Patents

Literature

60 results about "Amphoteric starch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amphoteric starch is a modified starch that contains positively and negatively charged substituent groups. It is used as wet-end additives, surface sizing agent and coating agent in the paper mill industries.

Composition and Process for Increasing the Dry Strength of a Paper Product

A dry strength additive composition generally includes an anionic and / or amphoteric polyacrylamide having a molecular weight of less than 1,000,000 Daltons, wherein the amphoteric polyacrylamide has a net negative charge; a cationic and / or amphoteric starch; and a cationic non-starch polymer having a charge density greater than 1 milliequivalent per gram (meq / g) at a pH of 3. The components defining the composition can be added to a pulp suspension sequentially or as a pre-blended mixture.

Owner:KEMIRA OY

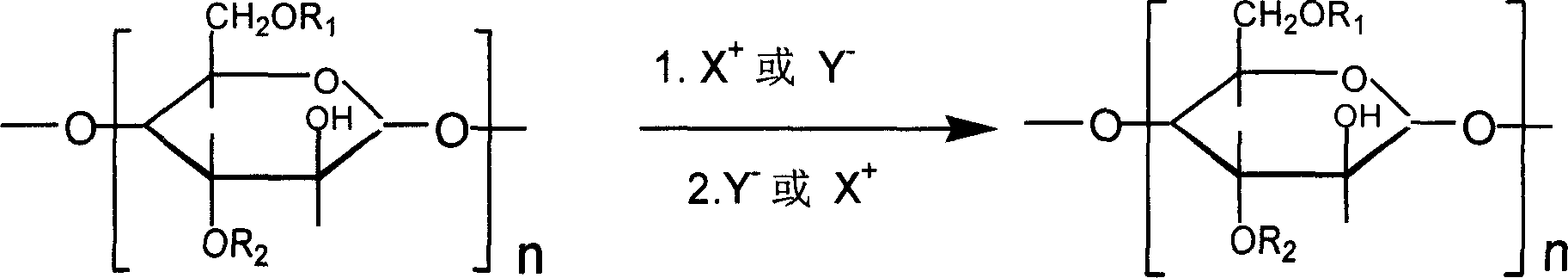

Synthesis of soluble amphoteric starch

Synthesis of amphoteric soluble starch is carried out by taking starch as raw material, taking any kind from sodium chloroacetate, butanedioic anhydride and 3-chlorine-2-cysteic acid as anion reagent, taking any kind from 3-chlorine-2-hydroxypropyl trimethyl-ammonia chloride and N-(2,3-epoxide)trimethyl-ammonia chloride as cation reagent, catalyzing by composite catalyst, synthesizing the final product at 30-150 degree for 1-8hrs by semi-drying method. It' simple, cheap and efficient, has no after-treatment and waste ejection.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Method for preparing amphiprotic starch solution for papermaking

ActiveCN101759880ASolve aging problemsAging does not occurNon-fibrous pulp additionPaper/cardboardPotassium persulfateHigh concentration

The invention provides a method for preparing amphiprotic starch solution for papermaking, which belongs to the field of fine chemicals for papermaking. The amphiprotic starch solution is added at a papermaking wet end, and has a dry strengthening effect on paper. Starch is used as the basic material, water, sodium hydroxide, sodium hypochlorite or potassium persulfate and cationic etherifying agent are added. The amphiprotic starch solution is obtained after the aqueous solution is heated. The preparation method is fulfilled by the heating reaction of aqueous solution. The amphiprotic starchsolution has high concentration, can be diluted by cold water to any concentration and cannot be aged, so the technical problem of starch aging is solved. When in use, the amphiprotic starch solutioncan be added at the wet end without being heated to gelatinize, the amphiprotic starch solution as dry-strengthening agent for papermaking can notably increase the dry strength indexes of paper, suchas burst index and ring crush index, and under the circumstance of the same added amount, the amphiprotic starch solution has a better effect than the like product. The innovation of the invention isthat a simple technique for producing the amphiprotic starch solution is provided, the production time is not longer than 2 hours, the aging and retrograding problems of the amphiprotic starch are solved, and the invented amphiprotic starch solution can be directly added at the papermaking wet end without going through the step of gelatinization by heating.

Owner:GUANGDONG PAPER IND RES INST

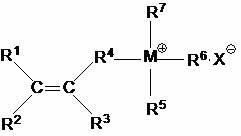

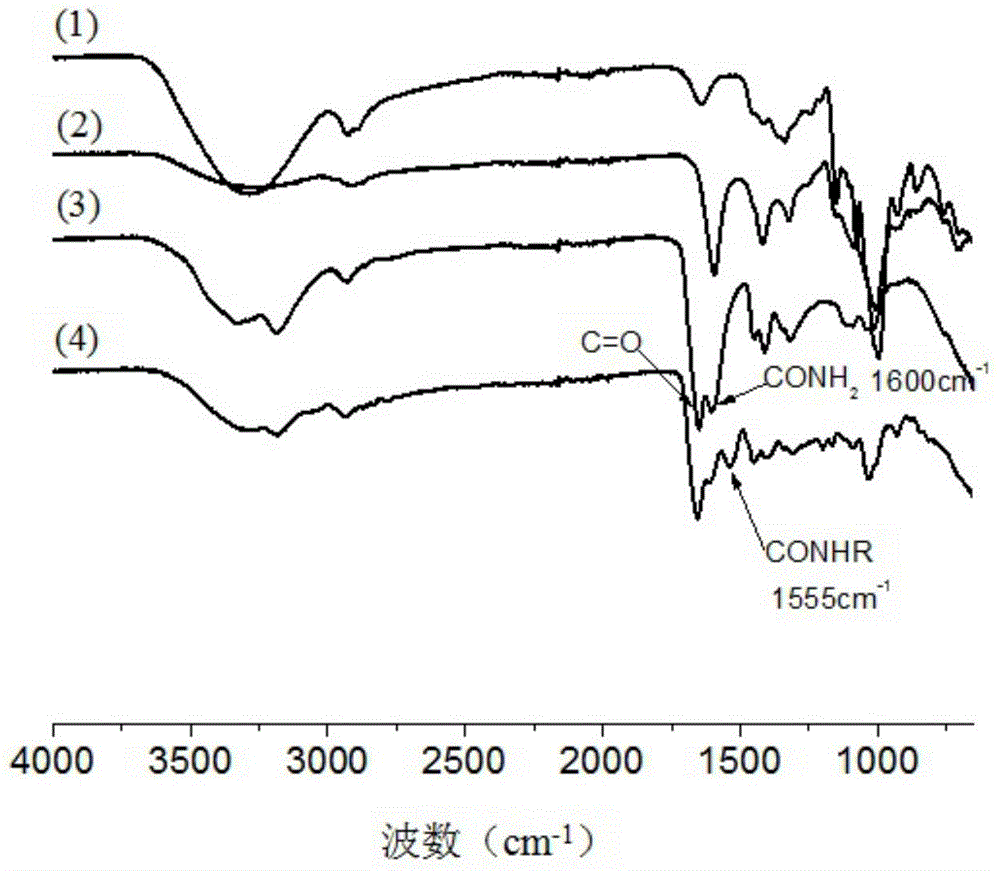

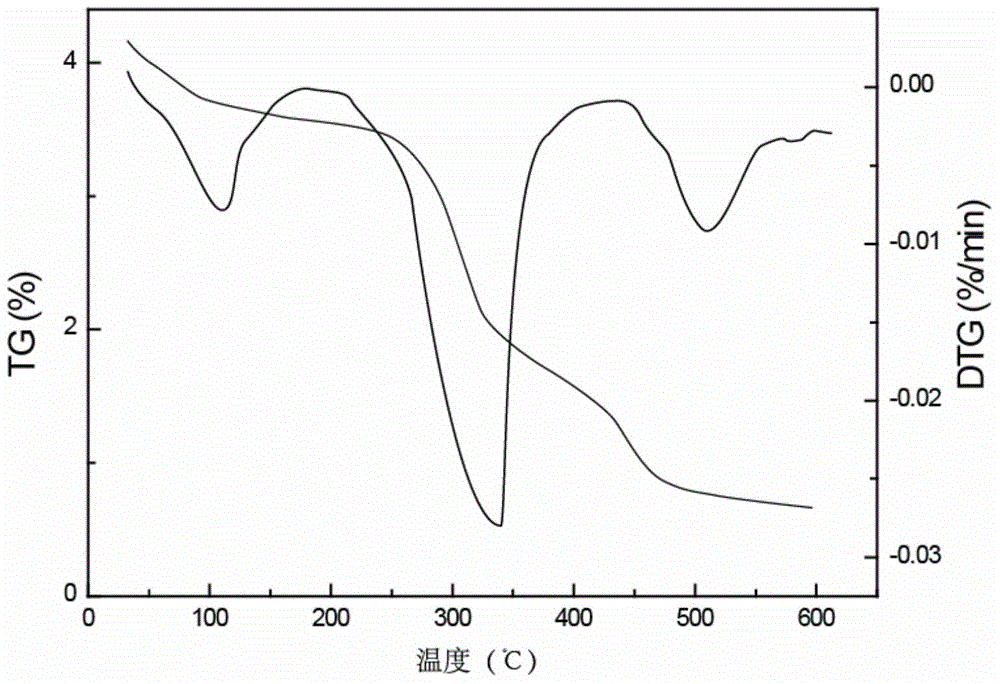

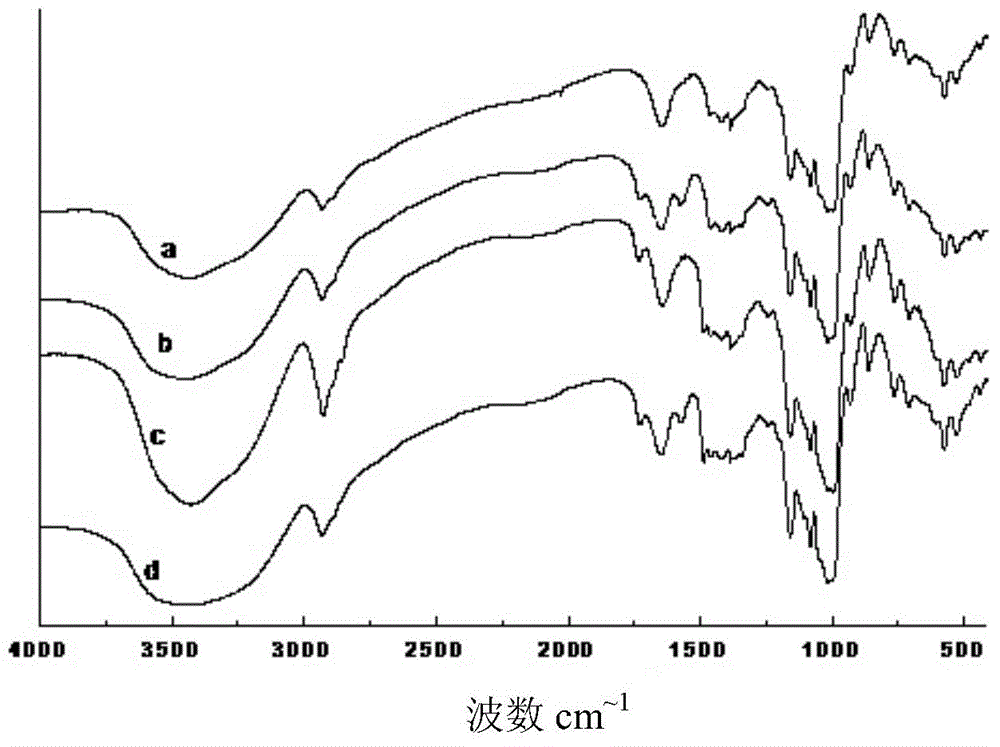

Preparation method of grafted amphoteric starch flocculants

InactiveCN103087265AImprove solubilityGood flocculation effectWater/sewage treatment by flocculation/precipitationFlocculationSalt resistance

