Method for evaluating consistency of batteries

A consistency and battery technology, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve the problems of not being able to truly and effectively judge the consistency of batteries, and achieve the effects of improving service life, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment is used to illustrate the battery consistency evaluation method provided by the present invention.

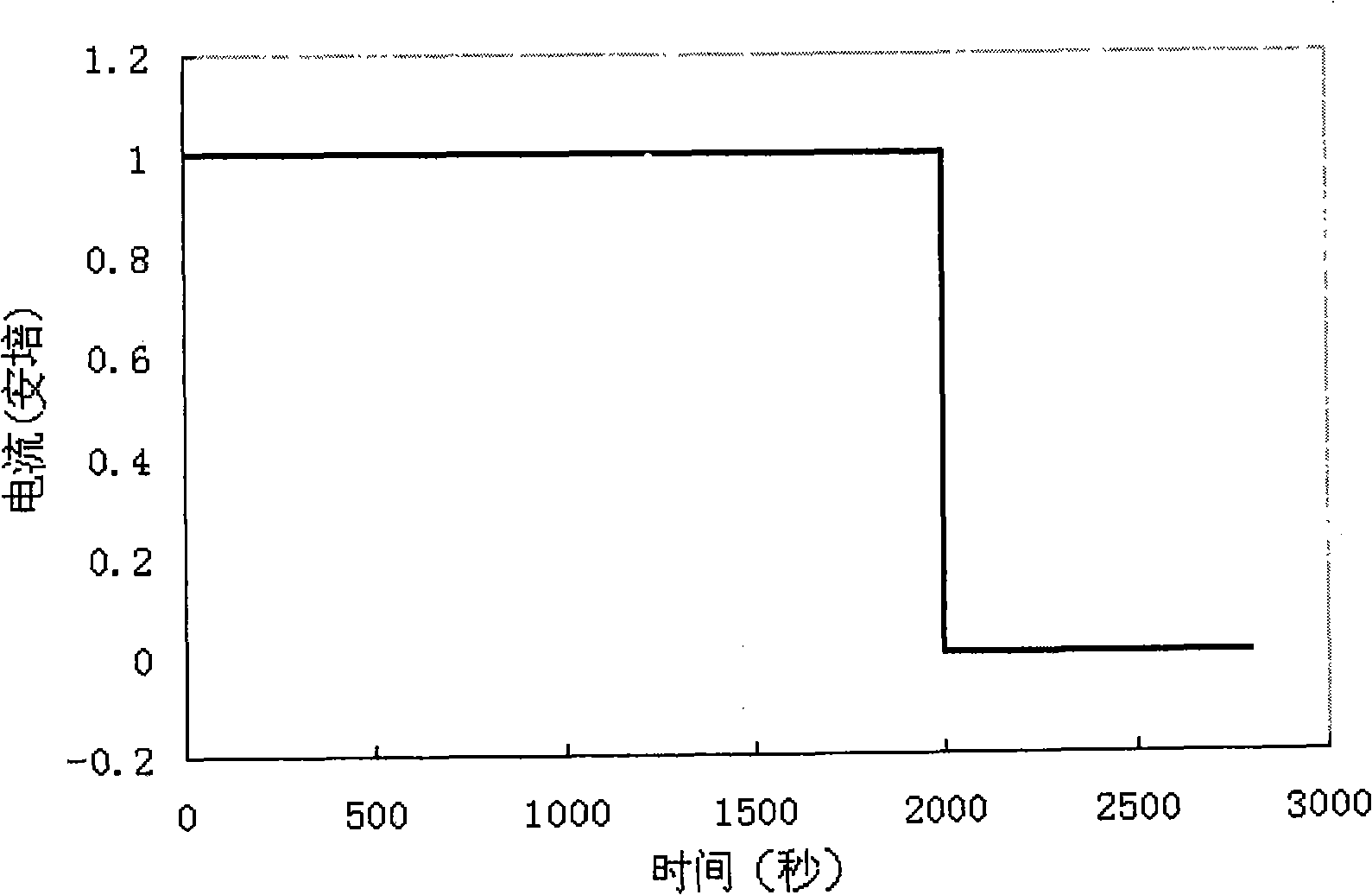

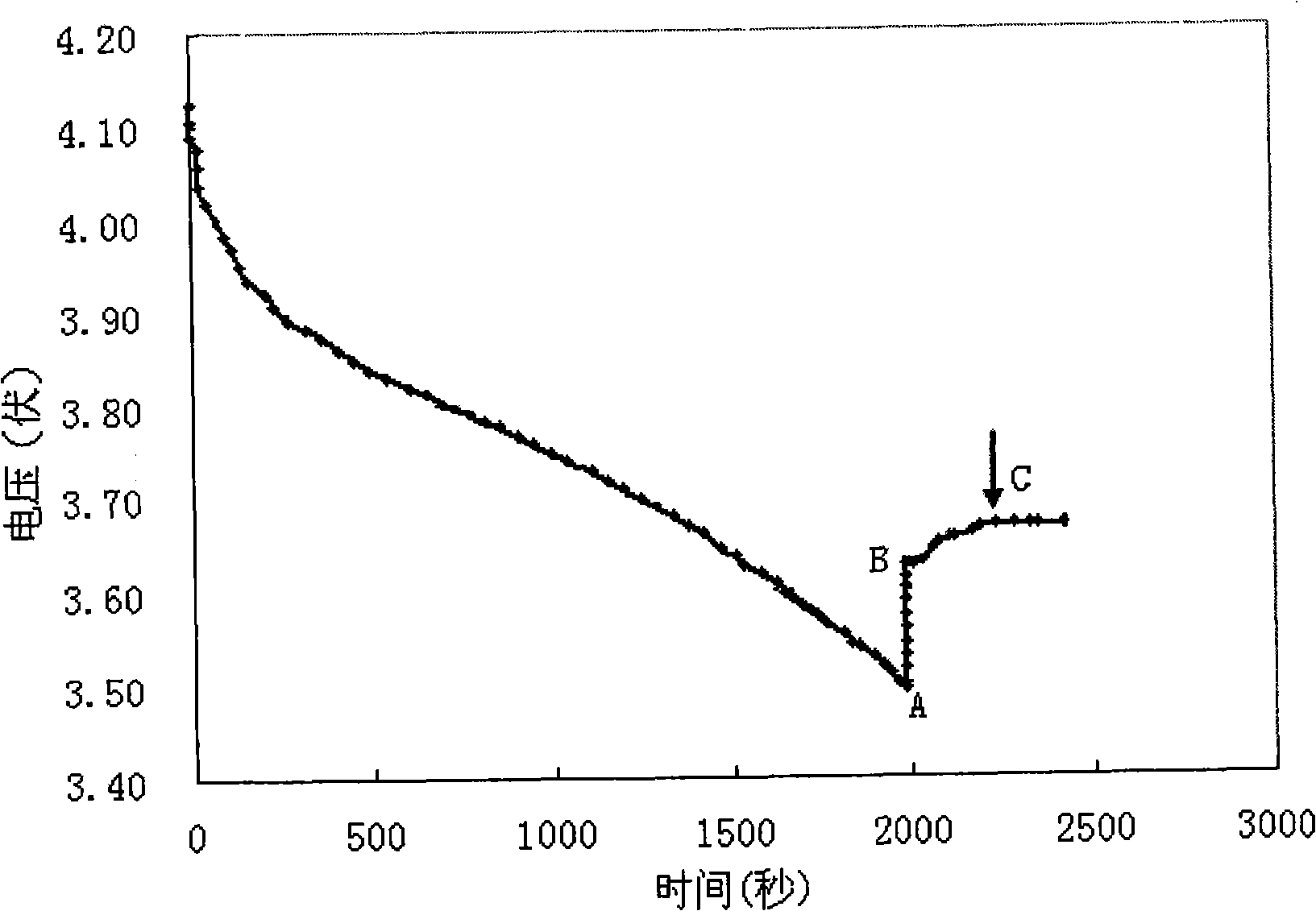

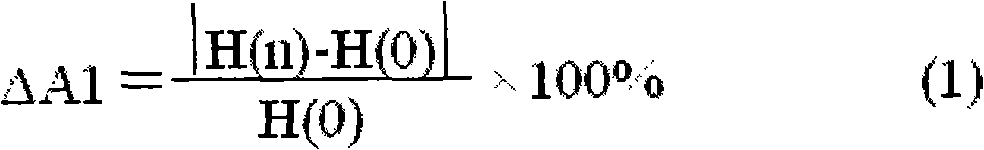

[0032] Put 10 fully-charged lithium-ion batteries (BYD company, LP053450 lithium-cobalt battery, working current of 1 ampere) respectively numbered a1, b1, c1, d1, e1, f1, g1, h1, i1, j1 The charging and discharging cabinet (Lanqi BK6016) is used for charging and discharging tests, and 10 batteries are subjected to constant current discharge. The constant current discharge current is 0.8 amps, the constant current discharge time is 35 minutes, and the shelf time is 12 minutes. At the same time, the voltage of the battery is detected to obtain the corresponding voltage-time curve. Measure the height of the instantaneous recovery segment AB and the slow recovery segment BC of the 10 battery voltage curves in the voltage direction and the length of the slow recovery segment BC in the time direction. Based on the height of the instantaneous recovery section ...

Embodiment 2

[0037] This embodiment is used to illustrate the battery consistency evaluation method provided by the present invention.

