Hot aerosol fire extinguisher with thermostable ablative-insulative layer and manufacture method

A technology of fire extinguishing device and thermal insulation layer, which is applied in fire protection equipment, fire rescue and other directions, can solve the problems of complex filling method of thermal insulation layer and poor thermal insulation effect, achieves good thermal insulation effect, enhanced moisture resistance, and is convenient for batch production. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

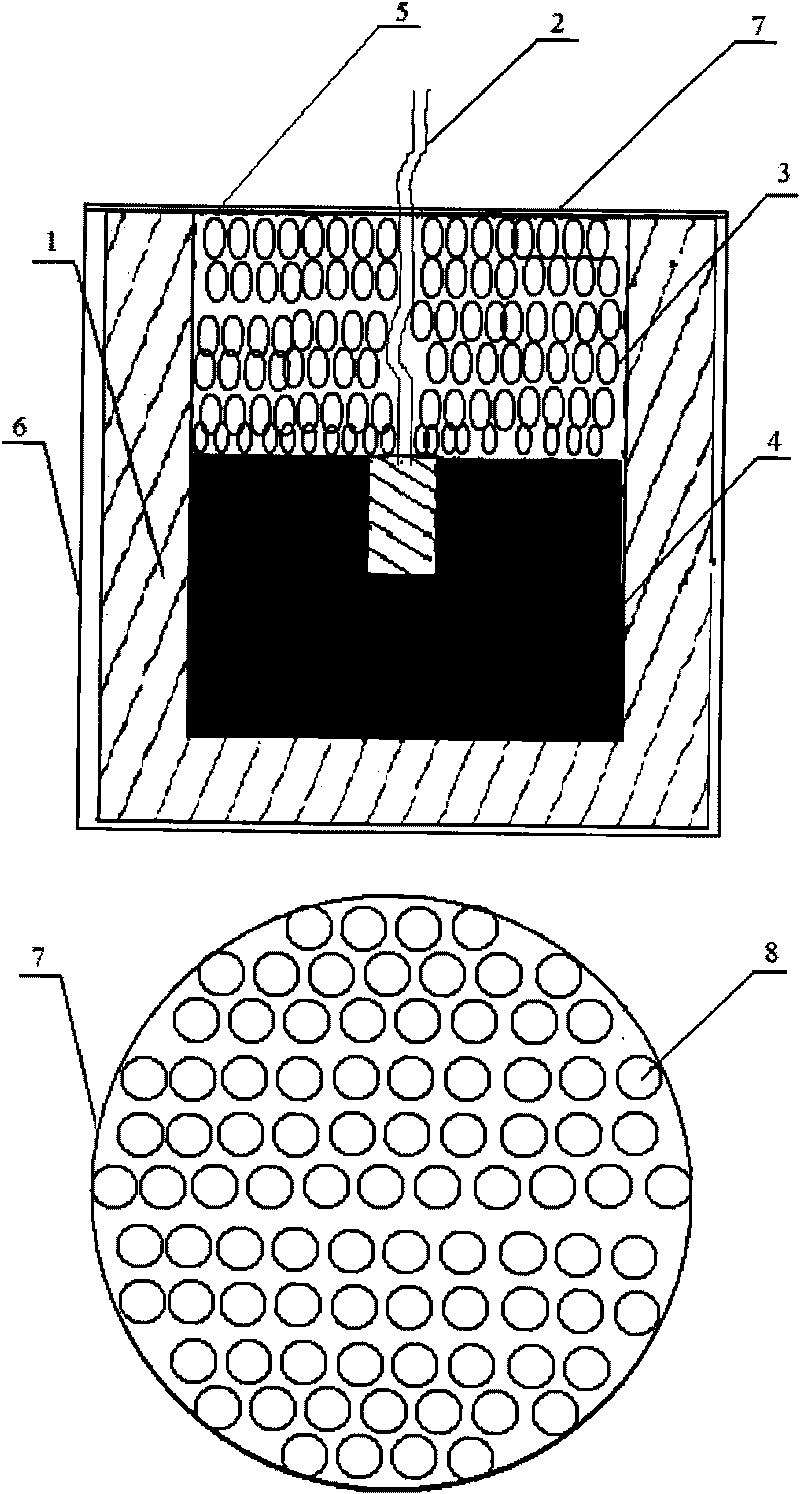

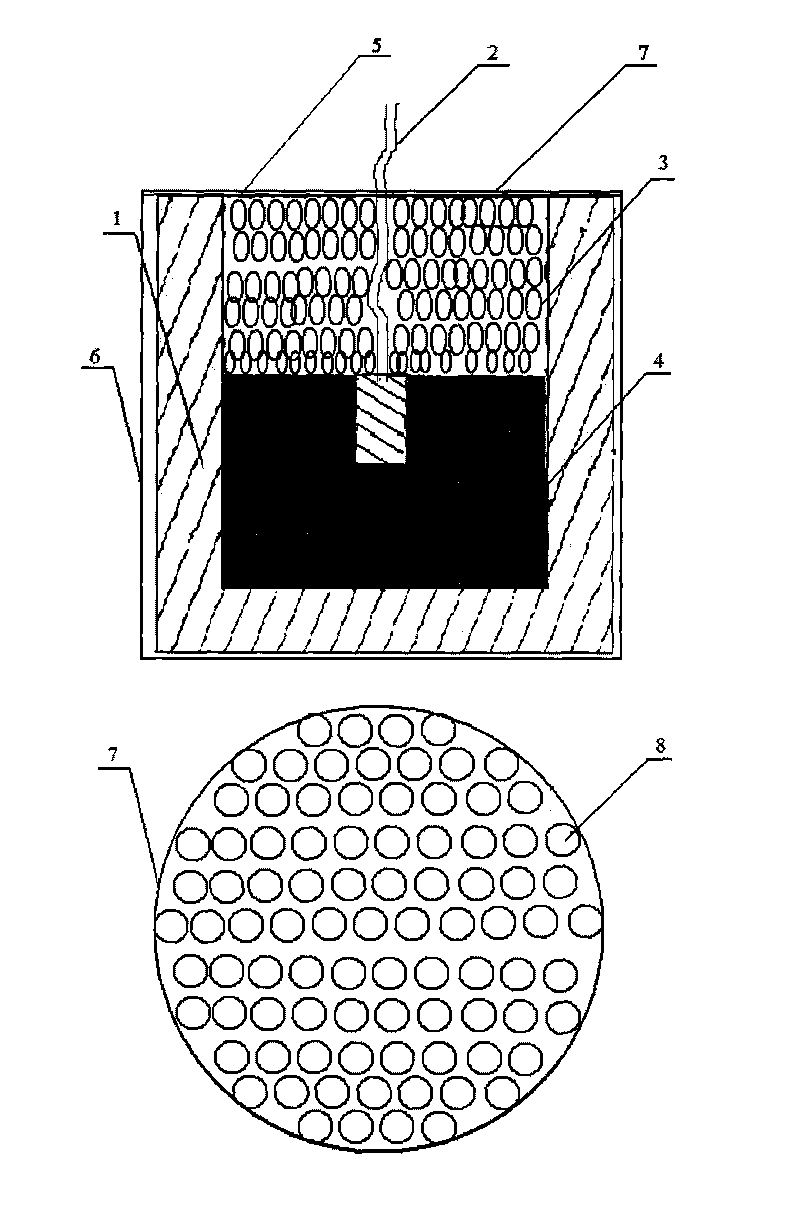

Embodiment 1

[0016] Stir 100g of 106 silicone rubber colloid evenly, then put 500g of Φ65mm strontium salt type aerosol generator grain into the mold, pour 106 silicone rubber into the mold, and vulcanize for 24 hours. After vulcanization and molding, the starter is placed in the generant grain column, the top is filled with cooling material 3, and the top of the cooling material is blocked by a screen. The heat insulation layer 1 equipped with the aerosol generating agent powder column 4, the starter 2 and the cooling material 3 is fixed in the device shell 6, and the top cover 7 is used to seal and fix it. After the device is started, the aerosol is ejected from the aerosol nozzle 8 on the top cover 7 . Measure the temperature of the spout, side wall and bottom with a temperature probe. The maximum temperature of the nozzle: 84°C, the maximum temperature of the side wall: 117°C, and the maximum temperature of the bottom: 145°C.

Embodiment 2

[0018] Stir 150g of 107 silicone rubber colloid evenly, then put 1000g of Φ75mm potassium salt-type aerosol generator grain into the mold, pour 107 silicone rubber into the mold, and vulcanize for 12 hours. After vulcanization and molding, the starter 2 is placed in the generant grain 4, the top is filled with the cooling material 3, and the top of the cooling material 3 is blocked by a screen 5. The heat insulation layer 1 equipped with the aerosol generating agent powder column 4, the starter 2 and the cooling material 3 is fixed in the device shell 6, and the top cover 7 is used to seal and fix it. After the device is started, use a temperature probe to measure the temperature of the spout, side wall and bottom. The maximum temperature of the nozzle: 122°C, the maximum temperature of the side wall: 130°C, and the maximum temperature of the bottom: 132°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com