Patents

Literature

439results about How to "Suitable for industrial production applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of boron modified phenolic resin

ActiveCN101805435AMild reaction conditionsSuitable for industrial production applicationsSynthesis methodsBoron

The invention discloses a preparation method of boron modified phenolic resin, which comprises the following steps that: (1) phenol and formaldehyde in the molar ratio of 1.0:0.1 to 1.0 is added into a reactor, to be stirred under acid environment and reflux for 5 to 6 hours; (2) a reaction product prepared in step (1) is distilled and hydrated at normal pressure, until the water content is less than 10 weight percent; (3) the produce dehydrated in step (2) is added with a compound which contains boron hydroxyl, to have esterification; and the input of the compound which contains boron hydroxyl is 20 weight percent of that of the phenol at most. The synthesis method provided by the invention is simple and feasible, the prepared resin has stable performance and is beneficial to large-scaleindustrial production, and the prepared boron modified phenolic resin has excellent thermal oxidation and ablation resistant performance, and can be widely applied to high-temperature brake materials, ablation resistant materials, heat insulation materials and other fields.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

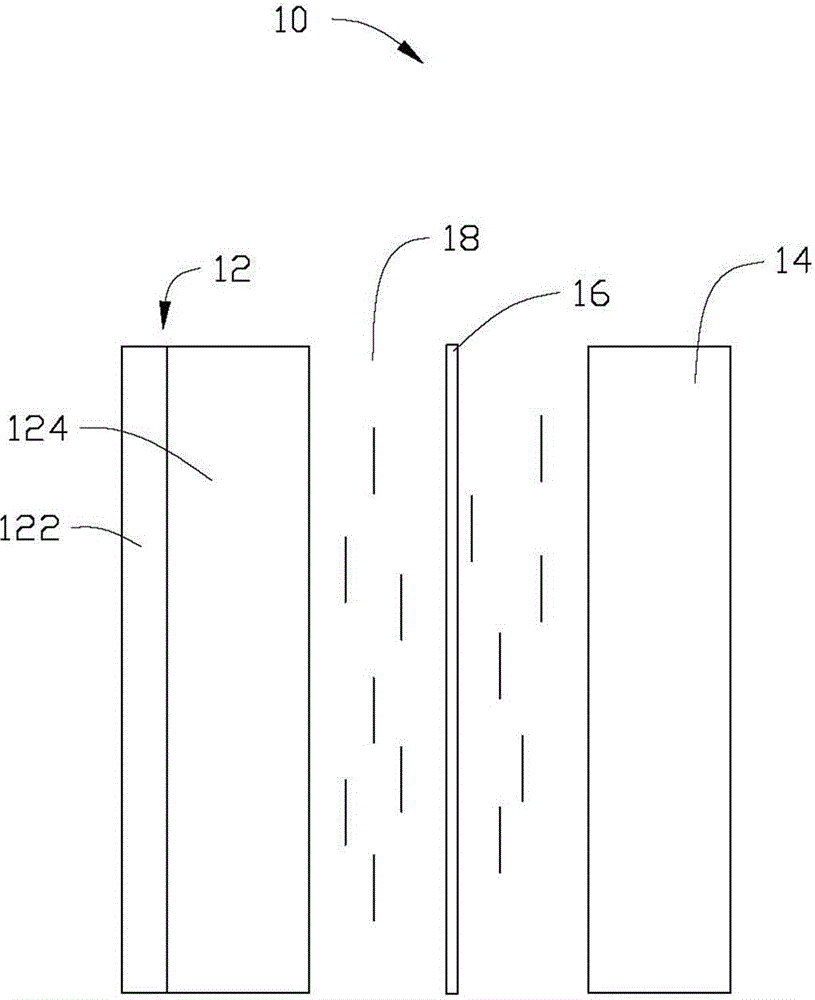

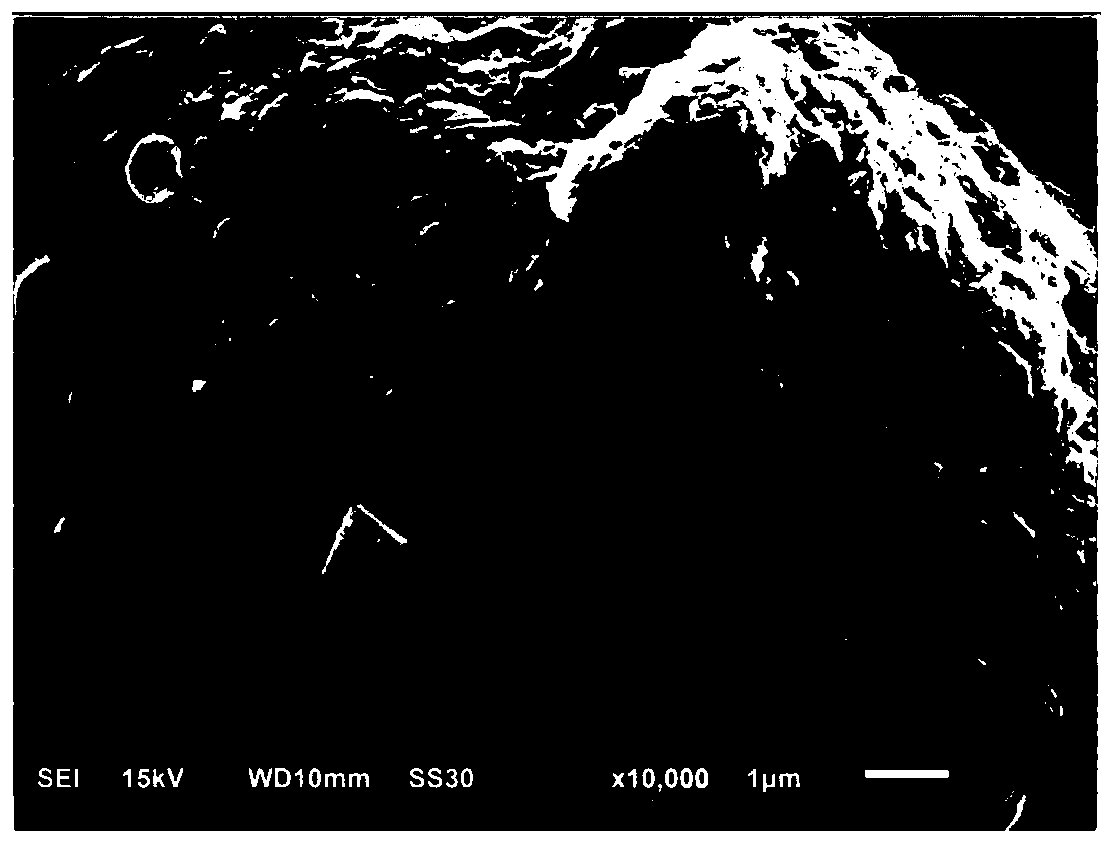

Method for preparing lithium-ion secondary battery pole piece

ActiveCN102694150AIncrease energy densityImprove electrochemical performanceCell electrodesPorosityLithium

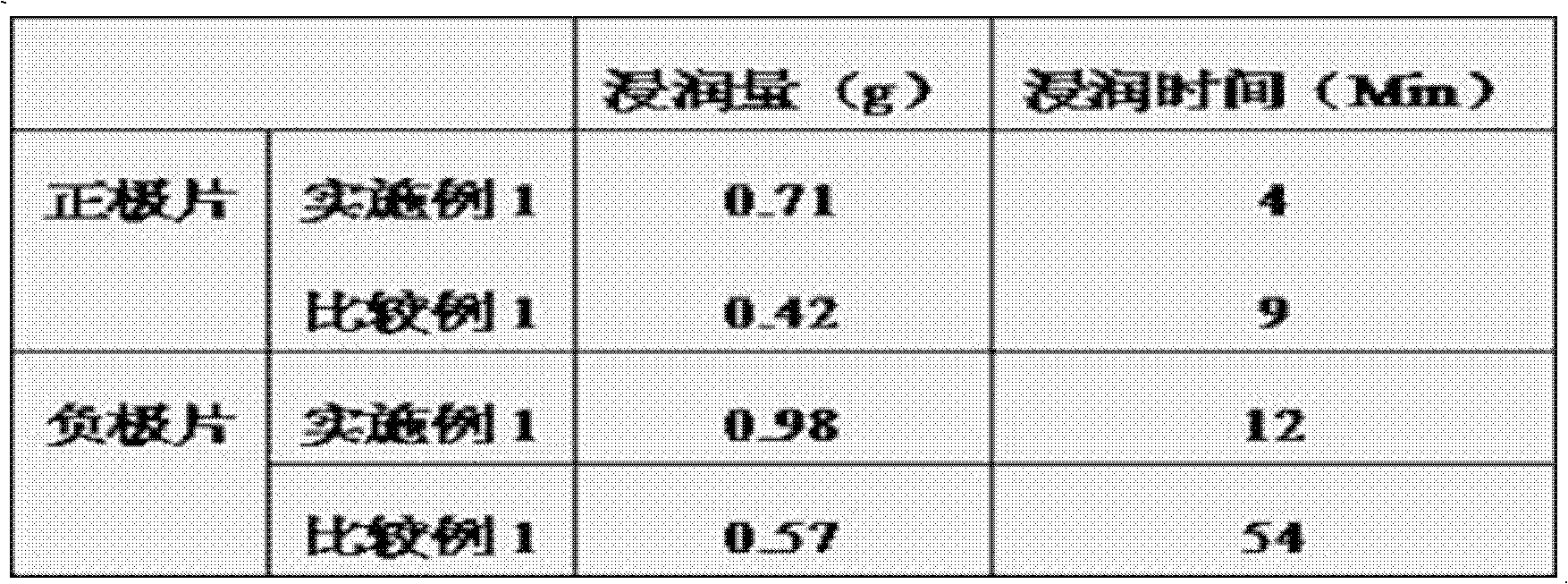

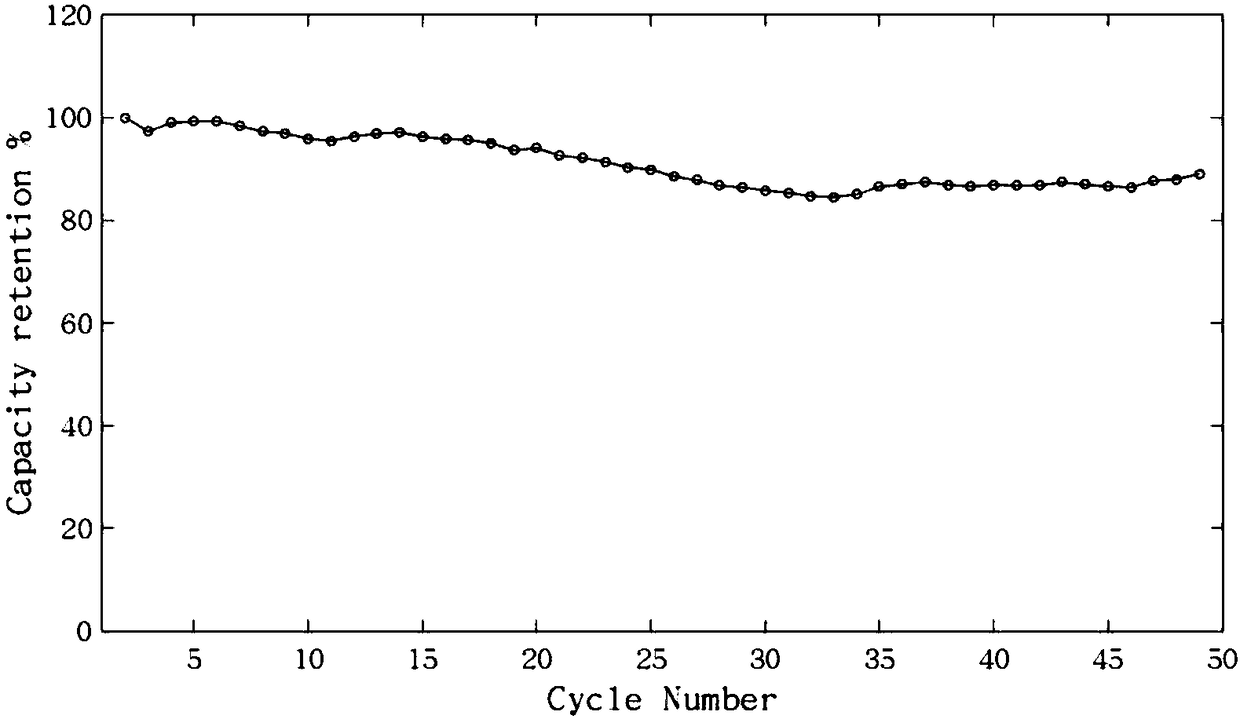

The invention belongs to the technical field of lithium-ion secondary batteries and in particular relates to a method for preparing a lithium-ion secondary battery pole piece. Poriness of a film piece is gradually increased from the direction close to the surface of a current collector to the direction far away from the surface of the current collector. The method comprises the following steps of: coating a sizing agent containing an active substance, a conductive agent, a polymer binding agent and a disperse solvent on the current collector to obtain a film piece containing the disperse solvent; and spraying nonsolvent to the surface of the film piece containing the current collector by adopting an ultrasonic spray method and drying and rolling the film piece to obtain the pole piece. Compared with the prior art, the thick pole piece prepared by the method has continuous gradient distribution poriness so that a battery assembled by the thick pole piece prepared by the method has higher energy density and good electrochemical performance. The capacity play is normal, the rate performance is obviously improved, the analysis lithium condition is obviously improved, and the cycling stability is also improved obviously.

