Patents

Literature

395 results about "Deflagration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deflagration (Lat: de + flagrare, "to burn down") is subsonic combustion propagating through heat transfer; hot burning material heats the next layer of cold material and ignites it. Most "fires" found in daily life, from flames to explosions such as that of black powder, are deflagrations. This differs from detonation, which propagates supersonically through shock waves, decomposing a substance extremely quickly.

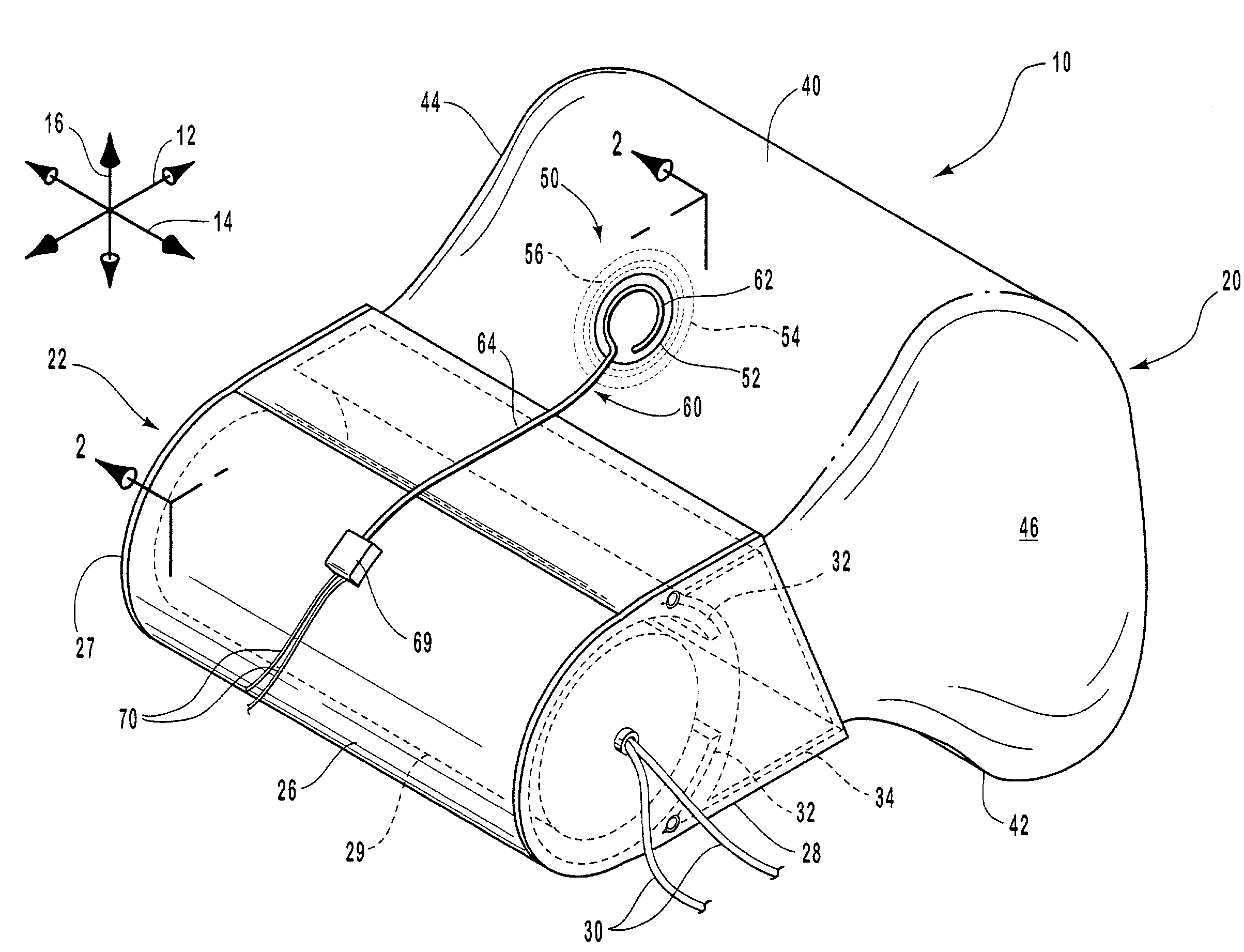

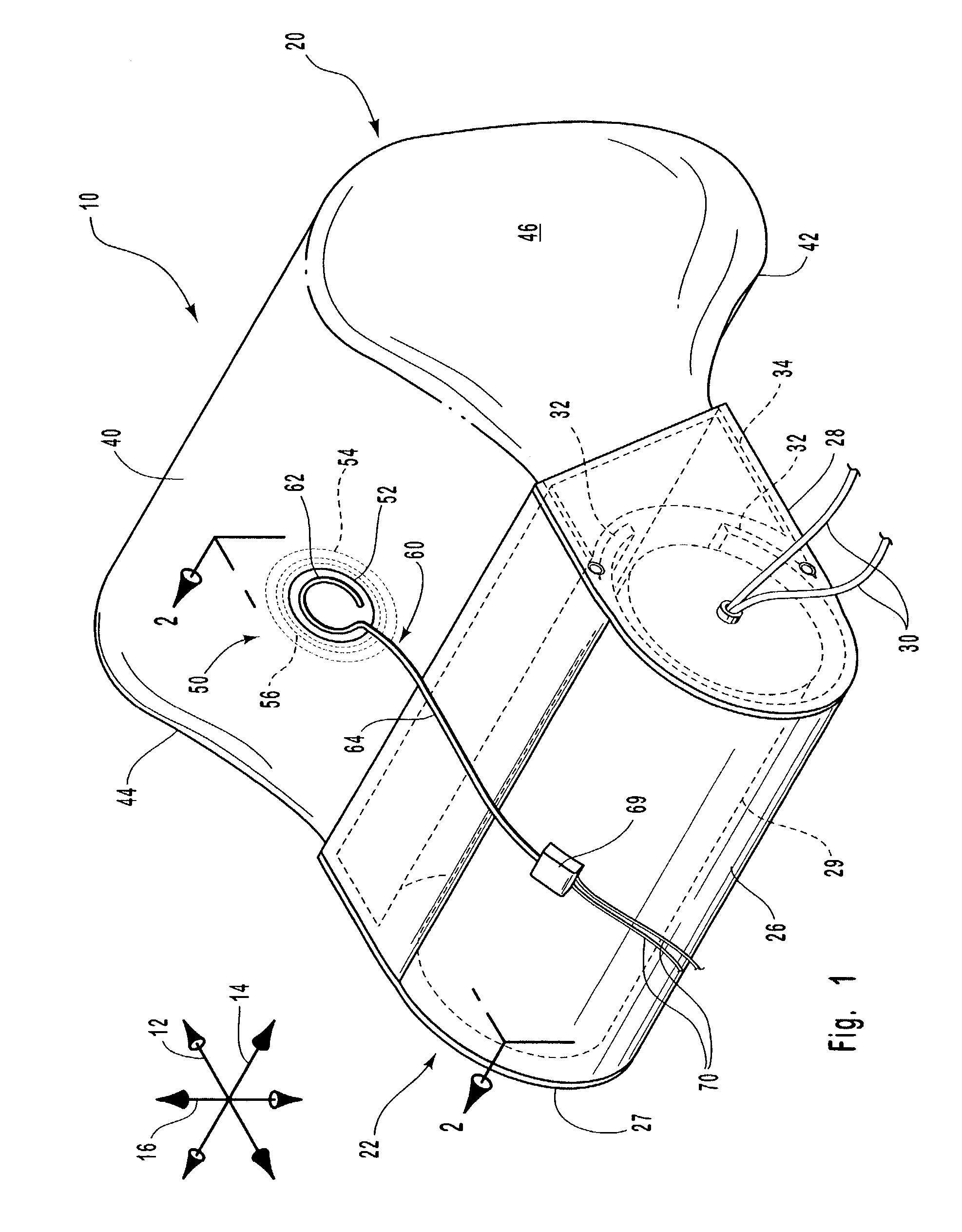

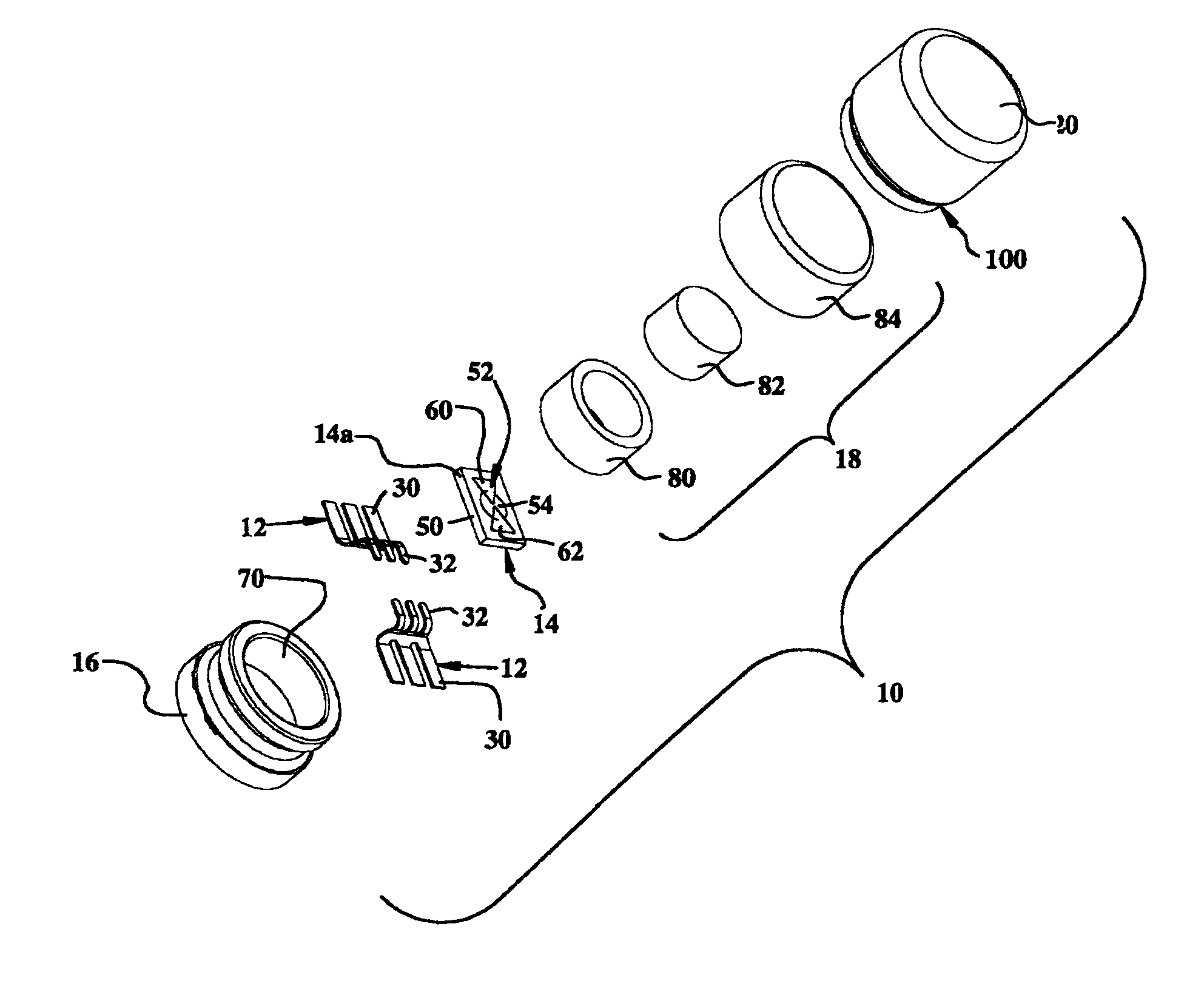

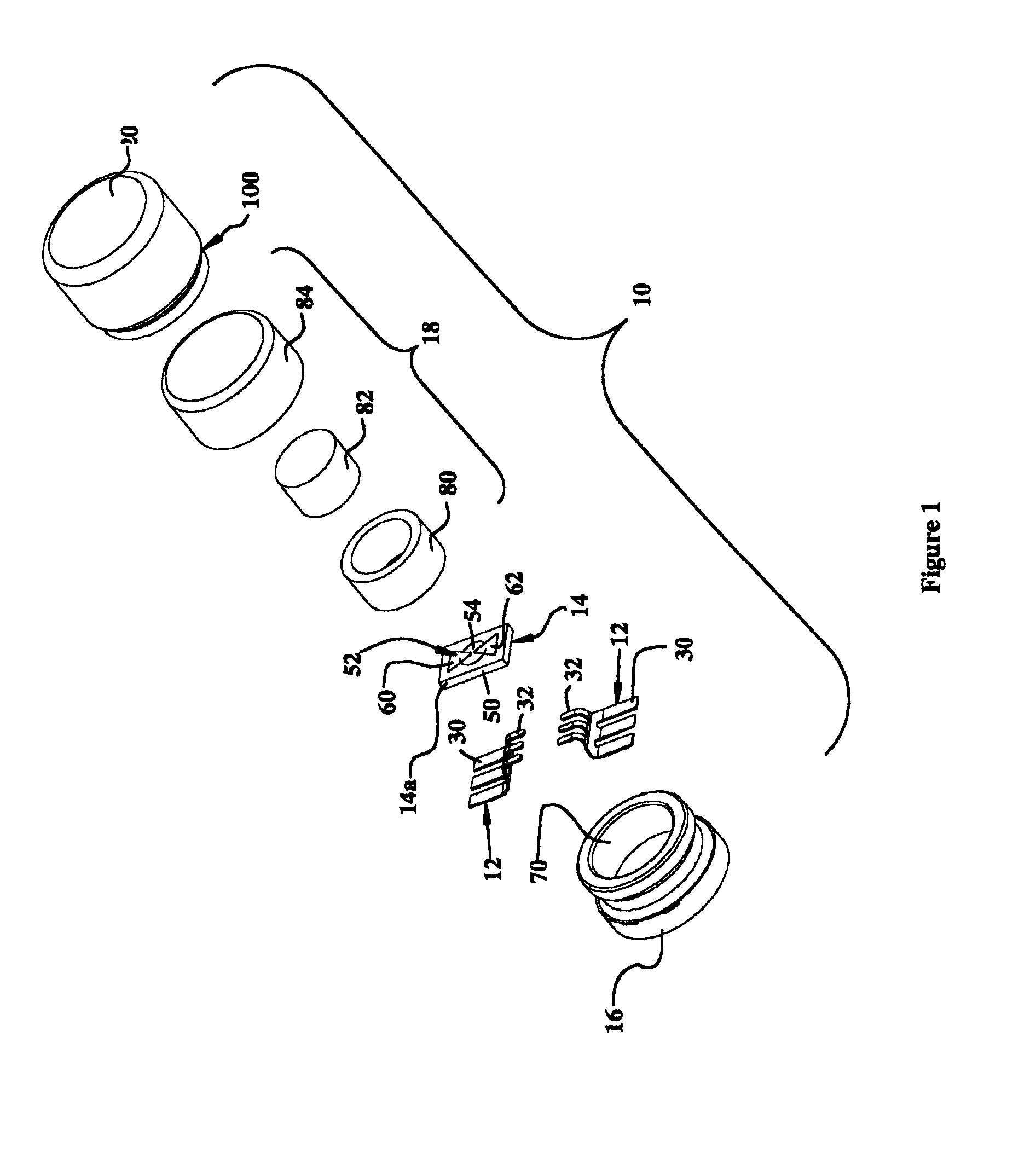

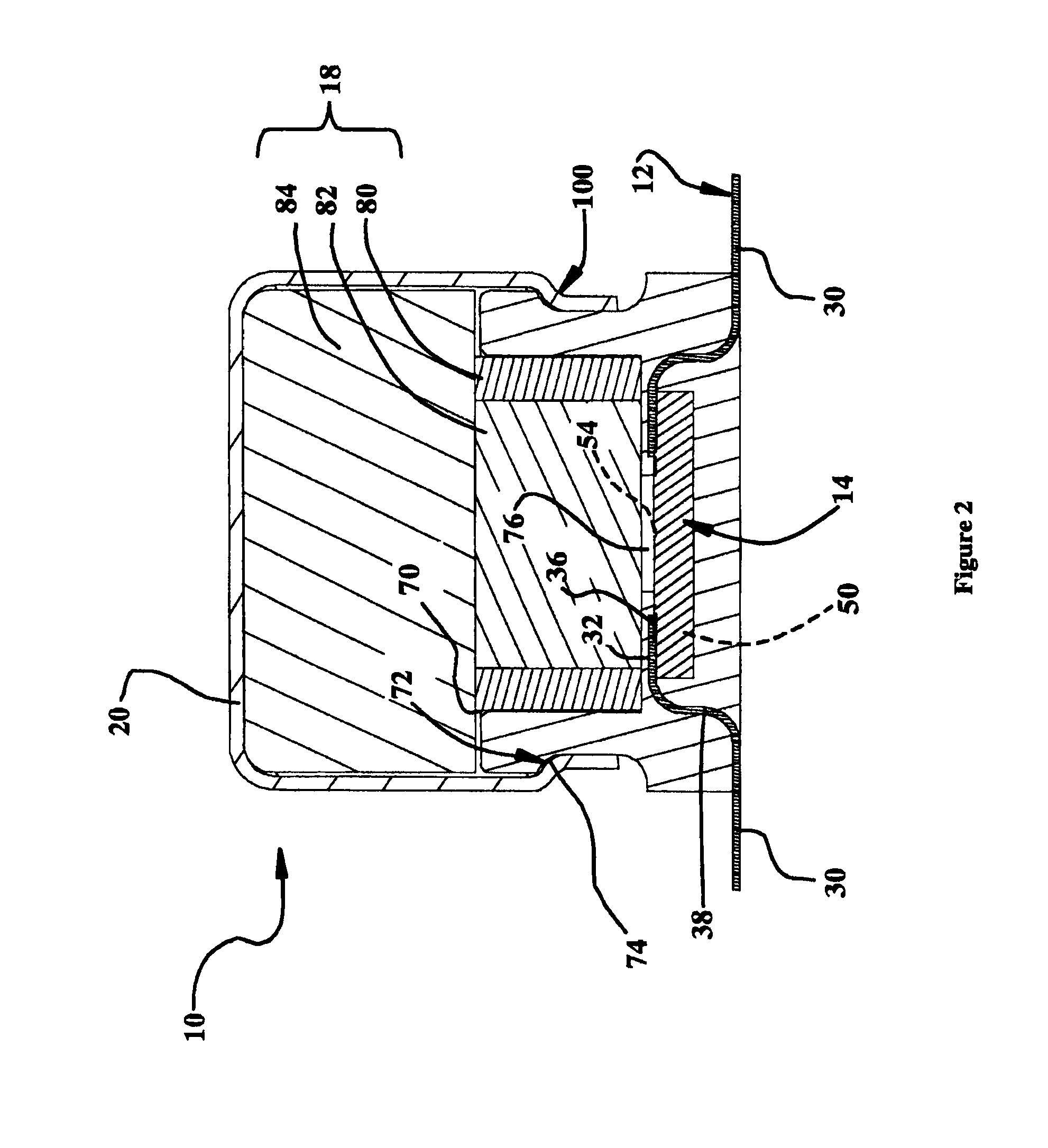

Active venting apparatus and method for airbag systems

InactiveUS6971671B2Rapidly stiffnessReduce stiffnessPedestrian/occupant safety arrangementAmmunition storageImpact velocityEngineering

Enhanced airbag modules and associated methods are provided. An airbag module according to the invention may have a cushion with a venting portion. During normal vehicle operation, the venting portion may be closed so that inflation gas is not permitted to flow through the venting portion. A pyrotechnic may be ignited to open the venting portion when venting is desired. The pyrotechnic may be directly attached to the venting portion to burn through or mechanically rupture the venting portion, thereby forming an exit port. Alternatively, the venting portion may have a flap that can be detached from the housing by ignition of a pyrotechnic to permit venting through an exit port of the housing. The pyrotechnic may then be disposed within a fastener designed to fracture upon ignition of the pyrotechnic to release the flap from attachment to the housing. The pyrotechnic may, for example, be an initiator or rapid deflagration cord (RDC). The cushion may thus be more stiffly inflated for a high velocity collision, or less stiffly inflated in the case of a lower impact velocity or an out-of-position occupant.

Owner:AUTOLIV ASP INC

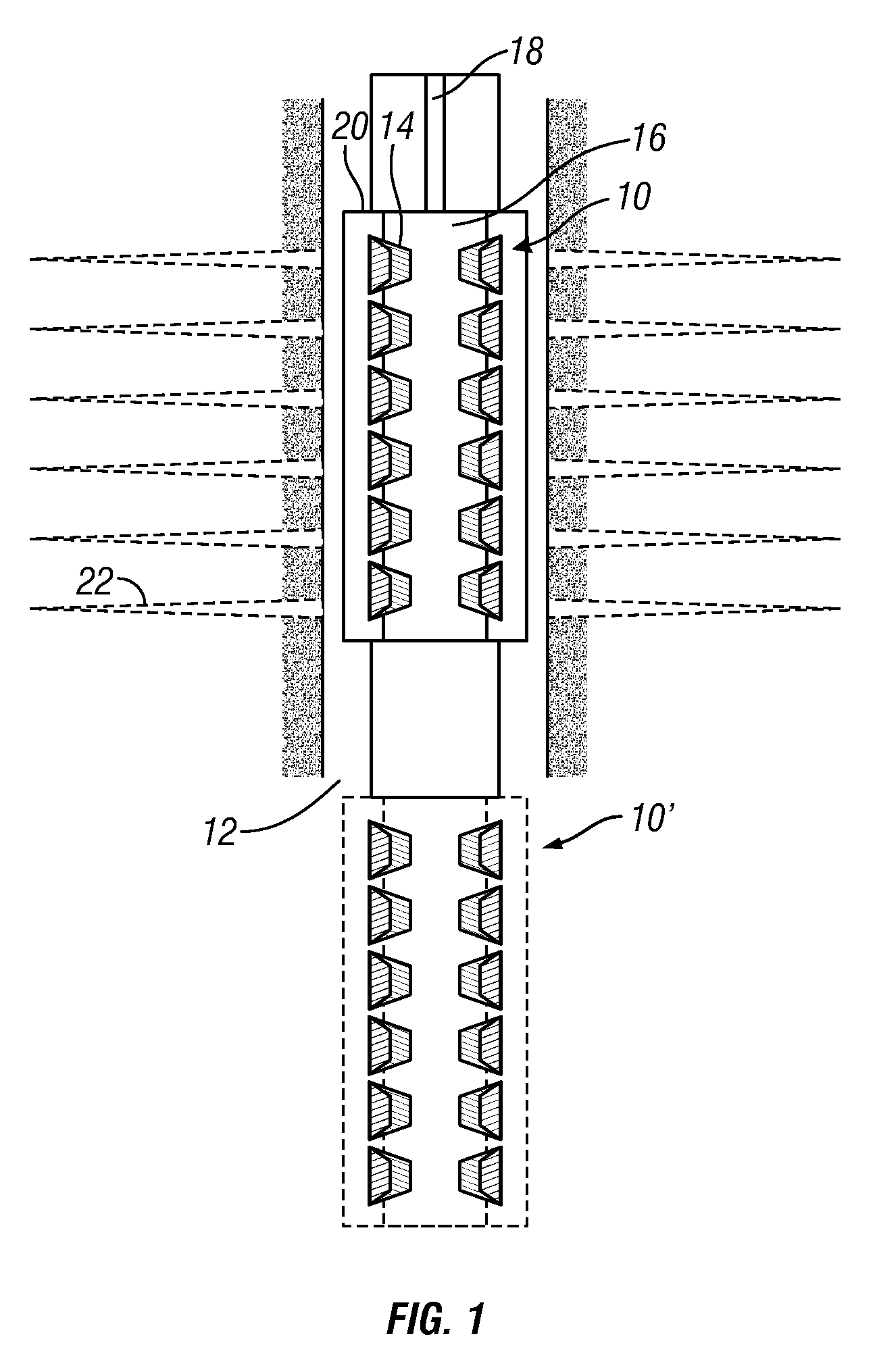

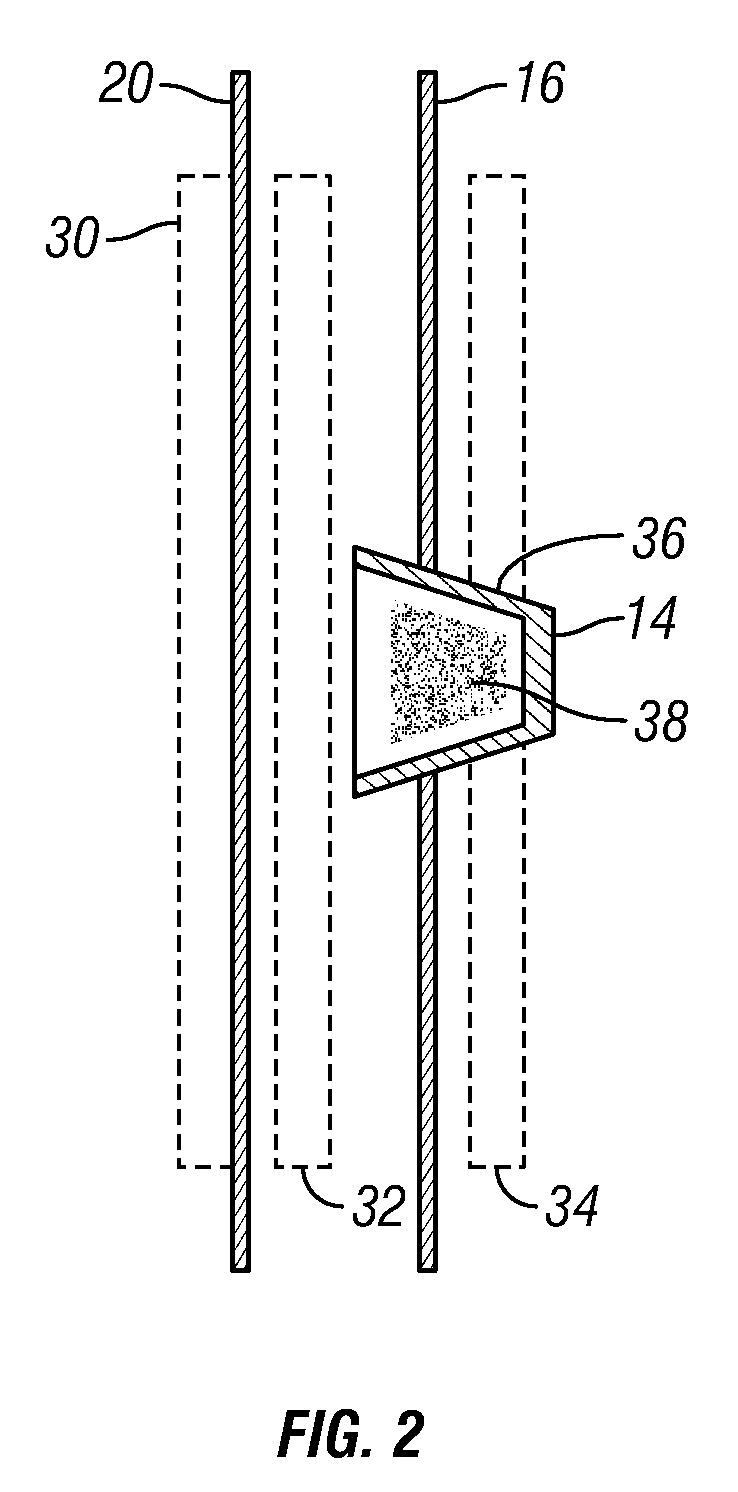

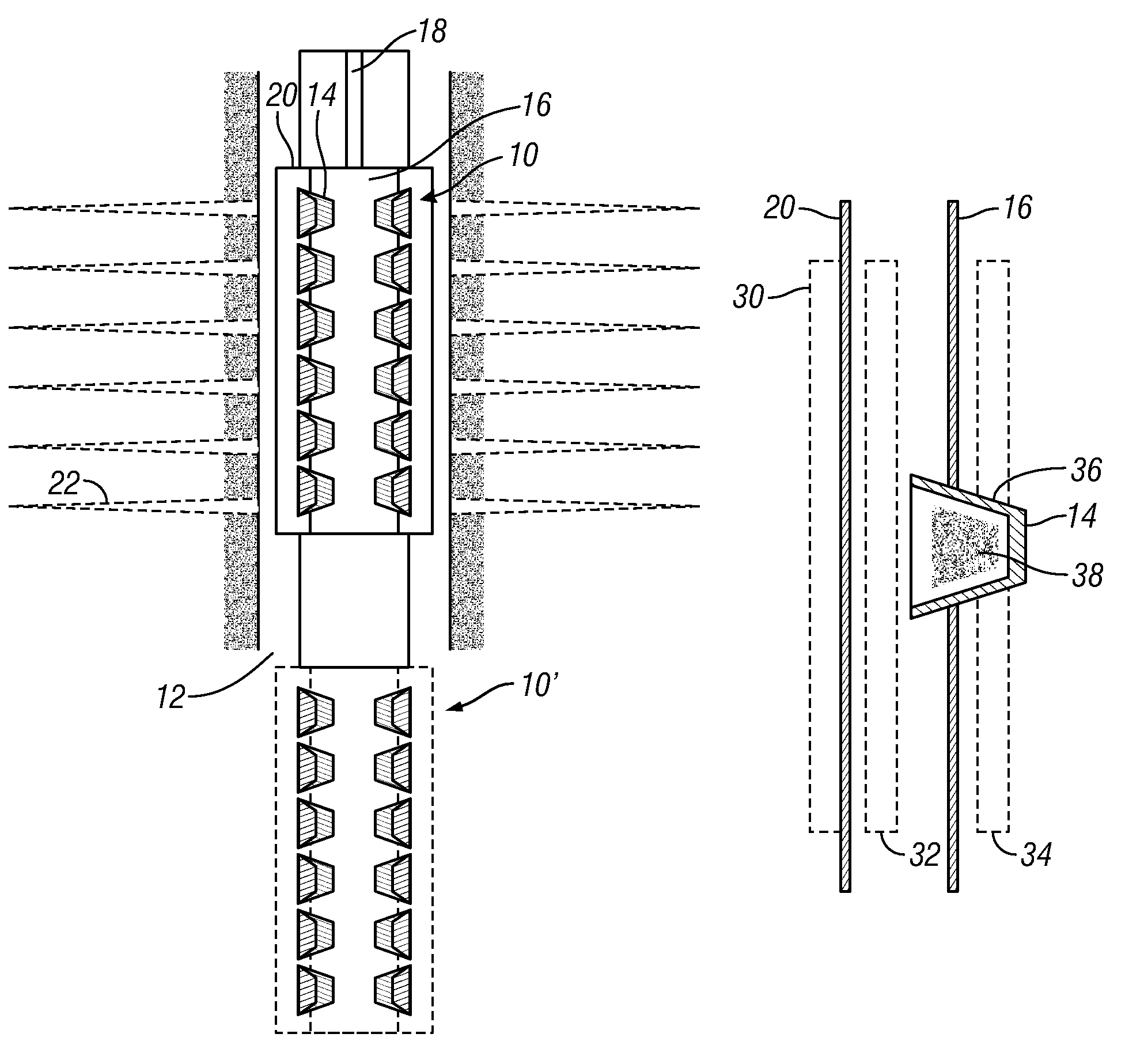

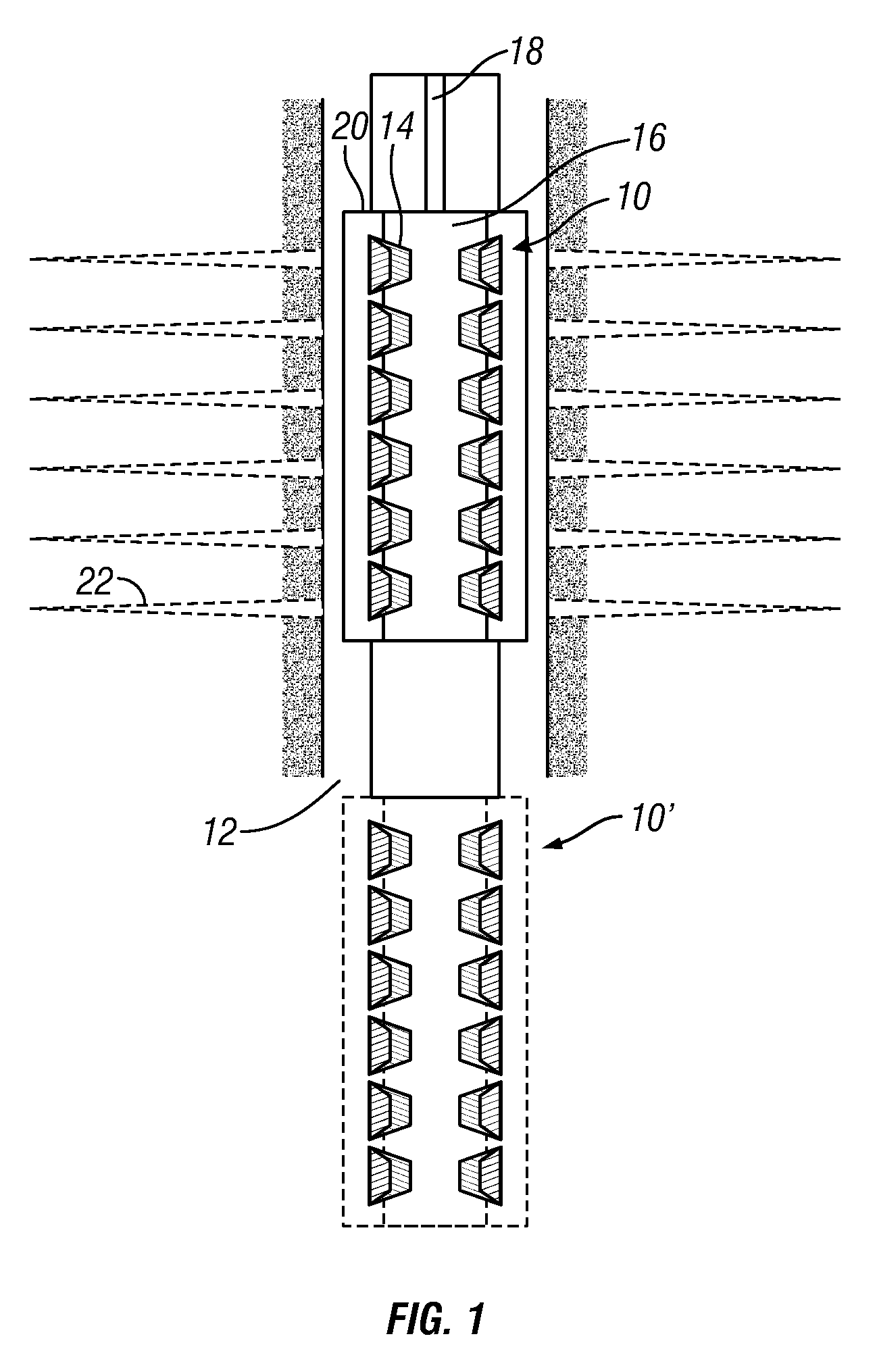

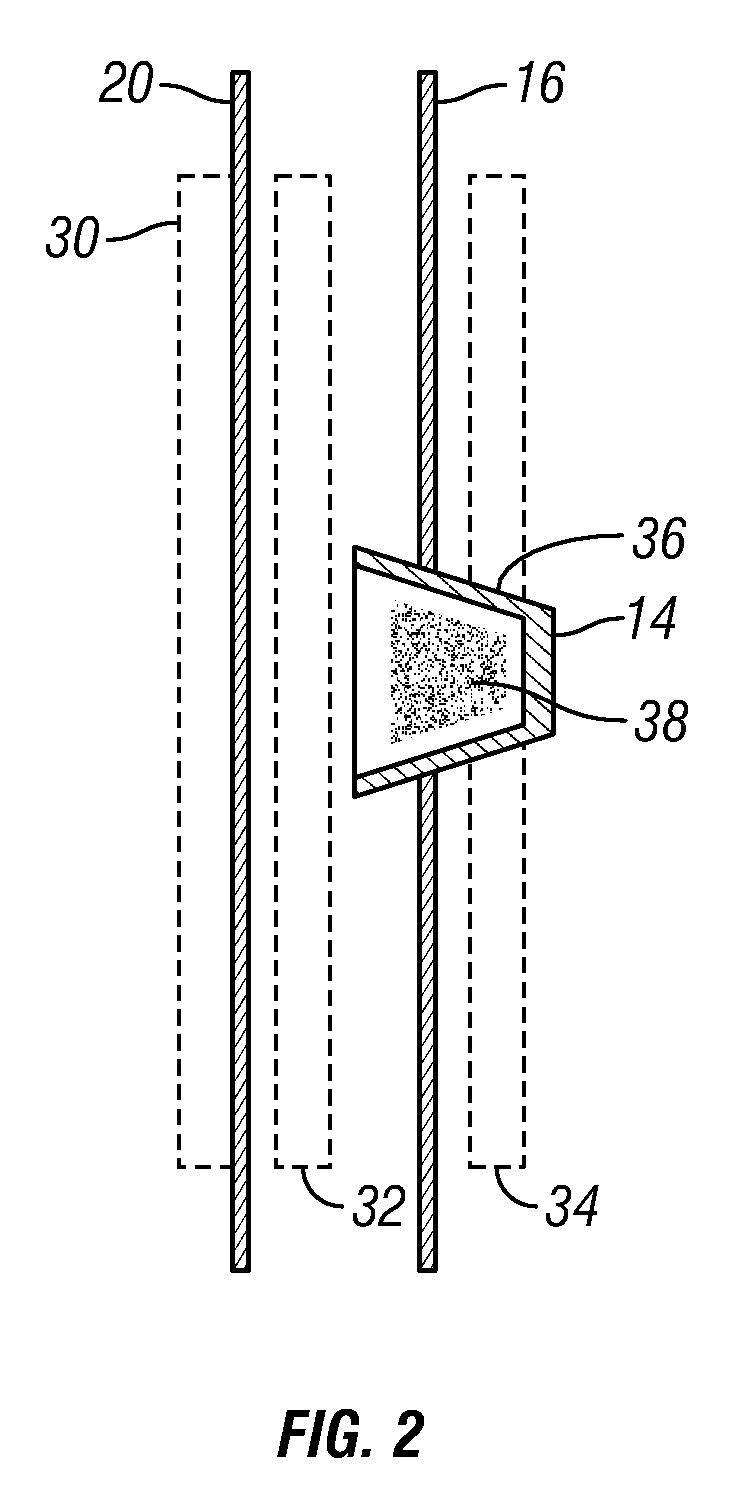

System and method for enhanced wellbore perforations

ActiveUS20090183916A1Effective perforationConsumes lotFluid removalDrilling machines and methodsShaped chargeOxygen

A method for perforating a subterranean formation includes positioning a shaped charge and a reactant composite material in a carrier; positioning the carrier in the wellbore; detonating the shaped charge; and disintegrating the reactant composite material using a shock generated by the detonated shaped charge. The method may also include initiating a first deflagration by using carbon and heat resulting from the detonation of the shaped charge and an oxygen component of the disintegrated reactant composite material. A system for performing the method may include a carrier, a shaped charge positioned in the carrier; and a reactant composite material positioned in the carrier. The reactant composite material may be configured to disintegrate upon detonation of the shaped charge.

