Patents

Literature

803results about "Turbine/propulsion fuel heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

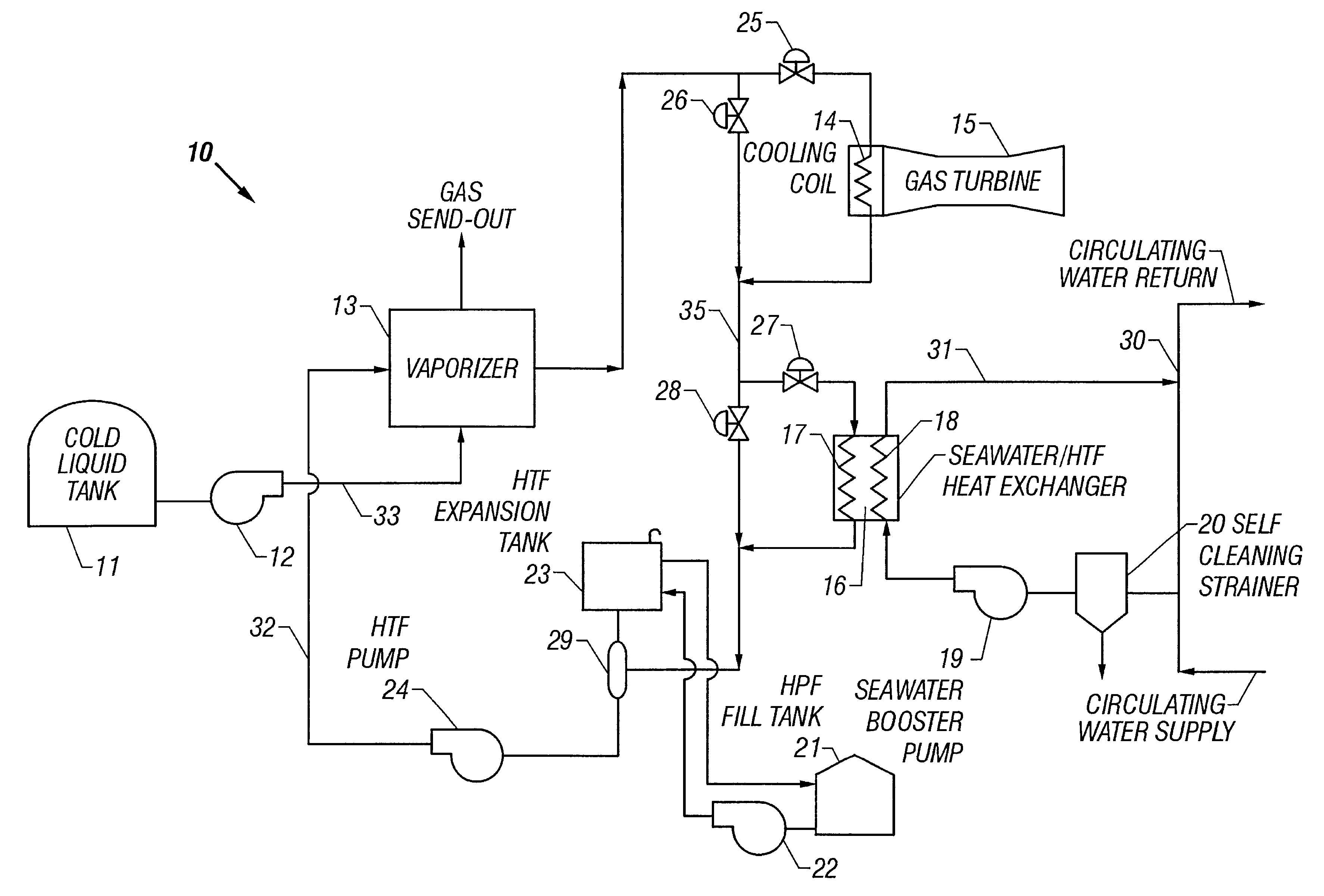

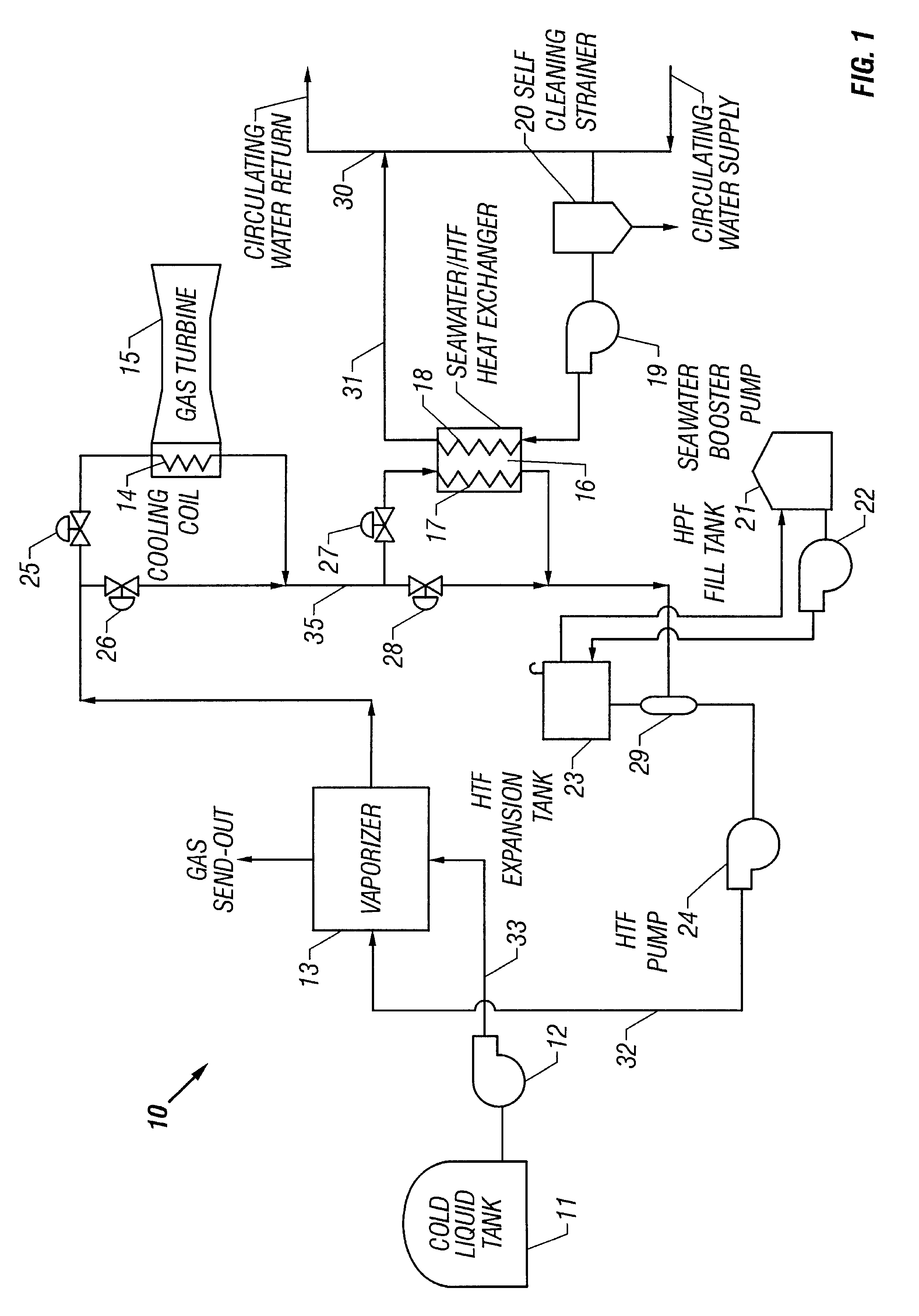

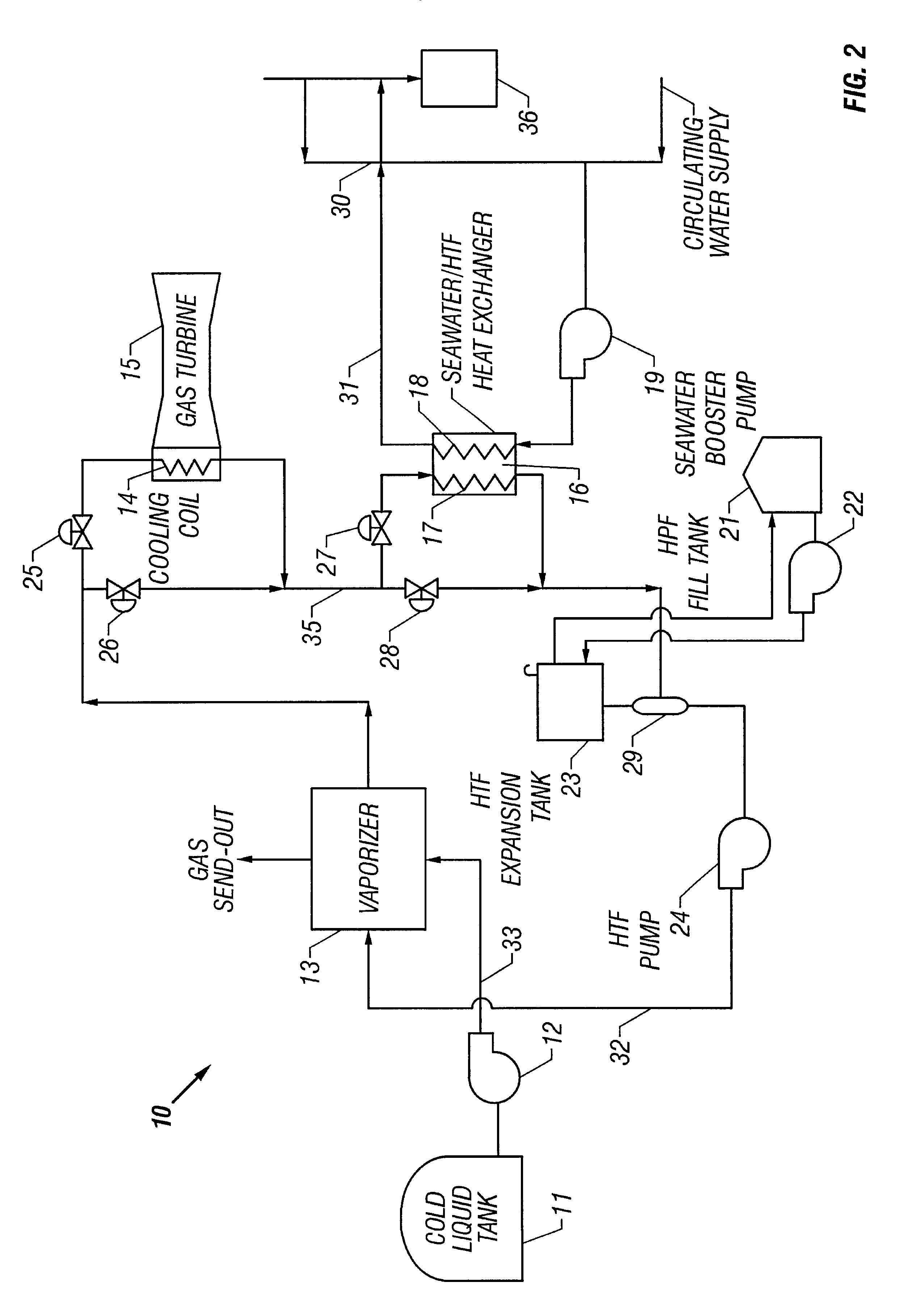

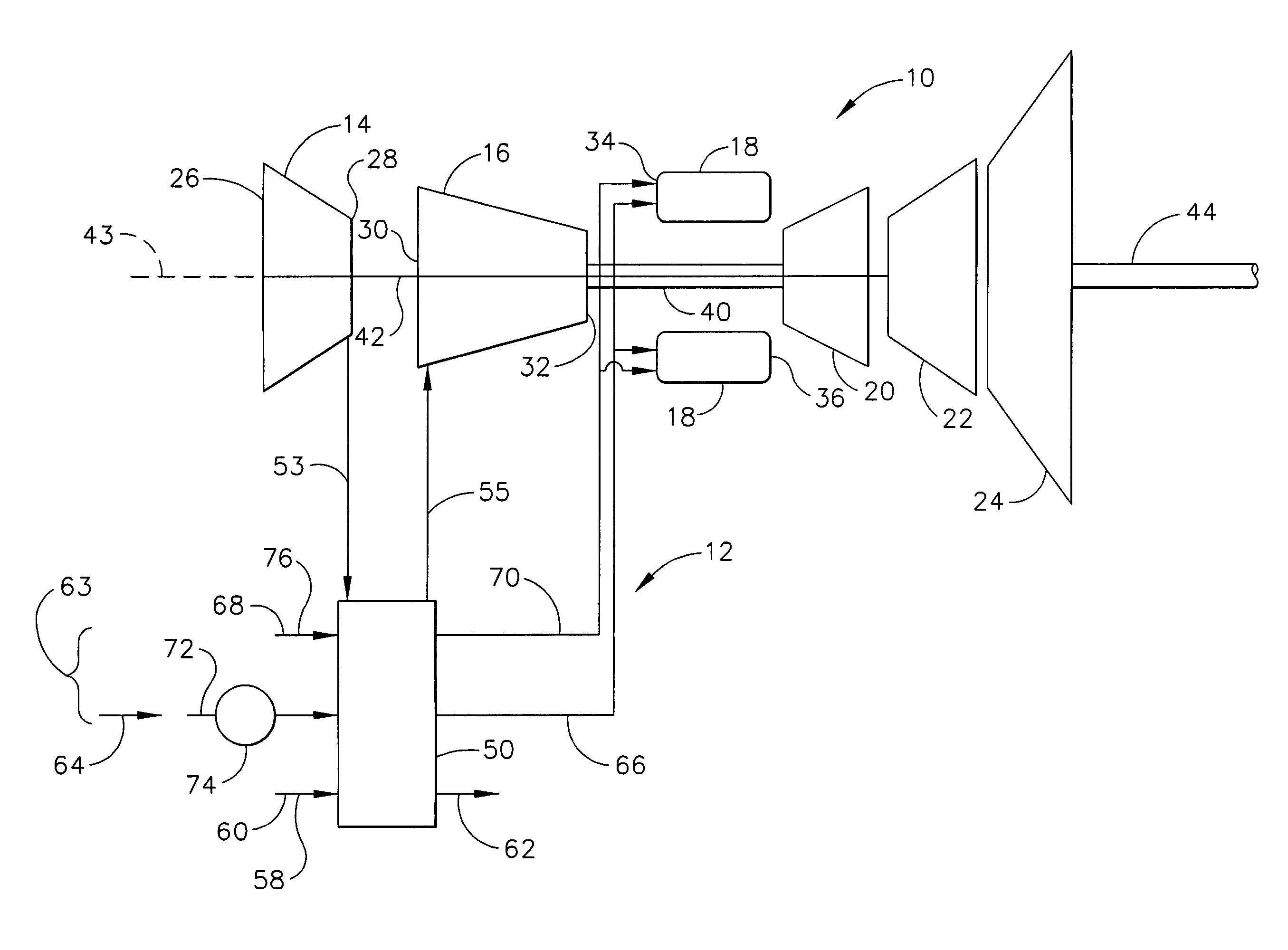

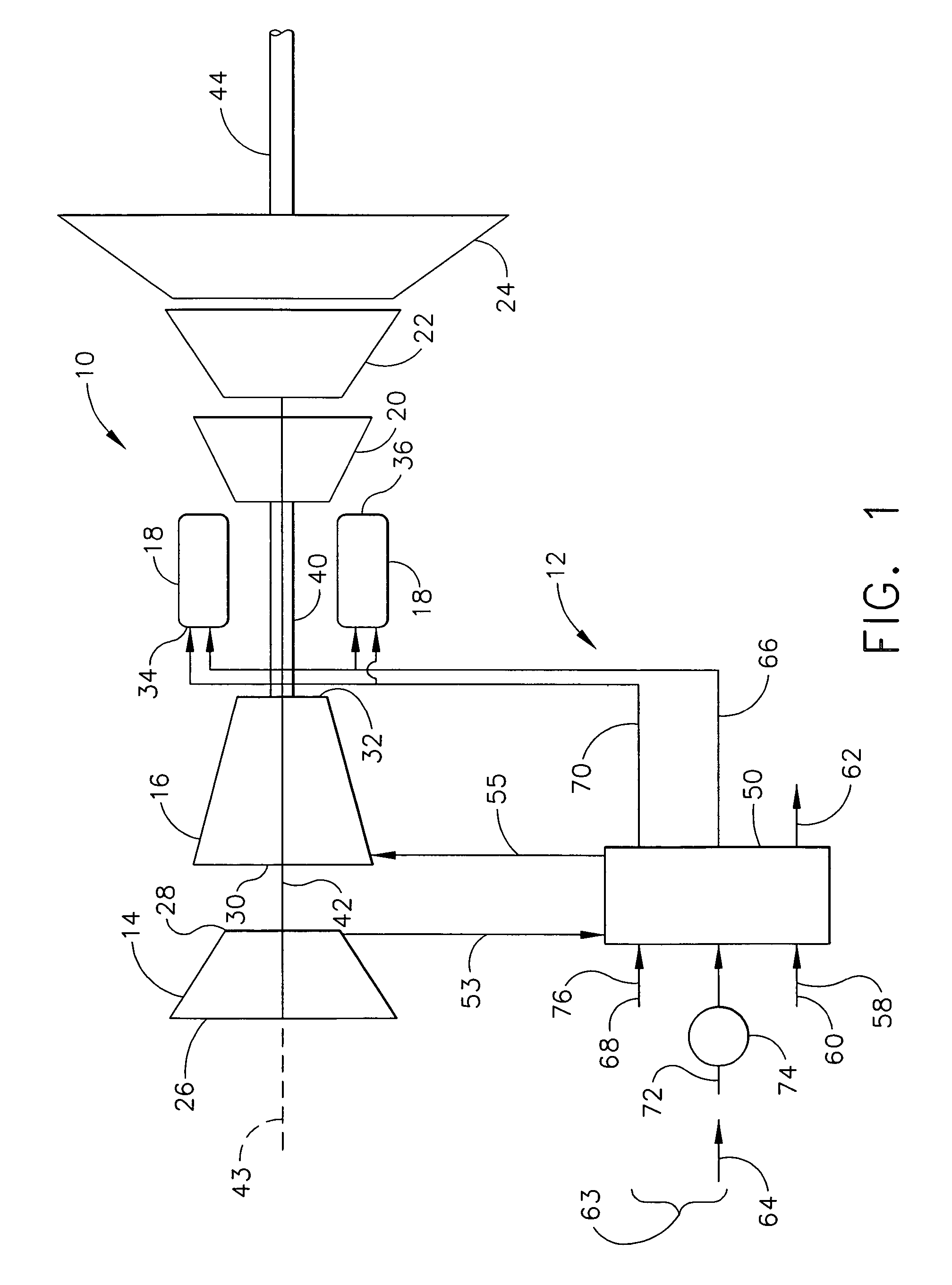

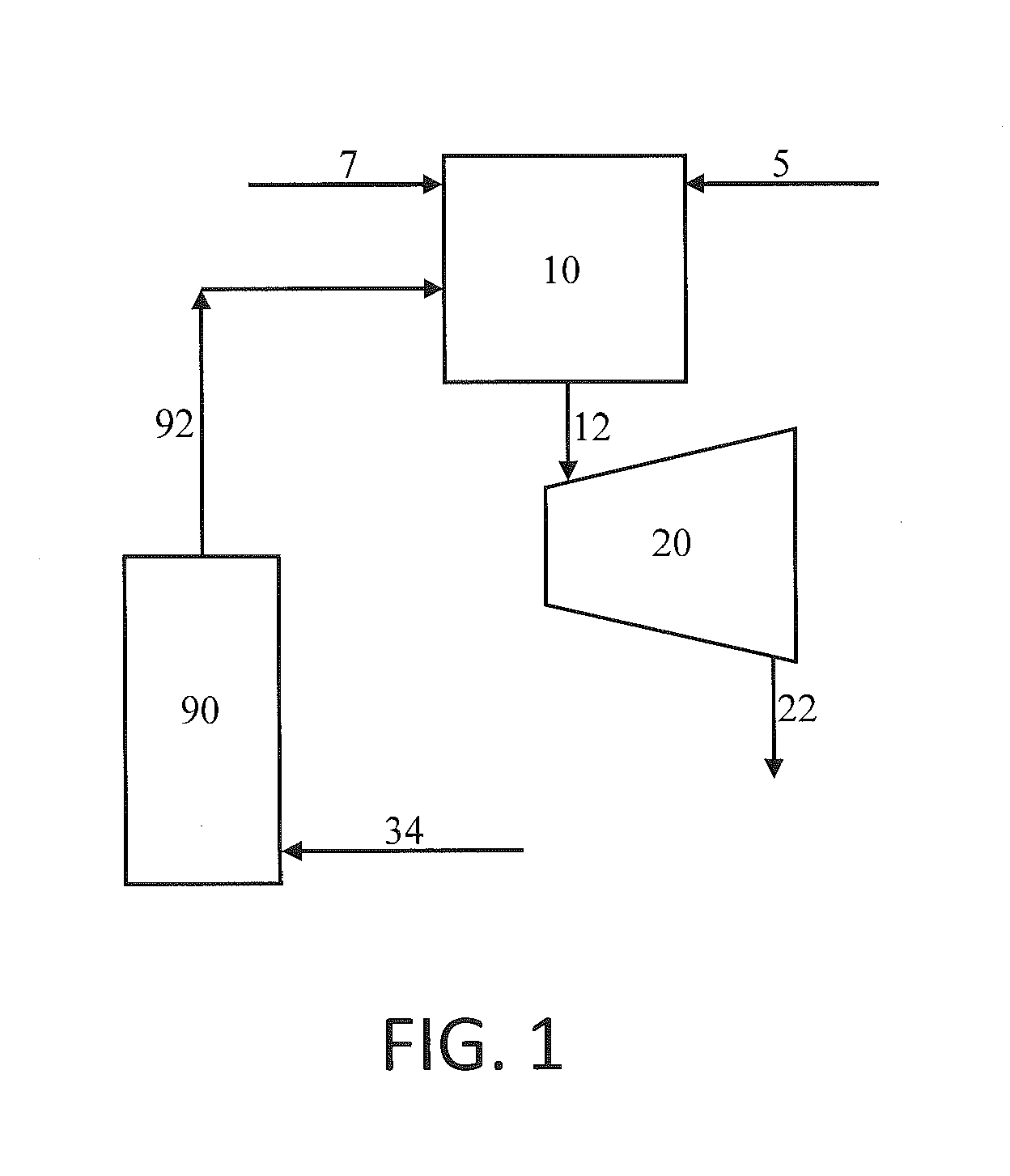

Method and apparatus for vaporizing liquid natural gas in a combined cycle power plant

InactiveUS6367258B1Turbine/propulsion engine coolingTurbine/propulsion fuel heatingPower stationProcess engineering

A method and apparatus for increasing the efficiency of a combined cycle generation plant by assisting the vaporization of cold liquid including liquefied natural gas ("LNG") or liquefied petroleum gas (LPG) in a combined cycle power plant. Cold liquid vaporization is assisted by circulating a warm heat transfer fluid to transfer heat to a LNG / LPG vaporizer. The heat transfer fluid is chilled by LNG / LPG cold liquid vaporization and warmed by heat from a gas turbine. The heat transfer fluid absorbs heat from the air intake of a gas turbine and from a secondary heat transfer fluid circulating in a combined cycle power plant. Chilling the gas turbine air intake densifies the air and increases the gas turbine output. Chilling the steam condenser cooling water increases steam turbine output. The effects of chill recovery is higher output and better efficiency of the combined cycle plant.

Owner:BECHTEL CORP

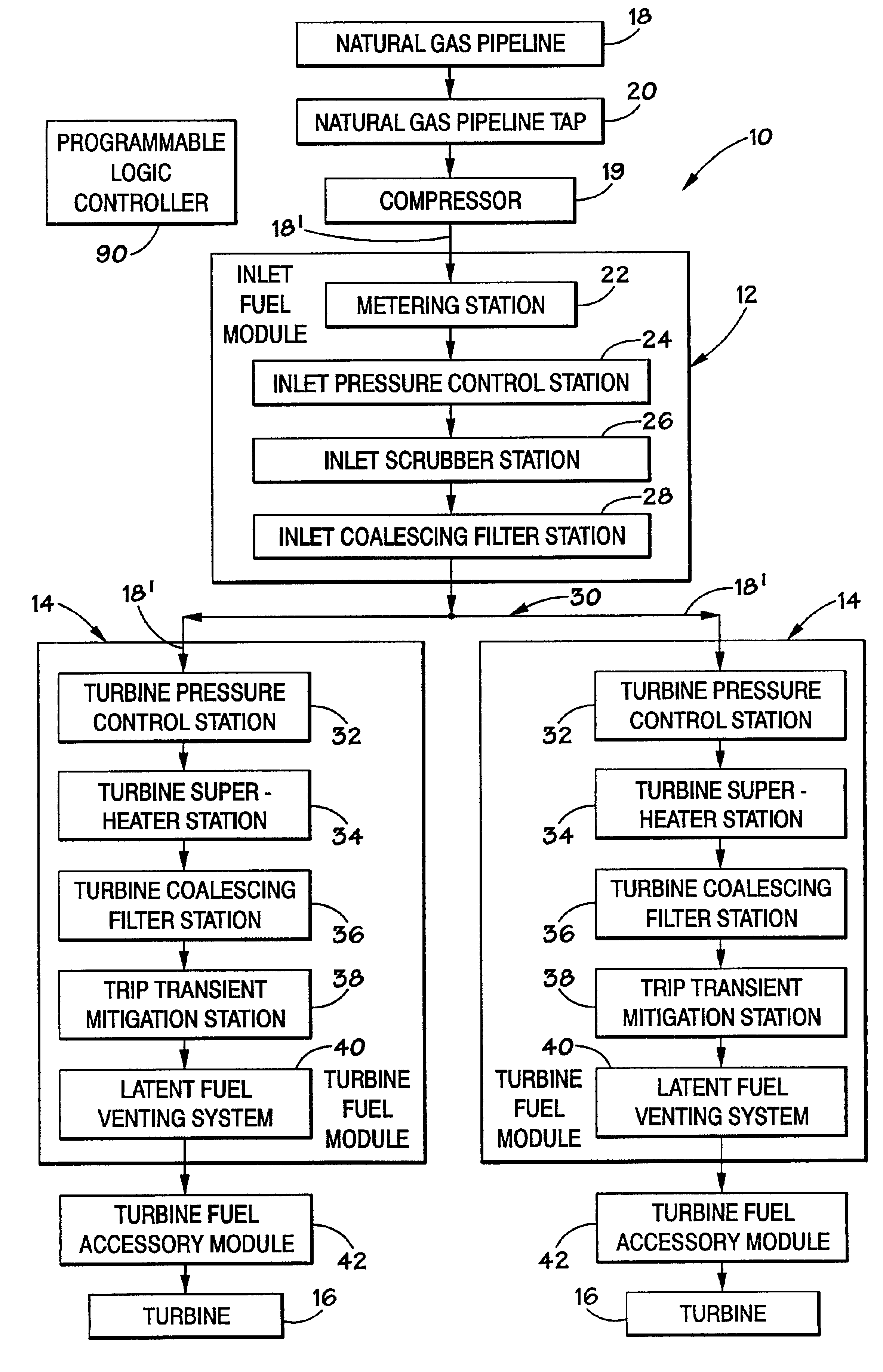

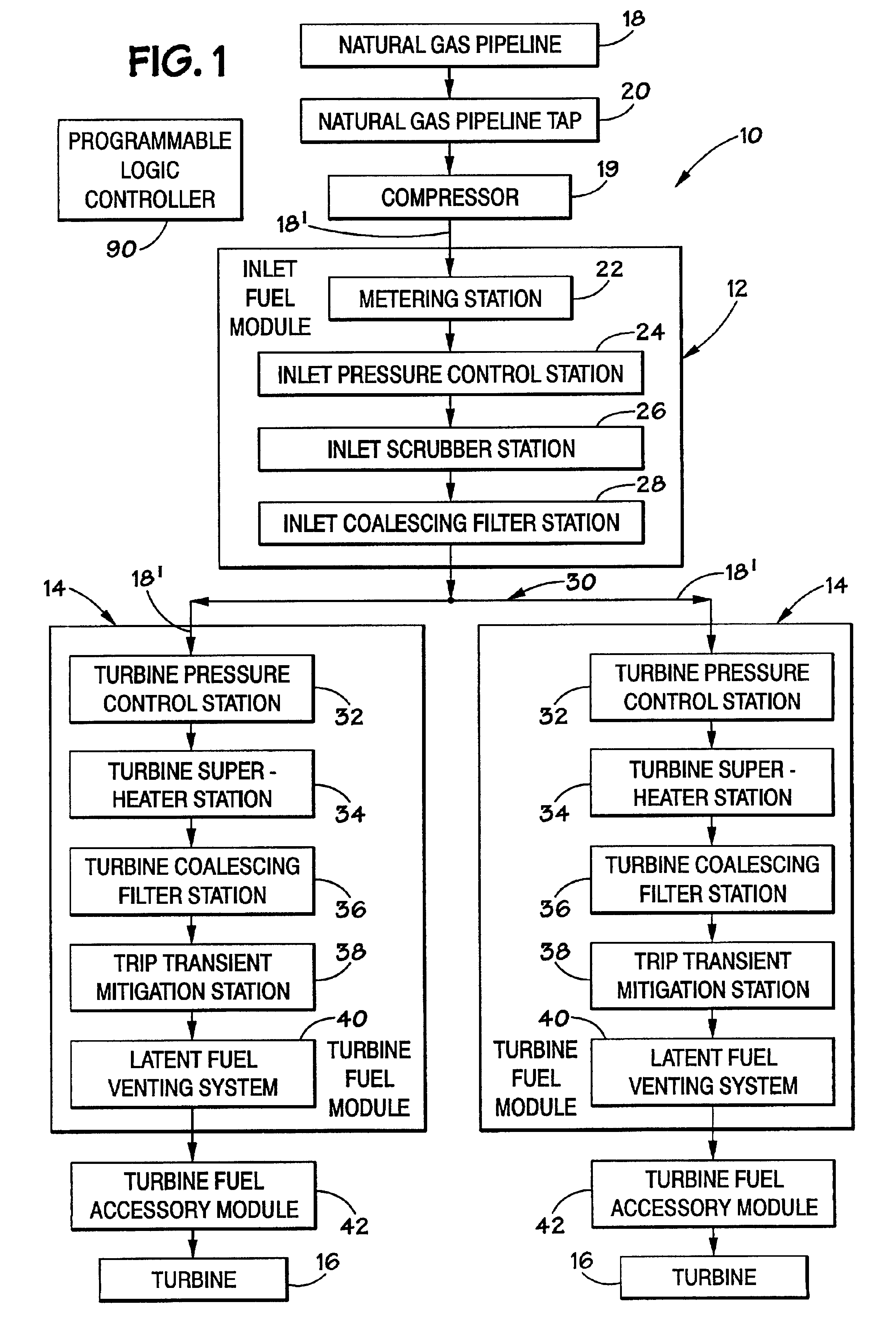

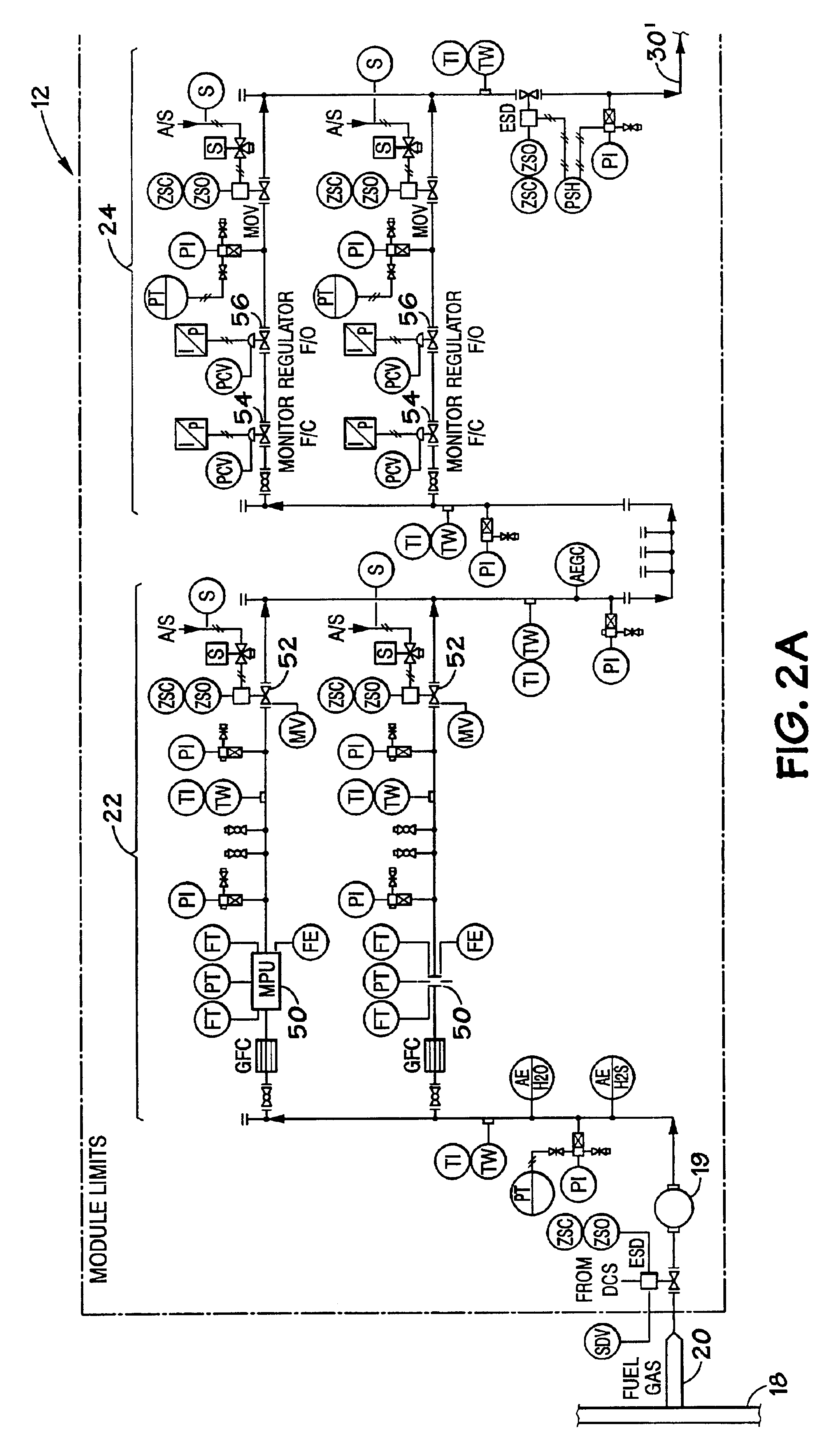

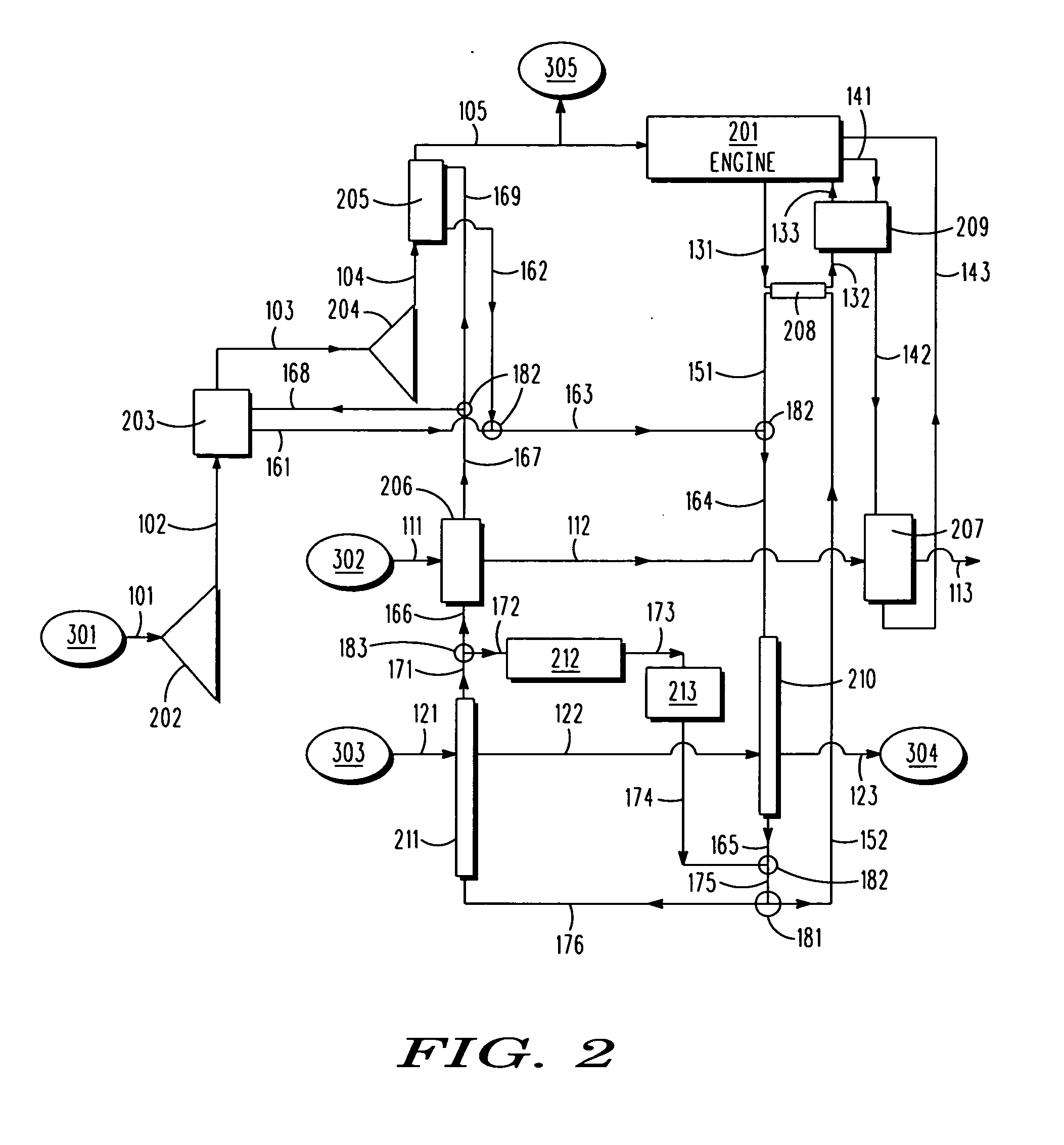

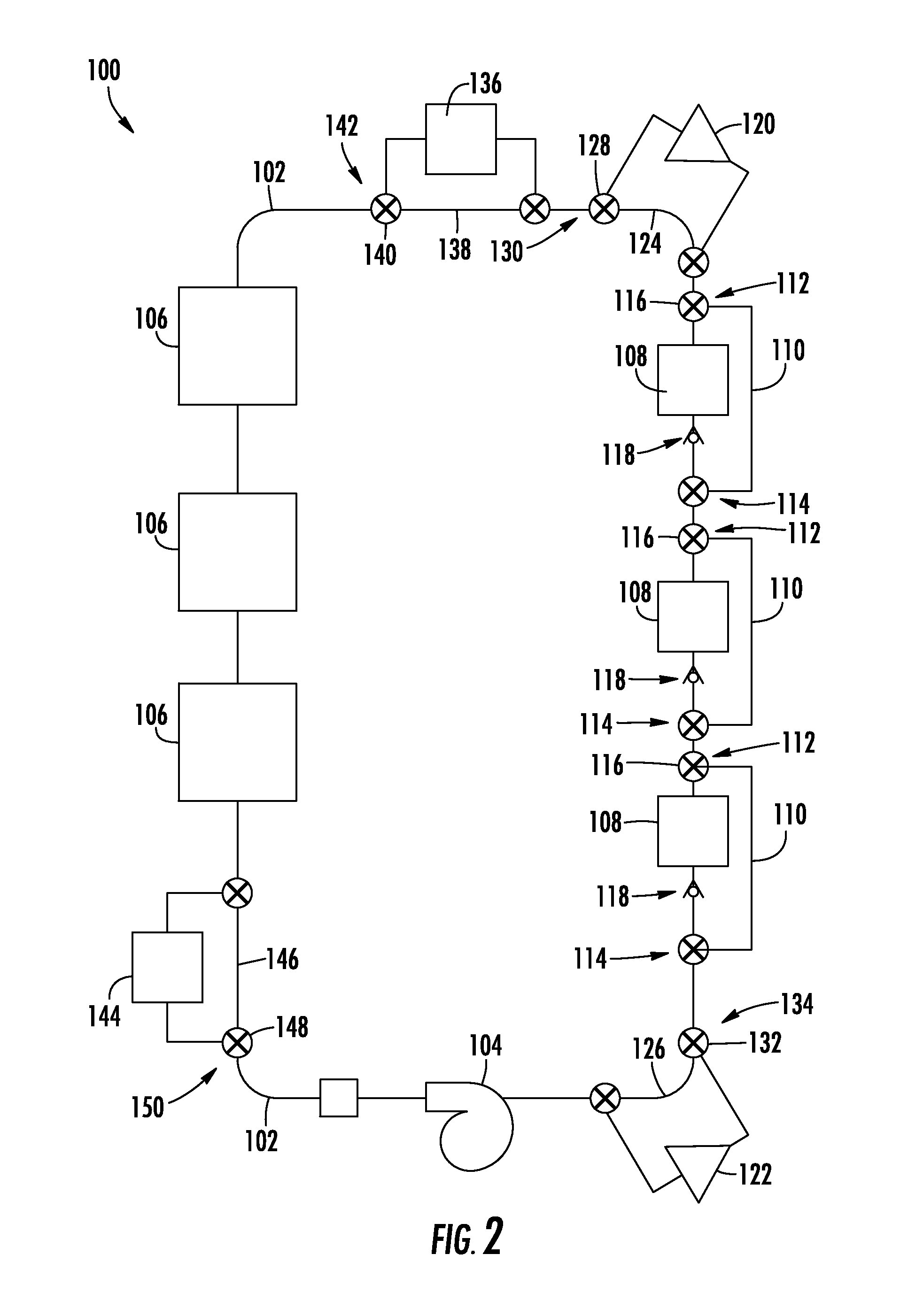

Modular fuel conditioning system

InactiveUS6901735B2Reduce pressureControl moreGas turbine plantsTurbine/propulsion fuel heatingProgrammable logic controllerModularity

A fuel conditioning system for a turbine plant may include an inlet fuel module followed by a turbine fuel module for each turbine, the modules being monitored and controlled by a programmable logic controller. The inlet fuel module may include a metering station, an inlet pressure control station, an inlet scrubber station, and an inlet coalescing filter station. Each turbine fuel module has a turbine pressure control station, a turbine super-heater station, and a turbine coalescing filter station. The fuel conditioning system may also include a trip transient mitigation system and a latent fuel venting system. The programmable logic controller collects data from all of the stations and systems as well as the turbine and then uses self-correcting algorithms to control the stations and systems. The programmable logic controller also stores the data collected and transmits the data to an off-site storage and verification center.

