Patents

Literature

256results about How to "Practical and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

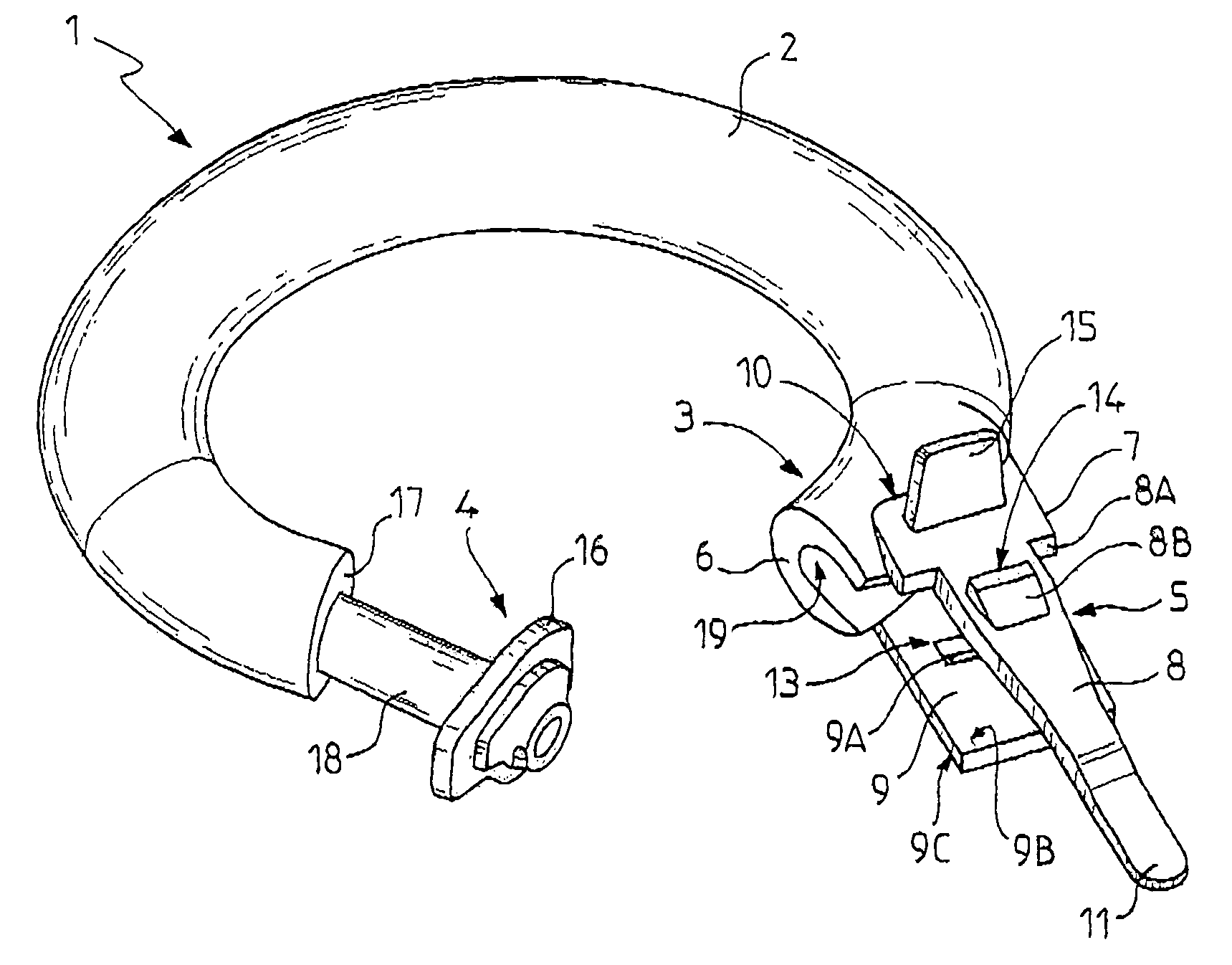

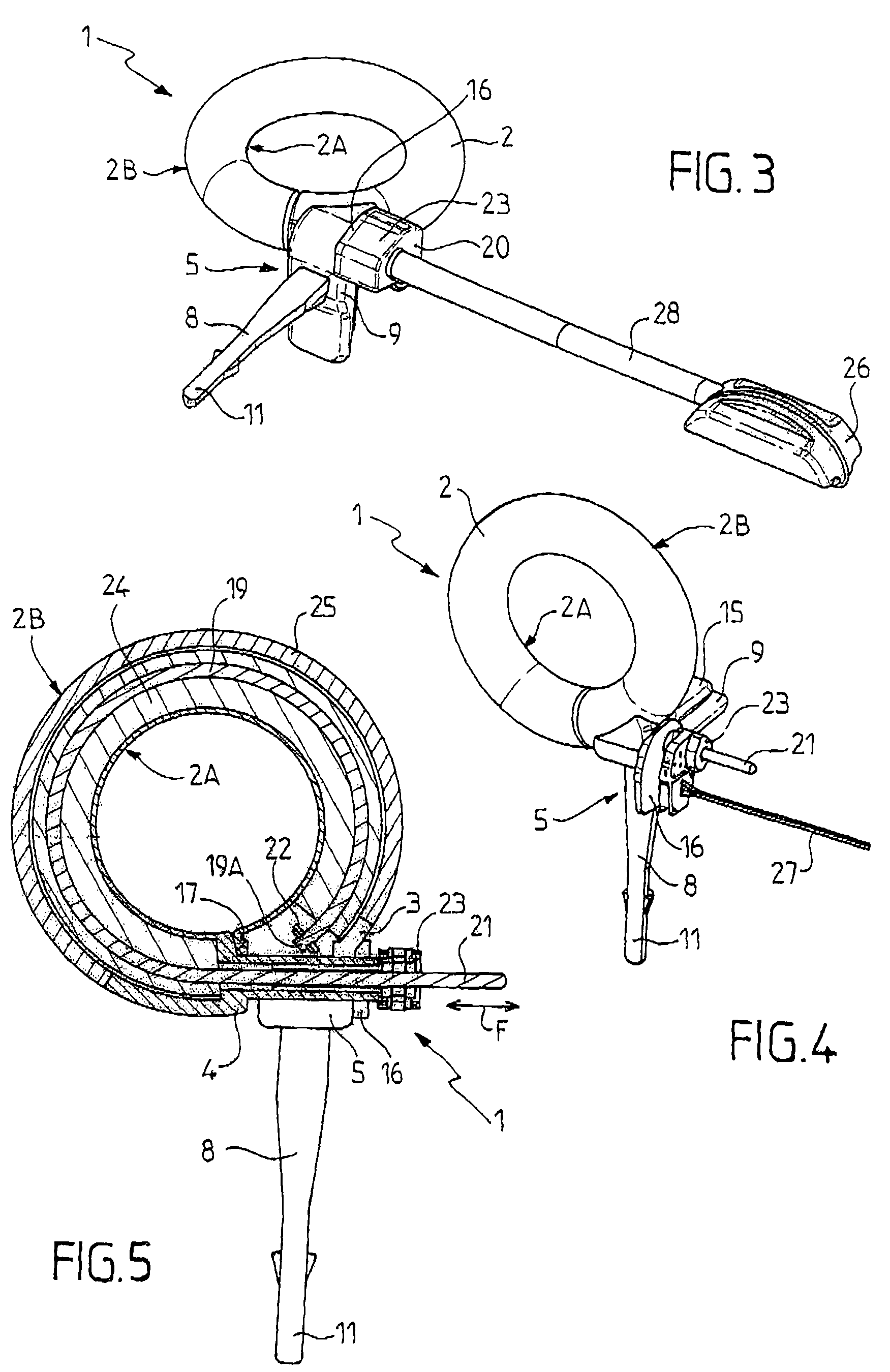

Closure system for surgical ring

InactiveUS7060080B2Reduce constraintsPractical and reliableNon-surgical orthopedic devicesTourniquetsReoperative surgeryBiomedical engineering

A surgical ring (1) designed to be implanted around (a) biological organ(s), the ring (1) being formed by a flexible band (2) including a first and second extremity (3, 4), the flexible band (2) being designed to be closed near its two extremities (3, 4) by a closure system so as to form a closed loop featuring an internal contact surface (2A) external 10 surface (2B). The closure system includes a means of encircling (5) that is integral with the first extremity (3) and arranged to evolve between a de-latching configuration, where the means of encircling (5) forms an open collar freeing the second extremity (4), and a latching configuration where the means of encircling (5) forms a closed collar designed to surround the second extremity (4) so as to unite it with the first extremity (3), the closed collar having opposite front (6) and rear (7) faces, between which an encircling opening extends that is designed to accept the second extremity (4).