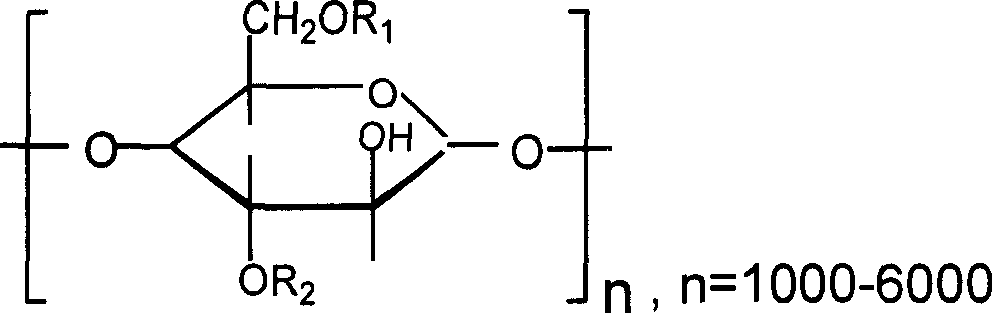

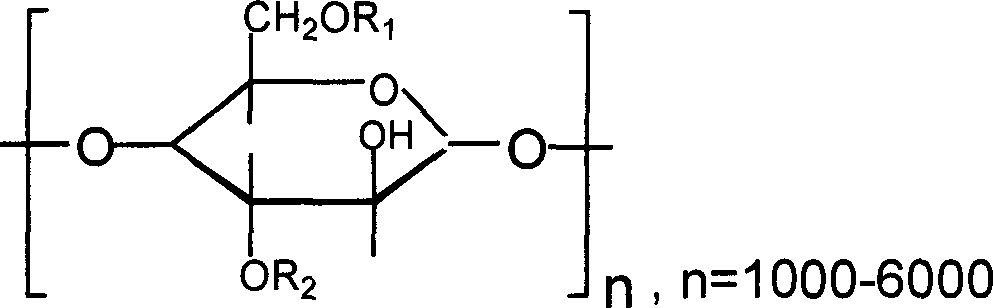

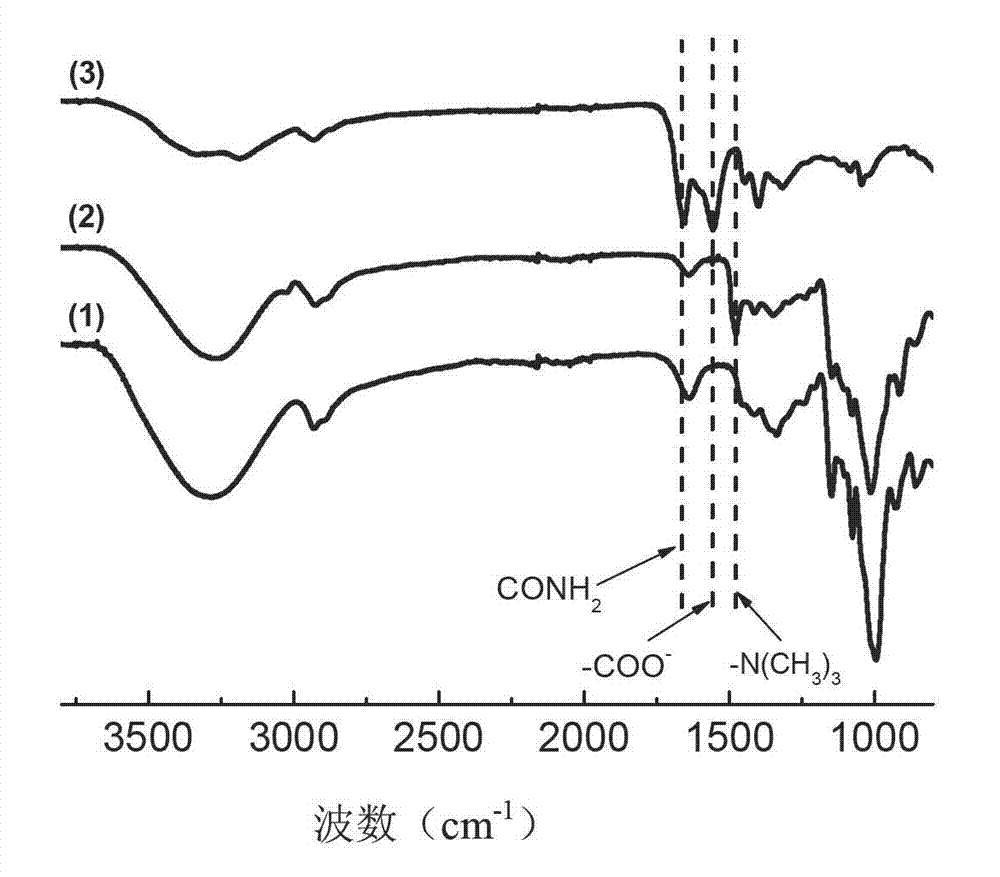

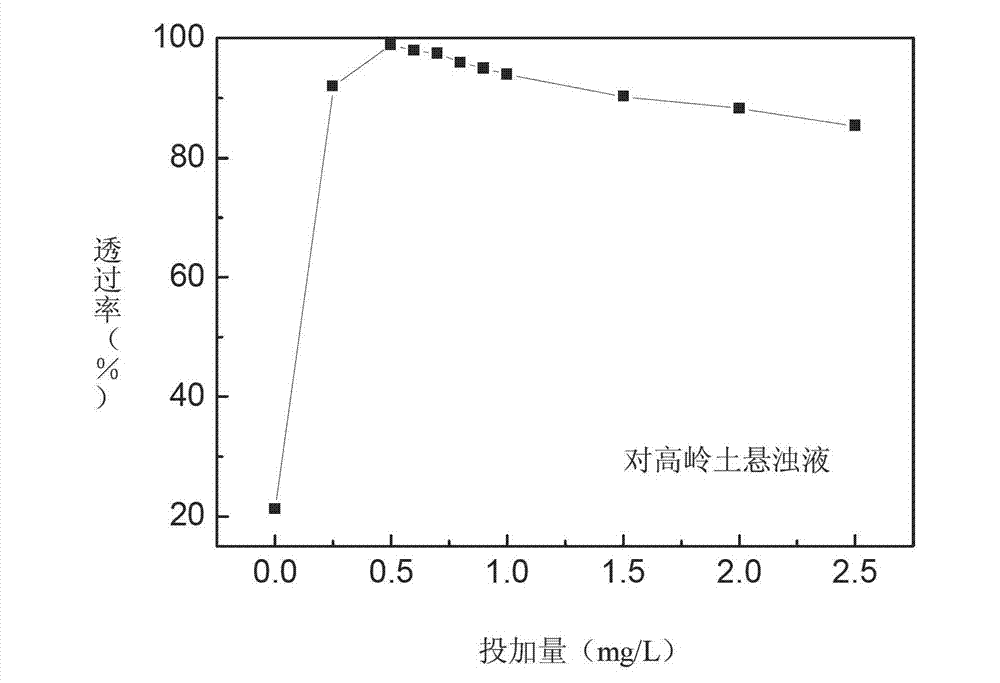

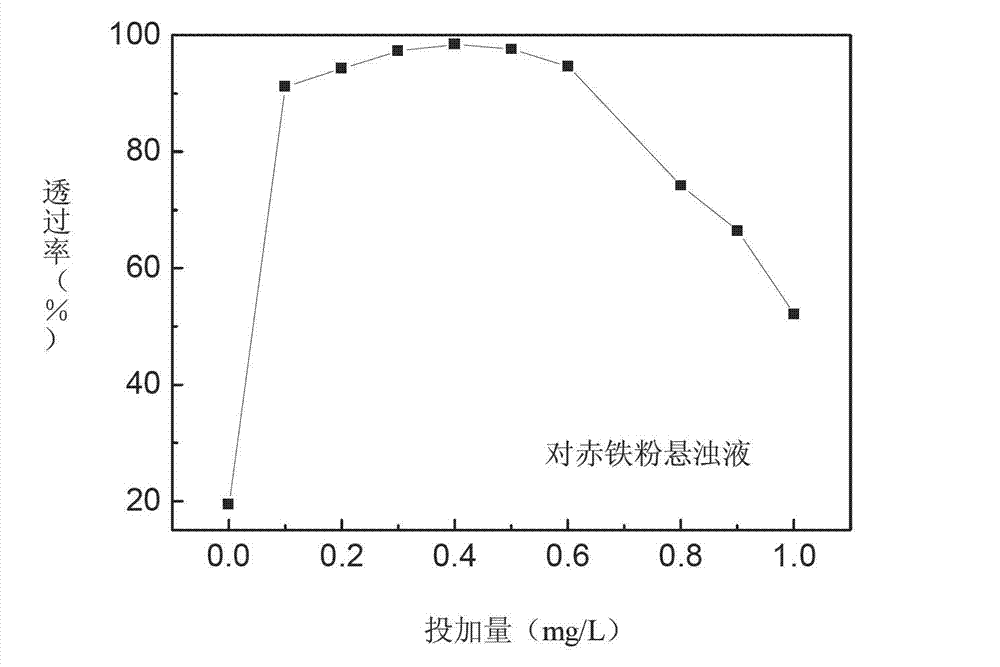

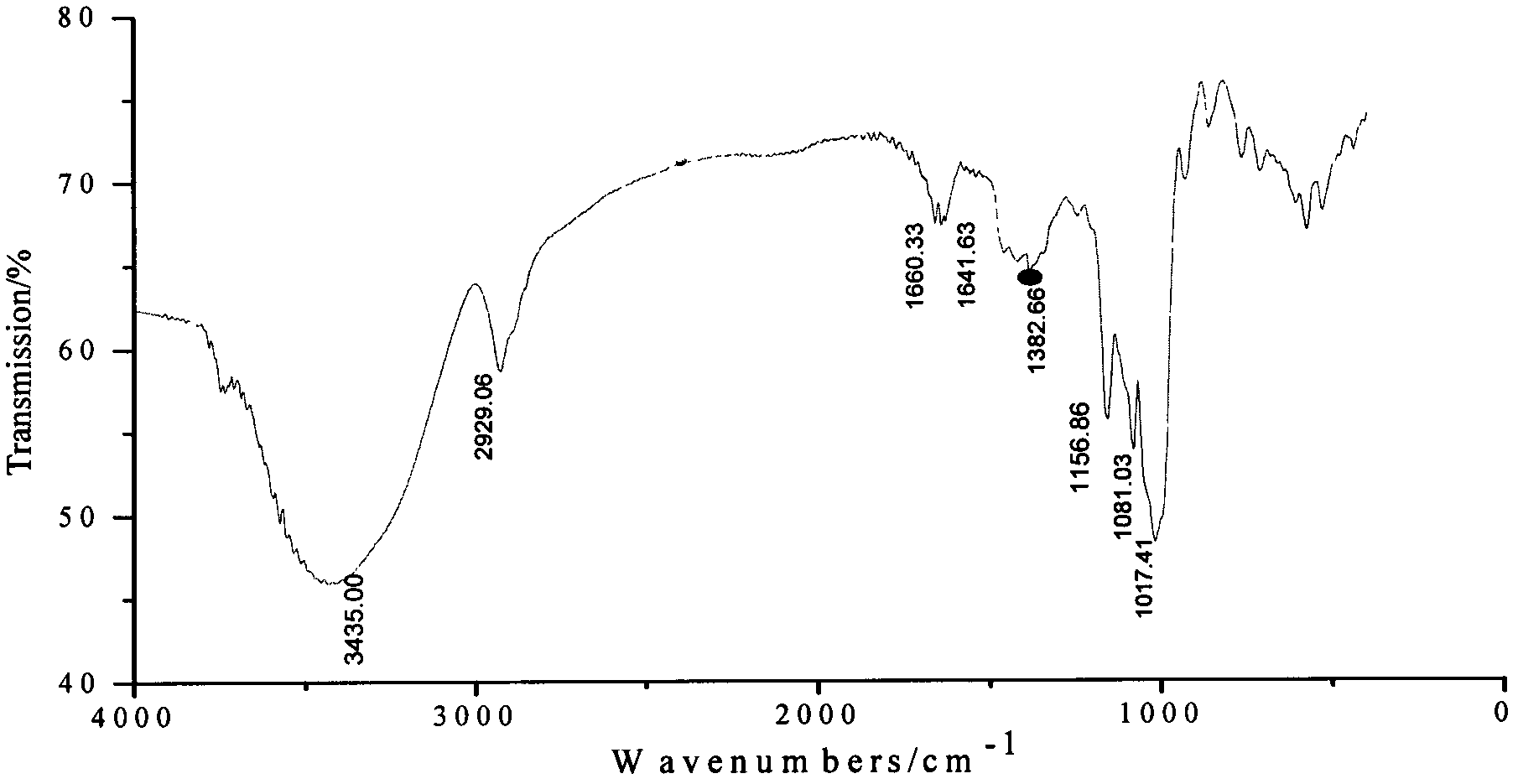

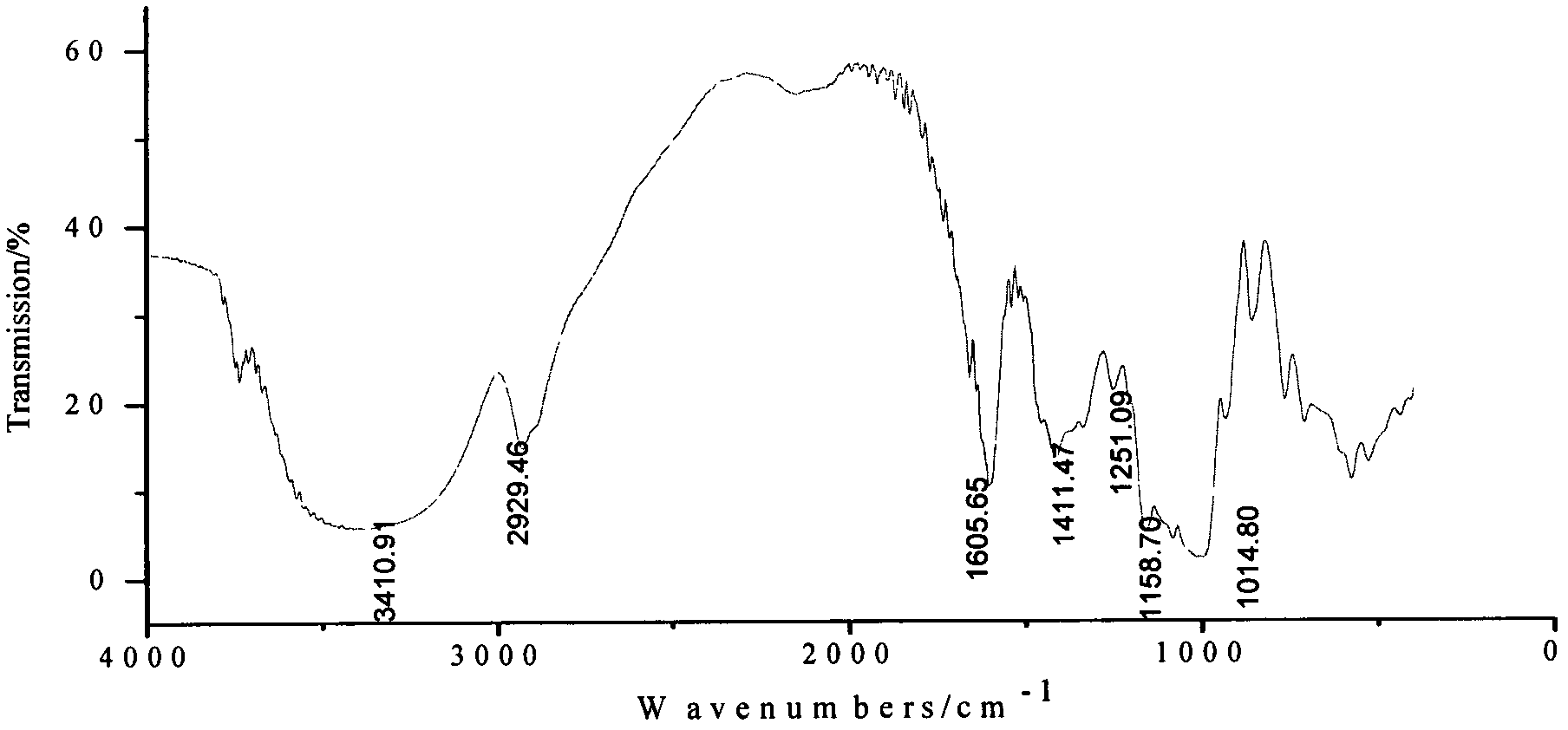

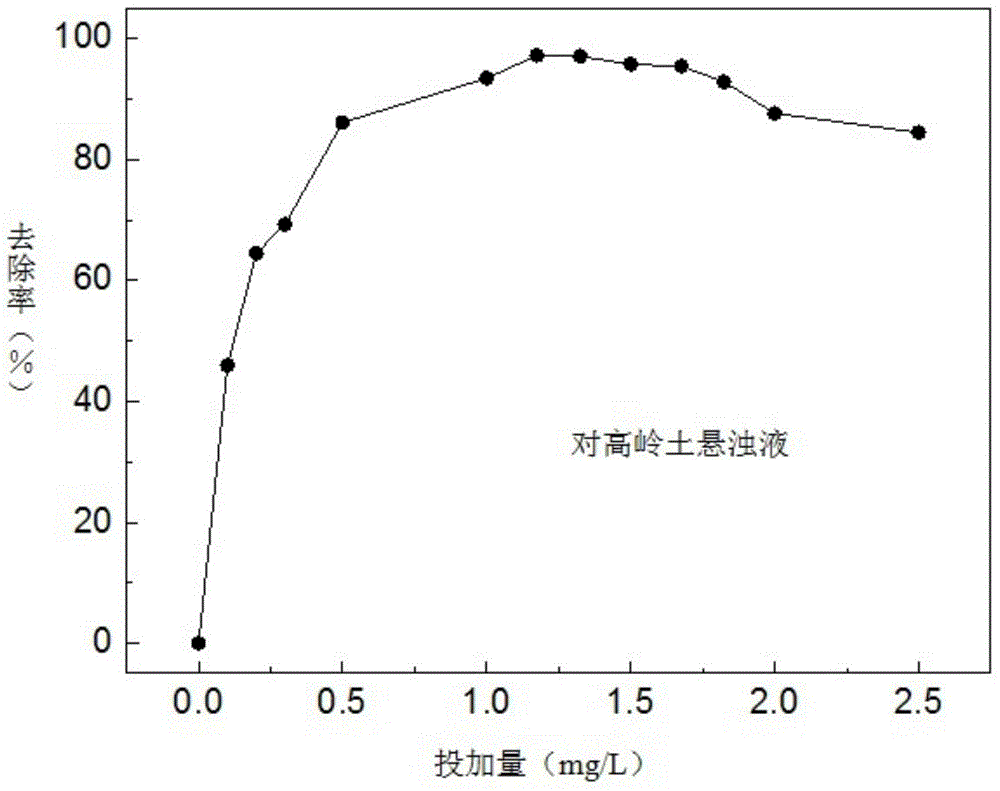

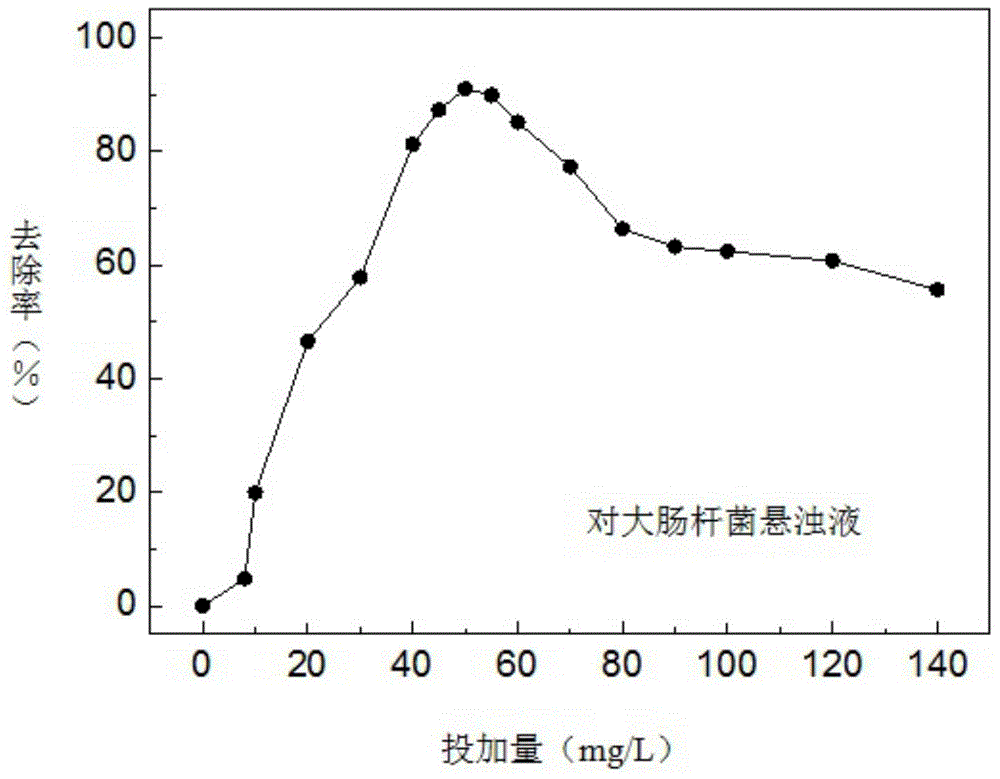

The invention discloses a preparation method of grafted amphoteric starch flocculants, which is implemented by carrying out graft copolymerization on cationic starches, acrylamide and an acrylic acid so as to obtain a grafted amphoteric starch flocculant, and the grafted amphoteric starch flocculant has the following structure shown in the abstract. The method disclosed by the invention has the following advantages that because a molecular chain is rich in anion-cation groups and has amphoteric characteristics, not only is the flocculation property of materials improved, and also the dissolving property of starches is improved; high polymer materials are wide in resource and low in cost, so that the grafted amphoteric starch flocculant has a high performance price ratio; starches have biodegradability and are non-toxic, so that starches do not produce secondary pollution to water bodies; the grafted amphoteric starch flocculant has various good effects such as flocculation, metal ion adsorption, bacteriostasis, deodorization, decoloring, and capability of effectively reducing the COD value; the grafted