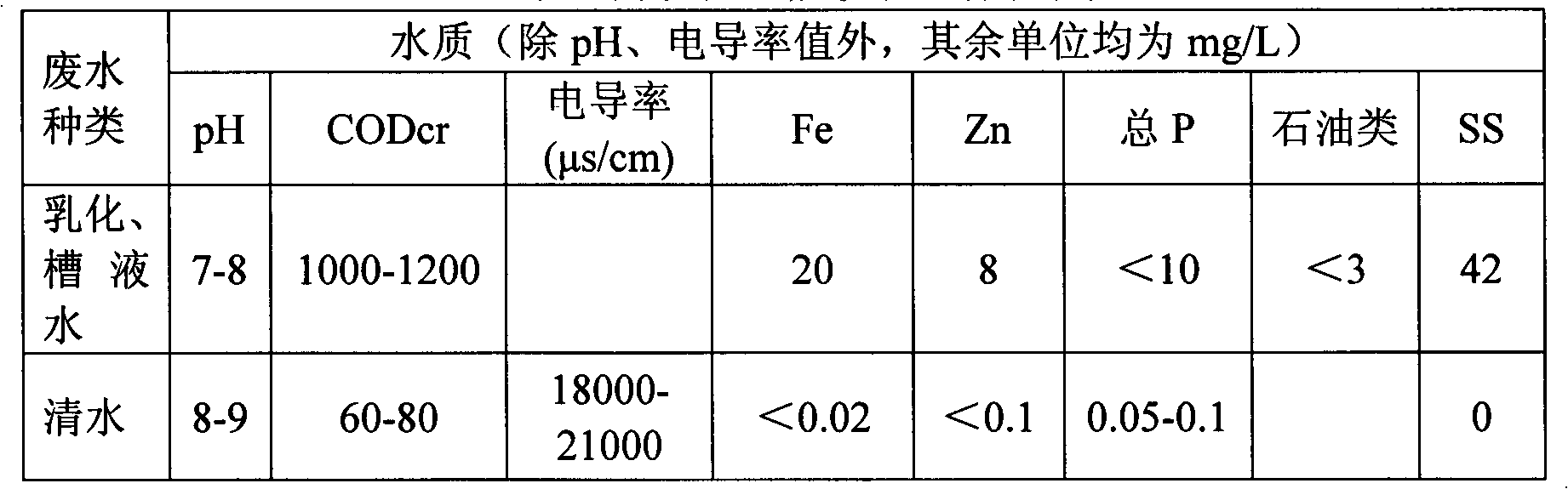

Reuse treatment method for industrial wastewater from refrigerator compressor factory

InactiveCN102642961AReduce COD valueReduce oil contentGeneral water supply conservationMultistage water/sewage treatmentWater useFiltration

The invention relates to a reuse treatment method for industrial wastewater from a refrigerator compressor factory. Firstly, independently collected emulsified bath solution wastewater is acidified and demulsified, free oil and emulsified oil in the wastewater are eliminated, and then the wastewater is subjected to Fe<2+> / H2O2 oxidation, the effluent pH is 7-8, and then coagulant aid is added forcoagulation sedimentation, and organic matter, metal salt and SS are removed, so that emulsified bath solution water is obtained. Subsequently, the emulsified bath solution water and the independently collected rinsing wastewater are uniformly mixed according to the ratio of 1:20-30 to serve as the source water for micro filter membrane treatment; the source water is subjected to air floatation oil separation dephosphorization, coagulation and activated carbon adsorption to obtain water with the pH value of 9-10 under micro filtration, and then the water under micro filtration enters the micro filter membrane, so clean water is obtained; and the clean water and tap water are mixed according to the ratio of 1:1-2, are subjected to filtering by activated carbon and 5um precise filtration and enter a reverse osmosis membrane, and then pure water is obtained after desalination, and the pure water can be reused for production. With the reuse treatment method, the water quality of reused water is stable and can reach the standard of pure water used by enterprises for production, the water is reused for a product line, so that the wastewater discharge of the enterprises is greatly reduced, the use volume of tap water is saved, and remarkable economical and social benefits are achieved.

Owner:TONGJI UNIV +1

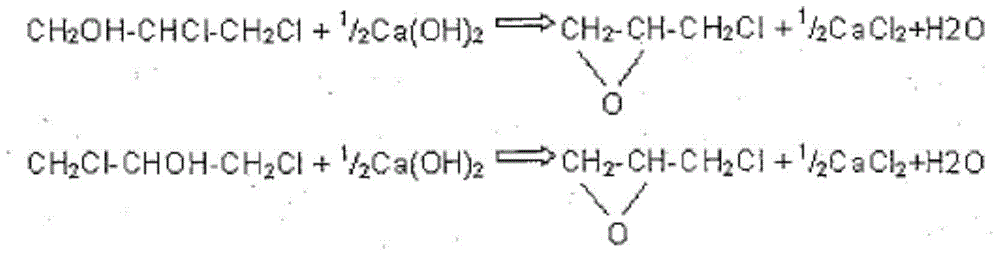

Epichlorohydrin production wastewater treating method

InactiveCN105271597AReduce COD valueImprove processing rateMultistage water/sewage treatmentChemistrySettling

The invention discloses an epichlorohydrin production wastewater treating method. Multiple technologies such as micro-electrolysis, deep oxidation, flocculent settling, adsorption retardance, membrane separation and the like are specifically combined, epichlorohydrin wastewater is treated online in a targeted manner, the COD value can be significantly reduced, and the method is high in treatment rate and removal rate, has the obvious effect and can treat both current problems and root causes. Repeated experiments and detection analysis indicate that the wastewater contains 10,000-20,000 ppm of COD and about 15,000 ppm of soluble salts originally, the COD value is decreased below 100 ppm and the treatment rate is up to 98% after the technological treatment, approximately 7,000 ppm of the soluble salts are left, and the removal rate is up to 95%.

