Preparation method of grafted amphoteric starch flocculants

An amphoteric starch and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of uncharged starch molecules, inactive chemical properties, and narrow applicable pH range, so as to improve water solubility and enhance cohesion. Bridge flocculation, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

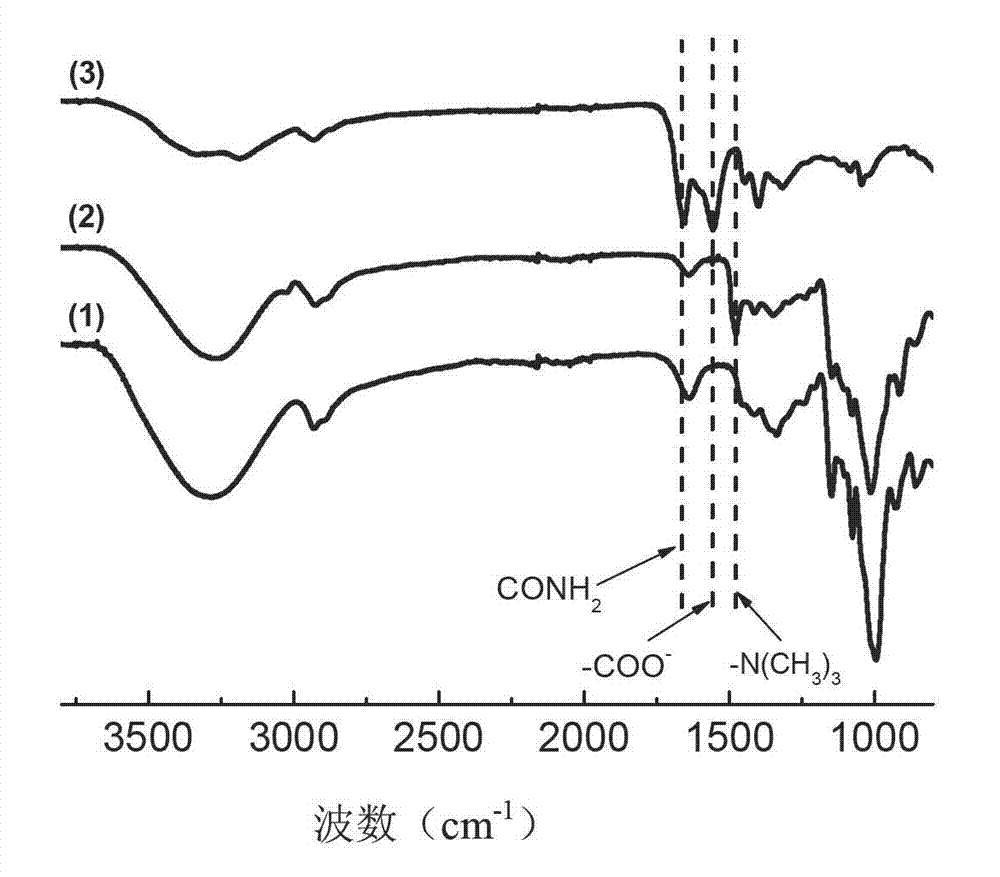

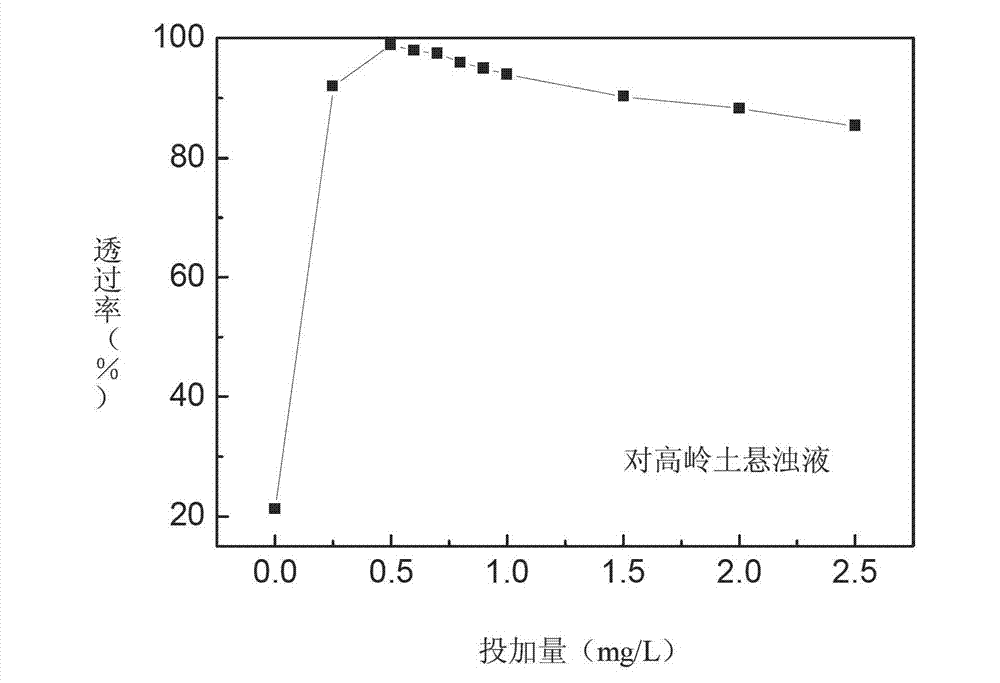

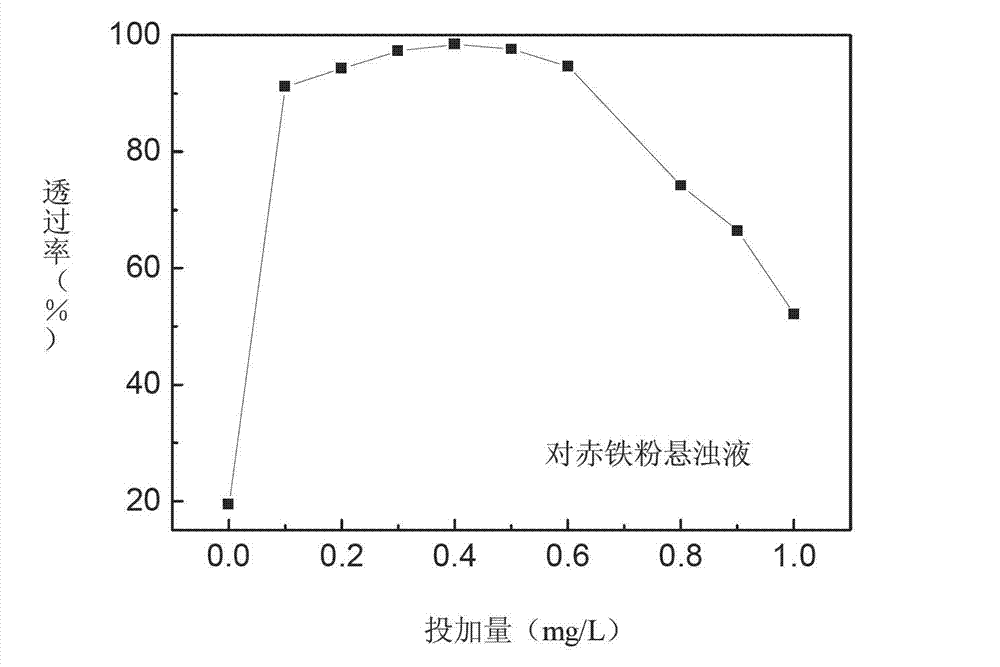

[0037]Disperse the starch in 5% aqueous sodium hydroxide solution (the ratio of starch to aqueous sodium hydroxide solution is 1:4), alkalize at 70°C for 1 hour; after that, add trimethyl chloride-(3-chloro-2-hydroxy ) propylammonium, trimethyl-(3-chloro-2-hydroxy)propylammonium chloride and starch mass ratio 2:1, react at 70°C for 2h; Obtain cationic starch, dissolve cationic starch in water, prepare a solution with a mass percentage concentration of cationic starch of 1%, after the solution is uniform, add ammonium persulfate as an initiator (the addition is 2% of the molar number of starch units), and then Add a mixture of acrylamide (mass ratio to cationic starch: 5:1) and acrylic acid (mass ratio to cationic starch: 3:1), react at 45°C for 4 hours, and then use acetone as a precipitant to precipitate and separate the product, namely A grafted amphoteric starch flocculant is obtained. According to nuclear magnetic analysis, the degree of substitution of cationic groups is...

Embodiment 2

[0039] Disperse the starch in 1% potassium hydroxide aqueous solution (the ratio of starch to sodium hydroxide aqueous solution is 1:5), alkalinize at 20°C for 2 hours; after that, add trimethyl chloride-(3-chloro-2-hydroxy ) propylammonium, trimethyl-(3-chloro-2-hydroxy)propylammonium