Patents

Literature

378results about "Intermittent jet plants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

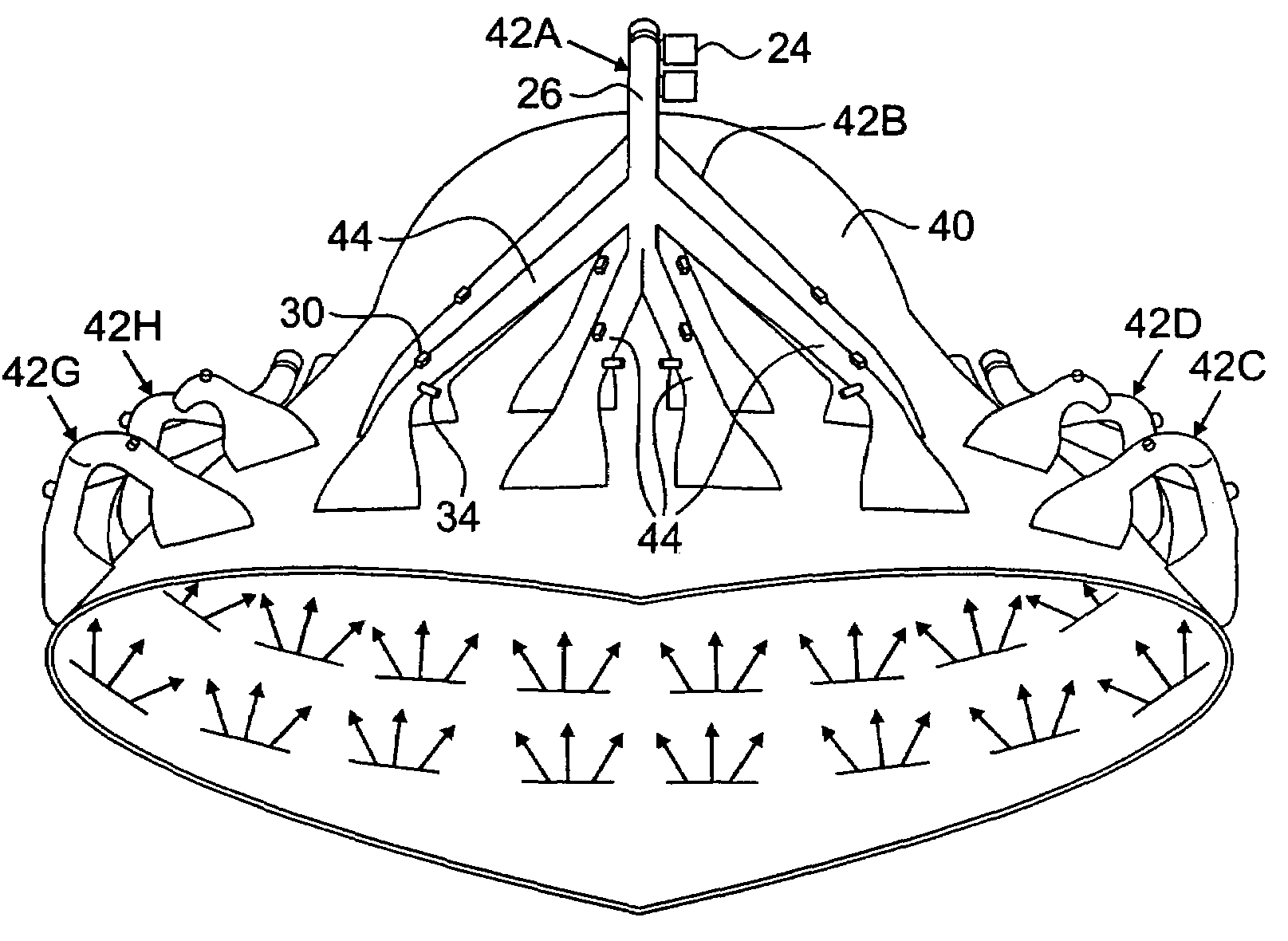

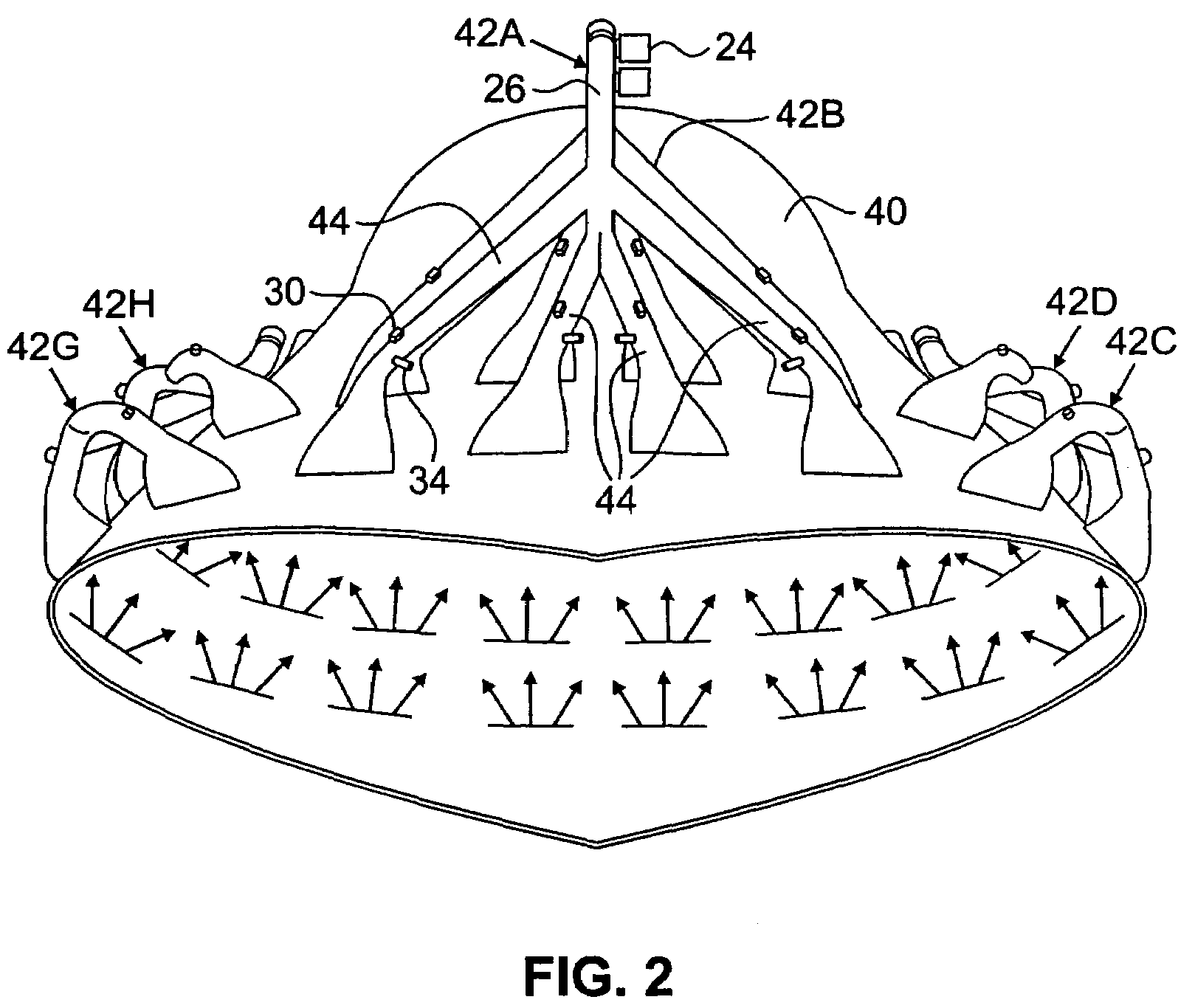

Combustion ignition

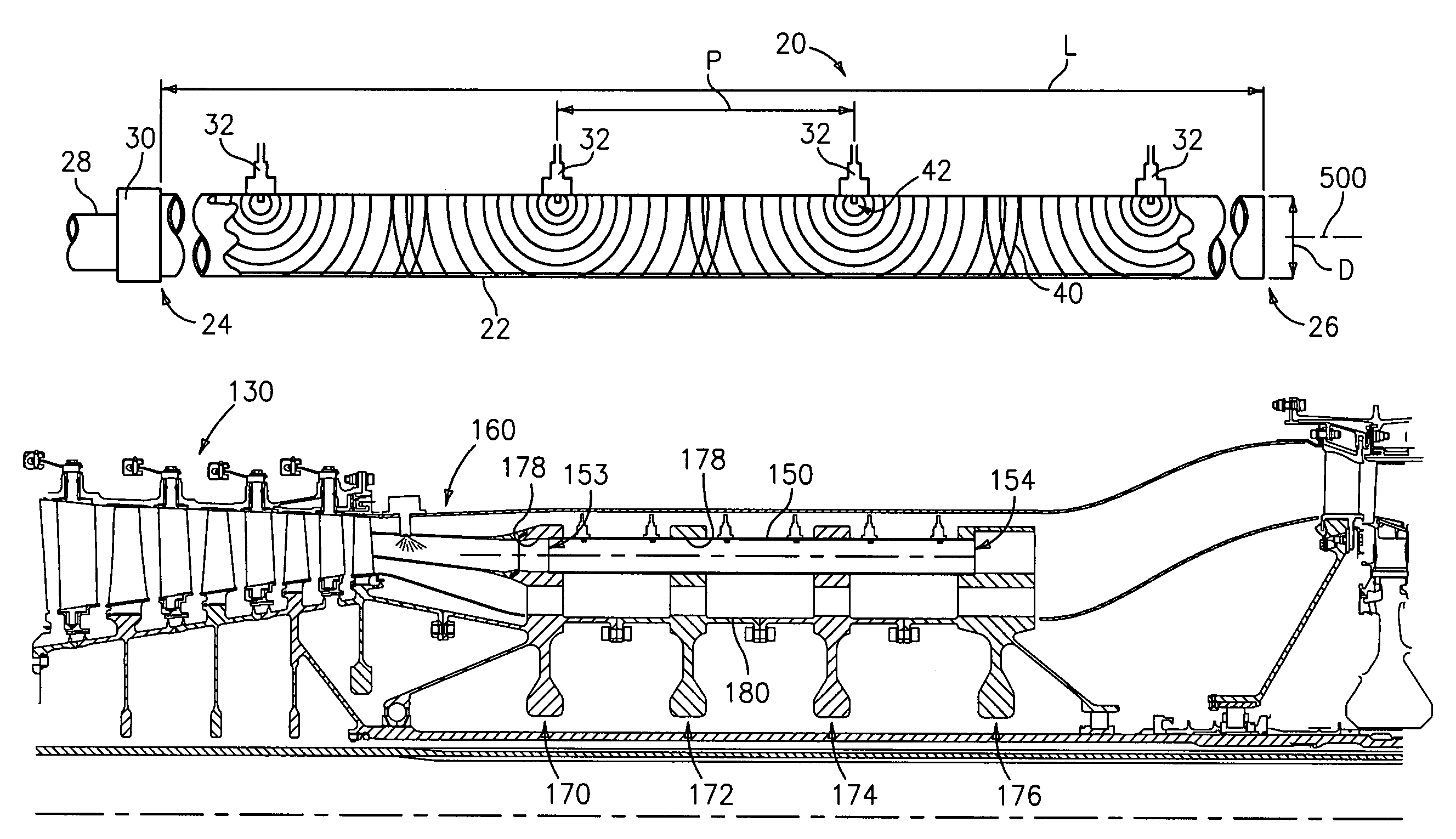

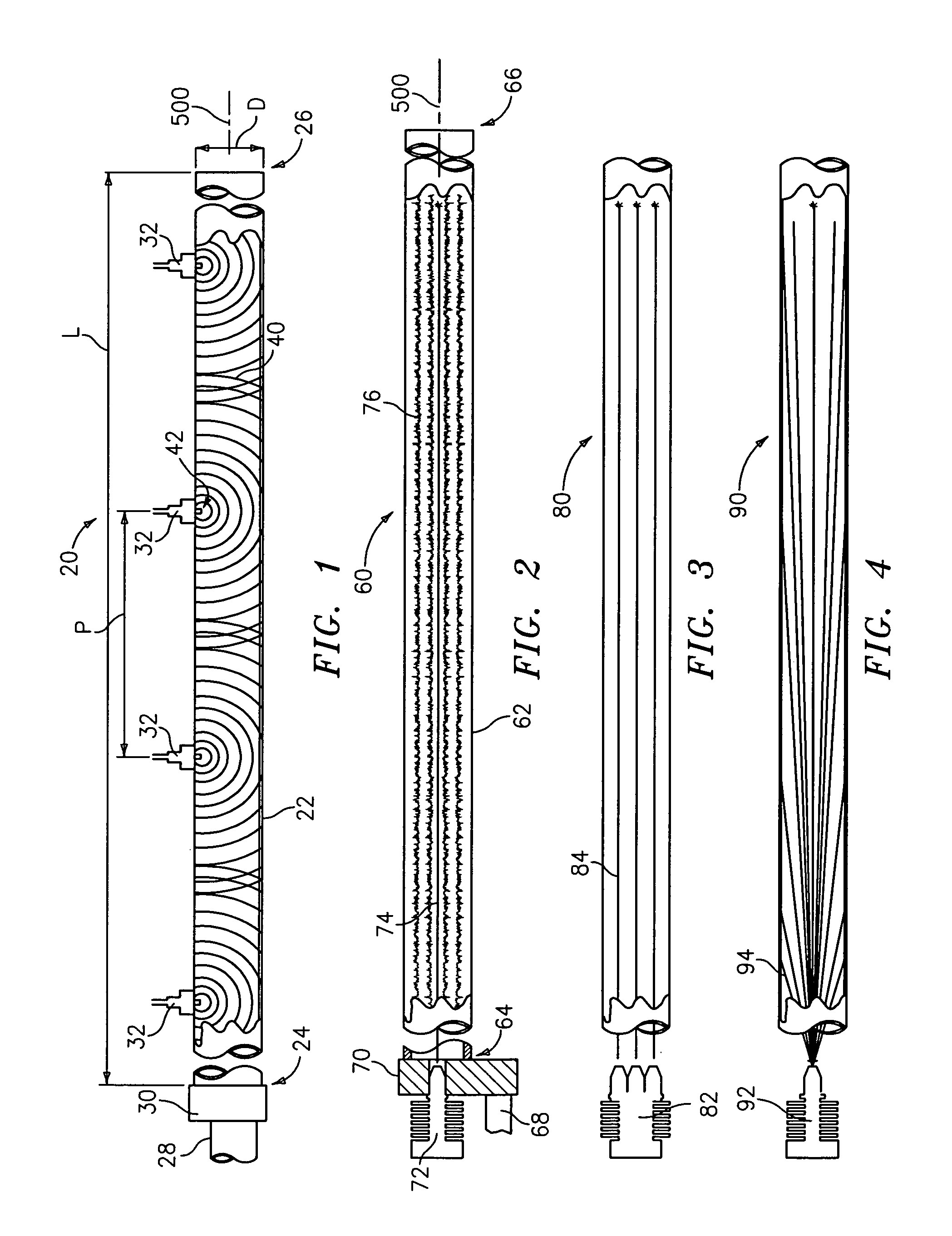

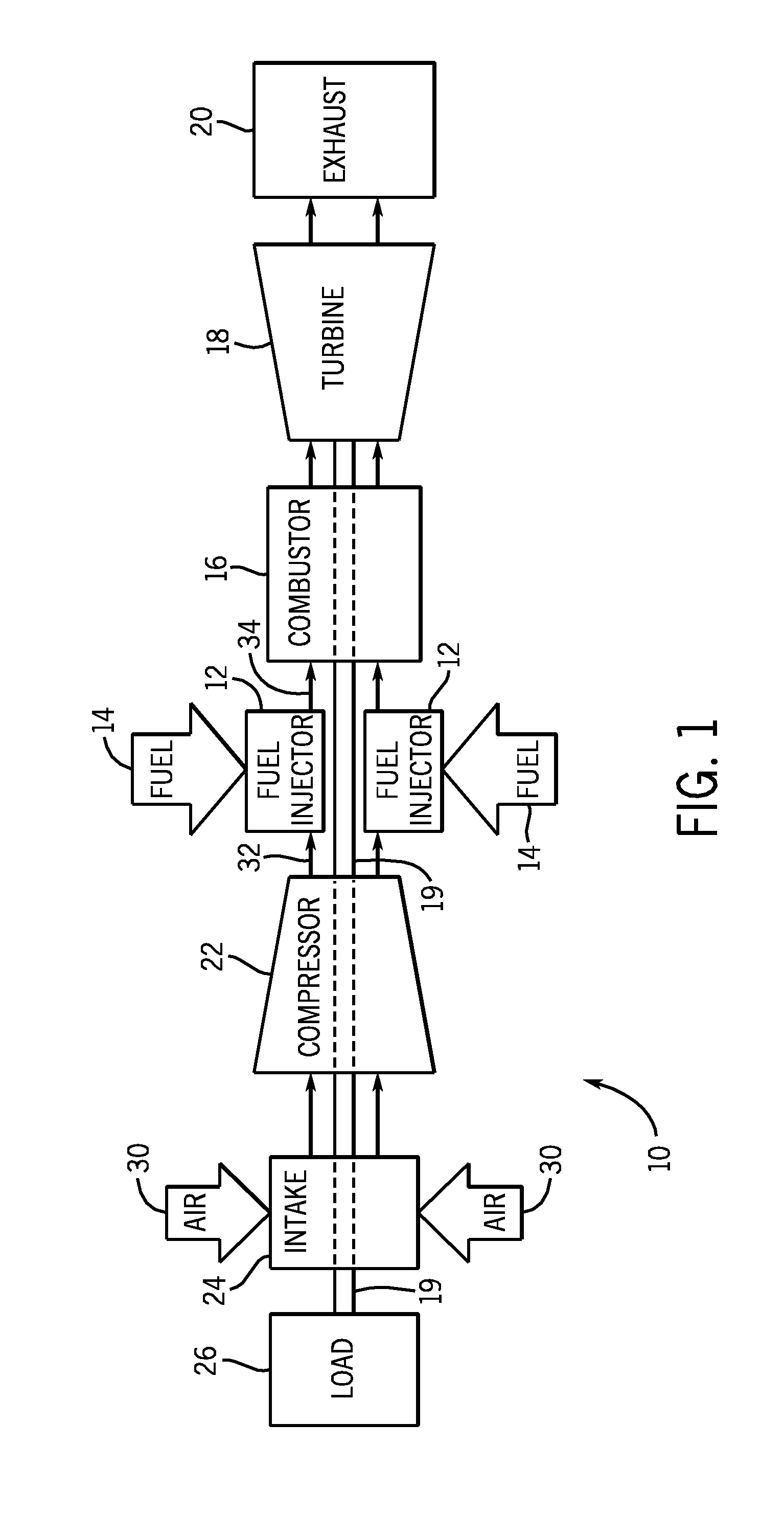

Distributed initiation (e.g., multipoint or continuous) is utilized to obtain constant volume-like combustion performance in a pulse combustion device in the absence of detonation. A number of such devices may be utilized as turbine engine combustors.

Owner:UNITED TECH CORP

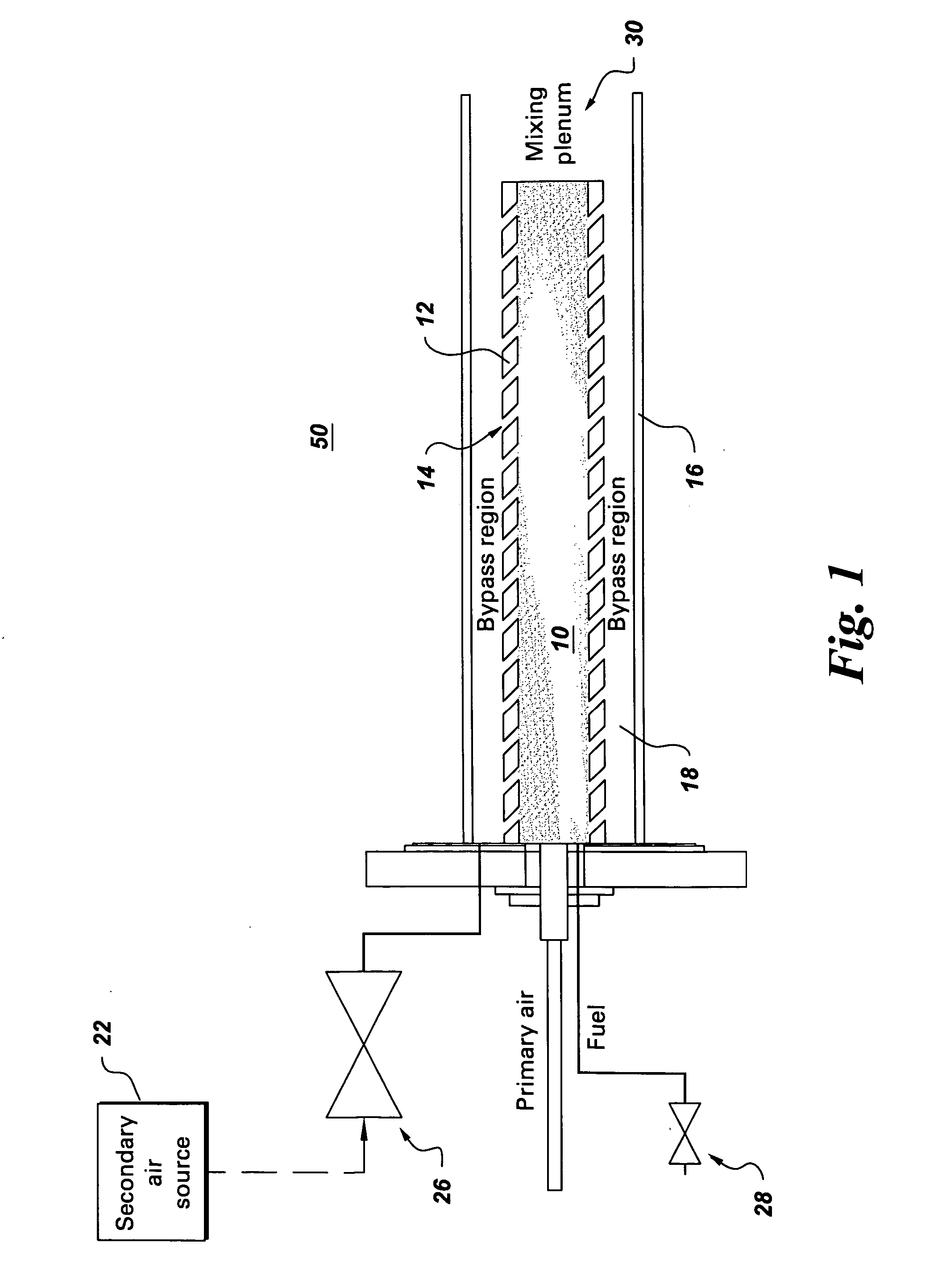

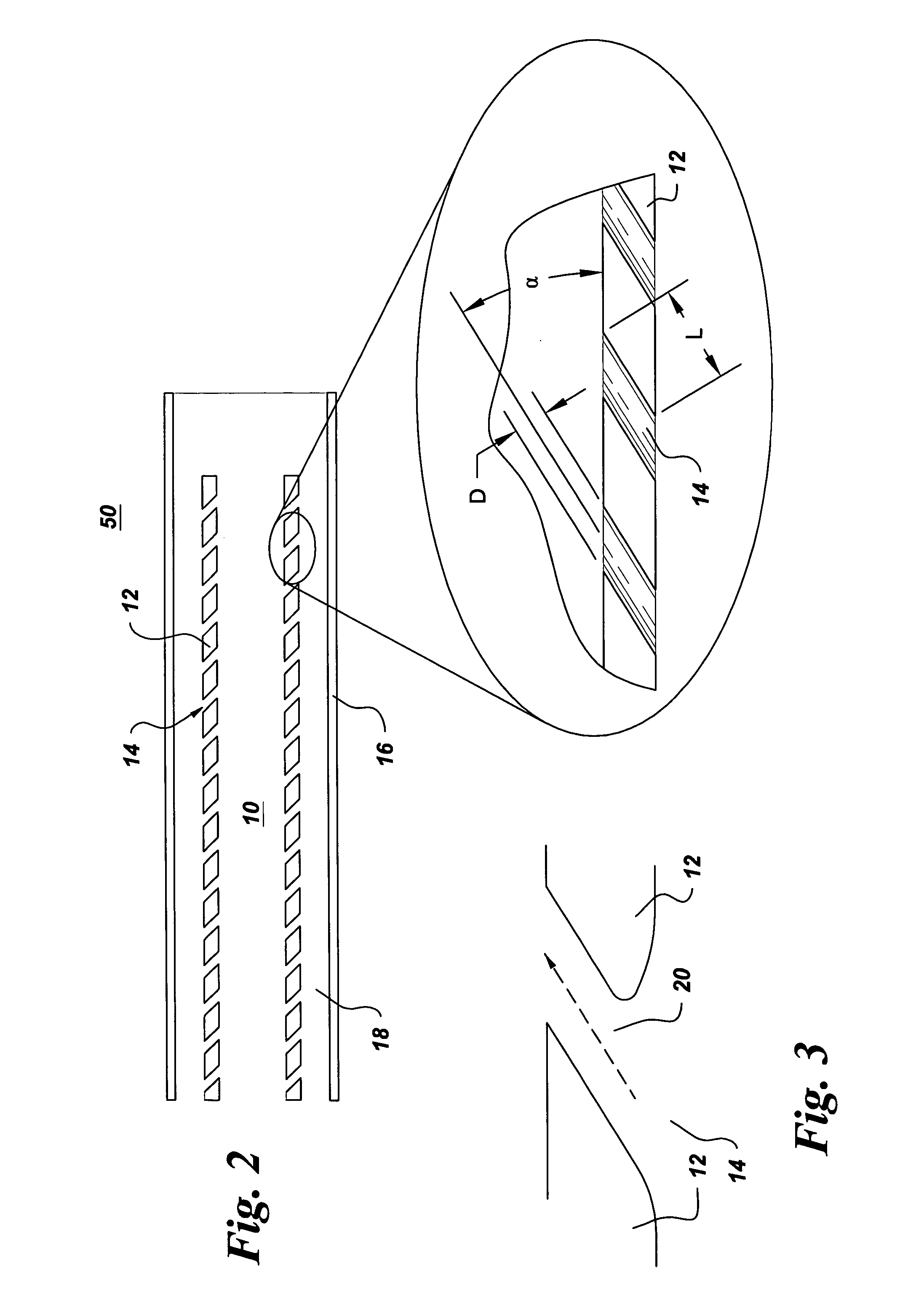

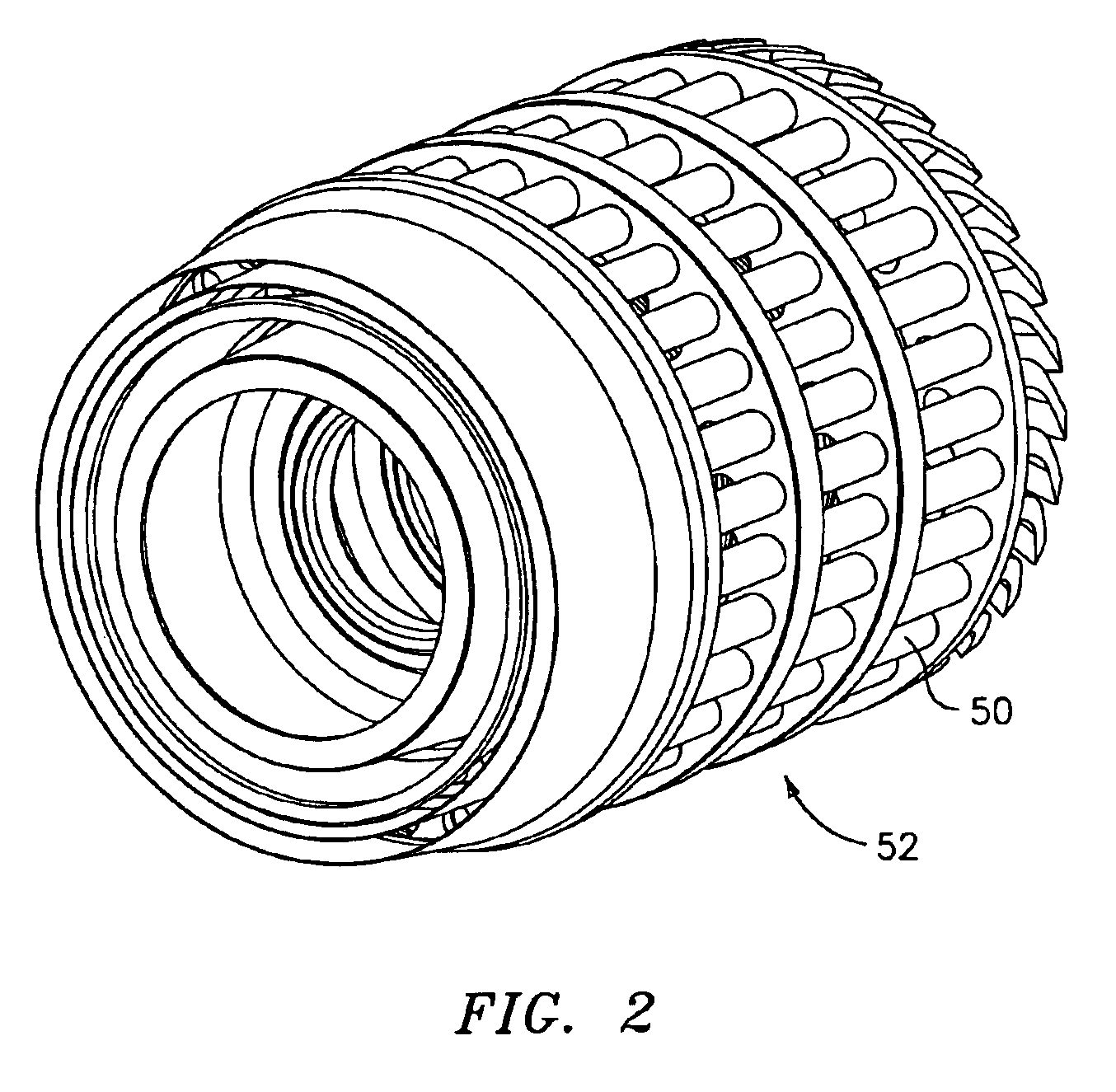

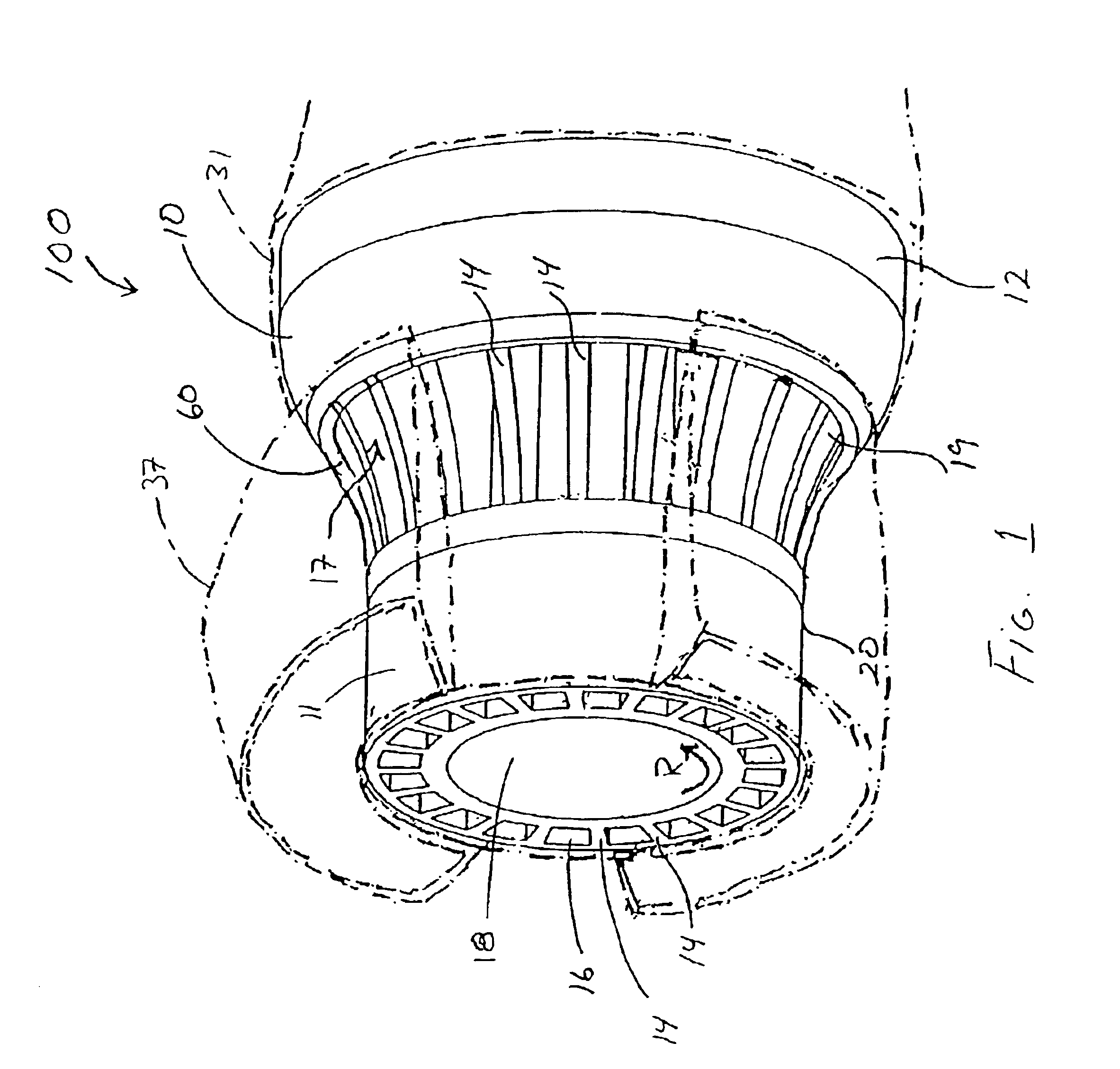

Pulse detonation assembly with cooling enhancements

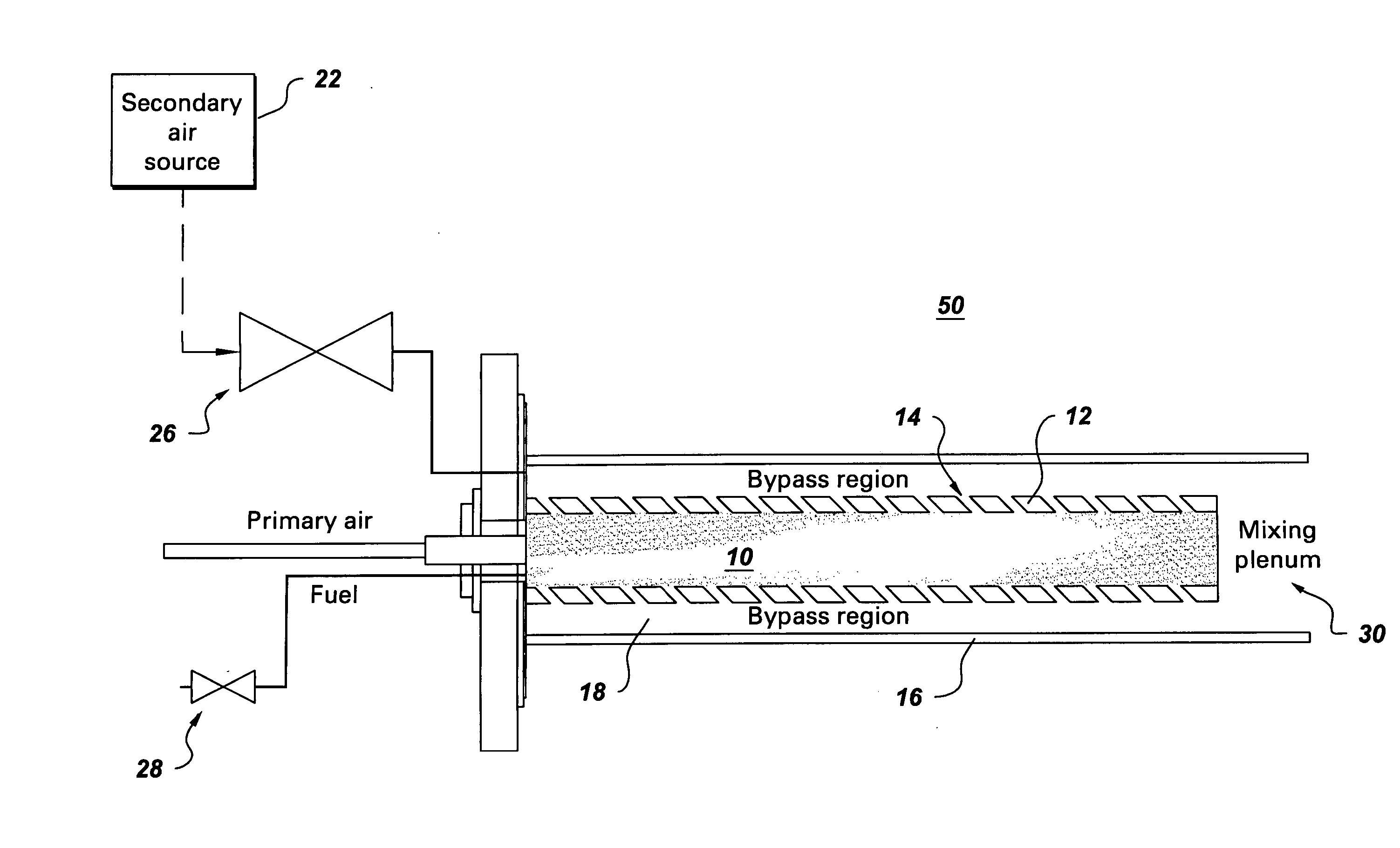

A pulse detonation (PD) assembly includes at least one PD chamber having a wall, which defines cooling holes arranged along at least a portion of the PD chamber. A manifold extends around the PD chamber. The manifold and PD chamber are separated by a bypass region. A PD assembly with reverse flow cooling includes at least one PD chamber. A sleeve extends around the PD chamber. The sleeve and PD chamber are separated by a reverse flow cooling passage configured to receive a flow of air and to flow the air in a reverse direction to supply the PD chamber. A PD assembly with bypass flow cooling includes at least one PD chamber and a manifold extending around the PD chamber(s), which are separated by a bypass region. The PD assembly further includes a mixing plenum configured to receive and mix the bypass flow from the bypass region and the detonation by-products from the PD chamber(s).