Owner:广西钦州环科水处理有限公司

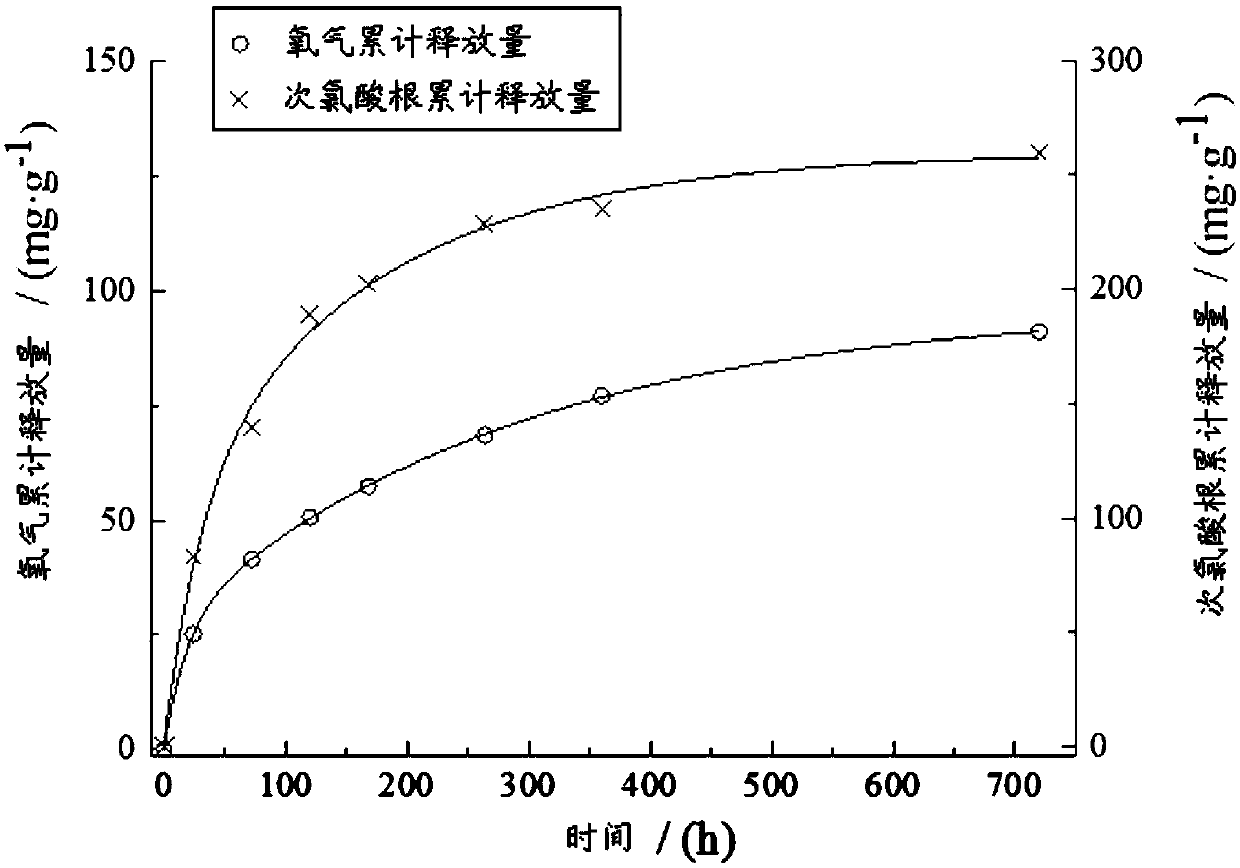

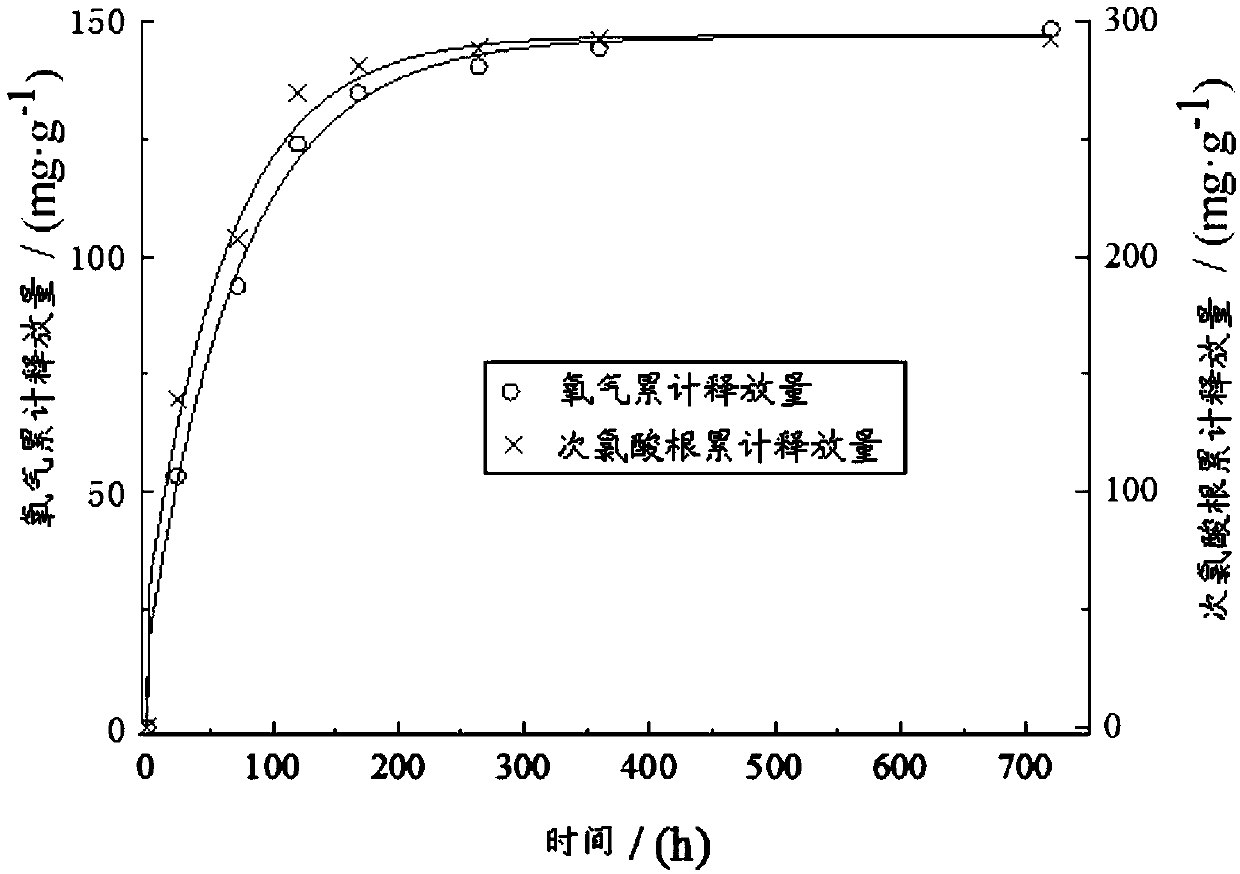

Black and odorous water bottom mud in-situ remediation material and preparation method thereof

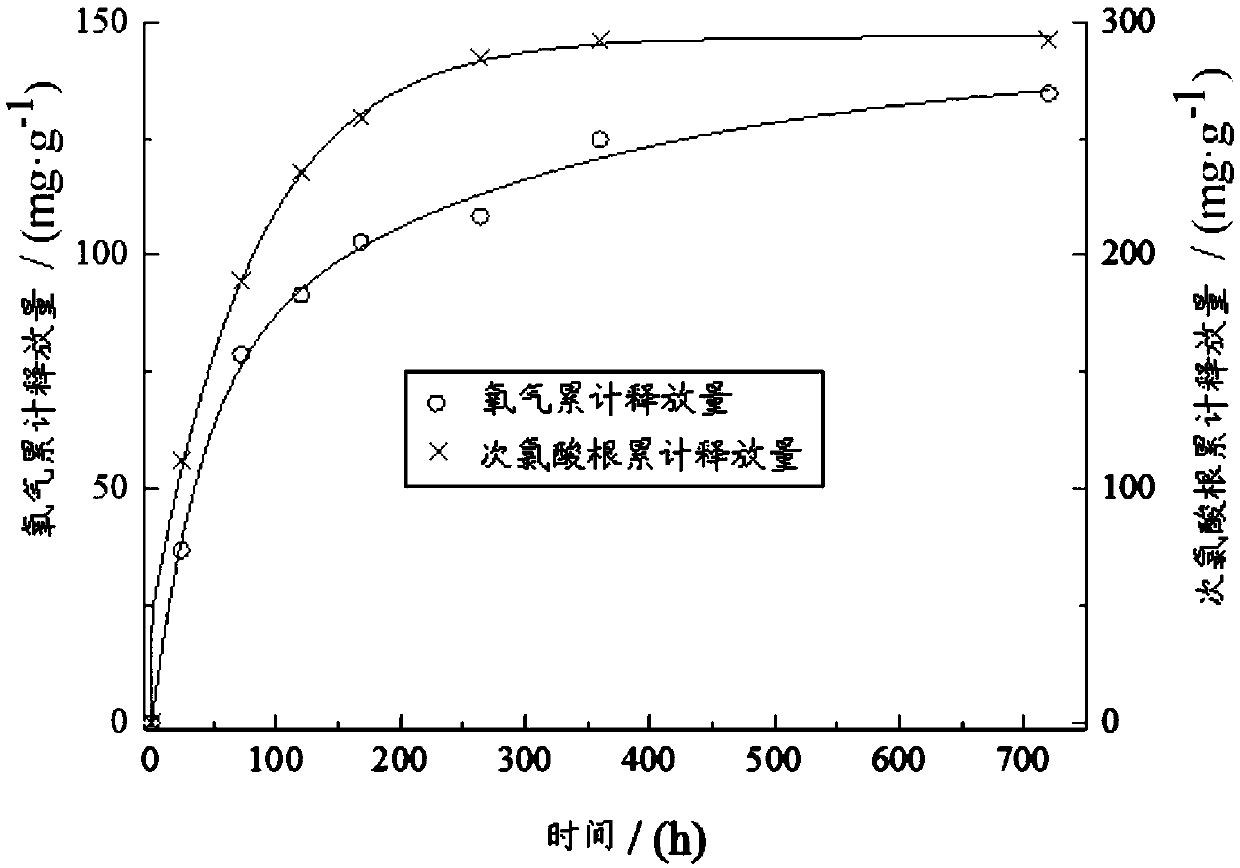

PendingCN109607993AIncrease dissolved oxygenEliminate black odorWater treatment parameter controlSpecific water treatment objectivesAmmoniacal nitrogenIn situ remediation

The invention discloses a black and odorous water bottom mud in-situ remediation material and a preparation method thereof. The material is prepared from an oxygen release agent, an ammonia-nitrogen oxidant, aggregates, a binder, a pH regulator and a solidification regulator. The black and odorous water bottom mud in-situ reduction and solidification function material is prepared from the following steps that all raw materials are mixed to be uniform, granulation is conducted, or a mold is filled with chemicals, maintenance is conducted, and after the maintenance period is finished, the material can be obtained. Accordingly, the applied materials are easy to obtain and friendly to environment, preparation is easy, and the cost is low; meanwhile, oxygen slowly released from the chemicals and hypochlorite ions can improve the redox potential of black and odorous water, ammonia and nitrogen can be oxidized, sulfur release is inhibited, and remediation can be provided for the black and odorous water efficiently and enduringly.

