Nitrogen-doped carbon-coated silicon nanoparticle composite material, preparation method and application

A technology of silicon nanoparticles and composite materials, applied in the preparation/purification of carbon, nanotechnology, nanotechnology, etc., can solve the problems of discharge specific capacity attenuation, poor cycle stability, large volume deformation, etc., to improve conductivity and cost. Low, simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

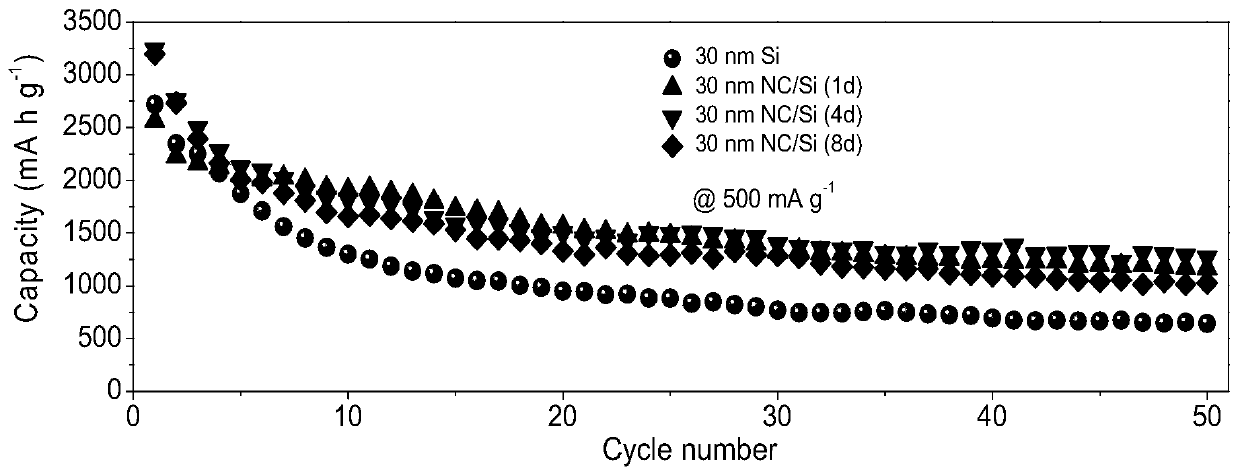

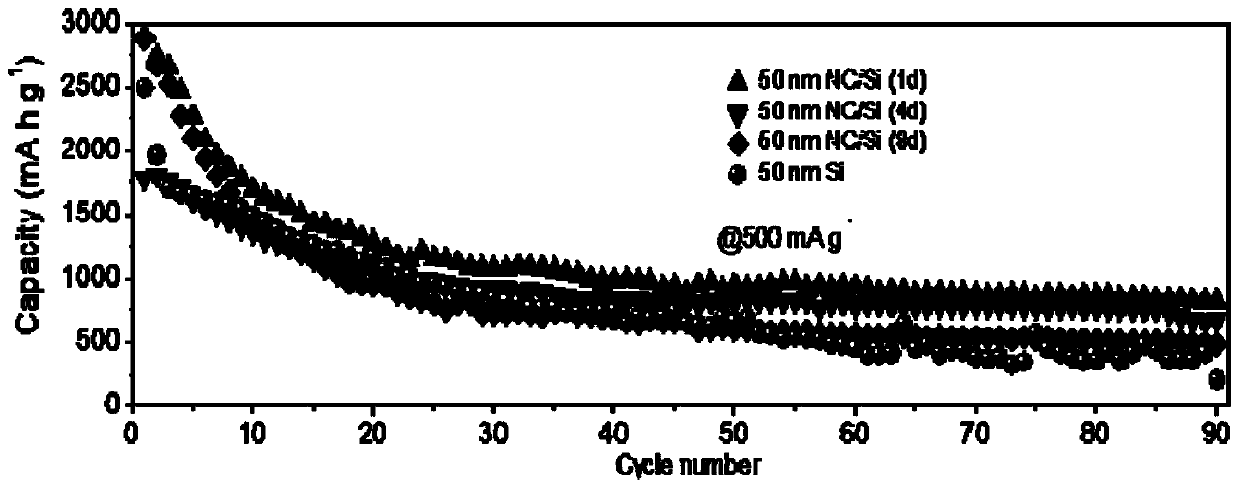

Embodiment 1

[0025] A preparation method of nitrogen-doped carbon-coated silicon nanoparticle composite material, comprising the following steps:

[0026] S1, placing 30nm silicon nanoparticles in a Tris-HCl buffer solution with a pH value of 7.5, fully cleaning (removing impurities on the surface of the particles), drying, and obtaining treated silicon nanoparticles;

[0027] S2. Add 0.1 g of dopamine hydrochloride into 50 ml of Tris-HCl buffer solution with a pH value of 8.5, and dissolve to obtain a dopamine solution;

[0028] S3, adding 0.1 g of the treated silicon nanoparticles obtained in S1 to 40 ml of the dopamine solution obtained in S2 with a concentration of 2 mg / ml, ultrasonically dispersed, transferred to a 100 ml round-bottomed flask, and then at room temperature, Set the rotation speed on the magnetic stirrer to 500r / min, stir the reaction for 1 day, then centrifuge and dry in a vacuum oven at 60°C for 12h to obtain the reactant;

[0029] S4. Under an argon atmosphere, calc...

Embodiment 2

[0031] The preparation method of the nitrogen-doped carbon-coated silicon nanoparticle composite material provided by the embodiment of the present invention is the same as the preparation method of the embodiment 1, except that in step S3, the stirring reaction time is 4 days.

Embodiment 3

[0033] The preparation method of the nitrogen-doped carbon-coated silicon nanoparticle composite material provided by the embodiment of the present invention is the same as the preparation method of the embodiment 1, except that in step S3, the stirring reaction time is 8 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com