Dual etherified starch, preparing method, and application of dual etherified starch

An etherified starch, dual technology, applied in fiber processing, textiles and papermaking, fiber types, etc., can solve the problems of poor serosal mechanical properties, poor starch adhesion, etc., and achieve improved serosal mechanical properties, high adhesion, Good serosal mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

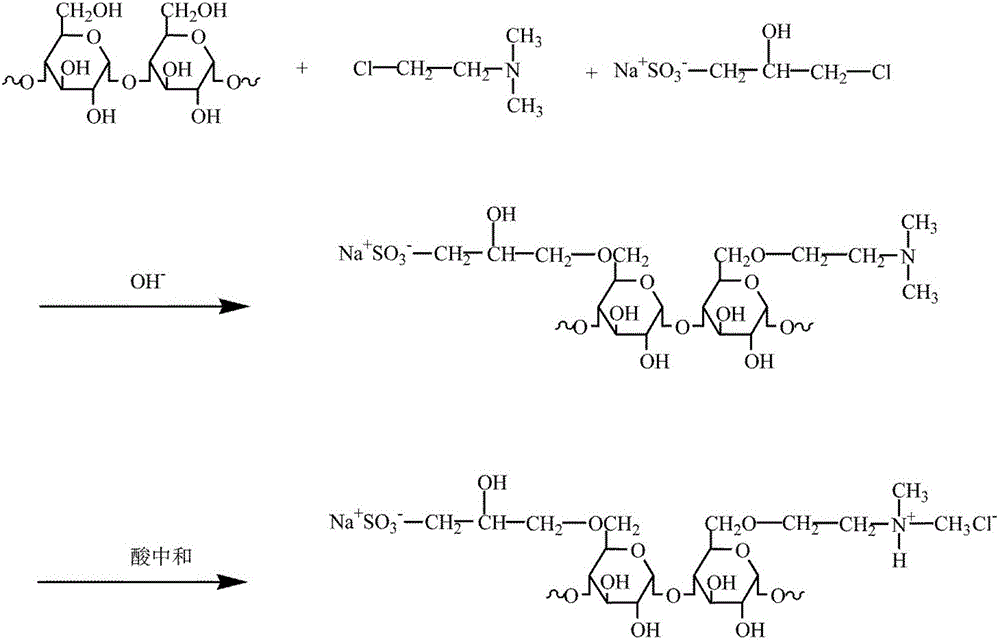

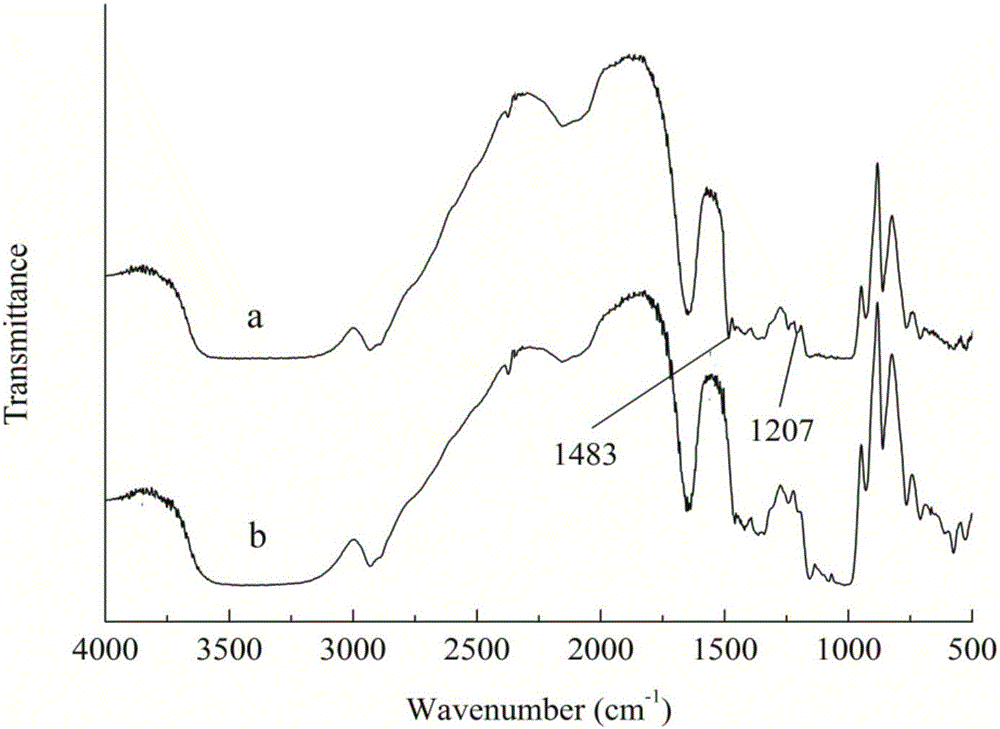

Method used

Image

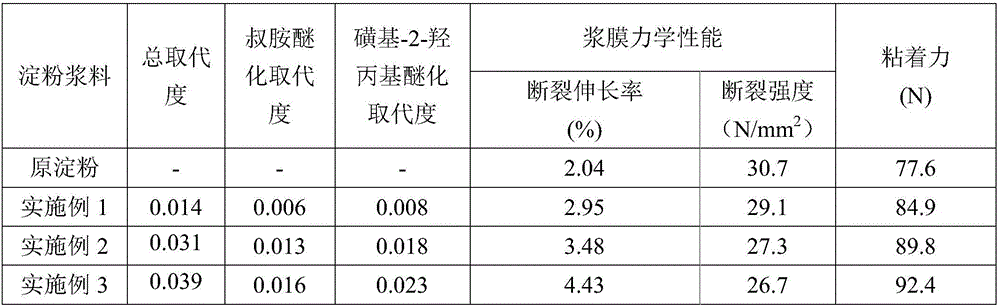

Examples

Embodiment 1

[0037] A preparation method of double etherified starch, comprising the following steps:

[0038] 1) Disperse 324g (dry weight) of acid-thinned cornstarch in distilled water containing 32.4g of sodium sulfate to make a 40% (w / w) starch emulsion, transfer the starch emulsion into a 1000mL four-neck flask, and put The stirring device is placed in a water bath, the pH of the system is adjusted to 10-11.5 with a 3% sodium hydroxide solution, and the temperature is raised to 45° C. to keep the temperature.

[0039] 2) Weigh 10g of 2-dimethylaminochloroethane hydrochloride, add 10mL of water to dissolve it, put it into a 100mL beaker, neutralize it with 3mol / L sodium hydroxide solution, add 10g of 3- Sodium chloro-2-hydroxypropylsulfonate, a mixed aqueous solution composed of 2.04g sodium hydroxide and 27g water, stirred evenly; the molar ratio of sodium hydroxide to sodium 3-chloro-2-hydroxypropylsulfonate is 1:1;

[0040] 3) Add the mixed solution prepared in step 2) to the starc...

Embodiment 2

[0044] A preparation method of double etherified starch, comprising the following steps:

[0045] 1) Disperse 324g (dry weight) of acid-thinned cornstarch in distilled water containing 32.4g of sodium sulfate to make a 40% (w / w) starch emulsion, transfer the starch emulsion into a 1000mL four-neck flask, and put The stirring device is placed in a water bath, the pH of the system is adjusted to 10-11.5 with a 3% sodium hydroxide solution, and the temperature is raised to 45° C. to keep the temperature.

[0046] 2) Weigh 16g of 2-dimethylaminochloroethane hydrochloride, add 16mL of water to dissolve it, put it into a 100mL beaker, neutralize it with 3mol / L sodium hydroxide solution, add 16g of 3-chloro - Sodium 2-hydroxypropyl sulfonate, a mixed aqueous solution formed by 3.26g sodium hydroxide and 37g water, stirred evenly, the molar ratio of sodium hydroxide to 3-chloro-2-hydroxypropyl sodium sulfonate is 1:1;

[0047] 3) Add the mixed solution prepared in step 2) to the star...

Embodiment 3

[0051] A preparation method of double etherified starch, comprising the following steps:

[0052] 1) Disperse 324g (dry weight) of acid-thinned cornstarch in distilled water containing 32.4g of sodium sulfate to make 40% (w / w) starch milk, transfer the starch milk into a 1000mL four-neck flask, and put The stirring device is placed in a water bath, and the pH of the system is adjusted to 10-11.5 with a sodium hydroxide solution with a mass fraction of 3%, and the temperature is raised to 45°C to keep the temperature;

[0053] 2) Weigh 26g of 2-dimethylaminochloroethane hydrochloride, add 26mL of water to dissolve it, put it in a 100mL beaker, neutralize it with 3mol / L sodium hydroxide solution, add 26g of 3-chloro -Sodium 2-hydroxypropyl sulfonate, a mixed aqueous solution formed by 4.23g sodium hydroxide and 45g water, stir evenly, the molar ratio of sodium hydroxide to 3-chloro-2-hydroxypropyl sulfonate sodium is 1:1;

[0054] 3) Add the mixed solution prepared in step 2) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com