chloride and starch mass ratio 3:1, react at 30°C for 0.5h; , to obtain cationic starch, dissolve cationic starch in water, and prepare a solution with a mass percent concentration of cationic starch of 2%. After the solution is uniform, add ammonium persulfate as an initiator (the amount added is 3% of the molar number of starch units) , then add acrylamide (mass ratio to cationic starch: 1:1) and acrylic acid (mass ratio to cationic starch: 8:1), react at 50°C for 6 hours, and then use ethanol as a precipitant to precipitate and separate the product. That is, the grafted amphoteric starch flocculant is obtained. According to the analysis by nuclear magnetic method, the degree of substitution ...

Embodiment 3

[0041] Disperse the starch in 15% aqueous sodium hydroxide solution (the ratio of starch to aqueous sodium hydroxide solution is 1:3.5), and alkalize it at 40°C for 2 hours; after that, add trimethyl chloride-(3-chloro-2-hydroxy ) propylammonium, trimethyl-(3-chloro-2-hydroxy)propylammonium chloride and starch mass ratio 1.5:1, react at 45°C for 4h; To obtain cationic starch, dissolve cationic starch in water, and prepare a solution with a mass percentage concentration of cationic starch of 3%. After the solution is uniform, add cerium ammonium nitrate as an initiator (addition amount is 1% of the molar number of starch units), Then add acrylamide (mass ratio to cationic starch: 3:1) and acrylic acid (mass ratio to cationic starch: 6:1), react at 60°C for 3 hours, then use acetone as precipitant to precipitate and separate the product, namely A grafted amphoteric starch flocculant is obtained. According to nuclear magnetic analysis, the degree of substitution of cationic grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com