Owner:GENERAL ELECTRIC CO

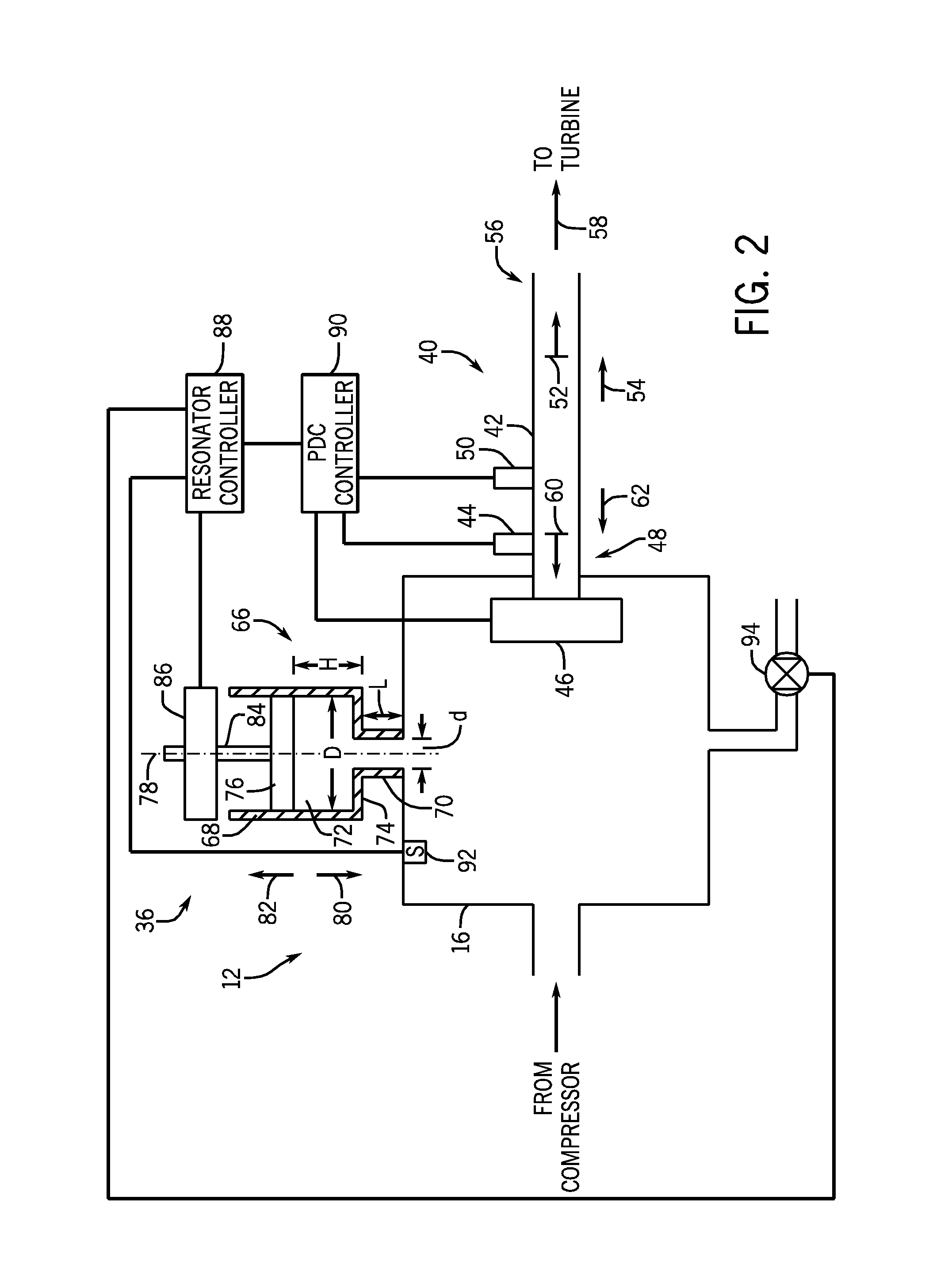

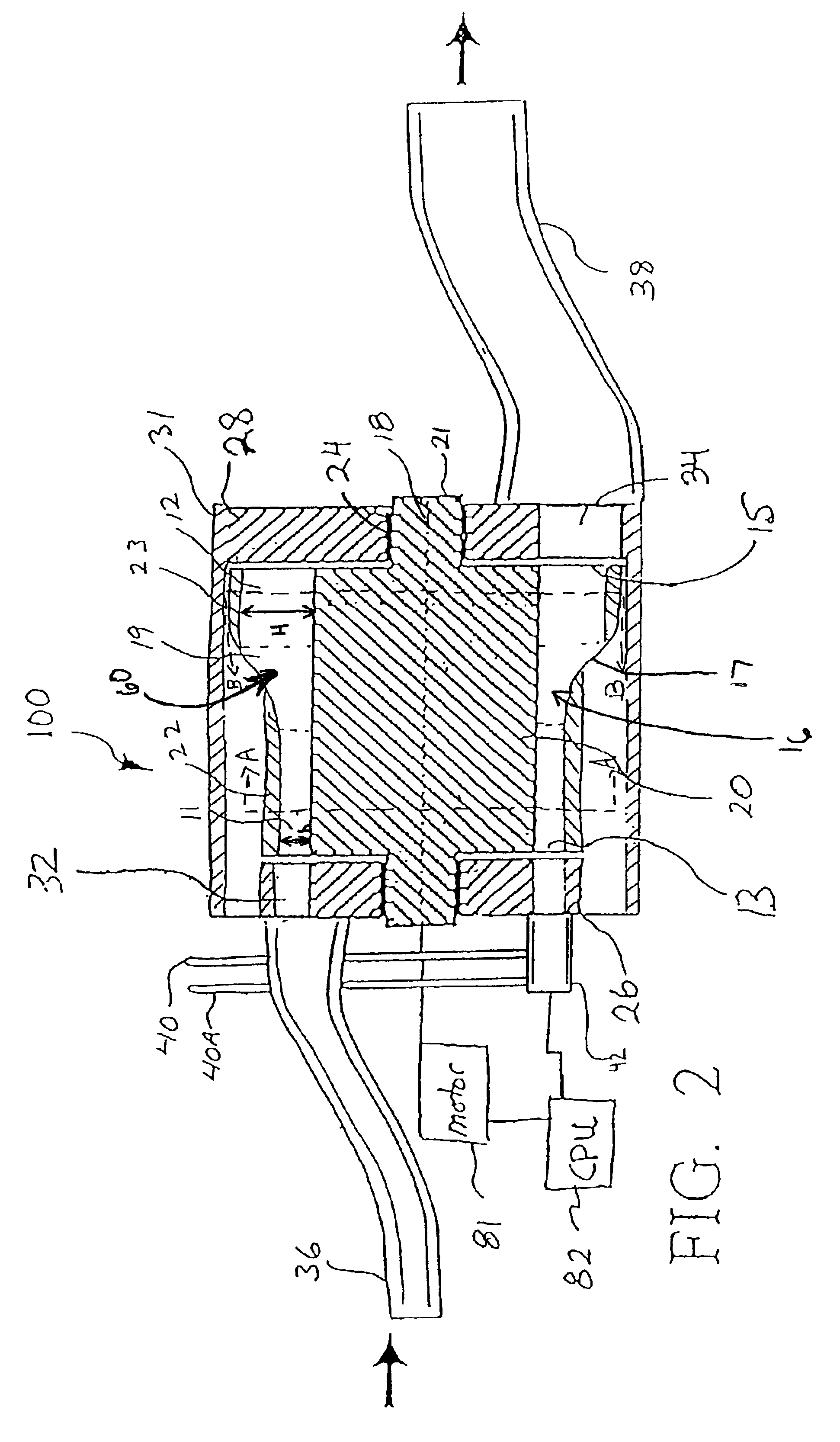

System and method for damping pressure oscillations within a pulse detonation engine

InactiveUS20120204534A1Continuous combustion chamberCosmonautic vehiclesOperating frequencyResonator

In one embodiment, a pulse detonation engine includes a resonator configured to fluidly couple to an air flow path upstream of a pulse detonation tube. The pulse detonation engine also includes a controller configured to receive signals indicative of an operating frequency of an air valve disposed at an upstream end of the pulse detonation tube, and to adjust a geometric configuration of the resonator in response to the signals.

Owner:GENERAL ELECTRIC CO

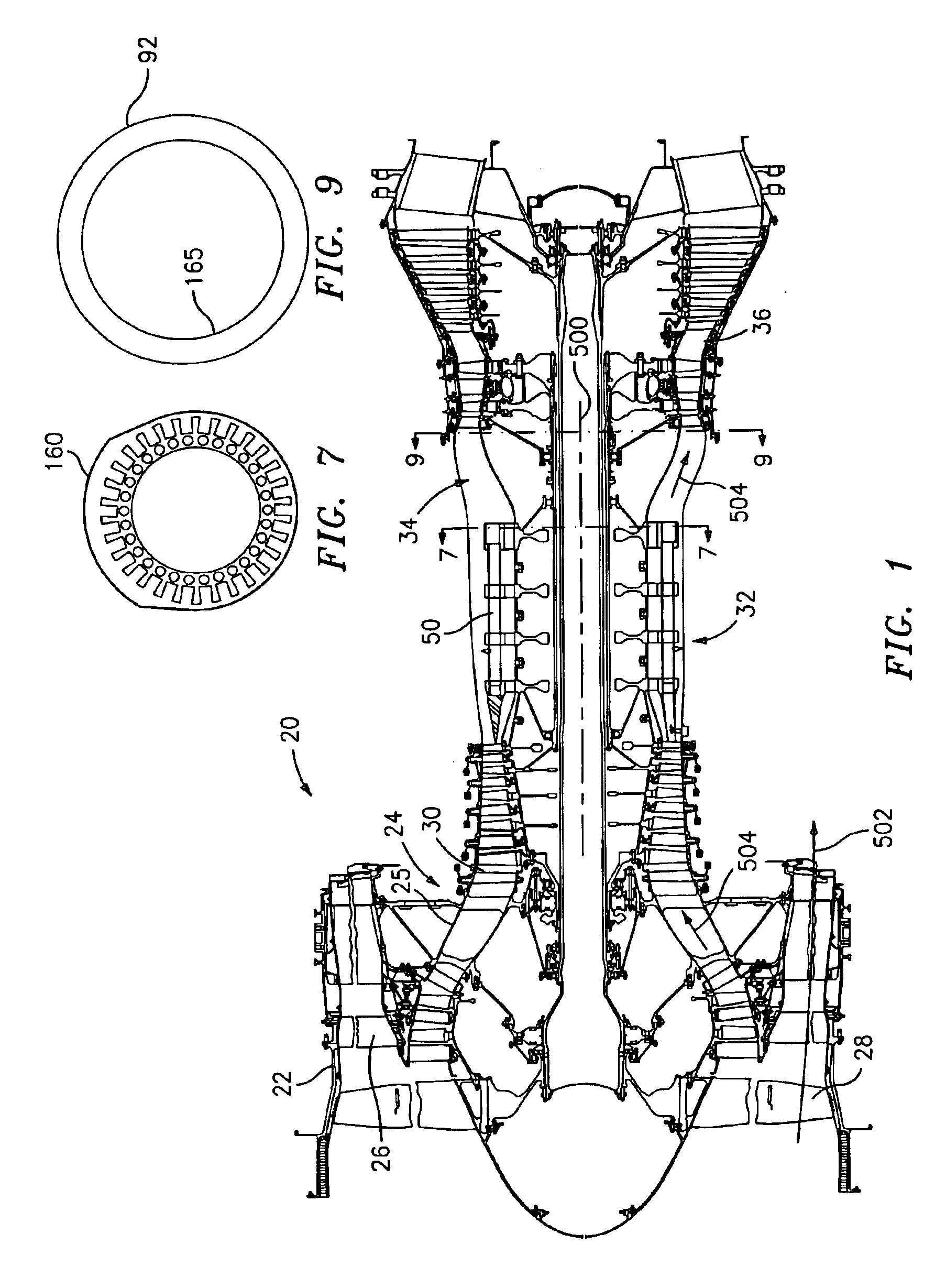

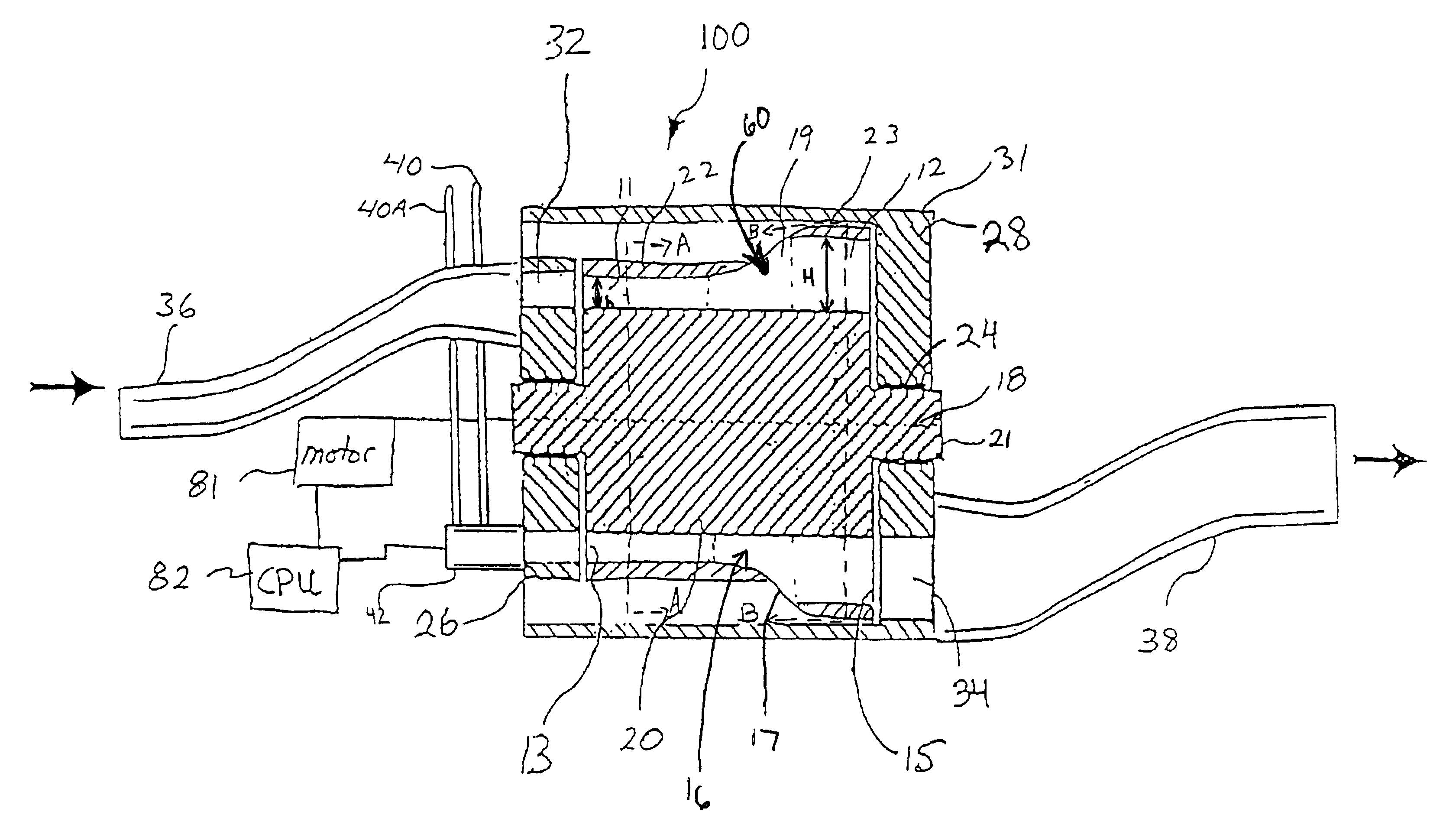

Pulsed combustion engine

A pulsed combustion device includes a support structure and a combustor carousel supported by the support structure and rotating relative thereto about an axis. The carousel has a number of combustion conduits in a circumferential array. Each conduit cyclically receives a charge and discharges combustion products of the charge. A venturi effect may help control fuel / air charge leakage from a flowpath spanning the carousel and a stationary manifold.

Owner:UNITED TECH CORP

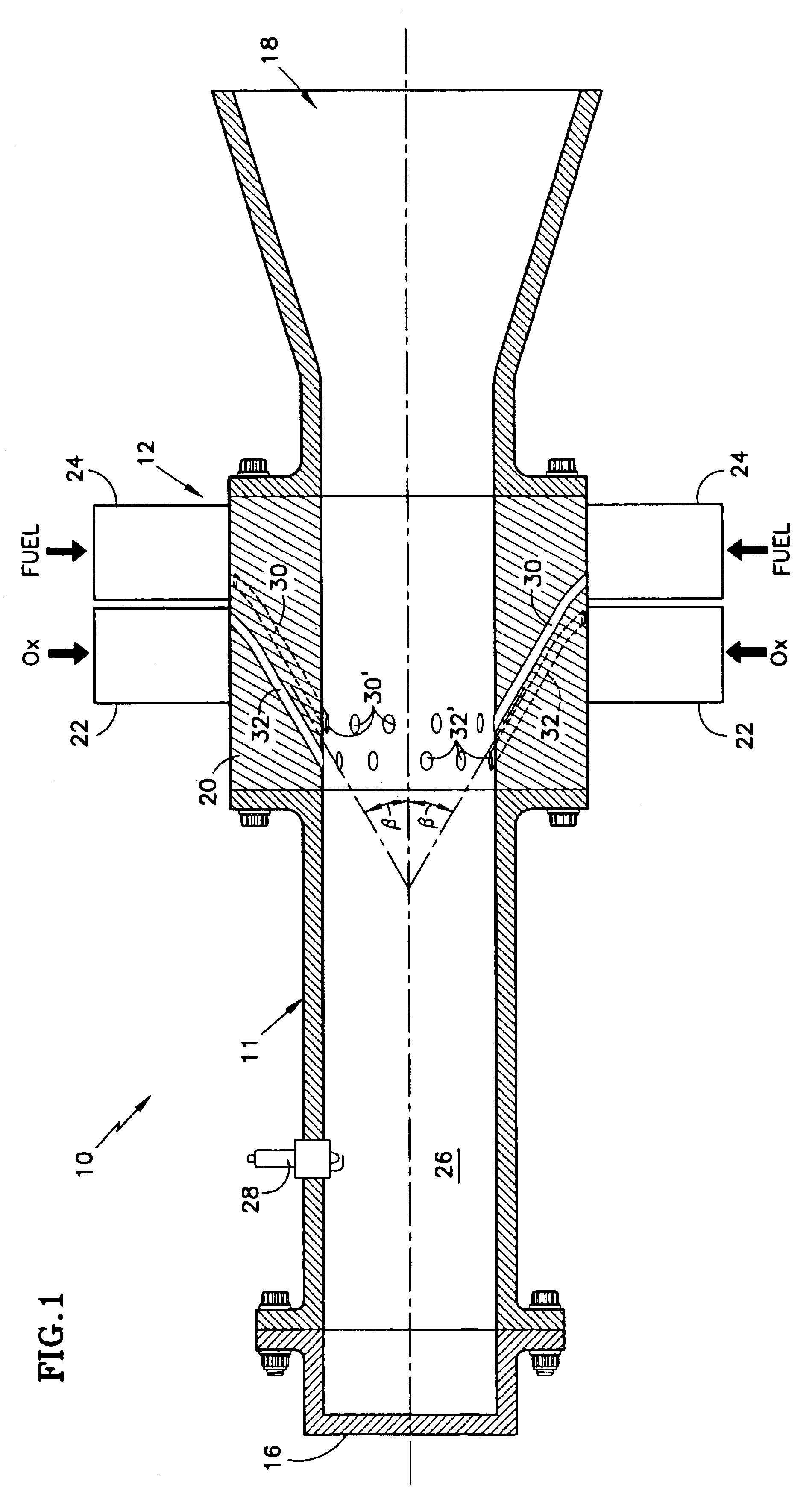

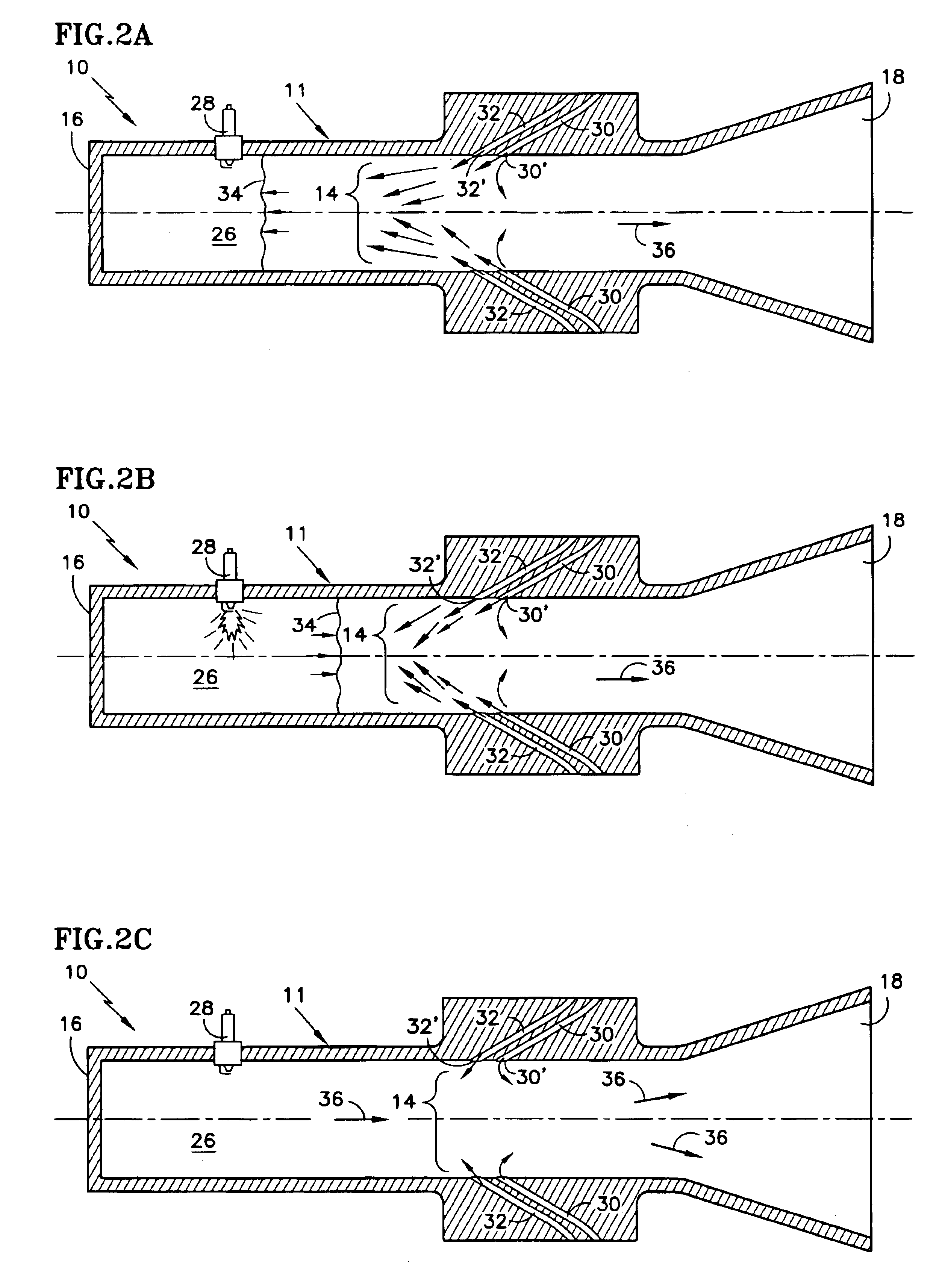

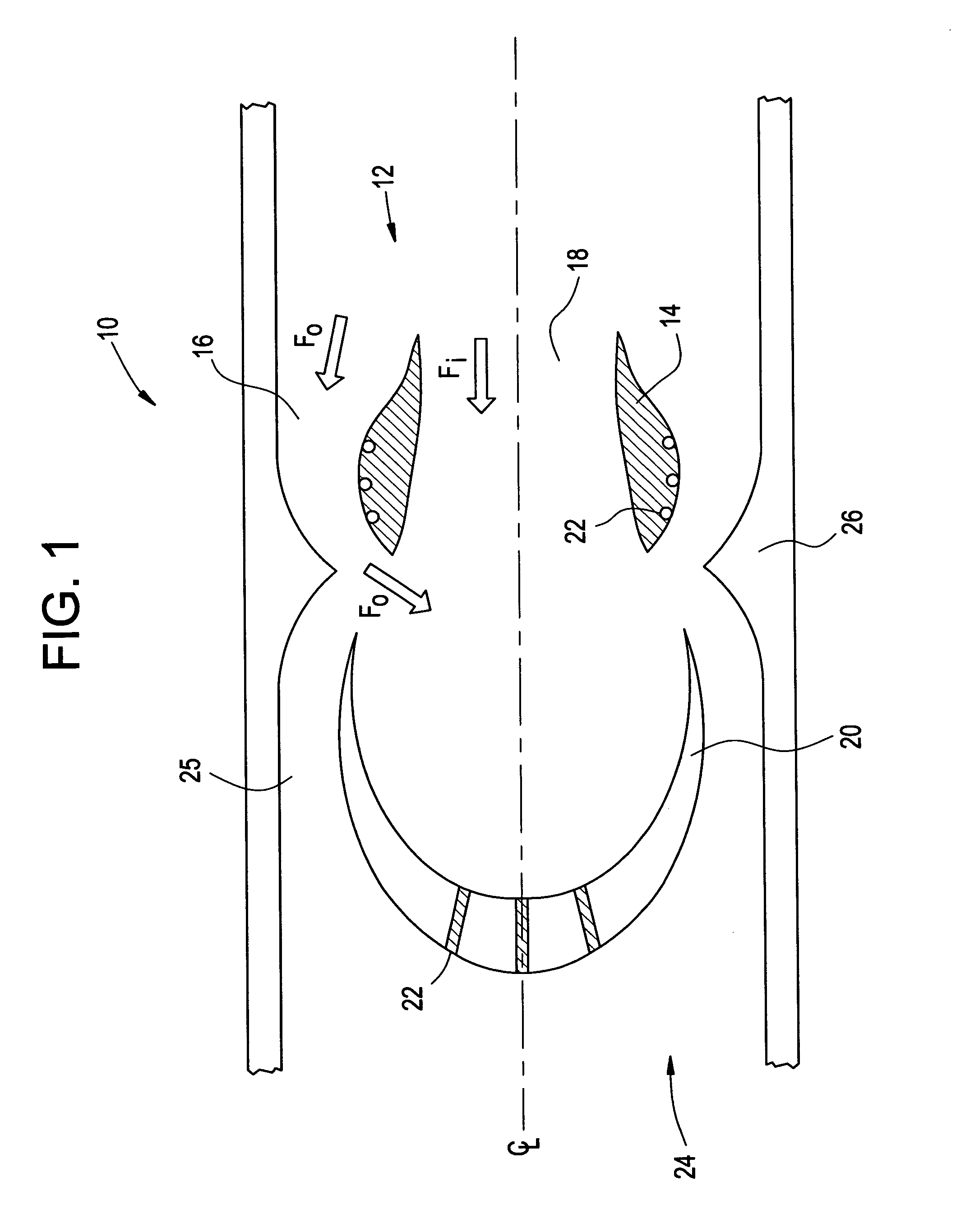

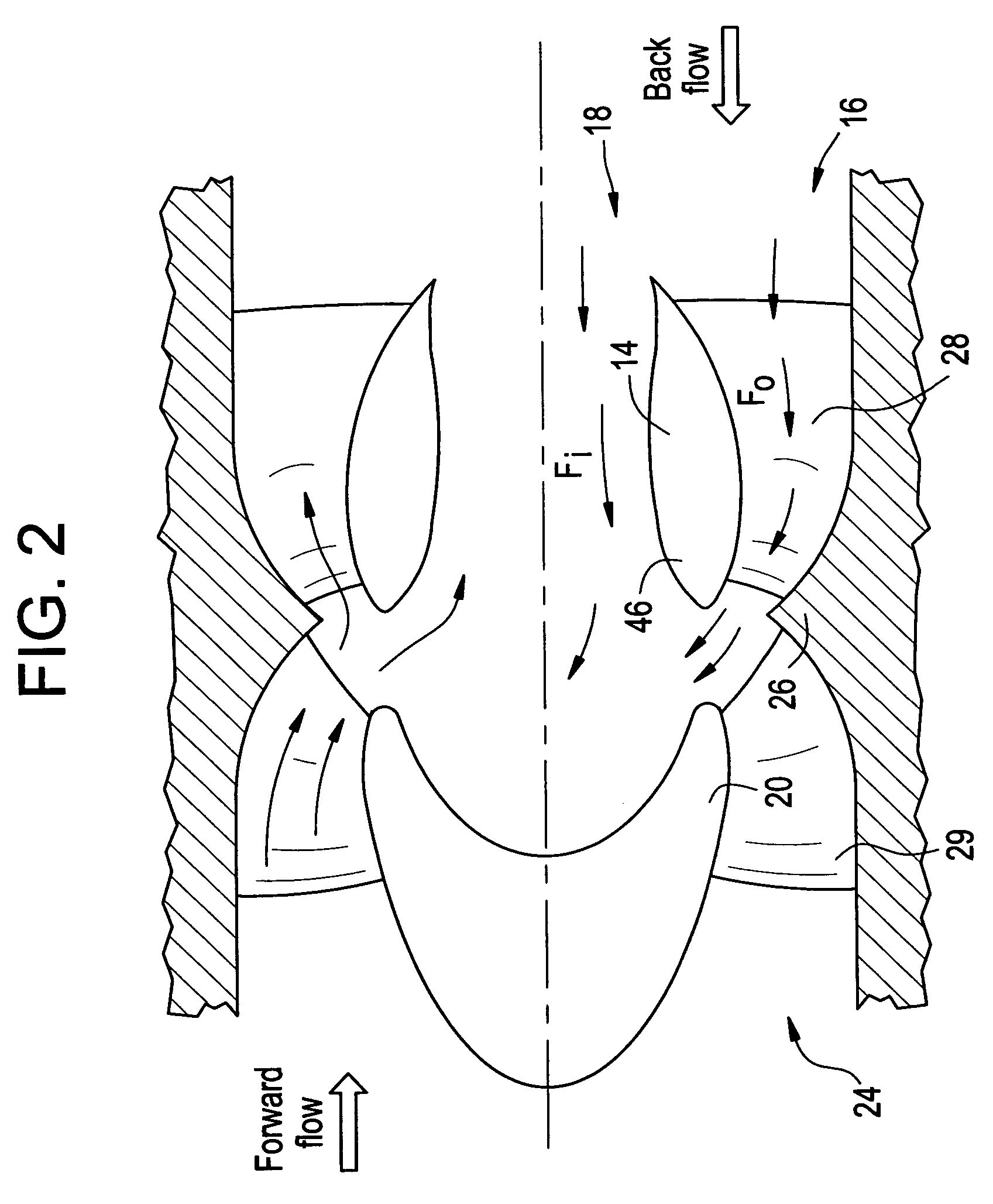

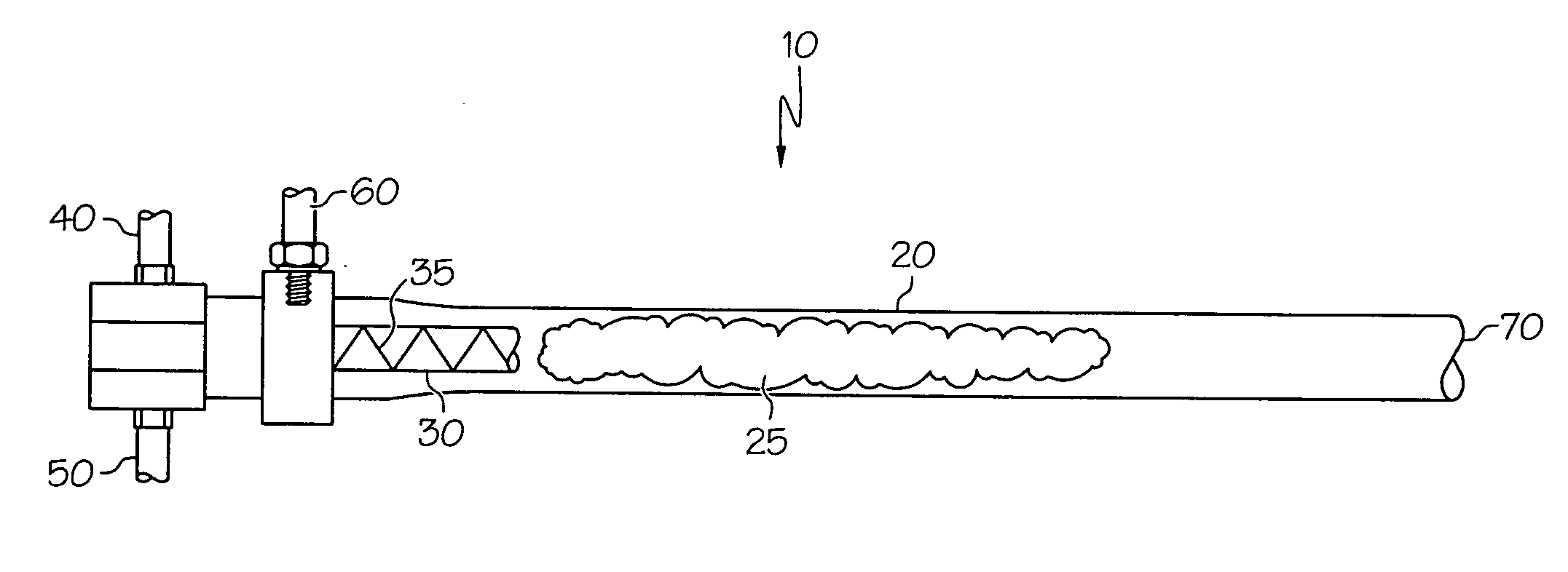

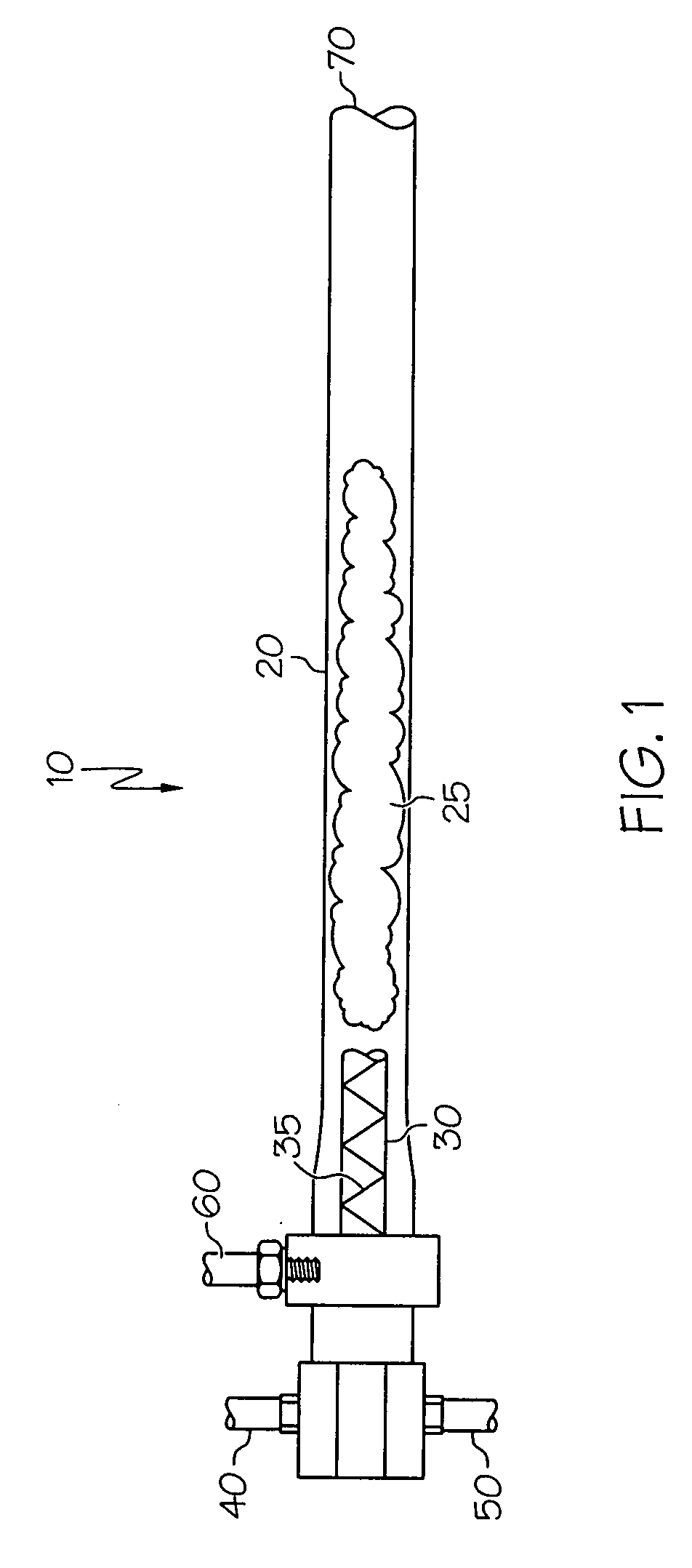

Pulse detonation engine having an aerodynamic valve

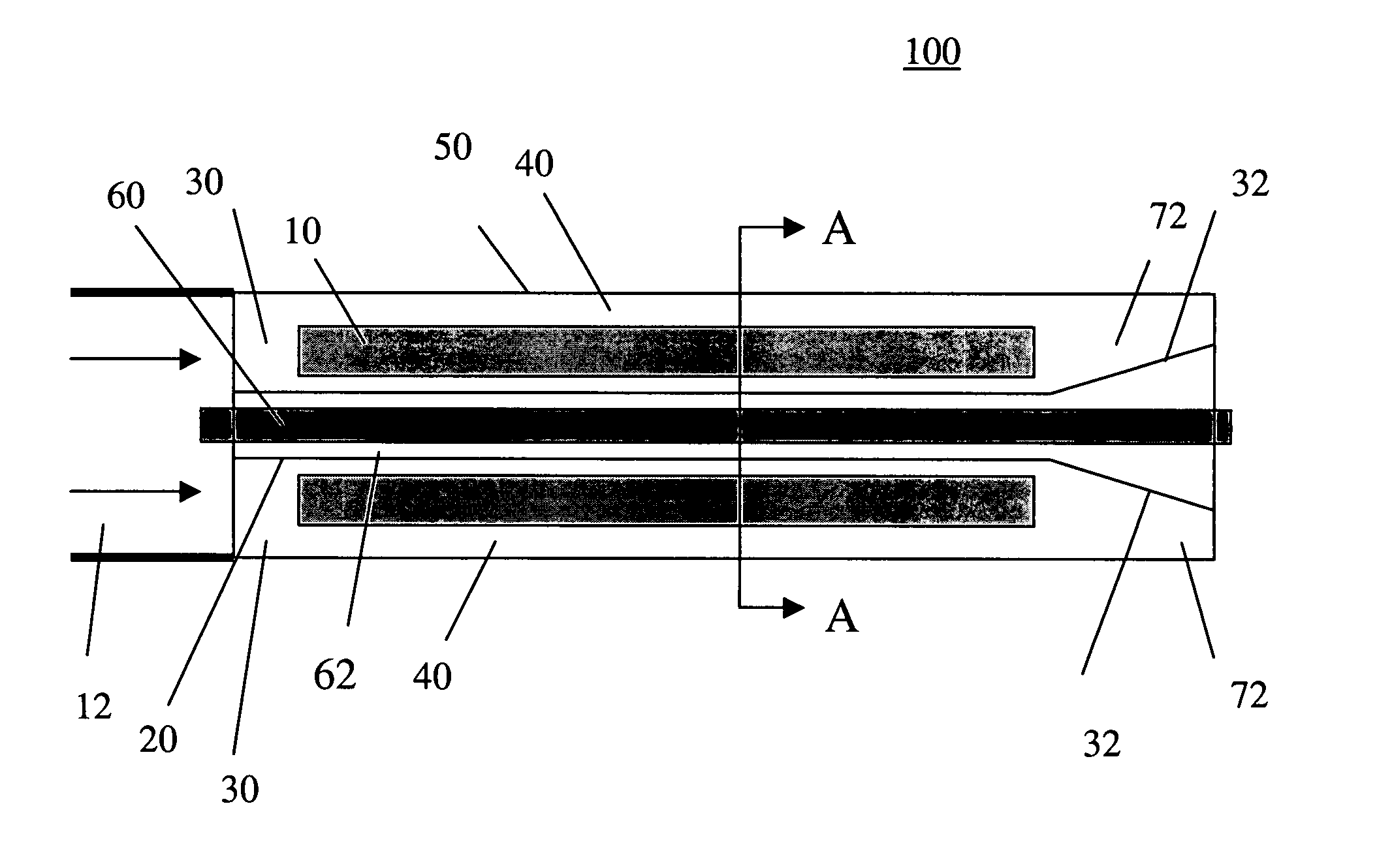

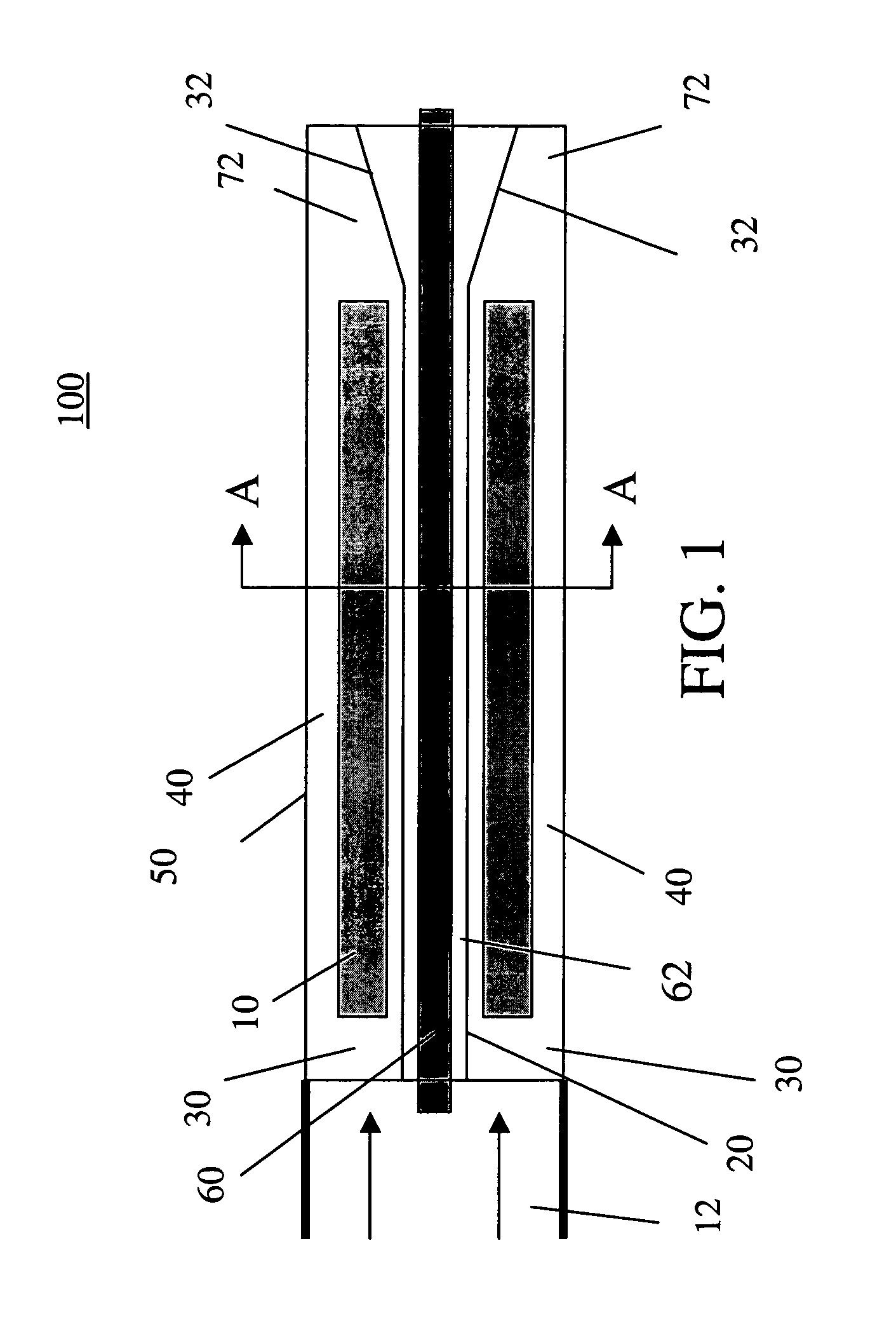

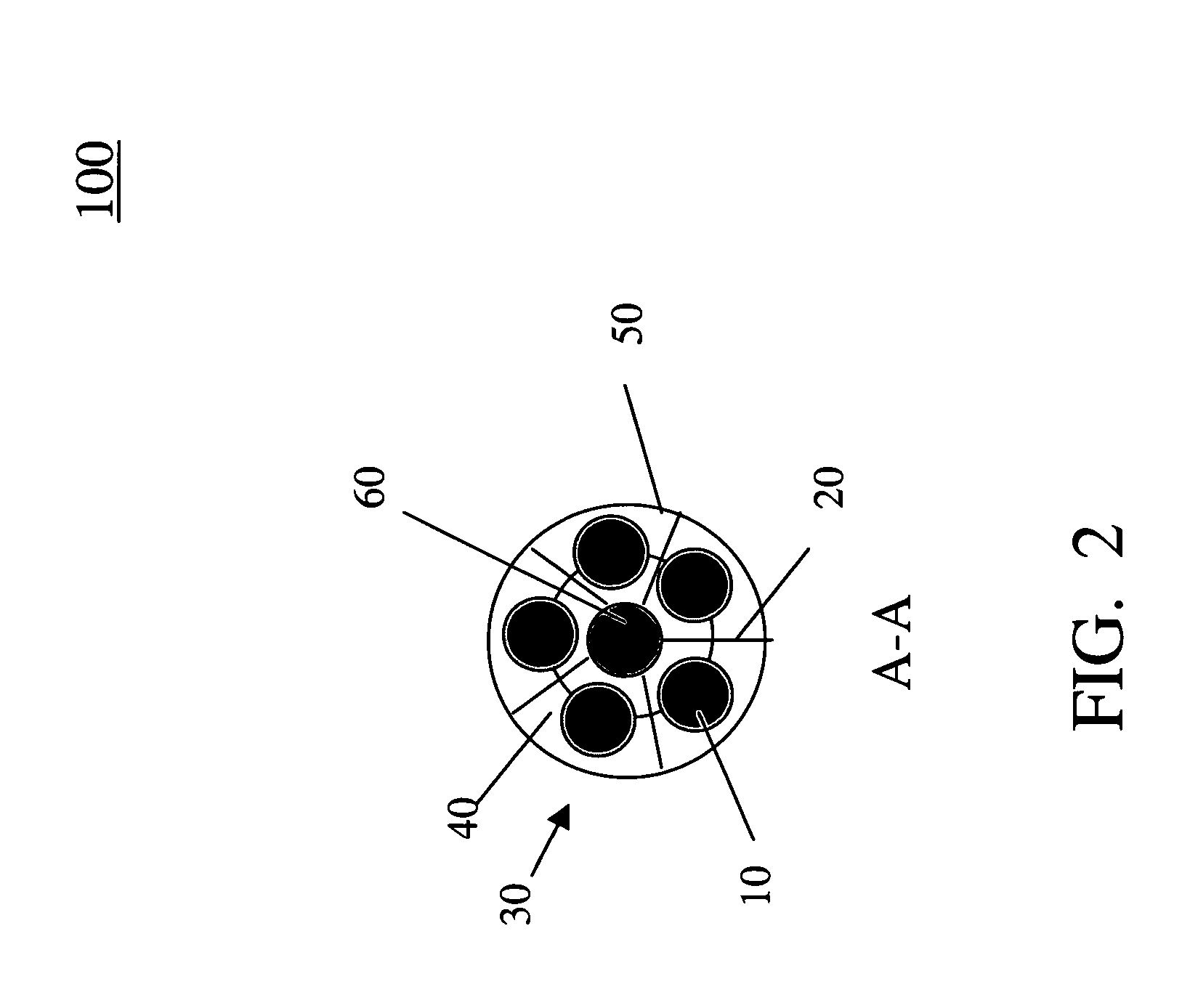

InactiveUS6883543B2Increase pressureSave pressurePulsating combustionCosmonautic vehiclesShock wavePropellant

A pulse detonation engine (10) is provided with an aerovalve (14) for controlling the pressure of injected propellants (Ox, Fuel) in an open-ended detonation chamber (26). The propellants are injected at such pressure and velocity, and in a direction generally toward a forward thrust wall end (16) of the detonation chamber (26), an aerovalve (14) is formed which effectively inhibits or prevents egress of the propellant from the detonation chamber (26). A shock wave (34) formed by the injected propellant acts, after reflection by the thrust wall end (16) and in combination with the aerovalve (14), to compress and conserve, or increase, the pressure of the injected propellant. Carefully timed ignition (28) effects a detonation pulse under desired conditions of maintained, or increased, pressure. Termination of the propellant injection serves to “open” the aerovalve (14), and exhaust of the combusted propellants occurs to produce thrust. Alternate embodiments of propellant injection mechanisms (12, 112) provide pulse valves (24, 122, 124) each having a fixed slotted disk (40, 140, 240) and a rotating slotted disk (42, 142, 242) to provide the desired high speed valving of discrete pulses of propellant for injection.