amphoteric starch flocculant has a characteristic of high efficiency, and is low in putting amount, and the putting amount is generally 0.1-10mg / L; and the the grafted amphoteric starch flocculant is suitable for treating water bodies with different charges, good in salt resistance and wide in applied pH range, and can be applied when the pH value is 1-12.

Owner:NANJING UNIV

Method for preparing double-crosslinking amphoteric tapioca starch

The invention discloses a method for preparing double-crosslinking amphoteric tapioca starch. The method includes: using tapioca starch as main materials, water as solvent, hydroxide 1-butyl-3-methyl imidazole and sodium hydroxide as catalysts for etherification reaction, and N, N'-methylene bisacrylamide as inner-crosslinking agent to enable the starch to be in a meshed form, and preparing double-crosslinking amphoteric tapioca starch by means of outer crosslinking of epichlorohydrin and modification of amphoteric agent such as dimethyl diallyl ammonium chloride cation monomers, monochloro acetic acid and the like to enable the tapioca starch to integrate advantages of crosslinking starch and amphoteric starch. The double-crosslinking amphoteric tapioca starch has high application value in papermaking auxiliaries, cosmetics and the like. Further, since the double-crosslinking amphoteric tapioca starch is swellable in water but insoluble, application of the double-crosslinking amphoteric tapioca starch in sewage treatment is more effective.