Owner:APOLLO ENDOSURGERY INC

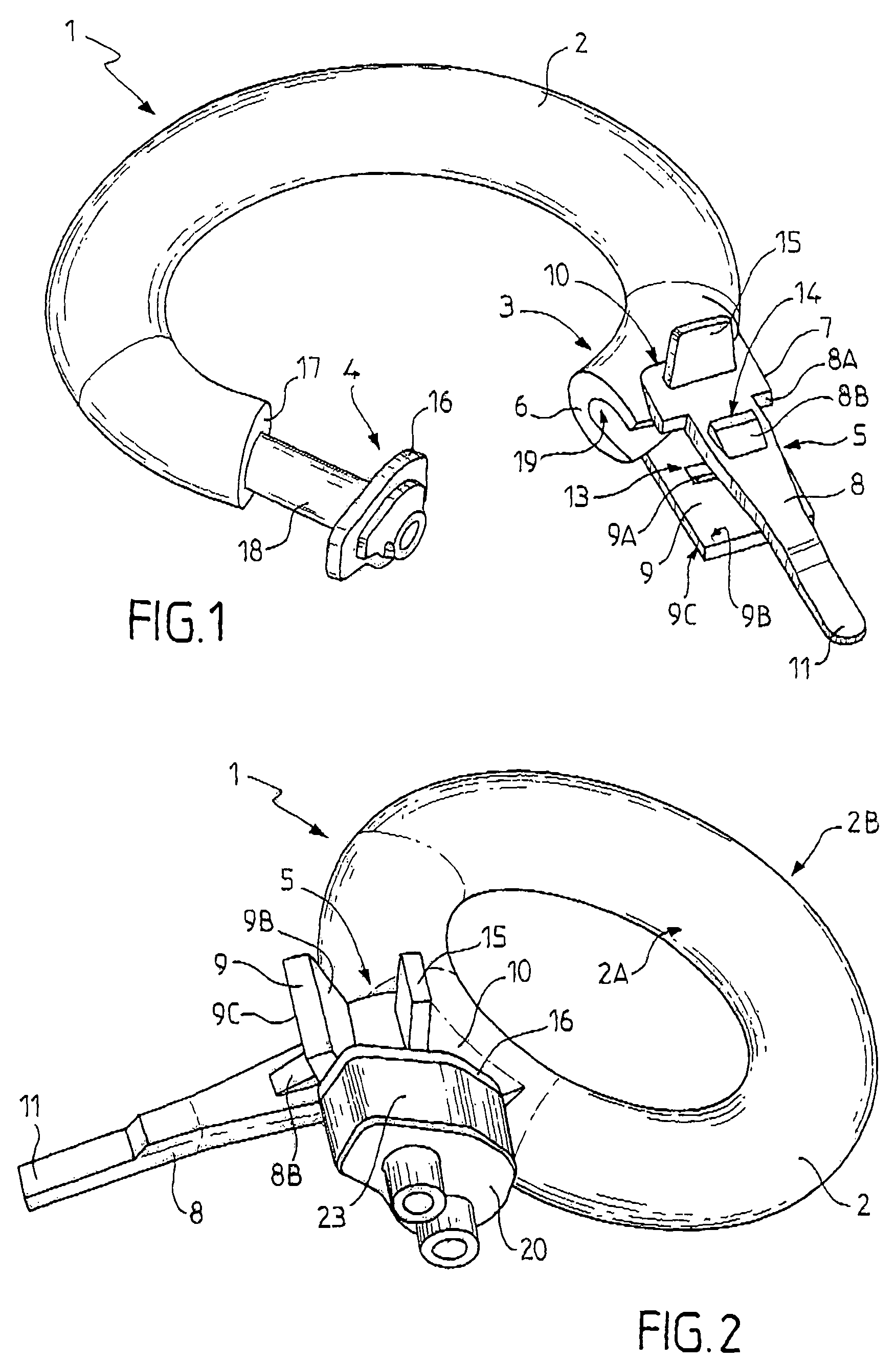

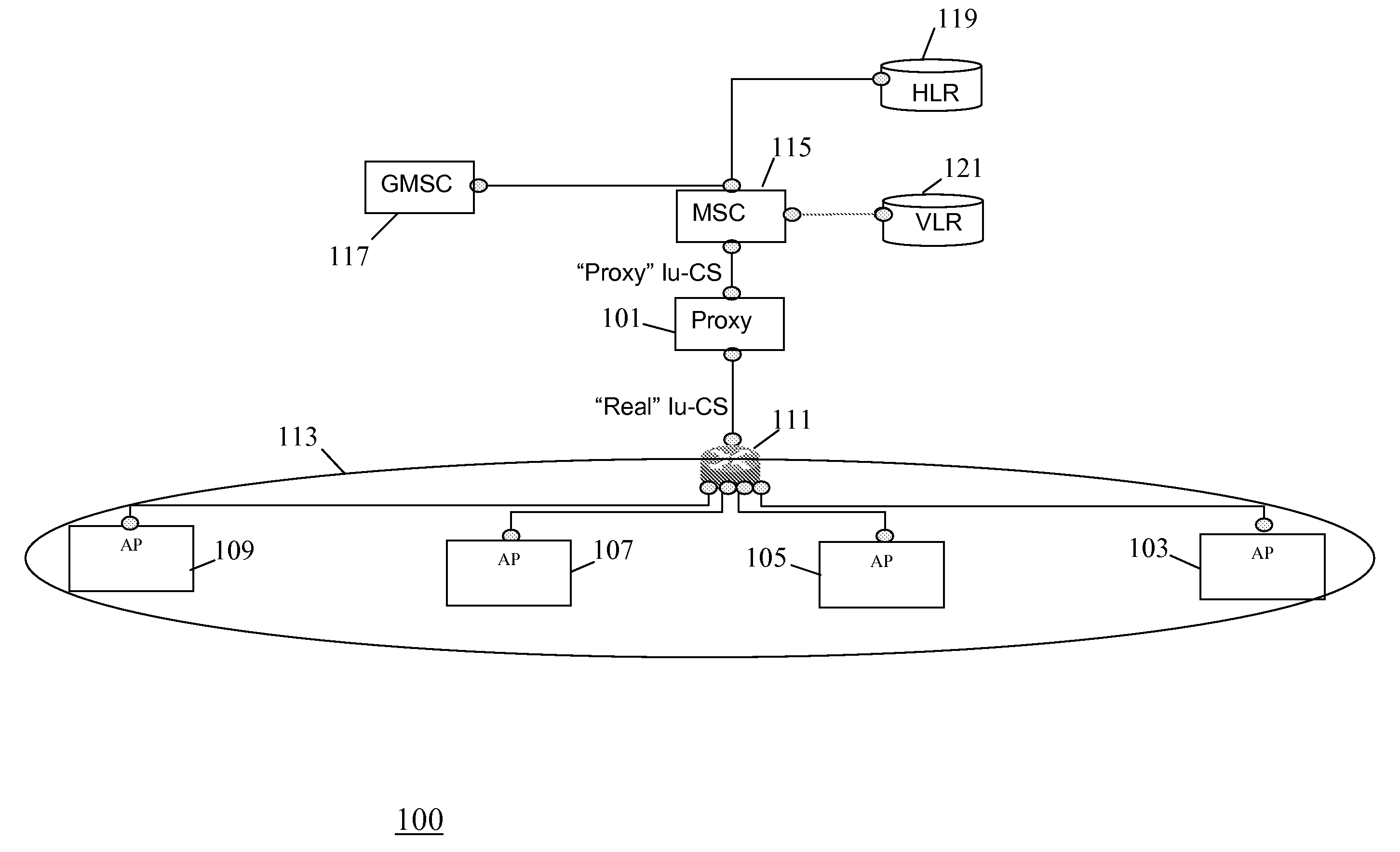

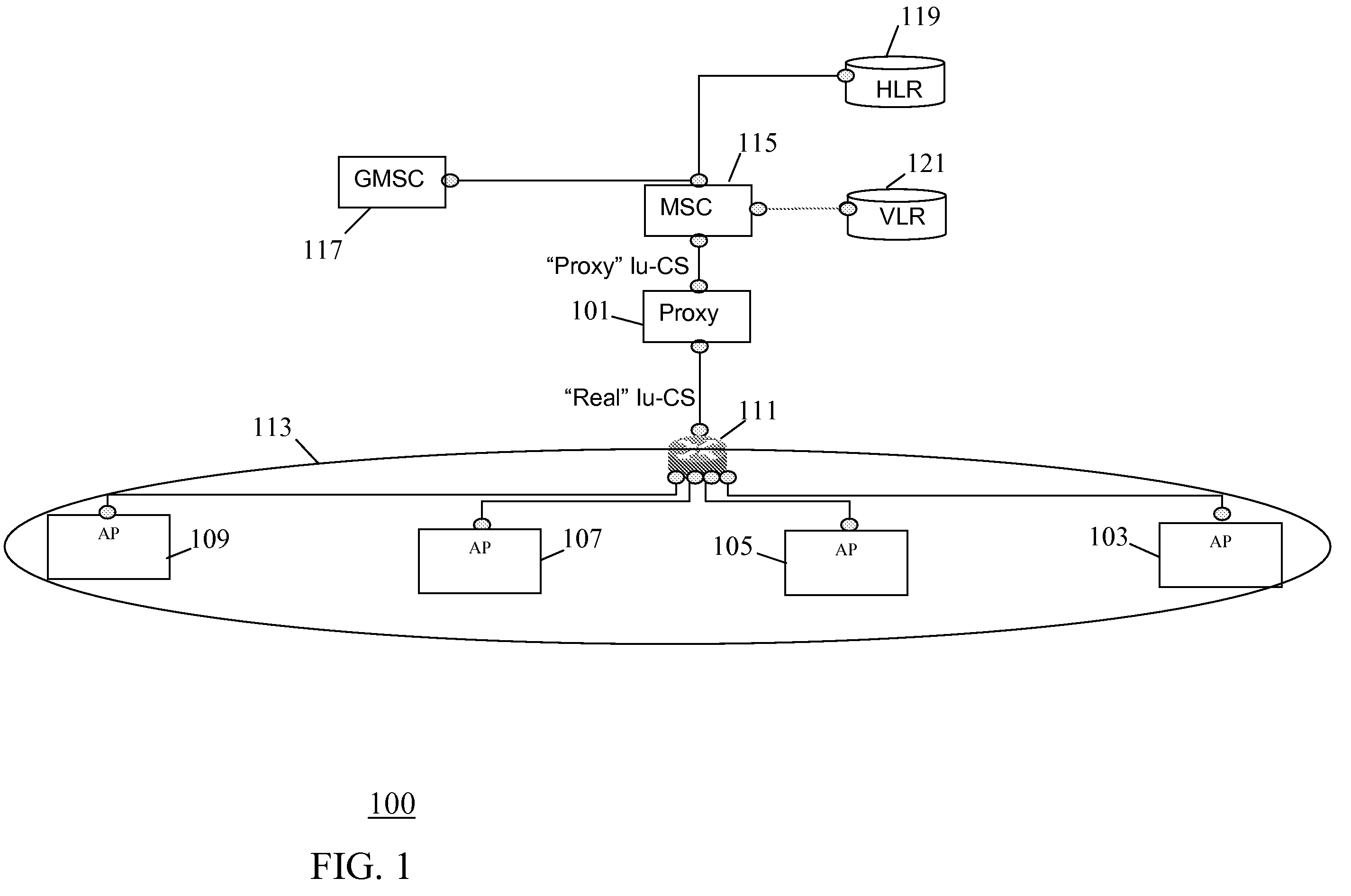

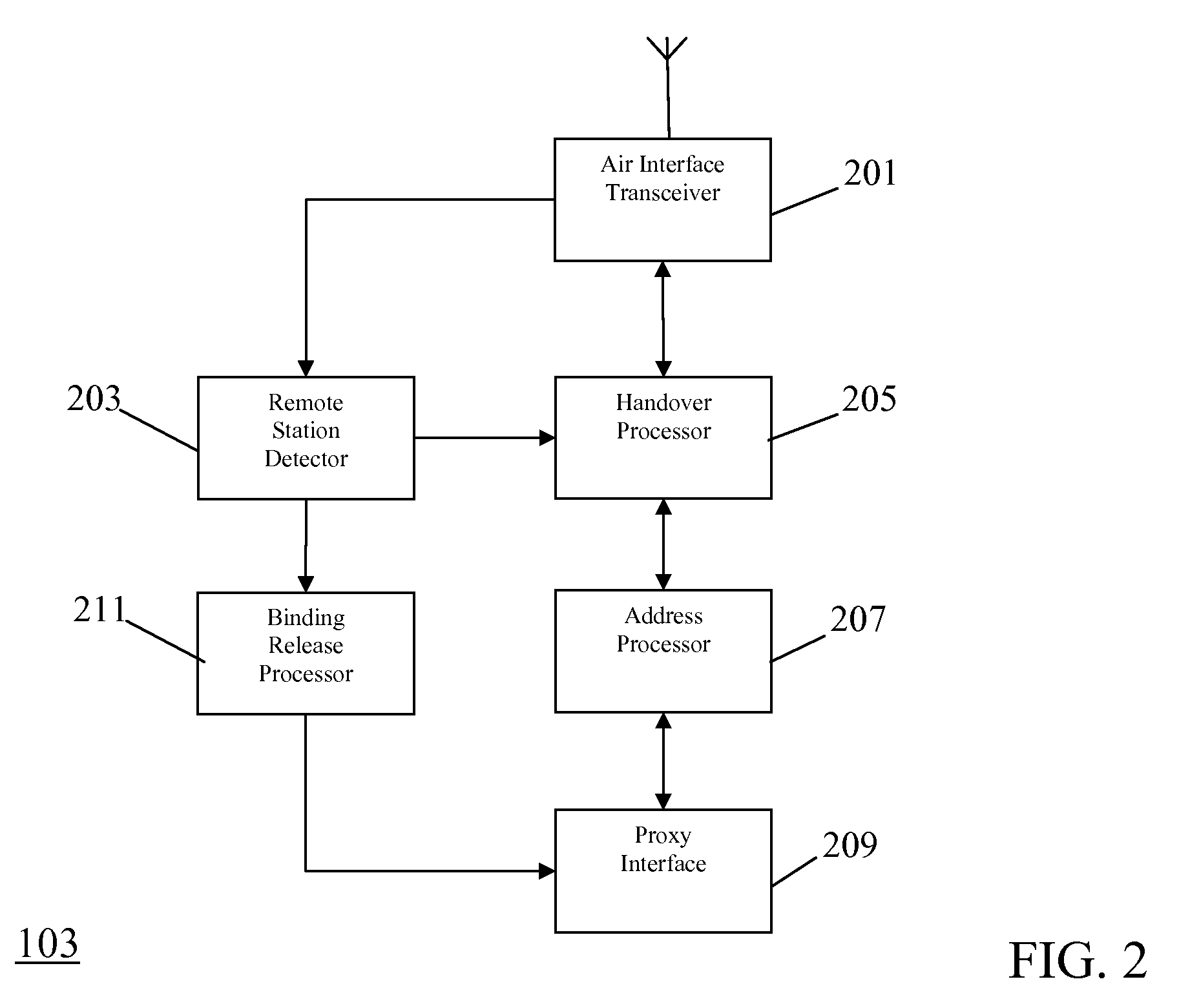

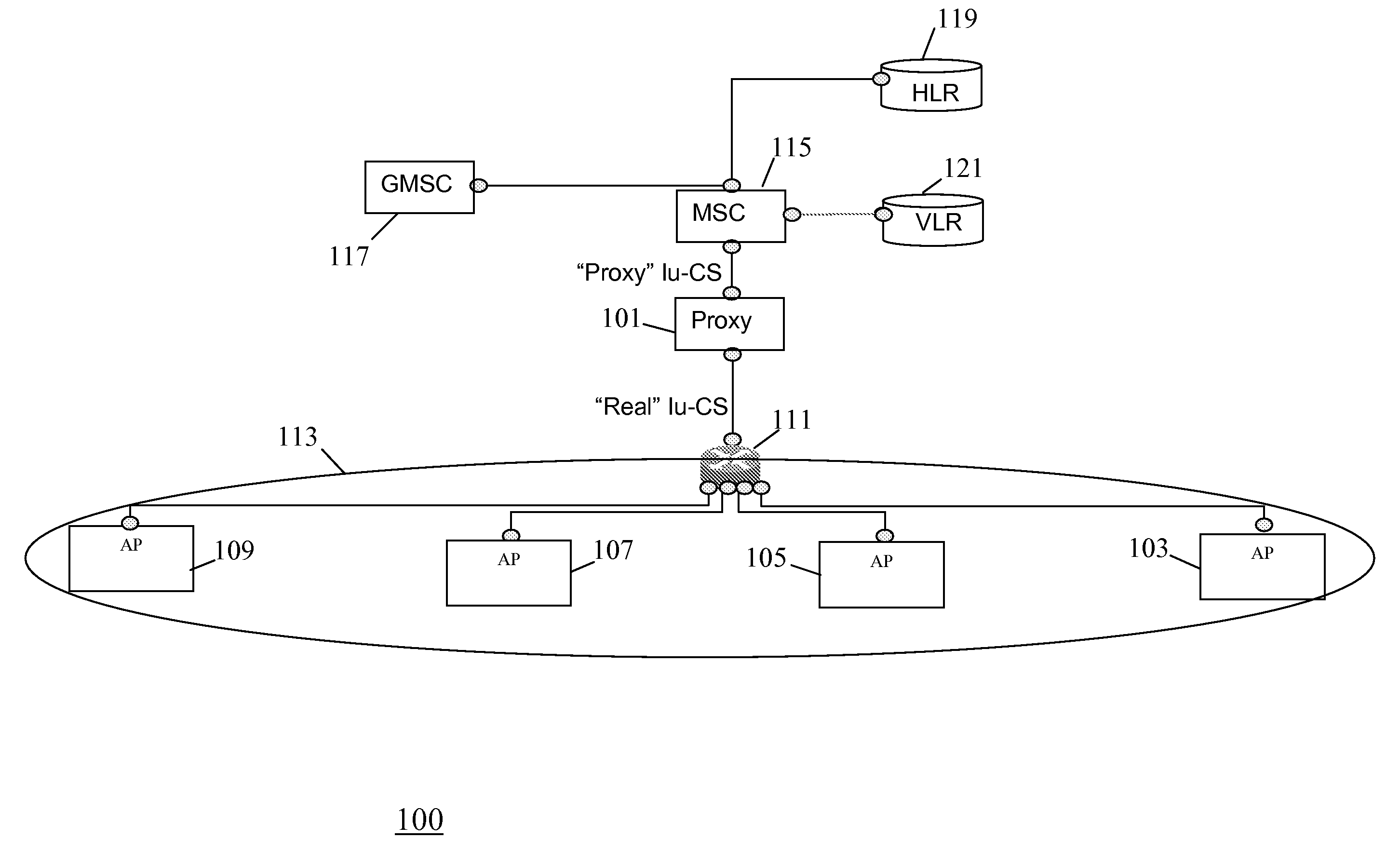

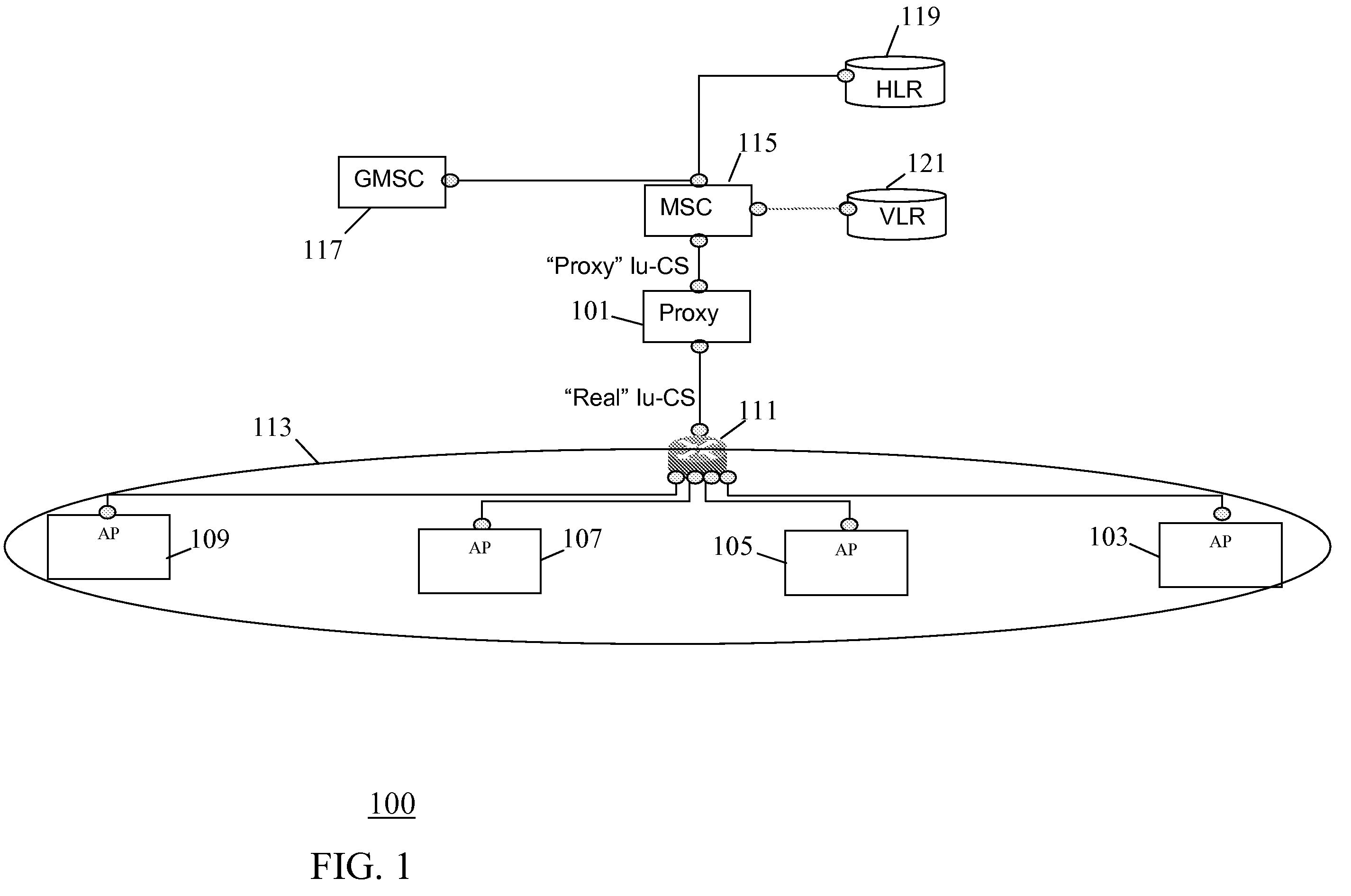

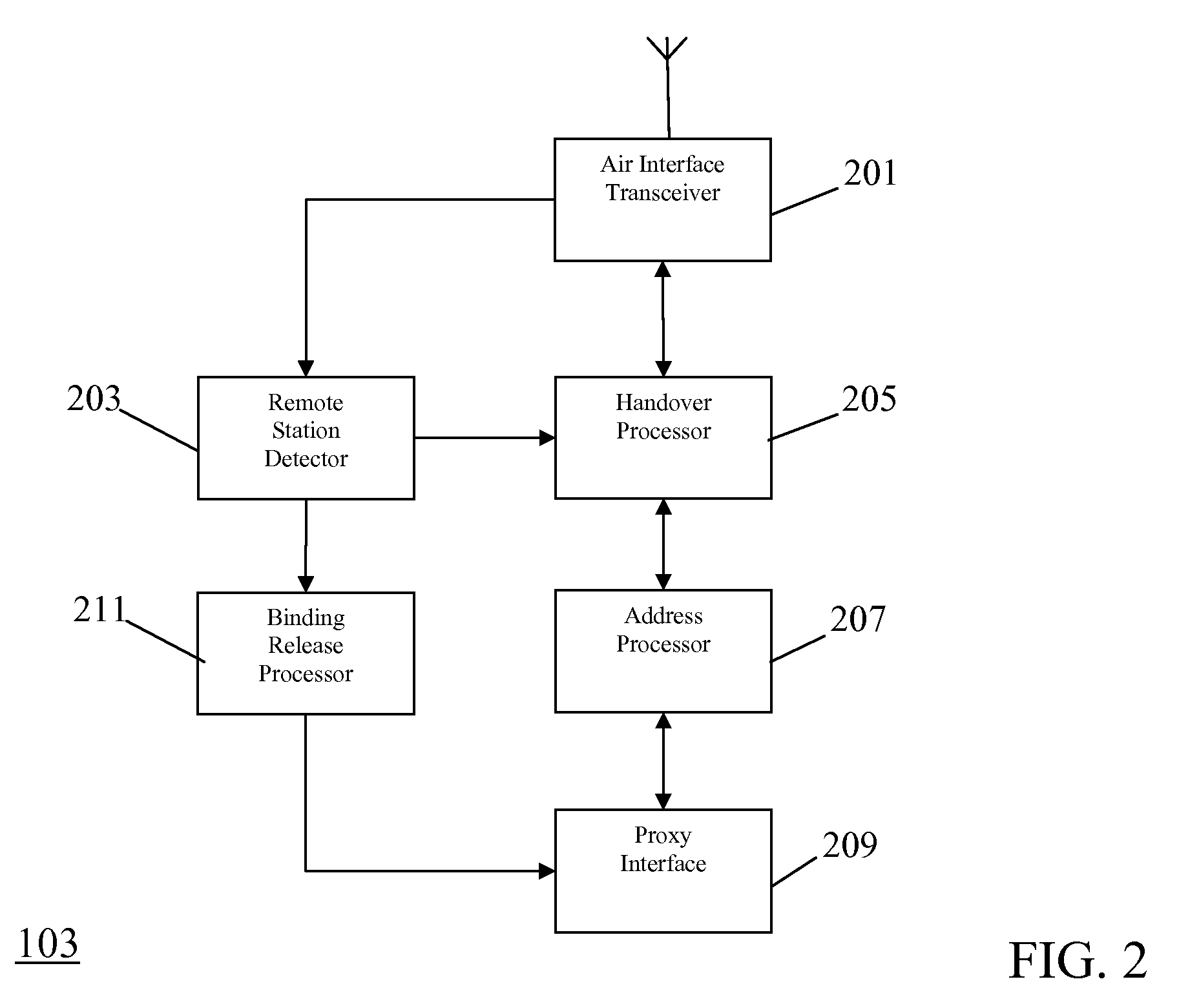

Network for a cellular communication system and a method of operation therefor

InactiveUS7724707B2Enable or facilitate the deployment of a large number of underlay cellsImproved addressingTime-division multiplexWireless network protocolsEntry pointNetwork addressing

A network for a cellular communication system comprises access points (105-109) supporting cells within a region (113). Each access point (105-109) has an individual proxy address of a proxy address space which is a local address space of an address proxy (101) and a common network address of a network address space which is a network wide address space. A gateway access point (103) covers an entry point to the region (113) and detects a remote station entering the region. It then determines an access point (105) in the region to which the remote station is handed over and transmits a binding message to the address proxy (101) with an indication of the access point (105). In response to receiving the binding message, the address proxy (101) establishes a binding between the common network address and the proxy address of the access point (105). Data for the remote station is then forwarded to the access point (105) using the binding.

Owner:GOOGLE TECH HLDG LLC

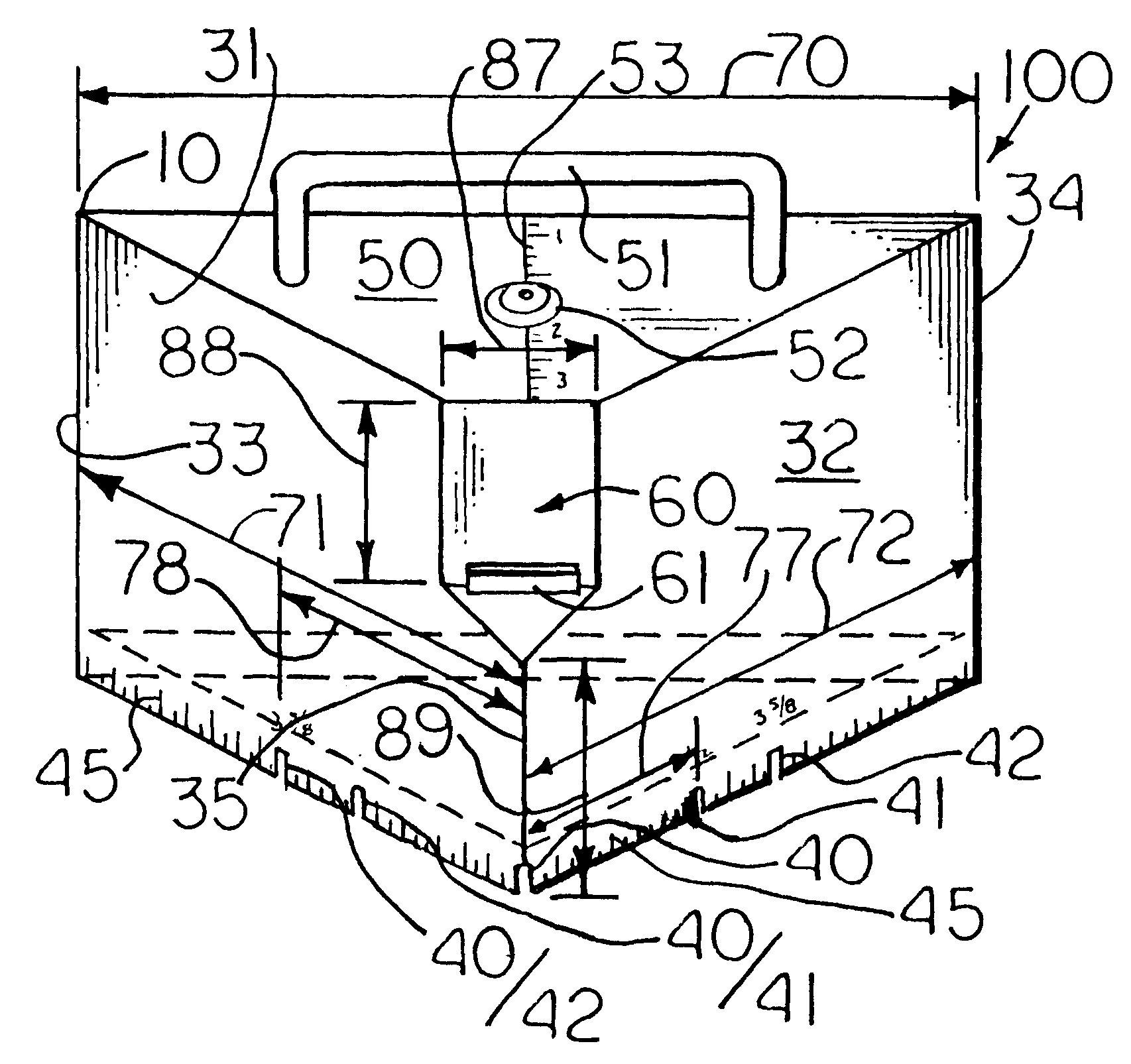

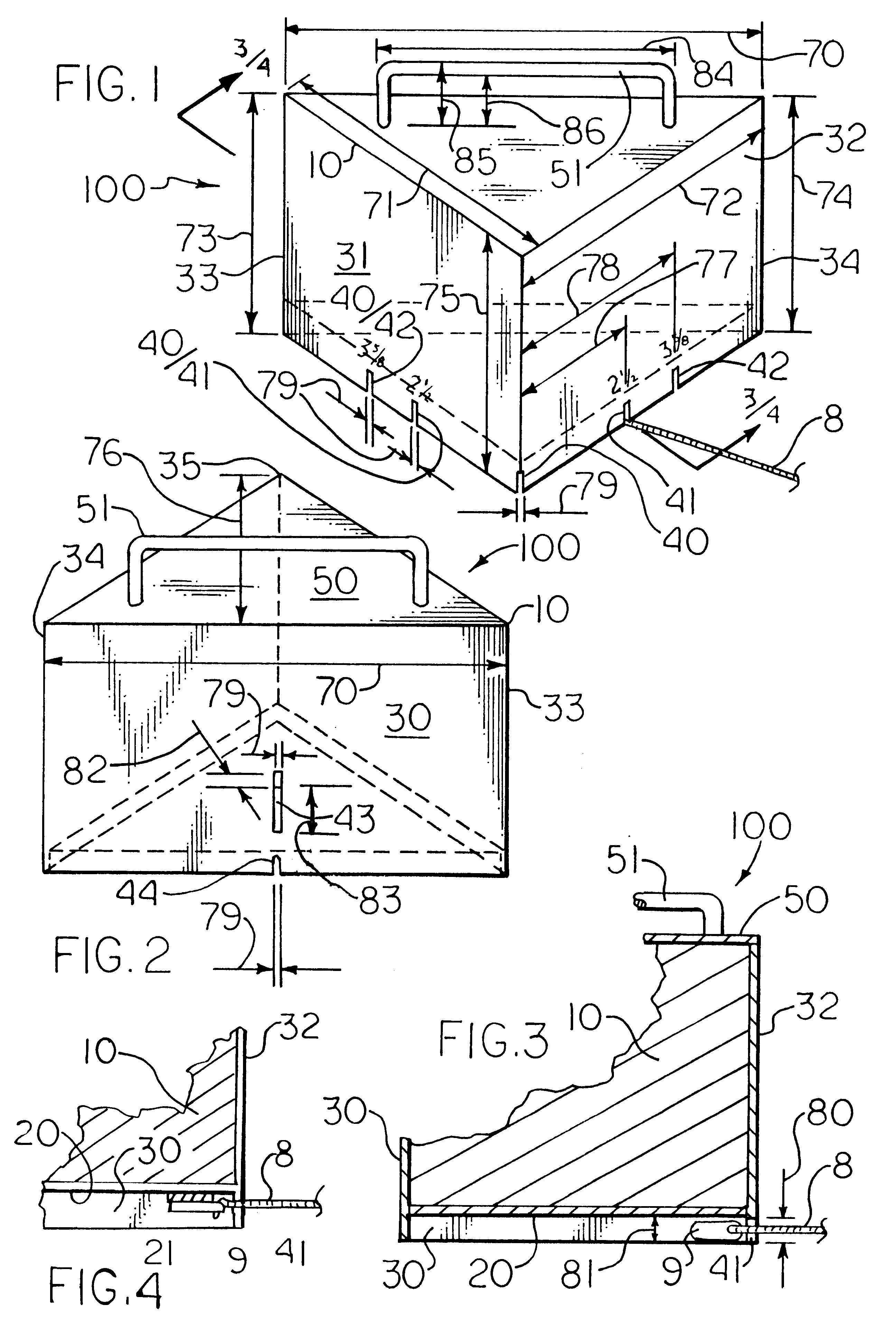

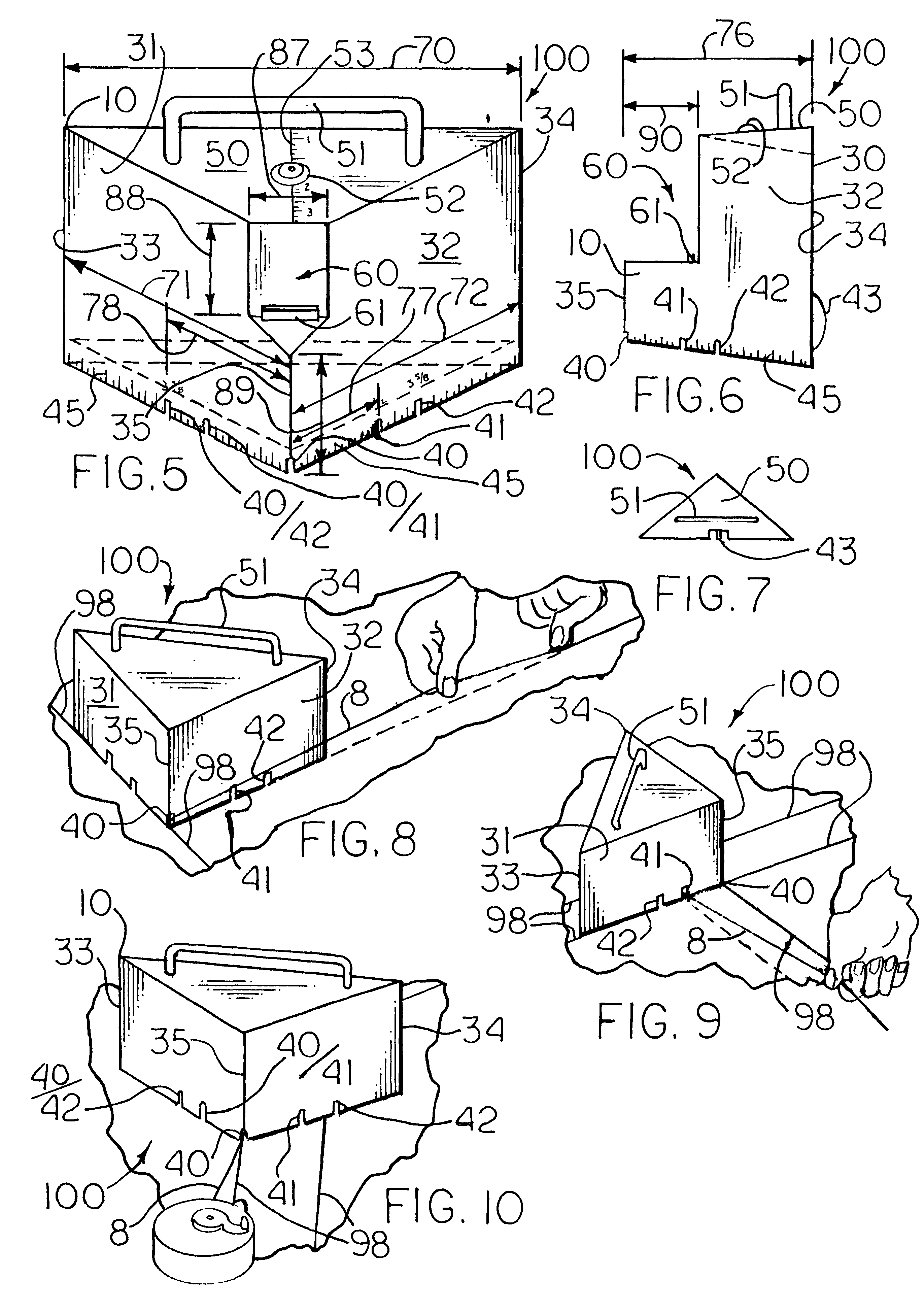

Construction layout block

InactiveUS6578274B1Facilitate measurement of distances from layout linesHigh degreeLiquid surface applicatorsWriting aidsLaser targetEngineering

Construction layout block can be provided with a triangularly shaped body with a triangular bottom; a base wall and two side walls extending up from the bottom; base wall junctures formed about intersections of the base wall and the side walls, and an apex juncture formed about intersections of the side walls. It may have one or more of an artifice capable of holding a chalk line; top, with a top carrying handle; a laser target notch; a rear reference system; a top alignment system; a ruler scale; an intrinsic level; and a contrivance for holding a tape measure by its distal end. The block has relative immovability, in general, to resist the force of pulling on a chalk line with the same attached to the block during layout. A construction layout block of any shape may be plastic-coated.

Owner:TANGO JR RONALD M +1

Network for a cellular communication system and a method of operation therefor

InactiveUS20090003263A1Increased address spaceEfficient routingTime-division multiplexWireless network protocolsEntry pointNetwork addressing

A network for a cellular communication system comprises access points (105-109) supporting cells within a region (113). Each access point (105-109) has an individual proxy address of a proxy address space which is a local address space of an address proxy (101) and a common network address of a network address space which is a network wide address space. A gateway access point (103) covers an entry point to the region (113) and detects a remote station entering the region. It then determines an access point (105) in the region to which the remote station is handed over and transmits a binding message to the address proxy (101) with an indication of the access point (105). In response to receiving the binding message, the address proxy (101) establishes a binding between the common network address and the proxy address of the access point (105). Data for the remote station is then forwarded to the access point (105) using the binding.