Owner:TSINGHUA UNIV

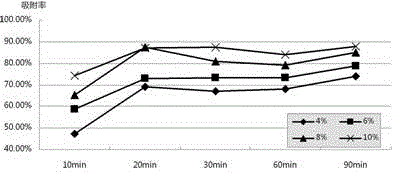

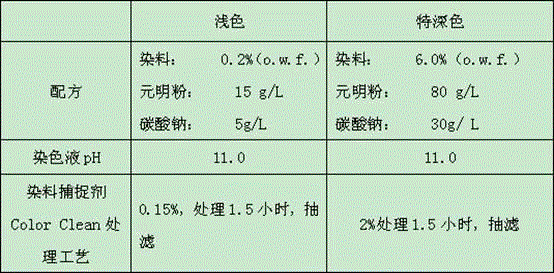

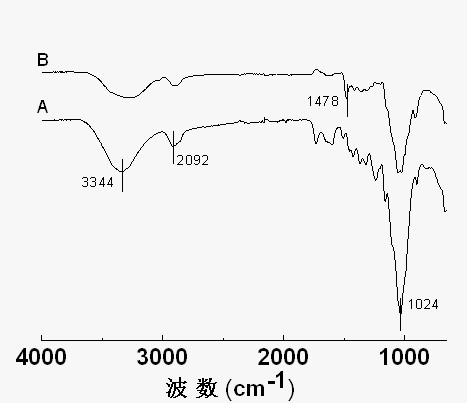

Recovery and utilization method for dyeing residual liquid of reactive dye

ActiveCN102745761AReduce dosageReduce COD valueWaste water treatment from textile industryWater/sewage treatment by sorptionWastewaterSewage

The invention provides a recovery and utilization method for a dyeing residual liquid of a reactive dye. The method comprises the following steps: (1) performing an absorption treatment for the dyeing residual liquid to get a treatment liquid; (2) filtering the treatment liquid; (3) determining salt and alkali content in the treatment liquid; (4) adding the dye into the treatment liquid; (5) supplying the salt, the alkali and the water so that the treatment liquid reaches to a concentration required by the dyeing technology; (6) dyeing according to the dyeing technology; and (7) repeating step (1) to (6), wherein an adsorbent used in the step (1) for absorption treatment is a dye capture agent. The recovery and utilization method for the dyeing residual liquid of the reactive dye provided by the invention can reduce the amount of the salt or the alkali during the dyeing process by using the salt (anhydrous sodium sulfate or sodium chloride) or the alkali in the residual liquid, thereby effectively resolving a problem that high salt in waste water of a dyeing factory is difficult to deal with, reducing an emission amount of sewage and a COD value of the wastewater, and reducing cost of sewage treatment.

Owner:DYMATIC CHEM

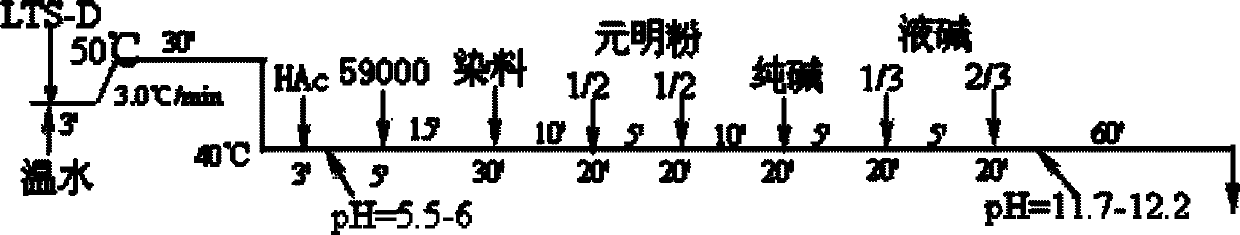

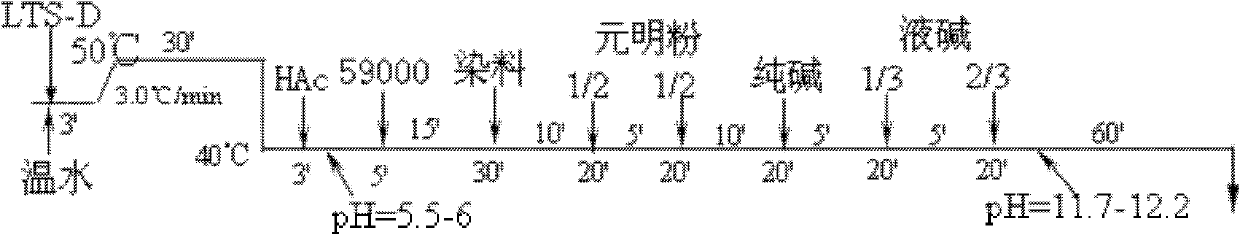

Low temperature dyeing technology for pure cotton fabrics

ActiveCN102561064AReduce consumptionReduce COD valueBiochemical fibre treatmentDyeing processSodium sulfateEnzyme

The invention relates to a low temperature dyeing technology for pure cotton fabrics. The technology which adopts low temperature preprocessing, polishing and low temperature dyeing one-bath process comprises the following steps: 1, carrying out low temperature preprocessing: adding a dyeing one-bath assistant to a dye solution, adjusting the temperature to 40-60DEG C, and continuously reacting for 15-30min; 2, polishing: adjusting the temperature to 35-60DEG C and the pH value to 5.5-6, adding a neutral polishing enzyme having a weight accounting for 0.2-0.5% of the weight of the fabrics, and continuously reacting for 15-20min; and 3, carrying out low temperature dyeing: adjusting the temperature to 35-45DEG C, sequentially adding a low temperature active dye, anhydrous sodium sulfate, soda ash and a caustic soda solution at a certain time interval, and reacting. The low temperature dyeing technology has the advantages of simple operation, small pollution, low energy consumption and the like.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