Owner:UNITED TECH CORP

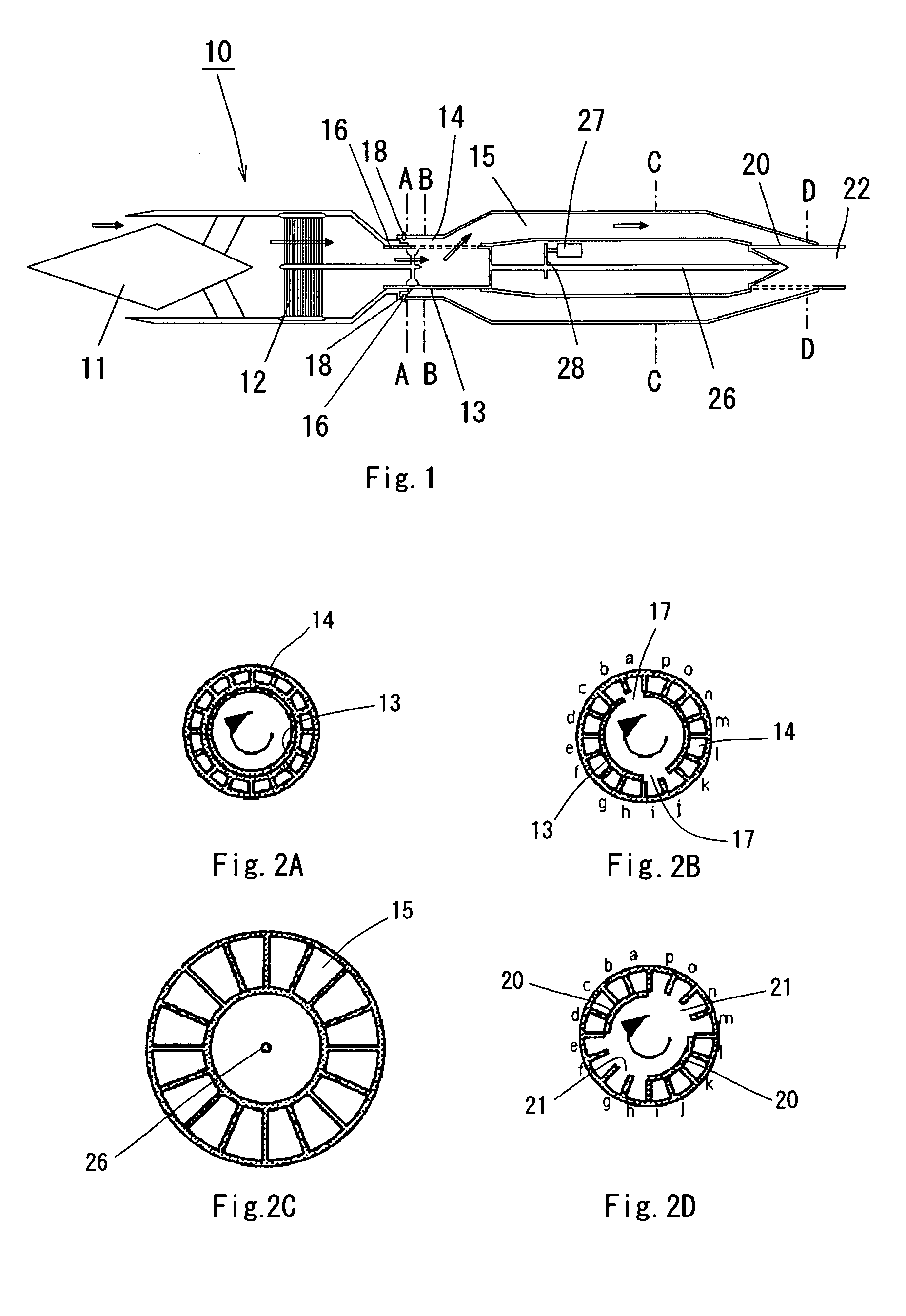

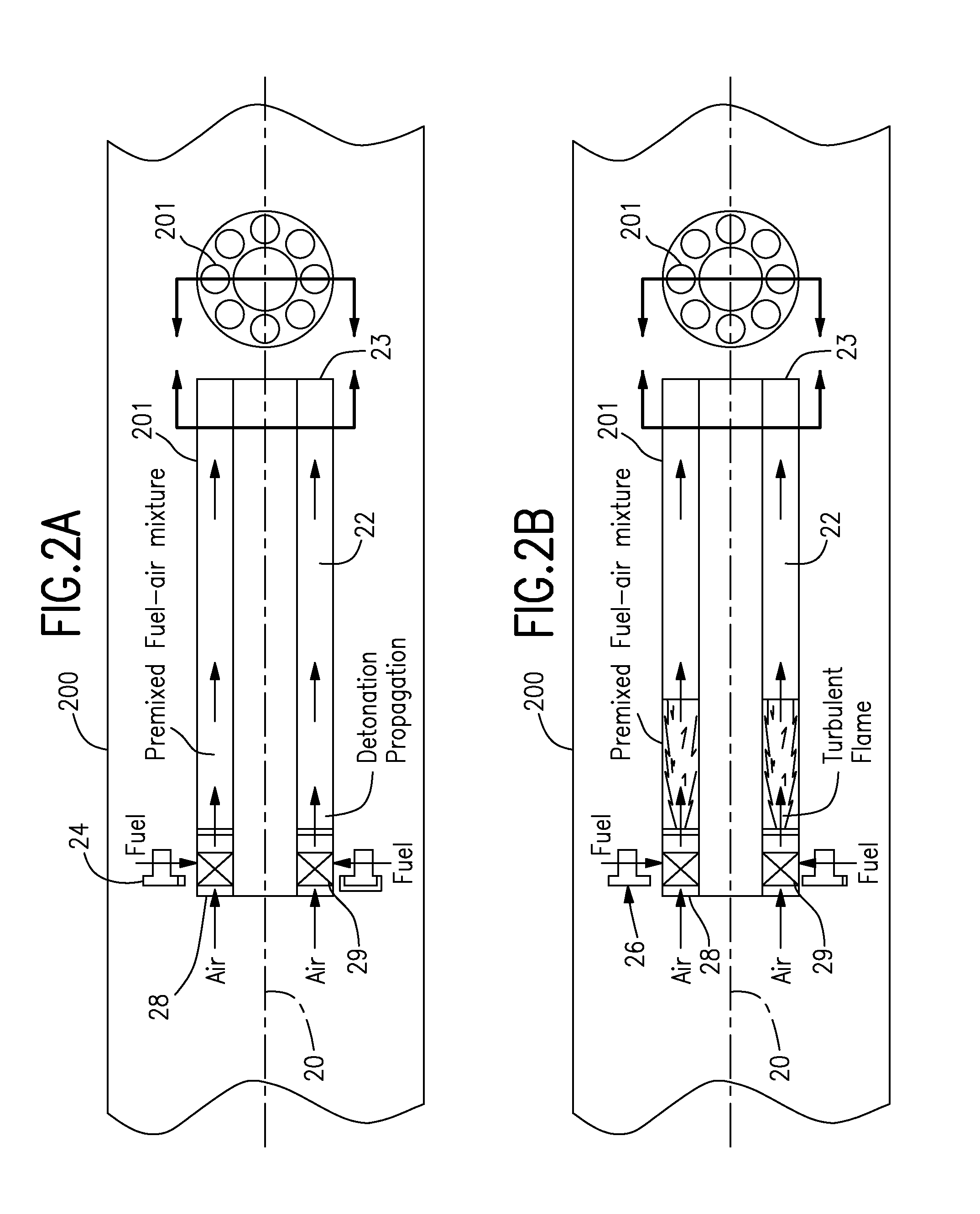

Rotary ejector enhanced pulsed detonation system and method

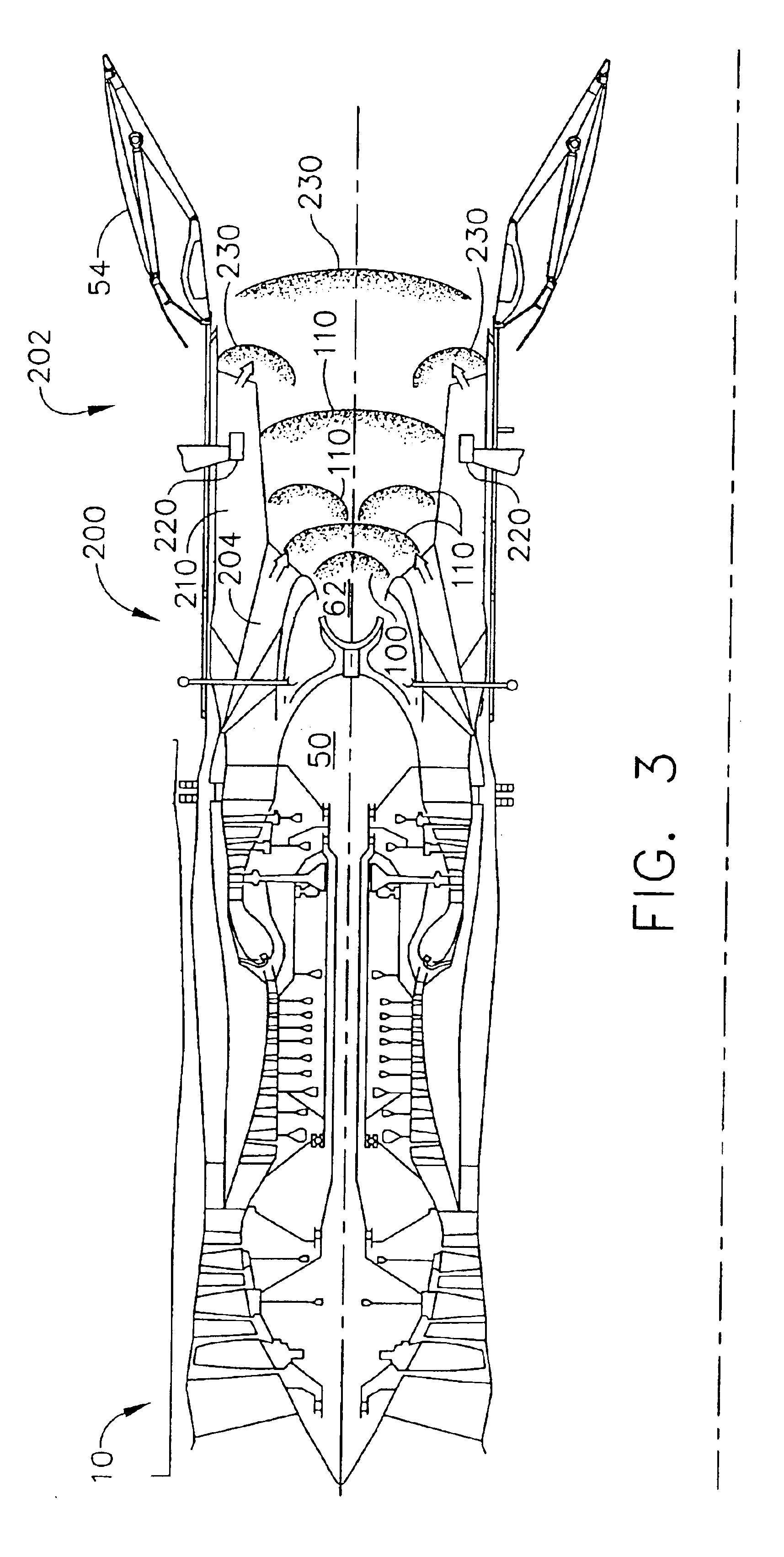

InactiveUS6845620B2More temperatureExcessive velocityTurbine/propulsion fuel supply systemsInternal combustion piston enginesCombustionDetonation

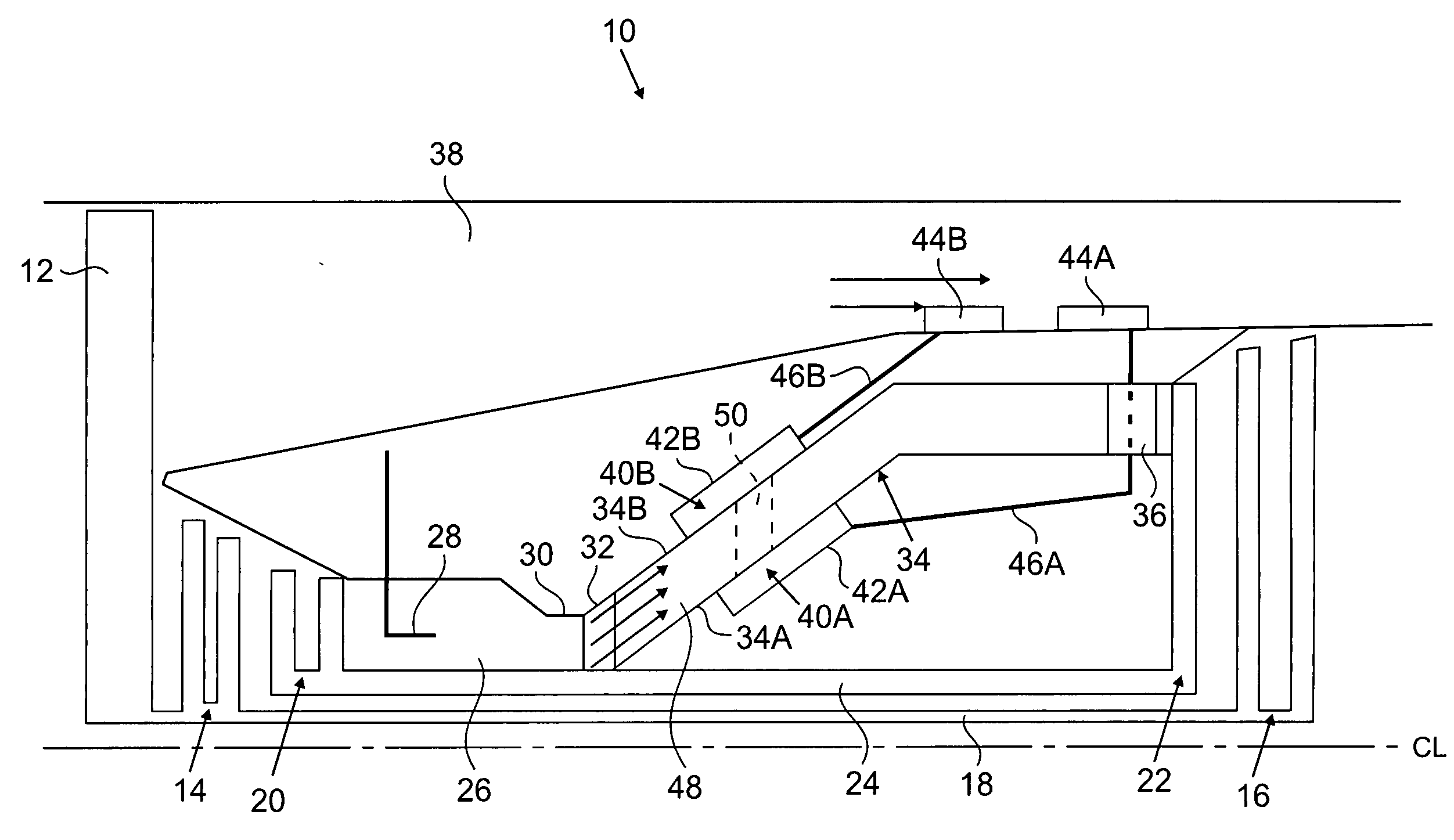

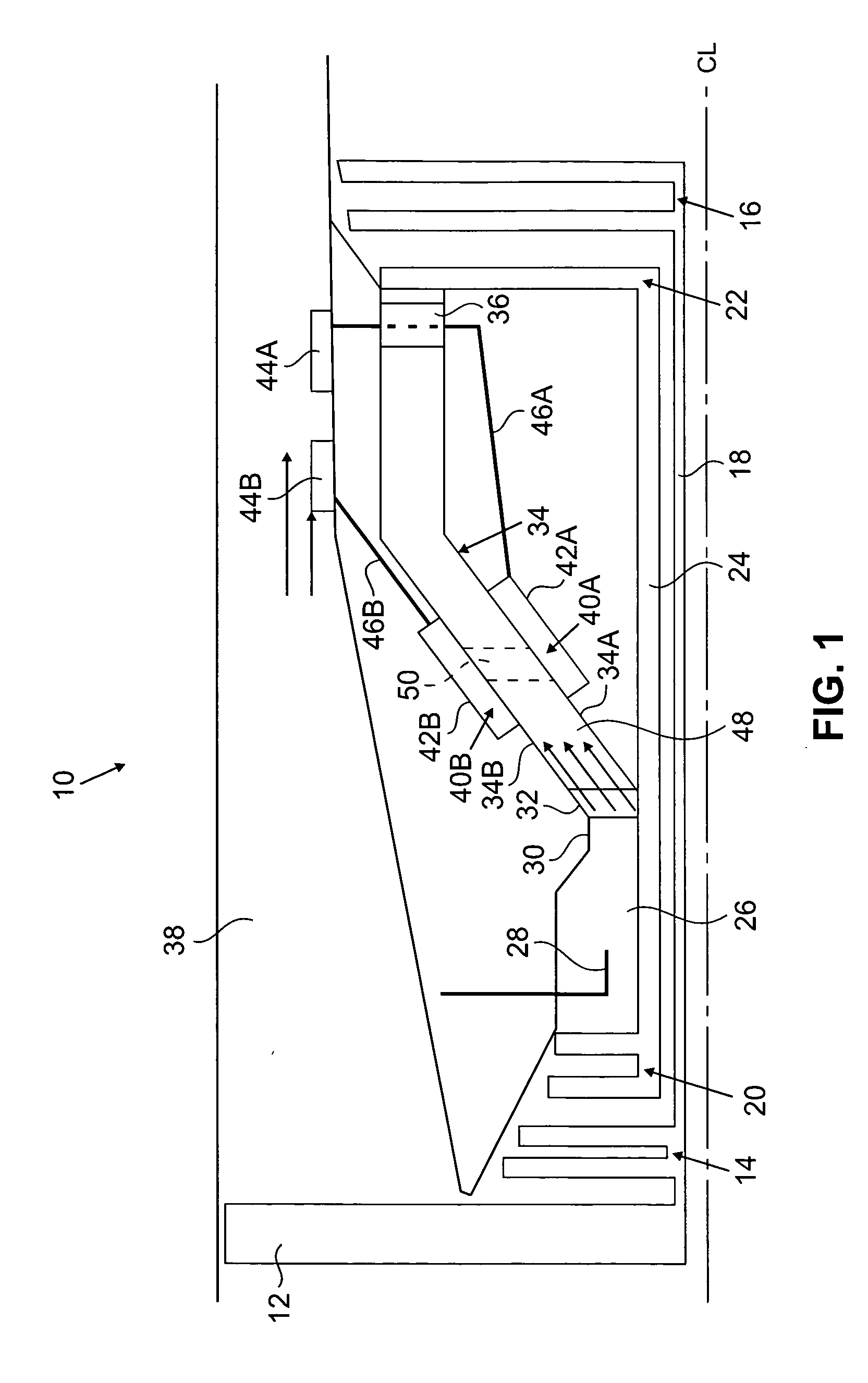

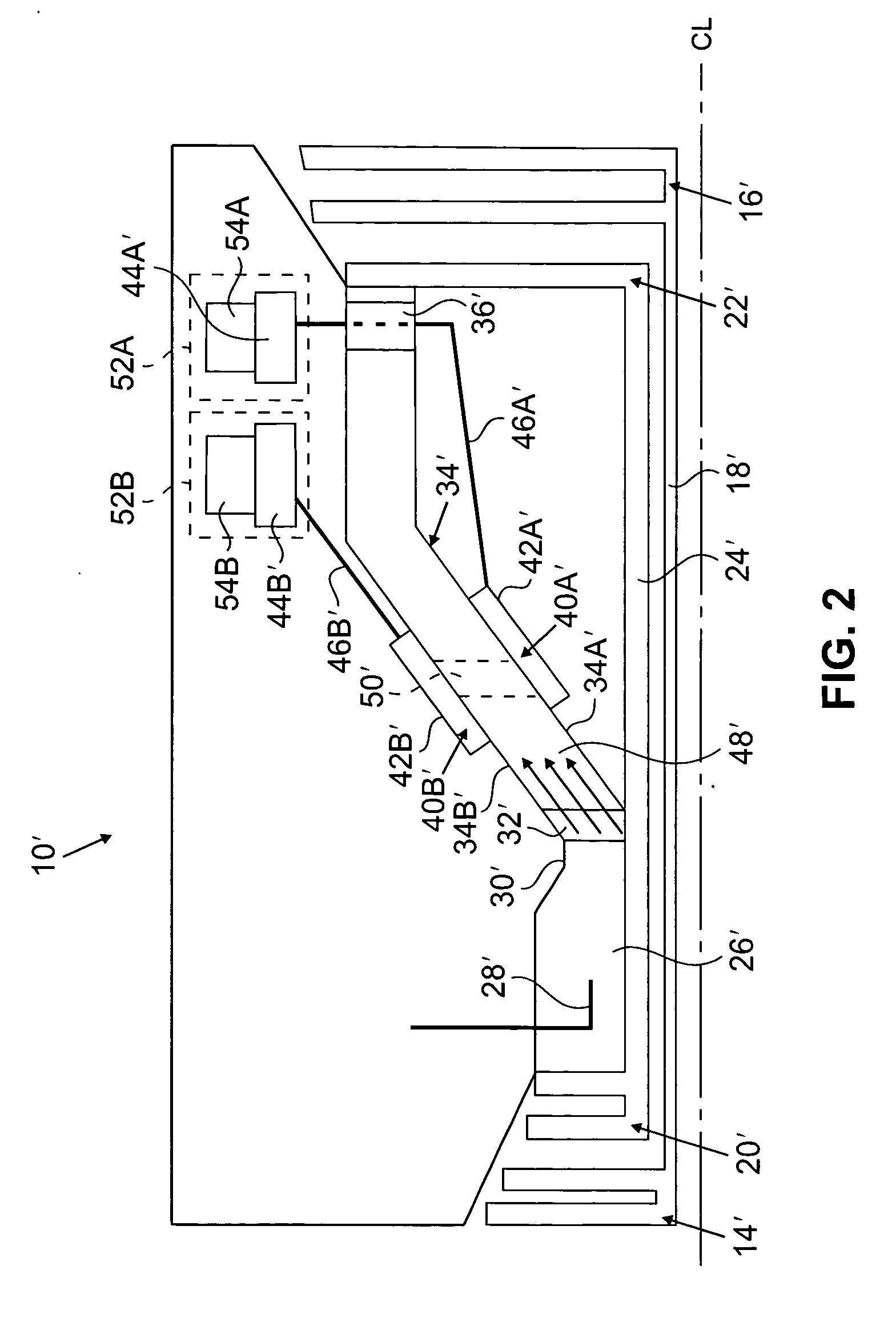

A rotary ejector enhanced wave rotor pulsed detonation (WRPDE) engine and method are provided. The rotary-ejector-WRPDE includes a housing, one or more inlet ports in the housing, and a rotor mounted within the housing. The rotor includes a plurality of shrouded forward combustion passages in which detonative combustion occurs. Each forward combustion passage has an inlet end for communication with the inlet port. The rotor also includes a plurality of rear combustion passages which are in gaseous communication with the forward combustion passages. The rotor further includes a plurality of transitional combustion passages which join the forward combustion passages to the rear combustion passages and communicate with a source of bypass gas to provide a rotary ejector.

Owner:ADVANCED RES TECH INST

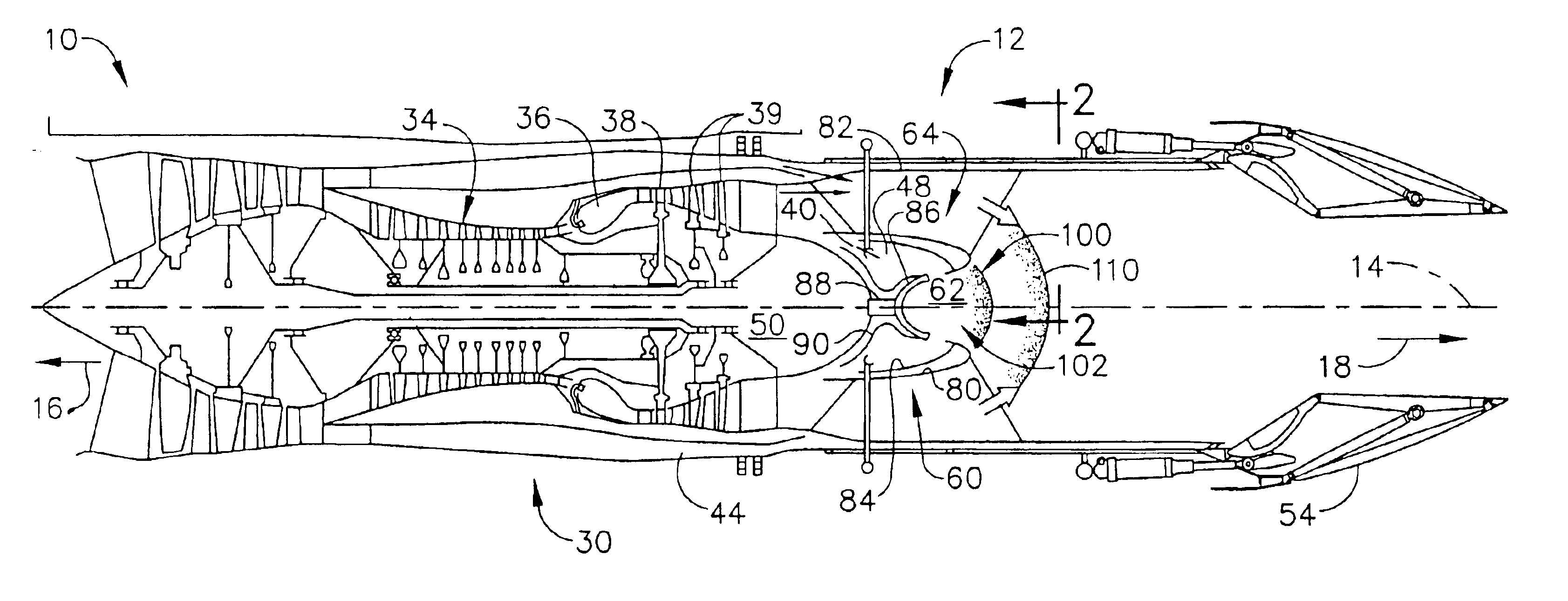

Methods and apparatus for generating gas turbine engine thrust with a pulse detonation thrust augmenter

InactiveUS6883302B2Increase temperatureIncrease pressureCosmonautic vehiclesCosmonautic propulsion system apparatusDetonationGas turbines

A method enables thrust to be generated from a gas turbine engine using a pulse detonation system is provided. The engine includes an inlet portion and an exhaust portion, and the pulse detonation system includes a multi-staged pulse detonation augmentor including predetonator. The method comprises supplying a less than stoichiometric fuel / air mixture to the pulse detonation system during a first operating stage, detonating the fuel / air mixture with the predetonator to increase the temperature and pressure within the engine and to generate engine thrust, and supplying additional fuel and air to the pulse detonation system during a second operating stage.