Owner:OWEN OIL TOOLS

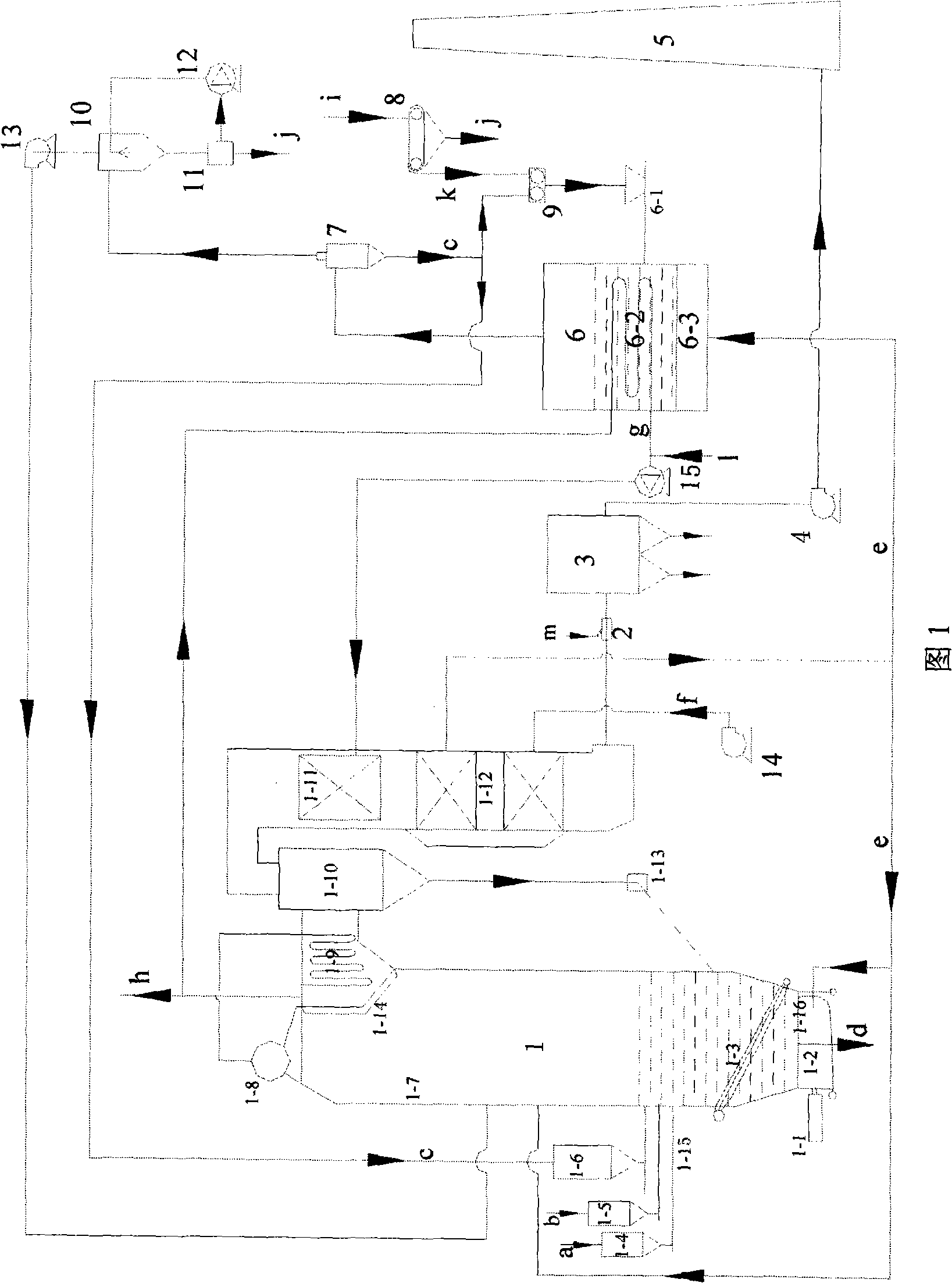

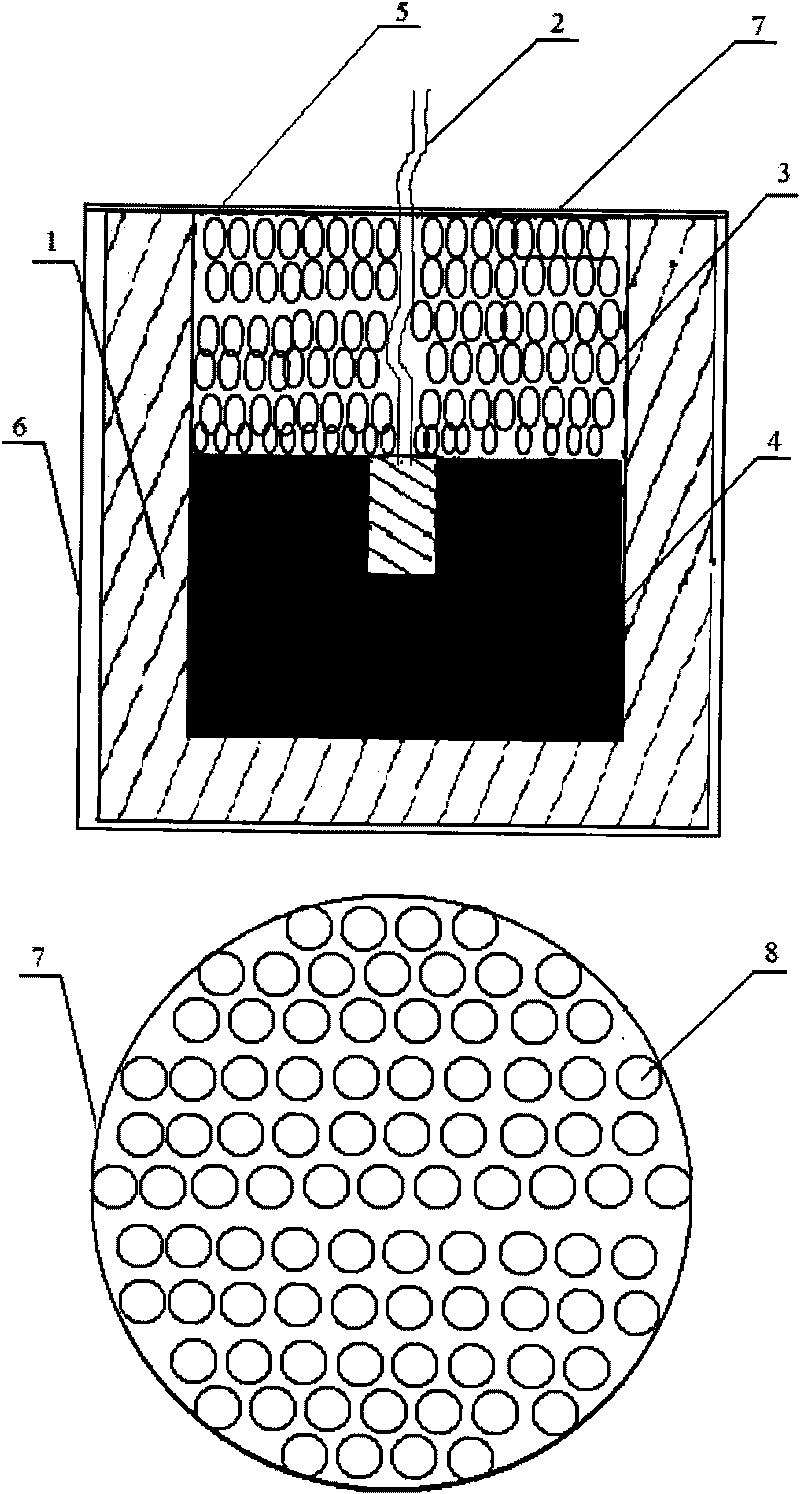

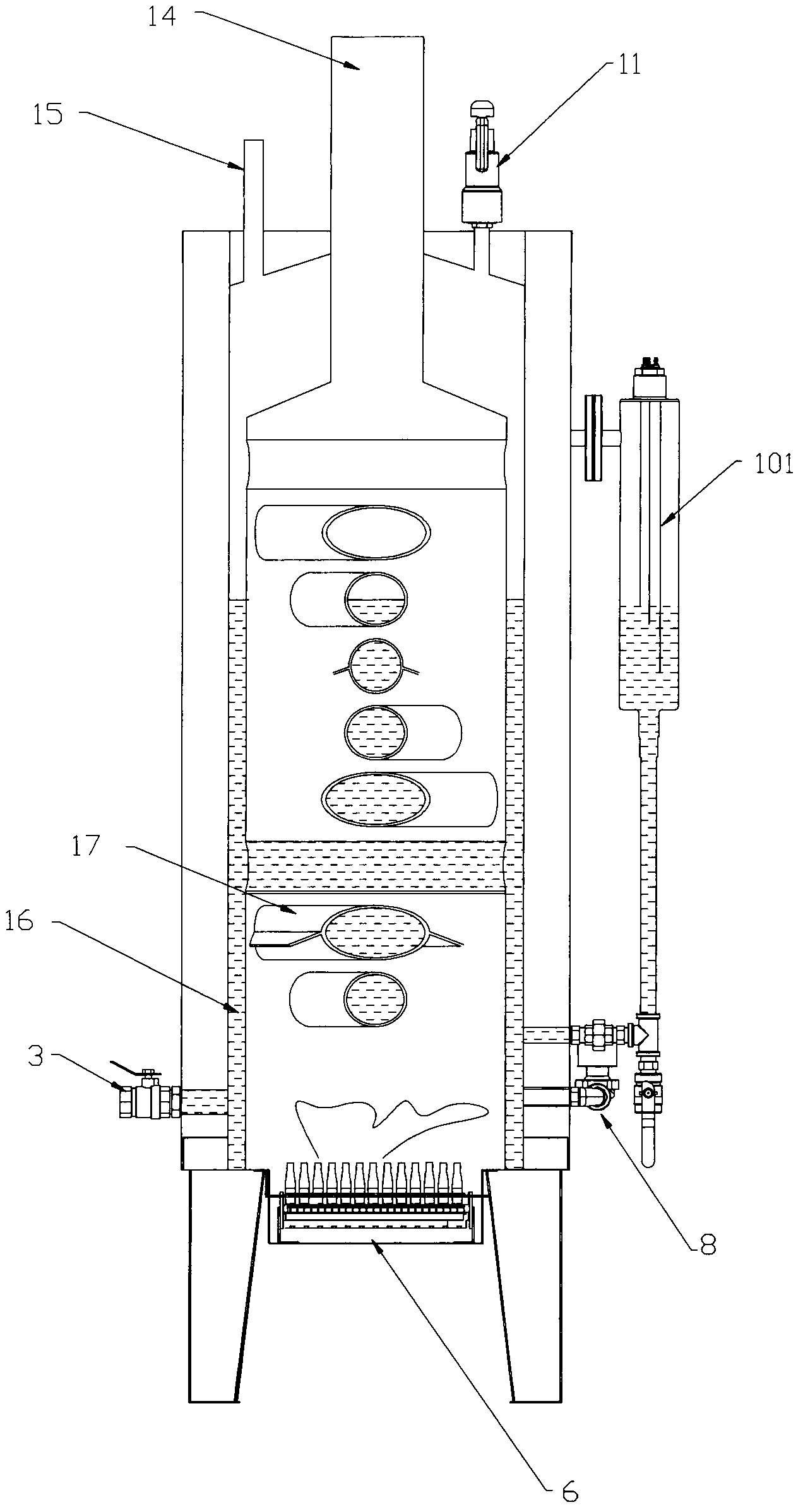

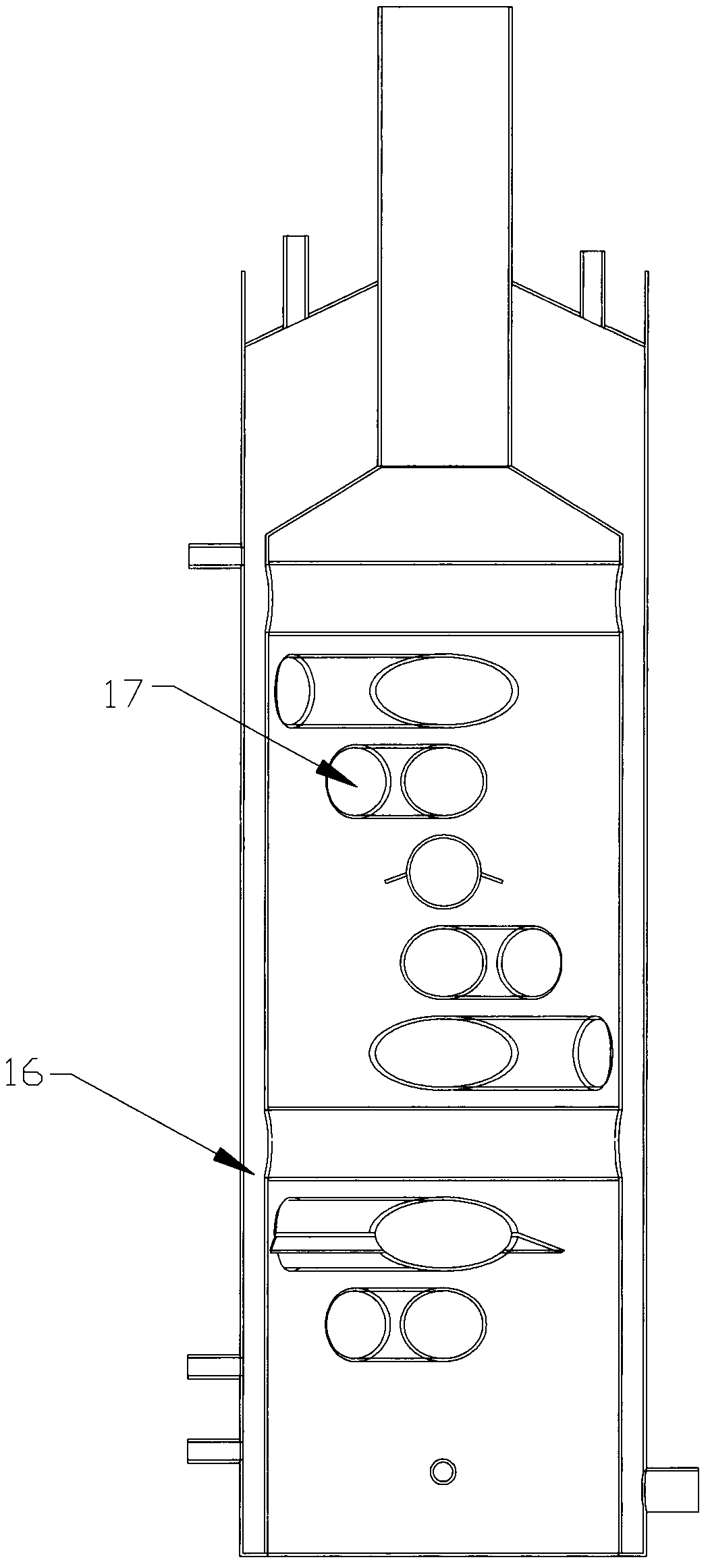

Sludge drying burning combination treatment method

ActiveCN101265008ASimple processLower the altitudeSludge treatment by de-watering/drying/thickeningIncinerator apparatusFluidized bed dryingTreatment effect

The invention relates to a sludge drying and incineration combined treatment method with good treatment effect, wide sludge adaptability, and safe and stability system. To avoid agglomeration of mechanically dewatered sludge (k) in a fluidized bed dryer (6), a part of dried sludge (c) is premixed with the mechanically dewatered sludge (k) and then fed into the fluidized bed dryer (6). The dried sludge (c) is incinerated into a circulating fluidized bed incinerator (1) to generate superheated vapor. The superheated vapor is condensed to hot water in a heat exchange tube (6-2) of the fluidized bed dryer (6) and then recycled to the circulating fluidized bed incinerator (1). The arrangement of buried pipes (1-3) and fractional air supply inside the circulating fluidized bed incinerator (1) can effectively control the lower temperature of the circulating fluidized bed incinerator (1) to prevent deflagration of dried sludge. The entire system has no emission of pollutants such as unpleasant odor, acidic gases, heavy metals and dioxin; is safe and reliable; and can operate for a long time.

Owner:JIANGSU JINSHAN SOLID WASTE RESOURCE TECH

System and method for enhanced wellbore perforations

A method for perforating a subterranean formation includes positioning a shaped charge and a reactant composite material in a carrier; positioning the carrier in the wellbore; detonating the shaped charge; and disintegrating the reactant composite material using a shock generated by the detonated shaped charge. The method may also include initiating a first deflagration by using carbon and heat resulting from the detonation of the shaped charge and an oxygen component of the disintegrated reactant composite material. A system for performing the method may include a carrier, a shaped charge positioned in the carrier; and a reactant composite material positioned in the carrier. The reactant composite material may be configured to disintegrate upon detonation of the shaped charge.

Owner:OWEN OIL TOOLS

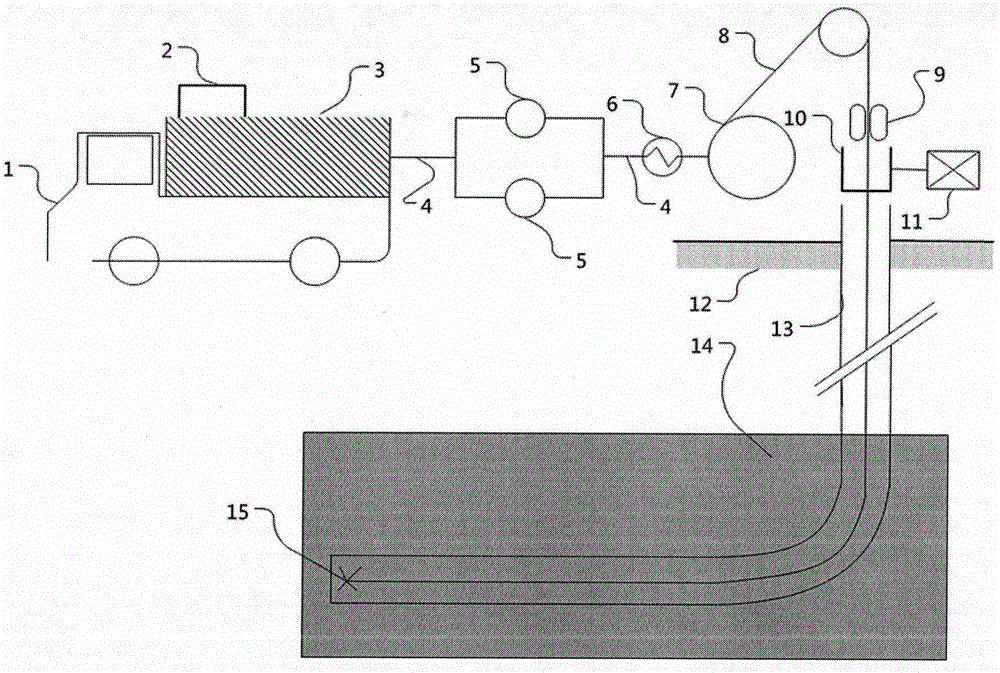

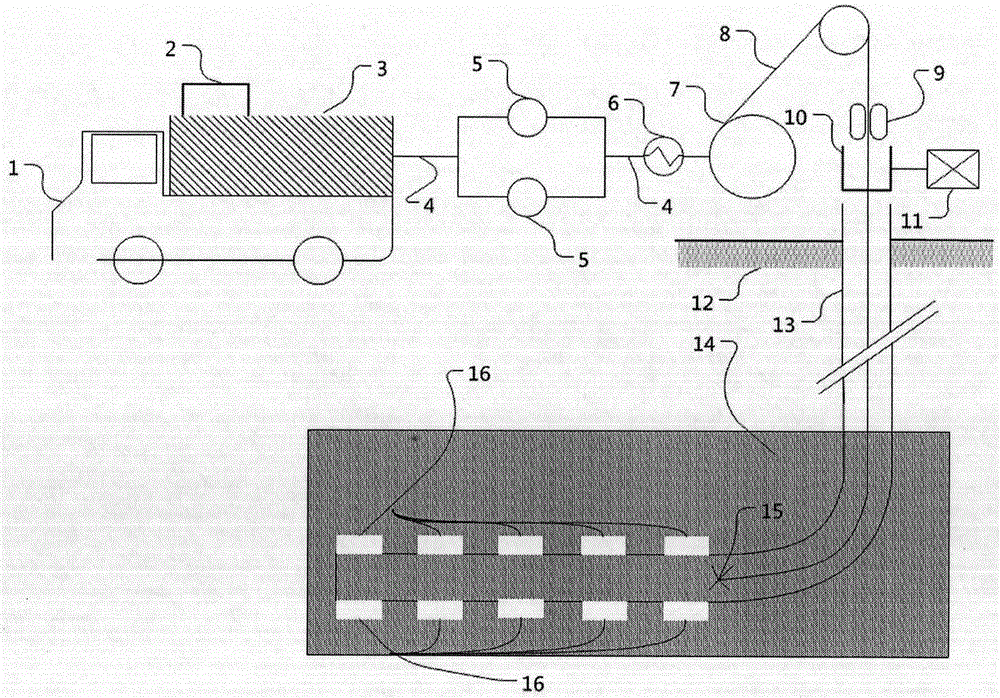

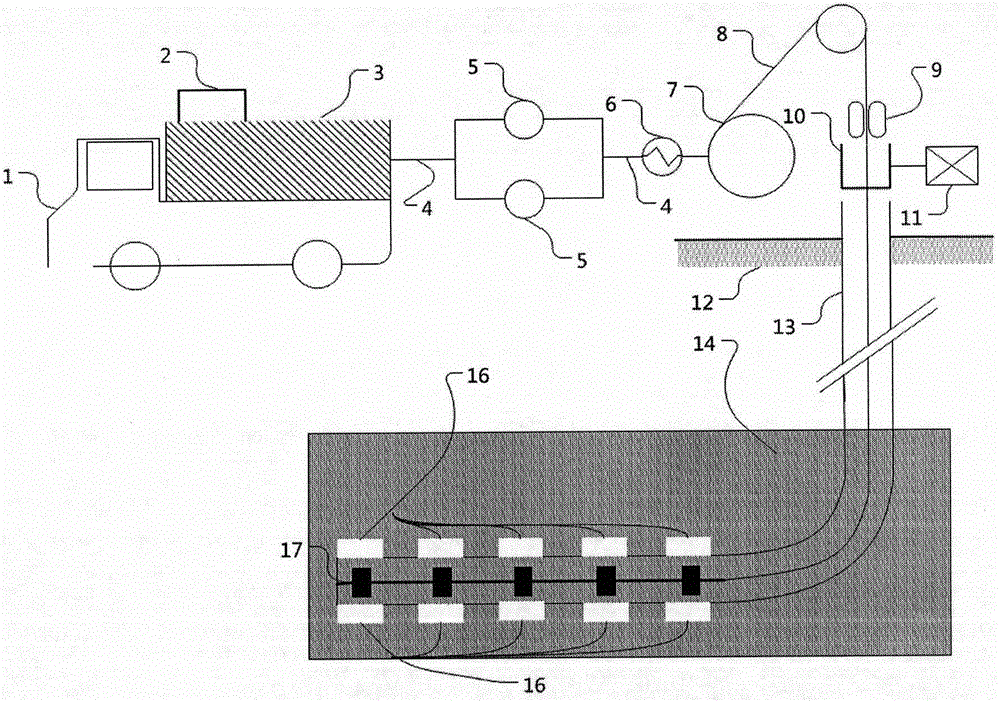

Coalbed methane horizontal well supercritical CO2 jet flow cavity construction and multi-segment synchronous deflagration fracturing method

InactiveCN105625946AAids in stress unloadingImprove permeabilityLiquid/gas jet drillingFluid removalHigh energyHigh pressure

The invention relates to a coalbed methane horizontal well supercritical CO2 jet flow cavity construction and multi-segment synchronous deflagration fracturing method. The method comprises the following steps: completing coalbed methane horizontal well drilling, introducing a coiled tubing into an supercritical CO2 rotary jet flow rock-breaking device to the bottommost end of a shaft, and performing pore broadening on the shaft by using an underground supercritical CO2 rotary jet flow rock-breaking device in order to form a cylindrical pore which is 1.0-1.5 meters in diameter and is 2-4 meters in length underground; after first-segment pore broadening is finished, lifting a rotary jet-flow tool to perform second-segment pore broadening work and so forth to finish pore broadening work of all well segments, wherein the segment distances are 80-100 meters; putting a solid explosive into a pore broadening cavity by using the coiled tubing after finishing pore broadening, and introducing a screen pipe; lastly, pressurizing by using a ground high-pressure CO2 pump to ignite the explosive, and mixing generated high-energy gas with a supercritical CO2 fracturing coalbed. By adopting the method, a plurality of complex volume cracks can be generated in the coalbed, explosive fracturing contributes to coalbed stress unloading after pore broadening, and the coal rock permeability can be improved effectively, so that the yield of a coalbed methane horizontal well is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

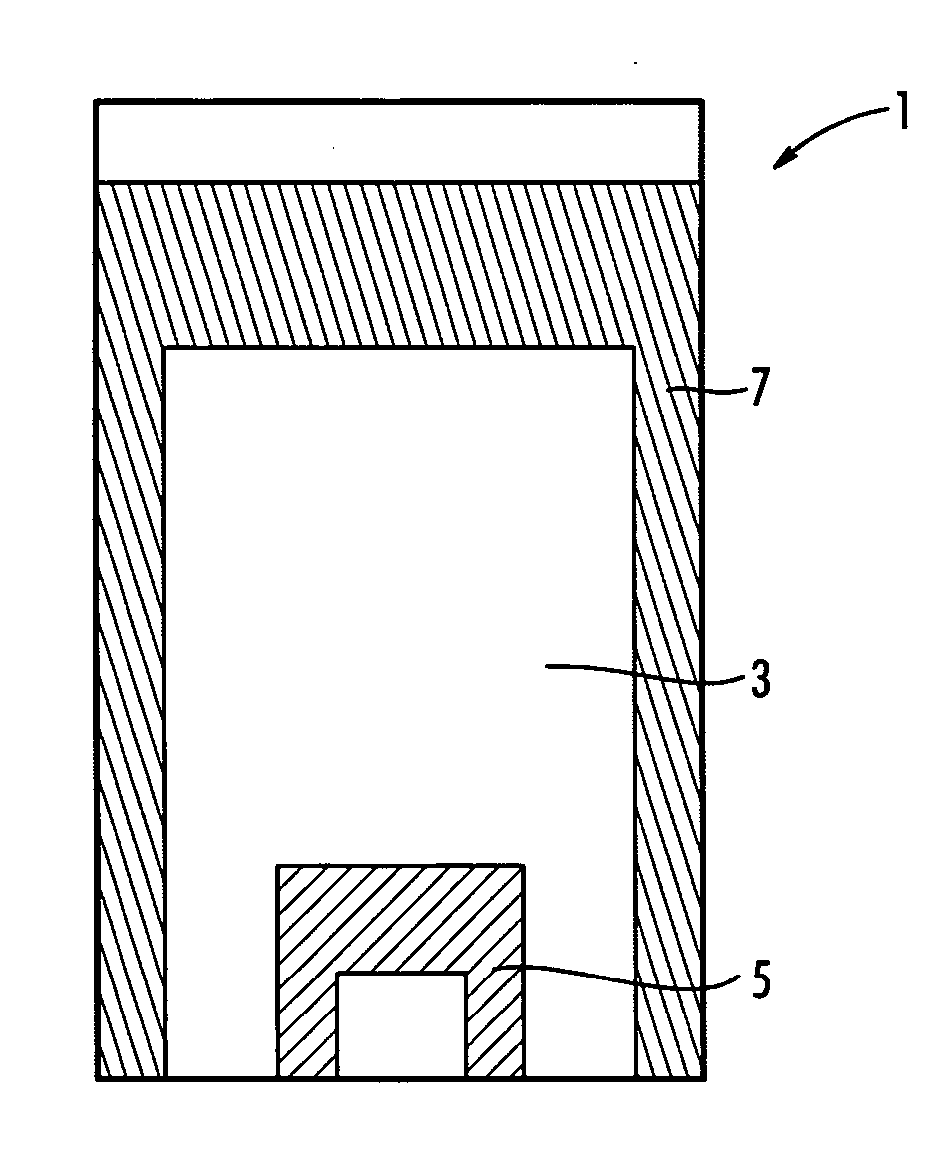

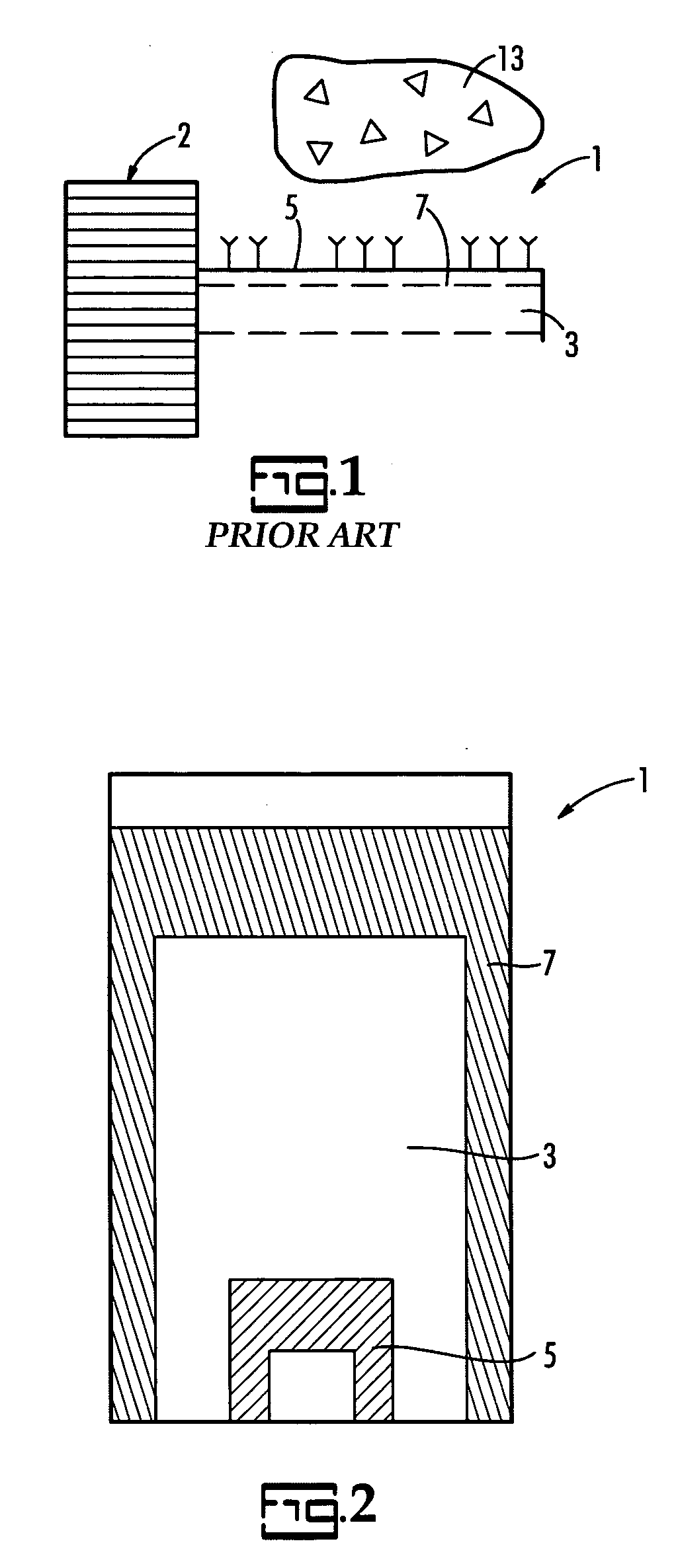

Non-optical explosive sensor based on two-track piezoresistive microcantilever

InactiveUS20060032289A1Comparable sensitivityCompact and more ruggedMaterial analysis using sonic/ultrasonic/infrasonic wavesUsing mechanical meansElectrical resistance and conductanceEngineering

A two-track piezoresistive cantilever detects explosives in ambient air by measuring resistance changes in the cantilever when one piezoresistive track is pulse heated to cause deflagration of explosive adhered to the surface of the cantilever. The resistance measurement is through the second piezoresistive track, which is located at the most resistance-sensitive area. The resistance change of this track is caused by the temperature change of the cantilever as well as the bending of the cantilever due to bi-material thermal expansion. The detecting method using this novel cantilever avoids the use of any optical components such as a laser and position sensing detector (PSD), which are necessary in traditional detecting systems using cantilevers. Therefore, it can extremely reduce the complexity of the detecting system and make a portable chemical detection system possible that is small, less expensive, and able to be mass produced and is particularly useful for the detection of explosives.