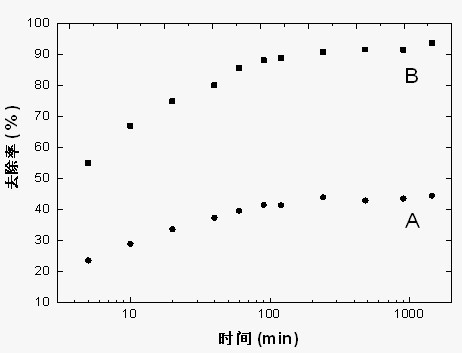

Straw modified into strong cation type absorbent and preparation method thereof

The invention discloses straw modified into a strong cation type absorbent. The straw is characterized in that the straw and 3-chlorine-2-hydroxypropyl trimethylammonium chloride, and 2-hydroxypropyl trimethylammonium chloride is grafted on a cellulose molecular chain or a lignin molecular chain of the straw. The main raw material of the straw modified into the strong cation type absorbent is the crop waste which is abundant in sources, namely straw, the cost is low, and the straw is suitable for large industrialized production, is a natural high polymer material, has the characteristic of environmental friendliness, and is a water treatment agent which is economical and high in quality. The invention discloses the preparation method of the straw modified into the strong cation type absorbent.

Owner:NANJING UNIV

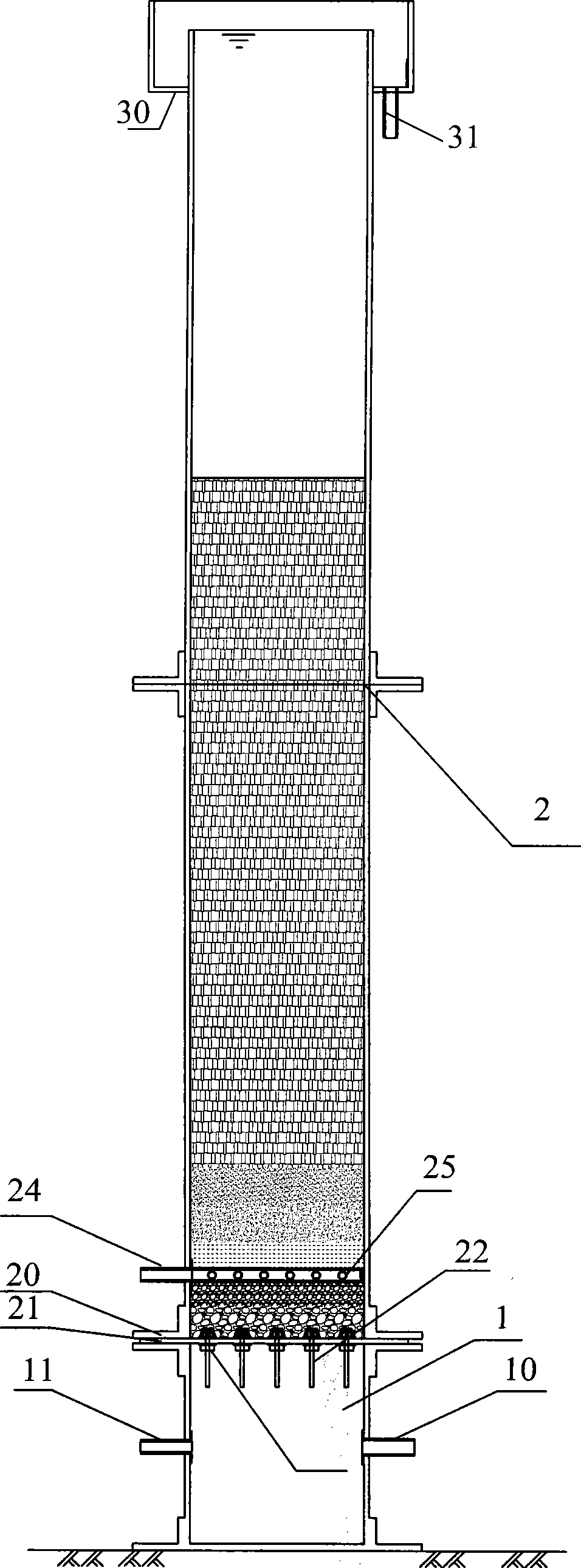

Advanced treatment process and apparatus for reverse osmosis concentrated water

ActiveCN101481196ALarge specific surface areaHigh porosityWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentBiological activated carbonFiltration

The invention relates to a technology and a device for the advanced processing of reverse osmosis condensed water, wherein the technology is as follows: reverse osmosis condensed water which is directly outputted and discharged is inputted into a processor with inside-arranged biological active carbon, then ozone of the reverse osmosis condensed water, which has the density of 5 mg / L to 50 mg / l, is added on the aeration grid part of the processor; the ozone reacts with hydroxide free radicals to form oxyhydrogen free radicals of strong oxidbility in the processor; the hydroxide free radicals are used for oxidizing and decomposing organic polluting substances in the reverse osmosis condensed water, and the reverse osmosis condensed water processed by the ozone is directly outputted from the processor. The device comprises a base, a filtration cylinder and a reverse washer, wherein active carbon is put in the filtration cylinder. The hydroxide free radicals of strong oxidbility generated by the reaction of the ozone and the hydroxide free radicals are used as an oxidization middle product for oxidizing the organic polluting substances which can not be degraded in the reverse osmosis condensed water to form the organic substances which can be conveniently absorbed by the active carbon and biologically degraded, and COD value is lowered.

Owner:HUEYA ENVIRONMENTAL ENG

Dyeing carrier for dyeing polyimide fiber product by virtue of disperse dyes

The invention relates to a dyeing carrier for dyeing a polyimide fiber product by virtue of disperse dyes, and belongs to the technical field of dyeing. The dyeing carrier is convenient, effective, safe, ecological, environment-friendly and high in boiling point and applicable to high-temperature high-pressure dyeing, can promote the swelling of polyimide fibers, increase the dissolved load of the dyes, increase the dyeing rate of the dyes, has a function of promoting the dyeing of the polyimide fibers so as to obtain a deep color, can realize the high-temperature high-pressure dyeing of the polyimide, is high in color yield and excellent in dyeing fastness, conforms to the national standard, and facilitates the implementation of industrialization of the polyimide dyeing.