Owner:GENERAL ELECTRIC CO

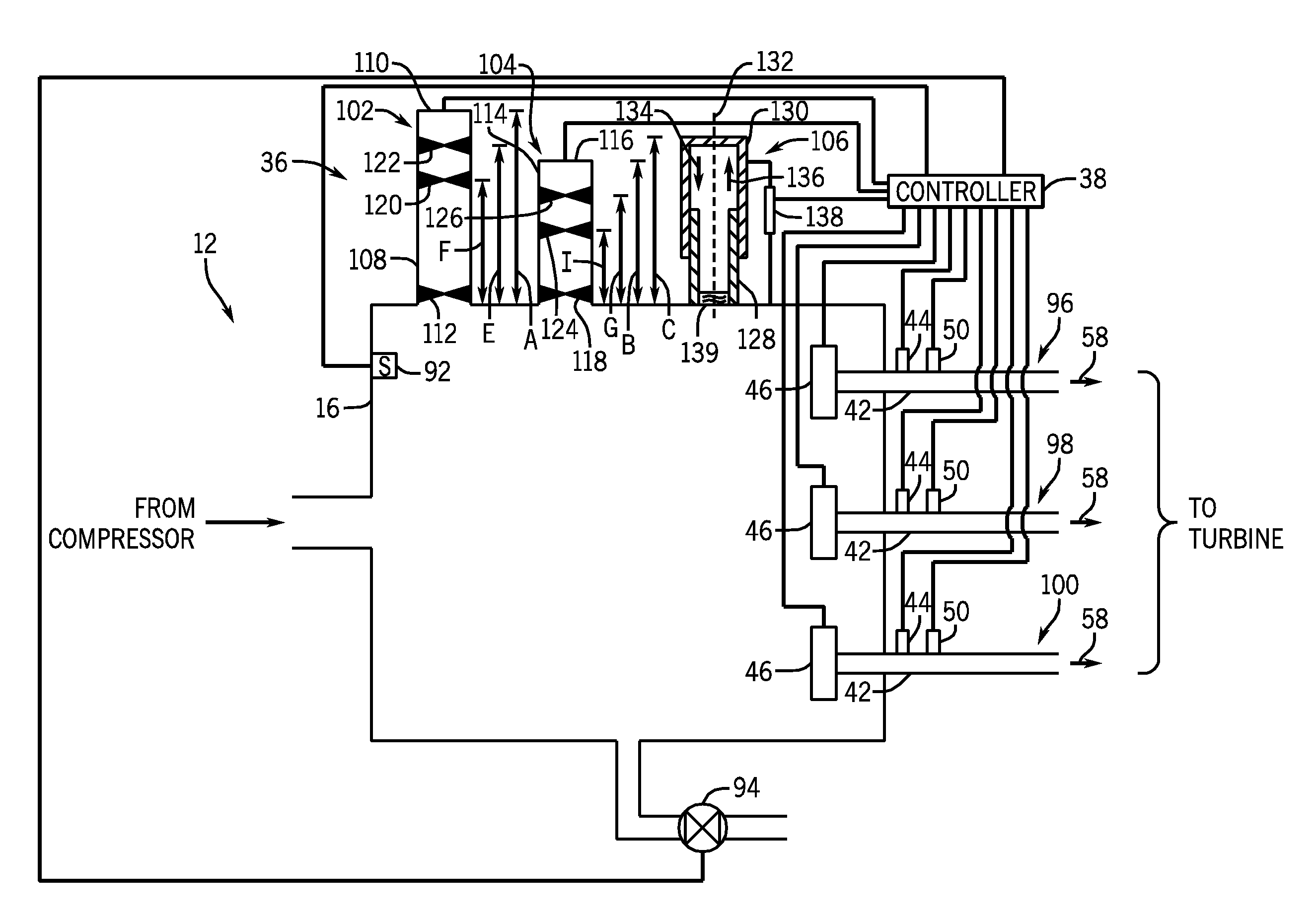

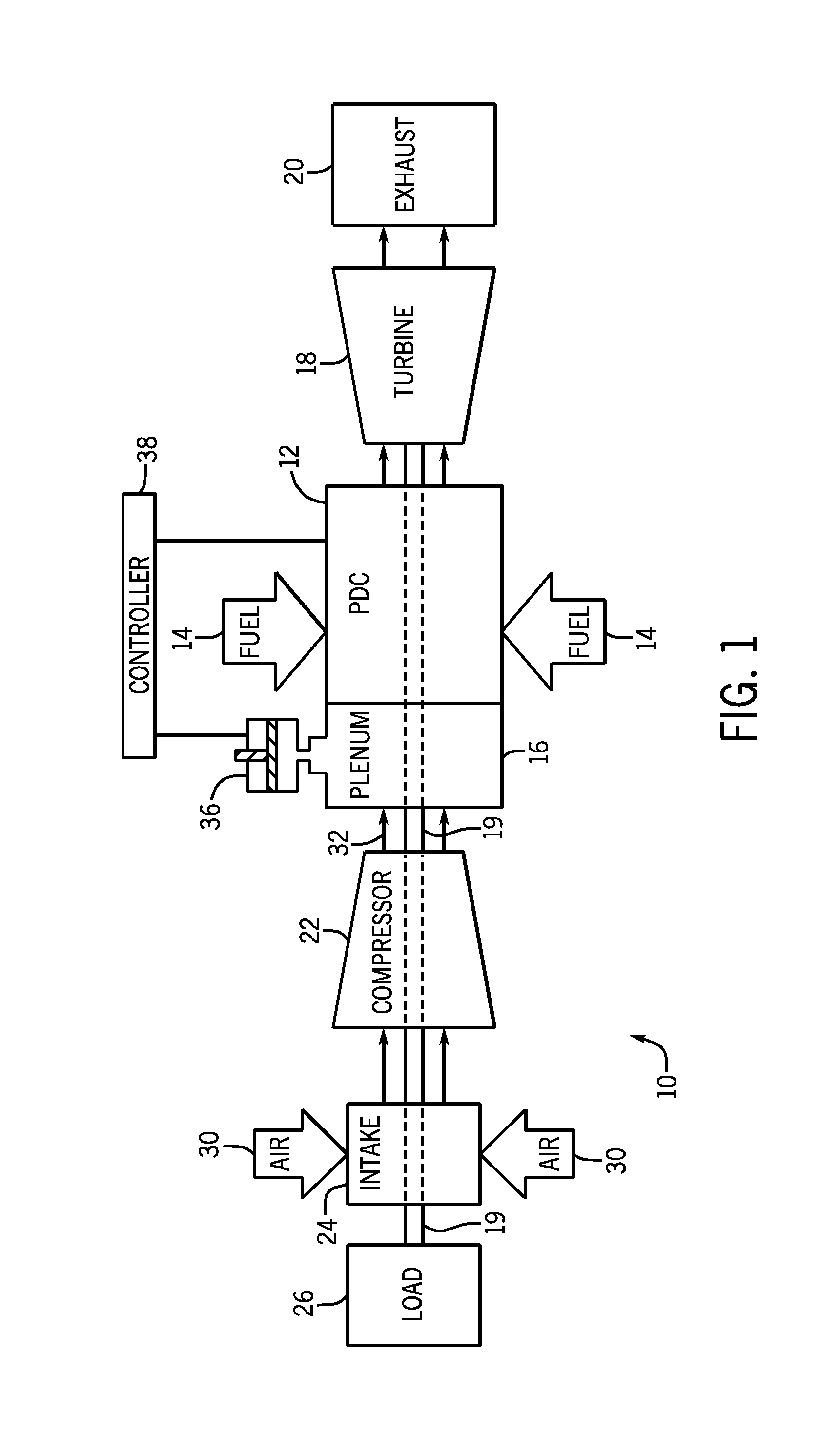

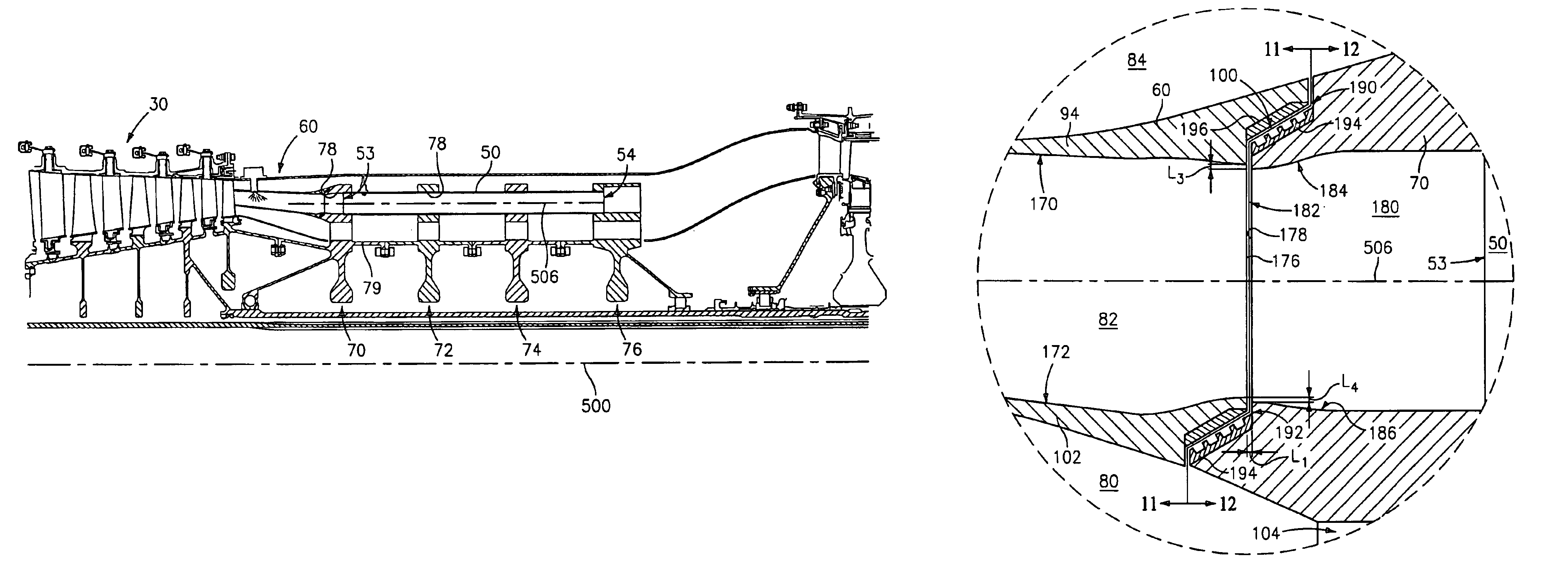

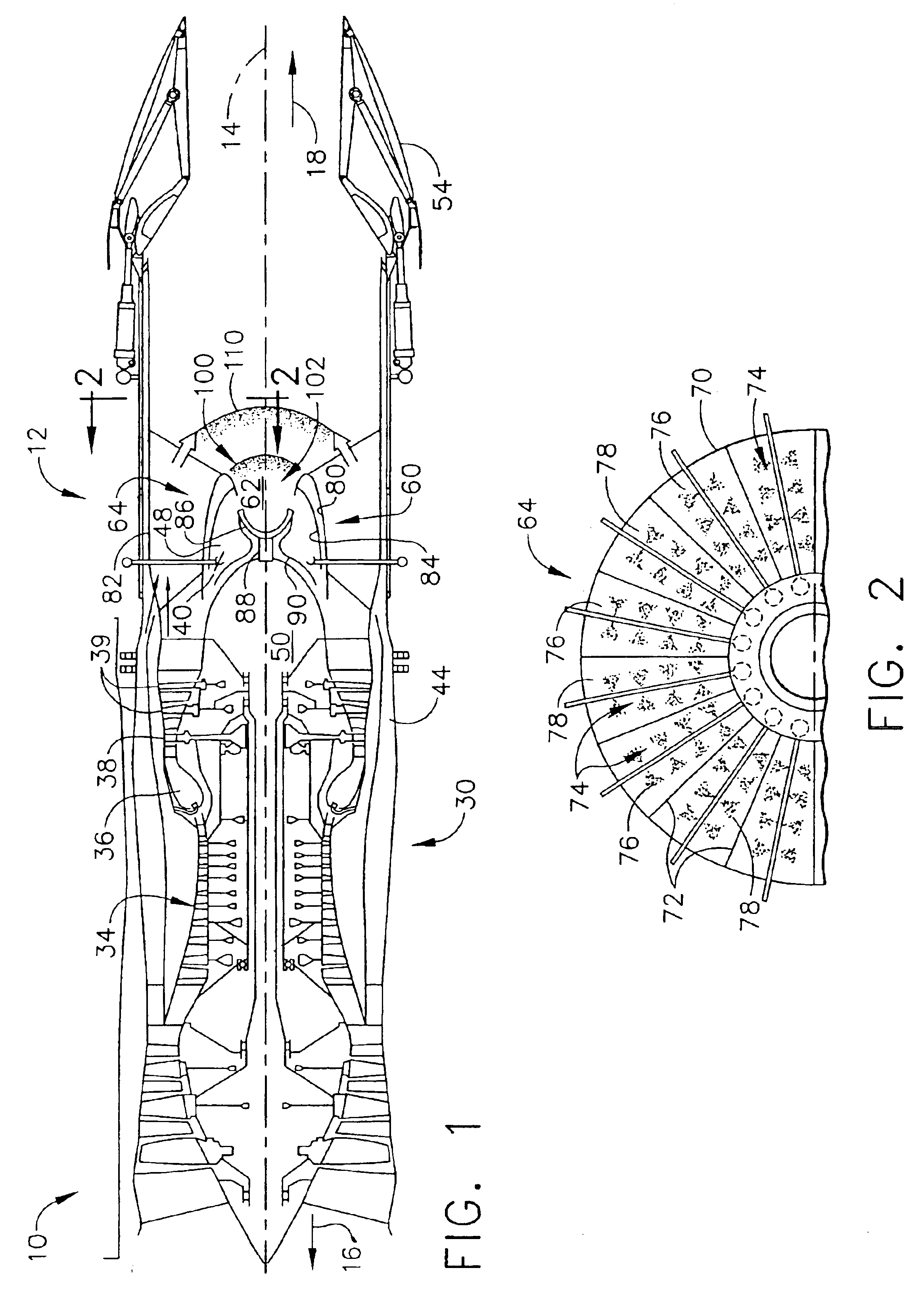

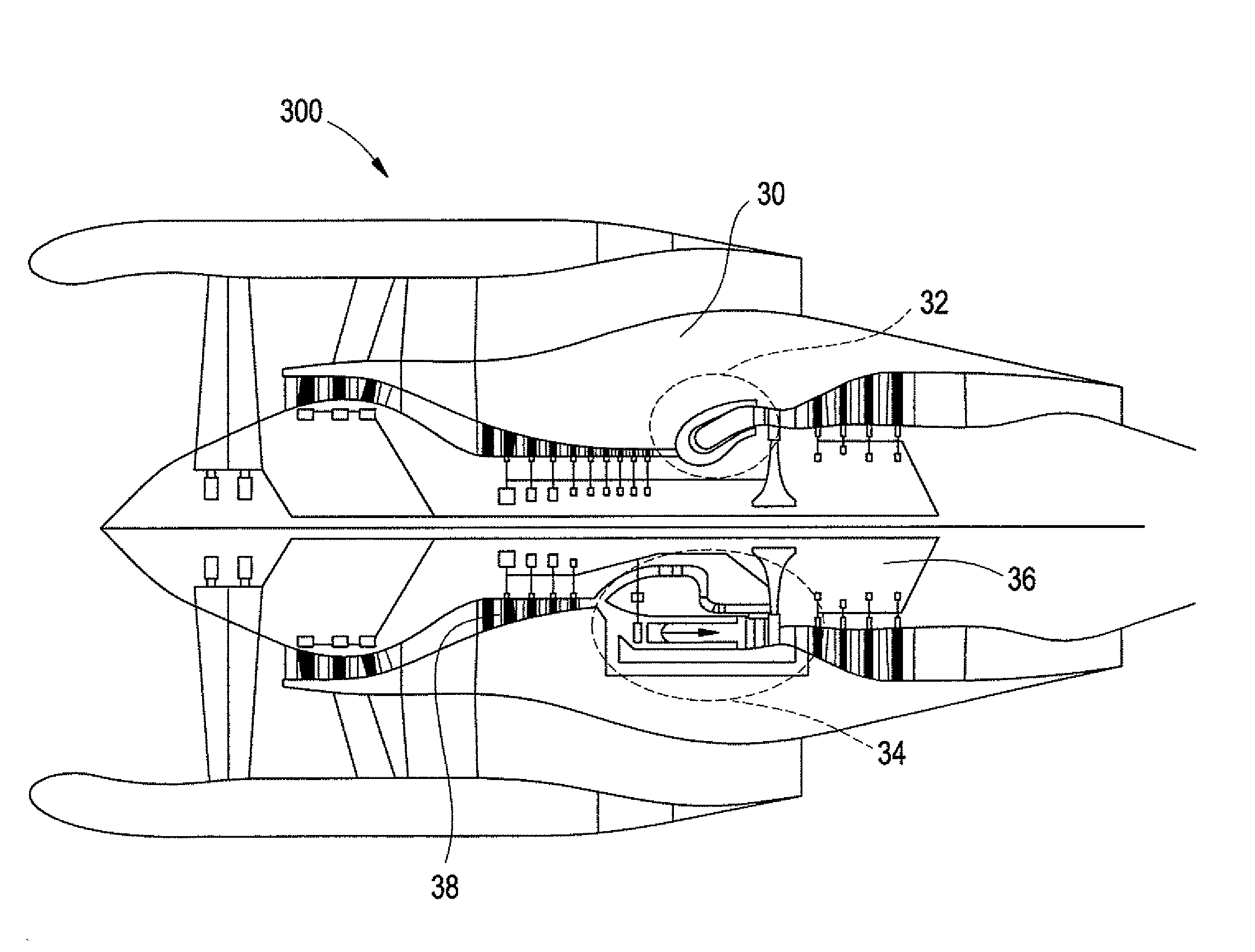

Pulse detonation assembly and hybrid engine

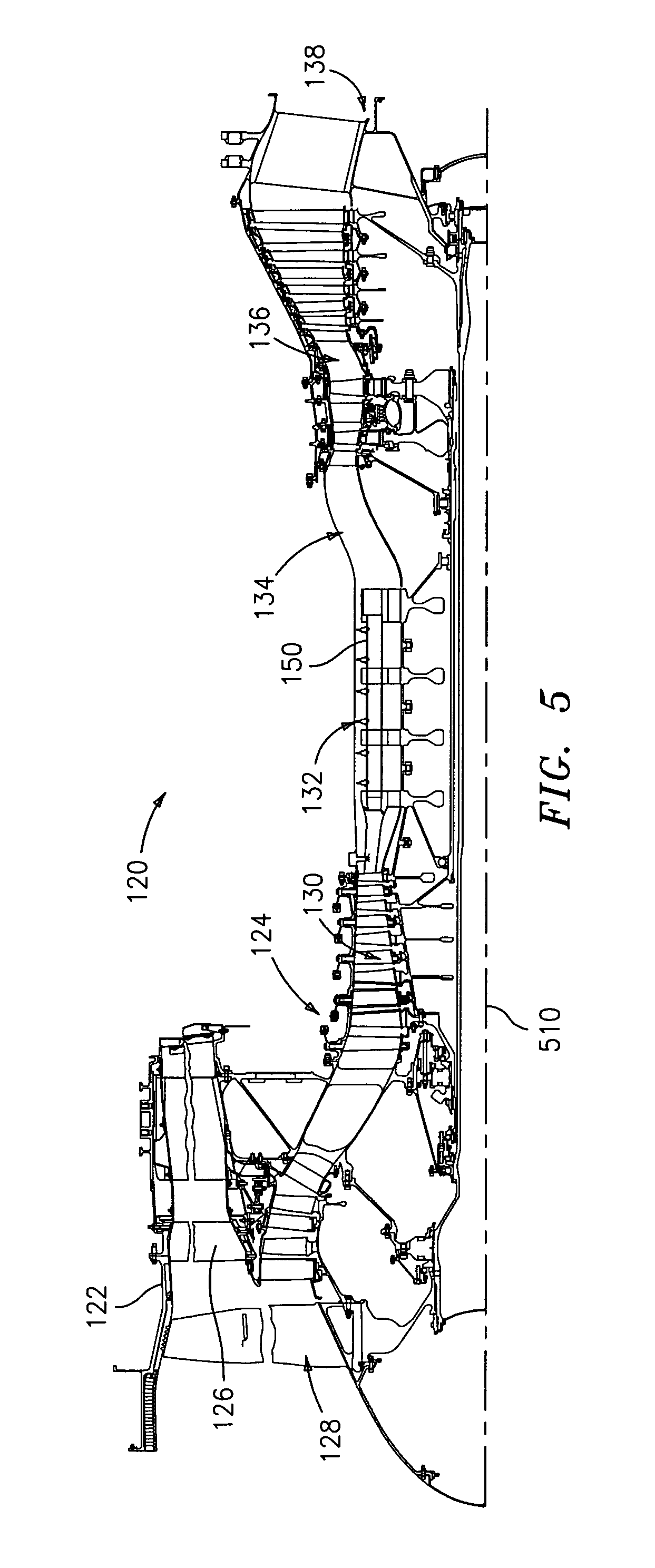

ActiveUS20060254252A1Reducing undesirable interactionReduce the overall heightPulsating combustionGas turbine plantsDetonationTurbine

A pulse detonation (PD) assembly includes a number of PD chambers adapted to expel respective detonation product streams and a number of barriers disposed between respective pairs of PD chambers. The barriers define, at least in part, a number of sectors that contain at least one PD chamber. A hybrid engine includes a number of PD chambers and barriers. The hybrid engine further includes a turbine assembly having at least one turbine stage, being in flow communication with the PD chambers and being configured to be at least partially driven by the detonation product streams. A segmented hybrid engine includes a number of PD chambers and segments configured to receive and direct the detonation product streams from respective PD chambers. The segmented hybrid engine further includes a turbine assembly configured to be at least partially driven by the detonation product streams.

Owner:GENERAL ELECTRIC CO

Compact, low pressure-drop shock-driven combustor

ActiveUS7739867B2Create efficientlyPromote combustionTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionCombustorCombustion chamber

A system for efficiently creating cyclic detonations is provided. The system includes at least a first initiator chamber configured to generate an initial wave, at least one main chamber coupled to the first initiator chamber. The main chamber is configured to generate a main wave and to output products of supersonic combustion. The products are generated within the main chamber. The main chamber is configured to enable the main wave to travel upstream and downstream within the main chamber when the first initiator chamber is located outside the main chamber. The system further includes an initial connection section located between the first initiator chamber and the main chamber that enhances a combustion process via shock focusing and shock reflection.

Owner:GENERAL ELECTRIC CO

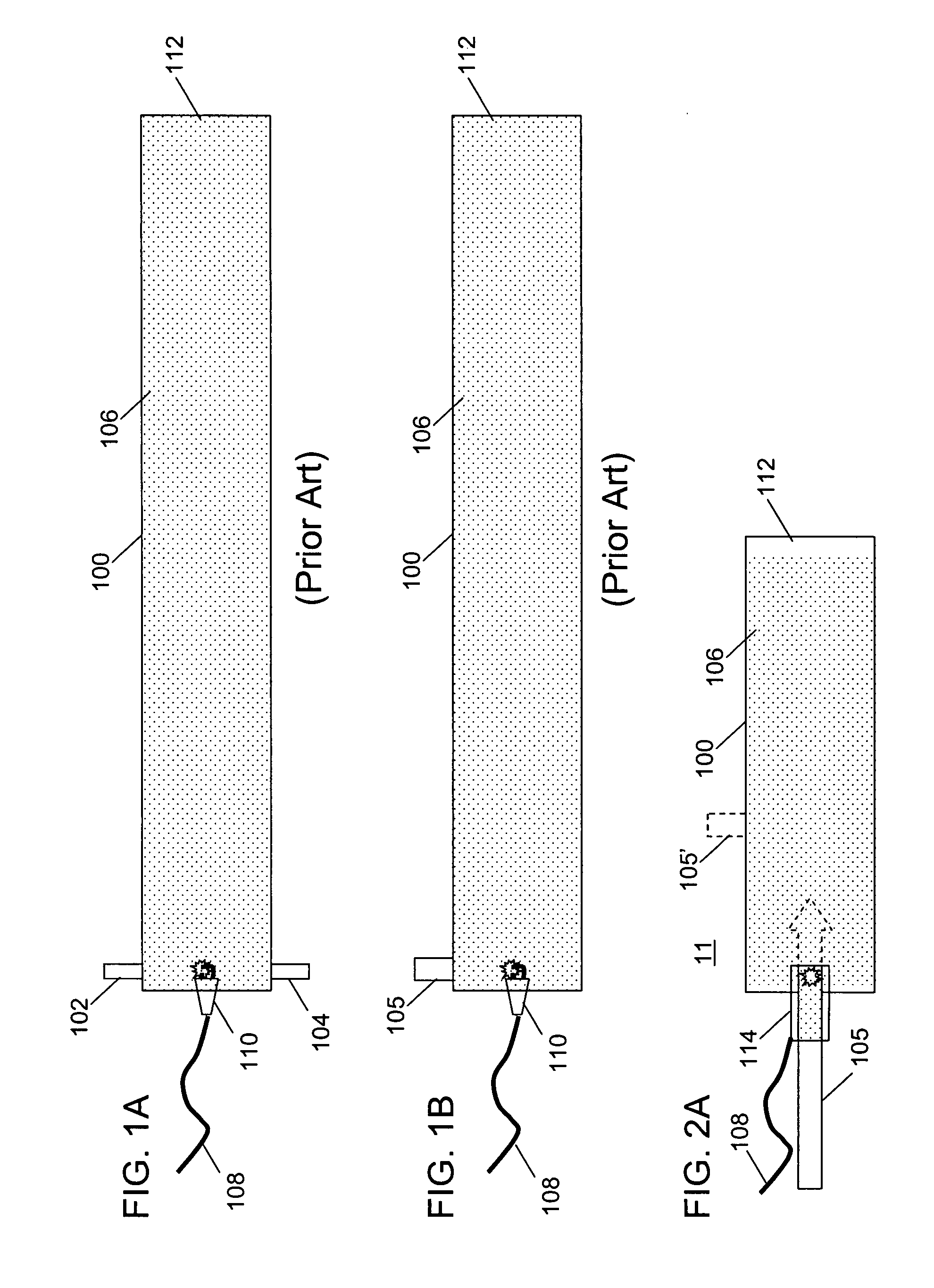

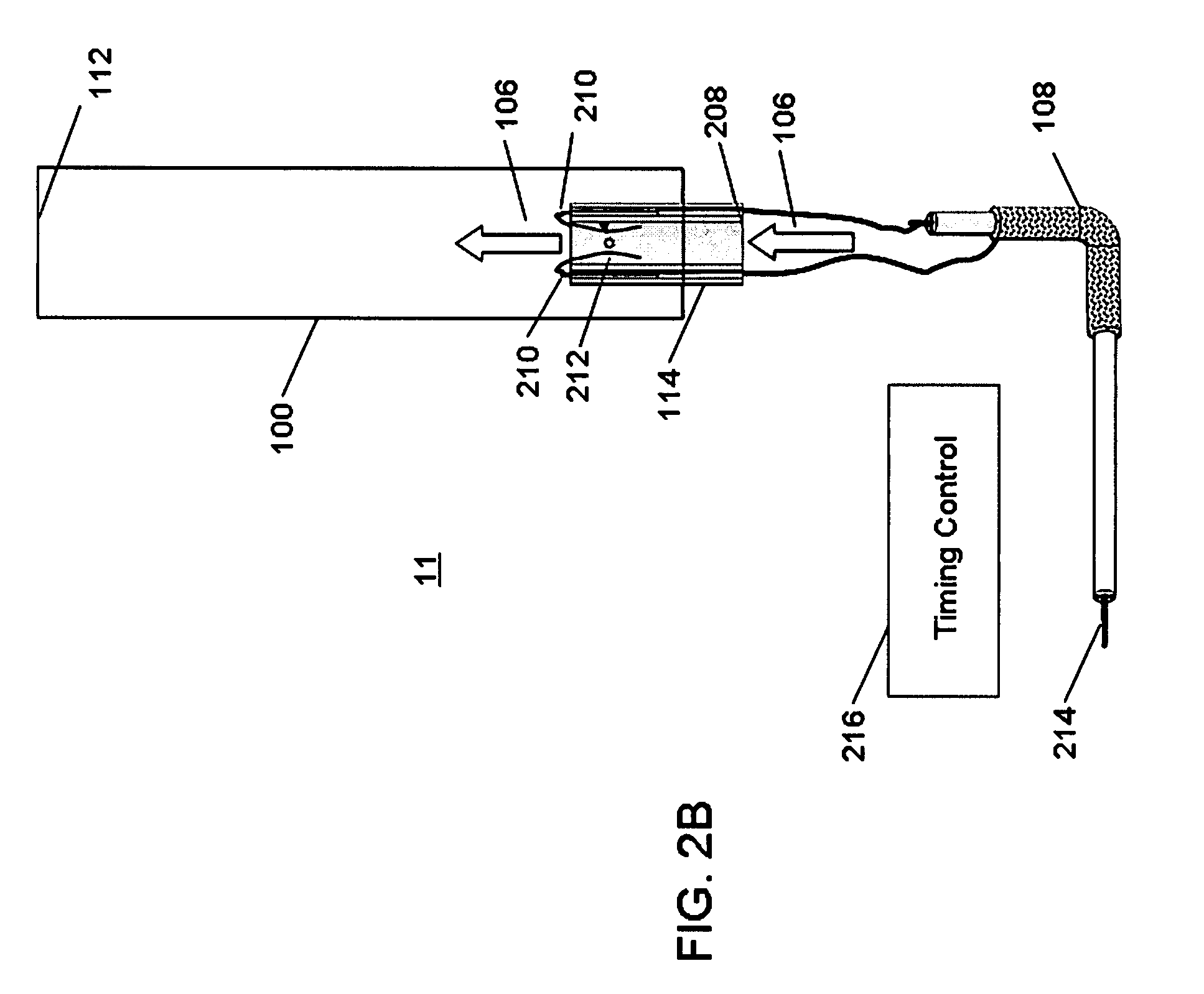

Valveless pulsed detonation combustor

Pulse detonation combustors of valveless construction. One valveless pulse detonation combustor, having a tube with a closed end and an open end, is constructed with a flame accelerator within the tube, adjacent the open end. A valveless, apertured flow restrictor is positioned between the flame accelerator and the closed end of the tube. A sparking device is positioned within the tube, between the flow restrictor and the flame accelerator. Valveless fuel and air ports are positioned between the flow restrictor and the closed end of the tube. Substantially right-angle manifold passageways are in communication with each of the ports.

Owner:PURDUE RES FOUND INC

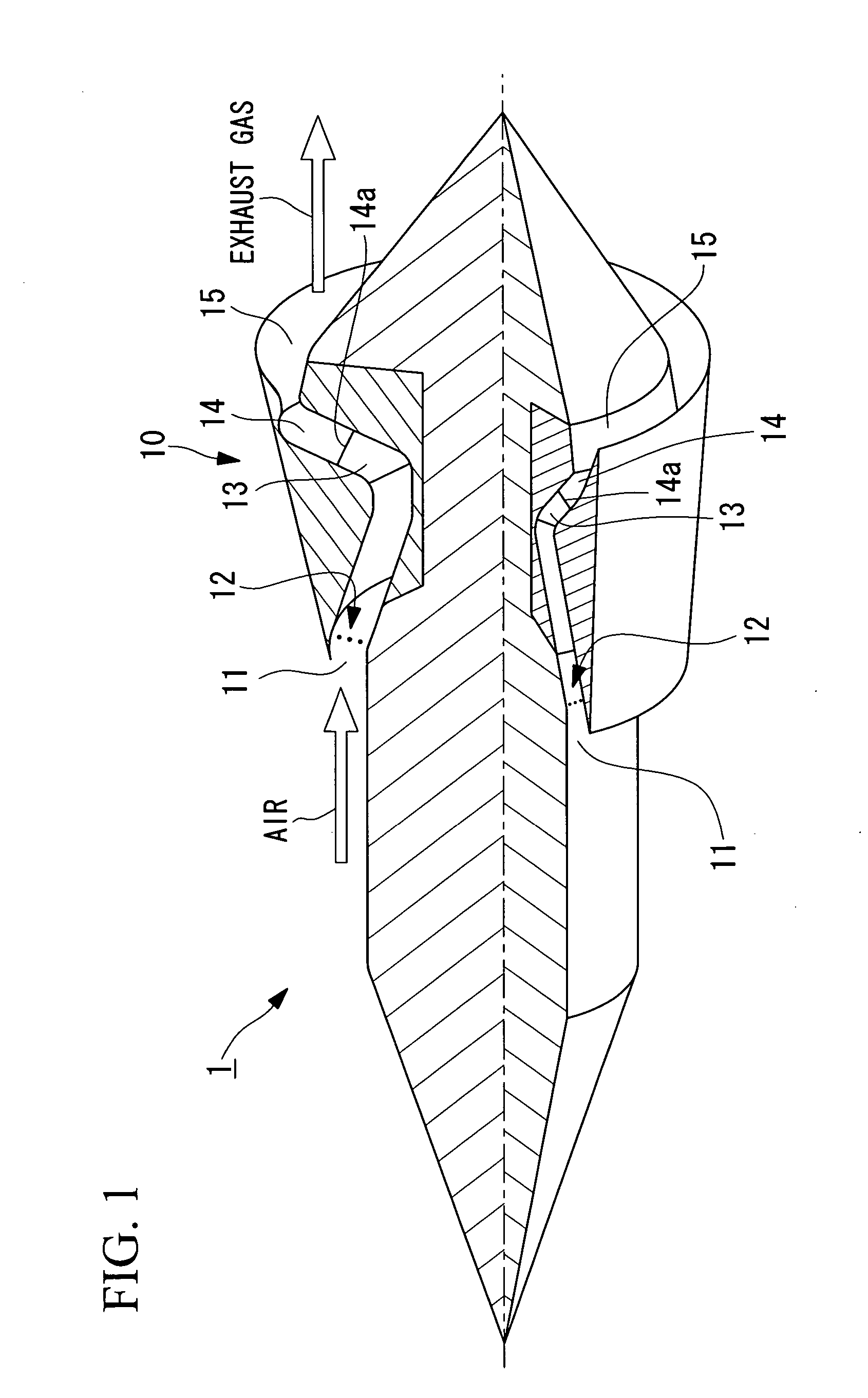

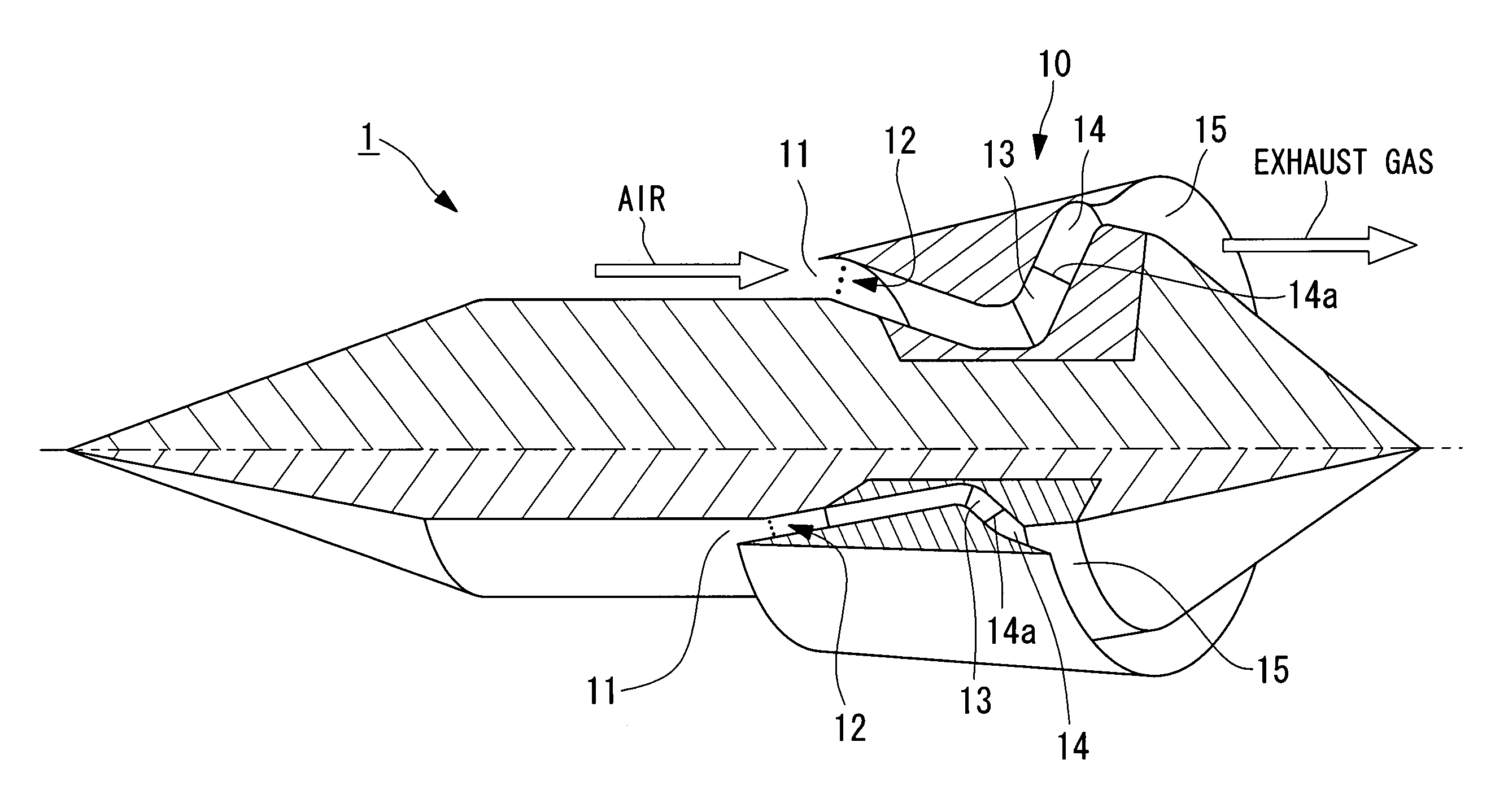

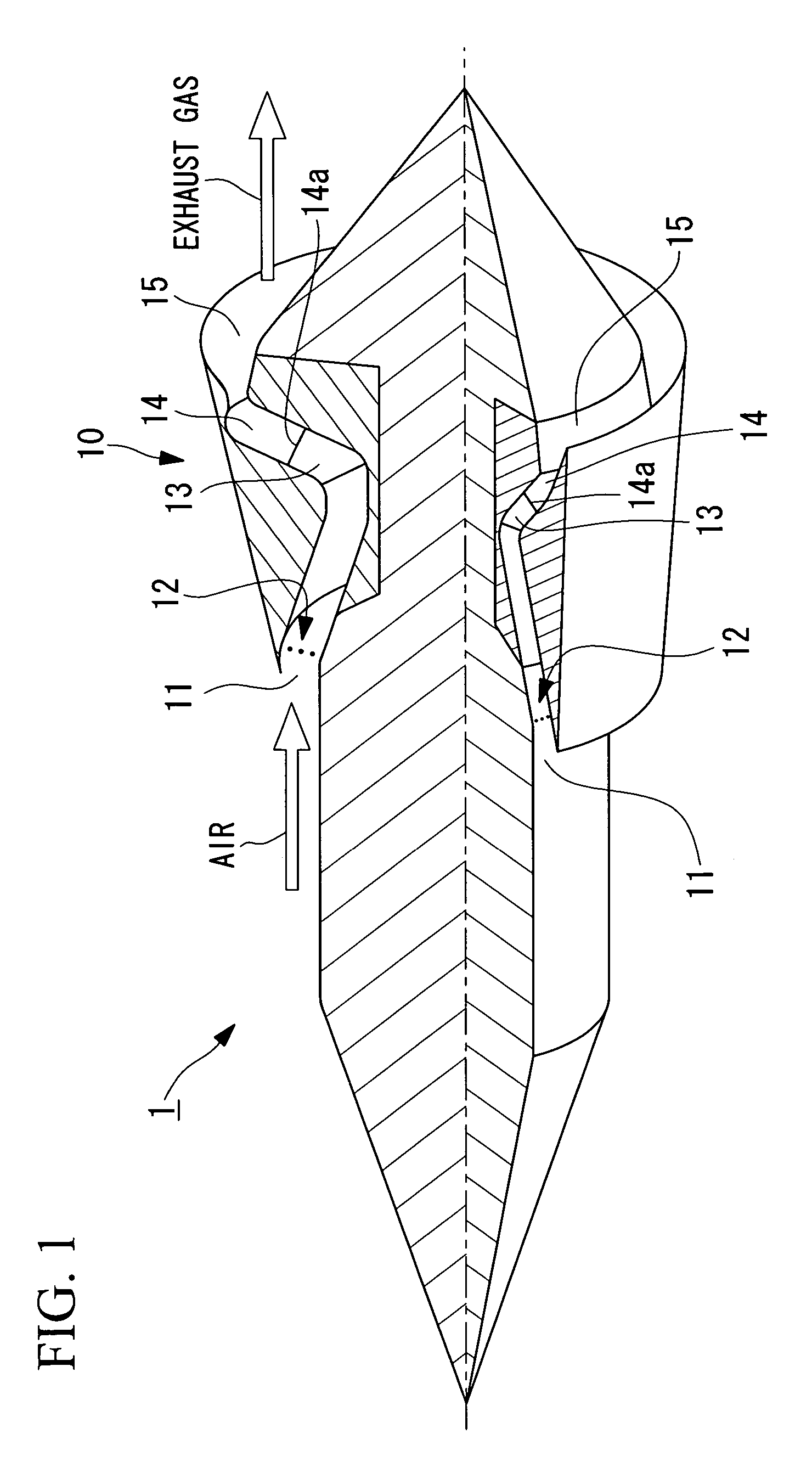

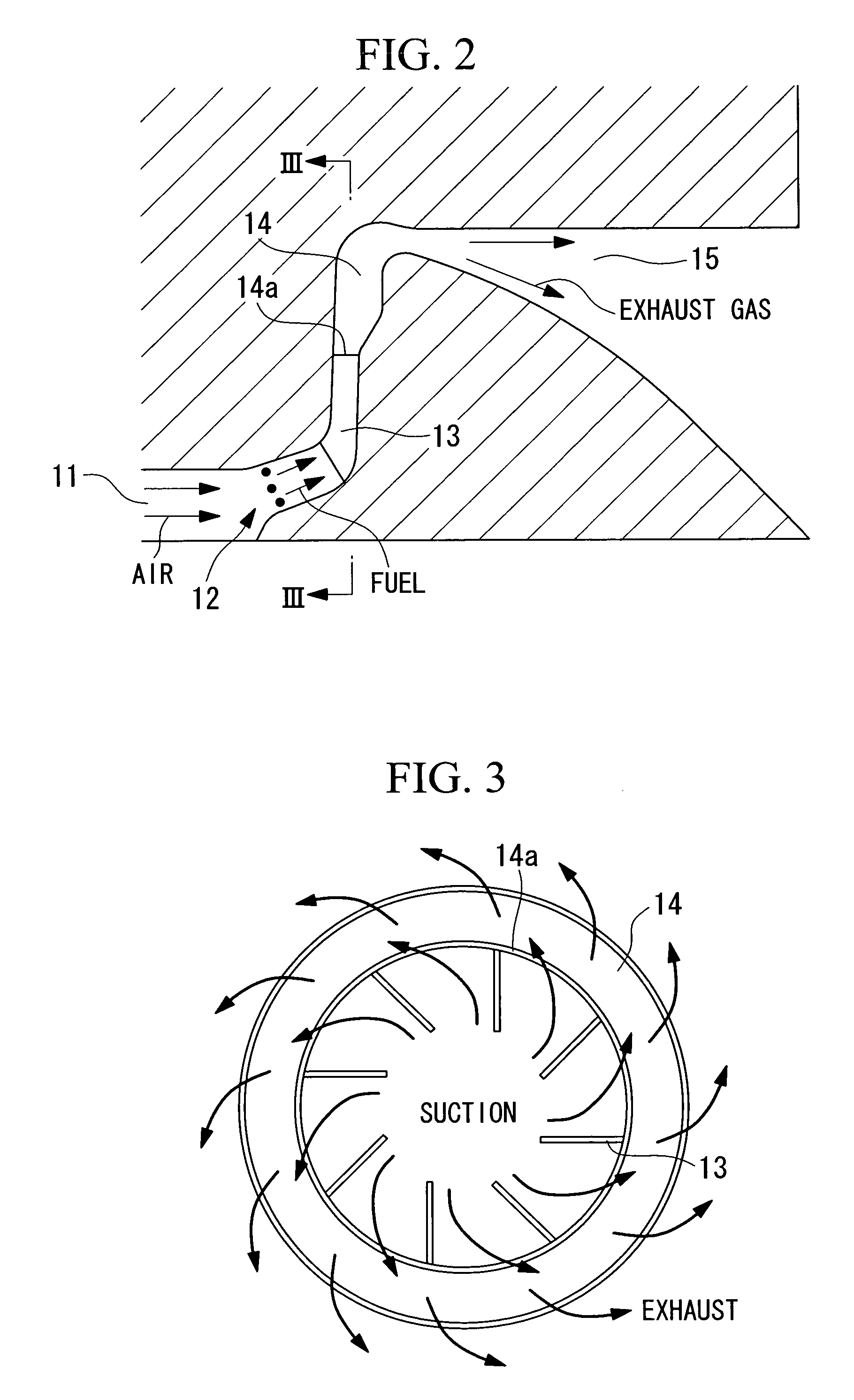

Detonation engine and flying object provided therewith

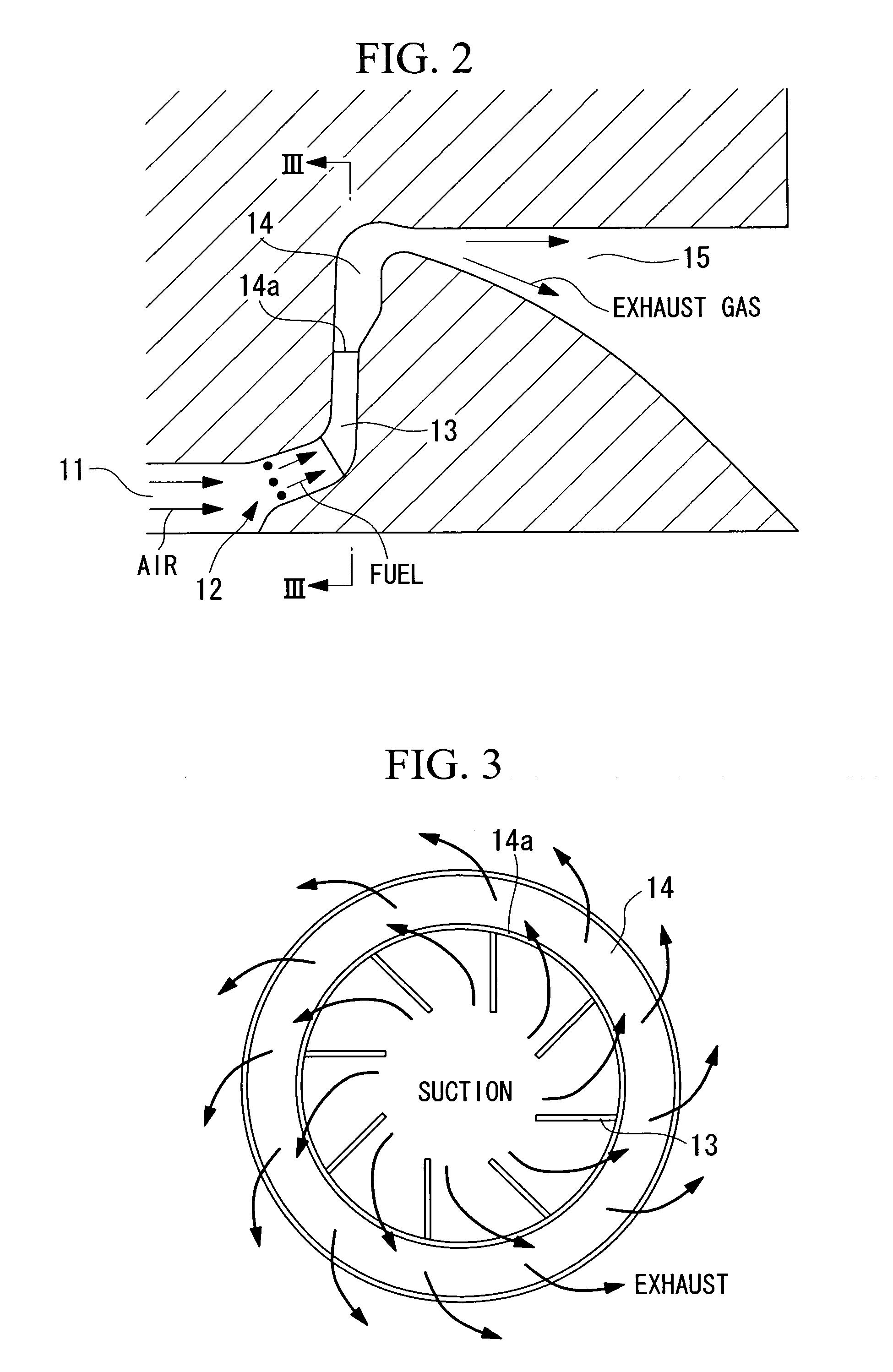

InactiveUS20050284127A1Structure of engine can be simplifiedGuaranteed continuous outputMolten spray coatingBlade accessoriesCombustionDetonation

A detonation engine which creates thrust by generating a detonation wave, wherein the overall engine structure is simplified, and continuous output can be obtained, comprises: a rotational flow generation device which generates rotational flow about an axis in a mixed gas of air and fuel or of oxygen and fuel; a detonation chamber arranged downstream from the rotational flow generation device, formed in a ring-shape radially extended and continuous in the circumferential direction, which continuously combusts in the circumferential direction the mixed gas in which the rotational flow is generated to generate detonation waves, and draws it in from the radial inside and exhausts it to the radial outside; and a nozzle which is connected to the detonation chamber, and jets the high temperature and pressure combustion gas generated by the detonation waves flowing from the detonation chamber, to the rear while expanding it, and converts it into thrust.