Owner:UT BATTELLE LLC +1

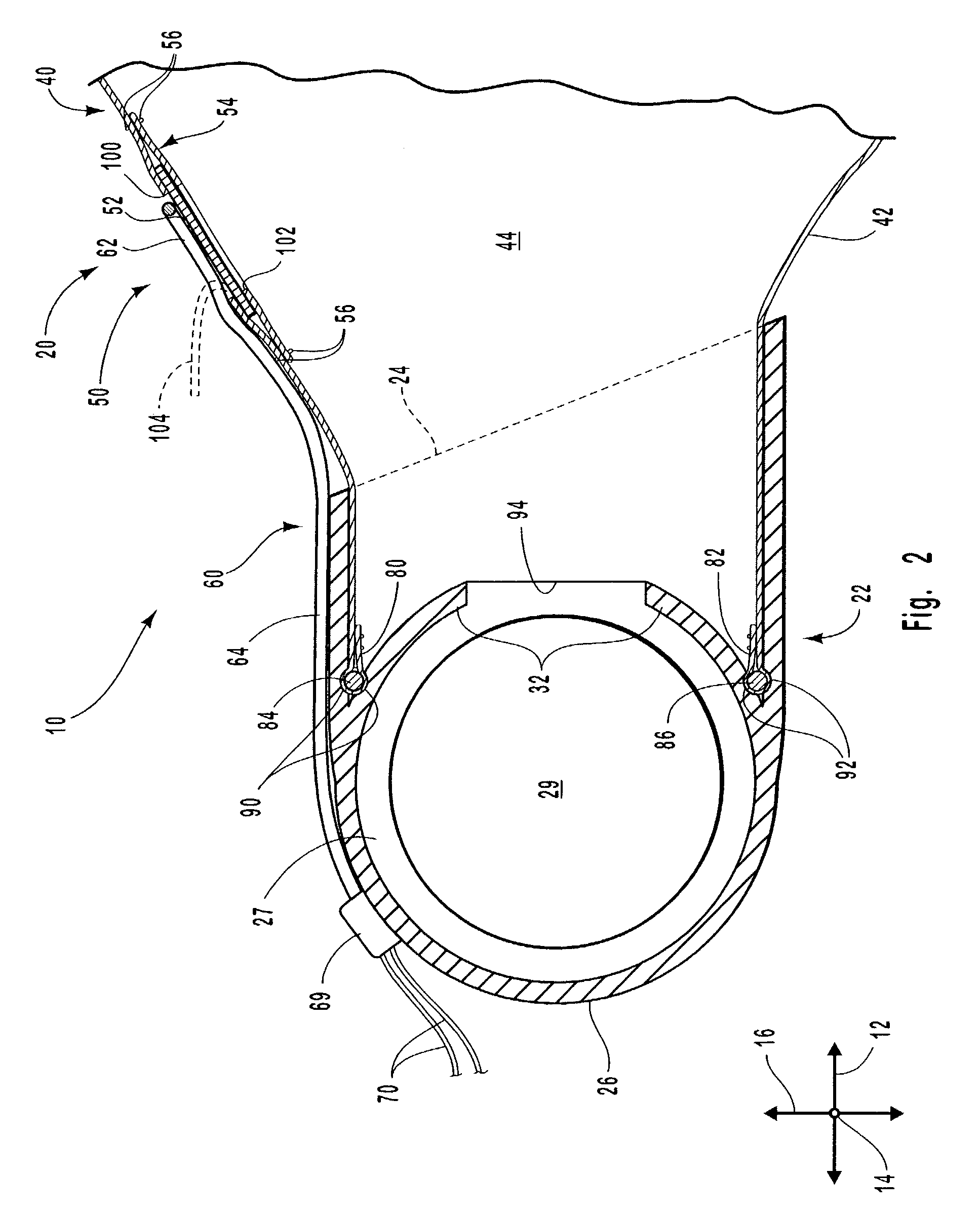

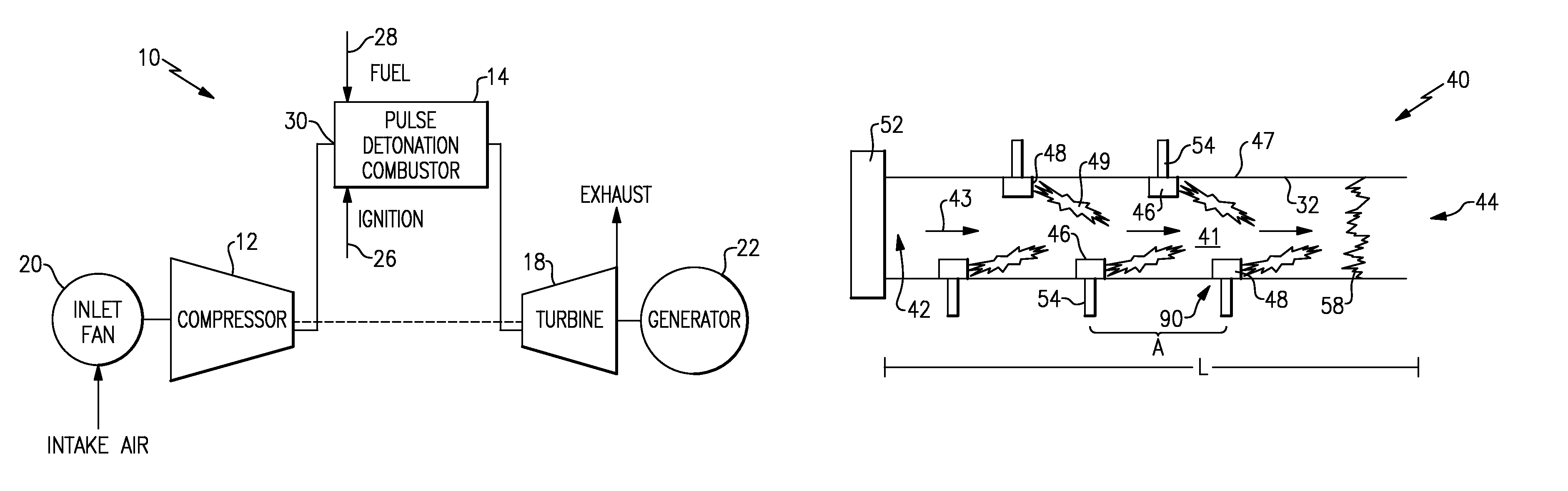

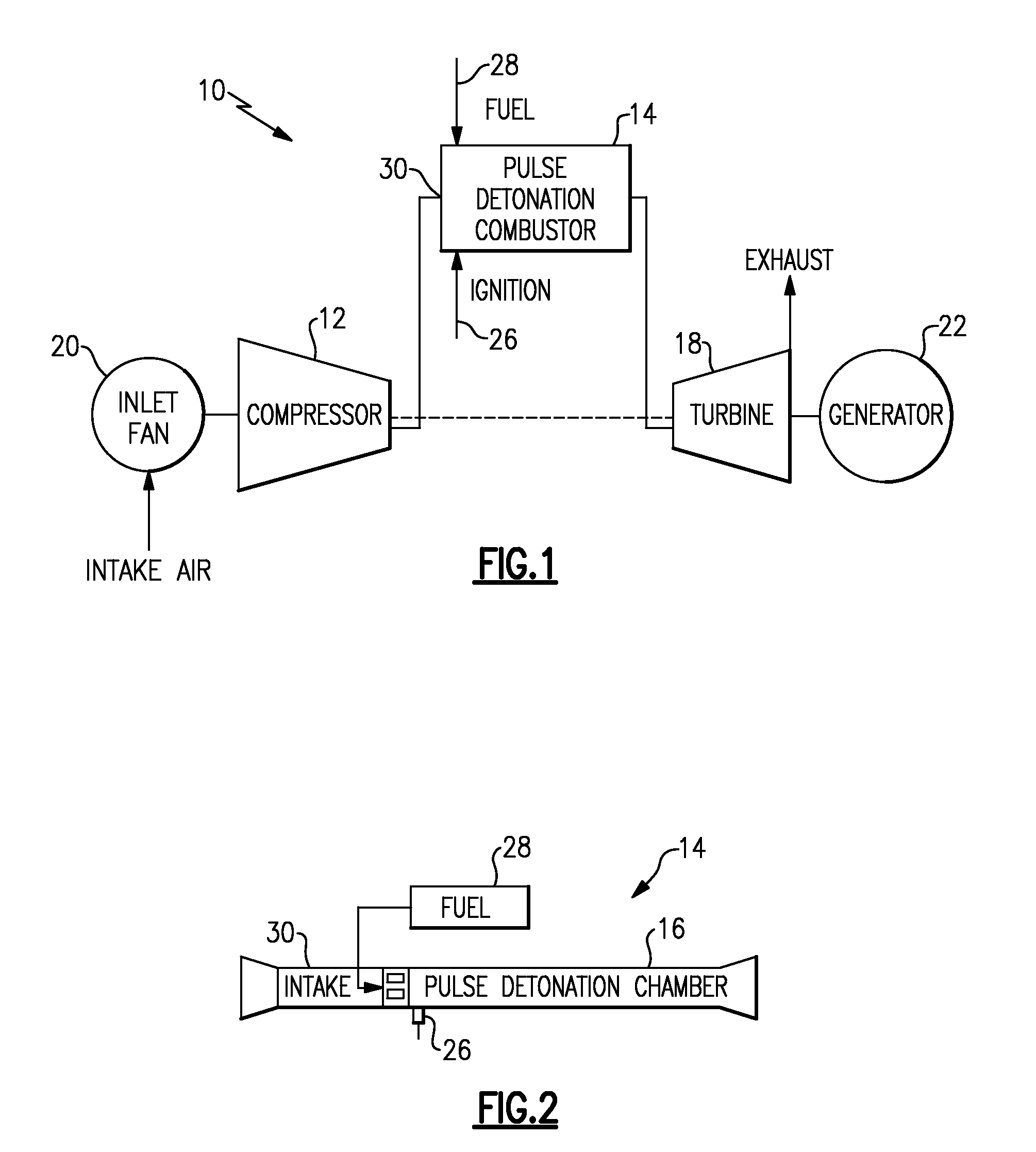

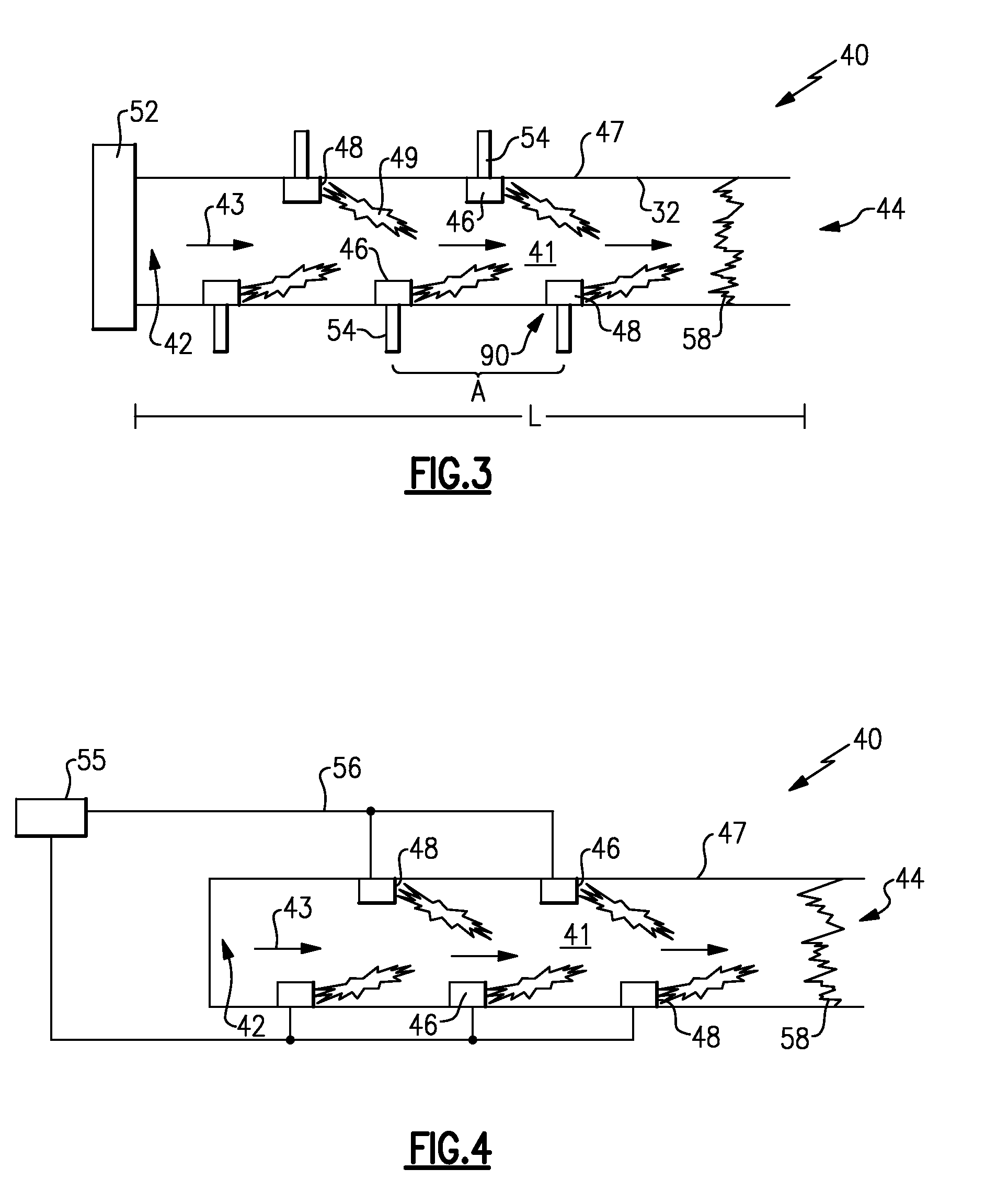

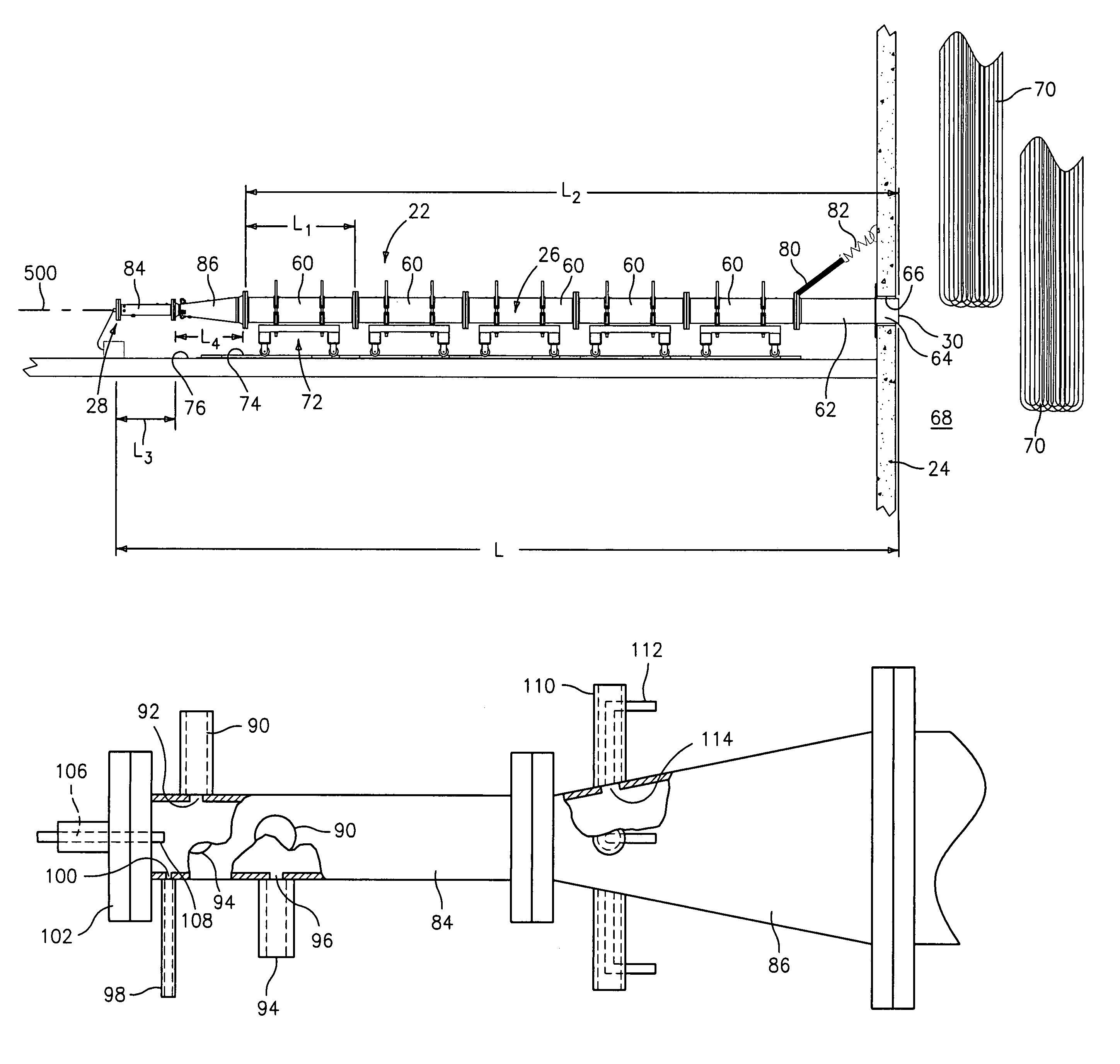

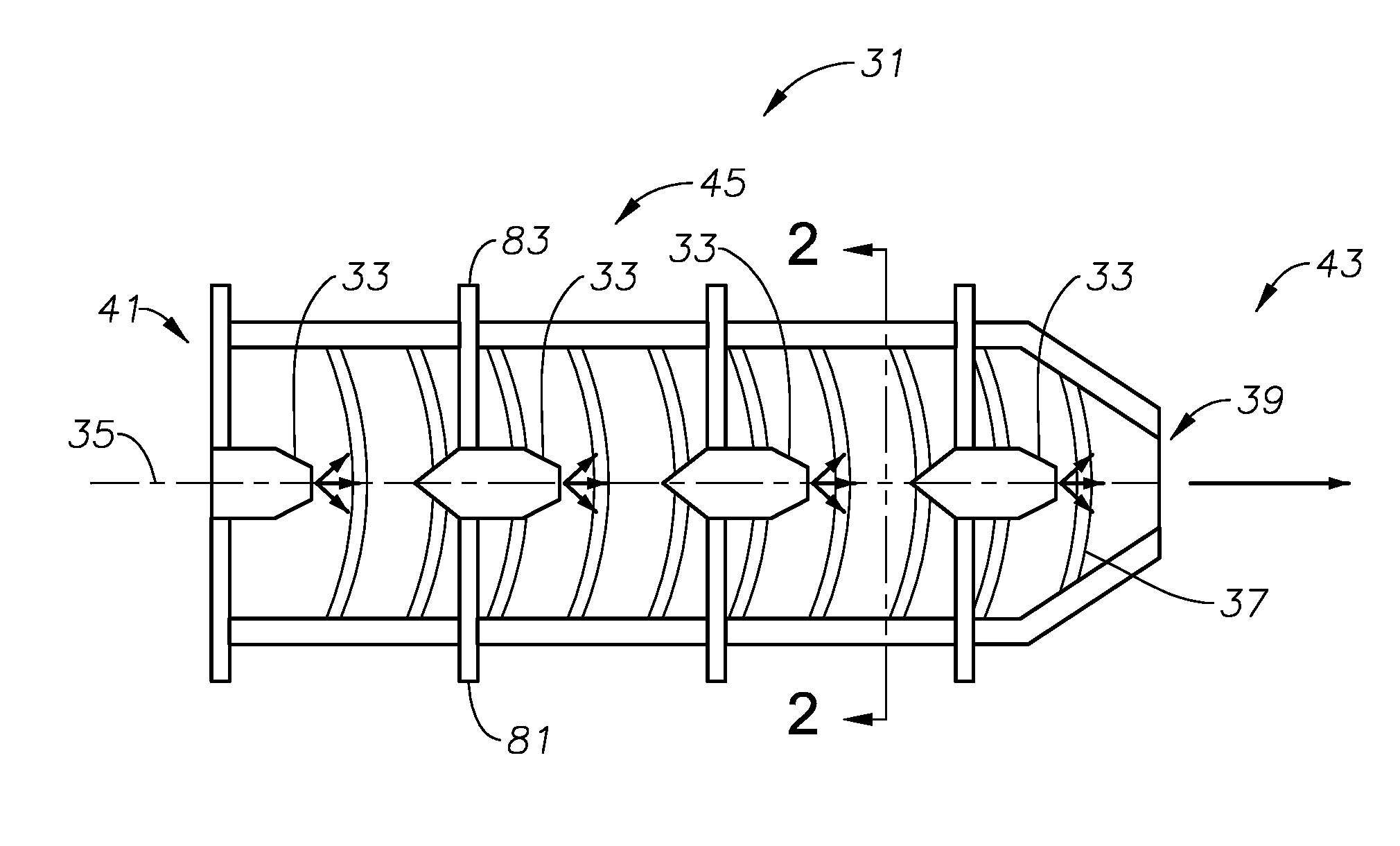

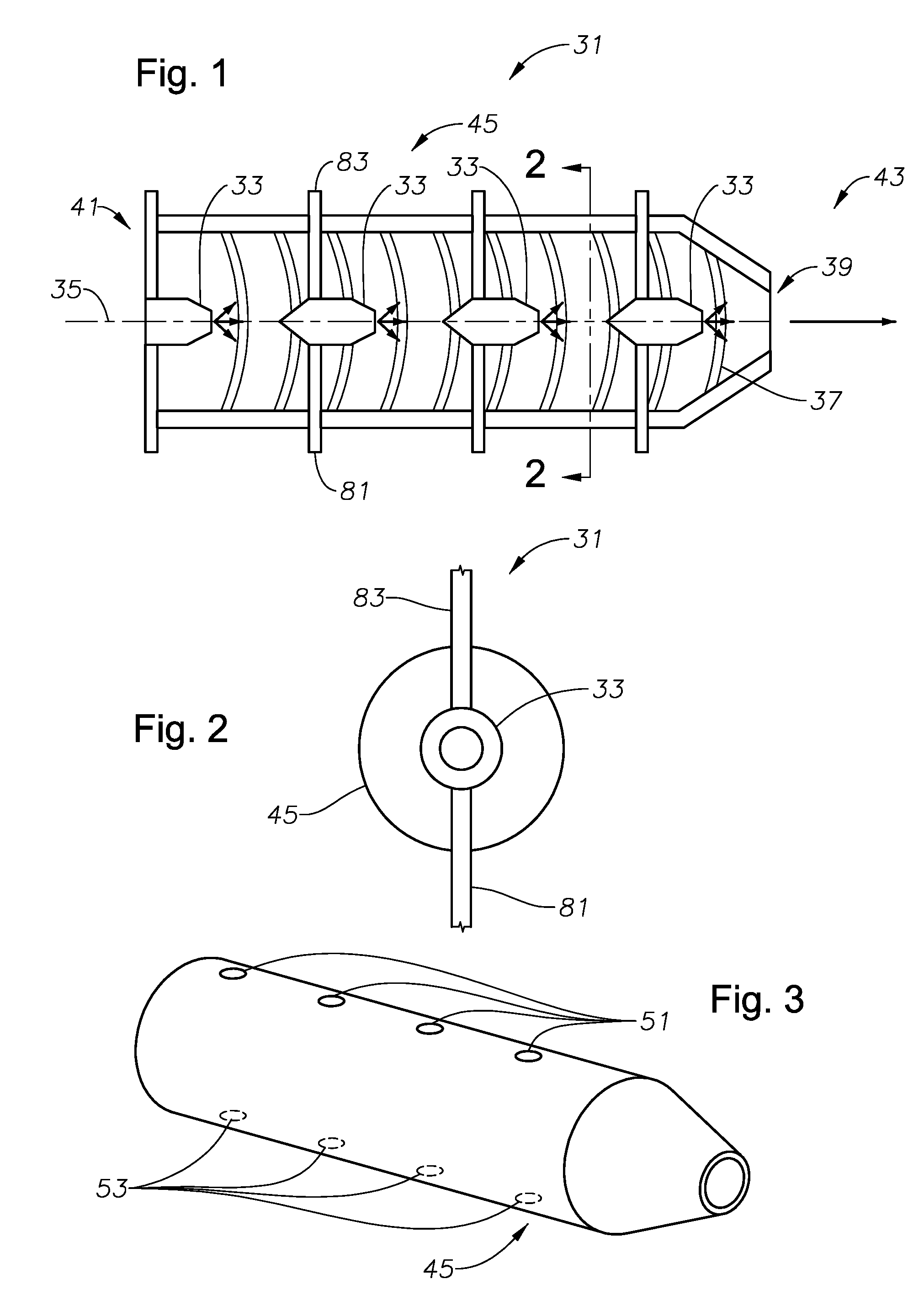

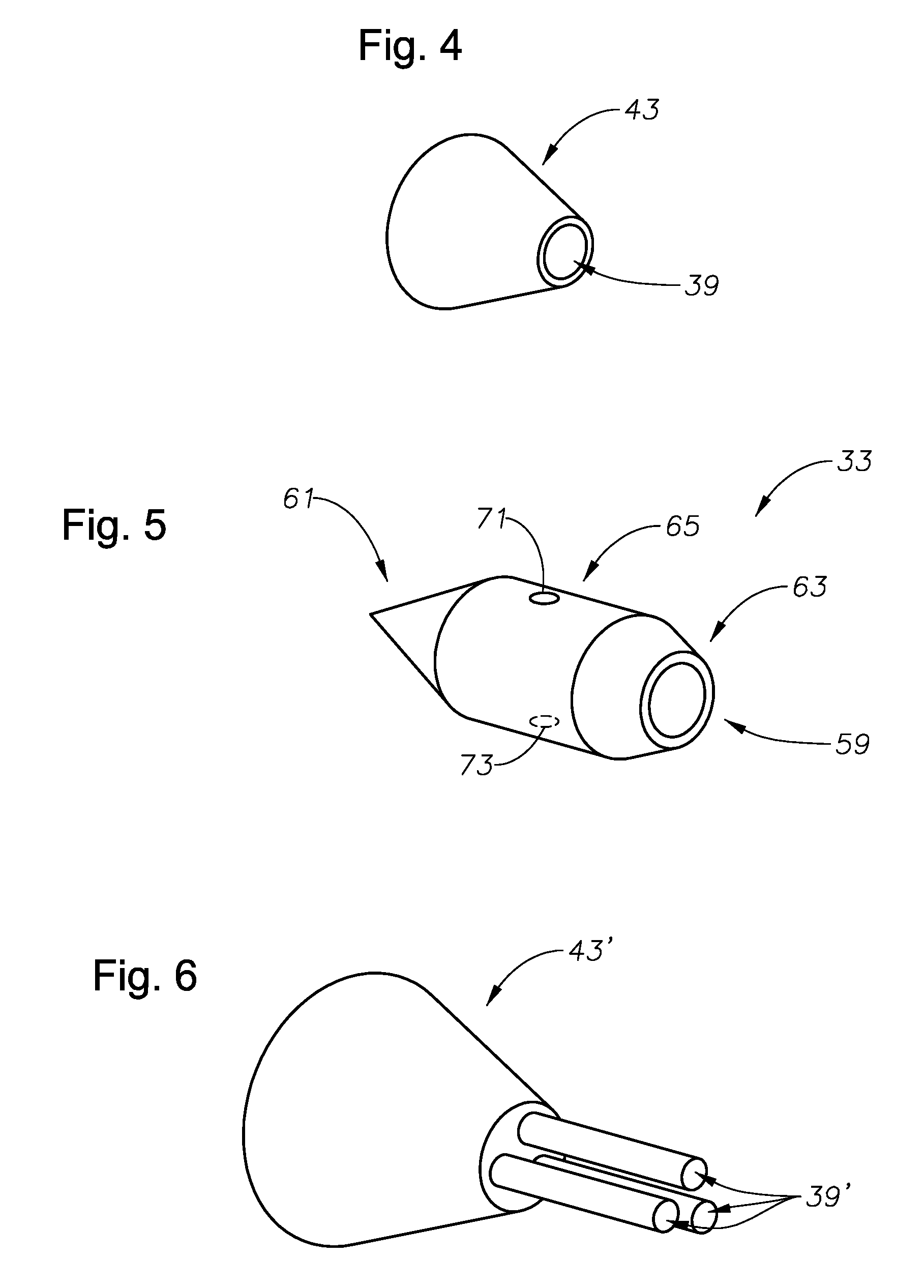

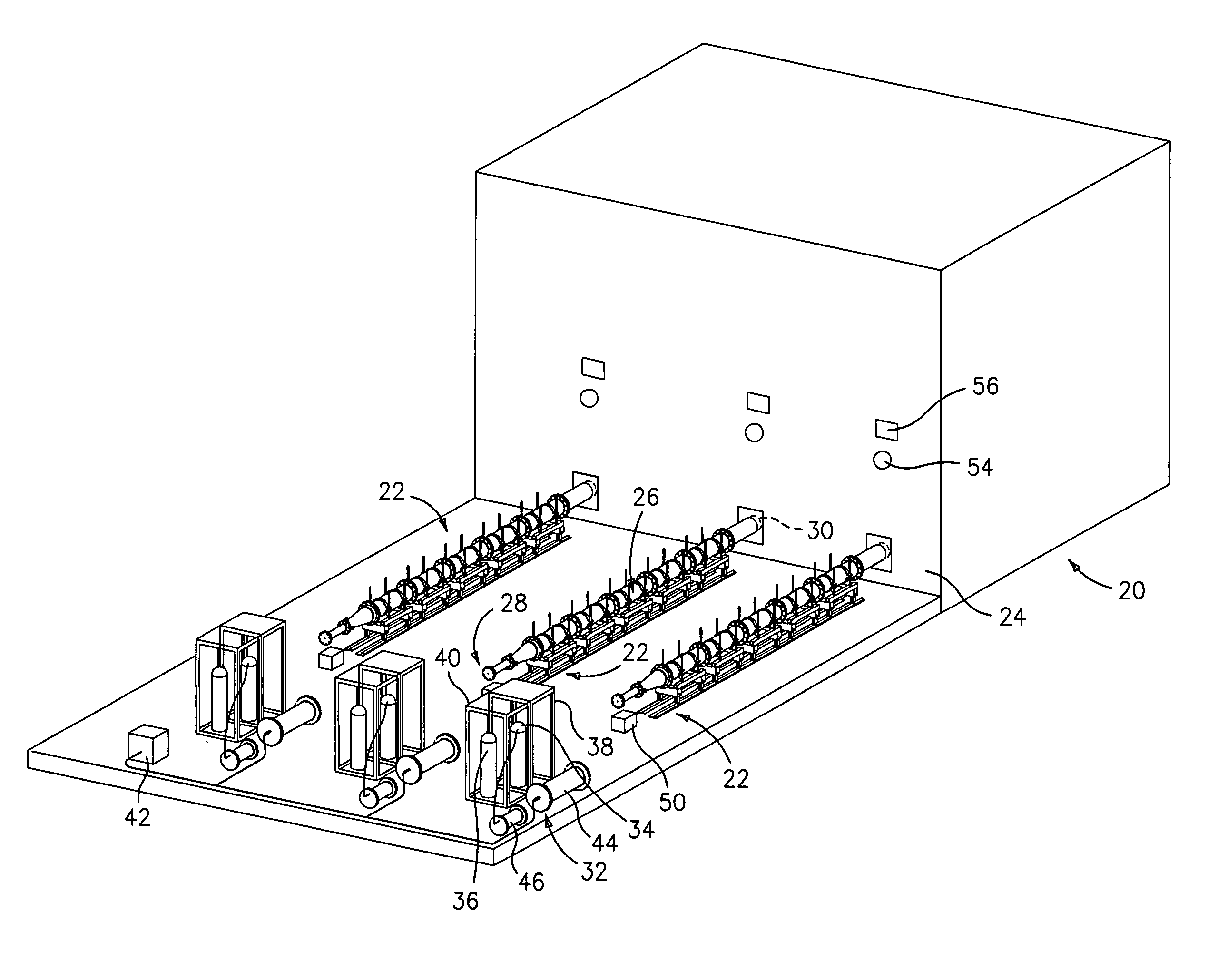

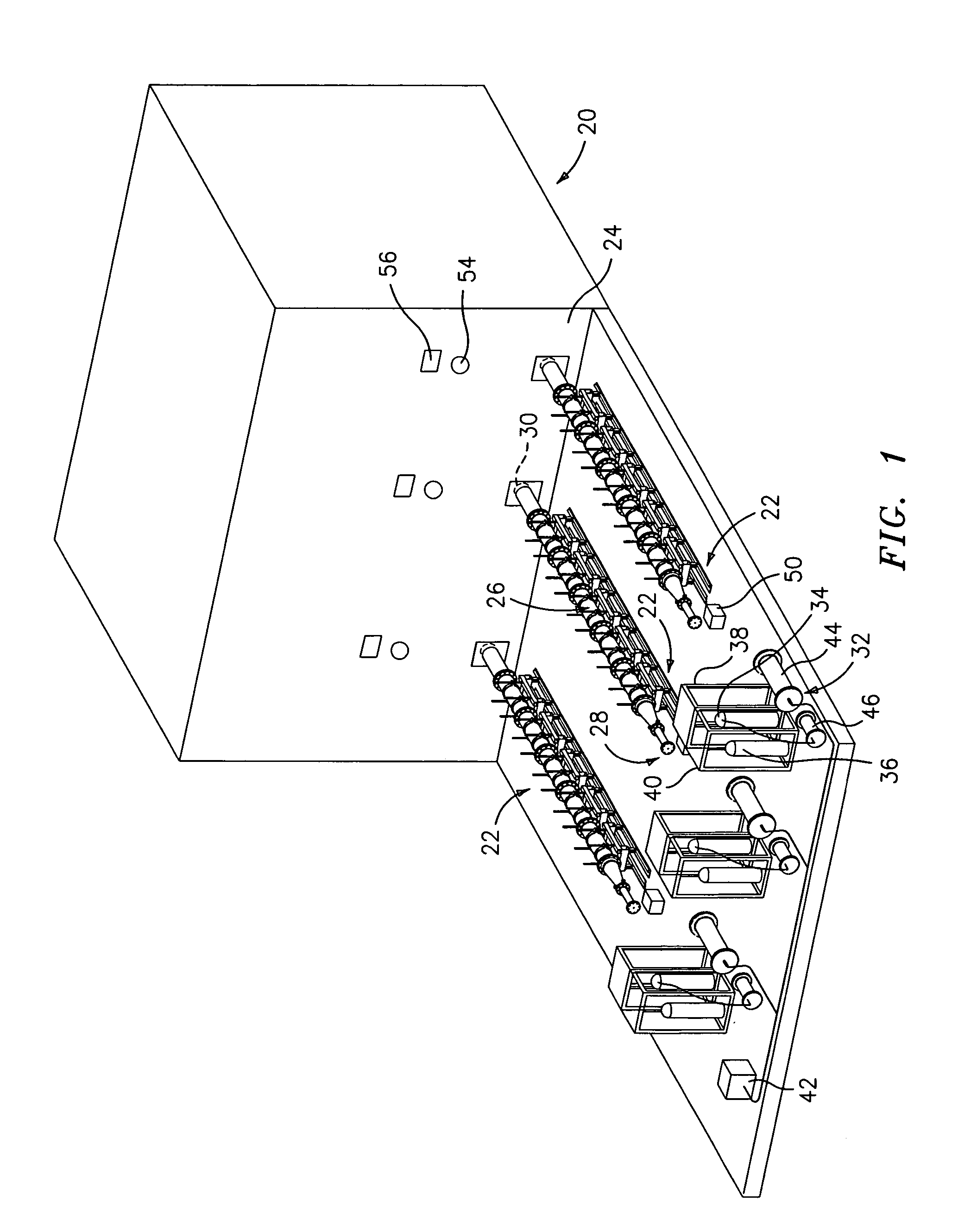

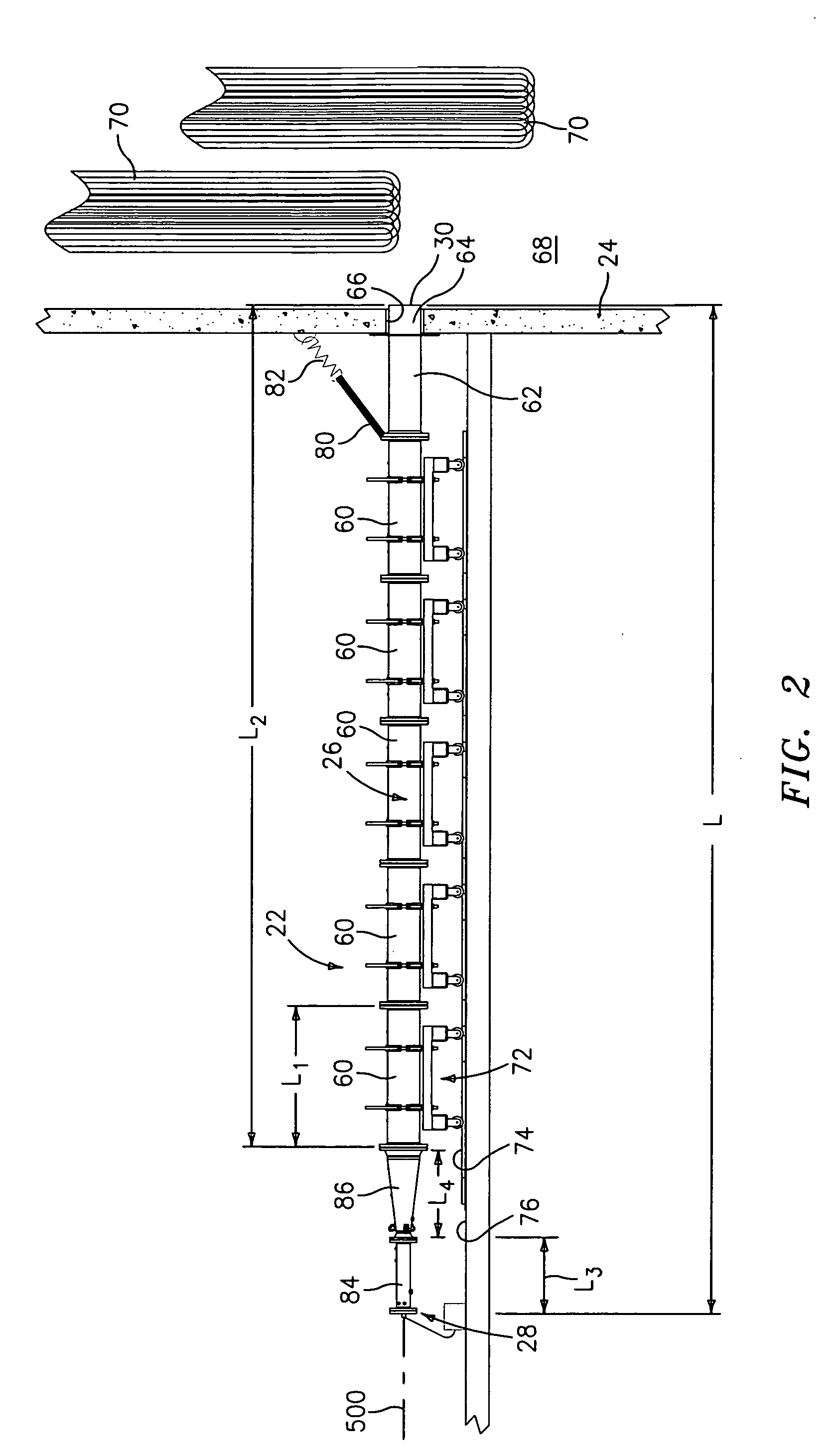

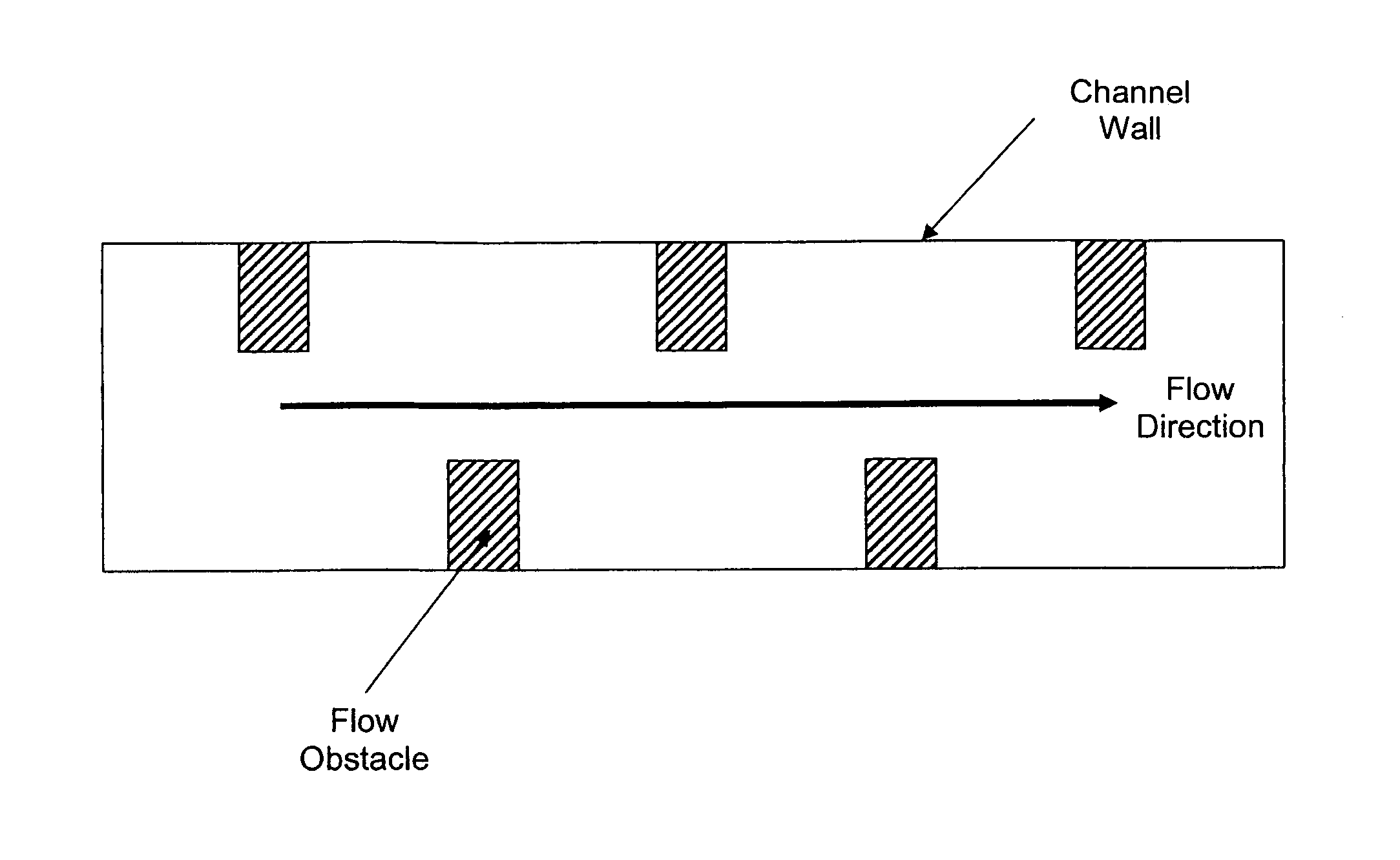

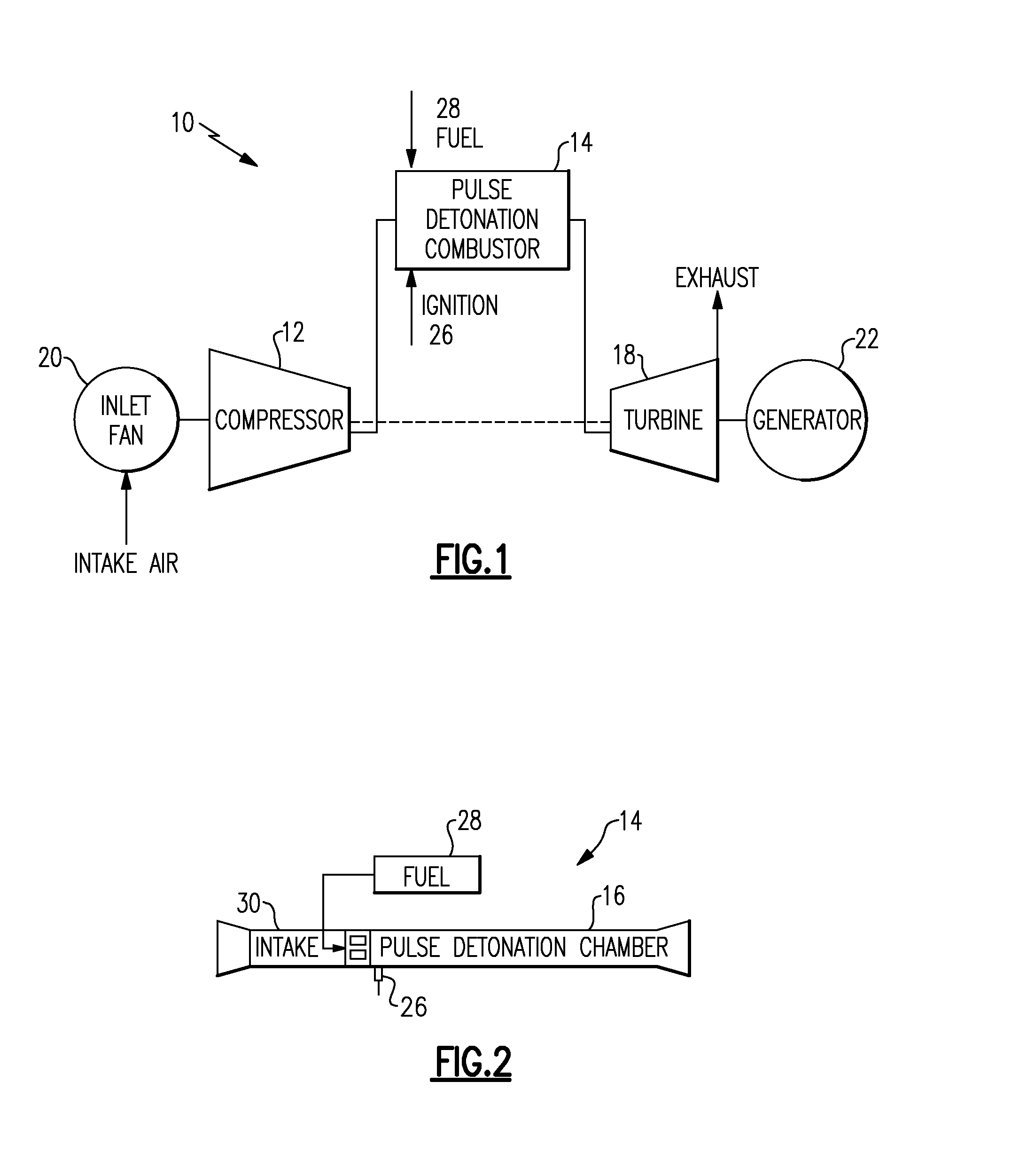

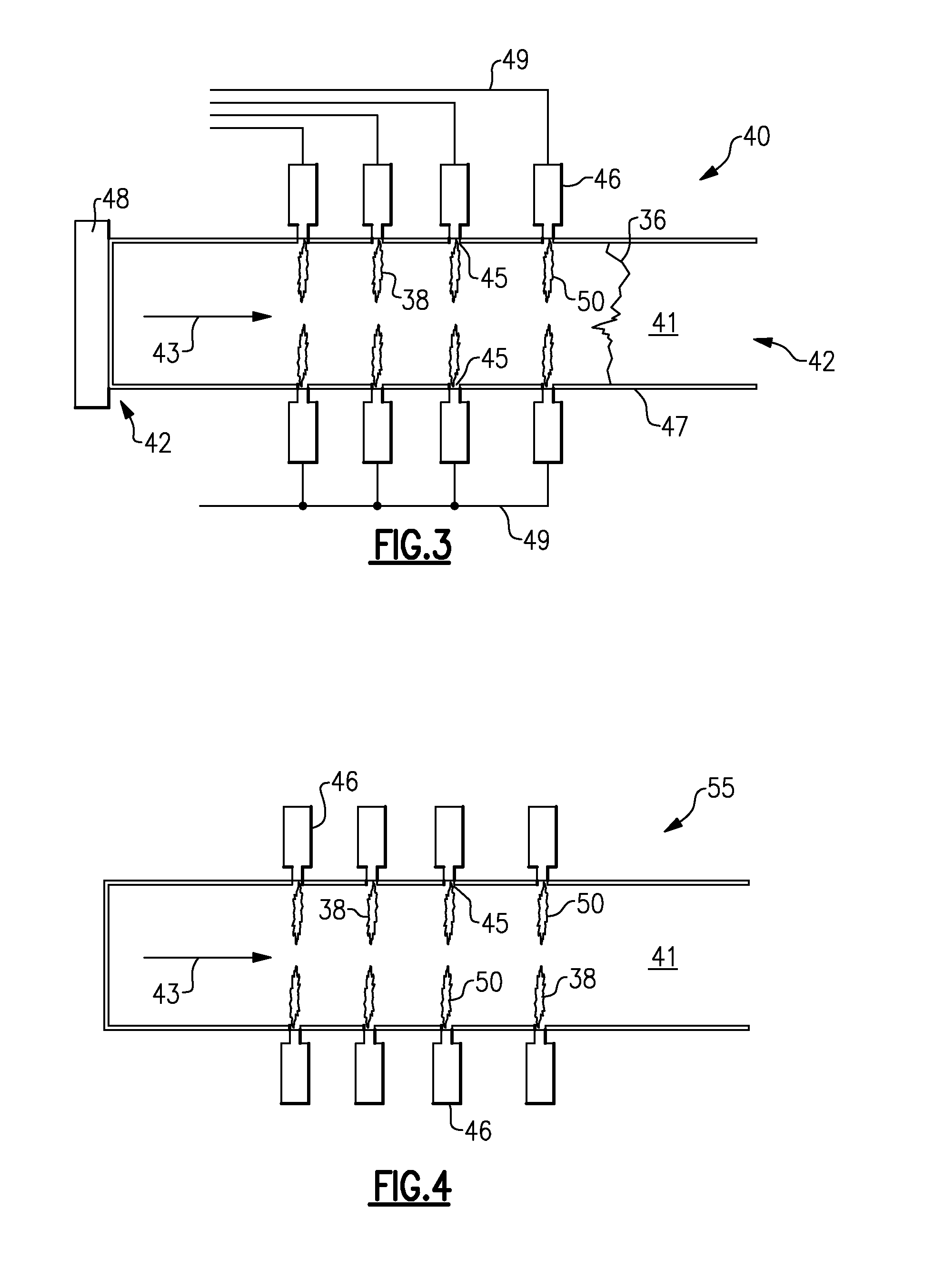

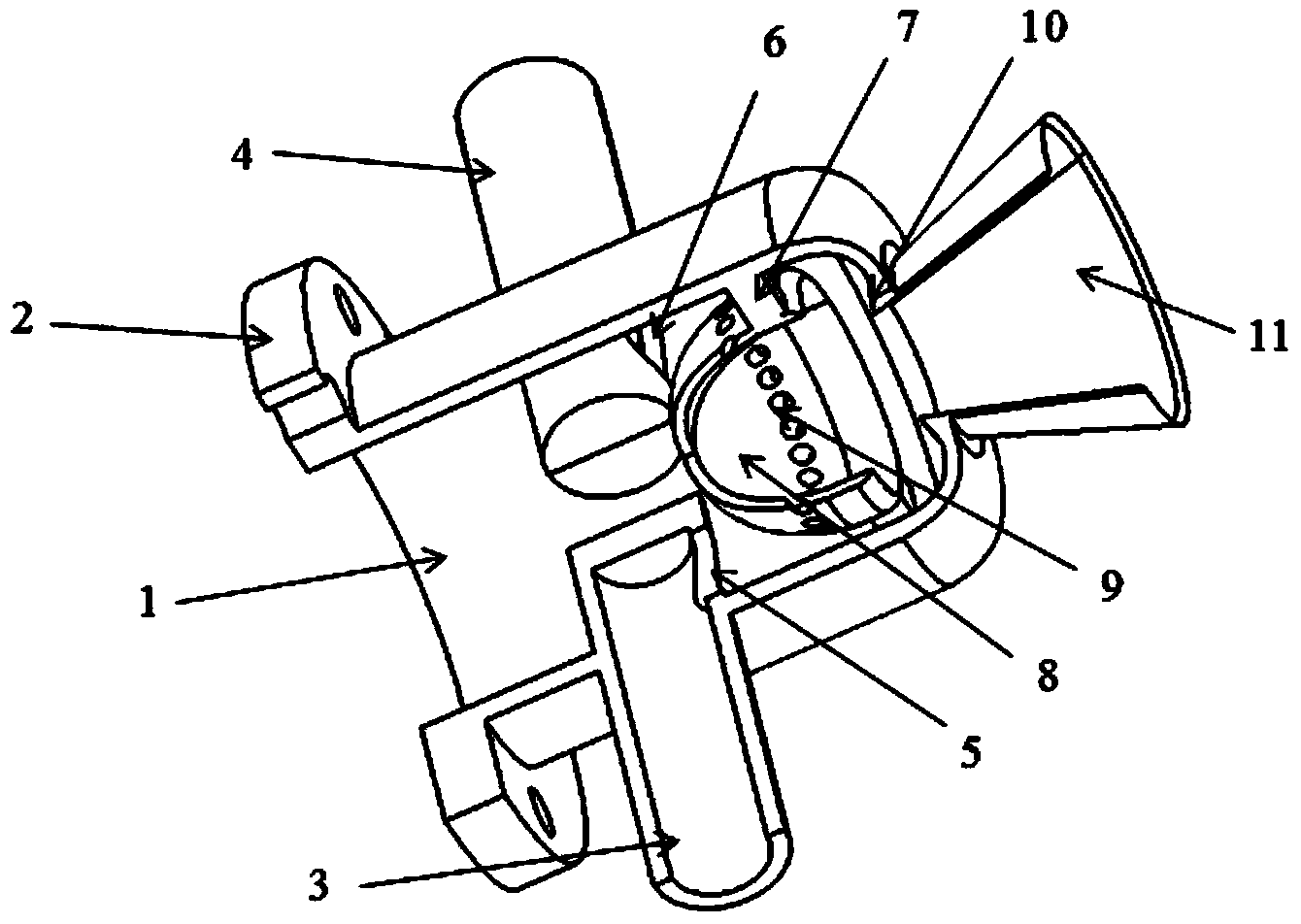

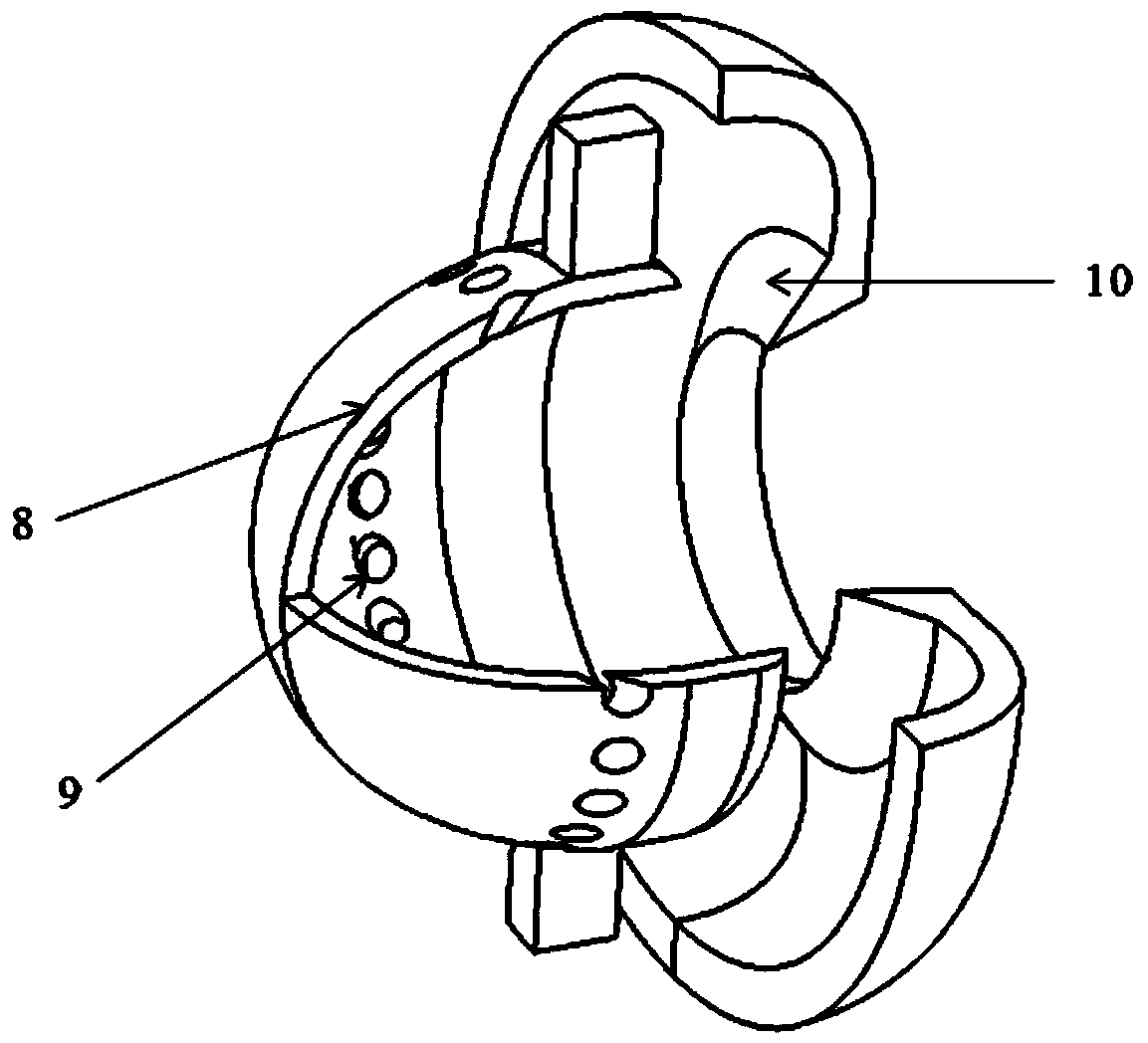

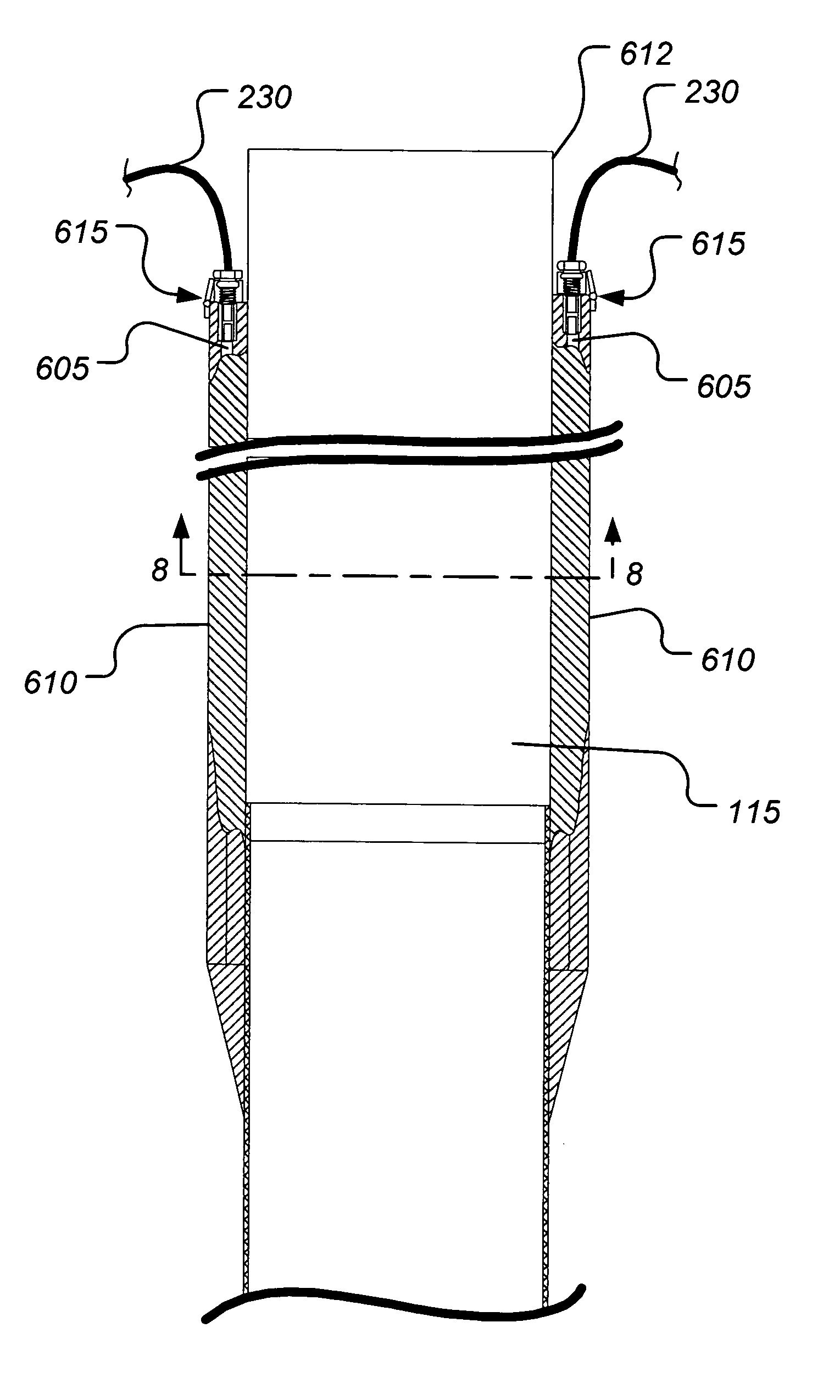

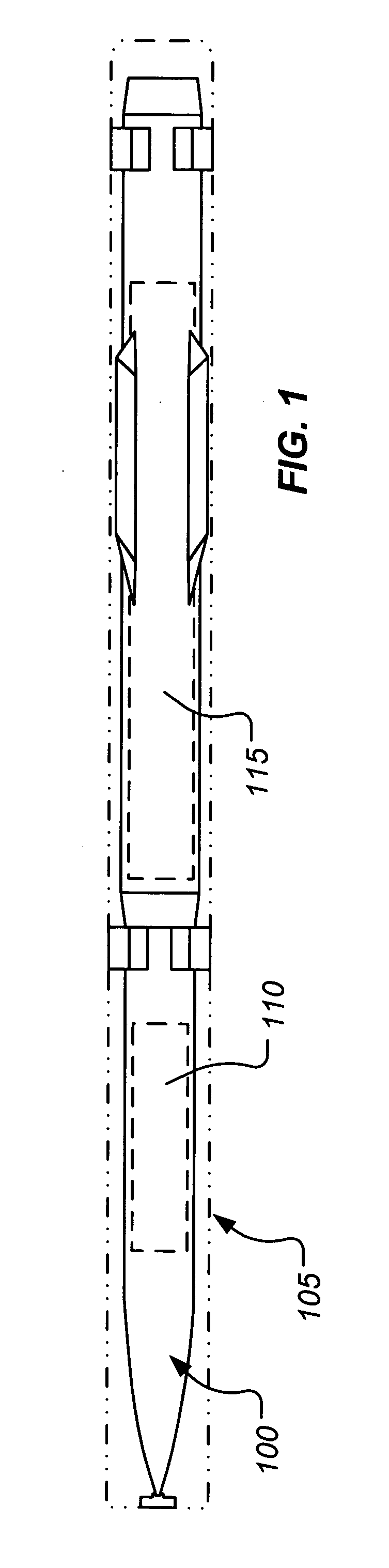

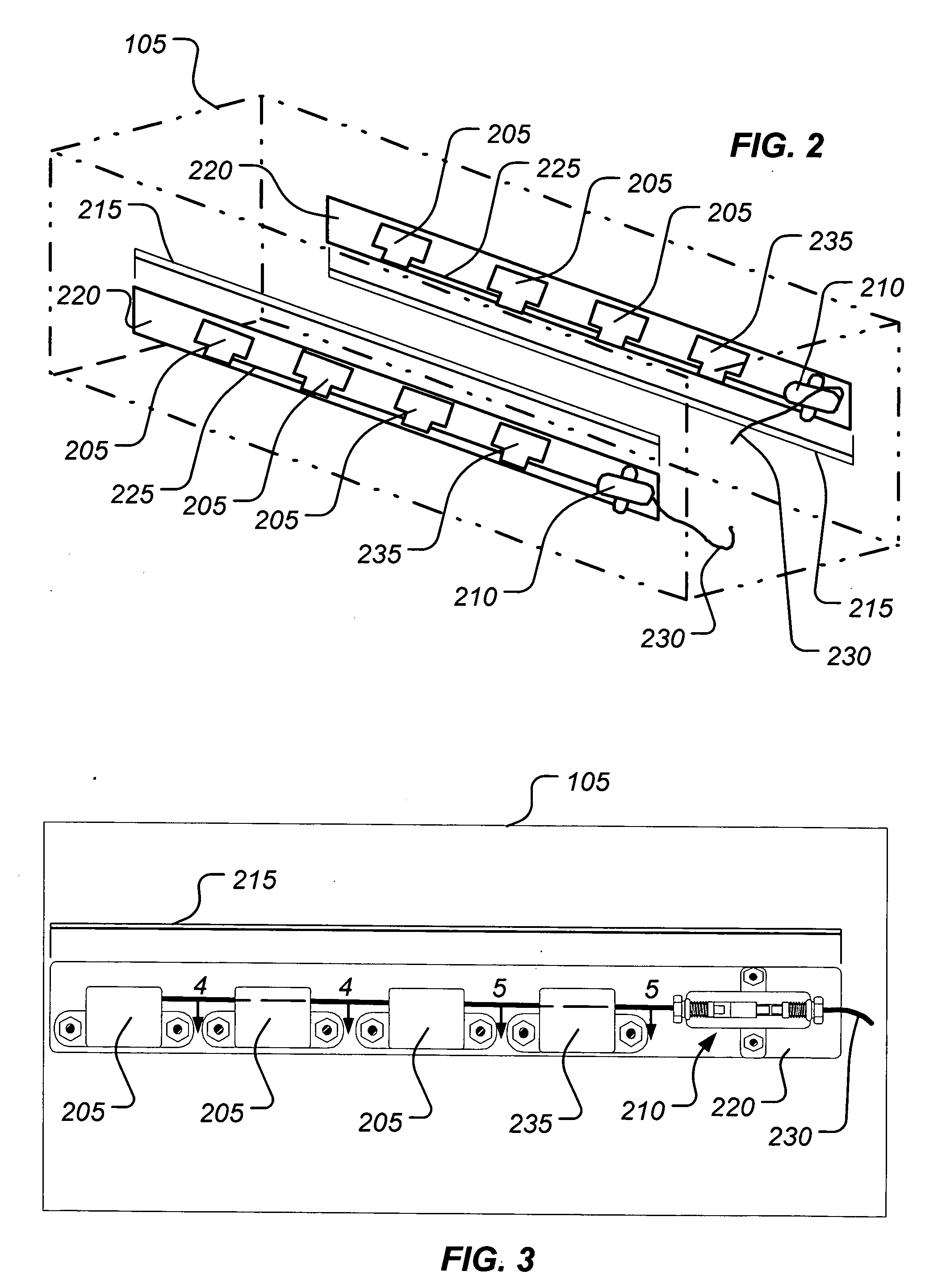

Integrated deflagration-to-detonation obstacles and cooling fluid flow

A detonation chamber and a pulse detonation combustor including a detonation chamber, wherein the detonation chamber includes a plurality of initiation obstacles and at least one injector in fluid flow communication with each of the plurality of initiation obstacles. The plurality of initiation obstacles are disposed on at least a portion of an inner surface of the detonation chamber with each of the plurality of initiation obstacles defining a low pressure region at a trailing edge. The plurality of initiation obstacles are configured to enhance a turbulence of a fluid flow and flame acceleration through the detonation chamber. The at least one injector in provides a cooling fluid flow to each of the plurality of initiation obstacles, wherein the cooling fluid flow is one of a fuel, a combination of fuels, air, or a fuel / air mixture.