Owner:建湖上冈产业园服务有限公司

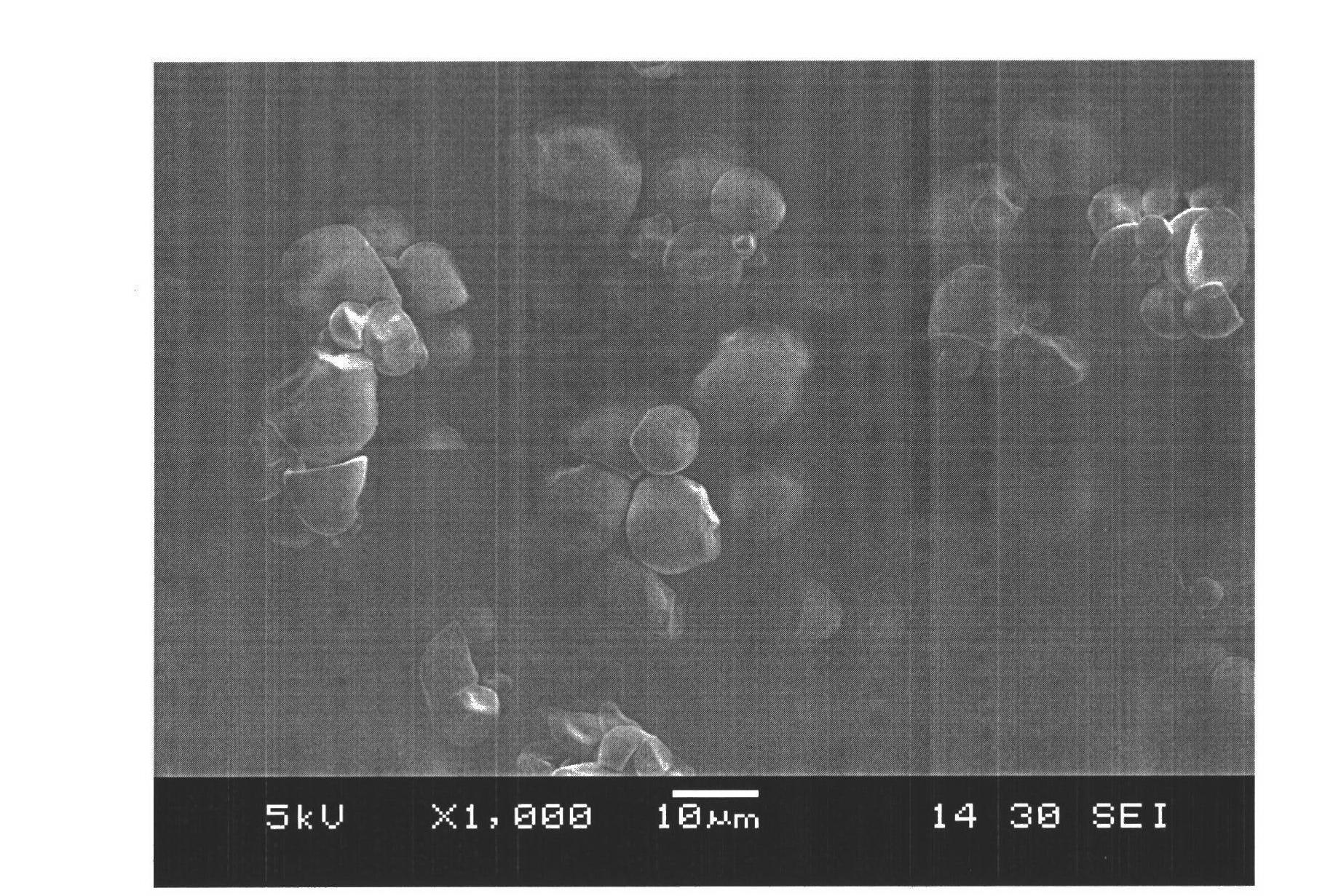

Preparation method of nanometer amphoteric starch

The invention discloses a preparation method of nanometer amphoteric starch. The preparation method comprises the following steps of: adding a plasticizing agent, a cationic etherifying agent and an alkalizer by taking native starch as a raw material; uniformly mixing in a high-speed stirrer; extruding through a double screw extruder (an eight-section cylinder body); injecting an anionic reagent and the alkalizer on a fifth-section cylinder body position through a liquid spray gun, and injecting a cross-linking agent on a seventh-section cylinder body position through the liquid spray gun; extruding materials, then discharging through the discharge port of the double screw extruder, and then drying, cooling and crushing to obtain the nanometer amphoteric starch. The nanometer amphoteric starch prepared through the method disclosed by the invention achieves the cationic substitution degree of 0.01-0.15, achieves the anionic substitution degree of 0.01-0.1 and achieves the average particle diameter of 100-400 nanometers; the method disclosed by the invention can be used for producing the nanometer amphoteric starch by firstly using the double screw extruder in domestic and provides a basis for the application of the nanometer amphoteric starch in a paper-making industry.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Amphiprotic starch graft copolymer and its one-step preparing process

A process for preparing the graft copolymer of amphiprotic starch prepared by one-step method includes such steps as preparing amphiprotic starch by both cationic and anionic reaction at 20-60 deg.C, where mixed water-alcohol solvent is used as reaction medium, tripolyphosphate or pyrophosphate as anionic reagent and 3-Cl-dihydroxytrimethylamine hydrochloride as cationic reagent, the graft copolymerizing between amphiprotic starch and acrylamide at 5-60 deg.C in water phase, and cationic reacting for the graft chain of said graft copolymer at 2-50 deg.C in water phase. Its advantages are better network structure, and high stability.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing low-viscosity amphoteric starch

The invention discloses a method for preparing low-viscosity amphoteric starch. The method comprises the following steps: mixing native starch, adding alkali liquor, and feeding 3-chloro-2-hydroxypropyltrimethyl ammonium chloride to perform a cationic etherification reaction for 8.0-24.0 hours; feeding an oxidant solution to oxidize for 3.0-6.0 hours, and adding a reducing agent for reduction; feeding alkenyl succinic anhydride to esterify for 8.0-20.0 hours; neutralizing by a hydrochloric solution, removing liquid, washing, dehydrating, pneumatically drying, cooling and packaging to obtain the product of low-viscosity amphoteric starch. Series of products prepared by the method have electric charge characteristics of anions and cations with different surface activities and different quantitative proportions, as well as different viscosity and mobility ranges, has the advantages of multiple functions and wide application range, and is applicable to non-food industrial applications, such as pesticide, daily-use chemical thickening agents, emulsifiers or microcapsule embedding materials with good effect.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing amphoteric starch

The invention discloses a method for preparing amphoteric starch. The method comprises the following steps of: (1) weighing the following raw material components by mass weight: 1 percent of starch, 0.1 to 2 percent of cationic monomer, 0.1 to 2 percent of anionic monomer, 0.1 to 2 percent of acrylamide and 0.1 to 20 percent of water, and weighing an initiator in an amount which is 0.1 to 3 percent of the total weight of the cationic monomer, the anionic monomer and the acrylamide; (2) pasting the starch by using the water, then adding the cationic monomer, the anionic monomer, acrylamide andthe initiator, and reacting for 0.5 to 10 hours at the temperature of 25-80 DEG C; and (3) cooling and drying, thus obtaining the amphoteric starch. The method has the characteristics of wide raw material source, simple process and the like, and is easy to biodegrade. The prepared amphoteric starch has the characteristics of anionic starch and cationic starch, is wide in application range, and can be used in neutral, acid and alkali media. Moreover, in different media, the carried ion type is different, and the amphoteric starch is particularly suitable for treating pollutants with different charges.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Flocculation sterilization difunctional grafting starch water treatment agent and preparation method thereof

InactiveCN104804139ANo toxicityNo secondary pollutionWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationFlocculationAmination

The invention discloses a flocculation sterilization difunctional grafting starch water treatment agent and a preparation method thereof. The flocculation sterilization difunctional grafting starch water treatment agent is a grafting amphoteric starch water treatment agent which is obtained by virtue of grafting copolymerization and tertiary amination reaction of anionic starch and acrylamide, and the molecular formula of the flocculation sterilization difunctional grafting starch water treatment agent is expressed as follows: (see the specifications), wherein in the grafting amphoteric starch water treatment agent, the substitution ratio of anion groups is 1 to 50 percent, the substitution ratio of cation tertiary amine salt is 5 to 70 percent, and the polyacrylamide accounts for 5 to 80 percent in the grafting amphoteric starch water treatment agent. The preparation method of the flocculation sterilization difunctional grafting starch water treatment agent comprises the following steps: (1) preparing anionic starch; (2) preparing polyacrylamide grafting cation starch; (3) preparing the flocculation sterilization difunctional grafting amphoteric starch water treatment agent. The flocculation sterilization difunctional grafting starch water treatment agent has advantages of excellent flocculation effect and good sterilization performance.