Owner:PIPELINE CONTROLS

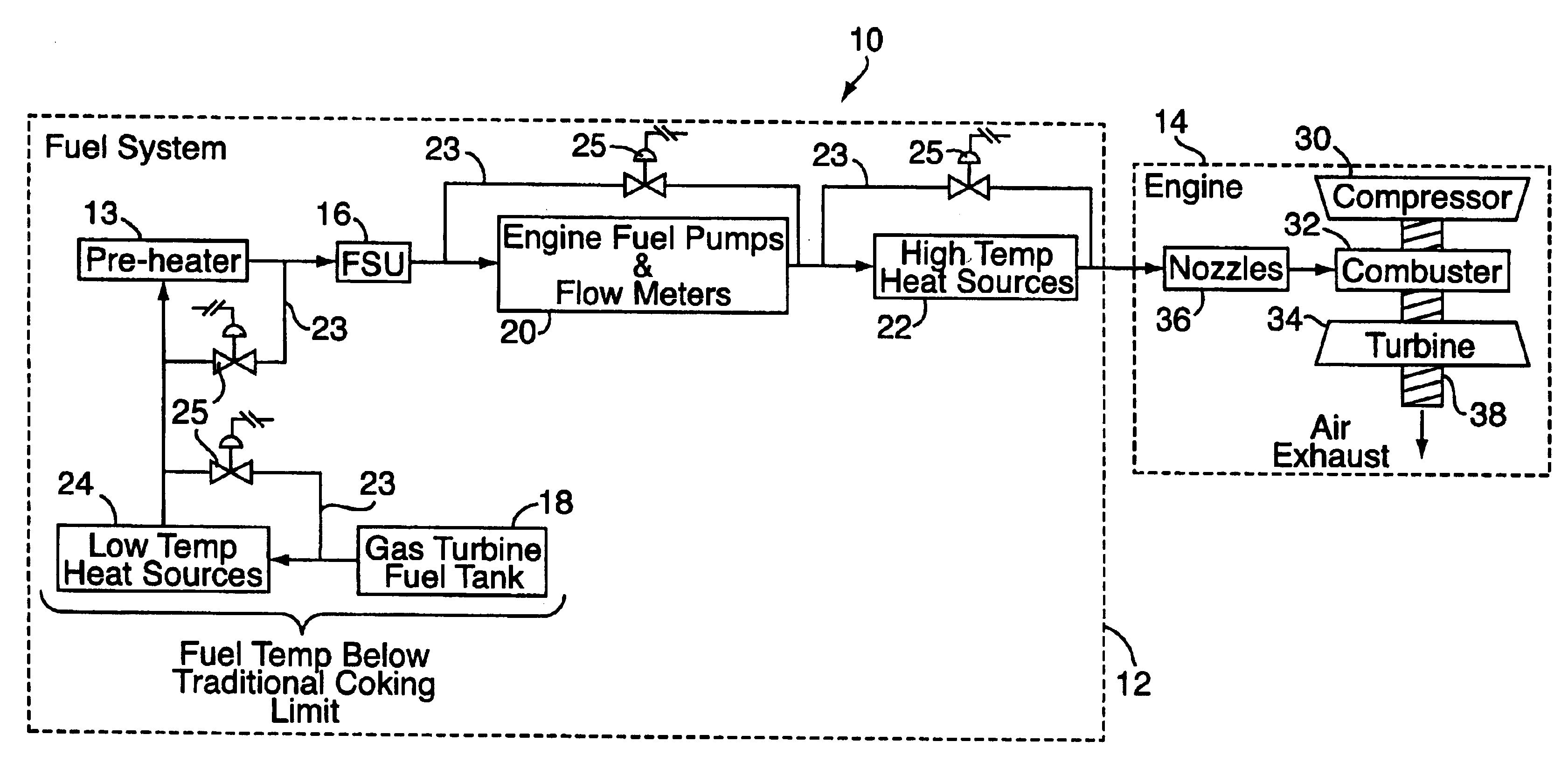

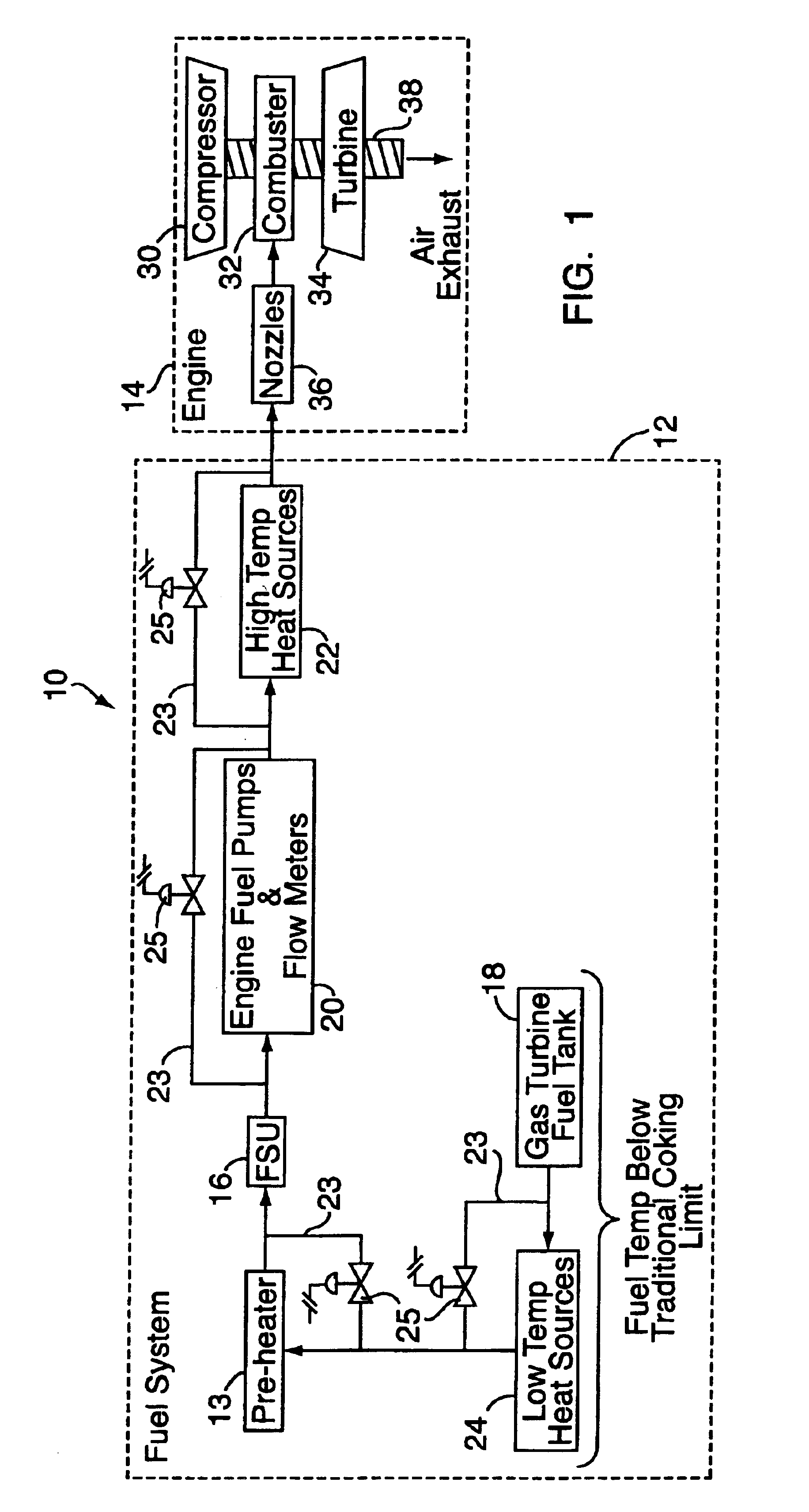

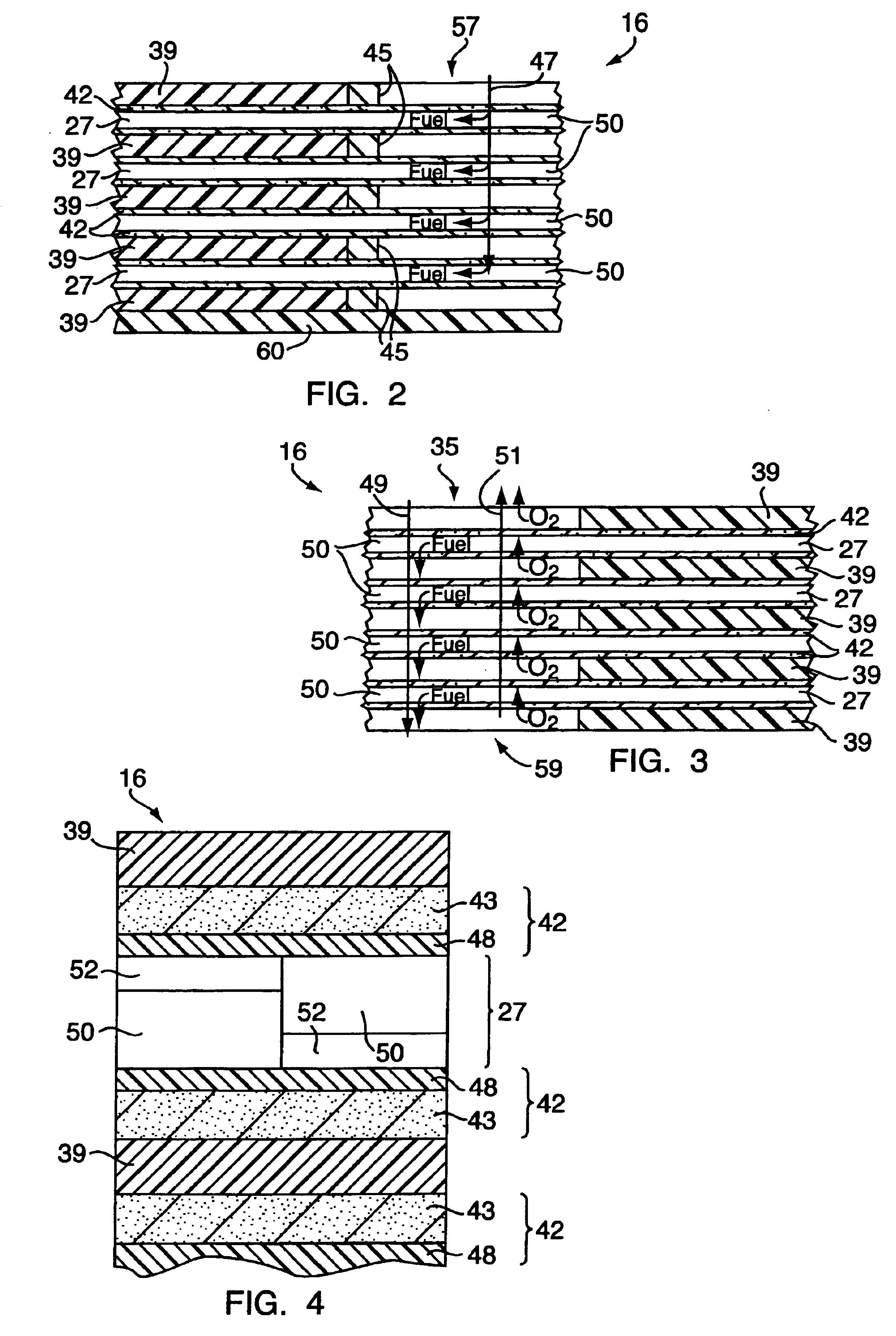

System and method for thermal management

InactiveUS6939392B2Increase in exploitable cooling capacity of fuelImprove cooling effectCombination devicesSemi-permeable membranesOxygenTurbine

A system for the management of thermal transfer in a gas turbine engine includes a heat generating sub-system in operable communication with the engine, a fuel source to supply a fuel, a fuel stabilization unit to receive the fuel from the fuel source and to provide the fuel to the engine, and a heat exchanger in thermal communication with the fuel to transfer heat from the heat generating sub-system to the fuel. A method of managing thermal transfer in an aircraft includes removing oxygen from a stream of a fuel fed to an engine used to drive the aircraft, transferring heat from a heat generating sub-system of the aircraft to the fuel, and combusting the fuel. A system for the thermal management of an aircraft provides for powering the aircraft, supplying a fuel deoxygenating the fuel, and transferring heat between a heat generating sub-system of the aircraft and the fuel.

Owner:RAYTHEON TECH CORP

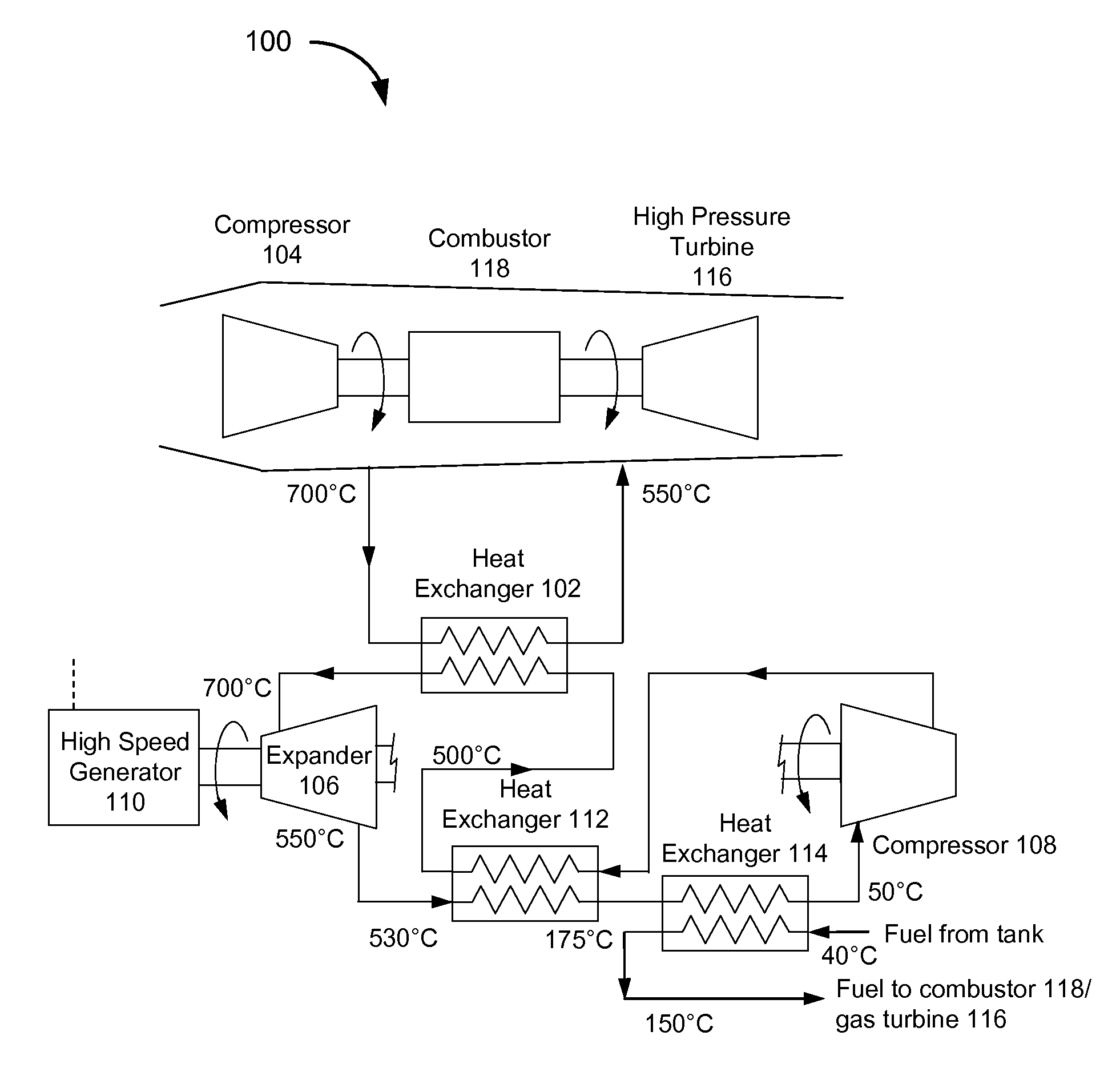

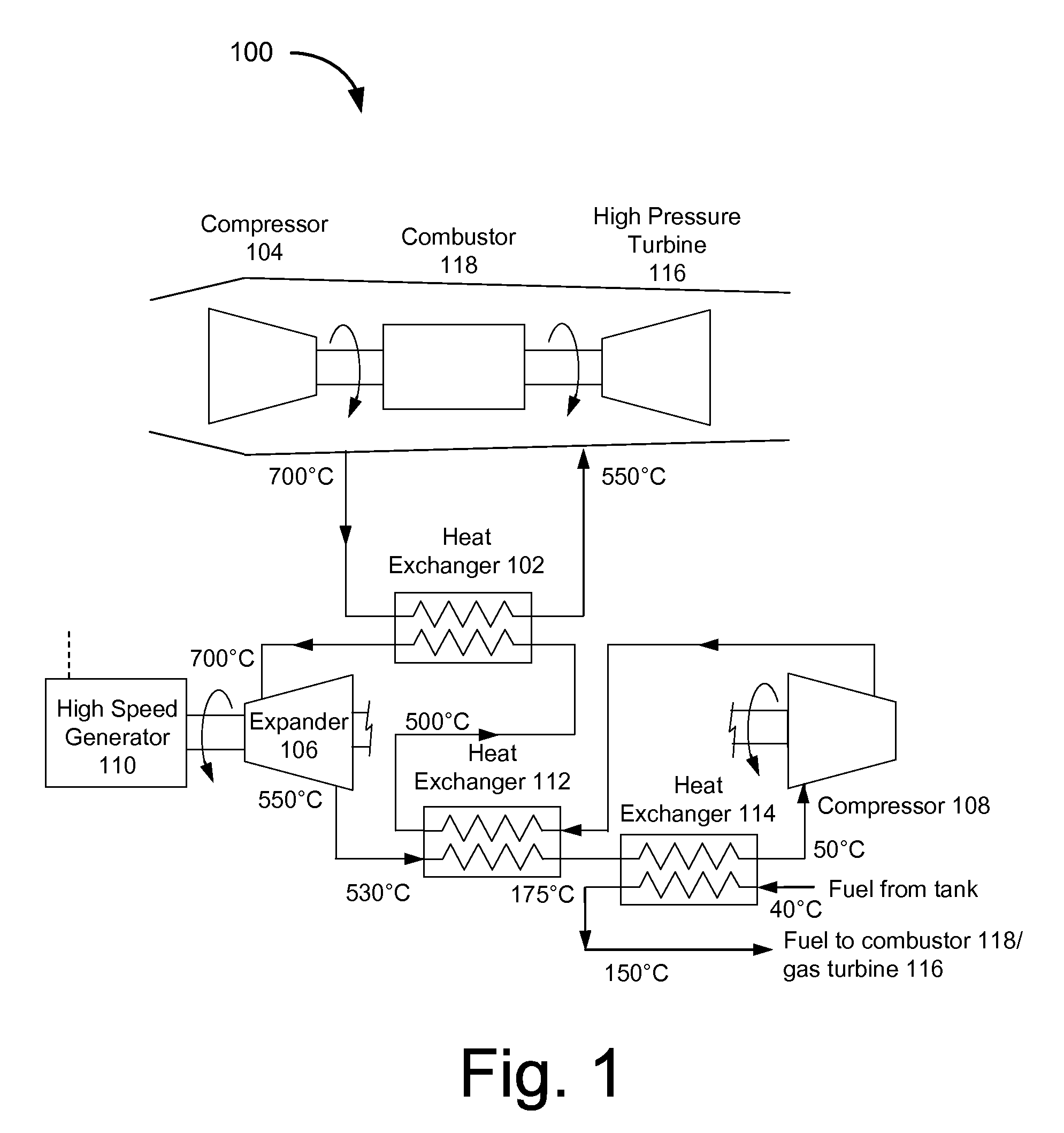

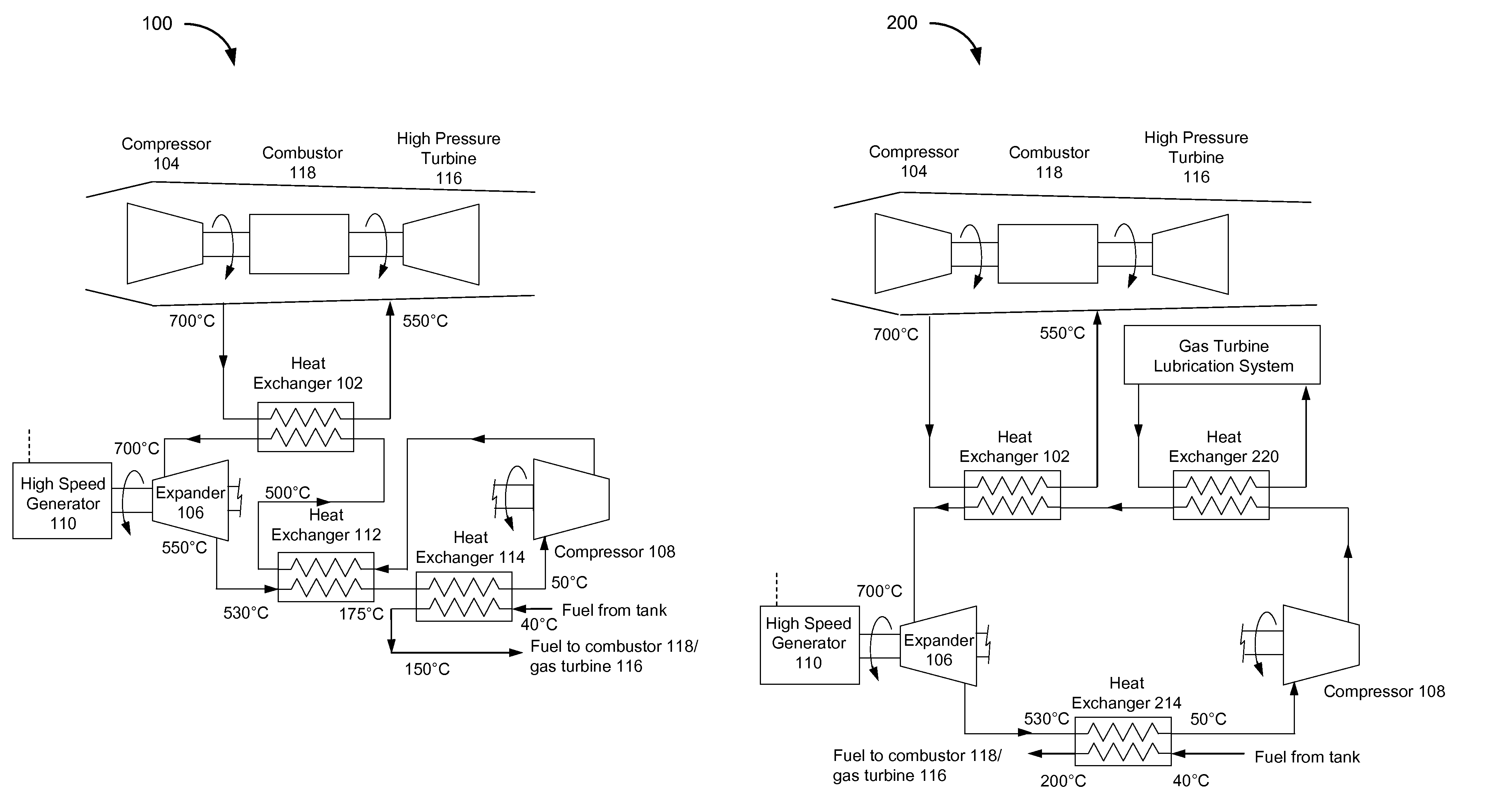

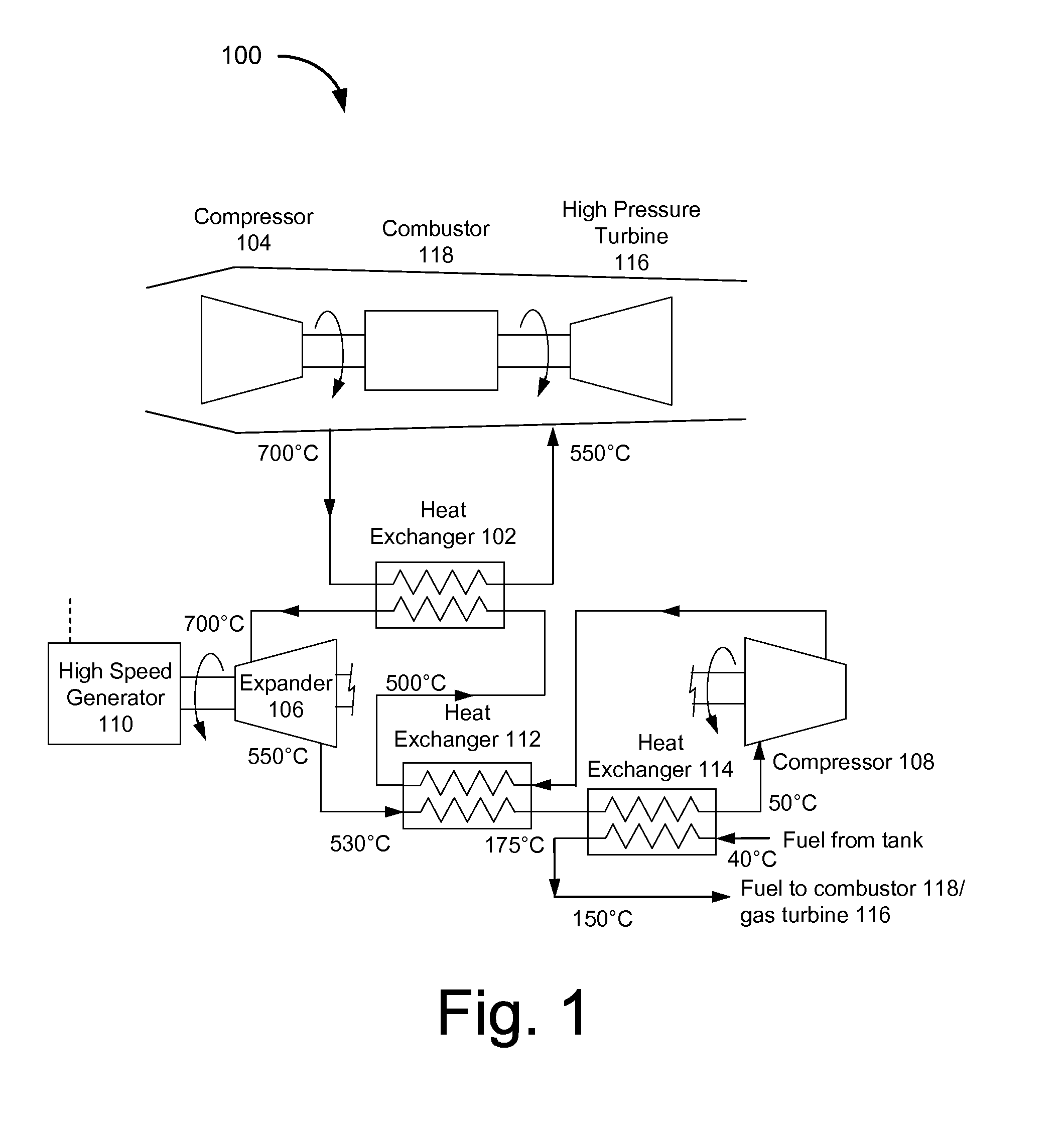

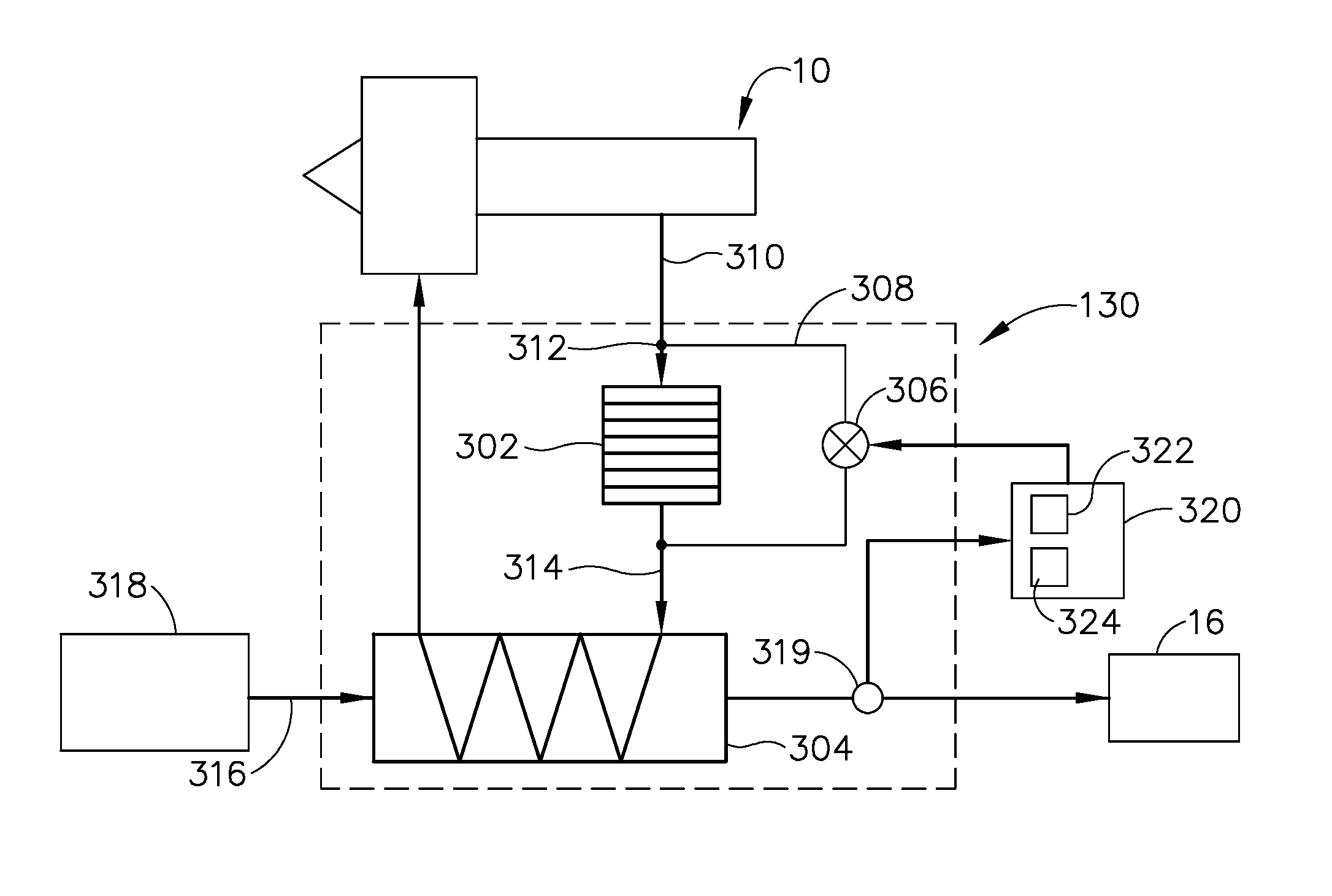

System and method for managing thermal issues in gas turbine engines

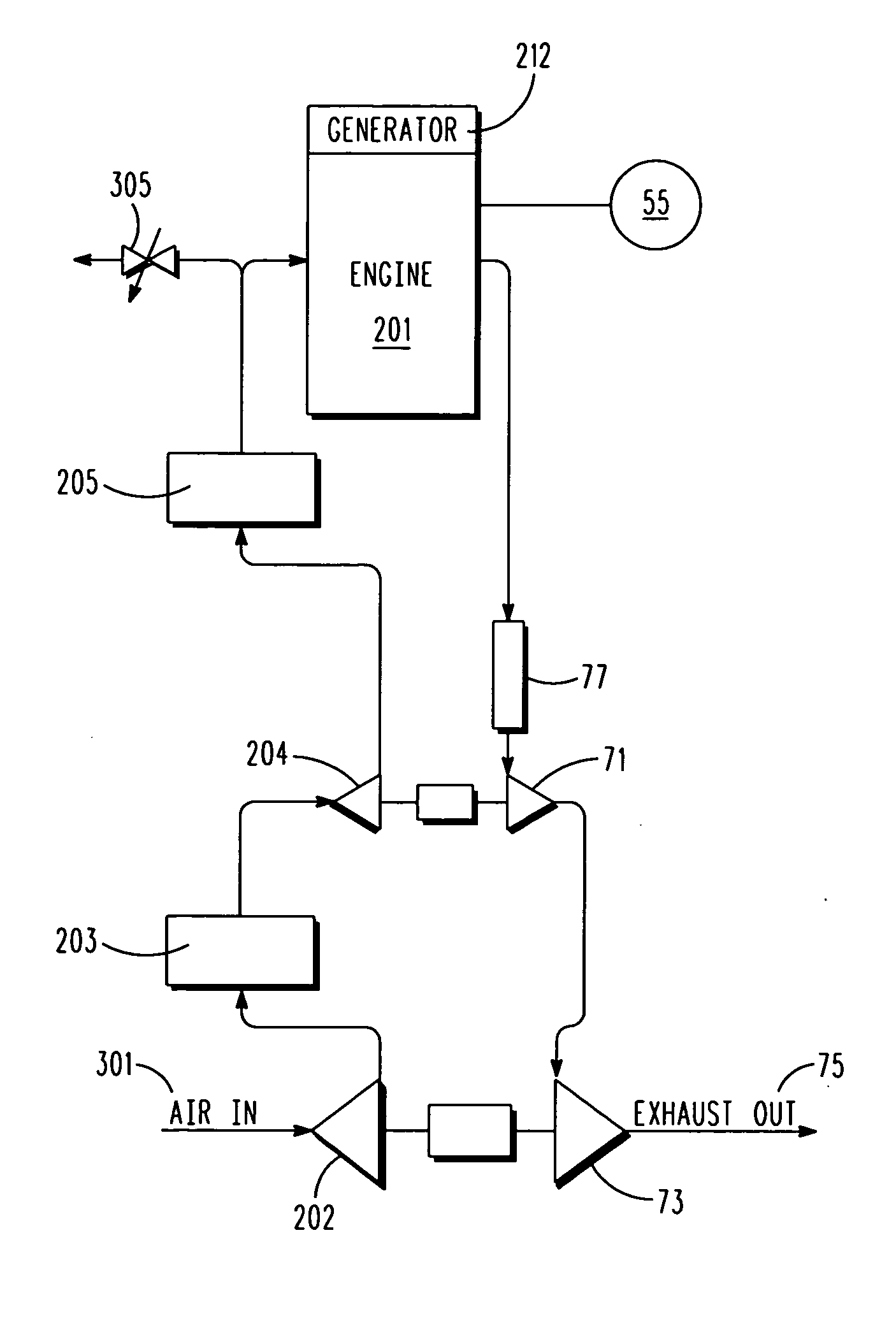

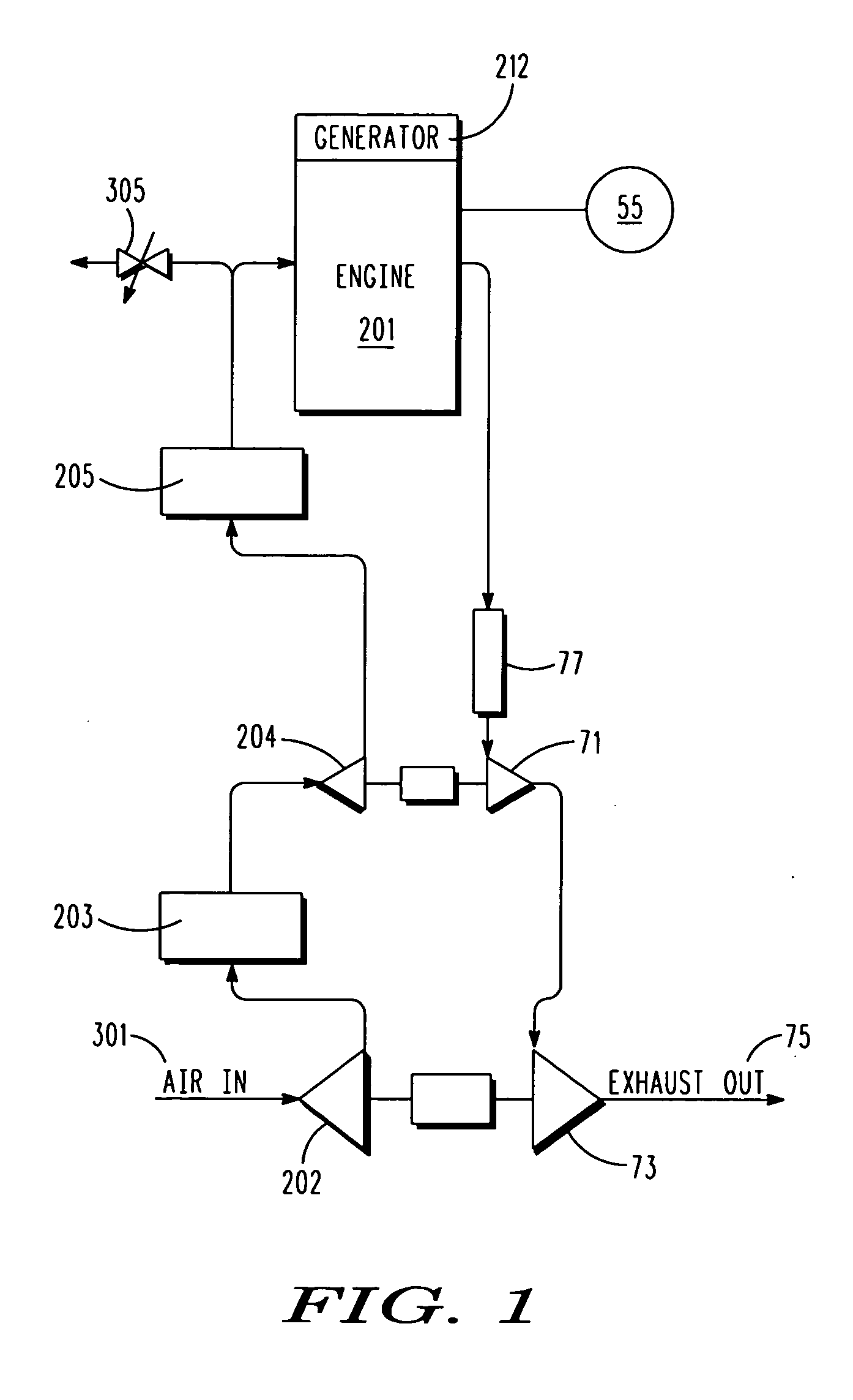

ActiveUS20120067055A1Turbine/propulsion engine coolingTurbine/propulsion fuel heatingEngineeringTurbine

The present invention generally relates to a system that enables one to address various thermal management issues in advanced gas turbine engines. In one embodiment, the present invention relates to a method to extract heat from an air stream, utilize a significant fraction for on-board power generation, and reject a small quantity of heat to the fuel stream safely at, for example, a lower temperature. In another embodiment, the present invention relates to a method to extract heat from an air stream, utilize a significant fraction for on-board power generation, and reject a small quantity of heat to the fuel stream safely at, for example, a lower temperature with no potential air / fuel contact is disclosed.