Owner:GOOGLE TECH HLDG LLC

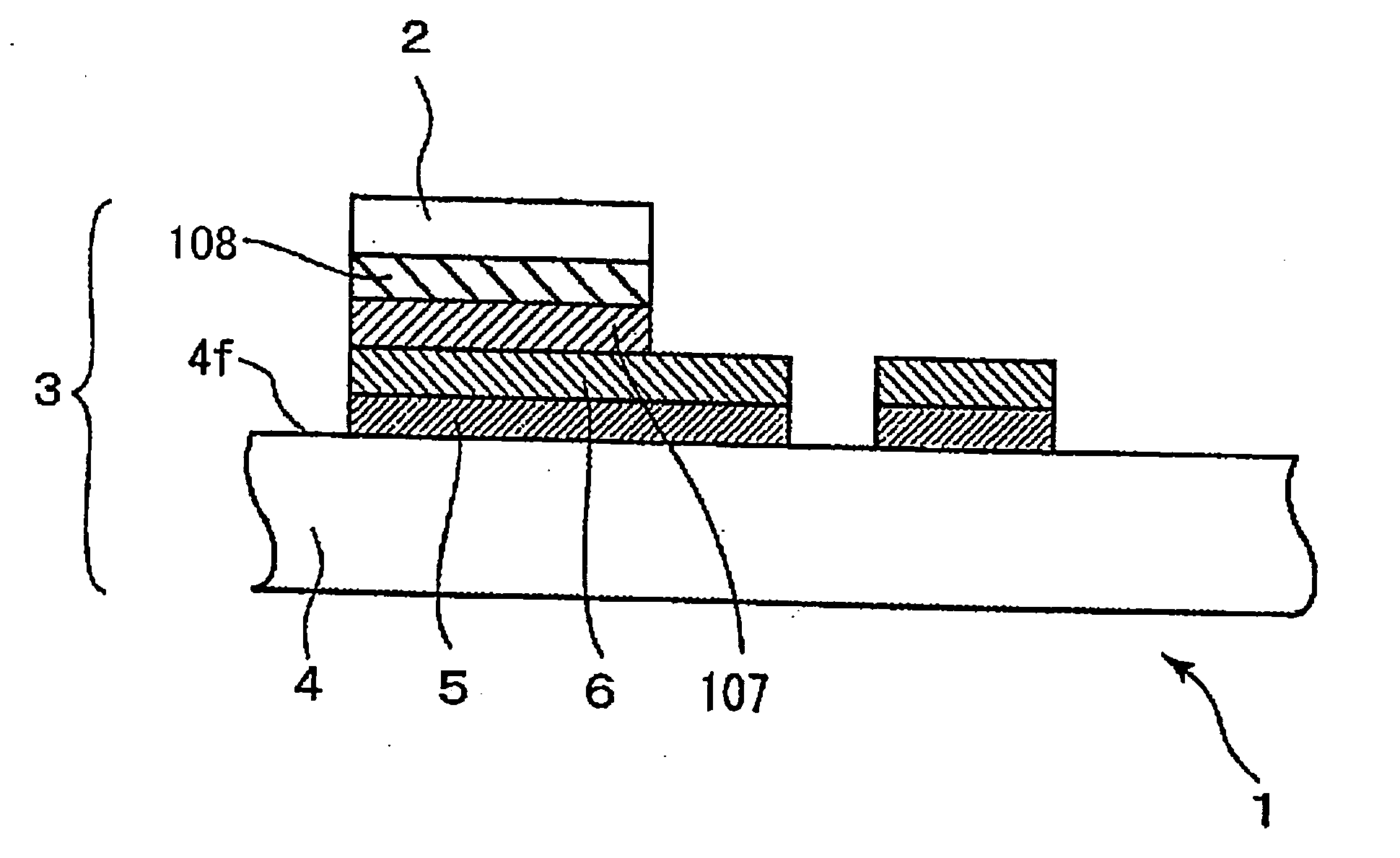

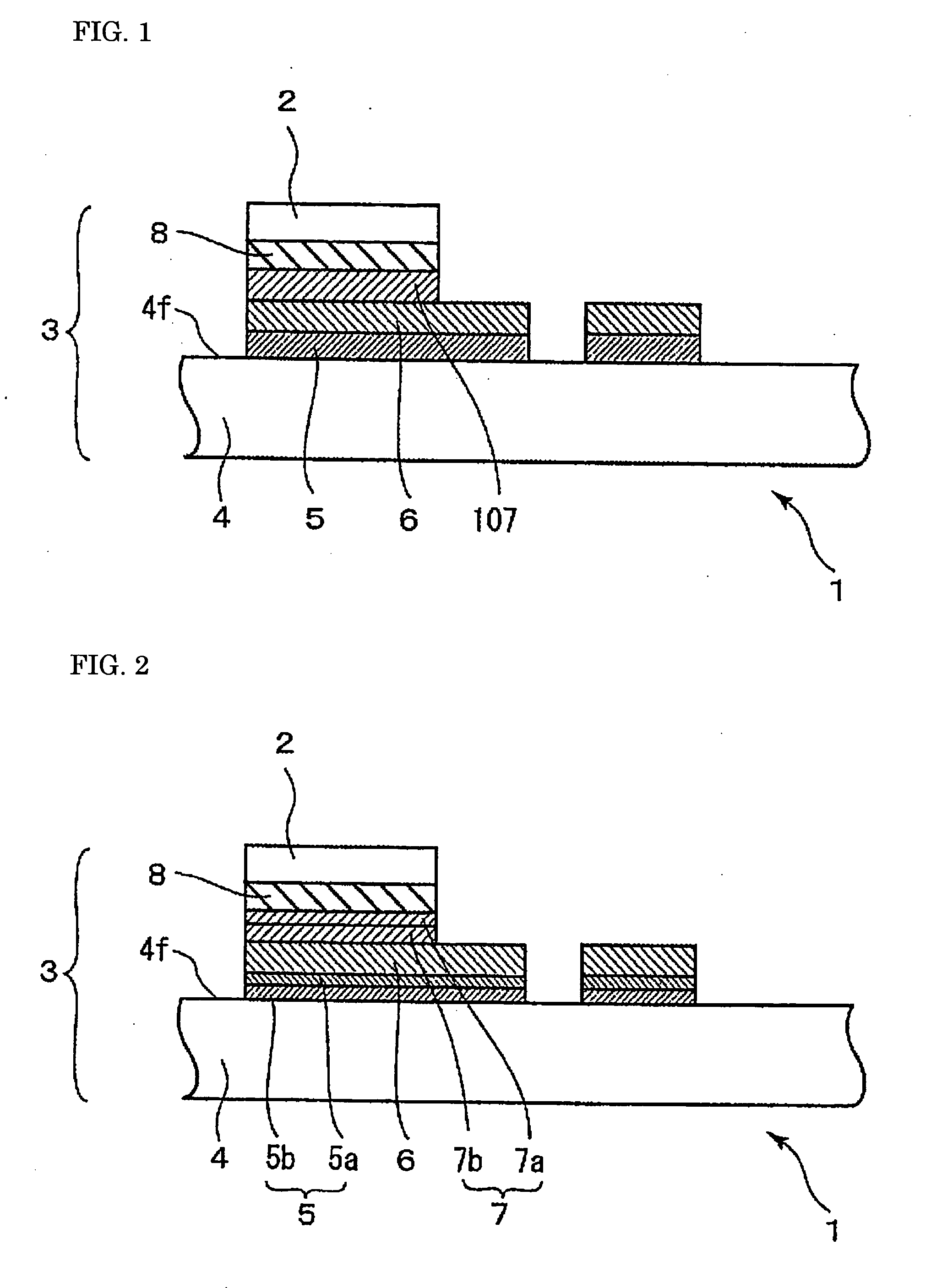

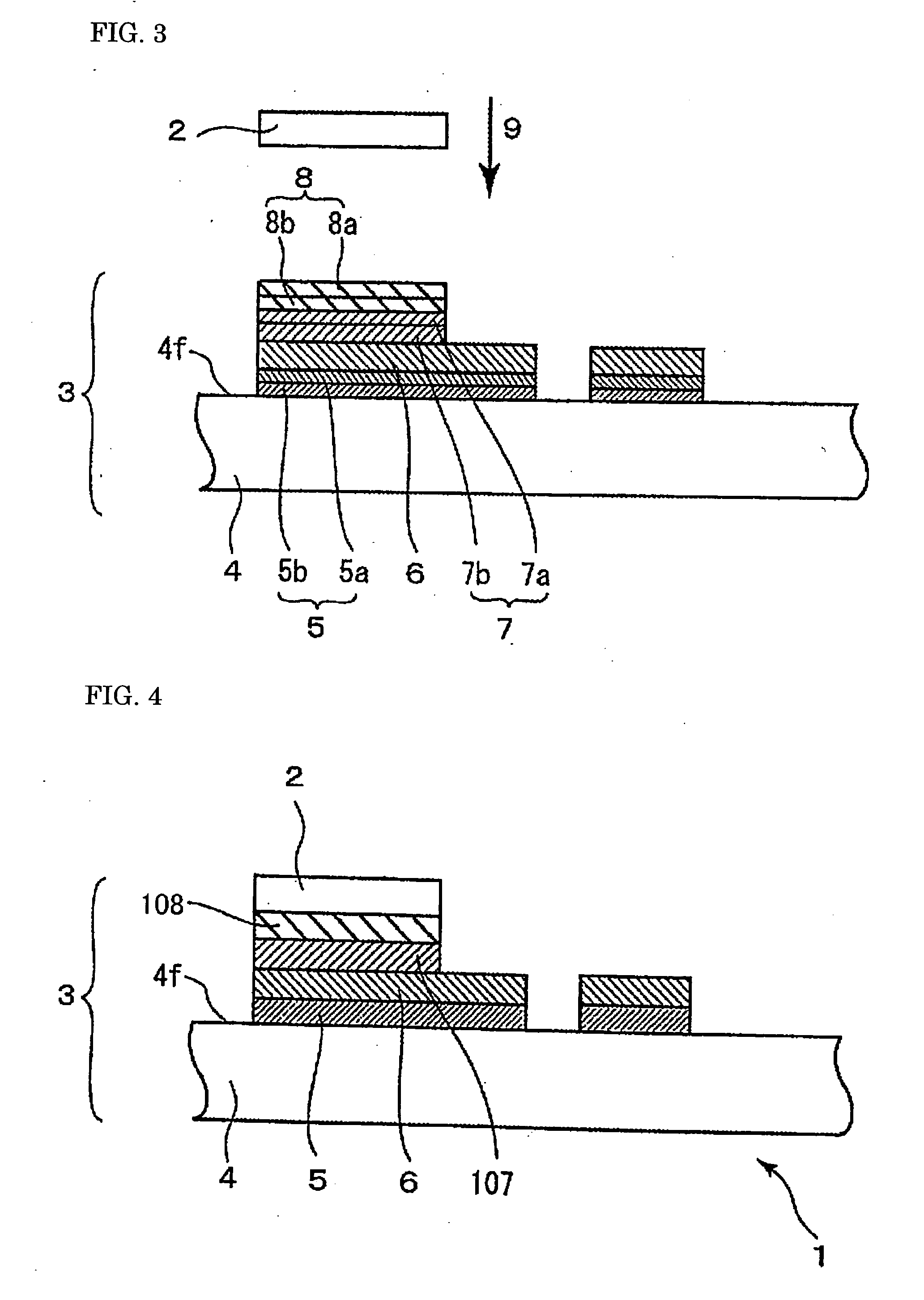

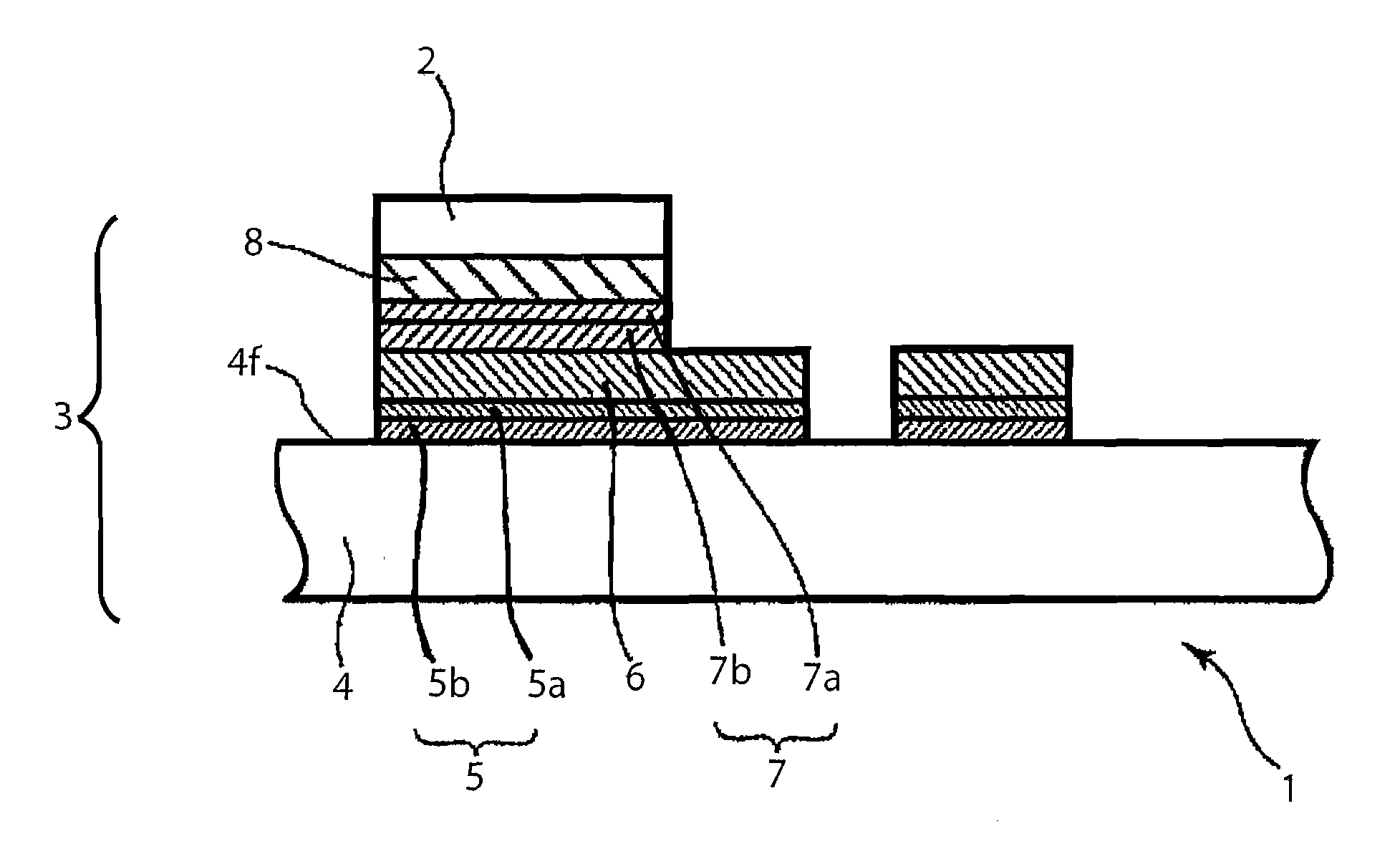

Submount and semiconductor device

ActiveUS20050194690A1Preventing heat-related damageLower bonding temperatureLaser detailsSemiconductor/solid-state device detailsDevice materialSemiconductor

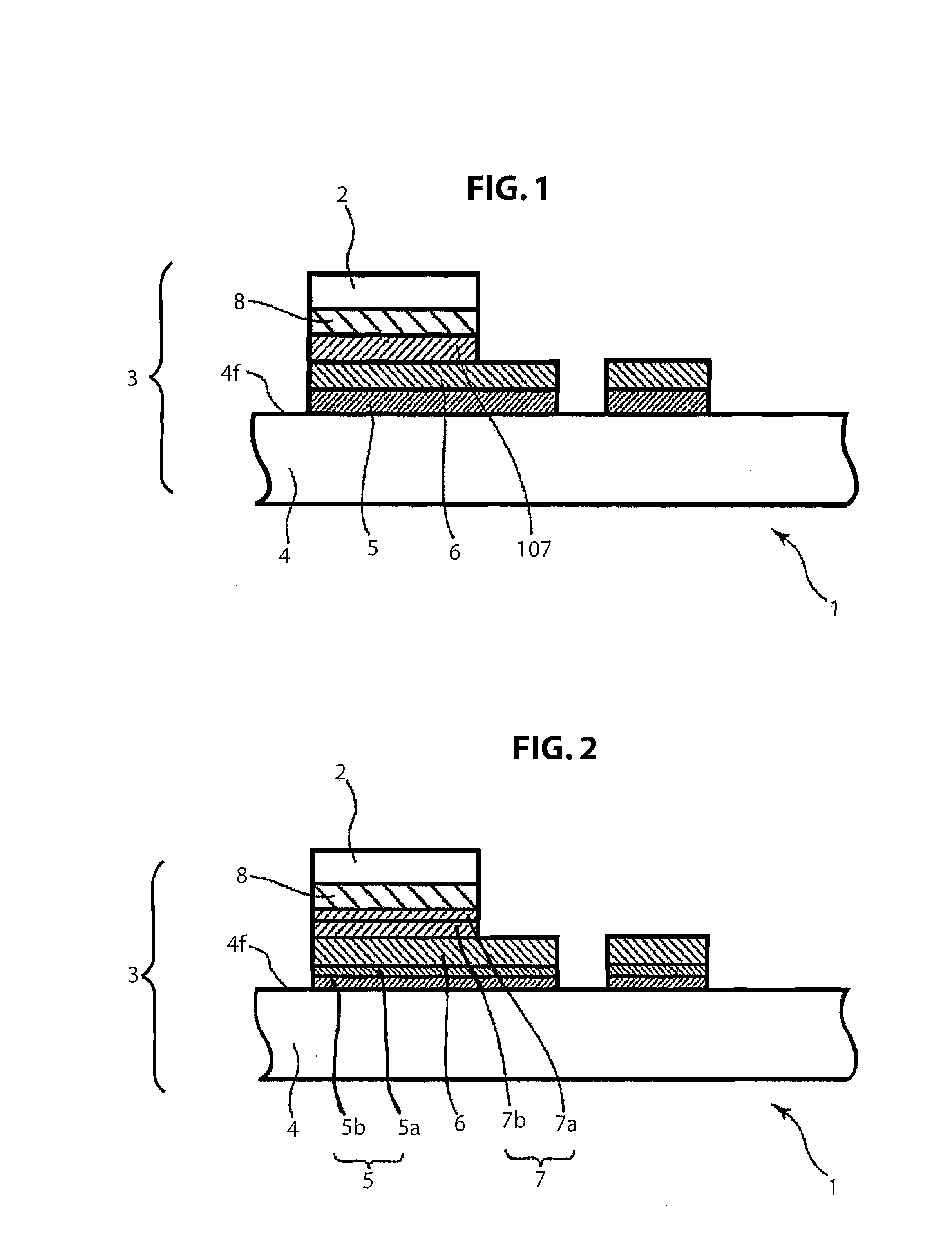

The present invention provides a submount that allows a semiconductor light-emitting element to be attached with a high bonding strength. A submount 3 is equipped with a substrate 3 and a solder layer 8 formed on a primary surface 4f of the substrate 4. The density of the solder layer 8 is at least 50% and no more than 99.9% of the theoretical density of the material used in the solder layer 8. The solder layer 8 contains at least one of the following list: gold-tin alloy; silver-tin alloy; and lead-tin alloy. The solder layer 8 before it is melted is formed on the substrate 4 and includes an Ag film 8b and an Sn film 8a formed on the Ag film 8b. The submount 3 further includes an Au film 6 formed between the substrate 4 and the solder layer 8.

Owner:SUMITOMO ELECTRIC IND LTD

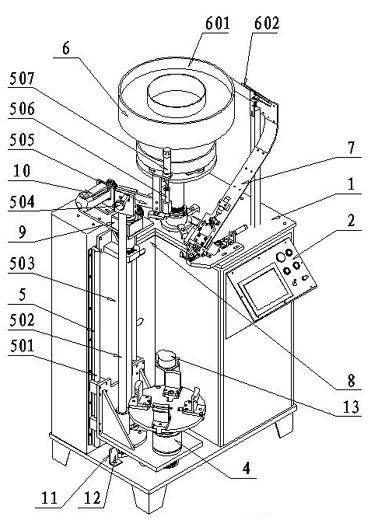

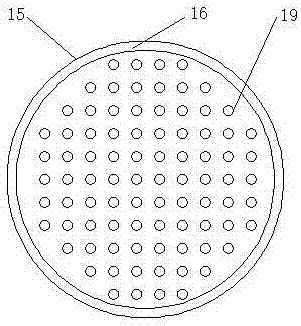

Suspending machine of zipper slider for electroplating

ActiveCN102433580AImprove work efficiencySolve the entanglementElectrolysis componentsSlide fastenersControl systemControl engineering

The invention provides a suspending machine of a zipper slider for electroplating, and belongs to the technical field of zipper suspending machine. The machine comprises a chassis with a PLC (programmable logical controller) panel, wherein a zipper slider storage device and a zipper slider conveying and hooking alignment detection device are cooperatively arranged on the chassis; a zipper slider hanger control device is cooperatively arranged on the lateral side of the chassis; the zipper slider hanger control device is connected with a rotating disk compressed air source conversion device; a zipper slider hanger is cooperatively arranged on the rotating disk compressed air source conversion device; the outlet end of the zipper slider storage device is connected with the inlet end of the zipper slider conveying and hooking alignment detection device; the outlet end of the zipper slider conveying and hooking alignment detection device is matched with a zipper slider hook on the zipper slider hanger; and the zipper slider storage device, the zipper slider conveying and hooking alignment detection device and other devices are controlled by the PLC. By adopting an electric signal control system, the machine has the advantages of convenience in whole operation, efficiency improvement, high accuracy, simple structure, time and labor saving and low production cost, and is suitable for industrial production and application.

Owner:临海市万宏机电配件厂

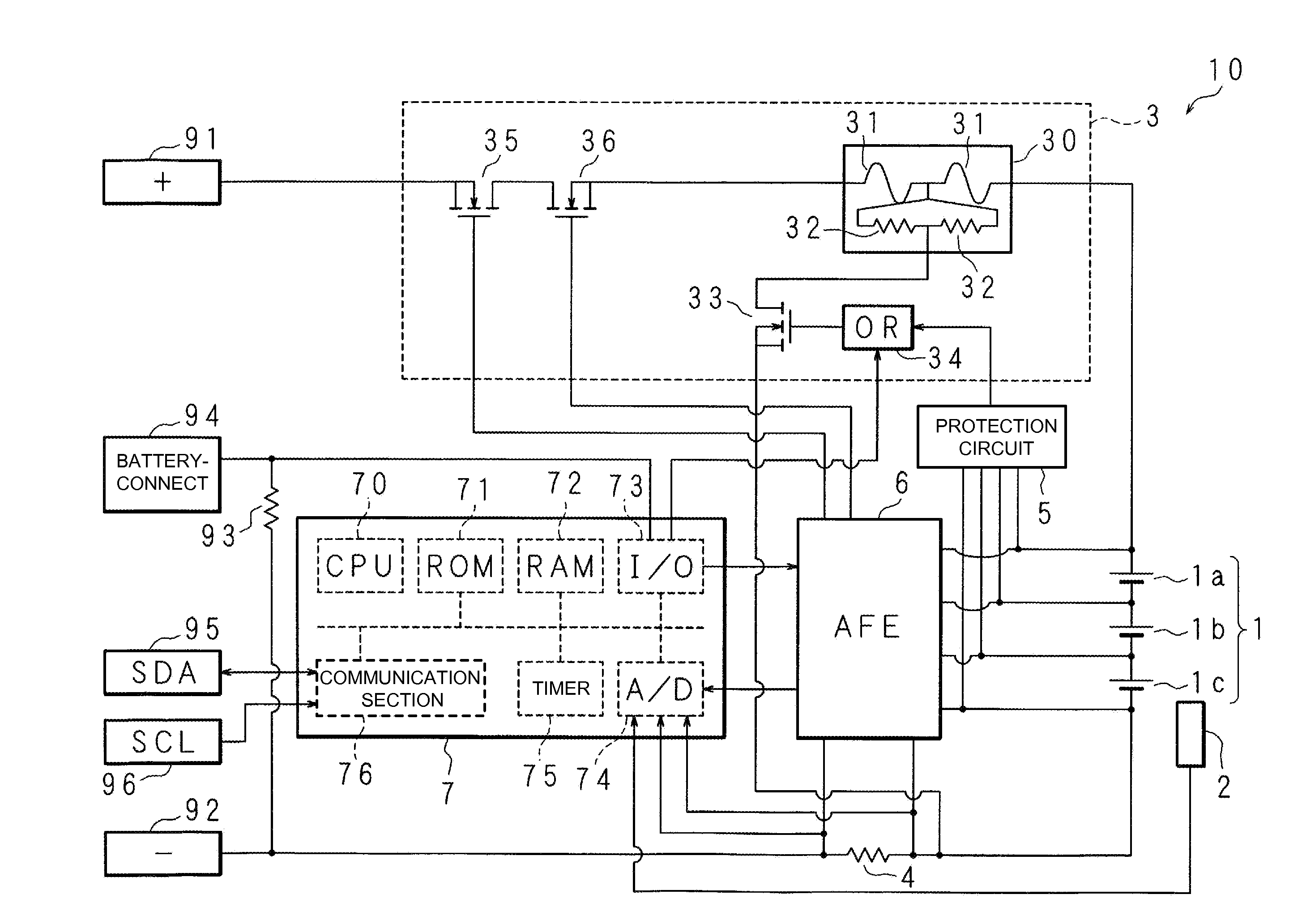

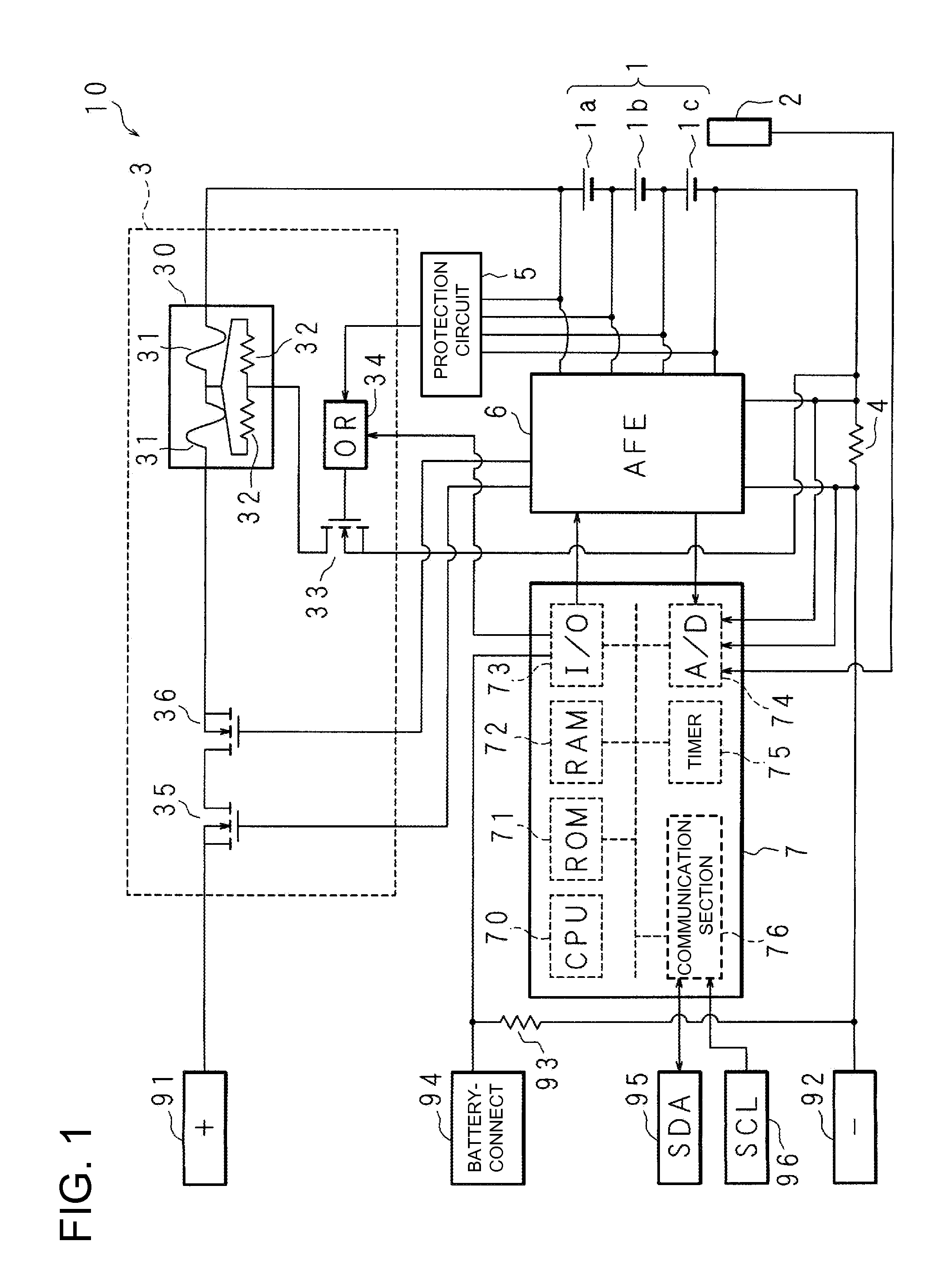

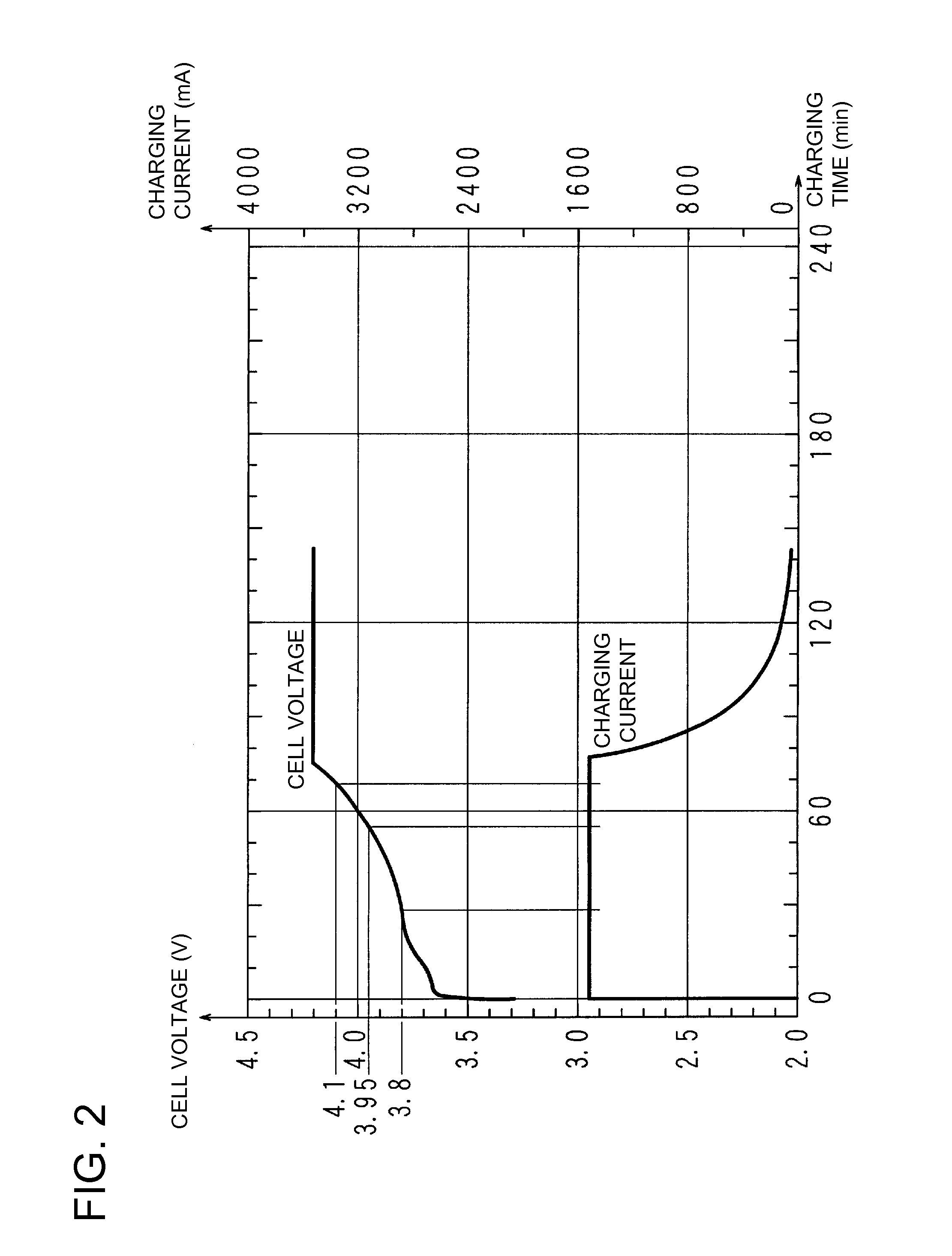

Battery pack, method of determining malfunction, and a malfunction decision circuit

ActiveUS20120274335A1Improve reliabilityReliably determineBatteries circuit arrangementsCurrent/voltage measurementCharge voltageCharge and discharge

Application of rechargeable battery 1 charging voltage is determined by a signal applied to a battery-connect terminal 94 from external electrical equipment. In the case of charging voltage application, the current detection section is judged as malfunctioning when the maximum battery cell 1a, 1b, 1c voltage detected as a time series rises from a voltage below 3.8V (the second voltage) to a voltage above 4.1V (the first voltage) even though rechargeable battery 1 charging and discharging current detected as a time series is (only) greater than −5 mA and less than 20 mA.

Owner:SANYO ELECTRIC CO LTD

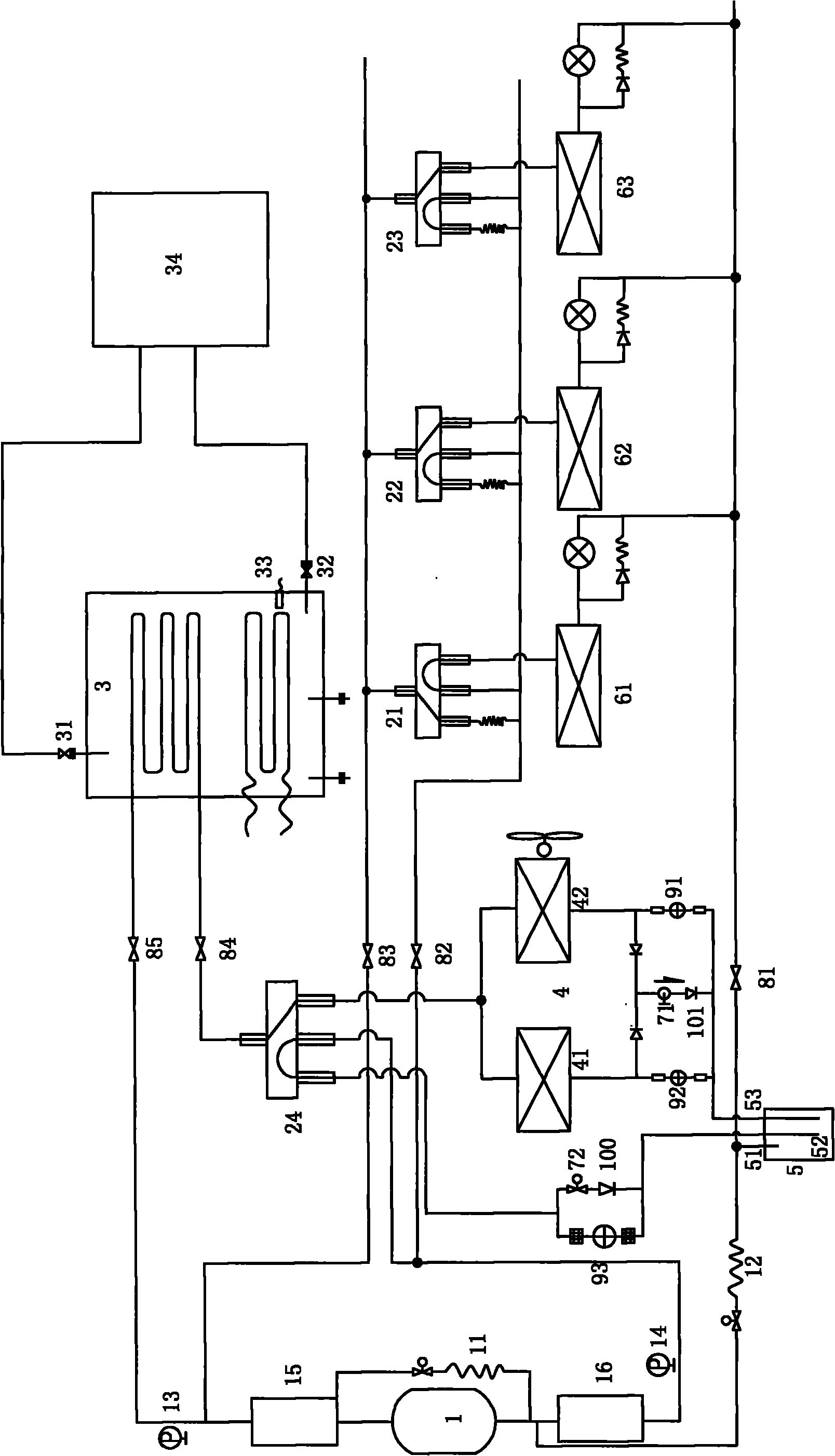

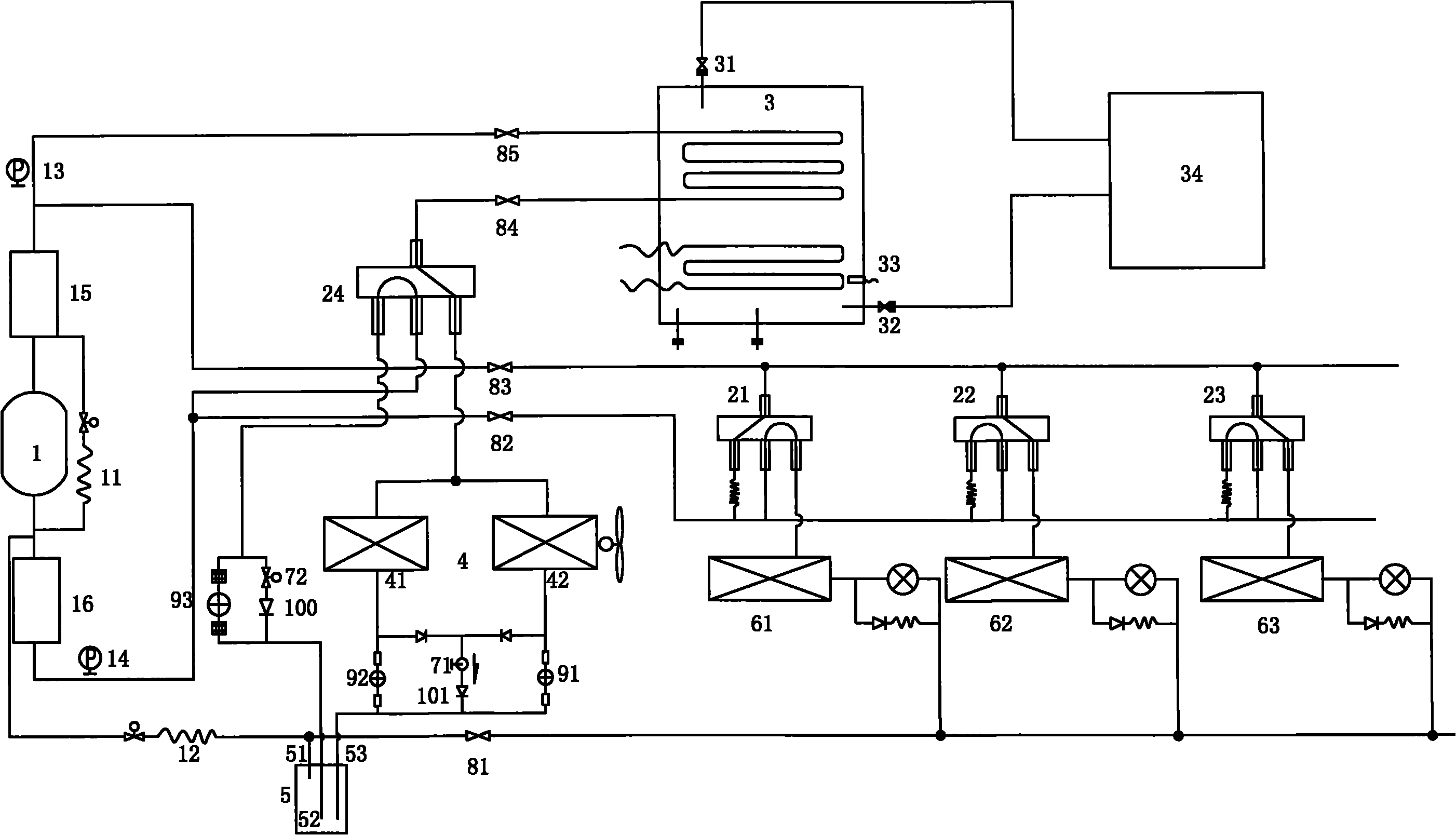

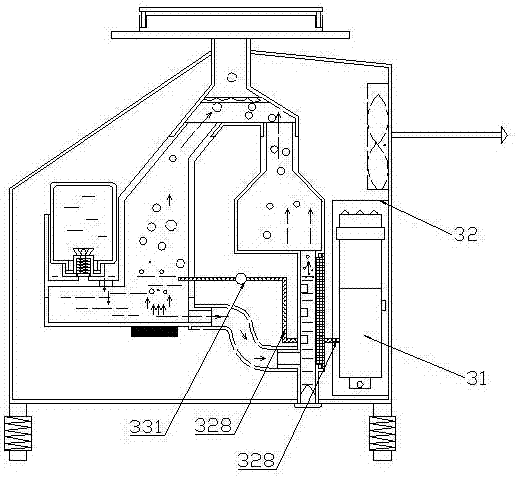

Air conditioner heat pump hot water unit and working method thereof

ActiveCN101769580ARealize sensible heat recovery functionAvoid frequent use of electric heatingFluid heatersEnergy recovery in ventilation and heatingFour-way valveHigh energy

The invention provides an air conditioner heat pump hot water unit and a working method thereof, the performance is optimized, waste heat generated by an air conditioning unit can be recycled, and a heat pump principle with high energy efficiency is utilized to produce hot water so as to save energy, protect environment and be favorable for realizing multi-mode and multifunctional control. The air conditioner heat pump hot water unit comprises a control system, an air conditioning outdoor unit, an indoor unit, a water heater and a plurality of refrigerant pipelines connected among the air conditioning outdoor unit, the indoor unit and the water heater, wherein the water heater comprises a water tank, a hot water generator and a water pipe; the air conditioning outdoor unit comprises a compressor, a heat exchanger, a throttling device and a refrigerant pipeline control device, and the compressor, the heat exchanger, the throttling device and the refrigerant pipeline control device are all connected via the refrigerant pipeline; the refrigerant pipeline control device of the air conditioning outdoor unit comprises a four-way valve A, the port 1 of the four-way valve A is connected with the hot water generator via the refrigerant pipeline; and each indoor unit is provided with a four-way valve, and the four-way valve arranged on the indoor unit is connected with the heat exchanger of the indoor unit via the refrigerant pipeline.