Owner:NINGDE AMPEREX TECH

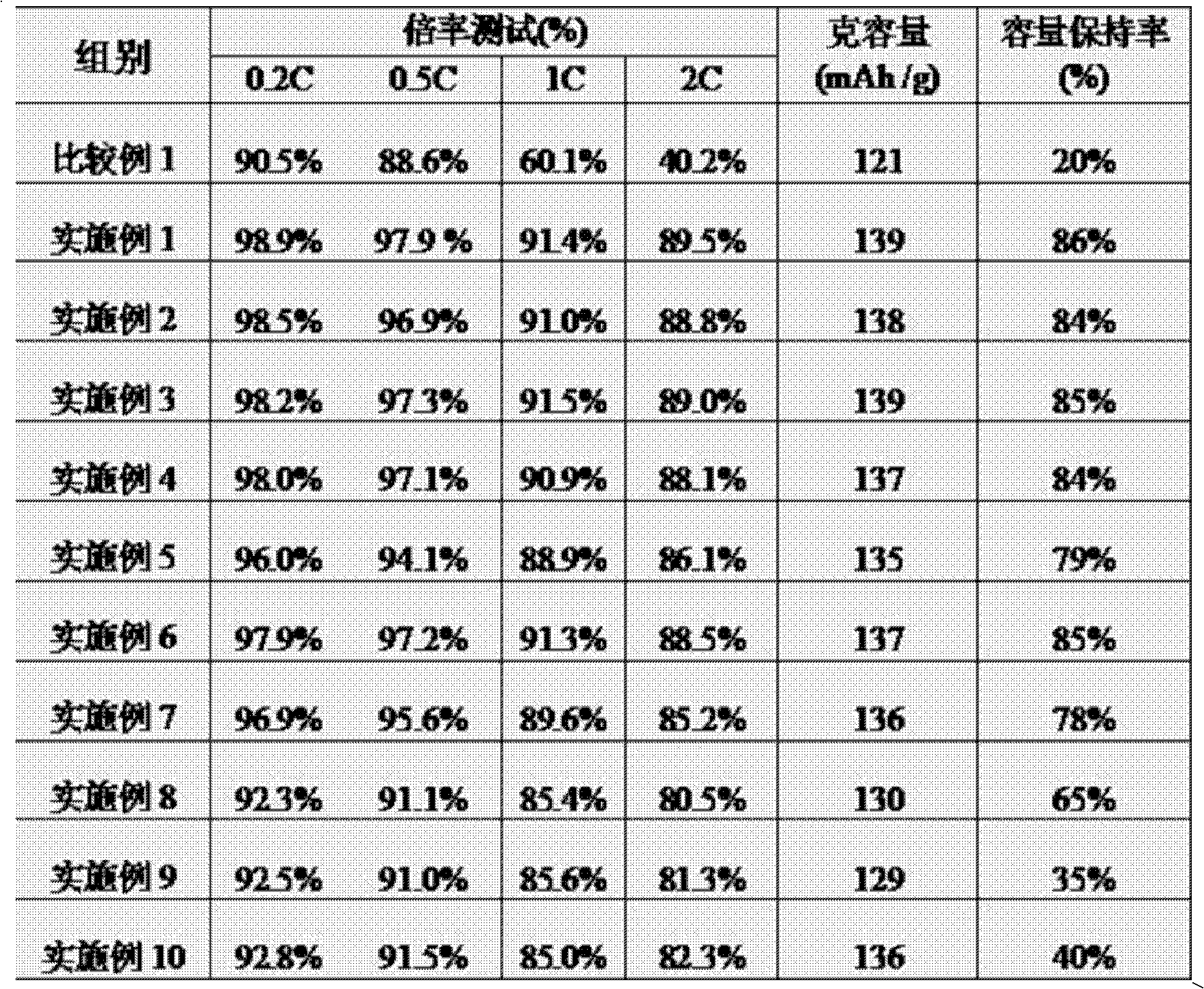

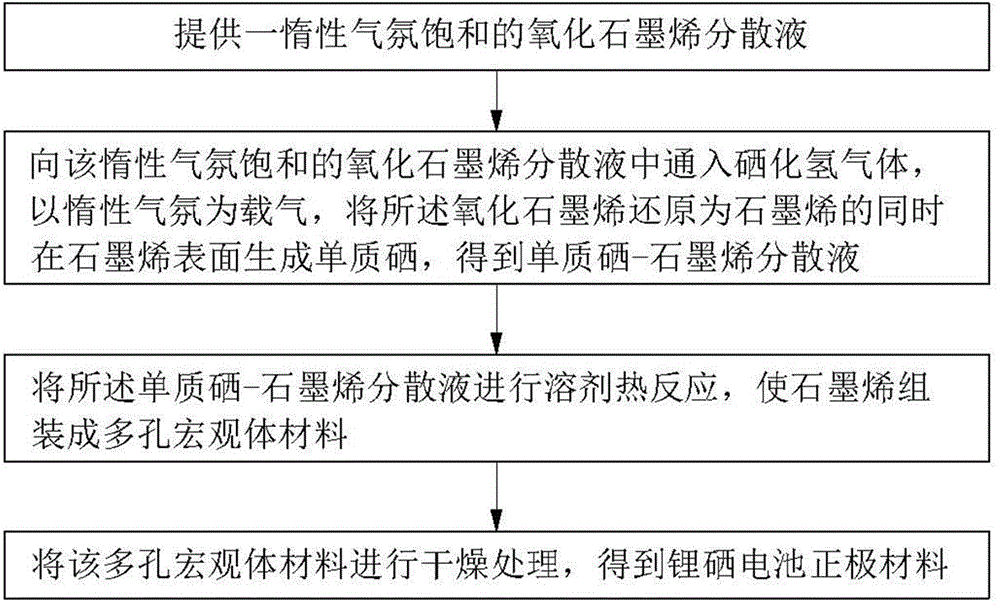

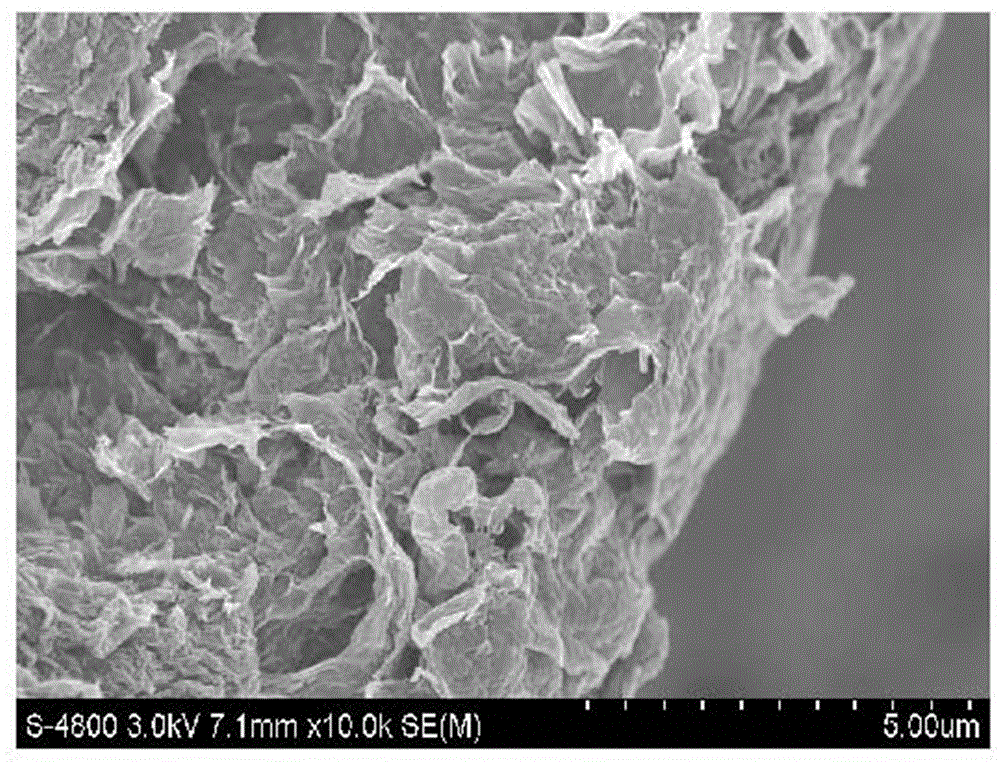

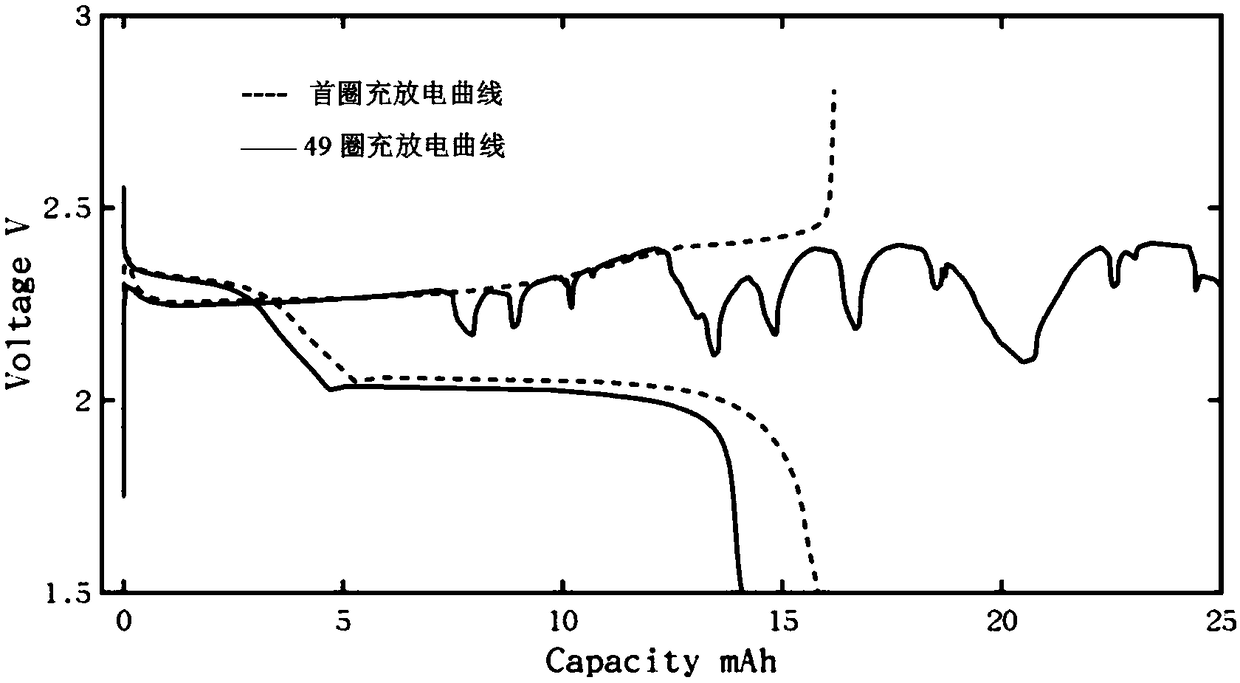

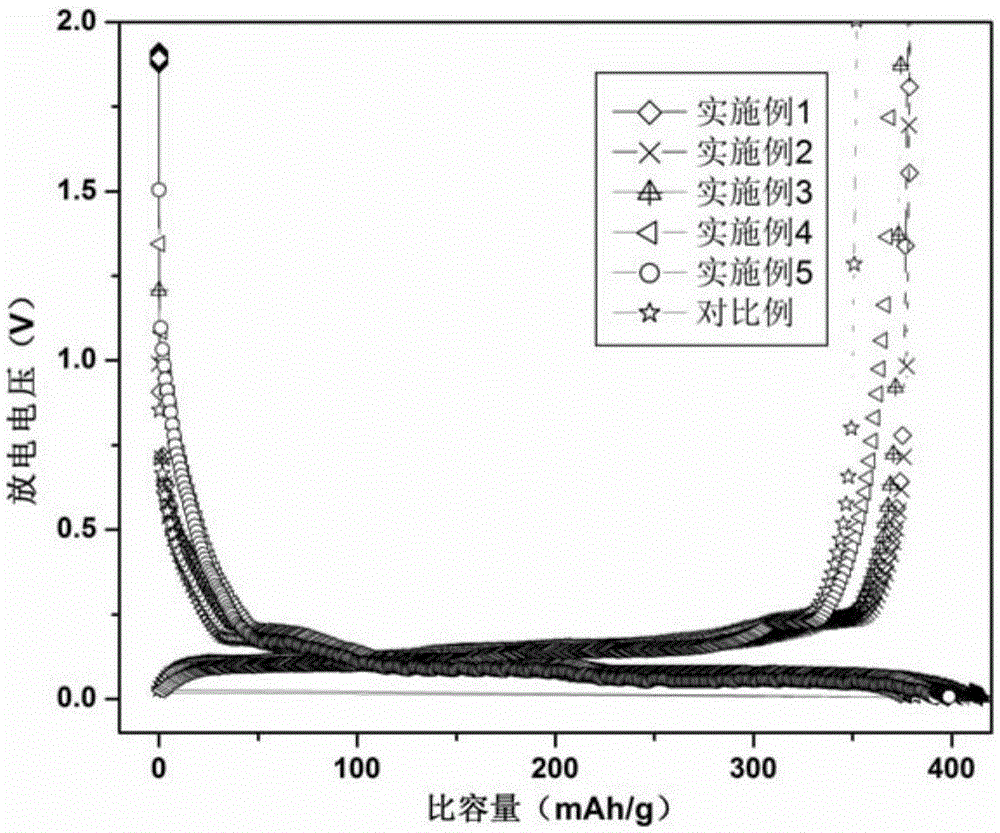

Lithium-selenium battery positive electrode material, preparation method thereof and lithium-selenium battery

ActiveCN104393304AImprove electrochemical performanceComposite method is simpleElectrode carriers/collectorsLi-accumulatorsLithiumSolvent

The invention provides a preparation method of a lithium-selenium battery. The preparation method comprises the steps of providing an oxidized graphene dispersing liquid with saturated inert atmosphere; feeding hydrogen selenide gas to the oxidized graphene dispersing liquid with saturated inert atmosphere, reducing the oxidized graphene to graphene by taking the insert atmosphere as carrier gas, and meanwhile, generating elemental selenium on the surface of the graphene to obtain an elemental selenium-graphene dispersing liquid; performing solvent thermal treatment on the selenium-loaded graphene dispersing liquid to obtain graphene-based gel; and drying the graphene-based gel. The invention further provides a lithium-selenium battery positive electrode material and a lithium-selenium battery using the positive electrode material.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