Owner:GENERAL ELECTRIC CO

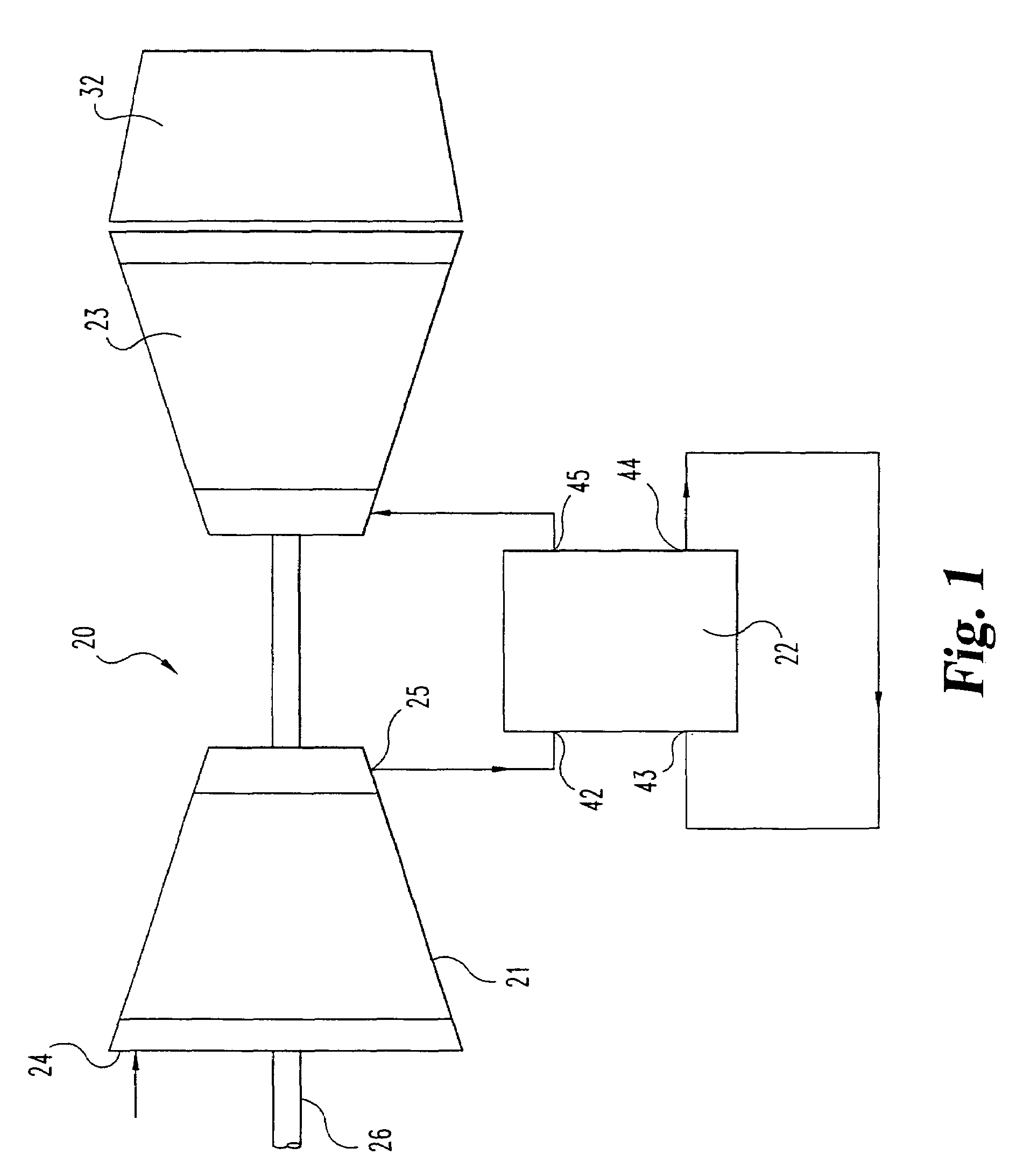

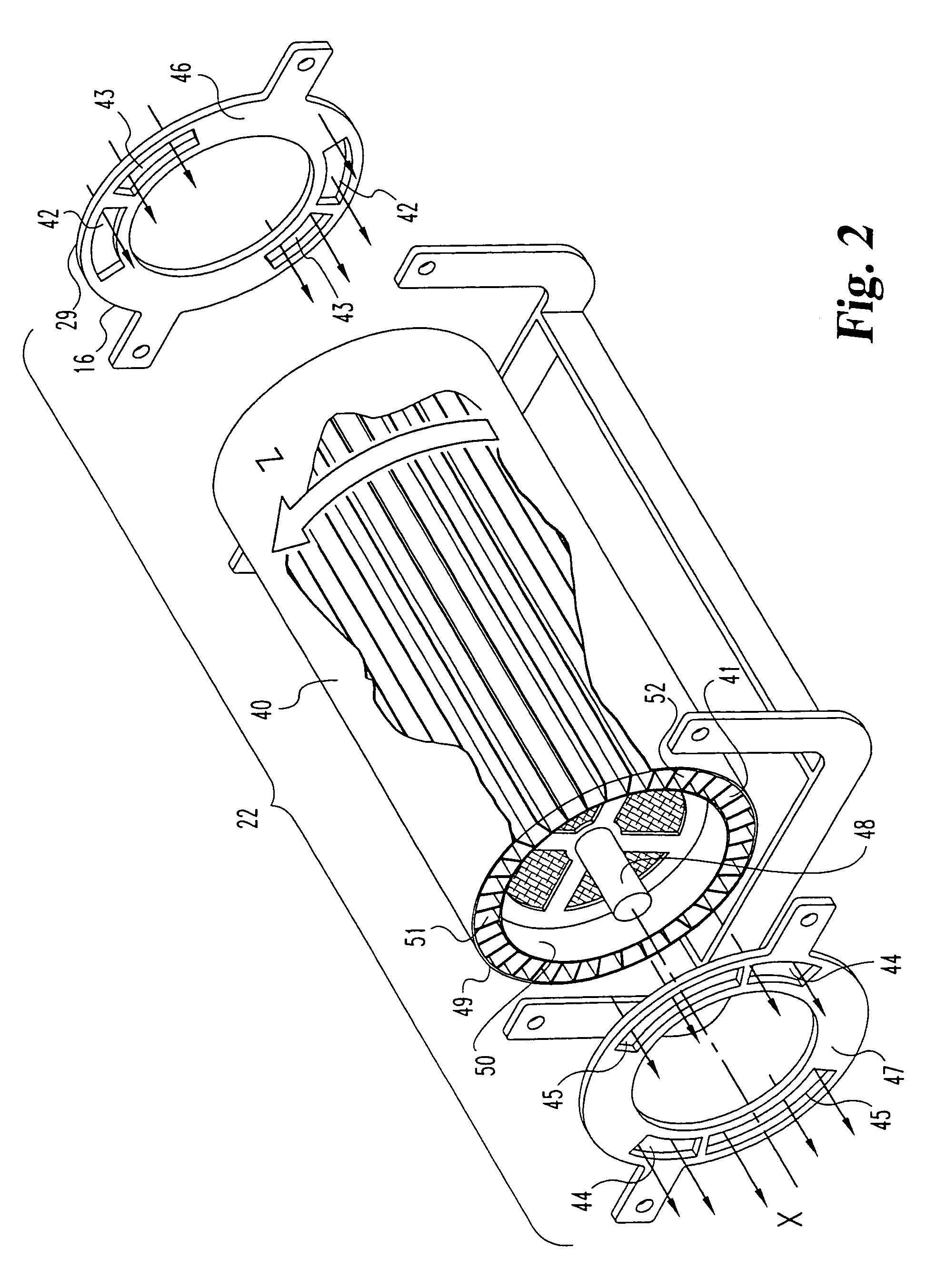

Constant volume combustor having a rotating wave rotor

InactiveUS7621118B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustorMagnetic bearing

A constant volume combustor device includes, in one form, a detonative combustion. In one form the wave rotor of the constant volume combustor is supported by magnetic bearings. The constant volume combustor device includes a rotor having a number of fluid passageways that rotate about an axis. End plates having at least one inlet port and at least one outlet port are located on either end of the rotor. Relatively compressed air enters the rotor through the at least one inlet port, is burned with fuel in a pulsed combustion process, and exits at least one exit port. The pulsed combustion process can be a pulsed detonation combustion process or a pulsed deflagration combustion process.

Owner:ROLLS ROYCE NORTH AMERICAN TECH

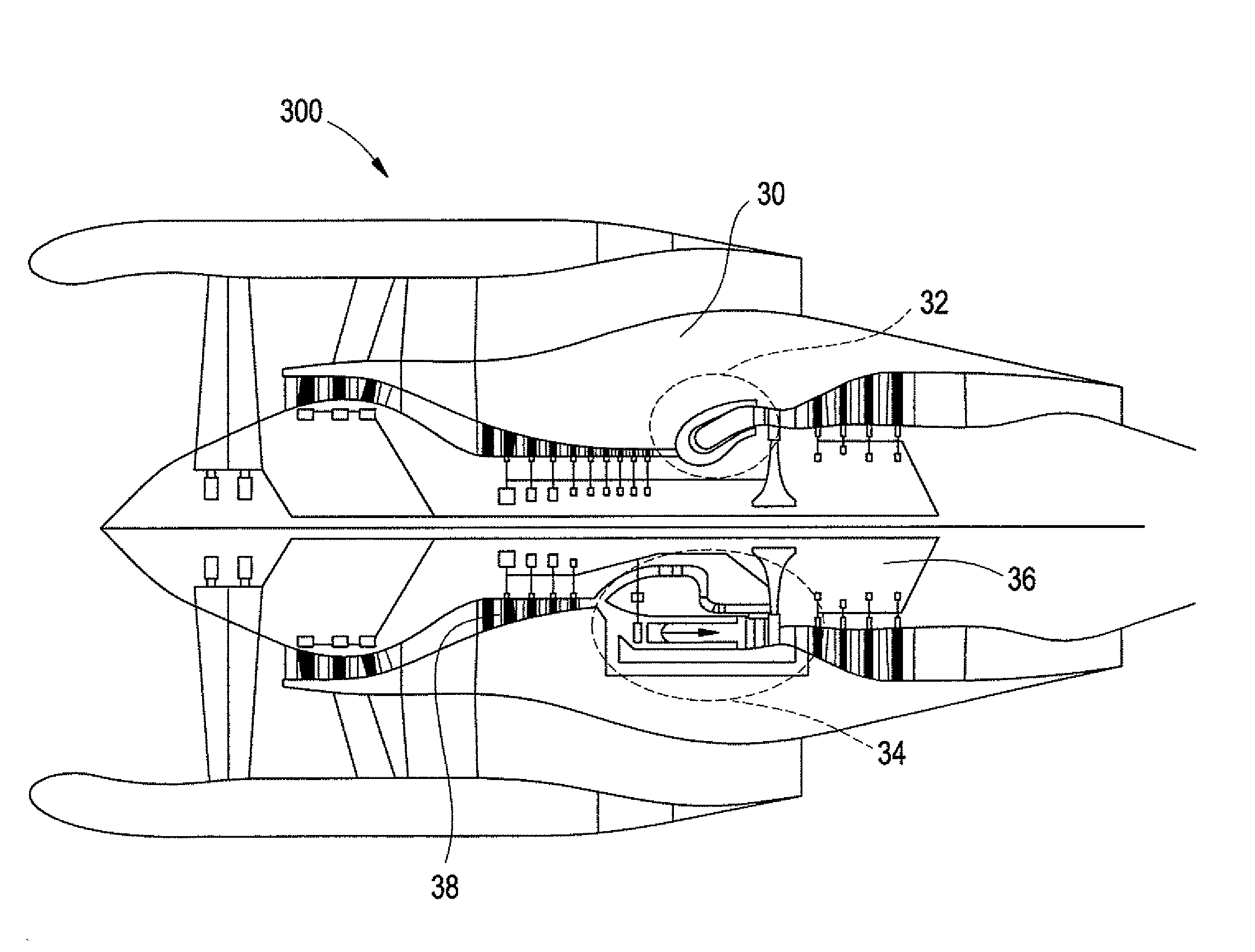

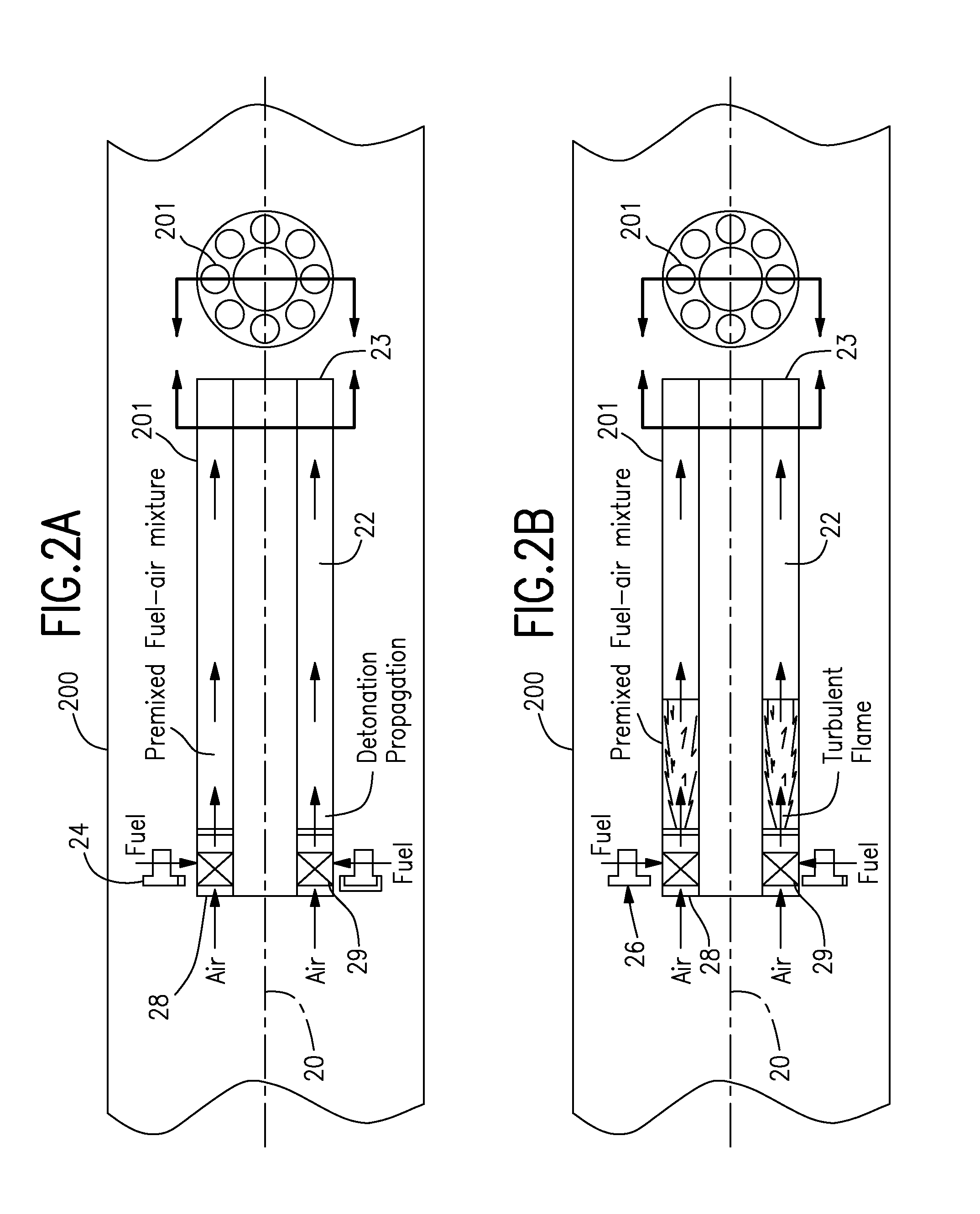

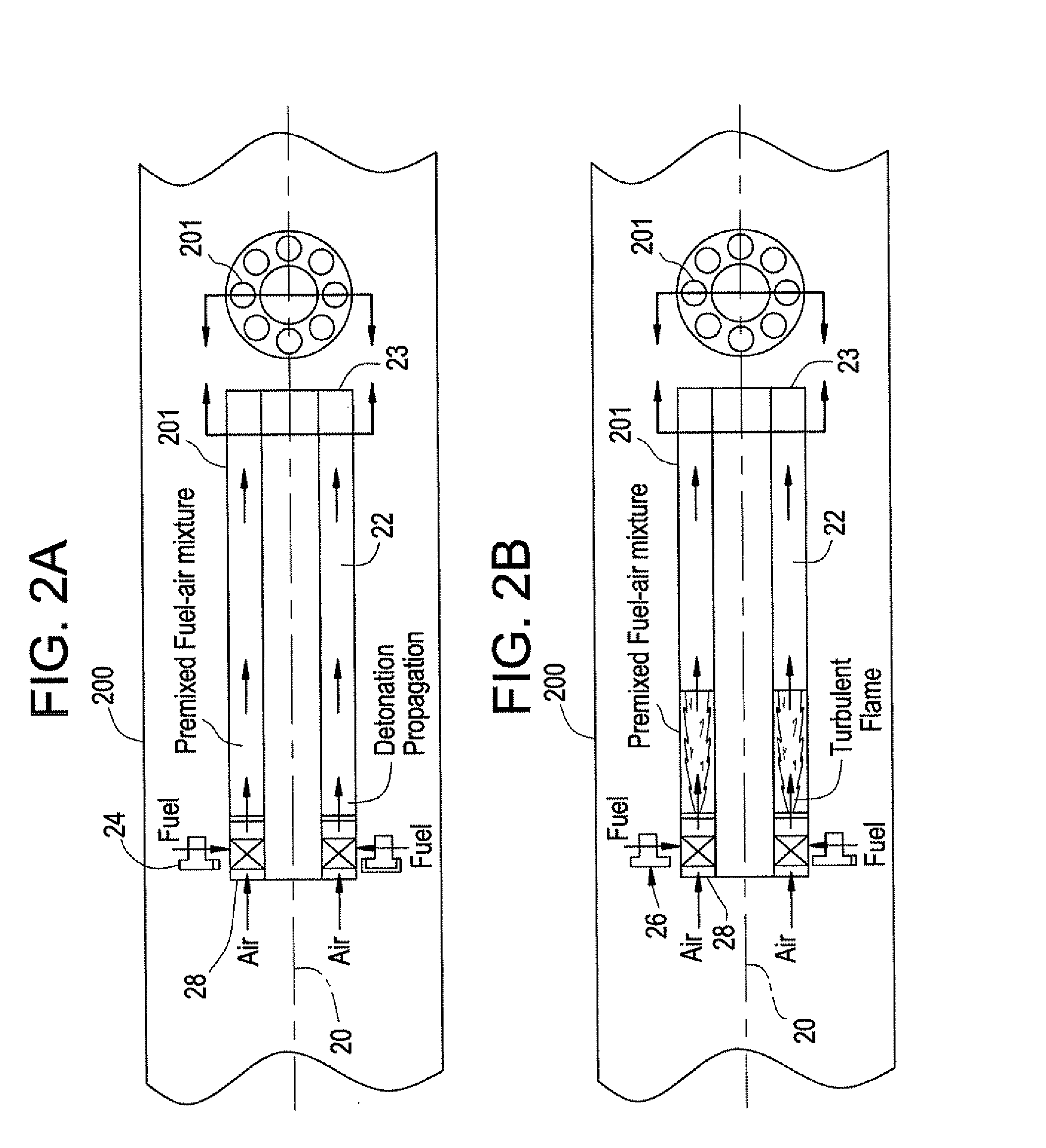

Dual mode combustion operation of a pulse detonation combustor in a hybrid engine

InactiveUS7950219B2Easy to operateEfficient combustionContinuous combustion chamberGas turbine plantsCombustion chamberSolenoid valve

A dual mode combustor of a gas turbine engine contains at least one dual mode combustor device having a combustion chamber, a fuel air mixing element, a high frequency solenoid valve and a fuel injector. During a first mode of operation the dual mode combustor device operates in a steady, constant pressure deflagration mode, receiving its fuel from the fuel injector. In a second mode of operation the dual mode combustor device operates in a pulse detonation mode, receiving its fuel from the high frequency solenoid valve.

Owner:GENERAL ELECTRIC CO

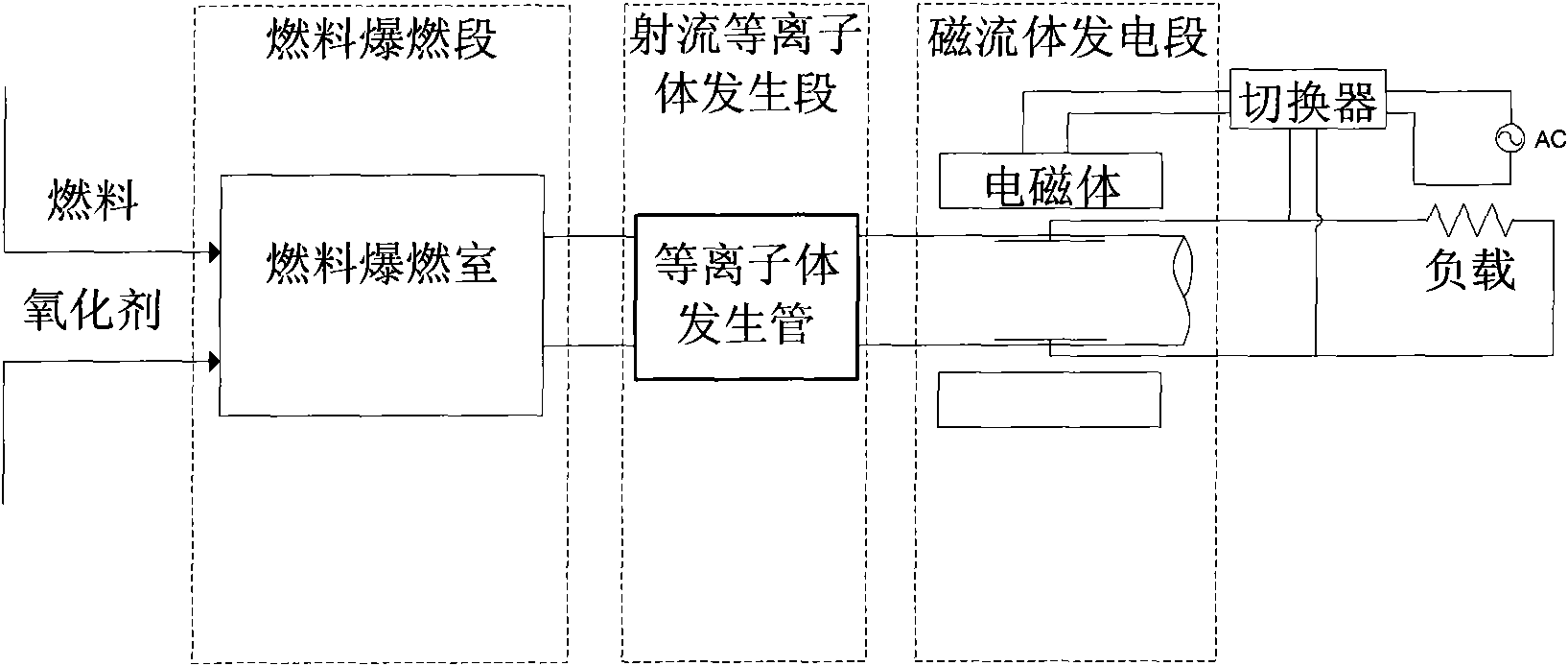

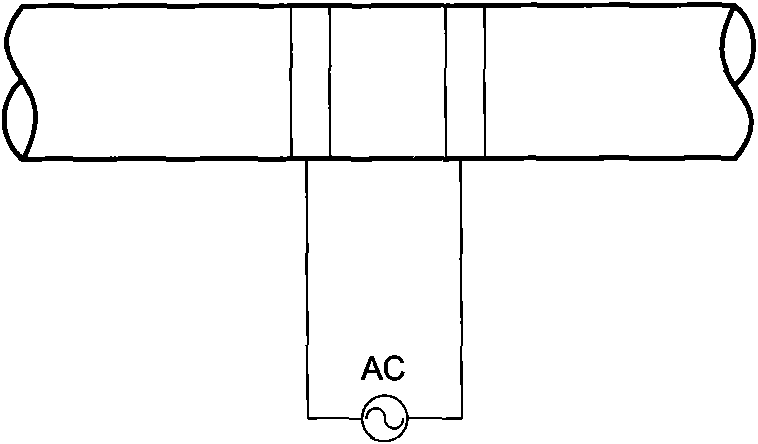

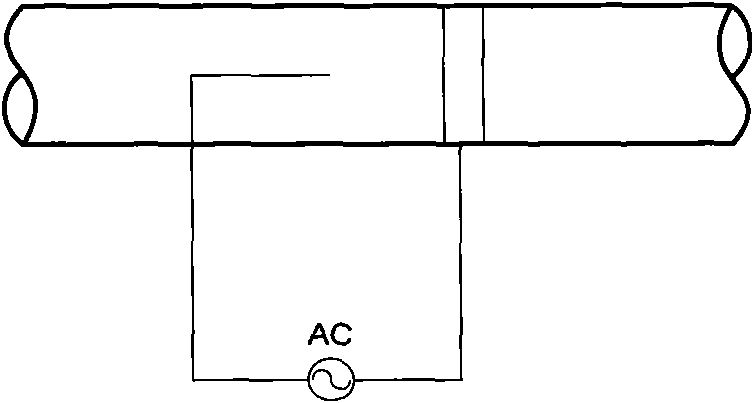

Deflagration-non-equilibrium plasma magnetohydrodynamics power generating method and device

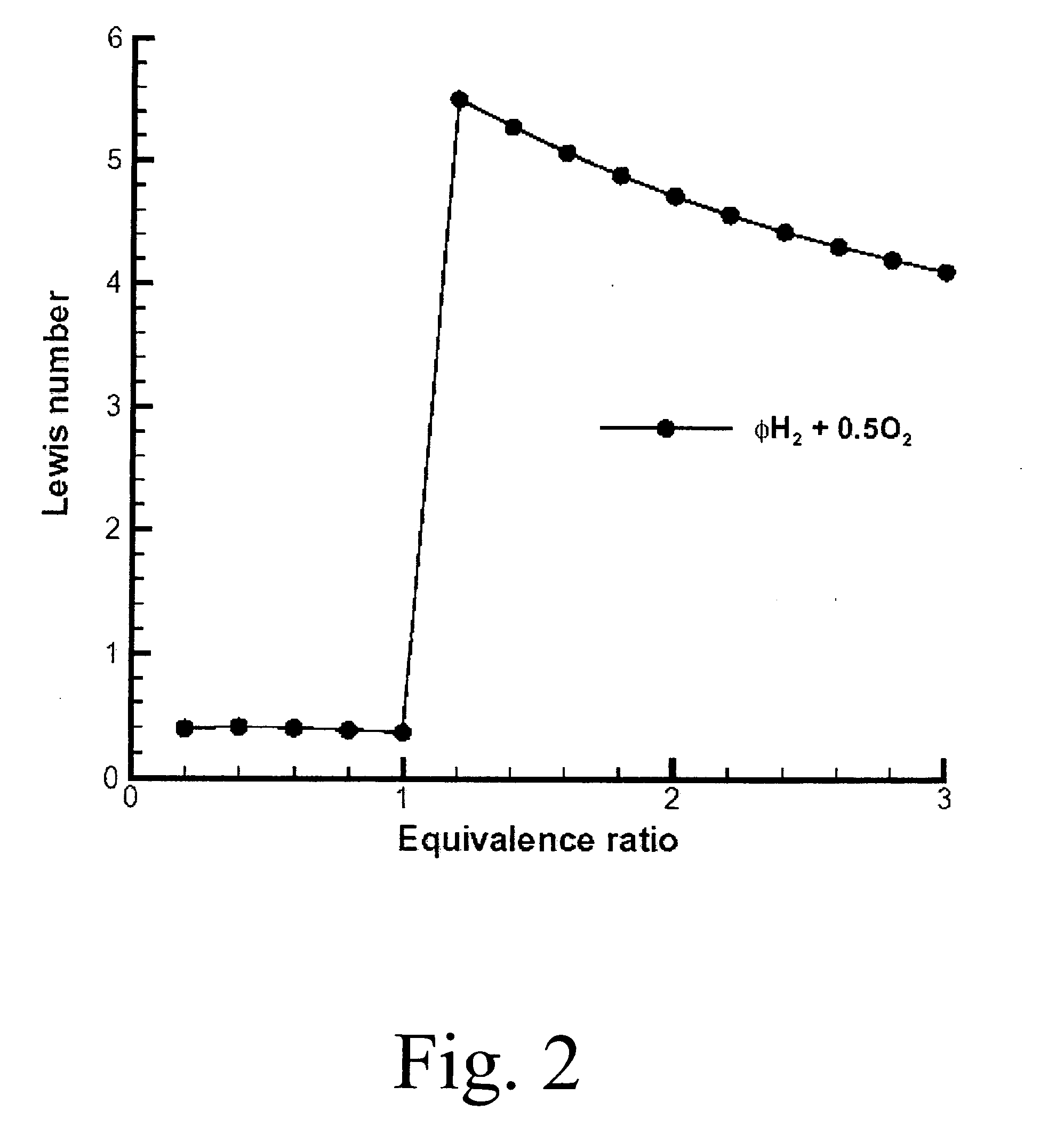

InactiveCN101572476ALow ionization energy consumptionReduce energy consumptionDynamo-electric machinesPlasma techniqueChemical reactionEquivalent weight

The invention provides a deflagration-non-equilibrium plasma magnetohydrodynamics power generating method and a device used by the method, which can generate a low-temperature non-equilibrium plasma flow which flows through magnetic fields to form a magnetic fluid power generating system. The method comprises the following steps: 1, deflagrating fuel, wherein an oxidant and the fuel are mixed in a ratio of 1.05 to 1.5 times of chemical reaction equivalent weight, and the mixture enters a fuel deflagration chamber for continuous deflagration so as to form high-pressure gas of which the pressure is between 0.5 and 2 MPa; 2, generating the jet plasma, wherein the high-pressure gas obtained in the first step enters a plasma generating pipe of which the voltage is between 5 and 50 kV and the frequency is between 10 kHz and 1 MHz at a speed of between 20 and 200 m / s so as to generate the non-equilibrium jet plasma which has the characteristics of the magnetic fluid and of which the conductivity is between 10 and 20 S / m and the temperature is between 1,000 and 1,200 K; and 3, generating power by the magnetic fluid, wherein the non-equilibrium jet plasma enters the magnetic fields of a normal conducting electromagnet of which the magnetic induction is between 0.5 and 2.5 T at a speed of between 20 and 200 m / s, and moves to generate electromotive force.

Owner:SOUTHEAST UNIV

Hot aerosol fire extinguisher with thermostable ablative-insulative layer and manufacture method

InactiveCN101700427AGood heat insulationImprove moisture resistanceFire rescueFire extinguisherPolymer scienceRoom temperature

The invention provides a hot aerosol fire extinguisher with a thermostable ablative-insulative layer and a manufacture method. The hot aerosol fire extinguisher with the thermostable ablative-insulative layer is provided with an outer cylinder, an insulative layer, an inner cylinder, an aerosol generating agent, a cooling layer and a starter, wherein the insulative layer is made of silicone rubber materials comprising a silicone rubber substrate, a crosslinker, a flame retardant, a thermostable substance, a coupling agent and a catalyst. The manufacture method comprises the following steps of: integrally casting the insulative layer and an aerosol generating agent grain; crosslinking and curing at a room temperature; and assembling parts. The silicone rubber insulative layer is internally provided with the starter, a cooling material and the aerosol generating agent grain and fixed in a device shell; and a top cover is arranged above the cooling material and provided with an aerosol nozzle. Compared with the traditional device, the invention has the advantages of simple silicone rubber casting process, convenient mass production and good insulative effect of the silicone rubber insulative layer, and the wrapped aerosol generating agent can be stably burnt so as to avoid phenomena, such as flame over, deflagration, and the like.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Fire suppressing gas generator composition

InactiveUS20020137875A1Increase volumeReduce the temperatureOther chemical processesFire extinguisherElastomerParticulates

A fire suppressing gas generator composition which has a low burn temperature which provides an adjustable mass flow rate, which provides high inert gas yields upon combustion, which generates flame suppressing gasses during composition, which provides exhaust gas with low particulate content, and which is suitable for use in pellet form. The gas generator composition of the invention generally comprises a high nitrogen content solid, preferably 5-amino tetrazole, and potassium perchlorate or other oxidizer salt in an amount sufficient to allow flameless deflagration of the high nitrogen contant solid. The composition of the invention also preferably comprises a flame inhibitor precursor such as perbrominated aromatic compound, an elastomeric binder, a powder pressing modifier or enhancer such as mica, and an electrostatic charge suppressant such as graphite.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

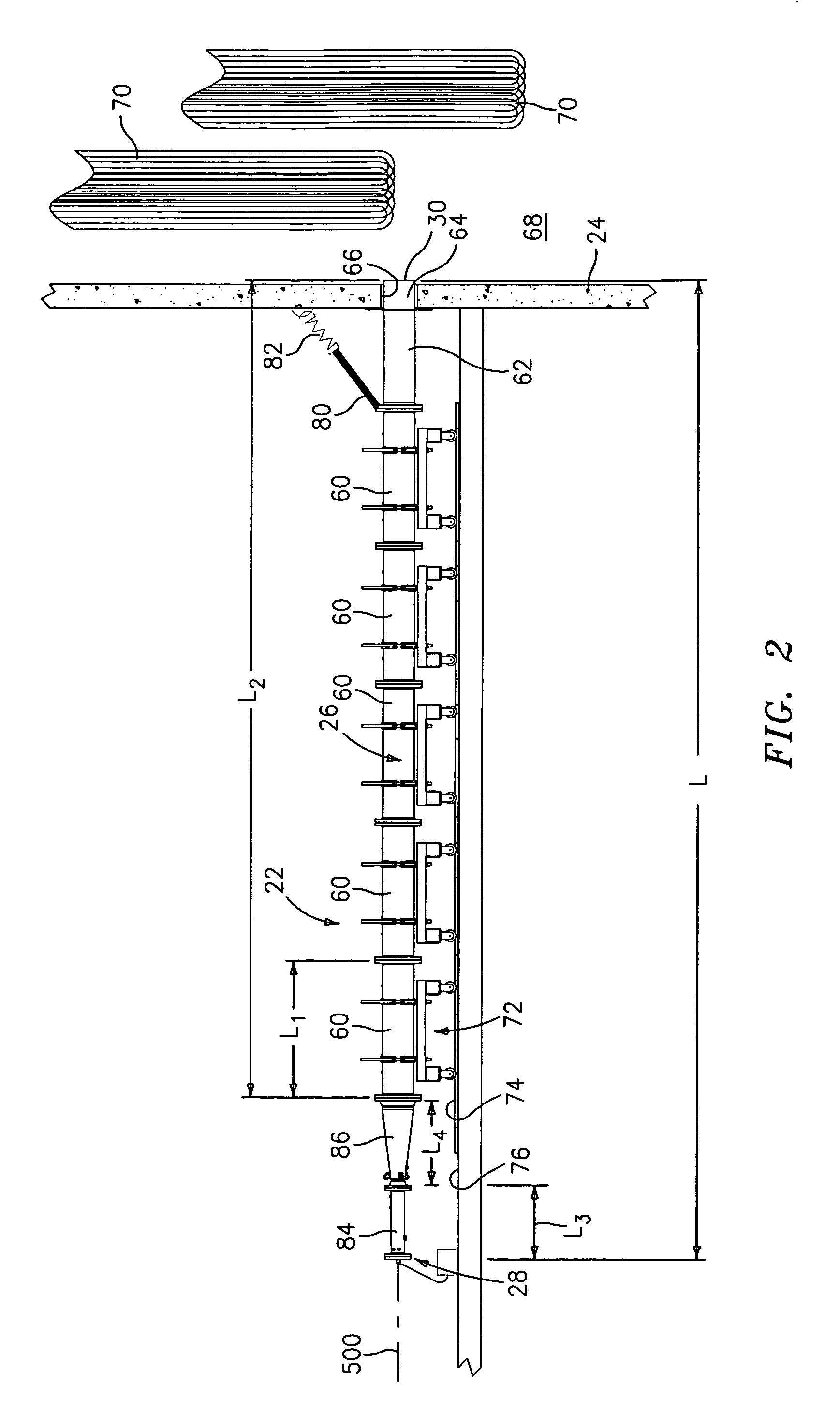

Detonative cleaning apparatus

InactiveUS7011047B2Pulsating combustionHollow article cleaningCombustionDeflagration to detonation transition

Methods and apparatus are provided for cleaning a surface within a vessel. A fuel / oxidizer charge is provided within a combustion conduit. An initial deflagration commenced in a first portion of the charge produces a final detonation at least in another portion of the charge to expel a shockwave from the conduit which impinges upon the surface. The deflagration-to-detonation transition may be encouraged by mechanical enhancements and / or by making the first charge portion more detonable than the second.