Owner:ECHOGEN POWER SYST

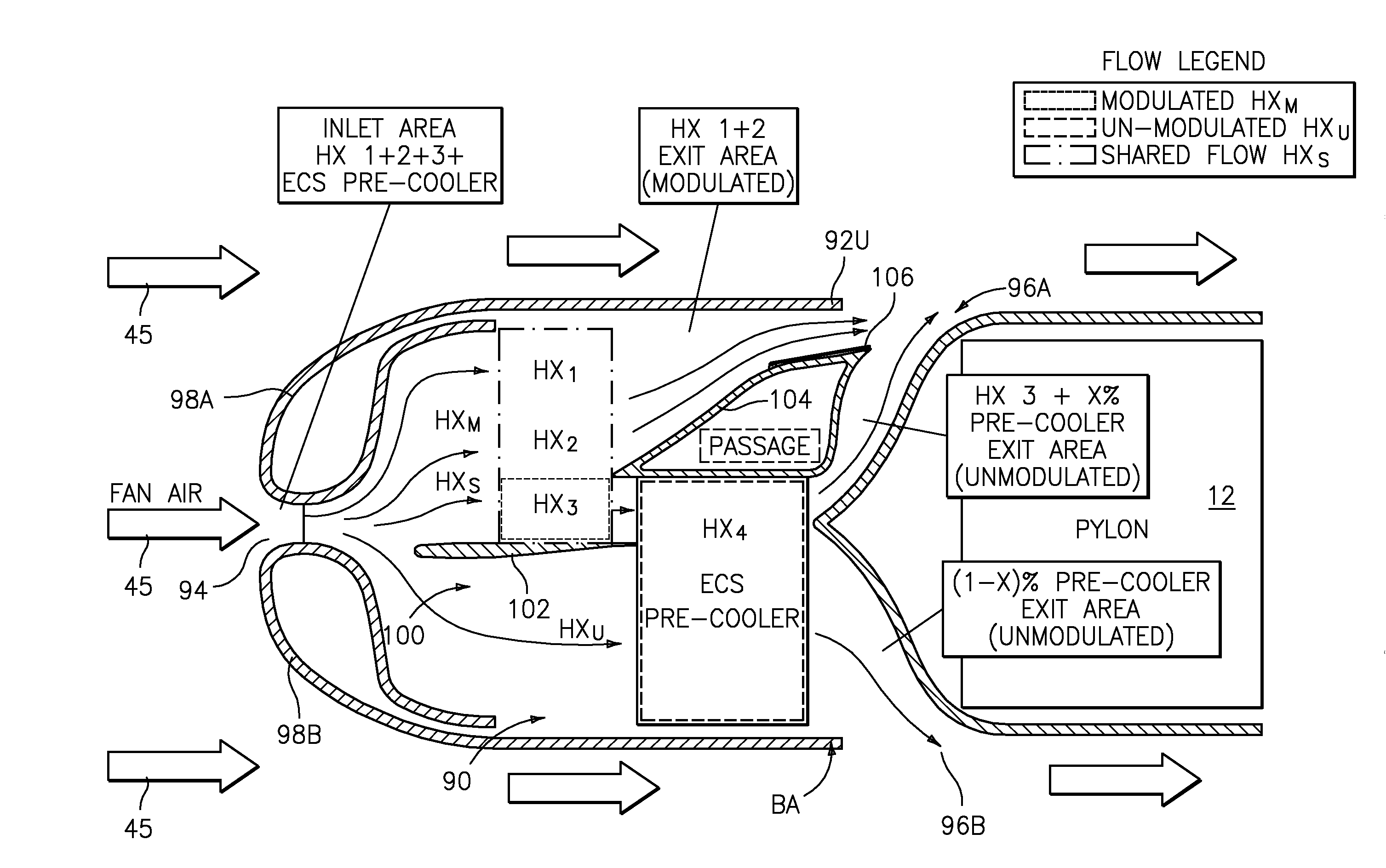

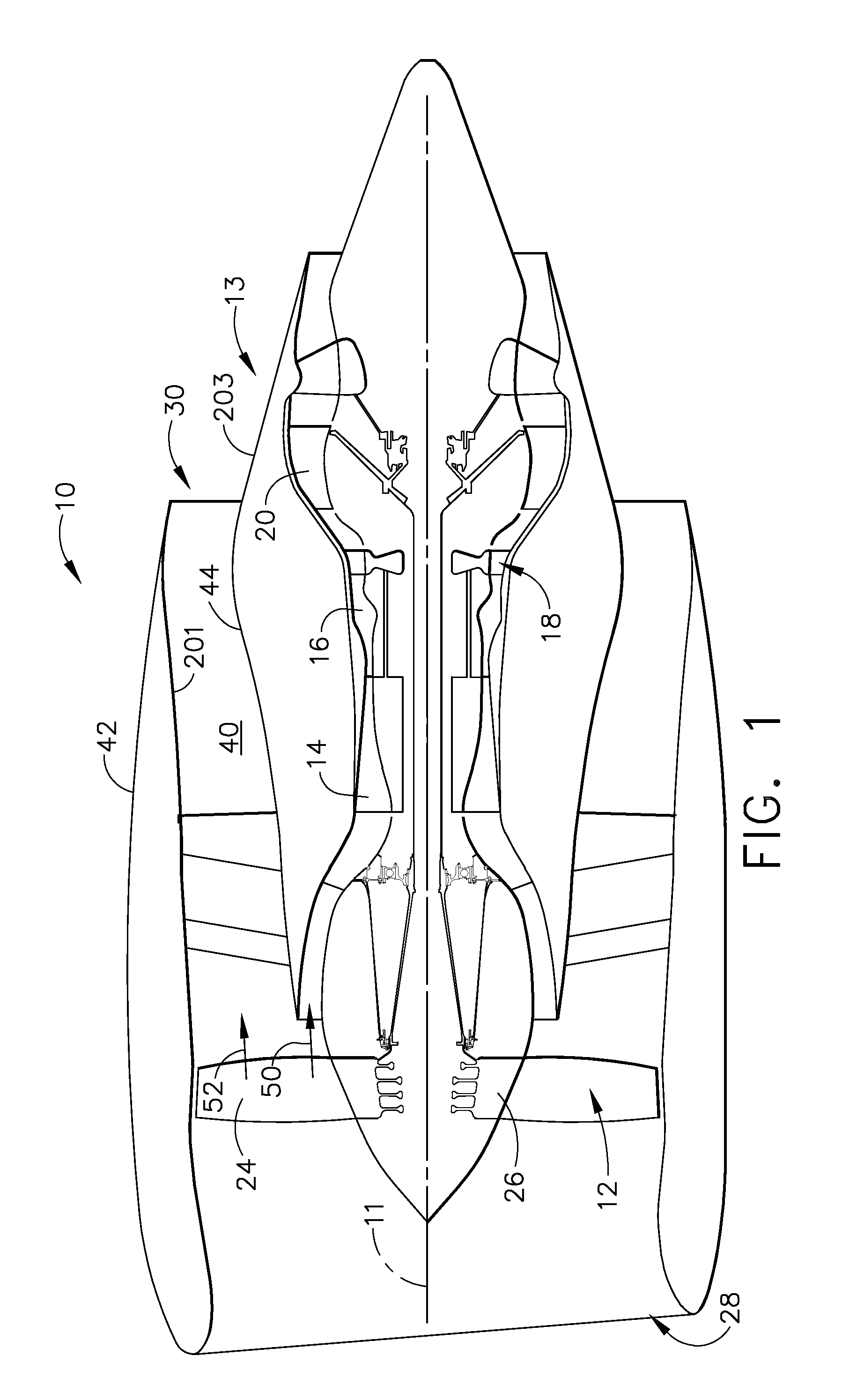

Shared flow thermal management system

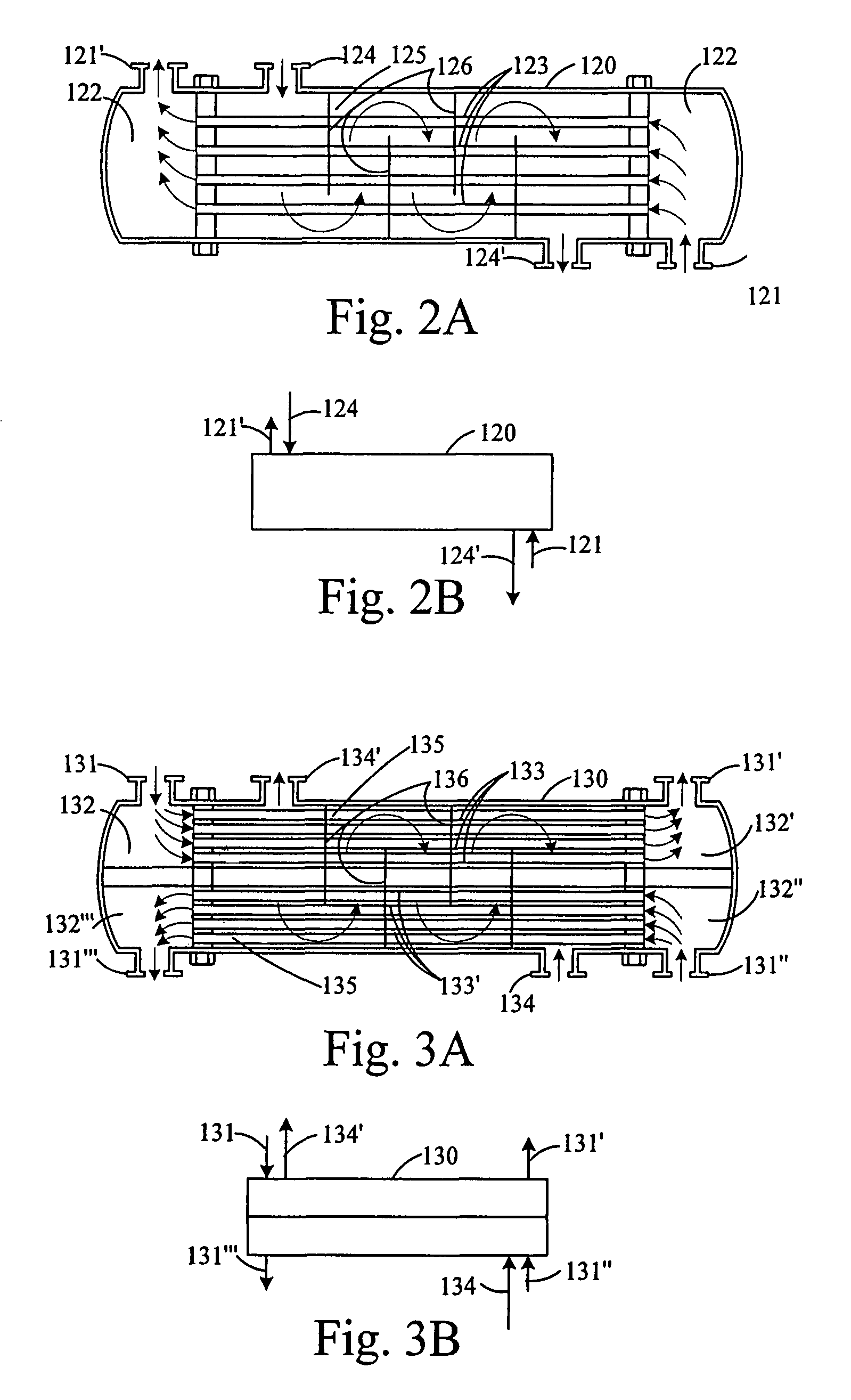

ActiveUS20090188234A1Turbine/propulsion engine coolingTurbine/propulsion fuel heatingThermal management systemEngineering

A thermal management system includes at least two of a multiple of heat exchangers arranged in an at least partial-series relationship.

Owner:RTX CORP

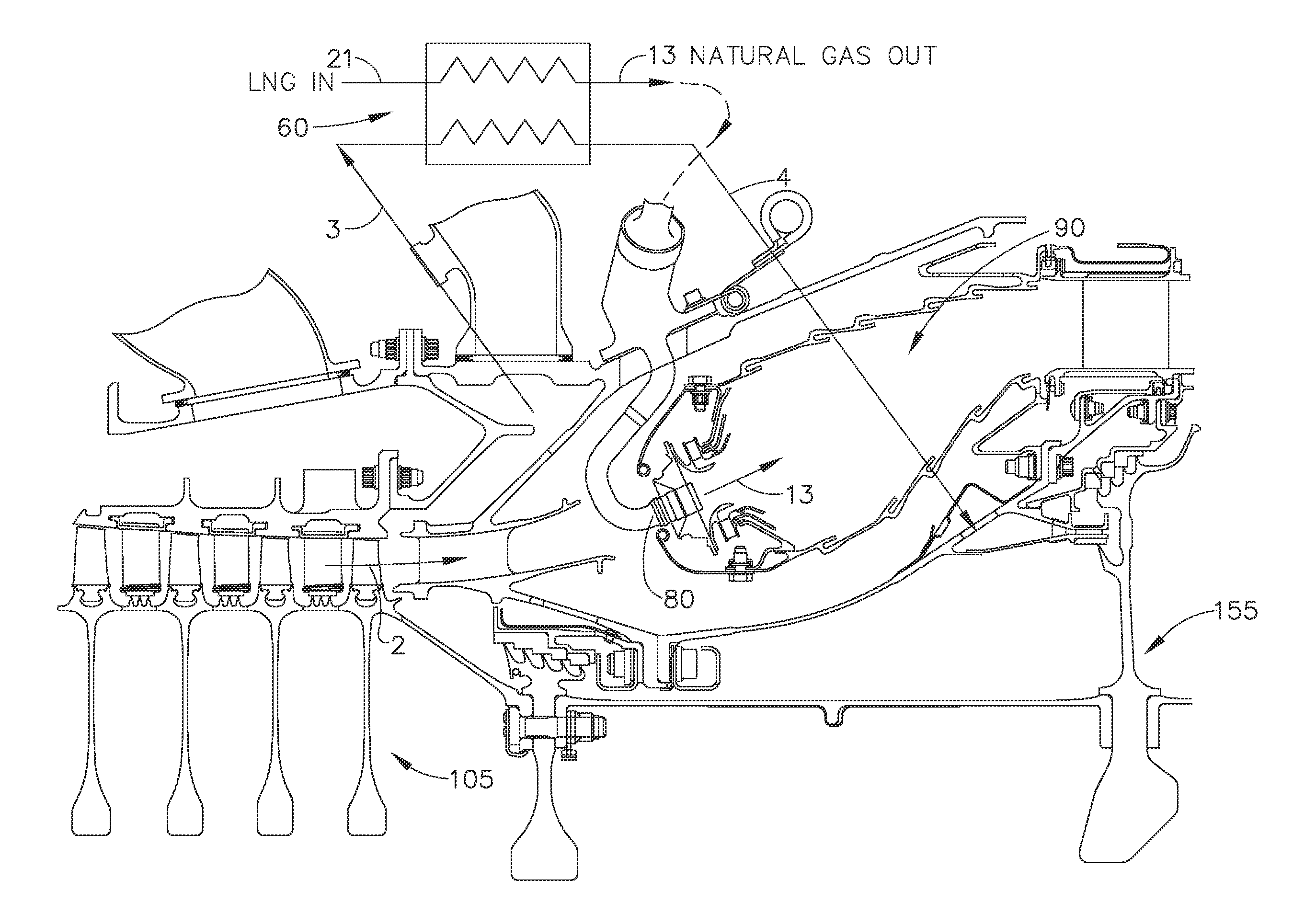

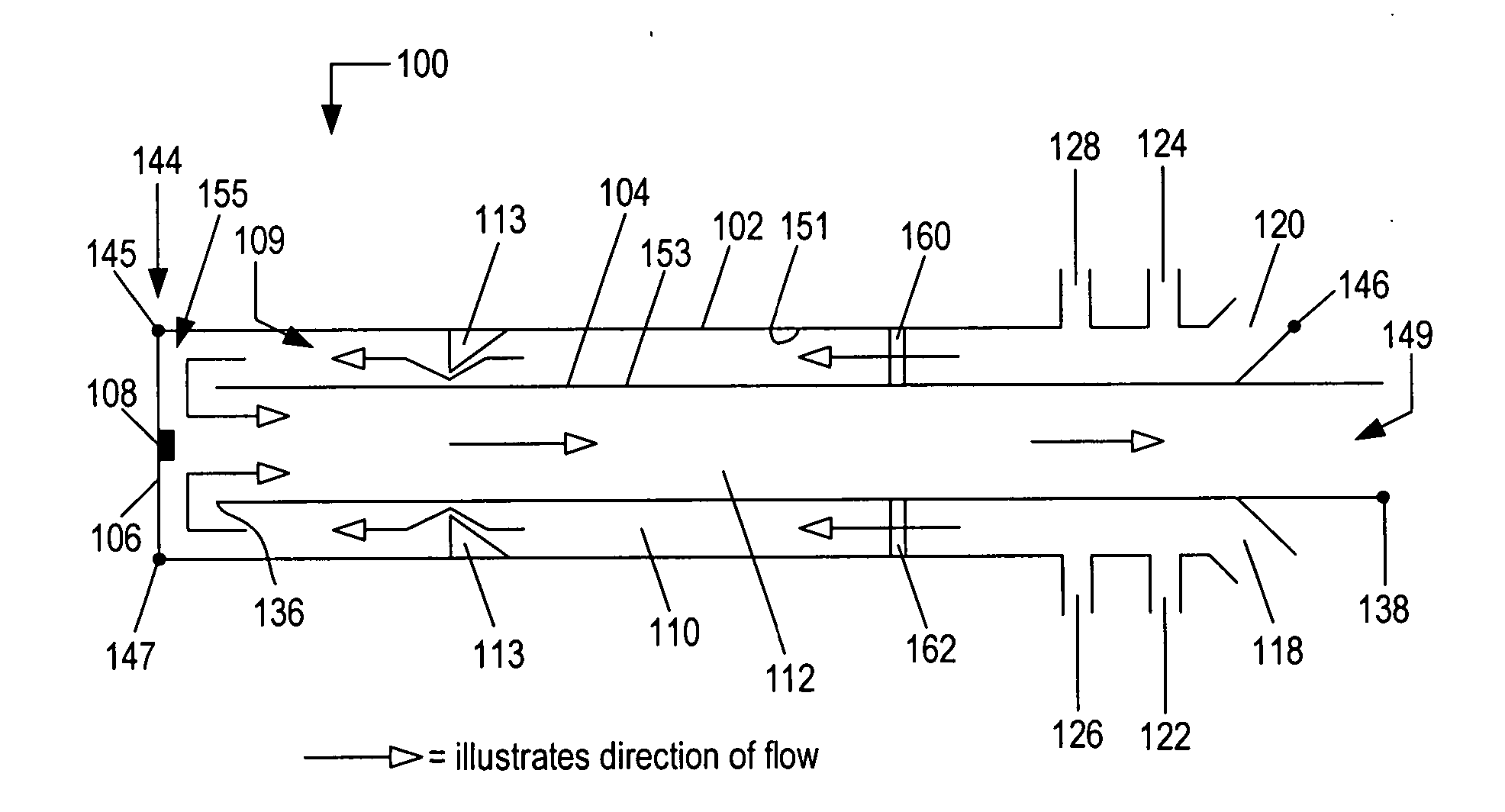

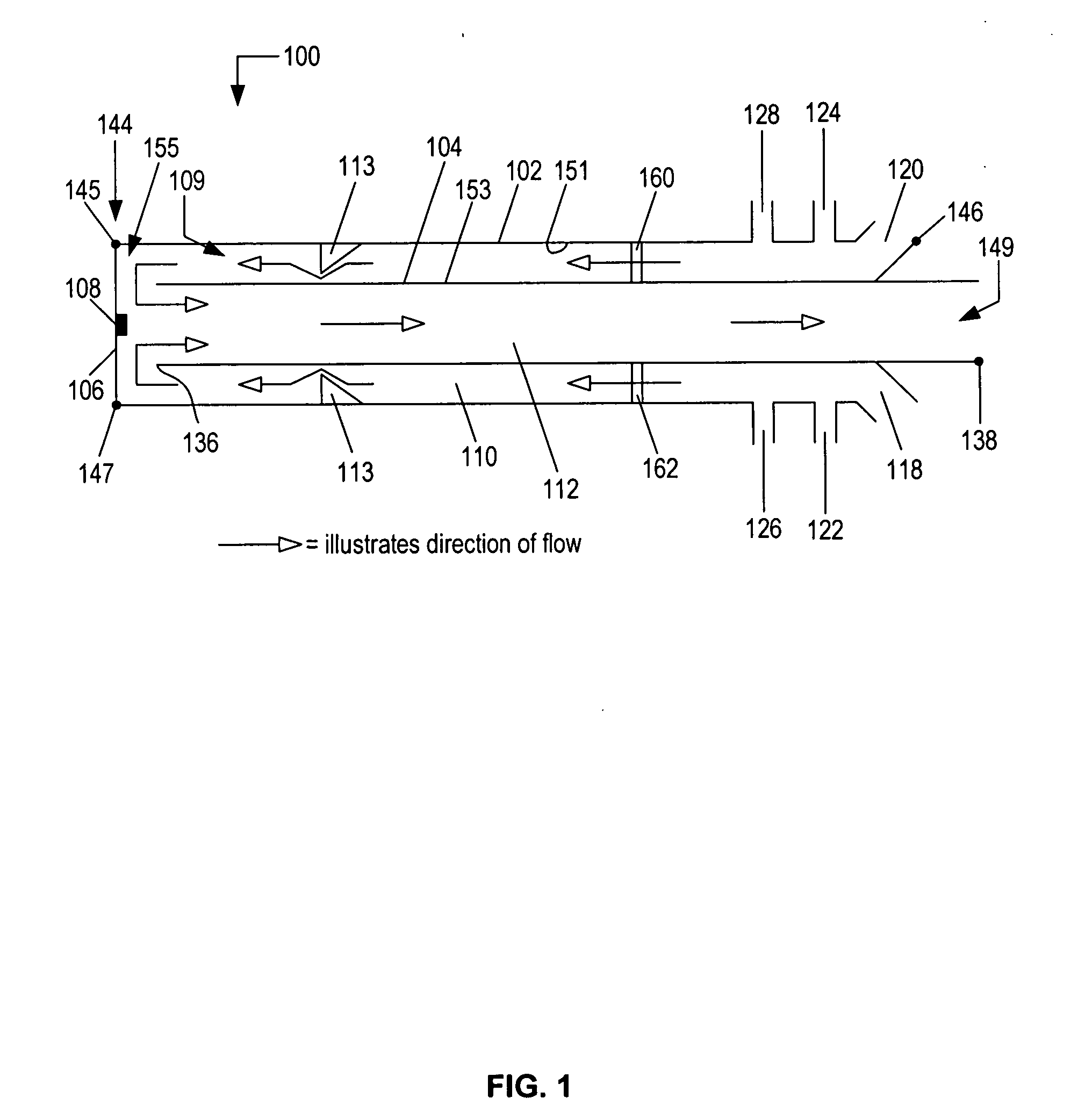

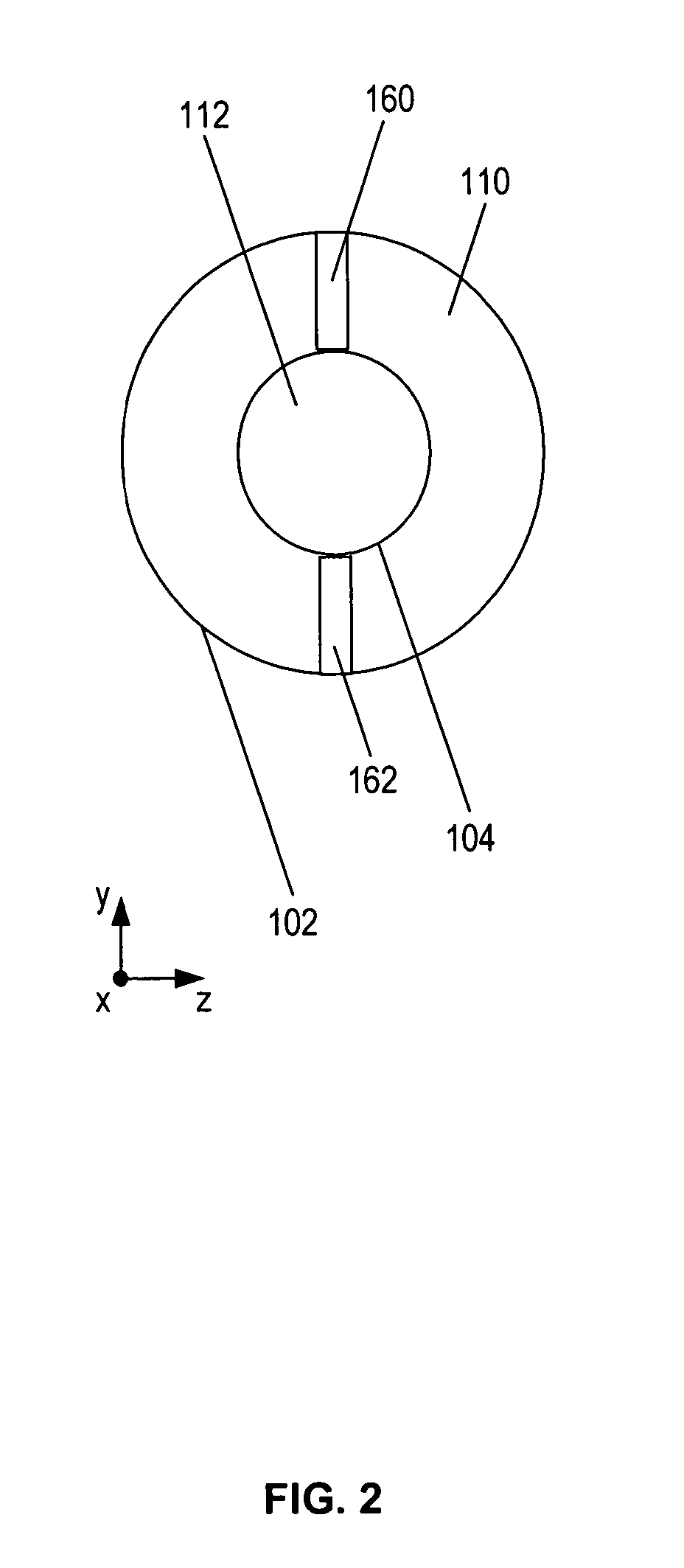

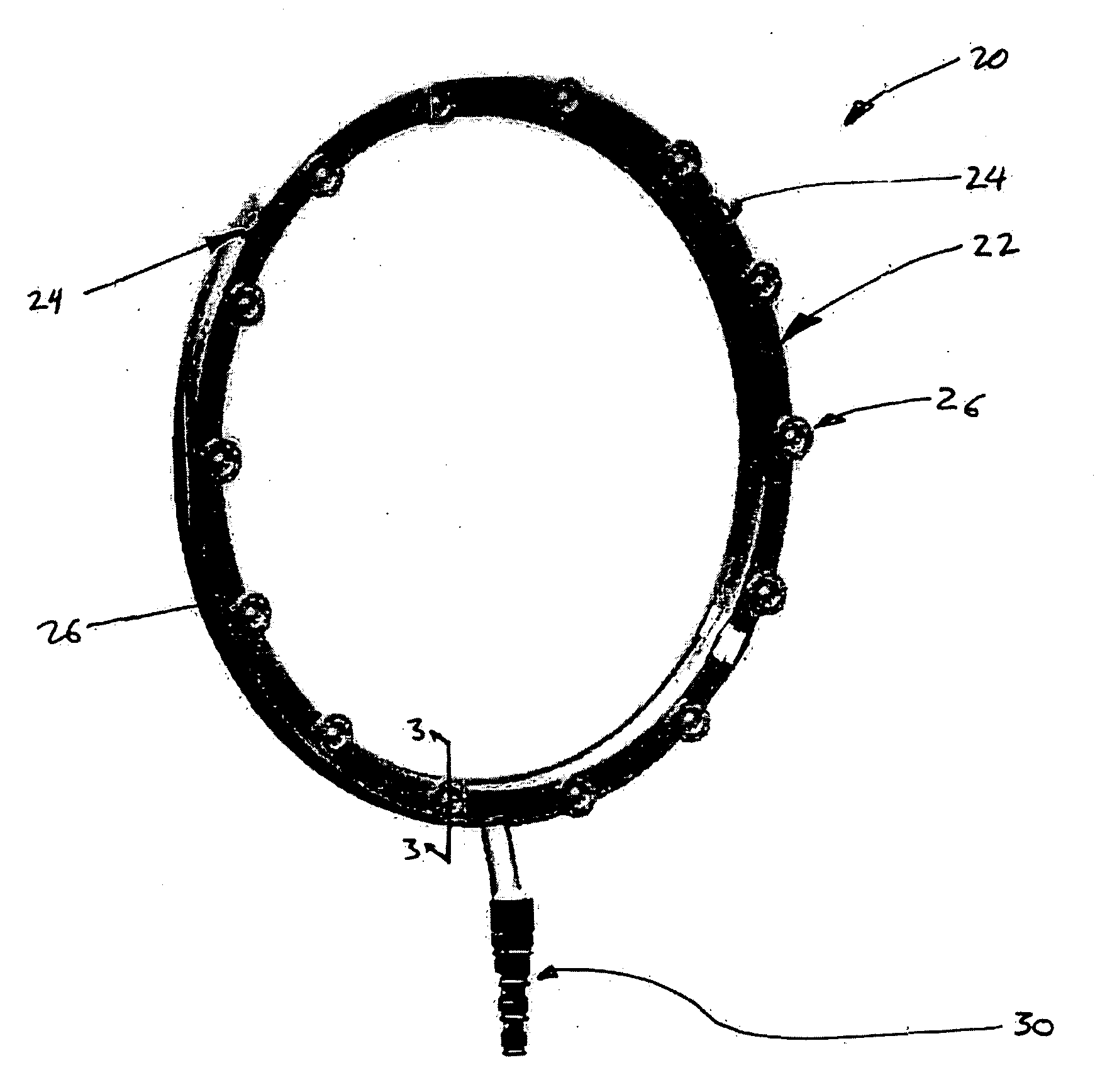

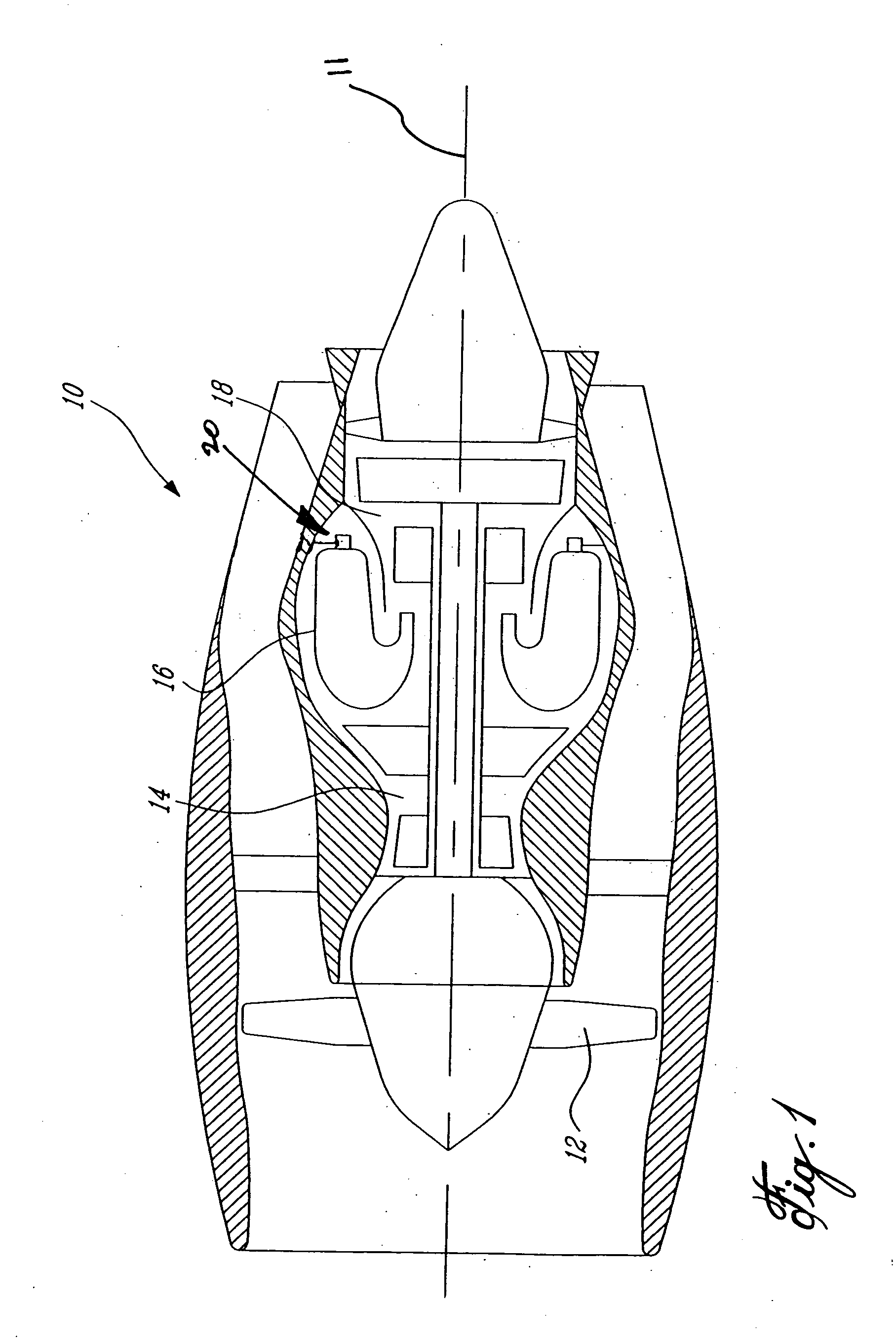

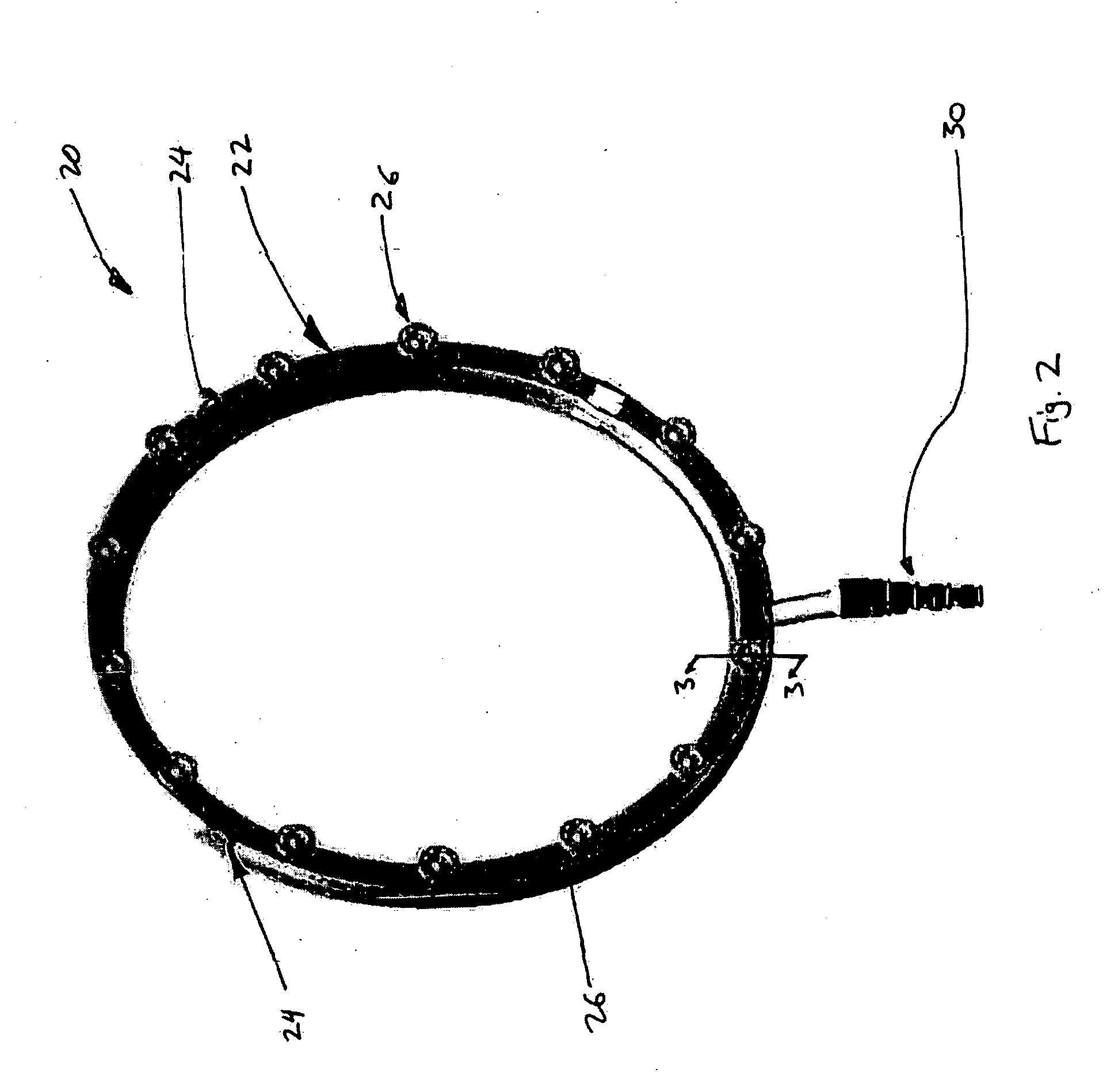

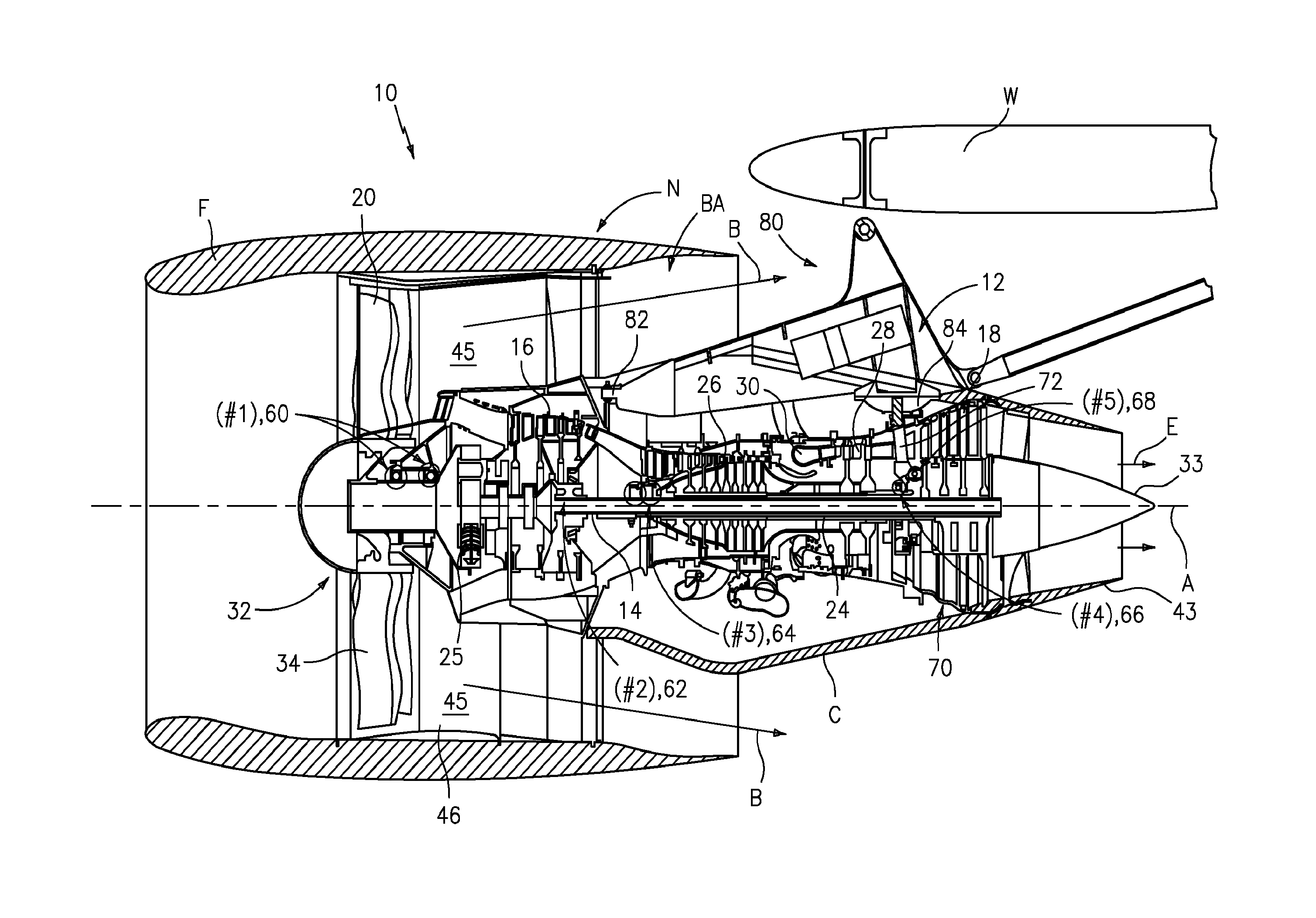

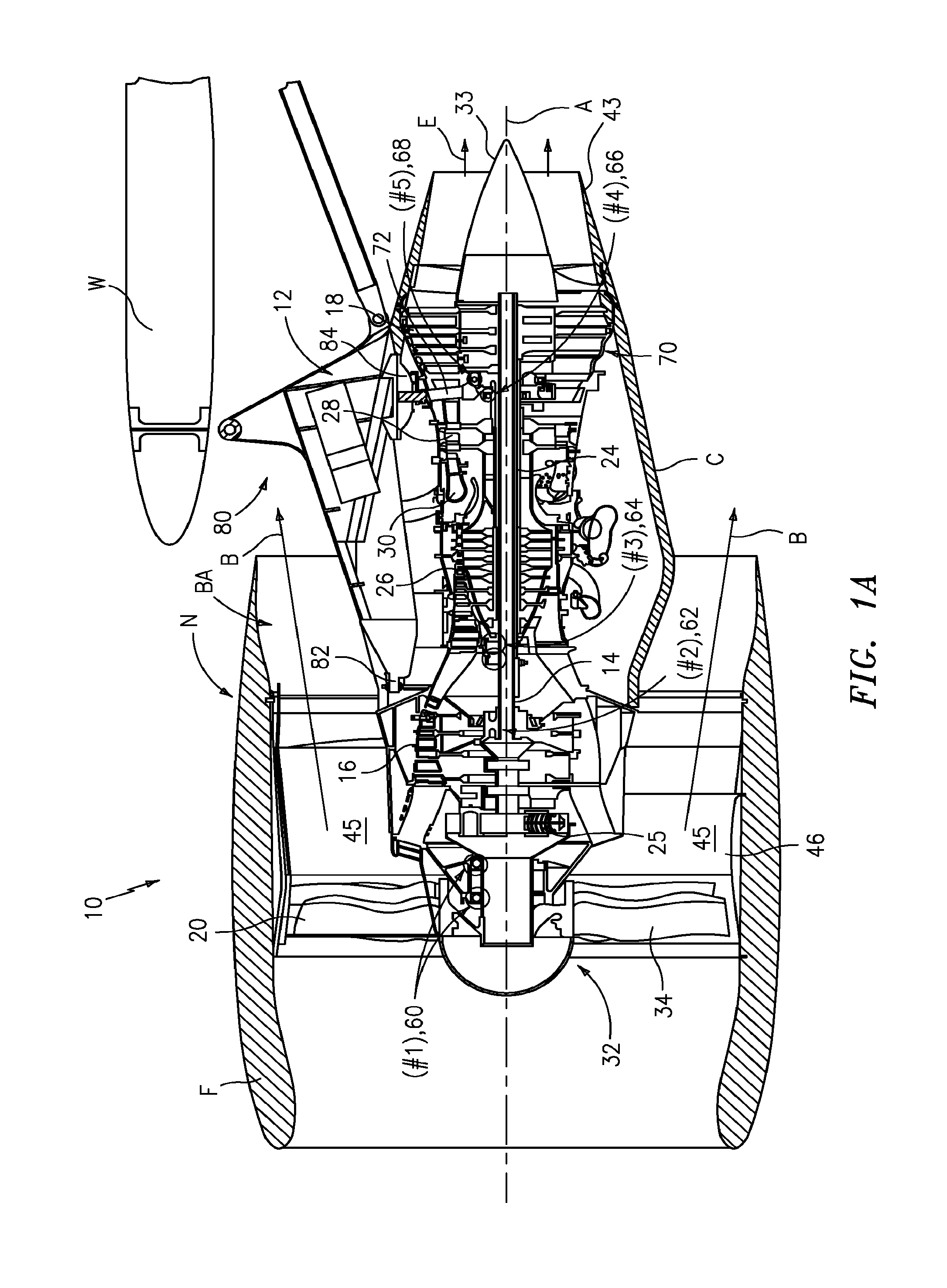

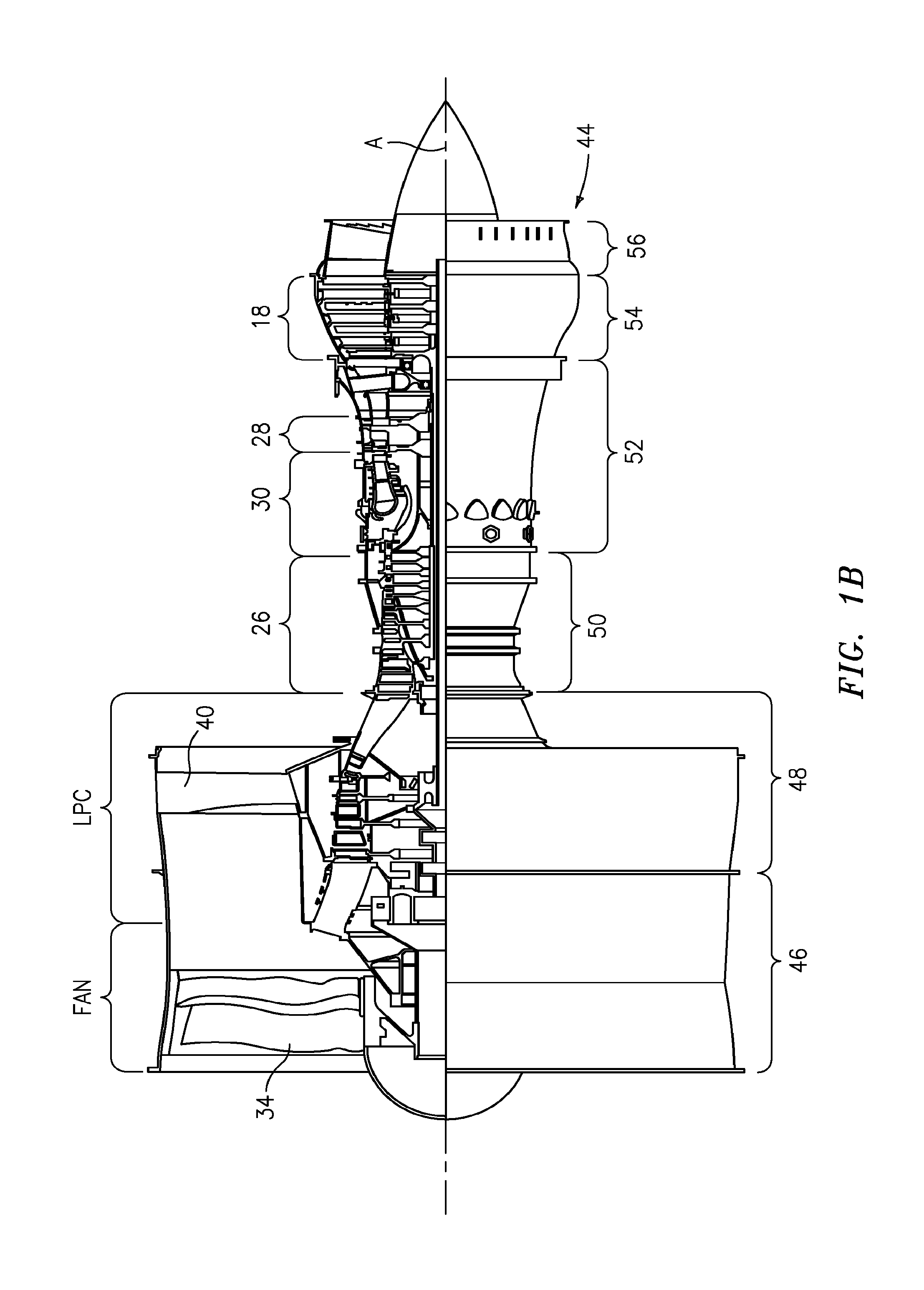

Turbine engine assemblies

Turbine engine assemblies including a turbine engine assembly having a turbine core comprising a compressor section, a combustion section, a turbine section, and a nozzle section, which are axially aligned, wherein the combustion section comprises a generally annular case having inner and outer walls, a heat exchanger comprising multiple passages in proximity to at least one of the inner and outer walls, with the passages arranged about at least a portion of the case and in fluid communication with each other such that fluid may flow through the passages and a cryogenic fuel system having a cryogenic fuel tank with a supply line coupled to one of the passages, wherein cryogenic fuel may be supplied from the cryogenic fuel tank, through the supply line, to the passages of the heat exchanger, where the fuel in the passages may be heated by the combustion section. The heat exchanger may be a single or multistage vaporizer.

