Surface-coated positive electrode material and preparation method and application thereof

A positive electrode material and surface coating technology, which is applied in the field of surface coated positive electrode materials and its preparation, can solve the problems of poor high-temperature cycle performance and achieve the effect of ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

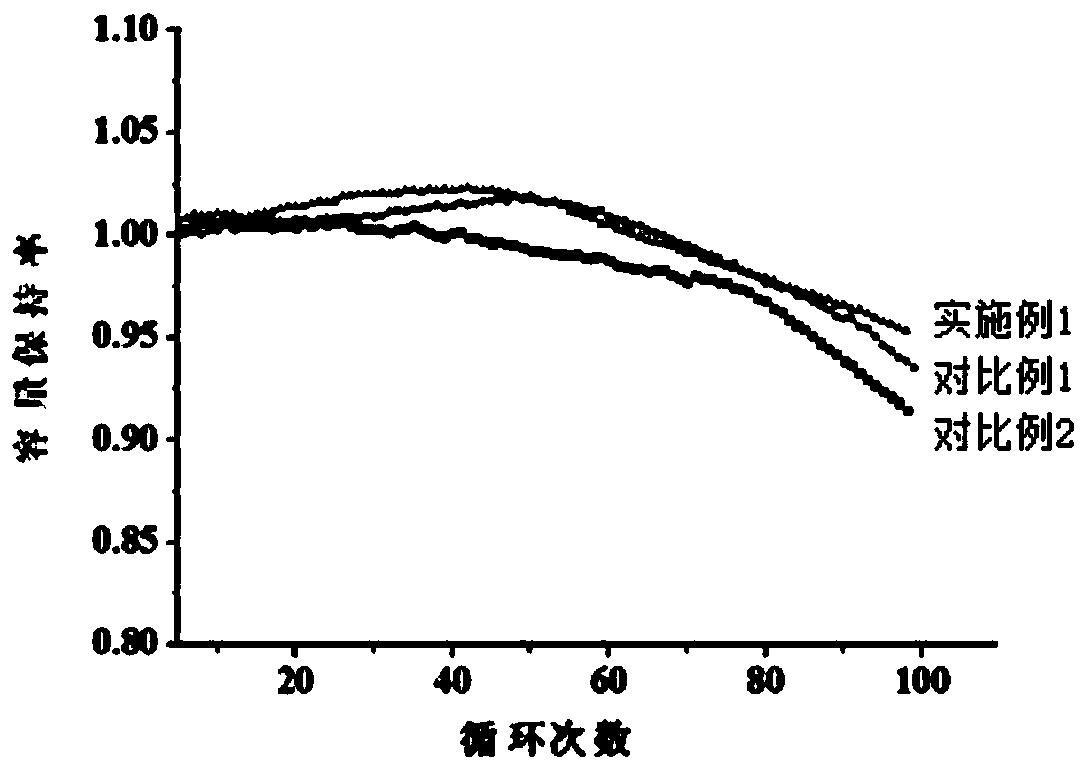

Examples

Embodiment 1

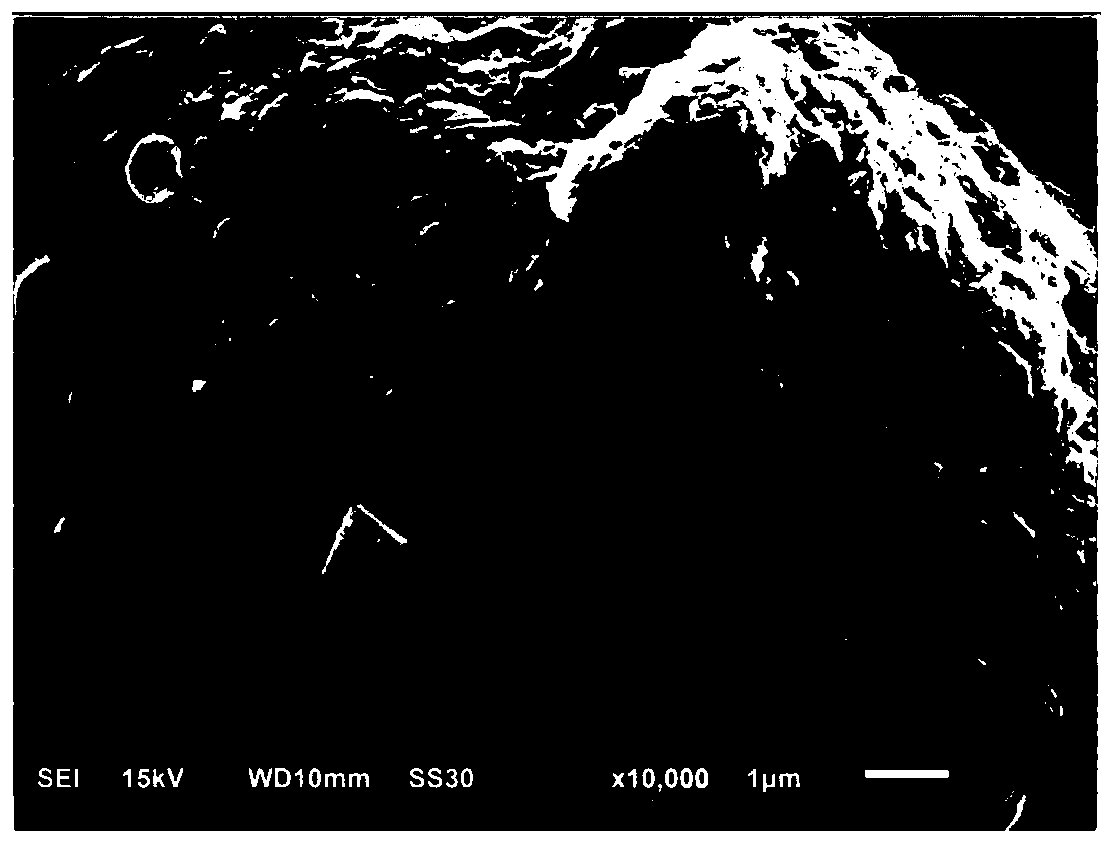

[0058] Aluminum metaphosphate and alumina co-coated cathode materials

[0059] Step 1: Weigh 0.72g of ammonium dihydrogen phosphate and 0.16g of aluminum hydroxide and dissolve them in 30ml of deionized water respectively, and stir evenly. Then drop the aluminum hydroxide aqueous solution into the ammonium dihydrogen phosphate solution, and stir at 60°C for 20 minutes. Continue to add aluminum hydroxide solution dropwise, adjust the pH to 7-8, and continue to stir for 10 minutes to make a mixed solution.

[0060] In the second step, 200g of NCM523 positive electrode material was weighed, added to the mixed solution of the first step, stirred at high speed for 30 minutes, and then dried in an oven to make the NCM523 coating material matrix.

[0061] The third step is to put the NCM523 coating material matrix into an air furnace, first sinter at a constant temperature of 350°C for 2 hours, then raise the temperature to 600°C, sinter at a constant temperature for 4 hours, then a...