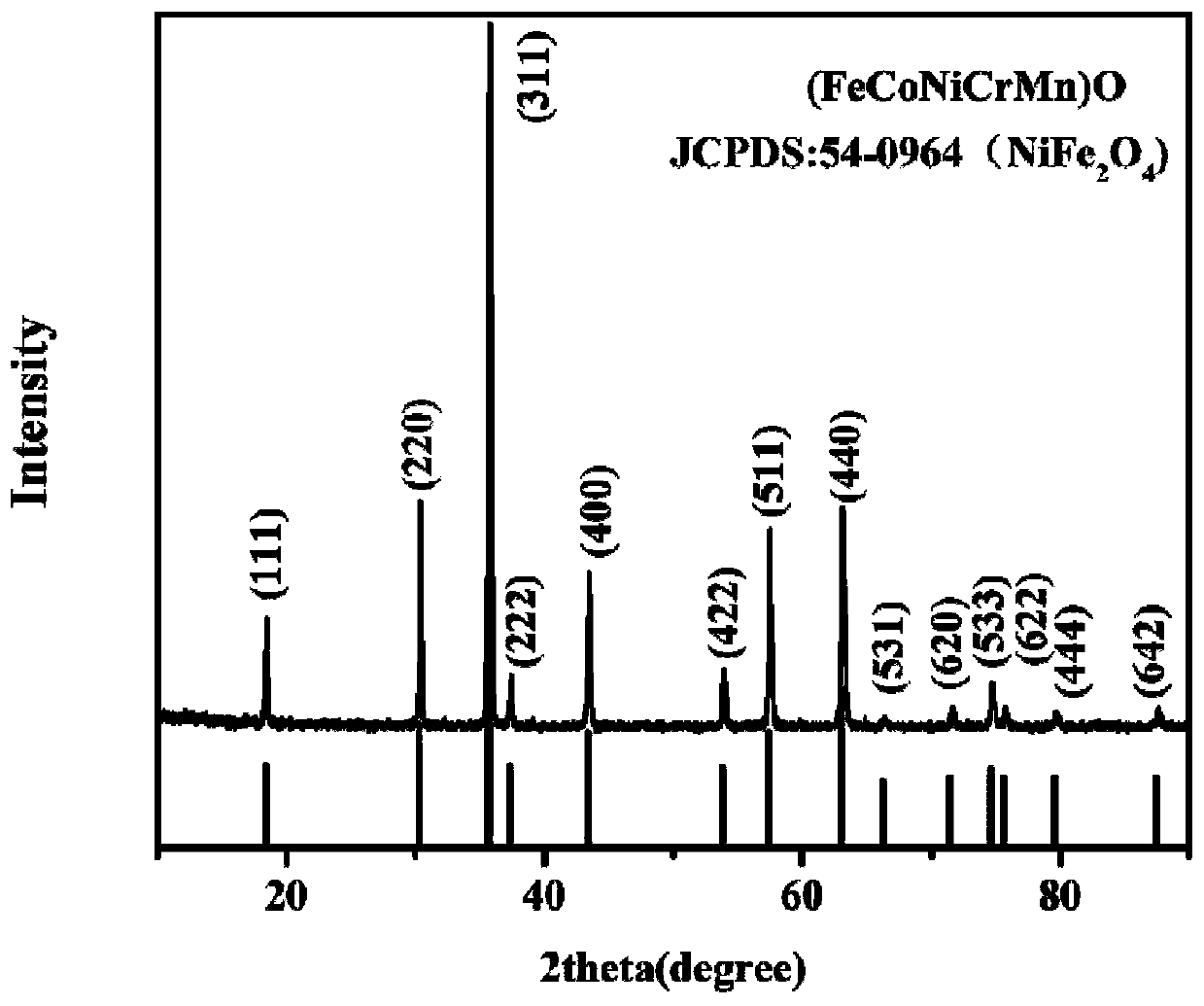

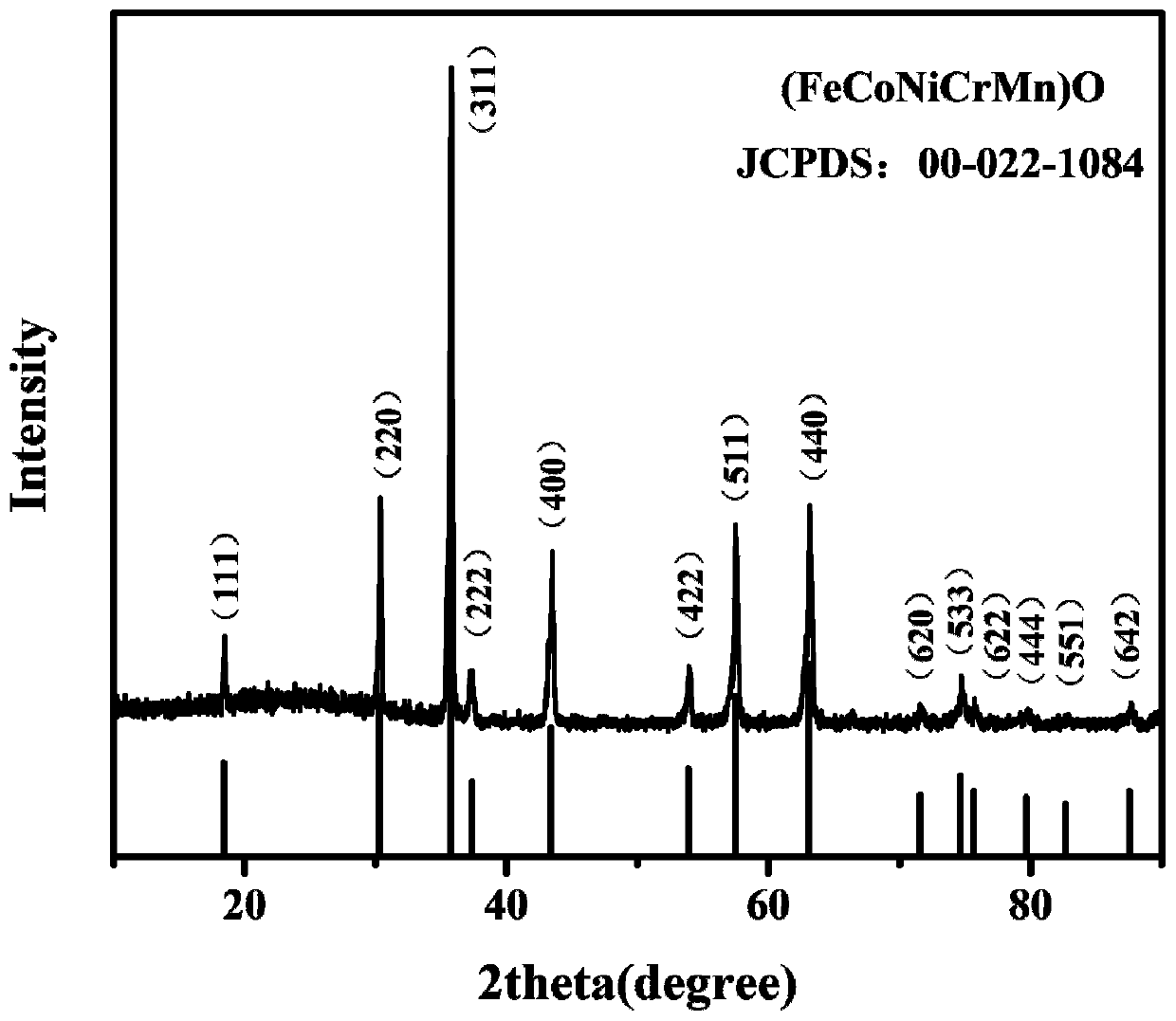

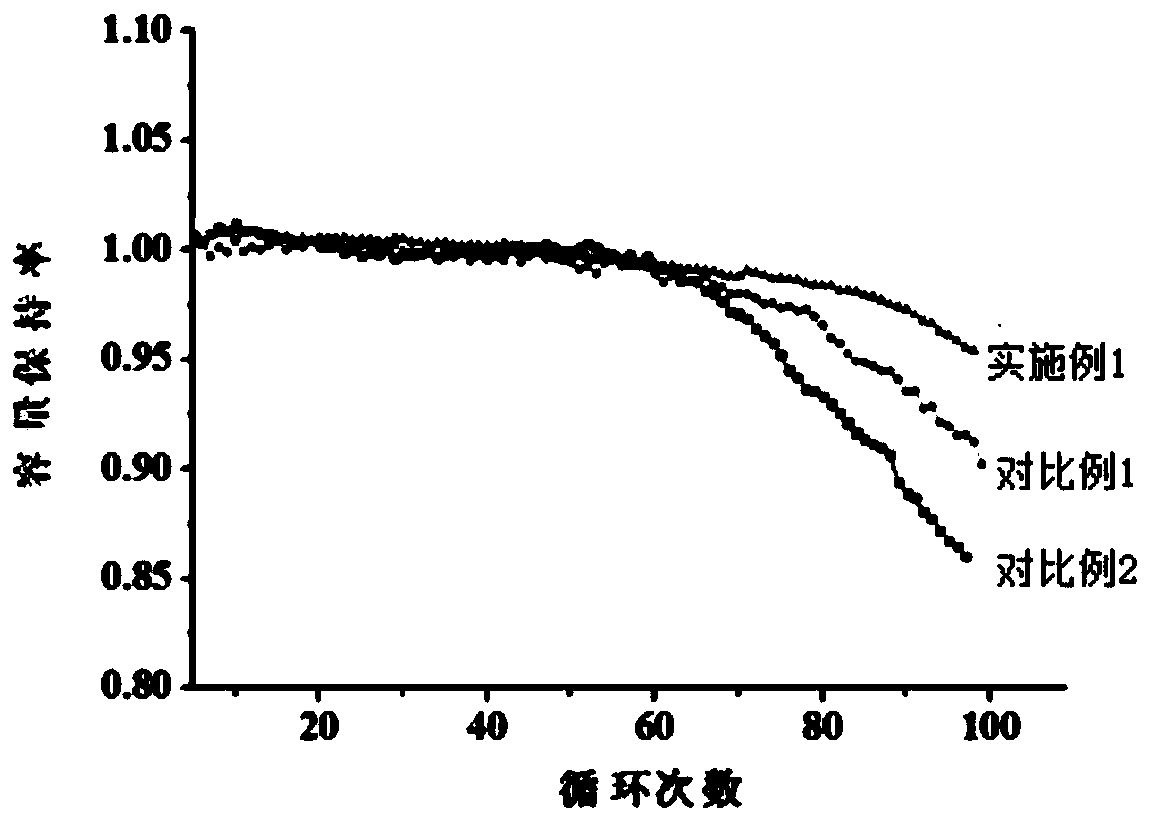

Spinel type high-entropy oxide electrode material and preparation method thereof

ActiveCN110364717AHigh specific capacityImprove cycle stabilityNegative electrodesSecondary cellsIron(II) oxideSpace group

The invention relates to a spinel type high-entropy oxide electrode material and a preparation method thereof, and belongs to the field of nanomaterial preparation and new energy. The chemical formulaof the high-entropy oxide electrode material is one of (FeCoNiCrMn)O, (FeZnNiCrMn)O, (FeCoZnCrMn)O and (FeCoNiCrMnCu)O. The preparation method includes the steps of 1) mixing and ball-milling iron oxide, chromium oxide, manganese oxide and M metal oxide, wherein the M metal oxide is two or more of nickel oxide, zinc oxide, copper oxide and cobalt oxide; and 2) carrying out high-temperature calcination, and obtaining the spinel type high-entropy oxide electrode material by adopting a cooling mode of furnace cooling, air quenching and liquid nitrogen quenching. The particle diameter of the high-entropy oxide is 100-500nm, and the high-entropy oxide is determined to be in a spinel structure according to XRD; and the space group of the material is Fd-3m, and the specific surface area is 5-100m<2>g<-1>.

Owner:东北大学秦皇岛分校

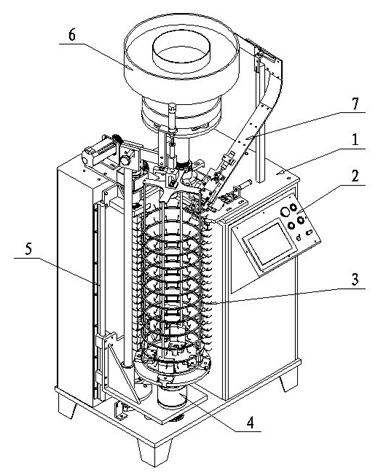

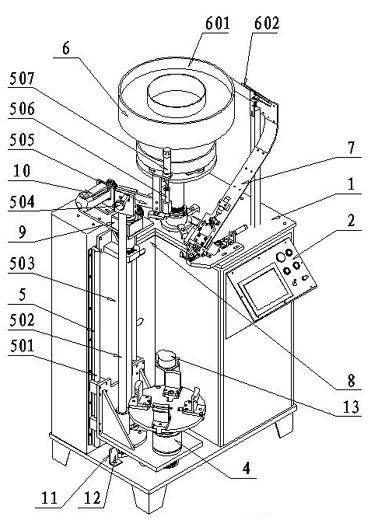

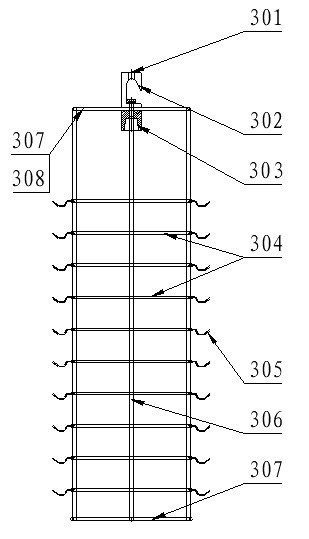

Suspending machine of zipper slider for electroplating

ActiveCN102433580AImprove work efficiencySolve the entanglementElectrolysis componentsSlide fastenersControl systemControl engineering

The invention provides a suspending machine of a zipper slider for electroplating, and belongs to the technical field of zipper suspending machine. The machine comprises a chassis with a PLC (programmable logical controller) panel, wherein a zipper slider storage device and a zipper slider conveying and hooking alignment detection device are cooperatively arranged on the chassis; a zipper slider hanger control device is cooperatively arranged on the lateral side of the chassis; the zipper slider hanger control device is connected with a rotating disk compressed air source conversion device; a zipper slider hanger is cooperatively arranged on the rotating disk compressed air source conversion device; the outlet end of the zipper slider storage device is connected with the inlet end of the zipper slider conveying and hooking alignment detection device; the outlet end of the zipper slider conveying and hooking alignment detection device is matched with a zipper slider hook on the zipper slider hanger; and the zipper slider storage device, the zipper slider conveying and hooking alignment detection device and other devices are controlled by the PLC. By adopting an electric signal control system, the machine has the advantages of convenience in whole operation, efficiency improvement, high accuracy, simple structure, time and labor saving and low production cost, and is suitable for industrial production and application.

Owner:临海市万宏机电配件厂

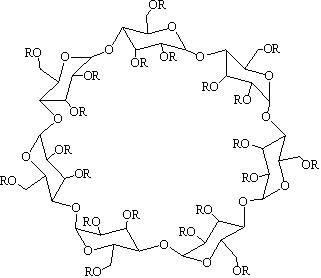

Method for preparing hydroxypropyl-beta-cyclodextrin

ActiveCN102040675AWill not cause decompositionLow impurity contentMacromolecular non-active ingredientsNanofiltrationPharmaceutic Adjuvant

The invention discloses a method for preparing hydroxypropyl-beta-cyclodextrin, which comprises the steps of etherification, neutralization, decoloring, nanofiltration, resin purification, and spray drying. The method of the invention is small in pollution, and the yield in weight is more than 80 percent; meanwhile, the product prepared by using the method of the invention is narrow in substituted ratio range and low in impurity content, and can be used as a pharmaceutic adjuvant.

Owner:石药集团中诺药业(石家庄)有限公司

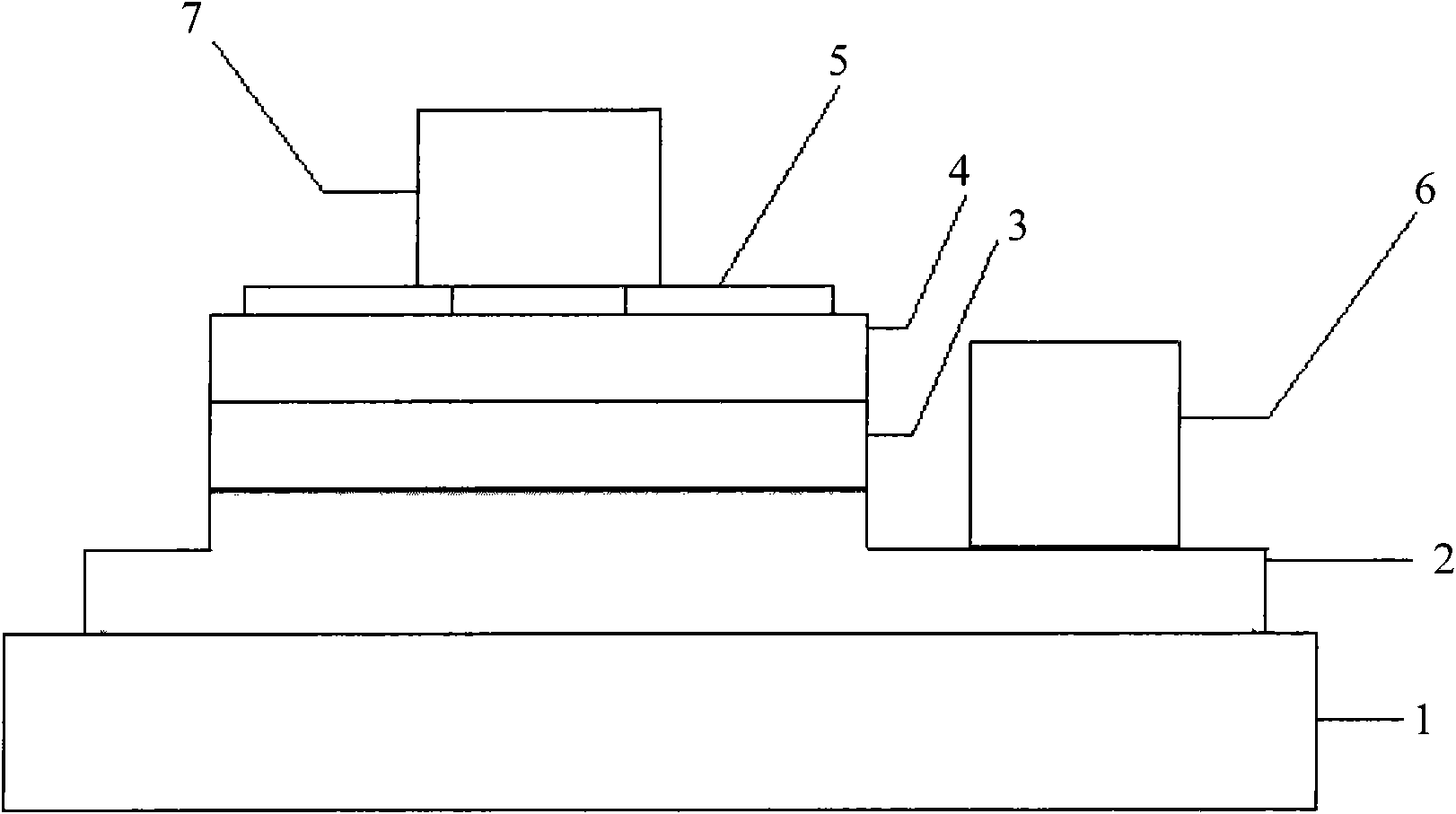

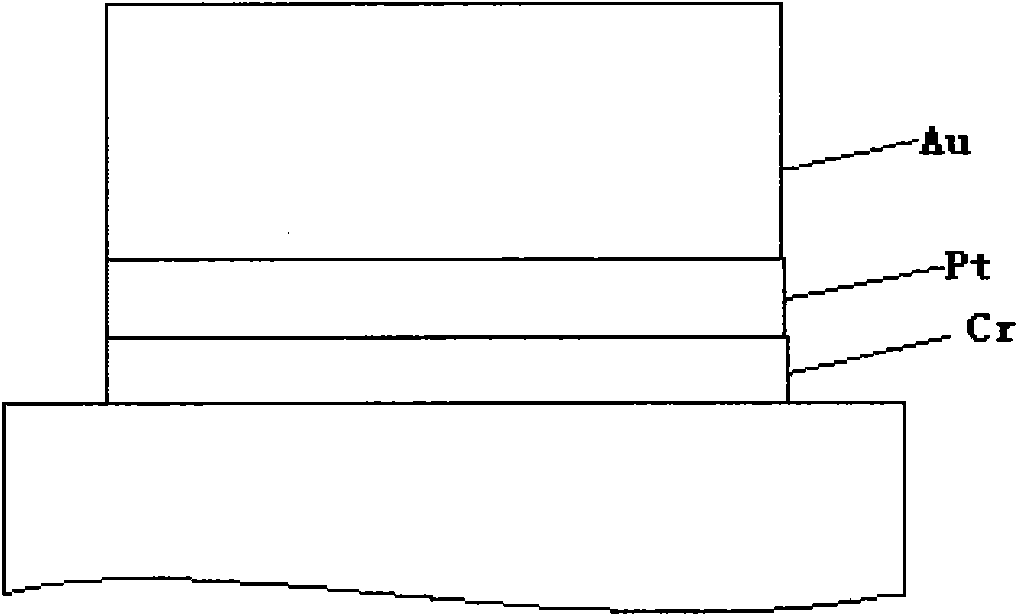

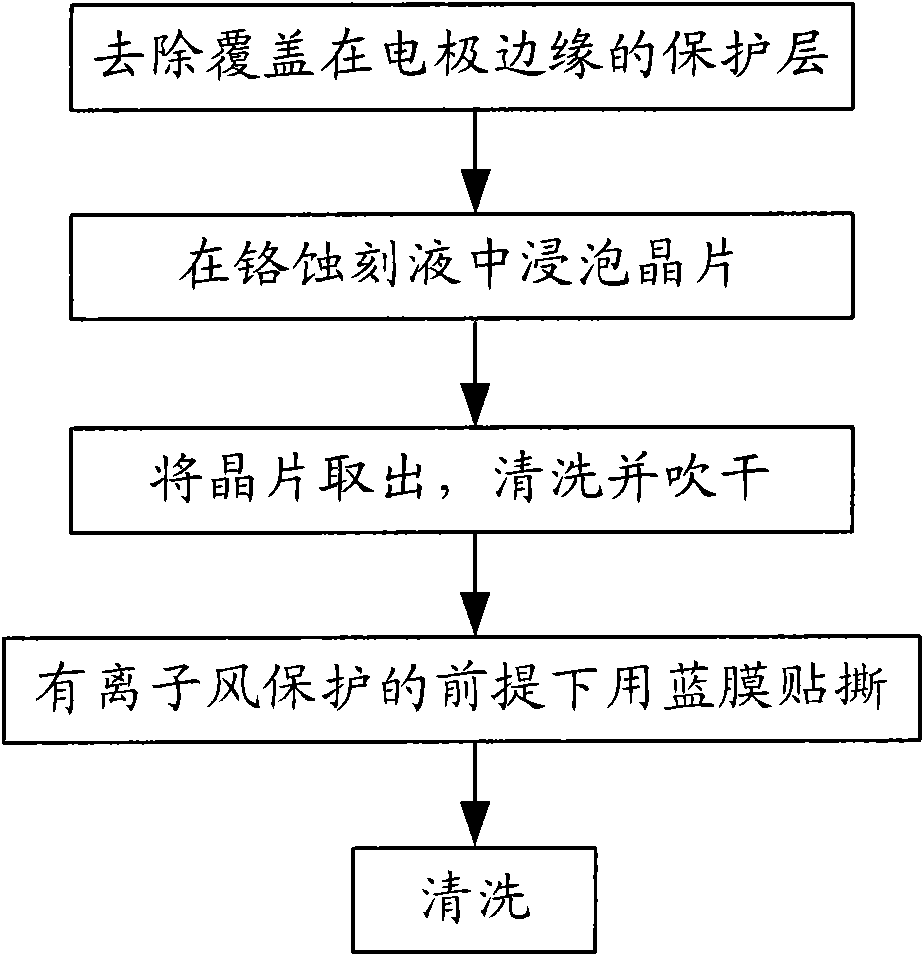

Method for removing light-emitting diode (LED) chip electrode

InactiveCN101944562AEfficient removalHigh selectivitySemiconductor devicesIndium tin oxideLight-emitting diode

