Patents

Literature

745 results about "Gunpowder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gunpowder, also known as black powder to distinguish it from modern smokeless powder, is the earliest known chemical explosive. It consists of a mixture of sulfur (S), charcoal (C), and potassium nitrate (saltpeter, KNO₃). The sulfur and charcoal act as fuels while the saltpeter is an oxidizer. Because of its incendiary properties and the amount of heat and gas volume that it generates, gunpowder has been widely used as a propellant in firearms, artillery, rockets, and fireworks, and as a blasting powder in quarrying, mining, and road building.

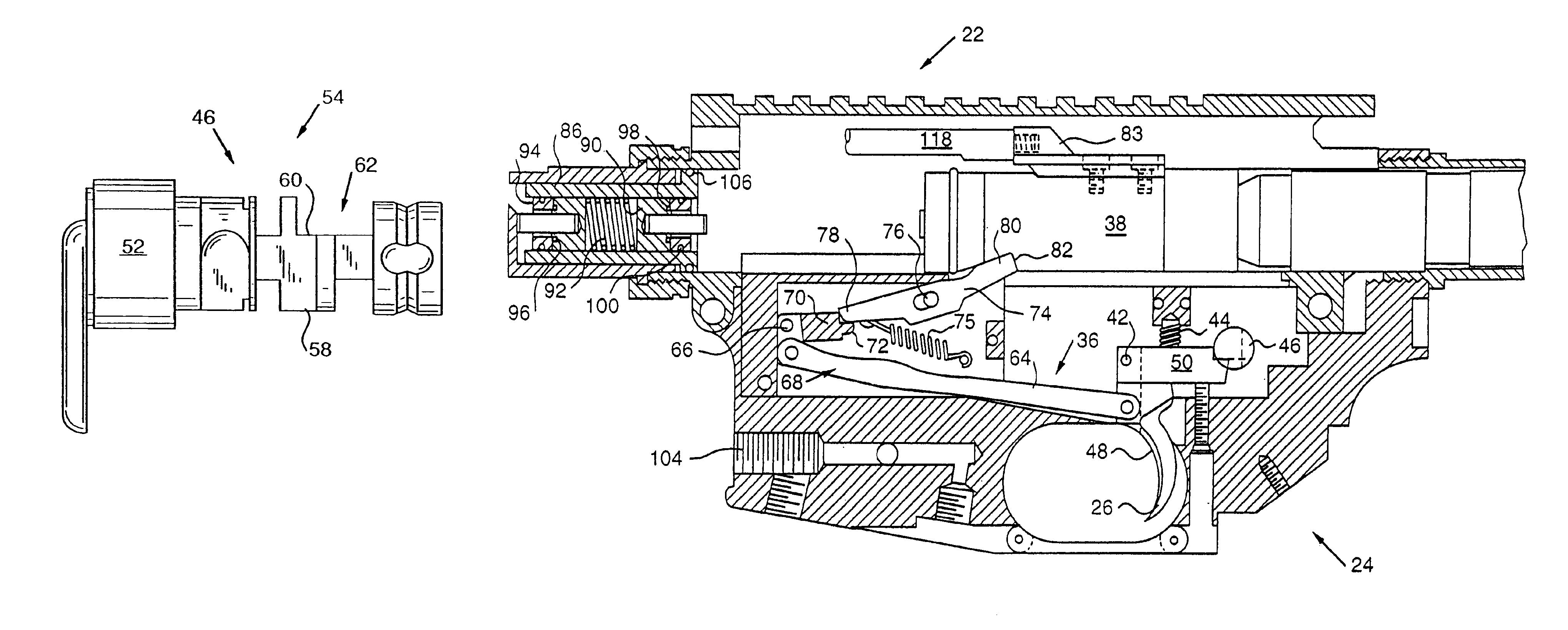

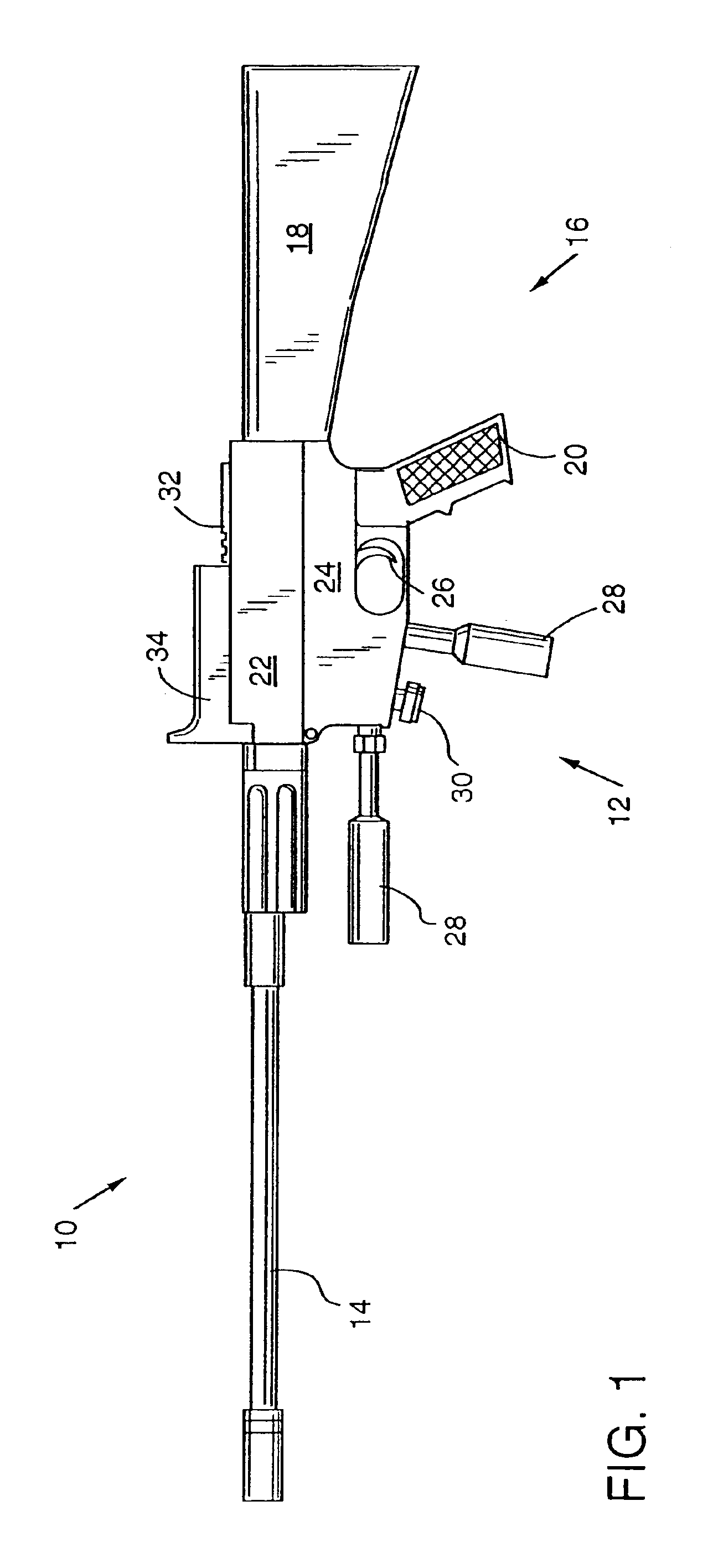

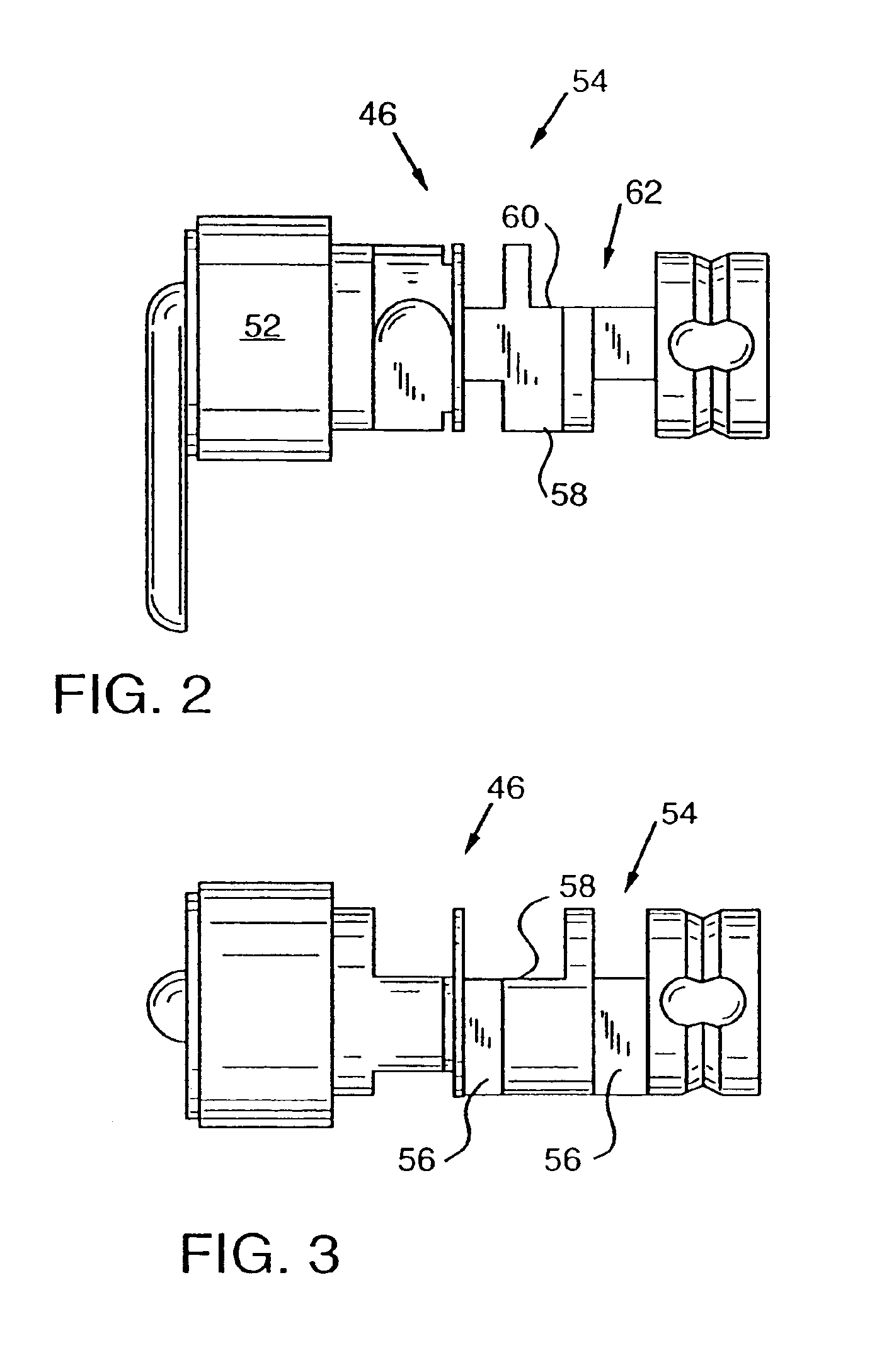

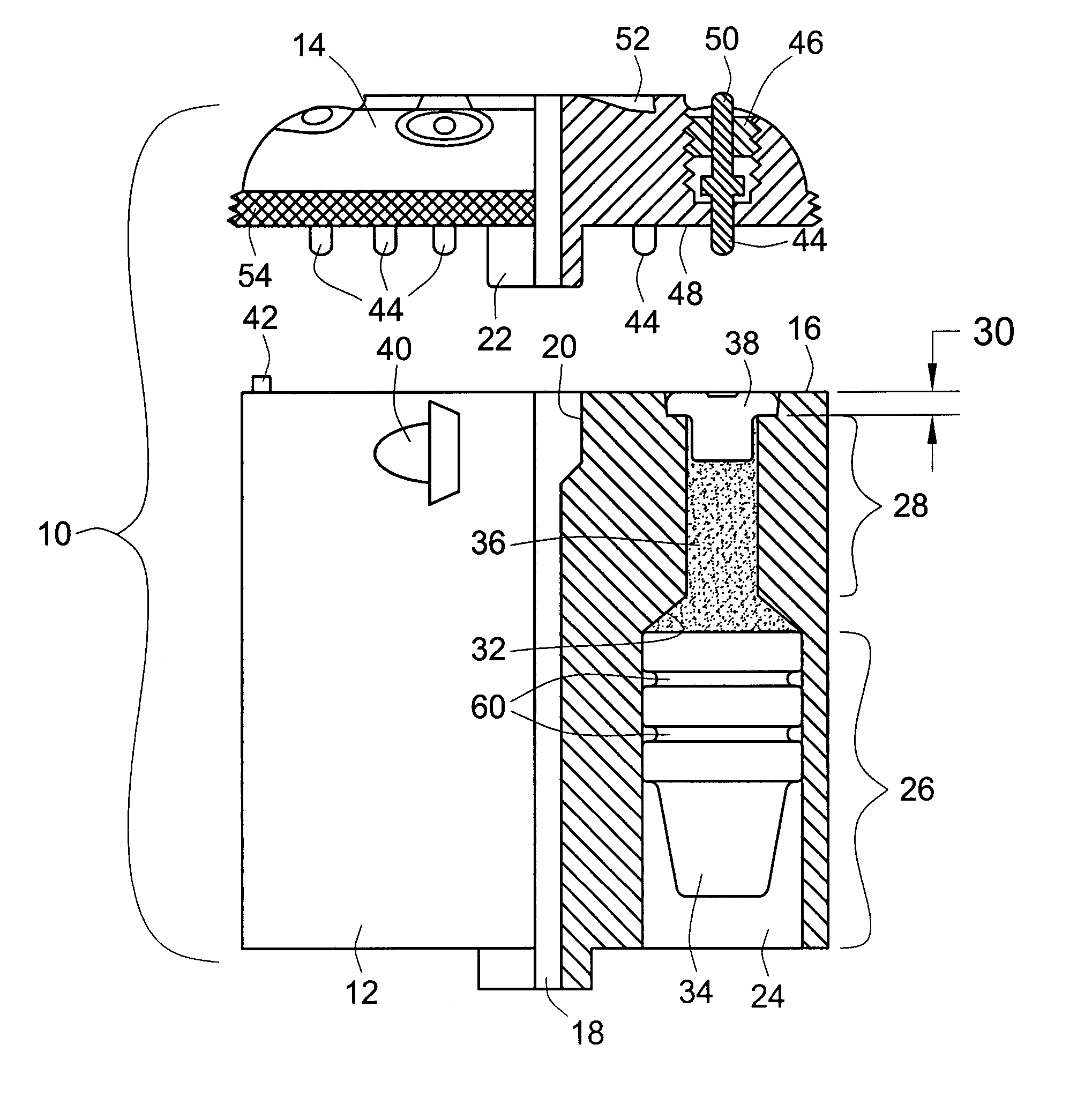

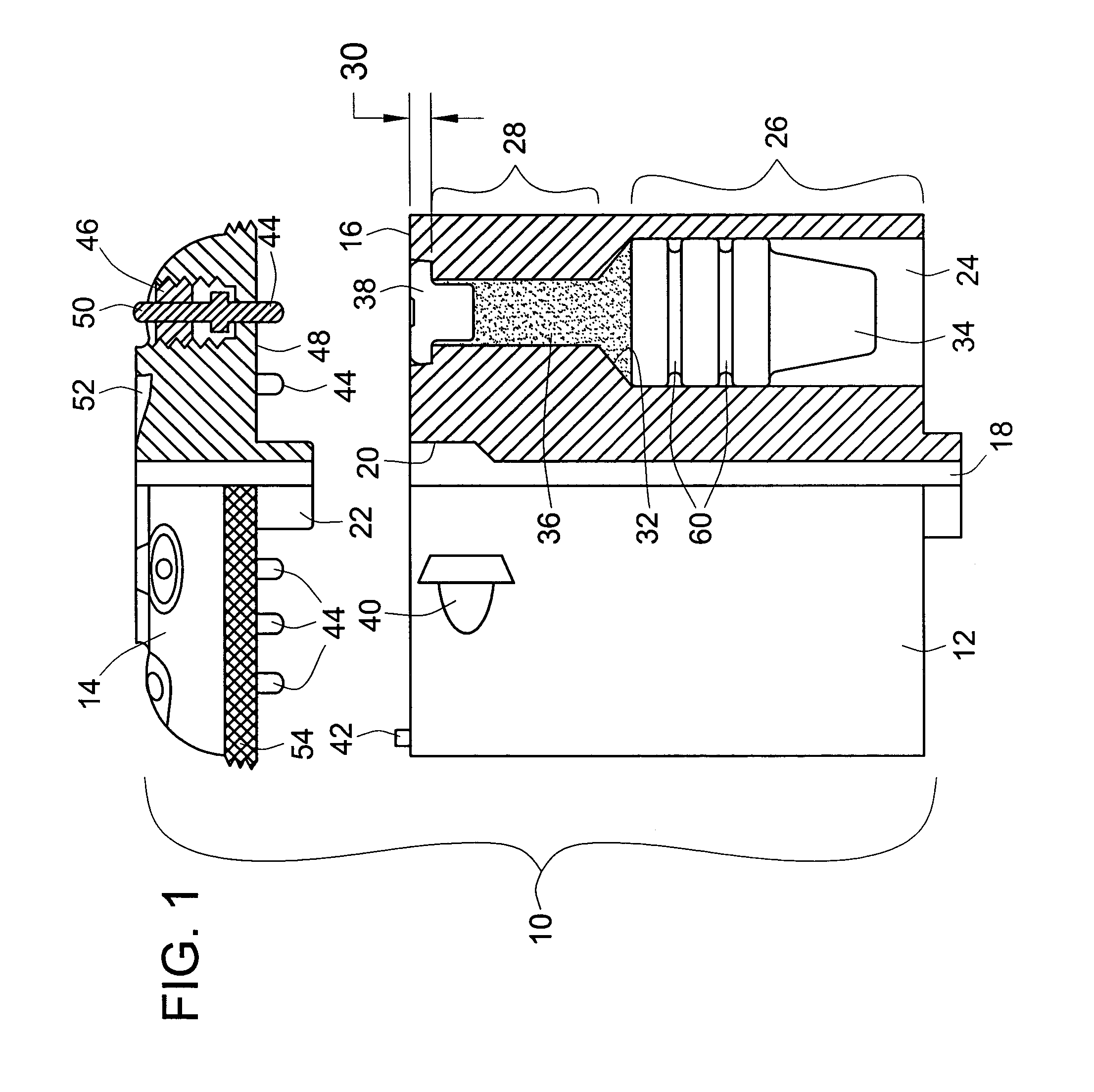

Compressed gas-powered gun simulating the recoil of a conventional firearm

InactiveUS6874492B1Contributing to accuracyHigh indexSafety arrangementFiring/trigger mechanismsGunpowderPneumatic pressure