Owner:NANJING UNIV

Paper having enhanced dry strength and wet strength

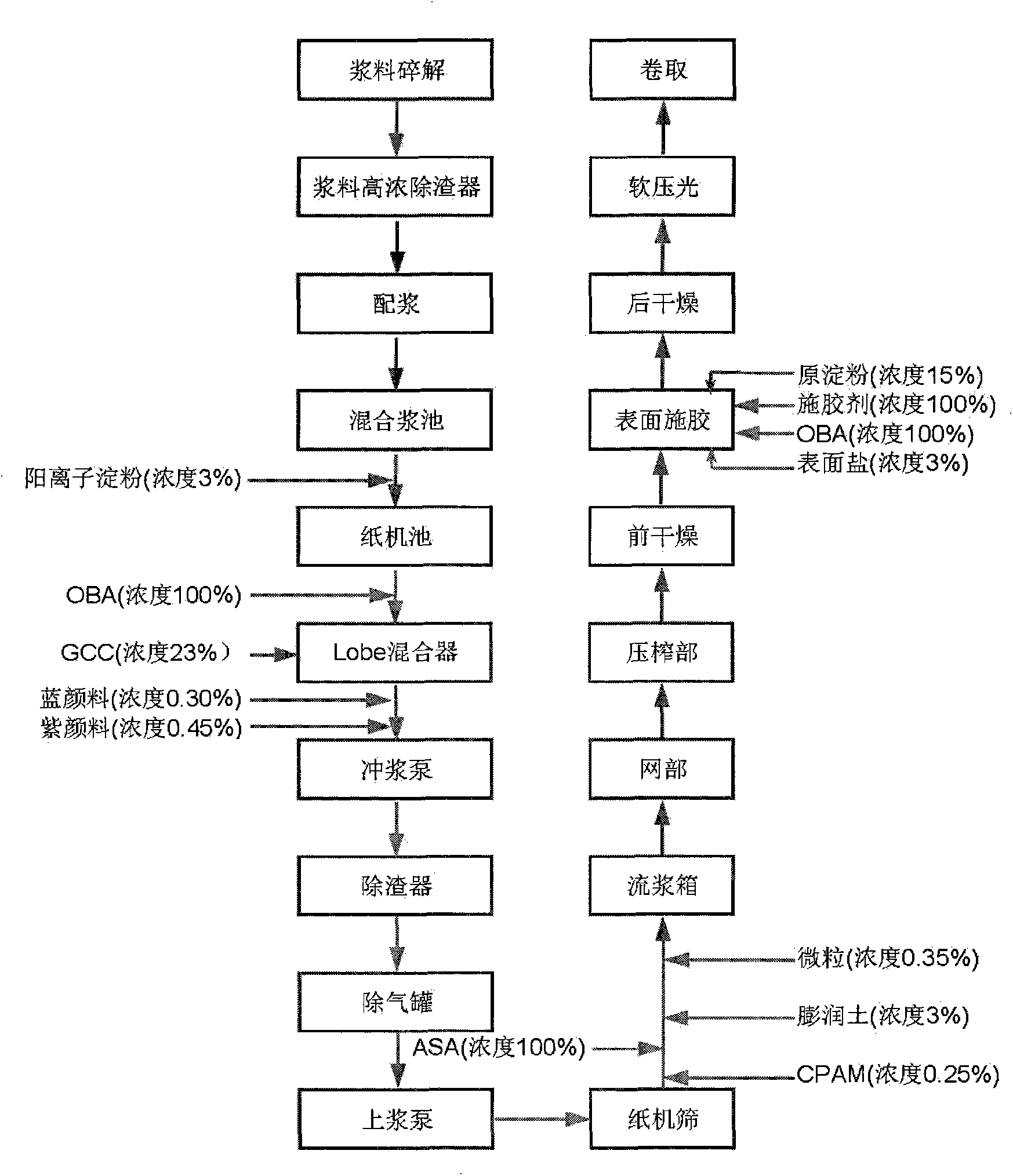

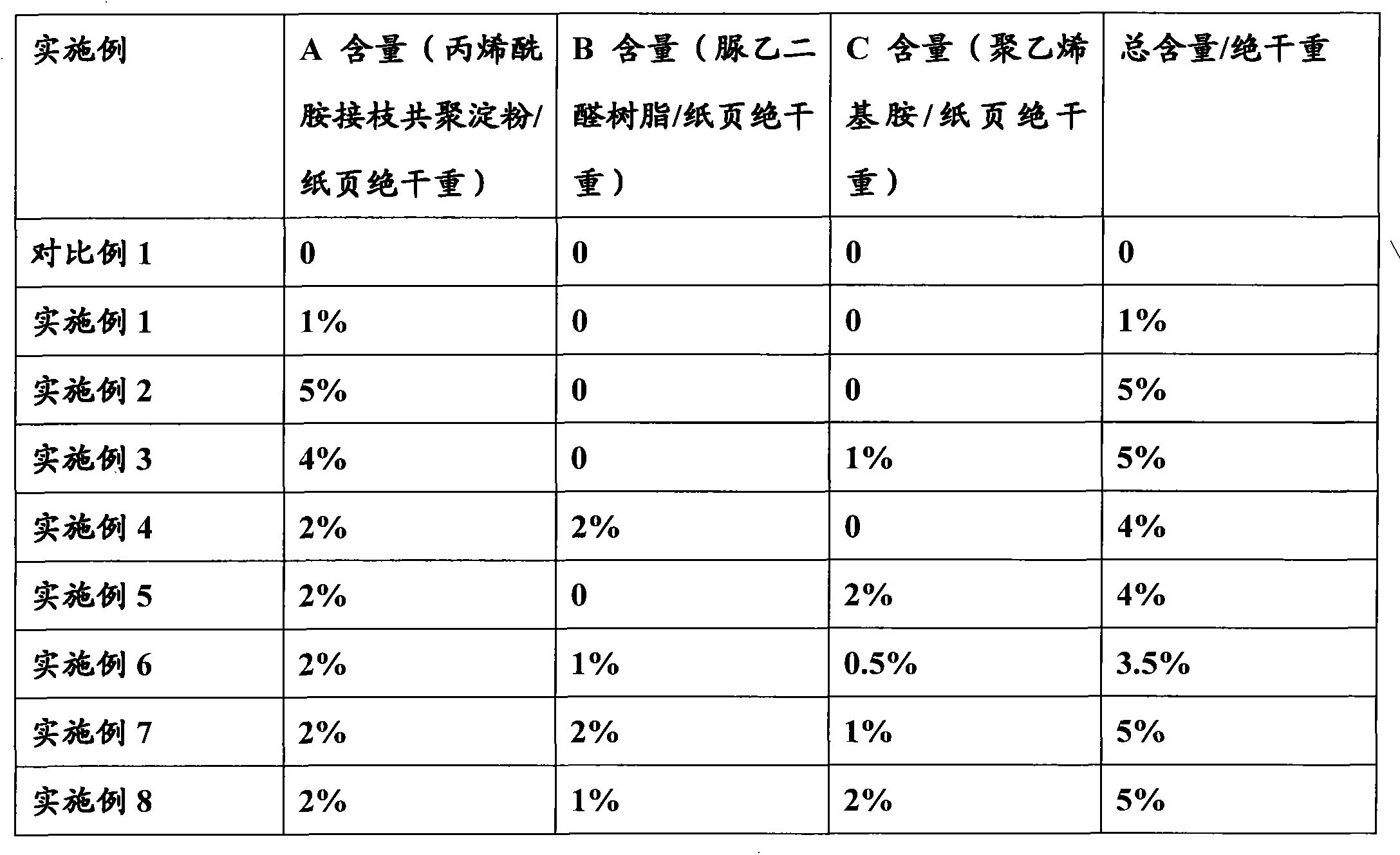

The invention relates to paper having enhanced dry strength and wet strength, which comprises a mixture of the following enhancers: a) amphoteric starch and / or graft copolymerization starch, b) urea glyoxal resin and c) polyvinylamine, wherein the three enhancers are added into the paper in a manner that the sum of the three enhancers accounts for 0.2-5% of the absolute dry weight of the paper. The invention also relates to an additive composition capable of simultaneously enhancing dry strength and wet strength of paper, which comprises: a) amphoteric starch and / or graft copolymerization starch, b) urea glyoxal resin and c) polyvinylamine, wherein the ratio of the three is preferably 2:2:1.

Owner:ASIA SYMBOL GUANGDONG PAPER

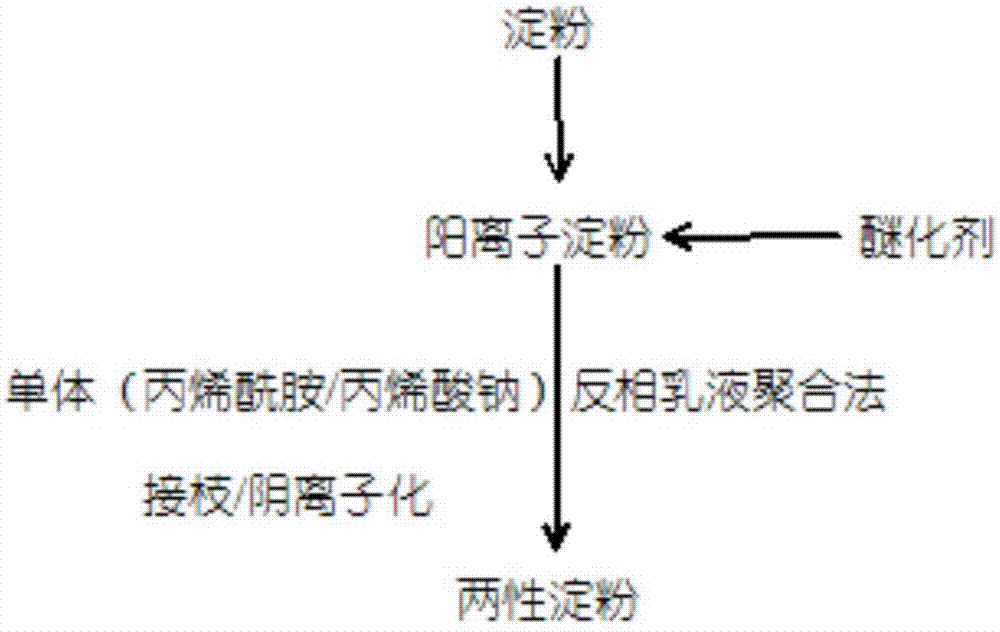

Biological flocculant and preparation method thereof

InactiveCN106957389AHigh molecular weightGood flocculation effectWater/sewage treatment by flocculation/precipitationFlocculationEmulsion polymerization

The invention provides a biological flocculant and a preparation method thereof. The preparation method comprises the following steps: acquiring cationic starch by adopting a semi-dry process for performing cationization treatment on starch, and by taking acrylamide and sodium acrylate as monomers, adopting an inverse emulsion polymerization method for performing graft copolymerization and anionizing treatment on the cationic starch, thereby acquiring the biological flocculant. The flocculation effect of the biological flocculant prepared according to the preparation method provided by the invention is better than that of common cationic starch; the biological flocculant is more effective in flocculating the wastewater containing complex components; the quantity and variety of the charges carried by amphoteric starch can be changed in the manner of regulating the pH value of the solution; and the use scope of the product is widened.

Owner:SHAANXI BANGXI CHEM

Novel environment-friendly energy saving spinning sizing agent and preparation method thereof

The invention discloses a novel environment-friendly energy saving spinning sizing agent. The novel environment-friendly energy saving spinning sizing agent is characterized by comprising the following raw materials in parts by weights: 0.2-0.3 part of oxidized starch, 1.4-1.5 part of cationic starch, 6-6.2 parts of acetic ester starch and 0.15-0.2 part of amphoteric starch. The invention also provides a preparation method of the novel environment-friendly energy saving spinning sizing agent. According to the preparation method, raw materials are wide in the source and low in the cost, the manufacturing cost is low, the novel environment-friendly energy saving spinning sizing agent is easy to degrade and is pollution-free to environment, the preparative technology is simple, environment-friendly and energy-saving.

Owner:重庆东联化工有限公司

Strong-redox biological treatment method for river pollution

ActiveCN106746176AReduce ammoniacal nitrogenReduce nitrousTreatment using aerobic processesTreatment involving filtrationPolyacrylamideOxidation reduction

The invention discloses a strong-redox biological treatment method for river pollution. The method comprises the steps of adding redox treating agent into river wastewater, starting an aeration fan, directly injecting microbubbles into the river wastewater and obtaining pretreatment fluid after treatment, wherein the redox treating agent is prepared from polyacrylamide, amphoteric starch, phosphoric acid, tannic acid, ferric oxide, aluminum sulfate, deionized water and polymerization ferric chloride; arranging the pretreatment fluid into a moving-bed bio-membrane reactor to be treated, then evenly spraying on a biodegradation bed to be treated in a biodegradation mode, finishing biodegradation when wastewater passes through bio-enzyme treating agent and filtering to obtain clean water, wherein the bio-enzyme treating agent is prepared from oxidation-reduction enzyme, cellulase, biological flocculant, chlorella, zoogloea, kieselguhr, sodium gluconate, montmorillonite powder and the like. The strong-redox biological treatment method can effectively remove most pollutant in river wastewater and further has the advantages of high efficiency, environment friendliness and no secondary pollution to environment.

Owner:沃邦环保有限公司

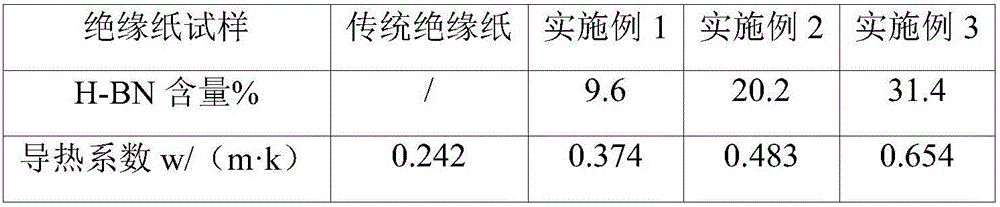

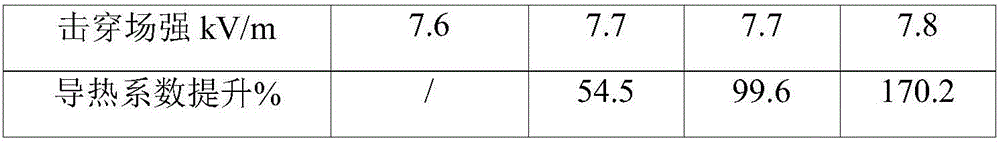

Preparation method of high-heat-conductivity electric-insulation paper

ActiveCN106498810AImprove retentionImprove tightnessPlastic/resin/waxes insulatorsSpecial paperFiberHexagonal boron nitride

The invention discloses a preparation method of high-heat-conductivity electric-insulation paper. The method comprises the following steps: 1) carrying out pretreatment on a natural-color softwood pulp board; 2) carrying out pretreatment on heat-conducting filler particles; 3) carrying out primary fluffing on the pretreated pulp in a fluffer; adding the filler particles treated by the step 2), and carrying out secondary fluffing; finally adding retention aids, and carrying out tertiary fluffing to obtain a suspension; and 4) injecting the suspension obtained in the step 3) into a paper former, carrying out dewatering formation, pressing, and drying to obtain the high-heat-conductivity electric-insulation paper. By using the atural-color softwood pulp fibers and hexagonal boron nitride particles as the raw materials, amphoteric starch and cationic polyacrylamide are used as retention aids to enhance the retention rate of the filler and fine components; and the pulping, filling, fluffing, formation, pressing and drying are carried out to obtain the high-heat-conductivity electric-insulation paper. The high-heat-conductivity electric-insulation paper has the advantages of high heat conductivity coefficient, and can enhance the heat dispersion property when being applied to electrical equipment.

Owner:NANJING FORESTRY UNIV

A process to improve the drain age rate and retention of fines during paper making

A method of improving drainage rate and retention of fines which is effective in unfilled, newsprint-type furnish without a silica / bentonite-type particle is disclosed. The method comprises adding a cationic or amphoteric starch, and a cationic polyelectrolyte followed by the addition of a high molecular weight anionic polyacrylamide copolymer.