Owner:MITSUBISHI HEAVY IND LTD +2

Air-breathing pulse detonation engine and detonation method thereof

InactiveCN101881238AShorten the lengthShorten the timeIntermittent jet plantsRocket engine plantsAir breathingEvaporator

The invention discloses an air-breathing pulse detonation engine and a detonation method thereof. An air inlet channel, a mixed evaporator, a detonation chamber and a tailpipe are connected along an air inlet direction in turn, and a leaf valve, a main fuel nozzle and an air discharge cavity are arranged in an air inlet ring cavity along the air inlet direction in turn, wherein the fuel radially injects through the main fuel nozzle; the air discharge cavity and an air discharge tube are communicated through a through hole of a central body bracket to the exterior of an outer wall of the air inlet channel; the leaf valve maintains a forward normally opened state; a detonation tube is arranged in the detonation chamber through a mounting bracket; a drainage tube, an igniter and a heat exchanger are arranged on the detonation tube; a plurality of jet holes are formed on a tail side wall or a tail end face; the igniter is positioned on the front section of the detonation tube; and the drainage tube is gapped in the detonation chamber and near the igniter inside the detonation tube respectively. The air-breathing pulse detonation engine has the advantages of capabilities of reliably working under severe condition, realizing lower forward flow resistance, simultaneously suppressing and using reverse flow and improving the engine thrust, along with simple structure and wide flight range.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

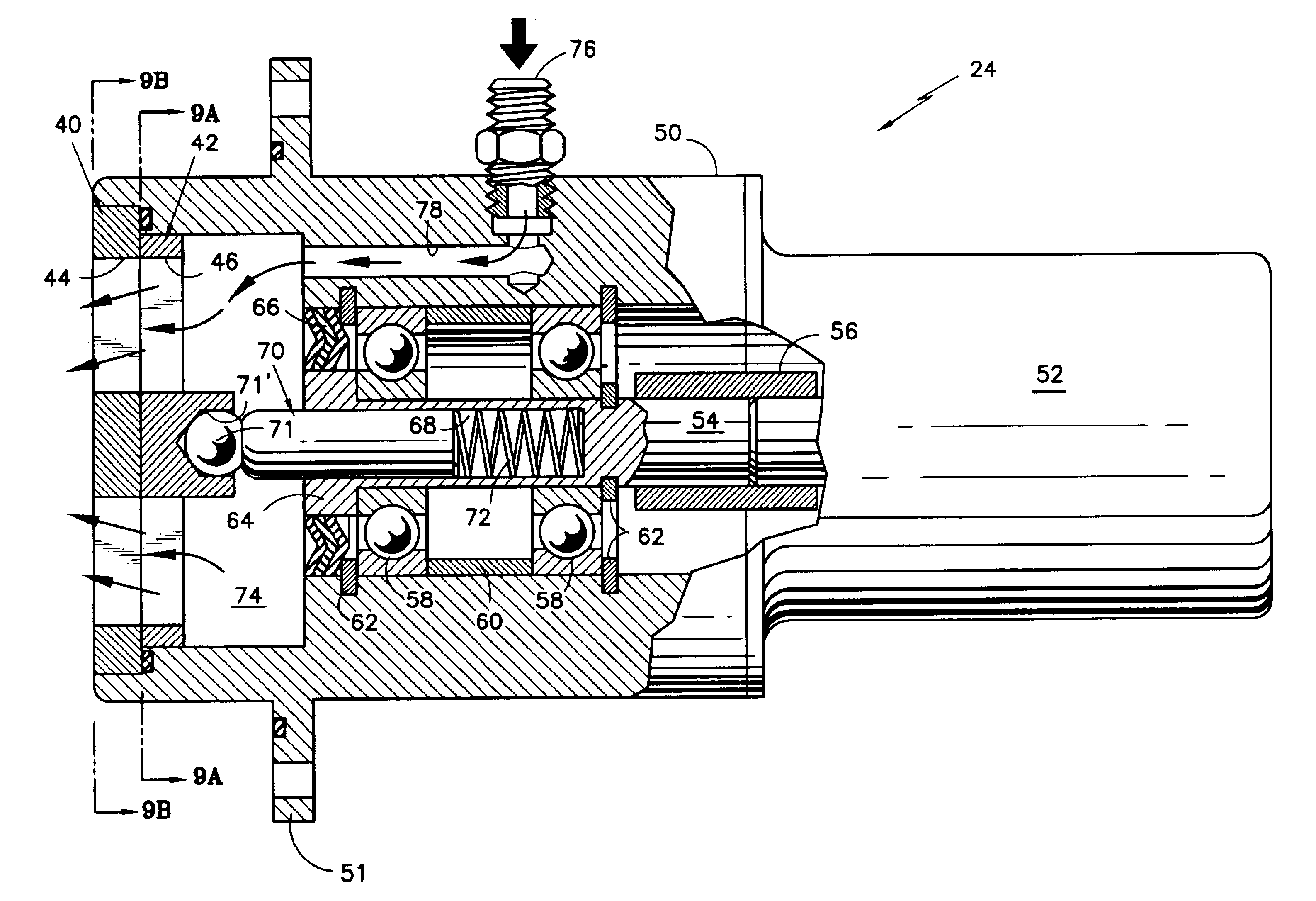

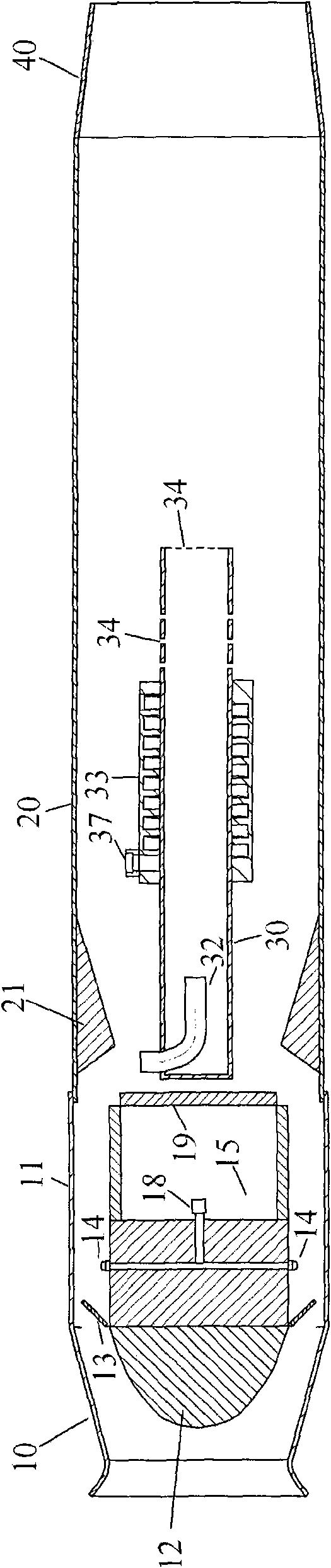

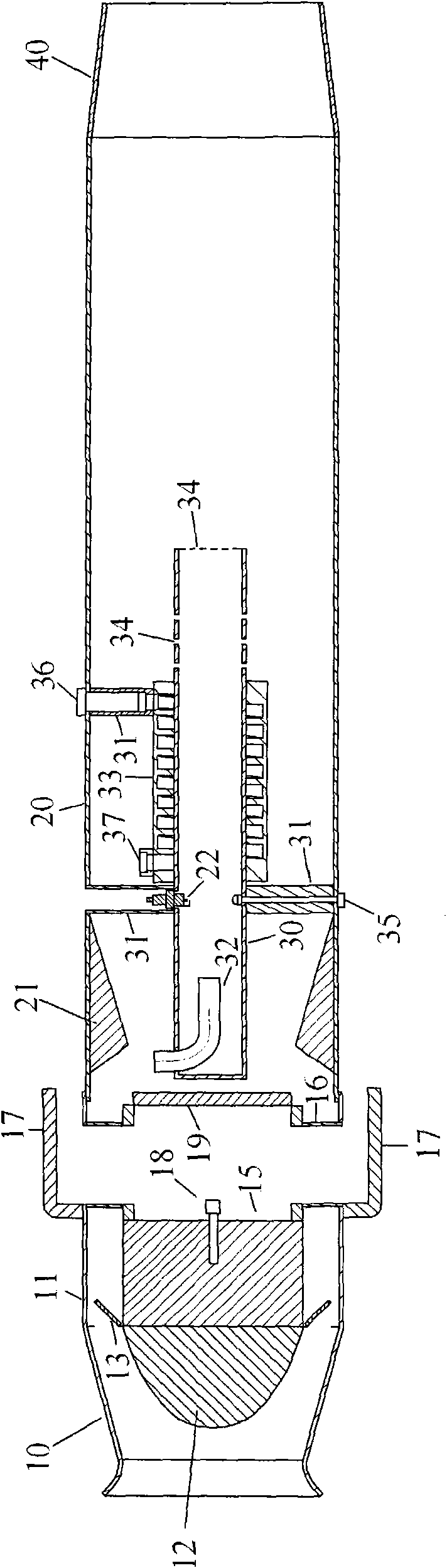

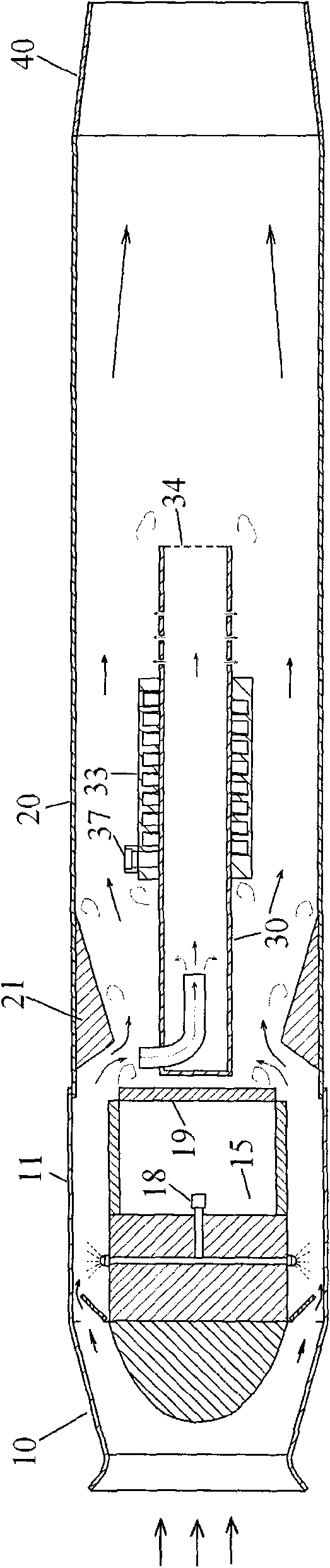

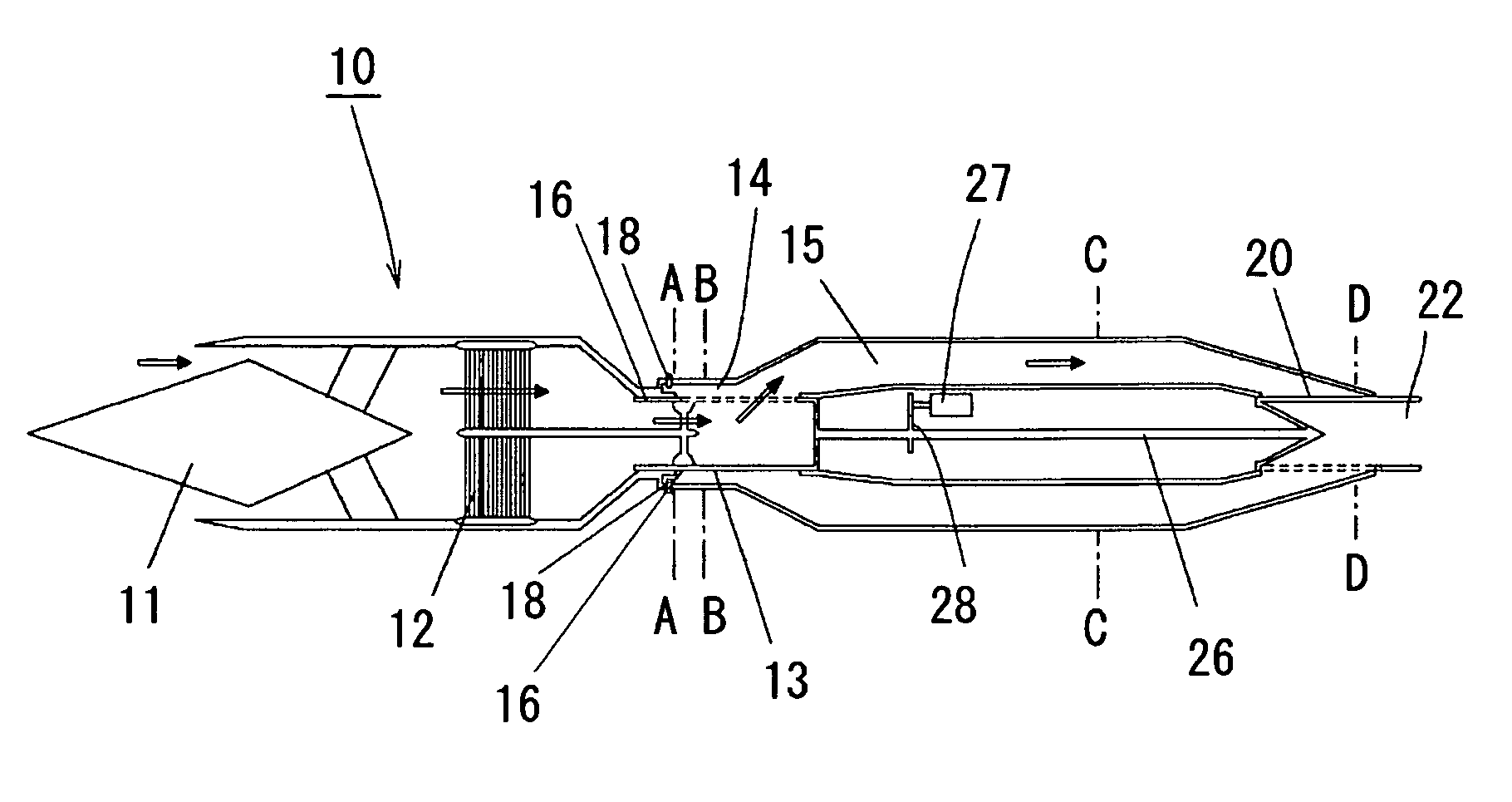

Pulse detonation engine and valve

InactiveUS20050183413A1Accurate timingIncrease air densityPulsating combustionTurbine/propulsion fuel heatingCombustion chamberCombustor

Pressure and density of a gaseous mixture are increased in the process of introducing the gaseous mixture into the combustor of an air-breathing pulse detonation engine employing atmospheric oxygen as an oxidizer. The exit valve 20 able to be opened and closed is provided at the outlet of the combustor 15, an air cooler 12 is provided in the exit of the intake, and density is increased by exchange of heat of the air received at the intake with a coolant in the air cooler 12. Furthermore, by closing the exit valve 20 provided in the outlet of the combustor during the process of loading the gaseous mixture, transition to the detonation process is possible without expansion of the high-pressure high density air obtained by ram-compression at the intake.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

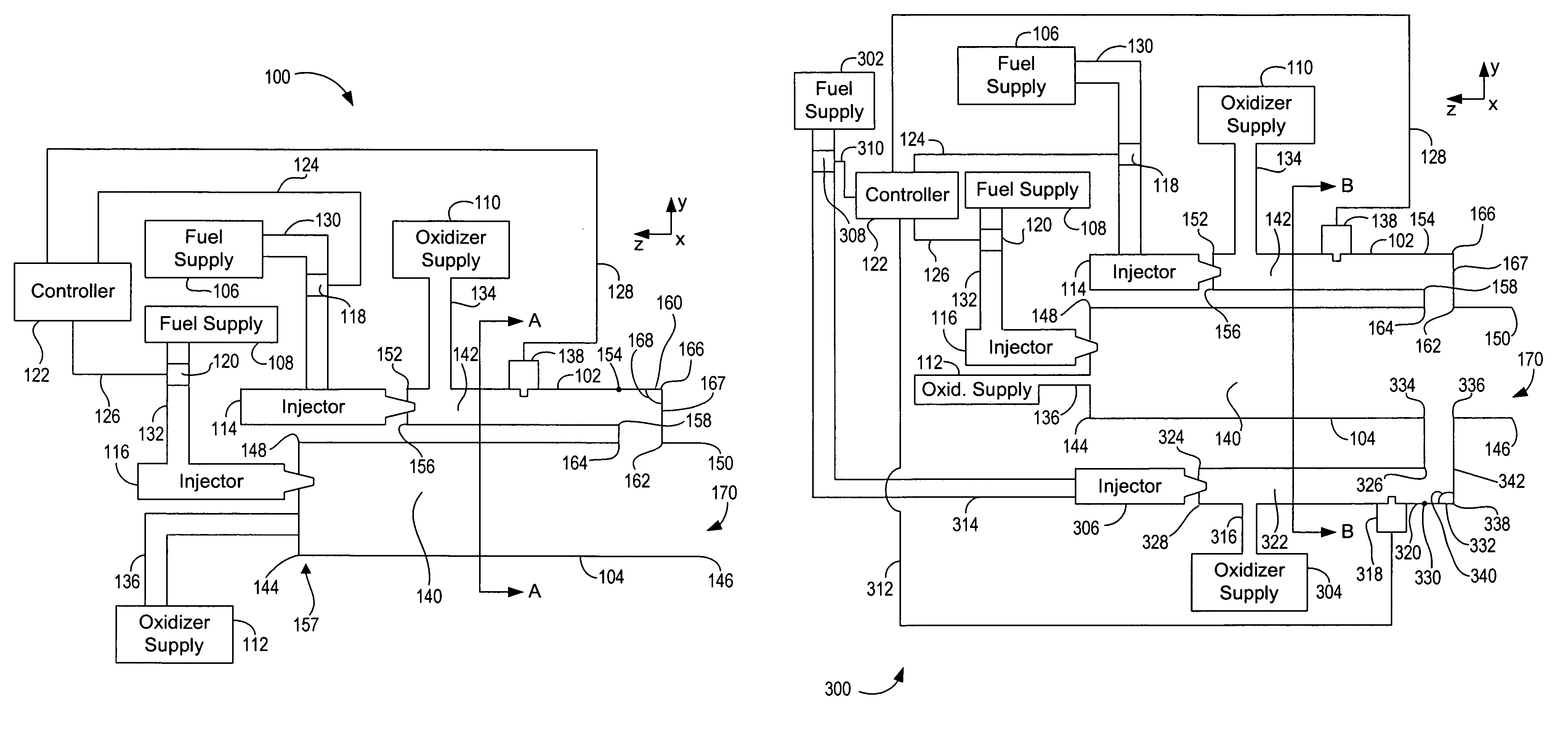

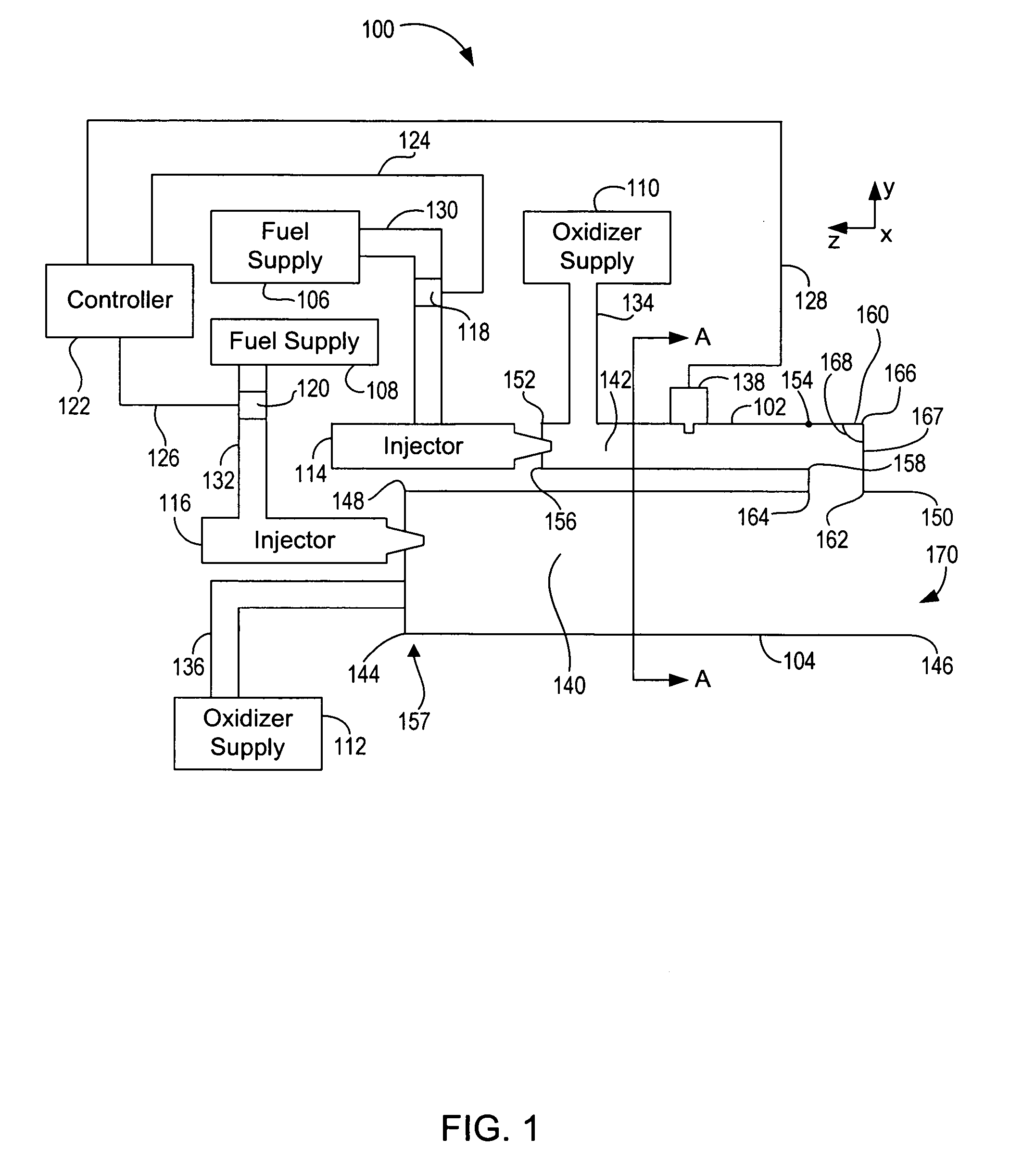

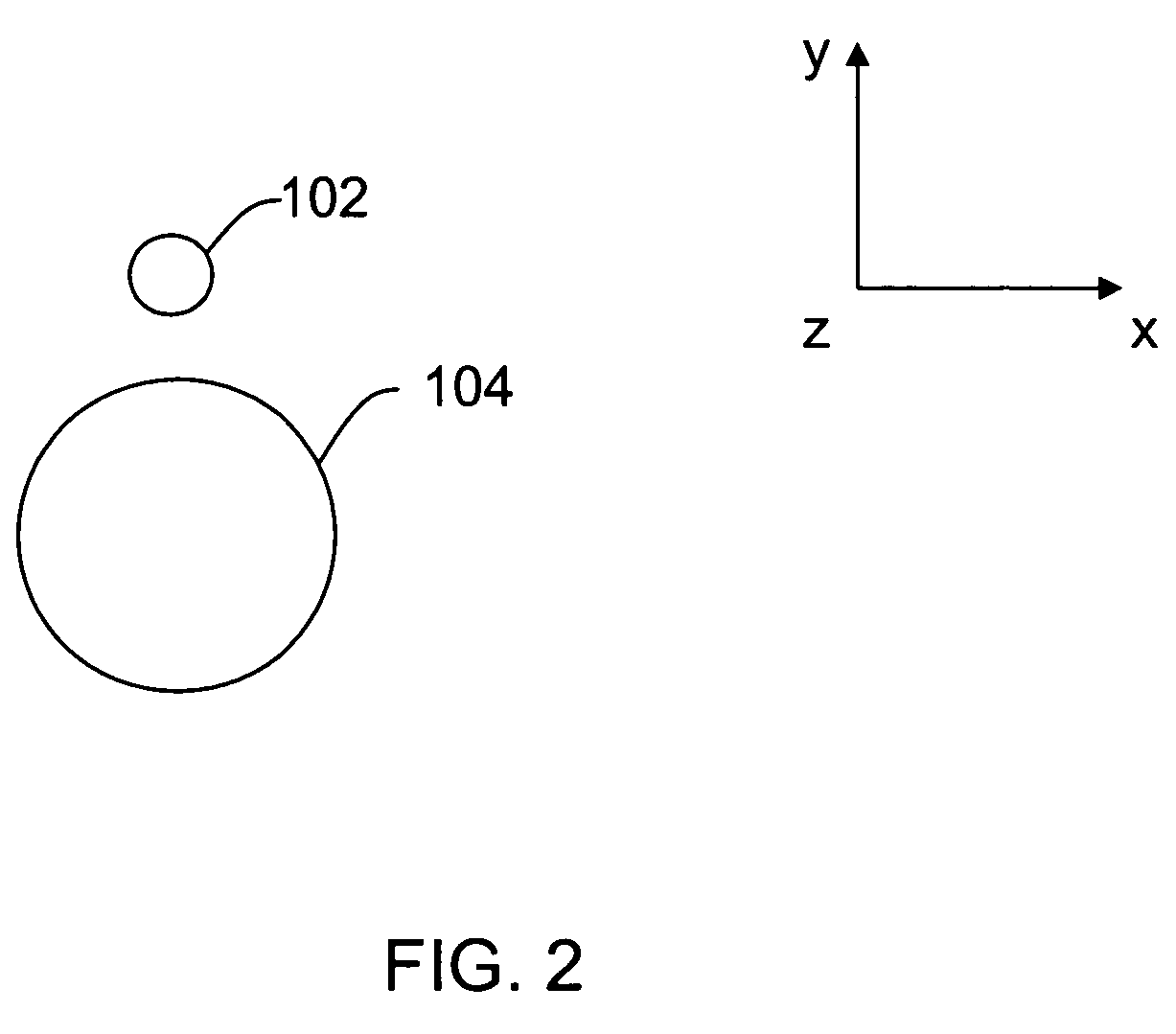

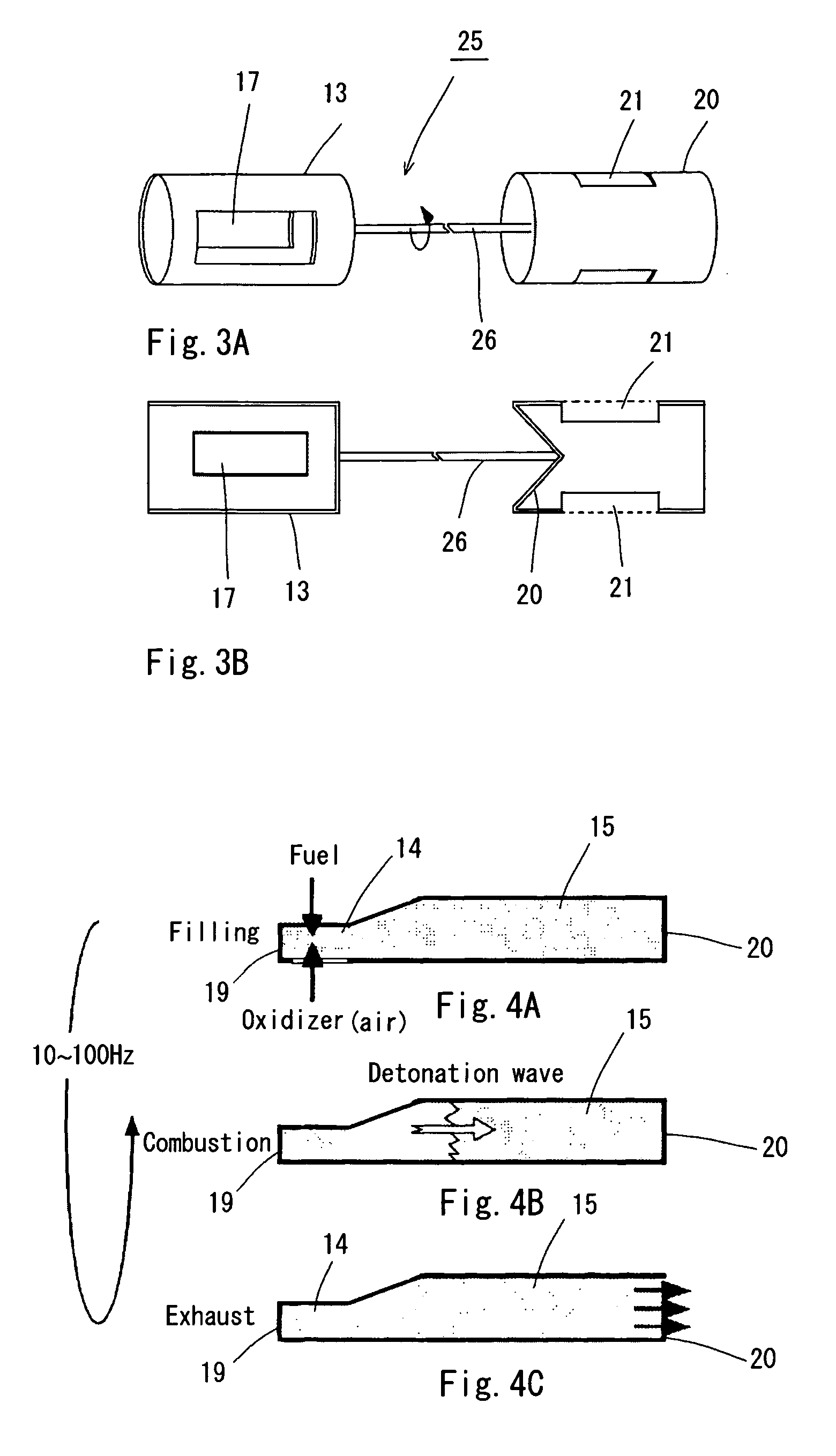

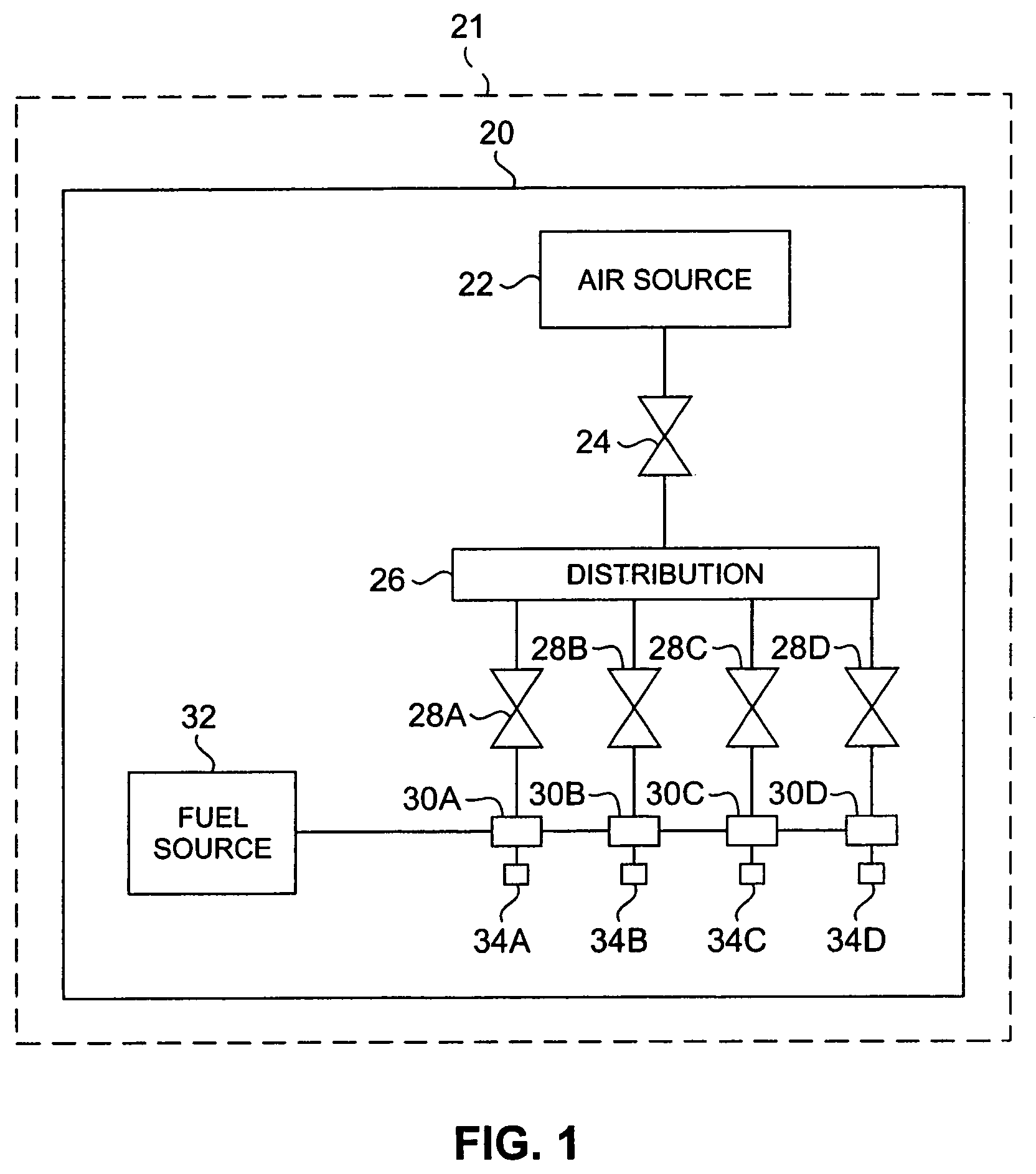

System and method for ignition of a gaseous or dispersed fuel-oxidant mixture

An improved system and method for ignition of a gaseous or dispersive fuel-oxidant mixture is provided where a gaseous or dispersive fuel-oxidant mixture is supplied to a detonator tube having a fill point and an open end and an igniter placed at an ignition point within the detonator tube is ignited while the gaseous or dispersive fuel-oxidant mixture is flowing through the detonator tube. A detonation impulse is produced at the ignition point that propagates to the open end of said detonator tube where it can be supplied to a detonation tube having an open end, to an internal combustion engine, a combustion chamber, and to a pulse detonation engine.

Owner:SOUNDBLAST TECH

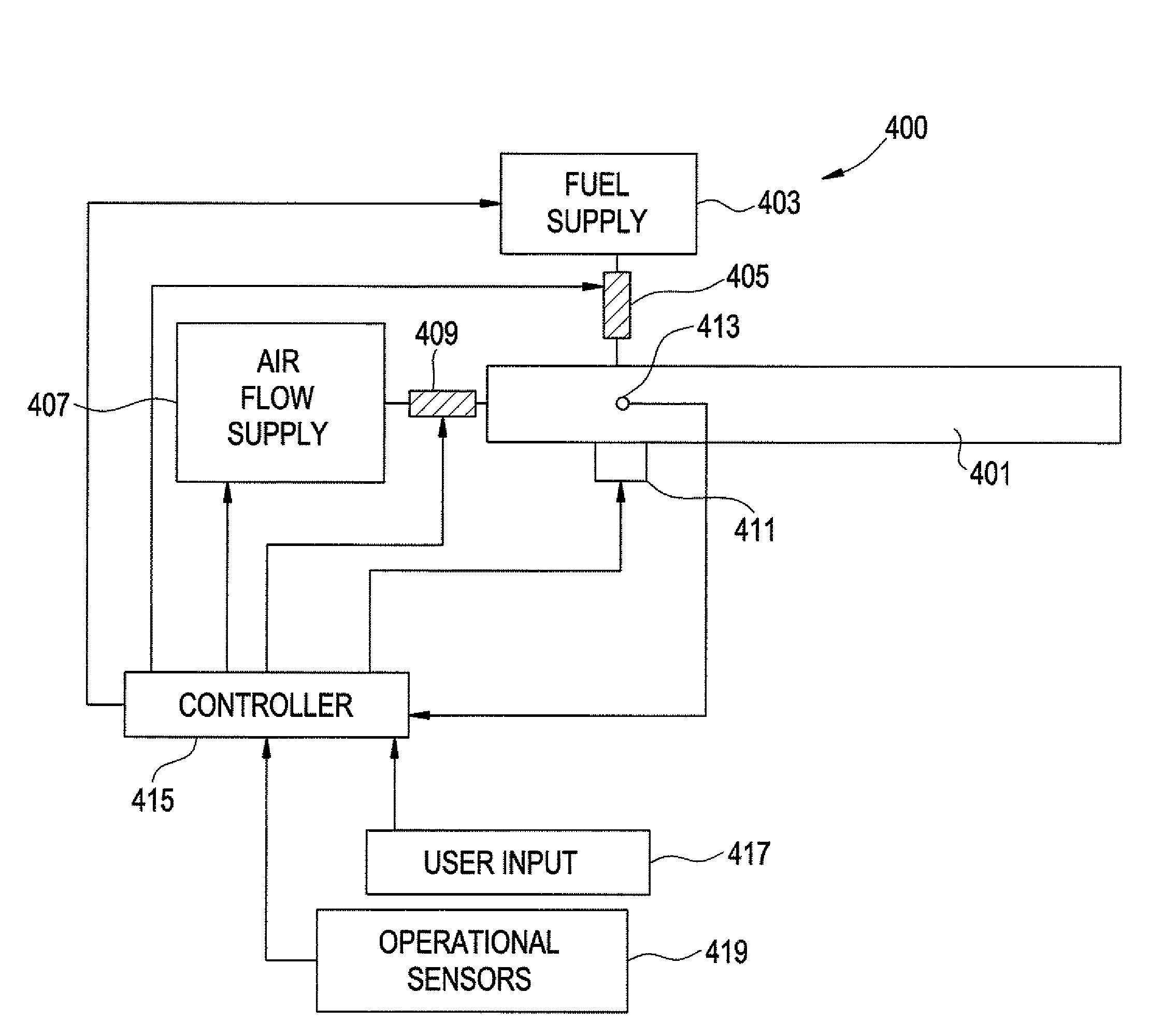

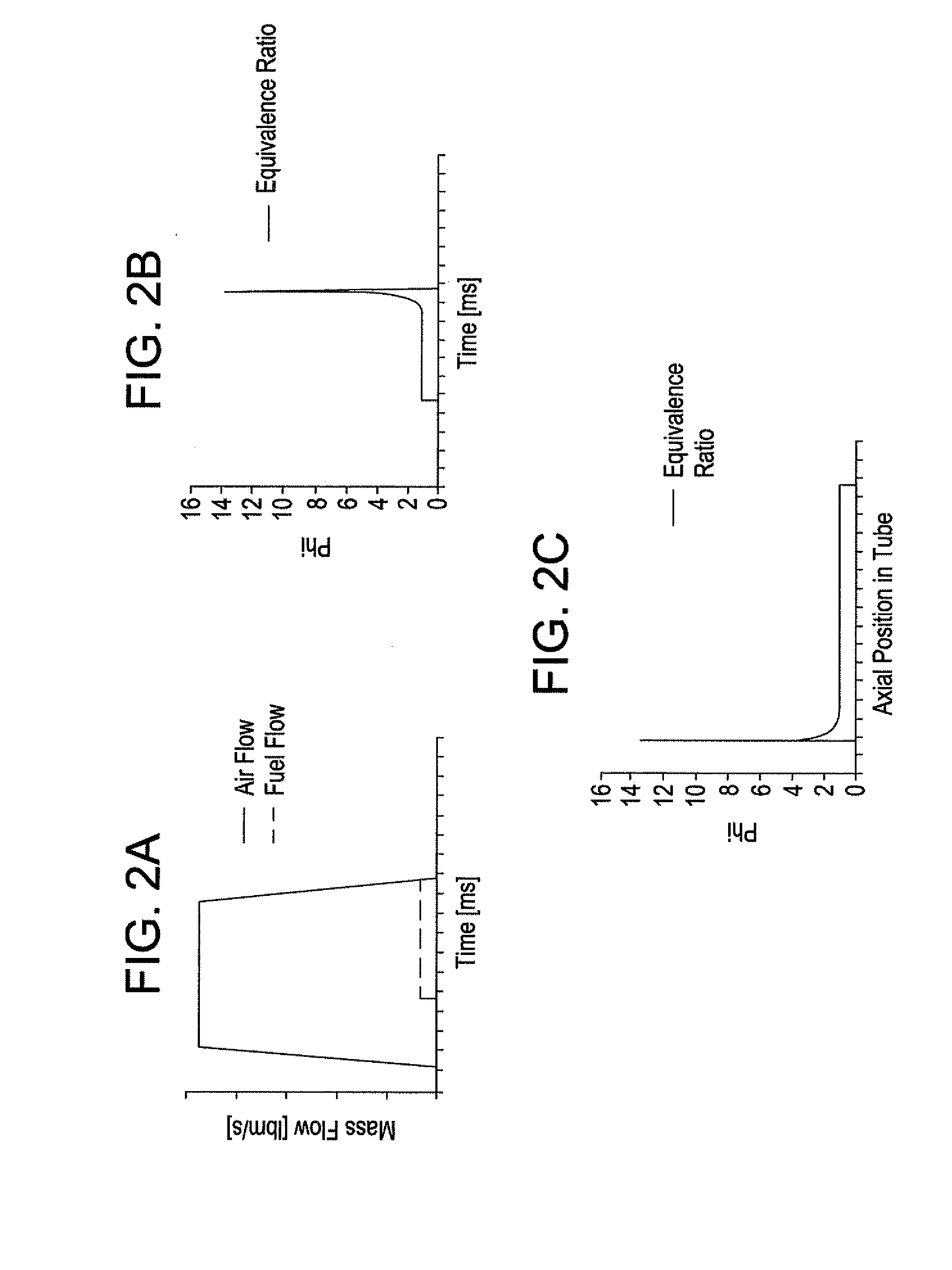

Method and apparatus for tailoring the equivalence ratio in a valved pulse detonation combustor

A pulse detonation combustor assembly contains at least one PDC tube, a mechanical air flow valve which directs an air flow into the PDC tube, where the mechanical air flow assembly changes a rate of the air flow into the PDC tube during a fill stage of the PDC tube. The assembly also contains a fuel flow control valve which directs fuel to the PDC tube and changes the rate of the fuel flow into PDC tube. By controlling the flow of the fuel and air into the PDC tube the equivalence ratio profile of the PDC tube can be tailored and controlled.