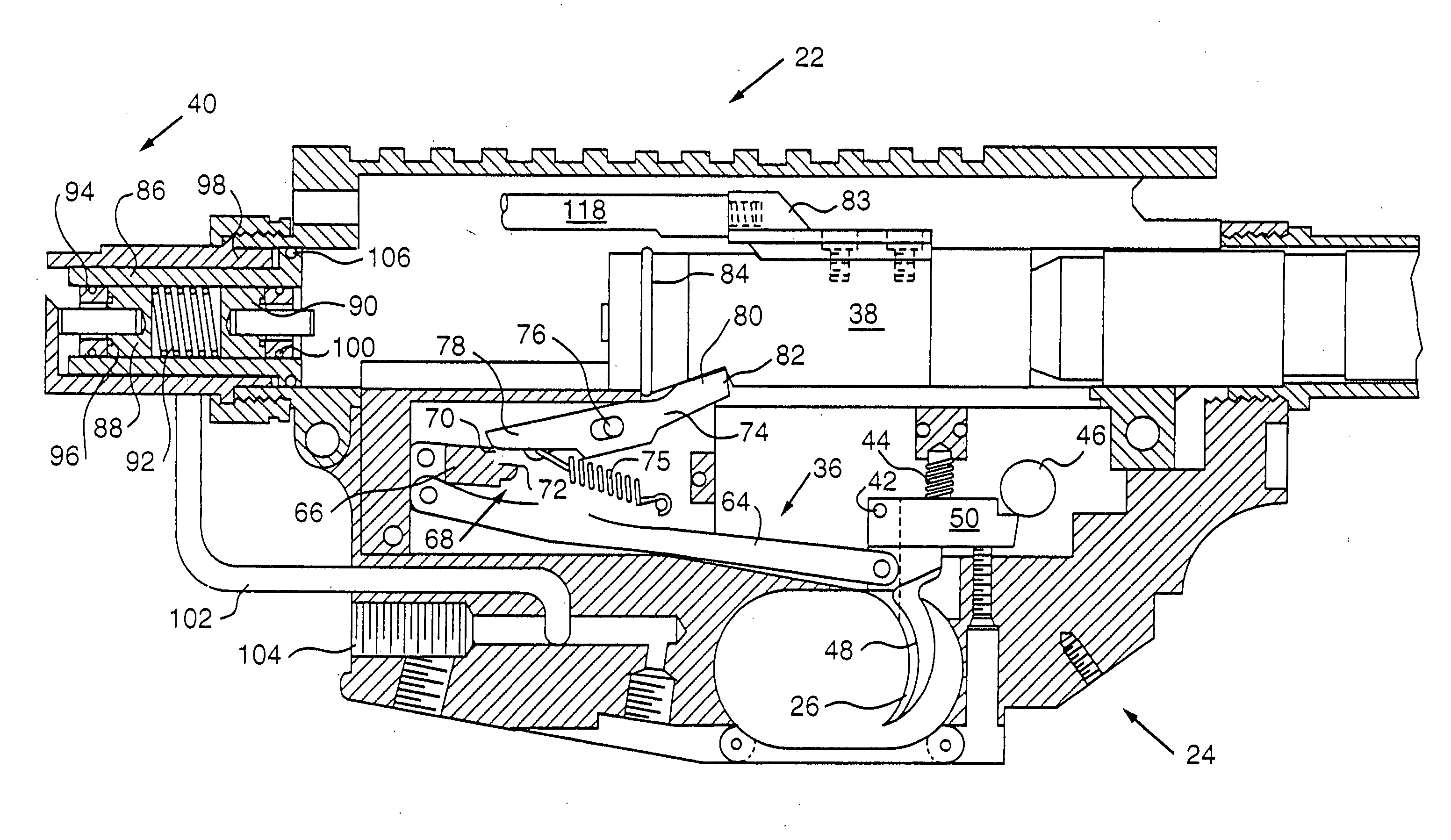

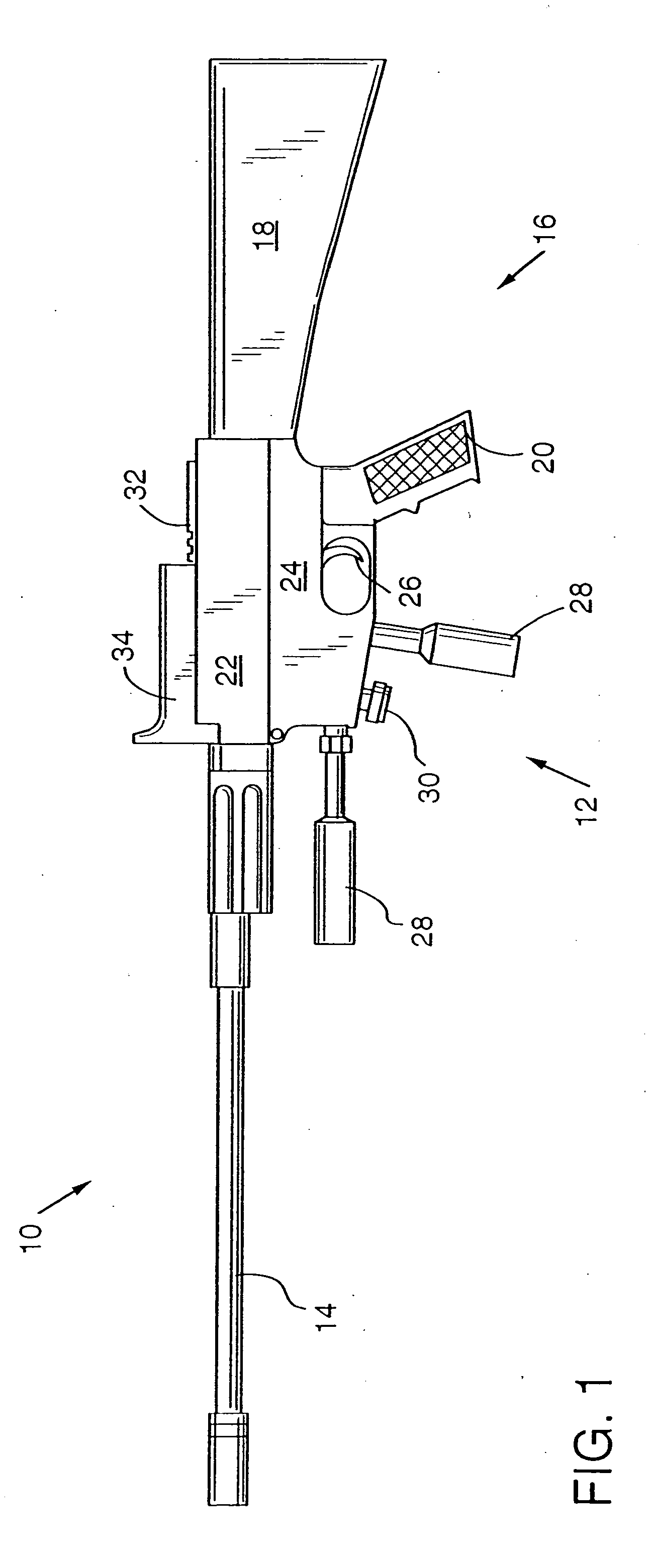

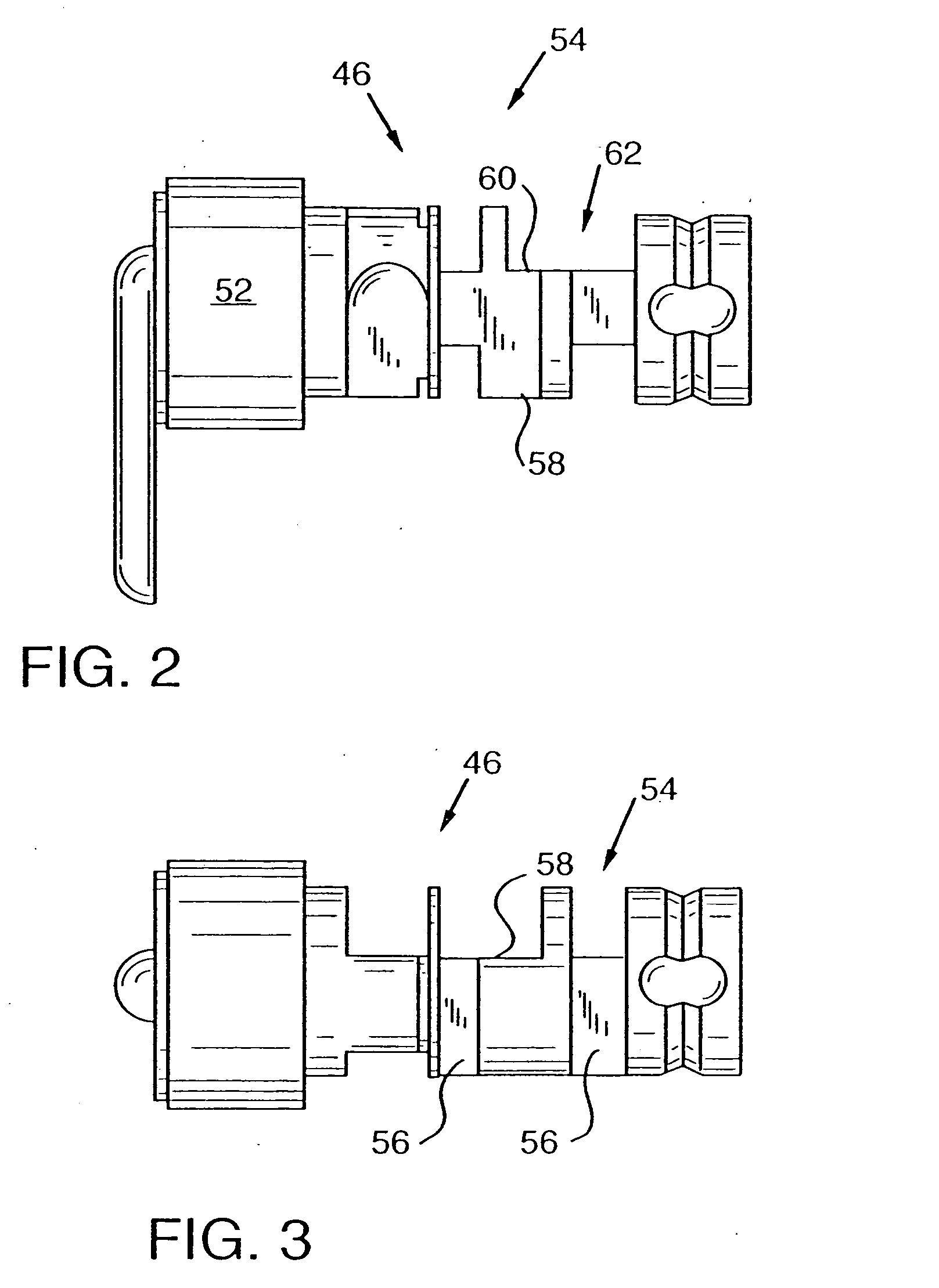

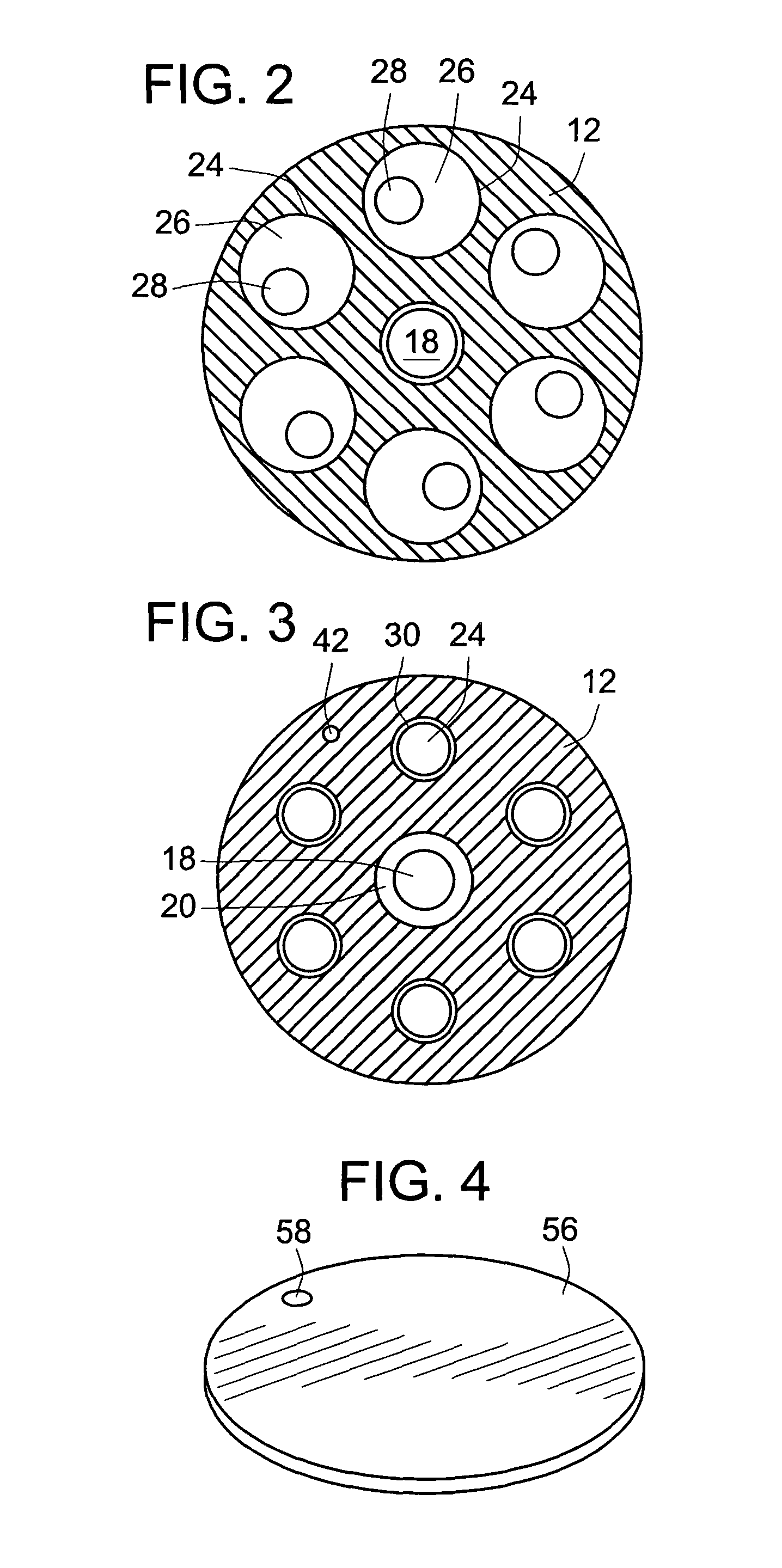

A compressed gas powered gun provides recoil simulating the recoil of a gun firing gunpowder propelled projectiles. The valve assembly provides both consistent shot to shot pressure, and rearward gas pressure for generating recoil. Preferred embodiments of the compressed gas powered gun may include a mechanism for adjusting the amount of recoil provided. A trigger mechanism permitting semi-automatic operation, or full automatic operation at a user selectable cyclic rate, is provided. The air gun provides consistent gas pressure behind the projectile from shot to shot. A magazine and magazine indexing system for loading projectiles into the firing chamber in a manner contributing to the accuracy of the air gun is also provided.