Owner:GREE ELECTRIC APPLIANCES INC

Submount and semiconductor device

InactiveUS7196356B2Preventing heat-related damageLower bonding temperatureLaser detailsSemiconductor/solid-state device detailsSemiconductorBonding strength

The present invention provides a submount that allows a semiconductor light-emitting element to be attached with a high bonding strength.A submount 3 is equipped with a substrate 3 and a solder layer 8 formed on a primary surface 4f of the substrate 4. The density of the solder layer 8 is at least 50% and no more than 99.9% of the theoretical density of the material used in the solder layer 8. The solder layer 8 contains at least one of the following list: gold-tin alloy; silver-tin alloy; and lead-tin alloy. The solder layer 8 before it is melted is formed on the substrate 4 and includes an Ag film 8b and an Sn film 8a formed on the Ag film 8b. The submount 3 further includes an Au film 6 formed between the substrate 4 and the solder layer 8.

Owner:SUMITOMO ELECTRIC IND LTD

Method for repairing large-scale roller

InactiveCN1796602ALow technical requirementsReduces the possibility of crackingMetallic material coating processesMaterials scienceRepair method

This invention publishes a repair method for large casting rollers. In this method, surface welding technology and laser cladding technology are well combined so that respective drawbacks are avoided and advantages are further exerted. Generally speaking, it is a low-risk and reliable repair method.

Owner:李贞

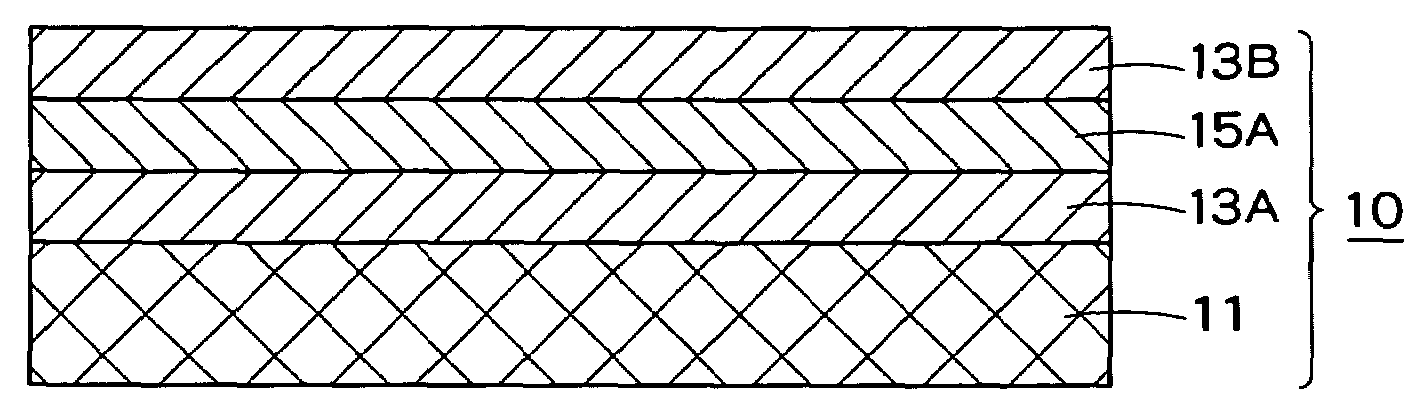

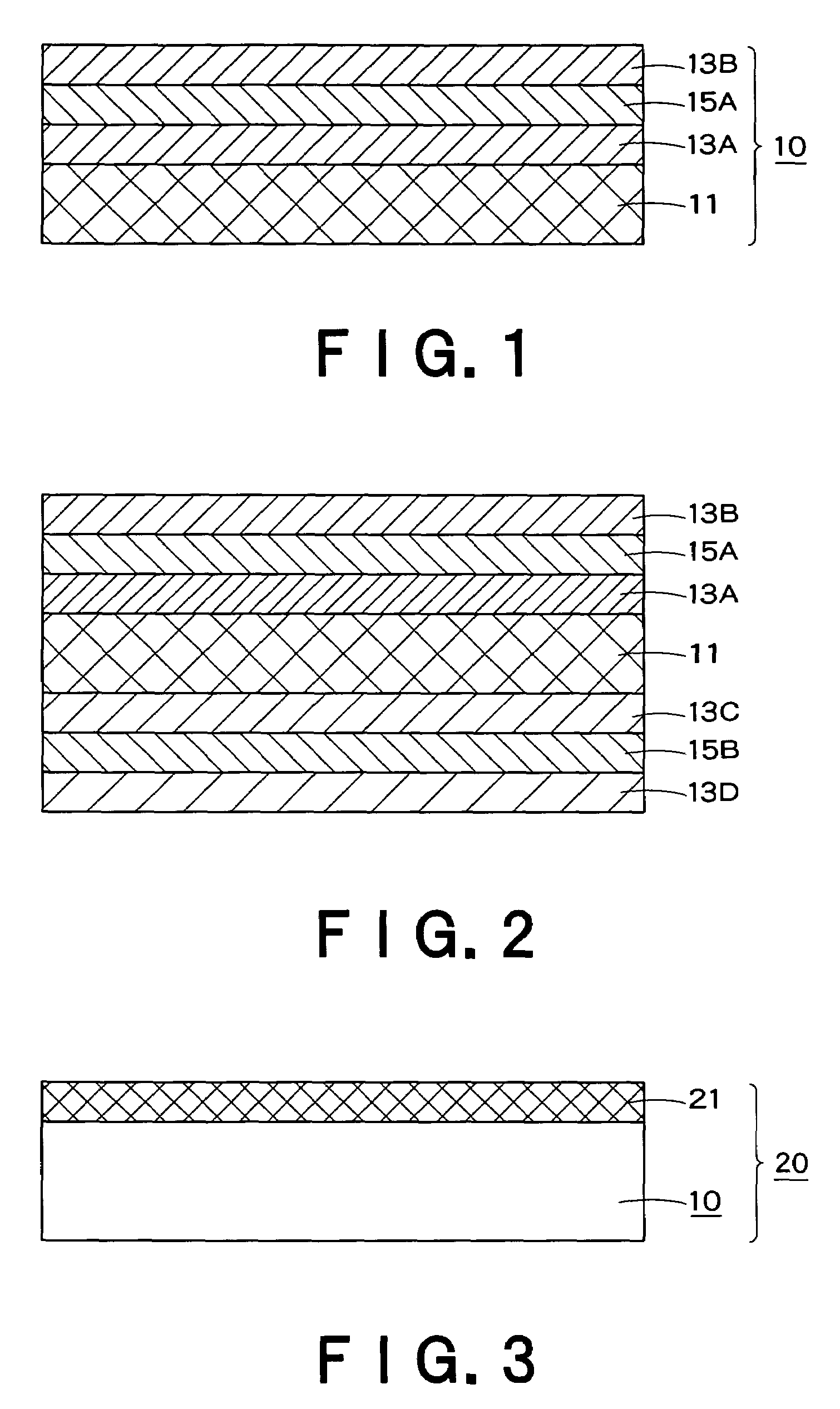

Gas barrier clear film, and display substrate and display using the same

InactiveUS20070026168A1Durable in practical useReduce crackingLiquid crystal compositionsCoatingsVitrificationHeat resistance

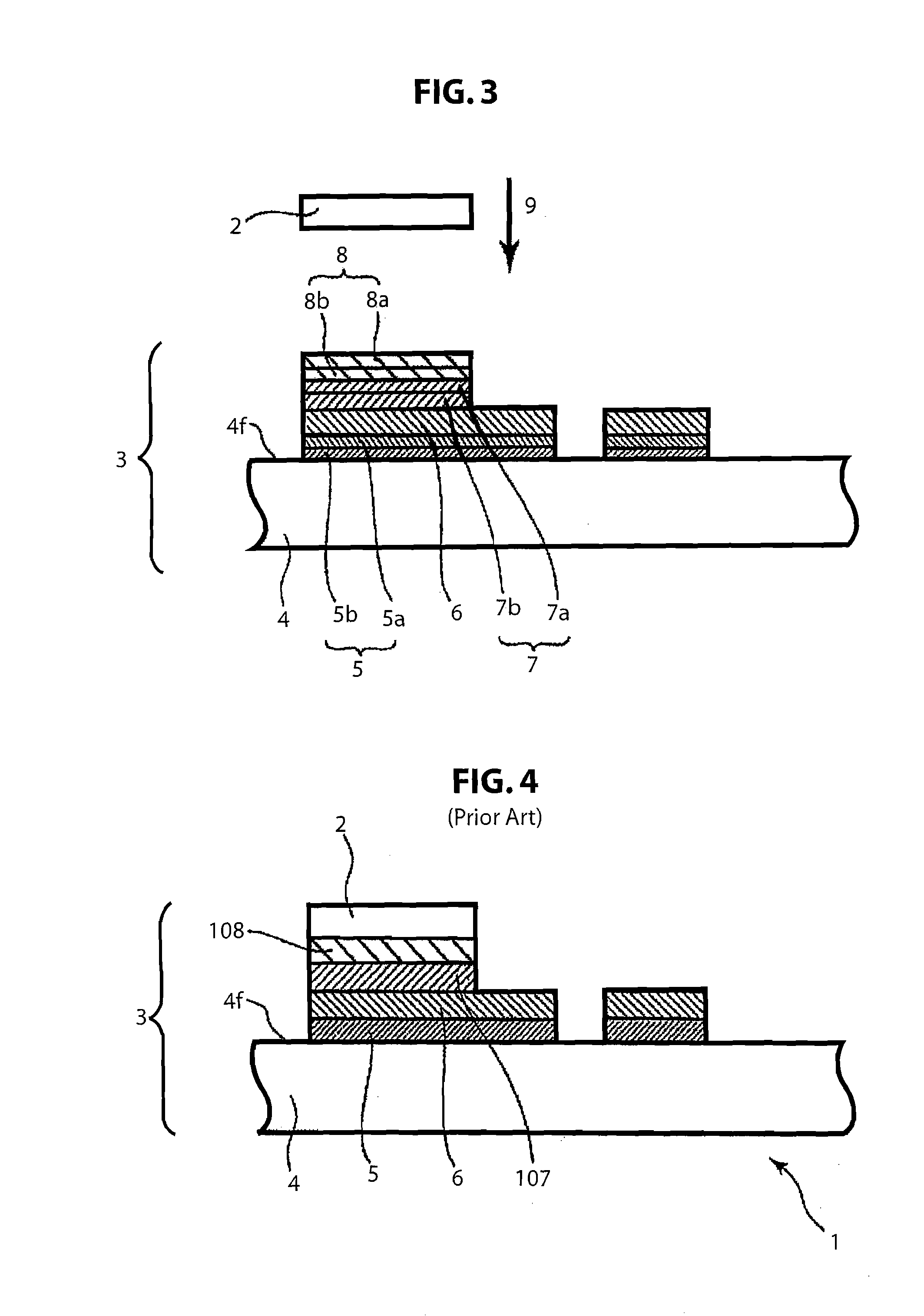

There is provided a gas barrier clear film 10 as a polymer substrate that is flexible, is light, is free from cracking, can be bent, has a high level of heat resistance, is excellent particularly in gas shielding properties, and can be used as an alternative to glass substrates. The gas barrier clear film comprises: a clear resin base material film 11 having a coefficient of linear expansion of 15 to 100 ppm / K and a glass transition temperature Tg of 150 to 300° C.; and a first clear inorganic compound layer 13A, a sol-gel coat layer 15A, and a second clear inorganic compound layer 13B provided in that order on the clear resin base material film 11. The second clear inorganic compound layer 13B has an Ra (average roughness) value of not more than 5 nm and an Rmax (maximum roughness) value of not more than 80 nm.

Owner:DAI NIPPON PRINTING CO LTD

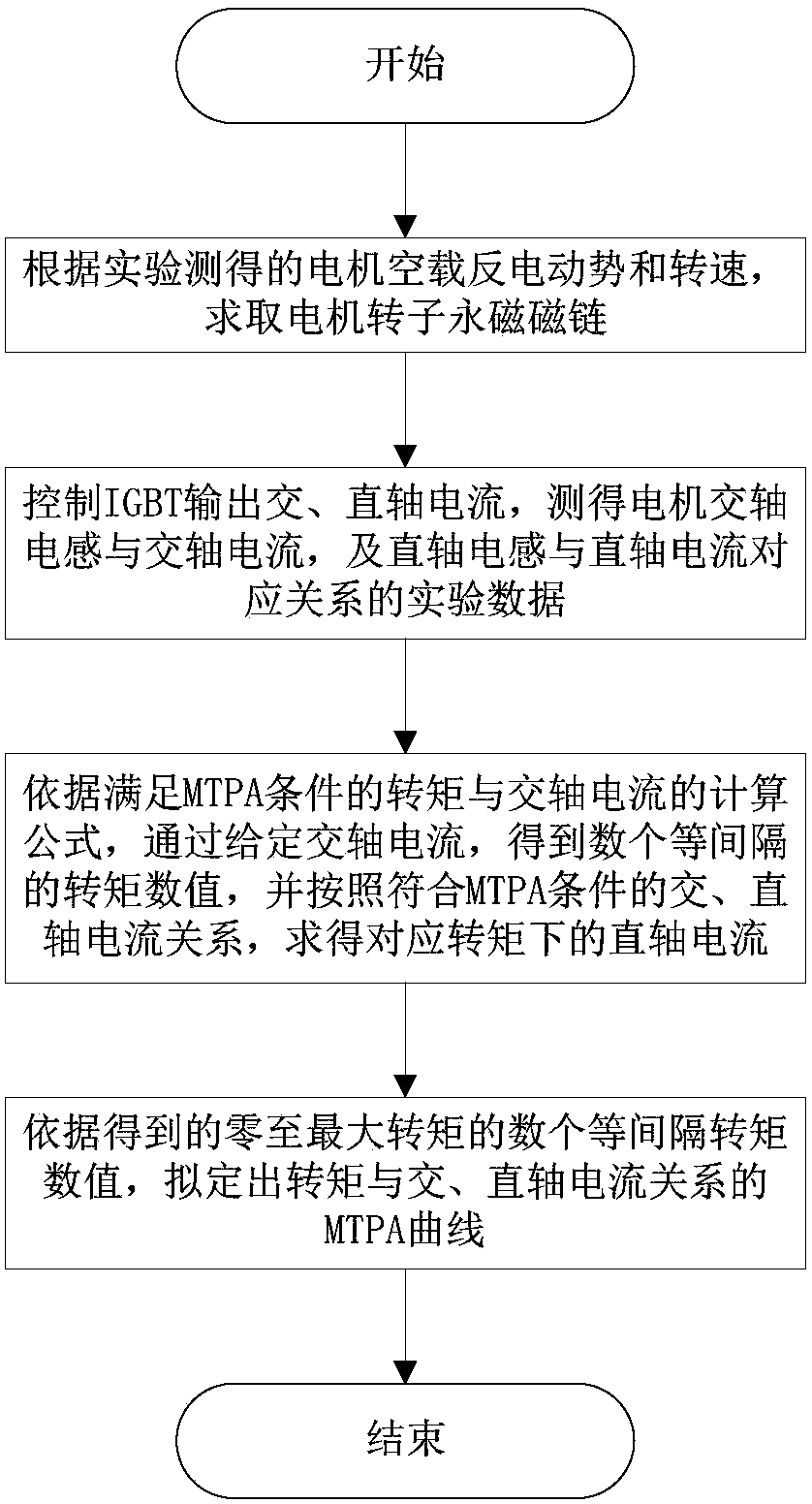

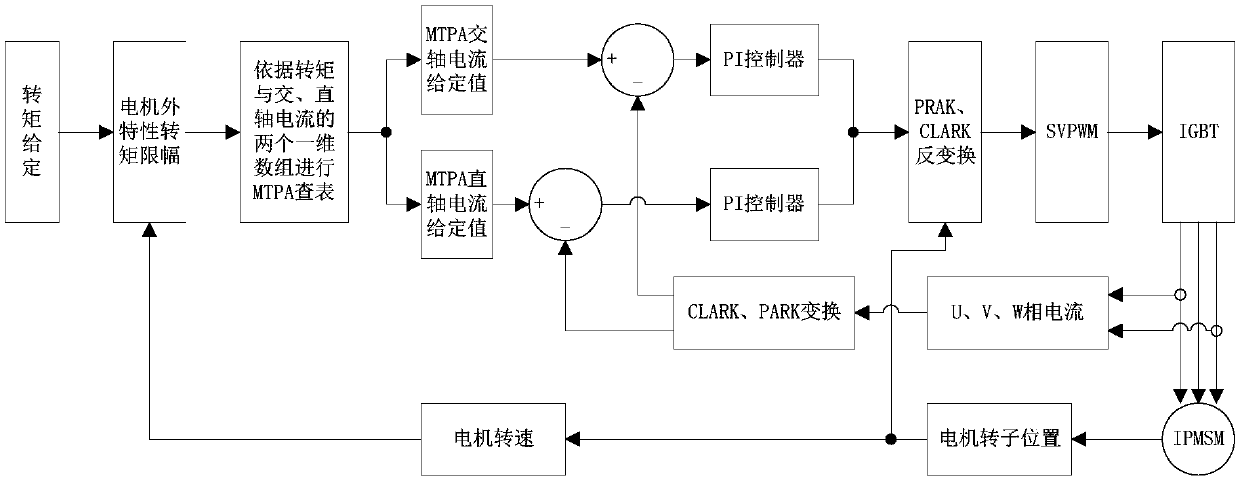

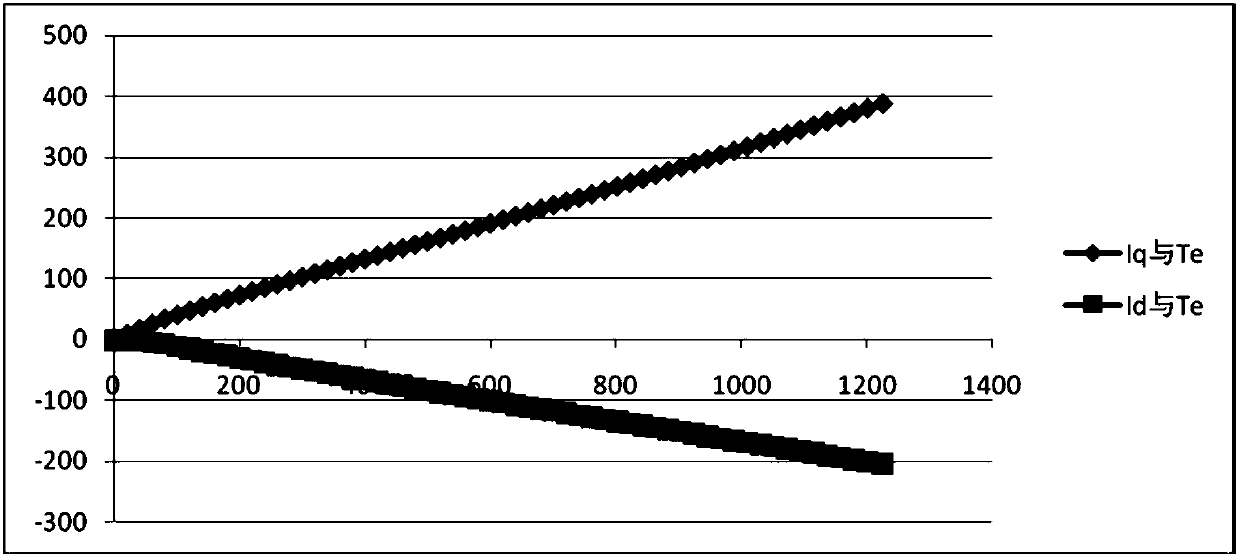

MTPA curve fitting method for embedded permanent magnet synchronous motor and control system

InactiveCN107896080ASimple calculationHigh precisionElectronic commutation motor controlVector control systemsMaximum torqueControl system

The invention discloses an MTPA curve fitting method for an embedded permanent magnet synchronous motor. The method includes the steps of solving a permanent magnet linkage of a motor rotor accordingto the motor zero-load counter electromotive force and a rotating speed measured through an experiment, controlling q-axis current and d-axis current, measuring the experimental data of the corresponding relation between the q-axis inductance and the q-axis current, and between the d-axis inductance and the d-axis current, obtaining plurality of equal-interval torque values according to the calculation formula of the torque and q-axis current meeting the MTPA condition and through giving the q-axis current, obtaining the d-axis current under the corresponding torque according to the q-axis current and d-axis current relation meeting the MTPA condition, and fitting a MTPA curve of the torque and q-axis current and d-axis current relation based on a plurality of obtained equal-interval torque values of zero-to-maximum torques. The method aims at solving the problems that a formula calculation method is not high in precision, the operation of an experiment test method is complicated. An embedded permanent magnet synchronous motor MTPA curve comprehensive drawing method and a control system which can meet calculation and precision requirements are provided.

Owner:CHENGDU RAJA NEW ENERGY AUTOMOTIVE TECH CO LTD

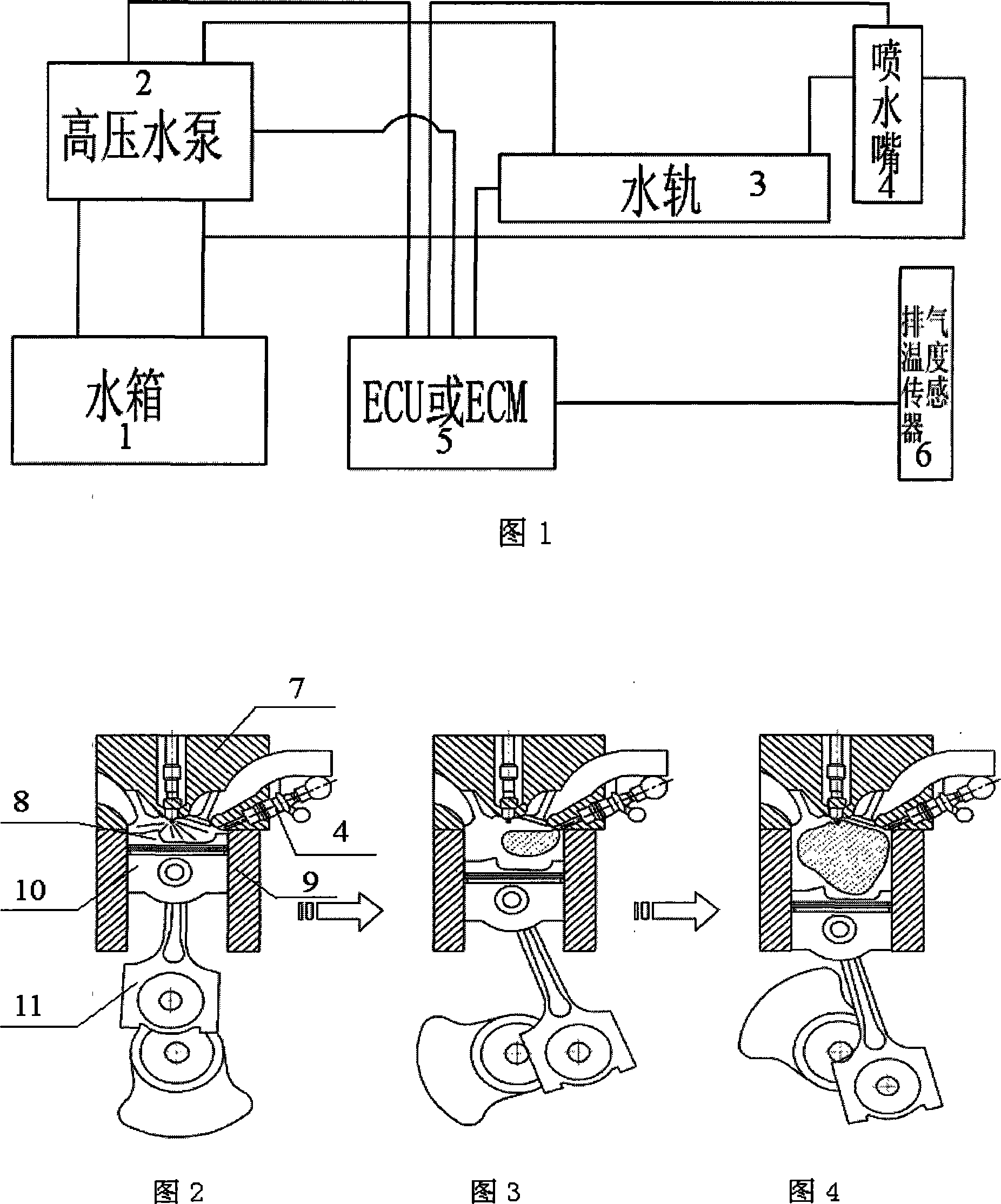

Four-stroke petrol engine inner-vat sprinkler

InactiveCN101135280ABurning does not affectReduce the temperatureNon-fuel substance addition to fuelInternal combustion piston enginesThermal energyCombustion chamber

A water-spray device for use in the cylinder of four-stroke gasoline engine, which comprises electric control unit, water tank, water pump controlled by the electric unit, water track and water-spray nozzle. The water-outlet of the water pump connects with the water-inlet of the water track by a water tube. The water-spray nozzle communicates respectively with the water-outlet of the water track, water tank and the water pump by water tube, the water-spray mouth of the water-spray nozzle is inserted into the combustion chamber of the gasoline engine. Advantages: water is sprayed in the cylinder at some stage of combustion stroke of engine, the temperature is controlled above combustion point of gasoline so as not to effect gasoline to continuous combust; water is gasified instantaneously to increase cylinder pressure so as to increase effective torque and power output; water is gasified to apply work to consume large amount of heat energy so as to reduce the load and power consumption of lubrication system; the temperature in cylinder is reduced so as to reduce burst risk and gasoline engine can use higher compression ratio to economize gasoline; the reduced combustion temperature in cylinder can inhibit the generation of oxynitride so as to reduce the exhaust of harmful matter to benefit environment protection.

