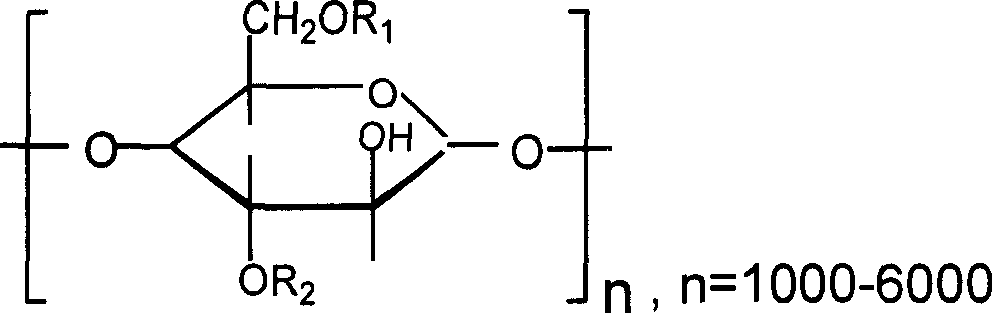

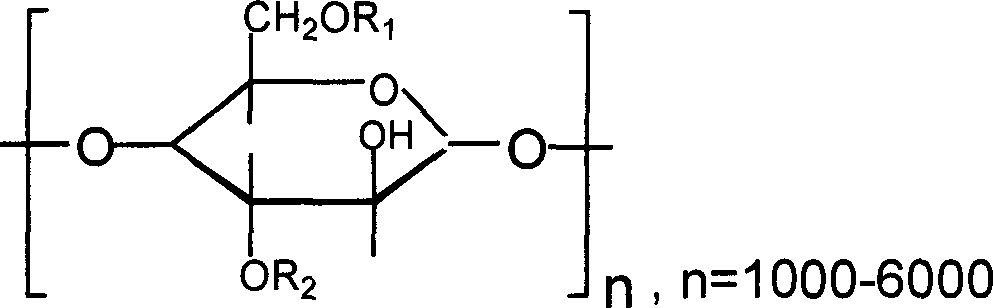

Synthesis of soluble amphoteric starch

A technology of amphoteric starch and synthesis method, which is applied in the field of synthesis of water-soluble amphoteric starch, can solve the problems of serious environmental pollution, complex preparation process, harsh reaction conditions, etc., and achieve high purity, reduce environmental pollution, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

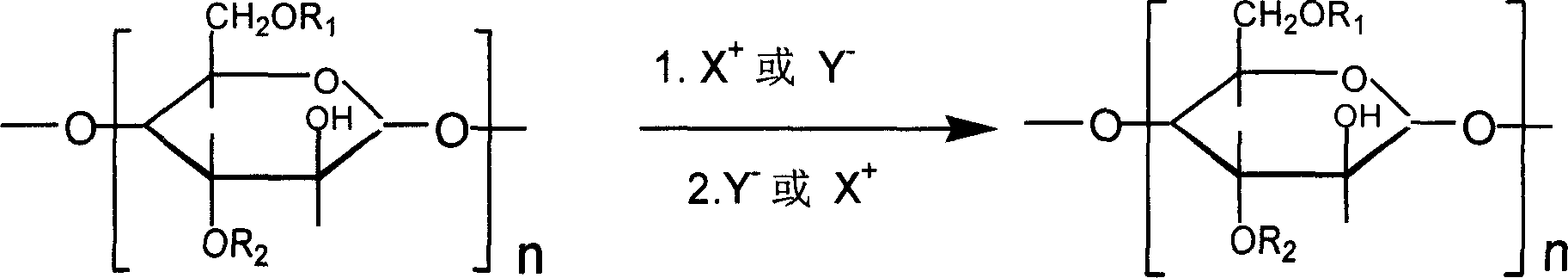

Method used

Image

Examples

Embodiment 1

[0021] Add 1000g of starch and 50g of powdery sodium hydroxide into a special reaction kettle and stir thoroughly for 10min, spray into 200ml of 20% isopropanol, and fully stir for 30min at a temperature of 50°C. Then 500g of N-(2,3-epoxypropyl)trimethylammonium chloride (GTA) was added, and after stirring at this temperature for 30min, the temperature was raised to 80°C for 3h. Cool down to 35°C, add 50ml of carbon disulfide and 25g of magnesium oxide, seal and react at 35°C for 30 minutes, and pulverize to obtain fine powder cationic starch sulfonate.

Embodiment 2

[0023] 1000g of starch and 50g of powdered sodium hydroxide were fully stirred in a special reaction kettle for 10min, then sprayed into 100ml of N,N-dimethylformamide, heated to 50°C and stirred for 30min. Then successively spray 150ml sodium chloroacetate solution (50g chloroacetic acid dissolved in 40% sodium hydroxide aqueous solution), 200mL quaternary ammonium salt solution (600g 3-chloro-2-hydroxypropyltrimethyl ammonium chloride dissolved in 10% carbonic acid sodium aqueous solution), fully stirred for 30 minutes, heated to 80°C for 3 hours, and pulverized to obtain white fine powder carboxymethyl cationic starch.

Embodiment 3

[0025]Add 1000g of starch and 350mL of quaternary ammonium salt solution (530g of 3-chloro-2-hydroxypropyltrimethylammonium chloride dissolved in 40% sodium hydroxide aqueous solution) and 30ml of fatty alcohol polyoxygen into a special reaction kettle Vinyl ether, stir well for 15 minutes, then raise the temperature to 50°C and stir for 30 minutes, then raise the temperature to 80°C for 3 hours, add 40g of succinic anhydride and 25g of calcium oxide, stir and mix evenly, raise the temperature to 130°C for 1 hour, and pulverize to obtain a fine powder Cationic starch succinate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com