Owner:NEW MATICS LICENSING

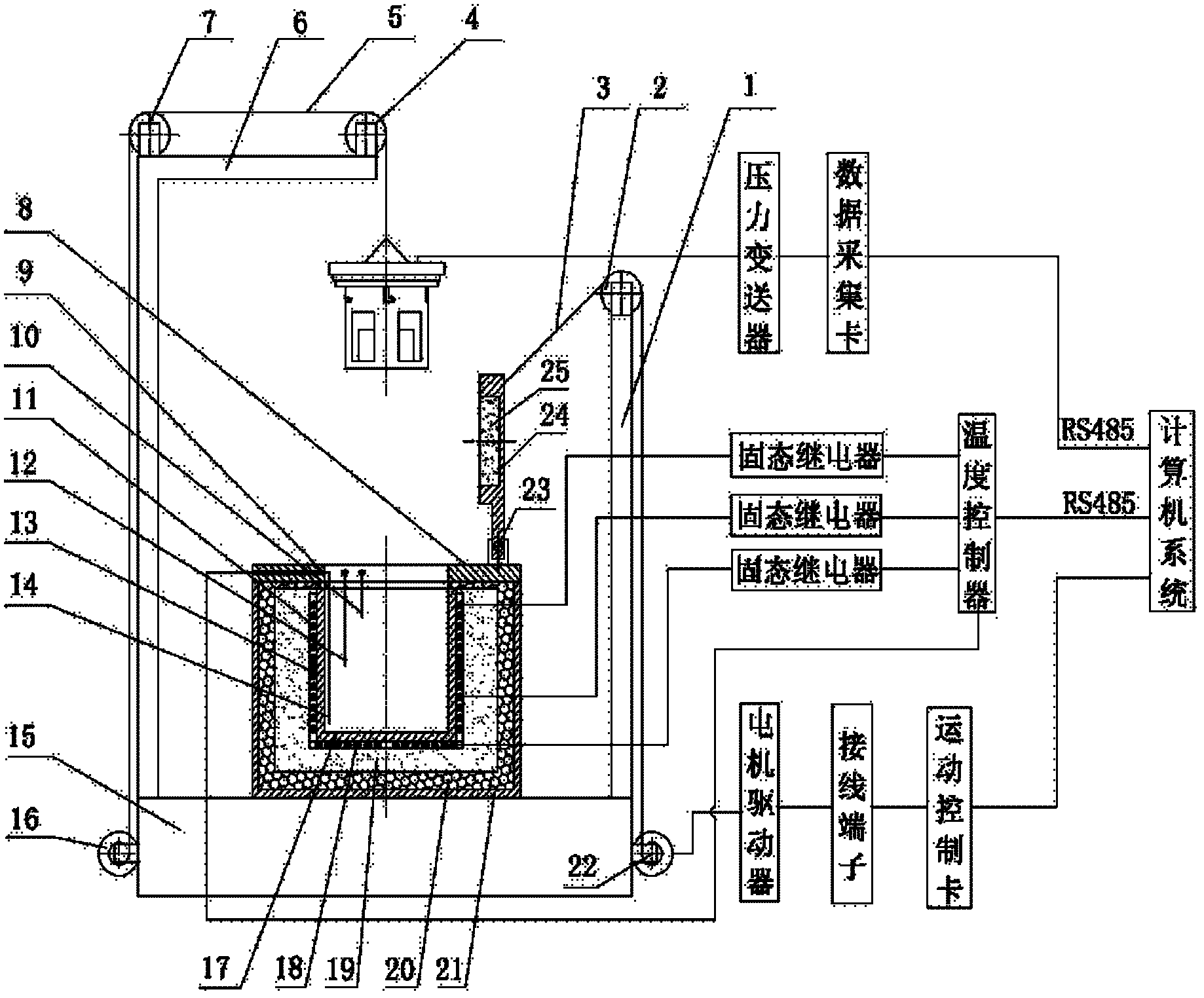

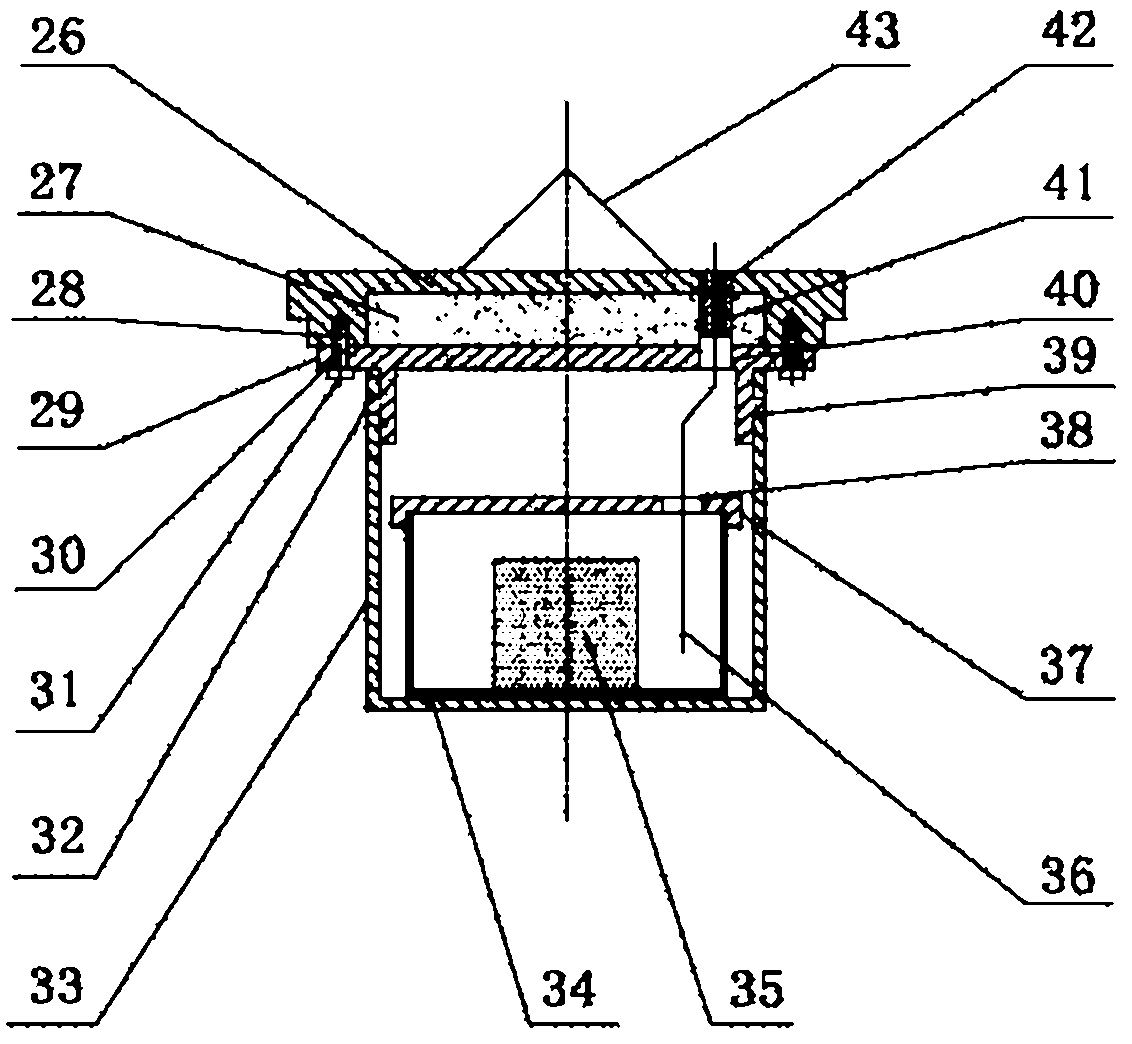

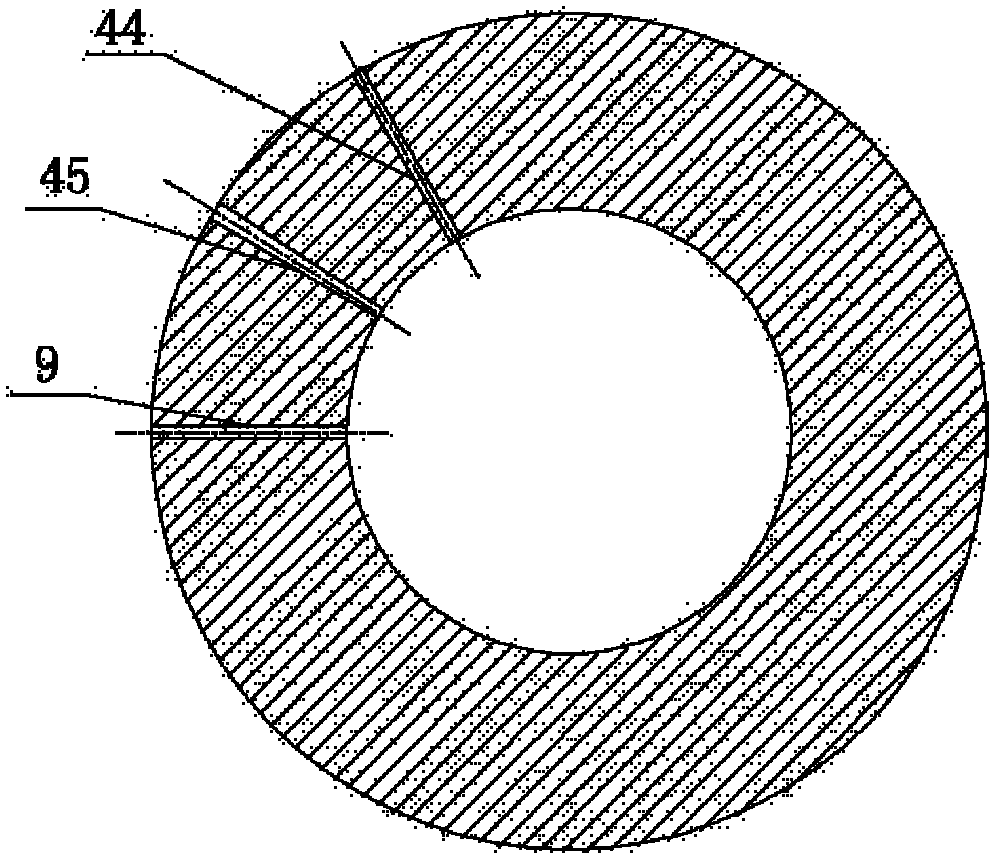

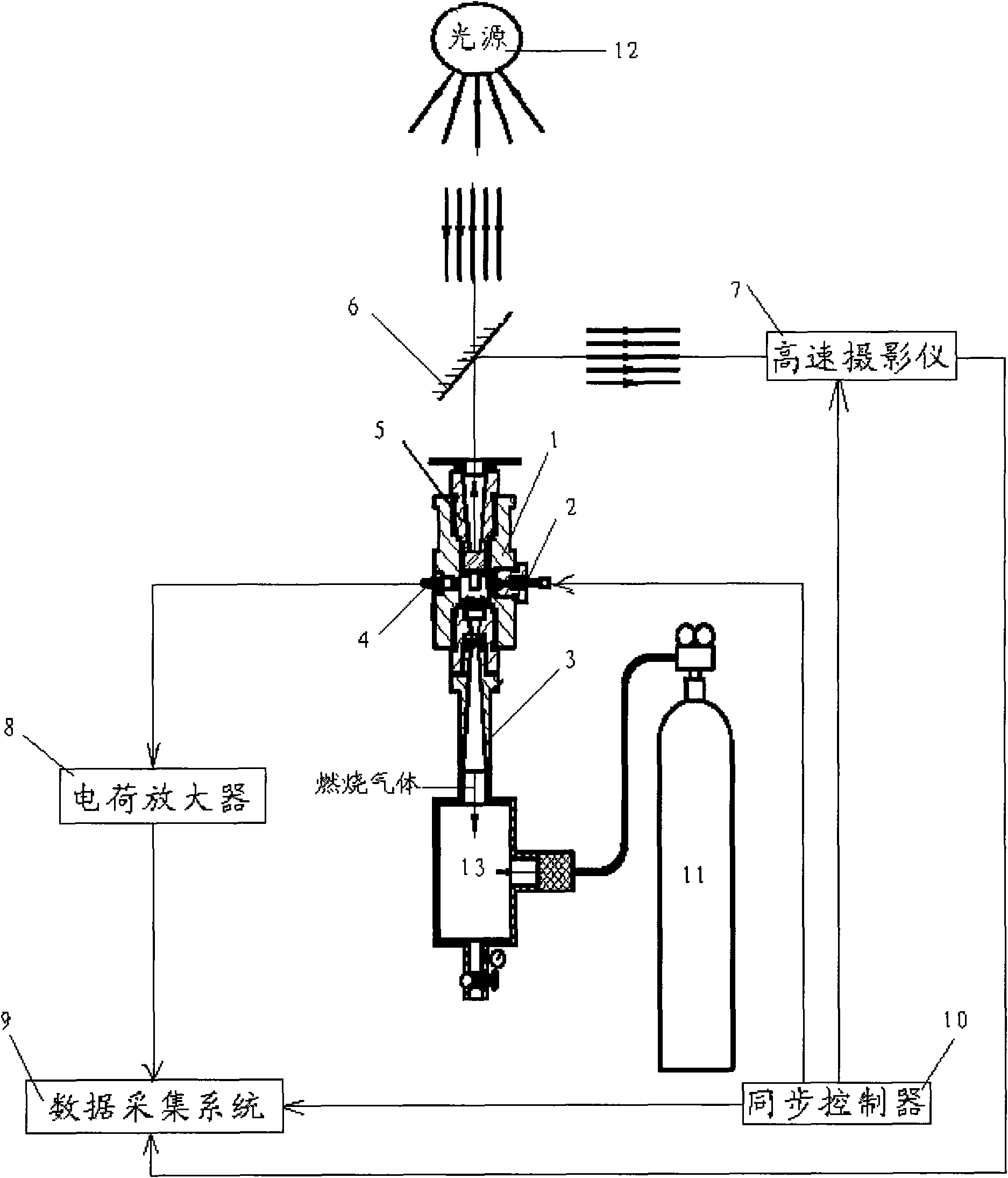

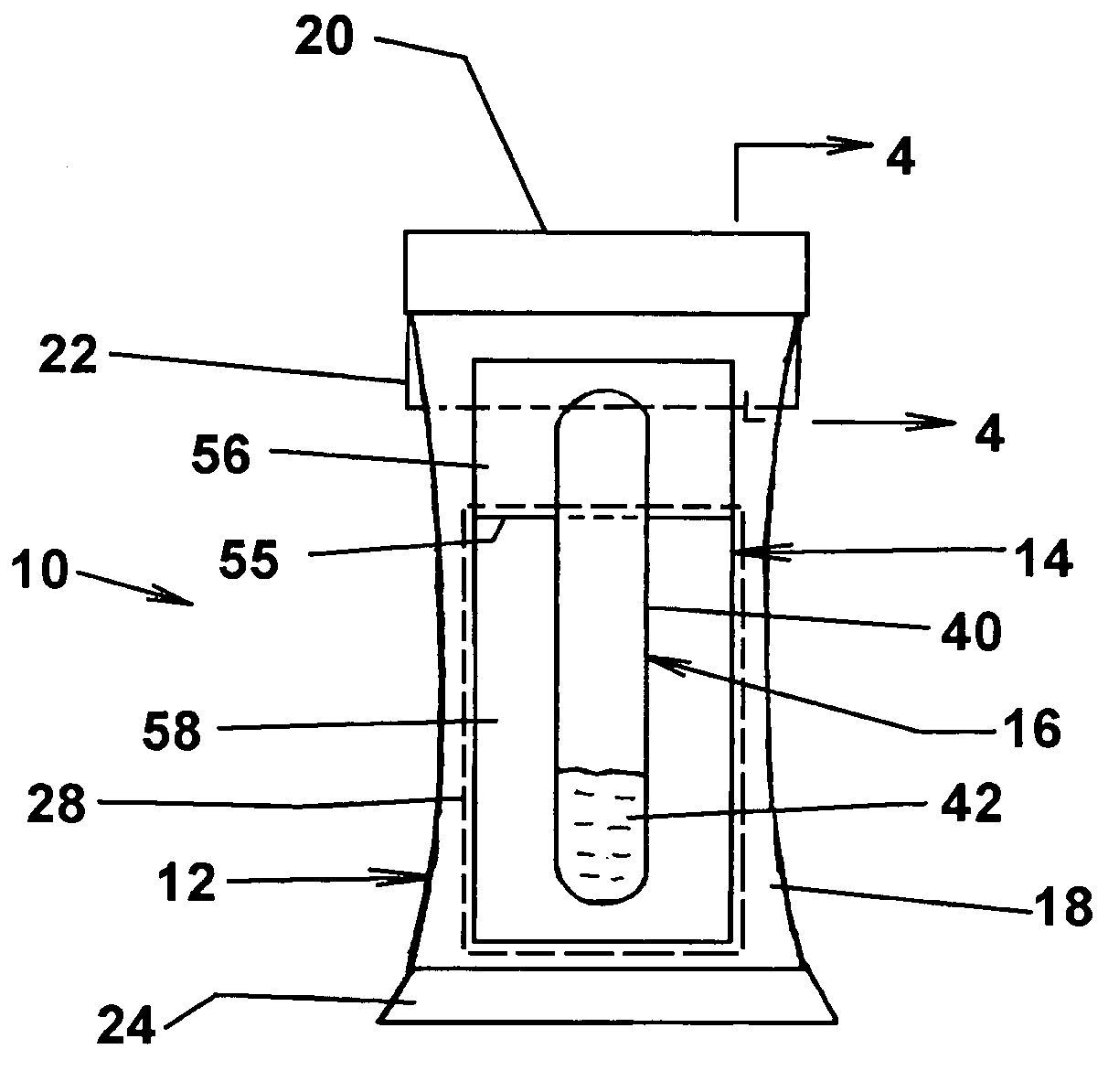

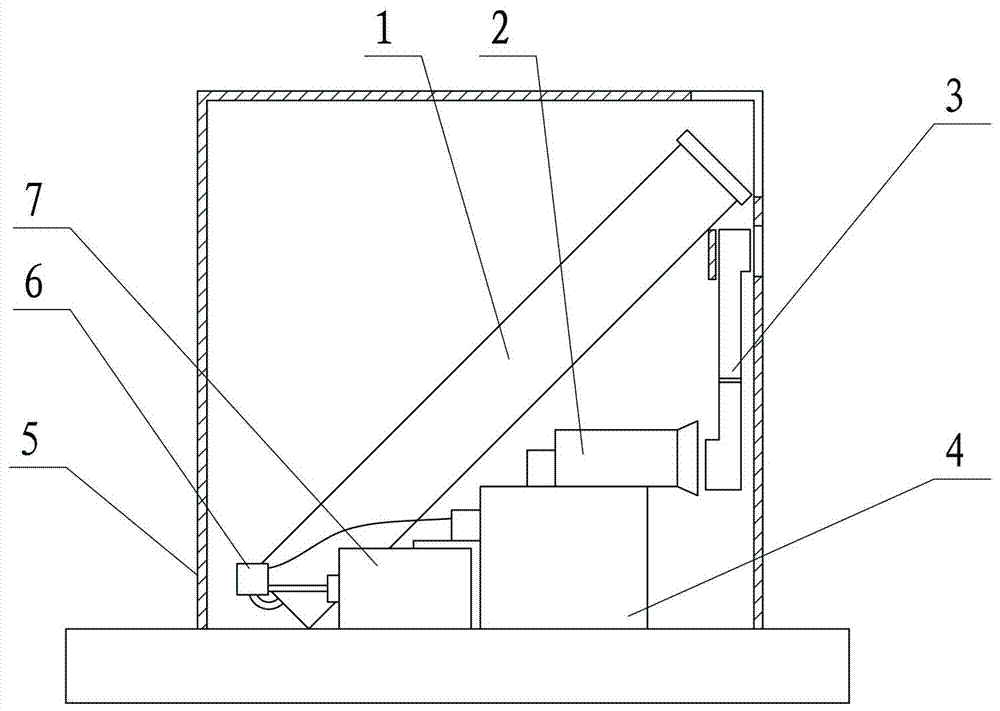

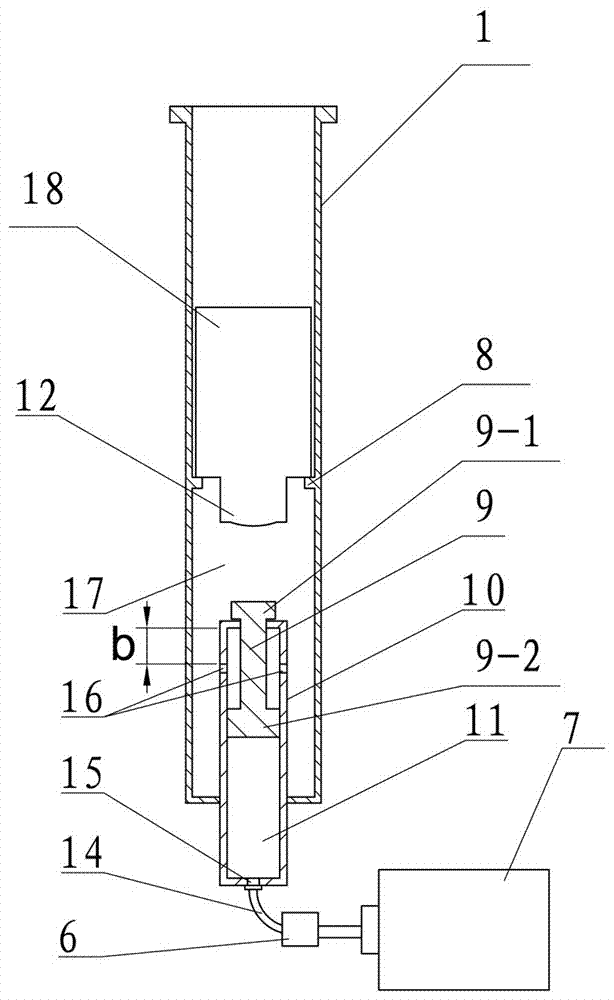

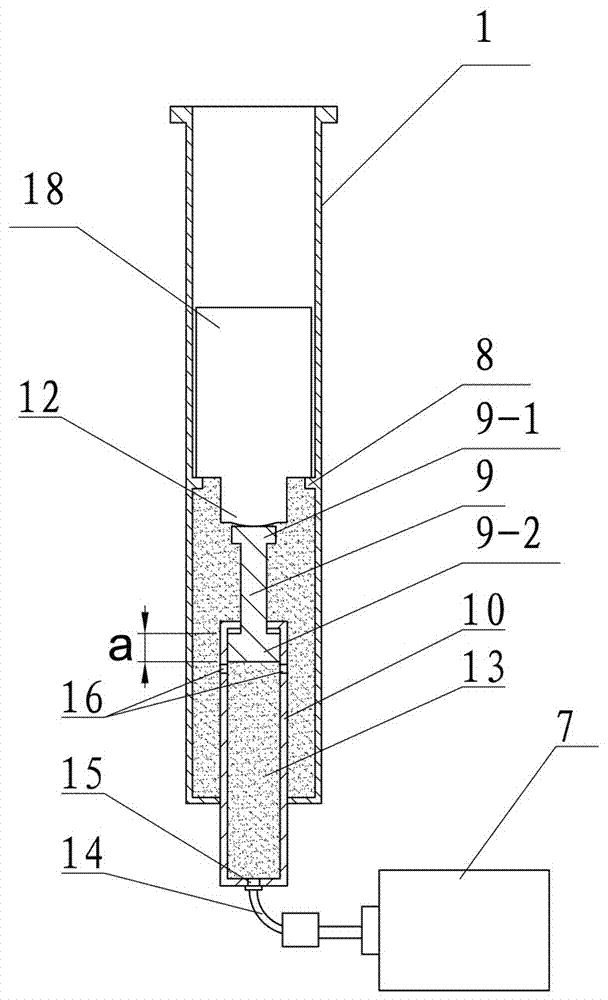

Critical temperature testing system of gunpowder and explosive thermal explosion

InactiveCN102608158ADifficult to collectChange the ambient temperatureMaterial heat developmentHeat conductingData acquisition

The invention discloses a critical temperature testing system of gunpowder and explosive thermal explosion, comprising a temperature-rising heating unit, a reactor unit, an automatic sample feeding unit, a pressure detection unit and a computer, wherein the temperature-rising heating unit comprises a heat-conducting layer, a heat preservation layer, and a single-cavity heating furnace body containing three groups of heating layers and ceramic heat-isolating layers; and the temperature and the temperature-rising speed of the heating furnace body are controlled by the computer. The reactor unit comprises a testing furnace cover, a lifting basket, a sample tank and a pre-heating furnace cover; the automatic sample feeding unit comprises a furnace body bracket, two stepping motors, a pulley wheel and a steel wire rope; the air pressure detection unit comprises a pressure sensor; the pressure sensor is mounted in the sample tank through the testing furnace cover and is connected with the computer; and the computer is provided with a data acquisition card, an image display control piece and a data processing unit. When the critical temperature testing system is used, a gunpowder or explosive sample with the certain size is placed into a special explosion-proof furnace and the sample is heated at the equal temperature or temperature-rising condition, so as to detect the thermal explosion critical temperature when the sample is combusted or exploded.

Owner:XIAN MODERN CHEM RES INST

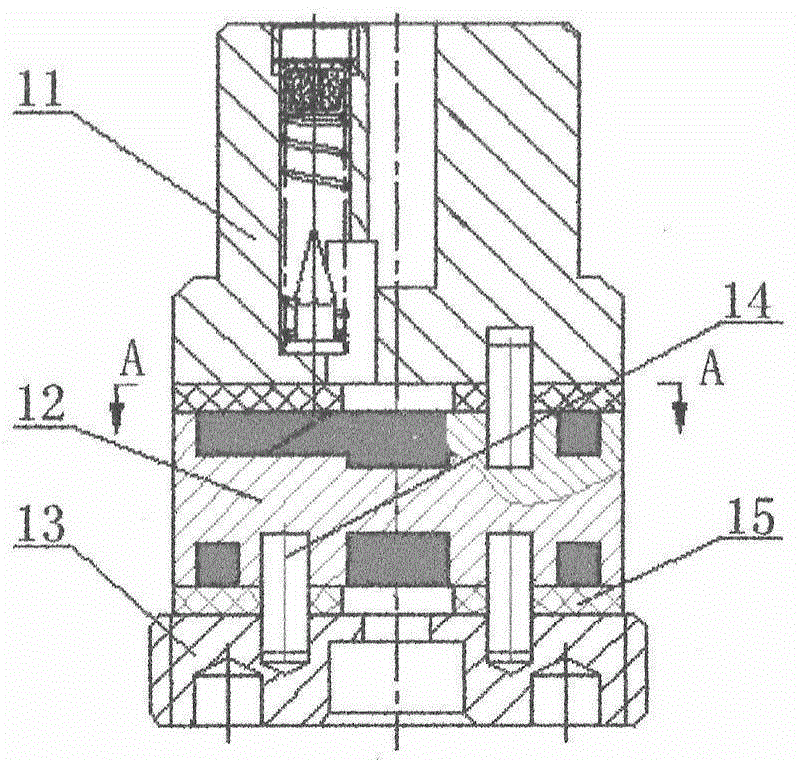

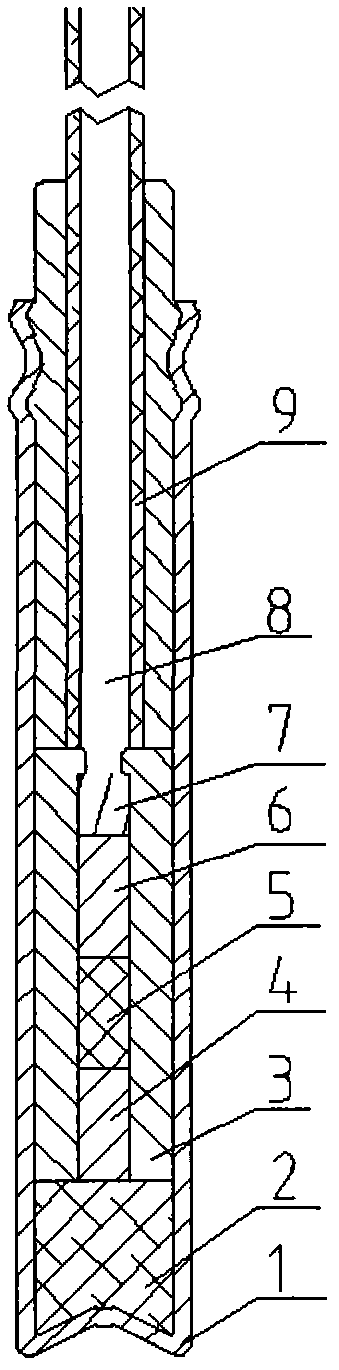

Full insurance type artificial rain bullet detonator

A full-insurance rain bomb fuze relates to an artificial hail-suppressing rain bomb fuze for antiaircraft guns. The present invention mainly includes a fuze body, an upper drug tray, a lower drug tray, a rotary body, a bracket, a pressure screw, and a detonator tube. There is a 134-136° circular groove on the bottom surface of the medicine tray and the top surface of the medicine tray respectively. The gunpowder column is installed on the side, and the gyratory body is installed in the medicine feeding tray. The left and right sides of the medicine feeding tray and the gyratory body are respectively equipped with centrifugal safety screw plugs, centrifugal springs, centrifugal pins and safety pins, and gunpowder safety screw plugs. The dimensions of the booster tube have also been improved. The invention has the advantages of small fragments, sufficient explosion, safe use, good delay reliability and more complete detonation.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

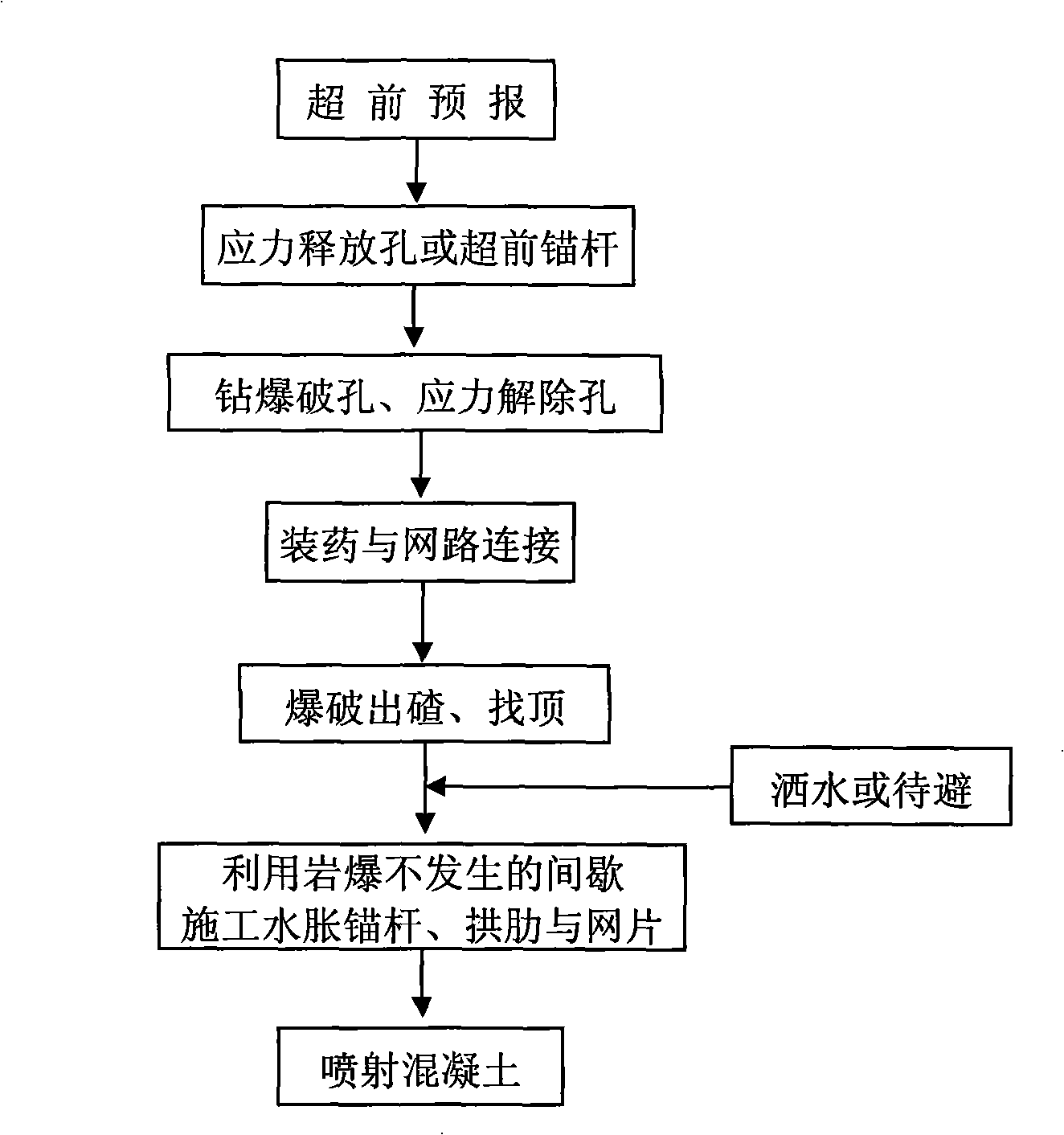

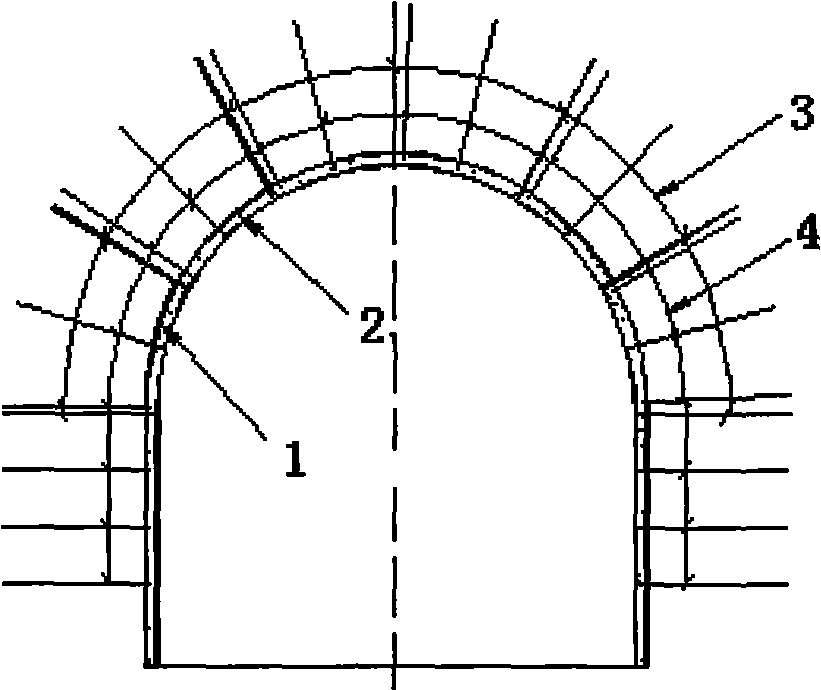

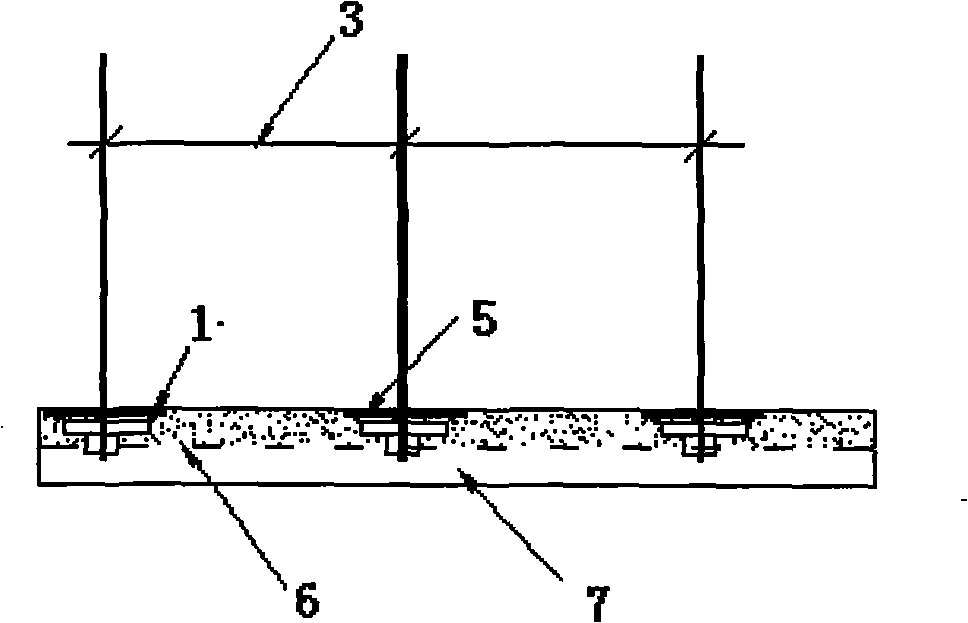

Safety rapid processing technique for strong zhiji rock burst

ActiveCN101256065AQuick installationReduce chance of security threatsBlastingRapid processingStress relief

The invention relates to a safe and rapid process for very strong rock outburst, when a very strong rock outburst is forecast, an advancing release hole and an advancing bolt are made near the place where rock outburst happens easily, then a blast hole is drilled, a stress relief blast hole is made on the tunnel face, gunpowder is charged in the blast hole and the stress relief blast hole, then followed with the steps of connecting network, disposing spoil, cleaning top, constructor avoidance, building water swelling bolt, supporting reinforcing steel bar arch rib and netting, and doing sprayed concrete enclosed work for the wall rock. The method provided by the invention can prevent the induction of the second rock outburst or collapse, which reduces the probability of threaten to the operating persons and construction equipment when the rock outburst happens, in order to secure the construction safety; can control the forming around the tunnel, which reduces unnecessary spraying and protecting workload; the water swelling bolt not only can be installed quickly, but also has the functions of reinforcing wall rock and fixing reinforcing steel bar arch rib, the heavy layer sprayed concrete replaces the quadratic lining cement, which saves a large mount of time.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