The invention discloses a method for removing an LED chip electrode, which comprises the following steps of: removing a protective layer covered on the edge of the LED chip electrode; immersing the chip in chrome etching liquid after the protective layer is removed; taking the immersed chip out, washing and drying by air; and adhering a blue membrane or a white membrane on the surface of the air dried chip and then peeling the blue membrane or the white membrane off. The method provided by the invention has very high selectivity, exerts no influences on the other parts of the LED chip structure and retains the conventional indium tin oxide (ITO) layer.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Method for extracting flavone and polysaccharide from mulberry leaf

InactiveCN101214279AHigh extraction rateImprove extraction efficiencyOrganic chemistryMetabolism disorderSolventAir drying

The present invention discloses a method of extracting flavone and polyoses from mulberry leaves, including air drying, grinding and screening. Mulberry leaf powder is immersed in 60 to 80 percent ethanol so as to extract flavone or in water so as to extract polyoses; the ultrasonic treatment with 100 to 400W power lasts for 5 to 25 minutes; extraction temperature is controlled within 60 to 85 DEG C and the extraction lasts for 1 to 2 hours; the extracting solution is centrifugalized and filtered by supernatant fluid, thus obtaining the filtrate; the flavone filtrate is concentrated so as to obtain the mulberry leaf flavone extract; or ethanol is added into the polyoses filtrate so as to make the ethanol concentration up to 70 percent in the final solution; the filtrate is placed for 18 to 24 hours under 4 to 10 DEG C, then deposited and dried, thus obtaining the mulberry leaf polyoses. The flavone yield can reach more than 25mg / g and the polyoses yield 110mg / g. The present invention, with the advantages of good repeatability, high selection, short operating time, less solvent consumption, high yield of effective ingredients, no noise, no pollution and relatively good application prospective, is applicable to industrial production.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

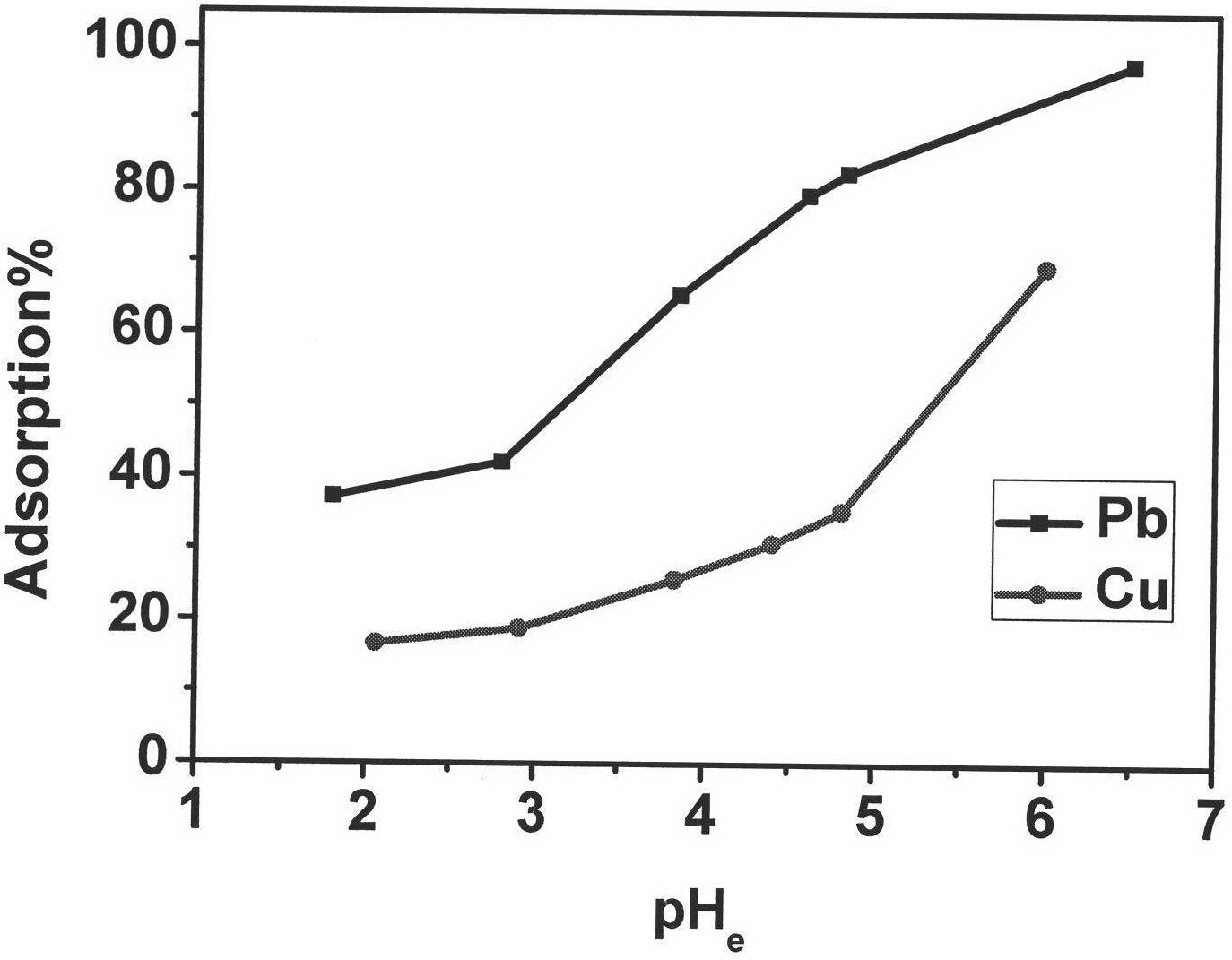

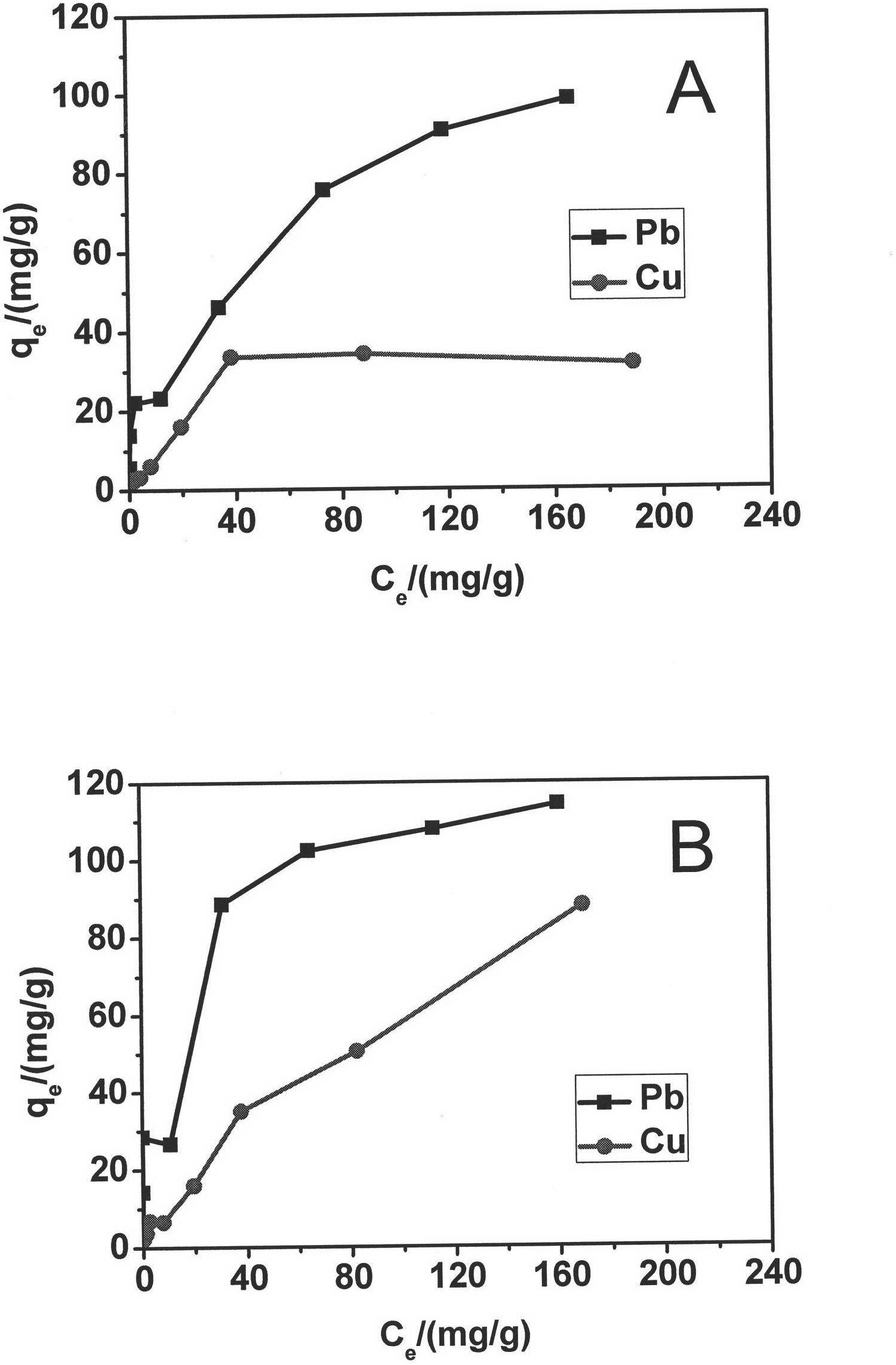

Preparation method and application of Beta-cyclodextrin grafted carbon nano tube adsorbing material

InactiveCN102688752ASimple processLow equipment requirementsOther chemical processesWater/sewage treatment by sorptionIonNanometre

The invention provides a preparation method and an application of Beta-cyclodextrin grafted carbon nano tube adsorbing material and belongs to the technical field of novel nano material and environmental protection. In order to solve the problem that the carbon nano tube is easy to aggregate and is poor in dispersivity, the invention adopts cheap and degradable amphipathic supramolecular Beta-cyclodextrin to synthesize Beta-cyclodextrin grafted carbon nano tube (CNTs-Beta-CD) composite efficient adsorbing material which has an excellent effect on removing heavy metal ions in waste water. The method has the advantages of simple preparation technology, mild conditions, no pollution, low cost, environment-friendliness, and high efficiency, and is suitable for industrial production and application.