Owner:GENERAL ELECTRIC CO

System and method for managing thermal issues in gas turbine engines

ActiveUS9014791B2Turbine/propulsion engine coolingTurbine/propulsion fuel heatingOn boardEngineering

The present invention generally relates to a system that enables one to address various thermal management issues in advanced gas turbine engines. In one embodiment, the present invention relates to a method to extract heat from an air stream, utilize a significant fraction for on-board power generation, and reject a small quantity of heat to the fuel stream safely at, for example, a lower temperature. In another embodiment, the present invention relates to a method to extract heat from an air stream, utilize a significant fraction for on-board power generation, and reject a small quantity of heat to the fuel stream safely at, for example, a lower temperature with no potential air / fuel contact is disclosed.

Owner:ECHOGEN POWER SYST LLC

Pulse detonation combustor with folded flow path

A pulsed detonation combustor (PDC) is described. The PDC includes an outer casing defining a first hollow chamber configured to receive a flow and an inner liner. The inner liner includes at least one portion positioned within the first hollow chamber and configured to receive the flow from a plenum formed between the outer casing and inner liner. The PDC further includes a flow turning device with geometric features configured to direct the flow from the plenum to a second hollow chamber defined within the inner liner. The PDC also includes at least one fuel injection port located downstream of an inlet to the outer casing and an ignition device located downstream of the at least one fuel injection port and configured to periodically ignite fuel.

Owner:GENERAL ELECTRIC CO

Nozzle with fluted tube

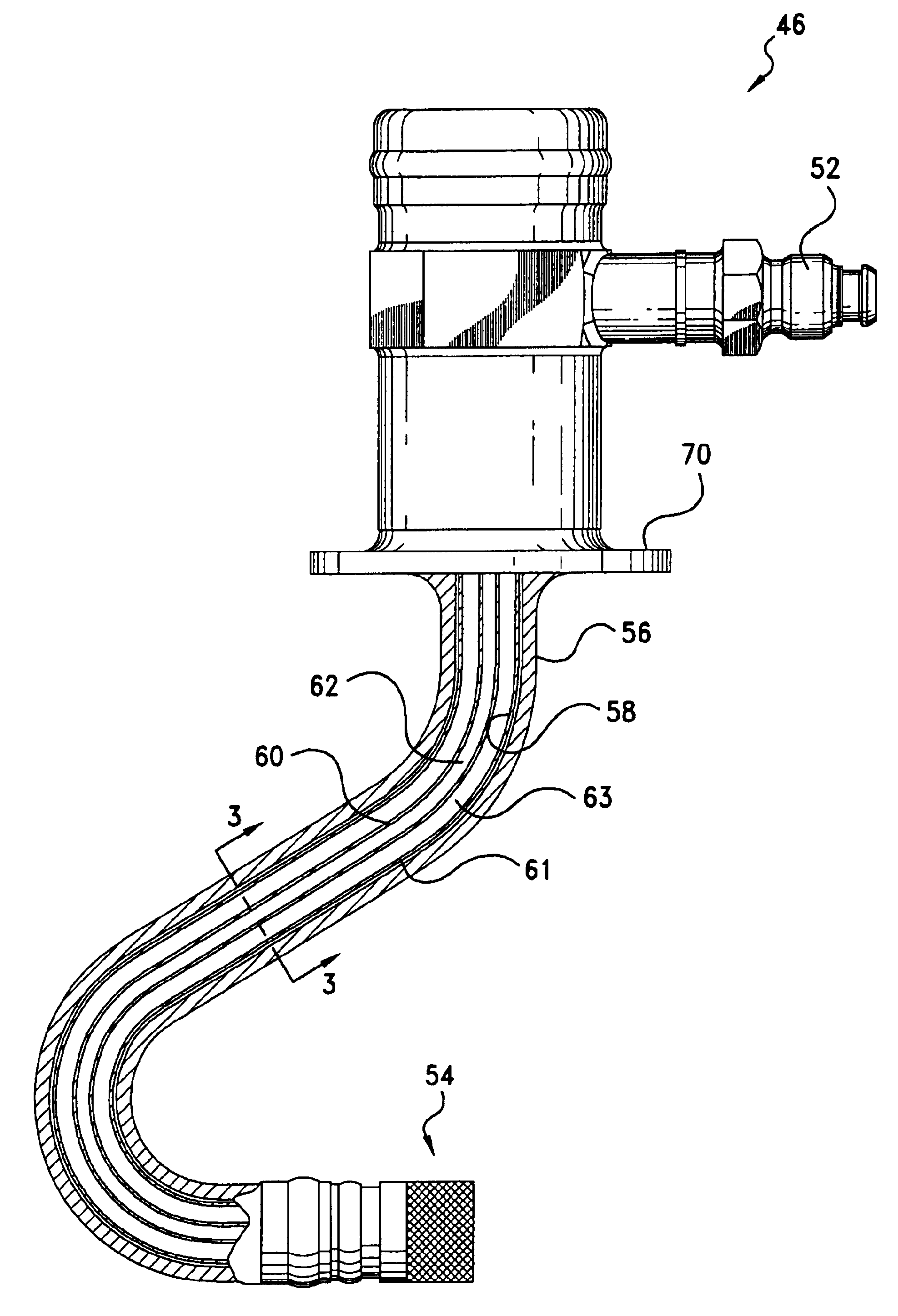

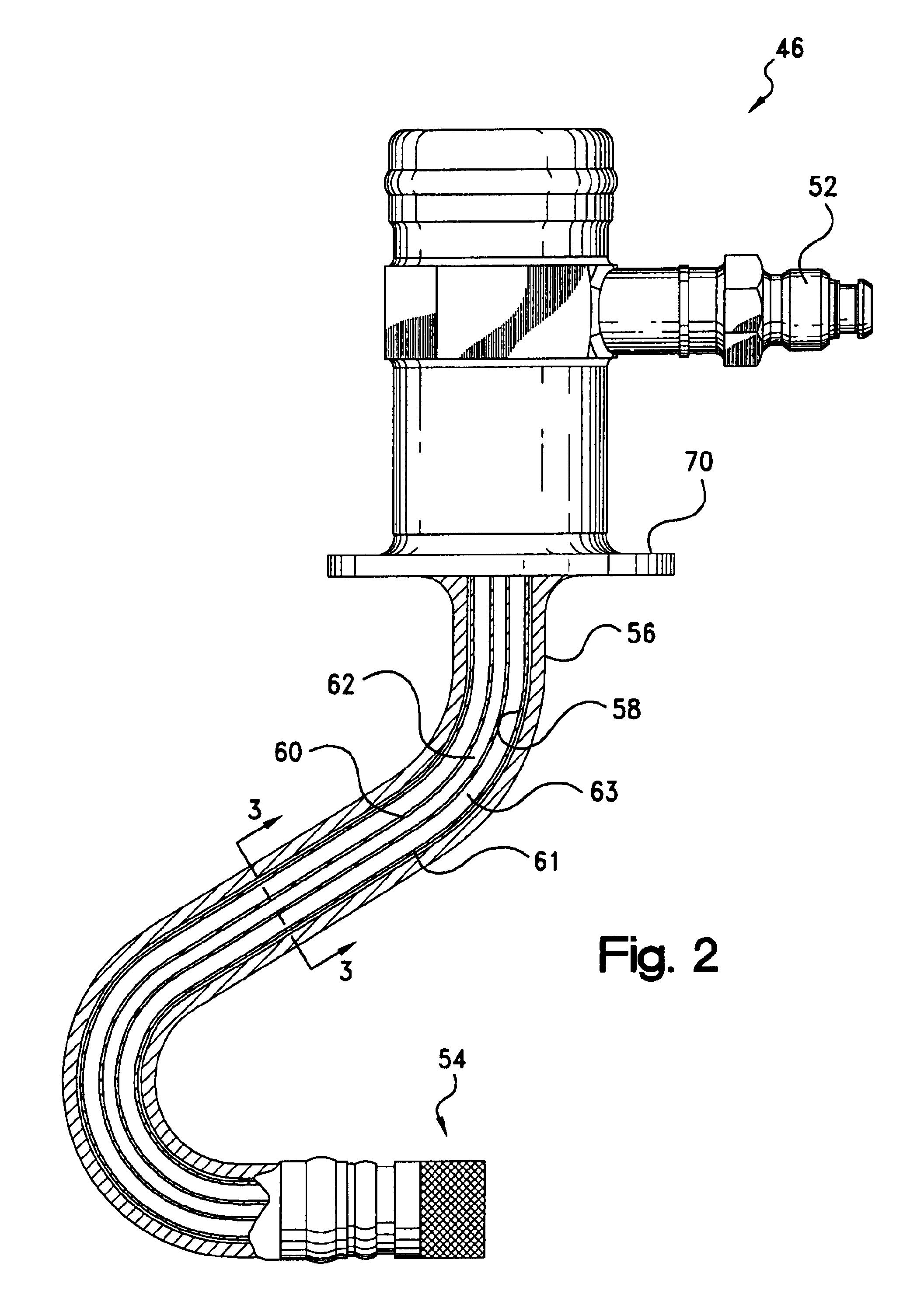

InactiveUS6915638B2Not bulkyReduces and in injectorTurbine/propulsion engine ignitionTurbine/propulsion engine startersEngineeringGuide tube

A fuel injector for gas turbine engines includes an inlet fitting, a housing stem, and a spray nozzle. A pair of fuel passages in the stem deliver fuel in a primary (continuous) flow and a secondary (non-continuous or reduced) flow to primary and secondary discharge orifices in the nozzle. The fuel passages are defined by inner and outer concentric conduits, with the primary flow directed through the inner conduit, and the secondary flow directed through the outer conduit. Fins are provided unitary with the inner conduit along the length of the housing stem, and are fixed at their radial outer ends to the outer conduit. The fins provide structural support and thermally connect the inner and outer conduits. During low power operation, the fins transfer heat energy between the outer conduit to the inner conduit to cool the outer conduit and thermally protect the fuel in the secondary fuel passage.

Owner:PARKER INTANGIBLES LLC

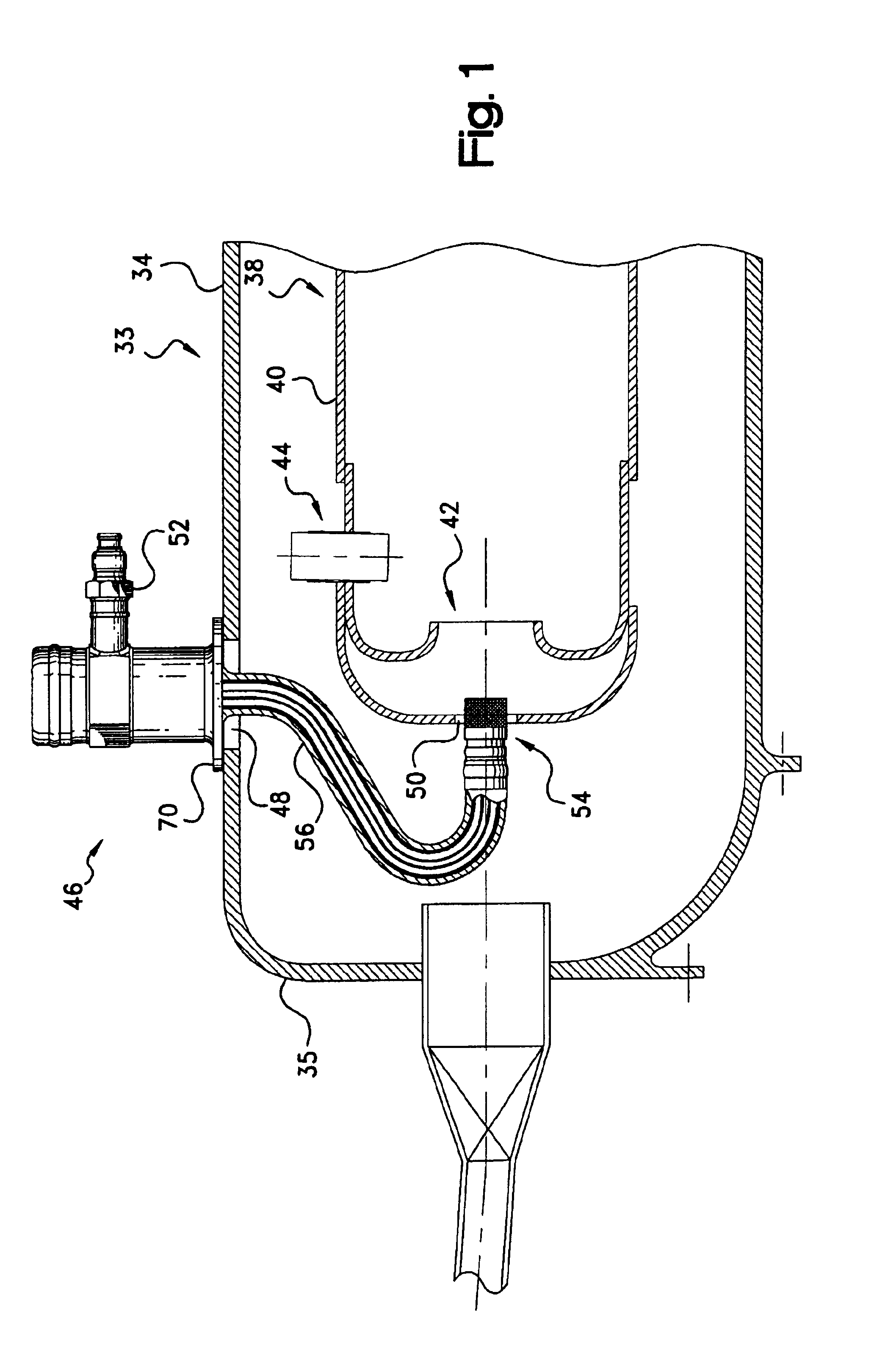

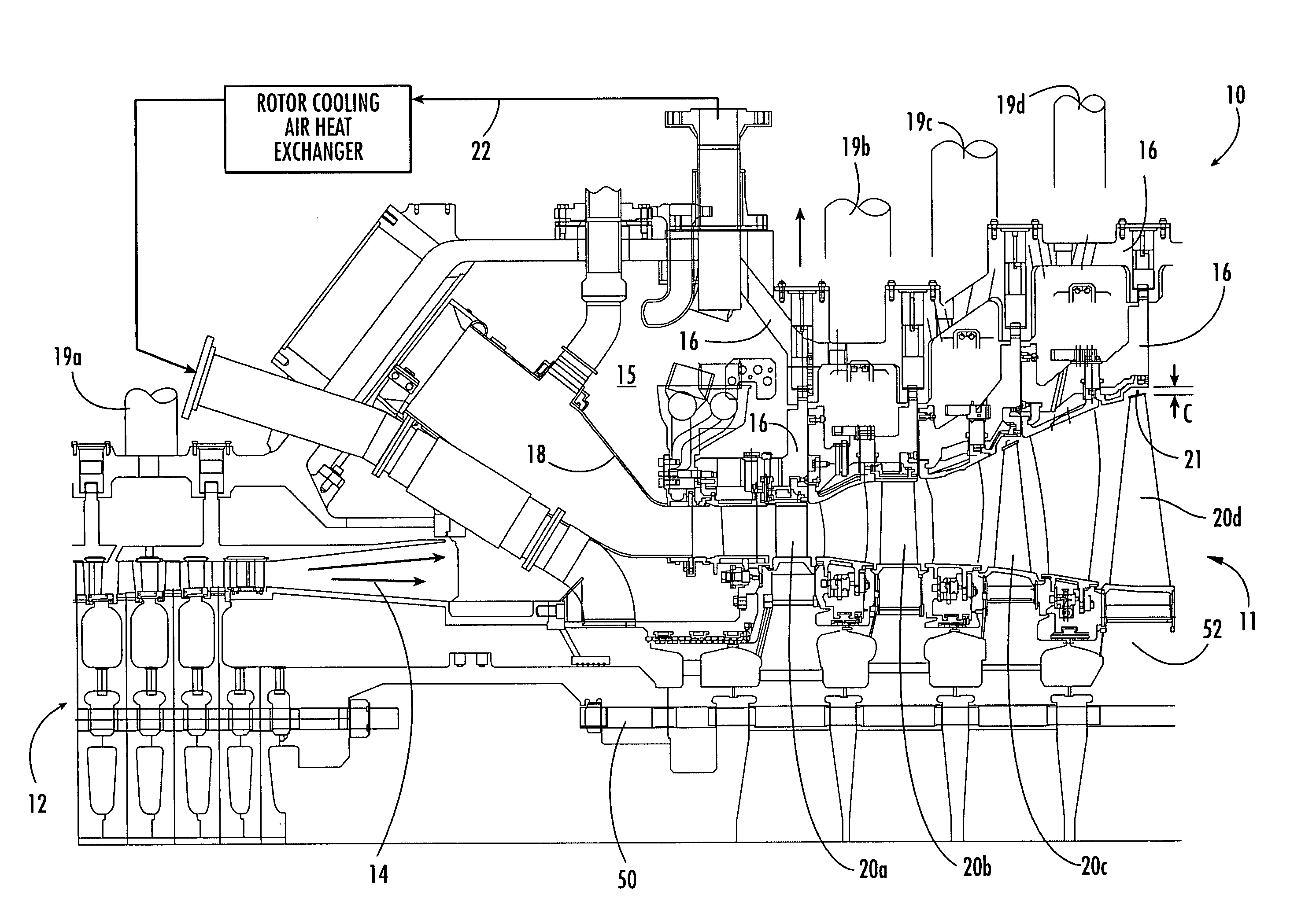

Part load blade tip clearance control

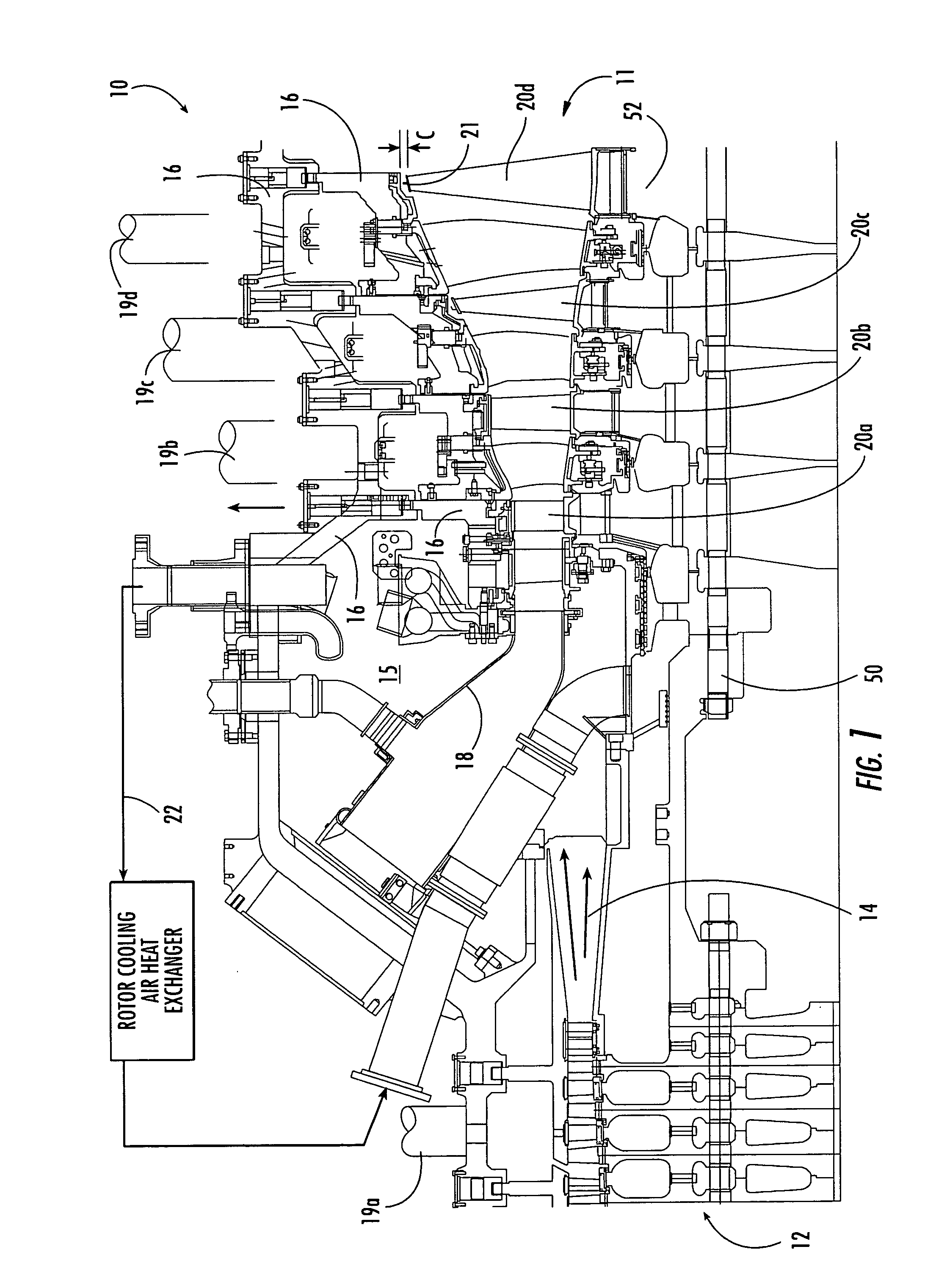

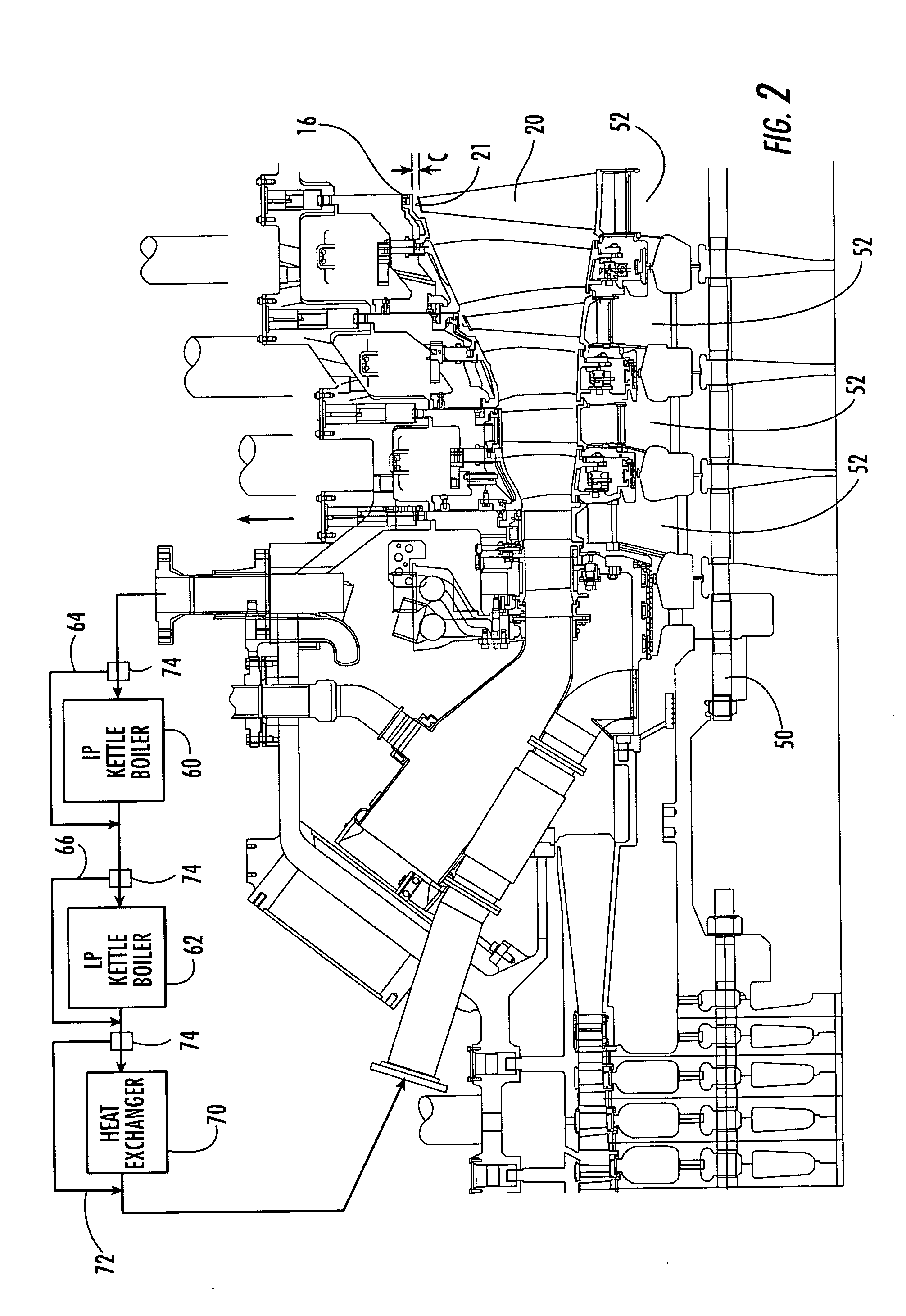

InactiveUS20050050901A1Reduce the temperatureLow cooling temperatureTurbine/propulsion engine coolingBlade accessoriesCircular discTurbine blade

Aspects of the invention relate to a turbine engine configuration and method for overcoming a turbine blade tip clearance problem that can arise when the turbine inlet temperature is maintained at a high level during part load operation of the turbine. Aspects of the invention relate to reducing rotor cooling air to a temperature below the design temperature level by using, for example, additional heat extraction devices or by reconfiguring or resizing existing heat exchanger devices. Upon exposure to the cooled air, the discs and blades of the turbine will shrink so as to provide a clearance between the blade tips and surrounding stationary support structure. The design rotor cooling air temperature can be from about 350 degrees Fahrenheit to about 480 degrees Fahrenheit. Aspects of the present invention can be used to decrease the rotor cooling air to about 150 degrees Fahrenheit at about 70 percent load.

Owner:SIEMENS ENERGY INC

Cold fuel cooling of intercooler and aftercooler

ActiveUS20130074812A1Reduce power consumptionNone have achieved superiorInternal combustion piston enginesPower plant arrangements/mountingTurbochargerNuclear engineering

Owner:AEROVIRONMENT INC

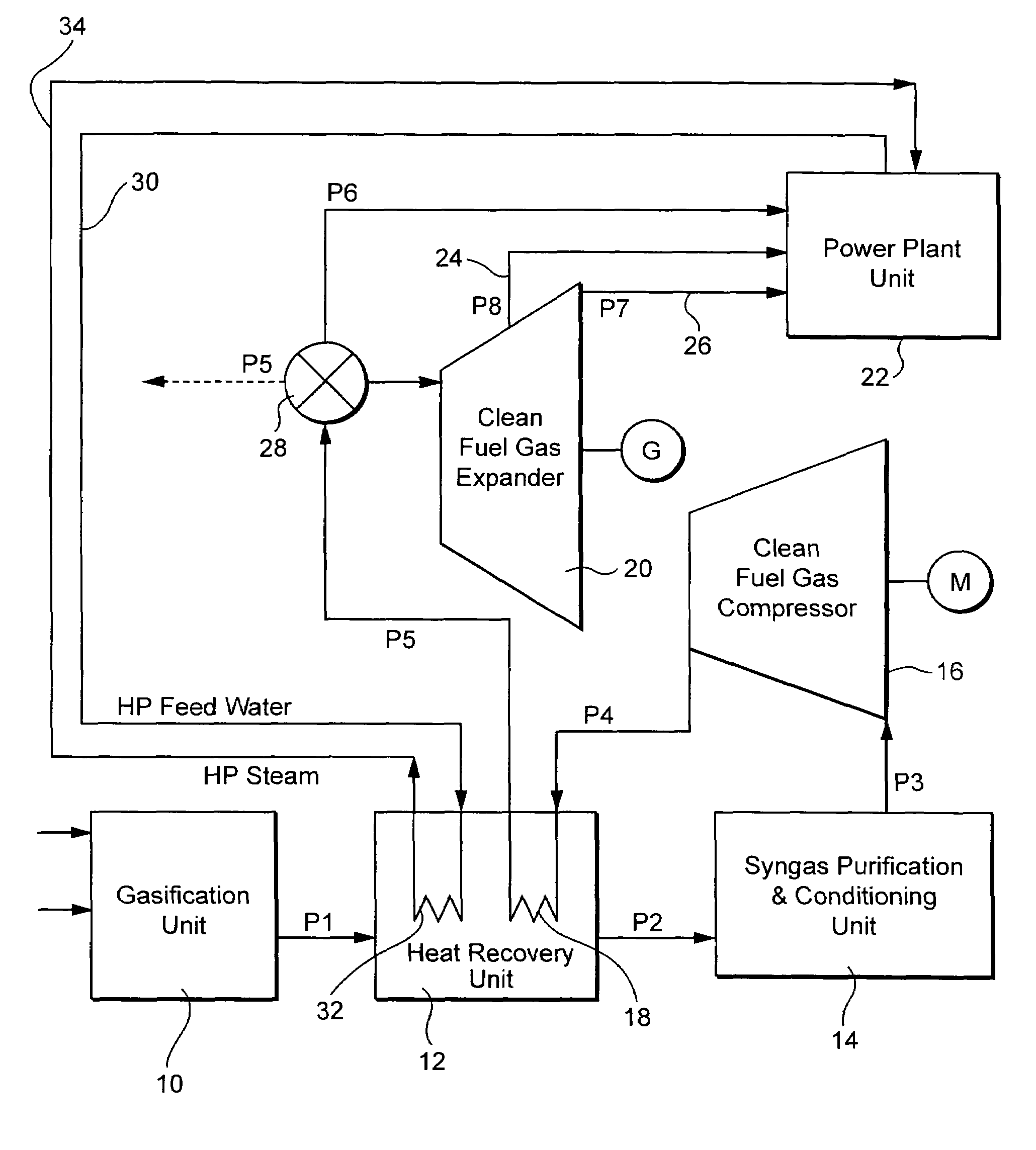

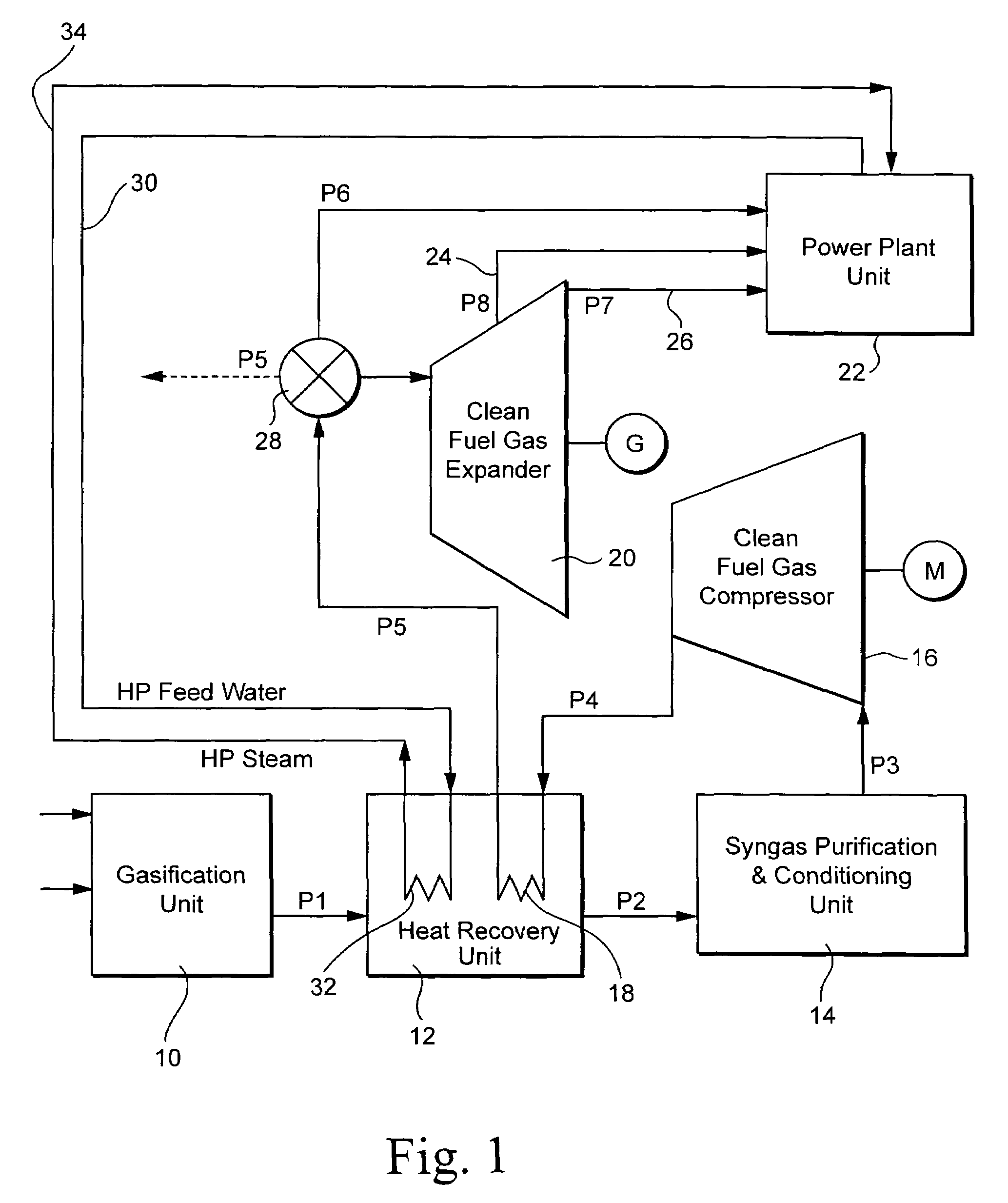

Method and system for heat recovery from dirty gaseous fuel in gasification power plants

A system and method for recovering heat from dirty gaseous fuel (syngas), wherein the pressure of clean fuel gas is elevated to a pressure higher than that of the dirty syngas and then the pressurized clean fuel gas is fed to a heat recovery unit for heat exchange with the dirty syngas. Consequently, in the event of a leak in the heat recovery unit, the flow is from the clean fuel side to the dirty syngas side, thereby avoiding the possibility of contamination of the clean fuel gas.