Owner:MIANYANG XINCHEN ENGINE

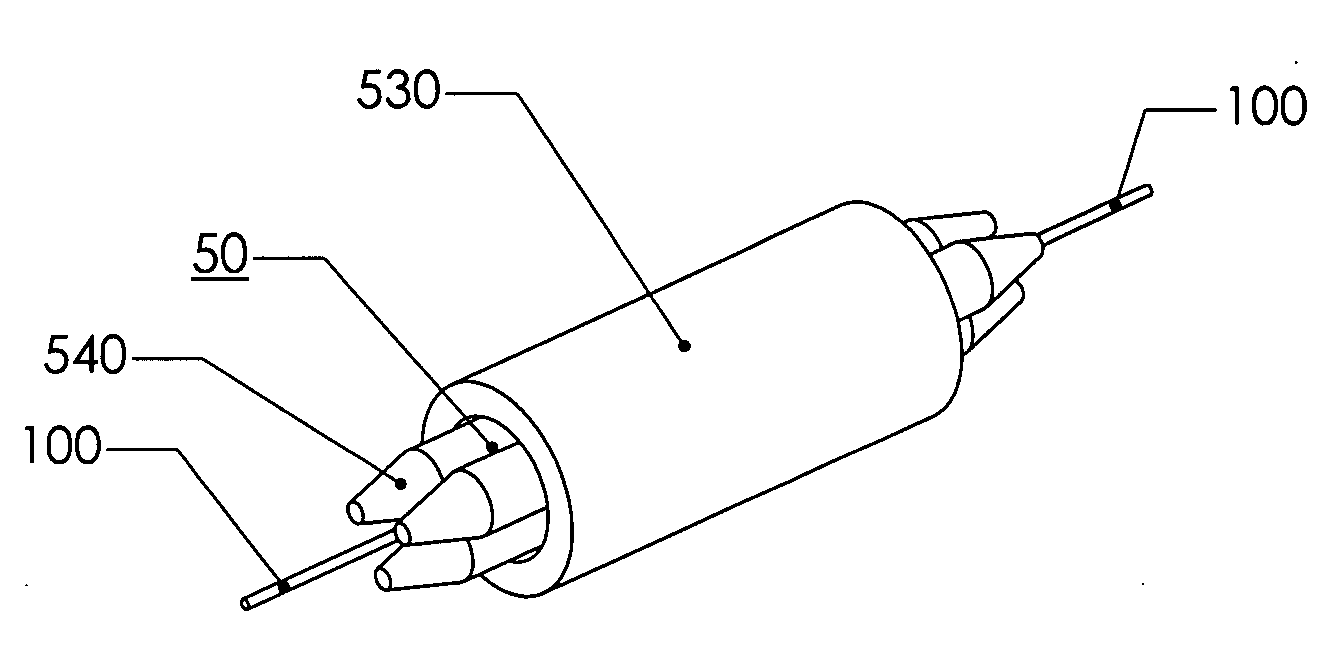

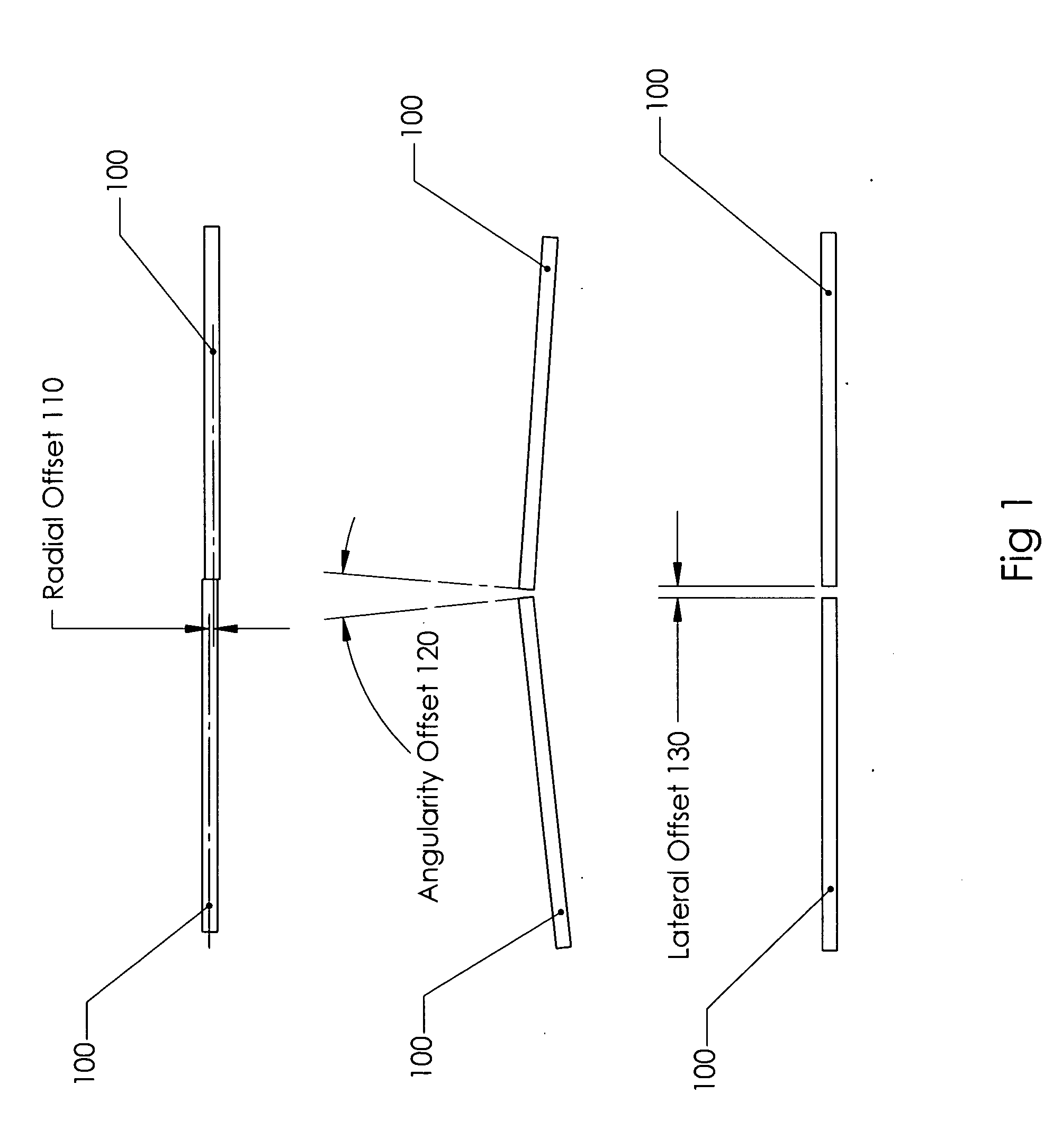

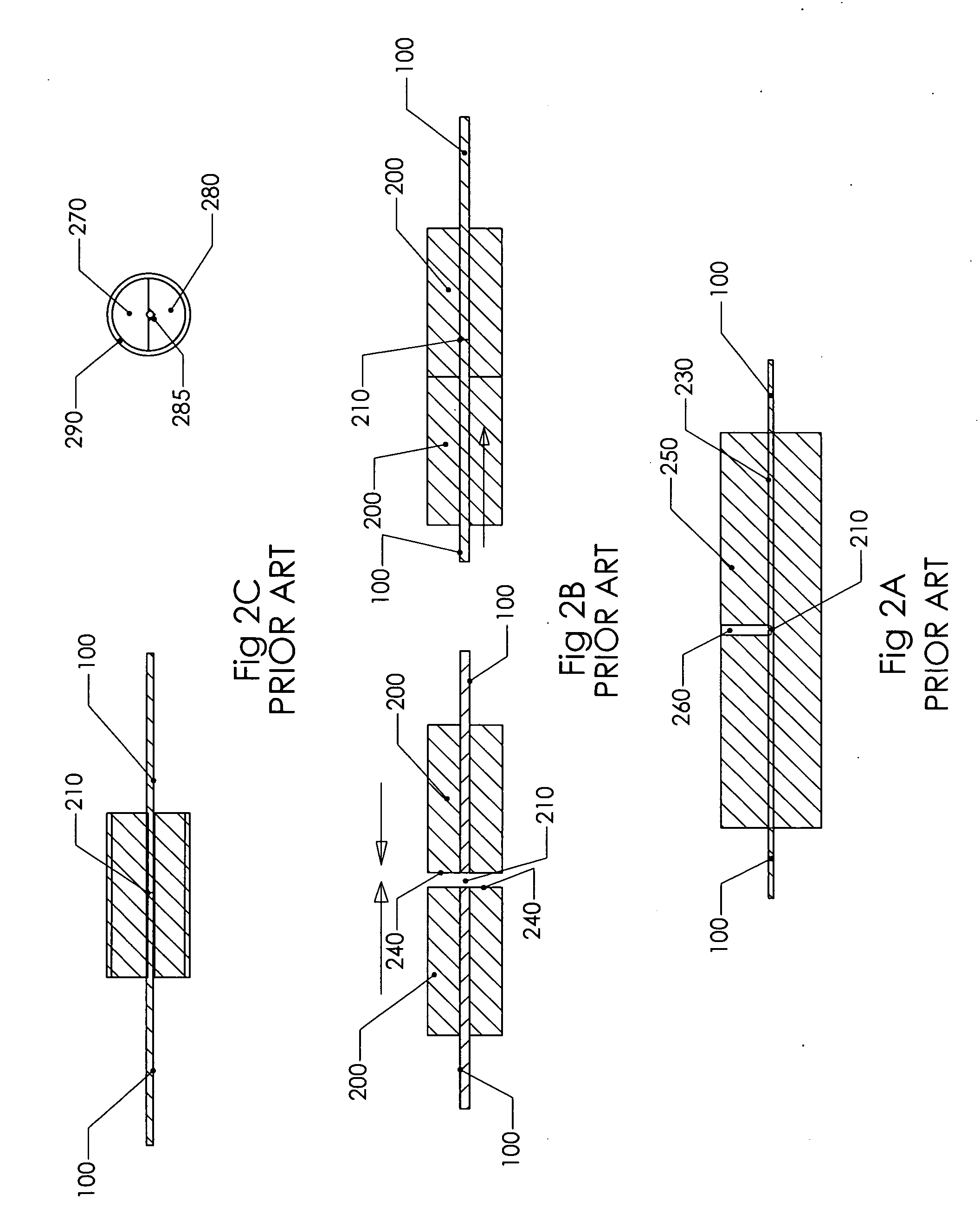

Fiber guiding platform for mechanical splicer, optical connectors, fiber holder and methods

A three rod bundle confined inside a sleeve is constructed as a light guiding fiber mechanical splicing device which is stiff, strong and precise, with no moving parts. The design also applies to splicing fibers to pre-polished optical connectors through a built-in model of this innovative mechanical splicer. Applying the Soddy circles formula and using a bin approach assists in deriving the exact rod sizes needed and sleeve bore size to accommodate the three-rod bundle, so that this apparatus can be properly designed to guide any size of light guide fibers and studs with minimum clearance. Rods of varying diameters are sorted into bins and chosen based upon the aperture desired, thus eliminating the need for tight tolerance of the diameters of the three rods. This unique design allows for construction of a precision virtual hole of very long depth, which enables two optical fiber studs to butt against each other with a core to core misalignment of less than 1 um for single mode fiber optics cables. Unlike prior arts, the sleeve holding the rods eliminates the need for any clamping mechanism to tighten a loose bundle, which induces undesirable mechanical strain. It also eliminates the need to use a fiber clamp to force the fiber studs against dimensionally unstable V or U groove alignment features which also induce undesirable mechanical strain. A fiber holder is also presented to depict the usefulness of this invention on hold fiber in position.

Owner:WANG WEI MIN

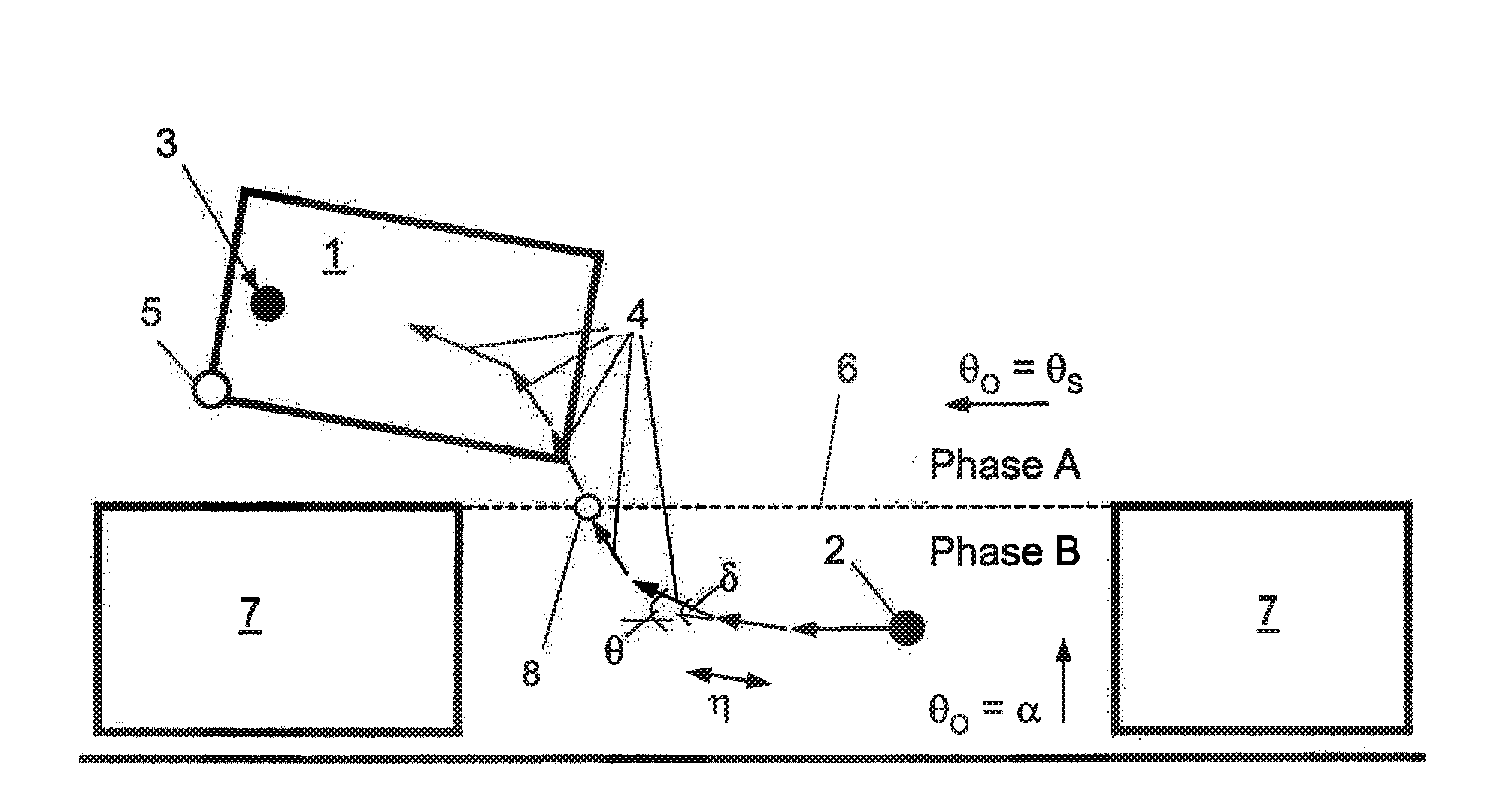

Method for steering a vehicle

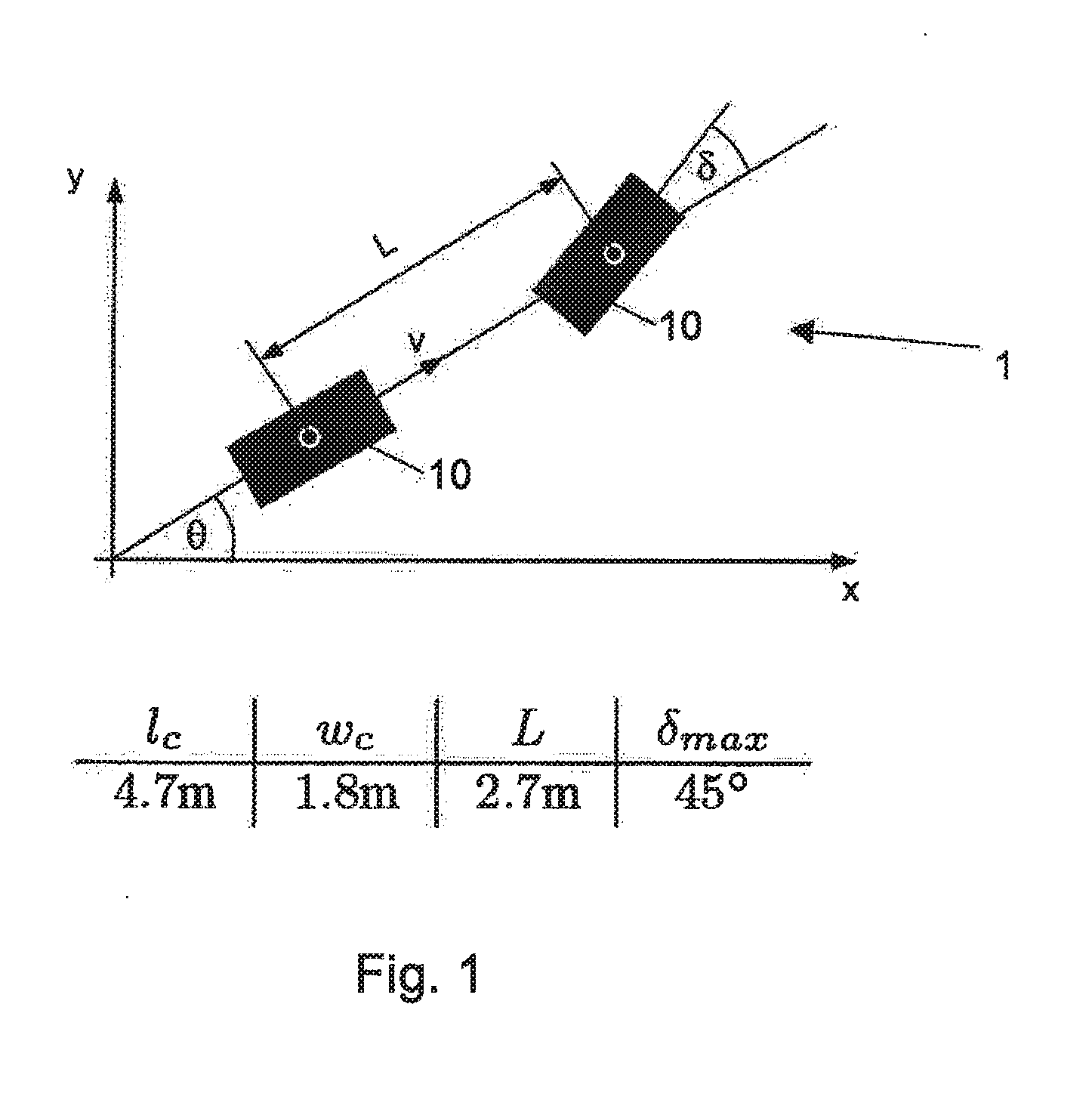

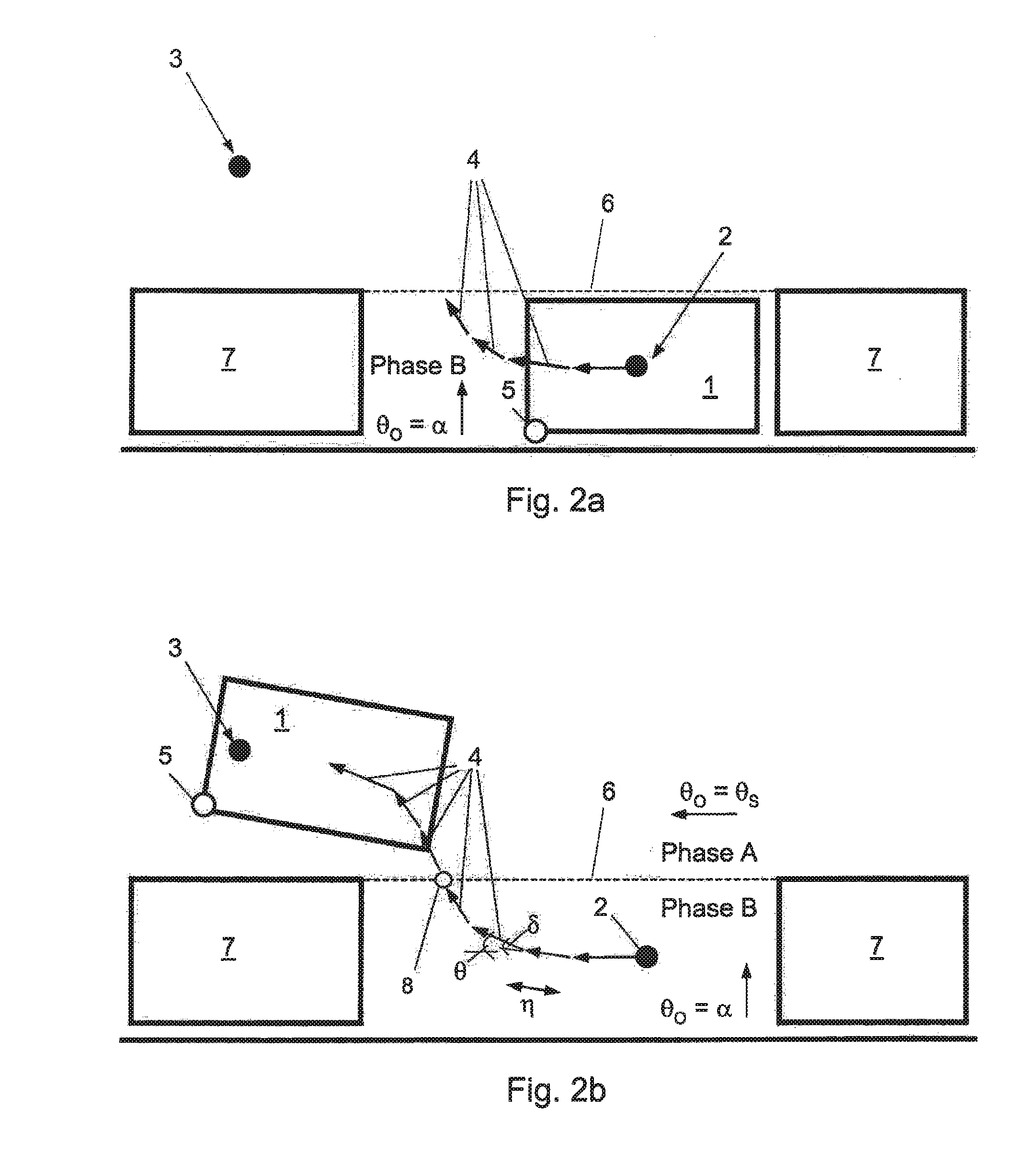

ActiveUS20160200359A1Low computing performanceThe process is simple and fastSteering initiationsDigital data processing detailsSteering angleSimulation

For steering a vehicle around obstacles, proceeding along a path from a starting position to an end position, the path including linear sub-paths which are defined by an increment η and a steering angle δ, a method includes: a) determining a maximum steering angle range and a maximum and a minimum increment range; b) determining the present distance eP from the end position, the target angle θO, and the angle difference eθ between the present vehicle angle and the target angle; c) performing an optimization method for ascertaining a sub-path by minimizing the value of a cost function lO assigned to the sub-path; d) determining the new position by adding the ascertained sub-path to the present position; and e) repeating steps (b) through (d) until the end position is reached.

Owner:ROBERT BOSCH GMBH

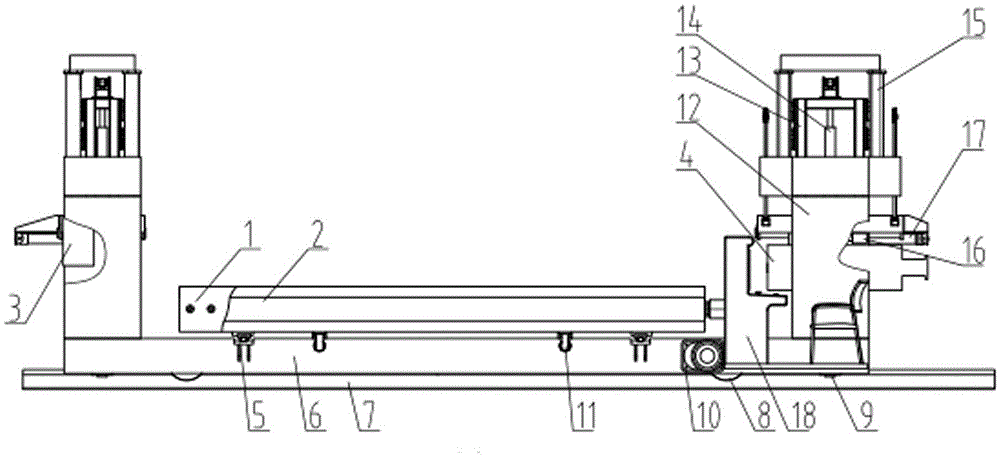

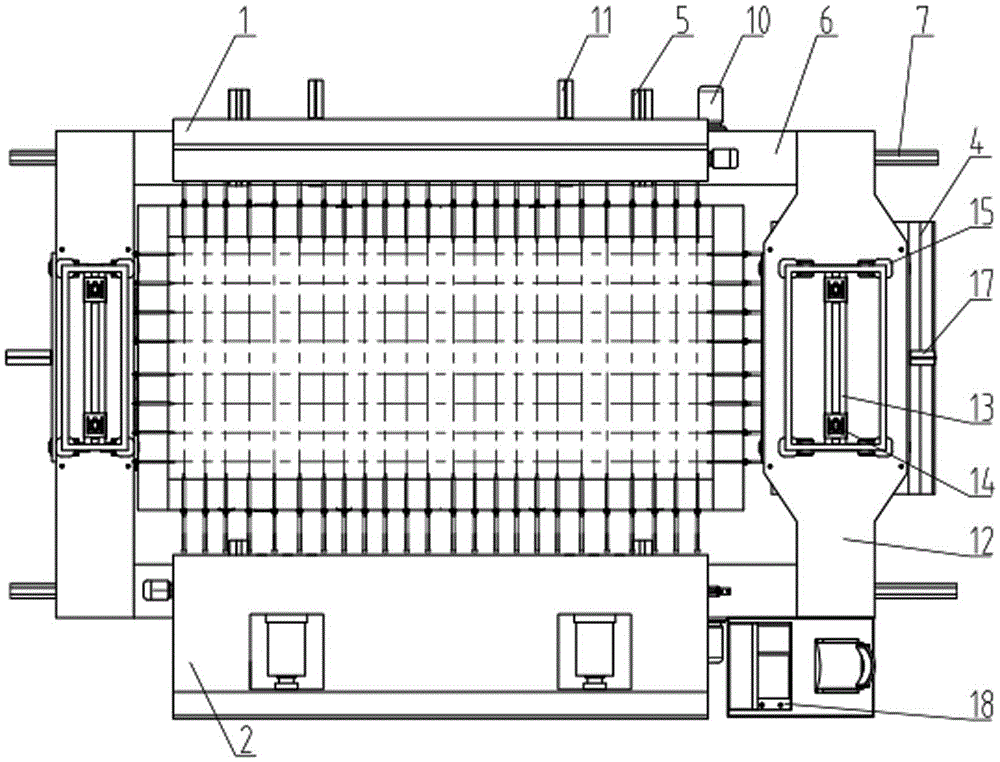

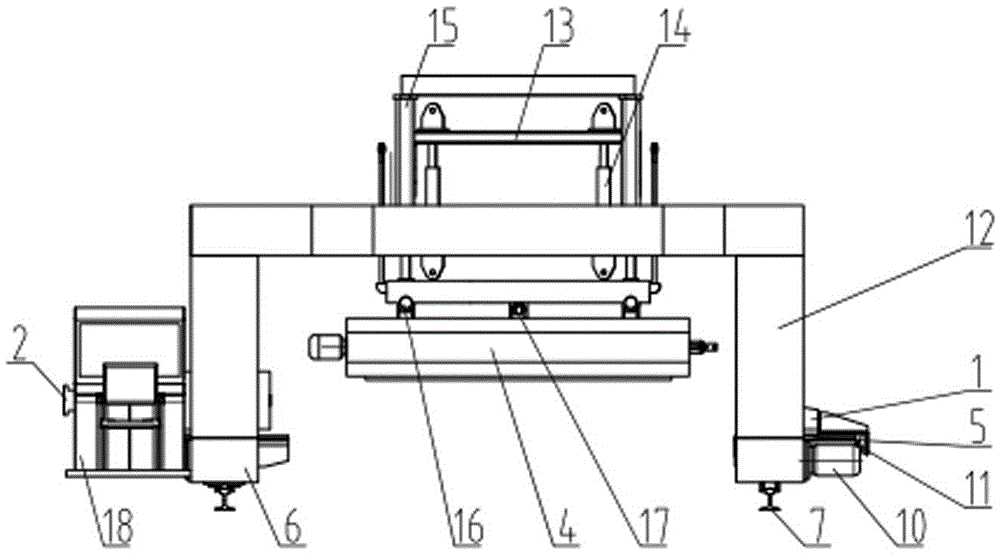

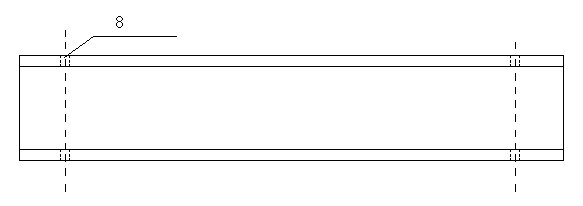

Two-direction pre-tensioned prestressing ballastless track slab movable tensioning equipment

ActiveCN105643792ASimple structureIncrease stiffnessCeramic shaping apparatusPre stressElectric machinery

Two-direction pre-tensioned prestressing ballastless track slab movable tensioning equipment comprises a side pre-locking beam, a side tensioning beam, an end pre-locking beam and an end tensioning beam; the side pre-locking beam and the side tensioning beam are assembled on two walking beams through a pair of side beam linear guide rails, and each walking beam is provided with wheels matched with a running rail, walking guide wheel sets, a wheel speed reduction motor and side beam advancing and retreating oil cylinders; portal frames are arranged at the two ends of the walking beams, and a lifting frame, a lifting frame lifting oil cylinder and a lifting frame lifting guide device are assembled on each portal frame; and the end pre-locking beam and the end tensioning beam are assembled on the lower faces of the lifting frames through a pair of end beam linear guide rails, and end beam advancing and retreating oil cylinders are arranged on the lifting frames. According to the equipment, the production preparation period can be effectively shortened, the engineering construction cost is reduced, industrial pollutions are avoided, and meanwhile a steel mold fixed mounting production manner facilitates simplifying of a mold structure, reduction of cost, improvement of precision and reduction of occupied areas and working energy consumption of production equipment.