Owner:GENERAL ELECTRIC CO

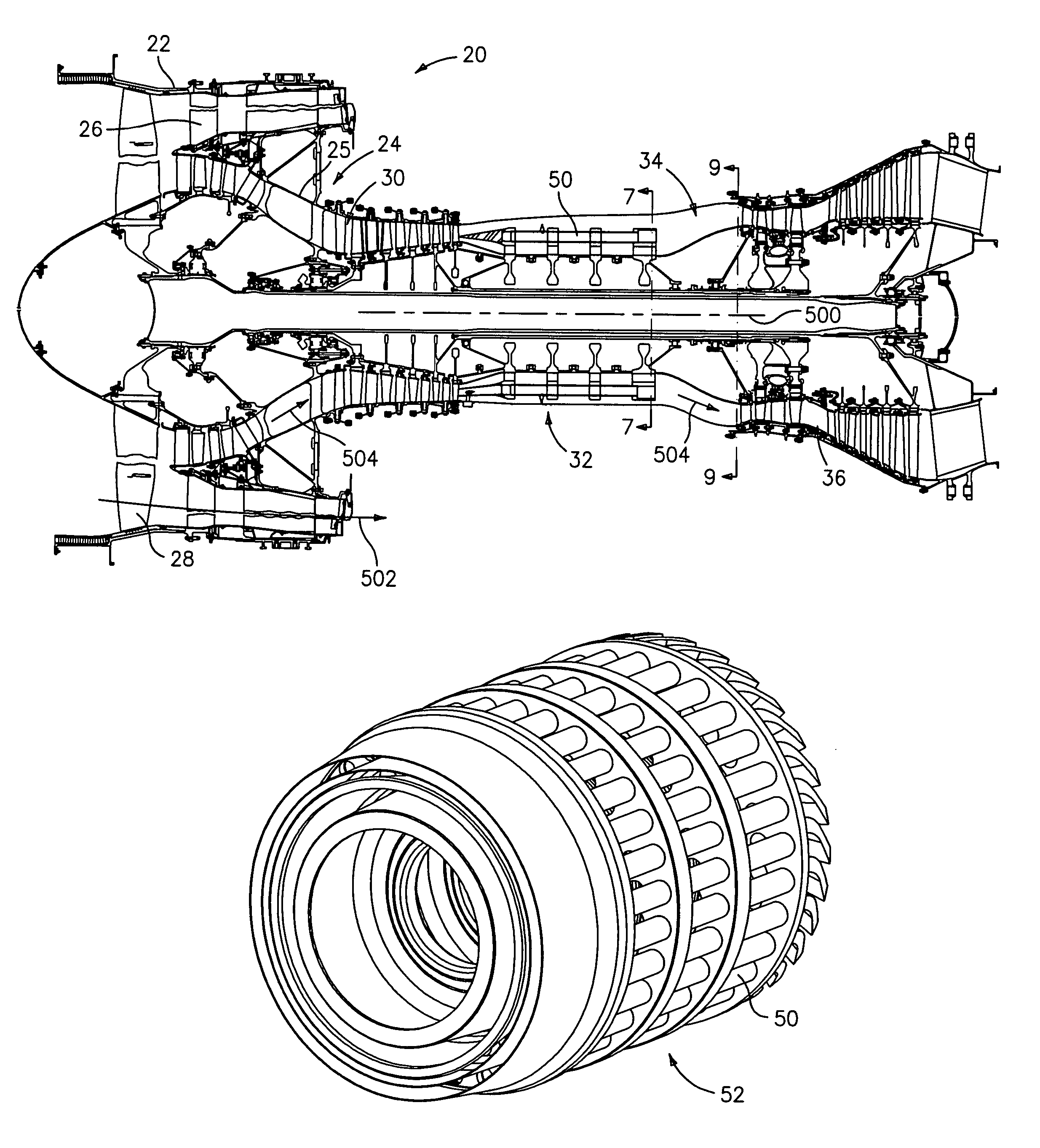

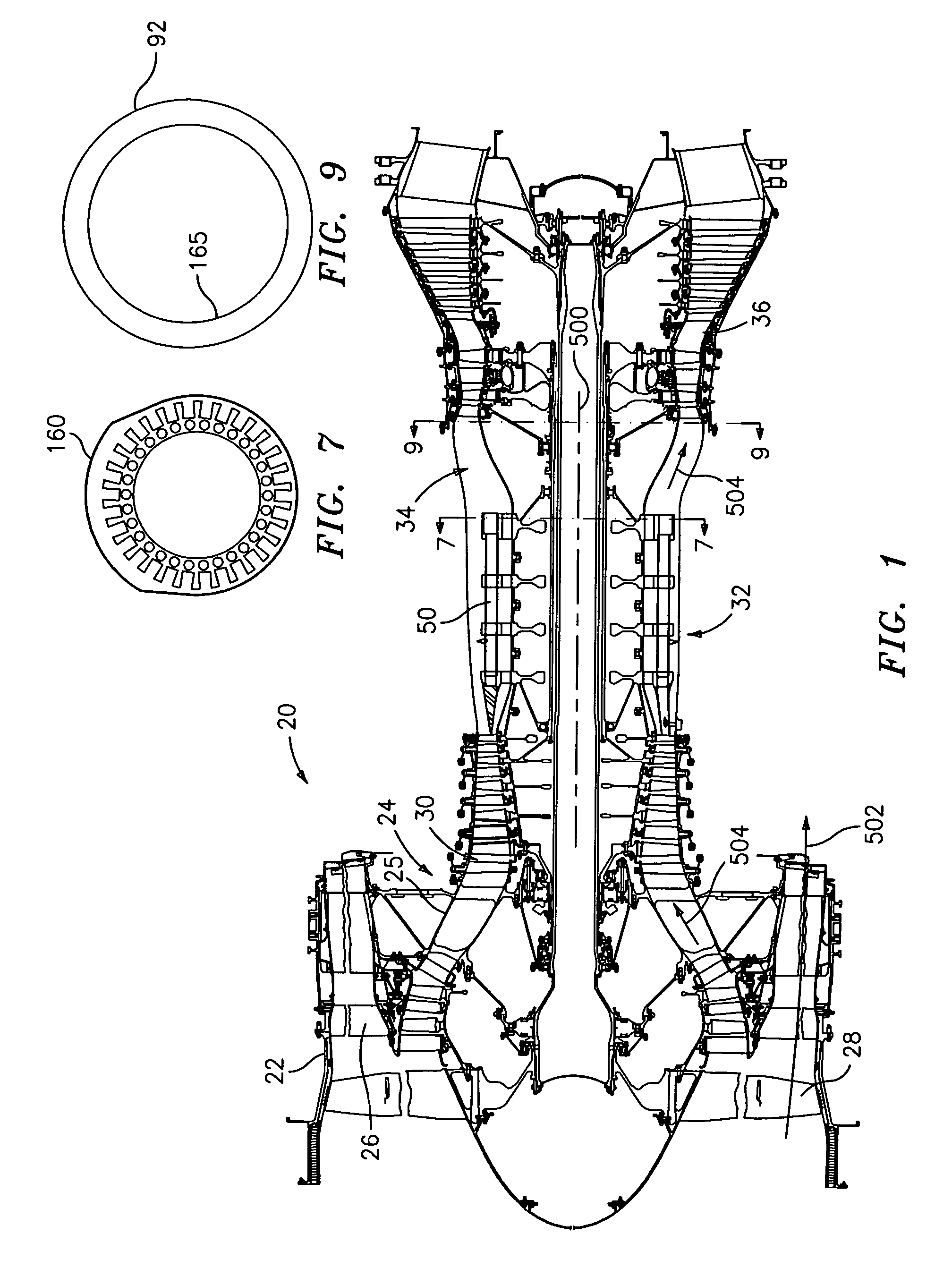

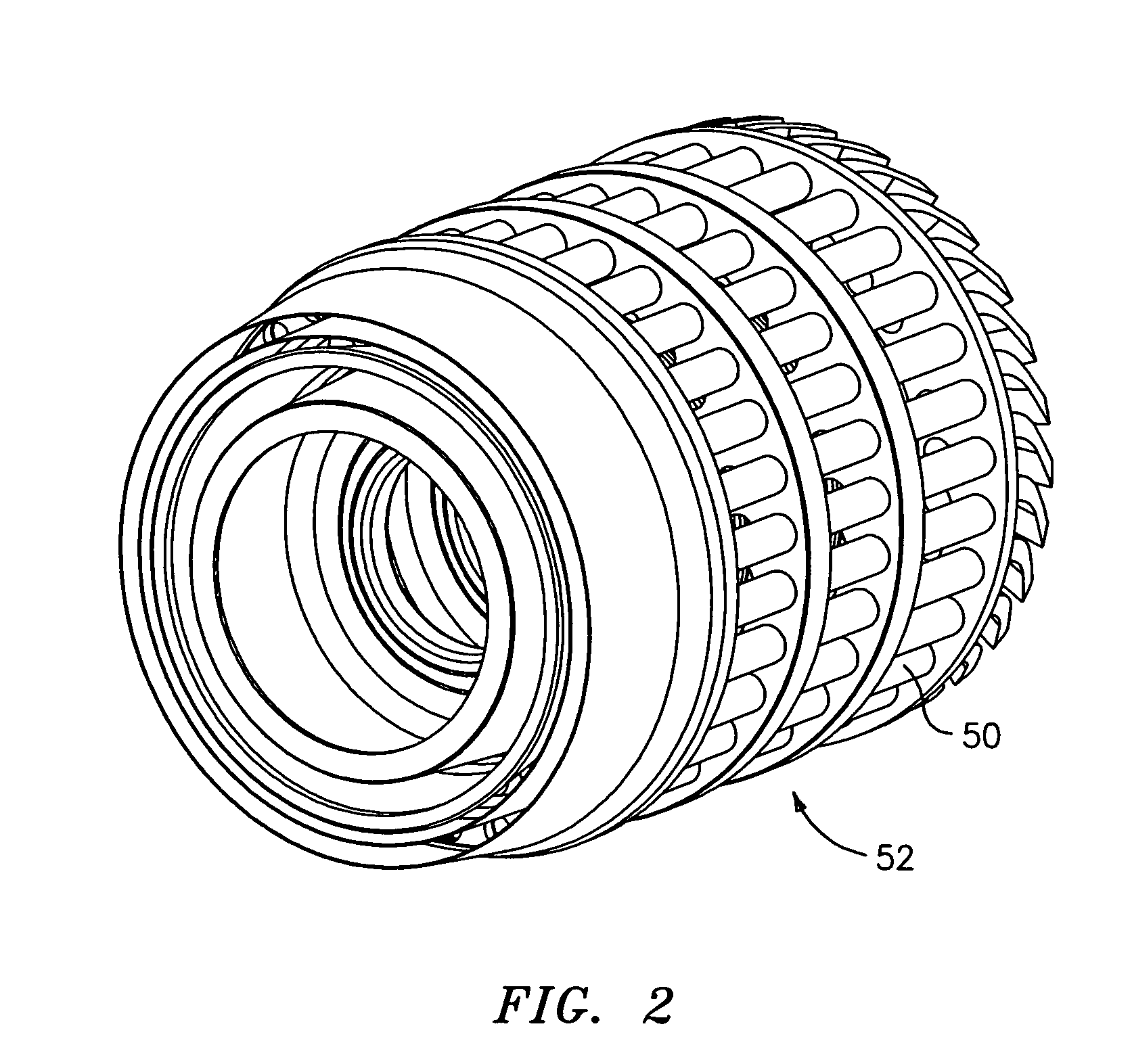

Pulsed combustion engine

A pulsed combustion device includes a support structure and a combustor carousel supported by the support structure and rotating relative thereto about an axis. The carousel has a number of combustion conduits in a circumferential array. Each conduit cyclically receives a charge and discharges combustion products of the charge.

Owner:UNITED TECH CORP

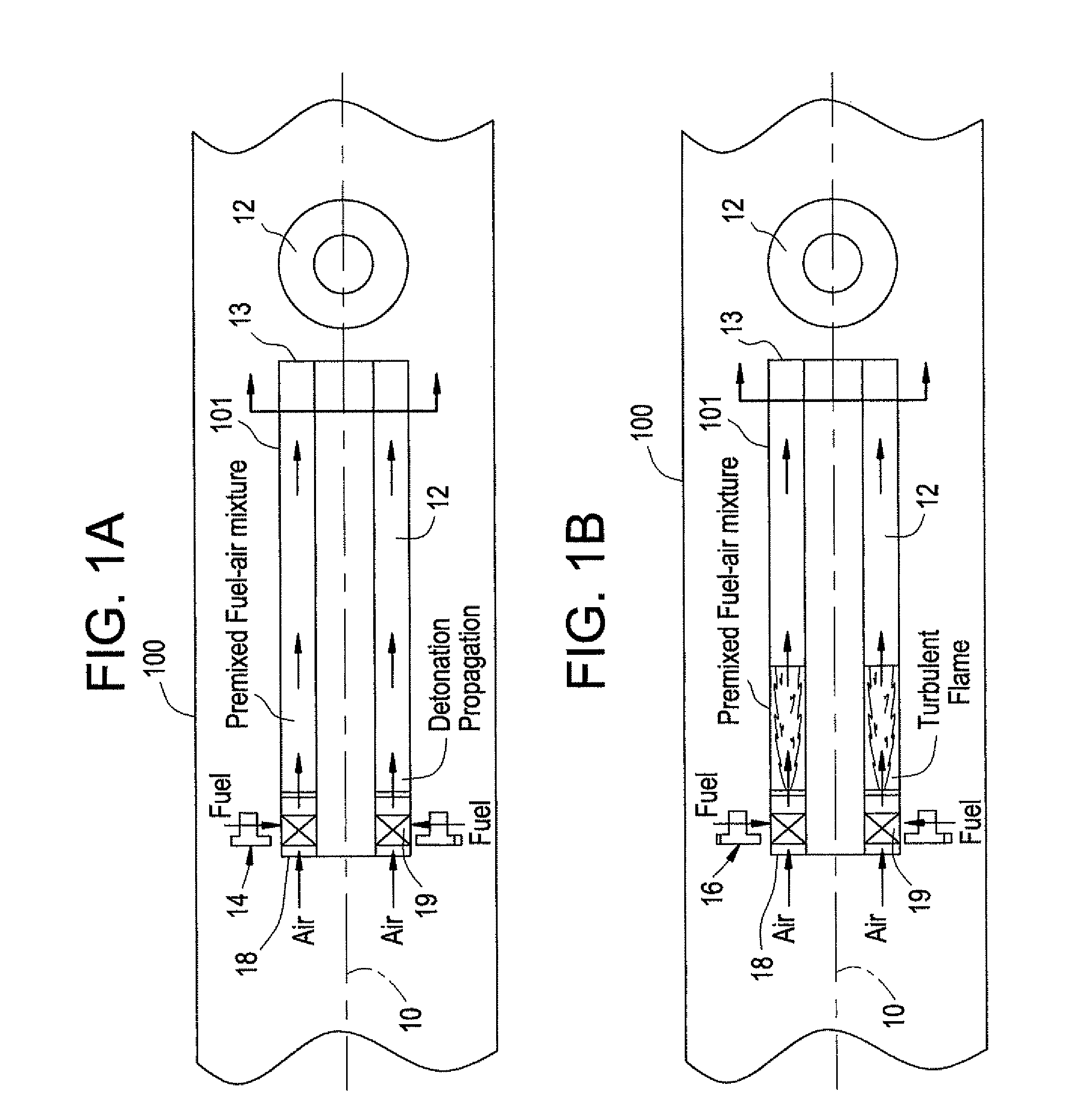

Dual mode combustion operation of a pulse detonation combustor in a hybrid engine

InactiveUS7950219B2Easy to operateEfficient combustionContinuous combustion chamberGas turbine plantsCombustion chamberSolenoid valve

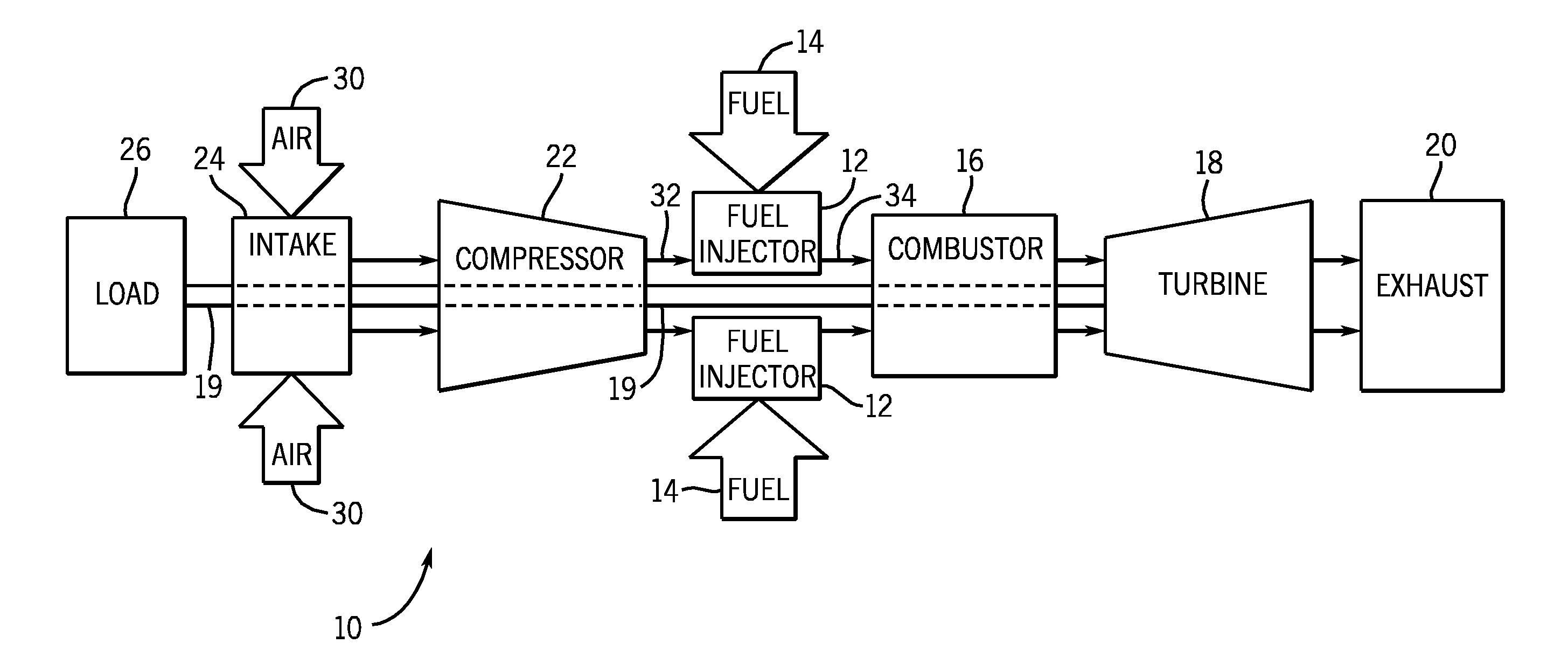

A dual mode combustor of a gas turbine engine contains at least one dual mode combustor device having a combustion chamber, a fuel air mixing element, a high frequency solenoid valve and a fuel injector. During a first mode of operation the dual mode combustor device operates in a steady, constant pressure deflagration mode, receiving its fuel from the fuel injector. In a second mode of operation the dual mode combustor device operates in a pulse detonation mode, receiving its fuel from the high frequency solenoid valve.

Owner:GENERAL ELECTRIC CO

Naturally aspirated fluidic control for diverting strong pressure waves

InactiveUS7828546B2Hinders its propagationIncreases net thrustTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionShock waveDetonation

A pulse detonation device for dividing a pulse detonation shock wave into an primary and control portion to reduce the strength of a propagating shock wave and / or change its direction. The device contains a flow separator which directs a portion of the shock wave into itself, thus reducing the shock wave's strength. In one configuration, the control region converges in cross-sectional area so as to accelerate the flow in the control region, while the primary region diverges to slow the flow in the primary region. The flow in the control region is directed, at an angle, into the flow of the primary region to impede and / or redirect the flow of the primary region.

Owner:GENERAL ELECTRIC CO

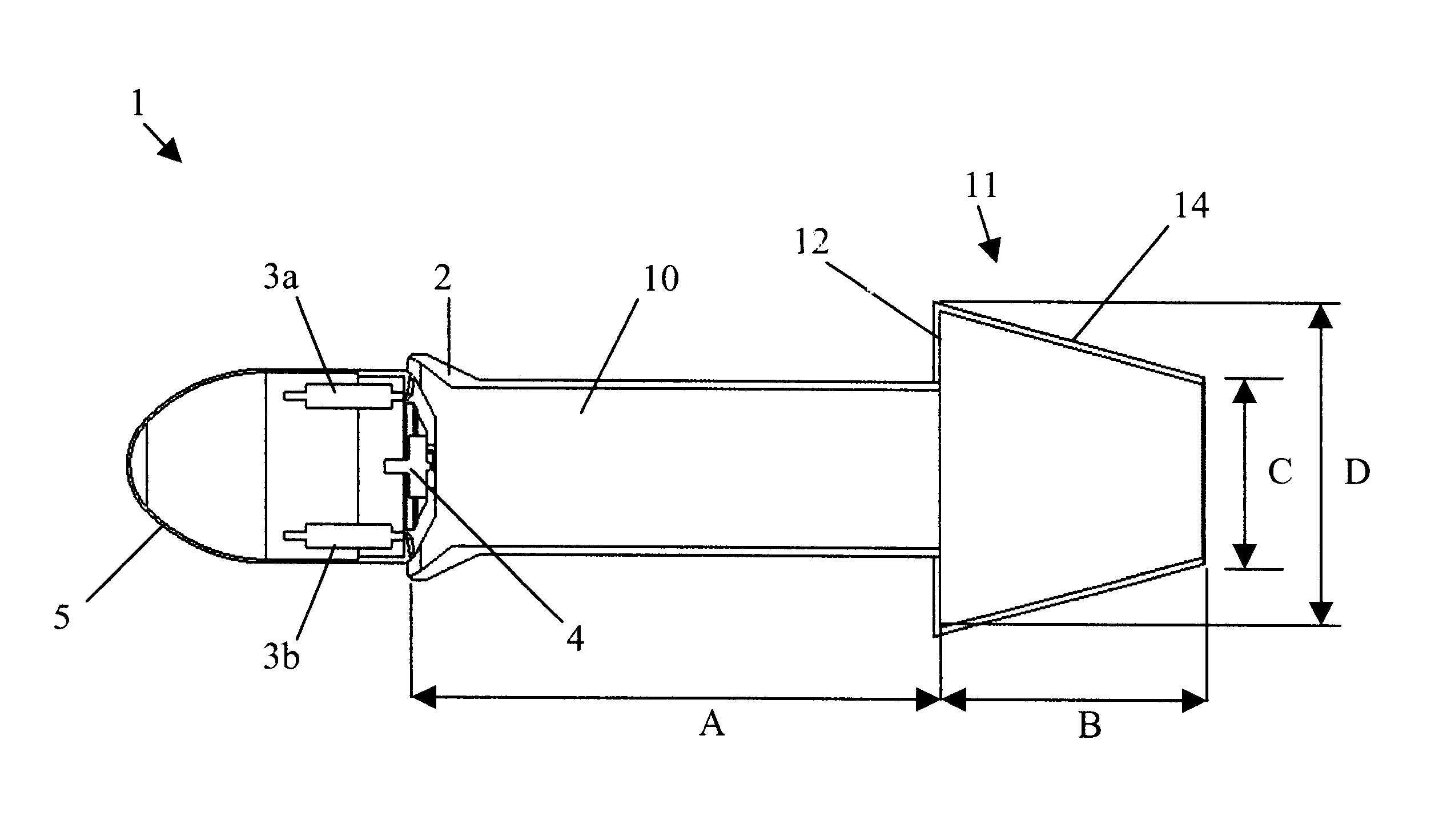

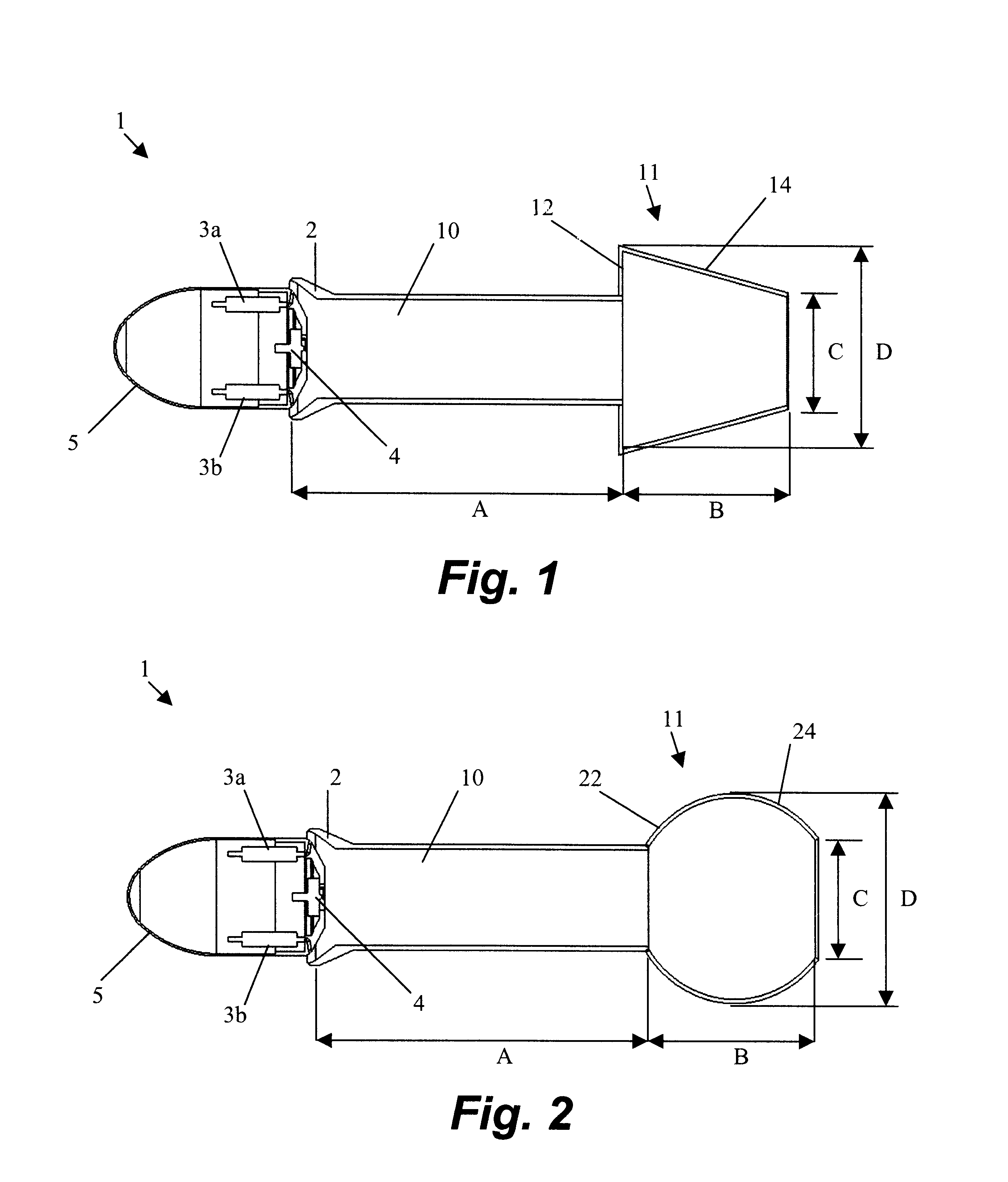

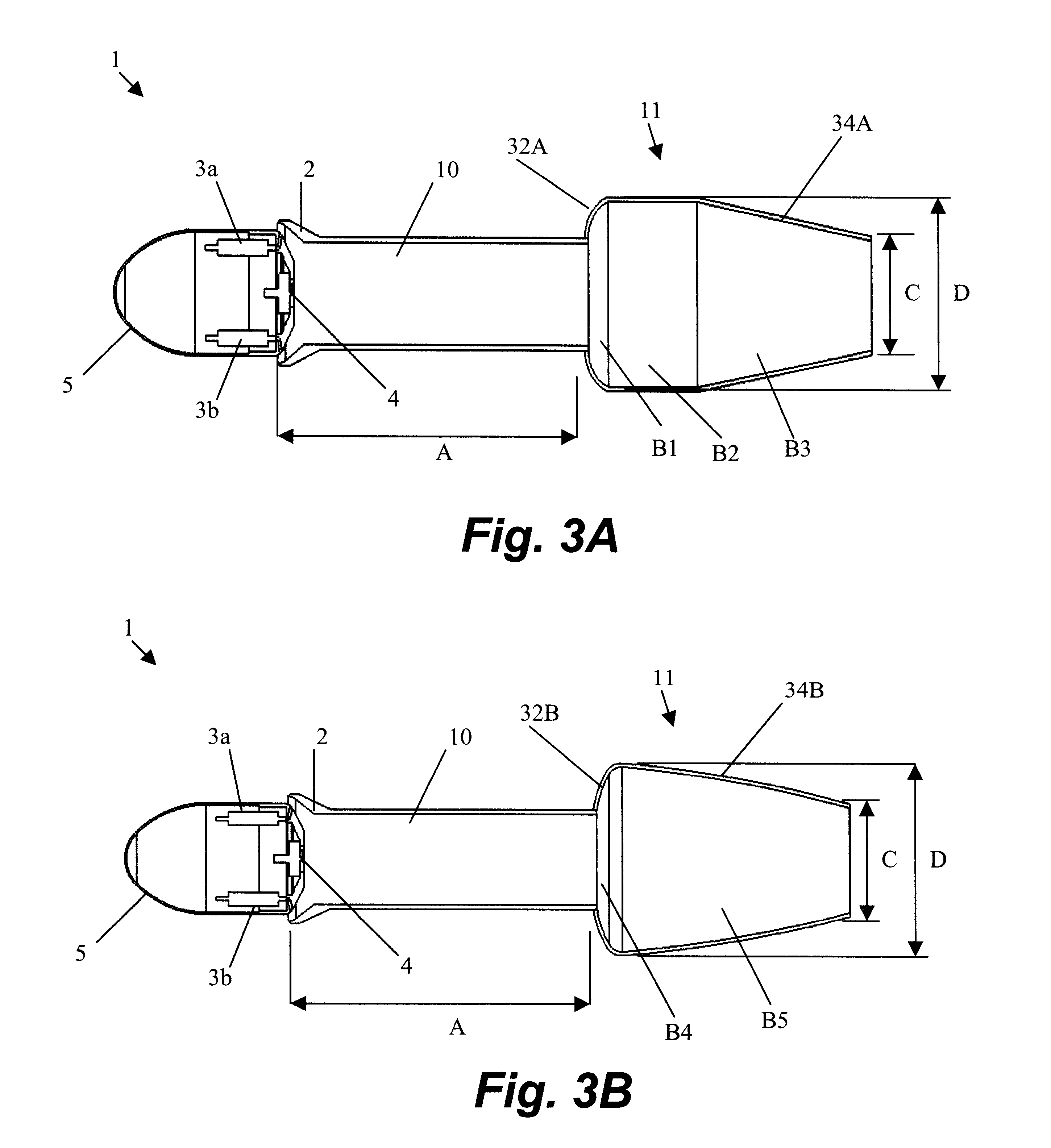

Performance improvements for pulse detonation engines

InactiveUS20090320446A1Reduce noiseImprove performanceEngine manufactureEngine fuctionsEquivalence ratioNoise reduction

A device and method for improving the performance of a pulse detonation engine. The device includes at least one of an exhaust structure and an ejector. The exhaust structure can be configured as a straight, converging or diverging nozzle device, and connected to the engine to control the flow of a primary fluid produced during a detonation reaction. The ejector is fluidly coupled to the engine, using the movement of the primary fluid to promote entrainment of a secondary fluid that can be mixed with the primary fluid. The secondary fluid can be used to increase the mass flow of the primary fluid to increase thrust, as well as be used to cool engine components. Device positioning, sizing, shaping and integration with other engine operating parameters, such as fill fraction, choice of fuel and equivalence ratio, can be used to improve engine performance. In addition to thrust augmentation and enhanced cooling, the disclosed device can be used for engine noise reduction.