Owner:GENERAL ELECTRIC CO

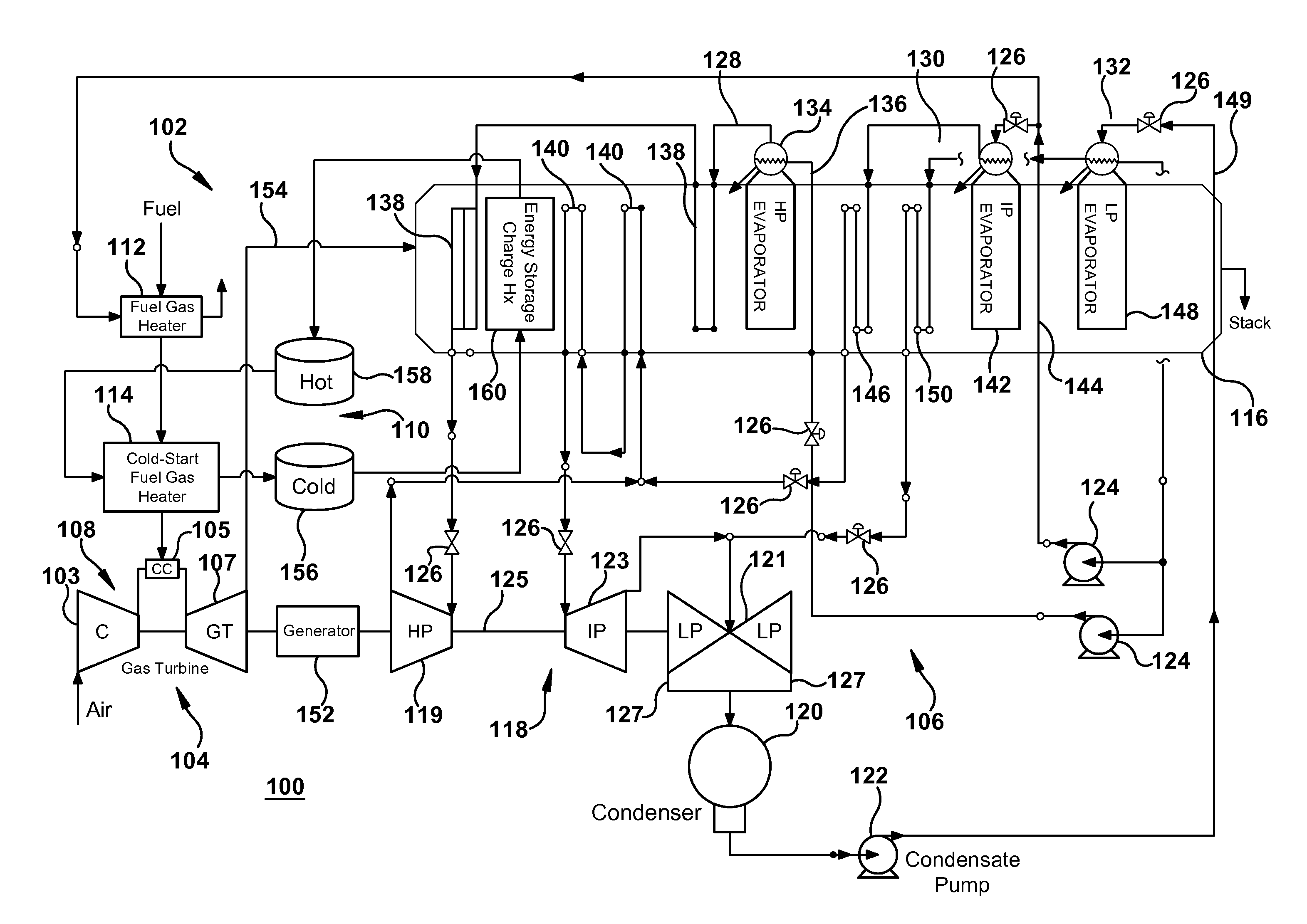

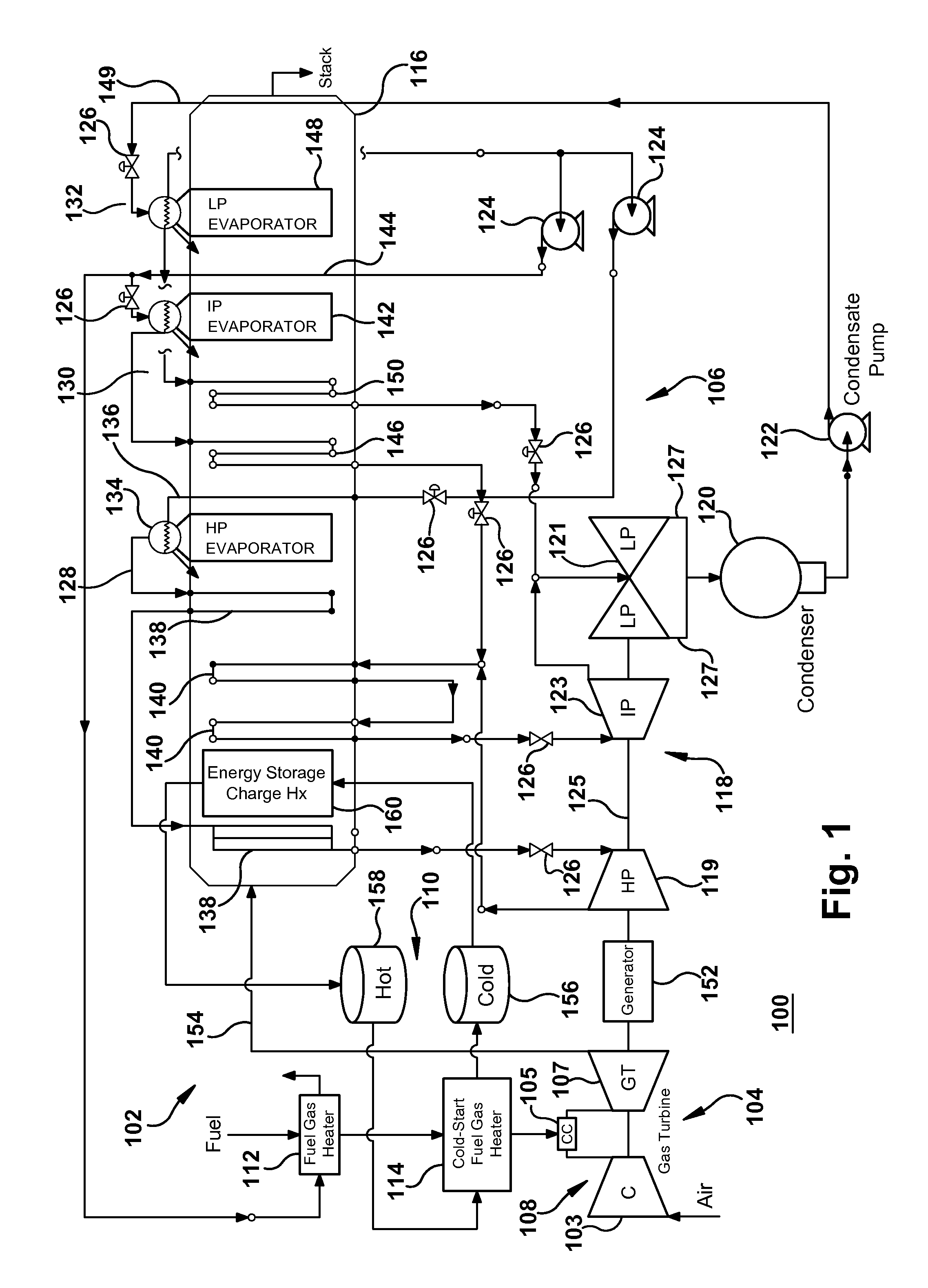

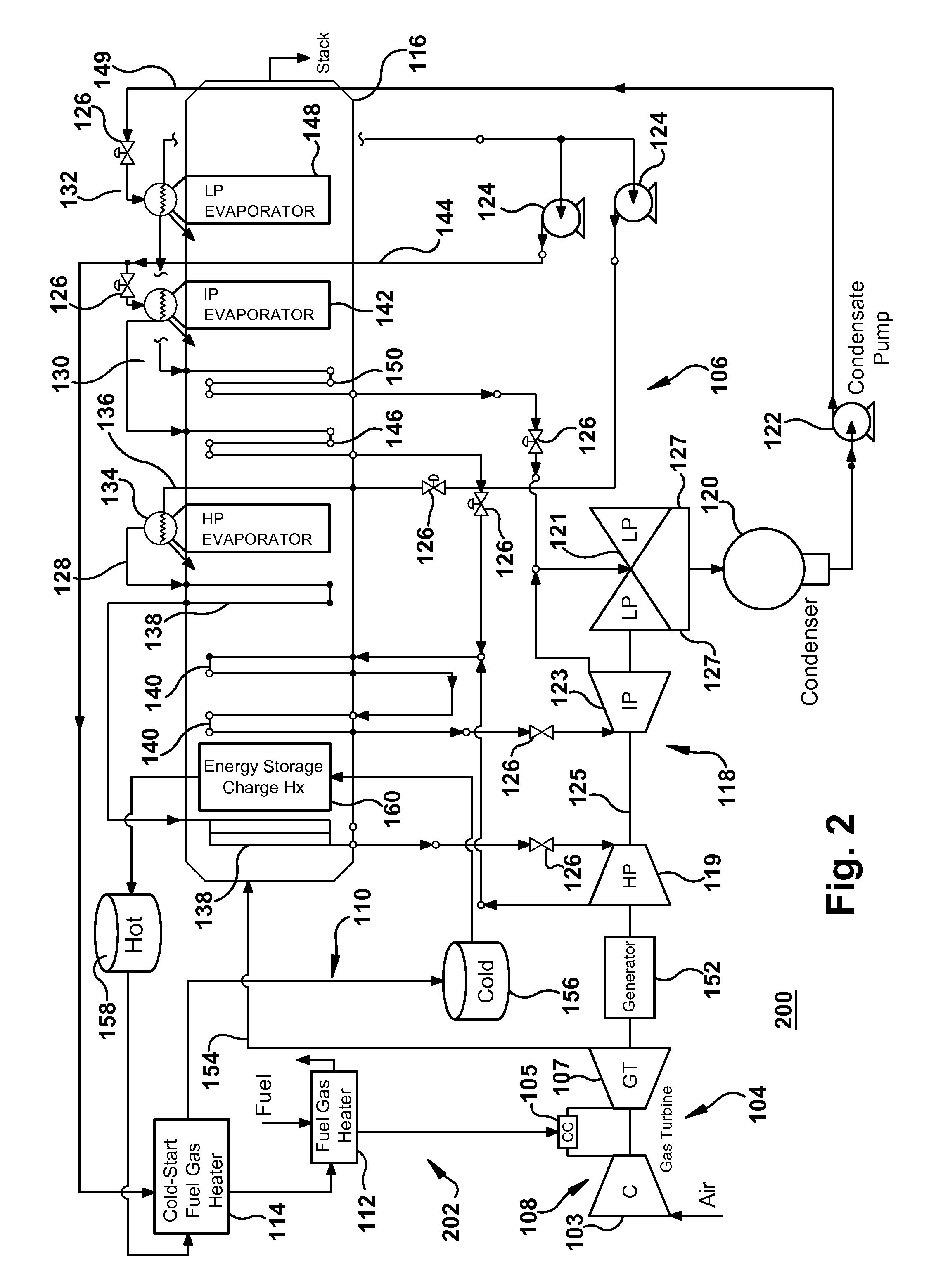

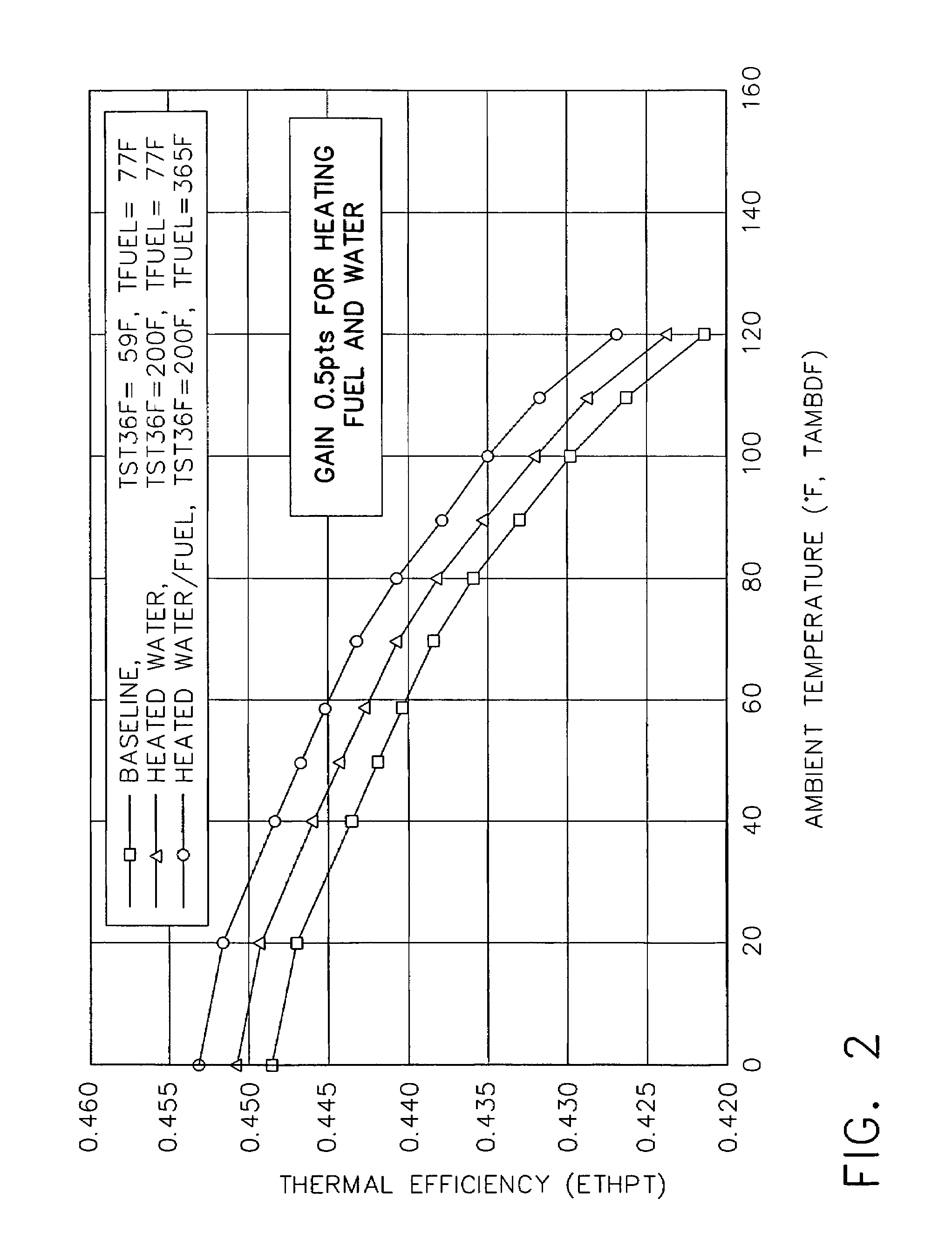

Fuel gas heating with thermal energy storage

Thermal energy storage containing thermal energy extracted from a bottom cycle heat engine is leveraged to heat fuel gas supplied to a gas turbine engine operating in a top cycle heat engine. Further, an extracted portion of a working fluid generated in a steam generation source of the bottom cycle heat engine can be used along with the thermal energy storage to heat fuel gas.

Owner:GENERAL ELECTRIC CO

Method and apparatus for operating an intercooler for a gas turbine engine

ActiveUS7284377B2Easy to operateImprove efficiencyEfficient propulsion technologiesGas turbine plantsWorking fluidCombustor

A method for operating a gas turbine engine includes channeling compressed airflow discharged from a first compressor through an intercooler having a cooling medium flowing therethrough, channeling a working fluid through the intercooler to facilitate increasing an operating temperature of the working fluid, and channeling the discharged working fluid to a combustor to facilitate increasing an operating efficiency of the gas turbine engine.

Owner:GENERAL ELECTRIC CO

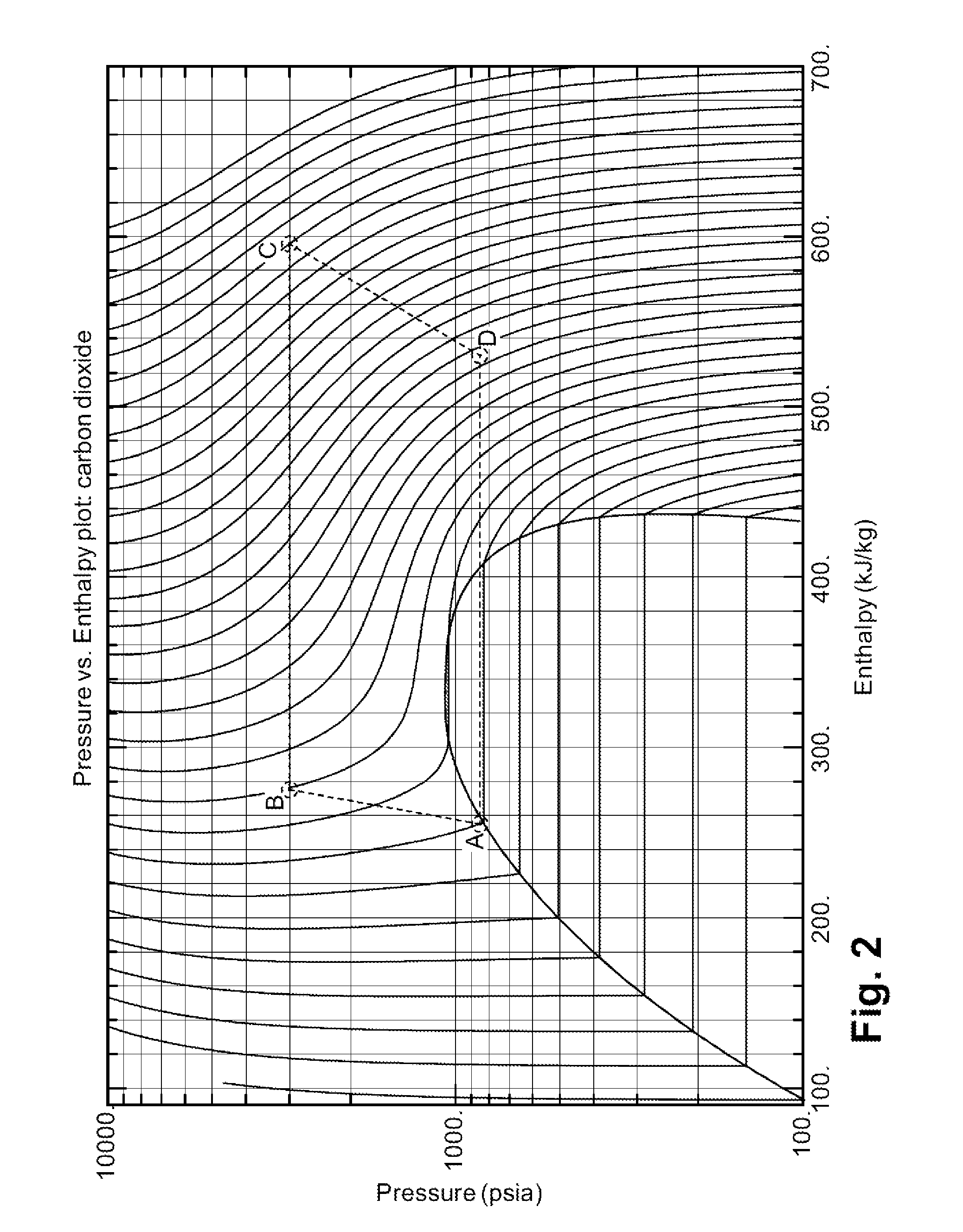

Hybrid fossil fuel and solar heated supercritical carbon dioxide power generating system and method

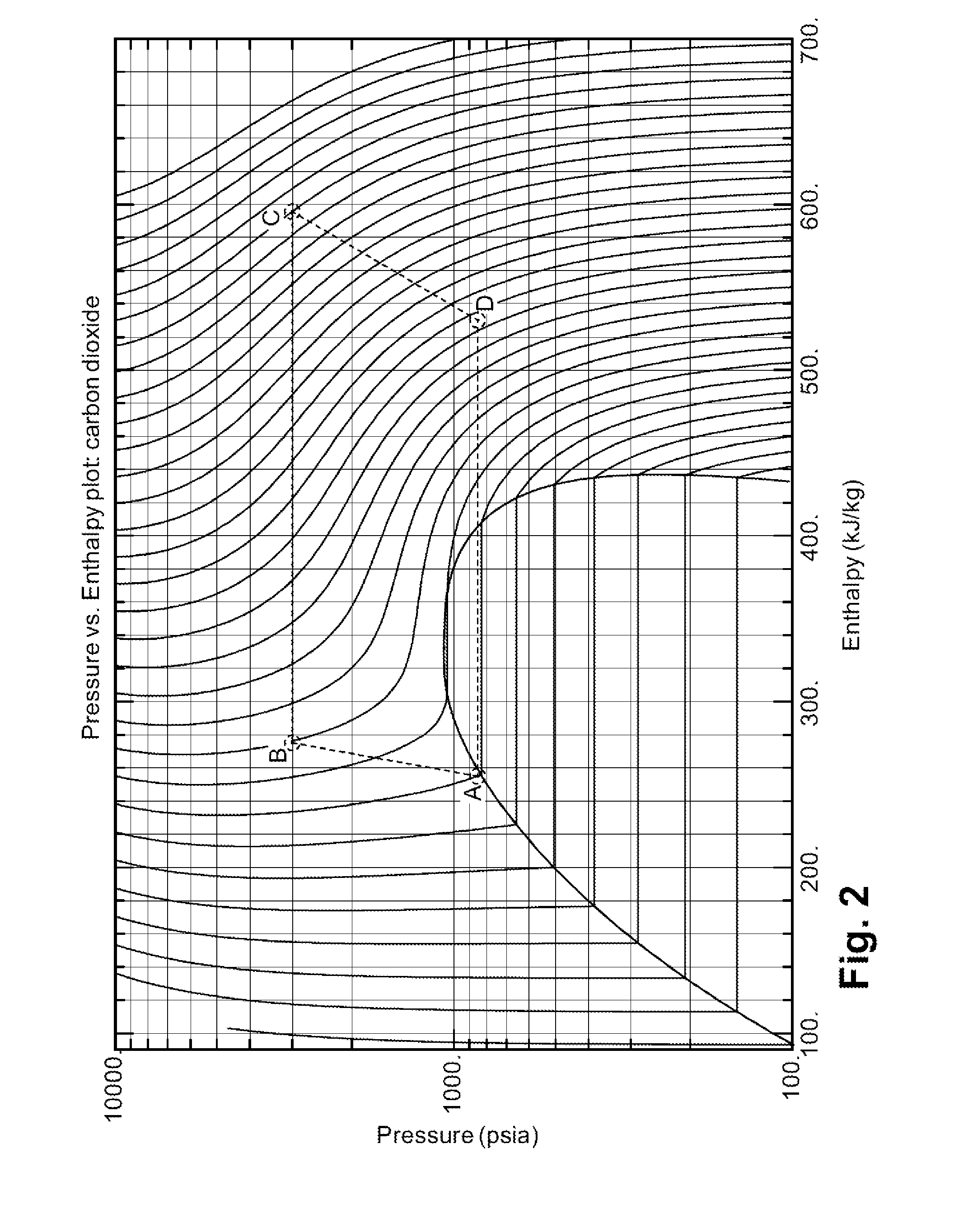

InactiveUS20130118145A1Improve efficiencyLow calorific valueSolar heating energyFrom solar energyCombustion systemWorking fluid

The present disclosure provides an integrated power generating system and method that combines combustion power generation with solar heating. Specifically, a closed cycle combustion system utilizing a carbon dioxide working fluid can be increased in efficiency by passing at least a portion of a carbon dioxide working fluid through a solar heater prior to passage through a combustor.