Owner:秦皇岛老虎重工有限公司

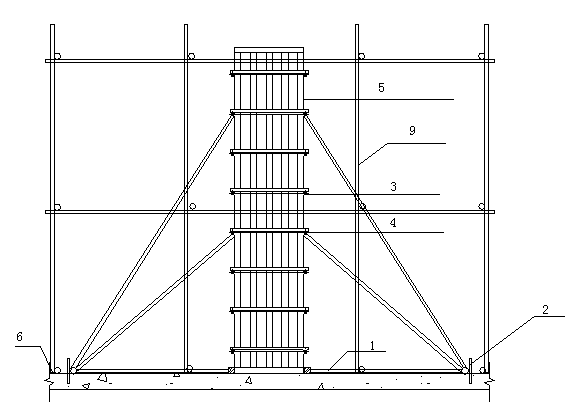

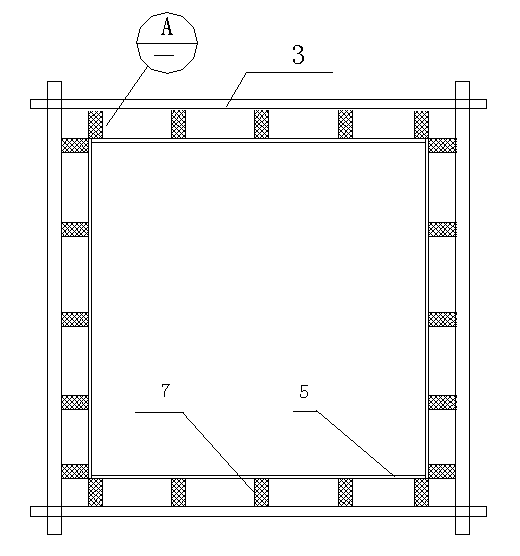

Reinforcing method for U-bar hoop formworks of large-section frame column

A reinforcing method for U-bar hoop formworks of a large-section frame column mainly comprises the implementation steps of 1, formwork design and checking calculation, 2, formworks arrangement, numbers giving and piling; 3, U-bar hoop processing, 4, pull screw manufacture, 5, column axis determination and elevation measurement, 6, column root formwork processing, 7, quality inspection, 8, erection of a support frame body, and 9, installation of the column formworks. The reinforcing method for U-bar hoop formworks of a large-section frame column fully utilizes rigidity and strength of U-bars, effectively controls section deformation of the frame column, avoids influence on building appearance quality caused by holes formed by penetrating the penetrating pull screws through components, solves the quality problems of jig displacement, formwork expansion, slurry leakage and the like to some extent, and meanwhile reduces use quantity of fasteners. All the construction materials can be reused, and cost is saved. The reinforcing method for U-bar hoop formworks of the large-section frame column is simple to operate and simple and easy in procedure, not only effectively shortens construction periods, improves quality and saves the cost, but also is simple in process, practical and reliable.

Owner:CHINA MCC17 GRP

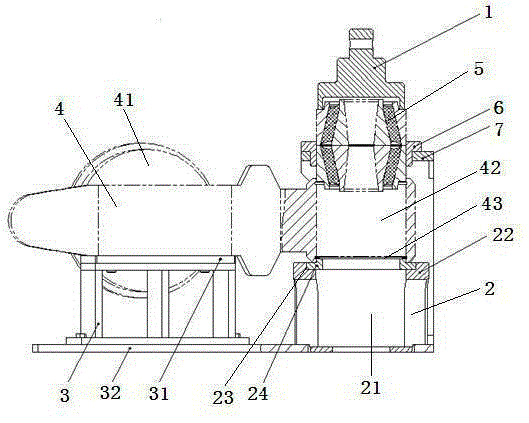

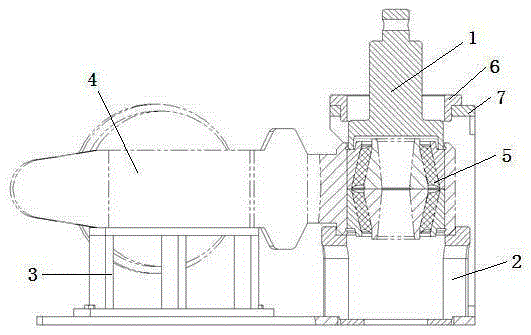

Automatic floating centering hydraulic clamp holder

PendingCN107420051AEliminate wear and tearHigh speedDrilling rodsDrilling casingsSingle degree of freedomEngineering

The invention discloses an automatic floating centering hydraulic clamp holder. The automatic floating centering hydraulic clamp holder comprises a clamping assembly used for clamping a drill rod and a base fixedly matched with a drilling machine rack and used for installing the clamping assembly. The clamping assembly is installed on the base in the radial swing direction of the drill rod in a single-degree-of-freedom sliding mode, and a fixing elastic part used for fixing the clamping assembly to avoid the situation that the clamping assembly slides under the gravity effect is arranged between the base and the clamping assembly in the single-degree-of-freedom sliding direction of the clamping assembly; external force floating centering can be increased, so that the situation that abrasion on the drill rod during clamp holder centering is guaranteed through force generated by rotating of the drill rod is avoided; and meanwhile in a lateral orientation drilling machine, the clamp holder can also be centered under the effect of floating external force, so that the eccentric problem of an existing clamp holder under the gravity effect or the problem that the initial position of the clamp holder is repeatedly adjusted to ensure centering in different orientations is avoided.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

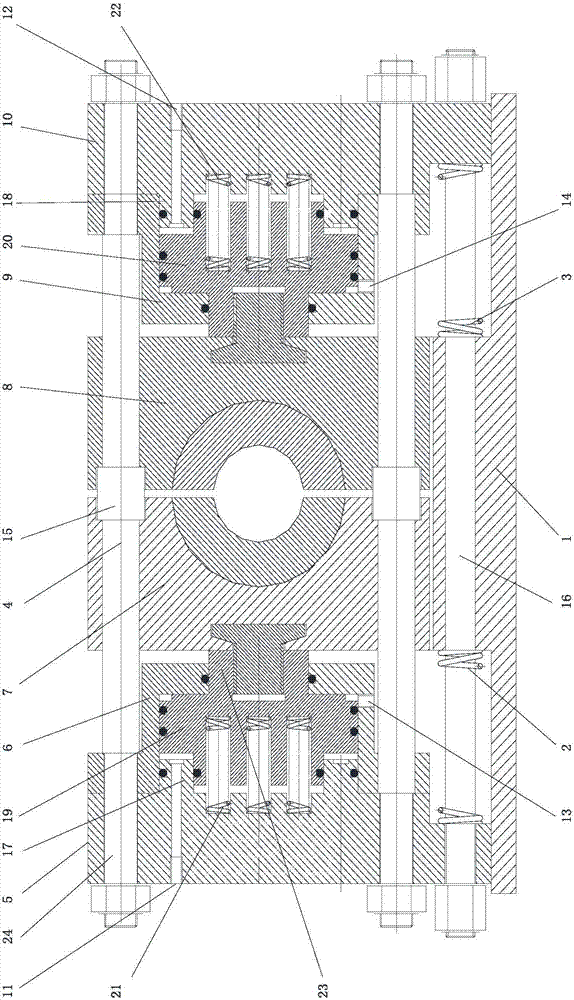

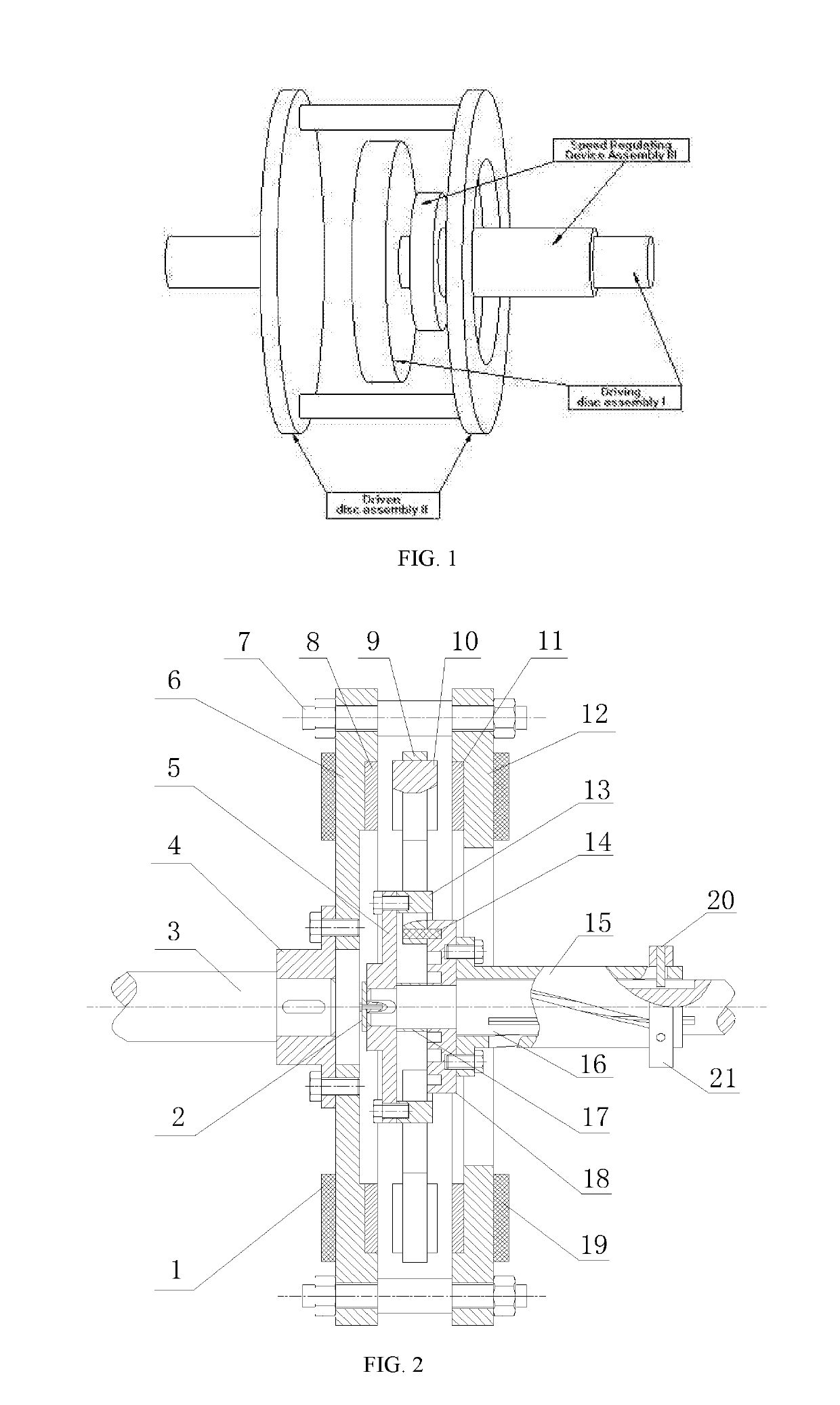

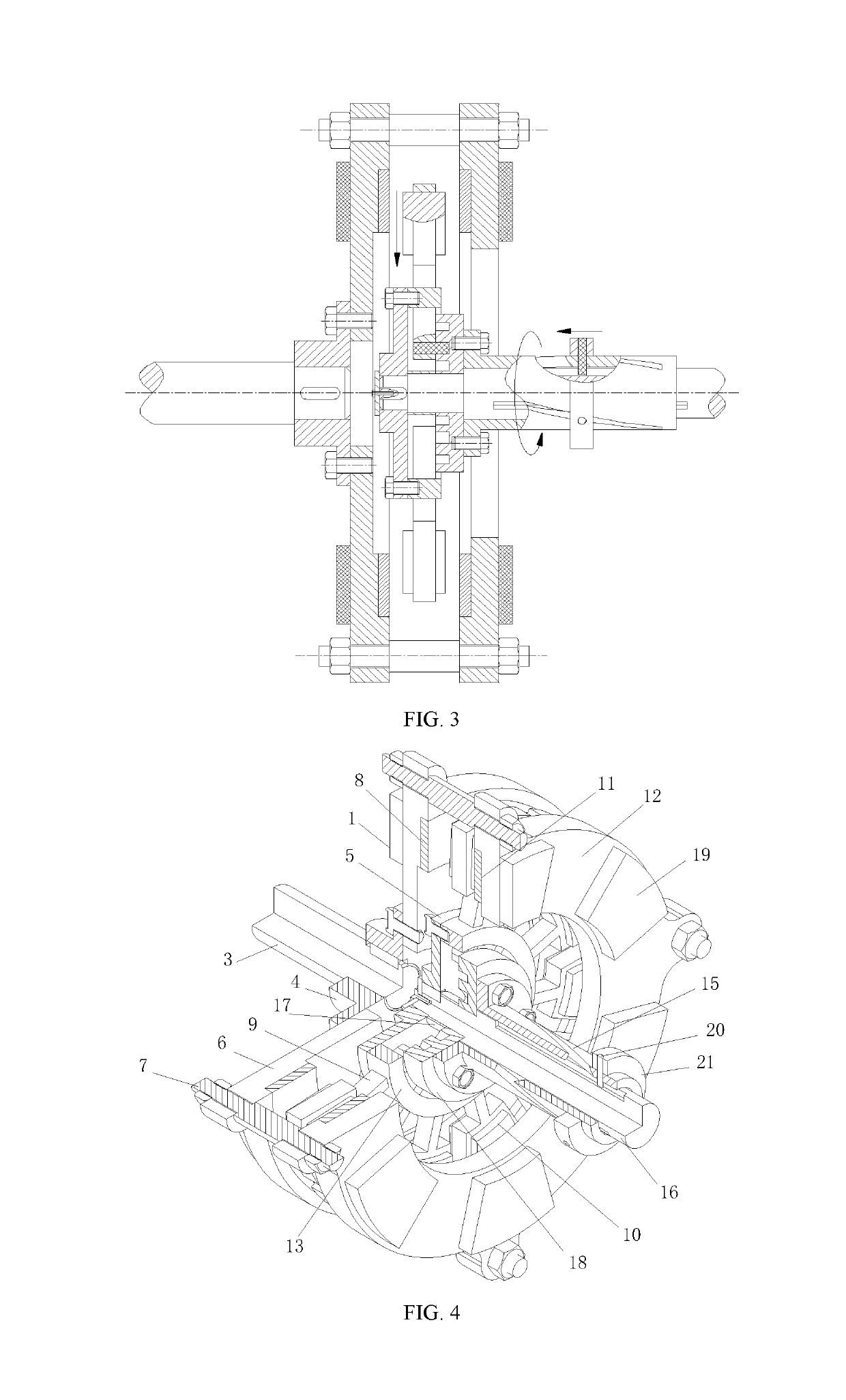

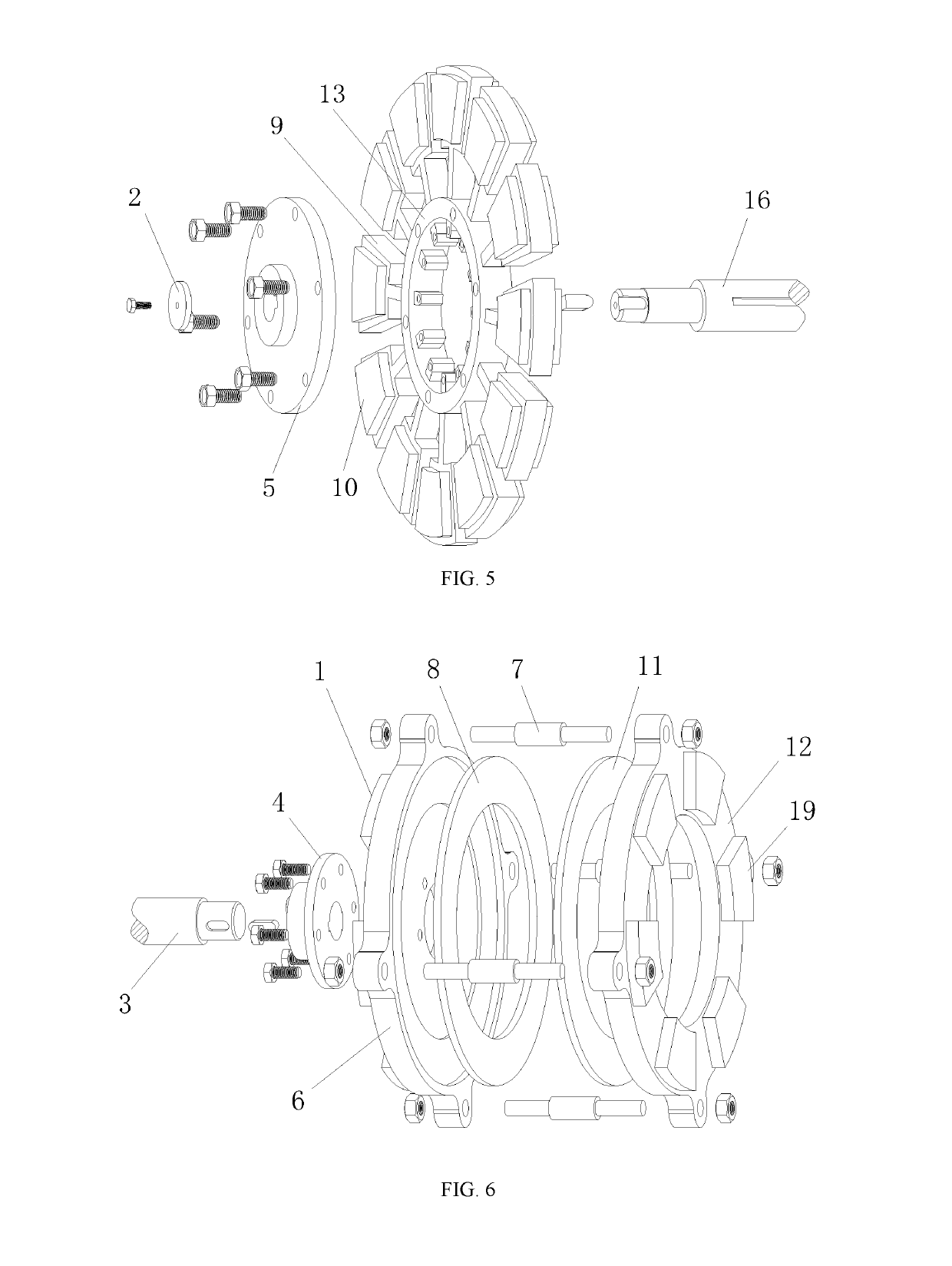

Variable-speed magnetic coupling having radially movable magnet

ActiveUS20190157963A1Reduce transmission component lossEffectively solve of even failureDynamo-electric gearsPermanent magnetsMagnetic tension forceDrive shaft

A variable-speed magnetic coupling having a radially movable magnet, comprising a drive disc assembly (I), a driven disc assembly (II), and a speed adjusting device assembly (III). Relative rotation of a speed adjustment sleeve (15) with respect to a drive shaft (16) is achieved by means of contact and fitting of a cylindrical pin (20) with respect to a vertical recess on an inner wall of the drive shaft and to an inclined recess on an inner wall of the speed adjustment sleeve. The speed adjustment sleeve is connected to a circular slotted disc (18) by means of a screw. A permanent magnet (10) is attached to a permanent magnet bearer (9) and inserted into a rectangular through hole of a circular frame (13), and a radial movement of the permanent magnet is enabled by means of a cam and groove sliding block mechanism consisting of the circular slotted disc, the circular frame, the permanent magnet bearer, and the permanent magnet. By moving a movement block (21) to drive the movement pin (20) to slide in the recesses of the drive shaft and the speed adjustment sleeve and then drive the speed adjustment sleeve to rotate, the present invention enables a radial movement of the permanent magnet, and then changes a coupling area or an air gap distance between the permanent magnet and conductive rings (8, 11) on two sides, thus changing a magnetic flux density of the air gap, and accordingly enabling speed adjustment.

Owner:JIANGSU UNIV

Gas barrier clear film, and display substrate and display using the same

InactiveUS7341766B2Practical and reliableReduce crackingLiquid crystal compositionsCoatingsPolymer substrateHeat resistance

There is provided a gas barrier clear film 10 as a polymer substrate that is flexible, is light, is free from cracking, can be bent, has a high level of heat resistance, is excellent particularly in gas shielding properties, and can be used as an alternative to glass substrates.The gas barrier clear film comprises: a clear resin base material film 11 having a coefficient of linear expansion of 15 to 100 ppm / K and a glass transition temperature Tg of 150 to 300° C.; and a first clear inorganic compound layer 13A, a sol-gel coat layer 15A, and a second clear inorganic compound layer 13B provided in that order on the clear resin base material film 11. The second clear inorganic compound layer 13B has an Ra (average roughness) value of not more than 5 nm and an Rmax (maximum roughness) value of not more than 80 nm.