Owner:UNIVERSITY OF CINCINNATI

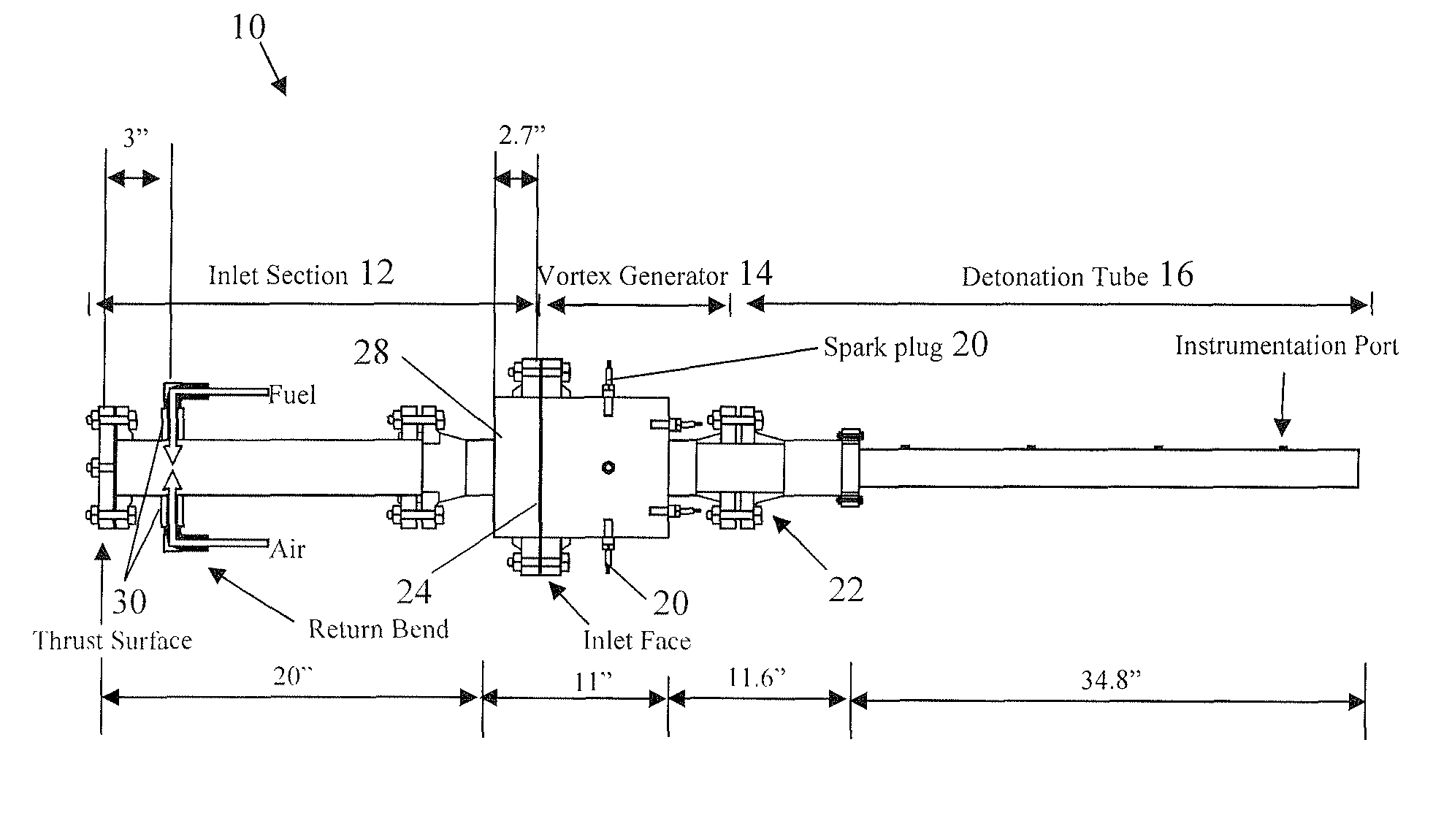

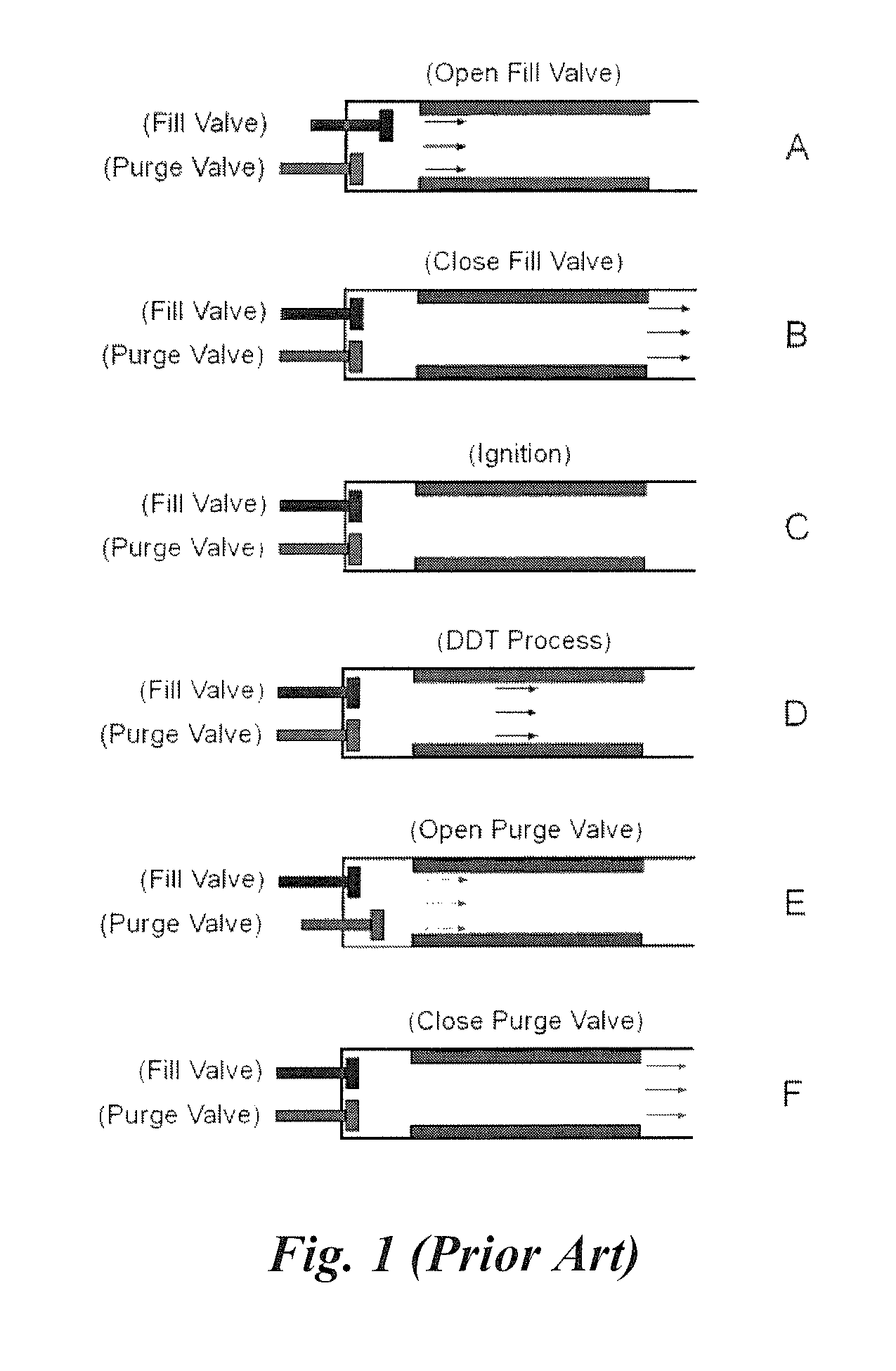

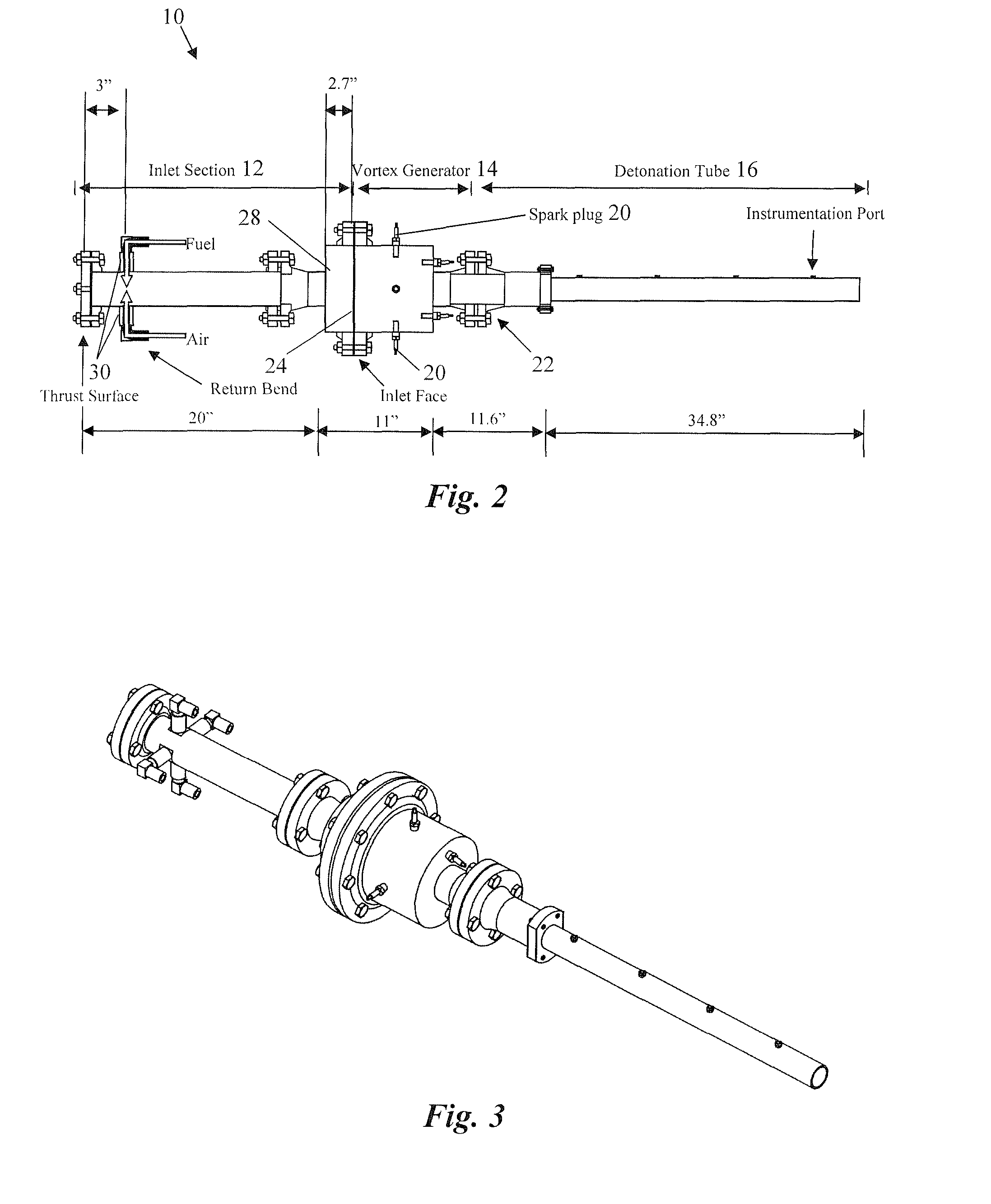

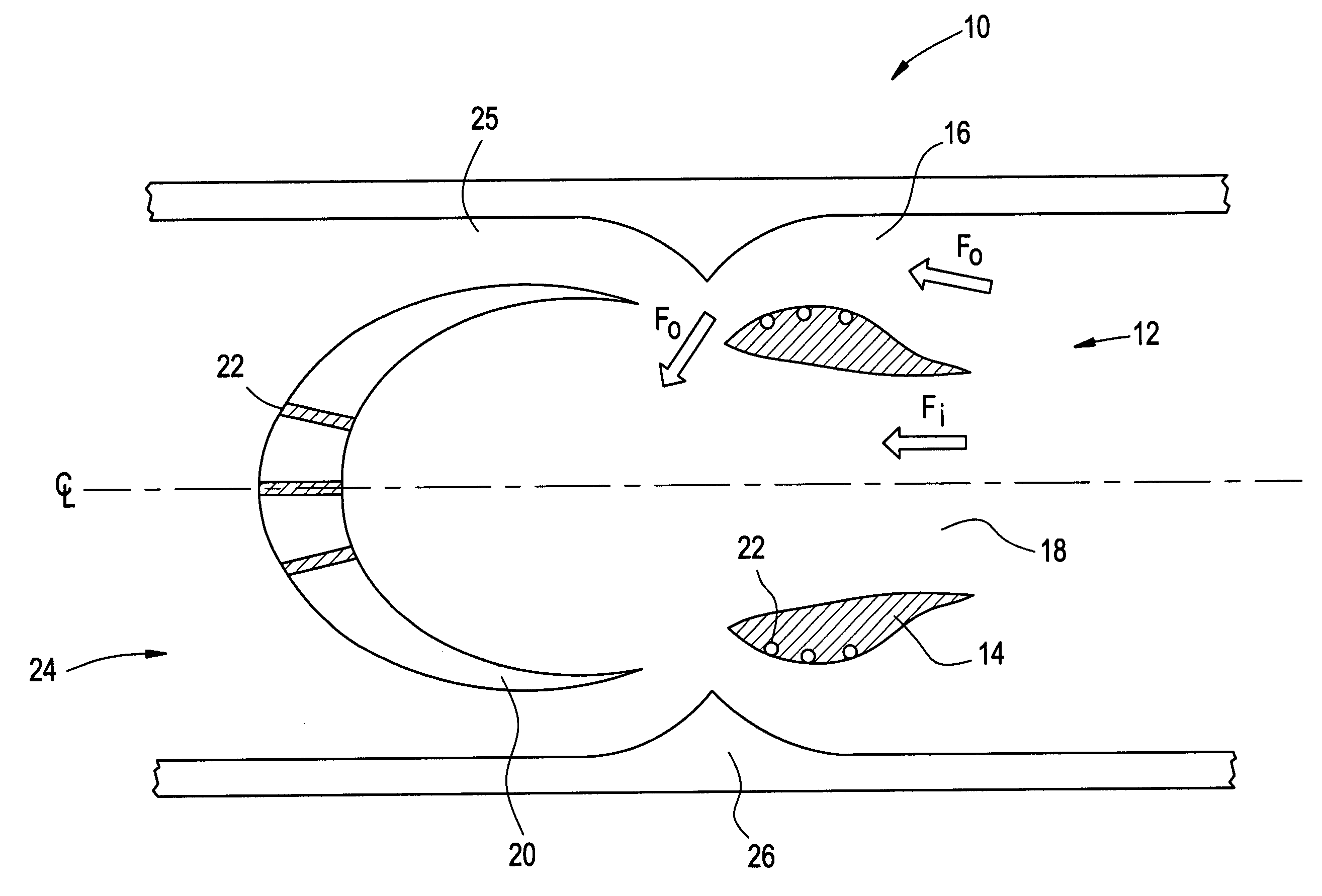

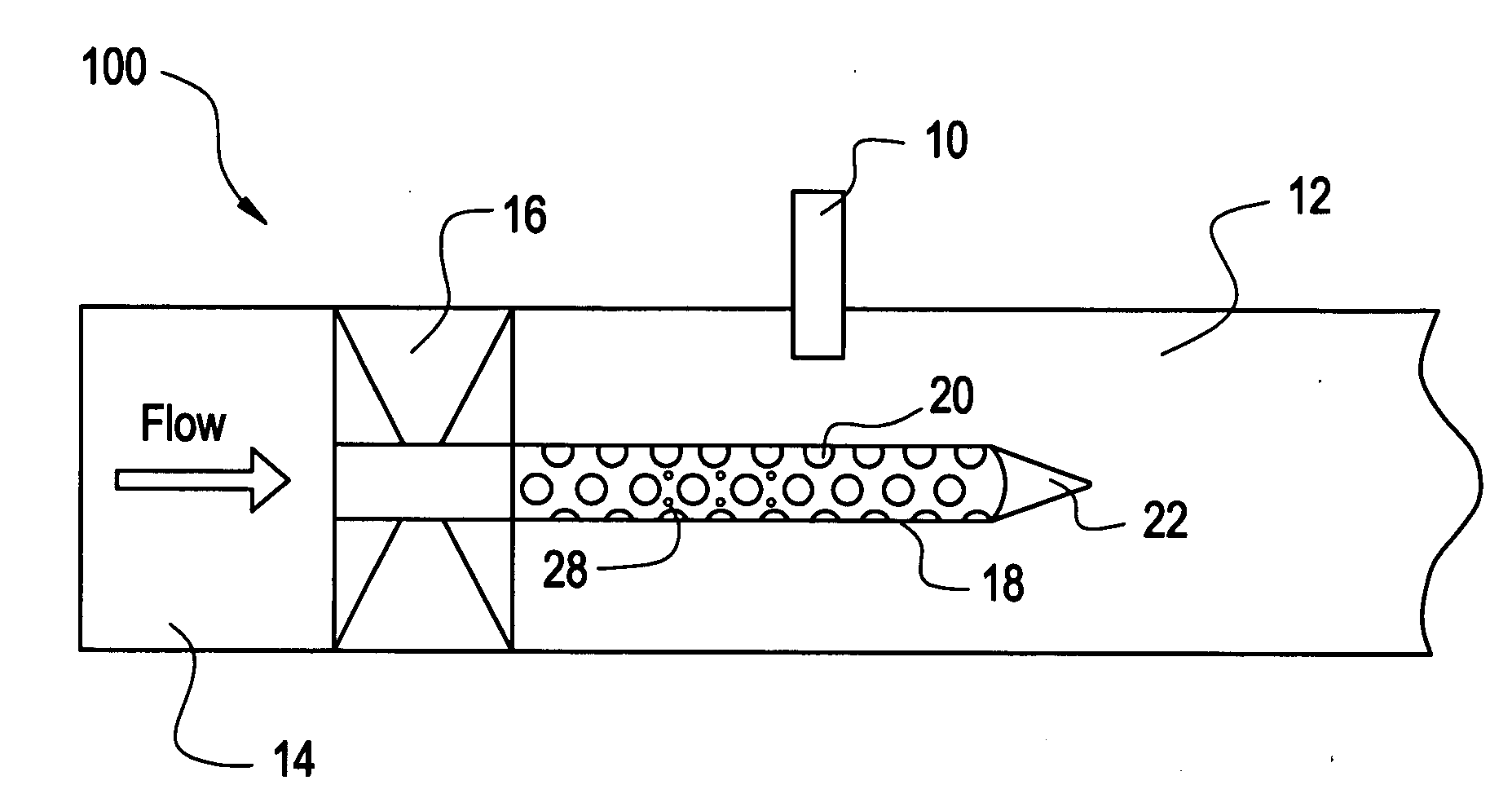

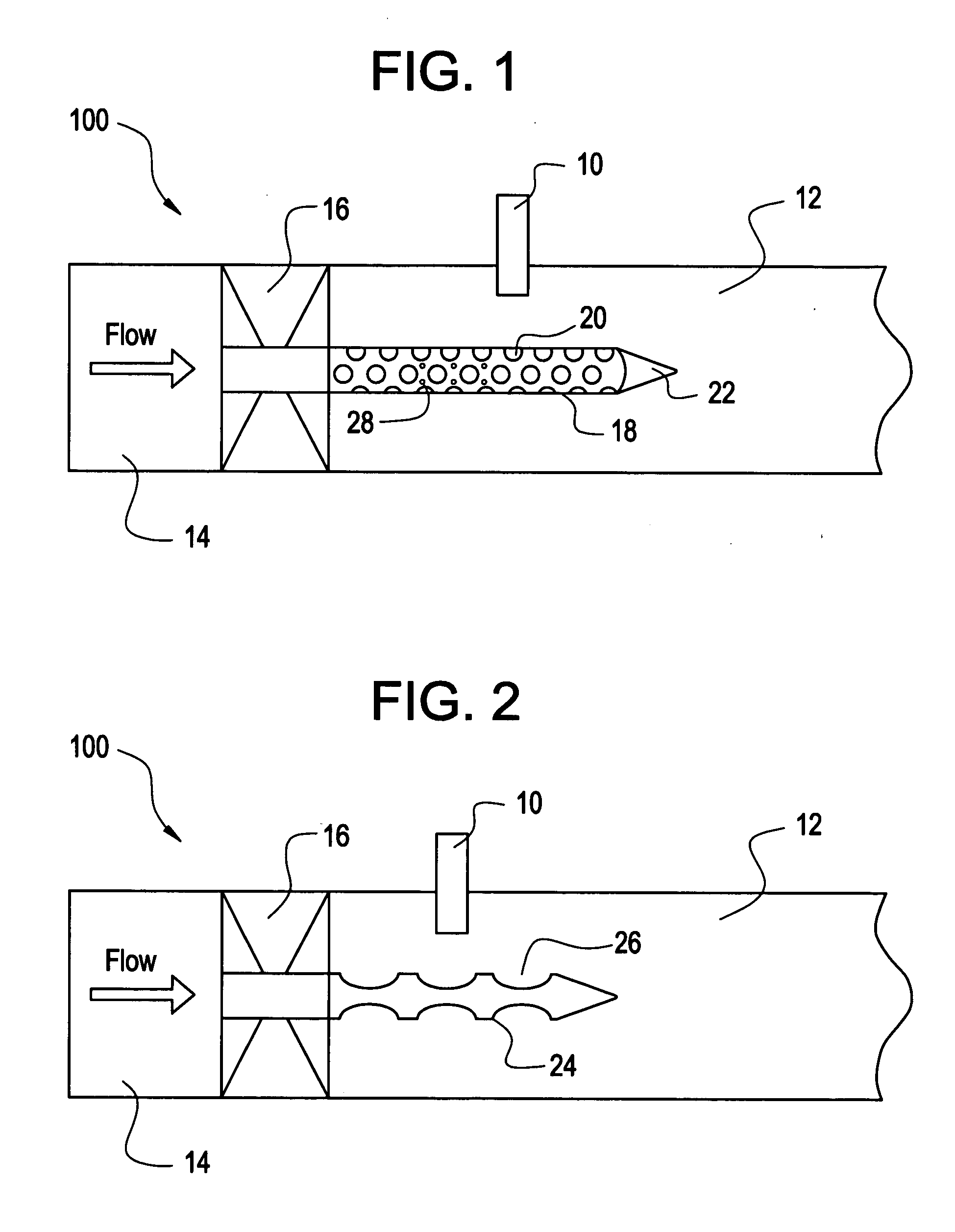

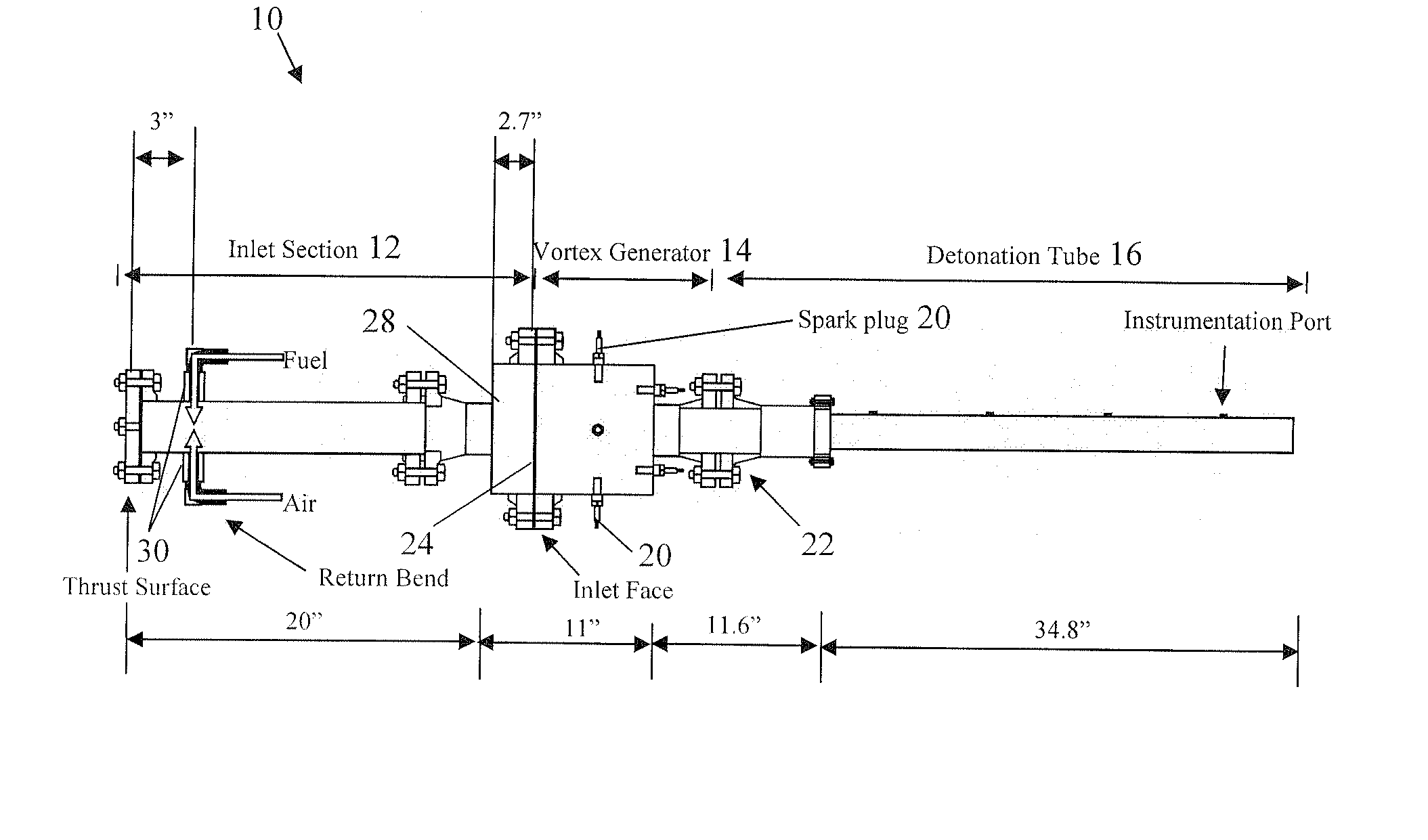

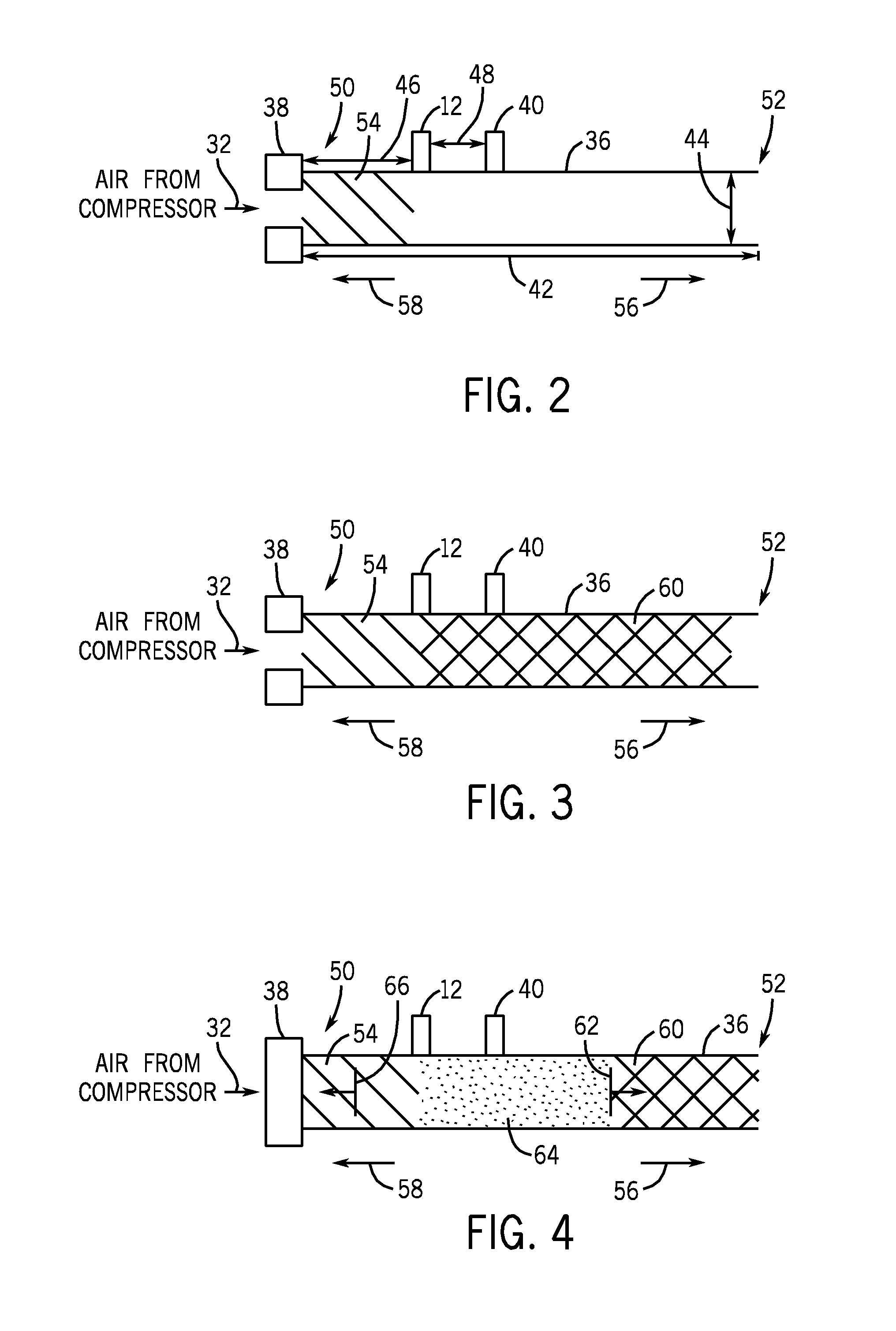

Geometric configuration and confinement for deflagration to detonation transition enhancement

InactiveUS20070137172A1Increase elasticityWell mixedContinuous combustion chamberEfficient propulsion technologiesCombustorDeflagration to detonation transition

A pulse detonation combustor is provided with a fuel-air mixer located upstream from a detonation chamber. A fuel-air mixture exits the fuel-air mixer and enters the detonation chamber, where it is ignited by an ignition source. The flow from the fuel-air mixer passes over the surface of a center body, which extends downstream from the fuel-air mixer. The surface of the center body contains at least one turbulence generator, which imparts additional turbulence in the fuel-air mixture passing through the chamber. The turbulence generator aids in the mixing of the fuel and air of the fuel-air mixture to enhance the deflagration to detonation transition within the pulse detonation combustor.

Owner:GENERAL ELECTRIC CO

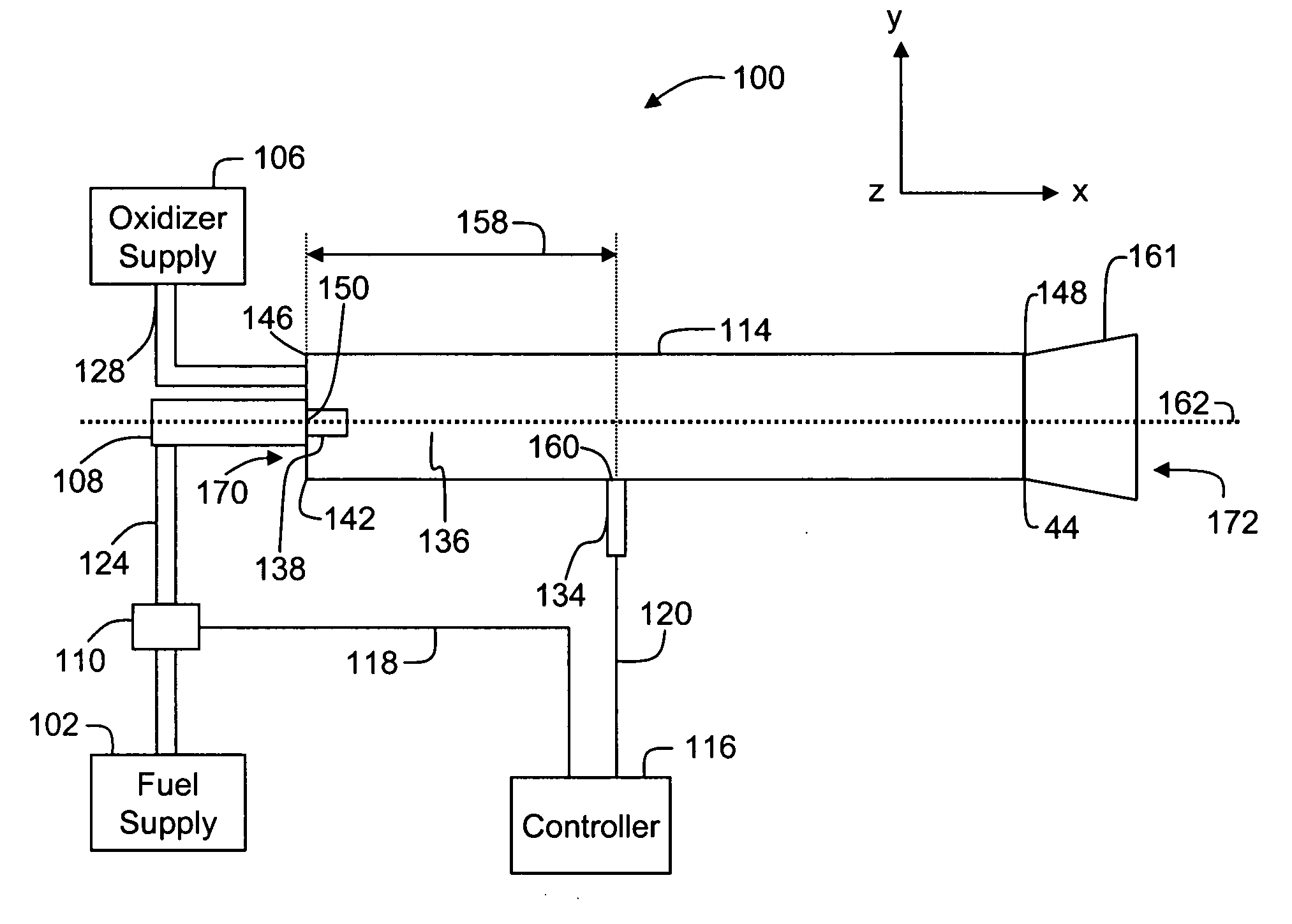

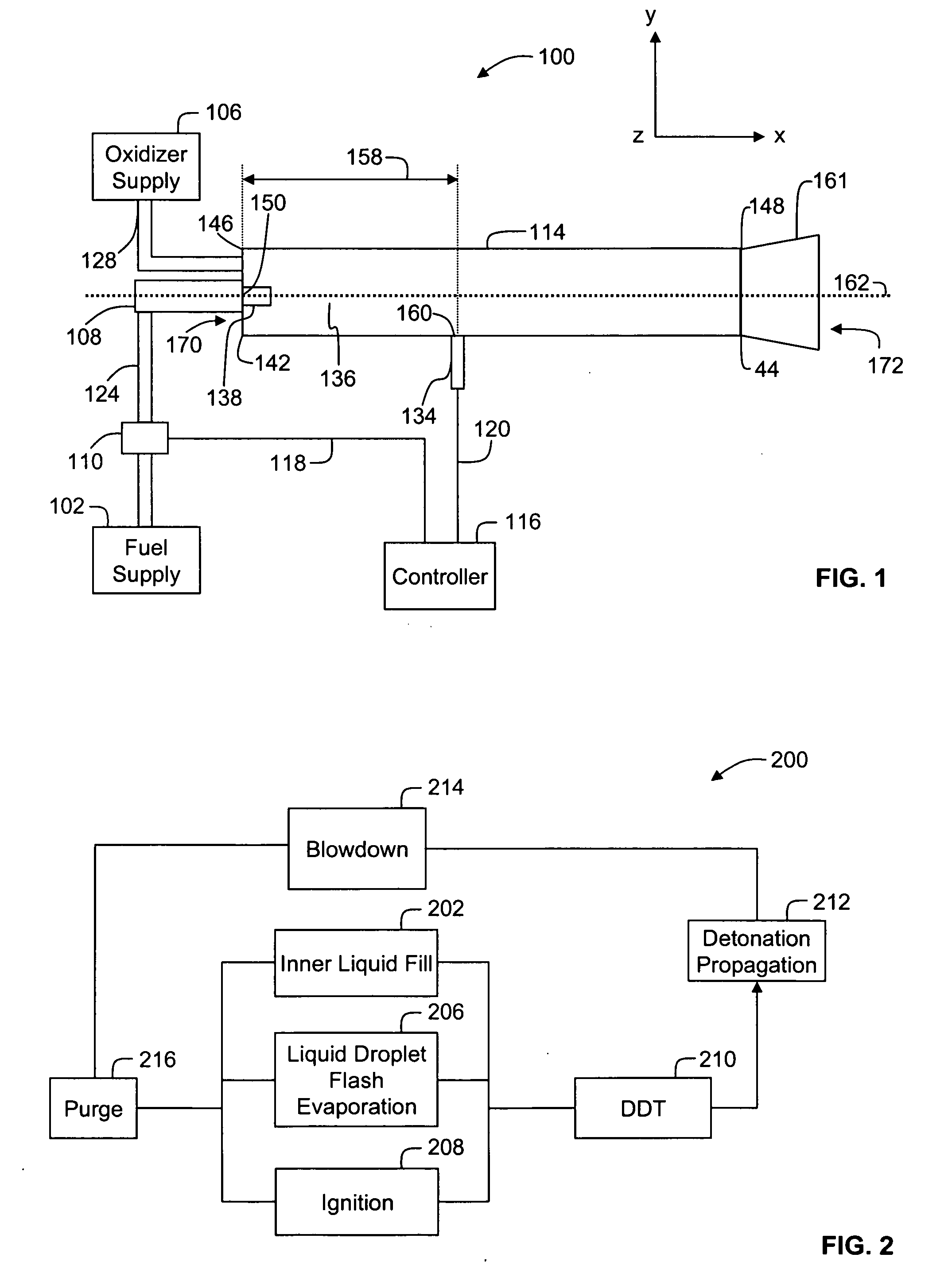

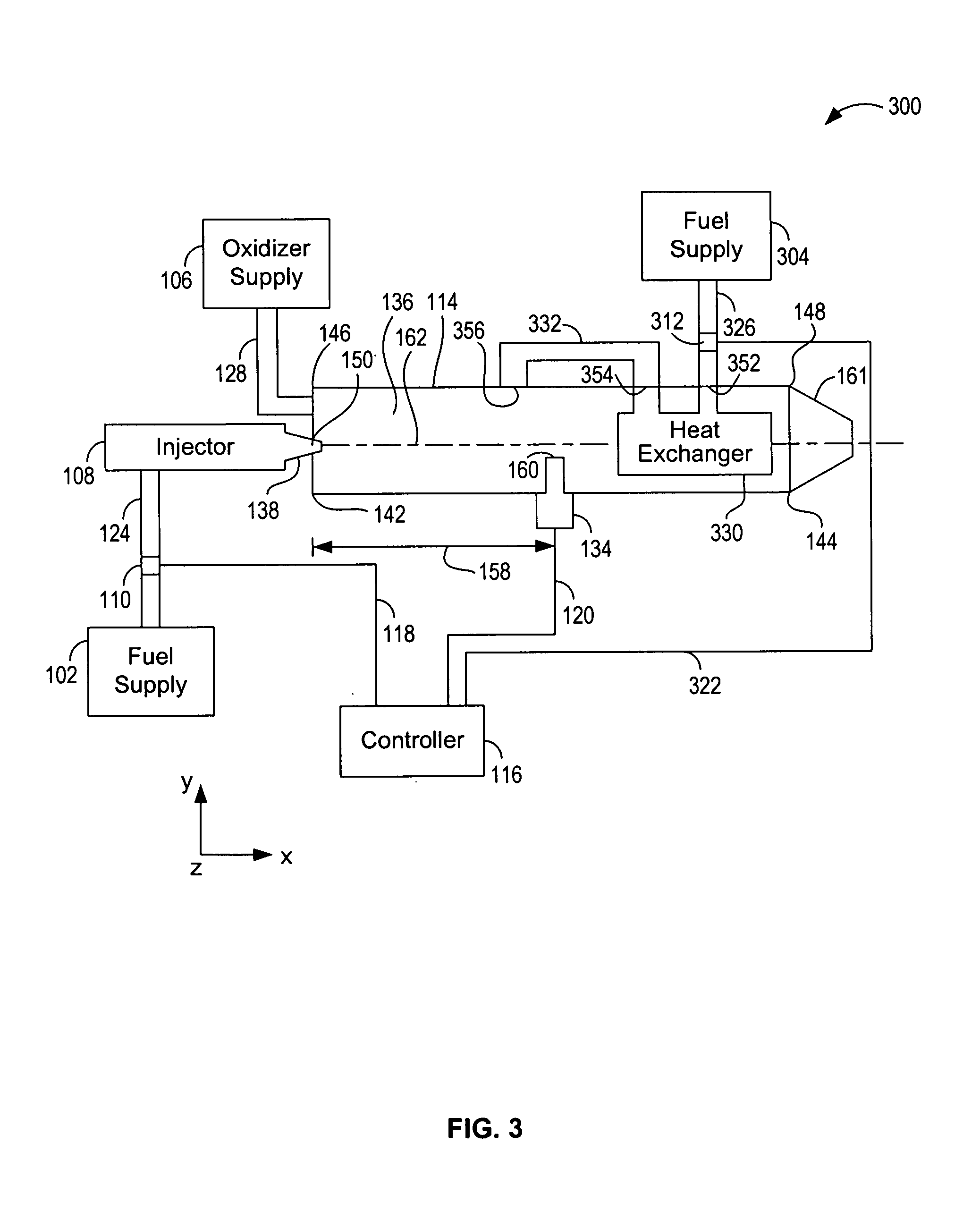

Direct liquid fuel injection and ignition for a pulse detonation combustor

InactiveUS20070180814A1Cosmonautic vehiclesCosmonautic propulsion system apparatusCombustorDetonation

A system for generating thrust is provided. The system includes a first injector, an inner tube configured to receive fuel from the first injector via a first port of the inner tube, where at least a portion of fuel in liquid phase received by the inner tube is configured to flash vaporize upon entering the inner tube via the first port.

Owner:GENERAL ELECTRIC CO

Valveless pulsed detonation combustor

Pulse detonation combustors of valveless construction. One valveless pulse detonation combustor, having a tube with a closed end and an open end, is constructed with a flame accelerator within the tube, adjacent the open end. A valveless, apertured flow restrictor is positioned between the flame accelerator and the closed end of the tube. A sparking device is positioned within the tube, between the flow restrictor and the flame accelerator. Valveless fuel and air ports are positioned between the flow restrictor and the closed end of the tube. Substantially right-angle manifold passageways are in communication with each of the ports.

