Reinforcing method for U-bar hoop formworks of large-section frame column

A formwork reinforcement and frame column technology, applied in formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problem of insufficient rigidity of the outer corrugation of steel pipes, improve labor efficiency and reduce the amount of fasteners , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

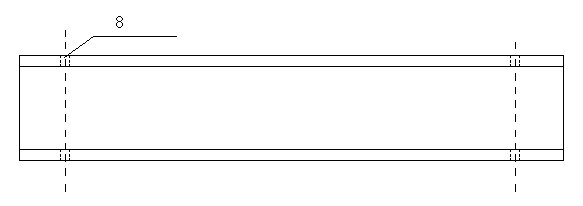

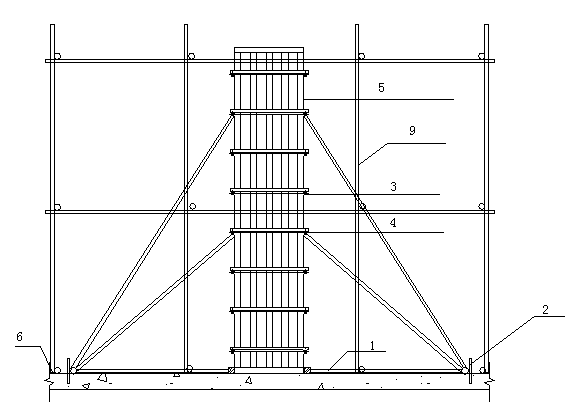

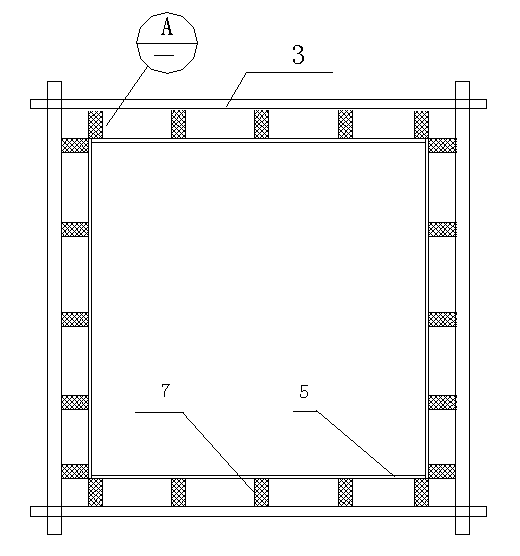

[0028] From Figure 1 to Figure 4 Visible, main implementation steps of the present invention are:

[0029] 1. Template design:

[0030] 1) According to the form, characteristics and site conditions of the project structure, reasonably determine the flow section of the formwork construction to determine the most economical formwork input, increase the number of turnovers, and balance the workload of the process engineering (reinforcement, formwork, concrete process) ;

[0031] 2) Calculate the column model, quantity, size and height according to the drawings, and number the replacement relationship and number of the same or slightly patched components, so as to reduce the type and quantity of matching plates and clarify the replacement flow direction and position of the formwork;

[0032] 3) Determine the plane layout and support layout of the column formwork: design the mold matching diagram according to the column size and number, mark the size of each formwork and its pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com