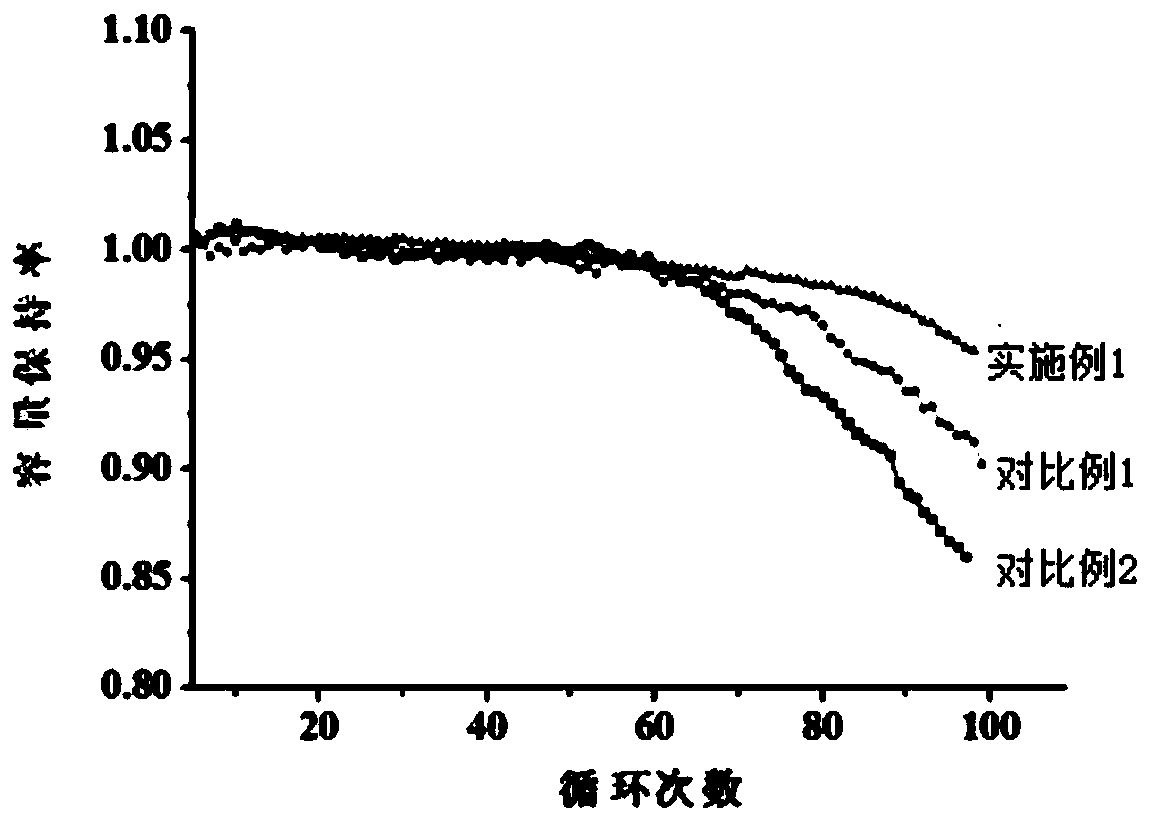

Embodiment 2

[0063] Aluminum metaphosphate and alumina co-coated cathode material

[0064] Step 1: Weigh 0.72g of ammonium dihydrogen phosphate and 0.16g of aluminum hydroxide and dissolve them in 30ml of deionized water respectively, and stir evenly. Then drop the aluminum hydroxide aqueous solution into the ammonium dihydrogen phosphate solution, and stir at 60°C for 20 minutes. Continue to add aluminum hydroxide solution dropwise, adjust the pH to 7-8, and continue to stir for 10 minutes to make a mixed solution.

[0065] In the second step, 200g of NCM523 positive electrode material was weighed, added to the mixed solution of the first step, stirred at high speed for 30 minutes, and then dried in an oven to make the NCM523 coating material matrix.

[0066] In the third step, put the NCM523 coating material matrix into an air furnace, sinter at a constant temperature of 600°C for 6 hours, then air-cool with the furnace, grind and sieve to obtain the surface-coated positive electrode ma...

Embodiment 3

[0068] Aluminum metaphosphate and alumina co-coated cathode material

[0069] Step 1: Weigh 0.72g of ammonium dihydrogen phosphate and 0.16g of aluminum hydroxide and dissolve them in 30ml of deionized water respectively, and stir evenly. Then drop the aluminum hydroxide aqueous solution into the ammonium dihydrogen phosphate solution, and stir at 60°C for 20 minutes.

[0070] In the second step, 200g of NCM523 positive electrode material was weighed, added to the mixed solution of the first step, stirred at high speed for 30 minutes, and then dried in an oven to make the NCM523 coating material matrix.

[0071] In the third step, the NCM523 coating material matrix was put into an air furnace, sintered at a constant temperature of 600°C for 6 hours, then air-cooled with the furnace, ground and sieved to obtain the surface-coated positive electrode material of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com