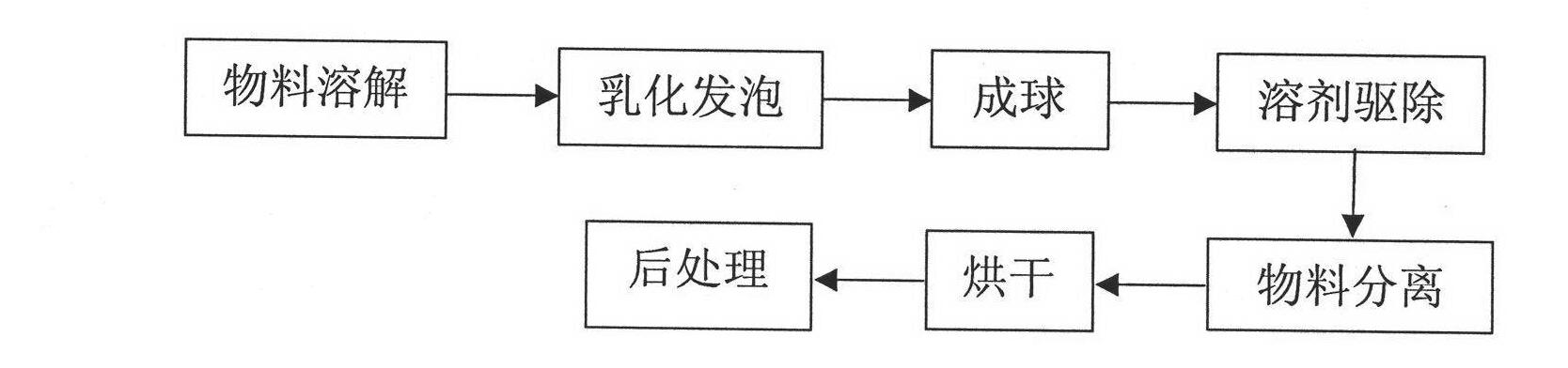

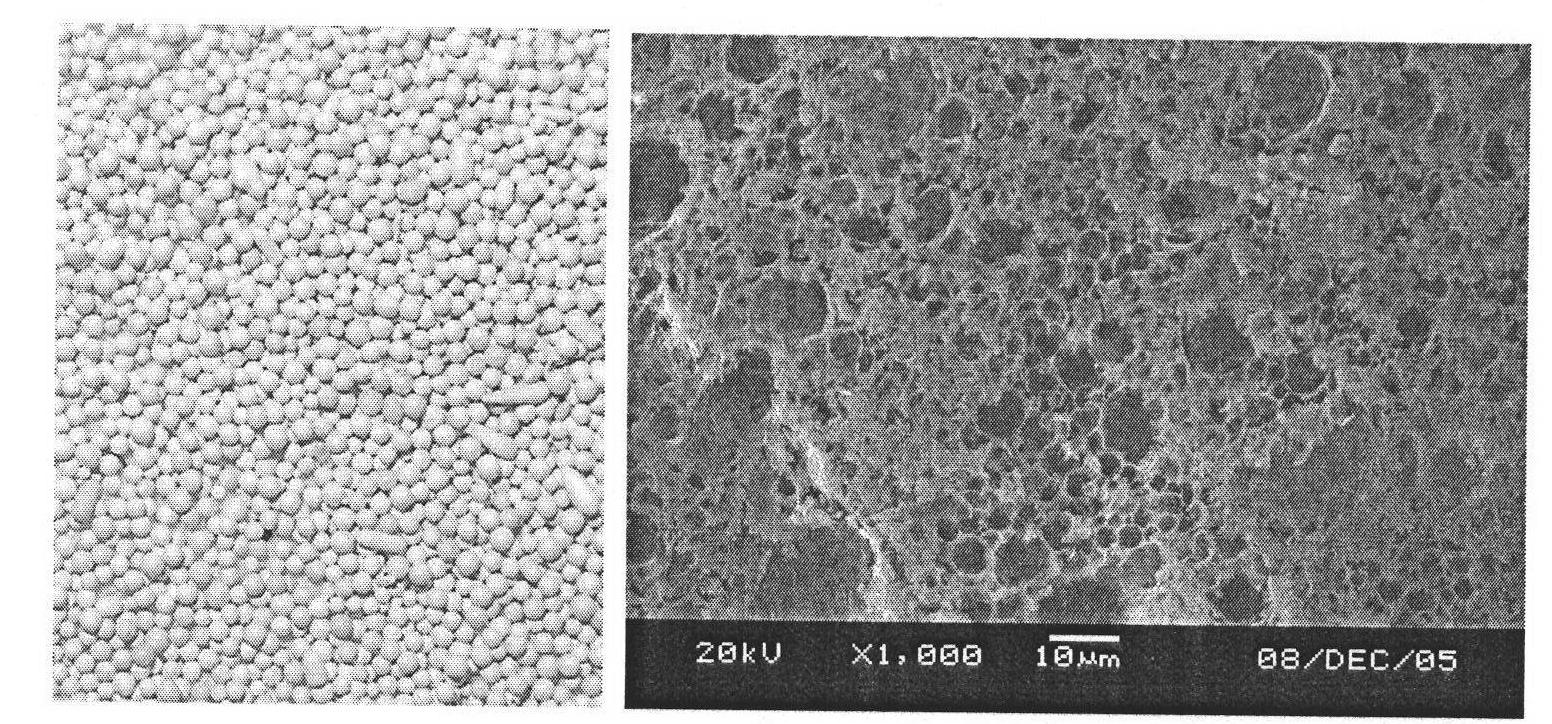

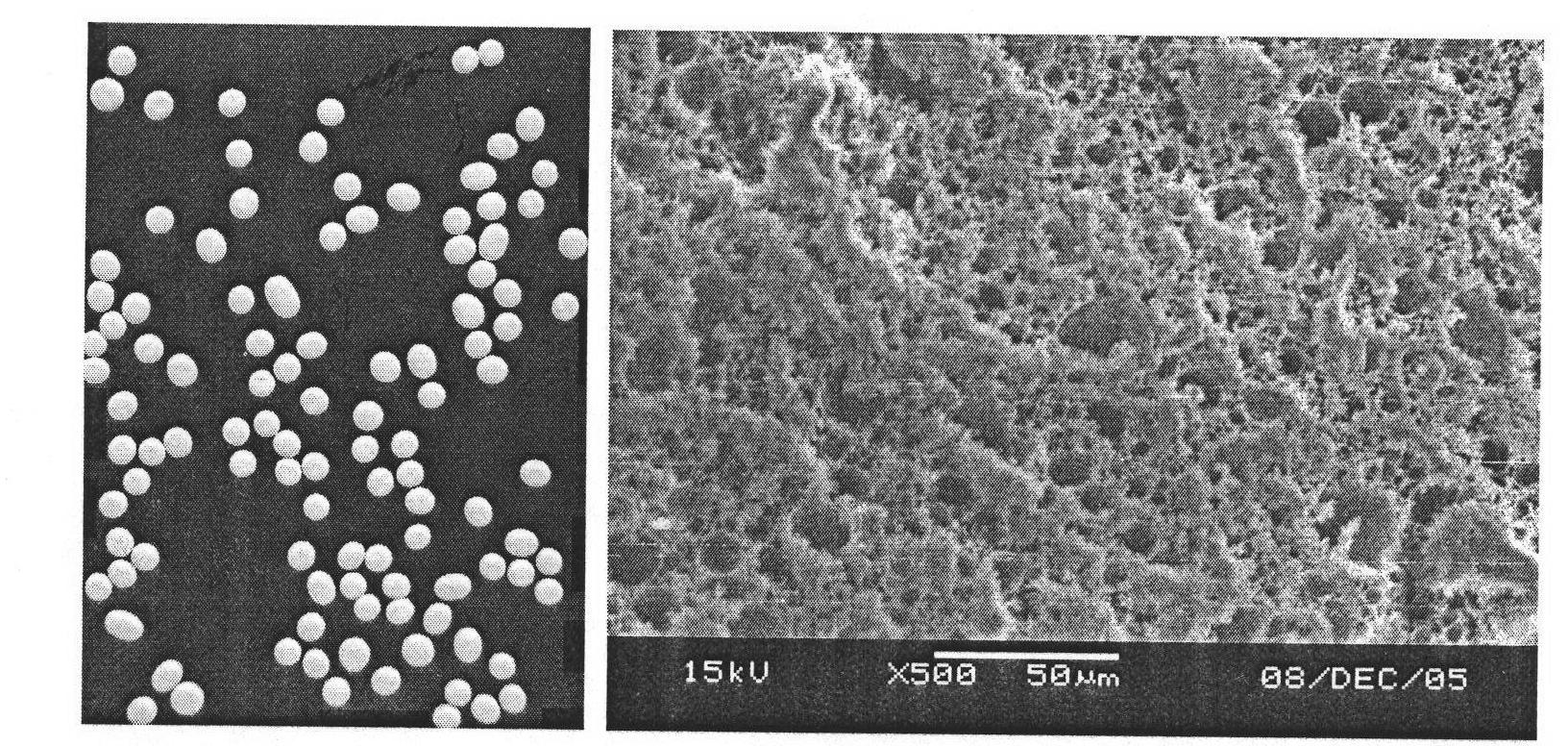

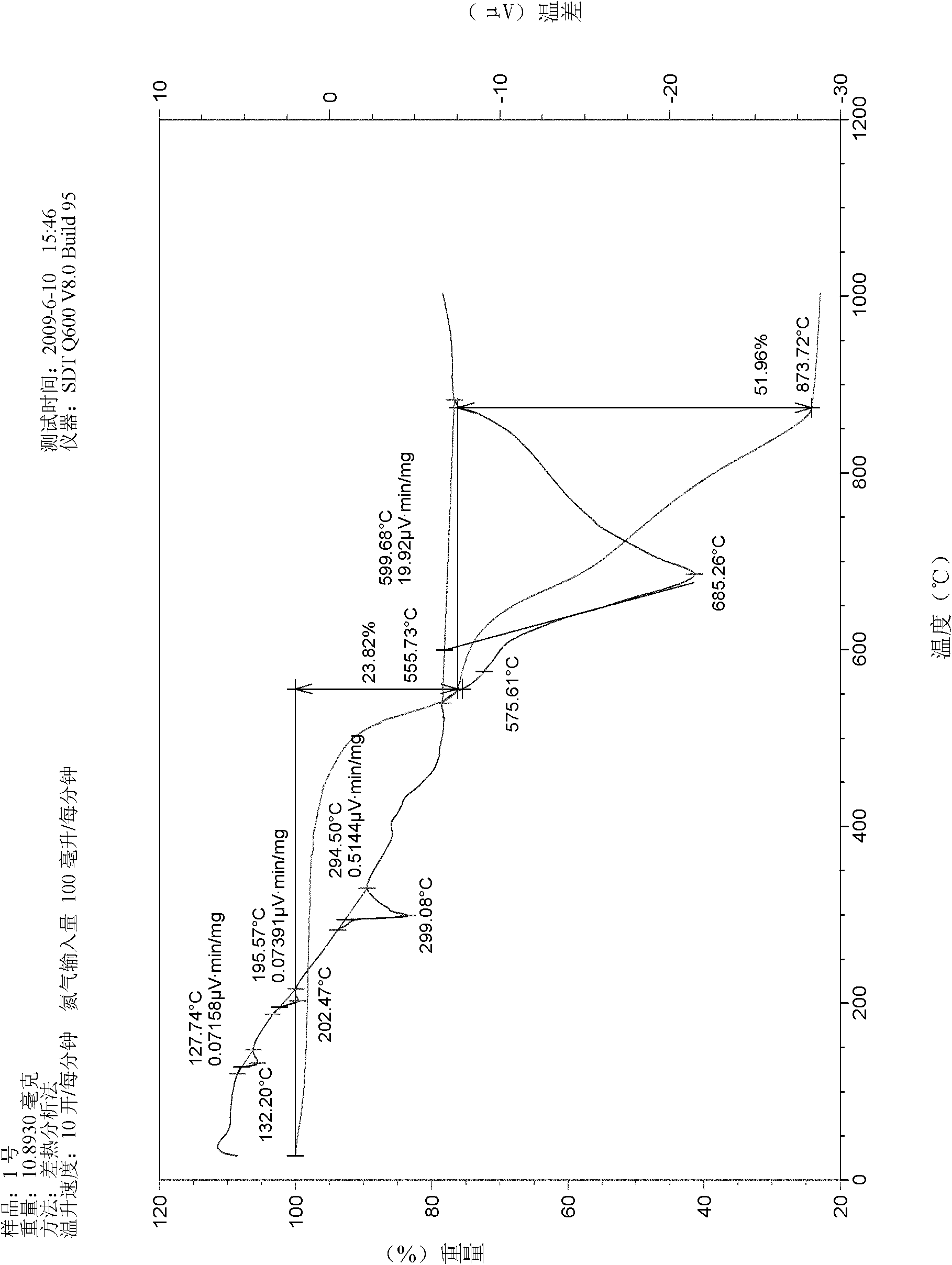

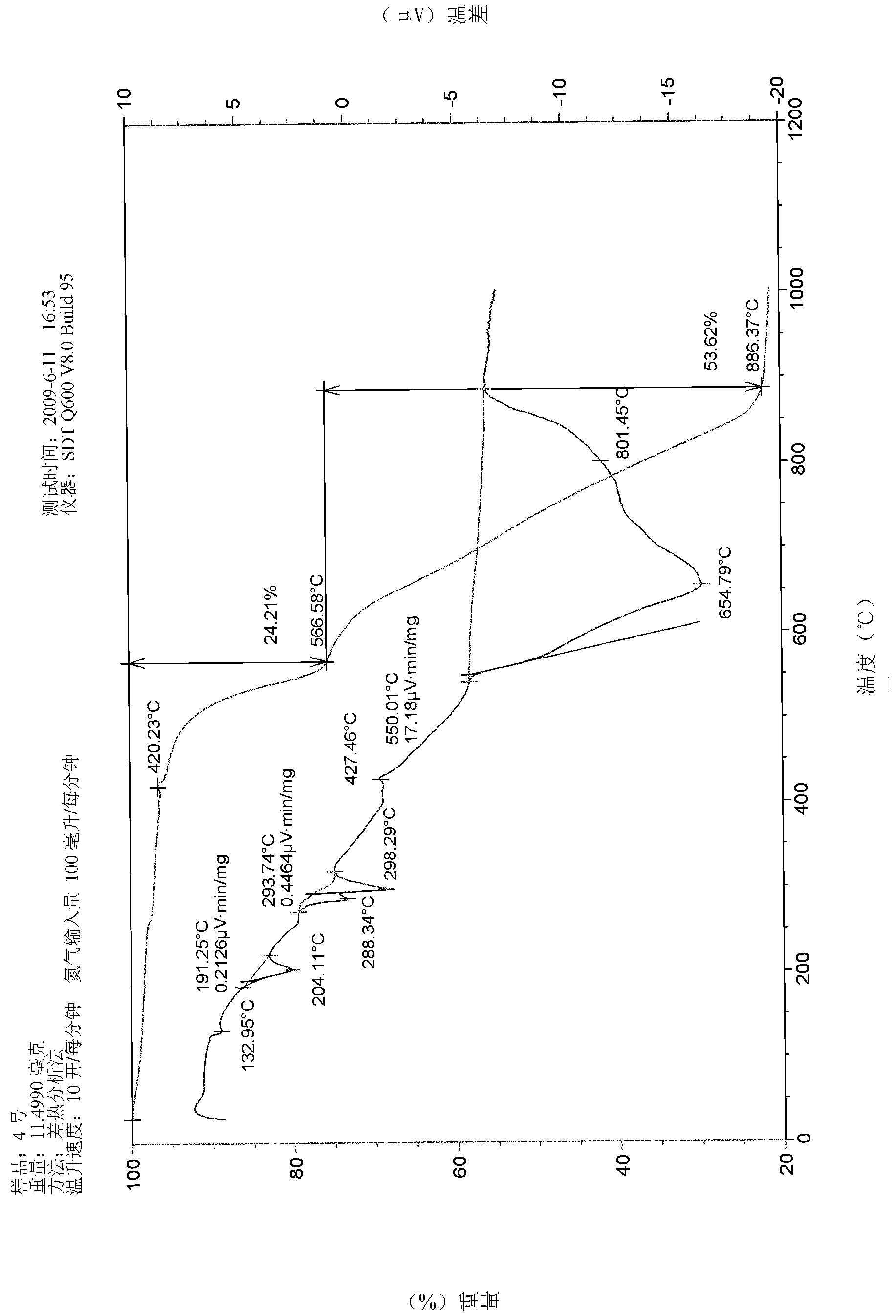

Microporous smokeless firework explosive and preparation method thereof

ActiveCN101844954AImprove securityReduce generationNitrocellulose explosive compositionsCelluloseNon solvent

The invention discloses microporous smokeless firework explosive and a preparation method thereof. The preparation method comprises the following steps of: dissolving scrapped military smokeless explosive containing nitrated cellulose into a solvent to form macromolecular sol, emulsifying and foaming the sol to form paint emulsion, dispersing the paint emulsion into a non-solvent medium under stirring action to form balls, then driving the solvent, separating the materials, and drying the materials to obtain explosive particles with microporous structures on the inner part for emitting and dissecting fireworks. The smokeless firework explosive has high fire transfer rate and adjustable stacking density and particle size because of a large amount of microporous structures on the inner part, the appearance of the microporous smokeless firework explosive is approximately spherical or oblate, the particle size is controllable, the stacking density is 0.05 to 0.4 g / cm<3>, and the aperture of the inner part is 0.01 to 500 microns in variety.

Owner:NANJING UNIV OF SCI & TECH

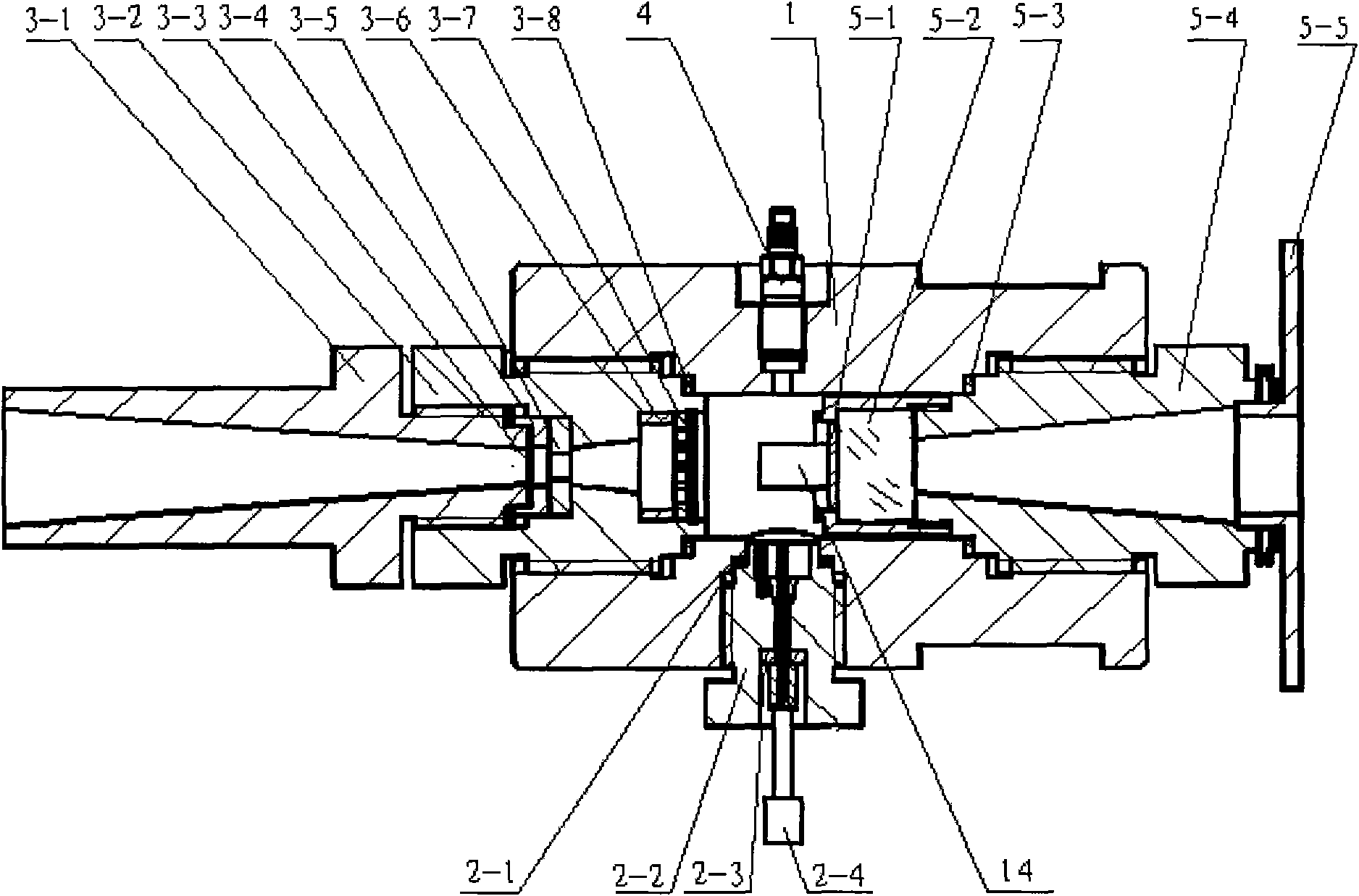

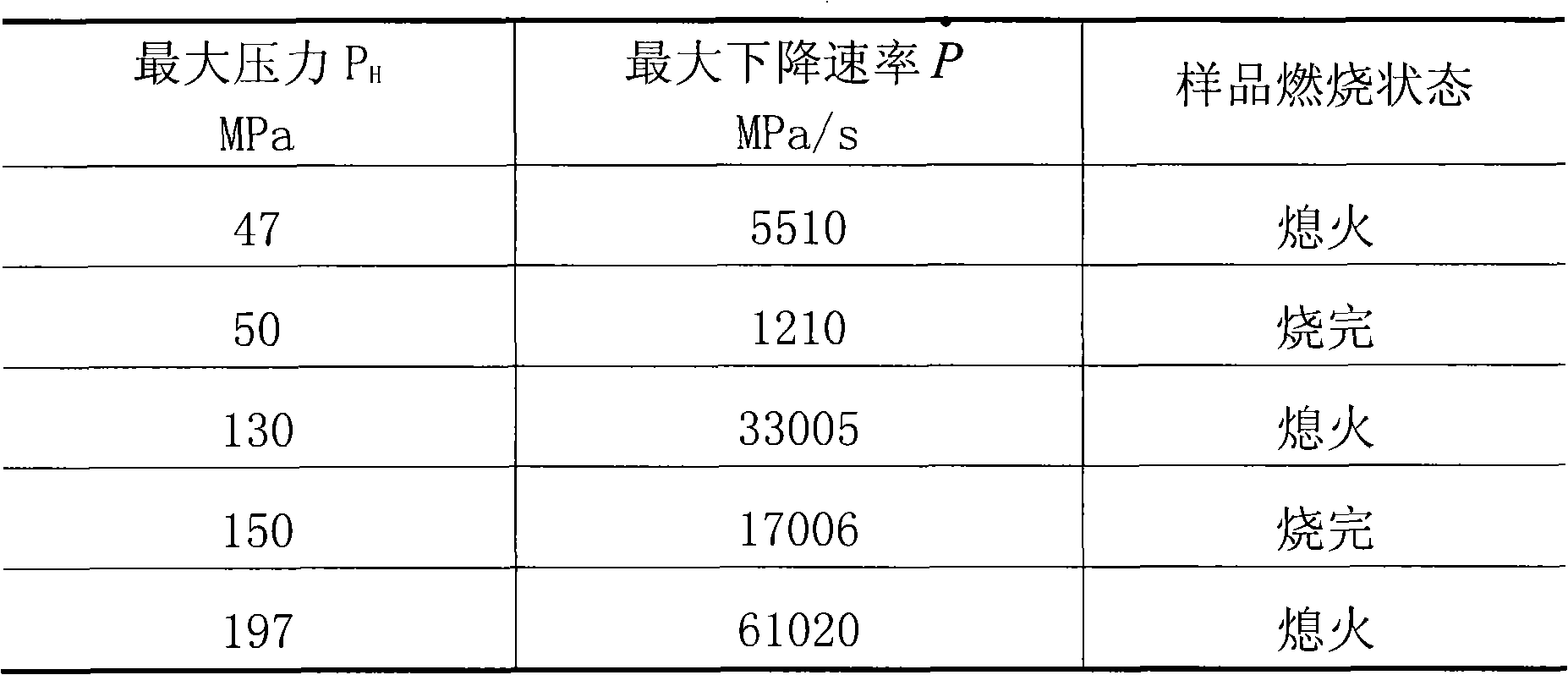

Gunpowder combustion property test device under pressure reduction condition

InactiveCN101650358APhotographing the combustion processShooting statusFuel testingGunpowderCombustion chamber

The invention discloses a gunpowder combustion property test device under pressure reduction condition, wherein, a watch window, a pressure discharge component, a pressure sensor and an igniting component are arranged on a combustion chamber of the device; the pressure discharge component is communicated with a pressure gas buffer tank which is filled with certain-pressure nitrogen and a high-speed camera can shoot combustion process of gunpowder sample through optical lens and the watch window; when the gas pressure in the combustion chamber reaches the pressure-proof critical value of the pressure discharge component by the combustion of gunpowder sample, the pressure discharge component discharges the gas in the combustion chamber into the pressure gas buffer tank; a data collection system collects and records the data output by the pressure sensor and the high-speed camera; and an operator can obtain related property parameters of the gunpowder sample based on analysis and calculation of recorded data. The invention can measure the combustion speed, flameout state and parameters of gunpowder under different pressures and pressure reduction rates and has the outstanding advantages of high measurement pressure, large regulating range of pressure reduction rate, low test cost and wide application scope.

