Press fitting-disassembling integrated tool for bogie rotary arm node rubber sleeve

A rubber sleeve and bogie technology, which is applied in metal processing, manufacturing tools, transportation and packaging, etc., can solve the problems of inconvenient use, high manufacturing cost, strained arm node holes, etc., and achieves practical reliability, low manufacturing cost, The effect of widely promoting the application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present application will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

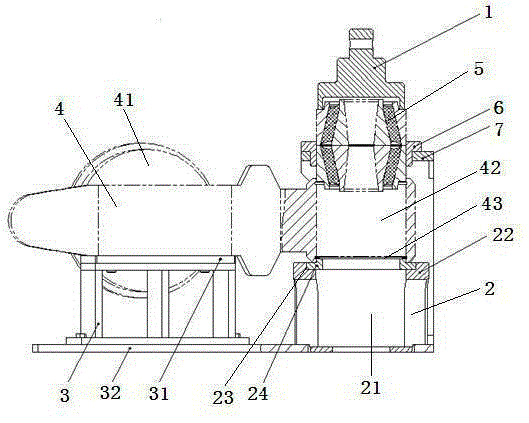

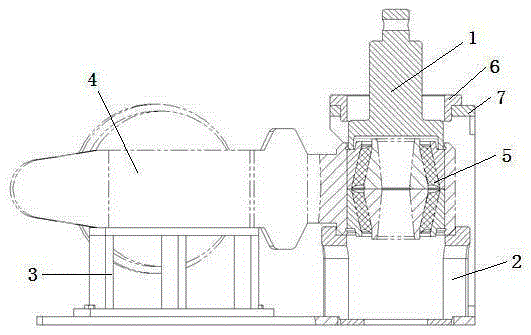

[0033] Such as figure 1 As shown, a bogie pivot arm node rubber sleeve press-fitting and dismounting integrated tooling includes a pressure head 1, a positioning and dismounting seat 2 and a support seat 3.

[0034] The integrated tooling of the present application can be used on the one hand to press the pivot arm node rubber sleeve 5 into the pivot arm node hole 42 of the positioning boom 4, and on the other hand can also be used to press the pivot arm node rubber sleeve 5 from the pivot arm node The unloading is carried out in the hole 42.

[0035] The above-mentioned indenter 1 is located directly above the positioning and unloading seat 2, and is coaxially arranged with the positioning and unloading seat 2, and the height of the indenter 1 can be raised and lowered.

[0036] The top of the pressure head 1 is prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com