Owner:YUNNAN UNIV

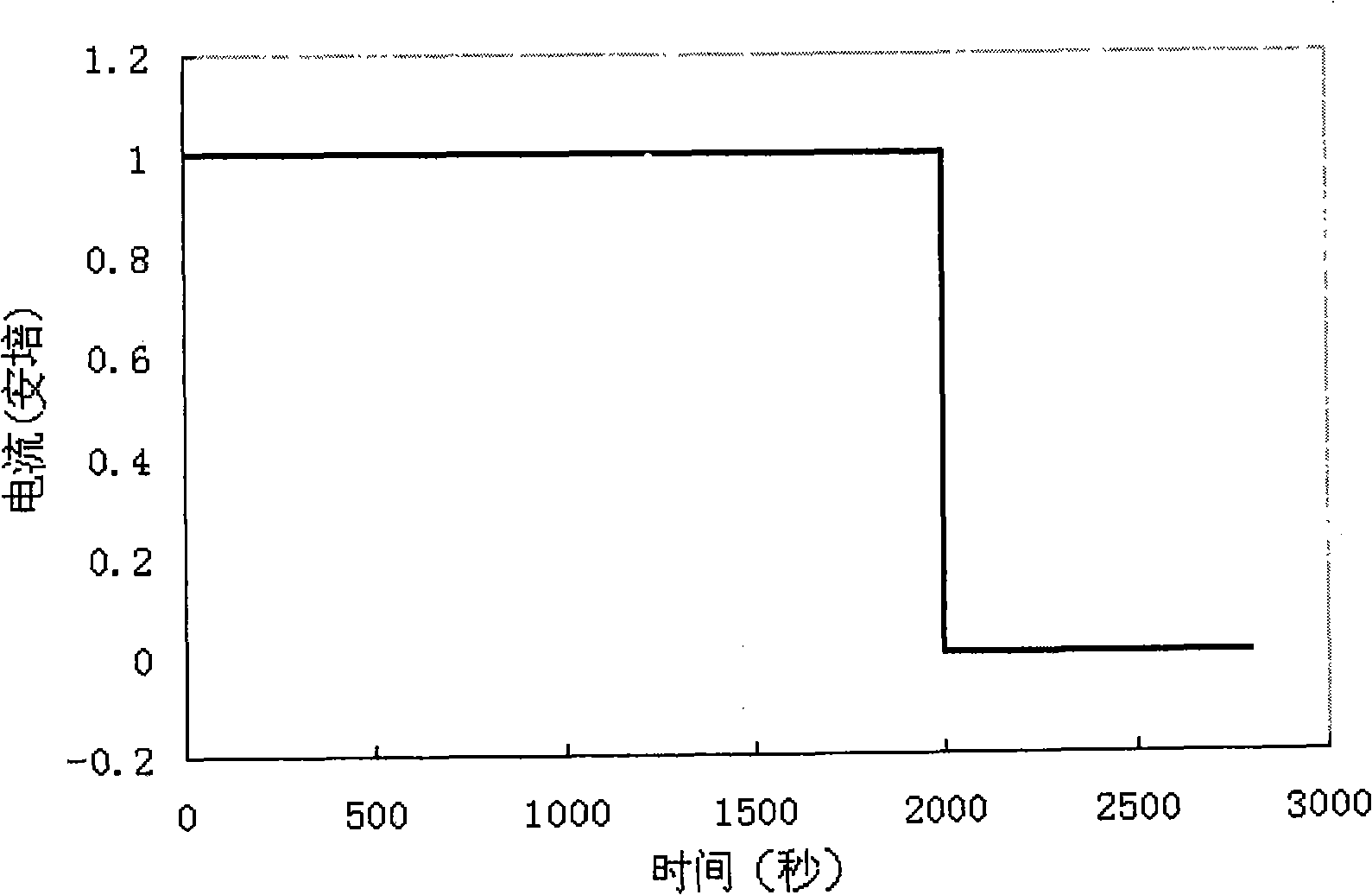

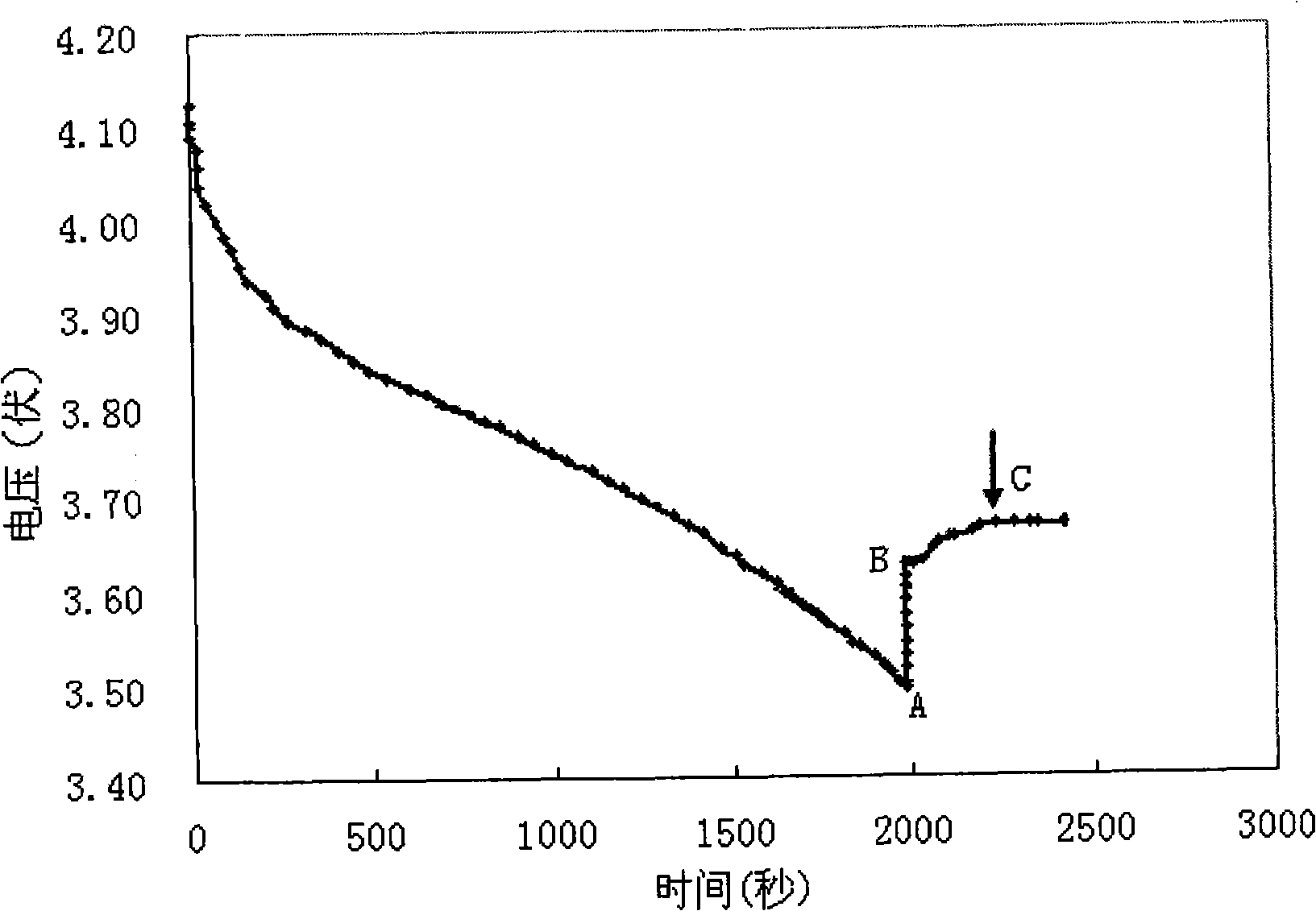

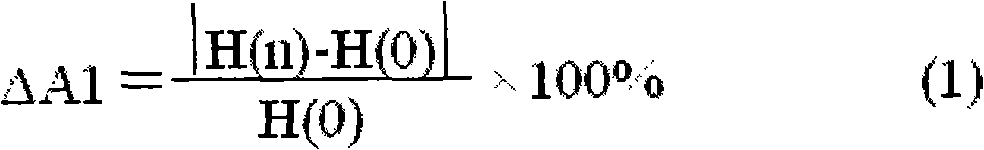

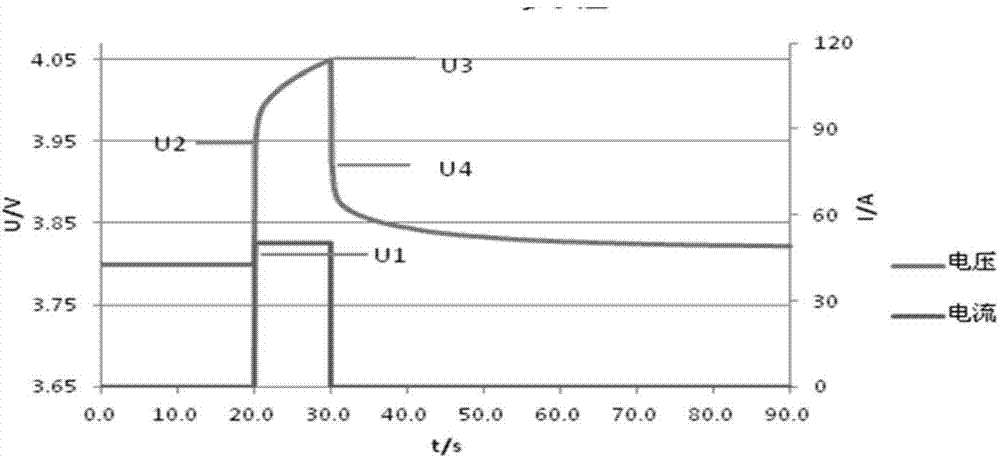

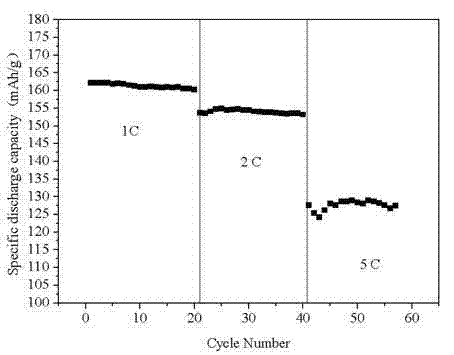

Method for evaluating consistency of batteries

The invention discloses a method for evaluating consistency of batteries, which is characterized by comprising the steps of acquiring voltage curves of a plurality of batteries, comparing heights in the voltage direction and distances in the time direction of slow recovering sections (BC)of the voltage curves of the plurality of batteries, and judging the consistency of the batteries according toa comparison result, wherein the voltage curves refer to curves of the changing of the voltage along with the time in the constant current charge or constant current discharge process and the following placing process of the plurality of batteries; and the slow recovering sections (BC) refer to sections having slow voltage increasing trend in the voltage curves. Essential distinctions of different batteries are more directly indentified through the voltage curves of the batteries so as to reduce damage to a battery pack due to inconsistency of the batteries and improve the service life of thebattery pack. In addition, the method for evaluating consistency of the batteries not only improves accuracy of evaluation, but also has low cost, simple and quick operation, and is suitable to be applied to industrial production.

Owner:上海诺昂汽车技术有限公司

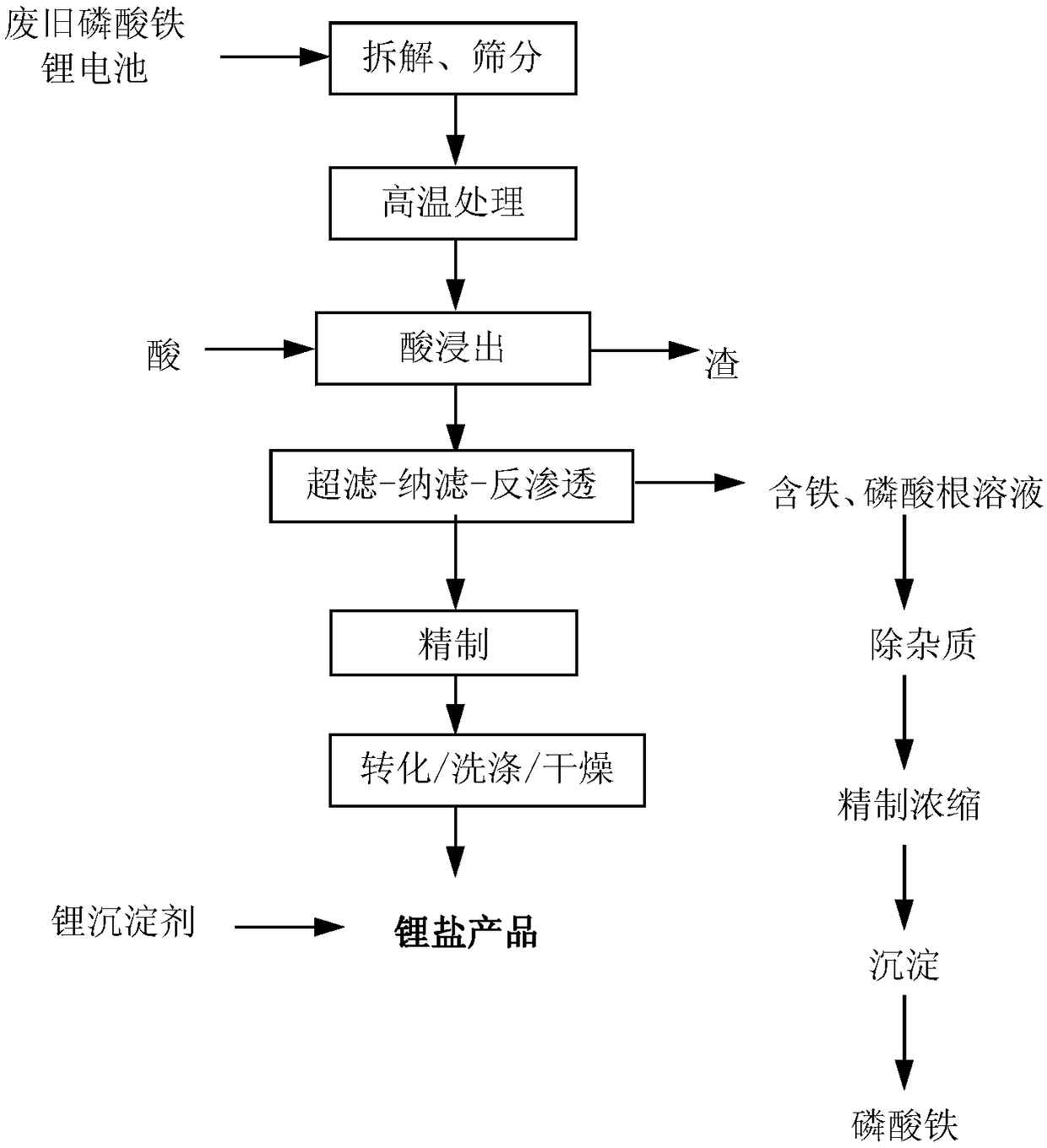

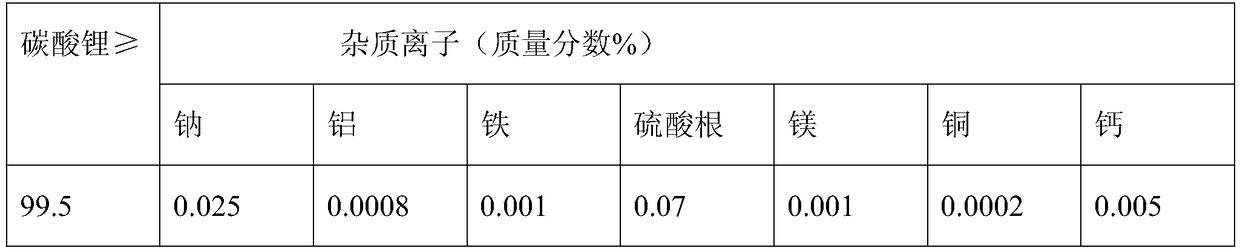

Method and system for recovering lithium from waste lithium iron phosphate battery

ActiveCN109207730AAdvanced separation technologyEasy to separateWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionLithium iron phosphate

The invention discloses a method and system for recovering lithium from a waste lithium iron phosphate battery. The method comprises the following steps that a positive plate is disassembled from thewaste lithium iron phosphate battery; a binder in the positive plate is removed, valuable metal elements in the positive plate are leached by an acid solution, and an acidified leaching solution is obtained; ultrafiltration treatment is carried out on the acidified leachate by using an ultrafiltration membrane; by using a nanofiltration membrane technology, lithium ions in the acidified leachate are separated from other cations different from lithium ions, a solution containing lithium and a solution containing other cations are obtained, and then a reverse osmosis technology is adopted for concentration and enrichment correspondingly, wherein the other cations comprise iron ions; and a lithium precipitant is adopted to precipitate and separate lithium ions in the lithium-containing solution, alkaline substances are adopted to precipitate and separate iron ions in the solution containing other cations, and lithium recovery is realized. According to the method and system, the ultrafiltration-nanofiltration-reverse-osmosis combined technology is adopted, and the method and system have the beneficial effects of simple process, environmental protection, less acid and alkali consumption, good and stable membrane separation effect and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Two-dimensional/one-dimensional heterogeneous nanochannel film and preparation method and application thereof

ActiveCN110170253AImprove energy conversion effectImprove throughputSemi-permeable membranesComposite filmRoom temperature

The invention provides a preparation method of a two-dimensional / one-dimensional heterogeneous nanochannel film. The method is characterized by comprising the following steps that step 1, graphene oxide is dissolved in an aqueous piperazine solution, and ultrasonic treatment is performed at the room temperature to obtain a uniformly dispersed first solution; step 2, the first solution is added dropwise to the upper layer of a porous aluminum oxide film, and after the solvent is evaporated at the room temperature, a first composite film with a graphene oxide film layer and a porous aluminum oxide film layer is obtained; step 3, a benzenetricarbonyl trichloride solution is added dropwise to the upper surface of the graphene oxide film layer of the first composite film, and drying is carriedout to obtain the two-dimensional / one-dimensional heterogeneous nanochannel film. The invention provides the two-dimensional / one-dimensional heterogeneous nanochannel film prepared by using the methodand application of the two-dimensional / one-dimensional heterogeneous nanochannel film in salt difference energy conversion.

Owner:FUDAN UNIV

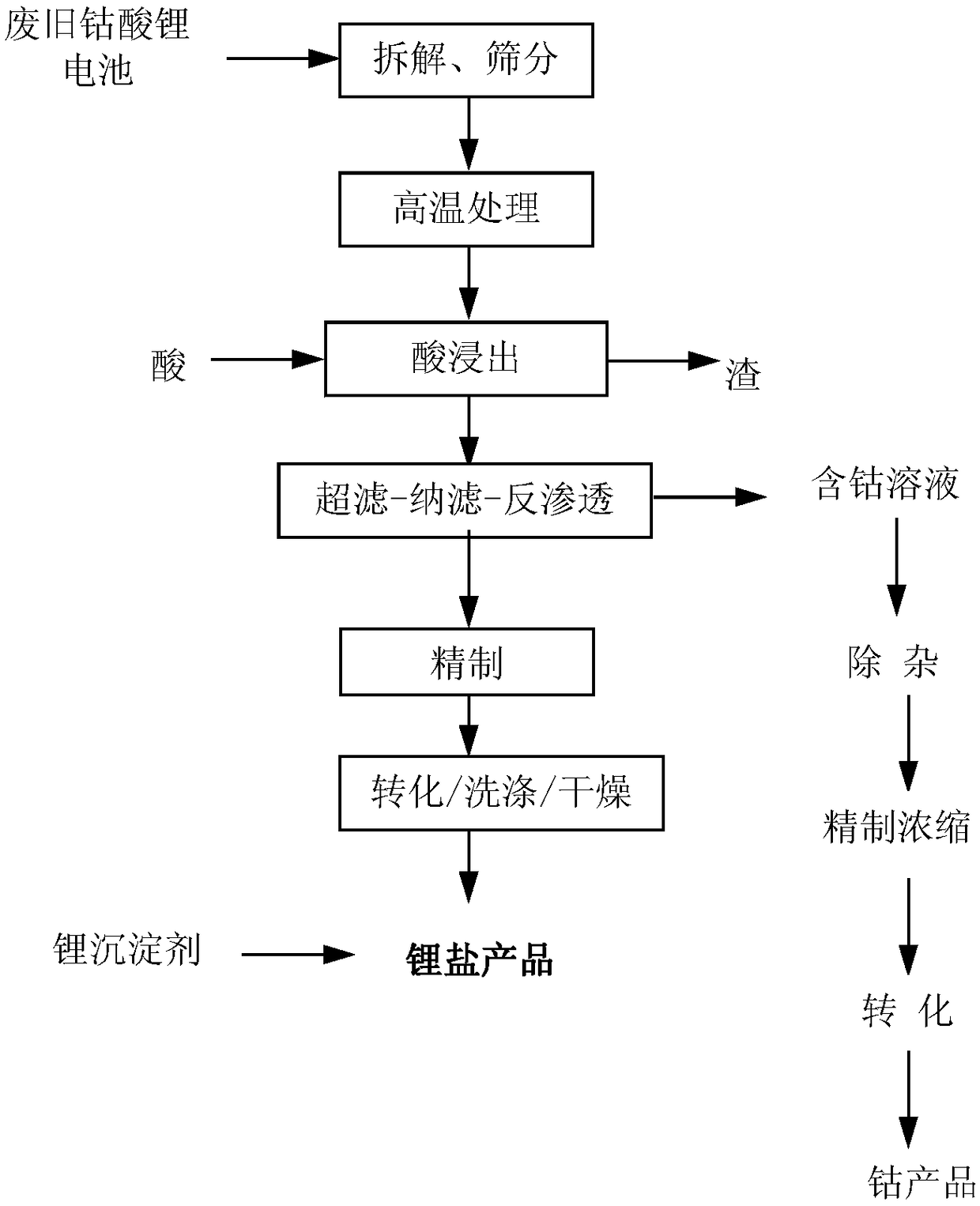

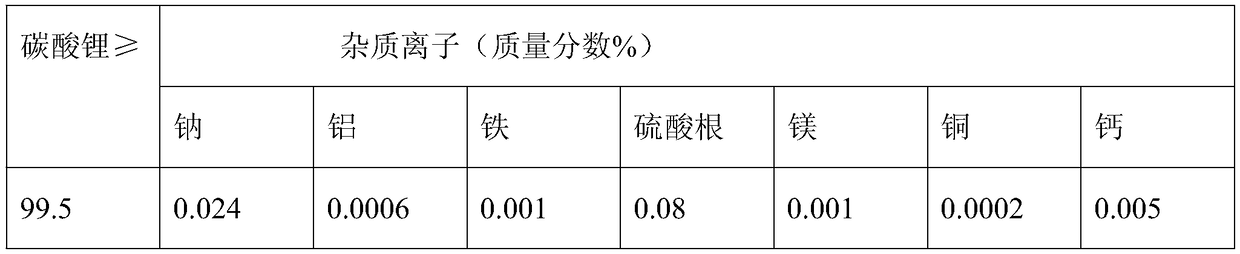

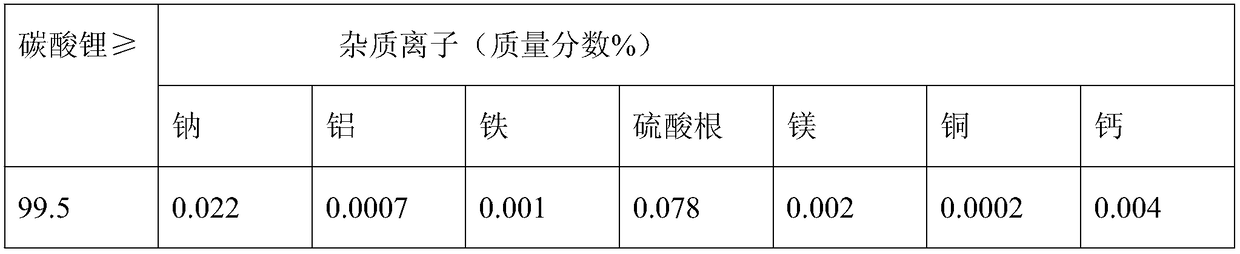

A method and system for recovering lithium and cobalt from spent lithium cobalt oxide batteries

ActiveCN109256597AAdvanced separation technologyEasy to separateWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionLithium

The invention discloses a method and a system for recovering lithium and cobalt from waste lithium cobalt oxide batteries. The method comprises the following steps of: disassembling a positive electrode sheet from a waste lithium cobalt oxide battery; Removing the binder in the positive electrode sheet, and then acid leaching the valuable metal elements in the positive electrode sheet to obtain anacidizing leaching solution; The acidified leachate was treated by ultrafiltration membrane. Separating lithium ions in acidified leaching solution from other cations different from lithium ions by using nanofiltration membrane technology to obtain lithium-containing solution and solution containing other cations, and concentrating and enriching the lithium-containing solution and the solution containing other cations respectively by reverse osmosis technology, wherein the other cations include cobalt ions; And a lithium precipitant is used to precipitate lithium ions from a lithium-containing solution, and an alkaline substance is used to precipitate cobalt ions from a solution containing other cations, thereby realizing the recovery of lithium and cobalt. The adoption of ultrafiltration-Nanofiltration-Reverse osmosis combined technology has the characteristics of simple process, less acid and alkali consumption, good and stable membrane separation effect and so on.