Owner:SHOCKSYST

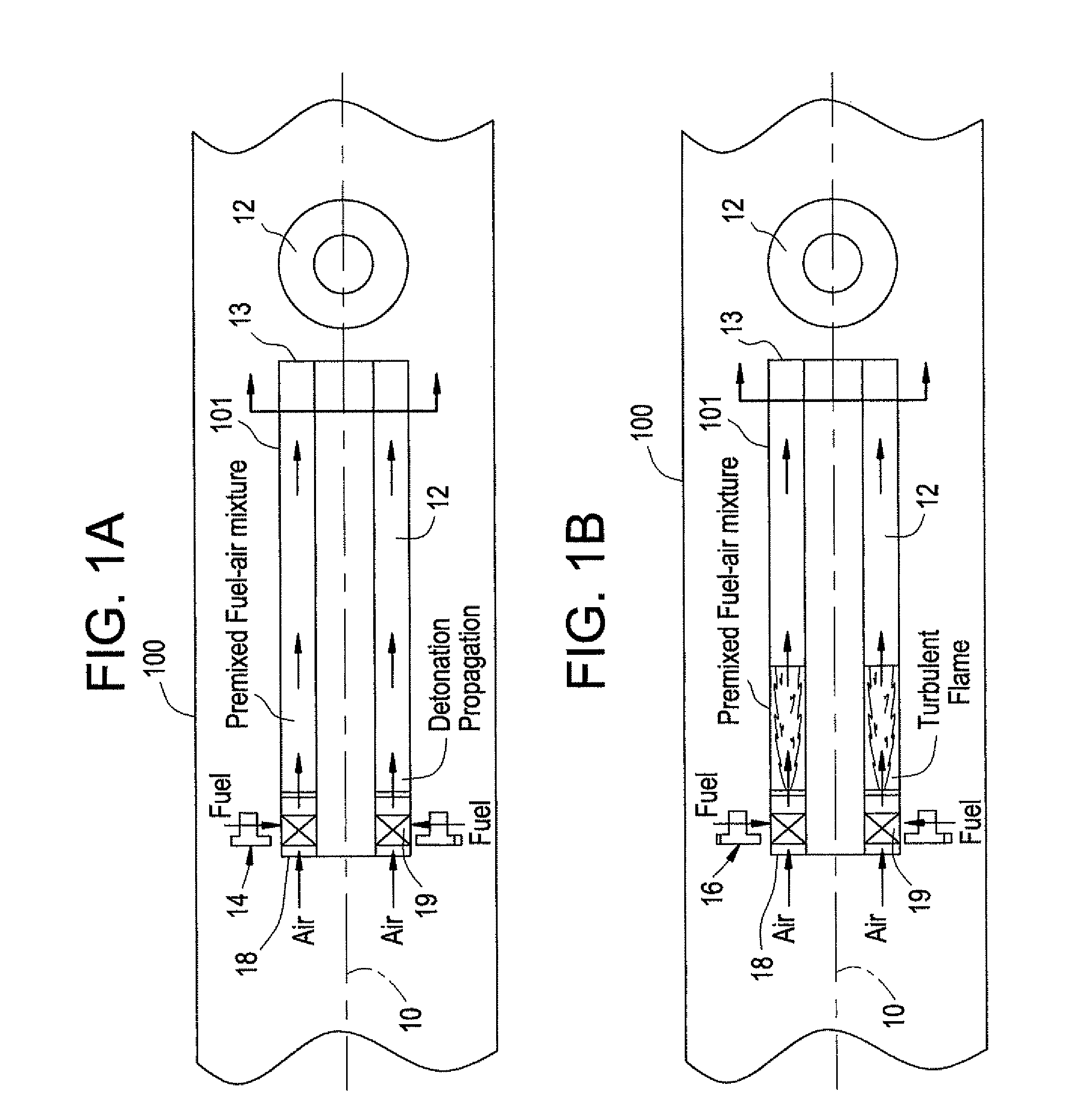

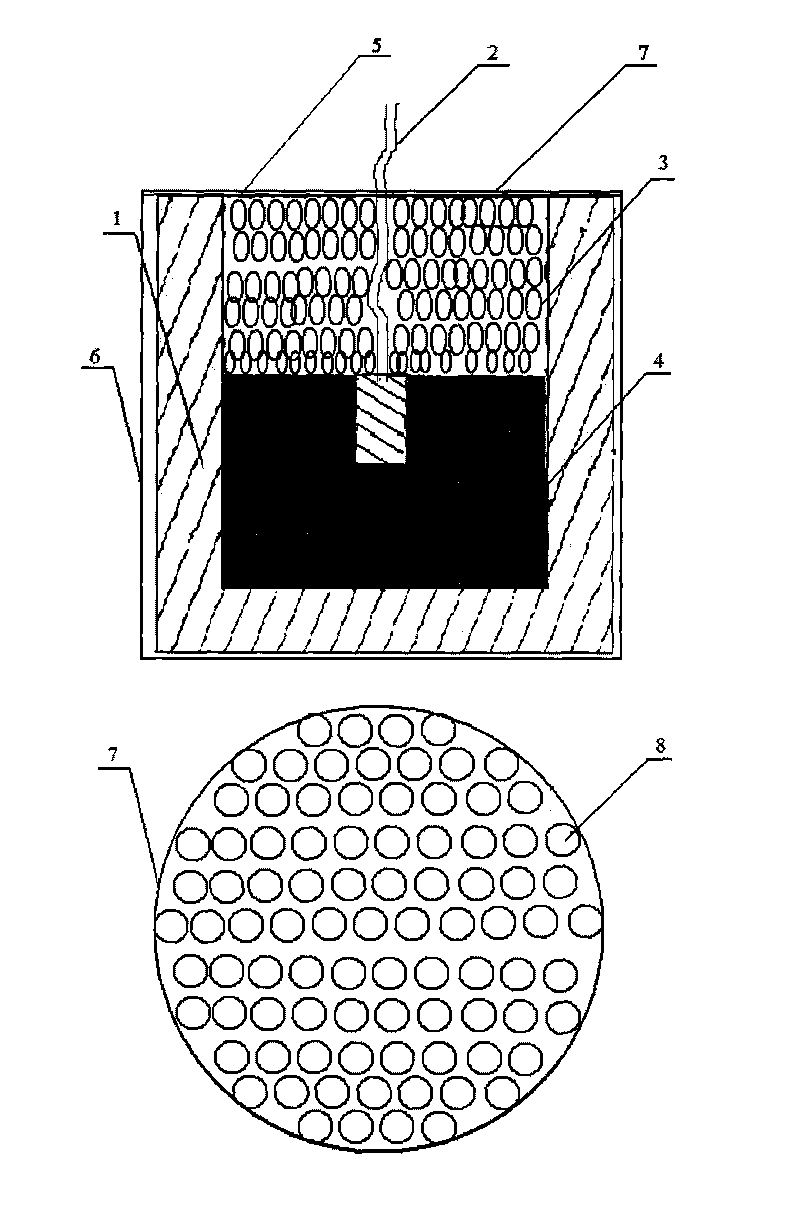

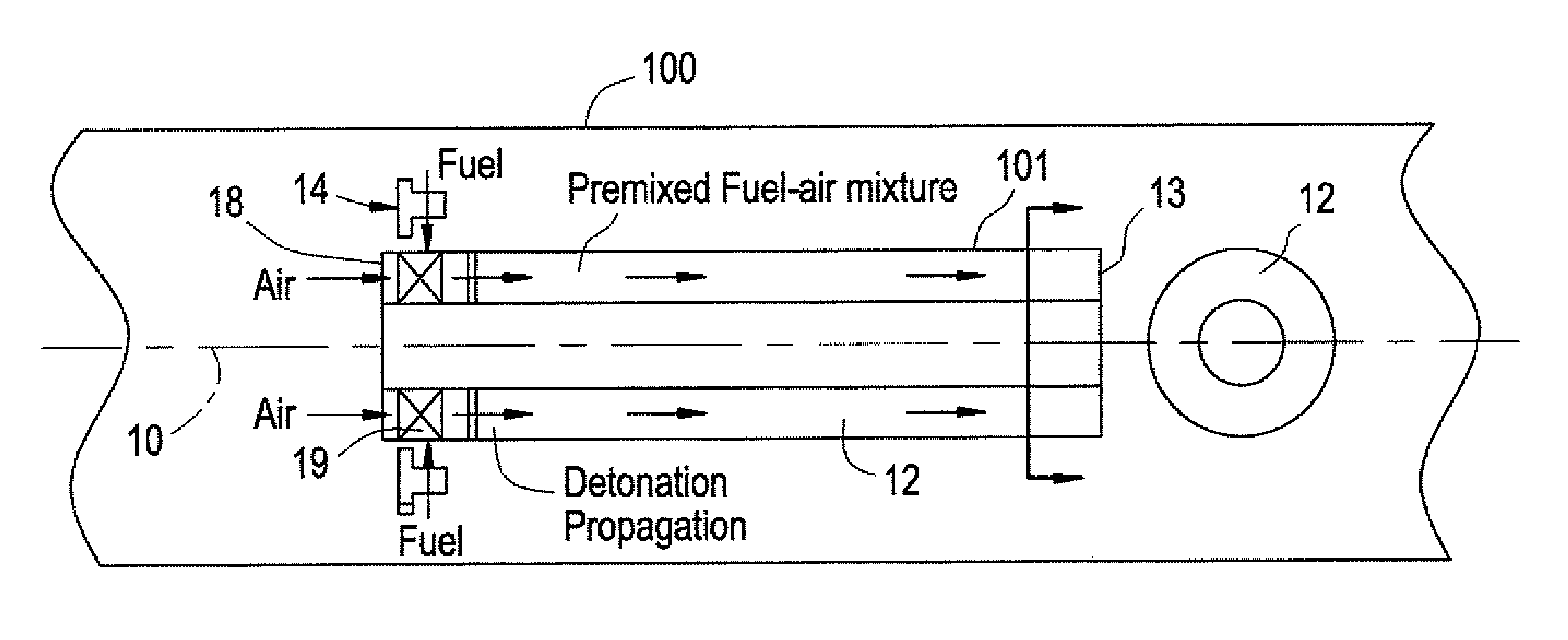

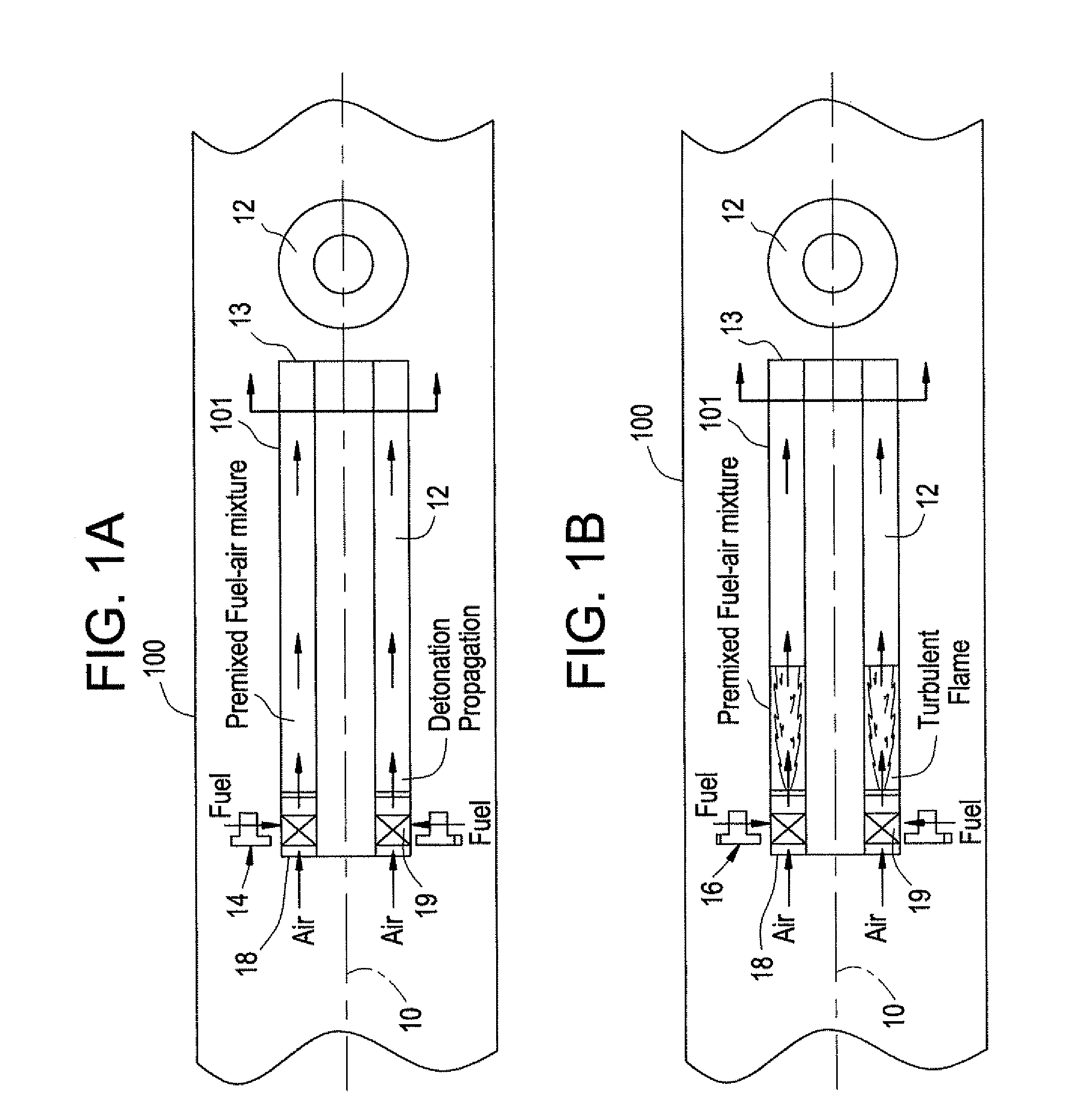

Pulse detonation/deflagration apparatus and related methods for enhancing DDT wave production

ActiveUS8205433B2Easy to implementEnhancing deflagration to detonation wave productionCosmonautic vehiclesEngine manufactureCombustion chamberEngineering

Pulse detonation / deflagration apparatus for providing enhanced pressure wave operating frequency and / or magnitude, and methods of increasing the frequency or the magnitude of deflagration to detonation waves, are provided. A pulse detonation / deflagration apparatus can include a main / outer pulse detonation / deflagration actuator / engine (PDA / E) with multiple smaller internal combustion chambers or tubes positioned inside the cavity of the main / outer PDA / E with each performing the function of individual PDA / Es. The output pressure waves created by the internal PDA / Es can be utilized for propulsion or for controlling large scale flows, where needed.

Owner:LOCKHEED MARTIN CORP

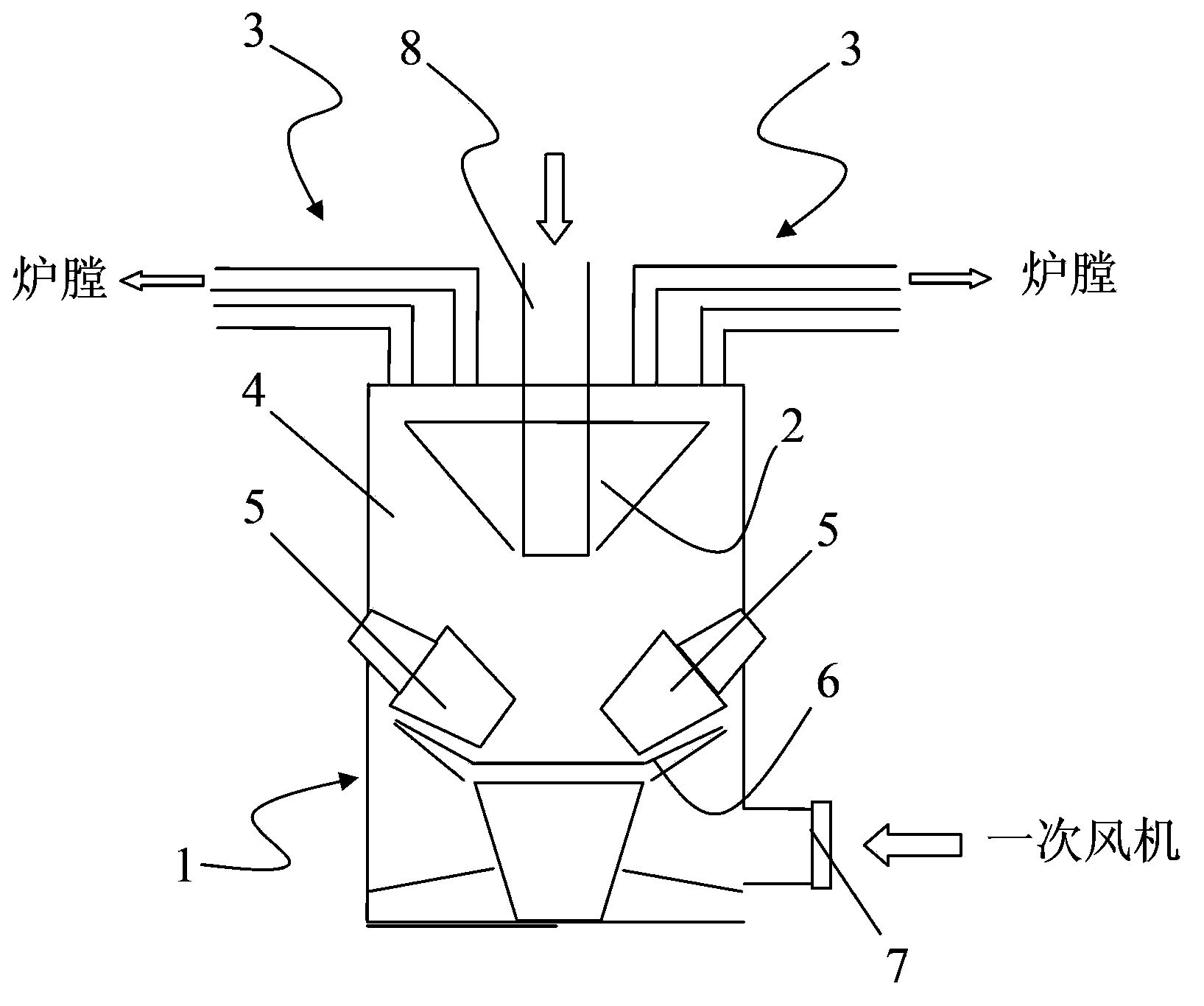

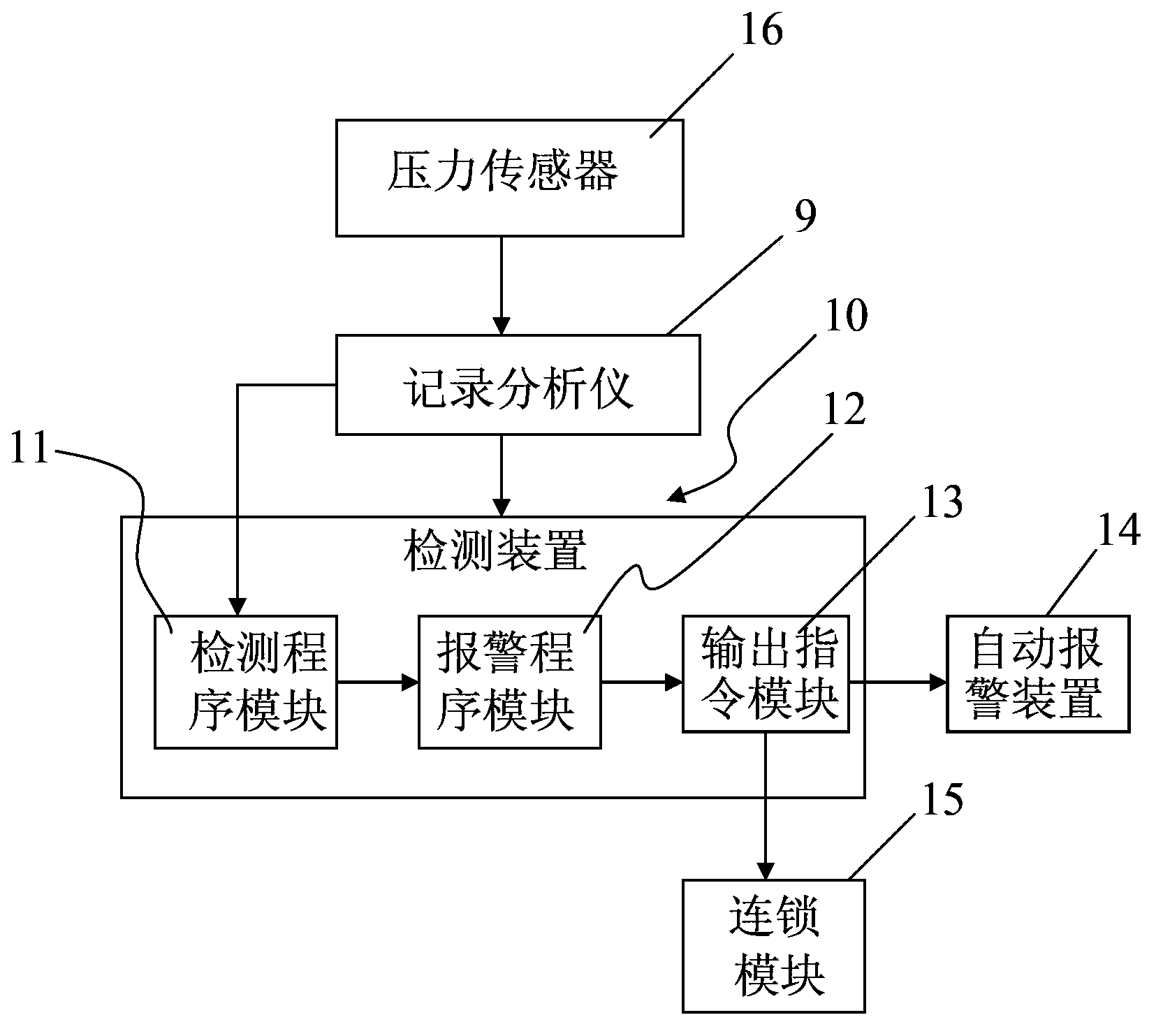

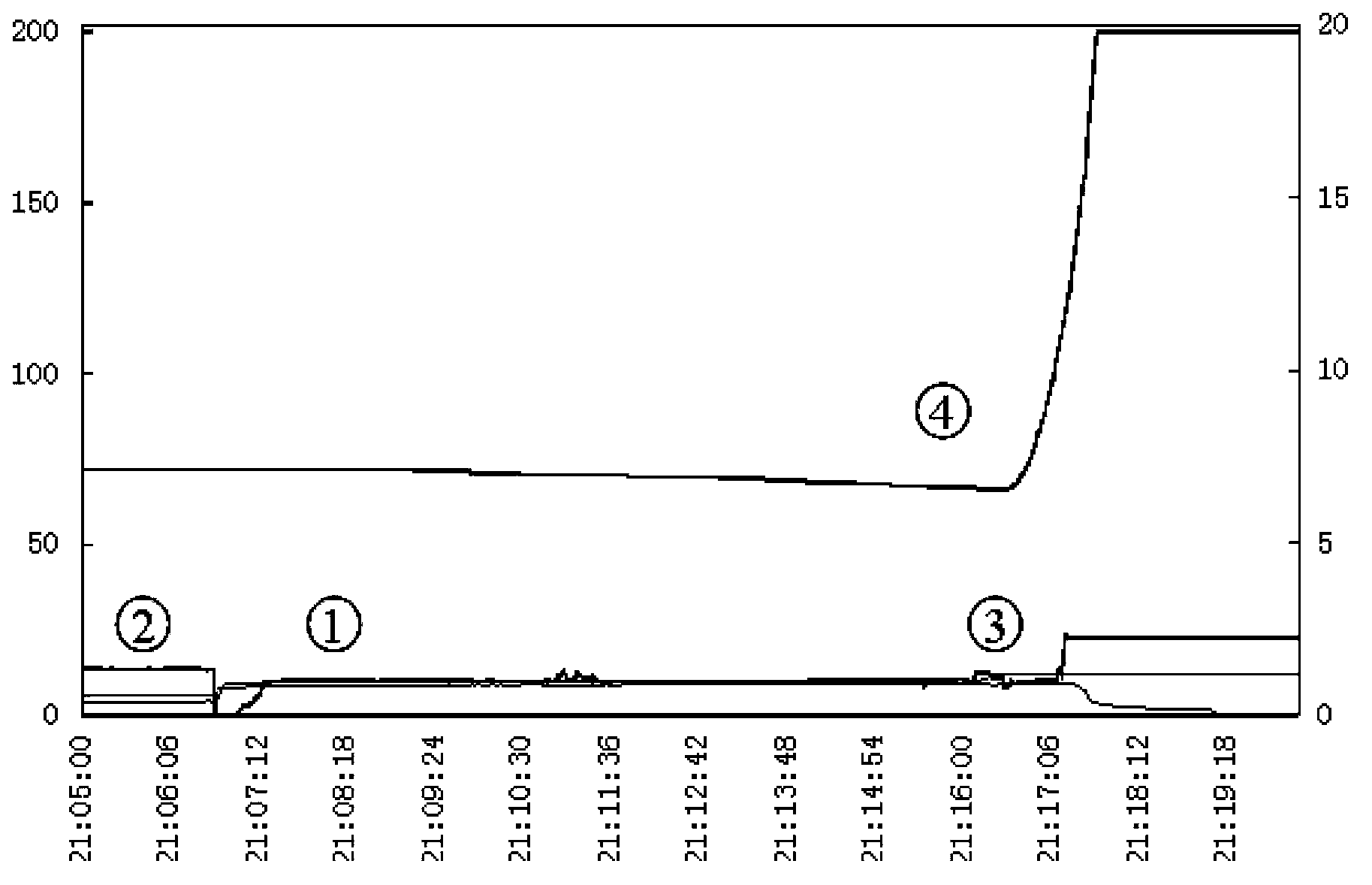

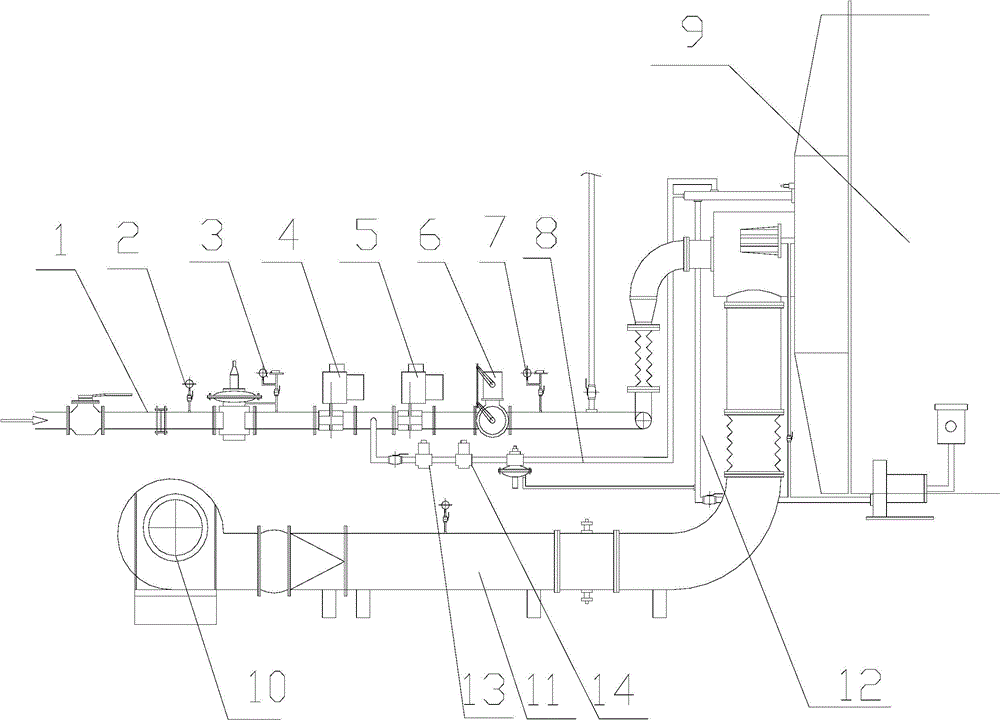

Method for detecting deflagration in coal mill outlet coal dust pipeline, and detection system thereof

ActiveCN103909006AEfficient detection and alarmSimple detection and alarmFluid pressure measurementGrain treatmentsCoal dustEngineering

The invention relates to a method for detecting deflagration in a coal mill outlet coal dust pipeline, and a detection system thereof. The detection method comprises the following steps: analyzing and screening all deflagration accident records to obtain parameter records having related characteristics and determine the deflagration instance of a milling system and characteristic parameters most related with the deflagration; sensing related pressure parameter signals by online arranged pressure sensors; recording a pressure parameter signal curve through a record analyzer; picking pressure signals through a detection device, determining and comparing abruptly changed pressure signal parameters, and instantly emitting an alarm signal through an alarm device if deflagration generation determination conditions are met; and instantly emitting a milling system running stopping command through a linkage module, and carrying out closed milling or steam fire extinguishing treatment in order to rapidly inhibit the deflagration of the milling system in an initial stage. The method and the system can realize efficient, stable and reliable detection and alarming, and can timely emit the signal after the deflagration and instantly stop the running of the milling system.

Owner:BAOSHAN IRON & STEEL CO LTD

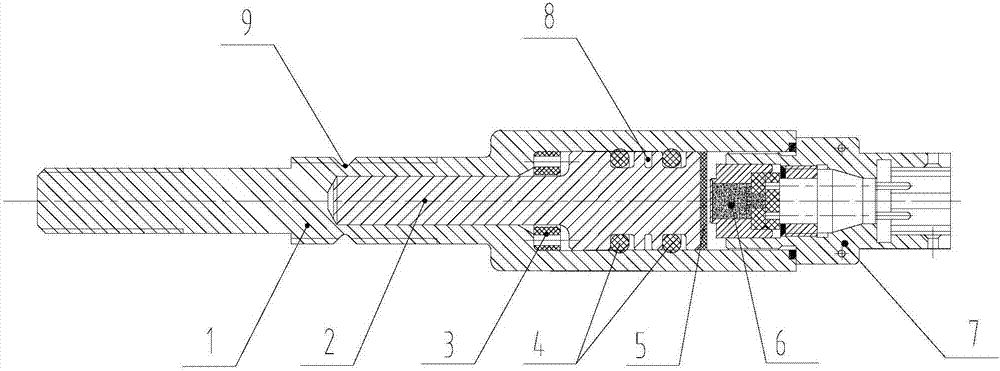

Strong seal explosion bolt device

ActiveCN107191459AEnhanced anti-explosion sealing abilityAvoid failureScrewsSelf-propelled projectilesRubber ringEngineering

The invention discloses a strong seal explosion bolt device. A bolt shell, a piston, a buffer ring, O-shaped rubber rings, a nonmetal gasket, explosive and an igniter are sequentially mounted on a main shaft from left to right; the piston and the buffer ring are mounted in a containing cavity of the bolt shell; a V-shaped groove is designed in the bolt shell to serve as a strength weak link; two sealing grooves and an explosion decompression groove are designed in the piston; the double O-shaped rubber rings are mounted in the two sealing grooves of the piston correspondingly; the nonmetal gasket is pasted on the bottom end face of the piston through curing glue; and the explosive is mounted in the igniter, and then the igniter is connected with the bolt shell in a thread fit mode. The situation that deflagration gas generated by the explosive is leaked from the V-shaped groove after a bolt is broken can be prevented, and a very good sealing effect is achieved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Detonative cleaning apparatus

InactiveUS20050112516A1Pulsating combustionHollow article cleaningCombustionDeflagration to detonation transition

Methods and apparatus are provided for cleaning a surface within a vessel. A fuel / oxidizer charge is provided within a combustion conduit. An initial deflagration commenced in a first portion of the charge produces a final detonation at least in another portion of the charge to expel a shockwave from the conduit which impinges upon the surface. The deflagration-to-detonation transition may be encouraged by mechanical enhancements and / or by making the first charge portion more detonable than the second.