Owner:JIANGNAN UNIV +1

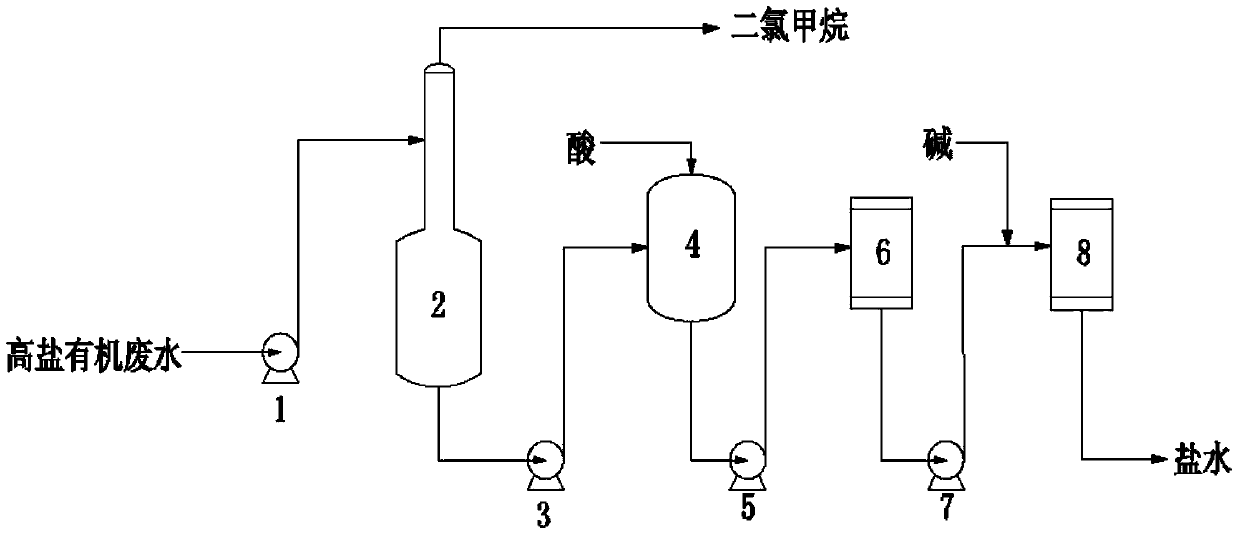

Method for processing hyper-saline organic wastewater

ActiveCN103739136AIncrease profitReduce consumptionWater contaminantsMultistage water/sewage treatmentGranularityWastewater

The invention discloses a method for processing hyper-saline organic wastewater. The method comprises the steps of gas stripping, resin absorption and active carbon absorption. The step of gas stripping comprises the steps of feeding wastewater into a polycarbonate producing process into a gas stripping tower, feeding a heating medium into the gas stripping tower to heat the wastewater, vaporizing a dichloromethane in the wastewater to condense and enter a solvent recycling system; the resin absorption step adopts macroporous resin; the active carbon absorption step adopts particle active carbon with a granularity of 10-24 meshes; before the resin absorption step, inorganic acid is added for adjusting pH value of the organic wastewater at 1-6; before the active carbon absorption step, alkaline liquid is added for adjusting pH value of the hyper-saline organic wastewater at 5-9. The method has the characteristics that operation is convenient and reliable and investment cost is low.

Owner:甘肃北方三泰化工有限公司

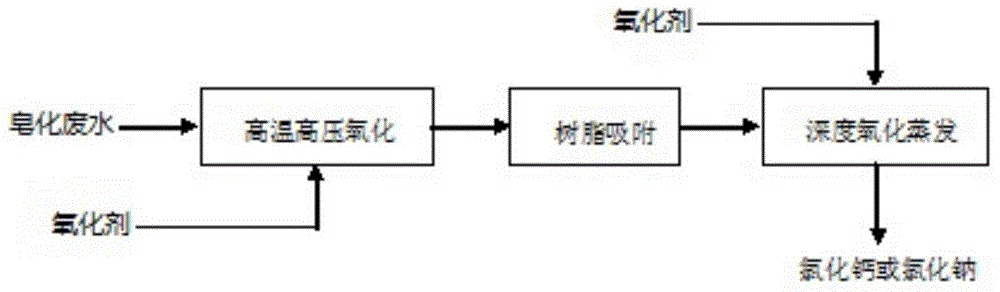

Method for treating glycerin-based epoxy chloropropane saponification wastewater

ActiveCN104609629AEfficient removalReduce COD valueWater contaminantsMultistage water/sewage treatmentChemistryGlycerol

The invention relates to a method for treating glycerol-based epoxy chloropropane saponification wastewater. The method comprises the following operating steps: step one, high temperature and high pressure oxidation technology; step two, resin adsorption technology; step three, deep oxidation evaporation technology. The method has the benefits that the technological process is simple and short in residence time, high-concentration organic matters remaining in the saponification wastewater and formed in the glycerol chlorination process can be effectively removed, and the COD value in the wastewater is obviously reduced.

Owner:CHINA TIANCHEN ENG +2

Pre-treatment process of cotton or cotton/polyester fabric before intermittent dipping of bioenzyme

The present invention belongs to the field of pre-treatment technology in printing and dyeing industry and aims at optimizin the printing and dyeing effect. Cotton or Dacron-cotton fabric is first soaking treated with hydrogen proxide and water washed and then bioenzyme treated through soaking, enzyme deactivation and water washing to complete the pre-treatment of knitted fabric. The said processhas good pre-treatment effect, less damage to fabric, high quality of the treated fabric, soft hand feeling of the treated fabric and less pollution of effluent.