Owner:XIAN MODERN CHEM RES INST

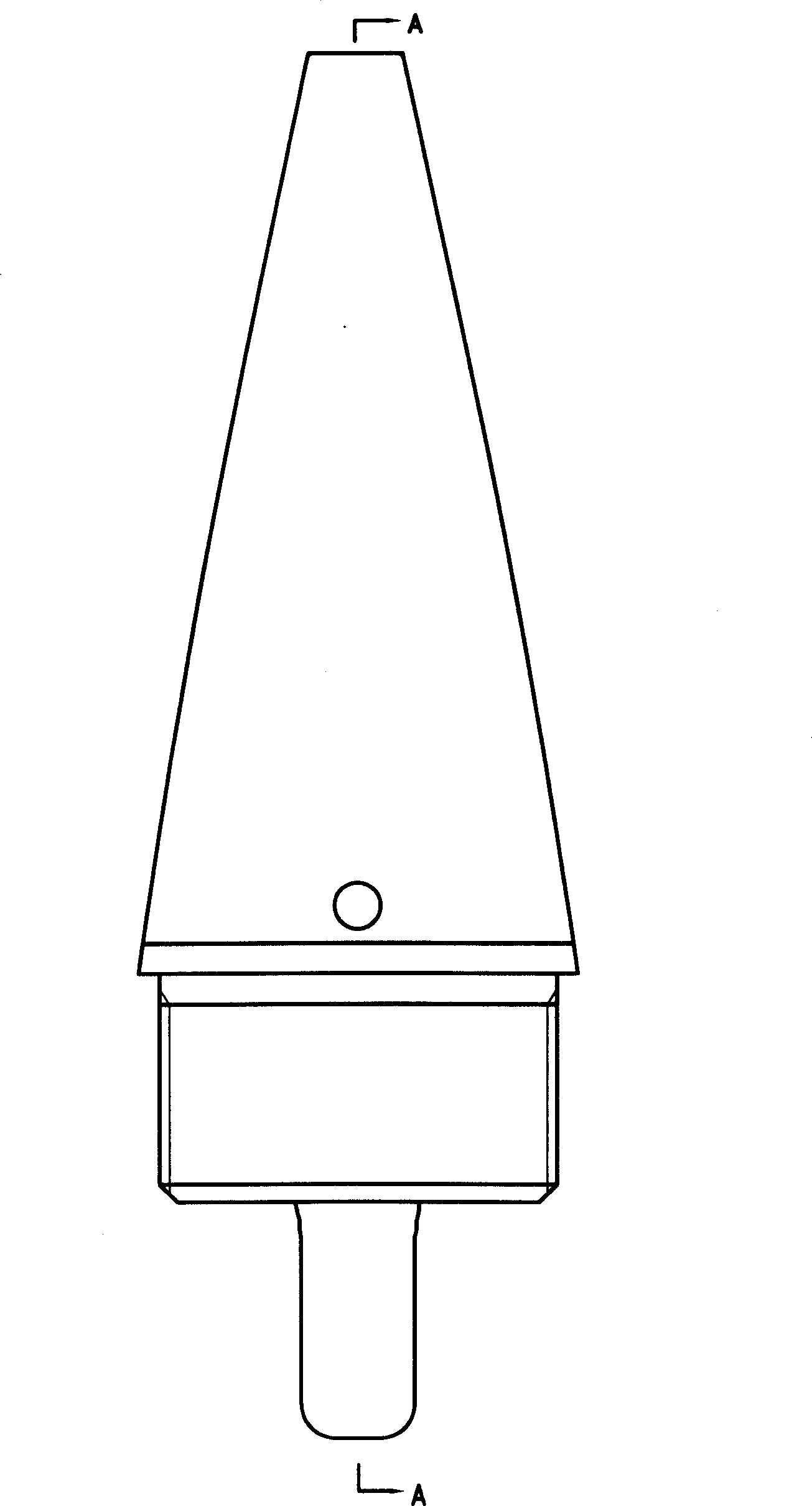

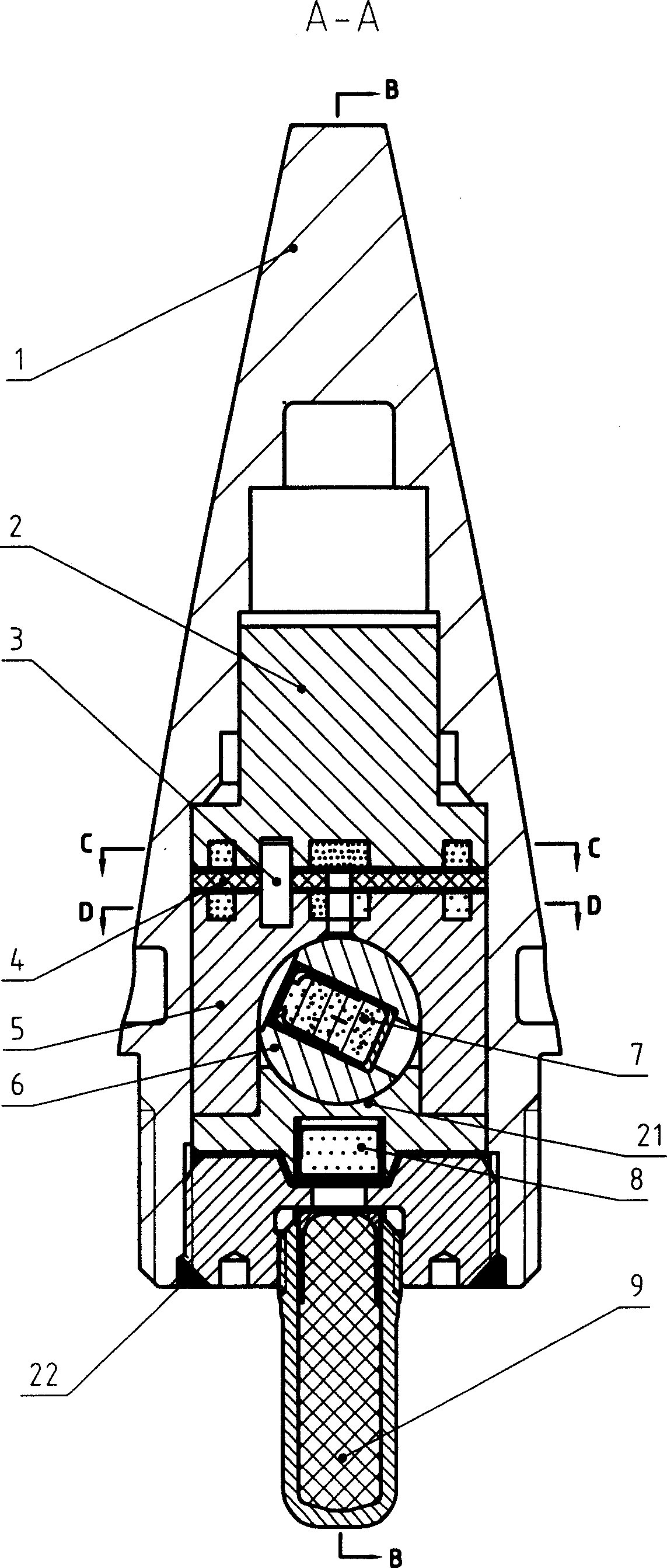

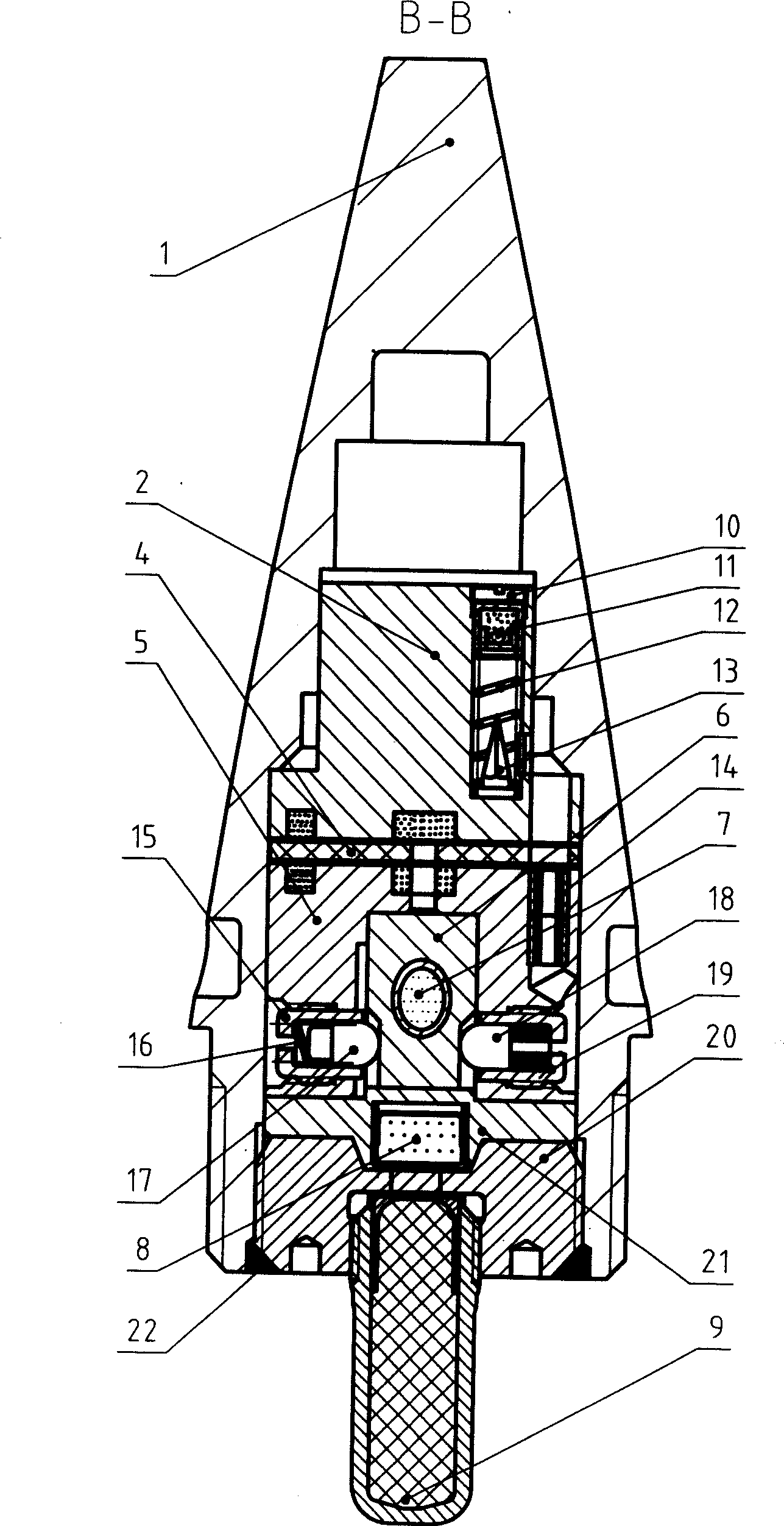

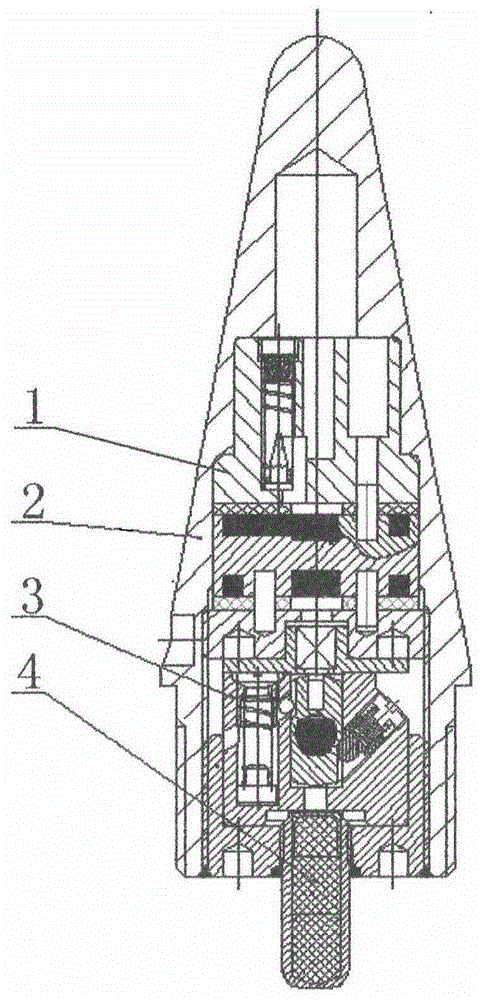

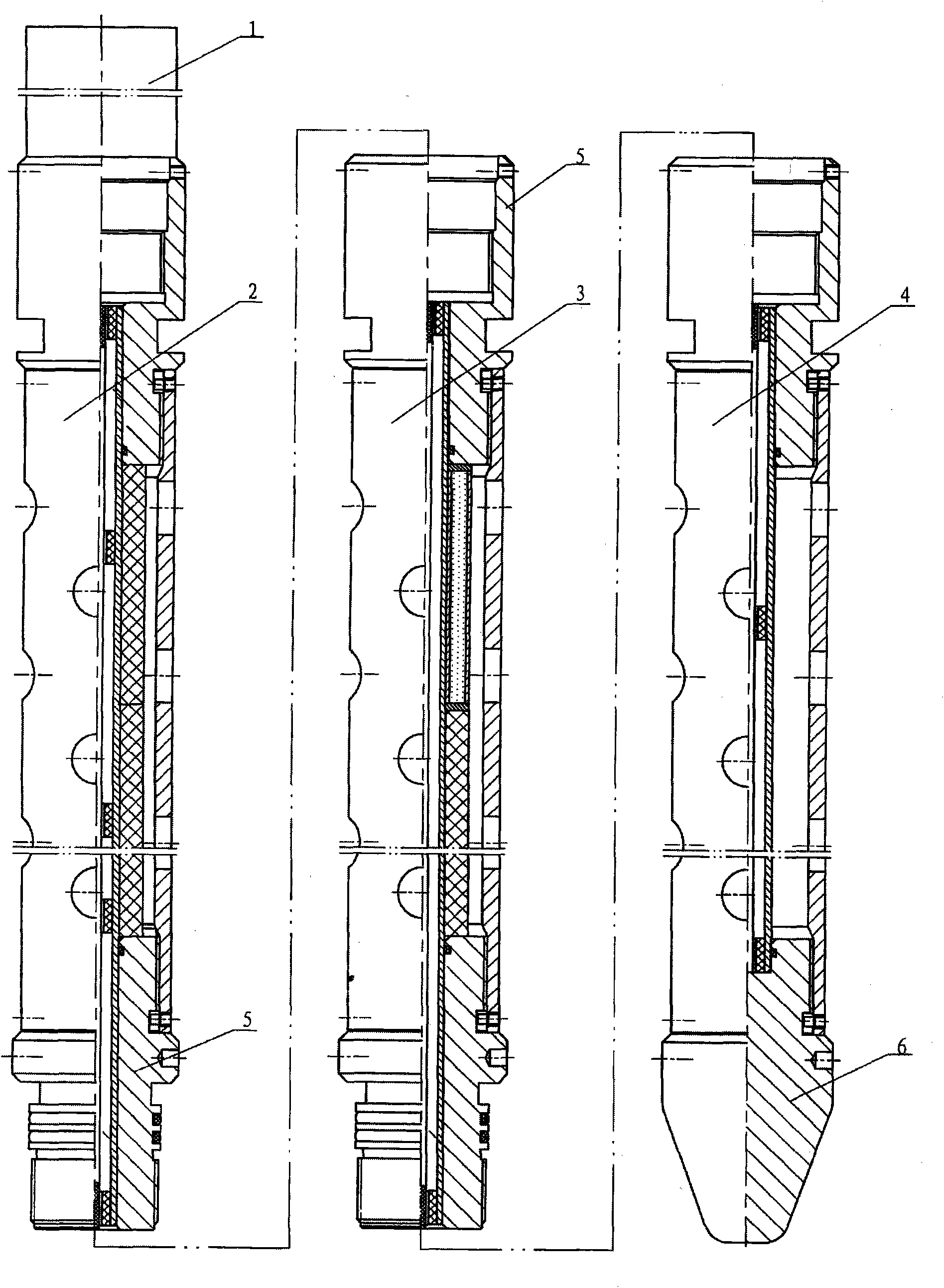

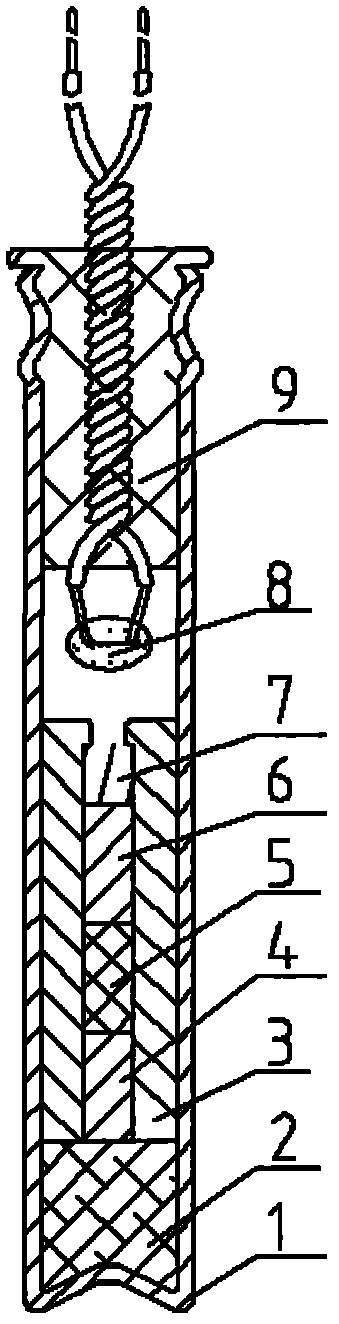

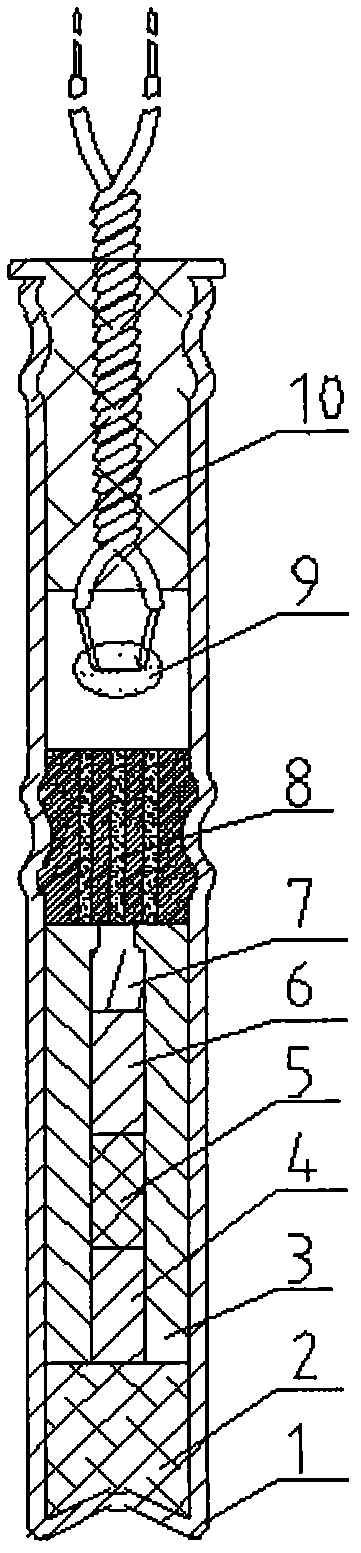

Fuze device for artificial precipitation projectile

InactiveCN105890473AImprove the reliability of fire transmissionImprove intrinsic safetyAmmunition fuzesDetonatorEngineering

The invention discloses a fuze device for an artificial precipitation projectile. The fuze device comprises a fuze body, an ignition self-destructive mechanism, a safety mechanism and a detonator, wherein the middle of the fuze body is a cavity structure; and in the cavity structure, the ignition self-destructive mechanism is arranged at the upper part of the cavity structure, the safety mechanism is arranged at the lower part of the ignition self-destructive mechanism, and the detonator is inserted into the lower part of the safety mechanism. The ignition self-destructive mechanism produces flames after being ignited, the flames are transmitted into the detonator under the control of the safety mechanism, a gunpowder charging projectile body of the artificial precipitation projectile is arranged at the lower part of the detonator, the flames enter the gunpowder charging projectile body via the detonator, and gunpowder in the gunpowder charging projectile body is detonated so as to produce thrust to launch the artificial precipitation projectile. The fuze device eliminates the potential safety risk that the chamber of the existing artificial hail preventing and precipitation increasing projectile explodes, solves the potential safety problems of the existing artificial precipitation increasing and hail preventing projectile, such as dud, half explosion and large explosion remnant fragments, and has high safety and high reliability.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

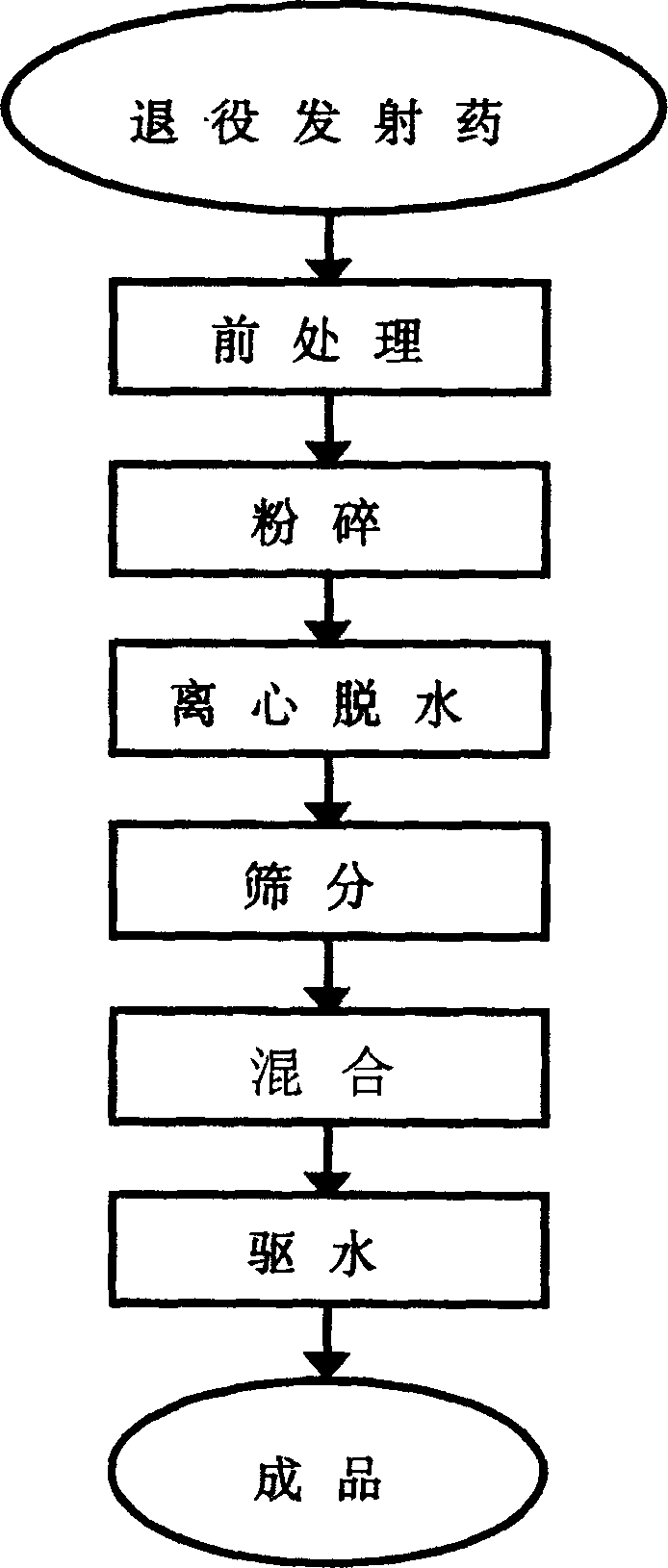

Smokeless gun propellant for fireworks and its prepn

InactiveCN1526687AReduce generationReduce pollutionExplosive working-up apparatusInorganic oxygen-halogen salt explosive compositionsFireworksOxidizing agent

The smokeless gun propellant for fireworks consists of retired gunpowder 70-90 wt%, oxidant 5-10 wt% and inflammable 1-5 wt%. The oxidant is nitrate, chlorate or perchlorate; and the inflammable is carbon powder, aluminum powder, magnesium powder or aluminum-magnesium alloy powder. The preparation process includes crushing, dewatering, mixing, dispelling water and drying. The smokeless gun propellant is used in ground fireworks product to replace black powder as propellant agent, and this can reduce smoke produced during firing fireworks greatly, reduce dust pollution to environment and lower production cost. The present invention paves one way of utilizing retired gun powder resource in large scale.

Owner:中国北方化学工业总公司

Blast black powder for fireworks

InactiveCN101270014ANo pollution in the processGood detonation effectInorganic oxygen-halogen salt explosive compositionsMetallic materialsFireworks

The present invention discloses explosive black powder that is used for fireworks. The black powder contains the following components with the following weight portions: 40 to 75 portions of potassium perchlorate, 0 to 35 portions of potassium nitrate, 1 to 5 portions of potassium dichromate, 5 to 15 portions of sulfur, 5 to 25 portions of charcoal, 0.5 to 2 portions of carbon black, and 5 to 20 portions of potassium terephthalic acid or potassium acid phthalate. The explosive black powder is made of the components according to the ratio. No metal material or toxic substances are used. The explosive black powder has the advantages of low mechanical sensitivity, excellent stability, large explosive scale, excellent explosive sound, black medicine, easily prepared raw materials and relatively low cost. Thus the explosive black powder is the ideal explosive black powder.

Owner:湖南省浏阳金生花炮有限公司

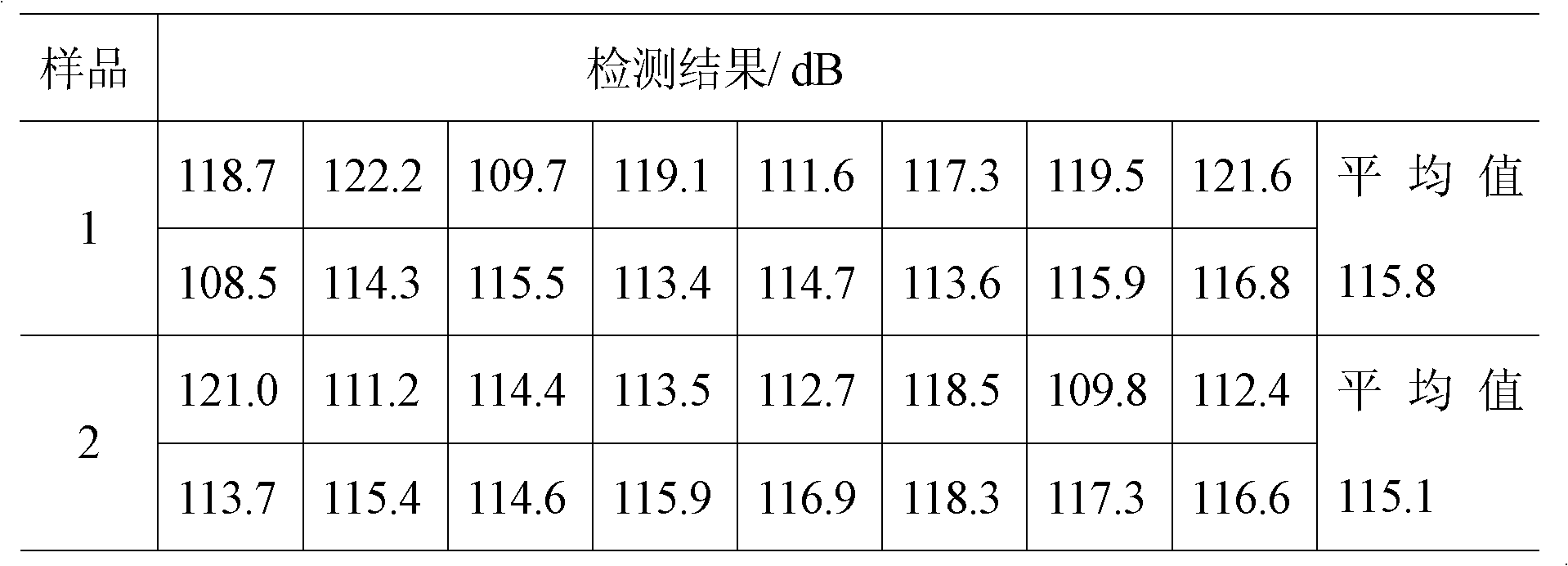

Sulfur-free and pearlite-free firecracker reagent and preparation method thereof

The invention discloses a sulfur-free and pearlite-free firecracker reagent and a preparation method thereof. The reagent comprises the following mass components: 35-65 percent of A component and 35-65 percent of B component, wherein the A component comprises the mass compositions: a mixture formed by 20-50 percent of potassium perchlorate, 0-30 percent of potassium nitrate and 30-50 percent of barium nitrate and a complexing agent occupying 1-5 percent of the mixture, and the B component comprises the mass compositions: 50-80 percent of aluminum powder, 10-25 percent of charcoal powder and 10-25 percent of organic foaming powder. The burning rate of a firecracker prepared from the reagent is more than 98 percent, the sound level value is no less than 100dB and is no more than 140dB, the time the gas product pressure rises from 0.69MPa to 2.07MPa is 1.74ms, a pH value of the pyrotechnic composition is 5-9, the moisture is no more than 1.5 percent, the hygroscopicity is no more than 2.0 percent, the thermal stability is 75 DEG C plus / minus 2 DEG C, the firecracker has no decomposition phenomenon under the condition of 48h, the friction sensitivity is no more than 40 percent, and the impact sensitivity of the pyrotechnic composition is no more than 0 percent. The key is that the reagent reduces the environmental pollution without harm to human bodies and has great application prospect.

Owner:HUNAN VOCATIONAL INST OF SAFETY TECH +1

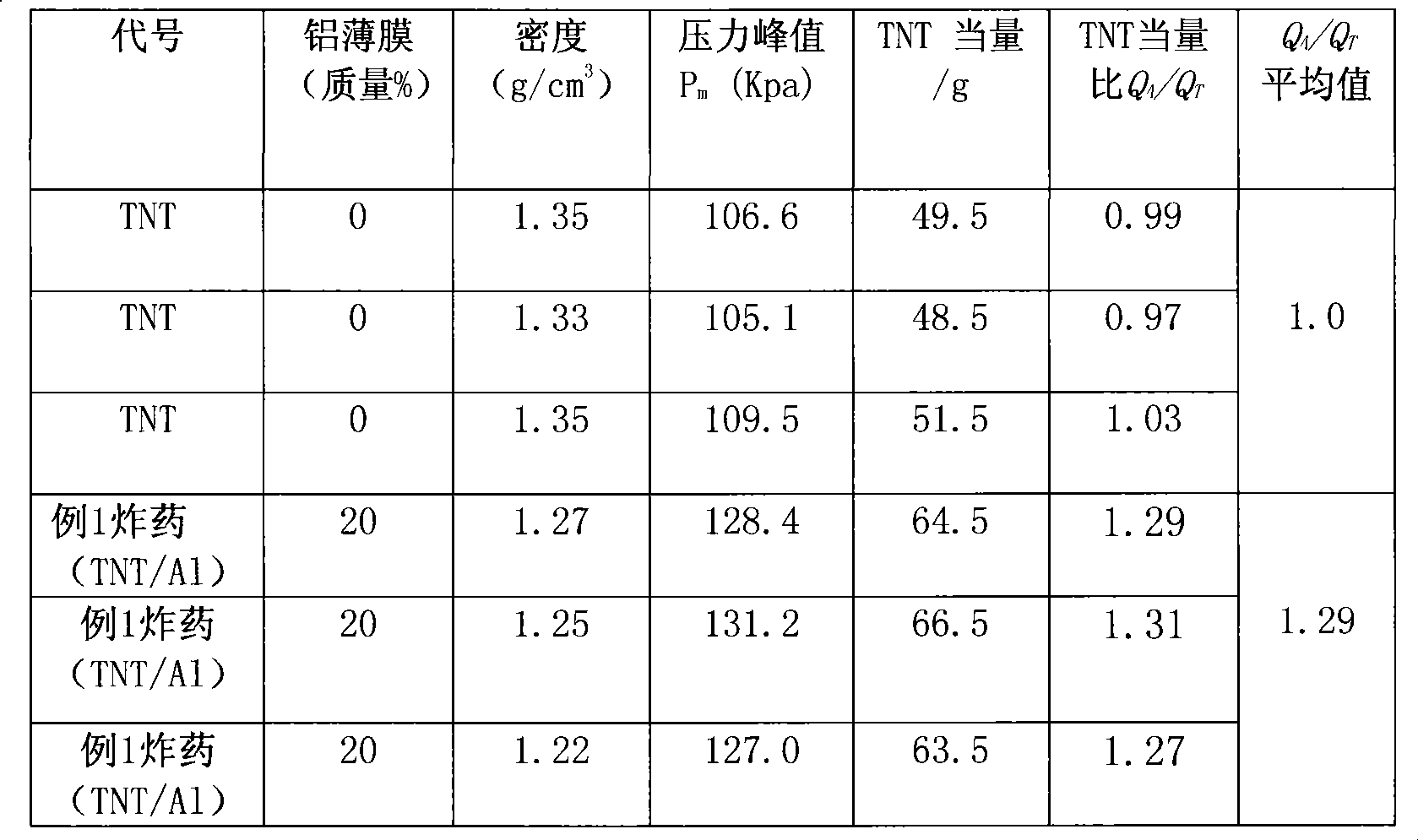

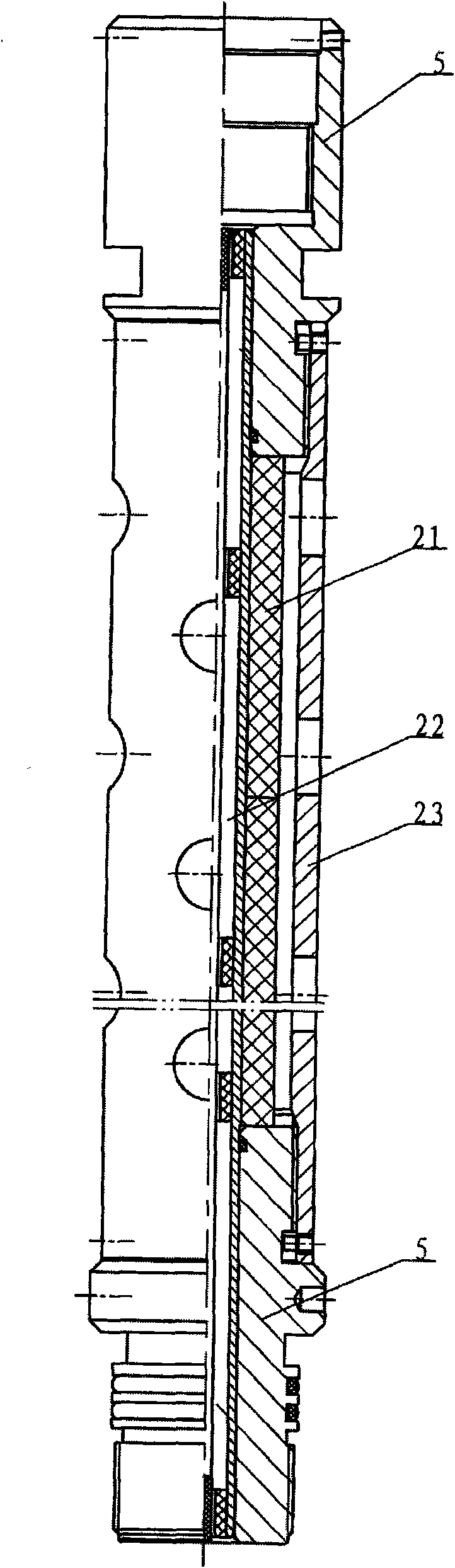

Energetic film composite type gunpowder and explosive, and preparation method thereof

InactiveCN101544525AImprove securityWill not polluteExplosive chargesExplosive working-up apparatusEmulsionMaterials processing

The present invention relates to energetic composite gunpowder / explosive and preparation technology thereof. the preparation method includes a step of processing energetic material into film with a thickness from 1 [Mu]m to 1mm; a step of preparing the gunpowder and explosive into limy explosive coating after a eliguation and emulsion process to coat on the surface of the film, so as to obtain energetic film composite gunpowder / explosive blank; a step of coiling the blank into helical structure charge column, or overlapping multilayer blank and pressing into a laminated structure, or glueing the multilayer blank into a laminated structure by binder to obtain the energetic film composite gunpowder / explosive; wherein the quality of the energetic film material is from 4% to 60%, that of the gunpowder / explosive material is from 40% to 96%, that of the binder is from 0% to 15%. The invention replaces the traditional powder material by film shape energetic material, the preparation process is simple, the housework circumstance and the safety are all improved; the energy output of the mixed gunpowder / explosive is improved, at the same time the performance of safety, mechanics and long storage of the gunpowder / explosive is improved, and the energetic composite gunpowder / explosive is capable of meeting the requirement of the modern blasting equipment.