Owner:BETZEARBORN INC

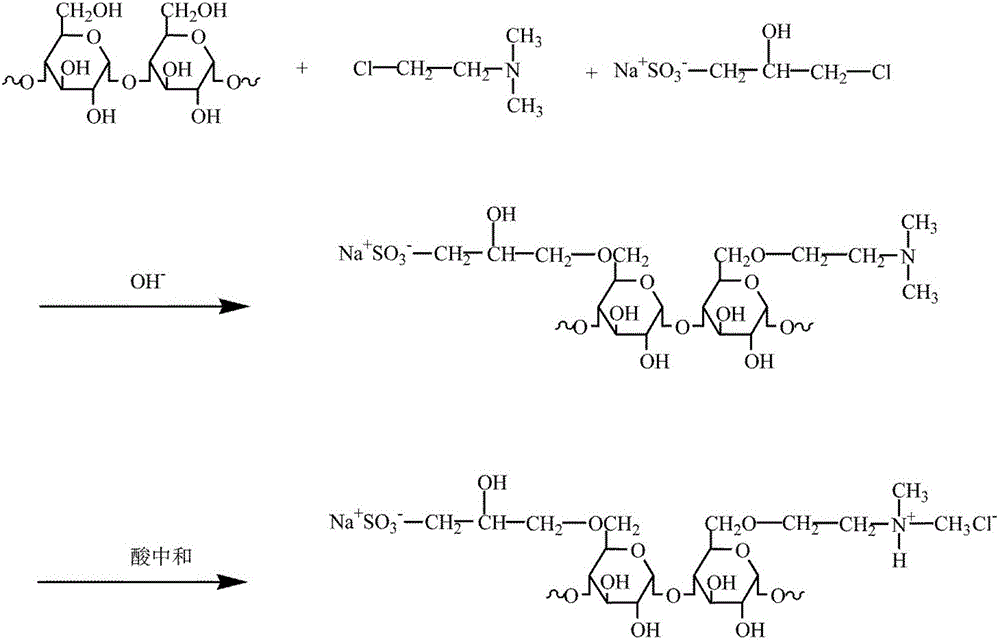

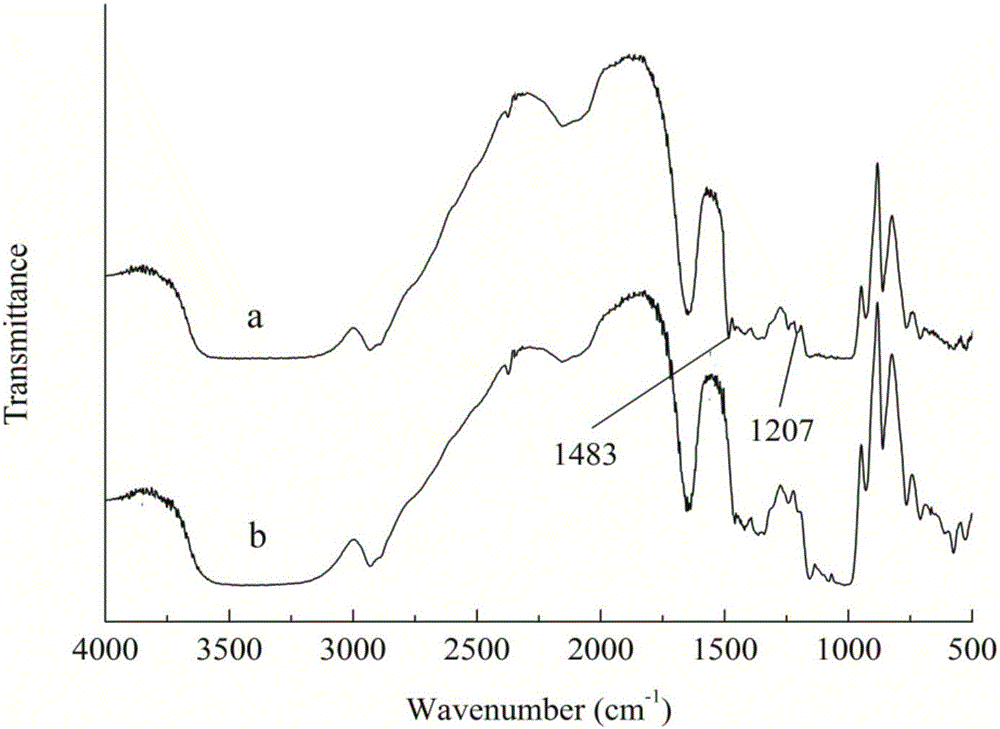

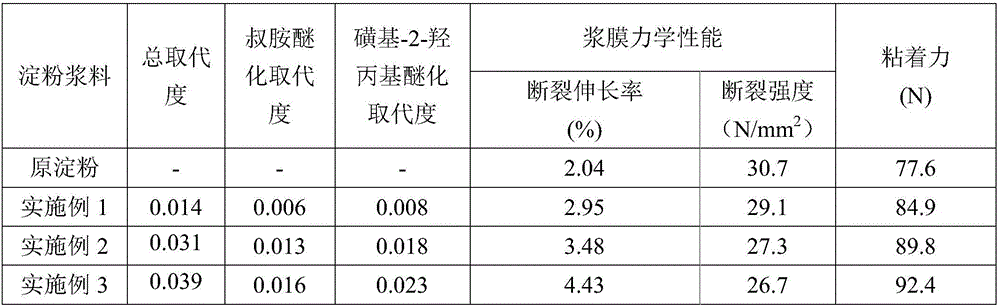

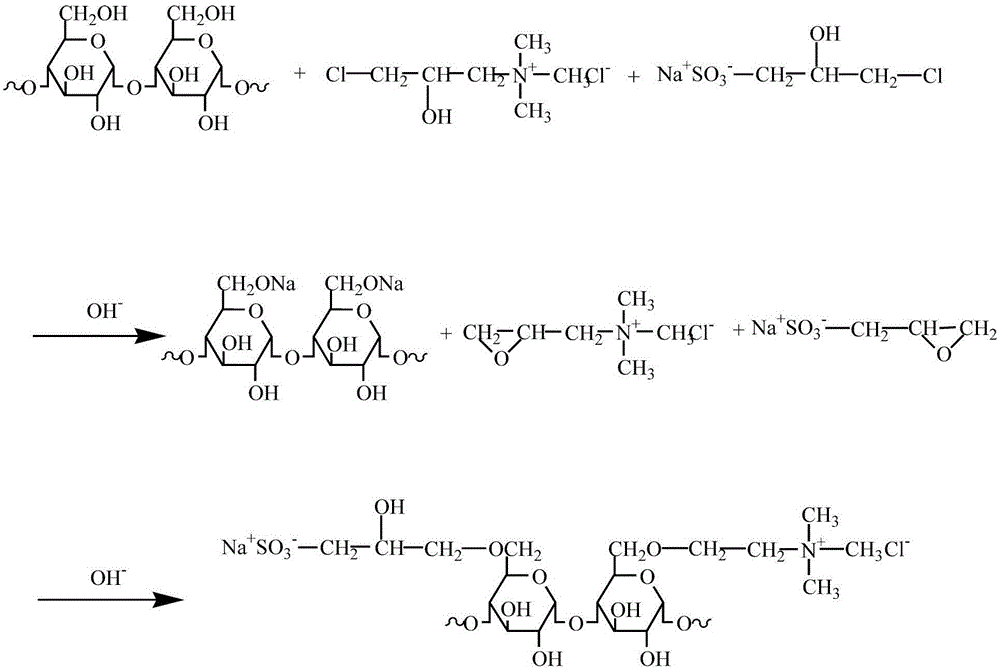

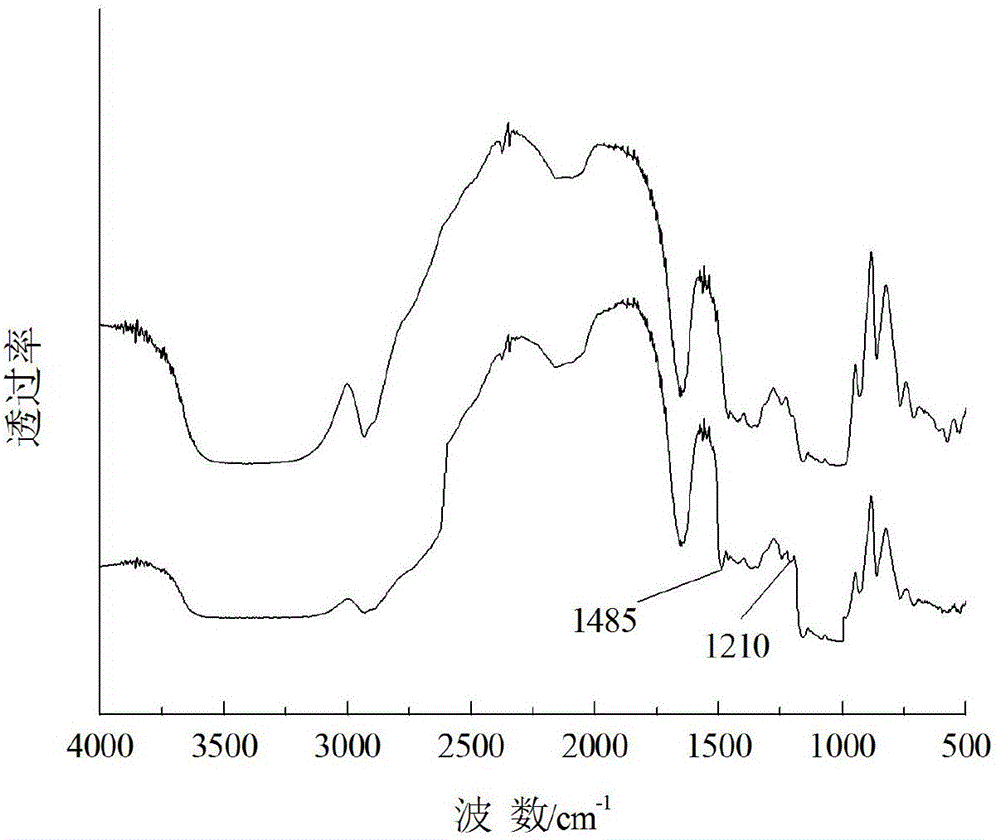

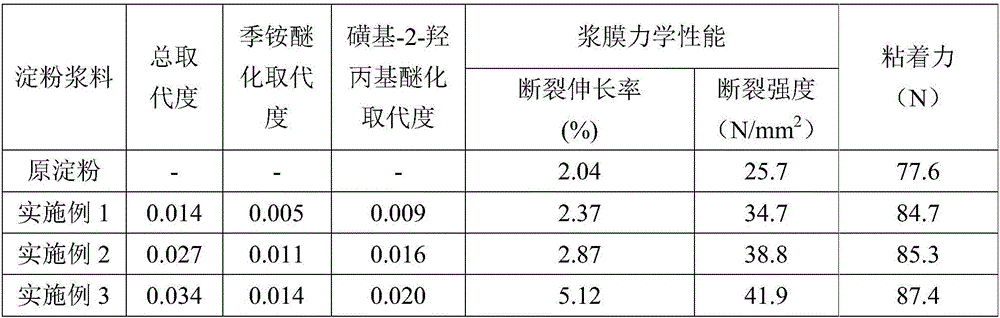

Dual etherified starch, preparing method, and application of dual etherified starch

The invention provides dual etherified starch, a preparing method, and application of the dual etherified starch. According to the technical scheme, tertiary amine positive ions in starch are etherified and sulpho-2-hydroxypropyl in the starch is subjected to etherification and denaturating treatment, the product is neutralized (tertiary amine is subjected to protonation to form positive ion perssad), dehydrated, washed and dried to form dual etherified amphoteric starch slurry. Through the method of adding dimethyl ammonium chloride ethyl and sulfonic acid group hydroxypropyl functional groups while performing the dual etherification and denaturating treatment, the structural defects of the starch are overcome, the mechanical property of starch slurry film is improved, the adhesive force of the starch to fibers like cotton is improved, the using effect of the starch slurry in warp starching of natural fiber and particularly in warp starching of purified cotton is better improved, which is conducive to improvement of the sizing warp quality and improvement of the weaving efficiency.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

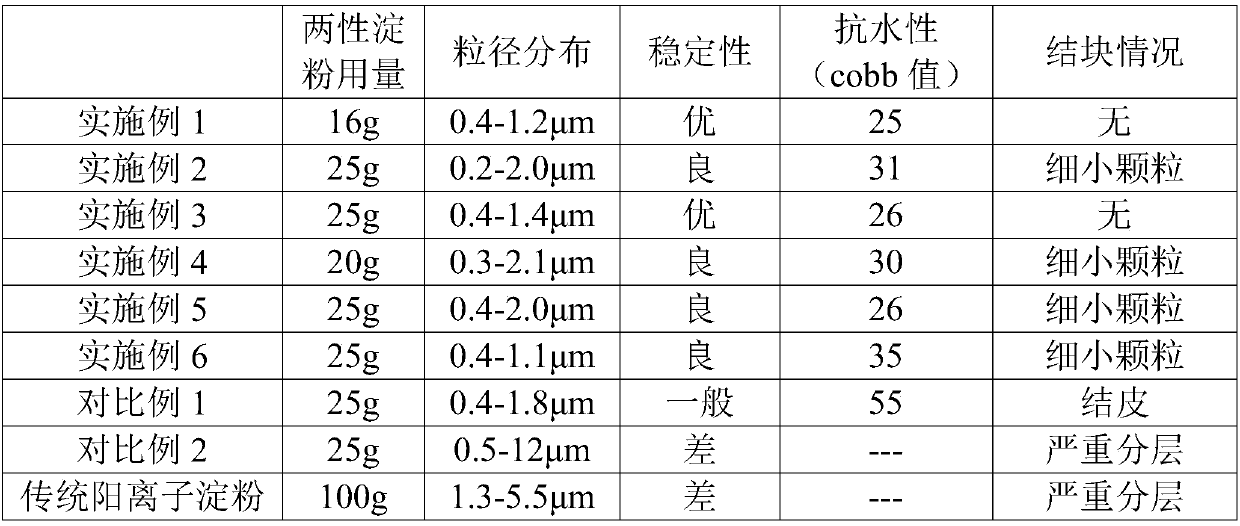

Amphoteric starch for AKD emulsification and preparation method and applications thereof

ActiveCN109651517ASimple structureStrong water resistanceWater-repelling agents additionPaper/cardboardEmulsionRoom temperature

The invention relates to an amphoteric starch for AKD emulsification and a preparation method and applications thereof. The preparation method comprises following steps: (1) adding starch into a solvent, then adding an alkali, and stirring for 30 to 120 minutes; (2) heating the reaction solution obtained in the step (1) to a temperature of 40 to 80 DEG C, then adding an cationic etherifying agent,carrying out reactions for 1 to 10 hours, adding a viscosity reducer, and carrying out reactions for 0.5 to 3 hours; and (3) adding an anionic etherifying agent into the reaction solution obtained inthe step (2), adjusting the pH value of the reaction solution to 9-14 by adding an alkali, carrying out reactions for 1 to 6 hours at a temperature of 40 to 80 DEG C; carrying out neutralization, washing, and drying to obtain the amphoteric starch. The prepared amphoteric starch has the advantage that the using amount of an emulsifying agent is greatly reduced during the AKD emulsification process. Moreover, the prepared AKD emulsion has the characteristics of uniform particle size distribution and good stability and can be stably stored for six months at a room temperature.

