Machine integrating functions of filling pads and closing-up of shotgun shell case

An all-in-one machine and cartridge casing technology, which is applied to ammunition, weapon accessories, offensive equipment, etc., can solve problems such as low production efficiency, misalignment of plug pads, and high labor intensity, so as to improve production efficiency, high precision, and save manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

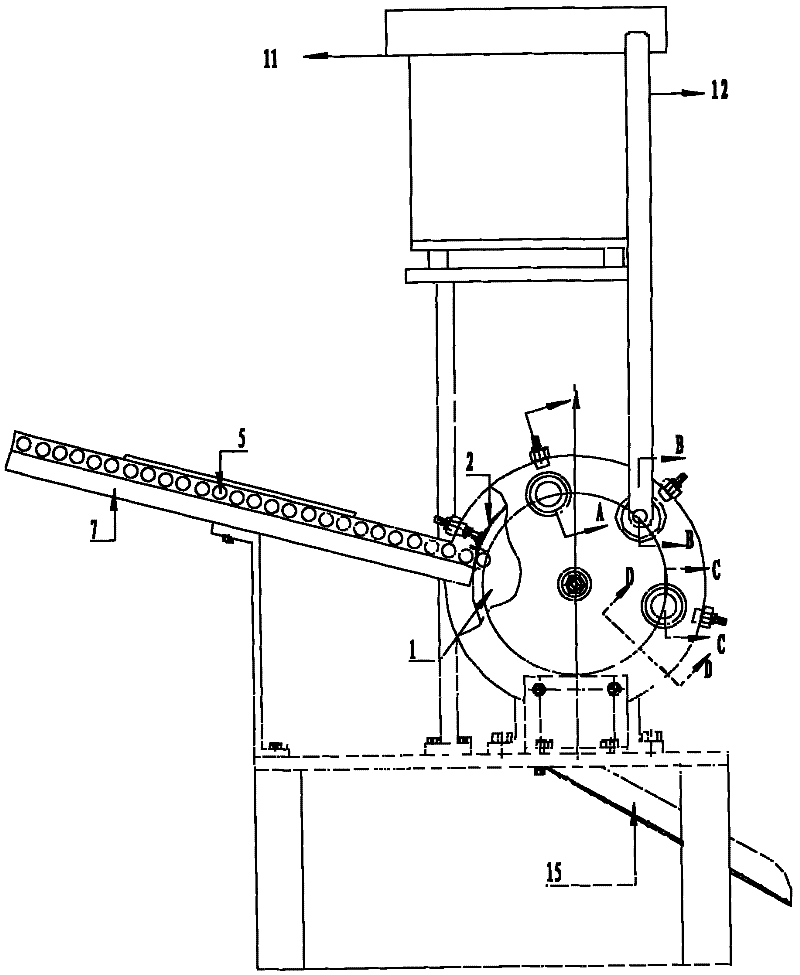

[0023] Such as figure 1 As shown, the all-in-one machine of this embodiment is composed of an AC motor, large and small pulleys, a worm gear reducer, a hexagonal indexing plate, a transmission box, and a six-station turntable. It is feeding, flaring, filling plug, closing and returning.

[0024] The feeding station is connected with the feeding chute.

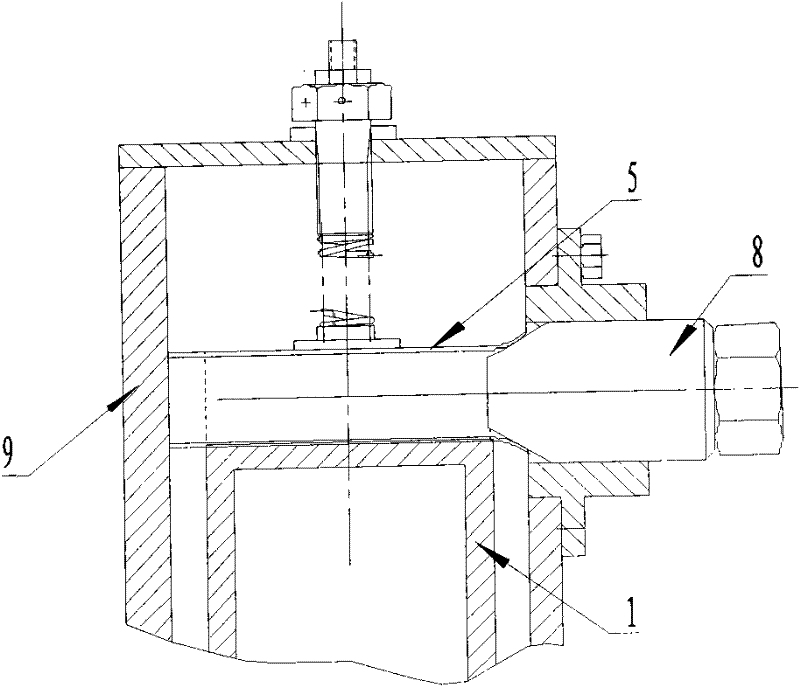

[0025] The described flaring station is that the cylinder drives the plug feeding pad punch 8 to slide back and forth in the guide sleeve, and pushes the cartridge case 5 to the position of the positioning baffle plate 9 .

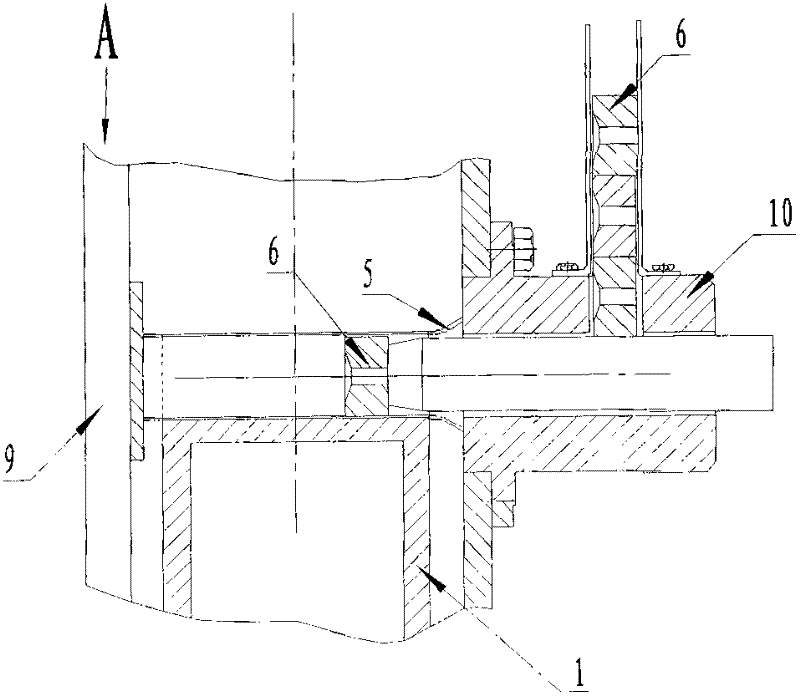

[0026] The described filling station is that when the intermittent six-station turntable 1 rotates, the end face bump 3 (direction A) pushes the cartridge case 5 forward to be close to the pad feeding mold 10; the pad 6 moves along the magnetic vibrating hopper 11 (generally components, adjustable in frequency), and move upward along the track in a counterclockwise direction in a vibrating manner; since t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com