Owner:PURDUE RES FOUND INC

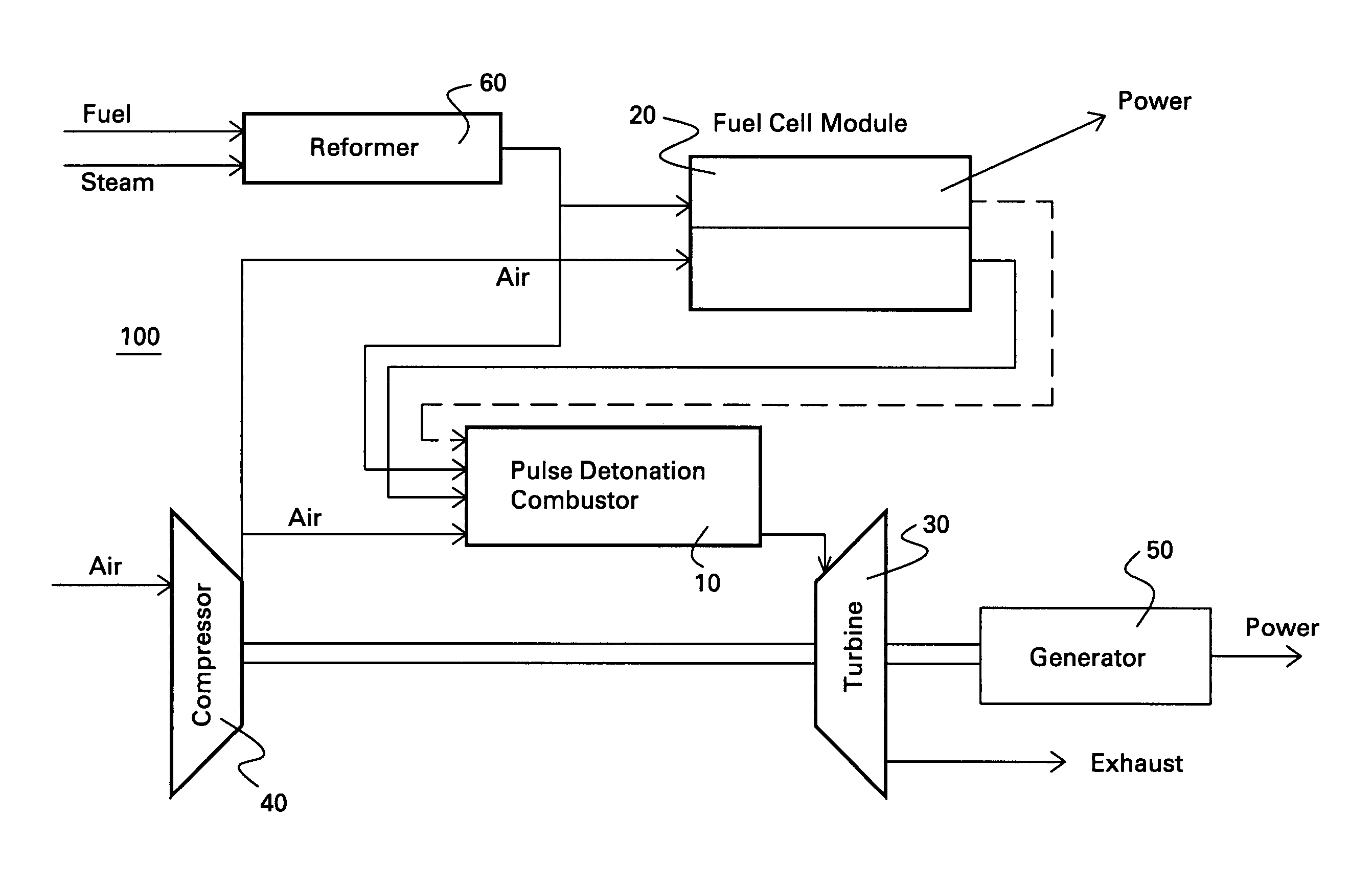

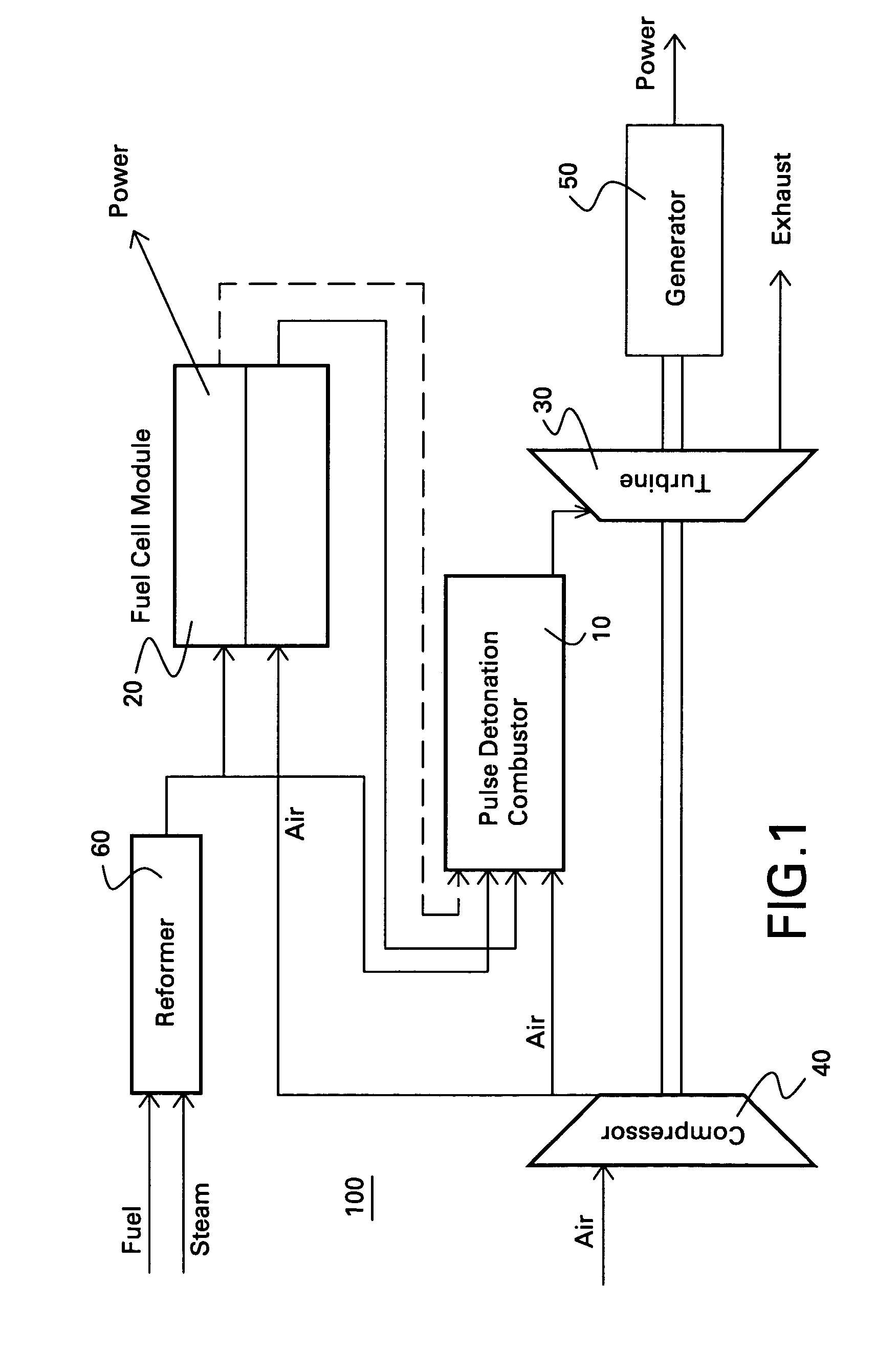

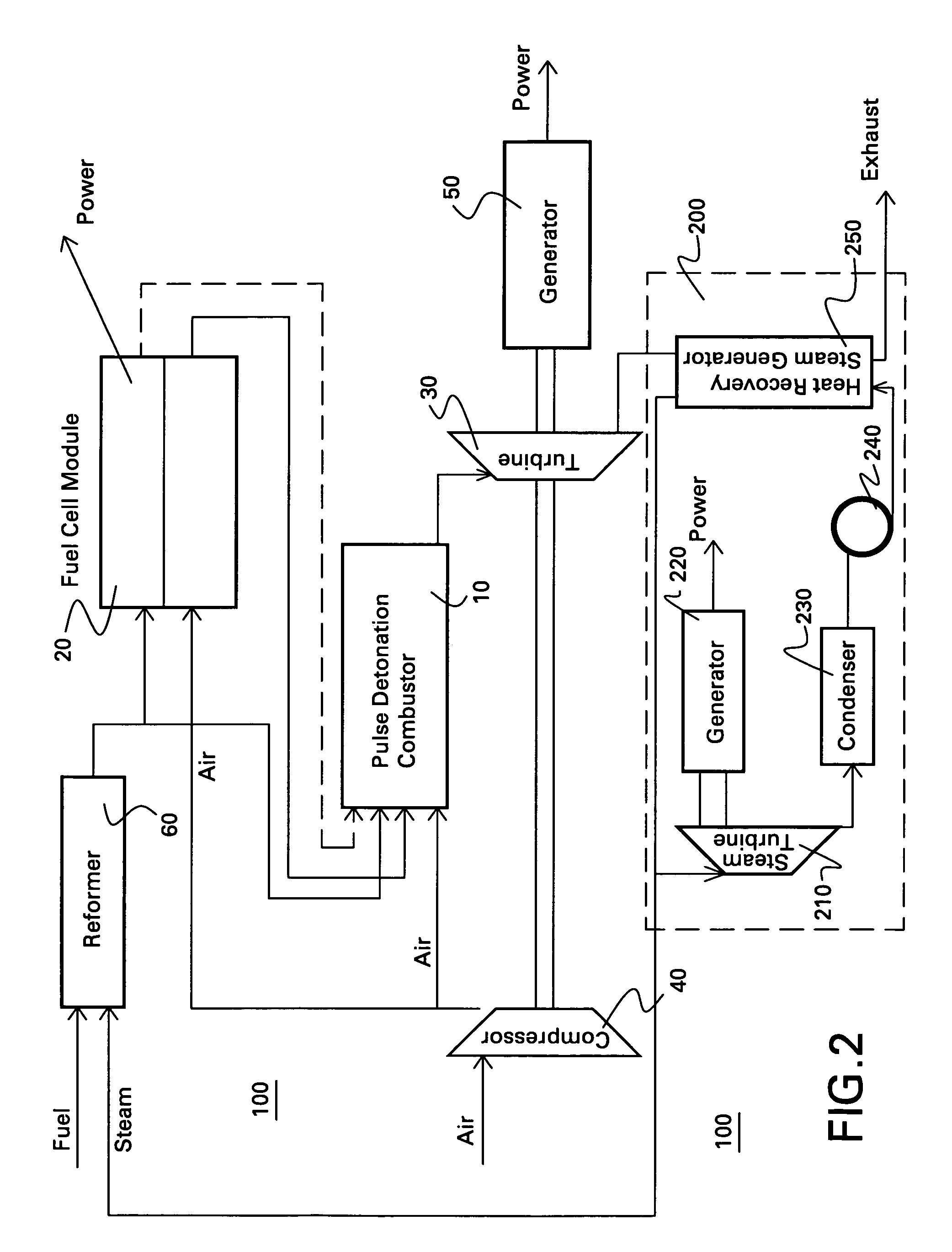

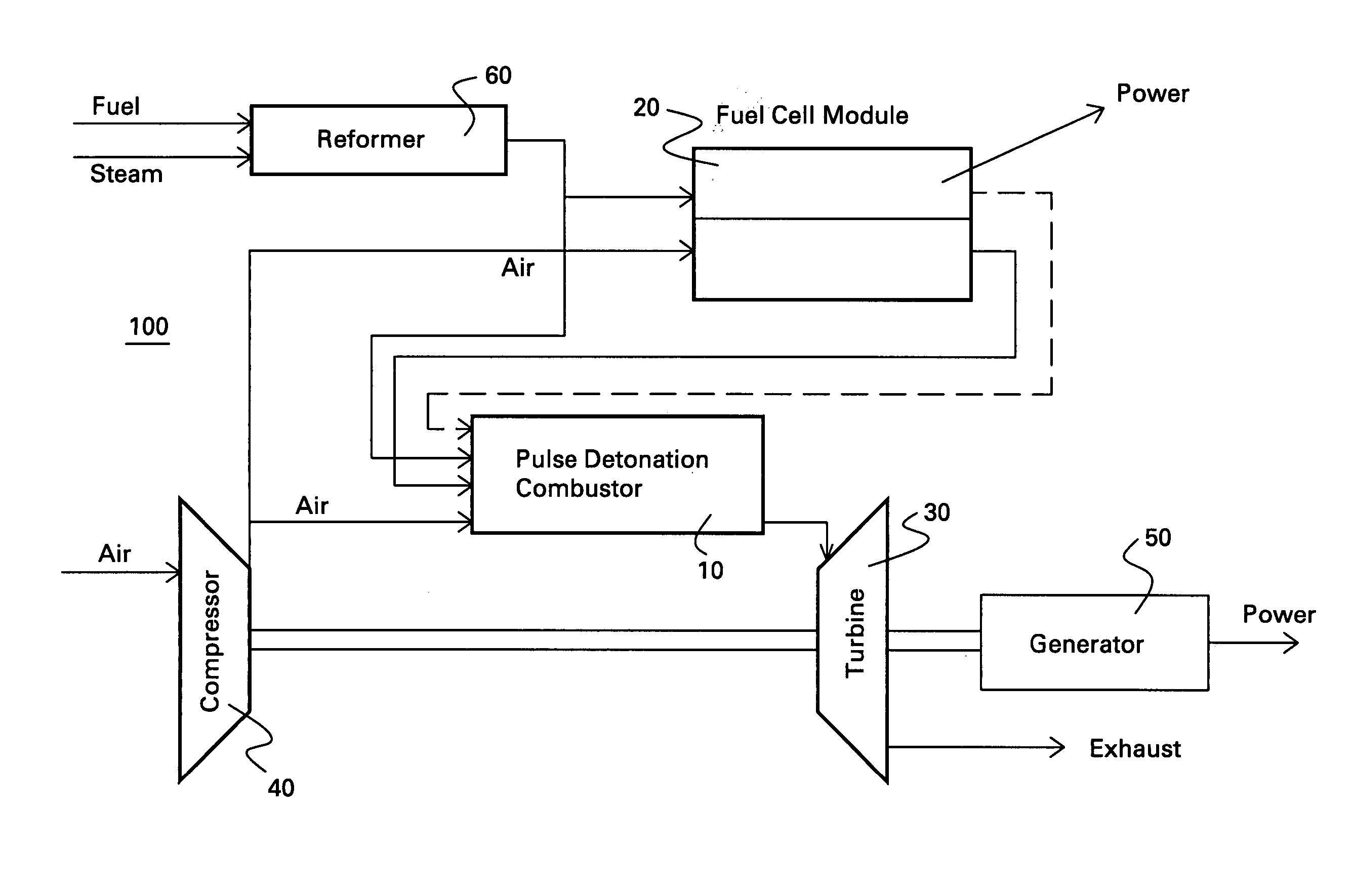

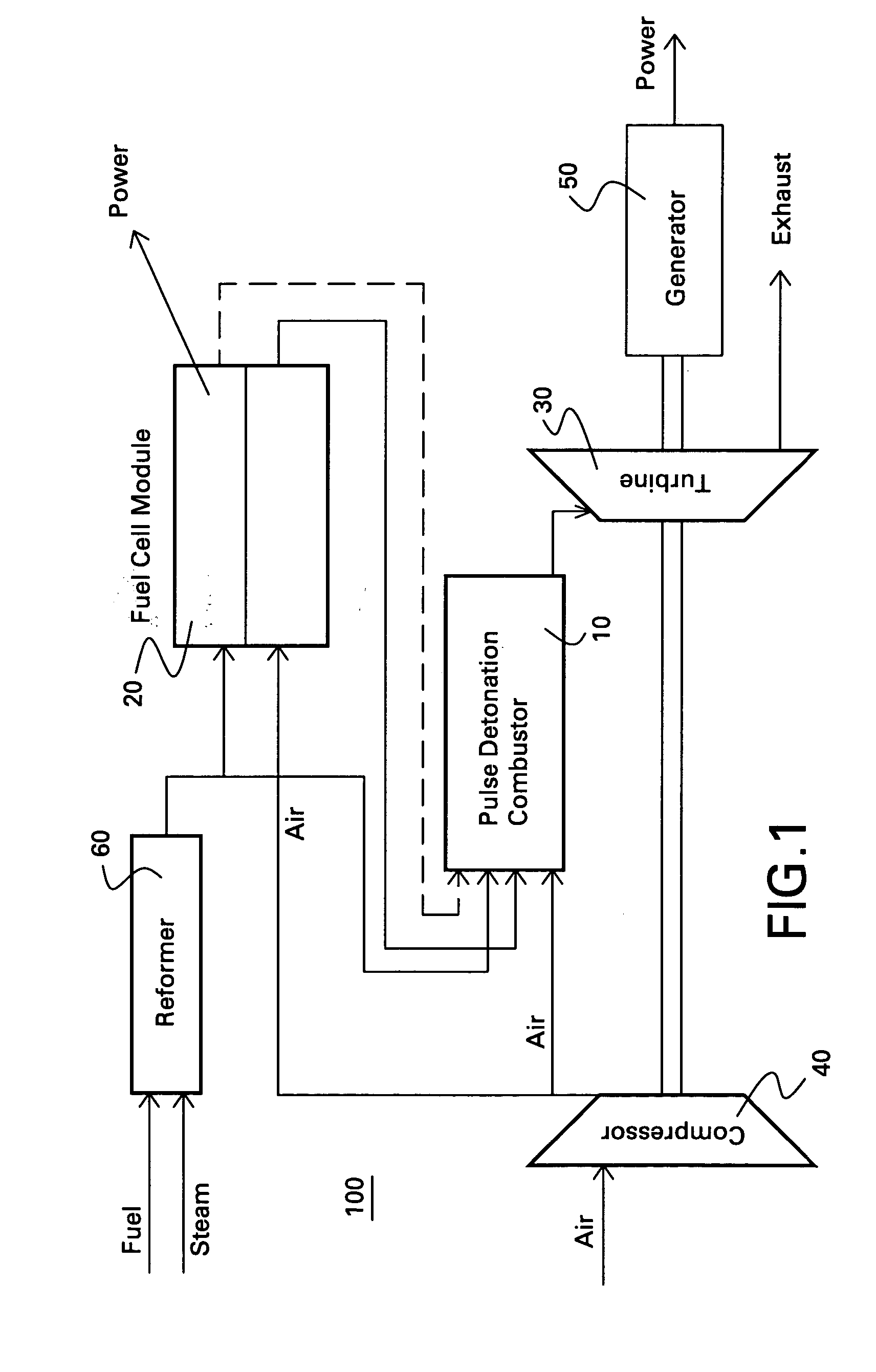

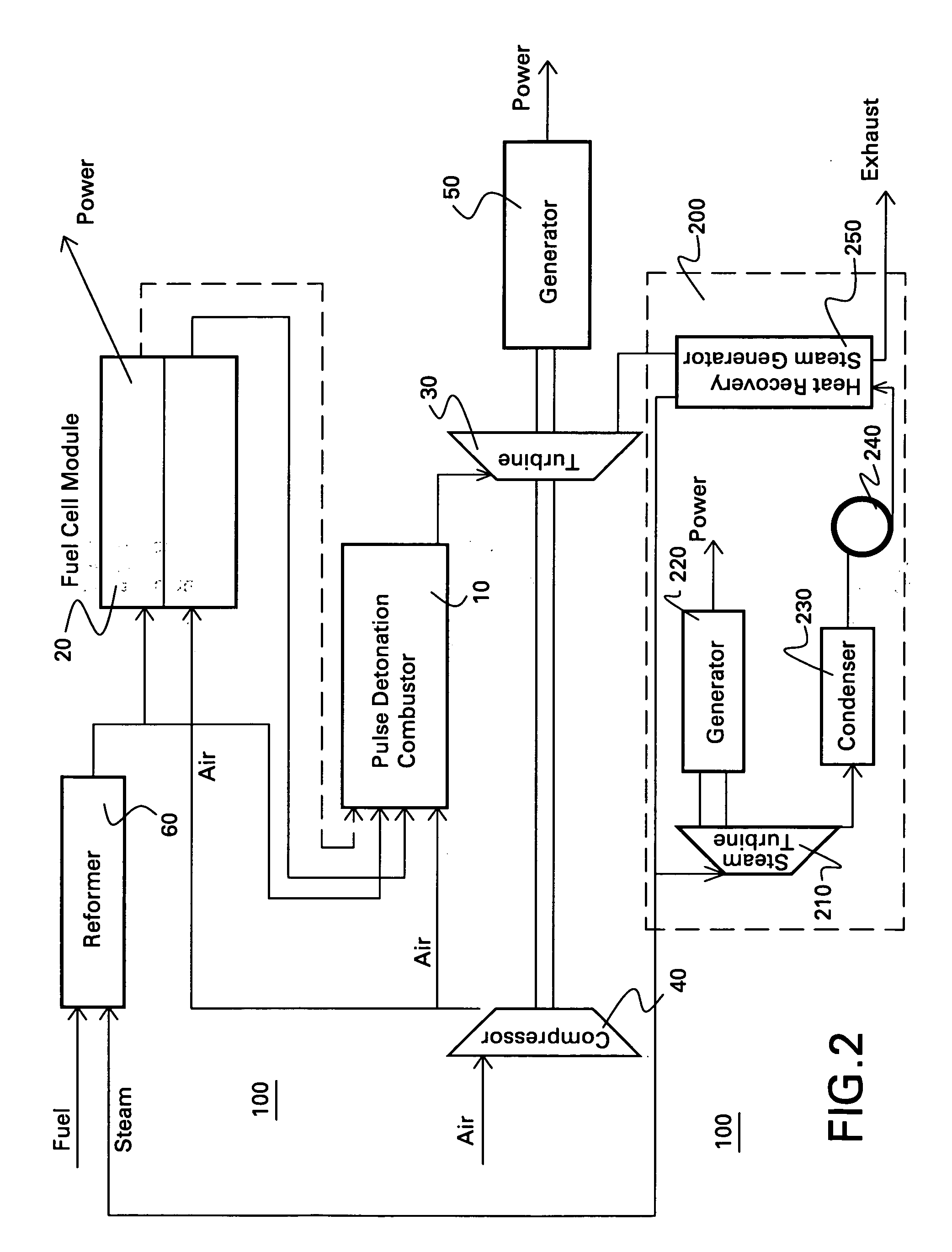

Hybrid fuel cell-pulse detonation power system

A power system includes a fuel cell module adapted to receive a first fuel and a pulse detonation combustor adapted to receive and detonate a second fuel and exhaust a number of detonation products to create thrust for propulsion, mechanical work extraction or electrical power production.

Owner:GENERAL ELECTRIC CO

Combustion nozzle fluidic injection assembly

Owner:UNITED TECH CORP

Pulse detonation combustor with plenum

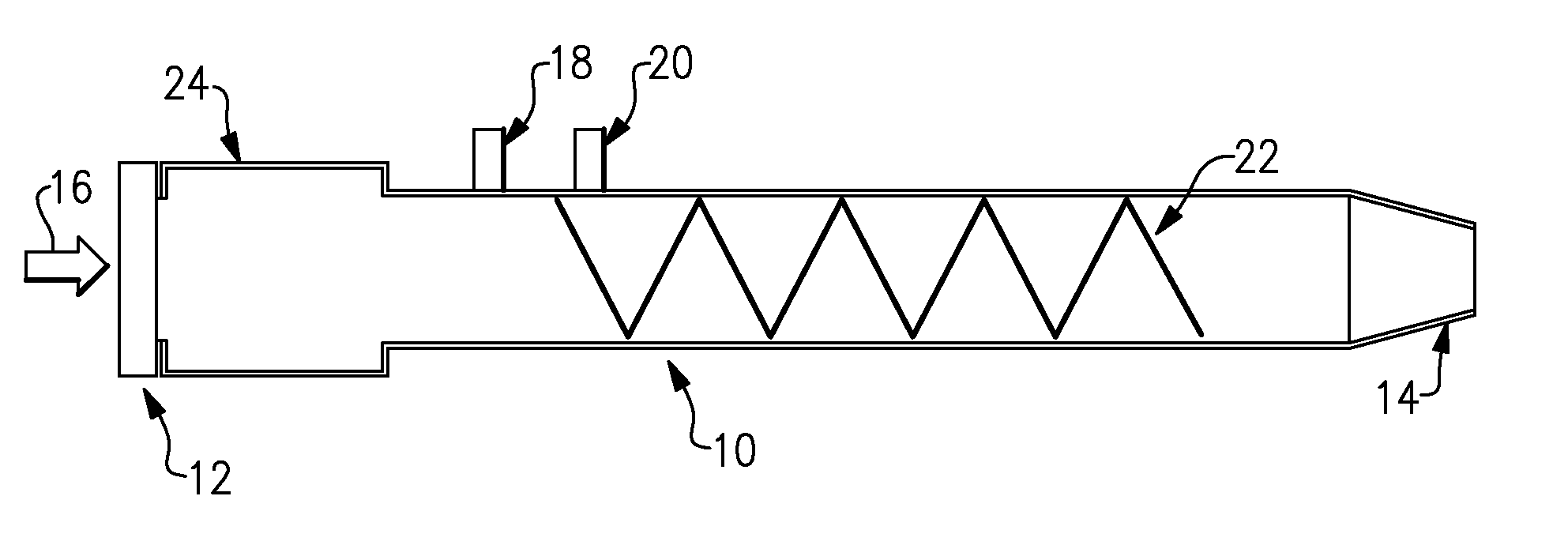

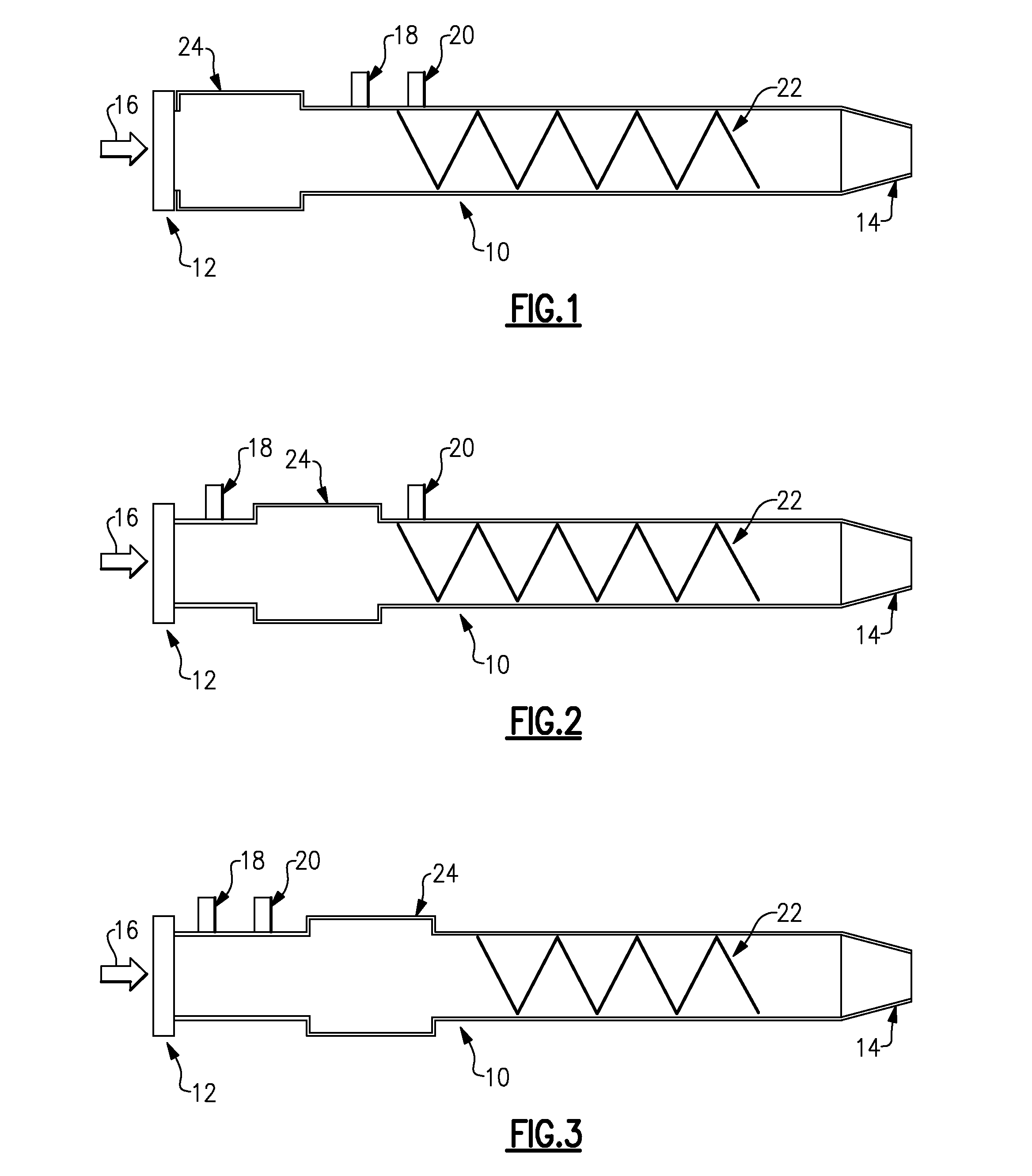

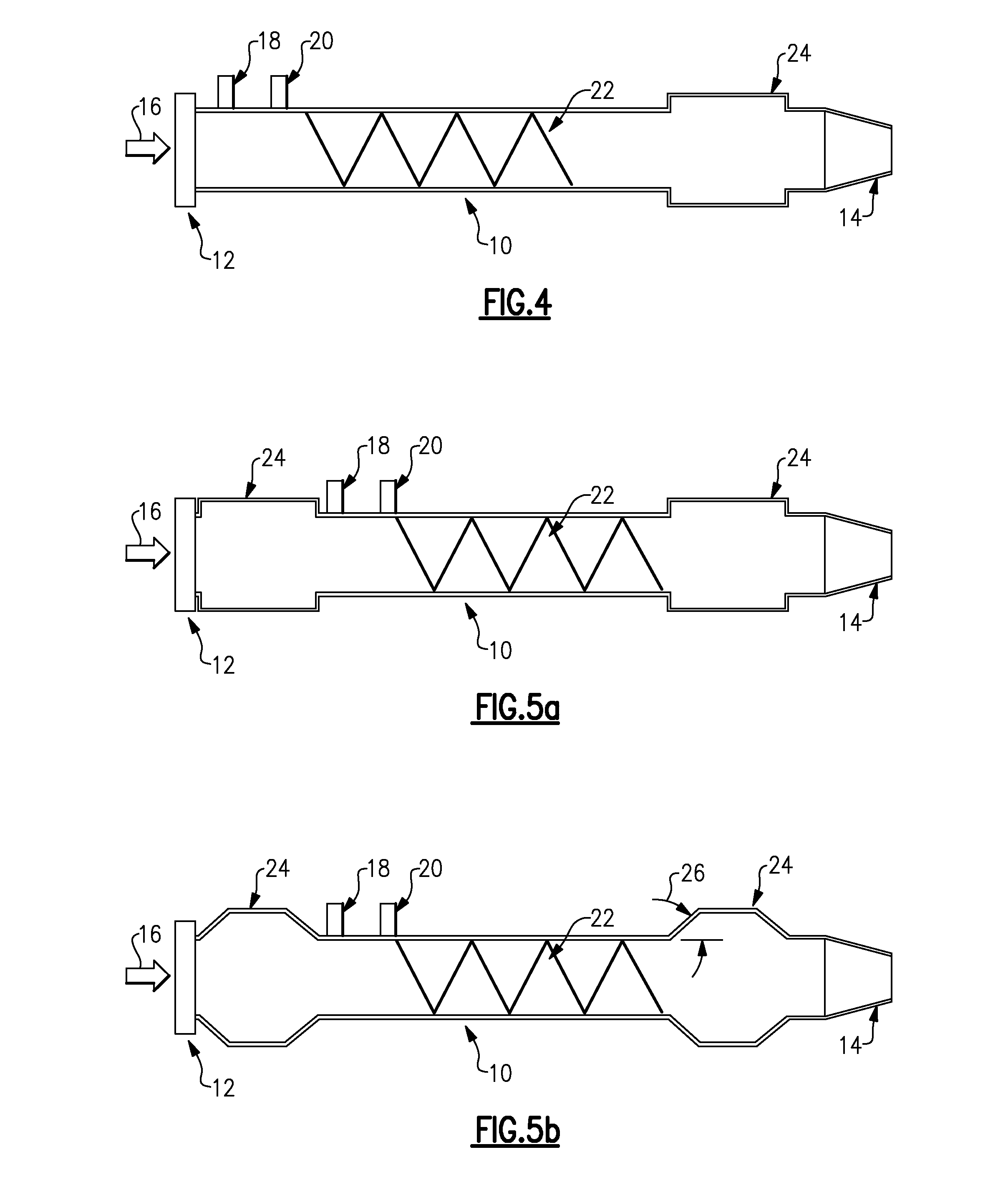

InactiveUS20130042595A1Extended durationExtension of timePulsating combustionIntermittent jet plantsCombustorDetonation

A pulse detonation combustor includes at least one plenum located along the length of the pulse detonation combustor. The plenum can be located: 1) proximate an air valve; 2) between a fuel injection port and an ignition source; 3) downstream of both the fuel injection port and the ignition source; and 4) proximate an exit nozzle of the pulse detonation combustor. In addition, the pulse detonation combustor can have multiple plenums, for example, proximate the air valve and proximate the exit nozzle. The location and dimensions of the plenum can be selectively adjusted to control mechanical loading on the wall, the velocity of fluid flowing within the combustor, and the pressure generated by the pulse detonation combustor.

Owner:GENERAL ELECTRIC CO

Hybrid fuel cell-pulse detonation power system

A power system includes a fuel cell module adapted to receive a first fuel and a pulse detonation combustor adapted to receive and detonate a second fuel and exhaust a number of detonation products to create thrust for propulsion, mechanical work extraction or electrical power production.

Owner:GENERAL ELECTRIC CO

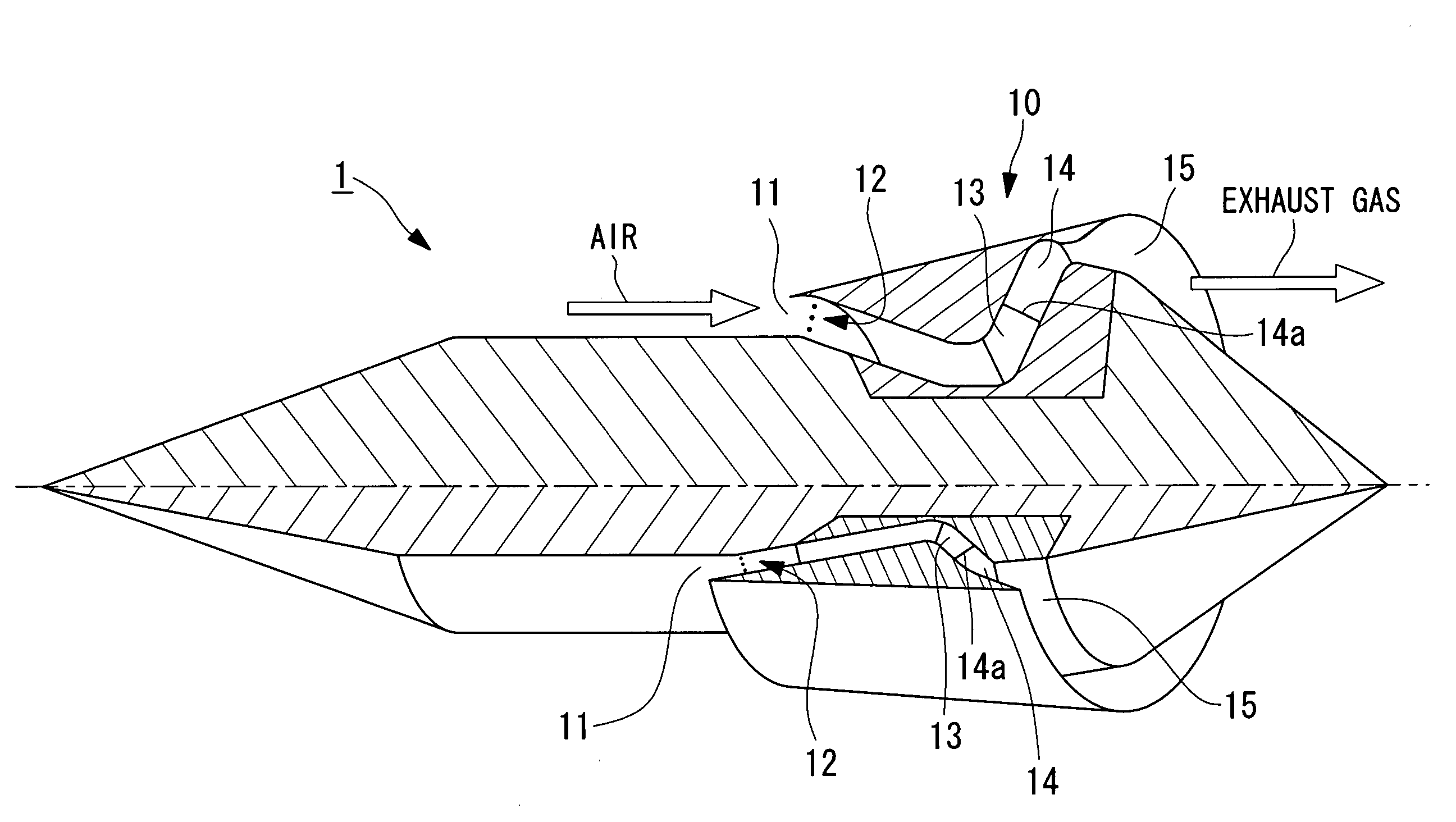

Detonation engine and flying object provided therewith

InactiveUS7784267B2Simple structureGuaranteed continuous outputMolten spray coatingBlade accessoriesDetonationCombustion

A detonation engine which creates thrust by generating a detonation wave, wherein the overall engine structure is simplified, and continuous output can be obtained, comprises: a rotational flow generation device which generates rotational flow about an axis in a mixed gas of air and fuel or of oxygen and fuel; a detonation chamber arranged downstream from the rotational flow generation device, formed in a ring-shape radially extended and continuous in the circumferential direction, which continuously combusts in the circumferential direction the mixed gas in which the rotational flow is generated to generate detonation waves, and draws it in from the radial inside and exhausts it to the radial outside; and a nozzle which is connected to the detonation chamber, and jets the high temperature and pressure combustion gas generated by the detonation waves flowing from the detonation chamber, to the rear while expanding it, and converts it into thrust.

Owner:MITSUBISHI HEAVY IND LTD +2

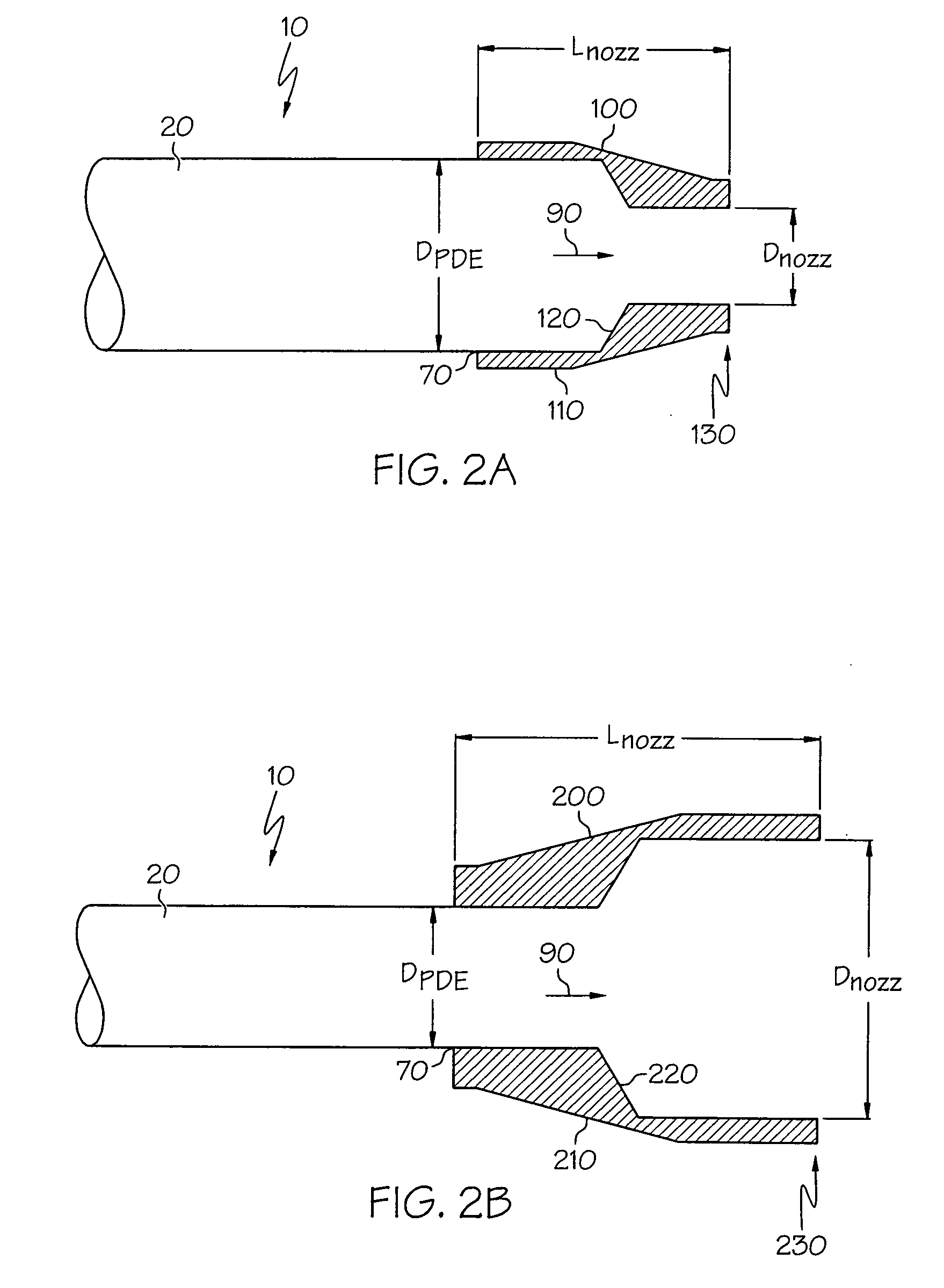

Method and apparatus for improving the efficiency of pulsed detonation engines

InactiveUS6662550B2Improve efficiencyShort and more compactTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionPulse detonation engineNozzle

A pulsed detonation engine having improved efficiency has a detonation chamber for receiving a detonable mixture, an igniter for igniting the detonable mixture, and an outlet for discharging detonation products. A diverging-converging nozzle is provided at the outlet of the detonation chamber. The geometry of the diverging-converging nozzle is selected to enable a relatively short nozzle to significantly improve efficiency of the pulsed detonation engine.

Owner:LEIDOS

Vapor cooling of detonation engines

An engine cooling system includes a combustion chamber assembly configured to generate detonation waves and a first vapor cooling assembly. The combustion chamber assembly defines a flowpath between an inner liner and an outer liner. The first vapor cooling assembly includes a vaporization section located adjacent to the flowpath and a condenser section spaced from the flowpath, and is configured to transport thermal energy from the vaporization section to the condenser section through cyclical evaporation and condensation of a working medium sealed within the first vapor cooling assembly.

Owner:RTX CORP

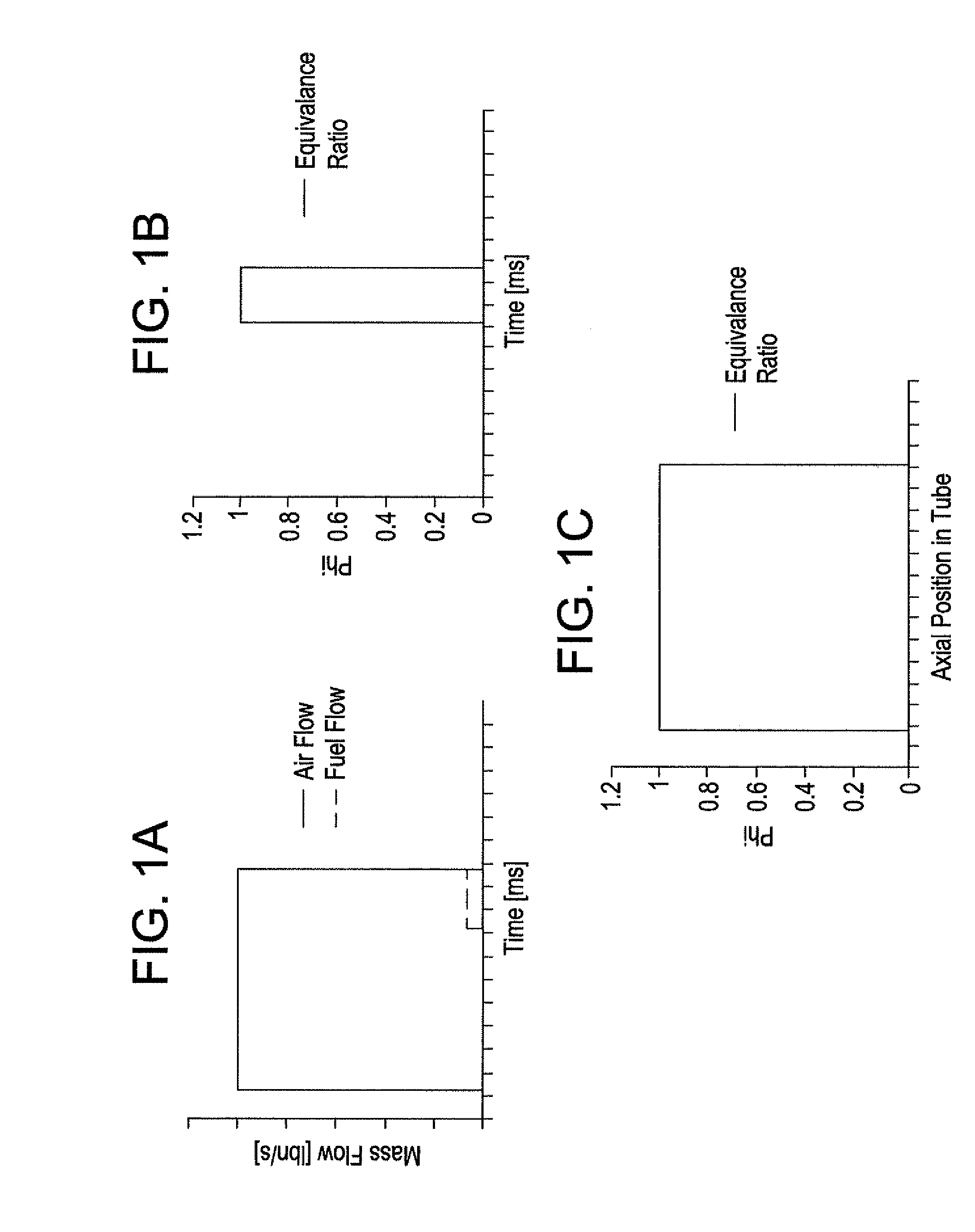

Pulse detonation system with fuel lean inlet region

InactiveUS20110146285A1Turbine/propulsion fuel supply systemsGas turbine plantsDetonationEngineering

In one embodiment, a pulse detonation system includes a pulse detonation tube and an air valve disposed at an upstream end of the pulse detonation tube. The air valve is configured to provide an air flow into the pulse detonation tube. The pulse detonation system also includes a fuel injector configured to inject fuel into the air flow to establish a fuel-air mixture configured to support detonation, and to establish a region in the fuel-air mixture having a fuel to air ratio insufficient to support a detonation wave. The pulse detonation system further includes an ignition source configured to detonate the fuel-air mixture when the region is disposed adjacent to the air valve.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com