Application of molybdenum disulfide/nanosilver composite serving as matrix to matrix-assisted laser desorption/ionization time of flight mass spectrometry

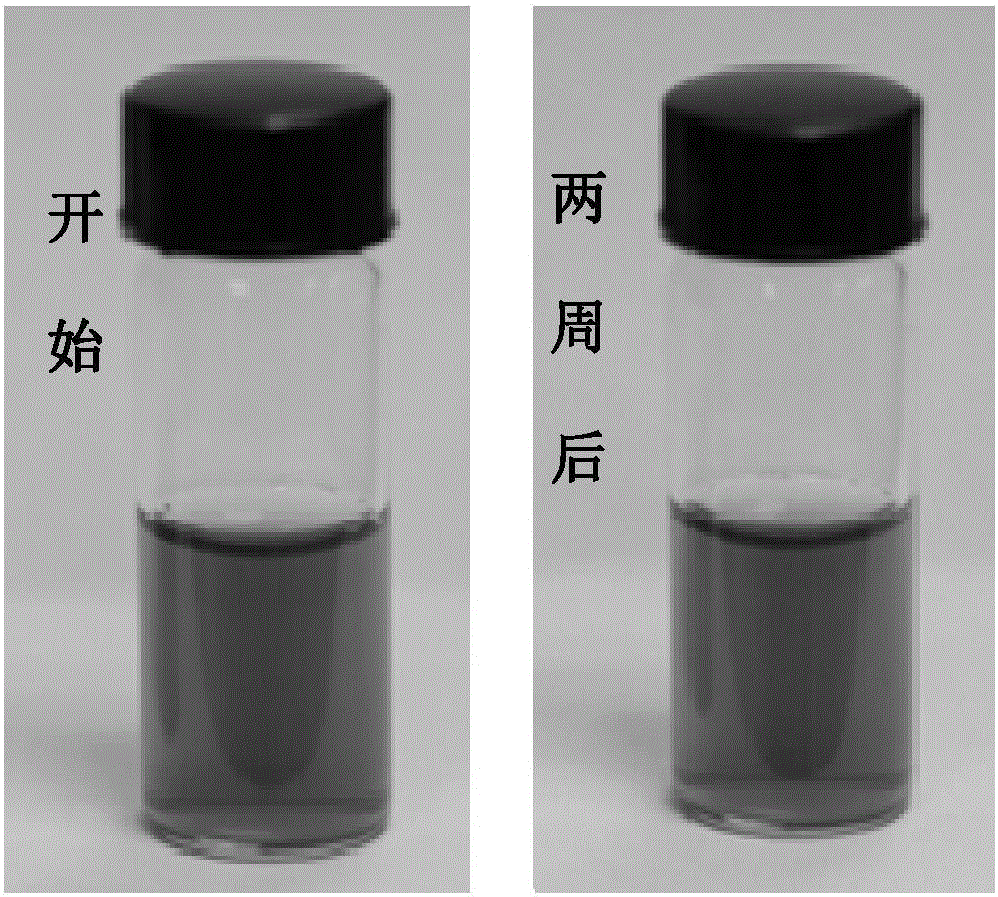

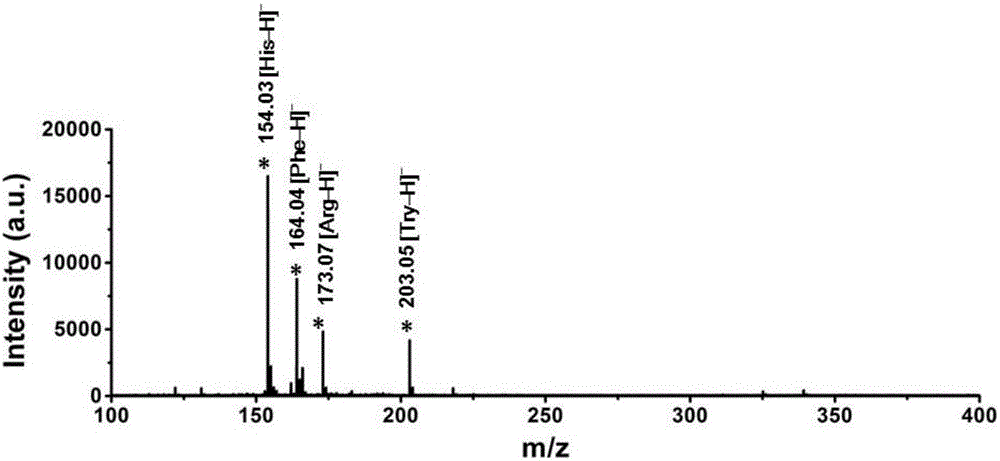

A matrix-assisted laser and time-of-flight mass spectrometry technology, which is applied in the preparation of test samples, material analysis by electromagnetic means, and measurement devices, can solve the problems of poor dispersion of metal oxides and carbon-based materials, poor signal repetition, Limiting the application of nanomaterials and other issues, achieving strong anti-salt interference, high sensitivity, and improving the efficiency of laser desorption ionization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