[0038] According to the method described in Example 1, 10 fully charged lithium-ion batteries respectively numbered a2, b2, c2, d2, e2, f2, g2, h2, i2, and j2 were evaluated for battery consistency. The constant current discharge current is 0.9 amps, the constant current discharge time is 50 minutes, and the rest time is 10 minutes. The results are shown in Table 2.

[0039] Table 2

[0040]

[0041] From the data in Table 2, it can be concluded that the comprehensive index value p of the consistency evaluation of the a2 battery and the f2, g2, and j2 batteries has the largest difference, and the q value is greater than 10%, and the consistency of the a2 battery and the f2, g2, and j2 batteries is determined Poor, can not be used in series or parallel to form a battery pack.

Embodiment 3

[0043] This embodiment is used to illustrate the battery consistency evaluation method provided by the present invention.

[0044] According to the method described in Example 1, 10 fully charged lithium ion batteries respectively numbered a3, b3, c3, d3, e3, f3, g3, h3, i3, and j3 were evaluated for battery consistency. The constant current discharge current is 1.2 amps, the constant current discharge time is 20 minutes, and the rest time is 11 minutes. The results are shown in Table 3.

[0045] table 3

[0046]

[0047] From the data in Table 3, it can be concluded that the comprehensive index value p of the consistency evaluation of the a3 battery and the h3, i3, and j3 batteries has the largest difference, and the q values are all greater than 10%, which determines the consistency of the a3 battery and the h3, i3, and j3 batteries Poor, can not be used in series or parallel to form a battery pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com