Owner:SHOCKSYST

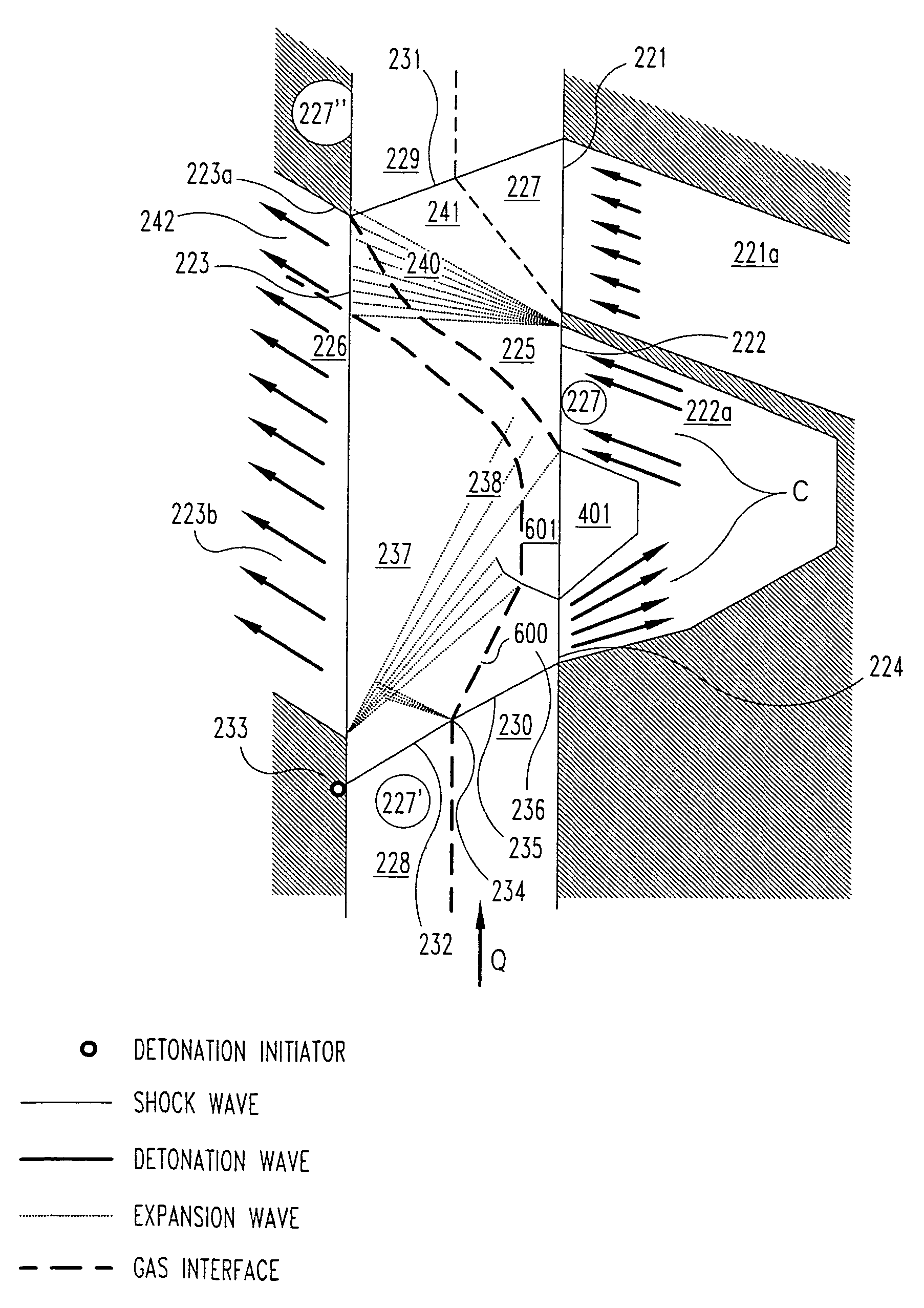

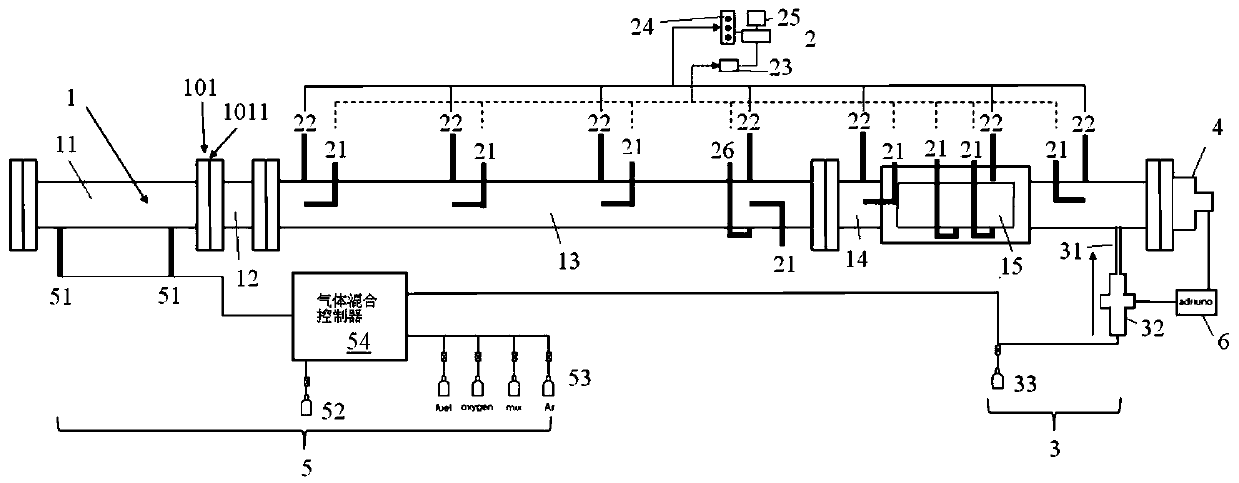

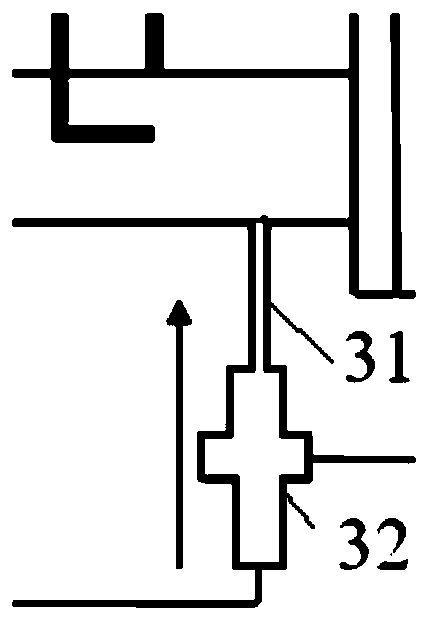

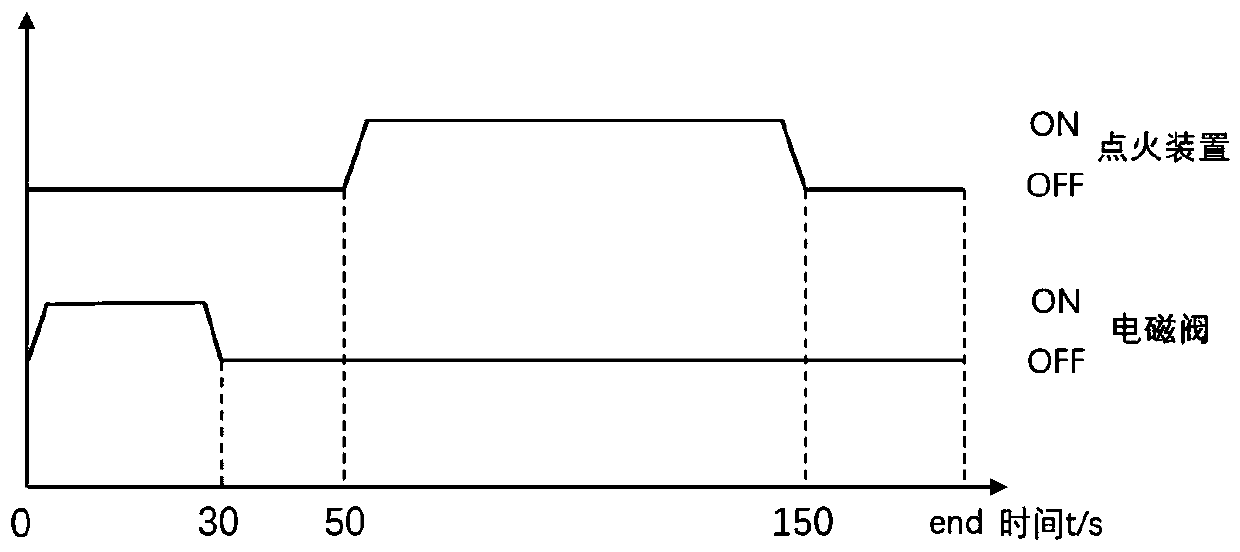

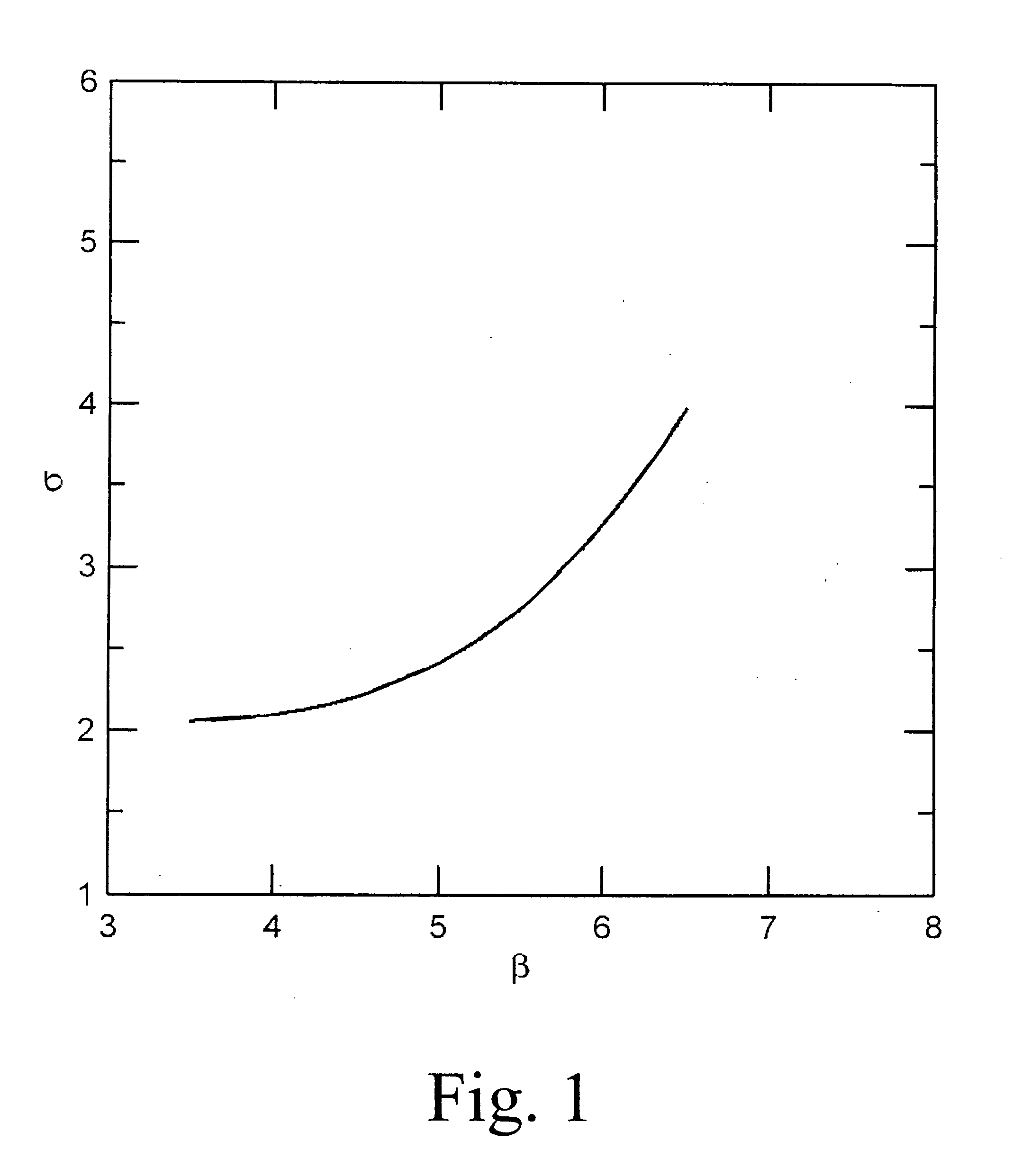

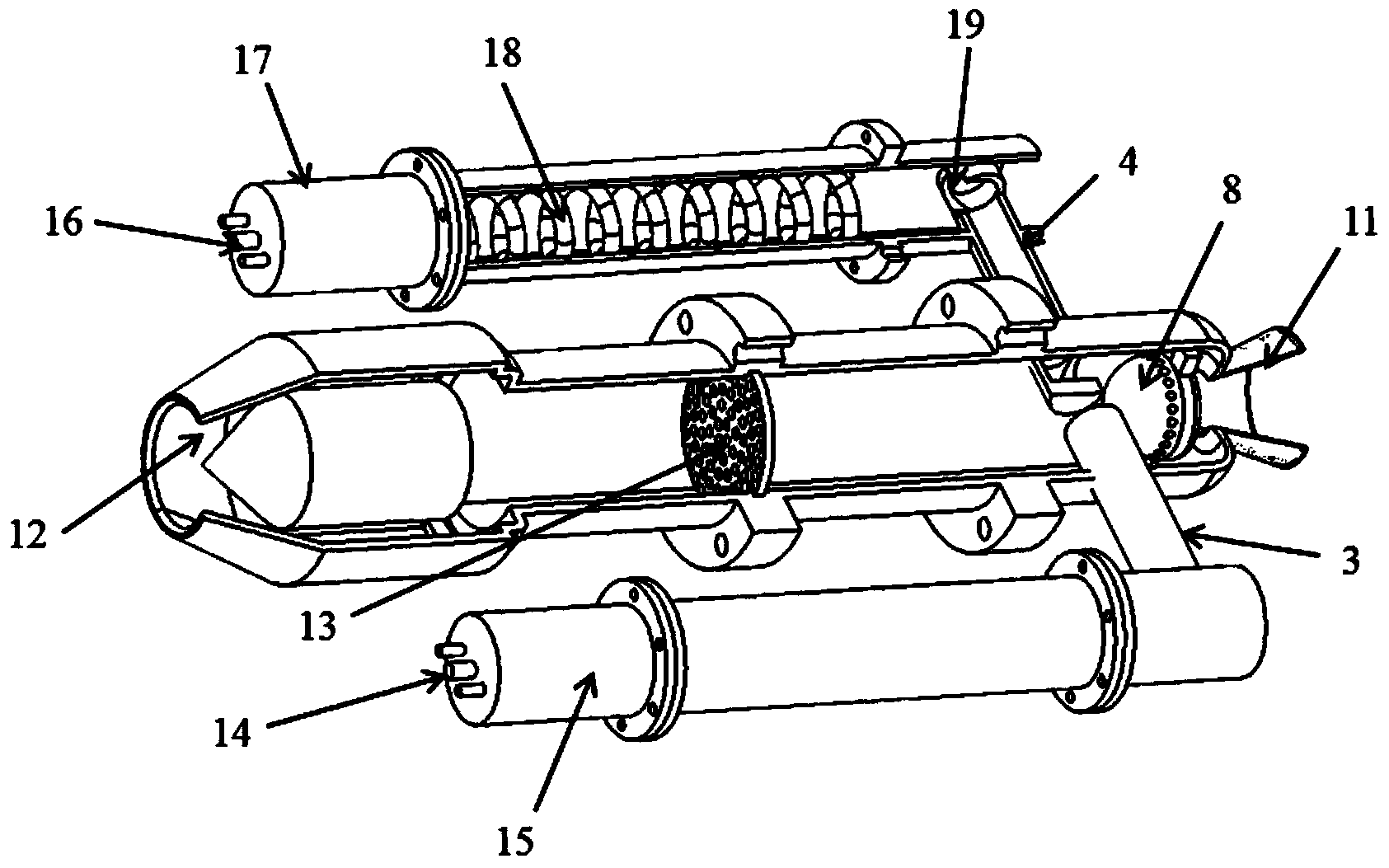

Detonation excitation system and method based on high speed jet

ActiveCN110220942AIncreased turbulenceShorten the distance from combustion to detonationMeasurement of fluid loss/gain rateSubsonic/sonic/ultrasonic wave measurementJet flowControl system

The invention provides a detonation excitation system based on high speed jet. The system comprises a shock tube, wherein a plurality of holes are set on the shock tube, through utilization of the holes; the shock tube is assembled with a test mixed gas system, a data collection system and a jet control system in sequence along a length direction of the shock tube; an ignition system is set at a tail end of the shock tube; the data collection system comprises a plurality of optical fiber sensors and a plurality of shock wave probes which are inserted into the holes of the shock tube at equal intervals, and the jet control system and the ignition system are connected with a control panel. The invention also provides a detonation excitation method. According to the detonation excitation system based on the high speed jet provided by the invention, through mutual effect of the high speed jet and flame, detonation is excited through the high speed jet, so a relatively small blockage ratiocan be achieved, deflagration to detonation distance can be effectively reduced, and total pressure losses in a whole detonation process can be reduced.

Owner:SHANGHAI JIAO TONG UNIV

Detonation safety in microchannels

InactiveUS20060035182A1Increased flame speedProcess control/regulationFuel lightersInherent safetyFlame propagation

The proper sizing of microchannel dimensions and the management of internal features offer the possibility of inherently safe operation within the flammable limits of a combustible fluid stream while preserving the largest-possible flow dimensions for industrial-scale process capacity. Specifically, the microchannel dimensions need not be restricted to gap distances below the quenching distance to be operated safely. Microchannel performance can be engineered to provide adequate heat transfer for flame propagation. However, it is essential to maintain flame characteristics in such a manner that it cannot transition to a detonation flame front. A detonation takes place when the combustion wave propagates at supersonic speeds at the existing local temperature and pressure conditions in the system. It results in a much larger energy release over a much smaller period of time as compared to a laminar flame or deflagration, the later of which is a combustion wave propagating at subsonic speed. Detonations can be potentially highly destructive and very hazardous and therefore should be avoided for most industrial applications.

Owner:VELOCYS CORPORATION

Plastic encapsulated energetic material initiation device

An initiator with a housing formed of plastic and a chip assembly for initiating at least one of a combustion event, a deflagration event and a detonation event. The chip assembly includes an electrically-actuated chip and a pair of electric leads that extend through the housing and are configured to couple the electrically-actuated chip to a fireset circuit. The electrically-actuated chip is partially encapsulated in the housing. A method for forming an initiator is also provided.

Owner:REYNOLDS SYST

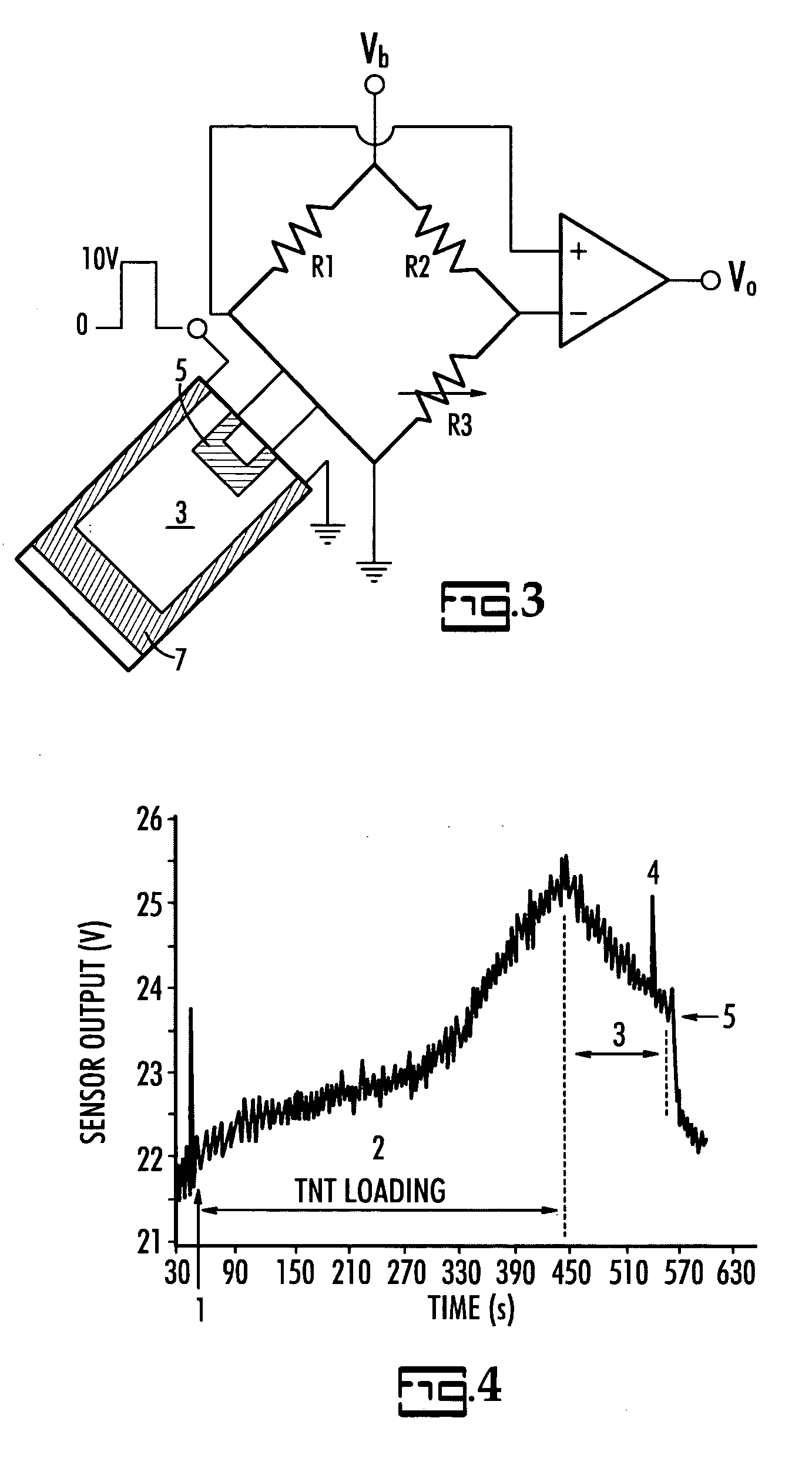

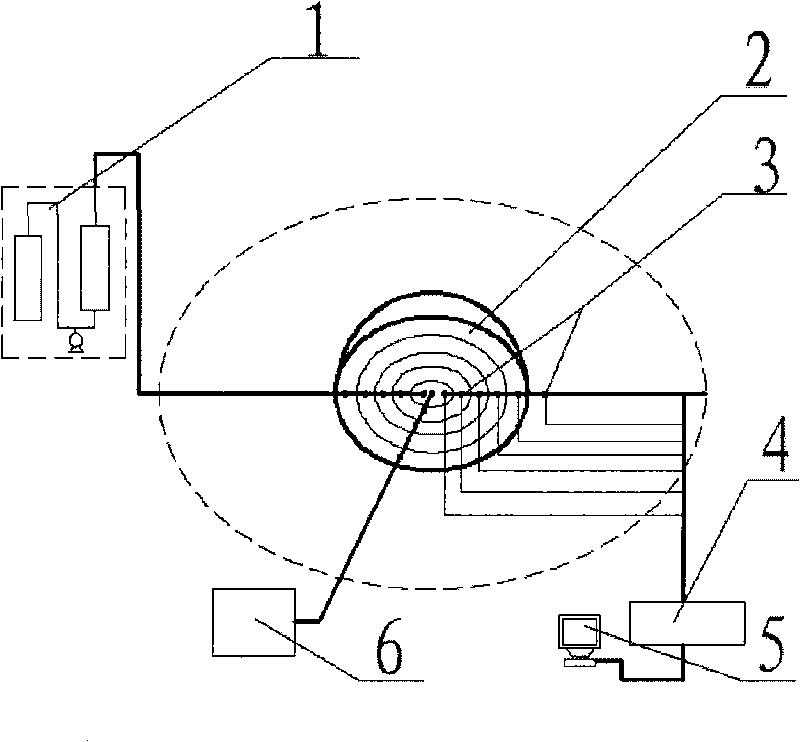

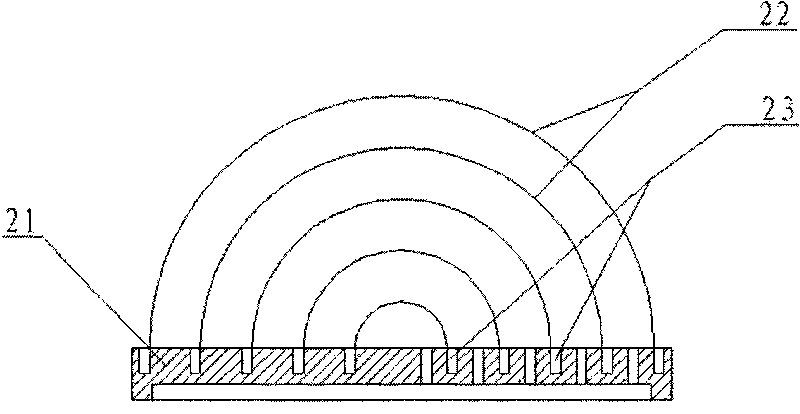

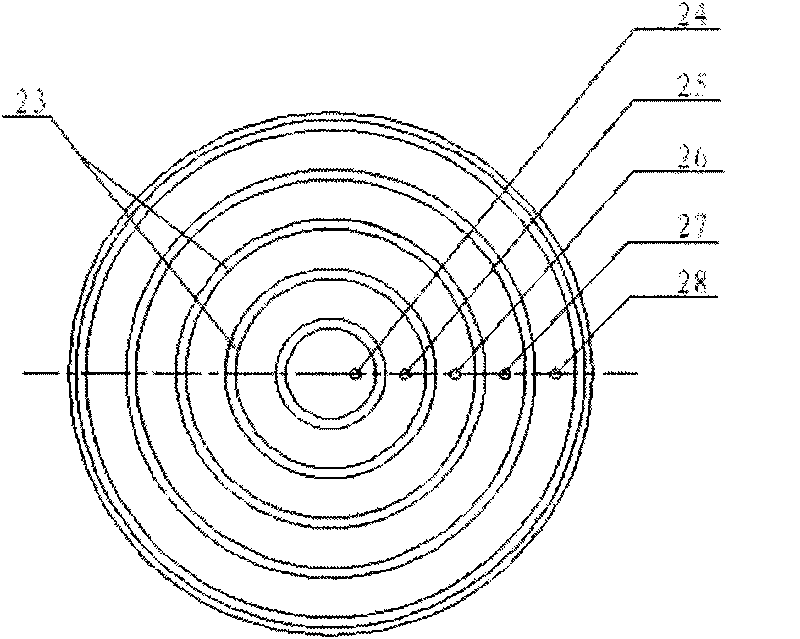

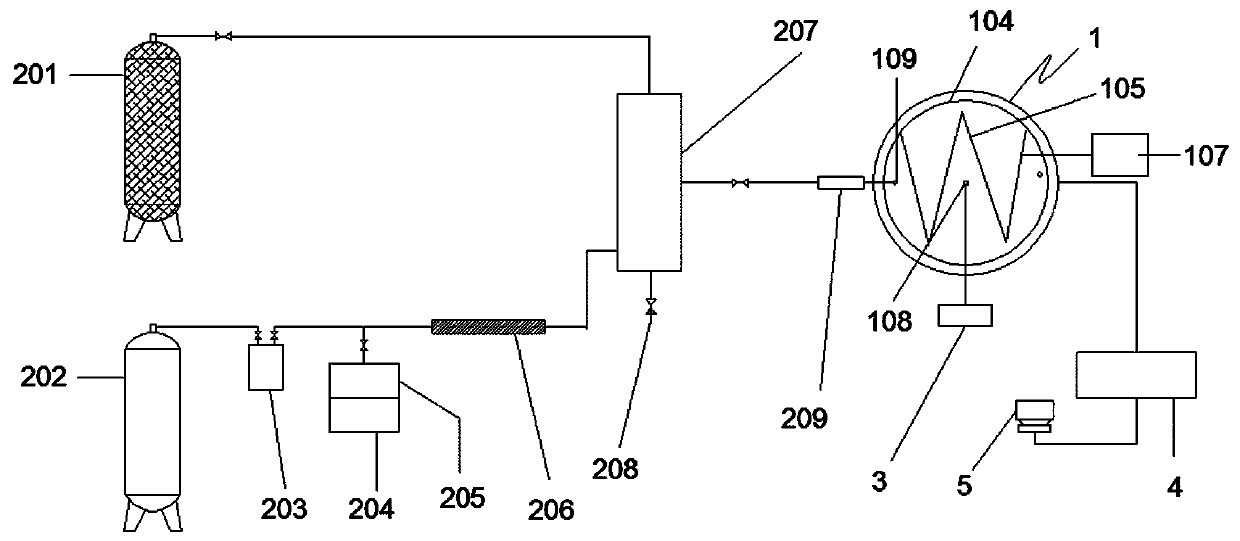

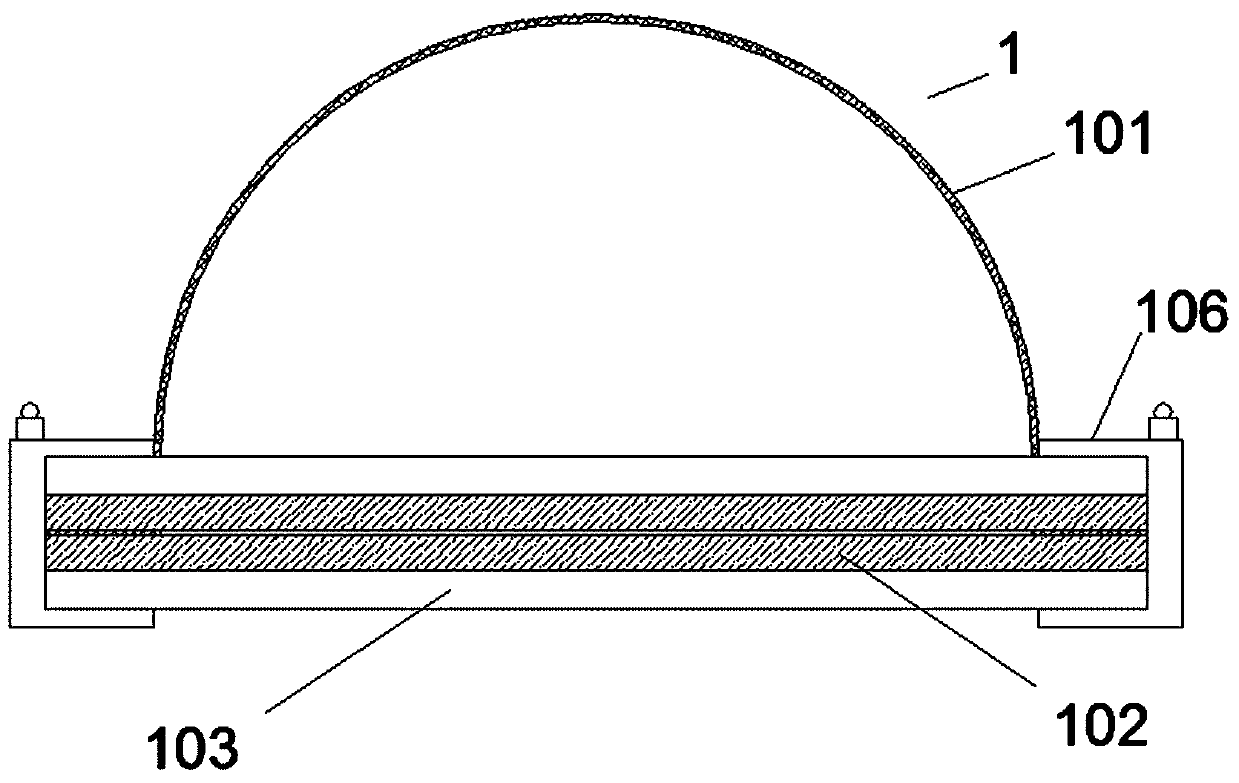

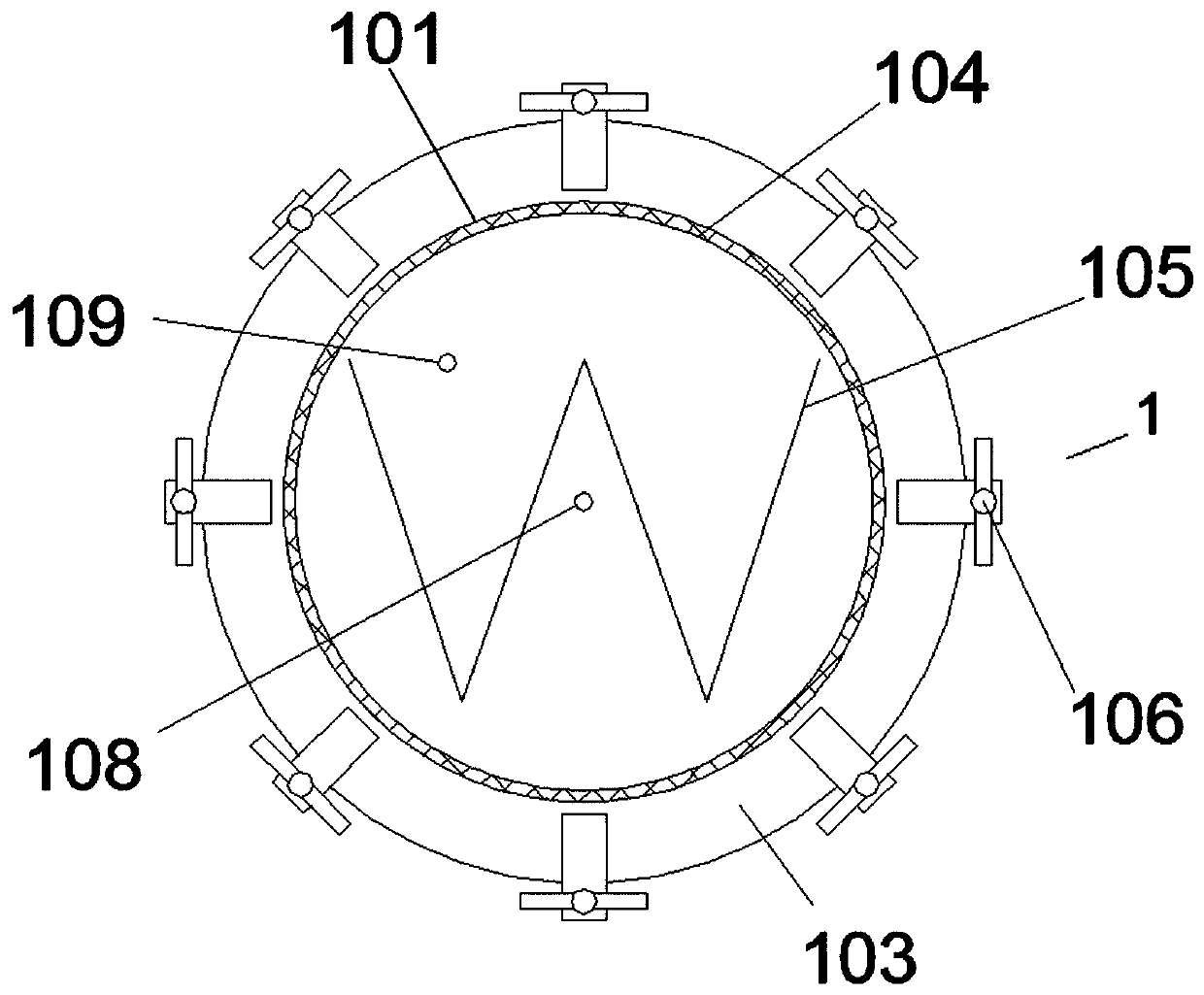

Deflagration experimental method and device for gas cloud with concentration gradient in open space

ActiveCN101726571AMeet deflagrationReal deflagration phenomenonFuel testingExperimental methodsConcentration gradient

The invention discloses a deflagration experimental method and a deflagration experimental device for gas cloud with concentration gradient in an open space, which are used by the gas deflagration test technology. The deflagration experimental method comprises the following steps: covering over two layers of hemispherical films on a circular gradient plate from inside to outside; removing air between each layer of film; injecting pre-mixed gas cloud with different concentrations between the gradient plate and the films and between every two layers of films; igniting in a pre-mixed gas cloud concentration area with any concentration; simultaneously acquiring an electrical signal of a pressure transmitter to transmit to a computer for comparison and obtain a deflagrating pressure variation curve. The invention also provides an experimental device according to the method. The deflagration experimental method and the deflagration experimental device can simulate the characteristics of the gas cloud with the concentration gradient in the open space, acquire results of overpressure values of the deflagration generated by ignition in areas with different concentrations, and simulate a real deflagration result.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

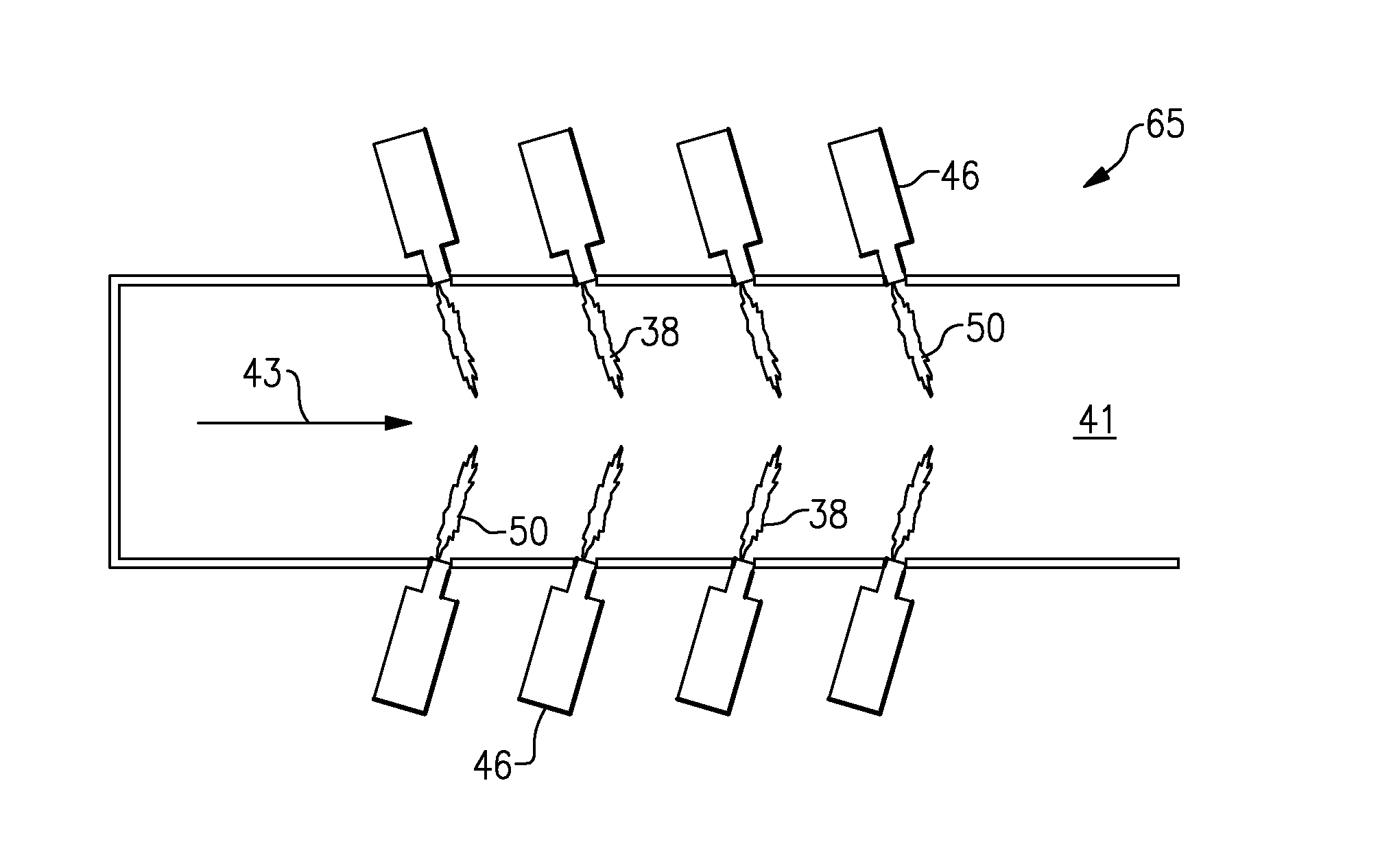

Fluidic deflagration-to-detonation initiation obstacles

ActiveUS20120144798A1Increased turbulenceGas turbine plantsIntermittent jet plantsCombustorDeflagration

A detonation chamber and a pulse detonation combustor including a detonation chamber, wherein the detonation chamber includes a plurality of aerodynamic jets disposed adjacent an exterior of a sidewall of the detonation chamber. The detonation chamber further includes a plurality of openings formed in the sidewall of the detonation chamber, wherein each of the plurality of openings is in fluidic communication with one of the plurality of aerodynamic jets. The plurality of aerodynamic jets are adapted to create a plurality of jet flows of a fluid within the detonation chamber during a combustion cycle defining a plurality of initiation obstacles within the detonation chamber to enhance a turbulence of a fluid flow and flame acceleration through the detonation chamber.