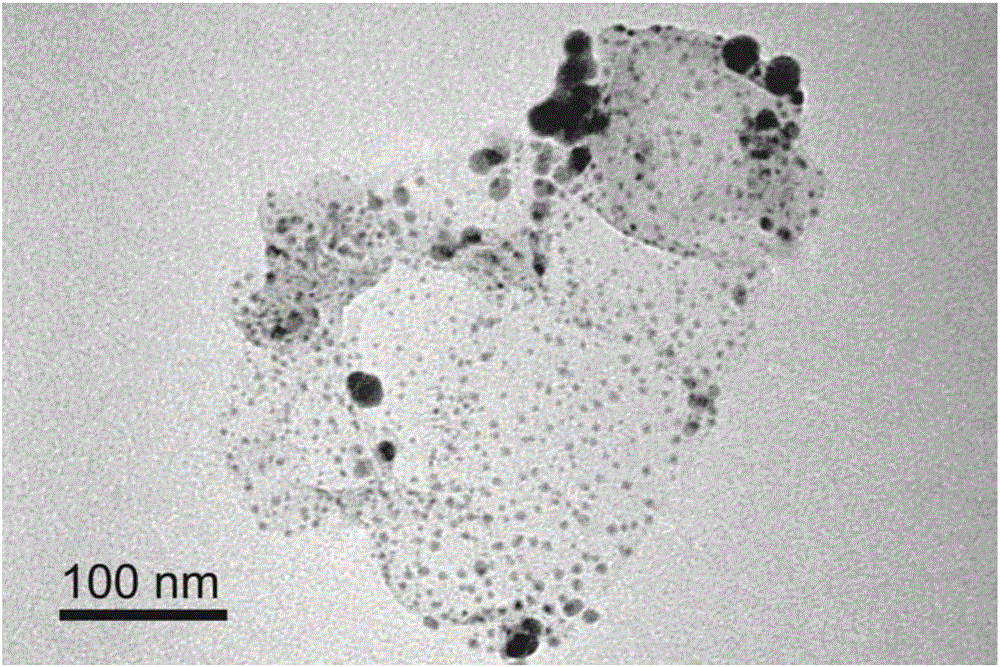

[0040] Example 1: Synthesis of molybdenum disulfide / nanometer silver composite.

[0041] (1) Under the protection of nitrogen, 0.019mol of molybdenum disulfide powder and 0.0475mol of n-butyllithium were quickly added to a 50mL polytetrafluoroethylene reactor, heated and reacted in an oven at 100°C for 4h, and naturally cooled to room temperature.

[0042] (2) The solution in step (1) was quickly transferred to a 250 mL three-necked bottle, and reacted at room temperature 25° C. for 48 h under nitrogen protection.

[0043] (3) Quickly filter the solution obtained in step (2) under reduced pressure, wash 3 times with 200 mL of n-hexane, then quickly transfer the product obtained by suction filtration to a certain amount of deionized water for ultrasonication for 4 hours, and centrifuge to remove the unstripped product Molybdenum disulfide, take the supernatant and save it, and finally measure its concentration.

[0044] (4) Take 16mL of the solution obtained in step (3) (conce...

Embodiment 2

[0046] Example 2: Synthesis of molybdenum disulfide / nanometer silver composite.

[0047] (1) Under the protection of nitrogen, quickly add 0.03mol molybdenum disulfide powder and 30mL n-butyllithium (1.6M) into a 50mL polytetrafluoroethylene reactor, heat and react in an oven at 150°C for 3h, and cool naturally to room temperature.

[0048] (2) The solution in step (1) was quickly transferred to a 250 mL three-neck flask, and reacted at 40° C. for 24 h under nitrogen protection.

[0049] (3) Quickly filter the solution obtained in step (2) under reduced pressure, wash with 200 mL of n-hexane for 3 times, then quickly transfer the product obtained by suction filtration to a certain amount of deionized water for ultrasonication for 2 hours, and centrifuge to remove the unstripped product Molybdenum disulfide, take the supernatant and save it, and finally measure its concentration.

[0050] (4) Get 30mL of step (3) gained solution (concentration is 0.05g / L), add 3mL trisodium c...

Embodiment 3

[0051] Embodiment 3: Synthesis of molybdenum disulfide / nano-silver composite.

[0052] (1) Under the protection of nitrogen, quickly add 0.06mol molybdenum disulfide powder and 40mL n-butyllithium (1.6M) into a 50mL polytetrafluoroethylene reactor, heat and react in an oven at 200°C for 6h, and cool naturally to room temperature.

[0053] (2) The solution in step (1) was quickly transferred to a 250 mL three-neck flask, and reacted at 50° C. for 48 h under nitrogen protection.

[0054] (3) Quickly filter the solution obtained in step (2) under reduced pressure, wash 3 times with 200 mL of n-hexane, then quickly transfer the product obtained by suction filtration to a certain amount of deionized water for ultrasonication for 8 hours, and centrifuge to remove the unstripped product Molybdenum disulfide, take the supernatant and save it, and finally measure its concentration.

[0055] (4) Get 4mL of step (3) gained solution (concentration is 0.5g / L), add 2mL trisodium citrate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com