Owner:JIANGNAN UNIV

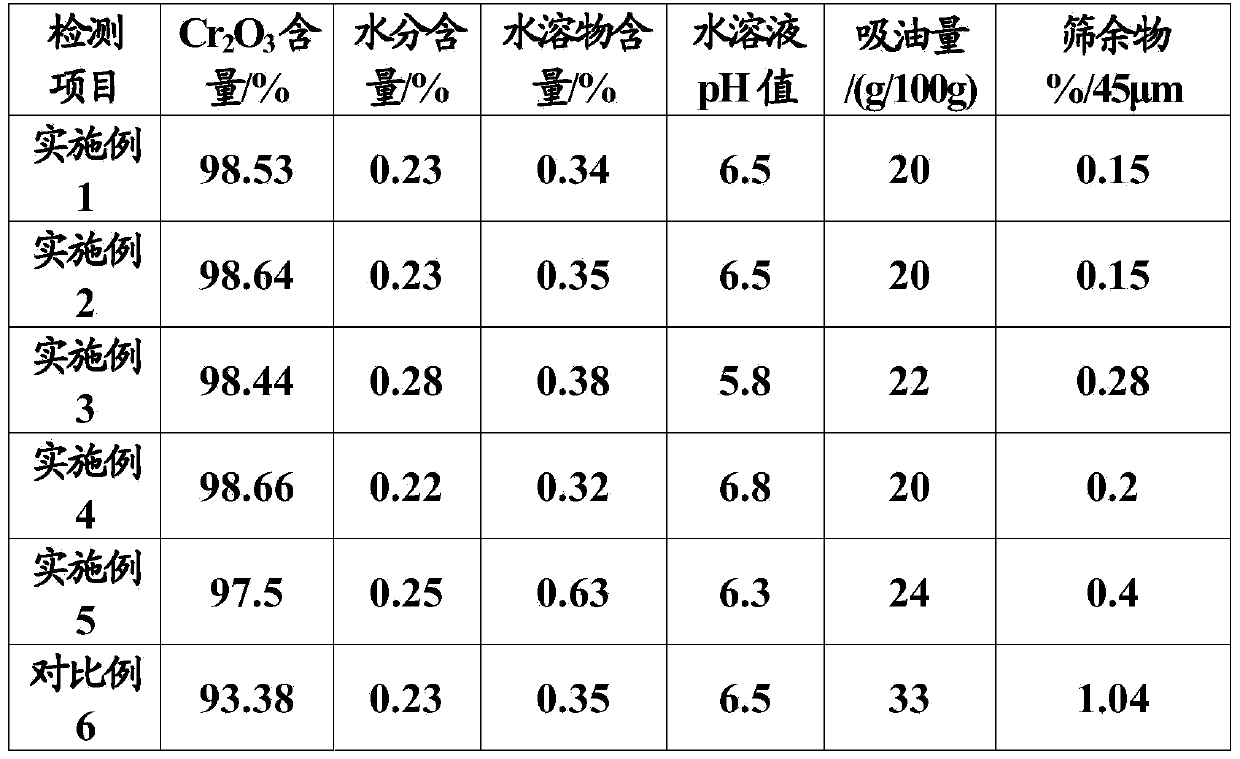

Method for treating naphthoquinone production liquid waste containing hexavalent chromium and vitamin K3 production wastewater and co-producing chromium oxide green

ActiveCN103613133AReduce COD valueEfficient disposalMultistage water/sewage treatmentChromium oxides/hydratesLiquid wasteNaphthoquinone

The invention relates to a method for treating naphthoquinone production liquid waste containing hexavalent chromium and vitamin K3 production wastewater and co-producing chromium oxide green. The method comprises the following steps: a) carrying out liquid phase reaction between the naphthoquinone production liquid waste and the vitamin K3 production wastewater at 80-260 DEG C, wherein the naphthoquinone production liquid waste is excessively used relative to a necessary dosage of complete reduction; b) adding a reducing agent into the obtained reaction mixture to reduce the residual hexavalent chromium; c) regulating the pH of the obtained reaction mixture to 5.5-8.5 to separate out chromium hydroxide, and separating to obtain the chromium hydroxide and filtrate; and d) transforming the chromium hydroxide obtained in the step c) into chromium oxide green. The method can be used for effectively treating the naphthoquinone production liquid waste and the vitamin K3 production wastewater generated in a vitamin K3 production chain and recycling effective components in the liquid waste to turn waste into wealth and improve the economic and environmental protection benefits at the same time.