Owner:8 RIVERS CAPTTAL LLC

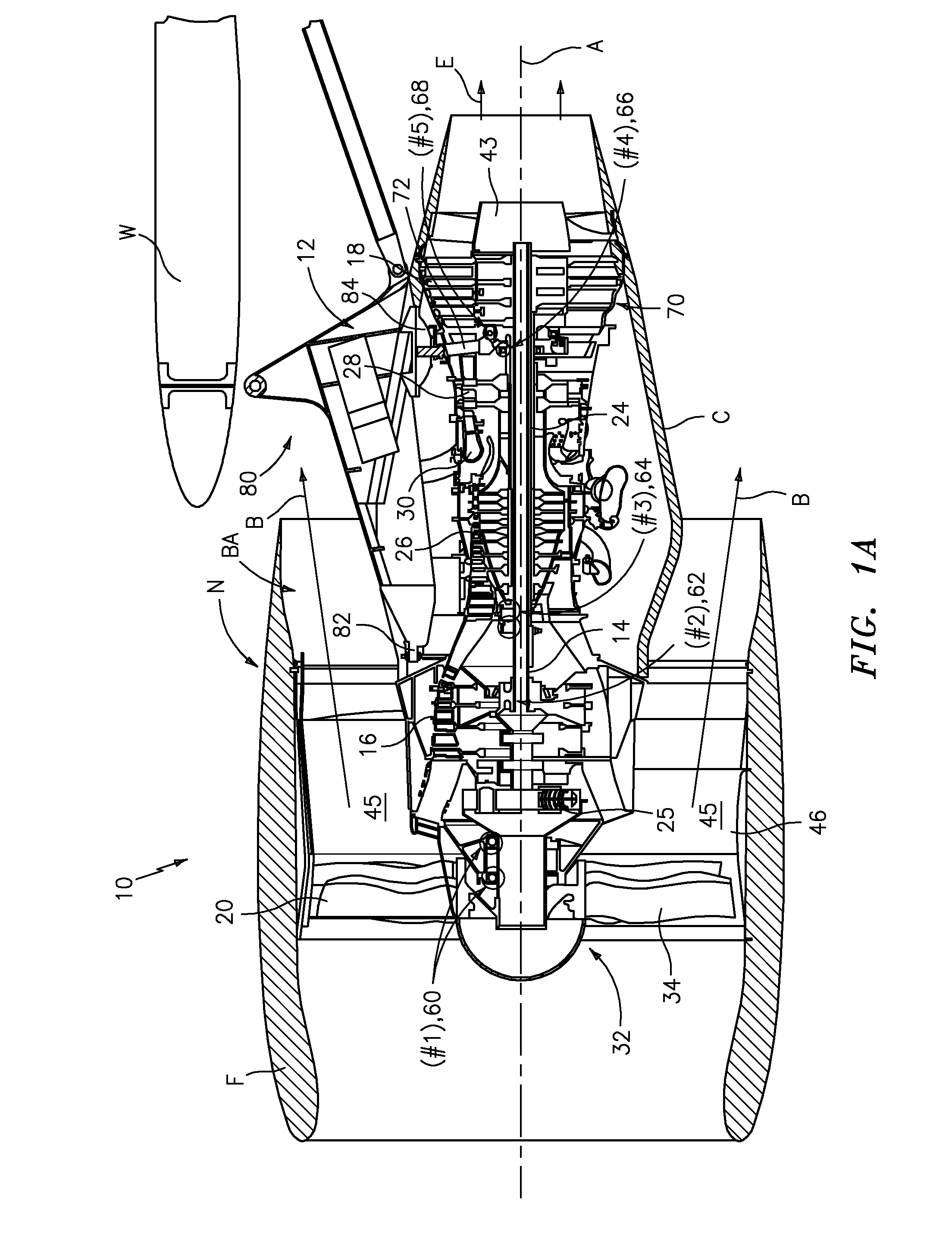

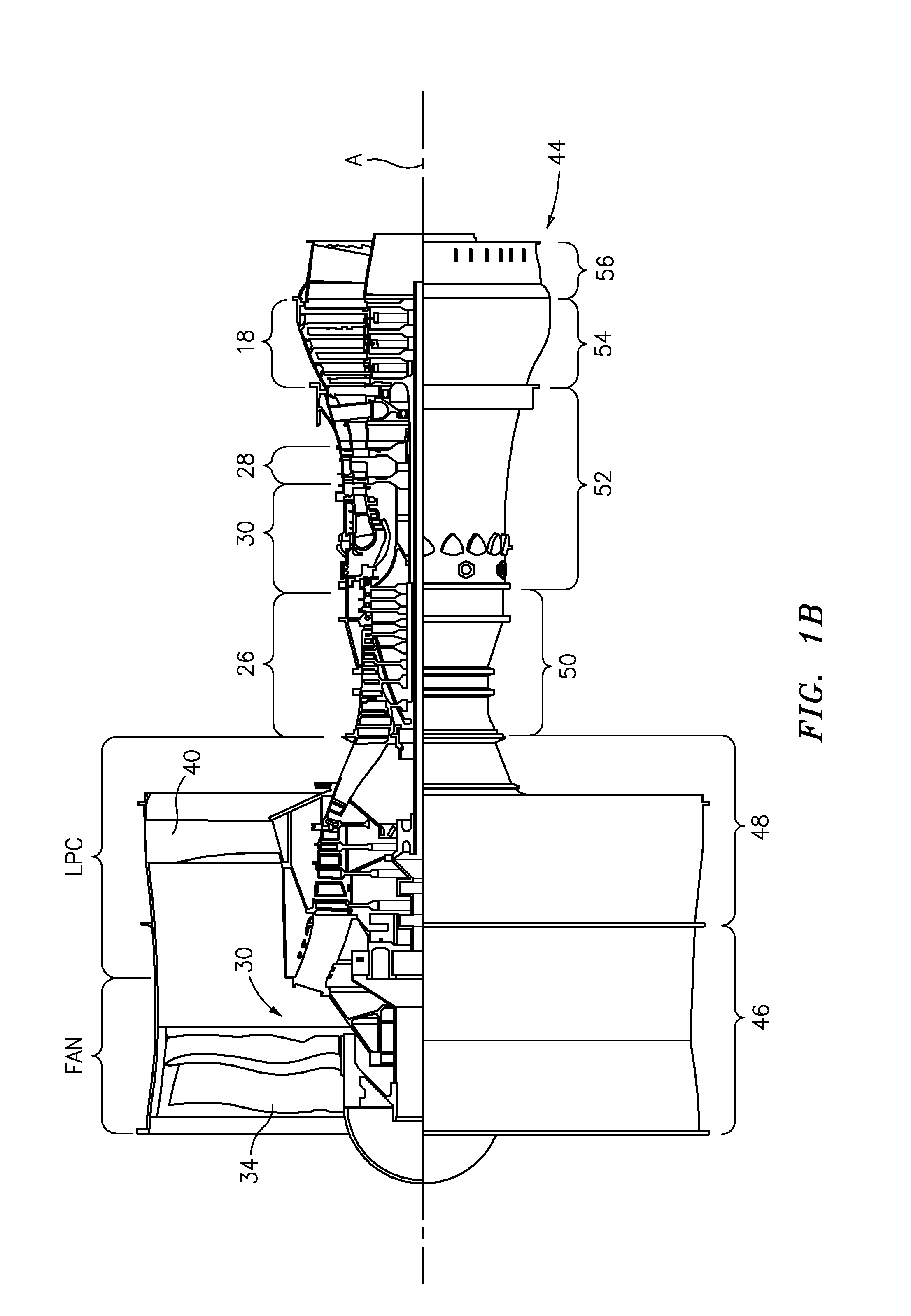

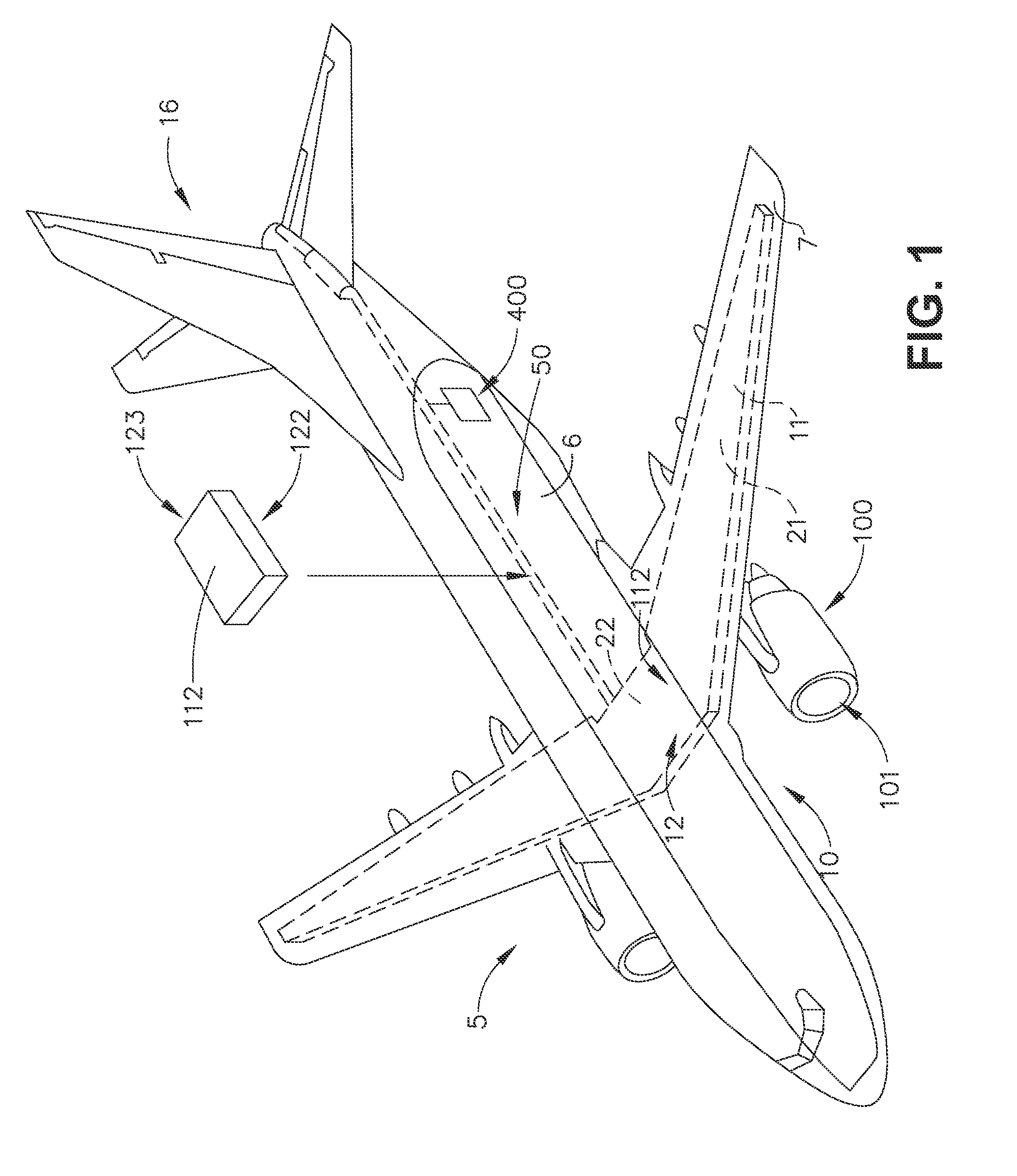

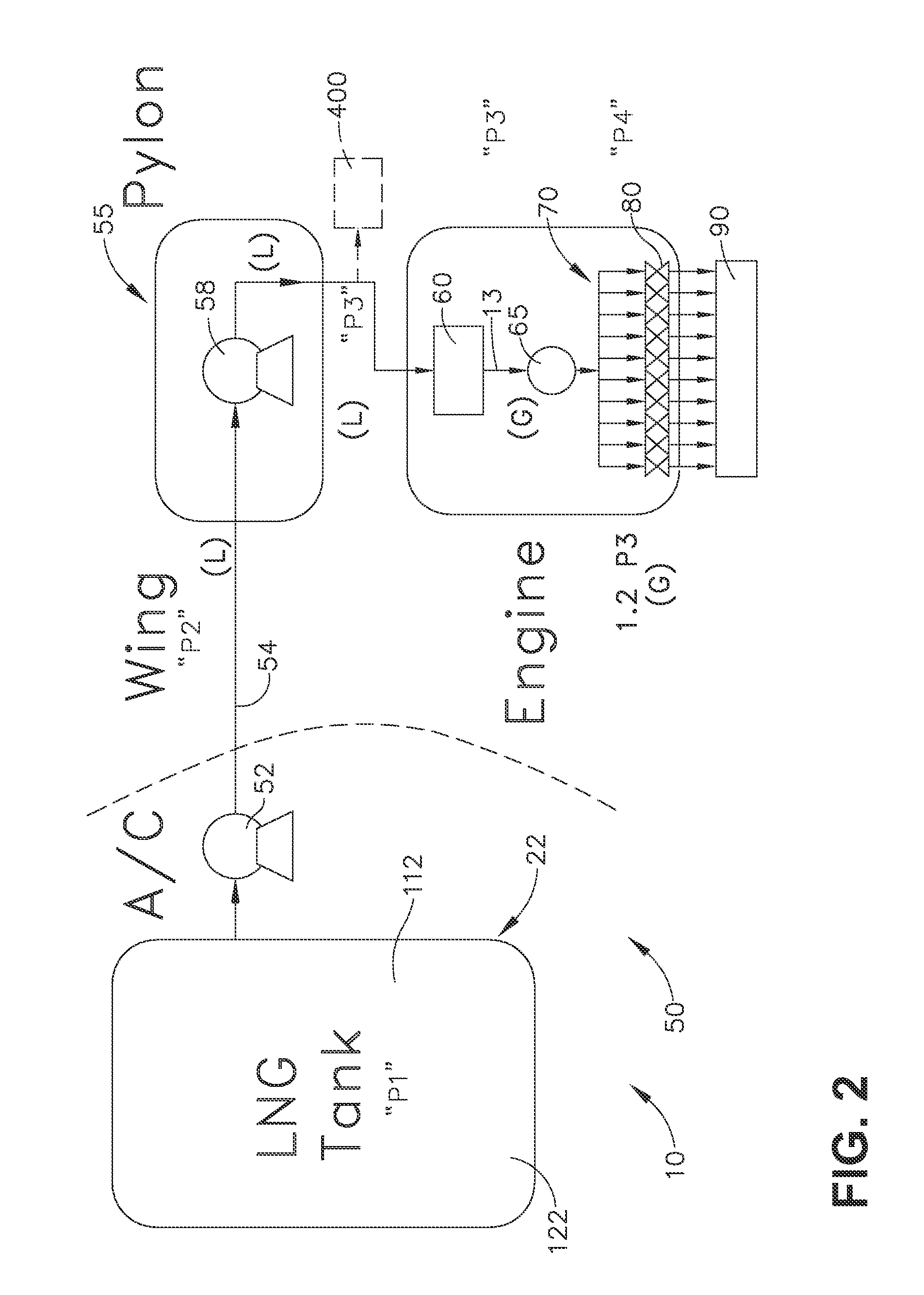

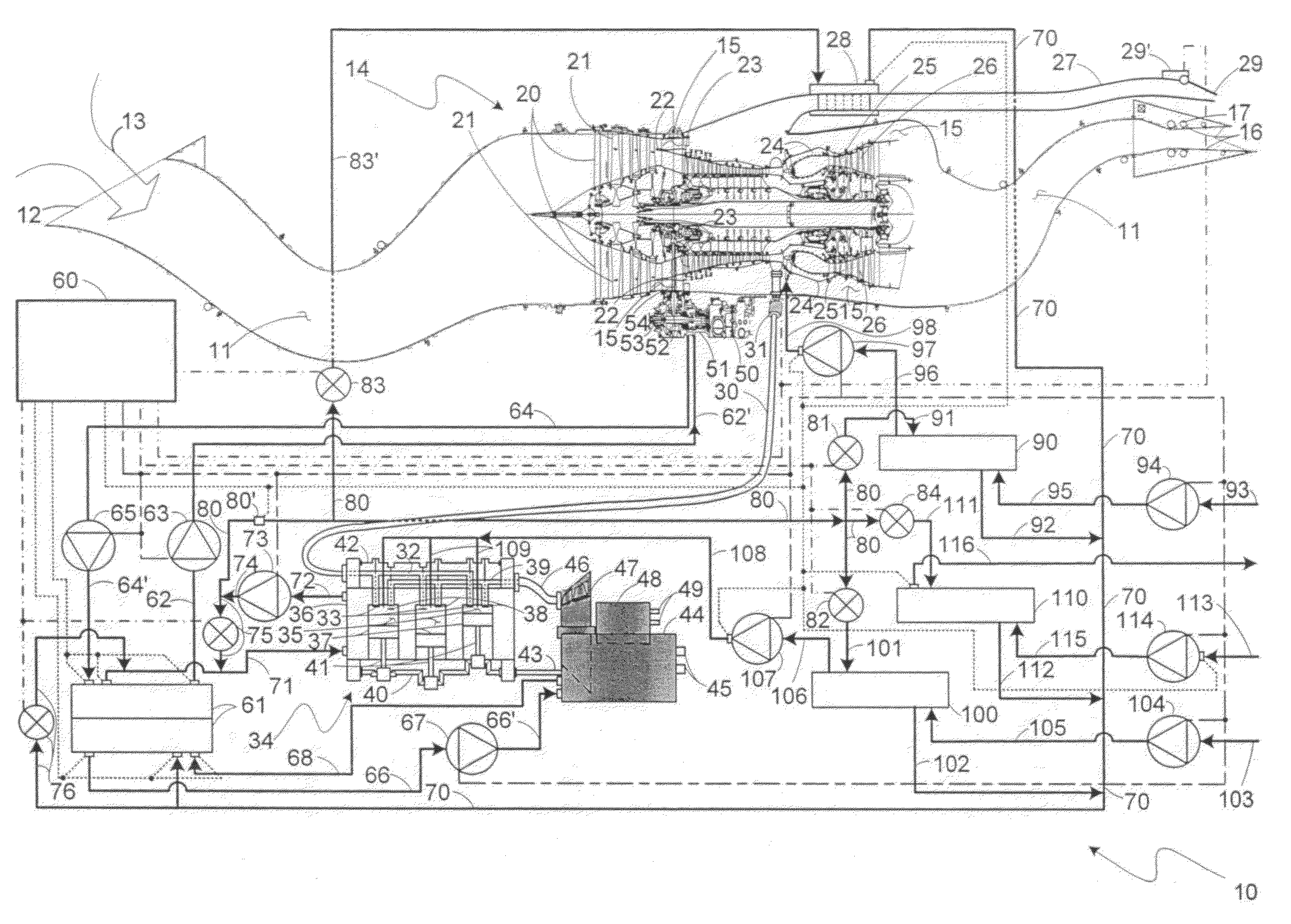

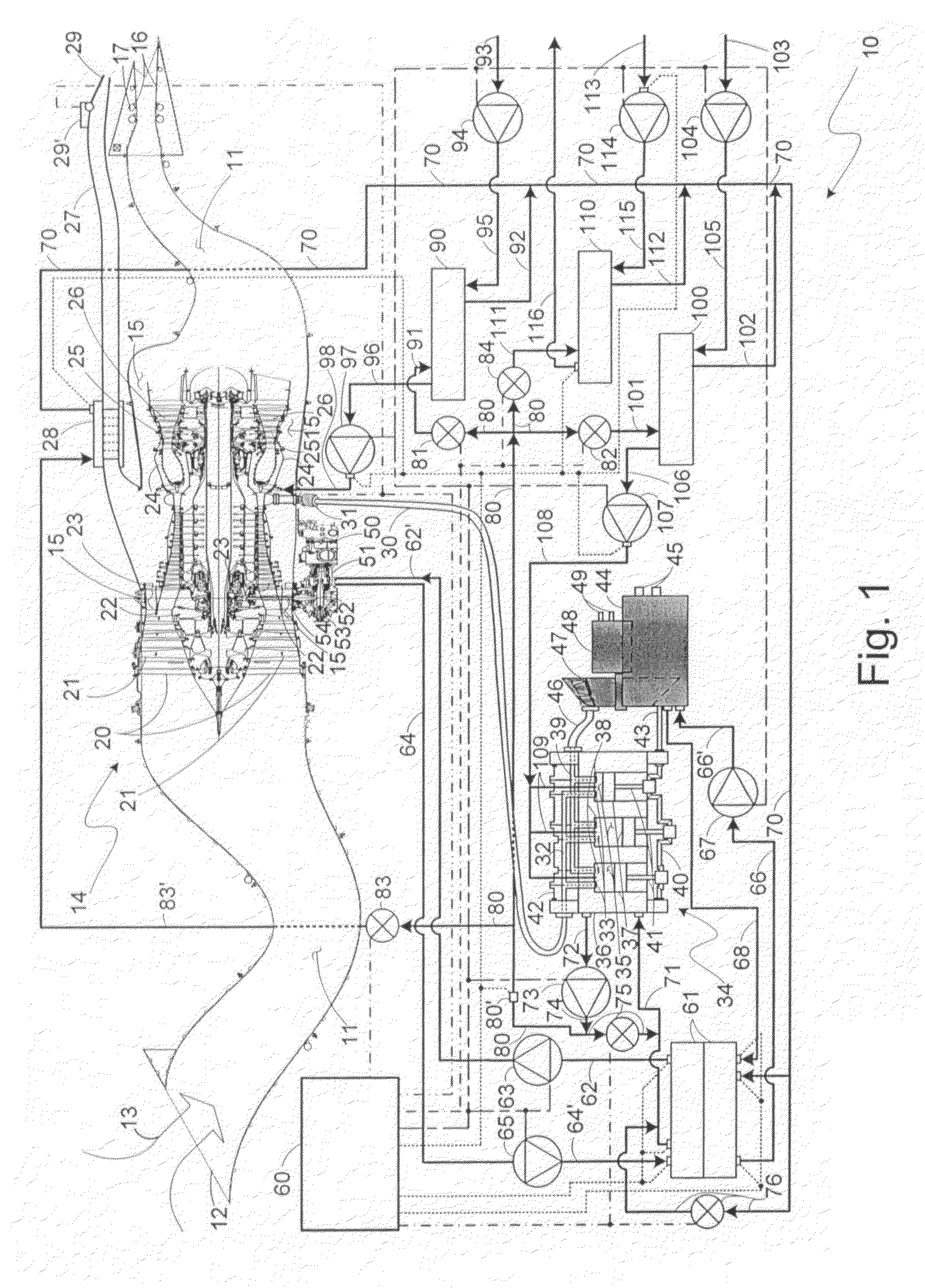

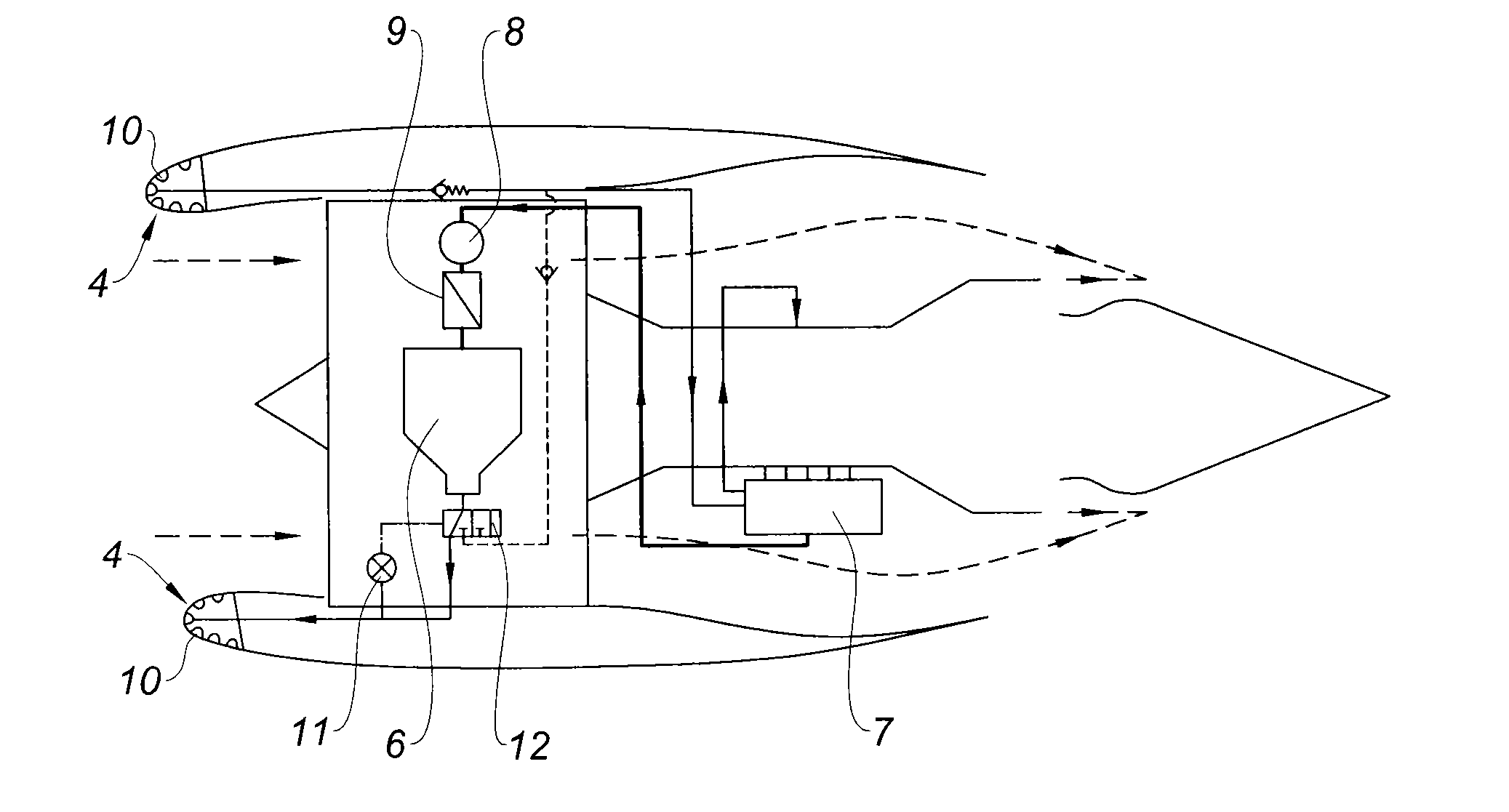

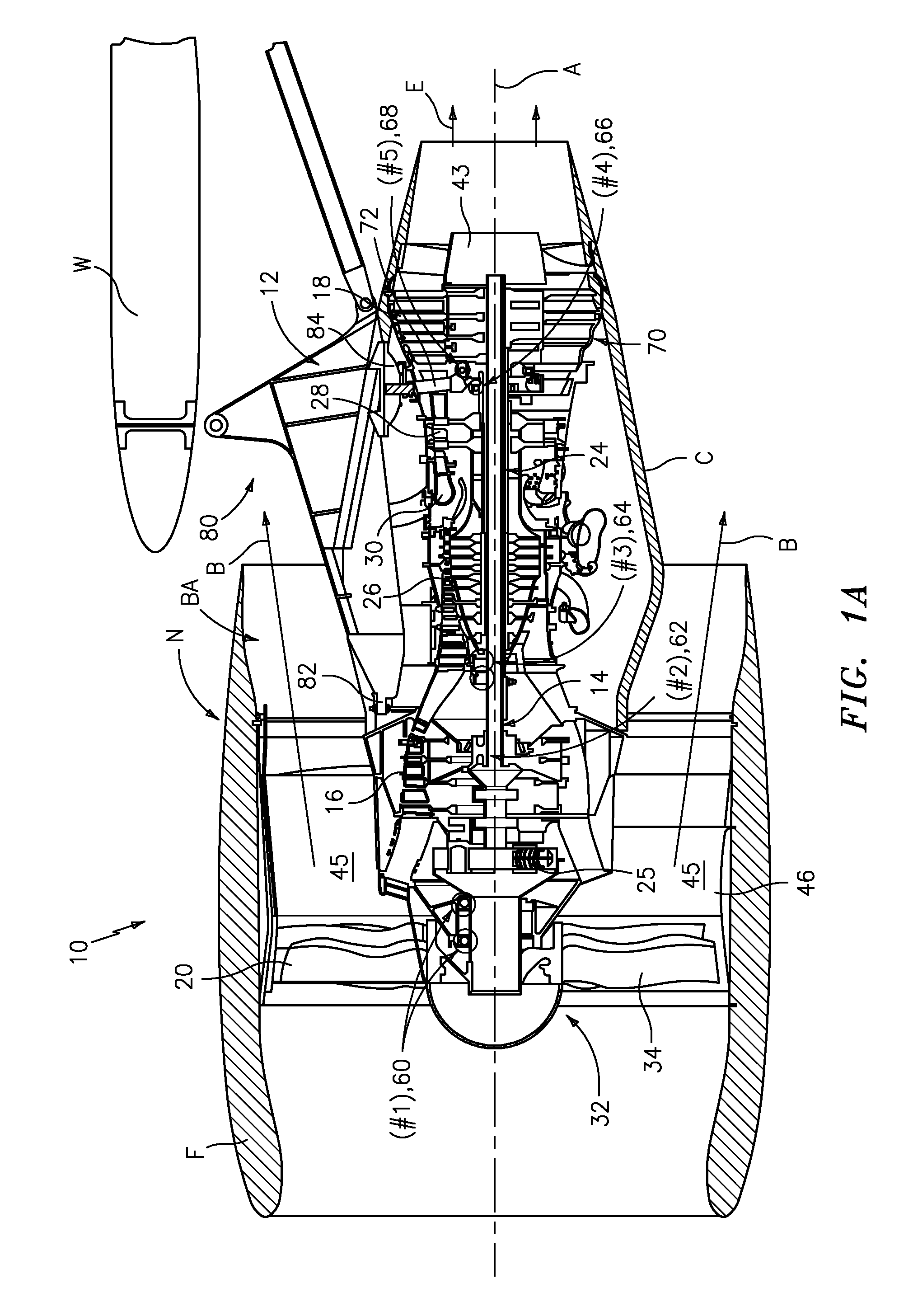

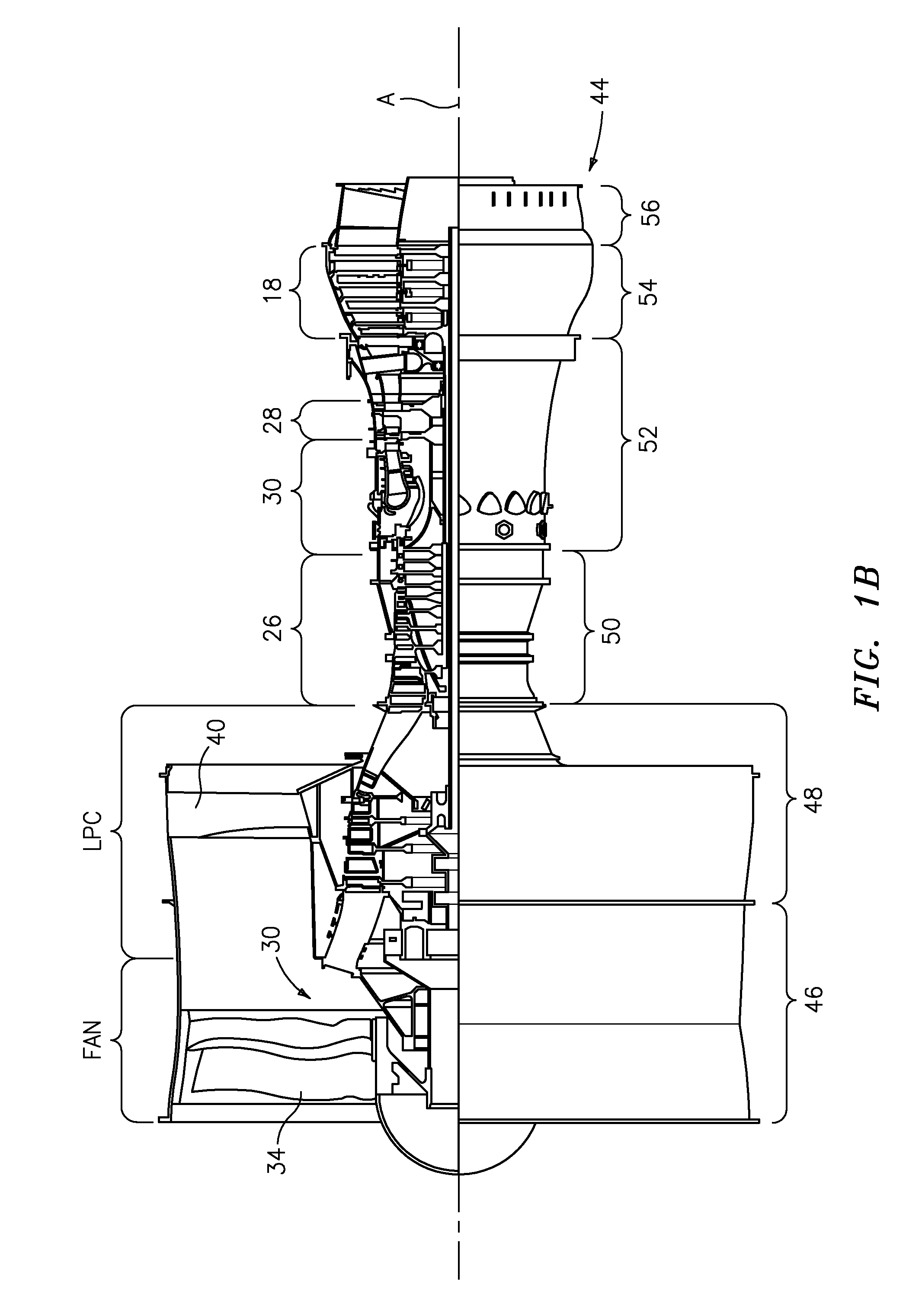

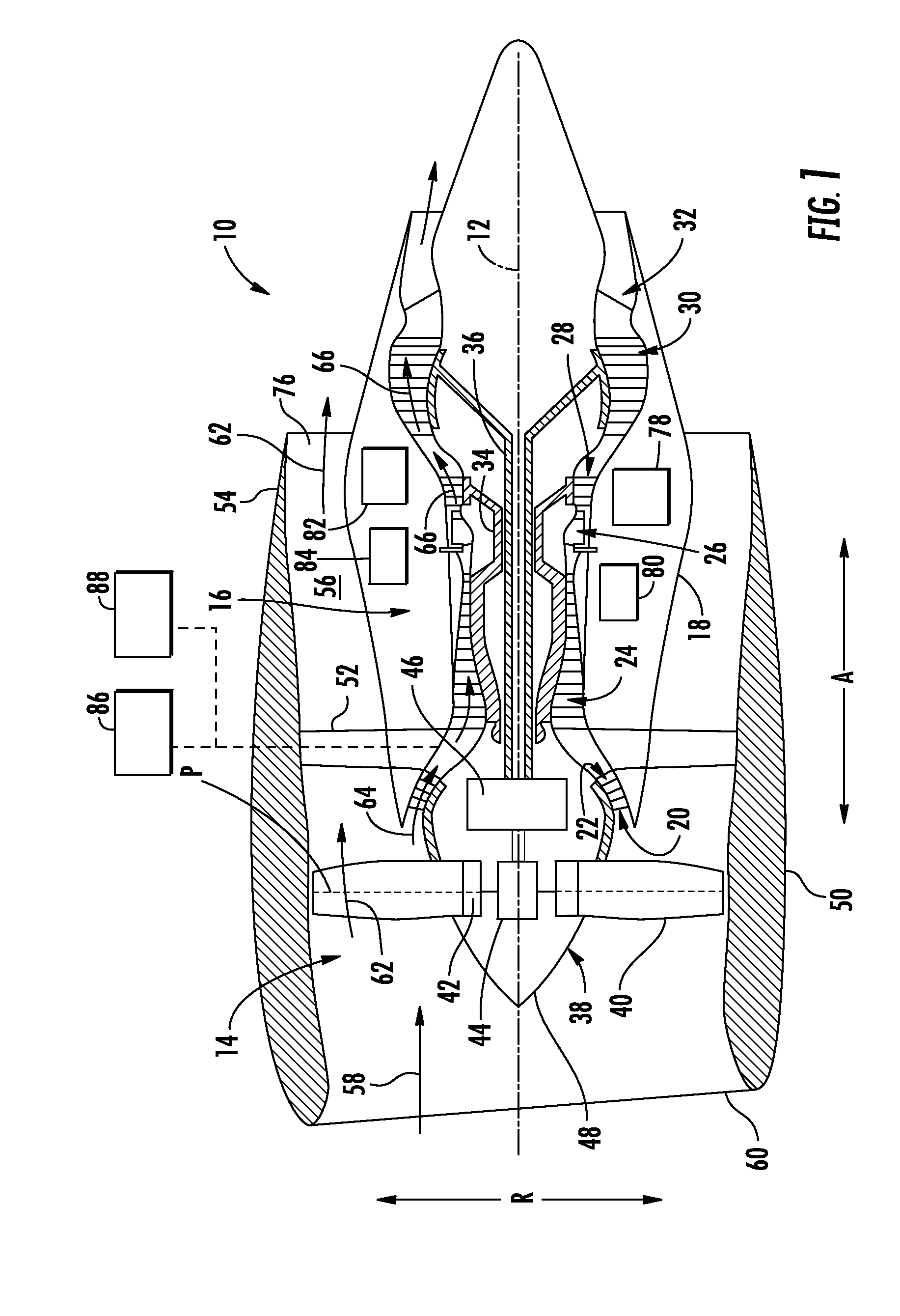

Aircraft combination engines thermal management system

InactiveUS7836680B2Engine fuctionsCombination enginesExternal combustion engineThermal management system

An engine combination for generating forces with a gas turbine engine generating force that utilizes an engine lubricant for lubricating moving components in the turbofan engine, and an internal combustion engine provided in the combination as an intermittent combustion engine generating force that utilizes a coolant for transporting heat generated in the intermittent combustion engine away therefrom and having an air intake, there being an air transfer duct connected from a compressor in the gas turbine engine to the air intake to transfer compressed air thereto. A coupling heat exchanger is coupled to both the gas turbine engine and the intermittent combustion engine to have the engine lubricant and the coolant pass therethrough. A further cooling heat exchanger is coupled to both the coupling heat exchanger and the intermittent combustion engine to have a remote fluid from a source thereof and the coolant pass therethrough.

Owner:RAYTHEON TECH CORP

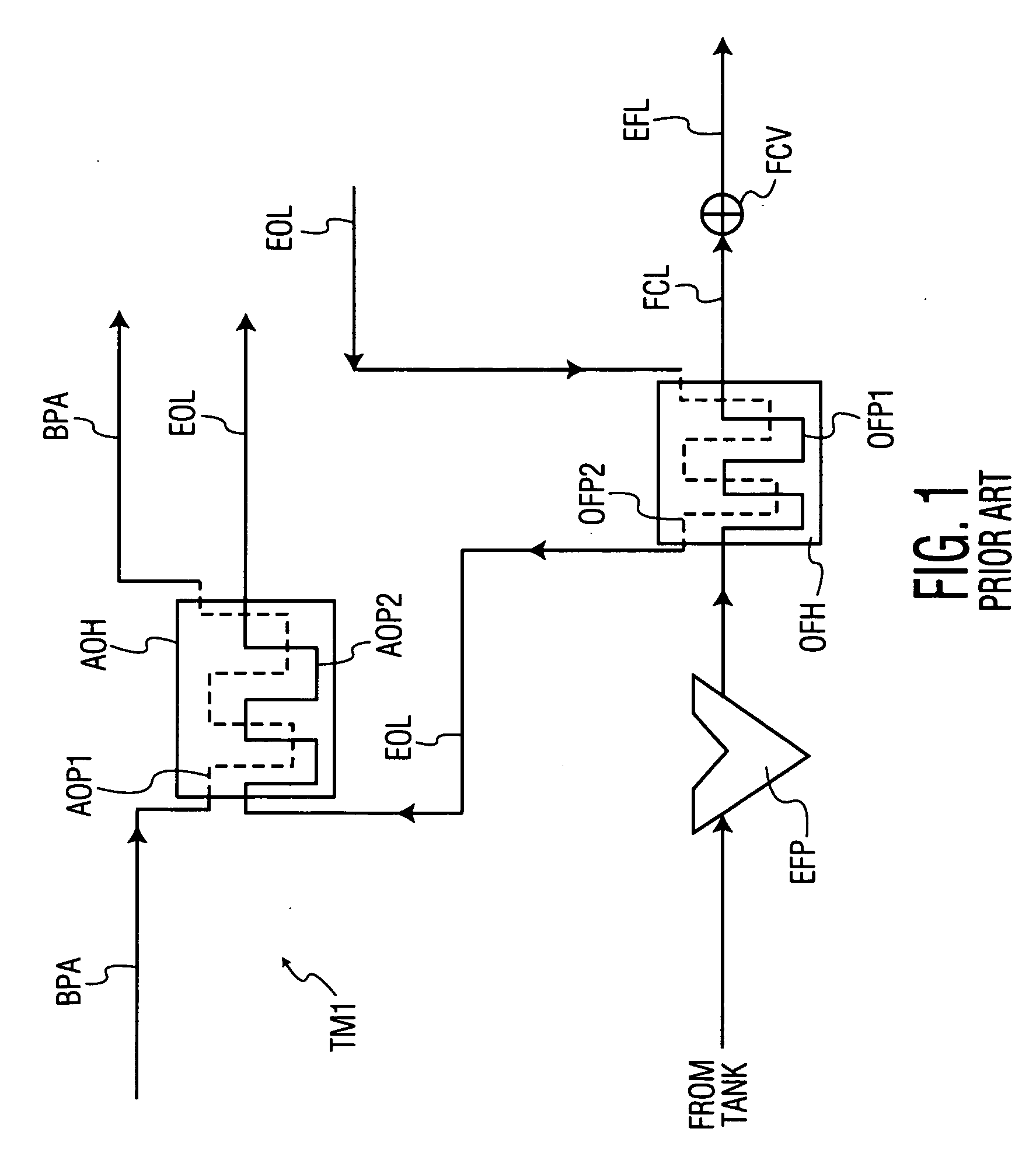

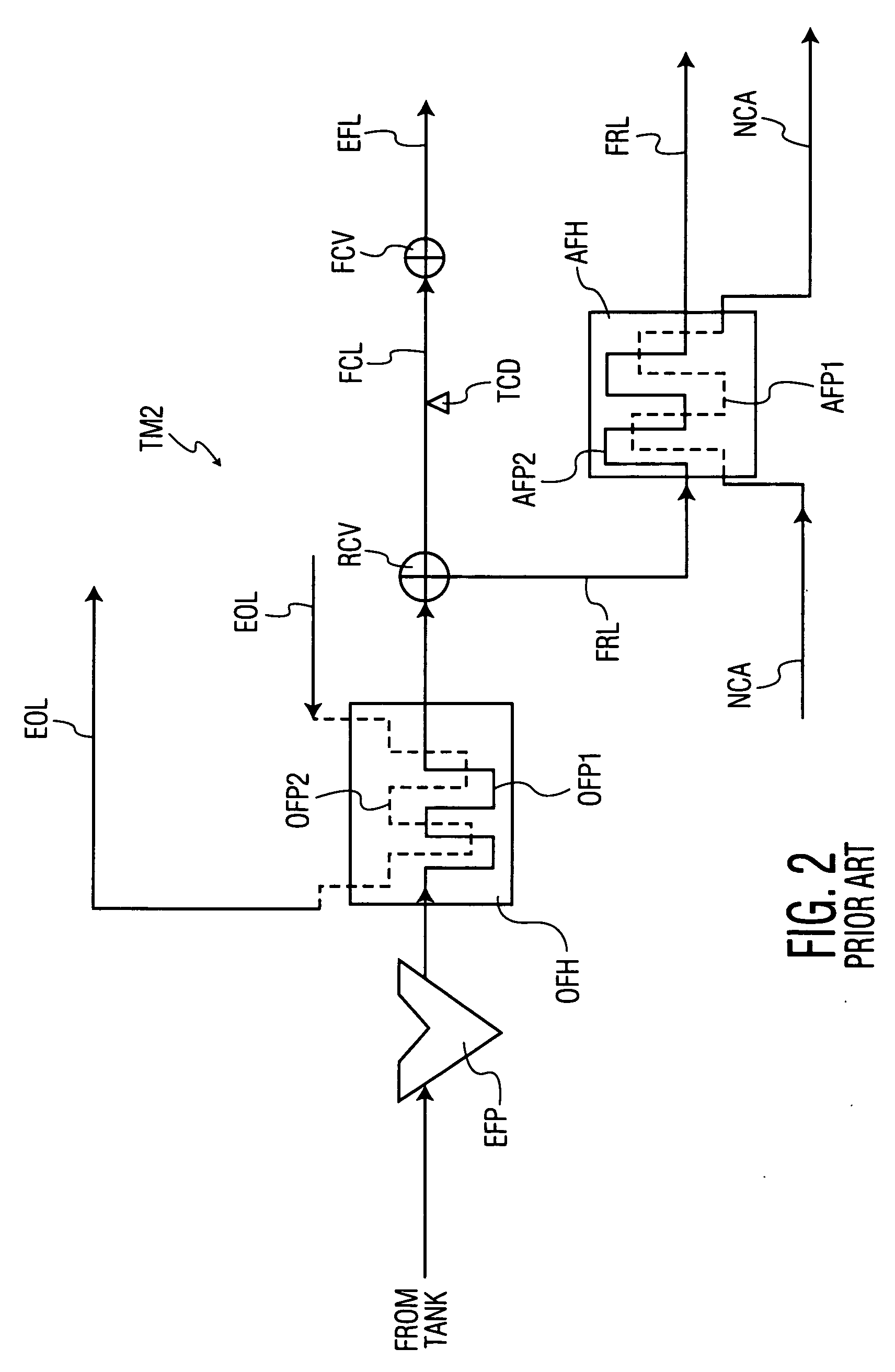

Method and apparatus for controlling fuel in a gas turbine engine

InactiveUS20090313999A1Solution value is not highTurbine/propulsion engine coolingTurbine/propulsion fuel valvesWorking fluidCombustor

A method and system for controlling fuel in a gas turbine engine including a fuel supply system channeling fuel to a combustor are provided. The system includes a first heat exchanger configured to transfer heat between a working fluid and a first cooling medium. The system also includes a second heat exchanger in series flow communication with the first heat exchanger wherein the second heat exchanger is configured to transfer heat between the working fluid and a second cooling medium. The system further includes a modulating valve configured to control the flow of at least one of the first and the second cooling media to maintain a temperature of the first or second cooling medium substantially equal to a predetermined limit.

Owner:GENERAL ELECTRIC CO

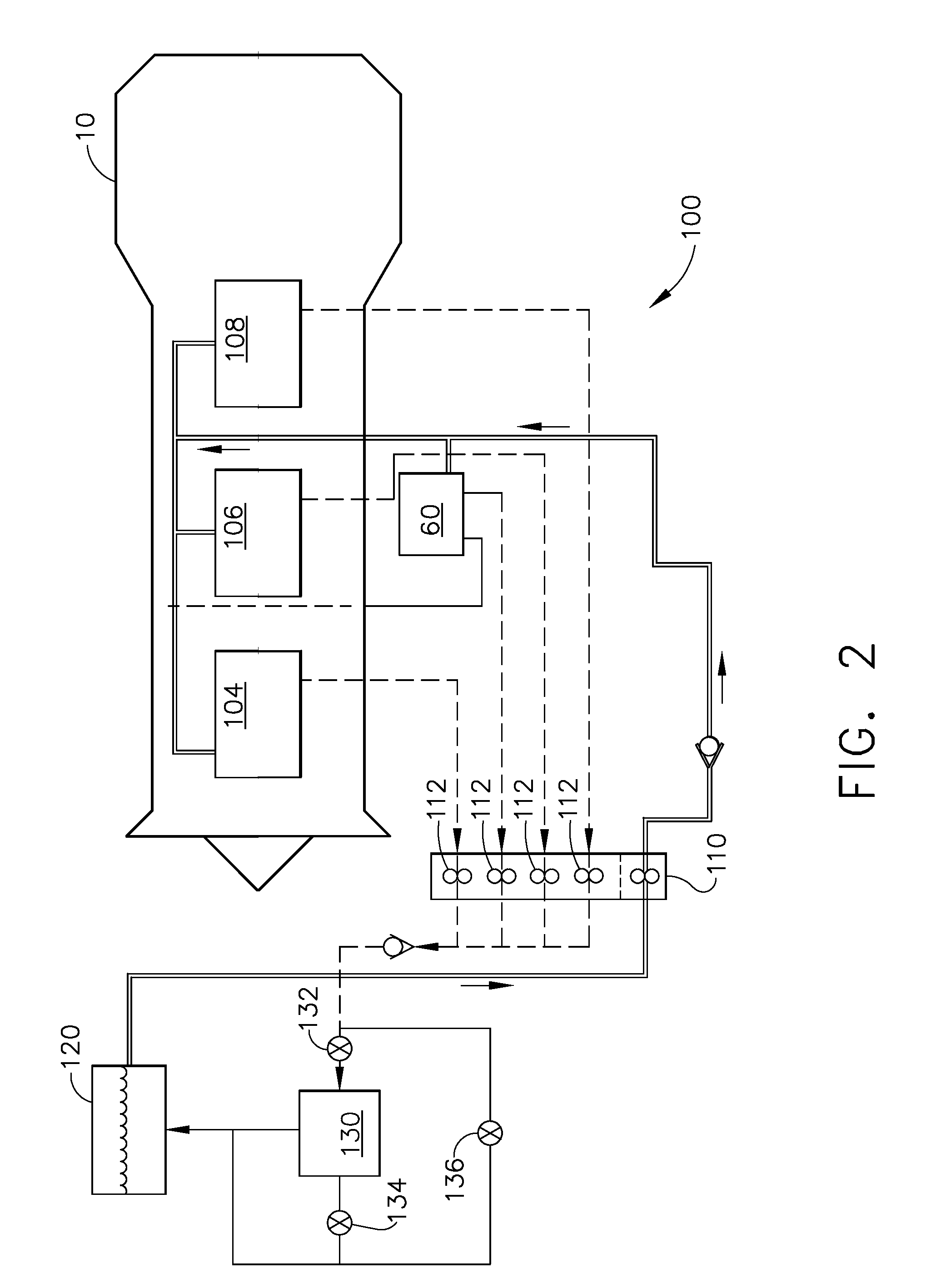

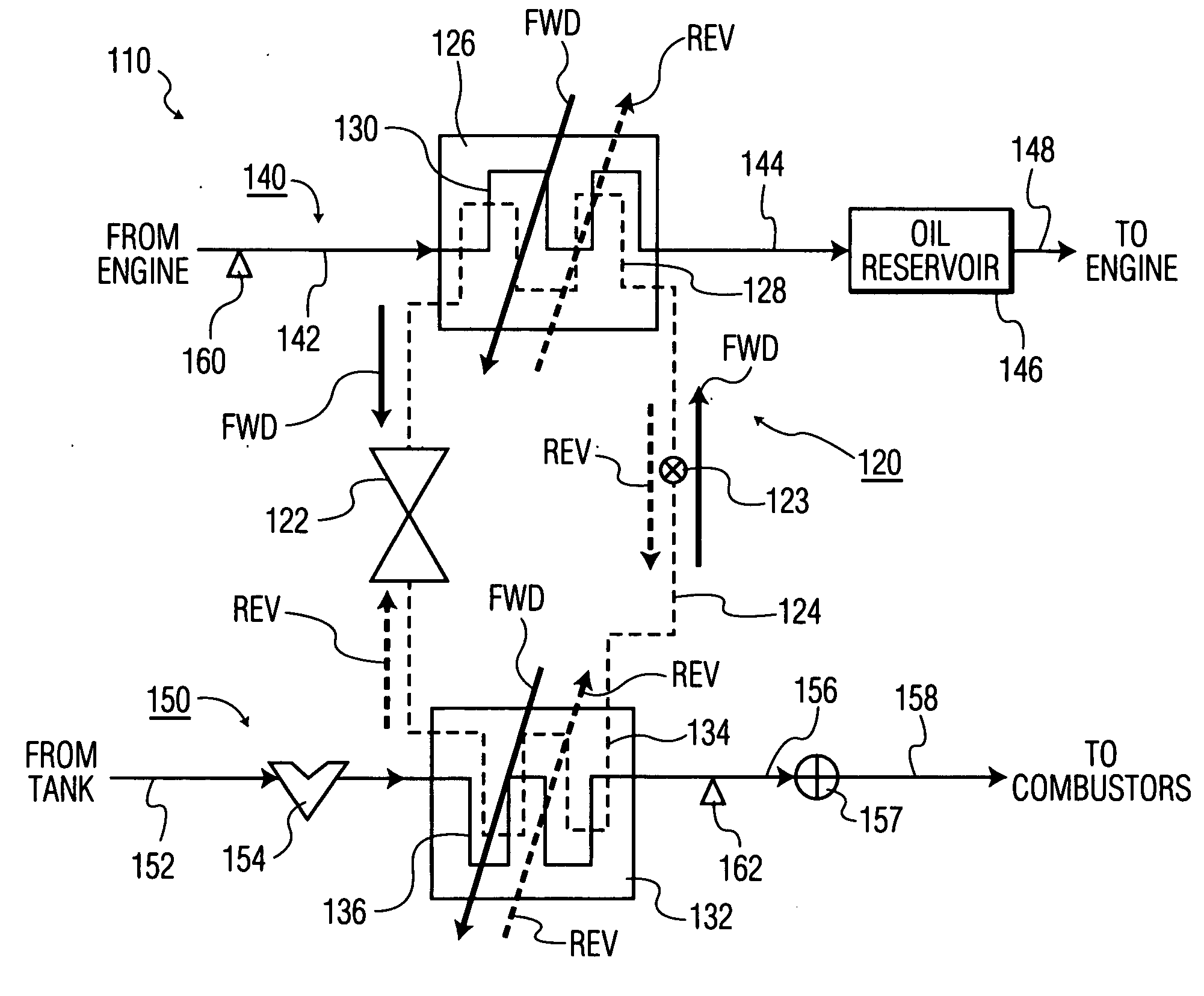

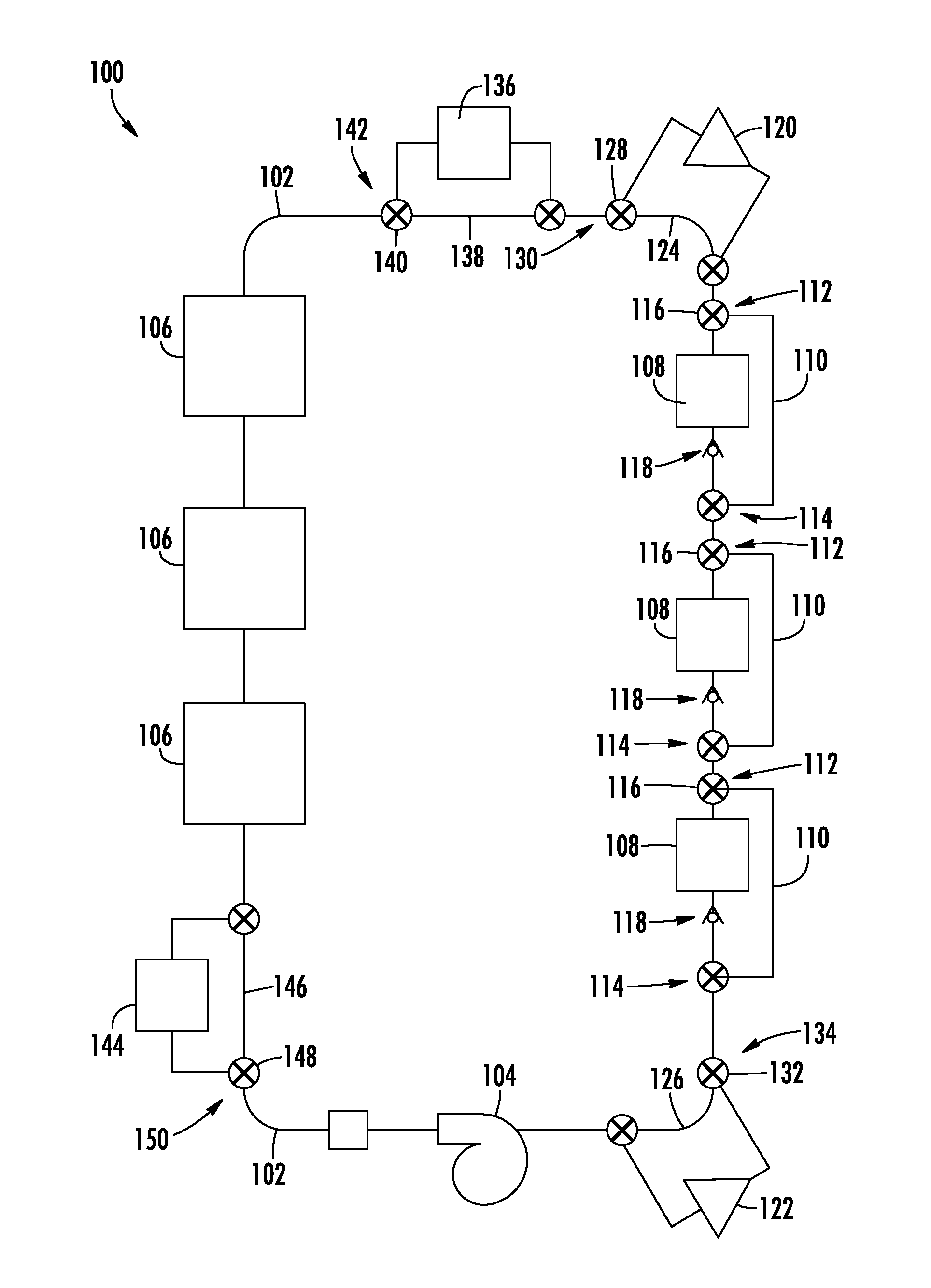

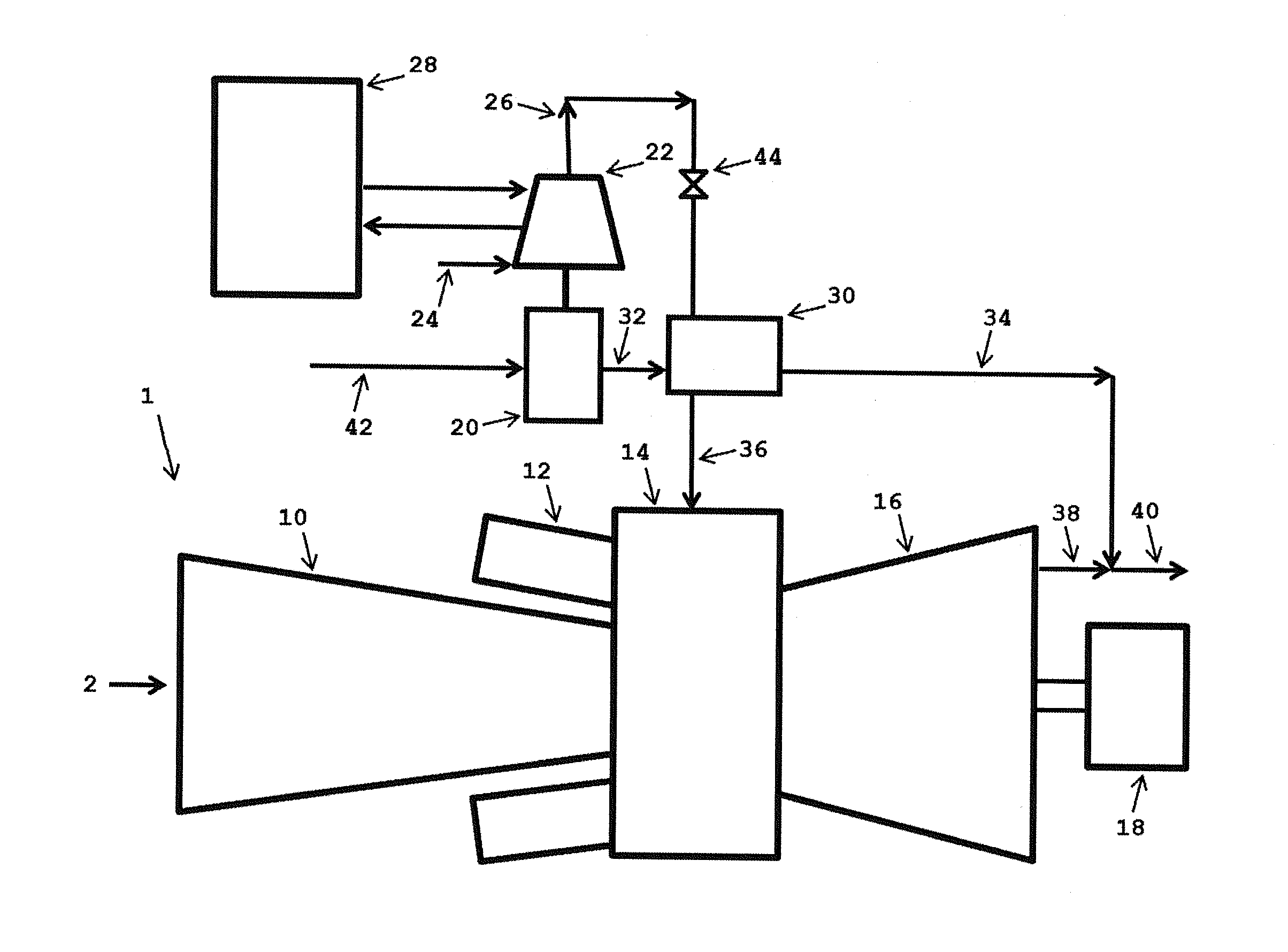

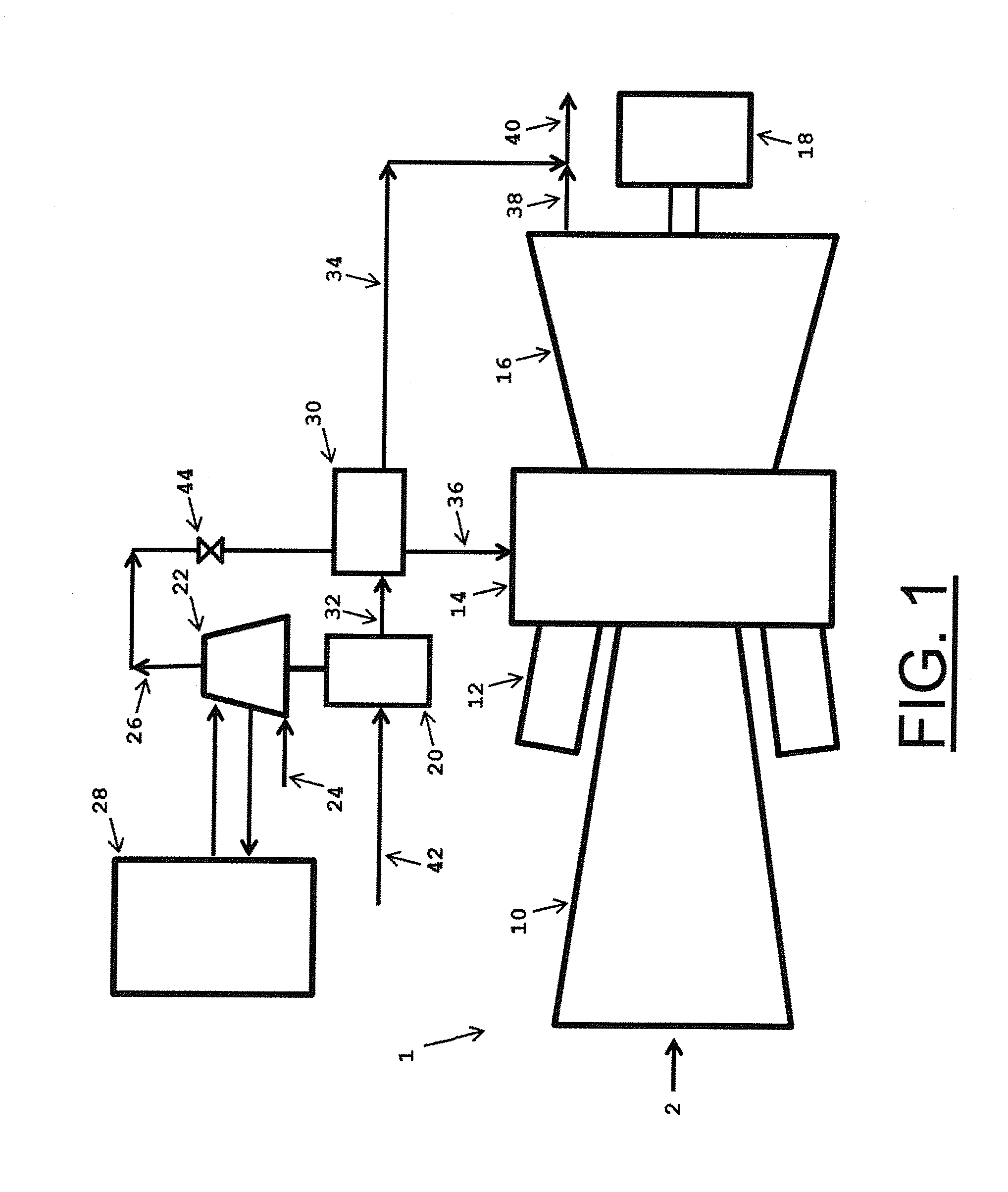

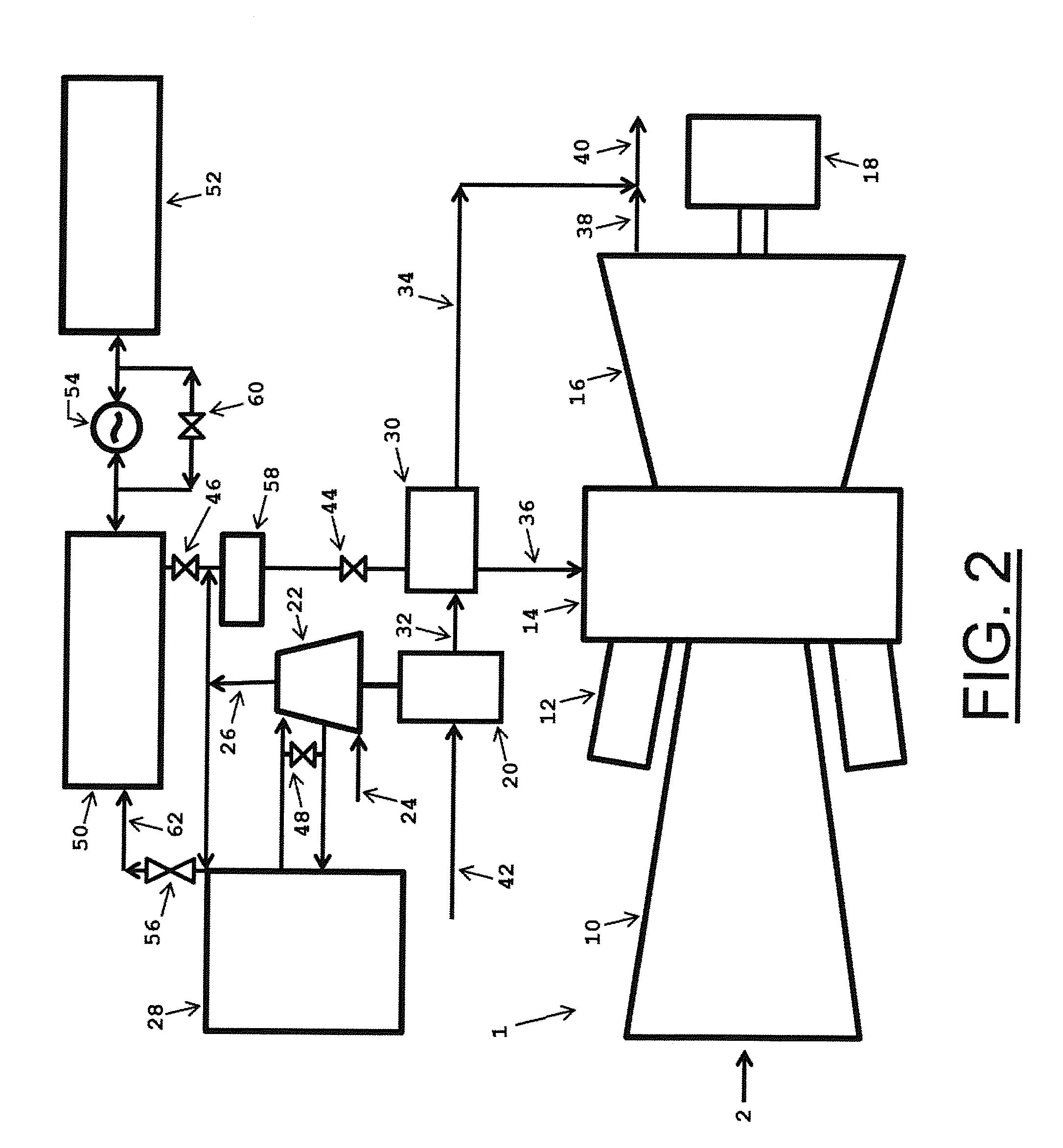

Systems and methods for thermal management in a gas turbine powerplant

InactiveUS20100107603A1Minimize impactReduce coke depositionAnalogue computers for vehiclesTurbine/propulsion engine coolingWorking fluidThermal management system

A thermal management system for a gas turbine powerplant with an engine oil line and an engine fuel line incorporates a heat transfer control module that includes a reversible heat pump with a heat pump compressor for circulating working fluid in forward and reverse directions through a working fluid line of the heat pump. The heat control module also includes a first heat exchanger having a heat exchange path for the working fluid between the compressor and a heat pump expansion valve and another heat exchange path for the engine oil. A second heat exchanger has a heat exchange path for the working fluid between the compressor and the expansion valve and another heat exchange path for the engine fuel. The heat pump can be operated in forward or reverse directions depending on whether heat is to be transferred from the engine oil or the fuel to the heat pump working fluid. In another embodiment an engine oil reservoir located between the first heat exchanger and the engine collects the oil before it is introduced to the engine and thus acts as a heat capacitor for the system.