Owner:UNIV OF SCI & TECH OF CHINA

Pulse fracturing sand injector for horizontal wells

ActiveCN101619654AIncrease profitImprove stabilityFluid removalDirectional drillingHigh energyHorizontal wells

The invention discloses a pulse fracturing sand injector for horizontal wells, which is formed by connecting a fracturing gun component, a sand-injecting gun component and an interlayer gun component via intermediate joints, wherein, the fracturing gun component is loaded with fracturing gunpowder with various burning speeds; the interlayer gun component is applied to the interlay where oil gas is not produced and achieves the effect of igniting; the sand-injecting gun component is internally loaded with a sand collecting cylinder and sand-expelling gunpowder and used for conveying propping agent to the formation fracture, thereby forming the fracturing sand injector with the length ranging from dozens of meters to hundreds of meters for horizontal wells by proper combining the components according to the distribution of the production pay and the interlayer. By introducing the propping agent to the high-energy gas fracturing process, the fracturing sand injector can improve the stability of fracture and extend the stimulation time, and the fracturing sand injector has the characteristics of low cost, obvious stimulation effect, simple process and safe and reliable application. The invention is applicable to horizontal wells with different completion manners, vertical wells or inclined wells, such as cased wells, sieved wells or uncased wells.

Owner:NORTH SCHLUMBERGER OILFIELD TECH XIAN

Smokeless flameless gunpowder agent

InactiveCN101215211AImprove stabilityImprove moisture resistanceNon-explosive/non-thermic compositionsFirecrackerFireworks

The invention discloses a firework agent with no smoke, which is characterized in that the invention is produced by nickel hydrazine nitrate blending with accessories , wherein, the nicker hydrazine nitrate is generated by mixing and reaction of nickelous nitrate hexahydrate and hydrazine hydrate, The weight ratio of raw materials of the nickel hydrazine nitrate is that nickelous nitrate hexahydrate takes 35-85 portions of weight per percentage, hydrazine hydrate takes 15-65 portions of weight per percentage, the weight ratio of raw materials of the fireworks agent with no smoke is that nickelous nitrate hexahydrate takes 20-62 portions of weight per percentage, excipients takes 40-80 portions of weight per percentage, wherein the excipients are mineral powders with 80-120 orders which are incombustible, such as pearlite powder or sepiolite powder or river sand, two or more of the excipients can be used in manufacture of different firework products. Protocol fireworks with color flowers and firecrackers which are made by the firework agent with no smoke are smokeless and flameless, and are in according with the environment-friendly requirement.

Owner:邹建文

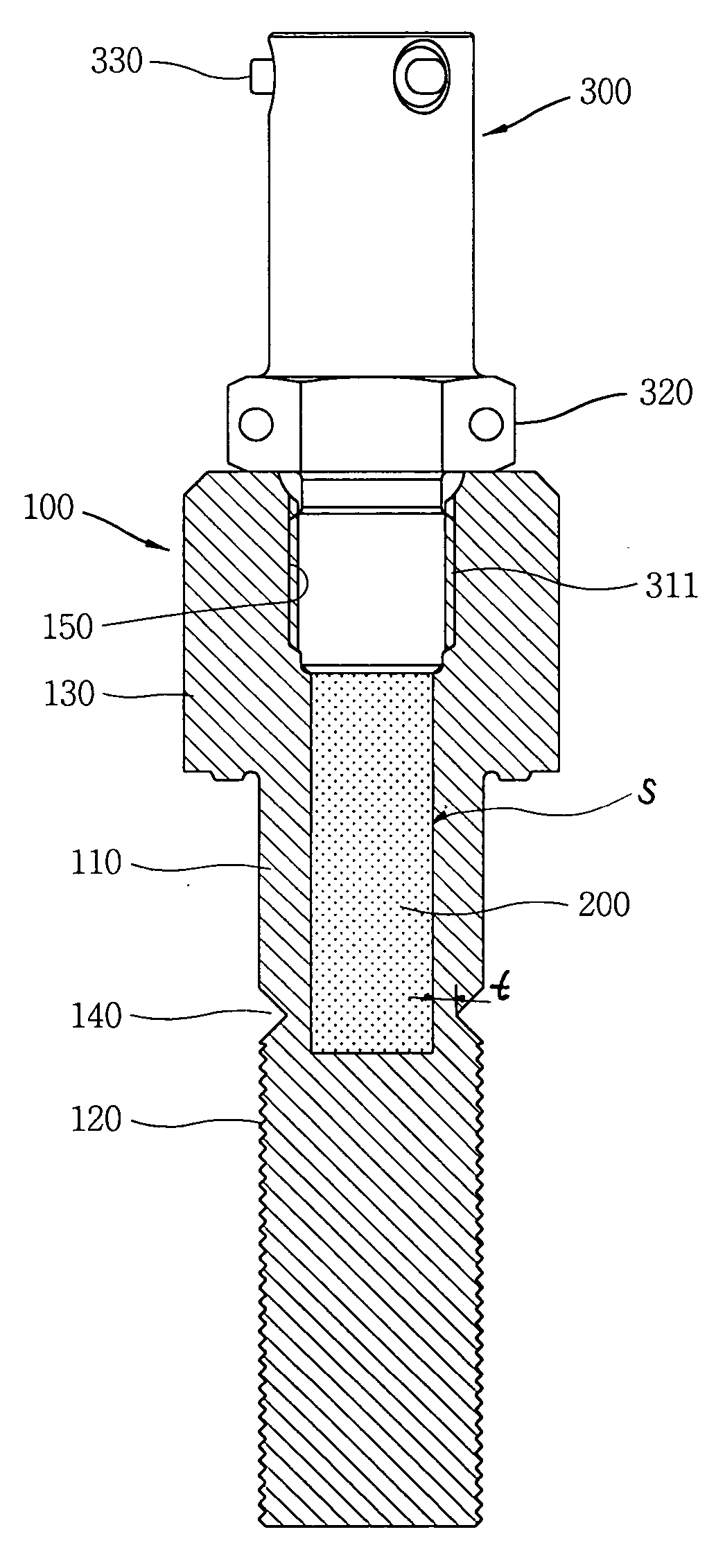

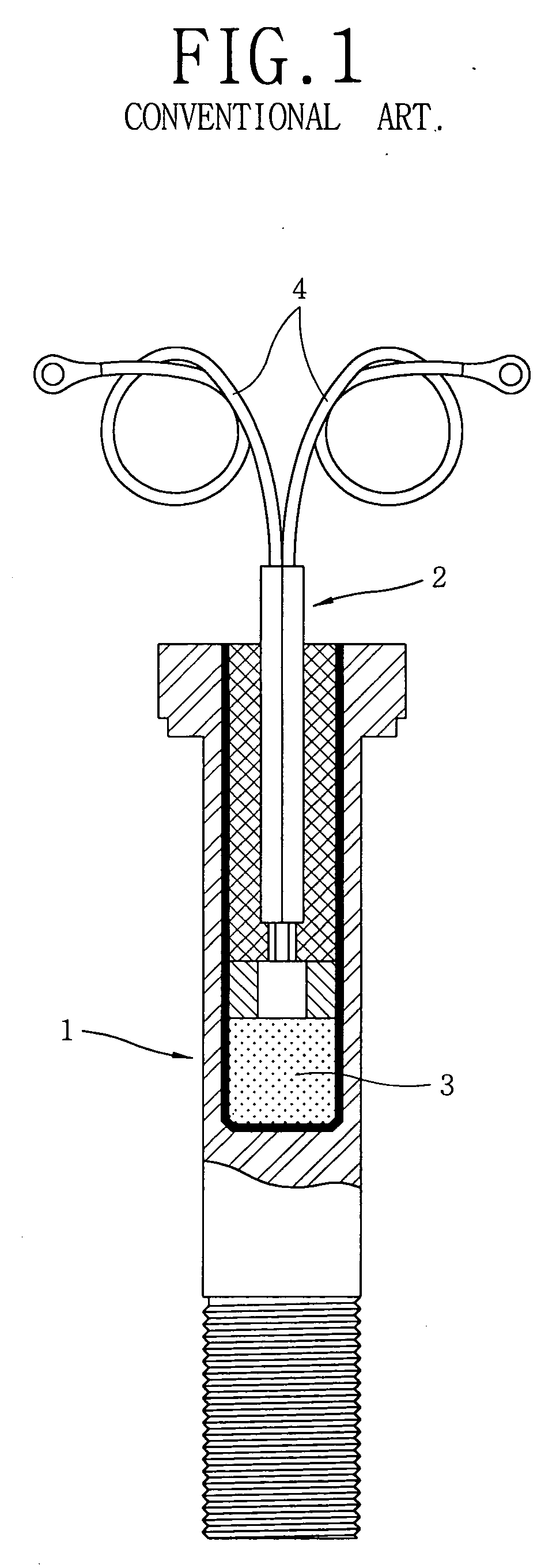

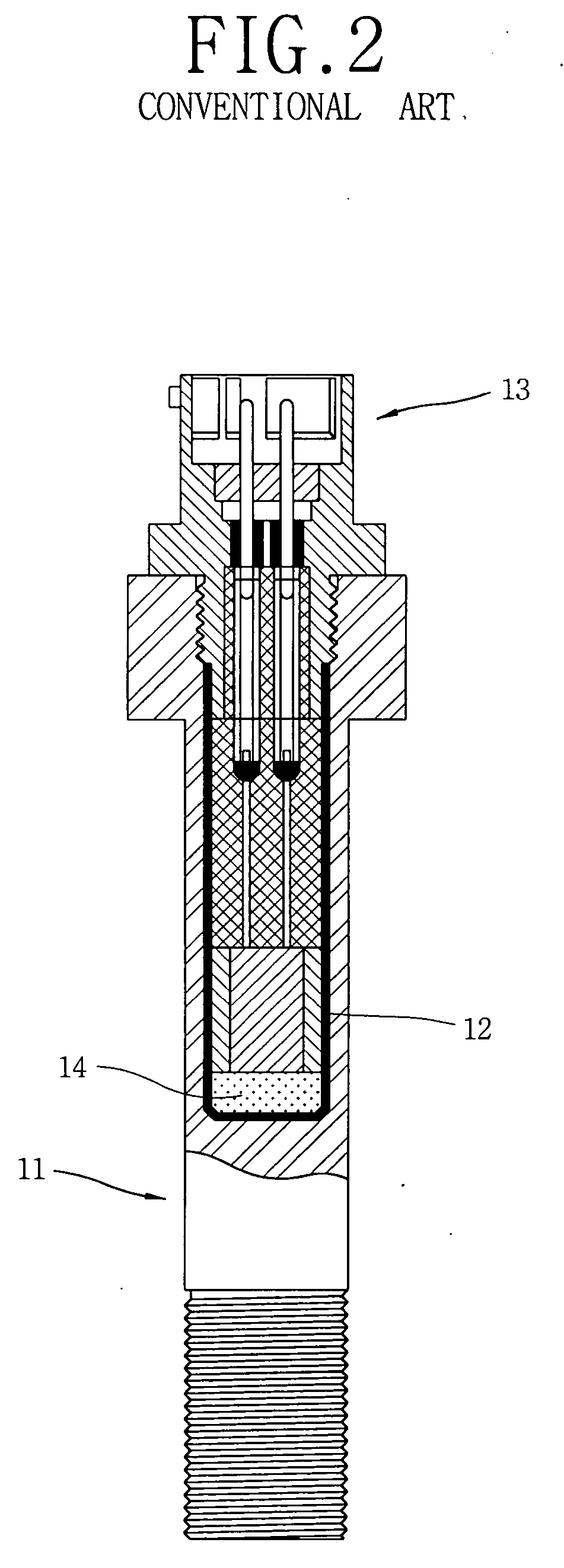

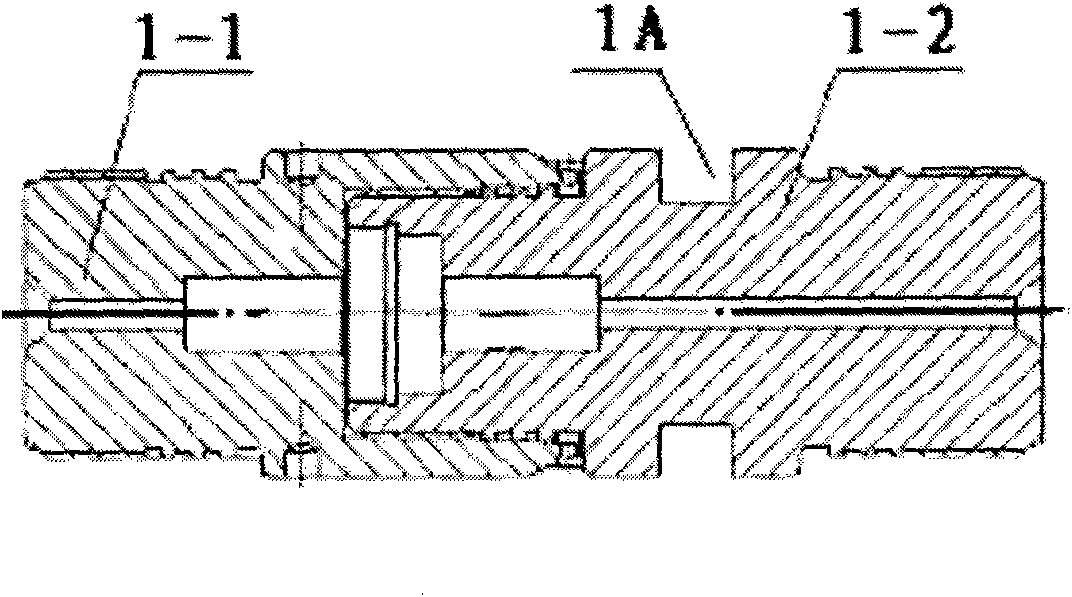

Explosive bolt

InactiveUS20060027083A1Minimize impactNoise minimizationAircraft componentsBlasting cartridgesProduction ratePressure transmission

An explosive bolt includes: a bolt body forming a receiving space therein; a pressure transmitting means received in the receiving space of the bolt body; a pressure generating means connected to the pressure transmitting means and generating pressure; and a cut portion formed at the bolt body and cut upon receiving pressure generated from the pressure generating means through the pressure transmitting means. Accordingly, the amount of gunpowder used is minimized, and a position of a cut portion can be freely designed and fixed, thereby not only minimizing explosion impact and noise but also improving productivity and reliability.

Owner:AGENCY FOR DEFENSE DEV

Compressed gas-powered gun simulating the recoil of a conventional firearm

InactiveUS20050072415A1Contributing to accuracyPrecise alignmentSafety arrangementFiring/trigger mechanismsSemi automaticEngineering

Owner:NEW MATICS LICENSING

Sulfur-smoke-free powder composition and preparation method thereof

InactiveCN103214322ADisadvantages of Avoiding Cryogenic DecompositionSolve the disadvantage of easy moisture absorptionExplosivesNitro compoundBarium nitrate

The invention discloses a sulfur-smoke-free firework powder composition and a preparation method thereof. According to the powder composition, potassium perchlorate and barium nitrate are used as oxidants, and a nitro-compound is used as a flammable agent, so that the safety and environment-friendliness of the firework production are greatly improved, the production cost of the firework powder is lowered, and various indexes are excellent through the detection. The preparation method of the sulfur-smoke-free firework powder composition is simple and mainly comprises the simple processes of mixing, pelletizing, drying and screening. According to the sulfur-smoke-free firework powder composition and the preparation method thereof disclosed by the invention, the problems that the conventional black powder is poor in safety, easy to absorb moisture, large in production risk and the like are solved. The sulfur-smoke-free firework powder composition has the advantages of having an emission effect better than that of black powder, achieving zero-exhaustion of sulfur dioxide and the like. The sulfur-smoke-free firework powder composition is extensively applicable to preparing firework propellant powder and 3-8-inch powder of large festive fireworks.

Owner:LIUYANG HELI HIGH TECH DEV CO LTD

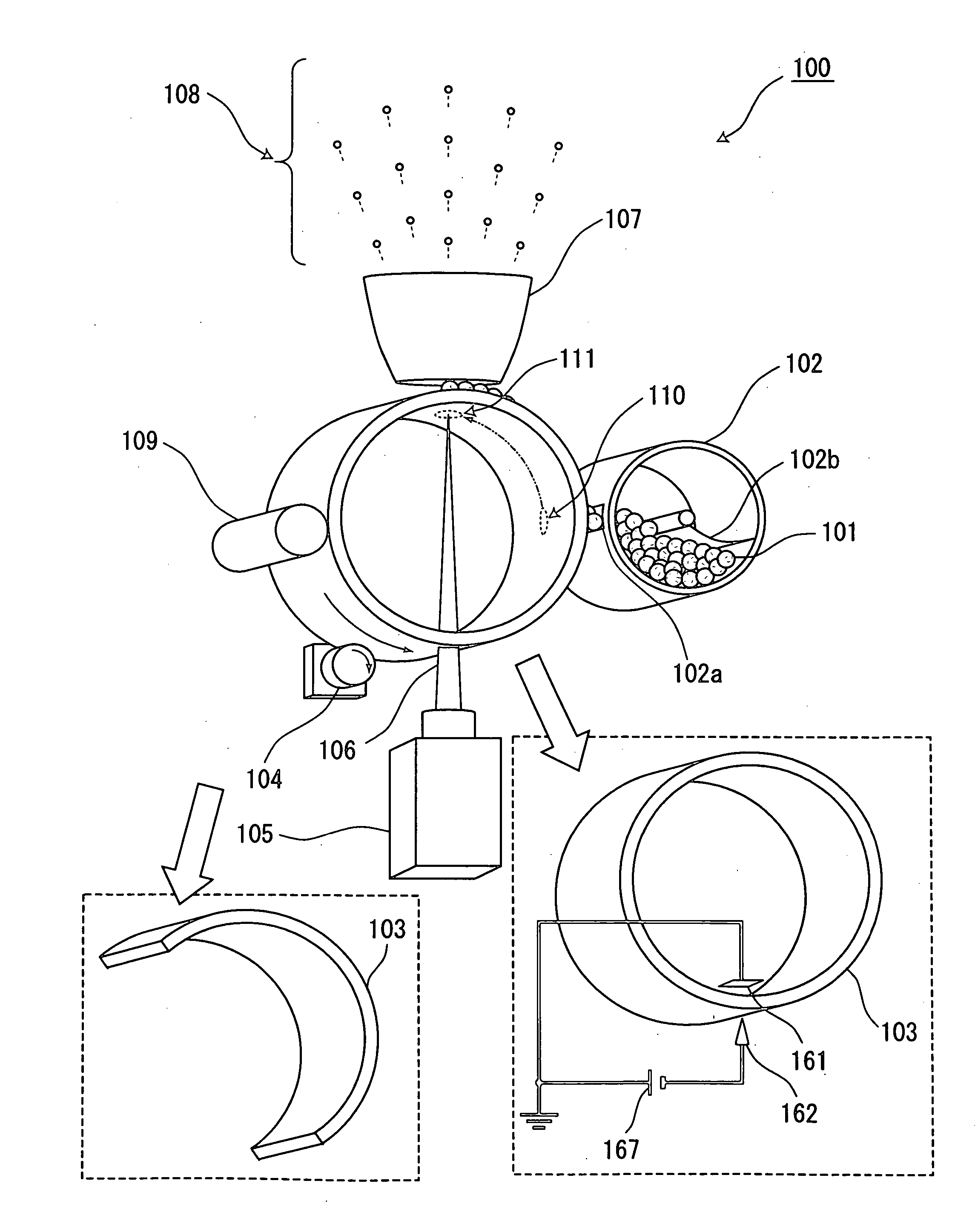

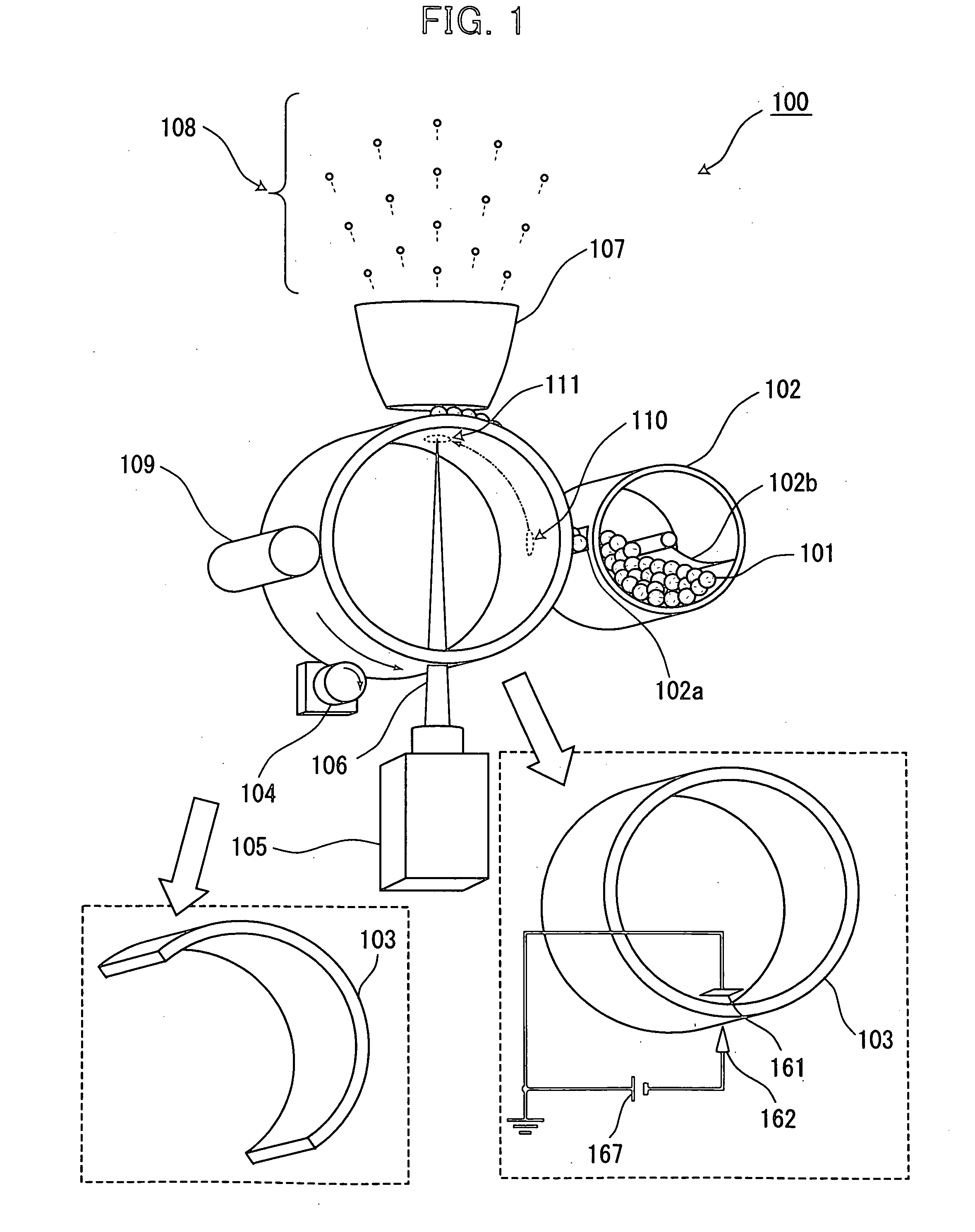

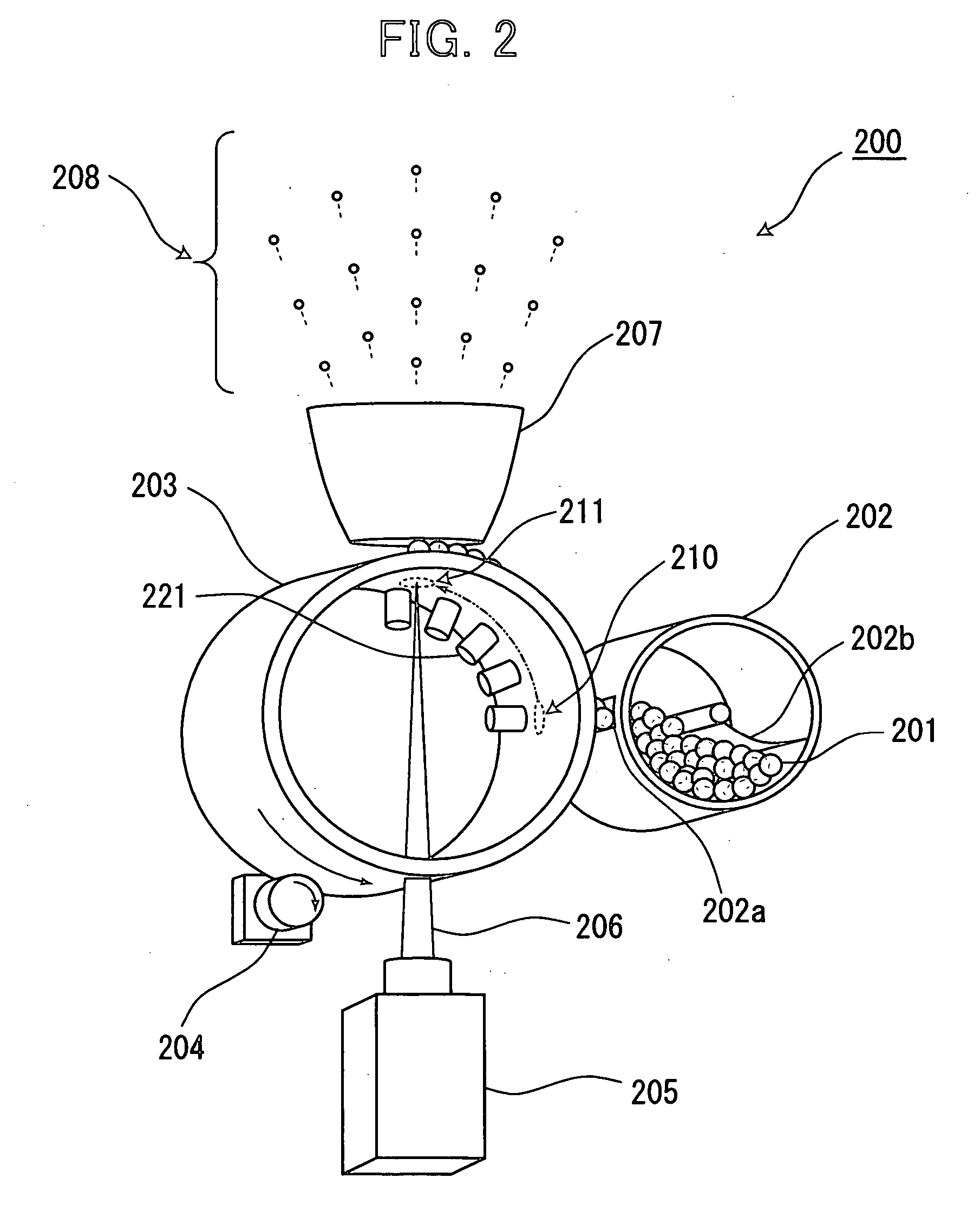

Powder propellant-based space propulsion device

InactiveUS20070044450A1High densityEasy to operateCosmonautic vehiclesCosmonautic partsHigh densityEnergy supply