Owner:GUANGZHOU TINCI MATERIALS TECH

Dry strength agent, preparation method thereof and slurry using dry strength agent

The invention provides a dry strength agent used in the paper making field, the dry strength agent comprises a reaction product of amphoteric starch and one or two selected from polyamide polyamine epichlorohydrin resin and polyamide polyurea resin, and polyacrylamide powder, the amphoteric starch is produced by reacting an anionic etherifying agent and a cationic etherifying agent with raw starch in alkaline conditions, and the anionic etherifying agent is monochloroacetic acid. The invention also provides a preparation method of the dry strength agent and paper slurry using the dry strength agent. The dry strength agent can be well and stably combined with fiber, the retention and draining are improved, the content in white water is less, and the white water system pollution is not easy to produce.

Owner:GOLD EAST PAPER JIANGSU

Amphoteric starch and preparing method thereof

The invention relates to amphoteric starch and a preparing method thereof. The amphoteric starch is characterized by being prepared from water serving as solvent, succinic anhydride serving as an anionized reagent, 3-chloro-2-hydroxypropyl-trimethylammonium chloride serving as a cationic etherifying agent, an acid-base pH modifier and a starch particle swelling inhibiting agent, and when different amounts of the cationic etherifying agent and the anion esterifying agent are added, a series of amphoteric starch products with different properties can be obtained. The novel anion chemical agent on a wet process production technology device is obtained, then the amphoteric starch with positive charges and negative charges at the same time is obtained, and according to the molecular structure characteristic of the products, groups with different polarity charges are connected to the different positions of the same molecular chain. The obtained amphoteric starch is excellent in performance, and low in cost, and the problems of the complex wet process and dry method two-step denaturation technology and the unstable quality in amphoteric starch industrial production are solved.

Owner:SHANGHAI YINGMEI ELECTRICAL & MECHANICAL ENG CO LTD

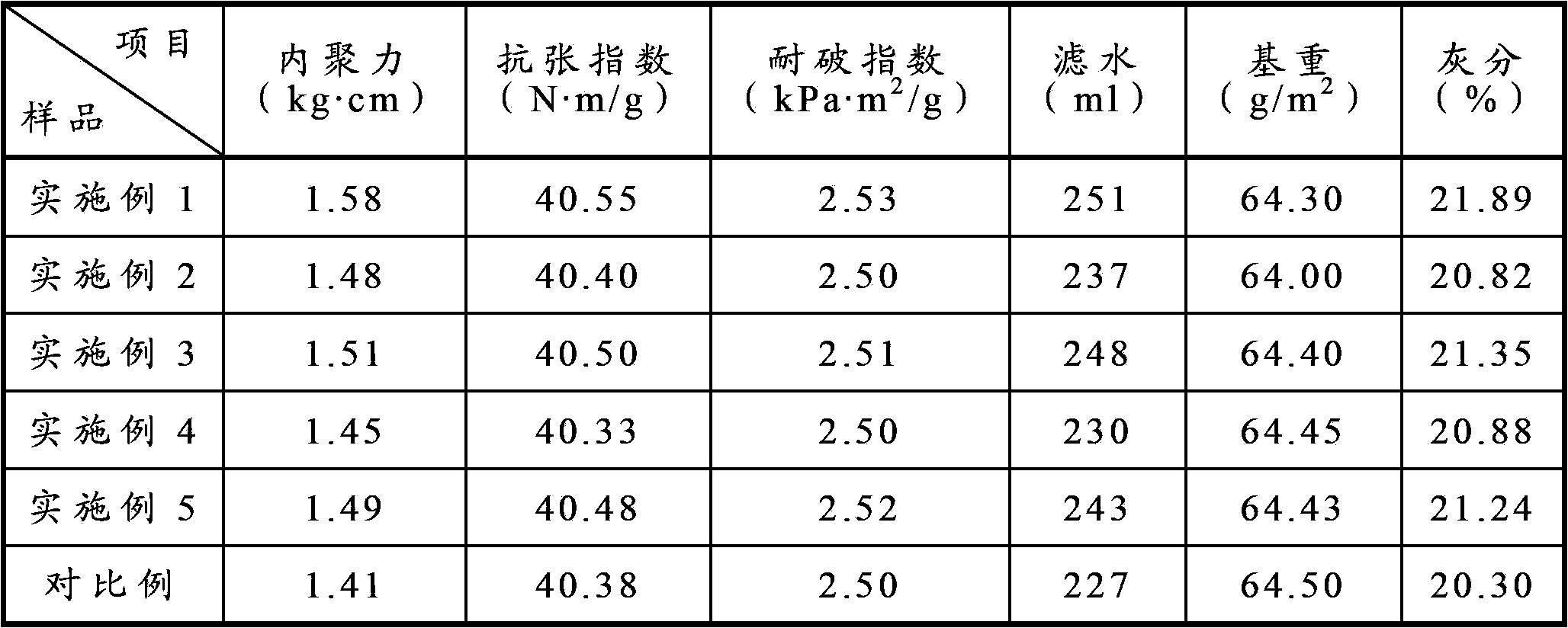

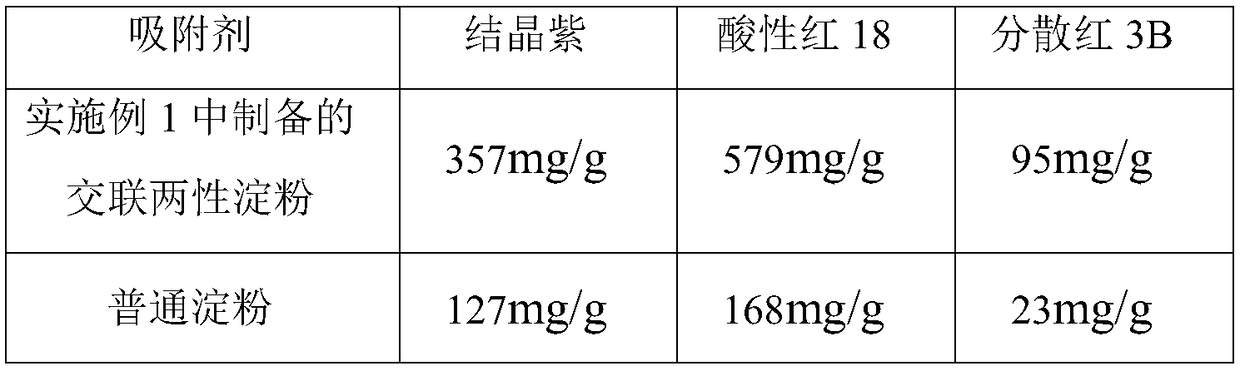

Preparation method for cross-linked amphoteric starch

The invention discloses a preparation method for cross-linked amphoteric starch, which is specifically implemented according to the following steps: starch is firstly dispersed into water, so that gelatinized starch is obtained; the gelatinized starch is then added with cationic monomer and anionic monomer and agitated for 30 minutes, a cross-linking agent and an initiator then continously are added, reaction temperature is controlled at 40 DEG C to 80 DEG C, and after 24 to 48 hours of agitation, a gelatinous product is obtained; finally, deionized water is then used for soaking and washingthe gelatinous product, and the gelatinous product is dried until weight is constant, so that the cross-linked amphoteric starch is obtained. The technique adopted by the method is simple and easy toimplement, the prices of the used materials are low, and the cost is low; moreover, because the cross-linked amphoteric starch prepared by the method cannot be dissolved into water, the cross-linked amphoteric starch can be easily separated from treated wastewater, and thereby the treatment cost is effectively reduced.

Owner:XI'AN POLYTECHNIC UNIVERSITY

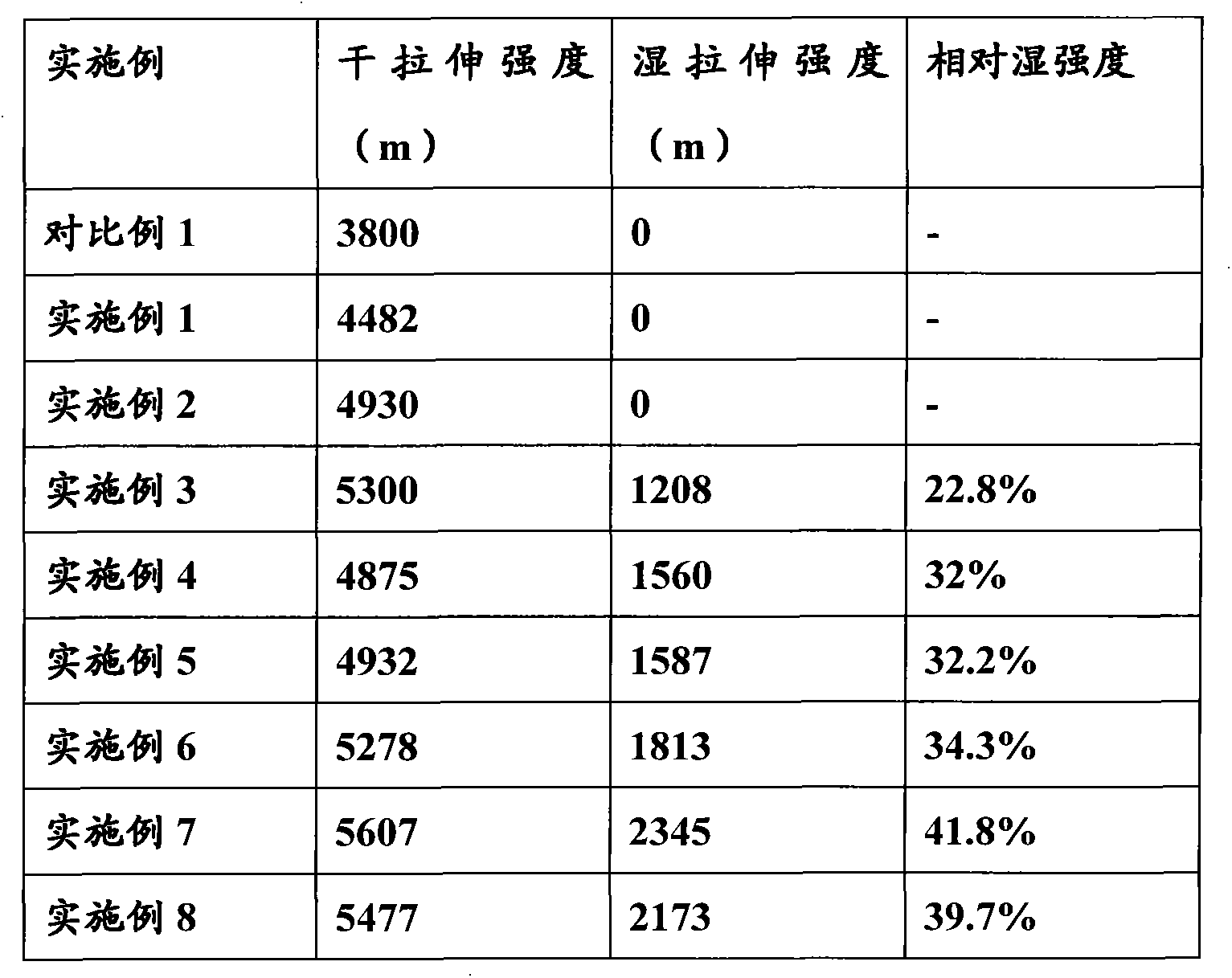

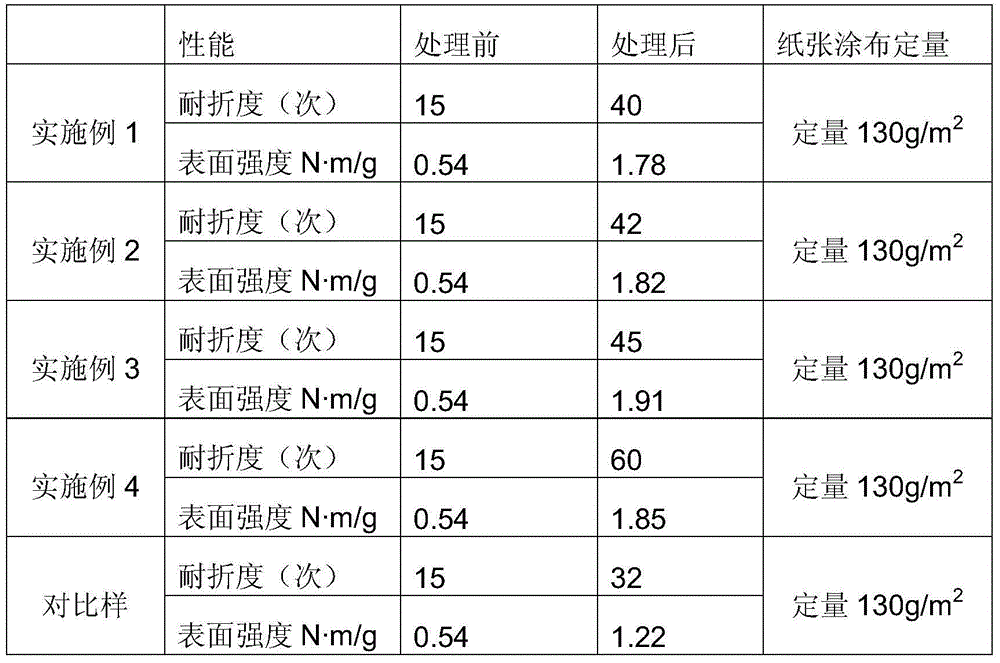

Paper fold-resistance reinforcing agent and preparation method thereof

InactiveCN105586805AHigh affinityGood film formingReinforcing agents additionSlurryUltimate tensile strength