Owner:青海中科德方能源科技研究有限公司

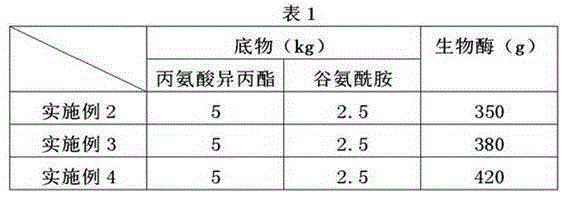

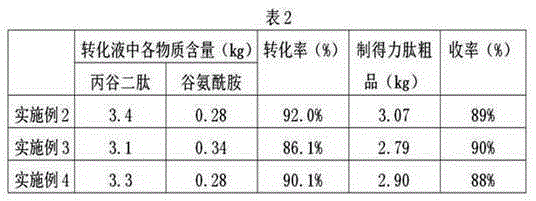

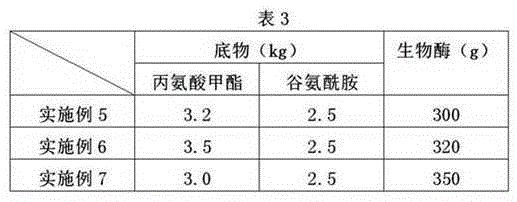

Method for preparing alanyl-glutamine dipeptide through biological enzyme conversion

InactiveCN105274174AHigh activityImprove catalytic conversion effectFermentationTemperature controlReaction rate

The invention relates to the technical field of the preparation for alanyl-glutamine dipeptide and particularly discloses a method for preparing alanyl-glutamine dipeptide through biological enzyme conversion. The method comprises the following steps: 1) preparing a biological enzyme liquid: dissolving the biological enzyme in a buffered liquid, controlling pH value within the scope of 7.0+ / -2.0, controlling the temperature at 5-10 DEG C, thereby acquiring the biological enzyme liquid, wherein the mass fraction of the ester acyl-containing transferring biological enzyme is 5%-20%; 2) dissolving the ester derivates of substrate L-alanine and glutamine in pure water, and then uniformly dropping the biological enzyme liquid into a reaction liquor, and meanwhile, adding acid liquor or alkali liquor, controlling the pH of the reaction liquor at 5-10, reacting under the temperature controlled at 15-25 DEG C, sampling and detecting the production of the alanyl-glutamine dipeptide during the reaction process, stopping reaction when the content of the alanyl-glutamine dipeptide is highest, and separating the acquired converted liquid, thereby acquiring the alanyl-glutamine dipeptide. According to the method provided by the invention, the enzyme activity is high, the reaction rate of the materials is higher, the method has the advantages of simple technique control, easy control on quality index and low cost, and the method is more fit for industrial production.

Owner:JING JING PHARMA

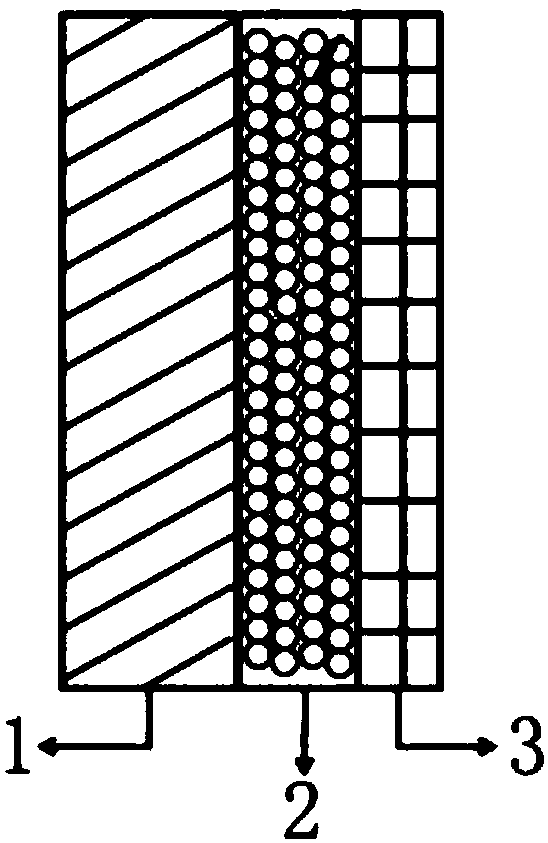

Lithium positive electrode surface protective coating and method for preparing same

ActiveCN108376783AEasy to operateReduce processing costsCell electrodesFinal product manufactureSolid state electrolyteNanoparticle

The invention discloses a lithium positive electrode surface protective coating and a method for preparing the same. The lithium positive electrode surface protective coating is characterized in thata protective coating mainly comprises nanometer particles which are stacked, and stacked pores of the nanometer particles are filled with solid electrolytes; the protective coating is arranged betweena lithium positive electrode and a diaphragm. The lithium positive electrode surface protective coating and the method have the advantages that the nanometer particles are stacked to form the protective coating, growth of lithium dendrites on lithium metal pole plates can be effectively inhibited by stacked structures formed by the nanometer particles by means of stacking, and accordingly the problem of diaphragm piercing due to growth of existing lithium dendrites can be solved; the solid electrolytes in the stacked pores of the nanometer particles are high in lithium ionic conductivity, accordingly, the transmission rate of the lithium metal pole plates can be guaranteed, side reaction between lithium metal and electrolyte solution can be effectively isolated, the recycling service lives of the lithium metal pole plates can be greatly prolonged, and the safety of the lithium metal pole plates can be improved.

Owner:四川华昆能源有限责任公司

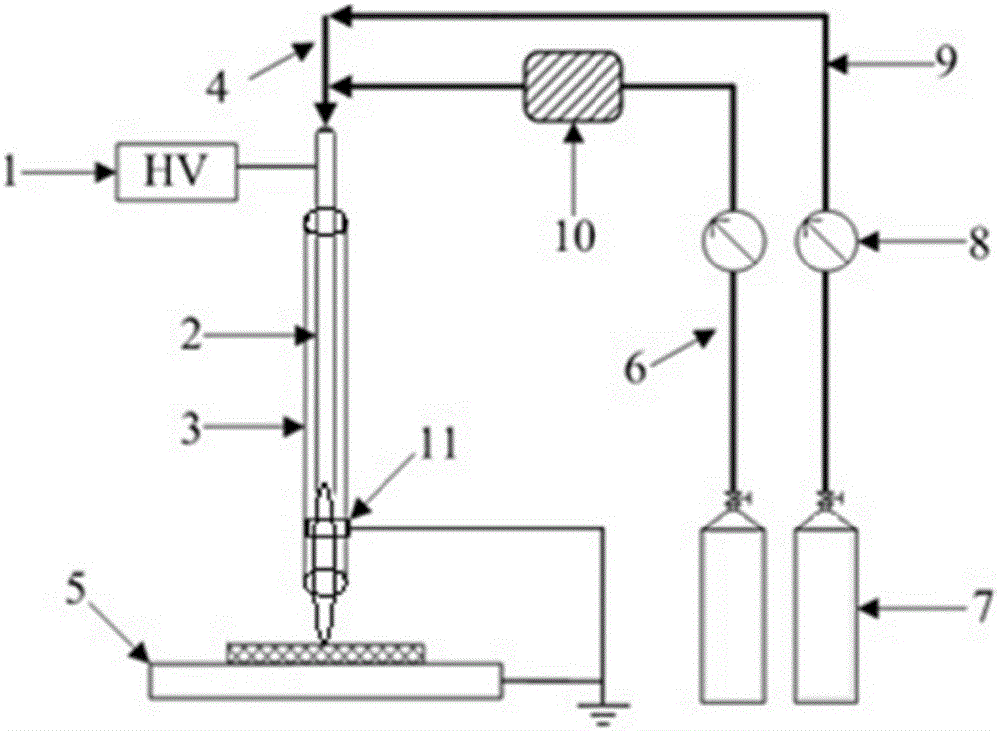

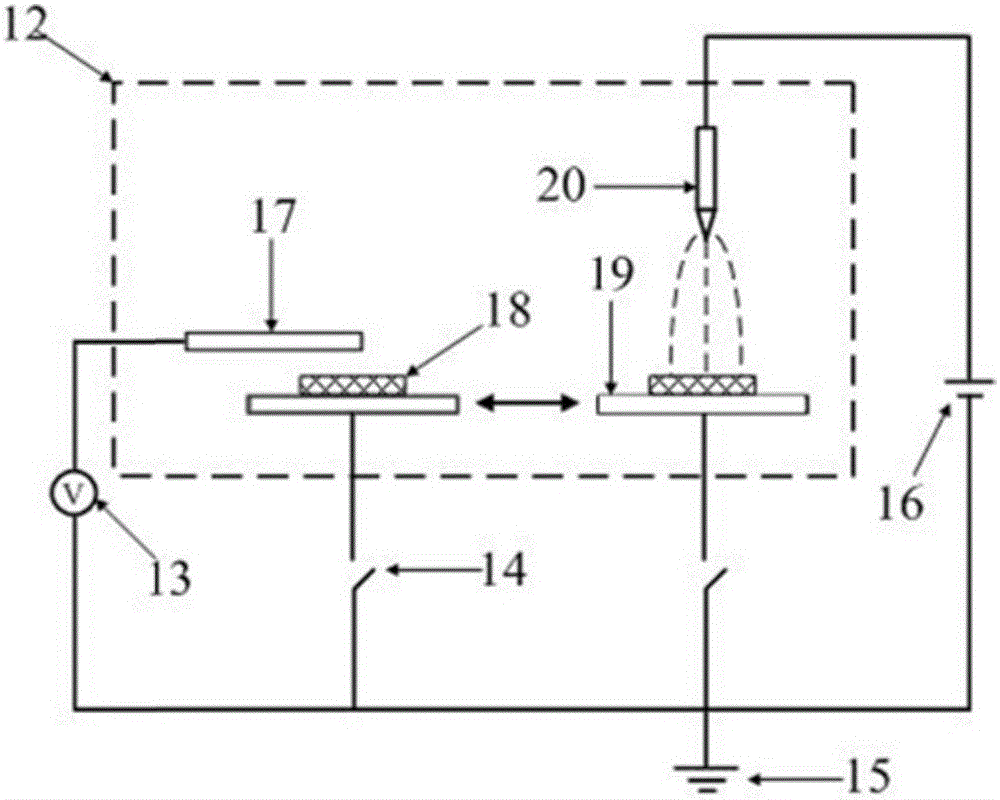

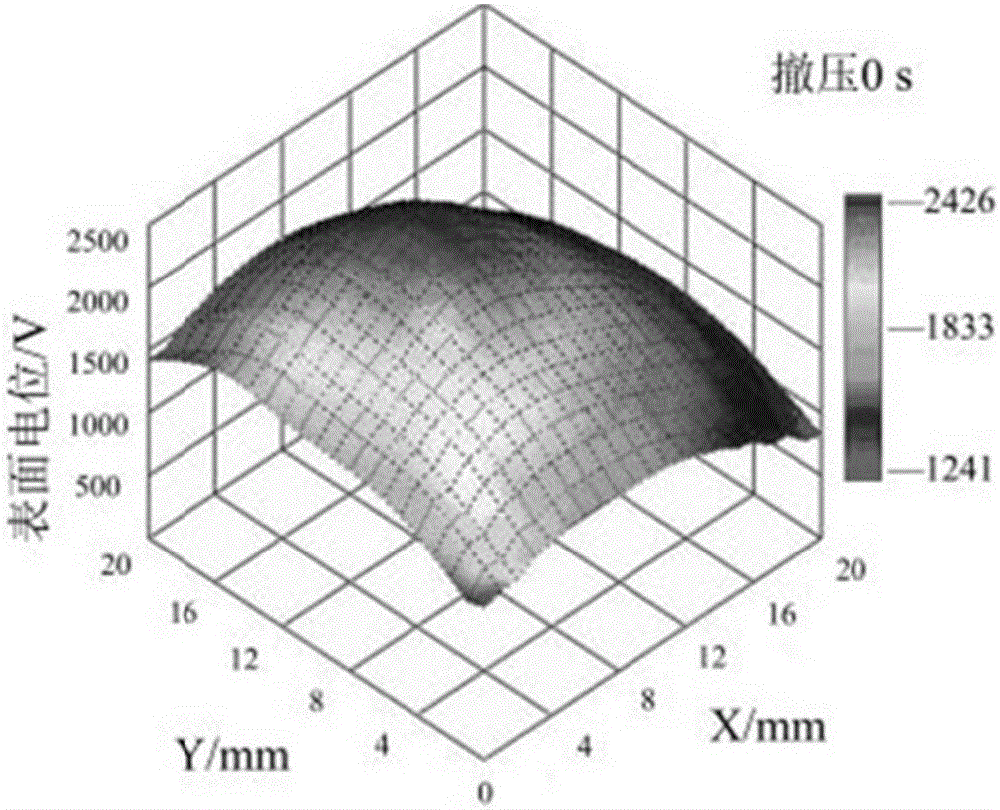

Plasma jet device and method for suppressing charge accumulation on epoxy resin surface

The invention relates to a plasma jet device and a method for suppressing charge accumulation on an epoxy resin surface. The plasma jet device comprises a hollow metal capillary tube and a heating platform, wherein a quartz glass tube sleeves the outside of the hollow metal capillary tube; the hollow metal capillary tube and the quartz glass tube are combined into a jet pipe of atmospheric plasma jet; the jet pipe is connected with a high-voltage power supply and simultaneously grounded; an air inlet is arranged in the top end of the hollow metal capillary tube; the heating platform is located at the bottom part of the jet pipe; a sample is placed on the heating platform; and the heating platform is grounded. The device is simple in structure; the method is simple and feasible; the effect is lasting; the treatment efficiency is high; and the environmental influence is small, so that the plasma jet device is suitable for industrial production and application.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

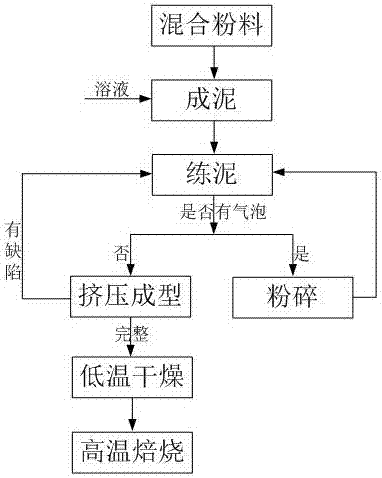

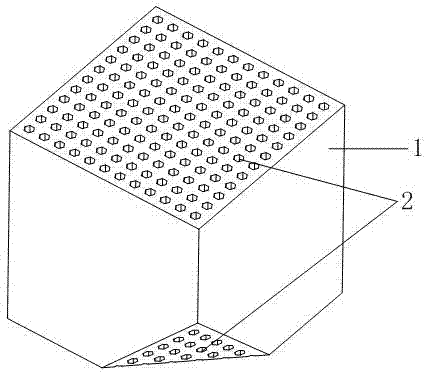

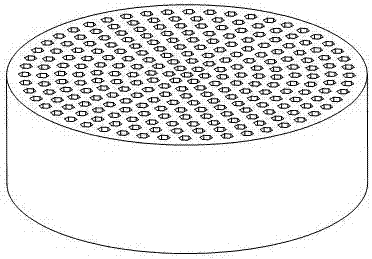

Honeycombed catalyst material and forming method thereof

InactiveCN106975493AUniform sizeUnified structureMolecular sieve catalystsDispersed particle separationOptimal matchingCatalytic efficiency

The invention belongs to the field of catalyst materials and forming methods thereof, and concretely relates to a honeycombed catalyst material and an extrusion forming method thereof. The invention discloses the honeycombed catalyst material and the forming method thereof, and discloses the optimal content, the optimal ingredients and the optimal matching ratio of the honeycombed catalyst material and the preparation forming method thereof at the same time. A result shows that the honeycombed catalyst material has high catalytic efficiency on harmful gases such as formaldehyde and methylbenzene.