Disclosed is a powder propellant-based space propulsion device using a powder propellant having high density and excellent handleability. The powder propellant-based space propulsion device comprises a powder-propellant storage container for storing a powder propellant, a powder-propellant attracting surface for attracting the powder propellant thereto through an opening of the powder-propellant storage container and attractively holding the attracted powder propellant thereon, powder-propellant transfer means for transferring the held powder propellant to a release position for releasing the powder propellant, and propulsive-energy supply means for energizing the transferred powder propellant to release the powder propellant from the powder-propellant attracting surface, toward a downstream side thereof as a propulsive jet, while accelerating the powder propellant in a direction approximately perpendicular to the powder-propellant attracting surface at said release position. The powder-propellant transfer means is designed to move the powder-propellant attracting surface in such a manner that a powder-propellant holding area of the powder-propellant attracting surface is returned to a position adjacent to the opening of the powder-propellant storage container in a repetitive manner.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

Preparation method of waste paper nitrocellulose blasting powder

InactiveCN103497076AReduce pollutionSimple processNitrated explosive compositionsCelluloseFirecracker

The invention discloses a preparation method of waste paper nitrocellulose blasting powder, and belongs to the field of production of waste paper nitrocellulose blasting powder. The preparation method sequentially comprises the following steps: removing impurities in waste paper; drying cellulose; carrying out esterification reaction; carrying out invariability treatment; dehydrating; carrying out forming treatment; drying and packaging to obtain a finished product of the waste paper nitrocellulose blasting powder. The preparation method is used for preparing the nitrocellulose blasting powder from waste paper and can be used for preparing the blasting powder which is low in cost, high in energy and less in environment pollution after combustion, and black powder greatly used in the current firework and cracker industry is replaced with the blasting powder, so that the environment pollution caused when fireworks and crackers are set off is greatly relieved, and meanwhile, the entertainment and practicability of the fireworks and crackers set off by people are achieved.

Owner:白雪

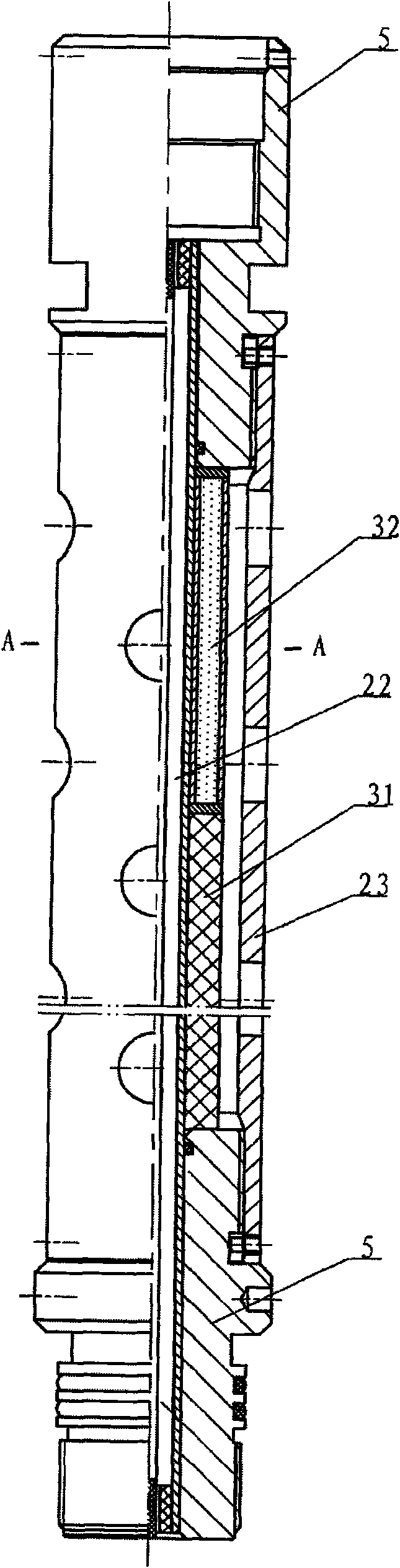

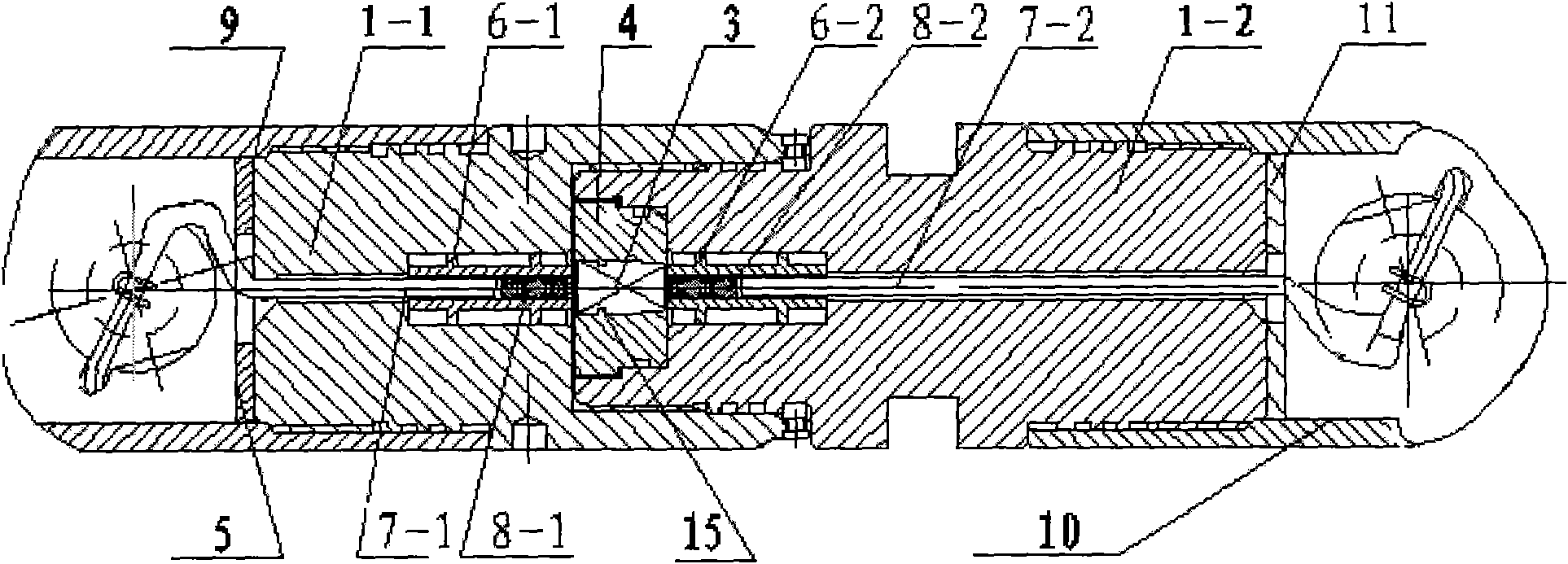

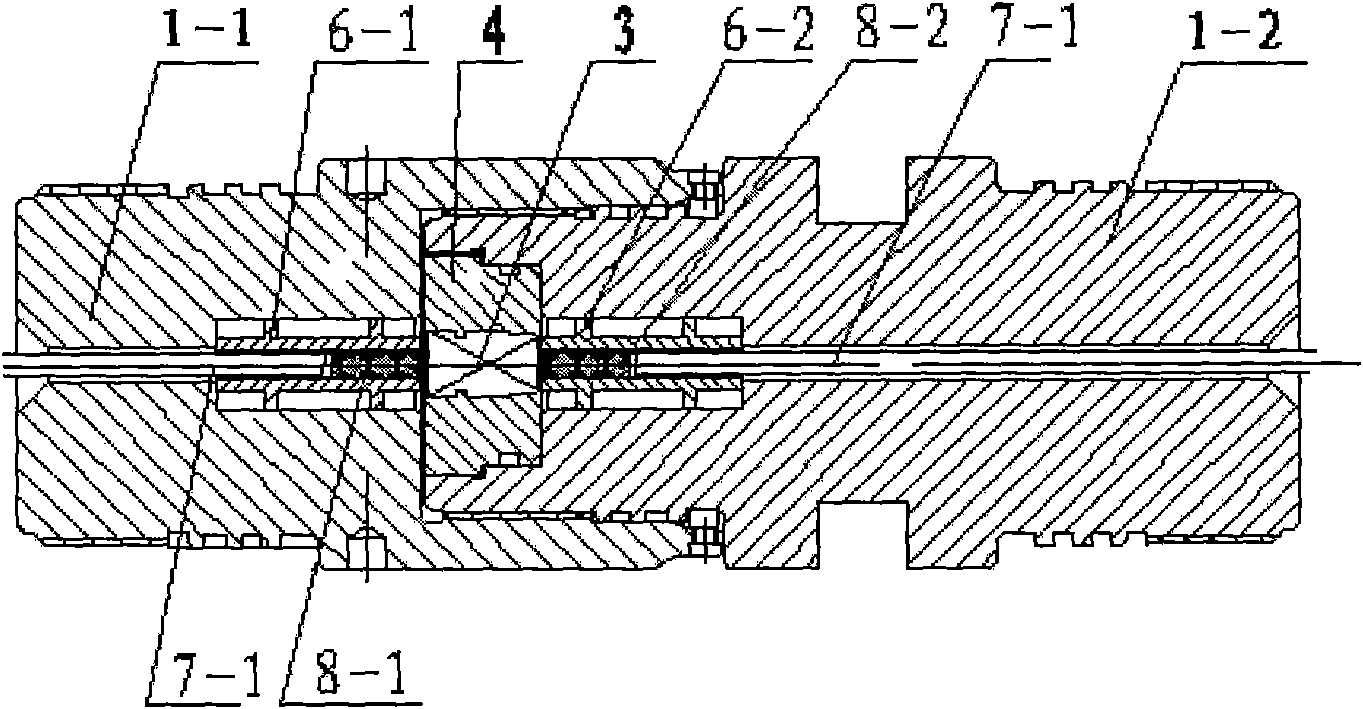

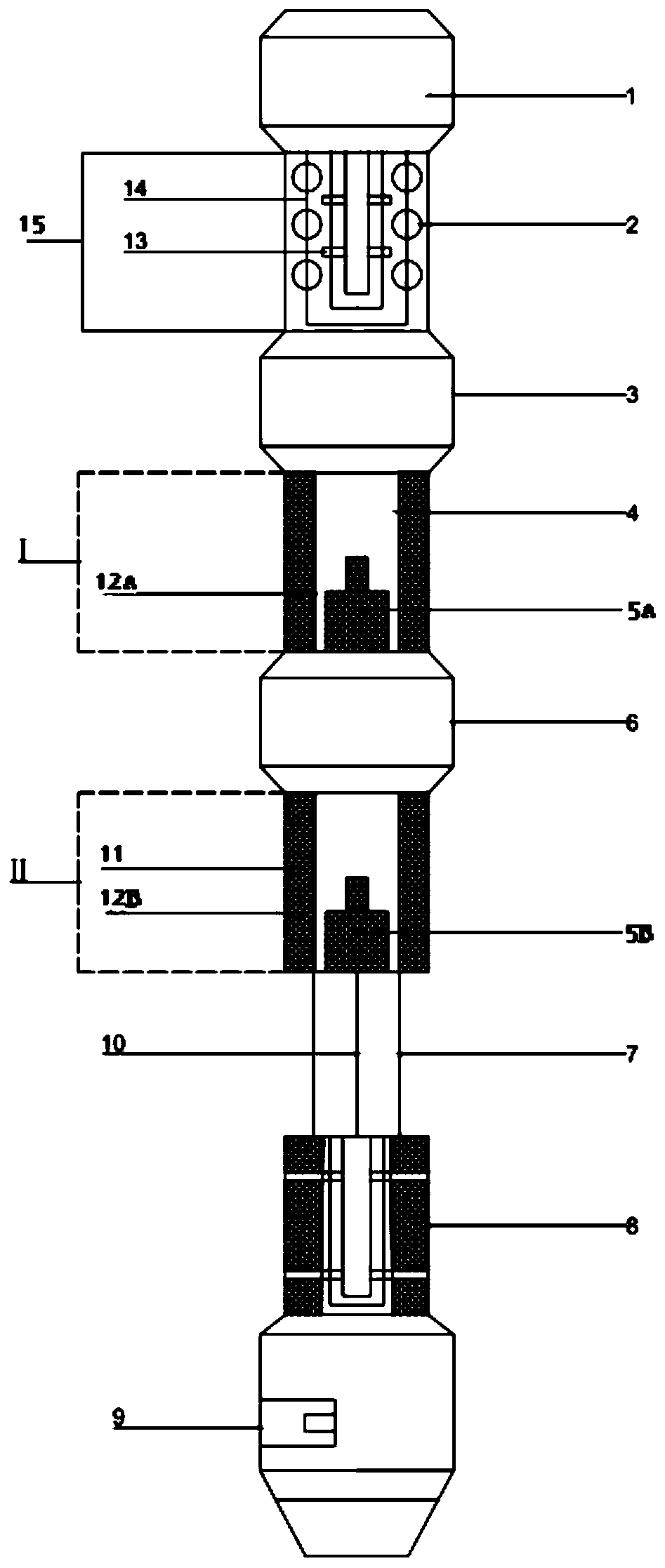

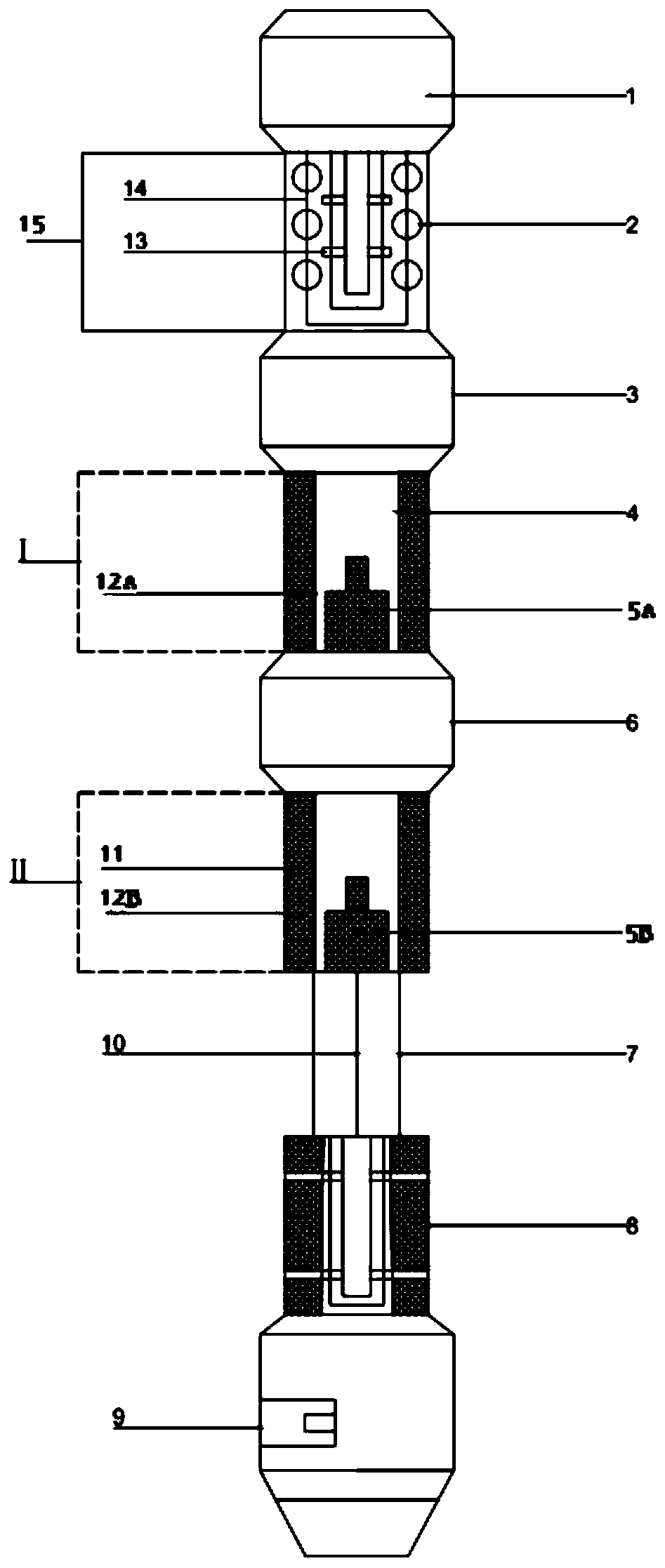

Detonation energization explosion-propagating device for perforating gun string

The invention discloses a detonation energization and transmission device for perforating gun strings, which comprises a body, an energizer, two detonating cords, two detonation tubes and a centralizing ring. The energizer is composed of a tube body, a point The ignition expansion tube formed by gunpowder and the expansion tube. The energizer is located in the middle of the main body and is centered by the centering ring, and the detonator and the detonating cord are on both sides in turn, and are centered by two centering sleeves. When forming a string of perforating guns, the two ends of the body are respectively connected to the upper and lower perforating guns, and the other ends of the two detonating cords are respectively connected to the perforating charges in the corresponding perforating guns. The invention is assembled between every two sections of perforating guns and interlayer guns in the perforating gun string used for oil and gas wells, which solves the problems of reliable perforation of the existing perforating gun string and reliable explosion transmission of the interlayer gun; Insufficient energy of the detonation equipment itself and the loss and attenuation of the detonation wave energy in the transmission process caused incomplete perforation and rework accidents such as gun jamming, which increased the reliability of perforation and improved the performance of perforation completion. security.

Owner:WUHUA ENERGY TECH CO LTD

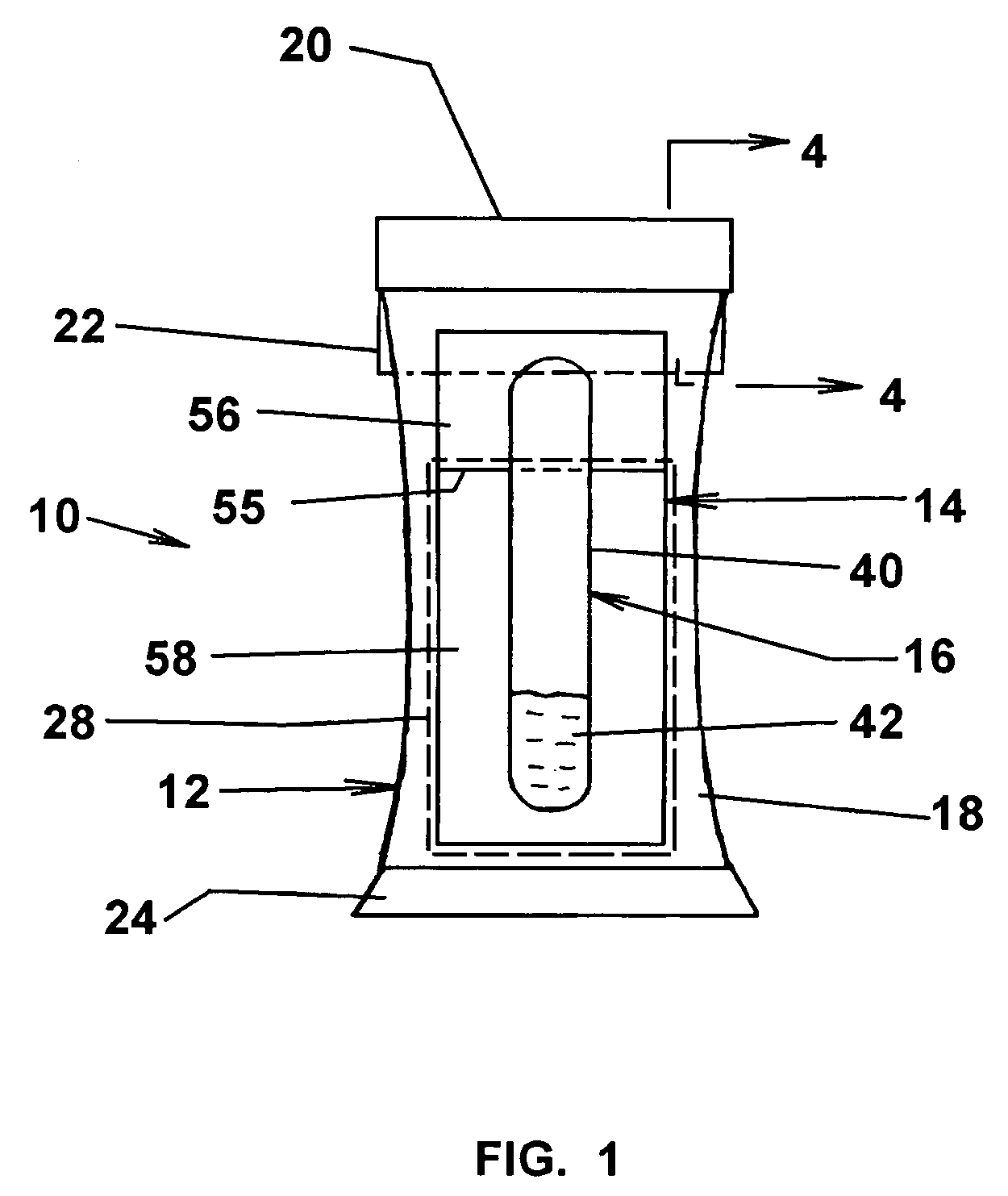

Gunpowder particle test kit

InactiveUS7410612B1Enhancing color differentiationSafe disposalAnalysis using chemical indicatorsFuel testingGunpowderAmpoule

A gunpowder particle test kit for determining gunpowder residue includes a transparent sleeve having a closed end and an open folded end sealed with a clip forming a sealed cavity carrying a test strip and a crushable ampoule carrying a diphenylamine solution. The test strip has an adhesive area on a front surface. An opaque label is provided on a rear surface on the sleeve opposite the adhesive area. In use, the clip is removed to open the cavity, the test strip removed and applied to possible residue areas on a subject. The strip is returned to the cavity; the clip reapplied to seal the cavity. Thereafter, the ampoule is crushed to release the solution, which develops a distinctive coloration observable against the label to indicate the presence of possible gunpowder residue.