The invention provides a preparation method of a paper fold-resistance reinforcing agent. The method comprises the following steps: 1, mixing starch, water, hydroxide, hypochlorite or persulfate, and a cationic etherifying agent and reacting to prepare amphoteric starch; 2, mixing resin and the amphoteric starch and reacting at 70-95 DEG C for 30-60 min; and 3, mixing a product obtained in the Step 2 and polyacrylamide and reacting at 60-80 DEG C for 30-120 min so as to obtain the fold-resistance reinforcing agent. On the precondition of reducing the wood-pulp ratio of slurry, by surface sizing or coating of the fold-resistance reinforcing agent prepared by the method, fold resistance of paper is raised. Meanwhile, in comparison with a traditional technology, surface strength is enhanced; and in comparison with the prior art, fold resistance and surface strength are both greatly improved.

Owner:DSSUN NEW MATERIAL SHANDONG

Quaternary ammonium etherified-sulfo-2-hydroxypropyl etherified starch as well as preparation method and application thereof

ActiveCN106632705AGood water dispersibilityChange chemical structureVegetal fibresNatural fiberMechanical property

The invention provides a quaternary ammonium etherified-sulfo-2-hydroxypropyl etherified starch as well as a preparation method and an application thereof. Starch is subjected to quaternary ammonium cationic etherification and sulfo-2-hydroxypropyl etherification denaturation treatment, a product is neutralized, dehydrated, washed and dried, and dual-etherification amphoteric starch size is obtained. With the adoption of a method for introducing hydroxypropyltrimethyl ammonium chloride and sulfonyl hydroxypropyl functional groups simultaneously into starch molecule chains through dual-etherification denaturation, structural defects of the starch are overcome, mechanical properties of a starch size film are improved, adhesive force of the starch to fibers such as cotton and the like is improved, the use effect of the starch size for sizing of natural fiber warp, especially, sizing of pure cotton warp is better improved, and improvement of sizing quality and weaving efficiency is facilitated.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

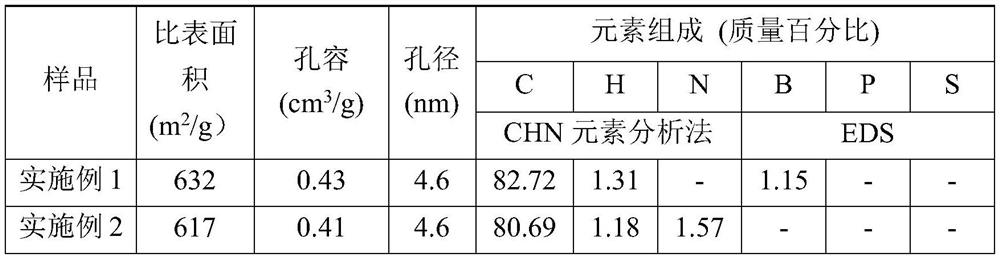

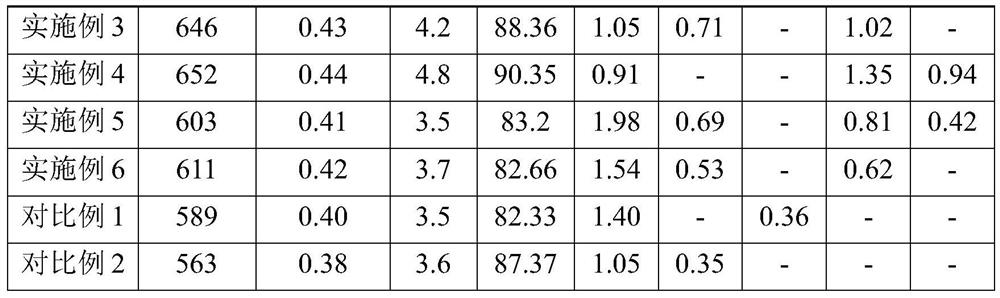

Heteroatom doped starch carbon and preparation method thereof

ActiveCN112551507AIncrease added valueRealize large-scale productionCarbon preparation/purificationOrganic acidHeteroatom

The invention discloses heteroatom-doped starch carbon and a preparation method thereof. The preparation method comprises the following steps: 1, drying modified starch containing heteroatoms, addinginto an organic acid solution to be evenly mixed, standing, and then drying so that a heteroatom-doped starch carbon precursor is obtained, wherein the modified starch is one or more of cationic starch, anionic starch and amphoteric starch, and (2) heating the heteroatom-doped starch carbon precursor to 400-1000 DEG C at a rate of 1-10 DEG C / min under the protection of an inert atmosphere, and roasting at a constant temperature for 0.5-5 h to obtain the heteroatom-doped starch carbon. The preparation method is simple and easy to operate, the production cost is greatly reduced, and the problemsthat an existing heteroatom doped carbon material is low in yield and small in doping amount are solved.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing low-viscosity amphoteric starch by using dilutedly cooked starch

The invention discloses a method for preparing low-viscosity amphoteric starch by using dilutedly cooked starch, which comprises the following steps: adding water into the dilutedly cooked starch to carry out paste mixing, adding alkali liquor, ceaselessly feeding 3-chloro-2-hydroxypropyltrimethyl ammonium chloride to carry out a cationic etherifying reaction, and reacting for 8.0-24.0 hours; and ceaselessly feeding alkenyl succinic anhydride to carry out esterification, reacting for 8.0-20.0 hours, and carrying out hydrochloric solution neutralization, fluid exhaustion, washing, dehydration, pneumatic drying, cooling, and packaging on the obtained product, so that low-viscosity amphoteric starch is obtained. According to the invention, multifunctional amphoteric starch series products which are different in fluidity, viscosity, surface activity, and quantitative proportions of anionic and cationic electric charge characteristics can be prepared by selecting dilutedly cooked starch such as acid-modified starch, oxidized starch, and the like which are different in fluidity and viscosity and insoluble in cold water as raw materials, therefore, the method is wide in application scope, good in effect, and applicable to the industrial applications of non-foods such as pesticides, daily chemical thickening agents, emulsifiers, or microcapsule embedding materials, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Water body purifier based on kieselguhr

InactiveCN108658135AWide variety of sourcesLow costWater/sewage treatment by irradiationWater treatment compoundsSolventAmphoteric starch

The invention relates to the technical field of water body purifiers and in particular relates to a water body purifier based on kieselguhr. The water body purifier based on kieselguhr is prepared from the following substances in parts by weight: 80-150 parts of kieselguhr, 20-40 parts of starch, 5-6 parts of glutaraldehyde, 30-60 parts of polyhydroxy-alcohol, 5-10 parts of acrylamide, 1-3 parts of an initiator, 0.1-0.5 part of organic silicate ester, 10-30 parts of organic titanate, 2-6 parts of a silane coupling agent and 50-60 parts of a solvent. As the kieselguhr, the grafted amphoteric starch and the modified titanium dioxide are compounded, the water body purifier has integral functions of adsorption, flocculation, catalytic degradation and the like, and a function of purifying waterbodies in all directions is achieved. In addition, the water body purifier provided by the invention is wide in raw material source, low in cost, wide in application range and wide in application prospect.

Owner:ANHUI LEJIN ENVIRONMENT TECH CO LTD

Manufacturing process for filling Nixing pottery green body with white clay

The invention discloses a manufacturing process for filling a Nixing pottery green body with white clay. The manufacturing process comprises the steps of preform body preparation, green body forming, painting, engraving, clay filling, drying and firing; in the clay filling step, a layer of ferric oxide powder and a layer of amphoteric starch are uniformly sprayed in engraved grooves, and then the engraved grooves are filled with the white clay; the white clay is formed by mixing eastern clay and western clay according to the weight ratio of (7-8):(2-3) and then processing the mixture according to the manufacturing process of a preform body; in the drying step, the green body filled with the clay is processed for 1-5 min under the condition of 10-15 Mpa and then aired naturally. By adding ferric oxide particles, electrostatic attraction between the white clay and the green body can be greatly enhanced; molecular long chains of the amphoteric starch have intertwining and cross-linking functions, so that the white clay and the preform body are tightly combined, certain water retention uniformity is also achieved, dewatering is more uniform, and neither cracking nor falling occurs.

Owner:钦州市永和坭兴陶艺有限公司

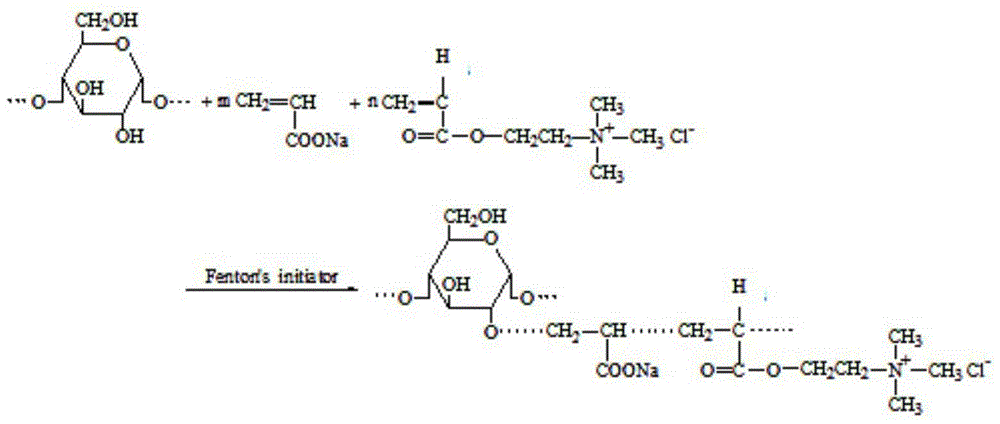

Preparation method of amphoteric starch size

The invention discloses a preparation method of amphoteric starch size. The method comprises the following steps: preparing an ATS (amylomaltase-treated starch) water solution with mass fraction of 20-50%, regulating the pH value of the ATS water solution to be 3-5, carrying out heating, stirring, nitrogen pumping and other treatment processes, dropwise adding 10-20g of grafted monomer, adding Fe2<+>-H2O2 as an initiator, reacting for 1-3 hours under the protection of nitrogen, adding 1.6-5mL of hydroquinone solution with mass fraction of 2%, regulating the pH value of the reactant to be 4-7 with 1-3mol / L of NaCO3 solution and then carrying out filtering, vacuum drying, grinding, sieving and other treatment processes, thus obtaining the product, wherein the mole ratio of DAC to sodium acrylate in the grafted monomer is (0.5-2) to 1. The amphoteric starch size disclosed by the invention has the advantages of simple process, high sizing viscosity, easiness in desizing, and the like, and is mainly applied to the field of warp sizing.

Owner:刘桂芹

Production method of high-strength textile spool paper

InactiveCN107587380AImprove stress resistanceNon-fibrous pulp additionSpecial paperWinding machineMaterials preparation

The invention provides a production method of high-strength textile spool paper. The production method comprises the following steps: 1) material preparation: adopting waste paper as main materials; in addition, preparing amphoteric starch, cationic starch, sprayed starch, rosin and an aluminum-sulfate precipitation agent as auxiliary materials; and 2) treating the materials by a hydraulic pulperand a round-net thickener to obtain a semifinished product, then treating the semifinished product by a centrifugal sieve and the round-net thickener to obtain paper pulp, treating the paper pulp by anet part, pressing, drying, and treating by a calendering machine, a paper winding machine and a rewinding machine to obtain the high-strength textile spool paper. The production method provided by the invention has the advantage that the produced textile spool paper has the technical effects of good compression resistance and no layering.

Owner:HAIAN JINXIN PAPER IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com