Owner:DAI NIPPON PRINTING CO LTD

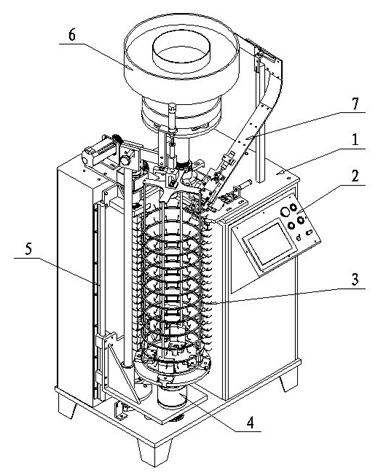

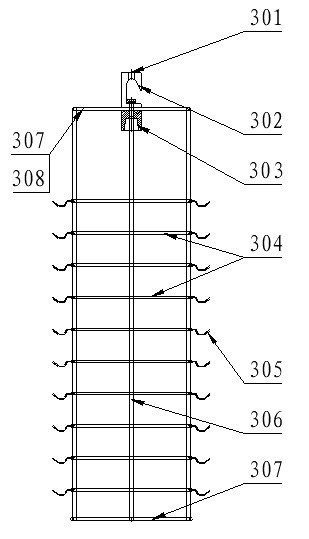

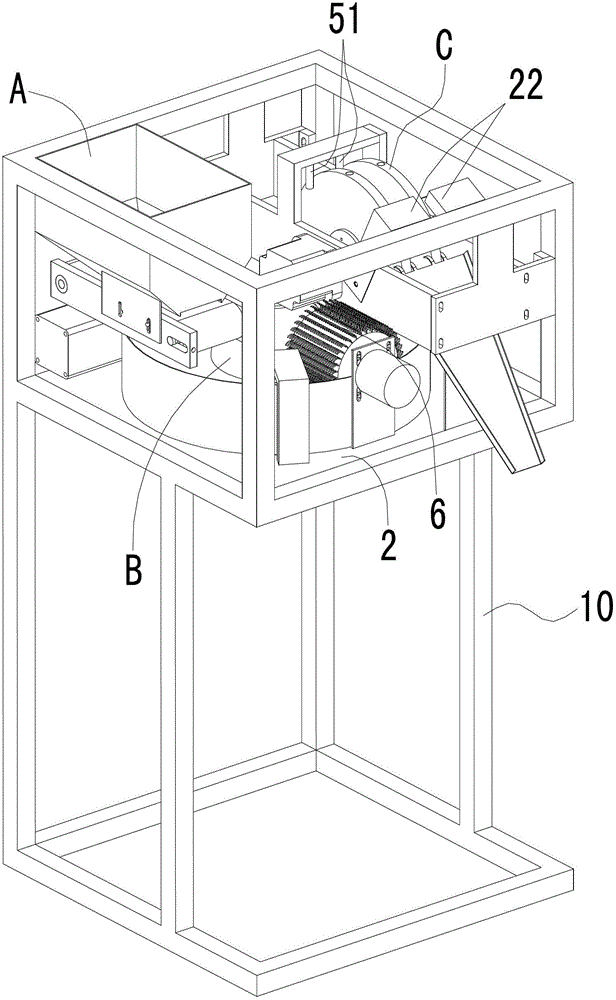

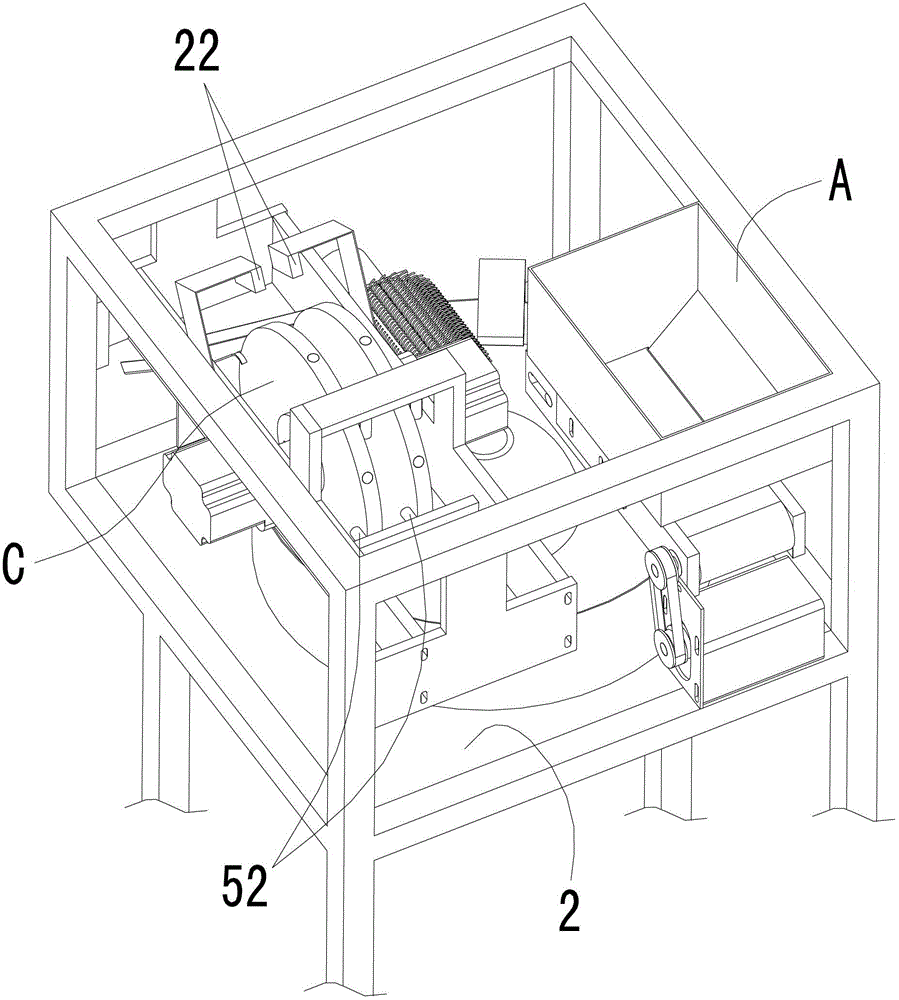

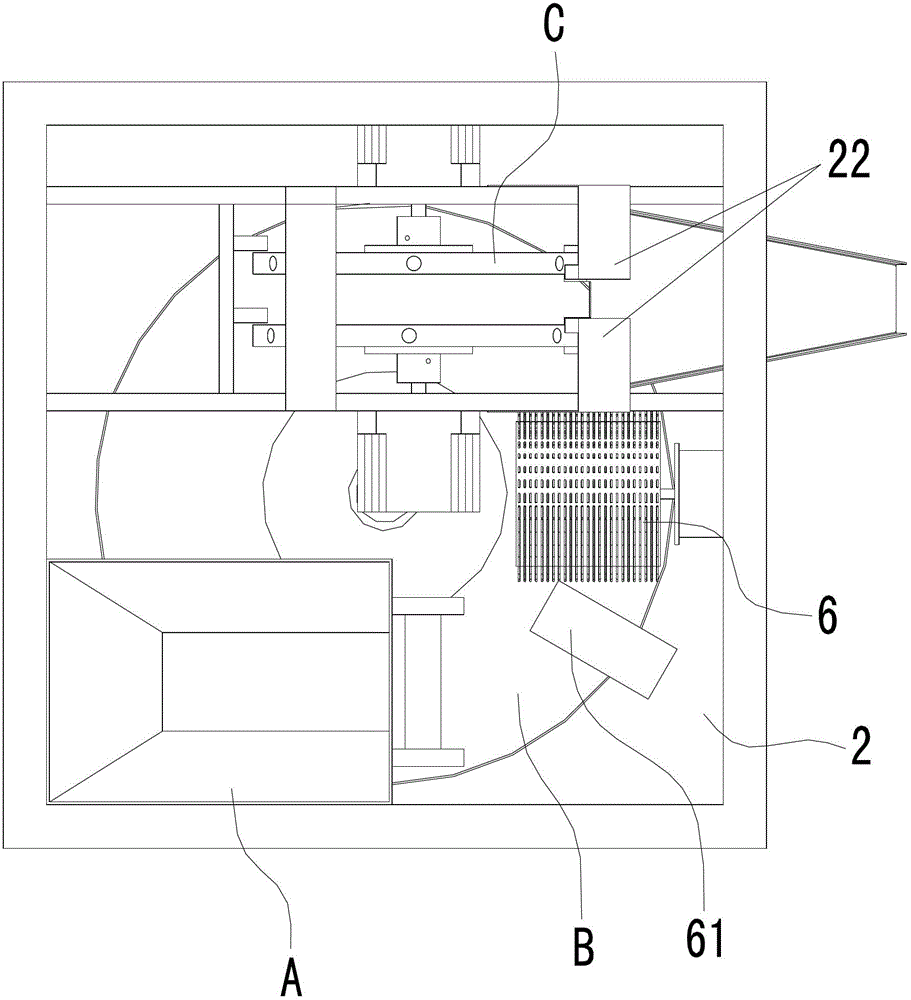

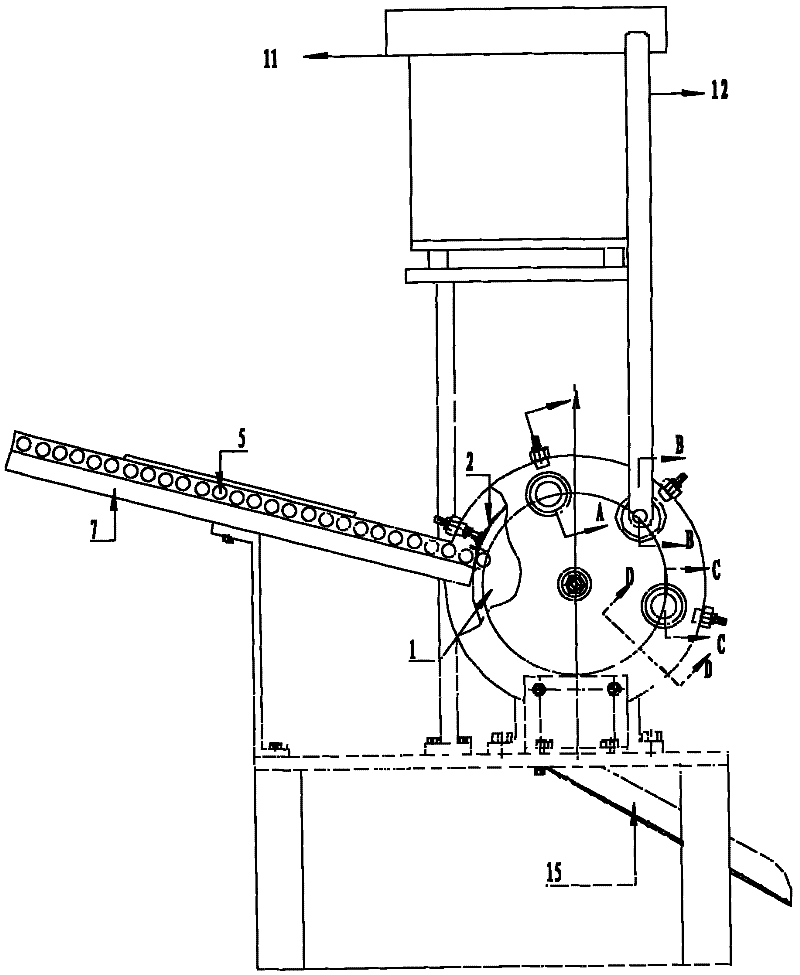

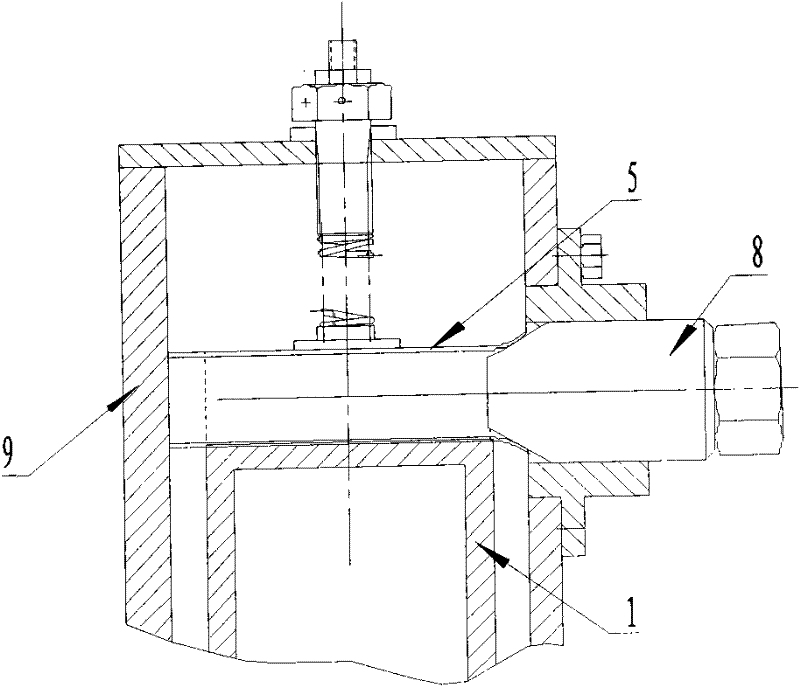

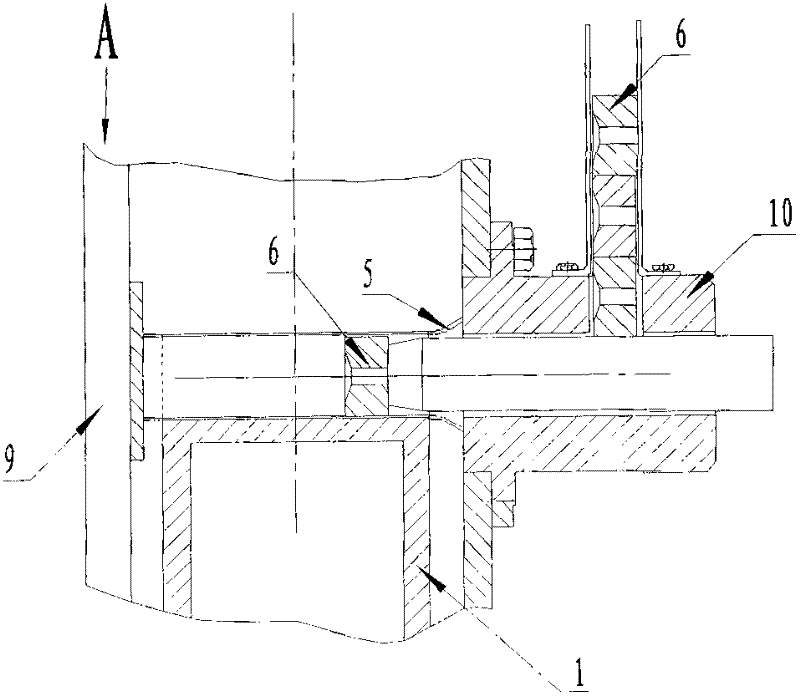

Automatic distribution machine for deoxidant

ActiveCN102745516ASolve the problem of blocking the discharge portPrevent excessive feedingControl devices for conveyorsPackagingEngineeringAdsorption separation

The invention relates to an automatic distribution machine for deoxidant, which comprises a working platform, a central controller, a blanking mechanism, a material conveying mechanism and an adsorption separation mechanism, wherein the blanking mechanism comprises a hopper and a belt transportation mechanism which are arranged on the working platform; the belt transportation mechanism comprises a belt; the hopper is provided with an upper port and a lower port, and is positioned above the belt transportation mechanism; the lower port of the hopper is shielded by the belt; the lower part of the side wall of the hopper is provided with a discharge port; the belt is positioned under the discharge port; the material conveying mechanism is a tray which is driven to rotate by a third motor; an output end of the belt transportation mechanism is arranged above the tray; the adsorption separation mechanism comprises an adsorption rotary table and the material conveying mechanism arranged under the adsorption rotary table; the adsorption rotary table is rotatablely arranged on the working platform and is driven to rotate by a driving mechanism; and the adsorption rotary table has magnetism. The automatic distribution machine for deoxidant is simple in structure, high in degree of automation, practical and reliable, improves the production efficiency, saves the labor force and reduces the packaging and production cost.

Owner:江苏永达电力电信安装工程有限公司

Machine integrating functions of filling pads and closing-up of shotgun shell case

The invention relates to a machine integrating the functions of filling pads and closing-up of a shotgun shell case, which belongs to the field of manufacturing of shotgun shells. Usually, the shotgun shell case is made of plastic material, and in the production process of shotgun shells, one end of the plastic shell case is closed and then pads are filled. The machine is special equipment integrating machinery, electrification and pneumatics, which realizes automation of filling pads and closing-up of the shotgun shell case. The equipment comprises an AC motor, a speed reducer, a driving part and a machining device, and the two procedures of filling pads and closing-up are completed by a slideway type roll feeding manner, wherein the machining device is a six-station turntable, and five stations of the turntable work at the same time at each rhythm to feed materials, flare, fill pads, close up and return materials. After being molded, the workpiece manufactured by the equipment has high precision and reliable practicability, and compared with the traditional machine, the machine provided by the invention increases the production efficiency by five times.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method of toughening and modifying ceramic and ceramic products

InactiveUS6884386B2Improve economyImprove toughnessCeramic shaping apparatusPlane surface grinding machinesCeramic sinteringCrazing

When a sintered body of ceramic is shot-blasted at normal temperatures to plastically deform the crystal structure of the shot-blasted surface to apply residual stress and is heat-treated to recrystallize fine cracks, dislocated cells in the grain boundary are formed, crystals are finely divided, and the fracture toughness is significantly improved. When the sintered body of ceramic is a thin product, an effective toughening can be attained by shot blasting both the front and back sides. After heat treatment, mechanical strength is significantly improved by removing a part of the modified surface layer by an abrasion treatment.

Owner:SINTOKOGIO LTD +2

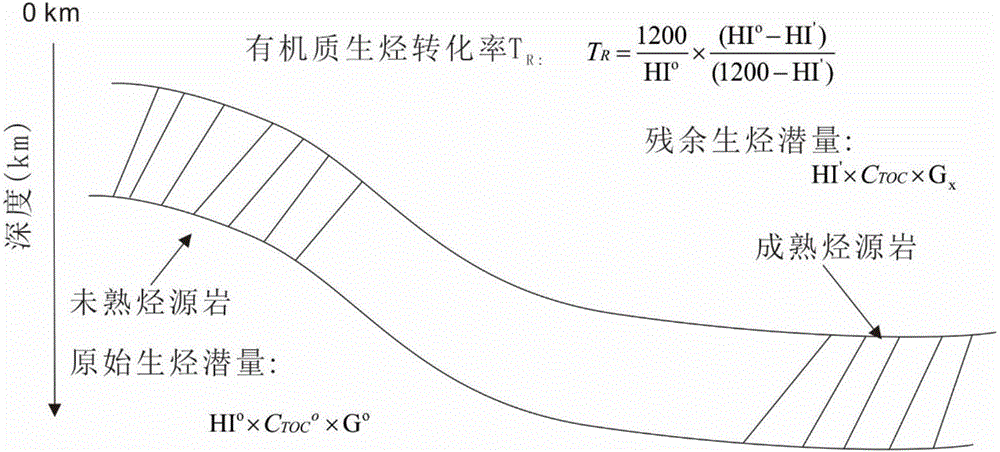

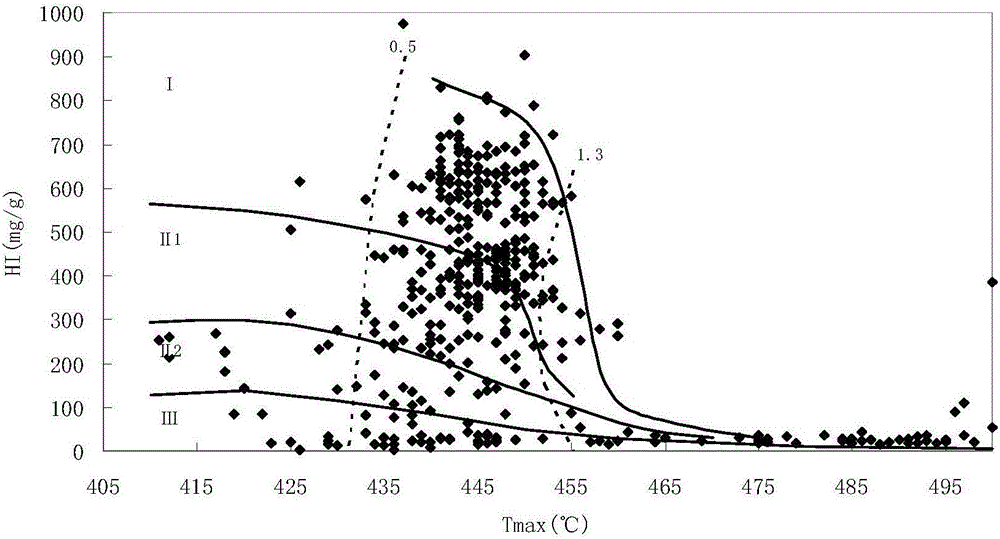

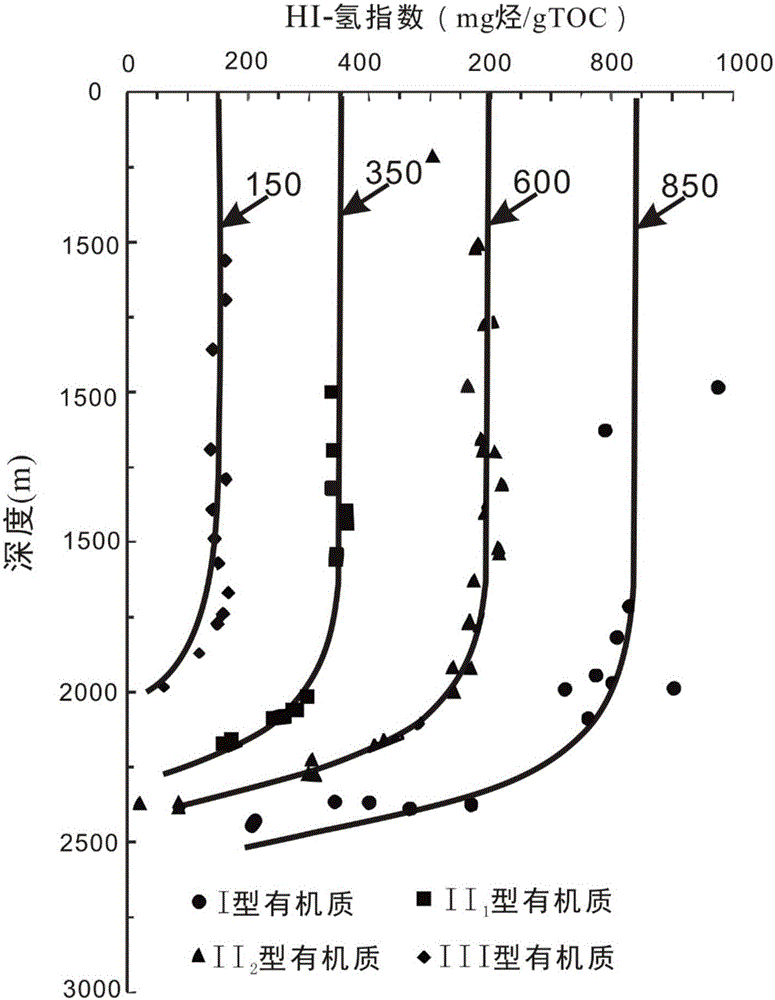

Method for evaluating hydrocarbon source rock organic matter hydrocarbon generation conversion rate

ActiveCN106053514AThe principle is correctEasy to calculateWithdrawing sample devicesPreparing sample for investigationResource assessmentMaterial balance

The invention relates to a method for evaluating the hydrocarbon source rock organic matter hydrocarbon generation conversion rate, in particular to a method for evaluating the organic matter hydrocarbon generation conversion rate based on the principle of material balance and belongs to the technical field of petroleum resource assessment. Actually-measured hydrocarbon source rock pyrolysis data and a simple mathematical model are adopted for calculation, meanwhile correction of HI is considered, the corrected HI is applied to analysis and evaluation of the organic matter hydrocarbon generation conversion rate, and result accuracy and reliability are remarkably improved. The method has the advantages of being rapid, low in application cost and high in operability, the obtained result is precise, and large-scale industrialized application is achieved conveniently.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

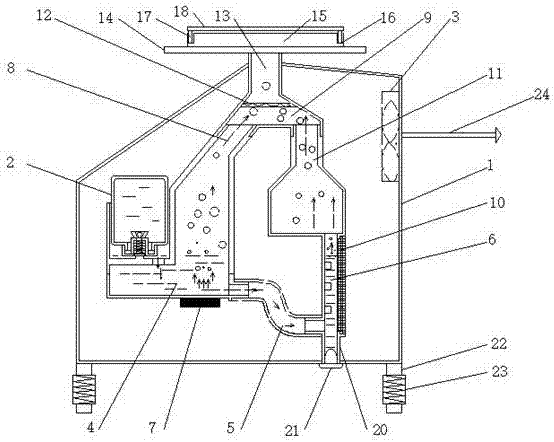

Cold and hot mixed humidifying facial vaporizer

InactiveCN107260527AControl dischargeReasonable structural designMedical applicatorsBathing devicesCold airEngineering

The invention relates to a cold and hot mixed humidifying facial vaporizer. A cold humidifying mist outlet chamber is arranged below a water tank assembly, the cold humidifying mist outlet chamber is connected with a hot humidifying atomizing chamber through a water passing pipe, an atomizer is arranged at the bottom of the cold humidifying mist outlet chamber, the top of the cold humidifying mist outlet chamber is connected with one side of the bottom of a medicine feeding cavity through a cold conveying pipe, a heating body is arranged in the cavity of the hot humidifying atomizing chamber, the hot humidifying atomizing chamber is connected with the other side of the bottom of the medicine feeding cavity through a heat conveying pipe, the inner cavity of the medicine feeding cavity is provided with a porous medicine bag installing base, a conveying pipe is arranged at the top of the medicine feeding cavity, a flange plate is formed on the top end face of the conveying pipe, so that cold air and steam can uniformly blow the face from a plurality of positions, the relative positions of air holes of a first heat dissipation plate and air holes of a second heat dissipation plate can be adjusted, then the discharge amount of the cold air and steam can be controlled, the effect of humidifying and steaming the face by adopting both the cold air and steam is further realized, and the cold air and steam permeate through a medicine bag in the porous medicine bag installing base, and then are sprayed to the face of the human body for realizing drug fumigation on the face of the human body; meanwhile, the temperature can be set, and the temperature can be adjusted to satisfy different requirements of users.

Owner:梁景青

Press fitting-disassembling integrated tool for bogie rotary arm node rubber sleeve

ActiveCN105196031AReduce manufacturing costPractical and reliableVehicle componentsMetal working apparatusBogieEngineering

The invention discloses a press fitting-disassembling integrated tool for a bogie rotary arm node rubber sleeve. The integrated tool comprises a press head, a positioning disassembling seat and a supporting seat, wherein the height of the press head can be increased and decreased; the supporting seat is arranged on one side of the positioning disassembling seat; a central through hole is formed in the positioning disassembling seat, and the hole diameter of the central through hole is larger than the outer diameter of the rotary arm node rubber sleeve; the top of the positioning disassembling seat is coaxially provided with a removable limit ring, and the inner diameter of the limit ring is smaller than the outer diameter of the inner wall of a rotary node hole; the section of the limit ring is in an L shape, and the top of the limit ring can extend into a rotary node hole and be attached to the inner wall of the rotary node h ole. By adopting the structure, only one set of the tool can achieve press fitting and disassembling of the bogie rotary arm node rubber sleeve, the manufacturing cost is low, and the wide application and popularization value is achieved. In addition, a positioning rotary arm can be effectively supported, the concentricity of the rotary arm node hole and the rotary arm node rubber sleeve is high, the press fitting or disassembling precision is high, and the rotary node hole is not prone to being damaged.