Owner:PROPULSION GAS TURBINE & ENERGY EVALUATIONS

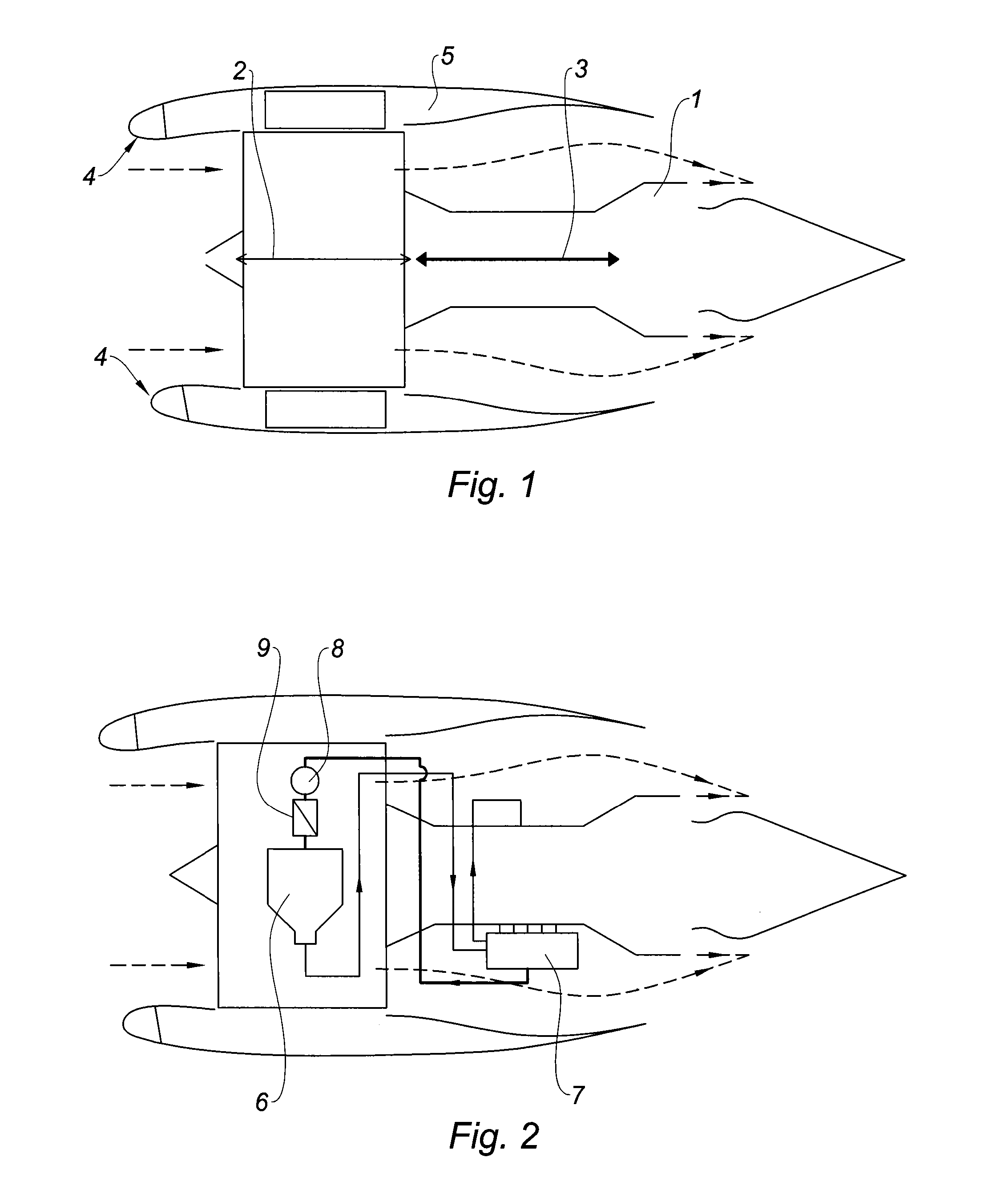

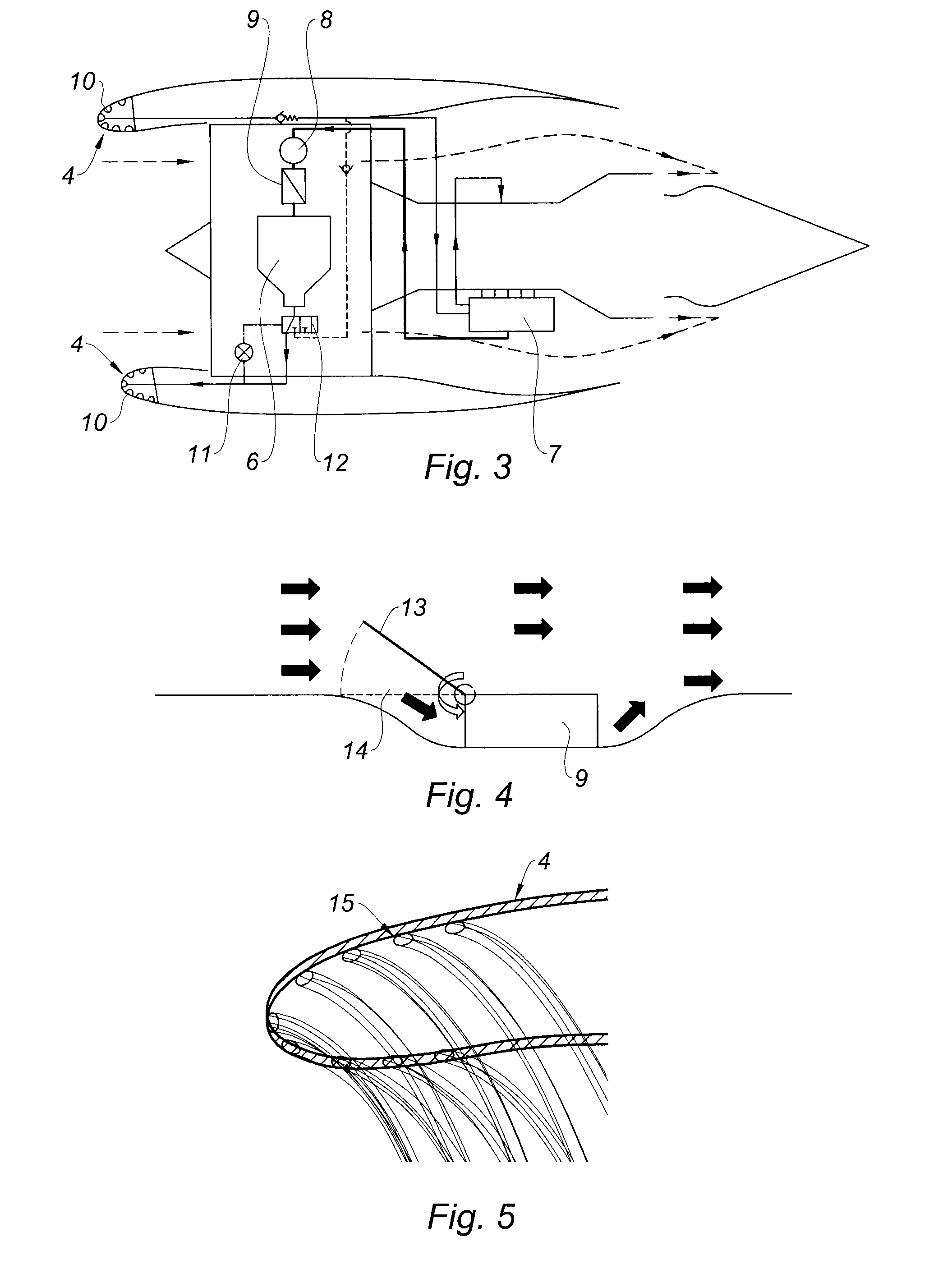

Regulated oil cooling system for a turbine engine with deicing of the nacelle

InactiveUS20140205446A1Many timesDischarging heatPump componentsGas turbine plantsNacelleCooling capacity

The invention relates to an oil cooling system of a turbine engine installed in an aircraft comprising a circuit suitable for circulating the oil between the engine and at least one external heat exchanger placing the oil in thermal communication with a part of the lip of the nacelle, wherein it also comprises at least one air / oil heat exchanger placing the oil in thermal communication with the air circulating in the cold zone of the turbine engine, equipped with a device suitable for varying its oil cooling capacity, and with a control means for said cooling capacity variation device.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Thermal management system integrated pylon

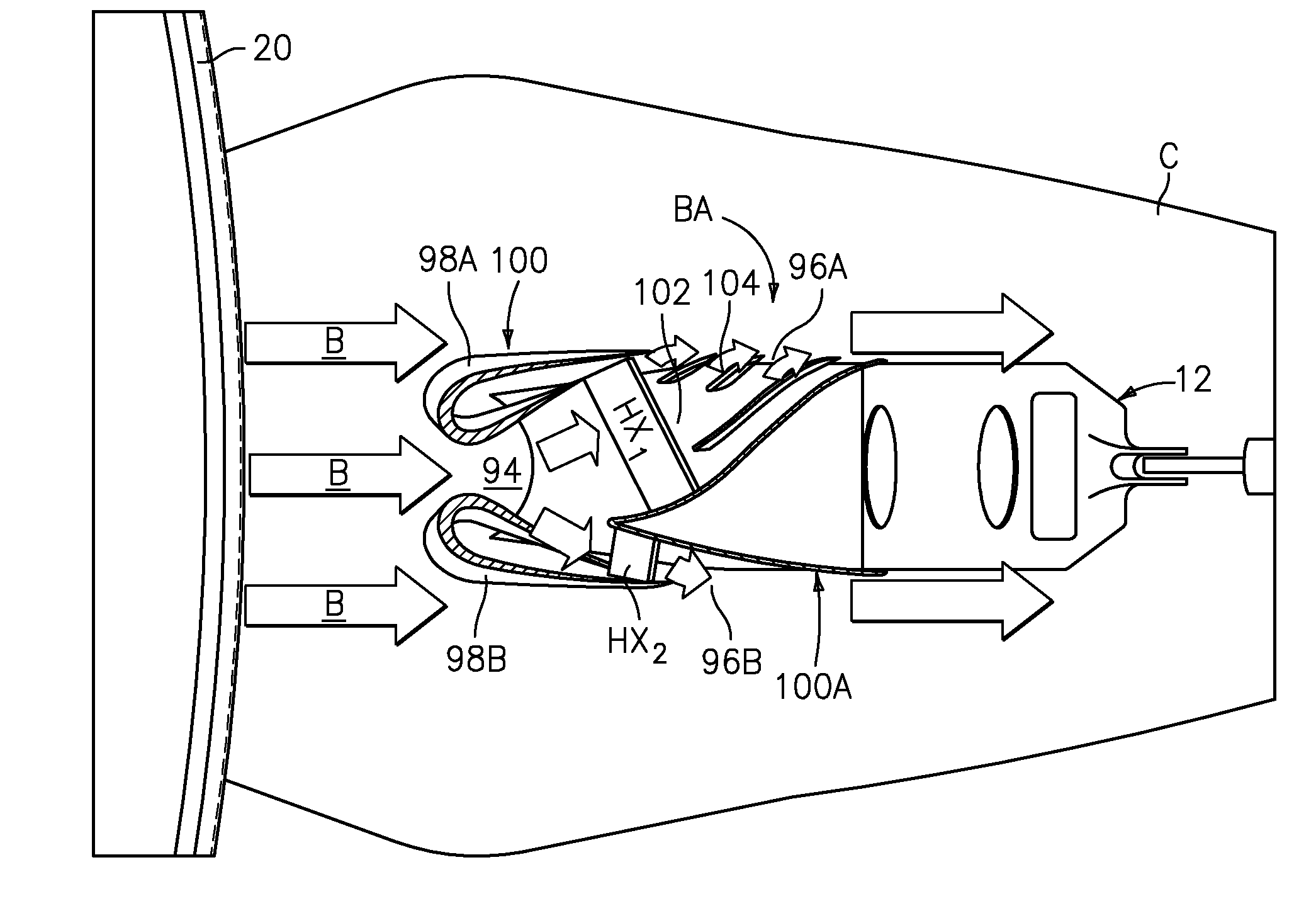

ActiveUS20090188232A1Power plant cooling arrangmentsTurbine/propulsion engine coolingEngineeringThermal management system

A thermal management system includes at least one heat exchanger in communication with a bypass flow of a gas turbine engine. The placement of the heat exchanger(s) minimizes weight and aerodynamic losses and contributes to overall performance increase over traditional ducted heat exchanger placement schemes.

Owner:RAYTHEON TECH CORP

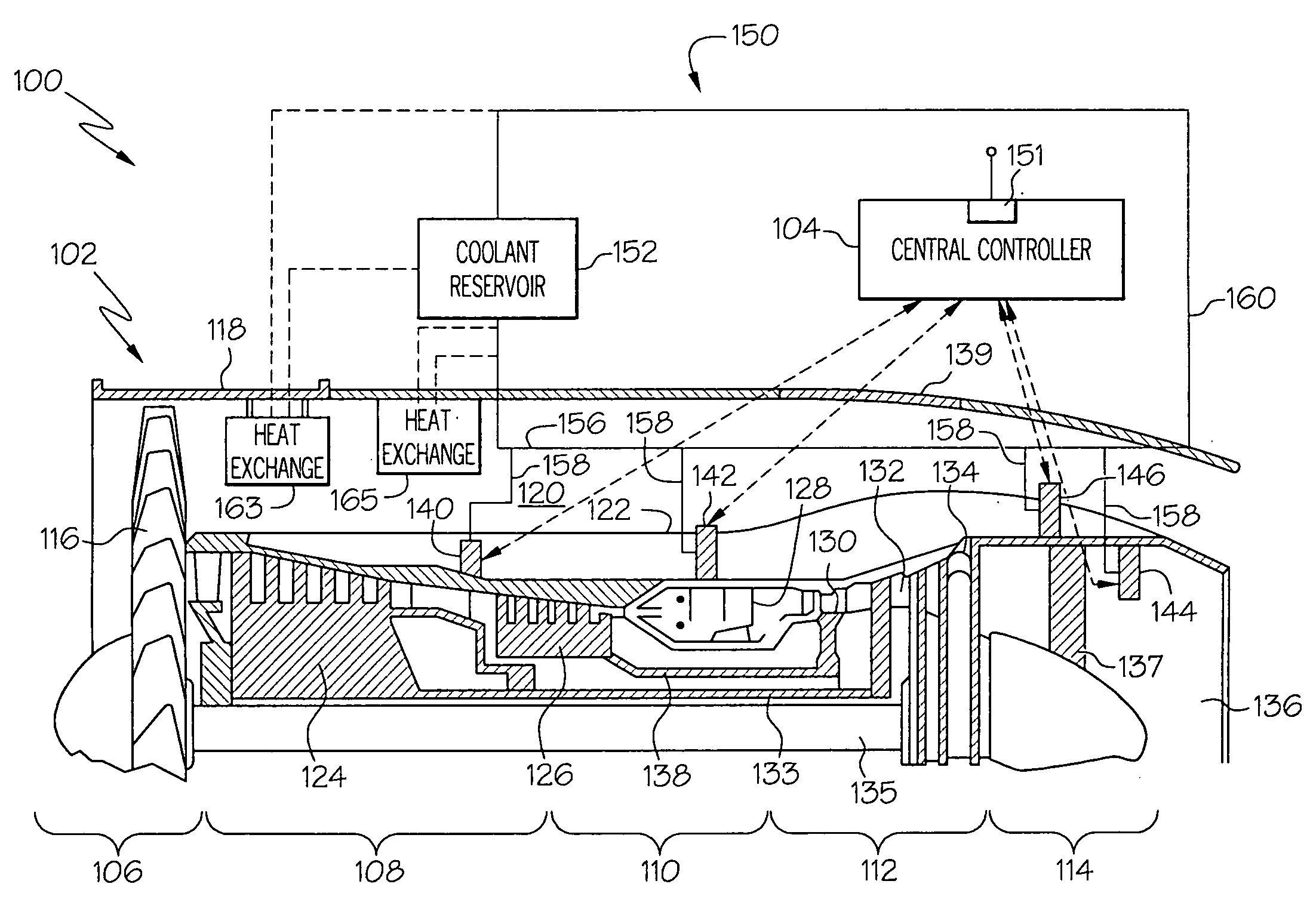

Distributed engine control systems and gas turbine engines

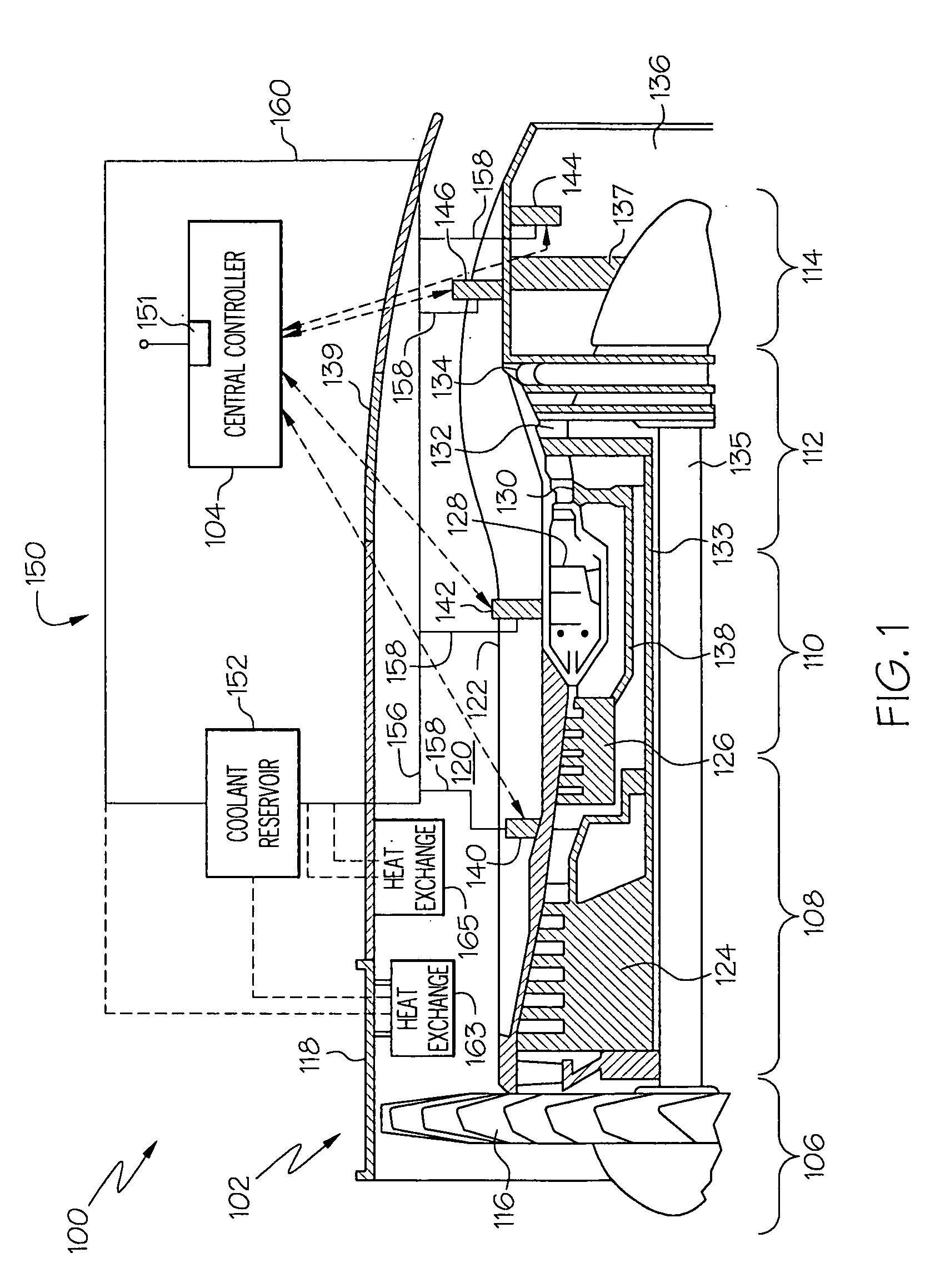

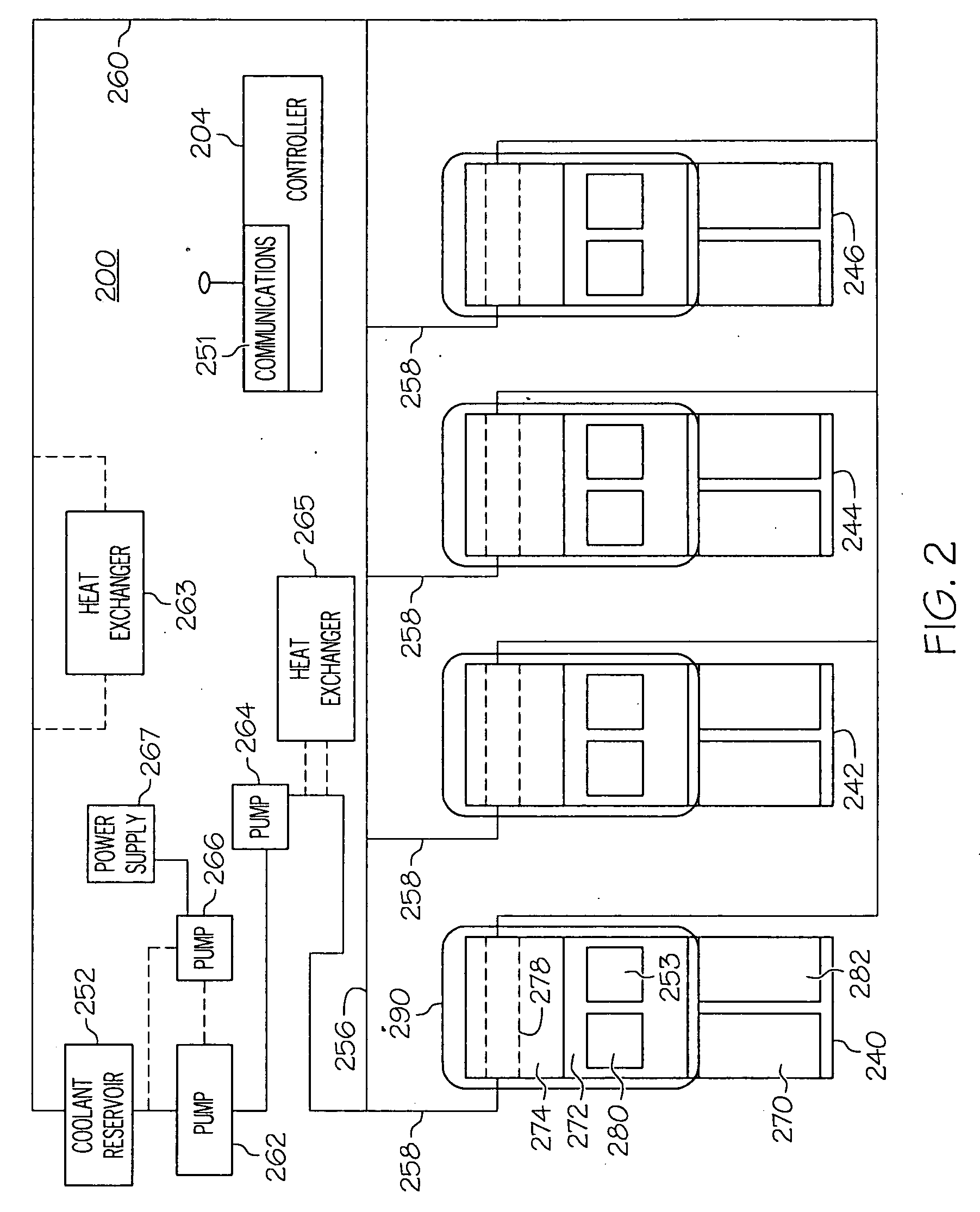

InactiveUS20100242492A1Turbine/propulsion engine coolingEfficient propulsion technologiesControl systemDistribution system

Distributed engine control systems and gas turbine engines are provided. In an embodiment, a distributed engine control system includes a central controller, a plurality of nodes in operable communication with the central controller, each node including an electronic circuit and a heat transfer element adapted to absorb heat from the electronic circuit, each node in communication with the central controller, and a coolant distribution system including a plurality of coolant interfaces, a coolant line, and a coolant source, each coolant interface of the plurality of coolant interfaces adapted to contain a coolant that is adapted to absorb heat from the heat transfer element of a node of the plurality of nodes, and the coolant line adapted to provide fluid communication between the nodes of the plurality of nodes and the coolant source

Owner:HONEYWELL INT INC

Cooling system

ActiveUS20170030266A1Engine fuctionsTurbine/propulsion engine coolingEngineeringThermal management system

A thermal management system for a gas turbine engine and / or an aircraft is provided including a thermal transport bus having a heat exchange fluid flowing therethrough. The thermal management system also includes a plurality of heat source exchangers and at least one heat sink exchanger. The plurality of heat source exchangers and the at least one heat sink exchanger are in thermal communication with the heat exchange fluid in the thermal transport bus. The plurality of heat source exchangers are arranged along the thermal transport bus and configured to transfer heat from one or more accessory systems to the heat exchange fluid, and the at least one heat sink exchanger is located downstream of the plurality of heat source exchangers and configured to remove heat from the heat exchange fluid.

Owner:GENERAL ELECTRIC CO

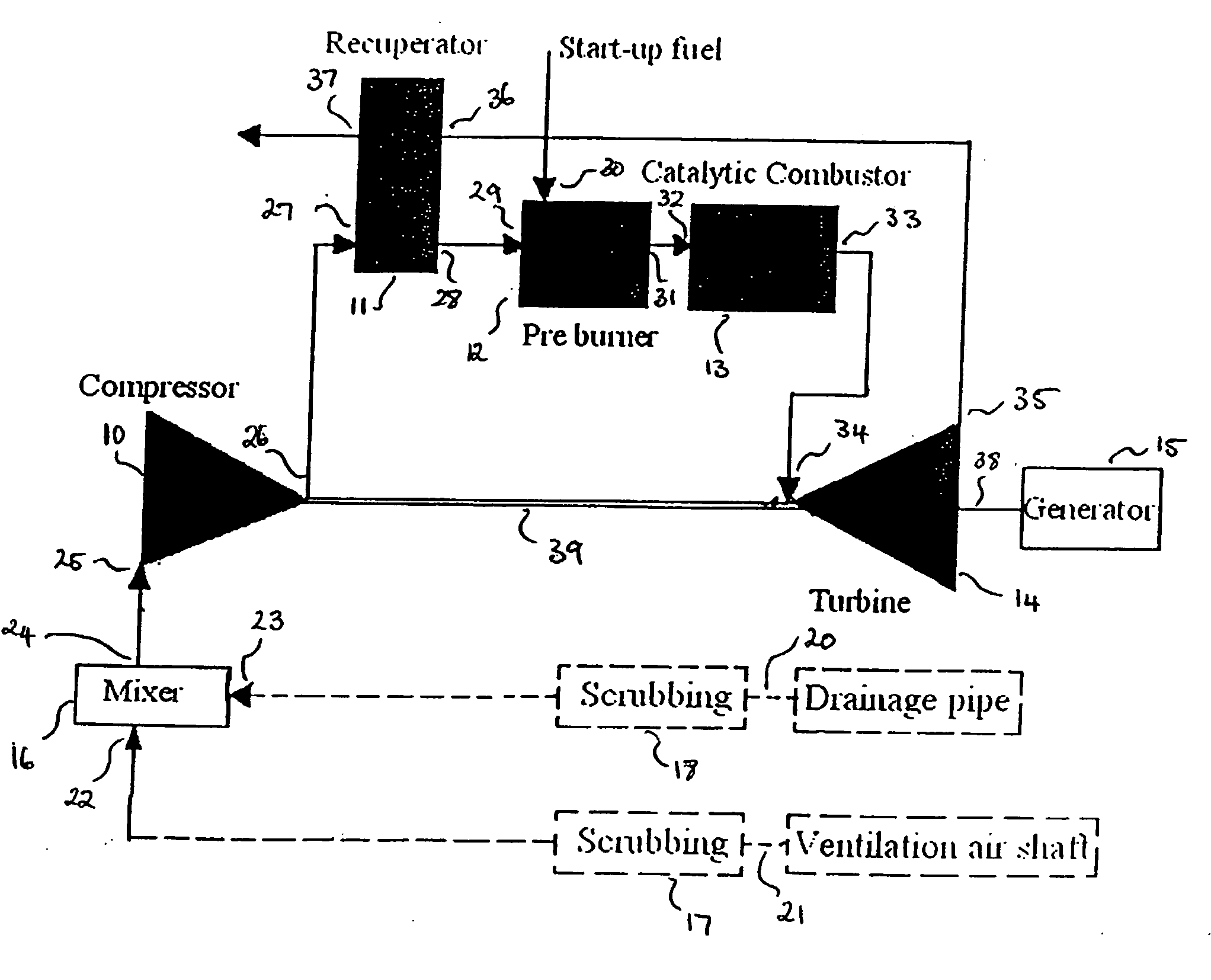

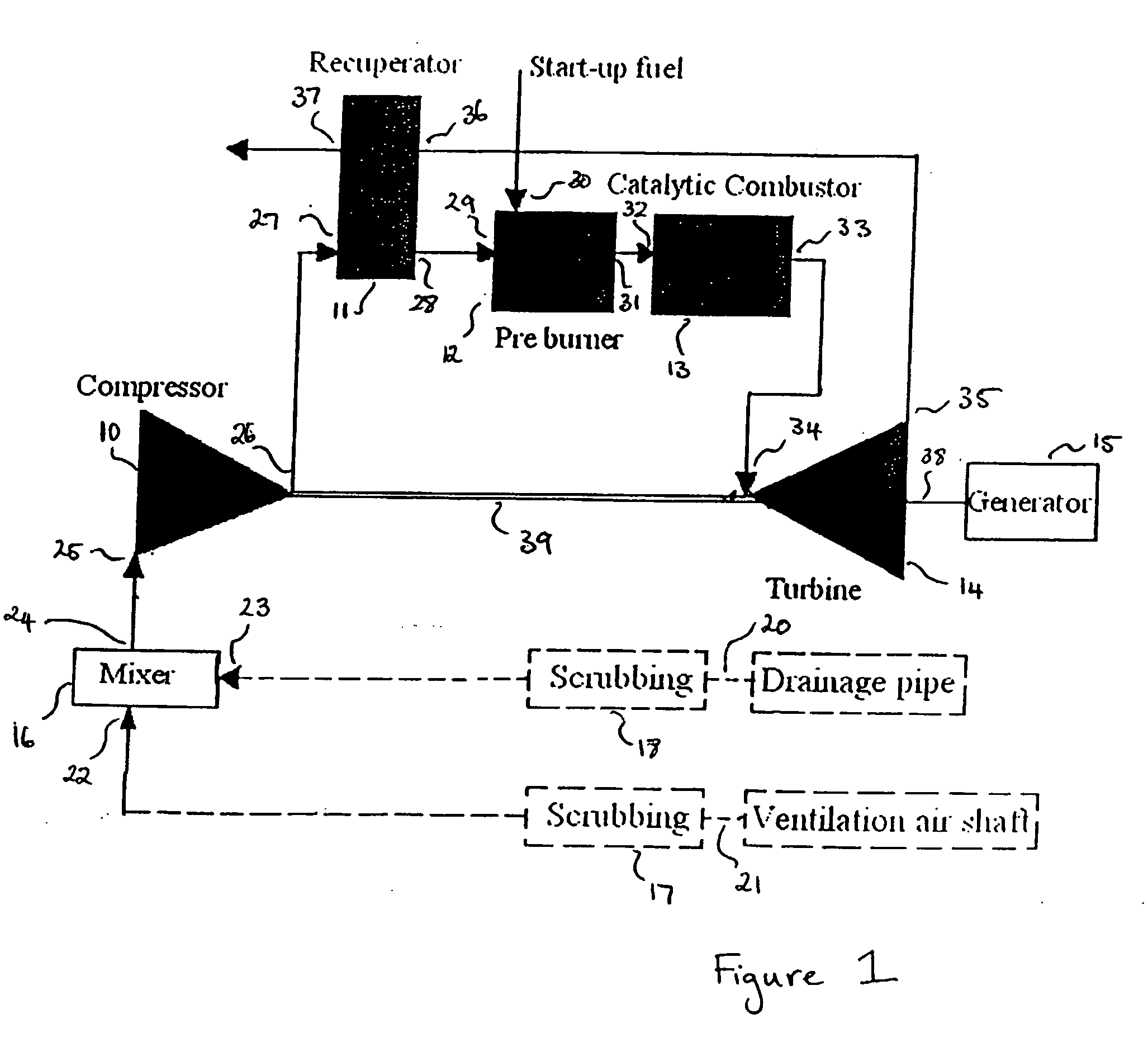

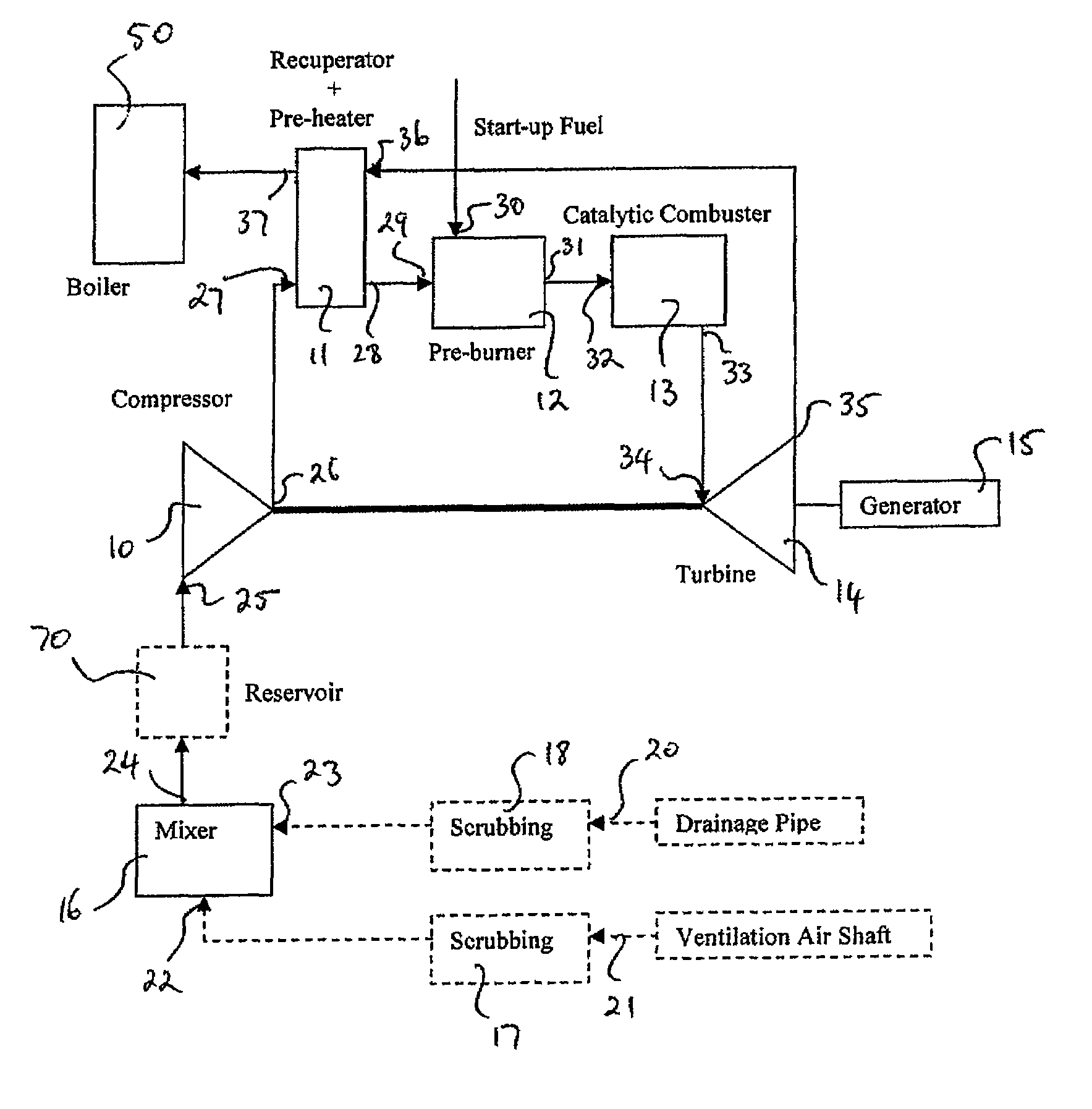

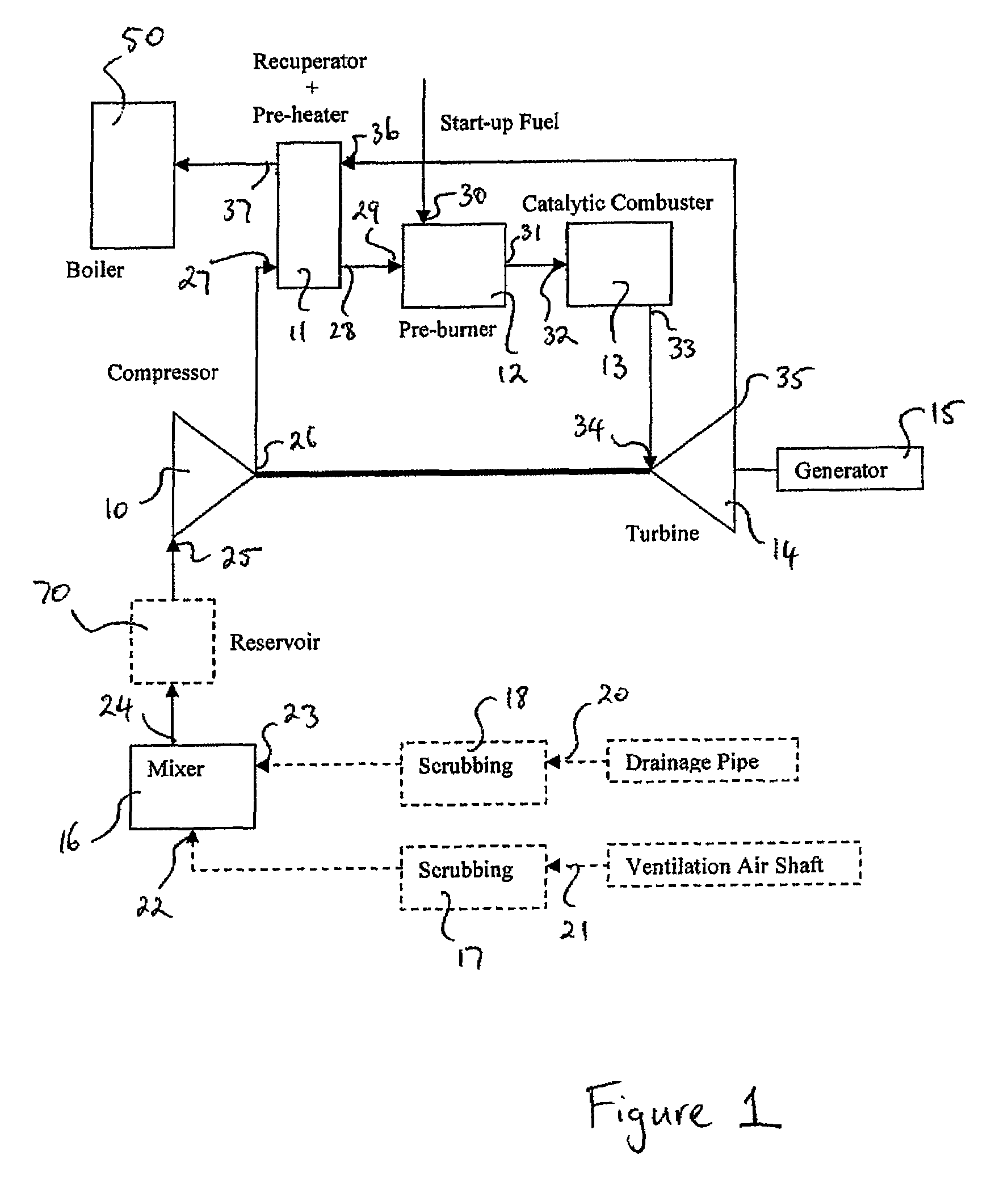

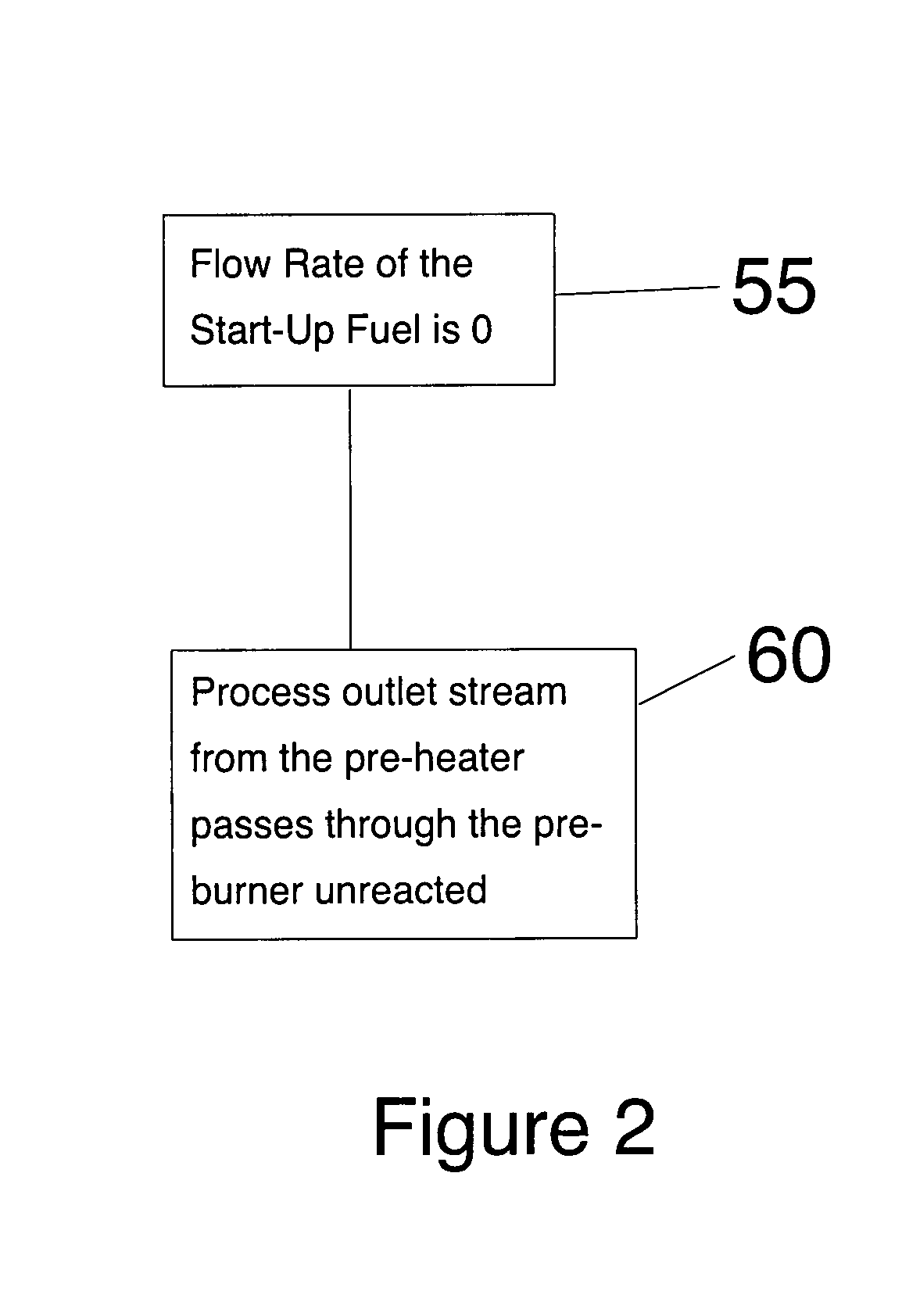

System for catalytic combustion

ActiveUS20060150635A1High activityLarge specific surface areaContinuous combustion chamberTurbine/propulsion engine ignitionEnvironmental engineeringTurbine

A system comprising a compressor (10) having an inlet stream (25) and an outlet stream (26), a pre-heater (12) having a process inlet stream (29) and a process outlet stream (31), a catalytic combustor (13) having an inlet stream (32) and an outlet stream (33) and containing an catalyst, and a turbine (14) having an inlet stream (34) and an outlet stream (35), wherein, the outlet stream (26) of the compressor(10) is connected to the process inlet stream (29) of the pre-heater (12), the process outlet stream (31) of the pre-heater (12) is connected to the inlet stream (32) of the catalytic combustor (13). The outlet stream (33) of the catalytic combustor (13) is connected to the inlet stream (34) of the turbine (14). During operation of the system, the inlet stream (25) of the compressor (10) has a substantially constant and low concentration of fuel.