Owner:绵阳市安剑皮革化工有限公司

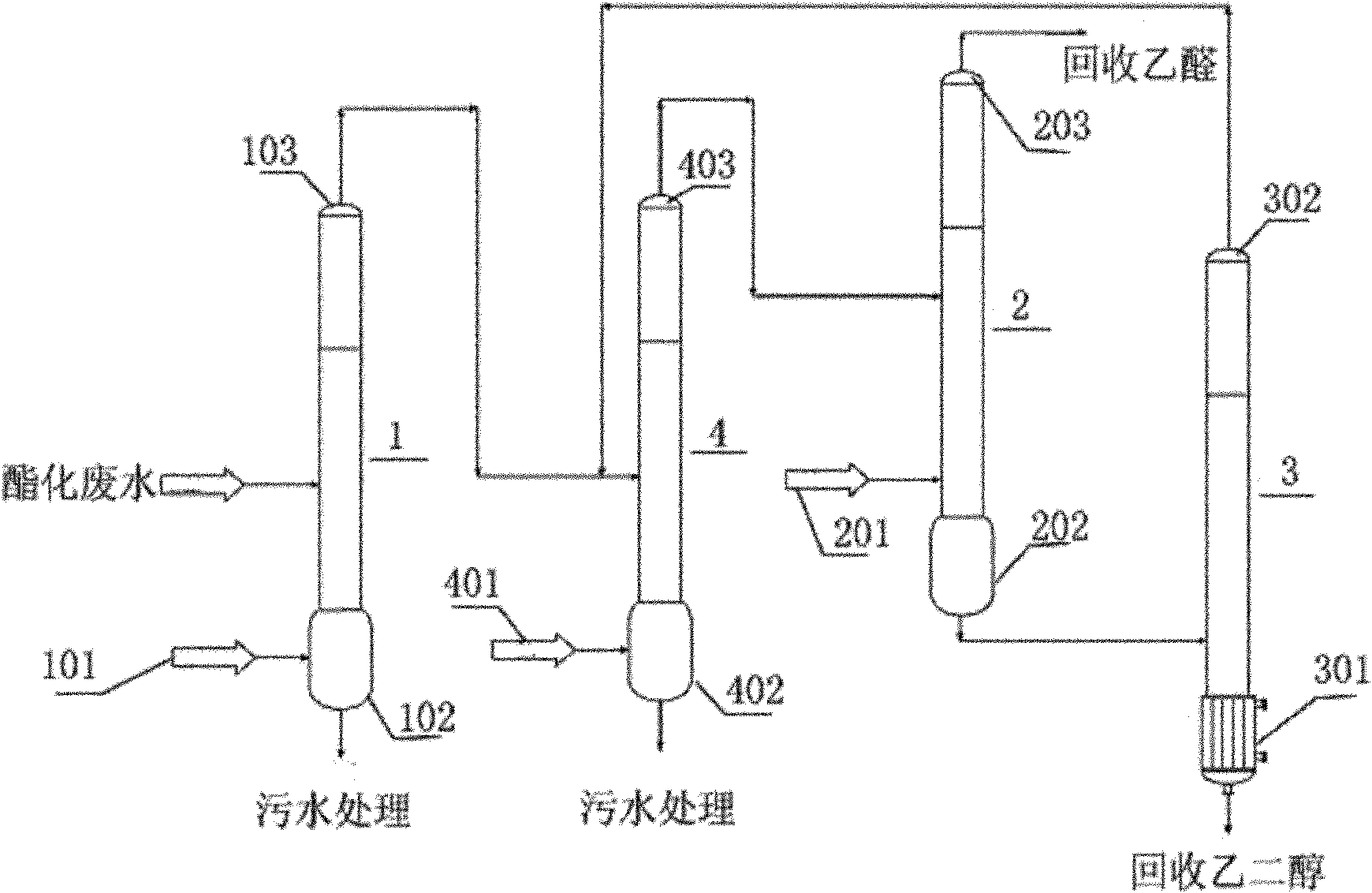

Method for recovering organic matters in polyester wastewater

ActiveCN103012090AReduce COD valueFix security issuesWater/sewage treatment by heatingPreparation from heterocyclic compoundsPolyesterAfter treatment

The present invention discloses a method for recovering organic matters in polyester wastewater. The method comprises the following steps that: (1) polyester wastewater enters a gas stripping tower to be subjected to a treatment, and organic matter gas and steam collected from the top of the tower directly enter an acetaldehyde rectification tower; (2) after treatment by the acetaldehyde rectification tower, high purity acetaldehyde is obtained from the top of the tower, and is divided into two parts, one part is externally collected, and the other part is reused for the gas stripping tower in the step (1), such that the acetaldehyde reacts with a small amount of ethylene glycol in the wastewater to produce 2-methyl-1,3-dioxolane, concurrently 2-methyl-1,3-dioxolane hydrolysis during the process is reduced, and the wastewater on the bottom of the tower enters an ethylene glycol distillation tower; and (3) after treatment by the ethylene glycol distillation tower, a high purity ethylene glycol solution is collected from the bottom of the tower, and waste gas and steam produced from the top of the tower re-enter the gas stripping tower to be recycled. According to the present invention, continuous acetaldehyde and ethylene glycol collection is adopted, such that gas stripping efficiency is increased so as to further reduce a COD value of the sewage on the bottom of the tower, wherein the sewage is subjected to the gas stripping treatment.

Owner:SHANGHAI JUYOU CHEM ENG +1

Pre-treatment of cotton fabrics by rolling and piling up of enzyme

The invention provided a fore treatment process of the enzyme rolling pile for the fabric which belongs to the fore treatment process of the dyeing and finishing field. The process is: first to impregnate the fabric into the alkali pectinase liquid, then to keep the temperature, next to wash with the hot water (killing the enzyme) and the cool water last to blanch with the H2O2. The pectinase is produced by the Bacillus subtilis WSHB04-03. The process has many merits such as high efficiency, low work output and the energy conservation and so on.

Owner:JIANGNAN UNIV

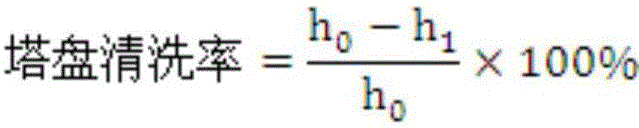

On-line cleaning agent for alkaline washing towers as well as preparation and use methods of cleaning agent

ActiveCN105754749AAvoid accumulationSolve tower blockageInorganic/elemental detergent compounding agentsCationic surface-active compoundsFiltrationSolvent

The invention relates to the technical field of ethylene and provides an on-line cleaning agent for alkaline washing towers as well as preparation and use methods of the cleaning agent. The cleaning agent is prepared from components in percentage by weight as follows: 20%-40% of a dispersing agent, 5%-10% of a stripping agent, 5%-10% of a penetrant, 25%-30% of an inhibitor and the balance of a solvent. The dispersing agent, the stripping agent, the penetrant, the inhibitor and the solvent are added to a reaction kettle in percentage by weight, stirred at the normal temperature and evenly mixed, and the cleaning agent is obtained through filtration. The cleaning agent is applied to the alkaline washing towers, stable production by devices can be guaranteed, further accumulation of scale in the alkaline washing towers is prevented, tower tray polymers are reduced, the blockage phenomenon of the alkaline washing towers can be eliminated by the aid of the cleaning agent for the alkaline washing towers, blockage of tower trays of new towers can be avoided, the butter amount and the COD value can be decreased, and accumulation of scale in old towers and the quantity of tower tray polymers can be reduced, so that real-time on-line cleaning of the alkaline washing towers can be realized.

Owner:天津市瑞德赛恩新材料开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com