Owner:CRRC NANJING PUZHEN CO LTD

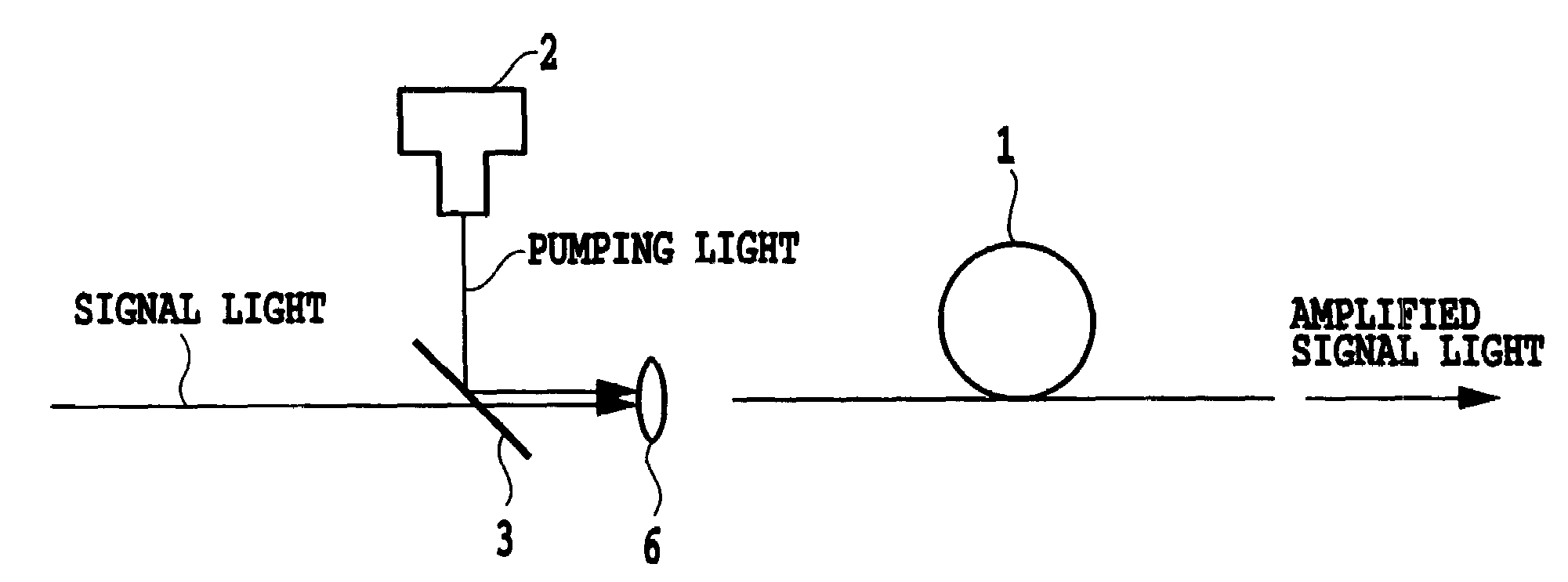

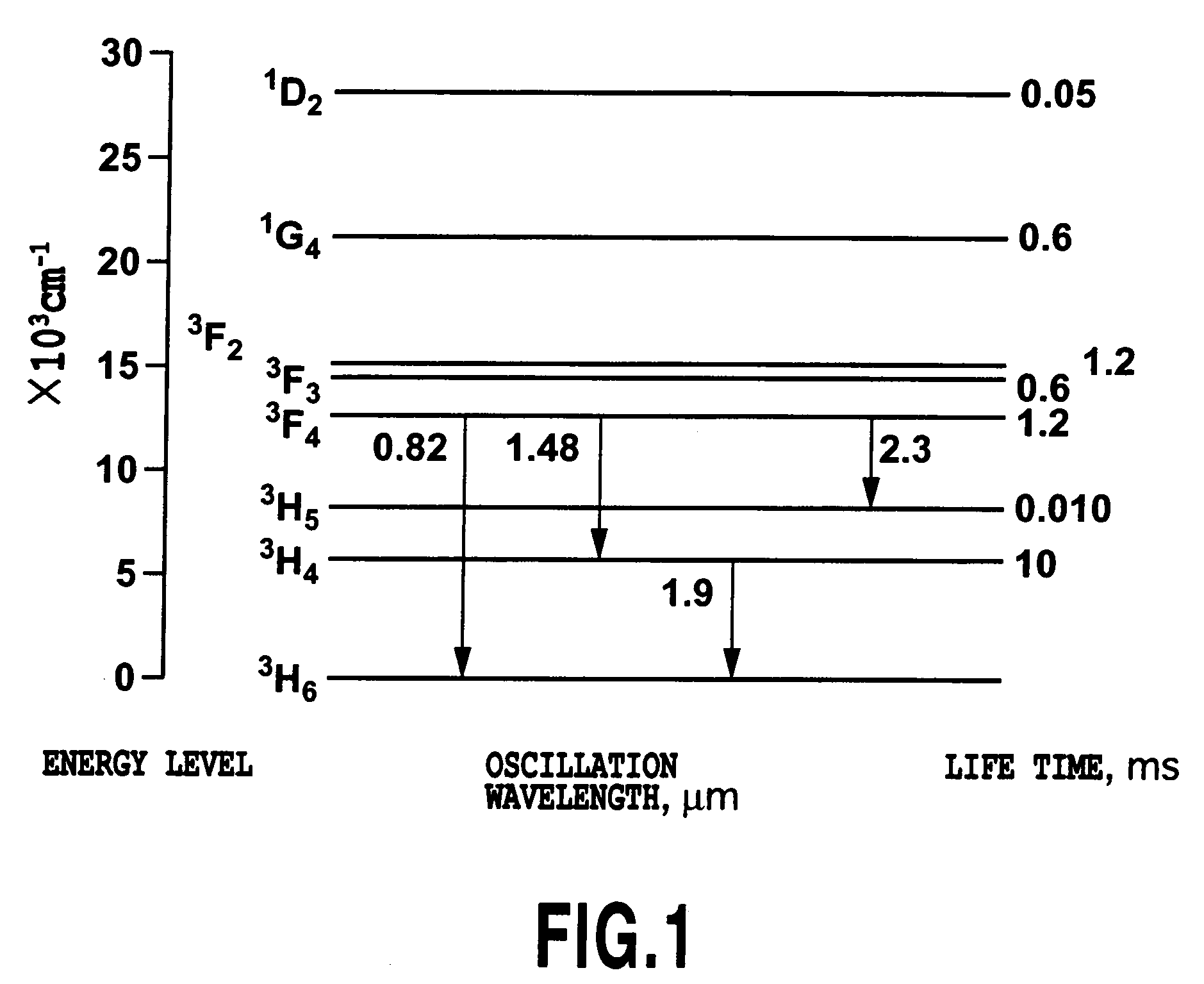

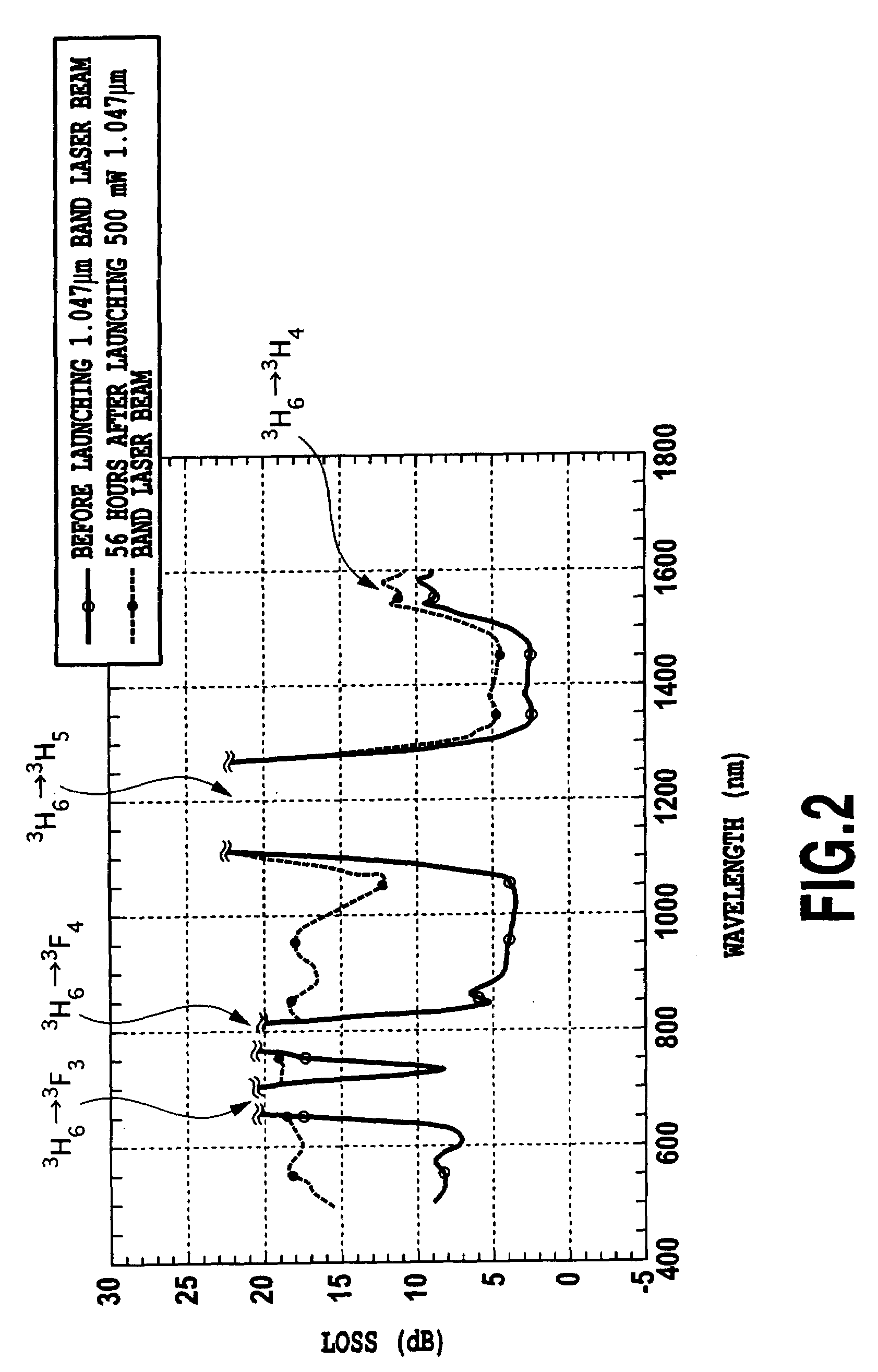

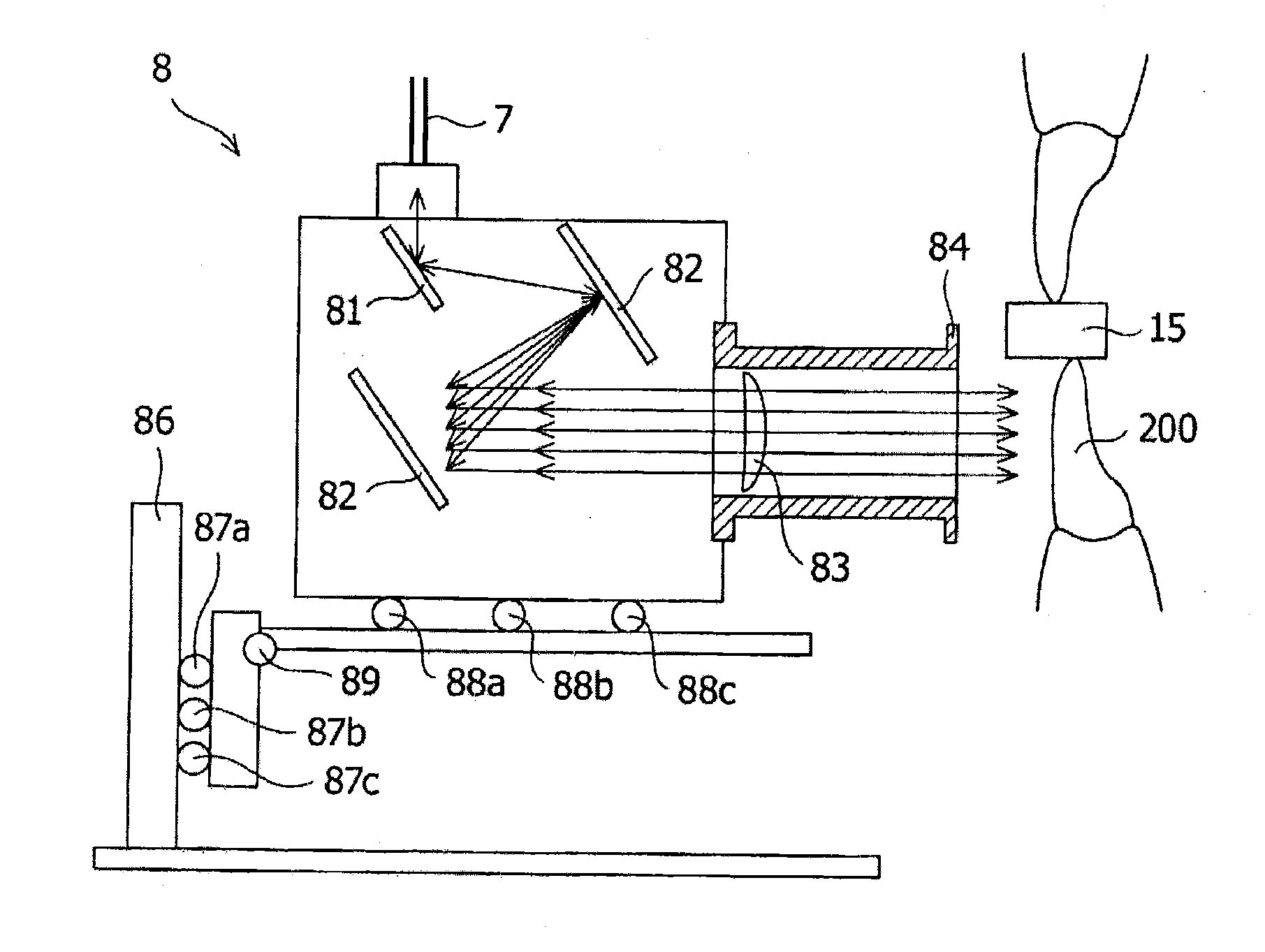

Fiber laser, spontaneous emission light source and optical fiber amplifier

ActiveUS7313306B2Little degradation in fiber characteristicPractical and reliableLaser using scattering effectsCladded optical fibreOptical fiber amplifiersThulium

New fiber lasers, spontaneous emission sources, and optical fiber amplifiers are provided. Their conventional counterparts, which have a fiber doped with thulium (Tm) ions and excited by 0.67 μm or 0.8 μm pumping light, have a problem in that their characteristics are deteriorated with the elapse of time. The new fiber lasers, spontaneous emission sources, and optical fiber amplifiers use 1.2 μm light as pumping light. Alternatively, they use a pumping source for exciting the thulium from the lowest energy level 3H6 to 3H5 excitation level. As a more preferable configuration, they improve the emission efficiency at 2.3 μm band by disclosing Tm-doped host glass.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

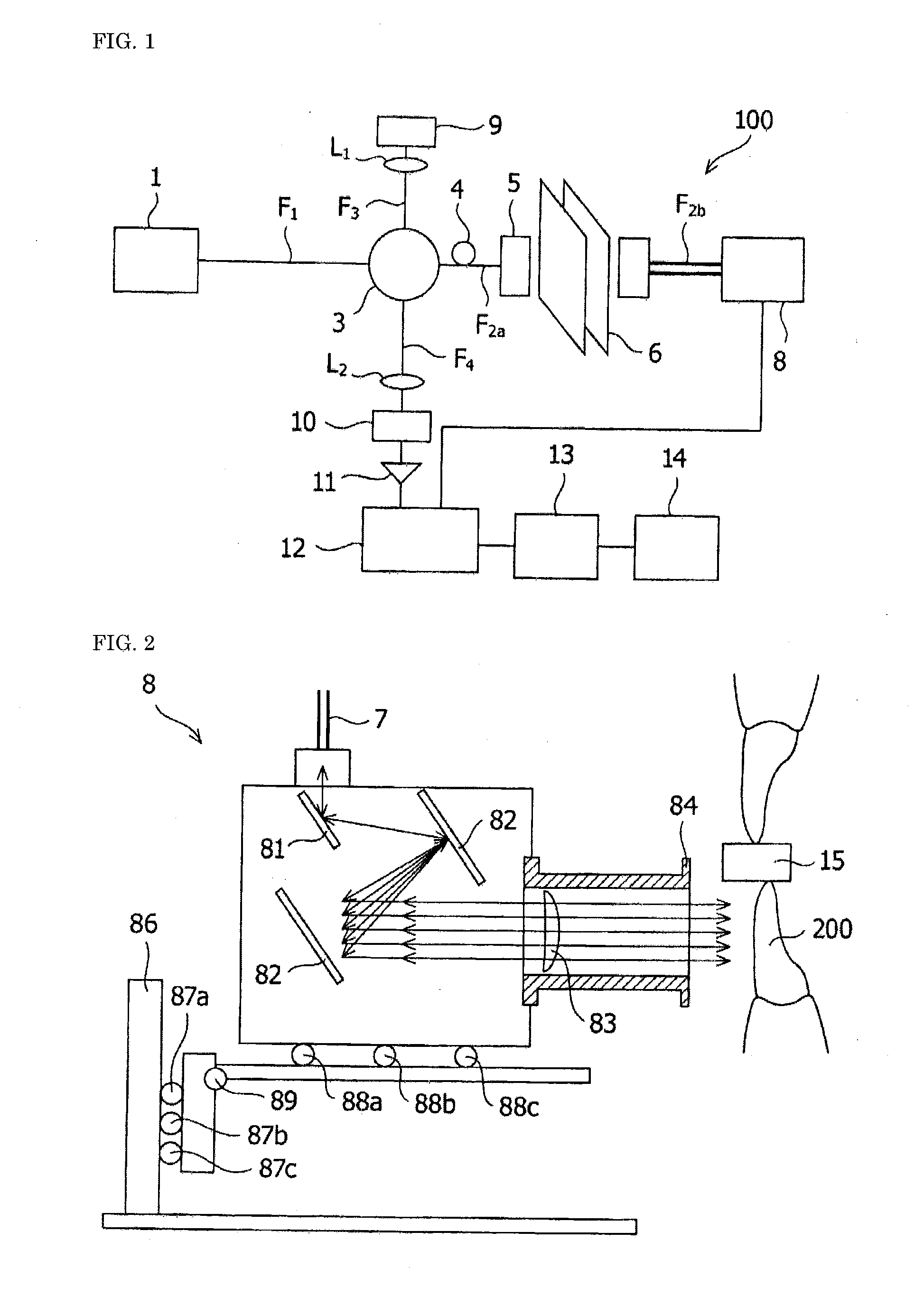

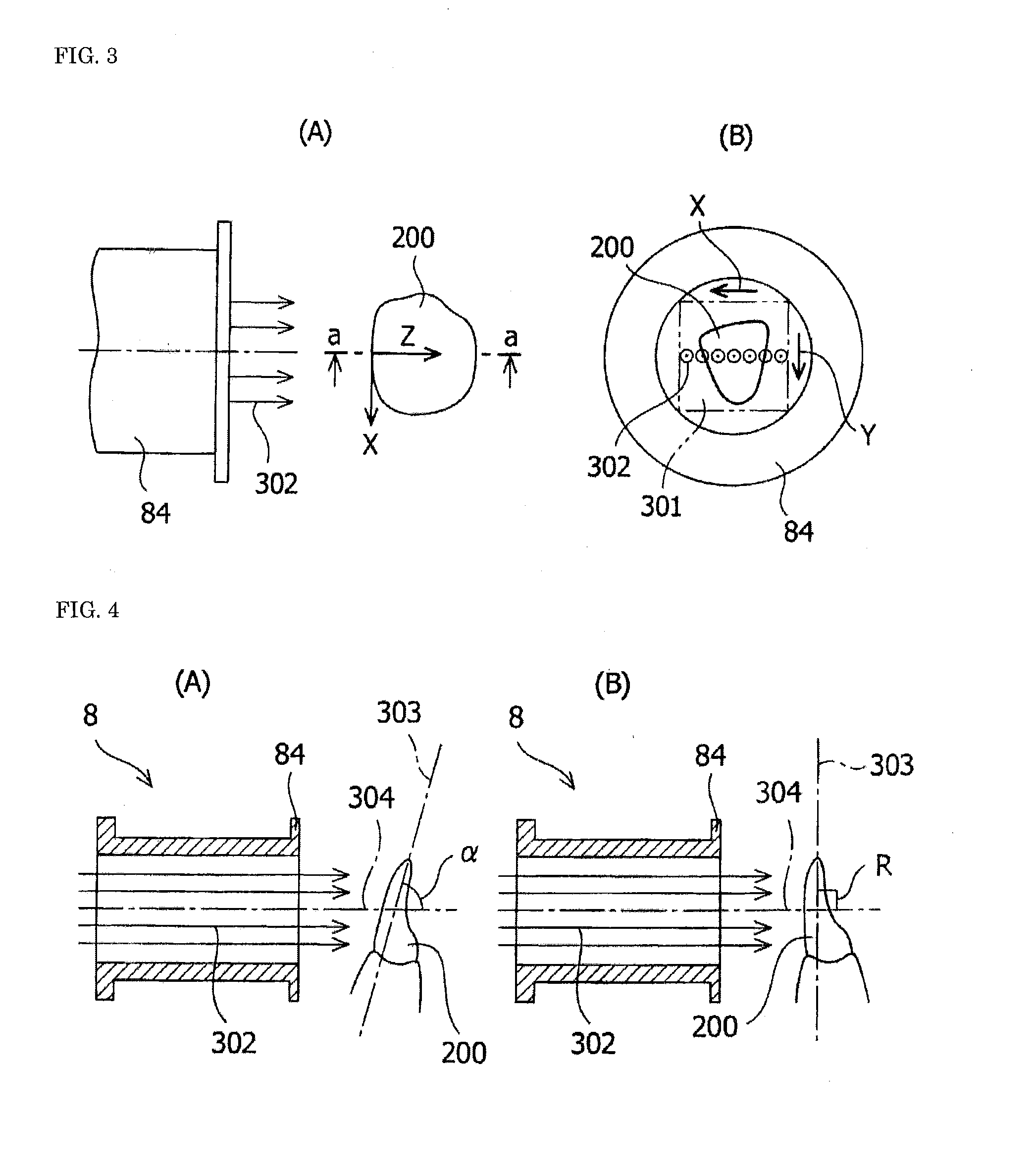

Method and apparatus for measuring and displaying dental plaque, gingiva, and alveolar bone

ActiveUS20150182120A1Practical and reliableGood reproducibilityMedical imagingTeeth fillingTomographic imageDental plaque

A method and an apparatus for measuring and displaying dental plaque are provided, and the method includes the steps of dividing near infrared light output from a light source into measurement light and reference light, applying the measurement light toward a tooth in an oral cavity and scanning the tooth with the measurement light, producing interference light from reflected light and back-scattered light from the tooth and the reference light, generating an optical coherence tomographic image based on a scattering intensity value of the interference light, extracting a dental plaque region having a specific scattering intensity value from the optical coherence tomographic image, and quantifying the dental plaque. A method and an apparatus for measuring and displaying gingiva and / or alveolar bone are further provided. A method and an apparatus for quantifying dental plaque, digitizing the dental plaque, and generating an image of the dental plaque are further provided.

Owner:NAT CENT FOR GERIATRICS & GERONTOLOGY

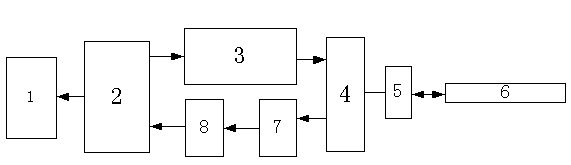

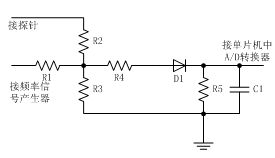

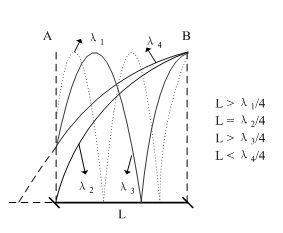

Device and method for nondestructive measurement of anchor rod length

InactiveCN102155905ASmall sizeReduce volumeUsing electrical meansMicrocontrollerMeasuring instrument

The invention discloses a device and a method for nondestructive measurement of anchor rod length; the device comprises a single chip, a measurement frequency signal generator, an impedance match circuit, and a probe in contact with an initial end of a measured anchor rod; an output end of the impedance match circuit is connected with an A / D converter through a peak value detection circuit, an output end of the A / D converter is connected with an input end of the single chip; a measurement probe is directly contacted with the initial end of the measured metallic anchor rod to send a test signal; the test signal is sent into the measured anchor rod from the initial end thereof till to a terminal of the measured anchor rod, then is returned to the initial end of the measured anchor rod from the terminal of the measured anchor rod, a returned electric signal is sent back to a measurement instrument through the probe, a frequency node capable of generating a voltage minimum value can be measured by changing an output frequency of the test signal; therefore, the length of the measured anchor rod can be computed; the device can perform online nondestructive measurement on the anchor rod length; and the device is simple in structure, convenient for operation, rapid and accurate in measurement, practical, reliable, small in volume and low in power consumption.

Owner:CHINA UNIV OF MINING & TECH +1

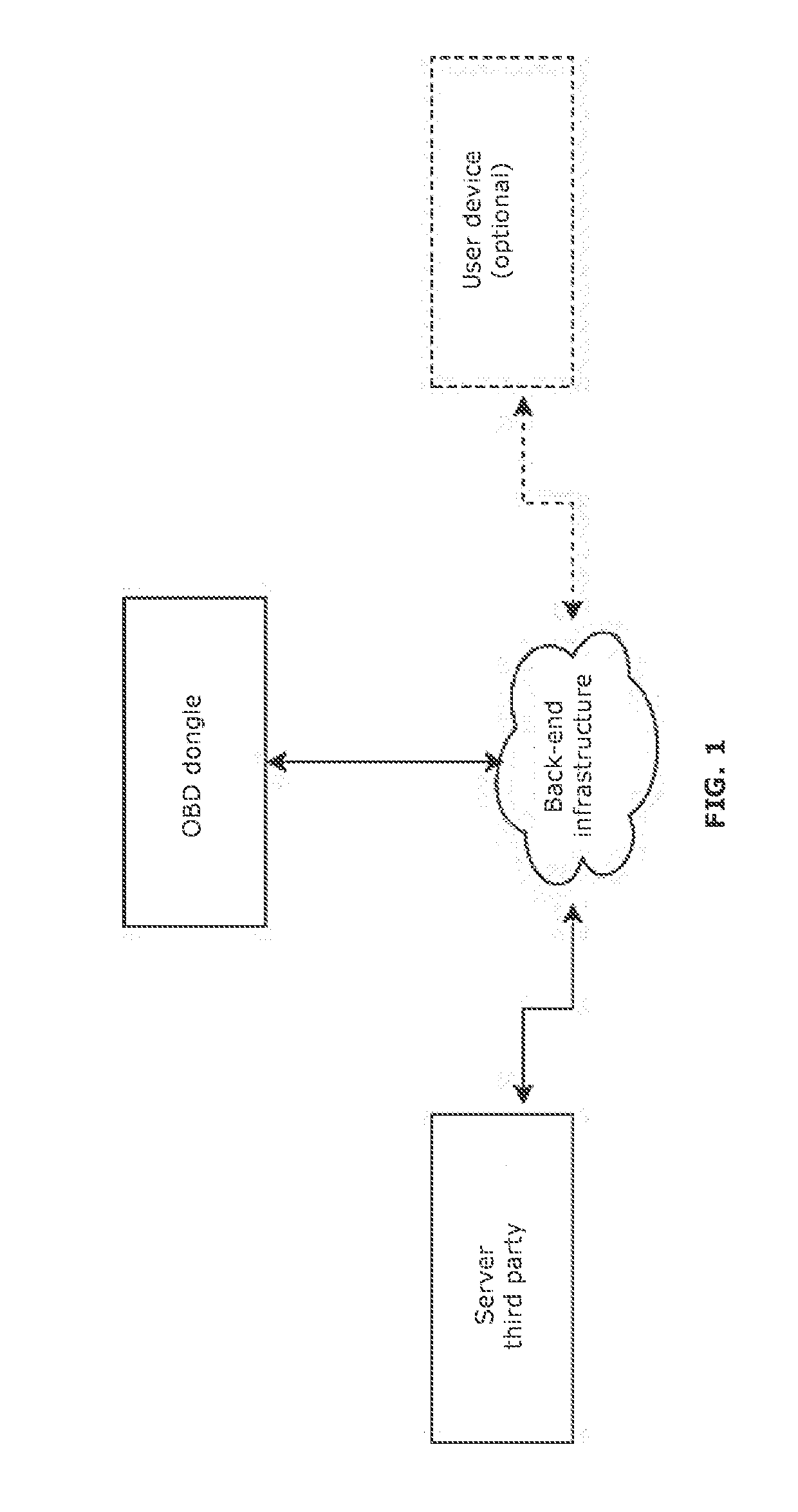

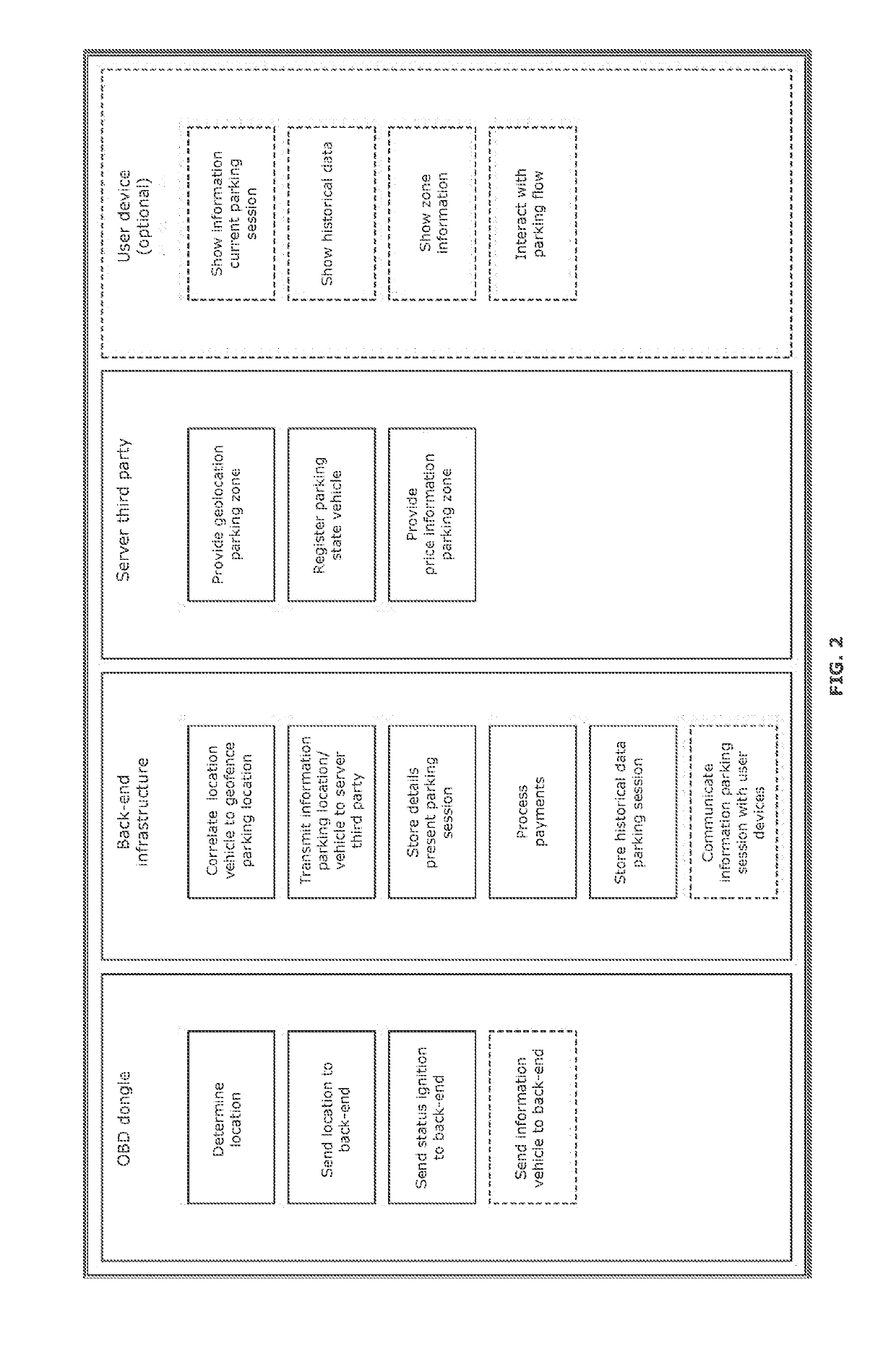

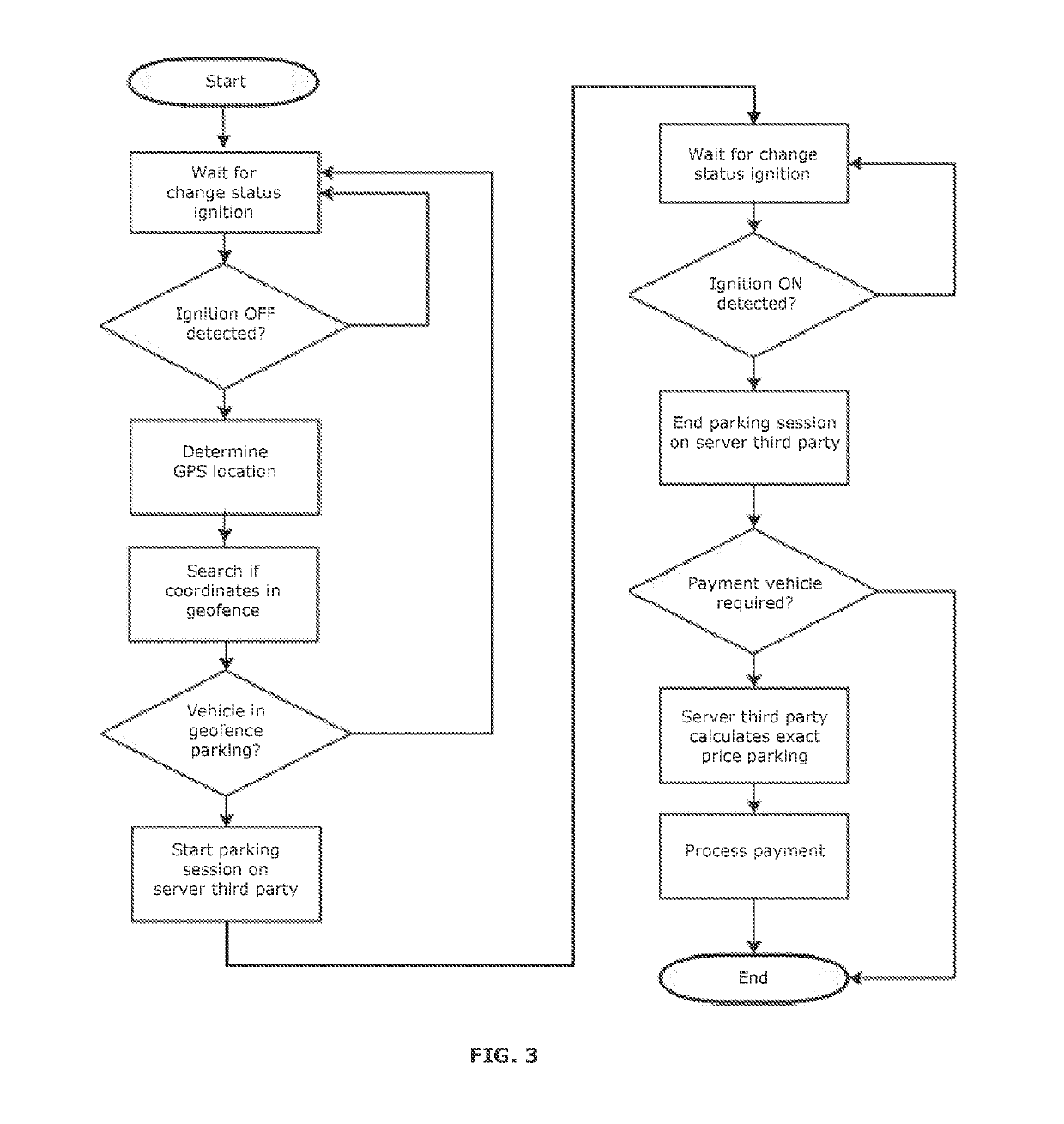

Method and System for the Payment of a Service and/or a Product with Respect to a Vehicle Location

ActiveUS20190188761A1Most efficientCost advantageTicket-issuing apparatusMarketingPaymentReal-time computing

The present invention relates to a method for the payment of a service and / or a product with respect to a vehicle and a parking location, wherein said vehicle is managed by a user, wherein said vehicle comprises a vehicle device, wherein said method comprises amongst other things the following steps: the arrival of said vehicle at said parking location; the transmission of a session request comprising a coordinate to a back-end infrastructure by said vehicle device; the receipt of an availability and / or a price indication of said parking location by said vehicle device of said back-end infrastructure; if said parking location is available, the initiation of a parking session belonging to said service and / or said product.

Owner:CONCAR NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com