Owner:COMMONWEALTH SCI & IND RES ORG

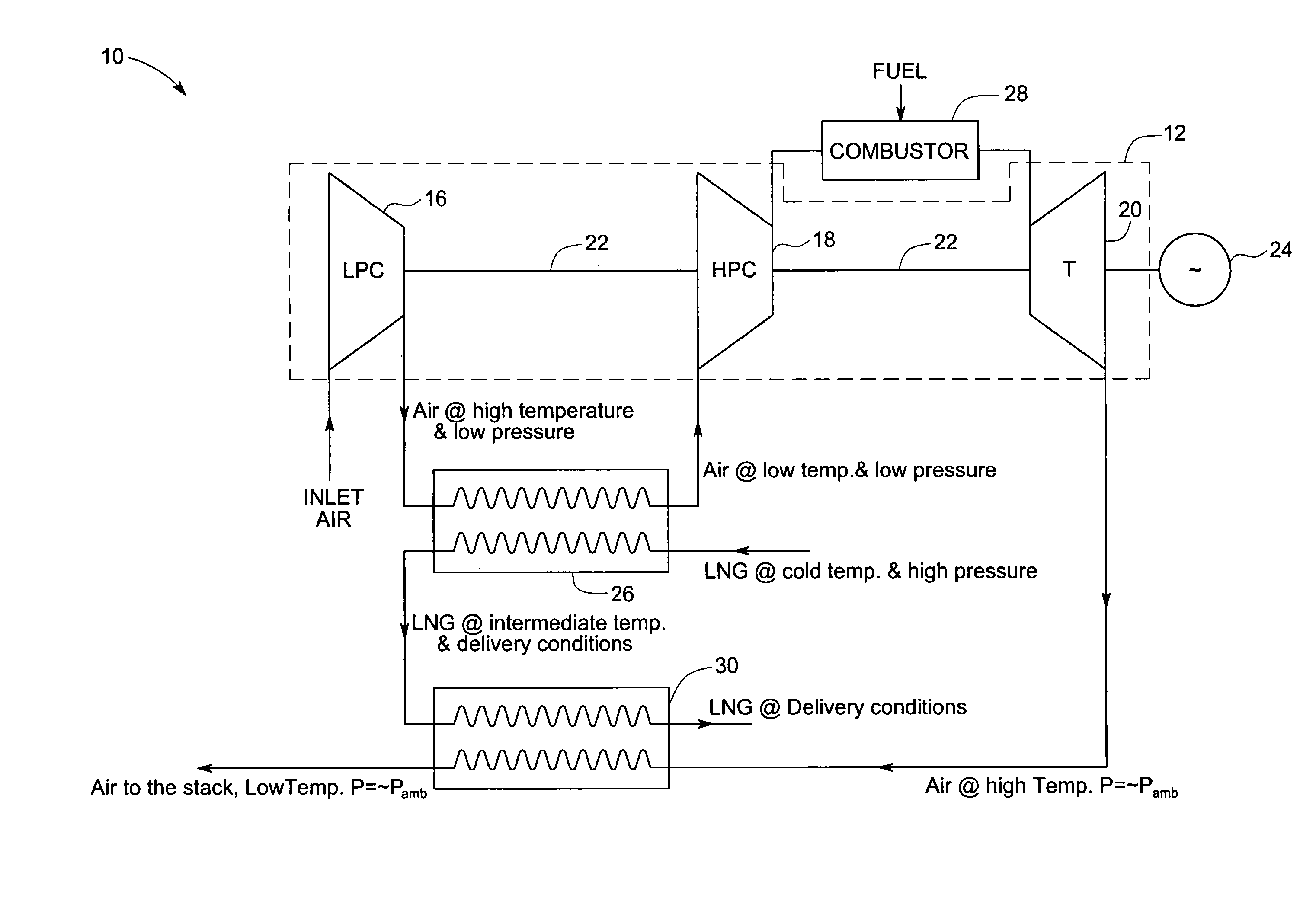

Gas turbine engine system and method of operating the same

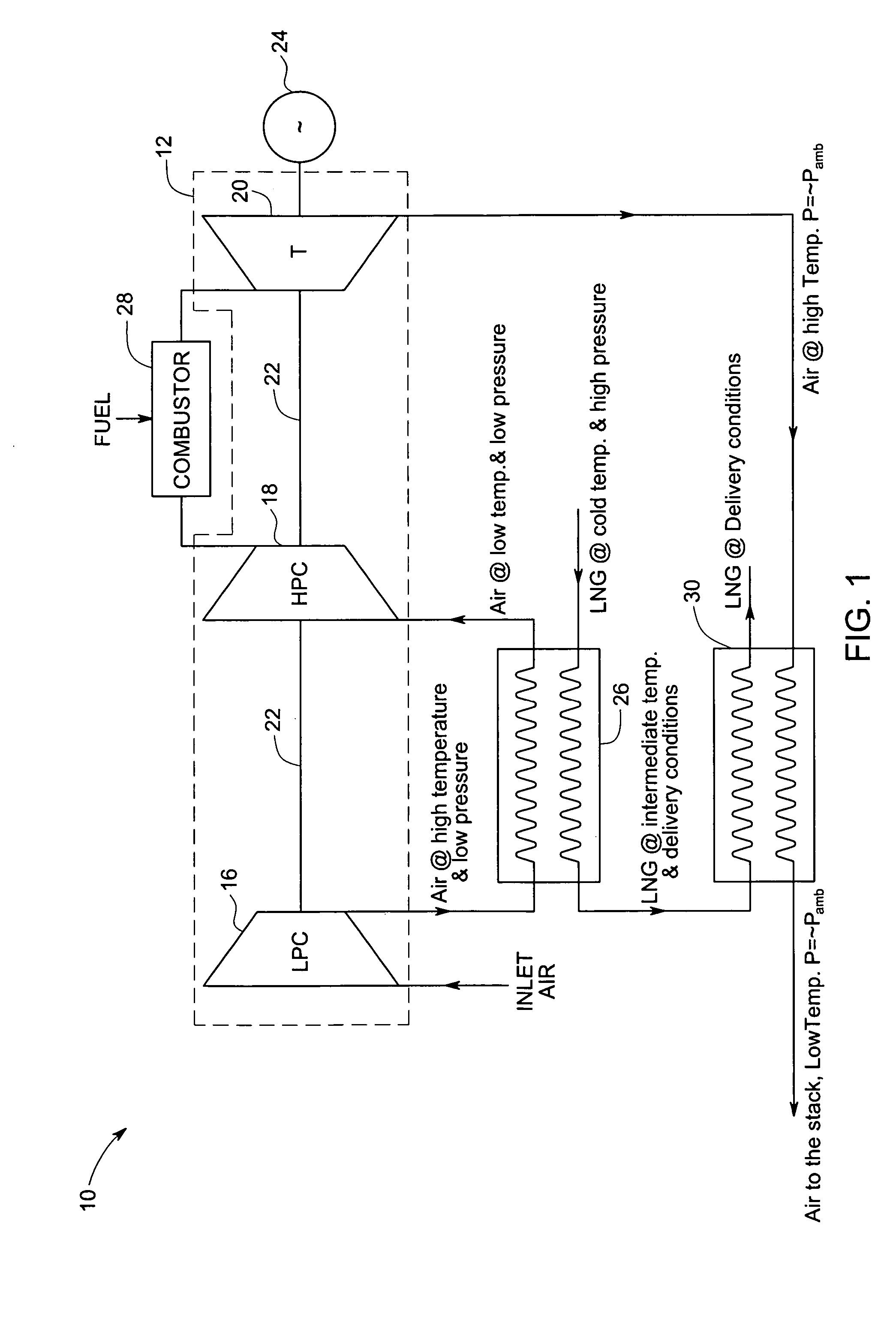

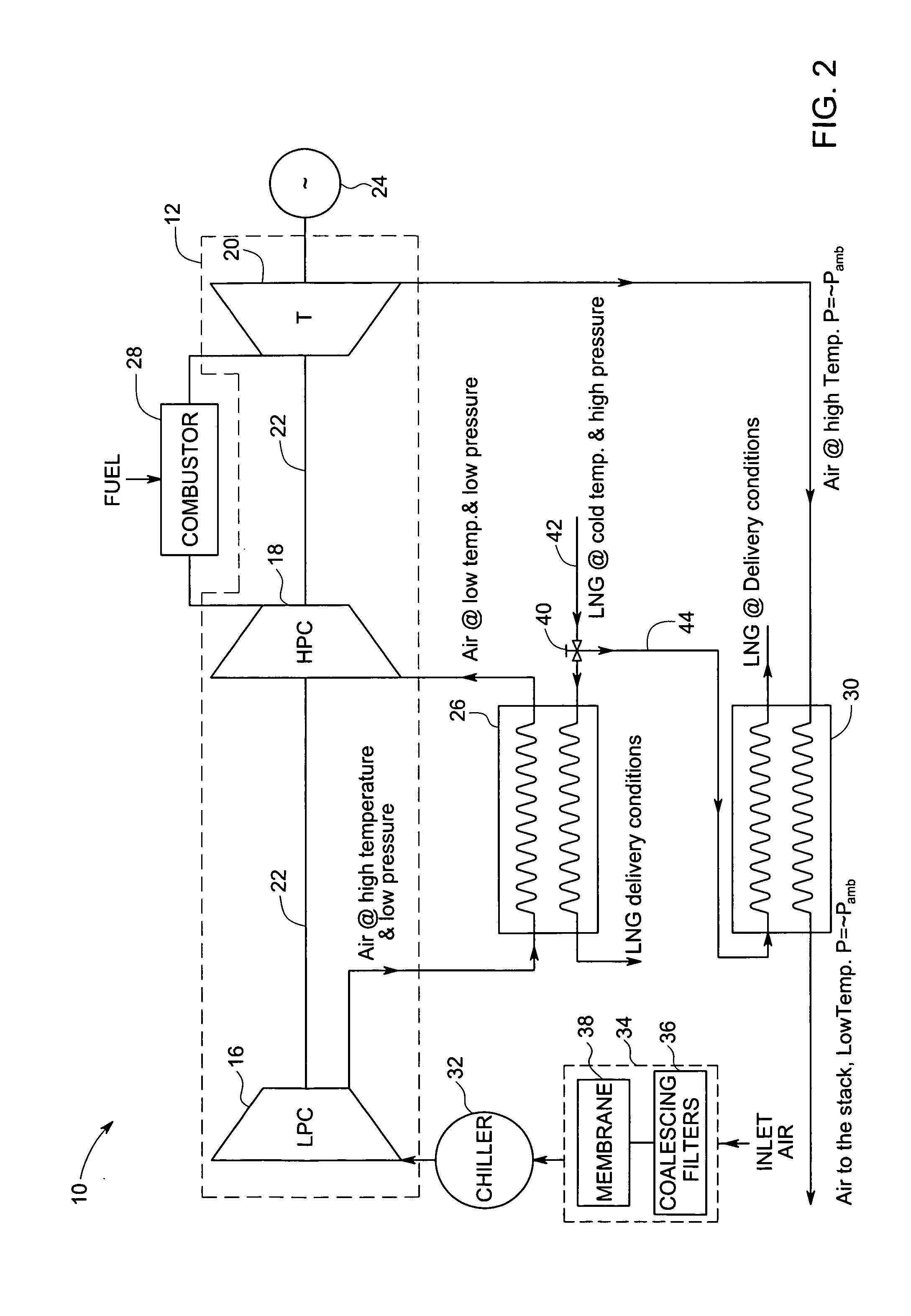

InactiveUS20070089423A1Simple systemTurbine/propulsion engine coolingGas turbine plantsCombustion chamberWorking fluid

A gas turbine engine system includes an intercooler coupled between a low-pressure compressor and a high-pressure compressor and configured to cool the compressed air exiting the low-pressure compressor. Liquid natural gas or a cooled intermediate working fluid is used in the intercooler to cool the compressed air exiting the low-pressure compressor. A mixture of fuel and compressed air from the high-pressure are combusted in a combustion chamber of an engine. A turbine is coupled to the engine and configured to expand combustion exhaust gas ejected from the engine to generate power. A heat exchanger is coupled to the turbine and the intercooler and configured to re-gasify the liquid natural gas. The exhaust air exiting the turbine or a heated intermediate working fluid is used to gasify the liquid natural gas in the heat exchanger.

Owner:GENERAL ELECTRIC CO

Integral heater for fuel conveying member

InactiveUS20060156733A1Combustion typesTurbine/propulsion fuel flow conduitsEngineeringMechanical engineering

A fuel conveying member for an engine, the fuel conveying member having heating means integrated therein to permit pyrolysis of carbonaceous deposits.

Owner:PRATT & WHITNEY CANADA CORP

Shared flow thermal management system

ActiveUS9234481B2Turbine/propulsion engine coolingEfficient propulsion technologiesThermal management systemEngineering

A thermal management system includes at least two of a multiple of heat exchangers arranged in an at least partial-series relationship.

Owner:RTX CORP

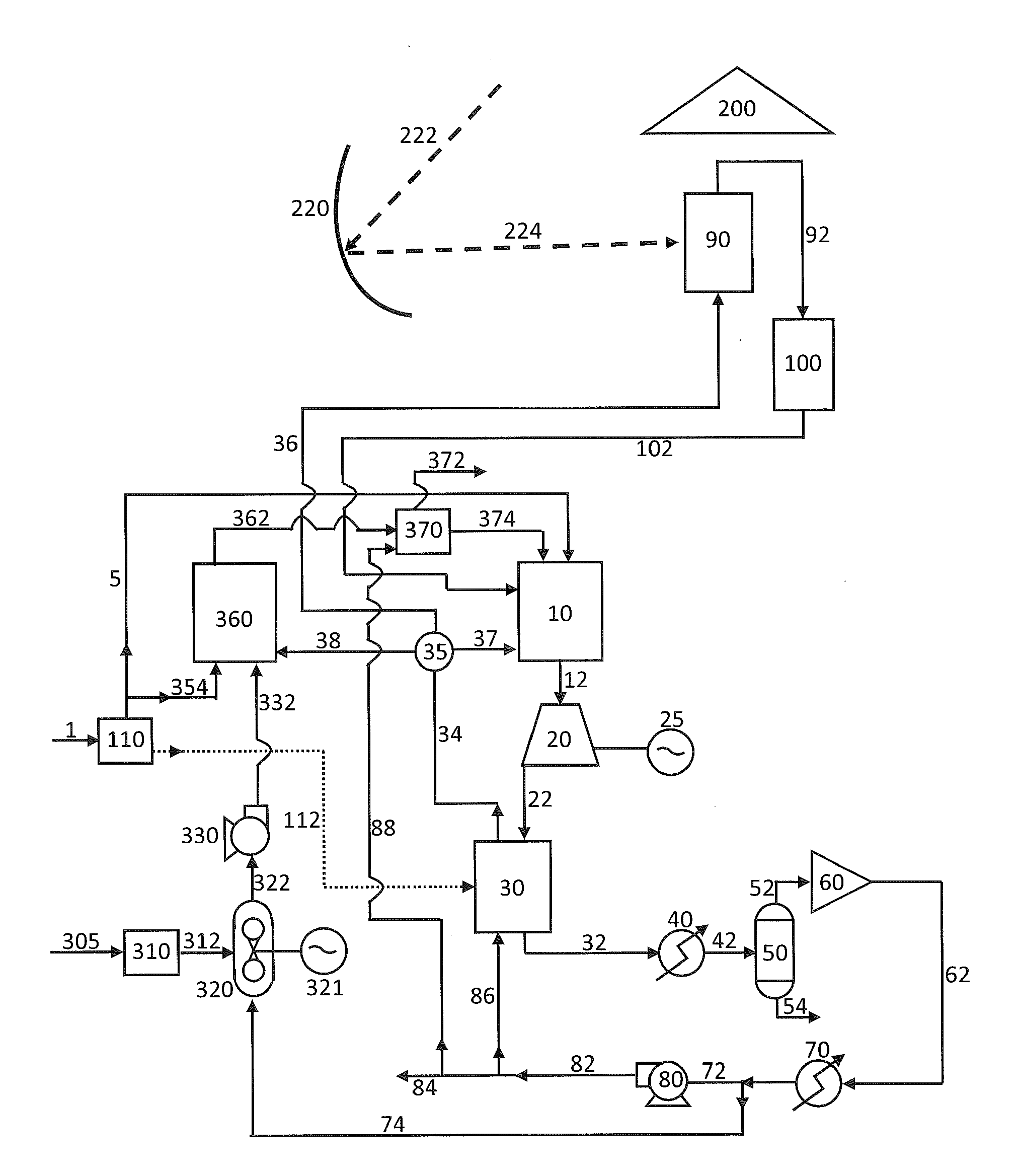

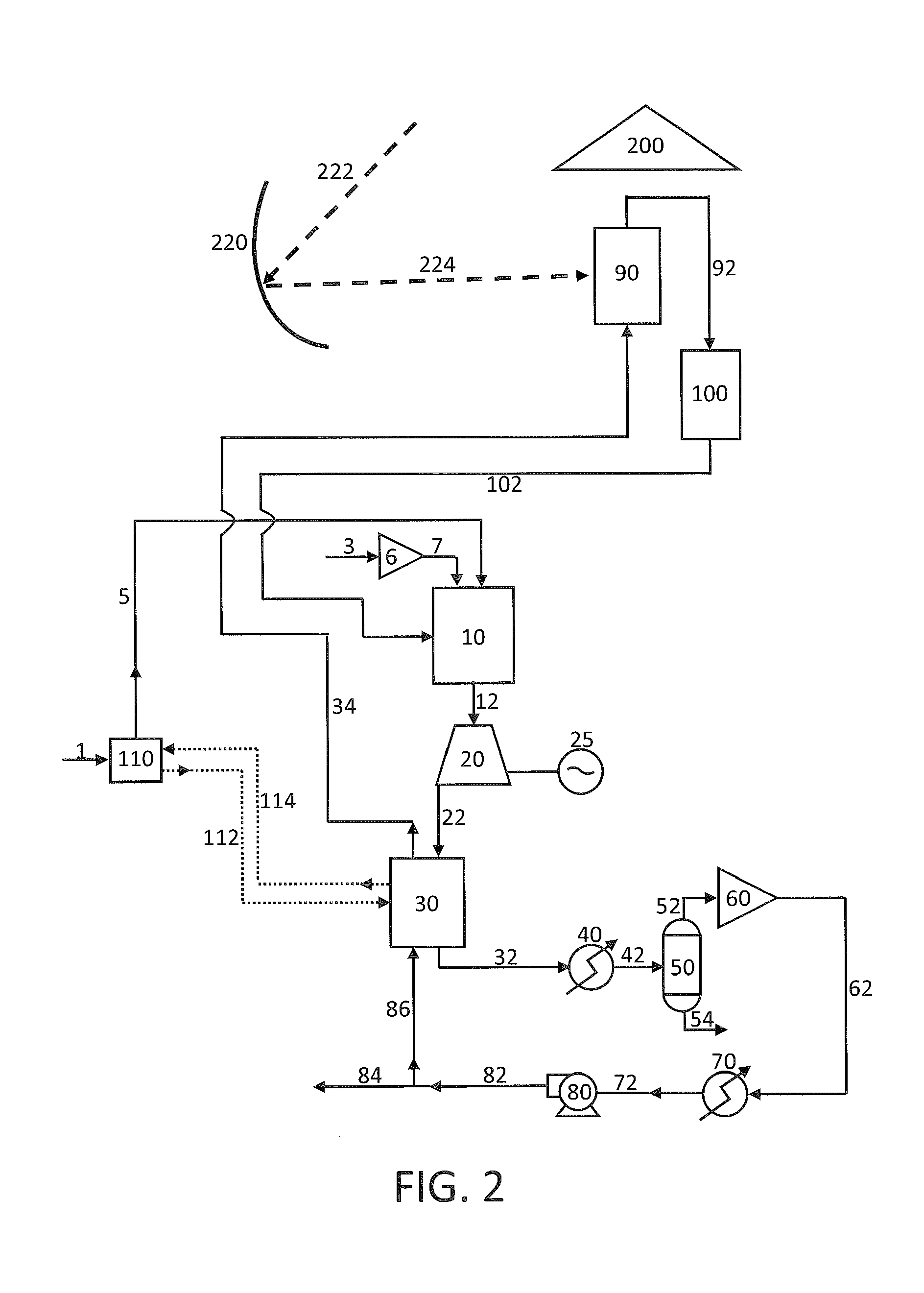

Gas turbine efficiency and regulation speed improvements using supplementary air system continuous and storage systems and methods of using the same

ActiveUS20140366547A1Improve efficiencyEliminating heating loadEngine fuctionsCombustion enginesPower stationExhaust fumes

The present invention discloses a novel apparatus and methods for augmenting the power of a gas turbine engine, improving gas turbine engine operation, and reducing the response time necessary to meet changing demands of a power plant. Improvements in power augmentation and engine operation include additional heated compressed air injection, steam injection, water recovery, exhaust tempering, fuel heating, and stored heated air injection.

Owner:POWERPHASE

System for catalytic combustion

InactiveUS7430869B2High activityLarge specific surface areaContinuous combustion chamberTurbine/propulsion engine ignitionEnvironmental engineeringTurbine

A system comprising a compressor (10) having an inlet stream (25) and an outlet stream (26), a pre-heater (12) having a process inlet stream (29) and a process outlet stream (31), a catalytic combustor (13) having an inlet stream (32) and an outlet stream (33) and containing an catalyst, and a turbine (14) having an inlet stream (34) and an outlet stream (35), wherein, the outlet stream (26) of the compressor(10) is connected to the process inlet stream (29) of the pre-heater (12), the process outlet stream (31) of the pre-heater (12) is connected to the inlet stream (32) of the catalytic combustor (13). The outlet stream (33) of the catalytic combustor (13) is connected to the inlet stream (34) of the turbine (14). During operation of the system, the inlet stream (25) of the compressor (10) has a substantially constant and low concentration of fuel.

Owner:COMMONWEALTH SCI & IND RES ORG

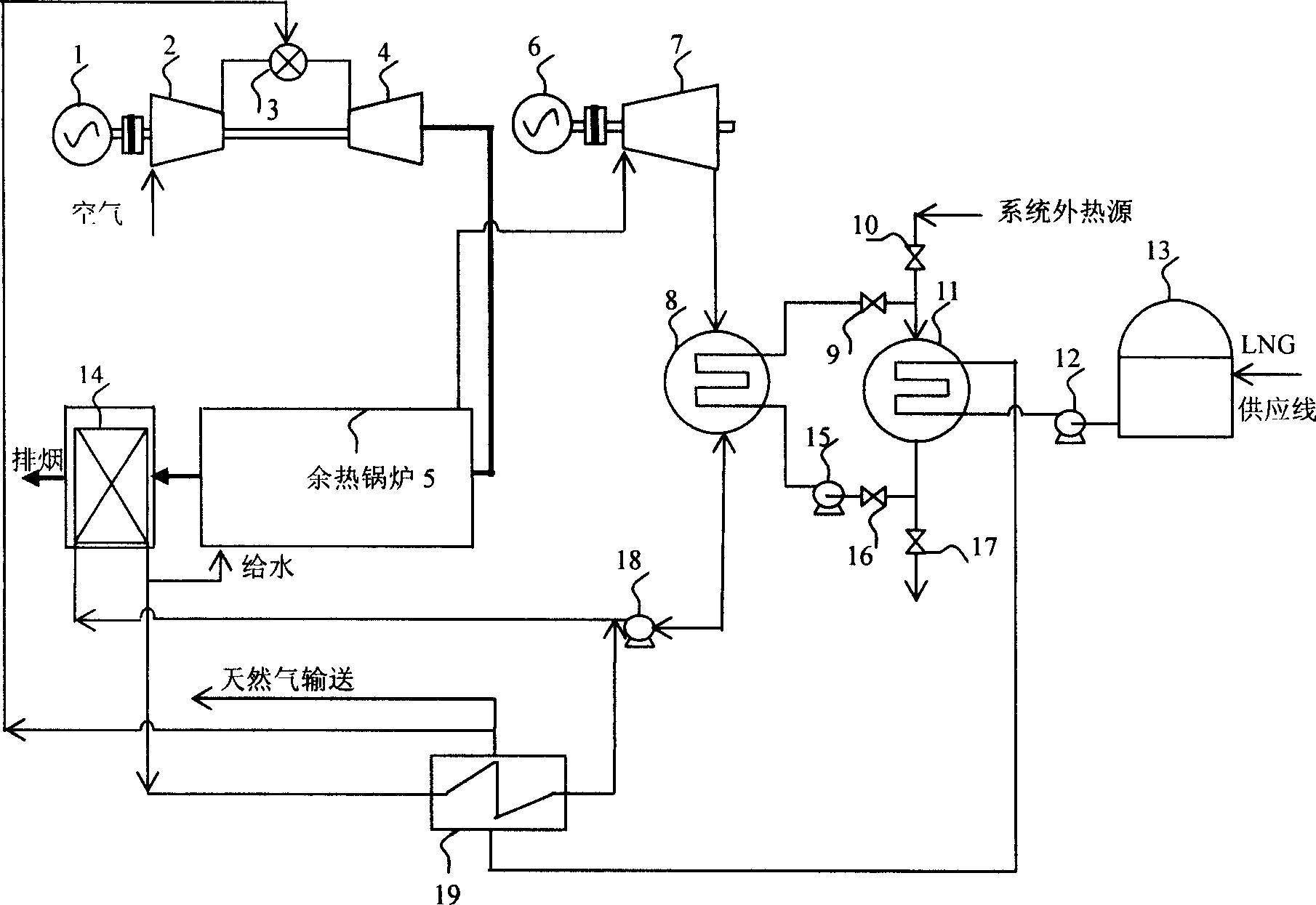

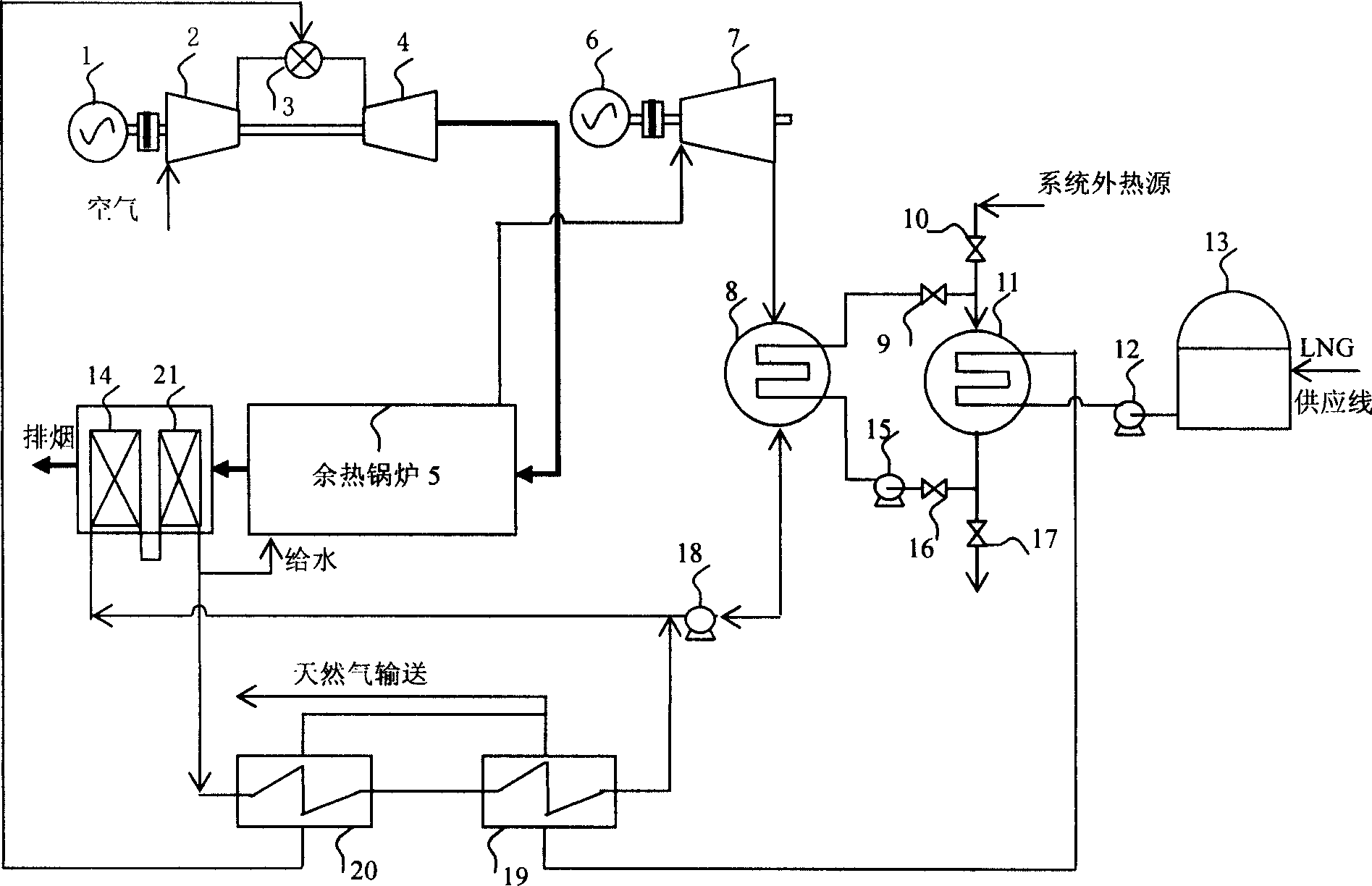

System and method for improving efficiency of combined cycle electric power plant

InactiveCN1737351AImprove efficiencyIncrease temperatureGas turbine plantsTurbine/propulsion fuel heatingCombustion chamberHeat transfer fluid

This invention relates to a system and method for increasing the efficiency of association circulating power plant, wherein the power plant uses liquefied natural gas as the fuel. The method comprises the following steps: a) passing the heat of steam turbine exhaust to LNG through heat transfer fluid; b) gasifying LNG, using the cool energy arising form gasifying to condense the exhaust to condensation water; c) decreasing the pressure at expulsion of the steam turbine, improving the output power and efficiency of the steam turbine. The condensation water will mix with the cool water, absorbing the sensible heat in the exhaust-heat boiler smoke discharging and the hidden heat in the steam, decreasing the smoke discharging temperature below dew-point temperature. One part of the water which has recovered the smoke after heat will be used as the water supply for the exhaust-heat boiler, the other will be used for heating natural gas, improving the temperature of the natural gas entry to the burning room.

Owner:XI AN JIAOTONG UNIV

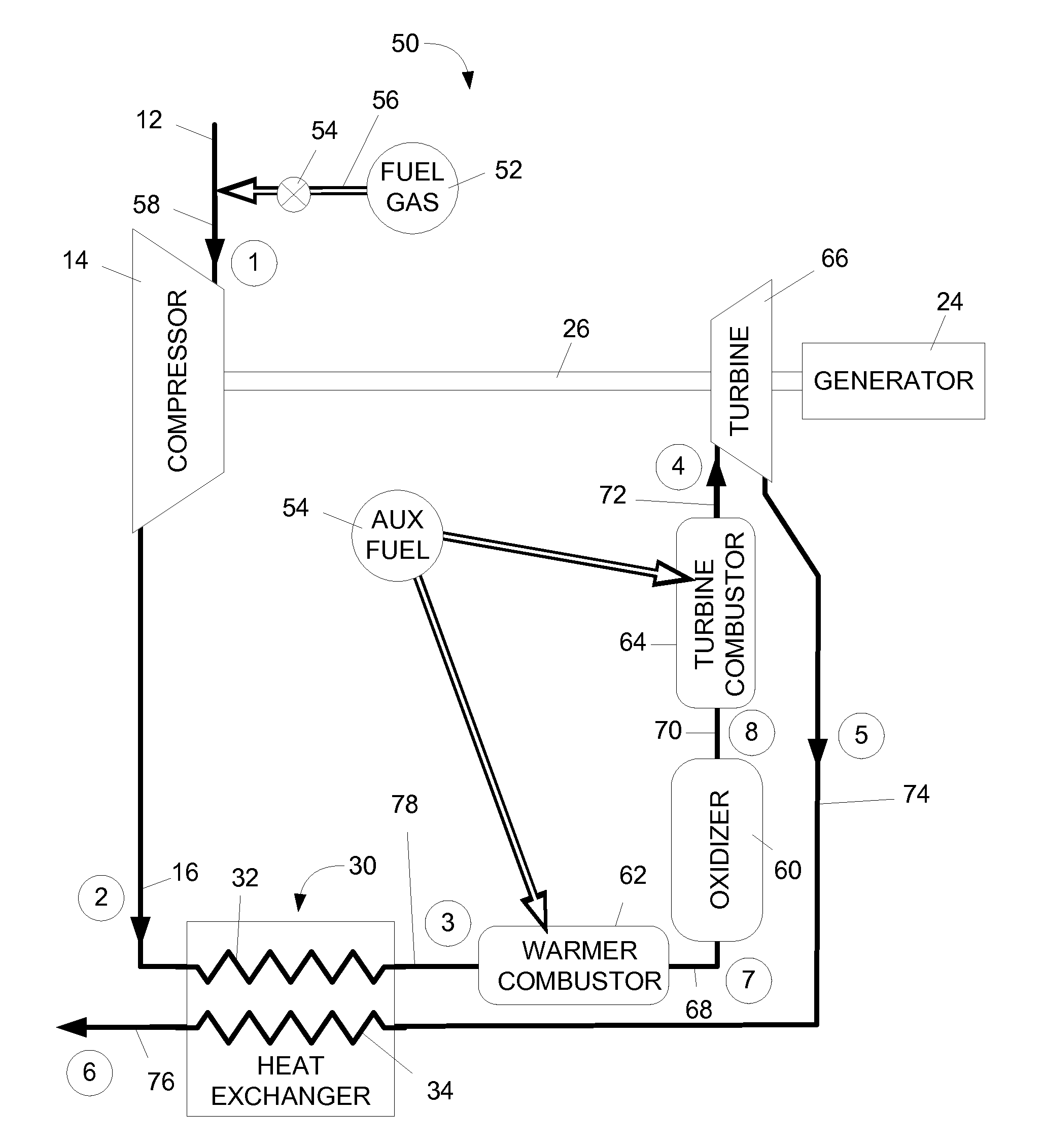

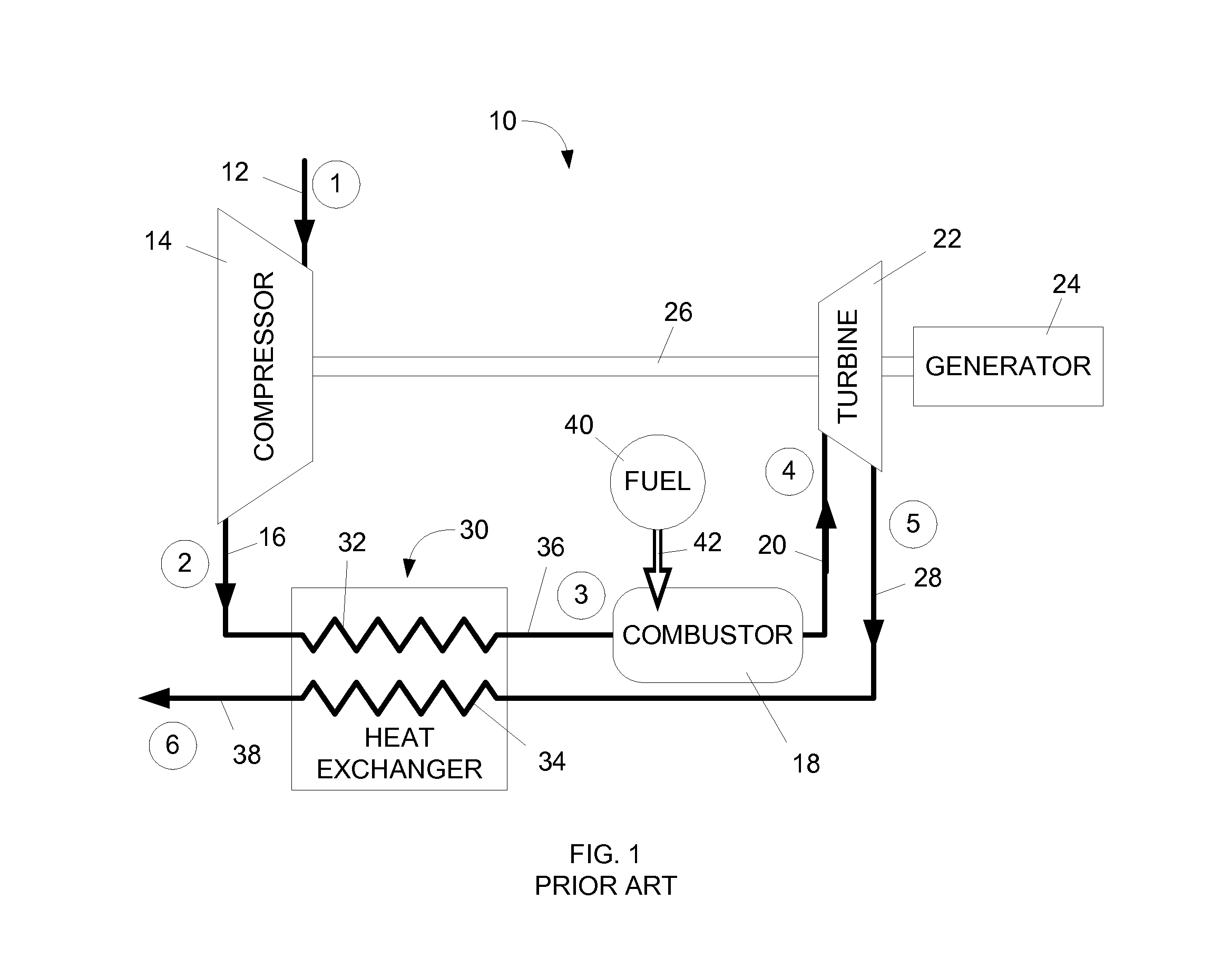

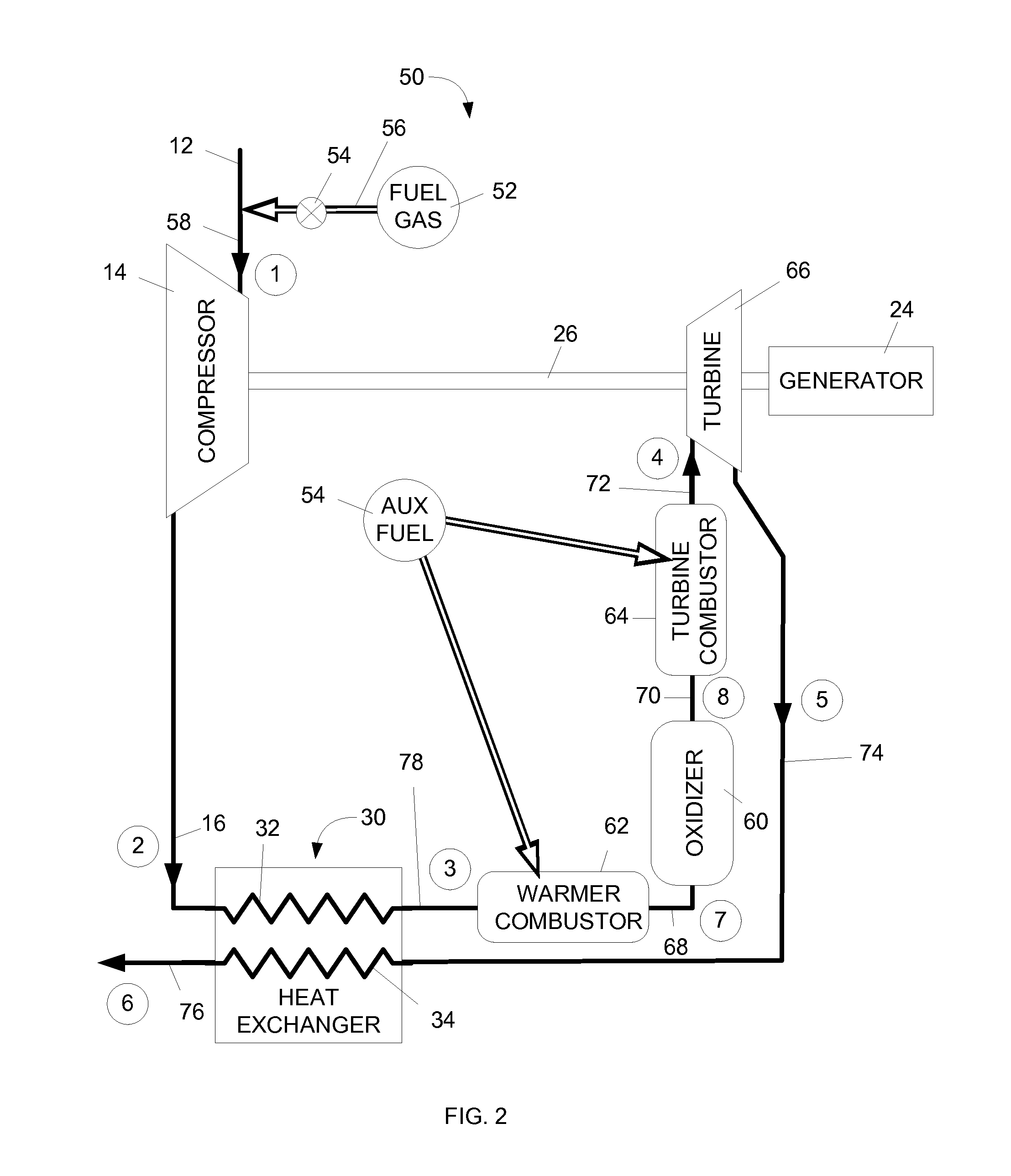

Multi-combustor turbine

A system for the gradual oxidation of fuel is disclosed. The system includes an oxidizer that has a reaction chamber with an inlet and an outlet. The reaction chamber is configured to receive a fluid comprising an oxidizable fuel through the inlet. The oxidizer is configured to maintain a flameless oxidation process. The system also includes a heating chamber with an inlet and an outlet. The inlet of the heating chamber is in fluid communication with the outlet of the reaction chamber. The heating chamber is configured to receive the fluid from the reaction chamber and selectably heat the fluid.

Owner:REDUCTONOX CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com