Owner:CARRINGTON JOHN H

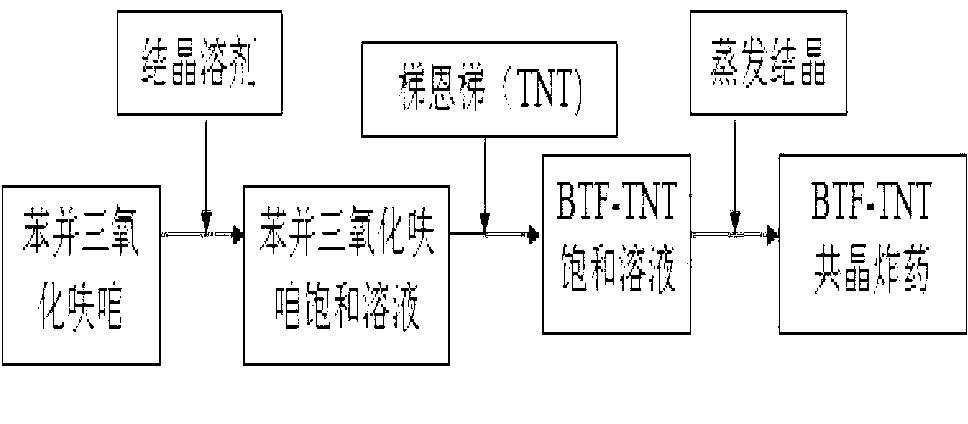

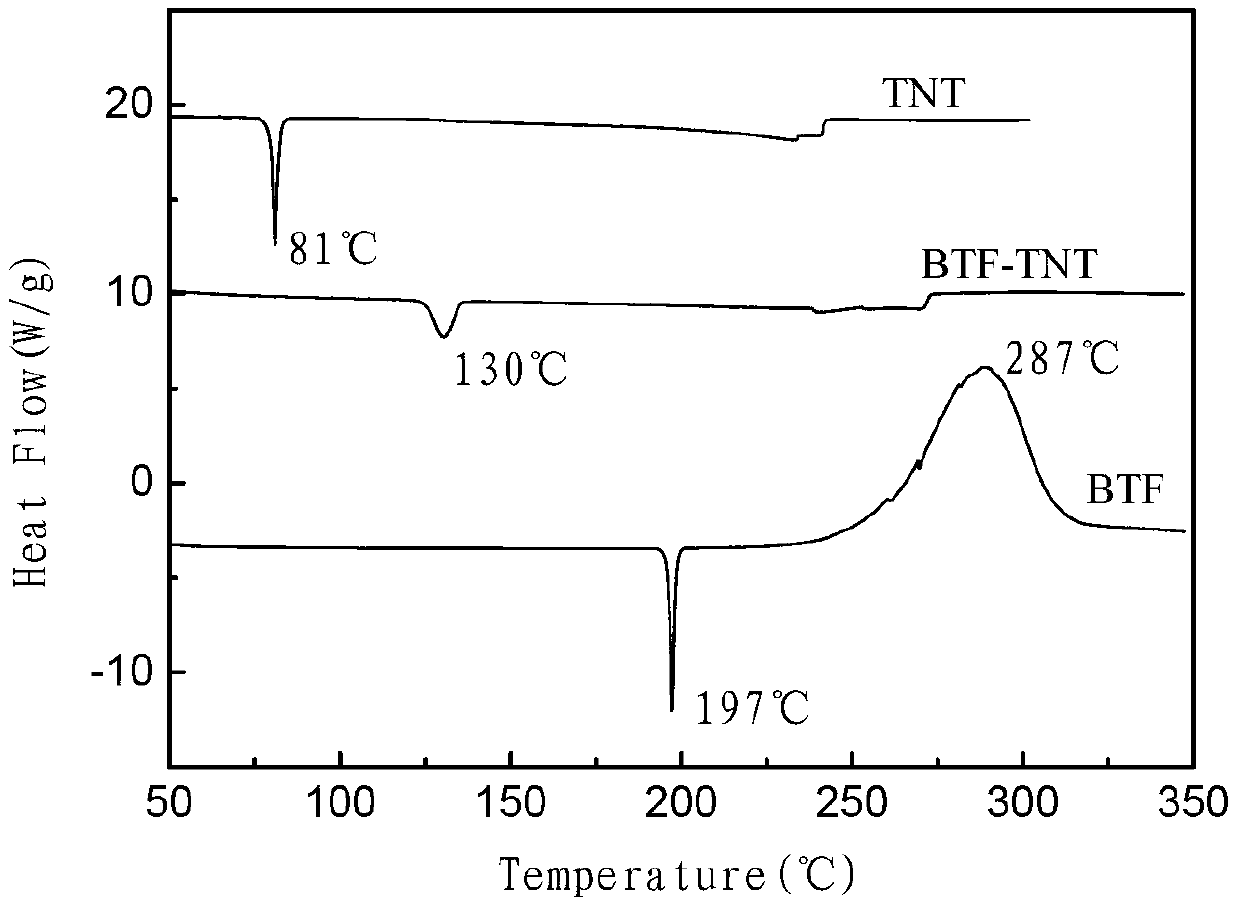

Preparation method of benzotrifuroxan (BTF) and trinitrotoluene (TNT) cocrystallized explosive

ActiveCN102992923AImprove securityImprove detonation performanceNitrated aromatic explosive compositionsBenzeneDetonation

The invention discloses a preparation method of a benzotrifuroxan (BTF) and trinitrotoluene (TNT) cocrystallized explosive. The preparation method comprises the following steps of: (1) preparation of BTF-TNT saturated solution, namely, adding sufficient quantity of BTF to a crystallization solvent, raising the temperature to 20-50 DEG C, dissolving BTF and filtering the solution to obtain the BTF saturated solution; and adding sufficient quantity of TNT to the BTF saturated solution to be dissolved and filtering the solution to obtain the BTF-TNT mixed saturated solution; and (2) preparation of the BTF-TNT cocrystallized explosive: putting the BTF-TNT mixed saturated solution into a beaker, then standing in a constant temperature incubator, evaporating the solvent and drying the product, thus obtaining the BTF-TNT cocrystallized explosive. The preparation method has the beneficial effects that the prepared BTF-TNT cocrystallized explosive has good safety and detonation property and excellent free-flowing property, can serve as the component of explosives, gunpowder and propellants and has better application prospect in high-energy insensitive ammunitions; and the preparation method has the advantages of simple process flow, convenience in operation, mild reaction conditions, good safety and high product quality.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Automatic ignition powder for gas generator of air bag restraint system of automobile and preparation method of automatic ignition powder

ActiveCN105777458AEasy to igniteAppropriate thermal decomposition temperatureNon-explosive/non-thermic compositionsDecompositionRare earth

The invention provides automatic ignition powder for a gas generator of an air bag restraint system of an automobile and a preparation method of the automatic ignition powder.The automatic ignition powder contains fuel, oxidant and flame accelerator; the flame accelerator is rare earth and perovskite type composite metal oxide; the general formula of the flame accelerator is La1-xAxMnO3, wherein A is Ce and / or Cu, and x is greater than zero and less than one.According to the automatic ignition powder, the specific flame accelerator is adopted and can effectively promote a redox reaction in the powder, thereby thermal decomposition of the automatic ignition powder is promoted, the decomposition temperature of the powder is lowered, and automatic ignition performance of the powder is improved.

Owner:BYD CO LTD

Smokeless cylinder for muzzle-loading revolver

InactiveUS20050016050A1Relieve stressAccurately indexedFiring/trigger mechanismsPistolsModem deviceEngineering

A replacement cylinder that enables the use of modem smokeless gunpowder in a black powder muzzle-loading revolver is provided. The cylinder includes a main cylinder body and a removable cylinder cap. The main cylinder body includes a number of chambers, each of which having a projectile portion, a propellant portion and a primer portion. The cylinder cap includes a number of captured firing pins positioned therein. During operation, the cylinder cap is allowed to axially translate relative to the main cylinder body. A method of muzzle-loading the cylinder of the invention using modern smokeless gunpowder and a primer is also provided and is facilitated by the provision of a loading plate.

Owner:HOWELL JR KENNETH P

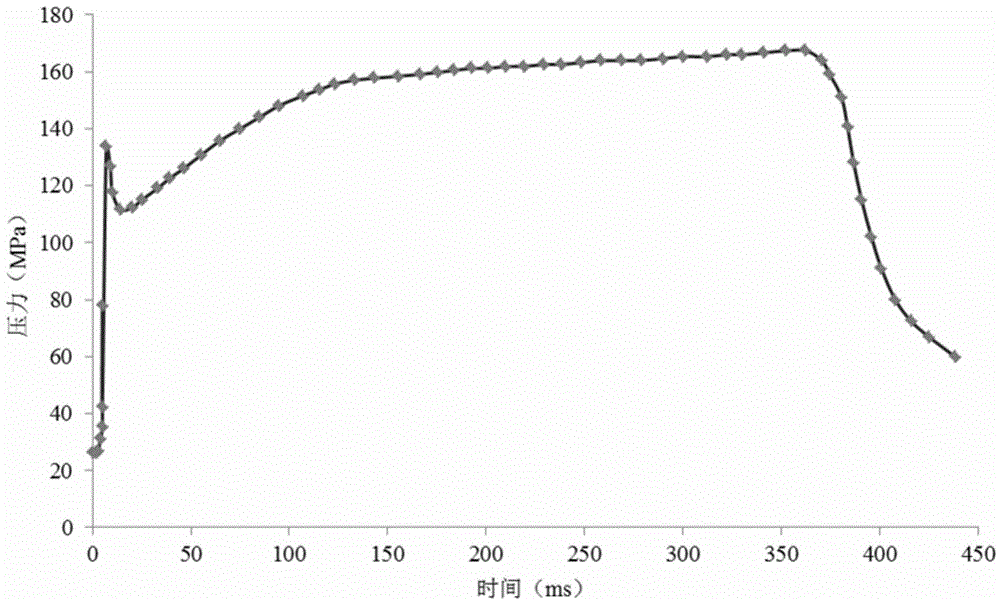

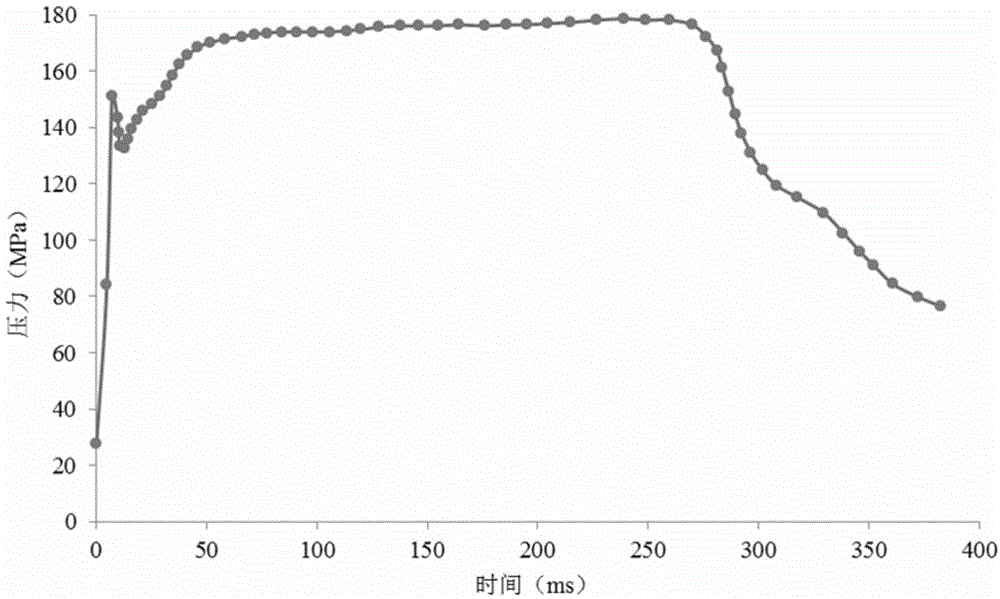

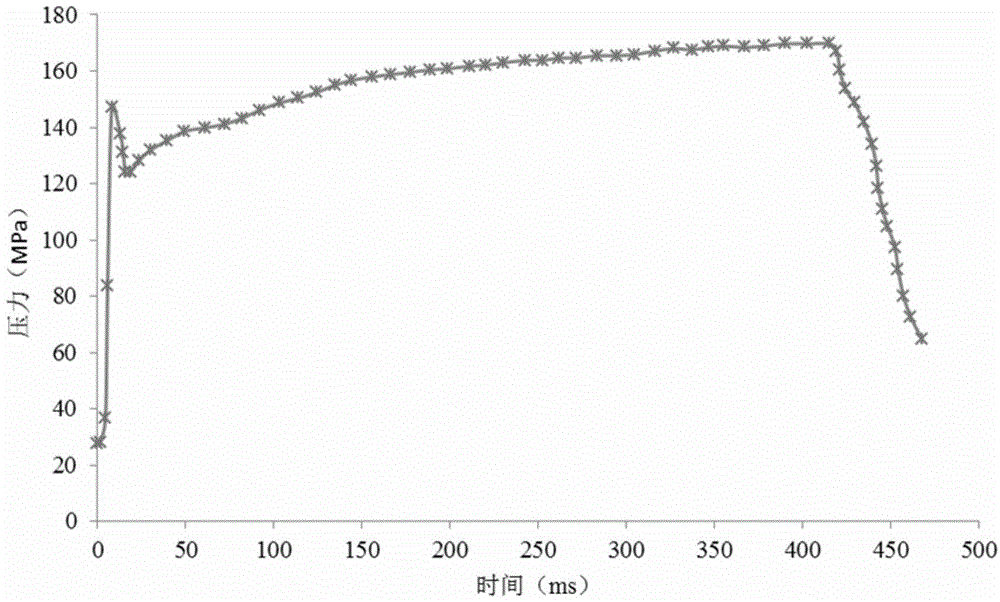

Gunpowder for realizing deep well deep bumming and fracturing

InactiveCN104402659AStable burning rateReduce burning rateExplosivesPtru catalystUltra high pressure

The invention discloses gunpowder for realizing deep well deep bumming and fracturing, the gunpowder includes solid powder and liquid powder; the solid powder comprises a binder, a plasticizer, an oxidizing agent, a metal combustion agent, a high-energy additive, a stabilizer and a catalyst; and the liquid powder comprises an oxidizing agent, a combustion agent, a performance modifier and water. The solid powder of the gunpowder can overcome the restriction of large stress difference coefficient and high fracturing pressure of deep-layer and ultra high pressure formation, a plurality of radial cracks and branched cracks are formed in a broken rock layer, main crack is preliminarily extended, the fracture pressure is reduced to help the liquid powder to continue to fracture the formation, at the same time, the role of ignition of the liquid powder is played, after the solid powder is burn out, the liquid powder continues to maintain a high pressure environment in a wellhole, and effects on the formation for longer time, the main crack length is further extended, the branched cracks are developed, natural cracks are communicated, and a complex fracture network structure is formed in a larger-range purpose layer near the wellbore.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

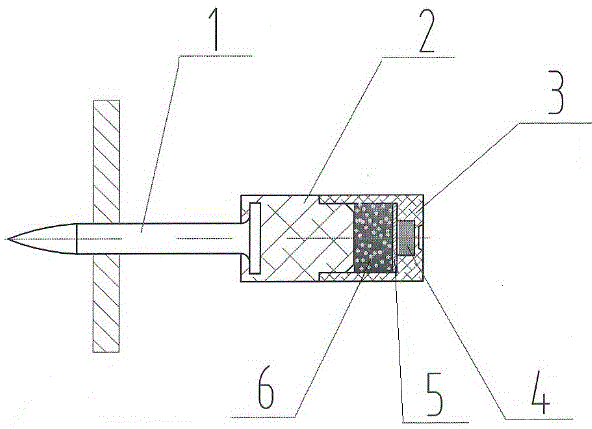

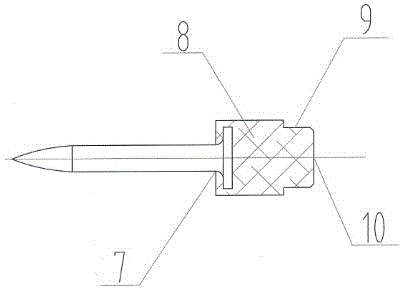

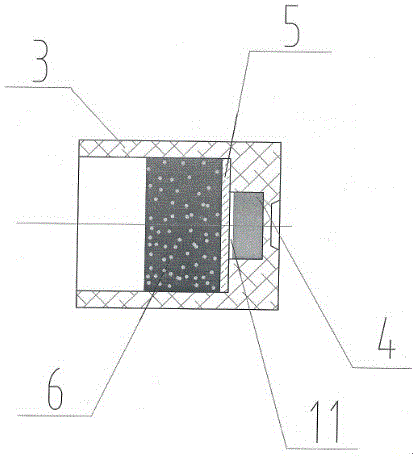

Plastic shell gunpowder fixing propelling system and fastener and machining process thereof

The invention discloses a plastic shell gunpowder fixing propelling system and a fastener and a machining process thereof and belongs to the field of fastener fastening instruments. The system comprises a gunpowder charging bin. A gun propellant hole is formed in one end of the gunpowder charging bin, the other end of the gunpowder charging bin is a primer end, and a powder load gun propellant is arranged in the gun propellant hole. A primer mixture hole is formed in the bottom of the gun propellant hole and a powder load primer mixture is arranged in the primer mixture hole. An anti-explosion gap is reserved between the powder load gun propellant and the powder load primer mixture. A stepped hole is formed by the gun propellant hole and the primer mixture hole and the gun propellant hole is larger than the primer mixture hole. Quality accidents caused by the reduction of the firing rate of a shell-free powder load due to the fact that the shell-free powder load is exposed outside and absorbs moisture are effectively avoided, safety accidents of explosion, caused by various factors such as collision, high temperature and open fire, of the shell-free powder load can be avoided as well, and meanwhile through the arrangement of the gun propellant and the primer mixture, it can be guaranteed that the powder load is effectively triggered, and the high firing rate is guaranteed.

Owner:NANXI NANSHAN EQUIP MFG +1

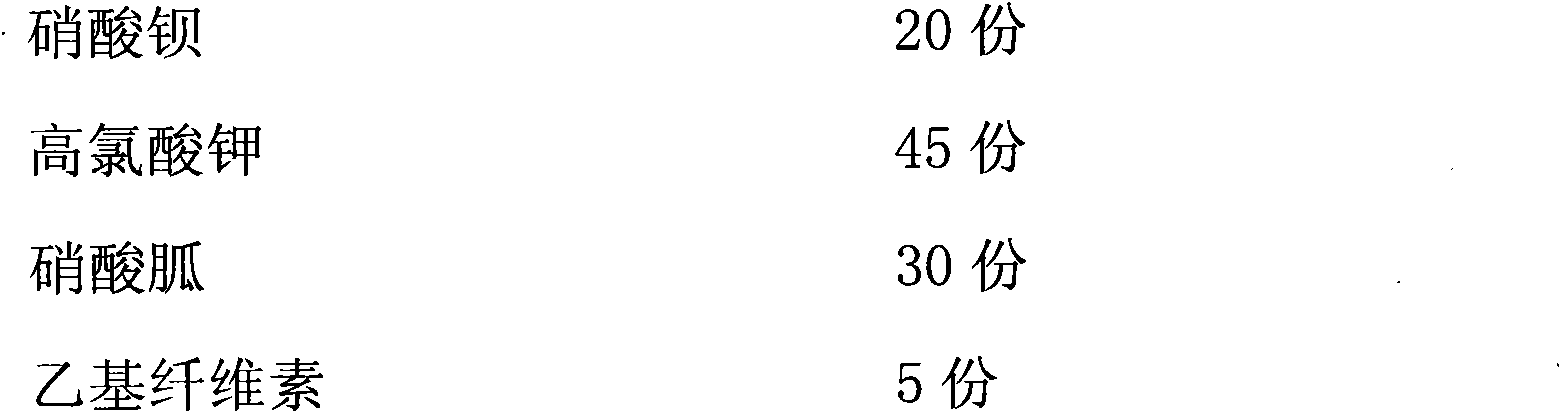

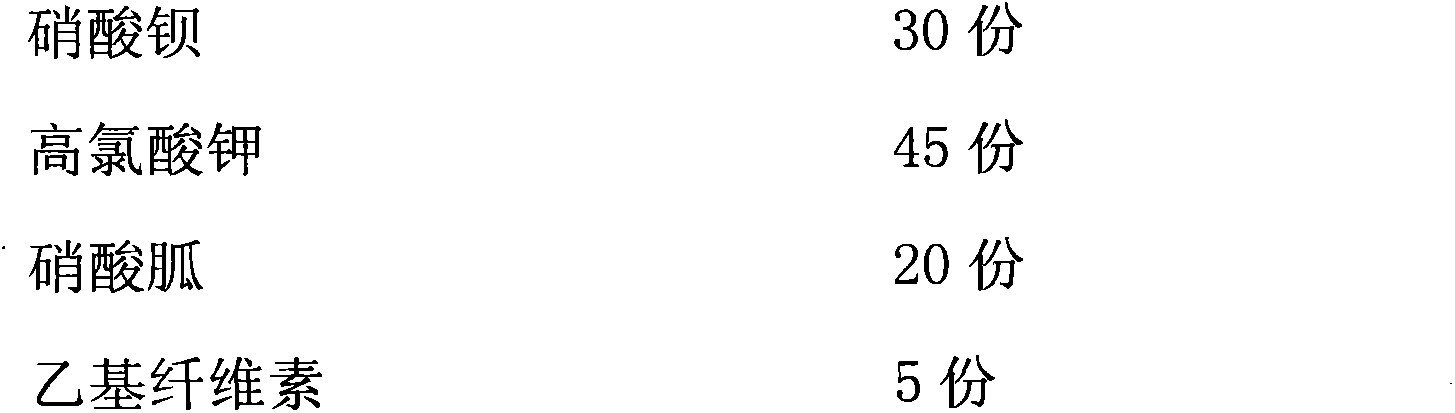

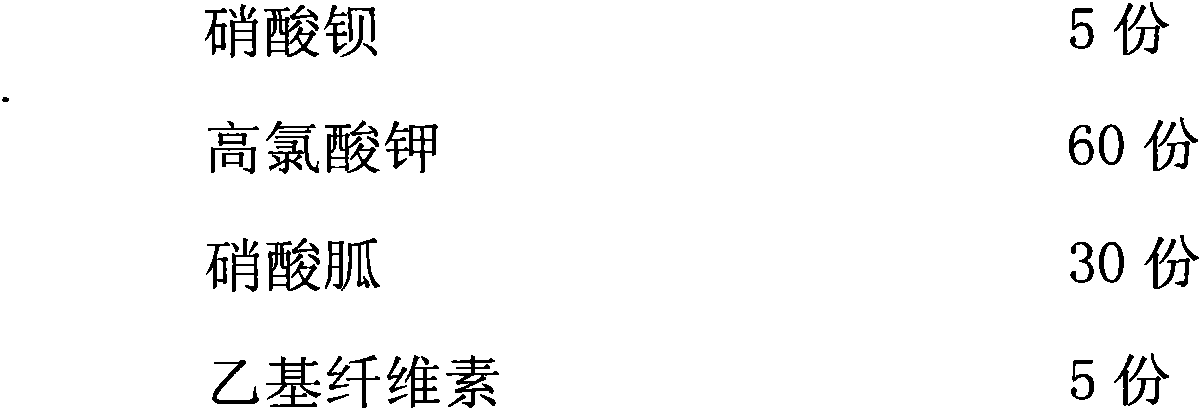

Formula of gunpowder for timing firing cable of display shell

InactiveCN102249824ASafe storagePromote safe productionInorganic oxygen-halogen salt explosive compositionsNon-explosive/non-thermic compositionsPotassium nitrateCombustion

The invention relates to a formula of gunpowder for a timing firing cable of a display shell. According to the invention, because in the formula provided by the invention, potassium perchlorate is used as a main component, thereby completely avoiding the use of a high-risk potassium nitrate product and effectively reducing the generation of risk accidents caused by a firing cable; barium nitrate in the components has combustion and speed regulation effects, so that the combustion speed of the firing cable meets the timing ignition requirement of the display shell, thereby effectively achieving the timing effect; and the combustion color of the firing cable is golden or silvery through using larch carbon powder, a yellow light agent or titanium sponge in the components.

Owner:徐敏

A non-priming charge detonator

The invention relates to the structure, charge and production process of a non-priming charge detonator. The invented non-priming charge detonator includes two types of instant detonators, electric igniter tip and non-electric plastic nonel, and a millisecond delay detonator with a lead core delay body. It stimulates the combustion of gunpowder in the steel pipe to generate high-pressure gas, which acts on the high explosive to make it burn in the steel pipe and develop into a high-speed detonation at the bottom of the steel pipe, thereby making a non-priming detonator. The design is optimized for reliable operation and simple fabrication.

Owner:ANHUI UNIV OF SCI & TECH

Multi-pulse combined fracturing device for perforation of coalbed methane reservoir

PendingCN109915080AOrderly and rapid extensionAchieve security isolationFluid removalEngineeringDeflagration

The invention relates to a multi-pulse combined fracturing device for perforation of coalbed methane reservoir, comprising a percussion initiator; the lower part of the percussion initiator is connected with a perforating barrel; the perforating barrel is internally provided with a frame type ammunition rack, and perforating bullets are loaded on the frame type ammunition rack; the perforating bullets are isolated from low-explosive-velocity liquid explosive by means of capsules, so that the low-explosive-velocity liquid explosive can be safely detonated; the lower part of the composite perforator is connected with a detonation convertor, the lower part of the detonation convertor is connected with a first-stage propulsion device, a central aluminum pipe is positioned in the center of thefirst-stage propulsion device, the lower part of the central aluminum pipe is connected with a delay ignition device, and the lower part of the delay ignition device is connected with a second-stage propulsion device; when the temperature of the outer wall of the central aluminum pipe reaches the ignition point of a propellant, a great deal of high-temperature and high-pressure gas produced by thepropellant acts on the coalbeds in a pulse loading way, thus enabling cracks to rapidly extend; the lower part of the second-stage propulsion device is connected with a connecting rod, a detonating cord is arranged in the connecting rod, the lower part of the connecting rod is connected with a perforator, and the perforator is connected with a pressure measurement tail plug, so that the deflagration pressure change of gunpowder in a fracturing process is reflected; the multi-pulse combined fracturing device has the advantages of treating the multiple coalbeds at a time, and being high in energy utilization rate and cost-saving.

Owner:XI'AN PETROLEUM UNIVERSITY

Automatic simulated dummy projectile launching system

ActiveCN107084640AEasy to useLong-term useAmmunition projectilesTraining ammunitionBlast effectsStructural engineering

The invention provides an automatic simulated dummy projectile launching system. The problems that in the conventional simulation actual combat training process, the blast effect of blasting ammunition in the close combat is difficultly simulated in a vivid manner, and the death cannot be avoided are solved, and the problem that the non-gunpowder means is adopted to motivate a fuse so that the simulated dummy projectile is launched is solved; according to the technical scheme, the automatic simulated dummy projectile launching system comprises a canister launcher, a canister launcher control device and the simulated dummy projectile used for being loaded in the canister launcher; the simulated dummy projectile comprises a bomb body shell, a bomb core and a fuse structure at the bottom of a projectile body; the side wall of a canister launcher air cylinder is provided with an air guide hole used for communicating an air cylinder inner cavity with a canister launcher inner cavity, the lower portion of the air cylinder is connected with a high-pressure air storage tank through an air guide pipe and a normally-closed electromagnetic valve, through automatic identification of a target, cooperative control over launching of the percussion fuse is achieved, the projectile body is launched, exploding is simulated, in the launching process, the dangerous hidden dangers brought by gunpowder launching are completely avoided, operation is easy, and the system is safe, reliable, simple in structure and suitable for civil production manufacturing.

Owner:SHENYANG DANGLANG TECH DEV CO LTD

Fireworks and crackers blasting-agent composition

The invention discloses a fireworks and crackers blasting-agent composition. Agents in the fireworks and crackers blasting-agent composition include, by weight, 40%-60% of potassium perchlorate, 15%-30% of potassium acid phthalate, 10%-20% of a metal-filled multi-walled carbon nanotube, 5%-10% of metal oxide and 3%-5% of black powder, the multi-walled carbon nanotube is filled with one or more combinations of metals of aluminum, silver, iron, nickel, potassium, magnesium, lithium, sodium and the like, and the metal oxide is one or more combinations of ferroferric oxide, iron sesquioxide, copper oxide, manganese oxide, zinc oxide, cobalt oxide and aluminum oxide. The fireworks and crackers blasting composition agents free from metal powder are obviously improved in security coefficient, the explosion dynamics of the agents is high, burning rate of bright points is high, shelf life is long and blasting effect is good.

Owner:WANZAI JIANKUN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com