Owner:NINGBO TAIAN NEW MATERIAL TECH CO LTD

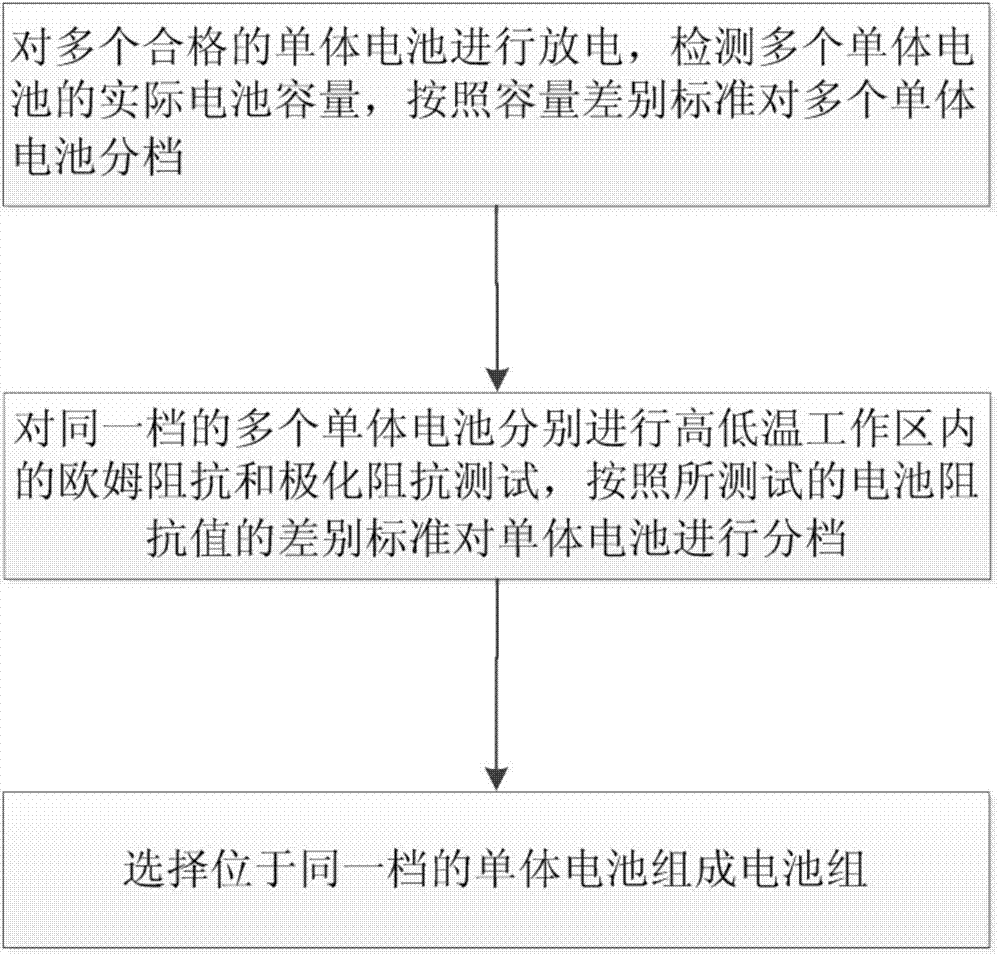

Method for detecting consistency of single batteries

InactiveCN104730463AReduce harmExtended service lifeElectrical testingTest batteryElectrical battery

The invention discloses a method for detecting consistency of single batteries. The method comprises the steps that the qualified single batteries are discharged, the actual battery capacity of the single batteries is detected, and the single batteries are graded according to the capacity difference standard; ohmic resistance testing and polarization resistance testing in high-temperature and low-temperature work areas are carried out on the single batteries of the same grade, and the single batteries are graded according to the difference standard of the tested battery resistance values; a battery unit is formed by selecting the single batteries of the same grade. The work characteristics of lithium ion batteries in the high-temperature area and the low-temperature area are considered comprehensively, the consistency of the batteries can be distinguished more directly, and therefore damage caused by inconsistency of the batteries to the battery set is reduced, and the service life of the battery set is prolonged.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

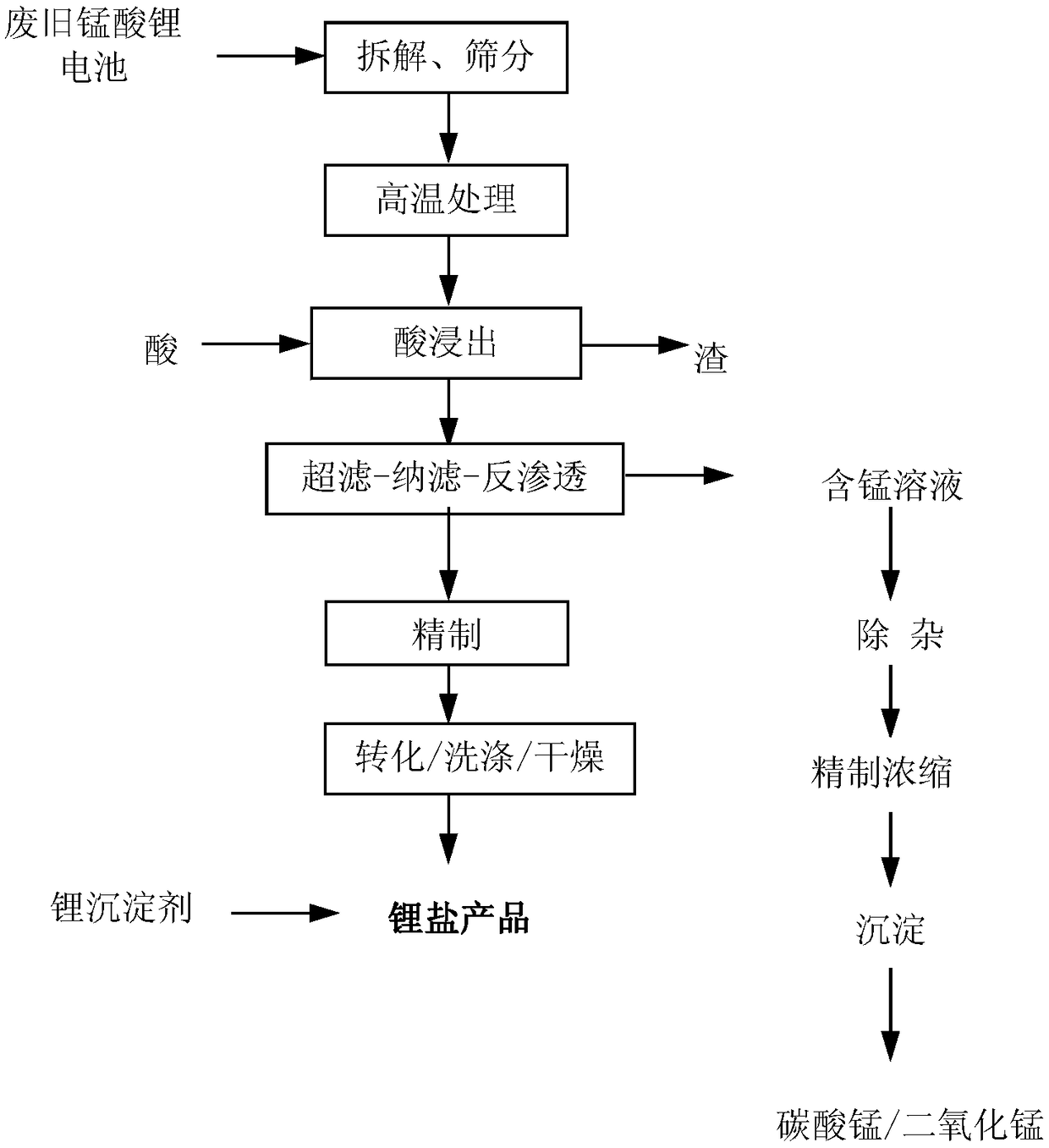

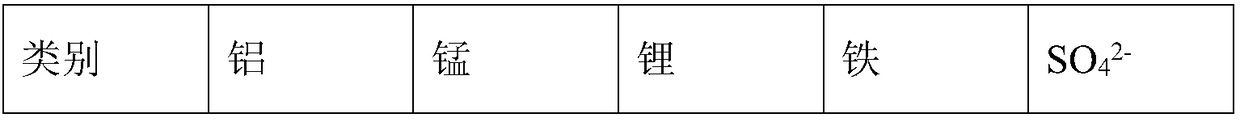

Method and system for recovering lithium and manganese from waste lithium manganate battery

ActiveCN109207725AAdvanced separation technologyEasy to separateWaste accumulators reclaimingBattery recyclingMembrane technologyManganese

The invention discloses a method and system for recovering lithium and manganese from a waste lithium manganate battery. The method comprises the following steps that a positive plate is disassembledfrom the waste lithium manganate battery; a binder in the positive plate is removed, valuable metal elements in the positive plate are leached by acid dissolution, and acidified leachate is obtained;ultrafiltration treatment is carried out on the acidified leachate by using an ultrafiltration membrane; by using a nanofiltration membrane technology, lithium ions in the acidified leachate are separated from other cations different from lithium ions, a solution containing lithium and a solution containing other cations are obtained, and then a reverse osmosis technology is adopted for concentration and enrichment correspondingly, wherein the other cations comprise manganese ions; and a lithium precipitant is adopted to precipitate and separate lithium ions in the lithium-containing solution,and alkaline substances are adopted to precipitate and separate manganese ions in the solution containing other cations, so that the recovery of lithium and manganese is realized. According to the method and system, the ultrafiltration-nanofiltration-reverse osmosis combined technology is adopted, and the method and system have the beneficial effects of simple process, environmental protection, less acid and alkali consumption, good and stable membrane separation effect and the like.

Owner:青海中科德方能源科技研究有限公司

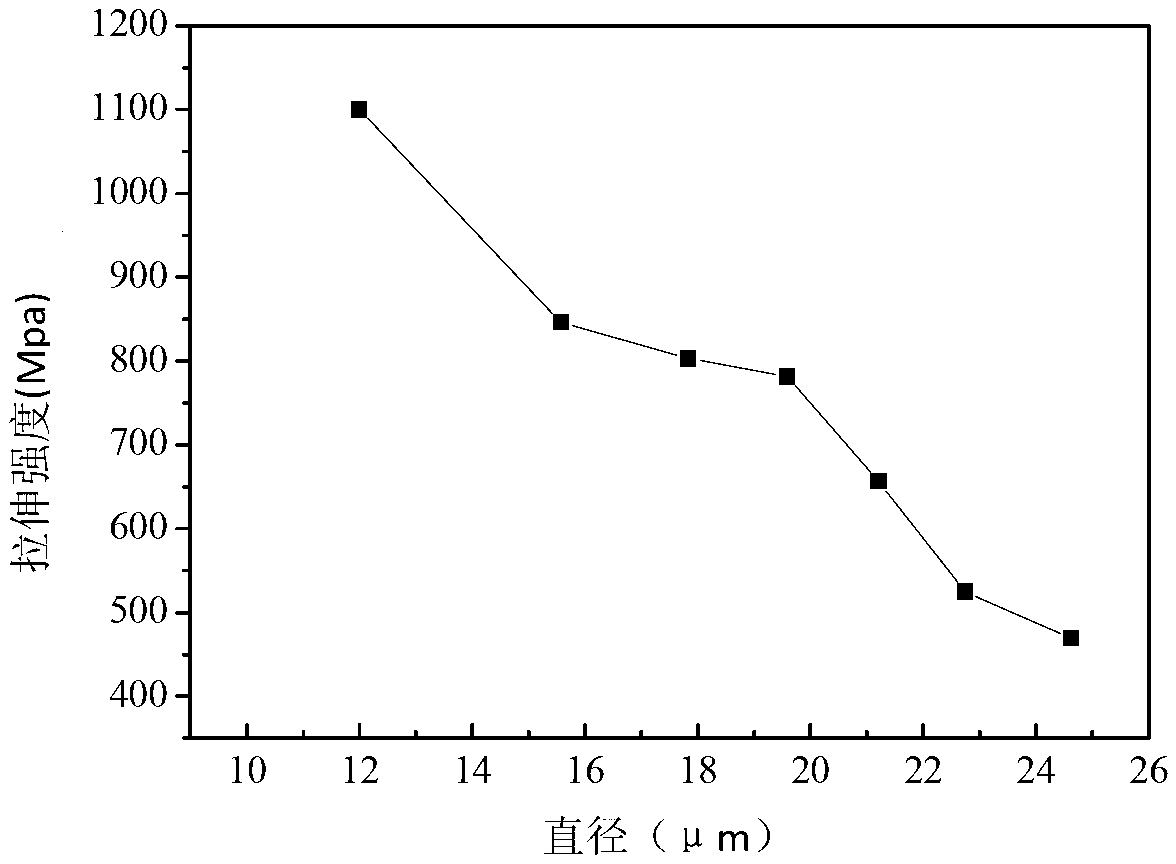

Preparation method of general purpose pitch-based carbon fiber

InactiveCN103014919AGood qualityHigh strengthWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansDistillationIntegrated processing

The invention relates to a preparation method of a general purpose pitch-based carbon fiber. The preparation method has the beneficial effects that isotropic pitch with high softening point and excellent spinnability is obtained through the comprehensive treatment technologies such as heat treatment, heat filtration, reduced pressure distillation, oxidation treatment and modification with an additive and then the general purpose pitch-based carbon fiber is prepared through melt spinning, non-melting treatment and carbonization treatment; the pitch blended by the method is low in heteroatom content, narrow in molecular weight distribution and high in carbon content, contains defined amount of short alkyl side chains and can solve the technical problems that the melt spinning materials are brittle and are not easy to operate and non-melting treatment costs long time; the carbon fiber prepared by the method has good quality, high strength and good continuity; and the preparation method is simple in process, mild in reaction conditions and low in environmental pollution and is applicable to industrial production.

Owner:SHAANXI NORMAL UNIV

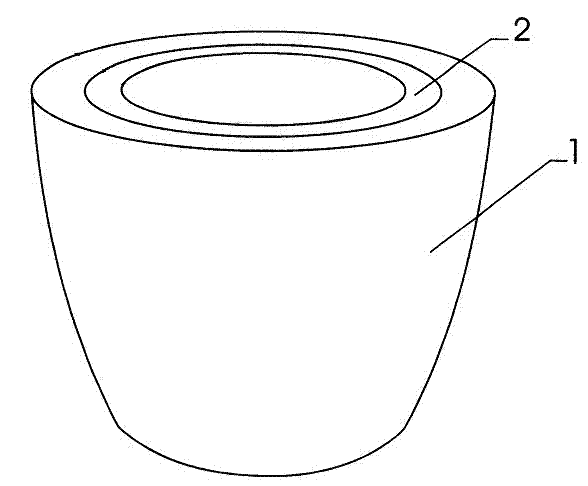

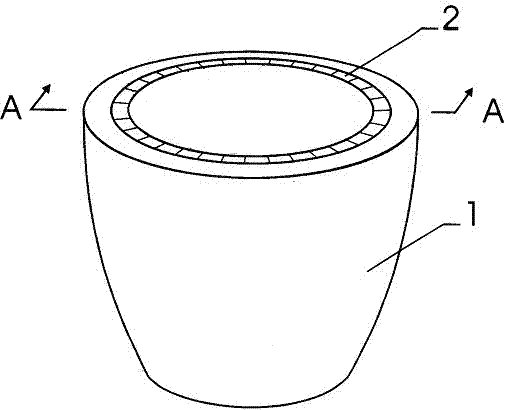

Molten titanium and titanium alloy crucible and preparation method thereof

InactiveCN103922769AEliminate defects that are prone to cracksEasy to replace and maintainCrucibleTitanium

The invention discloses a molten titanium and titanium alloy crucible which is at least formed by combining a crucible shell and a crucible lining, wherein the crucible lining is of an opened structure capable of holding a melt and is made of a composite material; the crucible shell is made of a high-temperature-resistant material with a high melting point and is of a force bearing structure capable of bearing pressure generated by titanium melts and titanium alloy melts; the crucible lining is made of a sintered composite prepared by mixing the following main components: 45-70wt% of barium oxide, 30-50wt% of zirconium oxide and 0-5wt% of fluxing agent, wherein the fluxing agent is titanium oxide, aluminum oxide or boron oxide. The invention also discloses a preparation method of the crucible; the crucible lining is assembled in a way of stacking and combining sintered bricks and can be disassembled in a decomposition way. An inner layer material of the crucible disclosed by the invention does not react with titanium; in addition, the crucible is nonstick, capable of meeting the requirements of industrialization, large capacity, low cost, easiness for maintenance and long service life, reasonable in structure and mature in preparation process.