Owner:GENERAL ELECTRIC CO

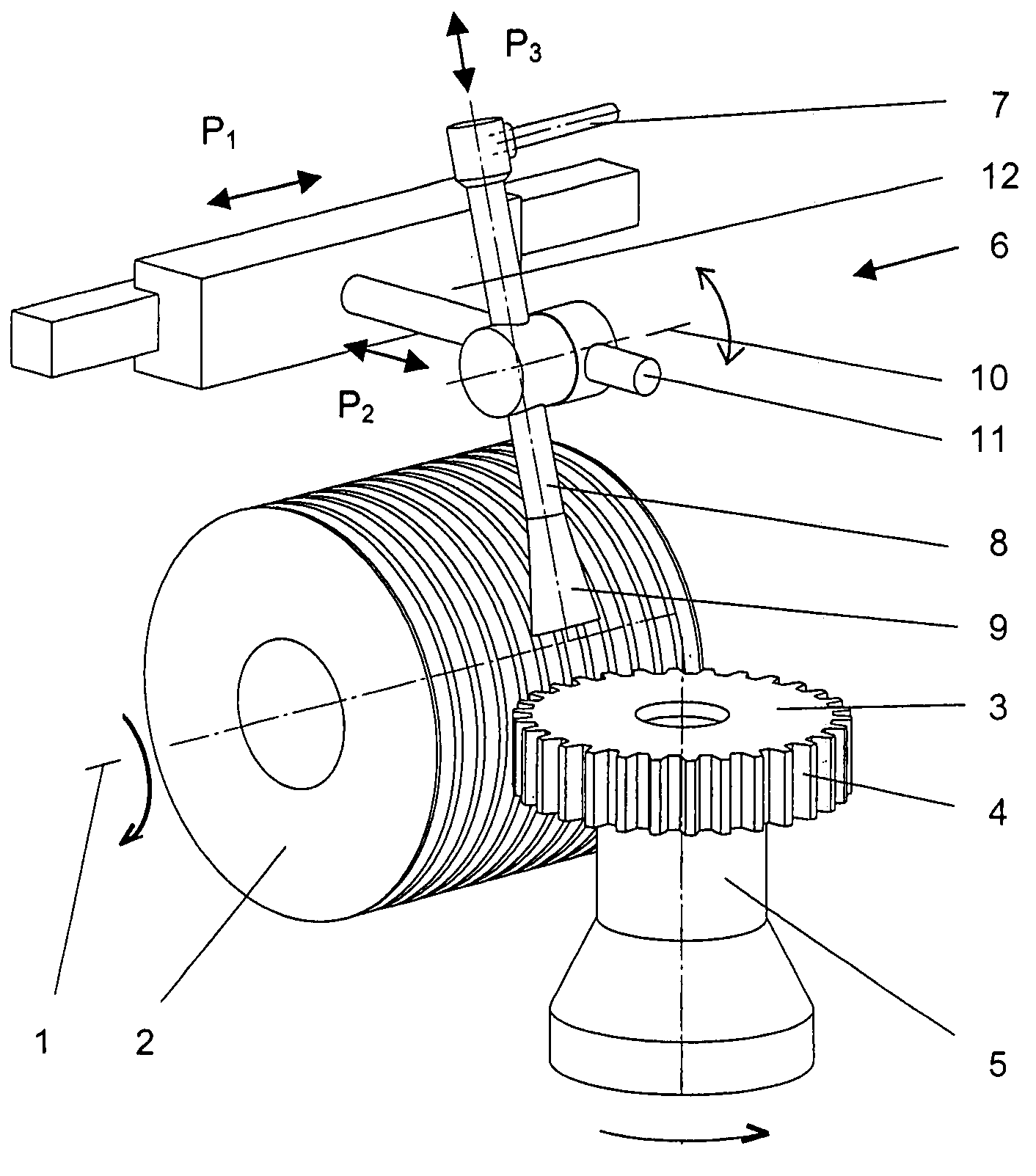

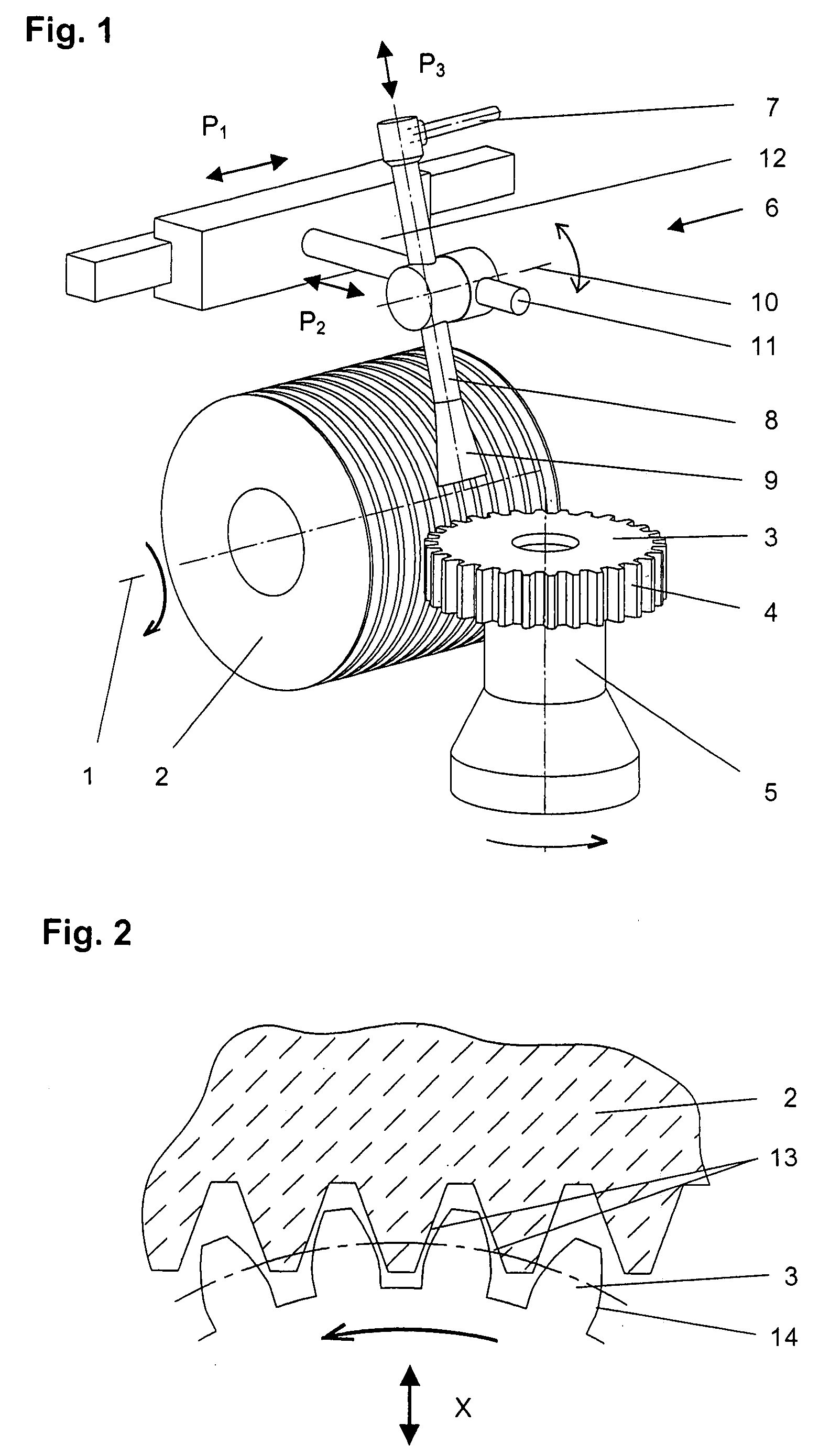

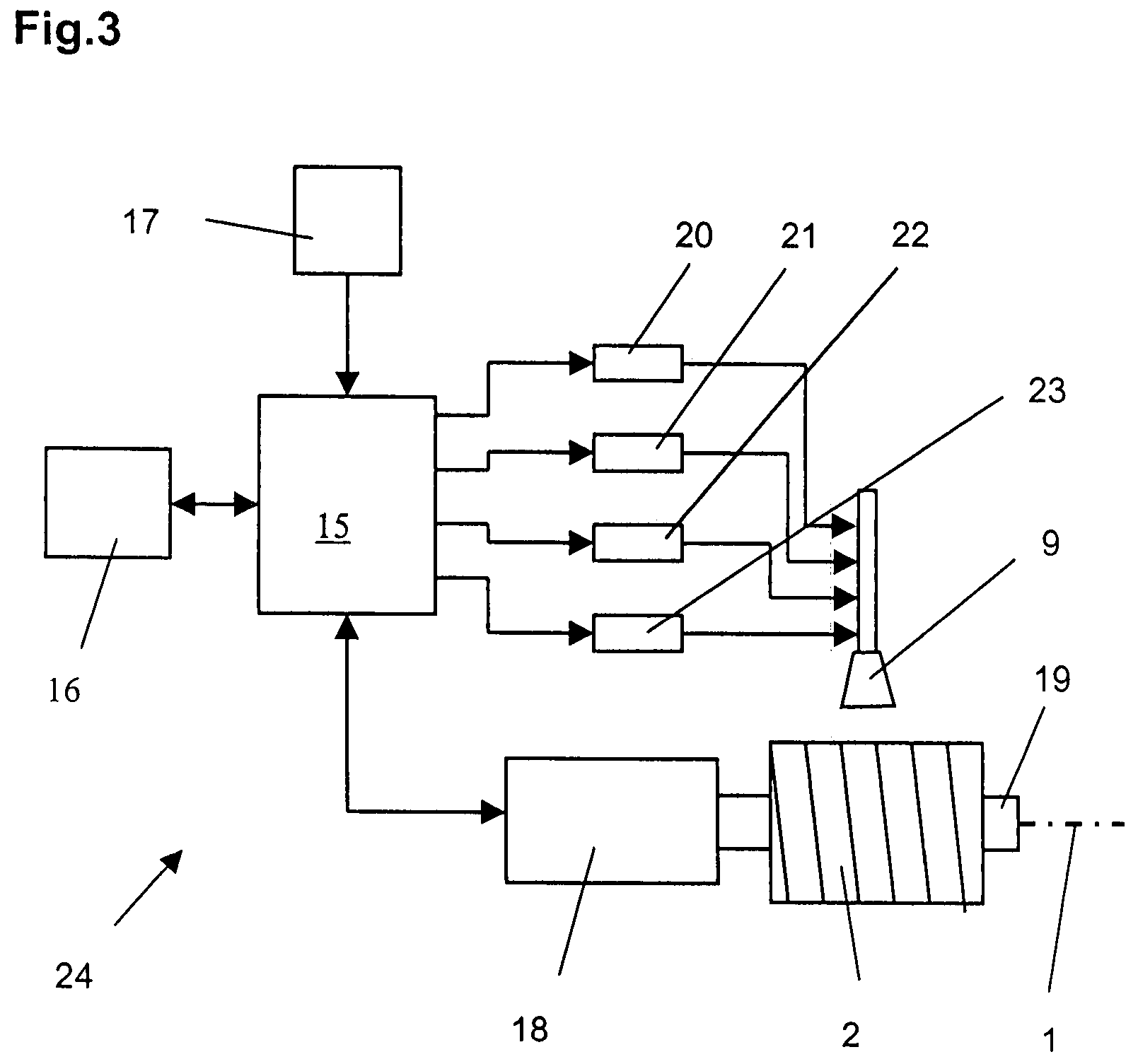

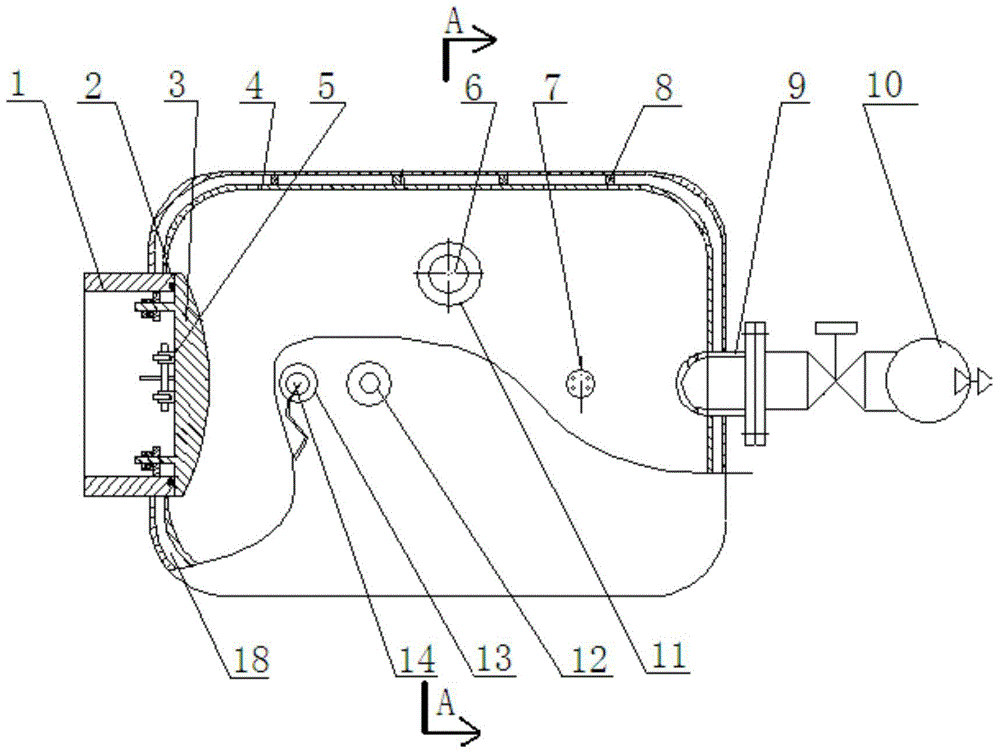

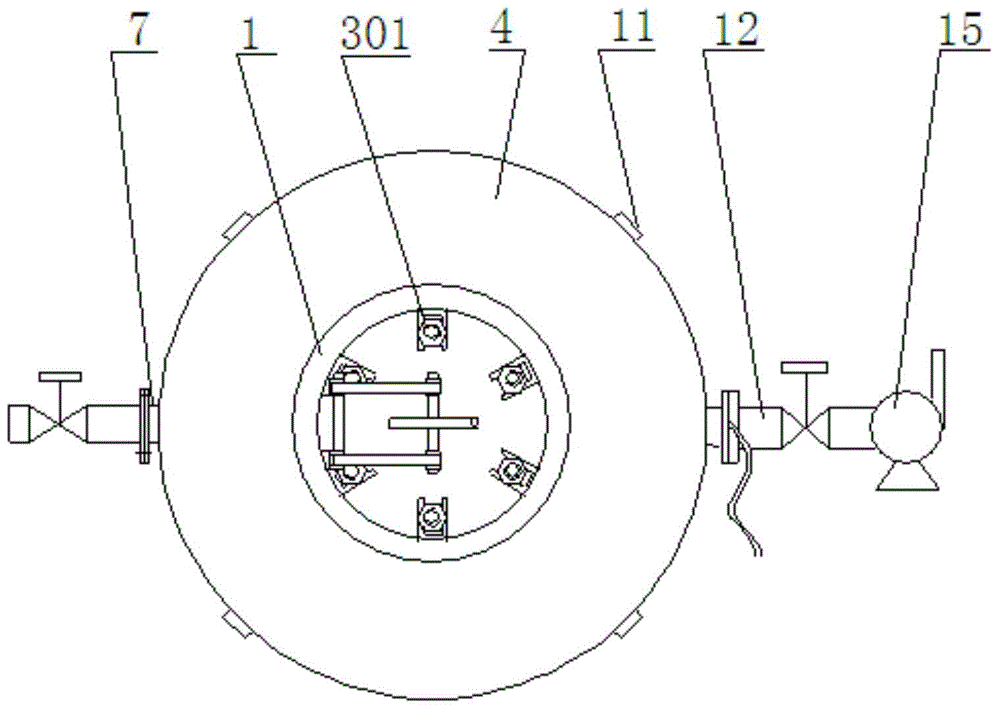

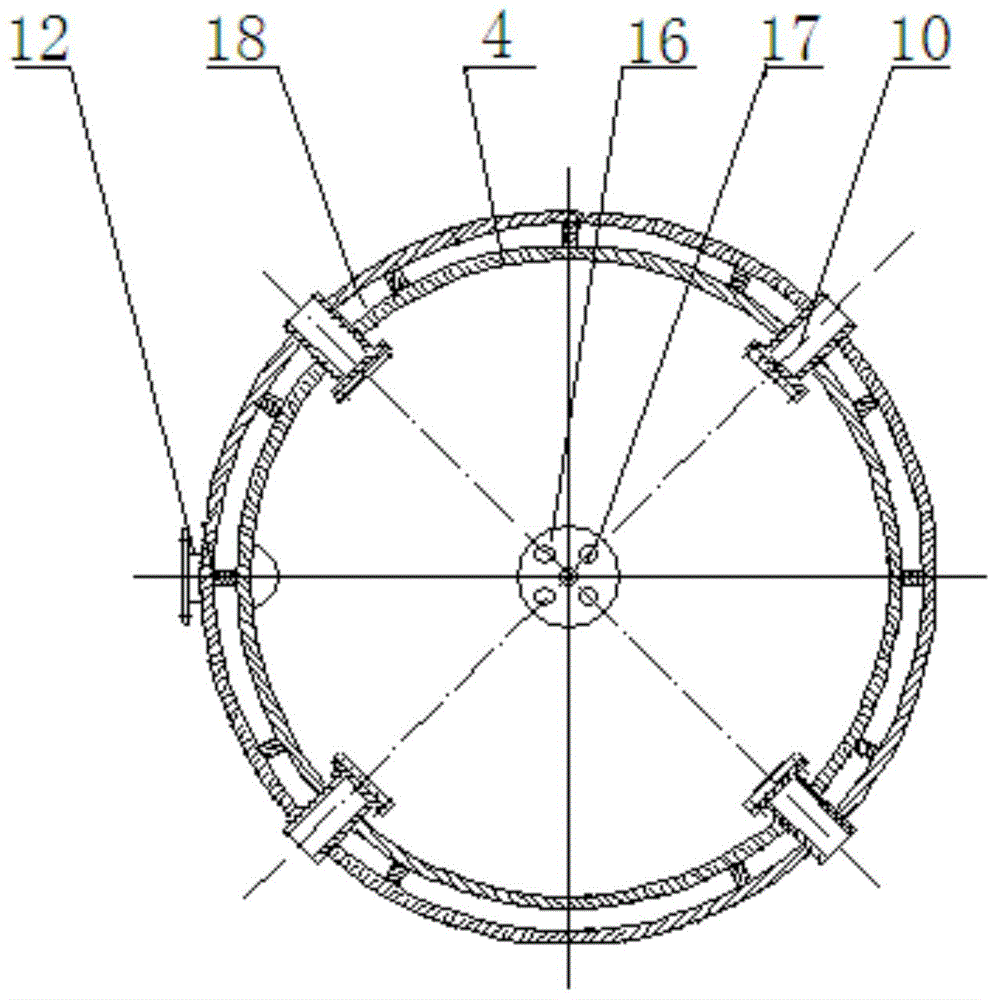

Process for monitoring the setting of the coolant nozzle of a grinding machine

InactiveUS20070202776A1Avoid settingAvoid disadvantagesGrinding feed controlAutomatic grinding controlMachine controlControl system

The present invention concerns a process for monitoring the correct setting of the coolant nozzle (9) of a grinding machine, in particular of a machine for grinding the tooth flanks of workpieces with premachined teeth. In an automatic test cycle after setting the machine, with the grinding wheel (2) at defined positions relative to the workpiece (3), the alterations in power consumption of the grinding spindle drive when switching on the coolant supply are measured, compared with the desired value ranges specified in the machine control system, and the machining process blocked in the event of measurements being below or above the desired value ranges. In a further embodiment of the invention, in the event of a deviation of a measured value from the desired value range, the setting of the coolant nozzle (9) is altered in a correction cycle following the test cycle by means of an automatic swivelling or displacement in at least one of the axes 10, P1, P2, and P3, such that the two measured values are brought to lie within the specified desired value range without the intervention of the setter or operator.In this manner the production of scrap and the occurrence of deflagration of the coolant / lubricant-air mixture in the machine working area, and hence a machine fire, can be effectively prevented.

Owner:REISHAUER

Internal explosion experiment based test method for quantitative evaluation on energy release of thermobaric explosive

The invention belongs to the field of explosives, and provides an internal explosion experiment based test method for quantitative evaluation on energy release of thermobaric explosive. The method is as below: determination of test devices; determination of the weight of the thermobaric explosive for test; determination of whether the amount of oxygen required by thermobaric explosive test is met; acquisition of quasi-static pressure data in a tank; acquisition of quasi-static pressure peak value of the thermobaric explosive; and finally acquisition of the test results of temperature and pressure effect of the thermobaric explosive. The invention employs the experiment explosion tank as a test carrier to simulate a closed environment for actual use of the thermobaric explosive, so as to obtain the for quasi-static pressure parameters of explosion of the thermobaric explosive and lay foundation for evaluation on explosion energy output the thermobaric explosive. A method for acquiring quasi-static pressure of the thermobaric explosive in limited space in different gas environment is employed to separate release energy from an anaerobic deflagration reaction stage and an explosion process of the thermobaric explosive, so as to obtain energy release in the oxygen combustion stage.

Owner:XIAN MODERN CHEM RES INST

Combined pulse detonation engine detonation chamber

InactiveCN103899435AIncrease working frequencyShorten the lengthIntermittent jet plantsShock waveShortest distance

The invention discloses a combined pulse detonation engine detonation chamber. An ignition combination mode of a two-stage shock wave focusing device and pre-detonation pipes is adopted. A main detonation chamber is connected with an engine, and a first pre-detonation pipe and a second pre-detonation pip are fixed on two sides of the engine, and are mounted parallelly to the main detonation chamber through a first jet pipe and a second jet pipe respectively. Detonation jet led out from pre-detonation pipe outlets by the jet pipes firstly fills the main detonation chamber and a shock wave focusing cavity via an intensively-mixed and atomized gas-oil mixture, after filling, the detonation jet led out from the pre-detonation pipes enters the detonation chamber from outlets of the jet pipes to ignite the oil-gas mixture in the detonation chamber, and deflagration waves with leading shock waves are formed to be propagated forwards. The deflagration waves form strong shock waves under the action of a flow guide ring, and the strong shock waves ignite an explosible oil-gas mixture to form detonation waves and generate high positive thrust. Initiation of explosion of the pulse detonation engine detonation chamber within a short distance is realized, so that the engine is shortened, and working frequency of the pulse detonation engine is increased.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

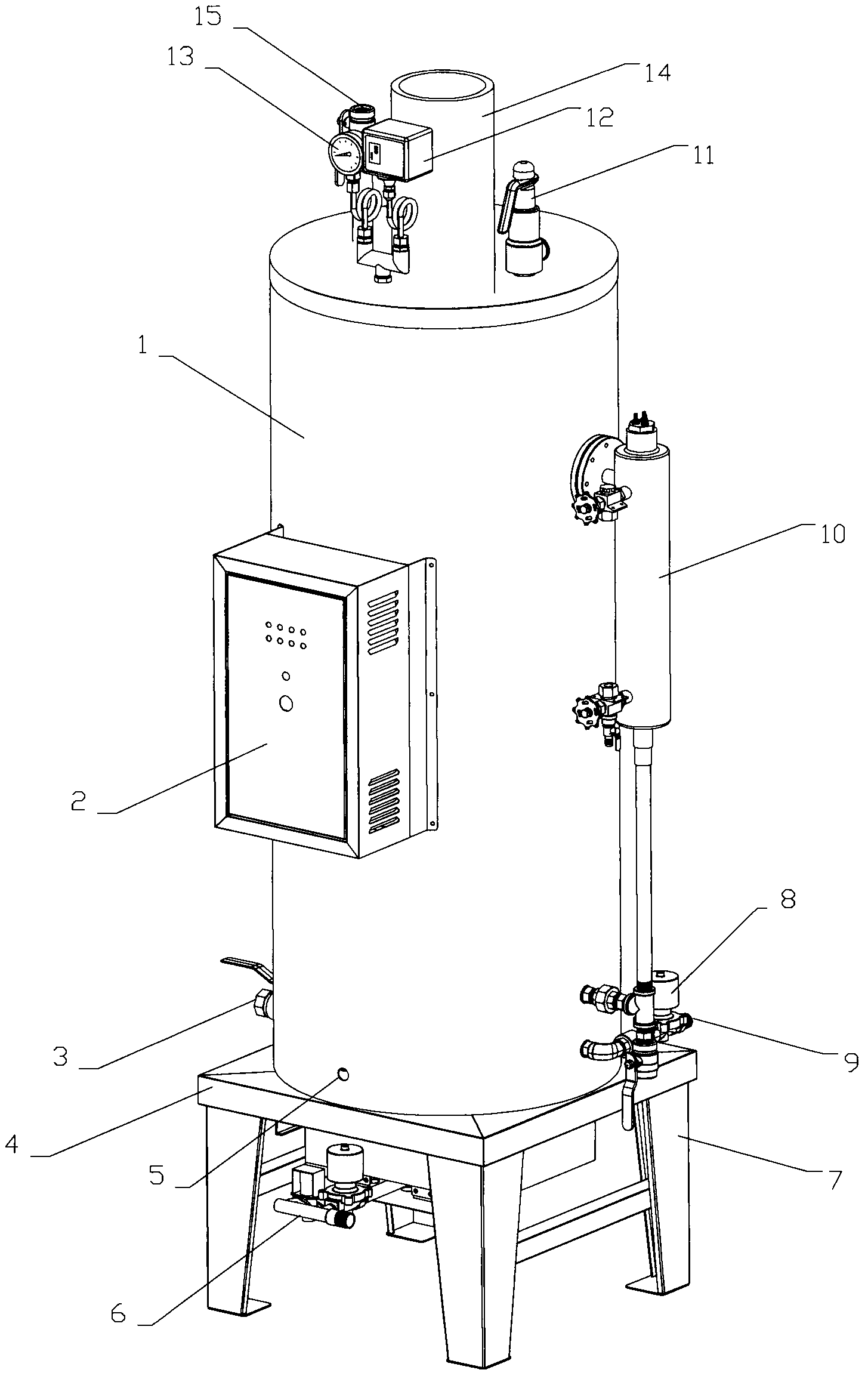

Gas steam generator

InactiveCN102679304AIntelligent machine workNew appearanceSteam boilersSteam boilers componentsElectronic controllerSolenoid valve

The invention provides a gas steam generator, which comprises a main body of the steam generator, a liner, a tap water inlet, a steam supplying outlet, a smoke exhaust pipe, a base, support legs and a burner, wherein the tap water inlet, the steam supplying outlet, the smoke exhaust pipe, the base and the support legs are arranged on one side of the main body; the burner is arranged below the base; the main body is cylindrical; the top end of the main body is provided with a safety valve, a pressure gauge and a pressure controller; the side wall of the main body is provided with an electronic controller panel and a water level controller; the burner adopts a safety control technology of controlling flames in a pure electronic manner; the water level of the water level controller is divided into a high water level, a middle water level and a low water level by built-in water level needles; and the side wall of the main body is also provided with a drain outlet, a flame viewing hole and a water supplement solenoid valve. The gas steam generator has the beneficial effects of intellectualization in mechanical operation, novel appearance, no deflagration phenomena, high safety, reasonable structure, small volume and high heat collection performance, and is convenient to clean.

Owner:鲍继勇

Dual mode combustion operation of a pulse detonation combustor in a hybrid engine

InactiveUS20080098748A1Improve efficiencyEasy to operateContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

A dual mode combustor of a gas turbine engine contains at least one dual mode combustor device having a combustion chamber, a fuel air mixing element, a high frequency solenoid valve and a fuel injector. During a first mode of operation the dual mode combustor device operates in a steady, constant pressure deflagration mode, receiving its fuel from the fuel injector. In a second mode of operation the dual mode combustor device operates in a pulse detonation mode, receiving its fuel from the high frequency solenoid valve.

Owner:GENERAL ELECTRIC CO

Thermally initiated venting system and method of using same

ActiveUS20070240600A1Ammunition storageAmmunition loadingShaped chargeDeflagration to detonation transition

An apparatus includes a thermally-activated, deflagration initiation device, a deflagration-to-detonation transition manifold, a first transfer line connecting the deflagration initiation device and the deflagration-to-detonation transition manifold, and a linear shaped charge coupled with the first transfer line. An apparatus includes a heat-to-detonation transition manifold, a heat pipe connected to the transition manifold, a linear shaped charge, and a transfer line connecting the heat-to-detonation transition manifold and the linear shaped charge. An apparatus includes a thermally-activated pyrotechnic train and a linear shaped charge coupled with the pyrotechnic train. A method includes initiating a deflagrating material at a predetermined temperature or within a predetermined range of temperatures, initiating a detonating material with the deflagrating material, and initiating a linear shaped charge with the detonated material.

Owner:LOCKHEED MARTIN CORP

Gas burning system and igniting method thereof

InactiveCN104421959AAvoid enteringImprove securityFuel supply regulationCombustion systemCombustion chamber

The invention discloses a gas burning system. The gas burning system comprises a burning chamber, a gas main pipeline, a gas branch pipeline, an air main pipeline and a central control unit, wherein the gas main pipeline and the air main pipeline are respectively connected with the burning chamber, the gas main pipeline is sequentially provided with a first gas pressure sensor, a first cutting valve, a second cutting valve and a second gas pressure sensor along the flowing direction of gas, the gas main pipeline between the first cutting valve and the second cutting valve is communicated with one end of the gas branch pipeline, the other end of the gas branch pipeline is connected with the burning chamber, the gas branch pipeline is provided with a third cutting valve and a fourth cutting valve, and an igniting device and a fire detecting device are arranged inside the burning chamber. The burning system ignites in a fire-leading mode and can control the process before and during fire-leading and during working and burning. Accidents caused by the deflagration phenomenon and the gas leakage are prevented.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Coupling test method and test system for flame and pressure after premixed gas cloud deflagration in open space with different humidity

PendingCN109613205ASuppress critical humidity valueImprove accuracyFuel testingGas cylinderData acquisition

The invention relates to the technical field of gas deflagration testing, in particular to a coupling test method and test system for flame and pressure after combustible premixed gas cloud deflagration in an open space with different humidity conditions. The system is composed of a main body part, a gas distributing device, an ignition device, a test device and a computer. The main body part is ahemispheric gas cloud device. The hemispheric gas cloud device is composed of a polyethylene film gas cloud cover, a flame retardant rubber ring plate, and a 16Mn steel ring plate. The gas distributing device is composed of a methane gas cylinder, a compressed air bottle, a calcium chloride container bottle, a humidity sensor, a humidity generator, a heating pipe, a gas premixing tank, a water outlet and a gas flow guide. The test device is composed of a pressure transmitter, a humidity sensor, a temperature sensor, a data collector, a high-speed camera, a high-speed infrared thermal imager and a high-speed schlieren system. The test device is connected with the computer.

Owner:NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com