Owner:SHANGHAI UNIV

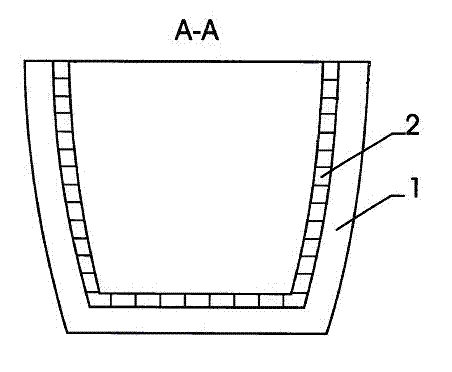

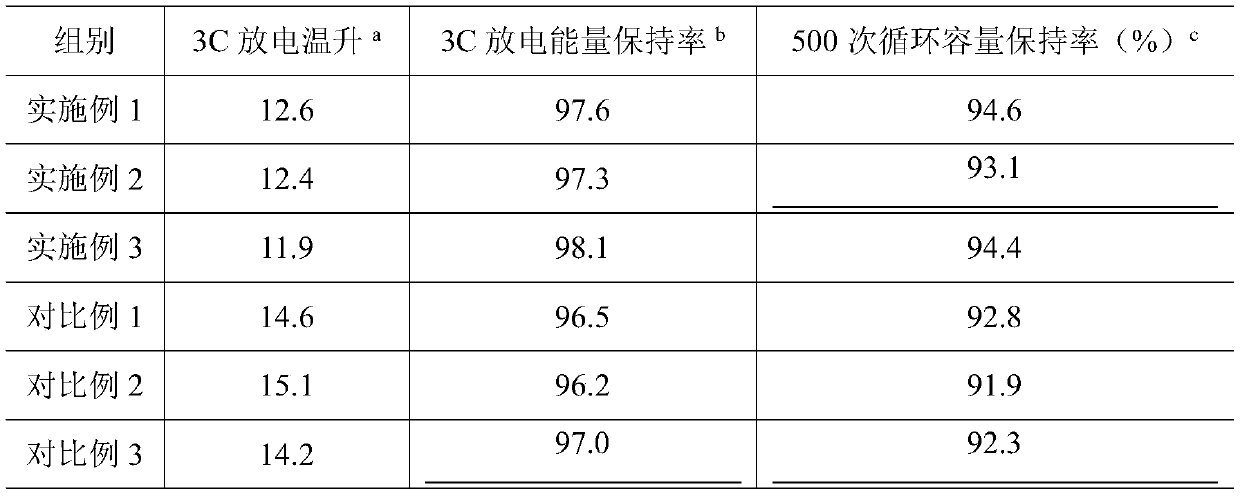

Surface-coated positive electrode material and preparation method and application thereof

PendingCN109742382AGuaranteed performanceExtended service lifeCell electrodesSecondary cellsPhosphoric acidAluminium

The invention relates to a surface-coated positive electrode material and a preparation method and application thereof. The surface-coated positive electrode material comprises a substrate and a coating layer covering the substrate, wherein the substrate is a positive electrode material, and the composition of the coating layer contains aluminum metaphosphate. The surface-coated positive electrodematerial adopts aluminum metaphosphate to form the coating layer, so that the cycle performance of the positive electrode material of a lithium-ion battery, especially the high-temperature cycle performance can be effectively improved.

Owner:湖南桑瑞新材料有限公司

Preparation method of multi-layer coating pole piece

ActiveCN111370649AFast transferReduce manufacturing costCell electrodesSecondary cells servicing/maintenanceElectrochemical responseConcentration polarization

The invention discloses a preparation method of a multi-layer coated pole piece, which comprises the following steps: in the process of preparing a lithium ion battery pole piece, preparing slurry 1,slurry 2 and slurry 3 of which the active substance content is gradually reduced and the binder content and the conductive agent content are gradually increased from an active substance, a conductiveagent, a binder and a dispersing solvent according to different proportions; and sequentially coating the slurry 1, the slurry 2 and the slurry 3 on the surface of a current collector, rolling and drying to obtain the pole piece. According to the pole piece prepared by the method, the active substance, the binder and the conductive additive are distributed in a gradient manner from the inner sideof the pole piece to the outer side of the pole piece, so that the purposes that the porosity of the pole piece is gradually reduced from inside to outside and the electronic conductivity is graduallyincreased are achieved. The pole piece prepared by the method can balance electron and ion conductivity and reduce concentration polarization and non-uniformity of electrochemical reaction rate, so that the pole piece has both high energy density and good electrochemical performance. The preparation method is simple and easy to implement, low in manufacturing cost and suitable for industrial production and application.

Owner:江西安驰新能源科技有限公司

Lithium battery cathode additive, lithium ion battery, preparation method and uses thereof

ActiveCN105355849AStrong metal activityHigh specific capacityNon-aqueous electrolyte accumulator electrodesSecondary cells servicing/maintenanceActive agentCarbon nanotube

The invention discloses a lithium battery cathode additive, a lithium ion battery, a preparation method and uses thereof, and belongs to the technical field of lithium secondary battery. The cathode additive is a core-shell structure, wherein the core is composed of nanometer silicon powder, lithium powder compound and hollow carbon spheres, and the shell is composed of carbon nanotubes, surfactants and doping agents; the mass proportion of the nanometer silicon powder, the lithium powder compound and the hollow carbon spheres is 10-70:0.1-10:20-80; the mass proportion of the carbon nanotubes, surfactants, doping agents and nanometer silicon powder is 5-20:2.5-10:0.5-7:10-70; the lithium powder compound is a core-shell capsule constituted by lithium powder and polymer wrapping the lithium powder; the doping agents are sodium chloride and / or sodium fluoride; the surfactants is sodium dodecyl benzene sulfonate. The cathode additive is added to the graphite cathode, thereby obviously promotes gram volume, initial efficiency and circulation performance of the cathode materials and absorbing ability of the cathode plate.

Owner:CALB CO LTD

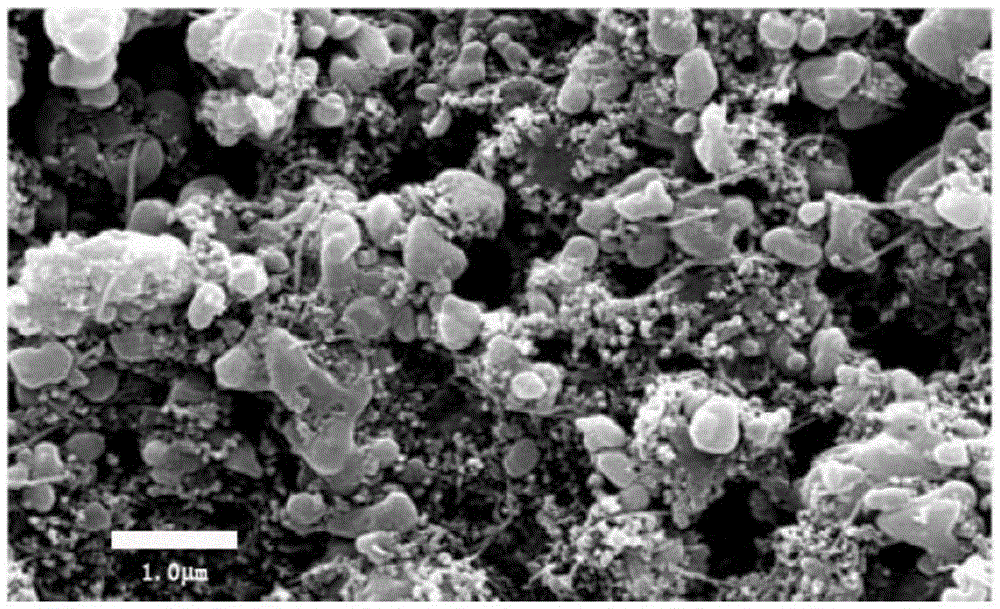

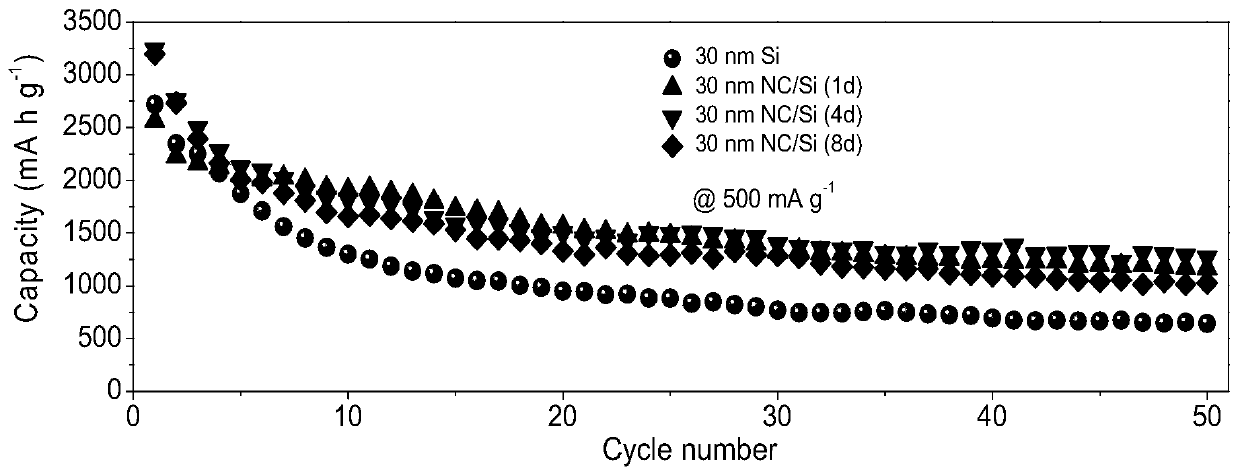

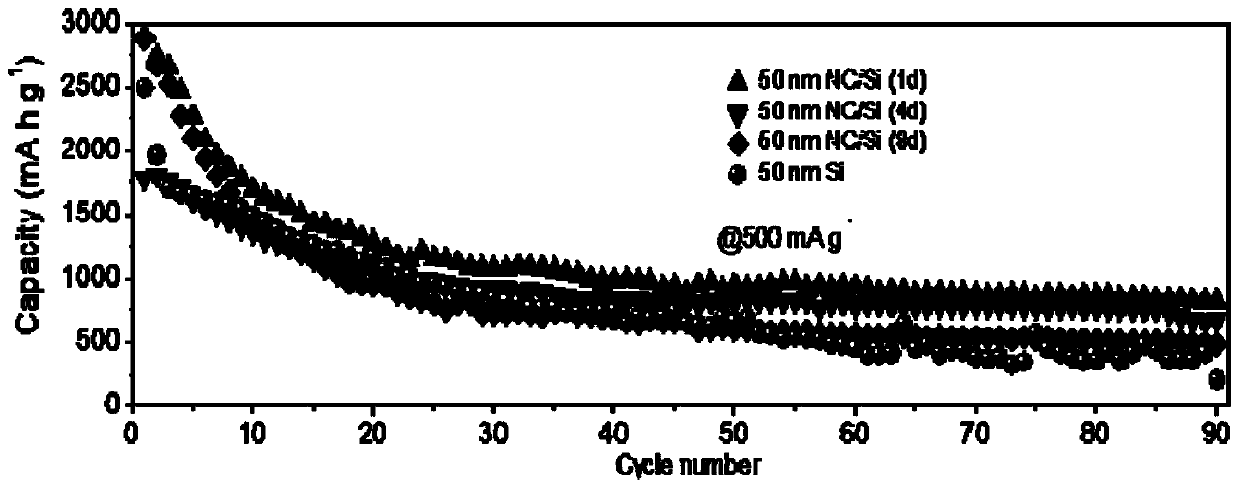

Nitrogen-doped carbon-coated silicon nanoparticle composite material, preparation method and application

InactiveCN109786666AEasy to operateEasy to implementMaterial nanotechnologySiliconCarbon coatedSilicon nanoparticle

The invention discloses a nitrogen-doped carbon-coated silicon nanoparticle composite material and a preparation method thereof. The preparation method comprises the following steps that: S1: puttinga silicon nanoparticle of which the grain diameter is 30-50nm in Tris-HCl buffer solution of which the pH (Potential of Hydrogen) is 7.5, cleaning, and drying to obtain processed silicon nanoparticles; S2: adding dopamine hydrochloride into Tris-HCl buffer solution of which the pH is 8.5, and dissolving to obtain dopamine solution; S3: adding the silicon nanoparticle processed in S1 into the dopamine solution obtained in S2, evenly dispersing, carrying out stirring reaction at the room temperature for 1-8 days, and carrying out separation and drying to obtain reactant; and S4: under an inert atmosphere, calcinating the reactant obtained in S3 at a temperature of 700-900DEG C for 1-2h to obtain a composite material. The invention also discloses the application of the above composite material on a lithium battery negative electrode. The composite material synthesized by the preparation method has excellent cycling stability.

Owner:BLUE OCEAN & BLACK STONE TECH CO LTD FUJIAN

Copper cleaning agent and preparation method thereof

The invention discloses a copper cleaning agent and a preparation method thereof. The copper cleaning agent disclosed by the invention consists of an inorganic acid, an organic acid, a surfactant, a penetrating agent, an emulsifier, a defoaming agent, a complexing agent and water. The inorganic acid and the organic acid are compounded, the hazards to health of cleaning workers caused by individual use of the inorganic acid in the traditional cleaning agent are avoided, over etching of a copper workpiece is also avoided, the copper cleaning agent is an environmental-friendly cleaning agent and has a certain oiliness, an effect of cleaning dirt such as oil attached to the surface of a copper part is improved by using the cleaning agent, the cleaning agent solution is acidic, and the oxide skin on the surface of the copper part can be well removed. The cleaning agent prepared by the invention is simple in using method, the copper part only needs to be soaked at normal temperature for 2-5 minutes so as to be cleaned, no greasy dirt residue is left on the cleaned copper part, the color of the surface of the copper part is the copper base color, and the cleaning effect is obvious. The copper cleaning agent disclosed by the invention is simple in preparation method, low in cost and obvious in effect and is suitable for industrial production and application.

Owner:PINGGAO GRP +1

Preparation method of phosphorus-silicon compound

The invention discloses a preparation method of a phosphorus-silicon compound which is shown in the general formula (1) disclosed in the specification. The method comprises: phosphate and chlorosilane are utilized to be subjected to direct polycondensation at the atmospheric pressure in one step so as to obtain the target product with high yield. By adjusting the molar ratio of the phosphate to the chlorosilane, the degree of polymerization of the product can be controlled. The phosphorus-silicon compound can be used as a fire retardant and used in macromolecular materials such as plastics and rubbers. In the formula (1), R1 represents C1-C4 alkyl; R2 represents C1-C4 alkyl, C1-C4 alkoxy or H; R3 represents C1-C4 alkyl or aryl; and n represents an integer within a range of 2-2000.

Owner:中国中化股份有限公司 +1

Nylon fabric dyeing technology

InactiveCN103276610ANot easy to creaseNot easy to form wrinklesHeating/cooling textile fabricsDry-cleaning apparatus for textilesProcess engineeringPre treatment

The invention discloses a nylon fabric dyeing technology. The technology adopts a process flow comprising the steps of blank pretreatment, presetting, jet dyeing, water washing, color fixation, water washing and air drying, the water washing and the high-temperature presetting treatments before dyeing make creases and wrinkles be difficultly formed in the dyeing process to obtain a special wrinkle effect, and the adoption of a jet dyeing machine for dying and the change cooperation addition of an assistant, a dye and the temperature effectively avoid variegation and color wrinkle phenomena and make the dyeing uniform and a finished product soft and fluffy, so the technology has a good coloring effect, is suitable for the large-scale industrial production and application, and has an improved market competiveness.

Owner:太仓市芸芸化纤有限公司

High-tap-density nickel-cobalt-manganese laminated composite material and low-energy-consumption preparation method thereof

InactiveCN102810667AHigh discharge specific capacityHigh rate capacityCell electrodesManganeseLithium-ion battery

The invention relates to a high-tap-density nickel-cobalt-manganese laminated composite material and a low-energy-consumption preparation method thereof, and provides a lithium-ion battery anode material lithium nickel 1 (LiNi1) / 3 cobalt (3Co1) / 3 manganese 1 (3Mn1) / 3 oxygen (O2)-yXy (wherein X is one or more of fluorine (F), chloride (Cl) or bromine (Br), and y is more than zero and less than or equal to 0.2) and a preparation method thereof. The preparation method comprises following steps that firstly the Ni1 / 3Co1 / 3Mn1 / 3(OH)2 is adequately mixed with fused salt and then is heat preserved for 2 to 20 hours under the temperature of 400 to 1000 DEG C to prepare the anode material. The lithium-ion battery anode material has characteristics of high tap density, good multiplying capacity and long service life under high cut-off voltage. According to the preparation method, the heat treatment temperature is reduced, the heat treatment time is shortened, a great amount of electric quantity is saved, the production efficiency is improved and a favorable industrialized application prospect is reflected.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-entropy mixed oxide electrode material and preparing method thereof

The invention discloses a high-entropy mixed oxide electrode material and a preparing method thereof, which relate to oxide materials and a process for material preparation. The high-entropy mixed oxide electrode material is composed of a metal conductive substrate and an oxide film, wherein the oxide film is of a high-entropy structure and is a high-entropy mixed oxide film formed by ruthenium oxide, manganese oxide, stannic oxide, tantalum oxide, cobalt oxide, zirconium oxide, titanium oxide and antimony oxide. The preparing method includes steps of brush coating, drying, thermal oxidation treatment and cooling. The high-entropy mixed oxide electrode material has high specific capacitance and is suitable for preparing high-performance super-capacitors. In addition, the method for preparing the high-entropy mixed oxide electrode material is simple in process, convenient to operate and suitable for being applied to large-scale production.

Owner:QUANZHOU NORMAL UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com